Service Guide

Agilent Technologies

89410A Vector Signal Analyzer

Part Number: 89410-90103

Supersedes: 89410-90065

Printed in USA

March 2002

© Copyright 2001-2002 Agilent Technologies Inc.

The information contained in this document is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Safety Information

The following safety notes are used throughout this manual. Familiarize

yourself with each of the notes and it’s meaning before operating this

instrument.

WARNING: Warning denot es a hazard. It calls attention to a procedure

which, if not correctly performed or adhere d to, could re sul t in injury or loss of lif e.

Do not proceed beyond a warning note until the indicated conditions are fully

understood and met.

CAUTION: Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or destruction of the

instrument. Do not proceed beyond a caution sign until the indicated conditions are

fully understood and met.

WARNING: This is a Safety Class 1 Product (provided with a protective

earthing ground incorporated in the power cord). The mains plug shall only be

inserted in a socket out let provid ed with a protected earth contact. Any

interruption of the pro te ctive conductor inside or outside of the product is likely to

make the product dangerous. Intentional interruption is prohibited.

ii

WARNING: These servicing instructions are for use by qualified personnel

only. To avoid electrical shock, do not perform any servicing unless you are

qualified to do so.

WARNING: The power cord is connected to internal capacitors that may

remain live for 5 seconds after disconnecting the plug from it’s power supply.

Warranty

This Agilent Technologies instrument product is warranted against

defects in material and workmanship for a period of three years from

date of shipment. During the warranty period, Agilent Technologies will,

at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a service

facility designated by Agilent Technologies. Buyer shall prepay shipping

charges to Agilent Technologies and Agilent Technologies shall pay

shipping charges to return the product to Buyer. However, Buyer shall

pay all shipping charges, duties, and taxes for products returned to

Agilent Technologies from another country.

Agilent Technologies warrants that its software and firmware designated

by Agilent Technologies for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Agilent Technologies does not warrant that the operation of the

instrument, or software, or firmware will be uninterrupted or error-free.

iii

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper

or inadequate maintenance by Buyer, Buyer-supplied software or

interfacing, unauthorized modification or misuse, operation outside of

the environmental specifications for the product, or improper site

preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT

TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT,

OR ANY OTHER LEGAL THEORY.

iv

In this manual…

Chapter 1 Troubleshooting the Analyzer

Chapter 2 Adjusting the Analyzer

Chapter 3 Replacing Assemblies

Chapter 4 Replaceable Parts

Chapter 5 Circuit Descriptions

● Provides step-by-step instructions for isolating most failures to the

faulty assembly

● Provides step-by-step instructions for adjusting the analyzer

● Provides step-by-step instructions to follow before and after replacing

an assembly. This chapter also provides step-by-step instructions for

disassembling the analyzer

● Provides ordering information and lists the replaceable parts

● Provides the overall instrument description and individual assembly

description

Chapter 6 Voltages and Signals

● Shows where the signals and voltages are used in the analyzer and

describes each signal

Chapter 7 Internal Test Descriptions

● Describes the power-on test, calibration routine, fault log messages,

and self tests

Chapter 8 Backdating

● Provides information necessary to modify this manual for

instruments that differ from those currently being produced

Chapter 9 Quick Reference

● Provides all the block diagrams and the “A90/A91 Motherboard

Voltages” table

v

Notation Conventions

Before you use this book, it is important to understand the types of keys on

the front panel of the analyzer and how they are denoted in this book.

Hardkeys

● Hardkeys are front-panel buttons whose functions are always the

same. Hardkeys have a label printed directly on the key. In this book,

they are printed like this: [

Softkeys

● Softkeys are keys whose functions change with the analyzer’s current

menu selection. A softkey’s function is indicated by a video label to

the left of the key (at the edge of the analyzer’s screen). In this book,

softkeys are printed like this: [

Toggle Softkeys

● Some softkeys toggle through multiple settings for a parameter.

Toggle softkeys have a word highlighted (of a different color) in their

label. Repeated presses of a toggle softkey changes which word is

highlighted with each press of the softkey. In this book, toggle softkey

presses are shown with the requested toggle state in bold type as

follows:

“Press [

selection on is active.”

Hardkey].

softkey].

key nameon]” means “press the softkey [key name] until the

Shift Functions

● In addition to their normal labels, keys with blue lettering also have a

shift function. This is similar to shift keys on a pocket calculator or

the shift function on a typewriter or computer keyboard. Using a

shift function is a two-step process. First, press the blue [

(at this point, the message “shift” appears on the display). Then press

the key with the shift function you want to enable. Shift function are

printed as two key presses, like this:

Shift] [Shift Function]

[

vi

Shift] key

Numeric Entries

● Numeric values may be entered by using the numeric keys in the

lower right hand ENTRY area of the analyzer front panel. In this

book, values which are to be entered from these keys are indicted

only as numerals in the text, like this:

Press 50, [

enter]

