VXIplug&play Driver User’s Guide

HP 4155B/4156B Semiconductor Parameter Analyzer

04156-90710

July 1998

© Copyright 1997,1998 Hewlett-Packard Company

Legal Notice

The information contained in this document is subject to change without notice.

Copyright © 1997,1998 Hewlett-Packard Company.

This document contains information which is protected by copyright. All rights are

reserved. Reproduction, adaptation, or translation with out prior written permission

is prohibited, except as allowed under the copyright laws.

• Product Warranty

Hewlett-Packard warrants Hewlett-Packard hardware, accessories and supplies

against defects in materials and workmanship for the p eriod of one year fro m the

warranty start date specified below. If Hewlett-Packard receives notice of such

defects during the warranty period, Hewlett-Packard will, at its option, either

repair or replace products which prove to be defective. Replacement products

may be either new or like-new.

For warranty service or repair, this product must be returned to a service facility

designed by Hewlett-Packard. Buyer shall prepay shipping charges to

Hewlett-Packard and Hewlett-Packard shall pay shipping charges to return the

product to Buyer. However, Buyer shall pay all shipping charges, duties, and

taxes for products returned to Hewlett-Packard from another country.

Hewlett-Packard warrants that Hewlett-Packard software will not fail to execute

its programming instructions, for the period of one year from the warranty start

date specified below , due to defects in material and workmanship when properly

installed and used. If Hewlett-Packard receives notice of such defects during the

warranty period, Hewlett-Packard will replace software media which does not

execute its programming instructions due to such defects.

Hewlett-Packard does not warrant that the operation of Hewlett-Packard

products will be uninterrupted or error free. If Hewlett-Packard is unable, within

a reasonable time, to repair or replace any product to a condition as warranted,

customer will be entitled to a refund of the purchase price upon prompt return of

the product.

The Hewlett-Packard products may contain remanufactured parts equivalent to

new in performance or may have been subject to incidental use.

2

The warranty period begins on the date of delivery or on the date of installation

if installed by Hewlett-Packard. If customer schedules or delays

Hewlett-Packard installation more than 30 days after delivery, warranty begins

on the 31st day from delivery.

Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supp lies not

supplied by Hewlett-Packard, (c) unauthorized modification or misuse, (d)

operation outside of the published environmental specifications for the product,

or (e) improper site preparation or maintenance.

To the extent allowed by local law, the above warranties are exclusive and no

other warranty or condition, whether written or oral, is expressed or implied and

Hewlett-Packard specifically disclaims any implied warranties or conditions of

merchantability, satisfactory quality, and fitness for a particular purpose.

Hewlett-Packard will be liable for damage to tangible property per incident up to

the greater of $300,000 or the actual amount paid for the product that is the

subject of the claim, and for damages for bodily injury or death, to the extent

that all such damages are determined by a court of competent jurisdiction to

have been directly caused by a defective Hewlett-Packard product.

To the extent allowed by local law, the remedies in this warranty statement are

customer’s sole and exclusive remedies. Expect as indicated above, in no event

will Hewlett-Packard or its suppliers be liable for loss of date or for di rect,

special, incidental, consequential (incl uding lost profit or date), or other damage,

whether based in contract, tort, or otherwise.

For consumer transactions in Australia and New Zealand: the warranty terms

contained in this statement, except to the extent lawfully perm itted, do not

exclude, restrict or modify and are in addition to the mandatory statutory rights

applicable to the sale of this product to you.

• Assistance

Product maintenance agreements and other customer assistance agreements are

available for Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales Office.

• Certification

Hewlett-Packard Company certifies that this prod uct met its published

specifications at the time of shipment from the factory. HP further certifies that

its calibration measurements are traceable to the National Institute of Standards

3

and Technology (NIST), to the extent allowed by the Institute’s calibration

facility, and to the calibration facilities of other International Standards

Organization members.

Microsoft, Windows, Windows NT, Visial Basic, and Visual C/C++ are registered

trademarks of M i crosoft Corpor ation.

Borland C/C++ Builder is registered trademark of International, Inc.

LabWindows and LabVIEW are registered trademarks of National Instruments

Corporation.

Prober Control Software (PCS) is a product of Cascade Michrotech, Inc.

4

Contents

1. Installation

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Hardware Requirements with HP VEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Installing the HP 4155B/4156B Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

To Configure the Interface using HP I/O Library . . . . . . . . . . . . . . . . . . . . . . . .20

To Install the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2. Driver Functions

