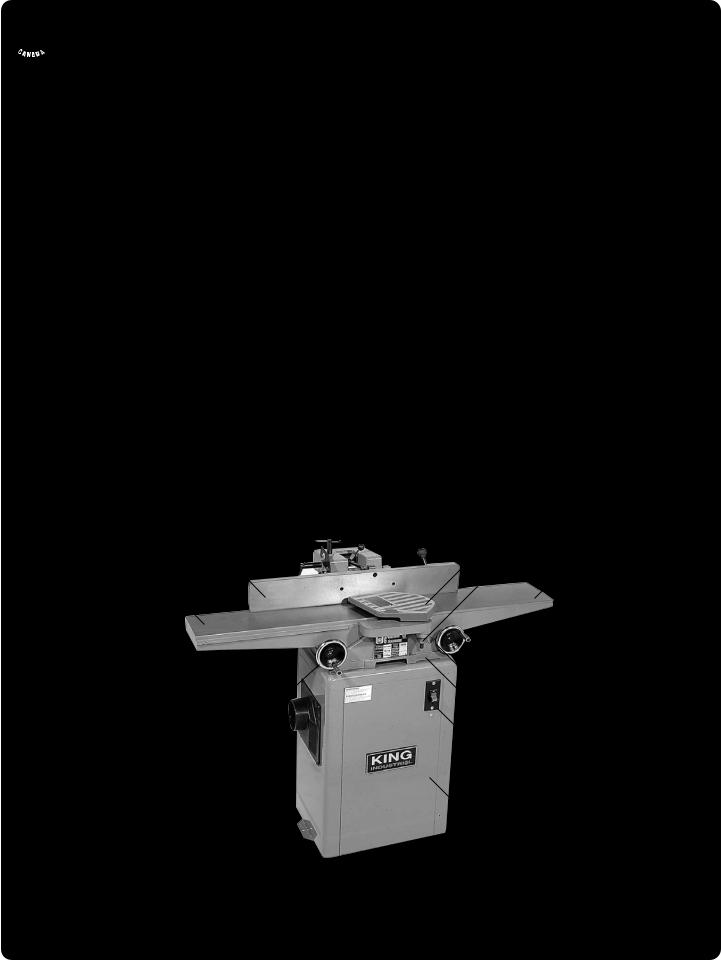

King Industrial KC-60FX User Manual

6’’ WOODWORKING

JOINTER

MODEL: KC-60FX

INSTRUCTION MANUAL

COPYRIGHT 2000 BY KING CANADA TOOLS INC.

GENERAL SAFETY RULES

WARNING:Do not attempt to operate until you have read thouroughly and have understood all instructions, rules ect. contained in this manual. Failure to comply can result in accidents involving fire, electric shock, or personal injury. Keep owners manual and review frequently for continuous safe operation.

1. KNOW YOUR MACHINE.

For your own safety, read the owner’s manual cafefully. Learn its application and limitations as well as specific potential hazards pertinent to this machine.

2.GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT WITH GROUNED SURFACES.

3.REMOVE ADJUSTING KEYS AND WRENCHES.

Form a habit of checking to see that keys and wrenches are removed from the machine before turning it on.

4.KEEP WORK AREA CLEAN.

Cluttered areas invite accidents.

5.DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do not use power tools in damp or wet locations, or expose them to rain. Keep work areas well illuminated.

6.KEEP CHILDREN AWAY.

All visitors should be kept at a safe distance from work area.

7.MAKE WORKSHOP CHILDPROOF.

With padlocks, master switches, or by removing starter keys.

8.DO NOT FORCE THE MACHINE.

It will do the job better and be safer at the rate for which it was designed.

9.USE THE RIGHT TOOLS.

Do not force the machine or attachments to do a job for which they were not designed.

10. WEAR PROPER APPAREL.

Avoid loose clothing, gloves, neckties, rings, bracelets, or jewelry which could be caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS WEAR SAFETY GLASSES.

Always use face or dust mask if operation is dusty. Everyday eyeglasses only have impact resistant lenses. They are NOT safety glasses.

12. SECURE WORK.

Use clamps or a vise to hold work when practical. It is safer than using your hand and frees both hands to operate the machine.

13. DO NOT OVERREACH.

Keep proper footing and balance at all times.

14. MAINTAIN MACHINE IN TOP CONDITION.

Keep machine clean for best and safest performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT THE MACHINE FROM POWER SOURCE.

Before servicing and when changing accessories, or when mounting and remounting motor.

16. USE RECOMMENDED ACCESSORIES

Consult the owners manual for recommended accessories.

17. CHECK DAMAGED PARTS.

Before further use of the machine, the guards and other parts should be carefully inspected to ensure it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts, mounting, and any other condition that may affect its operation. Guards and other parts that are damaged should be properly repaired or replaced.

18. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

SAFETY RULES FOR JOINTERS

1.KEEP cutterhead sharp and free of all rust and pitch.