Ghosted Softkeys

● A softkey label may be shown in the menu when it is inactive. This

occurs when a softkey function is not appropriate for a particular

measurement or not available with the current analyzer

configuration. To show that a softkey function is not available, the

analyzer ‘’ghosts’’ the inactive softkey label. A ghosted softkey

appears less bright than a normal softkey. Settings/values may be

changed while they are inactive. If this occurs, the new settings are

effective when the configuration changes such that the softkey

function becomes active.

vii

The Agilent 89410A at a Glance

viii

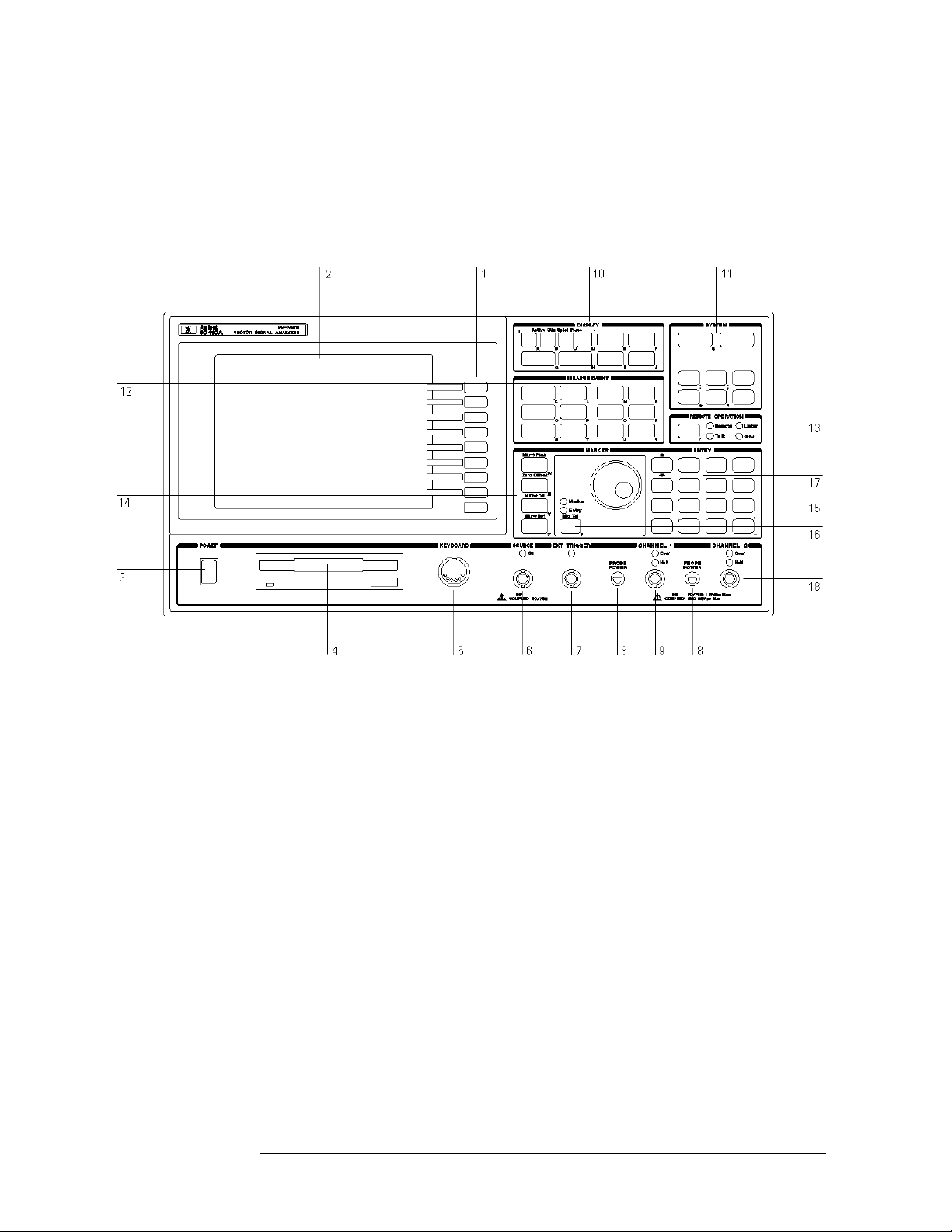

Agilent 89410A Front Panel

1-A softkey’s function changes as different menus are displayed. Its

current function is determined by the video label to its left, on the

analyzer’s screen.

2-The analyzer’s screen is divided into two main areas. The menu area, a

narrow column at the screen’s right edge, displays softkey labels. The

data area, the remaining portion of the screen, displays traces and other

data.

3-The POWER switch turns the analyzer on and off.

4-Use a 3.5-inch flexible disk (DS,HD) in this disk drive to save your work.

5-The KEYBOARD connector allows you to attach an optional keyboard to

the analyzer. The keyboard is most useful for writing and editing

Instrument BASIC programs.

6- The SOURCE connector routes the analyzer’s source output to your

DUT. Output impedance is selectable: 50 ohms or 75 ohms.