Driver Functions for HP 4155B/4156B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

hp4156b_abortMeasure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

hp4156b_addSampleSyncIv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

hp4156b_addSampleSyncPulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

hp4156b_addStressSyncIv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

hp4156b_addStressSyncPulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

hp4156b_autoCal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

hp4156b_clearSampleSync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

hp4156b_clearStressSync. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

hp4156b_close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

hp4156b_cmd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

hp4156b_cmdData_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

hp4156b_cmdInt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

hp4156b_cmdInt16Arr_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

hp4156b_cmdInt16_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

hp4156b_cmdInt32Arr_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

hp4156b_cmdInt32_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

hp4156b_cmdReal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

hp4156b_cmdReal64Arr_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

hp4156b_cmdReal64_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

hp4156b_cmdString_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

hp4156b_dcl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5

Contents

hp4156b_error_message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

hp4156b_error_query. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

hp4156b_errorQueryDetect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

hp4156b_errorQueryDetect_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

hp4156b_esr_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

hp4156b_execCal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

hp4156b_execOffsetCancel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

hp4156b_force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

hp4156b_forcePulse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

hp4156b_init . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

hp4156b_measureM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

hp4156b_measureP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

hp4156b_offsetCancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

hp4156b_opc_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

hp4156b_readData. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

hp4156b_readStatusByte_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

hp4156b_recoverOutput. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

hp4156b_reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

hp4156b_revision_query . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

hp4156b_sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

hp4156b_self_test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

hp4156b_setFilter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

hp4156b_setInteg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

hp4156b_setIv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

hp4156b_setPbias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

hp4156b_setPguR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

hp4156b_setPiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

hp4156b_setSample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

hp4156b_setStress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

hp4156b_setSweepSync. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

hp4156b_setSwitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

hp4156b_setVm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6

Contents

hp4156b_spotMeas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

hp4156b_startMeasure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

hp4156b_stopMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

hp4156b_stress. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

hp4156b_sweepIv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

hp4156b_sweepMiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

hp4156b_sweepPbias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

hp4156b_sweepPiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

hp4156b_timeOut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

hp4156b_timeOut_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

hp4156b_zeroOutput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

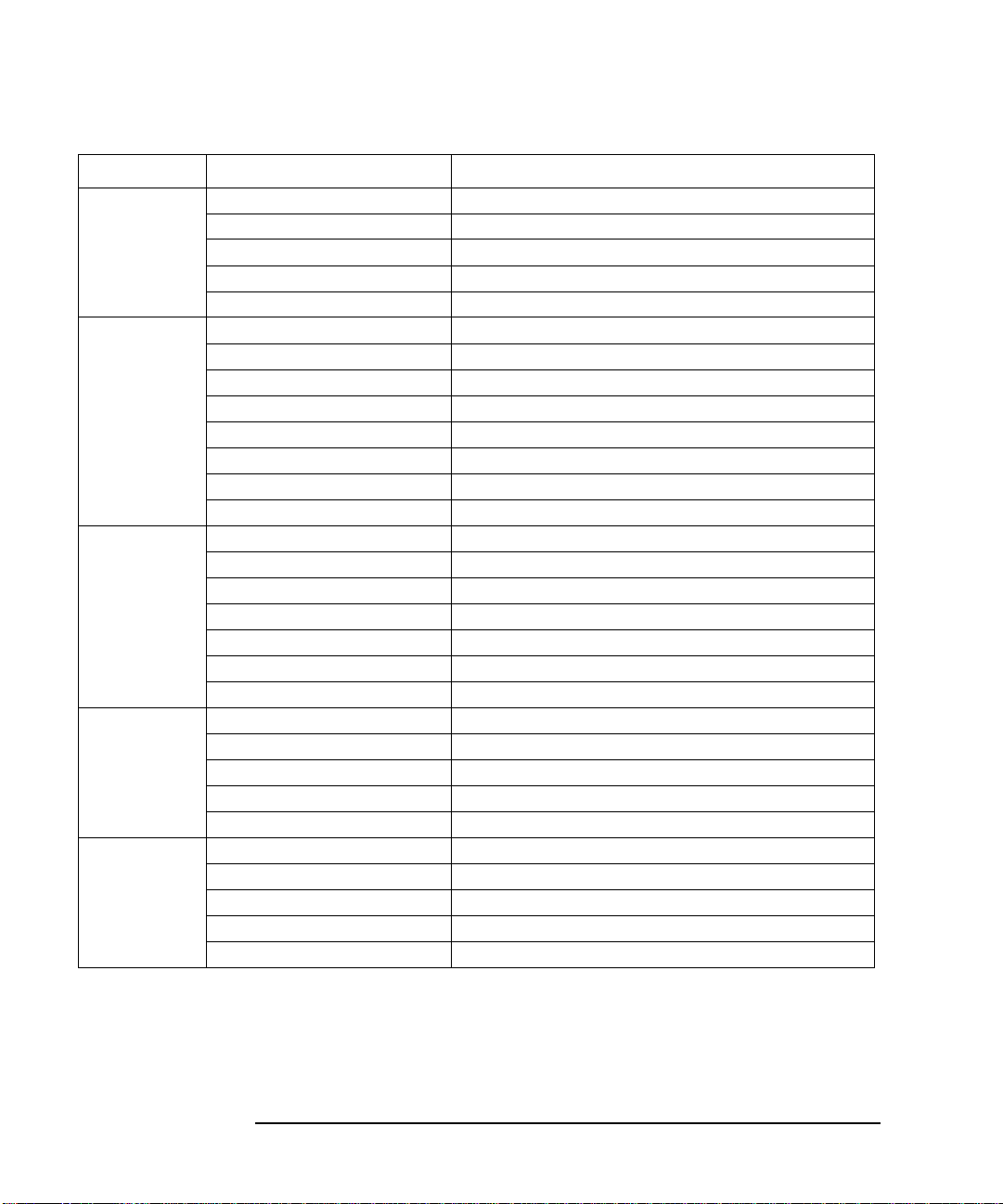

Driver Functions for HP E5250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