2.ALWAYS use a push block when jointing stock that does not give reasonable distance of safety for your hands.

3.NEVER pass hands directly over the cutterhead.

4.ALWAYS make sure exposed cutterhead behind the fence is guarded, especially when jointing near the edge.

5.DO NOT perform jointing or planing operations on material shorter than 8 inches, narrower than 3/4 inch, or thinner than 1/2 inch.

6.MAINTAIN the proper relationship between the infeed and outfeed table surfaces and cutterhead knife path.

7.SUPPORT the workpiece adequately at all times during operation, maintain control of the work at all times.

8.DO NOT back the workpiece towards the infeed table.

9.DO NOT attempt to perform abnormal or little-used operations without study and use of adequate holddown/push blocks, jigs, fixtures, stops, etc..

10.DO NOT make cuts deeper than 1/8’’ in a single pass. On cuts more than 1/2’’ wide, adjust depth of cut to 1/16’’ or less to avoid wood tearing.

UNPACKING THE MACHINE

1.Cafefully unpack the machine.

2.Check to see if there is any damage which occured to the machine during transportation. Report to your local distributor if there is damage.

3.Check to see if there are any parts missing. If so, contact your local distributor.

CLEANING THE MACHINE

1.The machine has been coated with a rust protection oil for transportation purposes.

2.Thoroughly remove the oil coating after unpacking the machine.

3.Use kerosene to remove the oil coating. Do not use gasoline or paint thinner to remove the oil coating, as this may damage the painted surfaces.

LEGEND OF THE MACHINE

1.Outfeed Table Adjustment Handwheel.

2.Outfeed Table.

3.Fence.

4.Fence Movement Fix Lever.

5.Fence Angle Adjustment Lever.

6.Depth Scale.

7.Lever.

8.Cutterhead Guard.

9.Spring Knob.

10.Infeed Table.

11.Infeed Table Adjustment Handwheel.

12.Base.

13.Power Switch.

14.Enclosed Floor Stand.

4 |

5 |

7 |

8 |

9 |

|

||||

|

|

3 |

10 |

|

2

11 |

|

12 |

6 |

1 |

|

13 |

|

14

SPECIFICATIONS

Cutting Capacity Width................................... |

6-1/8’’ (155mm) |

Cutting Capacity Depth...................................... |

1/2’’ (12.7mm) |

Rabbeting Capacity............................................. |

1/2’’ (12.7mm) |

Cutterhead:

Cutterhead Speed................................................. |

5,000 R.P.M. |

Cuts per Minute.............................................................. |

15,000 |

Number of Knives.................................................................... |

3 |

Diameter................................................................ |

2.4’’ (61mm) |

Table:

Dimensions............................... |

7.3’’ (185mm) X 45’’ (1143mm) |

Height................................................................ |

32.3’’ (820mm) |

Fence:

Dimensions................................... |

4’’ (102mm) X 28’’ (710mm) |

Tilts Right.............................................................................. |

450 |

Positive Stops................................................................ |

900, 450 |

Overall Dimensions:

Length................................................................. |

|

45’’ (1143mm) |

Height............ |

Enclosed Steel Stand................. |

36.6’’ (930mm) |

Net Weight...................................................... |

|

198 lbs. (90 kgs) |

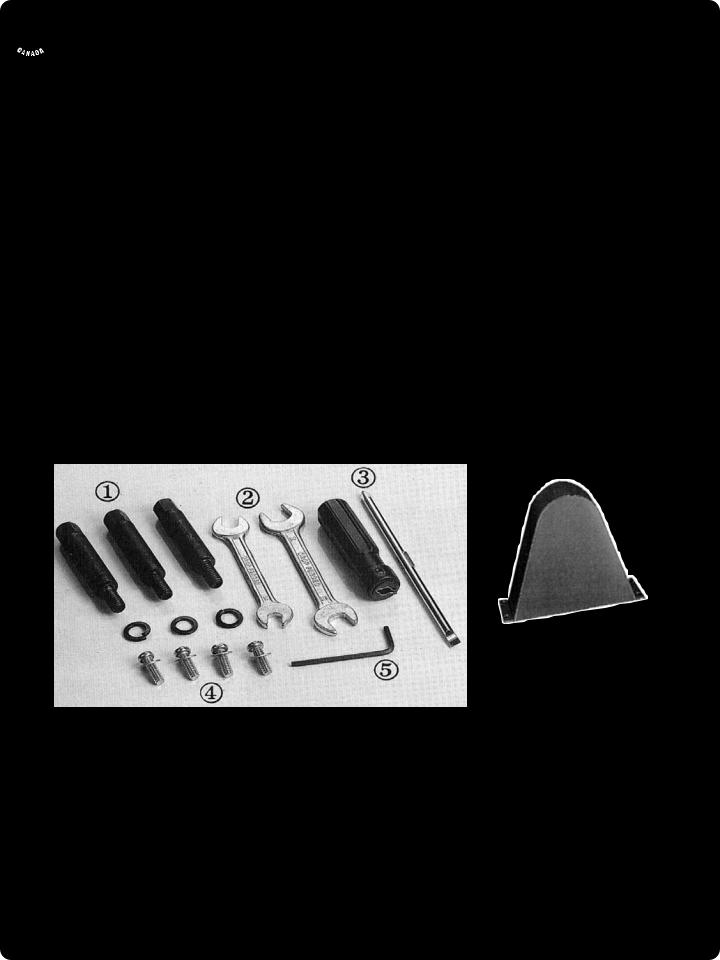

LOOSE PARTS BAG

1. |

Stand Mounting Screws with Washers |

................................3 pcs. |

|

2. |

Open End Wrench........................... |

8 X10 (1 pc.), 12 X14 (1 pc.) |

|

3. |

Screwdriver............................................................................ |

|

1 pc. |

4. |

Belt Guard Lock Screw................................... |

|

1/4’’ X 3/4’’ (4 pcs.) |

5. Allen Wrench............................................................ |

|

3mm (1 pc.) |

|

6. |

Belt Guard.......................................................................... |

|

1 pc. |

6

POWER CONNECTIONS

Set aside an electrical circuit that is used exclusively for tools. It should be at least a #12 wire and protected with a 15 AMP time lag fuse. Before connecting the motor to the power source, make sure that the voltage is the same as indicated on the machine, and that the machine is turned off. Check all connections for good contact. WARNING: If the machine runs on insufficient voltage, damage to the motor may occur.

GROUNDING

Failure to adequately ground the machine may result in electric shock to the operator. Always use a three prong extension cord and outlet. If there is any doubt that the outlet is not grounded properly, have it checked by a certified electrician. Only use three to two adapters temporarily.

EXTENSION CORDS

Check the condition of the extension cord regularly. Use a three wire extension cord with a three prong plug, and make sure it is plugged into an appropriate three hole receptacle. If you must use a two prong adapter temporarily, make sure the grounding extension on the adapter is connected to a permanent ground. Do not bend the grounding plug to fit it into a two hole receptacle. Remember to use a cord heavy enough to carry the jointer’s current. If the cord length is under 25 feet for 110V operation, and under 50 feet for 220V operation, use at least a 14 AWG gauge extension cord. If the cord length is between 25 and 50 feet for 110V operation, and between 50 and 100 feet for 220V, use at least a 12 AWG gauge extension cord. Do not use cords longer than 50 feet and 100 feet for 110V and 220V operations respectively.

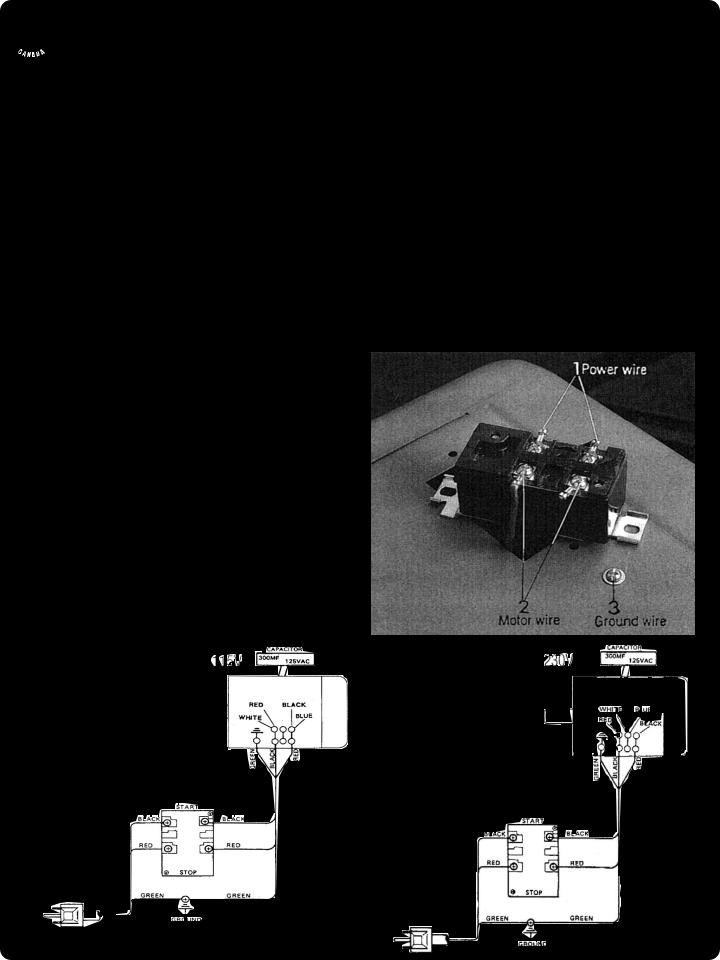

CHANGING VOLTAGE

This machine is set up at the factory for 110V use. To change the voltage to 220V, disconnect the machine from its power source and follow the electrical diagram as shown below.

SWITCH WIRING DIAGRAM

Loading...

Loading...