7-The EXT TRIGGER connector lets you provide an external trigger for

the analyzer.

8-The PROBE POWER connectors provide power for

various Agilent active probes.

9-The CHANNEL 1 input connector routes your test signal or DUT output

to the analyzer’s receiver. Input impedance is selectable: 50 ohms, 75

ohms, or 1 megohm.

10-Use the DISPLAY hardkeys and their menus to select and manipulate

trace data and to select display options for that data.

11-Use the SYSTEM hardkeys and their menus to control various system

functions (online help, plotting, presetting, and so on).

12-Use the MEASUREMENT hardkeys and their menus to control the

analyzer’s receiver and source, and to specify other measurement

parameters.

13-The REMOTE OPERATION hardkey and LED indicators allow you to

set up and monitor the activity of remote devices.

14-Use the MARKER hardkeys and their menus to control marker

positioning and marker functions.

15-The knob’s primary purpose is to move a marker along the trace. But

you can also use it to change values during numeric entry, move a cursor

during text entry, or select a hypertext link in help topics.

ix

16-Use the Marker/Entry key to determine the knob’s function. With the

Marker indicator illuminated, the knob moves a marker along the trace.

With the Entry indicator illuminated, the knob changes numeric entry

values.

17-Use the ENTRY hardkeys to change the value of numeric parameters

or to enter numeric characters in text strings.

18-The optional CHANNEL 2 input connector routes your test signal or

DUT output to the analyzer’s receiver. Input impedance is selectable: 50

ohms, 75 ohms, or 1 megohm. For easy of upgrading, the CHANNEL 2

BNC connector is installed even if option AY7 (second input channel) is

not installed.

For more details on the Agilent 89410A front panel, display the online help

topic ‘’Front Panel.’’

Before applying power

Verify that the product is set to match the available line voltage, the

correct fuse is installed, and all safety precautions are taken. Note the

instrument’s external markings described in “Safety symbols and

instrument markings” on page x.

Ground the instrument

To minimize shock hazard, the instrument chassis and cover must be

connected to an electrical protective earth ground. The instrument must

be connected to the ac power mains through a grounded power cable,

with the ground wire firmly connected to an electrical ground (safety

ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal

will cause a potential shock hazard that could result in personal injury.

Fuses

Use only fuses with the required rated current, voltage, and specified

type (normal blow, time delay). Do not use repaired fuses or

short-circuited fuse holders. To do so could cause a shock or fire hazard.