hpe5250a_biasChanCard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

hpe5250a_biasChanList . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

hpe5250a_biasChanList_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

hpe5250a_biasPort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

hpe5250a_biasState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

hpe5250a_close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

hpe5250a_closeCard_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

hpe5250a_closeList . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

hpe5250a_closeList_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

hpe5250a_cmd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

hpe5250a_cmdData_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

hpe5250a_cmdInt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

hpe5250a_cmdInt16Arr_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

hpe5250a_cmdInt16_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

hpe5250a_cmdInt32Arr_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

hpe5250a_cmdInt32_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

hpe5250a_cmdReal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

hpe5250a_cmdReal64Arr_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

hpe5250a_cmdReal64_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7

Contents

hpe5250a_cmdString_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

hpe5250a_compenC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

hpe5250a_connRuleSeq. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

hpe5250a_couplePort. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

hpe5250a_coupleState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

hpe5250a_dcl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

hpe5250a_error_message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

hpe5250a_error_query. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

hpe5250a_errorQueryDetect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

hpe5250a_errorQueryDetect_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

hpe5250a_esr_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

hpe5250a_func. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

hpe5250a_init. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

hpe5250a_opc_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

hpe5250a_openCard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

hpe5250a_openList . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

hpe5250a_openList_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

hpe5250a_readStatusByte_Q. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

hpe5250a_reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

hpe5250a_revision_query . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

hpe5250a_selectCompenFile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

hpe5250a_self_test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

hpe5250a_testClear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

hpe5250a_testExec_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

hpe5250a_timeOut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

hpe5250a_timeOut_Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

3. Programming Examples Using HP VEE

Programming Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Registrating the Driver on HP VEE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Basic Objects to Control the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

8

Contents

To display the To/From object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

To define transactions in the To/From object . . . . . . . . . . . . . . . . . . . . . . . . .104

To set input parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

To use the Help function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

To use input variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

To create output terminals in the To/From object. . . . . . . . . . . . . . . . . . . . . .108

To display/connect the Data object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

To display/connect the Display object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Debugging Your Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

To recover control mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

To check for instrument error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Restrictions When Using the Driver with HP VEE . . . . . . . . . . . . . . . . . . . . . .112

Invalid functions in the VEE program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Invalid use of the NULL pointer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

High-Speed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Multi-Channel Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Staircase Sweep Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Synchronous Sweep Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Multi-Channel Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Pulsed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Multi-Channel Pulsed Spot Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Pulsed Sweep Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Multi-Channel Pulsed Sweep Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Staircase Sweep with Pulsed Bias Measurements. . . . . . . . . . . . . . . . . . . . . . . . .135

Sampling Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Stress Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

9

Contents

4. Sample Application Programs for HP VEE

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

HP VEE Sample Program Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

What are Sample Programs? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Definition of Vth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Execution Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Measurement Connection and Source Setup . . . . . . . . . . . . . . . . . . . . . . . . .149

Measurement Data Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Required Equipment and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 51

Installing the Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Using sample1.vee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Program Execution Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

To Execute sample1.vee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Using sample2.vee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Program Execution Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

To Execute sample2.vee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Customizing Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

To Change an HP-IB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

To Change the Vth Measurement Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

To Remove a Test Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

To Remove a Source Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

To Add a Test Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

To Add a Measurement Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

To Add the Measurement Function and Dummy Data. . . . . . . . . . . . . . . . . .180

To Set the Id Measurement Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

To Save Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

To Modify the Show Result and Main Panel Displays. . . . . . . . . . . . . . . . . .184

10

Printing History

Edition 1. … August 1997

Edition 2. … July 1998

11

12

About This Manual

This manual provides information about VXIplug&play driver for the HP

4155B/4156B. This manual also introduces two sample applicatio n programs using

the HP VEE and the VXIplug&play driver for the HP 4155B/4156B.

• Installation

This chapter describes hardware and software requirements to use

HP 4155B/4156B VXIplug &pl ay driver, and how to install the driver.

• Driver Functions

This chapter lists the all driver functions for the HP 4155B/4156B and the

HP E5250A Low Leakage Switch Mainframe.

• Programming Examples Using HP VEE

This chapter describes how to create measurement program using HP VEE, and

provides programmin g exampl es .

• Sample Application Programs For HP VEE

This chapter provides how to install, execute, and modify the sample application

programs stored in the HP VEE Sample Program Disk furnished with th e HP

4155B/4156B.