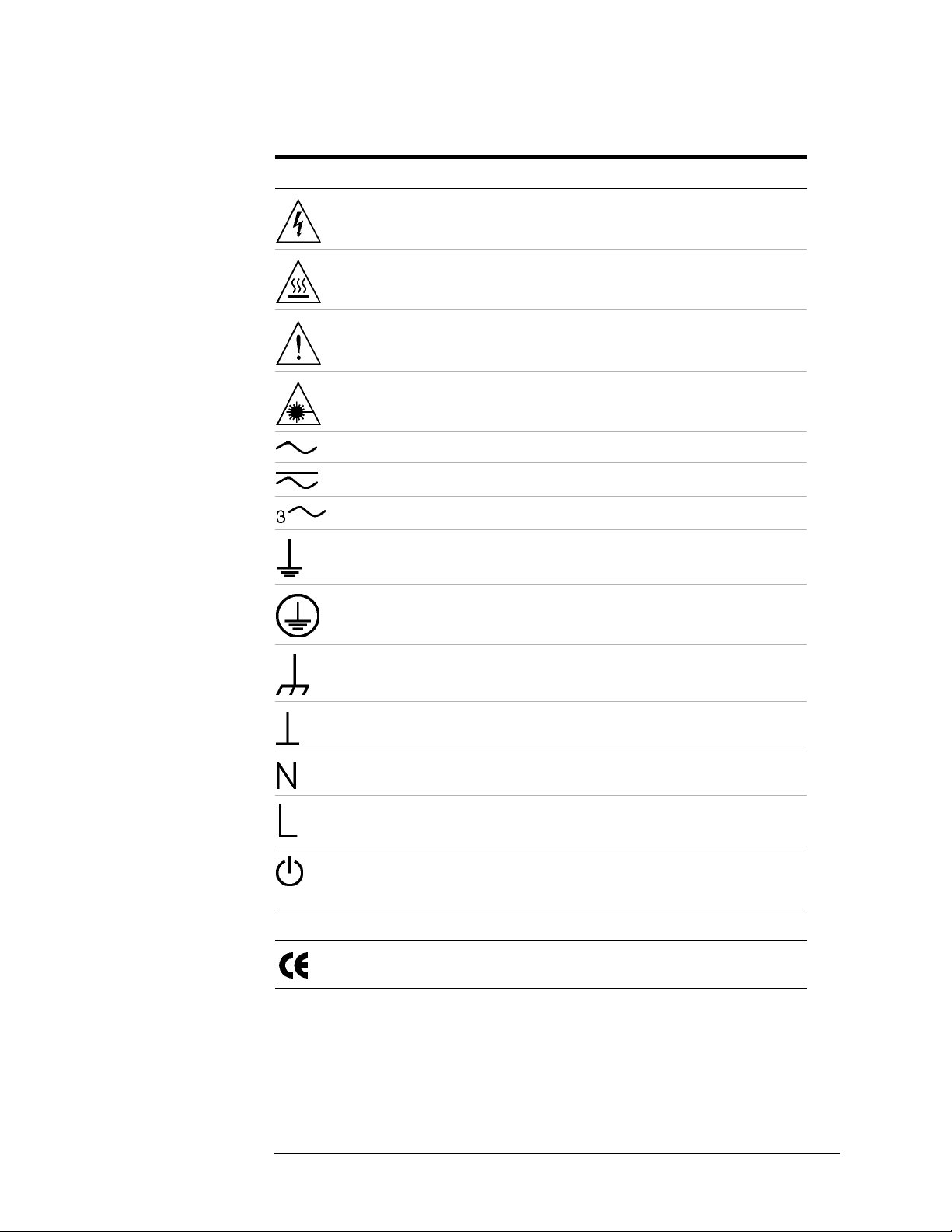

Safety symbols and instrument markings

Symbols and markings in manuals and on instruments alert you to

potential risks, provide information about conditions, and comply with

international regulations. Table 1 defines the symbols and markings you

may find in a manual or on an instrument.

x

Table 1 Safety symbols and instrument markings

Safety symbols

Warning: risk of electric shock.

Warning: ho t surface

Caution: refer to accompanying documents.

Laser radiat io n sym b ol : m arked on products that have a laser o ut put.

Alternating current.

Both direct and alternating current.

Three-phase alternating current.

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and control circuits designed to

be operated with one terminal at earth potential.

Terminal for neutral conductor on permanently installed equipment.

Terminal for line conductor on permanently installed equipment.

Standby (supply); units with this symbol are not completely disconnected from ac

mains when this switch is off. To completely disconnect the unit from ac mains, either

disconnect the power cord, or have a qualified electrician install an external switch.

Instrument markings

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

xi

Table 1 Safety symbols and instrument markings (continued)

Safety symbols

The CSA mark is a registered trademark of the Canadian Standards Association.

The C-tick mark is a registered trademark of the Spectrum Management Agency of

Australia. This signifies compliance with the Australian EMC Framework regulations

under the terms of the Radio Communications Act of 1992.

1SM1-A

This text indicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPER 11, Clause 4).

xii

Service and Support

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer engineer

through your local Agilent Technologies Service Center. You can find a

list of local service representatives on the Web at:

http://www.agilent.com/ services/English/index.html

If you do not have access to the Internet, one of these centers can direct

you to your nearest representative.

Table 2 Telephone numbers for Agilent Call Centers

United States: Test and Measurement Call Center

Canada: (905) 206 4725

Europe: (31 20) 547 9900

Japan: Measurement Assistance Center

(800) 452 4844 (toll-free in US)

(81) 426 56 7832

(81) 426 56 7840 (FAX)

Latin America: (305) 267 4245

(305) 267 4288 (FAX)

Australia/New Zealand: 1 800 629 485 (Australia)

0800 738 378 (New Zealand))

Asia-Pacific: (852) 2599 7777

(852) 2506 9285 (FAX)

xiii

xiv

Contents

1. Troubleshooting the Analyzer

How to troubleshoot the analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

To perform initial verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

To troubleshoot the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

To troubleshoot display failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

To perform self tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

To troubleshoot self-test lockup failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-48

To troubleshoot intermittent failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-52

To troubleshoot performance test failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-58

To troubleshoot front-end control failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-60

To troubleshoot source and calibrator out failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-62

To troubleshoot input and ADC failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-71

To troubleshoot two channel analyzer failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-75

To troubleshoot auto-range failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-80

To troubleshoot trigger failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-83

To troubleshoot disk drive failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-88

To troubleshoot serial port failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-91

To troubleshoot DIN connector failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-92

To troubleshoot memory battery failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-93

To troubleshoot sync out and parallel port failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-95

To troubleshoot system interconnect and LAN port failures. . . . . . . . . . . . . . . . . . . . . . . . .1-96

2. Adjusting the Analyzer

To adjust oven shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

To adjust input flatness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

To adjust input capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

To adjust input offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

To adjust anti-alias filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

To adjust ADC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

To adjust 10 MHz low pass filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

To adjust auto-range detect level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

To adjust reference oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

To adjust oven frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

To adjust calibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

3. Replacing Assemblies

What to do before replacing the analog source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

What to do after replacing an assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

To remove CPU and memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

To remove front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

To remove the Flat Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

To place the A82 in the test position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

To remove disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

To remove main power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

To remove analog motherboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

To remove rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

To remove digital motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

A100 Display, Backlights, and Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

xv

Contents

4. Replaceable Parts

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Instrument Covers and Handles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Front Panel Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Rear Panel Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Chassis Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Card Nest Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Screws, Washers, and Nuts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Miscellaneous Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