13

14

1 Installation

15

Installation

This chapter explains the environment requirements and installation of the

HP 4155B/4156B VXIplug&play driver.

• “Softwa re Require ments”

• “Hardware Requirements with HP VEE”

• “Installing the HP 4155B/4156B Driver”

NOTE The hardware required d epends on the oper atin g syst em and p rogrammin g lan guage

used. This manual provides hardware requirements when using the driver with

HP VEE. When using the driver with a programming language other than HP VEE,

refer to the appropriate programming manual.

16 Chapter 1

Installation

Software Requirements

Software Requirements

The following software is required to use the VXIplug&play driver for the

HP 4155B/4156B. You can select one from Windows NT and Windows 95. You can

also select the most comfortable programming language to develop and run

programs.

•Operating System

• Windows NT revision 3.51 or later

• Windows 95

• 32-bit VISA I/O Library

HP I/O Library for HP-IB Interface Card, or equivalent

• Programming Environ ment

•HP VEE

• Microsoft Visual Basic

• Microsoft Visual C++

• Borland C/C++

• LabView

• LabWindows

• VXIplug&play Driver Disk (furnished with the HP 4155B/4156B)

• HP 4155B/4156B Plug&Play Driver Disk

• HP E5250A Plug&Play Driver Disk

NOTE If you use the sample application programs, stored in the HP VEE Sample Program

Disk furnished with the HP 4155B/4156B, HP VEE must be version 4.0 or later.

See Chapter 4. Also, if you use the Cascade Microtech Summit series semi-auto

prober, confirm the operating system supported by the prober control software

(PCS) supplied from Cascade Microtech, Inc. PCS version 2.50 supports Windows

95 and Windows 3.1.

NOTE The HP E5250A Plug&Play Driver Disk stores the VXIplug&play driver for the

HP E5250A. This driver is required to use the sample application programs.

Chapter 1 17

Installation

Hardware Requirements with HP VEE

Hardware Requirements with HP VEE

The following hardware is required to use HP VEE and the VXIplug&play drivers.

• Controller

• 486/66 with Coprocessor (minimum recommendation)

• 586(Pentium)/90 or better is recommended.

•Memory

• For Windows 95: 16 Mbyte. 24 Mbyte or more is recommended.

• For Windows NT: 24 Mbyte. 32 Mbyte or more is recommended.

• Hard disk (minimum disk space)

• 20 Mbytes for HP VEE version 4.0

• 2 Mbytes for HP 4155B/4156B driver

• 1 Mbyte for HP E5250A driver

•Graphics

1024 × 768. 1280 × 1024 is recommended.

• IEEE 488 Interface card

HP 82341C HP-IB Interface Card, or equivalent.

•CD-ROM drive

A CD-ROM drive will be required to install the software needed to use the

VXIplug&play driver.

• Flexible disk drive

A 3.5 inch flexible disk drive is required to install the drivers.

18 Chapter 1

Installation

Installing the HP 4155B/4156B Driver

Installing the HP 4155B/4156B Driver

The installation flow for the VXIplug&play driver is shown below. If you have

already installed the IEEE 488 interface card, VISA I/O library, and programming

software on your PC, skip steps 1 through 4.

1. Install the IEEE 488 interface card into your PC.

See the interface card manual. Note the model number of the interface card, as

you may need it to configure the interface (in step 3).

2. Install VISA I/O library.

Follow the instructions in the I/O library’s setup program.

3. Configure and check the IEEE 488 interface.

See the I/O library manual. If you use HP I/O Library, also see “To Configure

the Interface using HP I/O Library” on page 20.

4. Install the programming software.

Follow the setup program instructio ns.

5. Install the VXIplug&play driver.

See “To Install the Driver” on page 21.

6. Register the driver in the programming software.

See the programming software manual. If you are using HP VEE, also see

“Programming Basics” in Chapter 3.