5. Circuit Descriptions

Overall Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

A10 Analog Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

A11 Front Panel Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

A12 Rear Panel Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

A21 A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

A30 Digital Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

A35 Analog Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

A36 Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

A40 CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

A42 Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

A43 Expanded Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

A47 DSP/Display Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

A50 Digital Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

A55 Sample RAM/A56 Expanded Sample RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

A60 Frequency Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

A61 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

A71 Pass Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

A81 Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

A82 LCD Interface Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

A85 Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

A90 Digital Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

A91 Analog Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

A92 Probe Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

A95 Main Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

A96 Primary Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

A100 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

A101 Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

A102 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65

6. Voltages and Signals

Assembly Locations and Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Power Supply Voltage Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

RF Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

A42 Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

A81 Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

xvi

Contents

A90 and A91 Motherboards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

A101 Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Interface Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

7. Internal Test Descriptions

Power-on Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Calibration Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Fault Log Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Self-Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

Individual Self-Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Self-Test Menu Map and HPIB Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

8. Backdating

To adjust clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

To adjust display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

To remove display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

Assembly Covers and Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14

Front Panel Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-15

Overall Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-18

A45 DSP/Display Controller Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

A80 Keyboard Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-21

Assembly Locations and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-22

9. Quick Reference

xvii

Contents

xviii

1 Troubleshooting the Analyzer

Troubleshooting the Analyzer

● How to troubleshoot the analyzer, page1-8

● To perform initial verificatio n, page 1-10

● To troubleshoot the power supply, page 1-15

● To troubleshoot display failures, page 1-25

● To perform self tests, page 1-32

● To troubleshoot self-test lockup failures, page1-48

● To troubleshoot intermittent failures, page 1-52

● To troubleshoot performance test failures, page 1-58

● To troubleshoot front-end control failures, page 1-60

● To troubleshoot source and calibrator out failures, page1-62

● To troubleshoot input and ADC failures, page 1-71

● To troubleshoot two channel analyzer failures, page1-75

● To troubleshoot auto-range failures, page1-80

● To troubleshoot trigger failures, page 1-83

● To troubleshoot disk drive failures, page1-88

● To troubleshoot serial port failures, page 1-91

● To troubleshoot DIN connector failures, page1-92

● To troubleshoot memory battery failures, page1-93

● To troubleshoot sync out and parallel port failures, page1-95

● To troubleshoot system interconnect and LAN port failures, page 1-96

1-2

Troubleshooting the Analyzer

This chapter contains troubleshooting tests that can isolate most failures

to the faulty assembly. The section ‘’How to troubleshoot the analyzer’’

tells you which test to start with based on the failure. The test you start

with will either isolate the faulty assembly or send you to another test to

continue troubleshooting.

Safety Considerations

The Agilent 89410A DC-10 MHz Vector Signal Analyzer is a Safety Class 1

instrument (provided with a protective earth terminal). Although the

instrument has been designed in accordance with international safety

standards, this manual contains information, cautions, and warnings

that must be followed to ensure safe operation and retain the instrument

in safe operating condition. Service must be performed by trained

service personnel who are aware of the hazards involved (such as fire

and electrical shock).

Troubleshooting the Analyzer

WARNING: Any interruption of the protecti ve (groundin g) conduct or inside or

outside the analyzer, or disconnection of the protective earth terminal can expose

operators to potentially dangerous voltages.

An operator should not remove any covers, screws, shields or in any other way

access the interior of the Agilent 89410A DC-10 MHz Vector Si gnal Analyzer unless

instructed by an option installation note. There are no operator controls inside the

analyzer.

Only fuses with the require d curre nt ratin g and of the specifi ed type sh ould be used

for replacement. The use of repaired fuses or s hort c ir cuit ing the fuse holder is not

permitted. Whenever it is likely that the protection offere d by the fuse has been

impaired, the analyzer must be made inoperative and secured against any

unintended operation.

When power is removed from the Agilent 89410A DC-10MHz Vector Signal

Analyzer, +11000volts are present in the CRT for approximately 3 seconds. Be

extremely careful wh en working in proximity to this area during this time. The

high voltage can cause serious personal injury if contacted.

1-3

Troubleshooting the Analyzer

CAUTION: Do not connect or disconnect ribbon cables with the power switch set

to on ( l ). Power transients caused by connecting or disconnecting a cable can

damage circuit assemblies.

Equipment Required

The following table lists the recommended equipment needed to adjust and

troubleshoot the analyzer. Other equipment may be substituted for the

recommended model if it meets or exceeds the listed critical specifications.

When substitutions are made, you may have to modify the procedures to

accommodate the different operating characteristics.

Recommended Test Equipment

Instrument Critical Spec ifications Recommende d Model

Frequency Standard Accuracy ±0.5 ppm Agilent 5061B

Frequency Synthesizer Frequency range 3 Hz to 10 MHz

Milliwatt Power Meter Range ±0.2 dBm

Spectrum Analyzer Frequency range 100 Hz to 40 MHz

Digital Multimeter Accuracy 25 ppm

Frequency Counter Frequency range 3 to 30 MHz

Network Analyzer Range 10 kHz to 60 MHz

Amplitude range −36 to +20 dBm

Amplitude resolution 0.01 Hz

Impedance 50 Ω

Harmonic distor tion <−30 dBc

Spurious <−70 dBc

External reference input

Accuracy ±0.0625 dB

Amplitude range −60 to +15 dBm

Dynamic range <−67 dBc

Tracking Source @ 0 dBm

Impedance 50 Ω and 75 Ω

External reference input

Maximum volts range ≥400 Vdc

Resolution <1 Hz

Frequency accuracy ±0.25 Hz

Impedance 1MΩ

Resolution 10 Hz

Input impedance 50 Ω

Amplitude

range −42dBm to +10 dBm

resolution 0.25 dB

dynamic acc u racy 0. 3 dBp-p from 10 kHz to 16 MHz

Agilent 3326A

Alternate

Agilent 3325A

Agilent 3325B

W&G EPM-1 †

Agilent 3585B

Alternate

Agilent 3585A

Agilent 3588A

Agilent 3589A

Agilent3458A

Alternate

Agilent 3456A

Agilent 5334B opt 010

Agilent3577B

Alternate

Agilent4195A

Agilent3589A with

Agilent35689A

†Wandel & Goltermann Inc., 1800 Wyatt Drive, Suite 2, Santa Clara, CA 95054 U.S.A (408)988-7622

1-4

Recommended Test Equipment (continued)

Logic Probe TTL/CMOS Agilent 545A

Oscilloscope Bandwidth ≥150MHz

Oscilloscope Probe Input R ≥1MΩ

Oscilloscope Probe Input R ≥1MΩ

50 Ω Feedthrough Termination

(2 for opt AY7)

(2) 50 Ω Termination ±2% at dc Pomona Model 3840-50 †

ThinLAN Transceiver AUI to ThinLAN adapter Agilent 28641B

Cables (4) 50 Ω BNC

Adapters BNC(f)-to-Dual Banana Plug

Service Kit

10 kW Series Re s is tor †† Value: 10 kΩ

CPU/Memory Service Utility

Disk

Troubleshooting the Analyzer

Alternate

Agilent5006A

Agilent5005A/B

Agilent54111D

Vertical sensitivity 10 mV/div

Input coupling AC, DC, 50Ω, 1MΩ

Trigger Ext, Int

Agilent10438A

Division Ratio 1:1

Agilent10431A

Division Ratio 10:1

Accuracy ±0.2% Agilent 11048C

Alternate

Agilent11048C with

Agilent1250-0774

Agilent 8120-1840

Test clips-to-double banana plug

N(m)-to-BNC(f) (2)

Test Clips-to-BNC(f)

BNC Tee

N(f)-to-BNC(f)

BNC(f)-to-Dual Banana Plug(m)

BNC(f)-to-BNC(f)

Includes

A10/A35 extender board

A36/A60 extender board

A61 extender board

Motherboard cable extraction tool

Plastic screw driver

Flat-edge adjustment tool

SMB extender cable (2)

BNC(m)-to-SMB(f) cable (2)

SMB(m)-to-SMB(m) adapter (2)

Accuracy: 1%

Power: 0.125 Ω

Agilent11002A

Agilent1251-2816

Agilent1250-0780

Pomona Model 2631 †

Agilent 1250-0781

Agilent 1250-1536

Agilent 1251-2277

Agilent 1250-0080

Agilent 89410-84401

Includes

Agilent 89410-B1001‡

Agilent 89410-B1002‡

Agilent 89410-B1008‡

Agilent 8710-2050

Agilent 8710-2056

Agilent 8710-1928

Agilent 03585-61601

Agilent 03585-61616

Agilent 1250-0669

Agilent 0757-0442

Agilent89410-19463

†ITT Pomona Electronics, 1500 East Ninth Street, Pomona, CA 91769 U.S.A. (714) 469-2900 FAX (714) 629-3317

‡Individual extender boards cannot be ordered. To order all three extender

Agilent 89410-66515.

††See the following for assembly.