Chapter 1 19

Installation

Installing the HP 4155B/4156B Driver

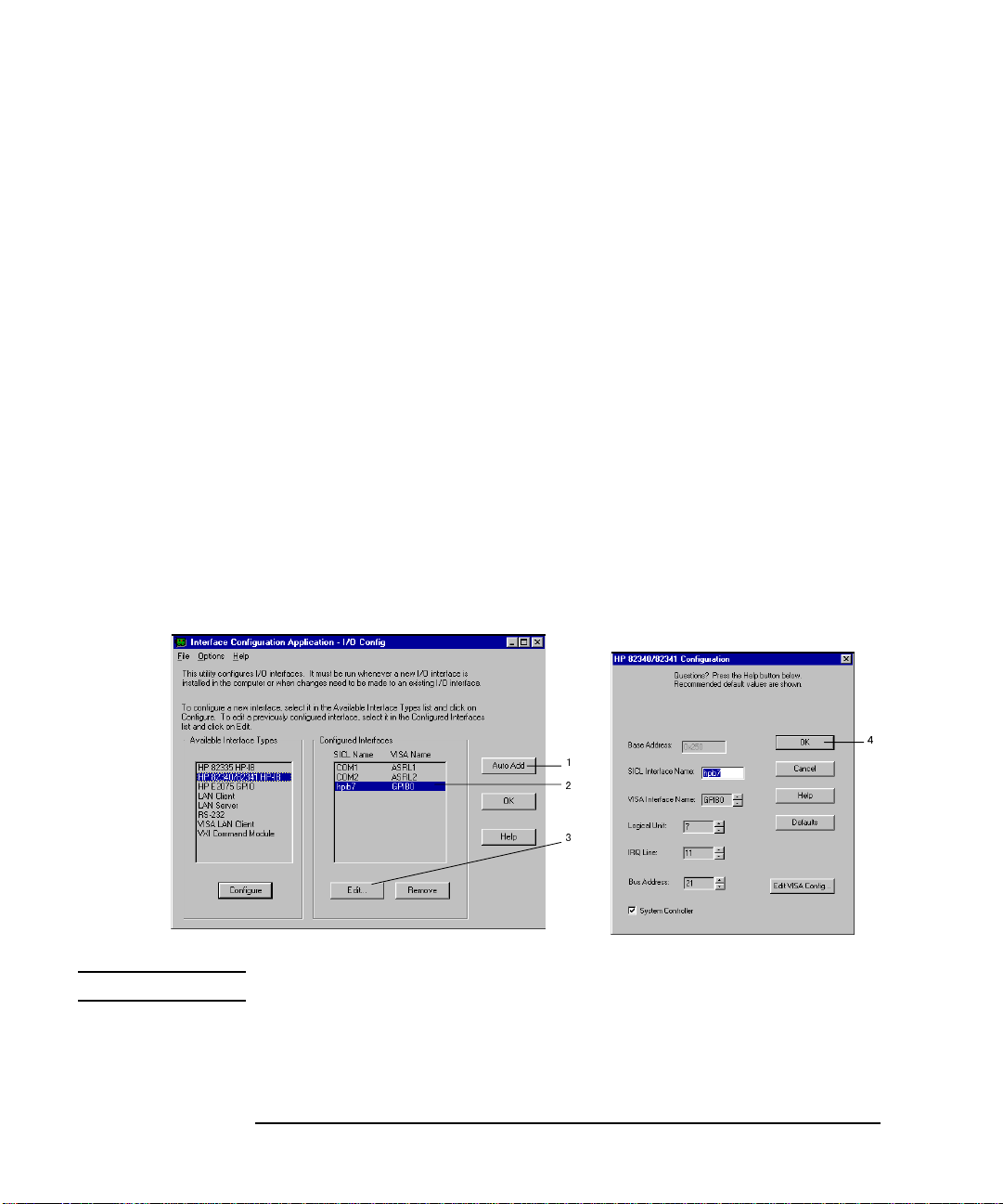

To Configure the Interface using HP I/O Library

After installing the IEEE 488 interface card and HP I/O Library, configure the

interface. The procedure shown below is the easiest way to configure the interface.

First, execute I_O Config in the HP I_O Libraries folder. The I/O Config window is

displayed. See Figure 1-1.

1. Click Auto A dd.

If the interface card is installed properly, I_O Config automatically detects the

hardware configuration. The default names for SICL and VISA are assigned and

listed, as shown in the Configured Interface list.

2. Click hpib7 GPIB0.

3. Click Edit to display the Configuration dialog box for the interface card.

If you find any conflicts in the dialog box, such as IRQ line, you may need to

change them manually. Normally you can exit without modifying the default

setup.

4. Click OK to exit. Reboot your PC to configure the interface.

Figure 1-1 To Configure the Interface using the HP I/O Library

NOTE VISA Name is used by the VXIplug&play drivers to access the interface.

20 Chapter 1

Installation

Installing the HP 4155B/4156B Driver

To Install the Driver

1. Insert the HP 4155B/4156B Plug&Play Driver Disk into the flexible disk drive

connected to your PC.

2. Execute th e 4156B.EXE p rogram stored on the diskette. The program

automatically installs the driver in the following directory.

• For Windows NT: \Vxipnp\Winnt\Hp4156b

• For Win dows 95: \ Vx i pnp \Win95\Hp4156b

Following files are installed in the directory.

• hp4156b.bas

• hp4156b.c

• hp4156b.def

• hp4156b.fp

• hp4156b.GID

• hp4156b.h

• hp4156b.hlp

• readme.txt

•DelsL1.isu

3. If you are also installing the driver for the HP E5250A, do the following.

a. Ins e rt the HP E5 250A Plug&Play Driver Disk into the flexible disk drive

connected to your PC.

b. Execute the E5250A.EXE program stored on the diskette. The program

automatically installs the driver in the following directory.

• For Windows NT: \Vxipnp\Winnt\Hpe5250a

• For Win dows 95: \Vxipnp\W i n9 5\ Hpe5250a

Following files are installed in the directory.