boards in this kit, order

1-5

Troubleshooting the Analyzer

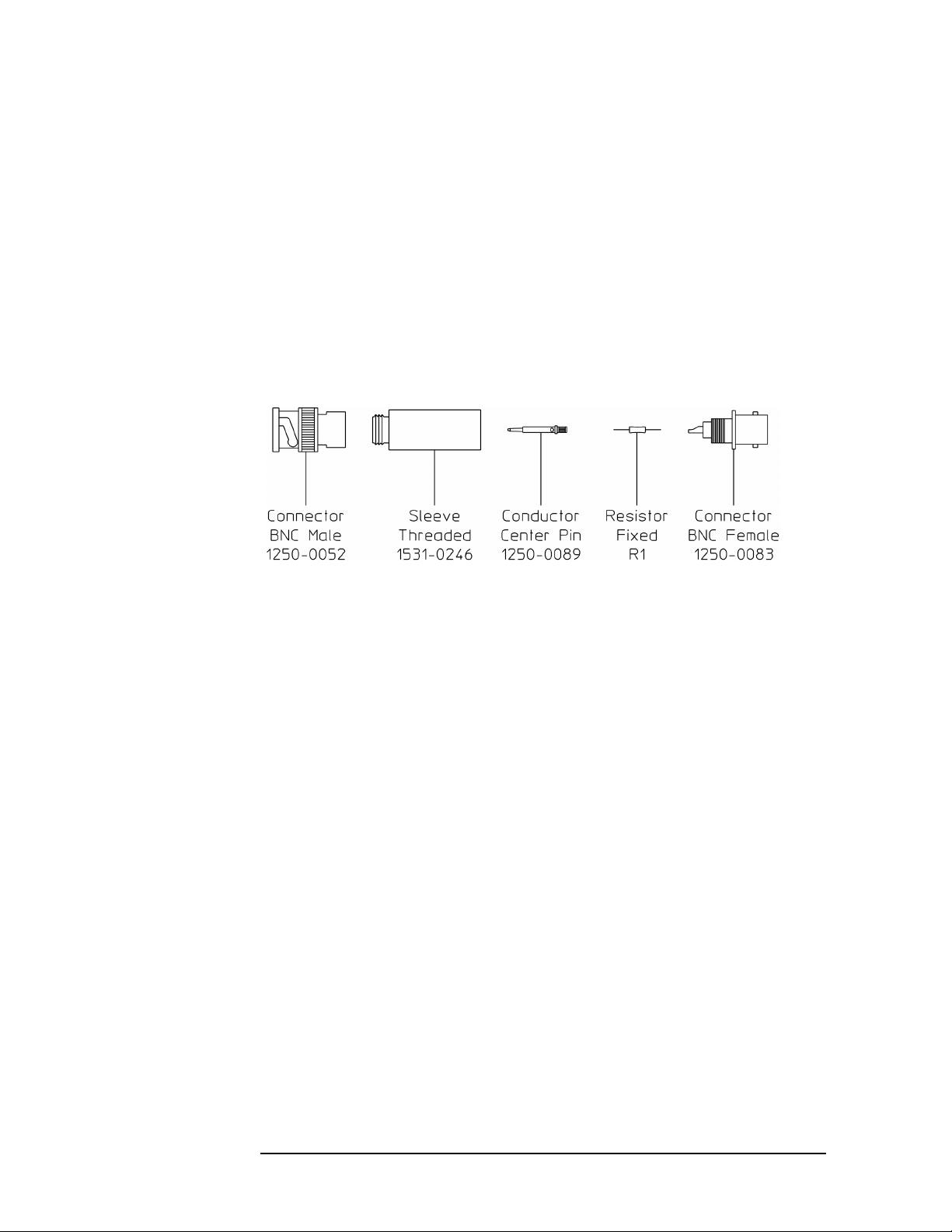

Suggested Assembly for Series Resistor

The following is a suggested assembly for the 10 kW series resistor. The

Ω series resistor is required for the Input Offset adjustment.

10 k

1 Cut resistor leads to 12 mm on each end.

2 Solder one resistor lead to the center conductor of the BNC female

connector.

3 Solder the conductor center pin to the other lead of the resistor.

4 Screw the sleeve and the BNC male connector into place. Tighten

securely.

Troubleshooting Hints

● Check that the analyzer has the latest firmware before starting the

troubleshooting procedures.

● Incorrect bias supply voltages can cause false diagnostic messages.

Most troubleshooting procedures do not check the power supply

voltages through the motherboard. If you suspect incorrect supply

voltages to an assembly, use the ‘’A90/A91 Motherboard Voltages’’

table on page 6-24 and an extender board to check the voltages at the

assembly.

● The troubleshooting procedures do not isolate failures to cables or

connectors. If you suspect a cable or connector failure, check the

device for continuity.

● Cables can cause intermittent hardware failures.

● Noise or spikes in the power supply can cause the analyzer to fail.

● Measurements in this chapter are only approximate (usually ±1 dB or

10%) unless stated otherwise.

● Use chassis ground for all measurements in this chapter unless stated

otherwise.

1-6

Troubleshooting the Analyzer

● Logic levels in this chapter are either TTL level high or TTL level low

unless stated otherwise. Toggling signal levels continually change

from one TTL level to the other.

● Configure a logic probe with an external bias supply for testing digital

signals. This analyzer does not have easily accessible +5 V supplies.

● If you abort a self test before the self test is finished, the analyzer may

fail its calibration routine. To prevent this from happening press

Preset] or cycle power after you abort the self test.

[

● The troubleshooting tests in this chapter assume only one

independent failure. Multiple failures can cause false results.

1-7

Troubleshooting the Analyzer

How to troubleshoot the analyzer

How to troubleshoot the analyzer

1 Review ‘’Safety Considerations’’ and ‘’Troubleshooting Hints.’’

WARNING: Service must be performed by tr ained service personnel who are

aware of the hazards involved (such as fire and electrical shock).

2 See Replacing Assemblies in chapter 3 to determine how to

disassemble and assemble the analyzer.

3 Determine which test to start with by comparing the analyzer’s

symptoms to the symptoms in the following table.

Symptom Troubleshooting Test

Screen blank

Screen grid is dist orted or not displaye d

After power up, >3 minutes before keys active

No response when key is pressed

Incorrect response when key is pressed

Fatal System Error Please Cycle Power message displayed

Fan not turning

Keys are active and screen grid is displayed but screen is

defective

Error messages

Calibration fails

Performance test fails

Intermittent failure

HPIB fails

Serial port fails

External monitor port fails

Parallel port fails

Sync out fails

System interconnect port fails

ThinLAN port fails

AUI port fails

Probe power fails

Oven reference fails

HPIB trigger fails

External trigger fails

Initial verification,

page 1-10

Display, page 1-25

Self tests, page1-32

Trigger, page 1-83

1-8

Troubleshooting the Analyzer

How to troubleshoot the analyzer

External keyboard does not work DIN connector,

page 1-92

NVRAM or Battery failure message displayed

Nonvolatile states not saved after powe r cycled

Memory battery,

page 1-93

4 Follow the recommended troubleshooting test until you locate the

faulty assembly.

5 Replace the faulty assembly and follow the directions in ‘’What to do

after replacing an assembly’’ in chapter 3, ‘’Replacing Assemblies

page 3-5.’’

1-9

Troubleshooting the Analyzer

To perform initial verification

To perform initial verification

Use this test to check signals that are vital to the operation of the

analyzer.

1 Check voltage selector switch and fuse.

a Check that the voltage selector switch on the rear of the analyzer

is set for the local line voltage.

b Check that the correct line fuse is installed in the rear panel fuse

holder.

For information on the voltage selector switch and line fuse, see

‘’To change the line-voltage selector switch’’ and ‘’To change the

fuse’’ in chapter 1 of the Agilent 89410A Installation and

Verification Guide.

2 Check power supply LEDs and fan.

a Check that no power supply fault LEDs are lit and that DS 440

(green) is lit.

b If any fault LEDs are lit or if the green power valid LED (DS 440)

is not lit, go to page 1-15, ‘’To troubleshoot the power supply.’’

c Check that the fan is turning at a moderate speed for normal room

temperature.

The fan speed increases as the analyzer’s internal temperature

increases. If the fan is turning too fast, check that the air flow

around the analyzer is not constricted and that the ambient

temperature is between 0 and 55 °C.

d If the fan is not turning, go to page 1-15, ‘’To troubleshoot the

power supply.’’

This quick check does not completely check the power supply. If a

power supply failure is still suspected, go to page 1-15 ‘’To

troubleshoot the power supply.’’

1-10

Troubleshooting the Analyzer

To perform initial verification

3 If the grid appears after power up, check that the calibration routine

is not locking up the analyzer.

a Set the power switch to off (

b Press and hold

[Return] (below softkeys) while setting the power

O ).

switch to on ( l ).

Pressing

[Return] while setting the power switch to on ( l ) causes

the analyzer to bypass the calibration routine.

c If the keys are now active, go to page page 1-48, ‘’To troubleshoot

self-test lockup failures.’’

4 If the analyzer powers up normally with no error messages (see

illustration below), the screen is continually updating, but the

analyzer does not respond to key presses, the A80 Keyboard assembly

is probably faulty.

1-11

Troubleshooting the Analyzer

To perform initial verification

5 Check frequency reference signals.

a Turn the analyzer upside down.

b Remove the bottom cover.

c Press

d Using an oscilloscope and a 1

[Preset].

MΩ 10:1 probe with a grounding

spanner, check the TTL signals in the following table.

The probe may load the 64 MHz, 48 MHz, and 80 MHz signals

causing their amplitude level to be low.

Test Location Ground Connectio n Frequency Probable Faulty Assembly

A91 P6 pin 16 A91 P6 pin 15 25.6MHz A60 Frequency Reference

A91 P6 pin 11 A91 P6 pin 12 25.6MHz A60 Frequency Reference

A91 P6 pin 18 A91 P6 pin 19 3.2MHz A60 Frequency Reference

A91 P4 pin 5 A91 P4 pin 6 378kHz A61 Clock

A91 P4 pin 21 A91 P4 pin 22 64MHz A 61 Clock

A91 P4 pin 24 A91 P4 pin 23 48MHz A 61 Clock

A91 P4 pin 25 A91 P4 pin 26 80MHz A 61 Clock

e If a signal is incorrect, replace the probable faulty assembly.

Before replacing the A60 Frequency Reference assembly, go to

page 1-15, ‘’To troubleshoot the power supply,’’ and do Step 7 to

check the power supply voltages.

1-12

Loading...

Loading...