• hpe5250a.bas

• hpe5250a.c

• hpe5250a.def

• hpe5250a.fp

Chapter 1 21

Installation

Installing the HP 4155B/4156B Driver

• hpe5250a.GID

• hpe5250a.h

• hpe5250a.hlp

• readme.txt

•DelsL1.isu

22 Chapter 1

2 Driver Functions

23

Driver Functions

This section explains all the driver fincti ons available for the HP 41555B/415 6B and

the HP E5250A.

• “Driver Functions for HP 4155B/4156B”

• “Driver Functions for HP E5250A”

NOTE For additional information on each function. refer to the on-line help for the

VXIplug&play drivers, or open the hp4156b.hlp or hpe5250a.hlp file in the

direcroty the driver is installed. See “Installing the HP 4155B/4156B Driver” in

Chpater 1.

24 Chapter 2

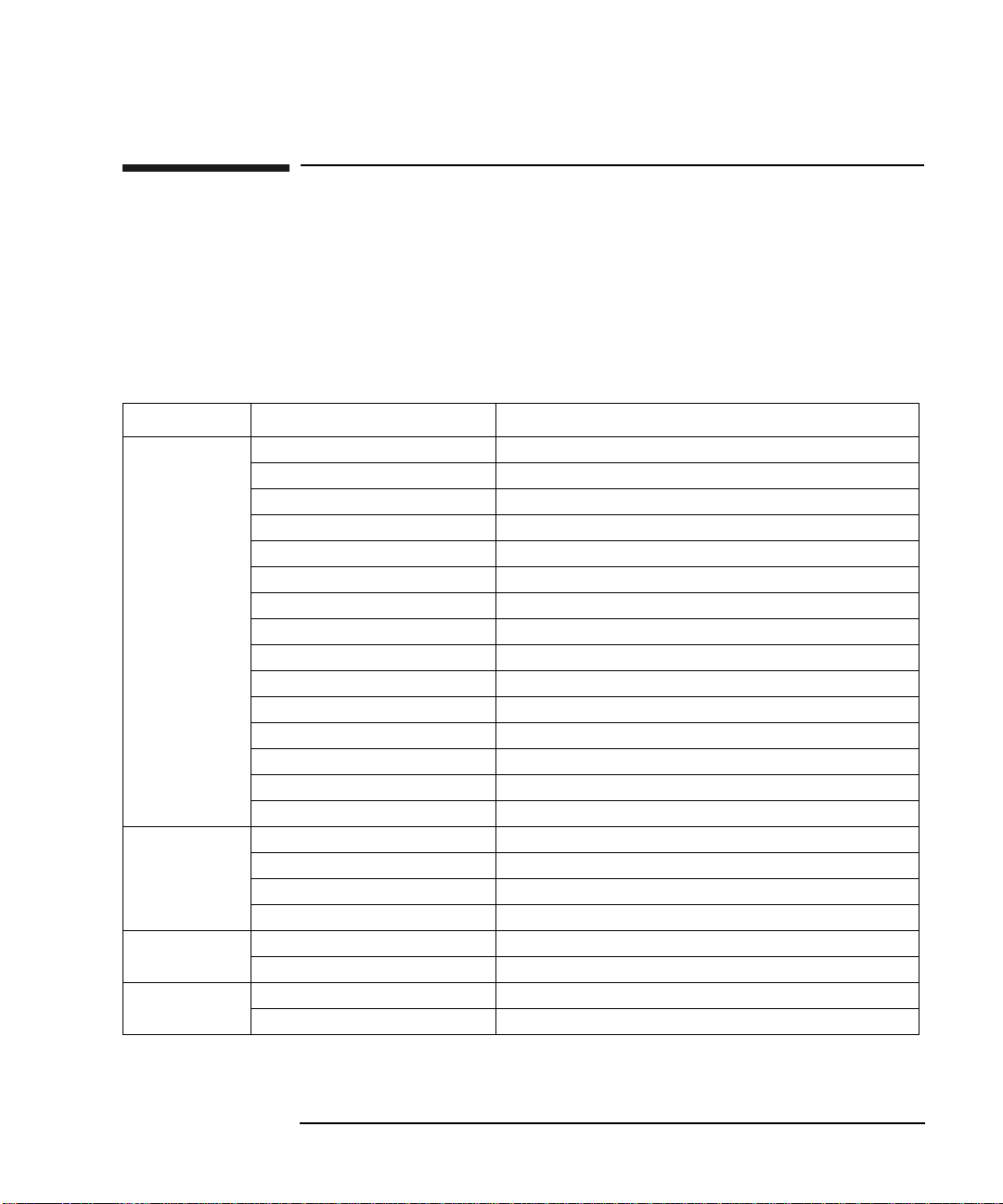

Driver Functions for HP 4155B/4156B

Table 2-1 lists all the functions for the HP 4155B/4156B. You will see a brief

description of the functions in th e table.

For the description, syntax and parameters of the function, refer to the reference

section following this table. The driver functions in the reference section will appear

in the alphabetical order.

Table 2-1 HP 4155B/4156B Driver Function Lists

Category Function Description

Miscellaneous hp4156b_init Initializes the HP 4155B/4156B.

hp4156b_close Closes the connection with the HP 4155B/4156B.

hp4156b_reset Executes the HP 4155B/4156B reset.

hp4156b_self_test Executes the HP 4155B/4156B self-test.

hp4156b_error_query Queries the HP 4155B/4156B for error code/ mess age.

hp4155b_error_message Queries for the driver errors.

hp4156b_revision_query Queries for HP 4155B/4156B firmware/driver revisions.

hp4156b_timeOut Sets the timeout.

hp4156b_timeOut_Q Queries for the timeout setting.

hp4156b_errorQueryDetect Sets the automatic error checking.

hp4156b_errorQueryDetect_Q Queries for the automatic error checking setting.

hp4156b_dcl Sends the Device Clear.

hp4156b_esr_Q Queries the ESR status.

hp4156b_readStatusByte_Q Reads the HP 4155B/4156B status byte.

hp4156b_opc_Q Checks HP 4155B/4156B operation completion status.

Primitive

Measurement

Functions

Calibration hp4156b_ a utoCal Sets the auto calibration mode

Zero Offset

Cancel

hp4156b_startMeasure Starts a measurement.

hp4156b_readData Reads a measurement result.

hp4156b_stopMode Sets the measurement completion mode.

hp4156b_abortMeasure Aborts output or measurement.

hp4156b_execCal Executes the HP 4155B/4156B calibration

hp4156b_offsetCancel Sets the zero offset cancel.

hp4156b_execOffsetCancel Executes the zero offset cancel.

Driver Functions

Chapter 2 25

Driver Functions

Category Function Description

Measurement

Unit Setup

Source Setup hp4156b_force Applies a dc current or voltage.

Measurement

Execution

Sampling

Measurements

Stress Force hp4156b_setStress Sets the timing parameters.

hp4156b_setSwitch Sets the output switch.

hp4156b_setFilter Sets the output filter.

hp4156b_setInteg Sets the integration time.

hp4156b_setVm Sets the VMU measurement mode.

hp4156b_setPguR Sets the PGU output impedance.

hp4156b_forcePulse Applies a pulse by using PGU.

hp4156b_zeroOutput Disables output.

hp4156b_recoverOutput Recovers output.

hp4156b_setIv Sets the sweep source.

hp4156b_setPbias Sets the pulsed bias source.

hp4156b_setPiv Sets the pulsed sweep source.

hp4156b_setSweepSync Sets the synchronous sweep source.

hp4156b_spotMeas Executes a high speed spot measurement.

hp4156b_measureM Executes a multi-channel spot measurement.

hp4156b_sweepIv Executes a one channel sweep measurement.

hp4156b_sweepMiv Executes a multi-channel sweep measurement.

hp4156b_measureP Executes a pulsed spot measurement.

hp4156b_sweepPiv Executes a pulsed sweep measurement.

hp4156b_sweepPbias Executes a sweep measurement with pulsed bias.

hp4156b_setSample Sets the timing parameters.

hp4156b_addSampleSynclv Sets the dc source.

hp4156b_addSampleSyncPulse Sets the pulse source.

hp4156b_sample Executes a sampling measurement.

hp4156b_clearSampleSync Clears the source setup.

hp4156b_addStressSyncIv Sets the dc stress source.

hp4156b_addStressSyncPulse Sets the pulse stress source.

hp4156b_stress Forces stress.

hp4156b_clearStressSync Clears the source setup.

26 Chapter 2

Category Function Description

Passthrough

Functions

hp4156b_cmd Sends a command.

h4156b_cmdInt Sends a command with an integer parameter.

hp4156b_cmdReal Sends a command with a real parameter.

hp4156b_cmdData_Q Sends a command to read any data.

hp4156b_cmdString_Q Sends a command to read string response.

hp4156b_cmdInt16_Q Sends a command to read 16 bit integer response.

hp4156b_cmdInt16Arr_Q Sends a command to read 16 bit integer array response.

hp4156b_cmdInt32_Q Sends a command to read 32 bit integer response.

hp4156b_cmdInt32Arr_Q Sends a command to read 32 bit integer array response.

hp4156b_cmdReal64_Q Sends a command to read 64 bit real response.

hp4156b_cmdReal64Arr_Q Sends a command to read 64 bit real array response.

Driver Functions

Chapter 2 27

Driver Functions

hp4156b_abortMeasure

hp4156b_abortMeasure

This function aborts the HP 4155B /4156B’s present operation, such as the

measurement executed by the hp4156b_startMeasure function, the pulse output by

the hp4156b_forcePulse function, the stress force by the hp4156b_stress function,

and so on.

Syntax ViStatus _VI_FUNC hp4156b_abortMeasure(ViSession vi);

Parameters vi Instrument handle returned from hp4156b_init( ).

hp4156b_addSampleSyncIv

This function specifies the constant current source or constant voltage source used

for the sampling measurements, and sets the parameters. Source output starts at the

beginning of the sampling measurement (beginning of the hold time), and stops at

the end of the last sampling measurement point.

Sampling measurement channels are defined by the hp4156b_sample function, and

sampling measurement timing is defined by the hp4156b_setSample function.

Syntax ViStatus _VI_FUNC hp4156b_addSampleSyncIv(ViSession vi, ViInt32 channel,

ViInt32 mode, ViReal64 range, ViReal64 base, ViReal64 bias, ViReal64 comp);

Parameters vi Instrument handle returned from hp4156b_init( ).

channel Channel number of the source unit. 1 to 6 (SMU1 to SMU6),

21 (VSU1), 22 (VSU2), 27 (PGU1), or 28 (PGU2)

mode Output mode. 1 (current output, only for SMU) or 2 (voltage

output).

range Output range. 0 (auto ranging) or positive value (limited auto

ranging). See be low.

For current output: 1E-11 to 1.0 A, or 0.

For voltage output: 2.0 to 200.0 V, or 0.

base Base value. -1.0 to 1.0 A for curr ent output, -200.0 V to 200.0 V

for voltage output.

bias Bias value. -1.0 to 1.0 A for current ou tput, -200.0 V to 200.0 V

for voltage output.

comp Compliance valu e. -200. 0 V to 200.0 V for v oltage complian ce,

-1.0 to 1.0 A for current compliance.

28 Chapter 2

Driver Functions

hp4156b_addSampleSyncPulse

hp4156b_addSampleSyncPulse

This function specifies the pulse source (PGU) used for the sampling measurements,

and sets the parameters. Pulse outputs start at the beginning of the sampling

measurement (beginning of the hold time), and stop at the end of the last sampling

measurement point or stop at the last pulse if it com e s earlier than the last sampling

measurement point.

Sampling measurement channels are defined by the hp4156b_sample function, and

sampling measurement timing is defined by the hp4156b_setSample function.

If you want to let the pulse output synchronize with the sampling measurement

timing, you should define carefully both the hp4156b_addSampleSyncPulse timing

parameters (count, period, width, delay, rise and fall) and the hp4156b_setSample

timing parameters.

Syntax ViS tatus _VI_FUNC hp4 156b_addSampleSyn cPulse(V iSessi on vi, V iInt32 chan nel,

ViReal64 base, ViReal64 peak, ViInt32 count, ViReal64 period, ViReal64 width,

ViReal64 delay, ViReal64 rise, ViReal64 fall);

Parameters vi Instrument handle returned from hp4156b_init( ).

channel Channel number of the pulse generator unit.

27 (PGU1) or 28 (PGU2)

base Pulse base value. -40.0 to 40.0 V.

peak Pulse peak value. -40.0 to 40.0 V.

count Pulse count (number of pulses). 1 to 65535, or 0 (free run

mode).

period Pulse period. 1E-6 to 1 0.0 seconds.

width Pulse width. 1E-6 to 9.99 seconds.

delay Pulse delay time. 0.0 to 10.0 seconds.

rise Pulse leading time. 0.1E-6 to 10E-3 secon ds.

fall Pulse trailling time. 0.1E-6 to 10E -3 seco nds.

Chapter 2 29

Driver Functions

hp4156b_addStressSyncIv

hp4156b_addStressSyncIv

This function specifies the DC stress source, and sets the parameters. You can use

maximum 4 stress sources at once by using the hp4156b_ad dStressSyncIv and/or

hp4156b_addStressSyncPulse functions.

Syntax ViStatus _VI_FUNC hp4156b_addStressSyncIv(ViSession vi, ViInt32 source,

ViInt32 channel, ViInt32 mode, ViReal64 range, ViReal64 base, ViReal64 stress,

ViReal64 comp);

Parameters vi Instrument handle returned from hp4156b_init( ).

source Reference number of the stress source. 1, 2, 3, or 4.

channel Channel number of the stress source.

1 to 6 (SMU1 to SMU6), 21 (VSU1), 22 (VSU2), 27 (PGU1),

or 28 (PGU2)

mode Output mode. 1 (current output, only for SMU) or 2 (voltage

output).

range Output range. 0 (auto ranging) or positive value (limited auto

ranging). See be low.

For current output: 1E-11 to 1.0 A, or 0.

For voltage output: 2.0 to 200.0 V, or 0.

base Base value. -1.0 to 1.0 A for curr ent output, -200.0 V to 200.0 V

for voltage output.

stress Stress value. -1.0 to 1.0 A for current output, -200.0 V to 200.0

V for voltage output.

comp Compliance valu e. -200. 0 V to 200.0 V for v oltage complian ce,

-1.0 to 1.0 A for current compliance.

30 Chapter 2

Loading...

Loading...