Page 1

Sauter GmbH

Ziegelei 1

E-Mail: info@sauter.eu

Internet: www.sauter.eu

Ultrasonic Thickness Gauge

SAUTER TN-EE

Version 1.0

02/2014

D-72336 Balingen

Instruction Manual

Multi Mode

GB

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

TN_EE -BA-e-1410

Page 2

GB

SAUTER TN-EE

Instruction Manual Ultrasonic Thickness Ga uge

Version 1.0 02/2014

Thank you for buying a SAUTER Material Thickness Gauge. We hope you are

pleased with your high quality instrument and with its big functional range. If you

have any queries, wishes or helpful suggestions, do not hesitate to call our service

number.

Summary:

1 Overview ......................................................................................................... 3

1.1 Product Specifications............................................................................................................. 3

1.2 Main Functions ......................................................................................................................... 3

1.3 Measuring Principle ................................................................................................................. 4

1.4 Configuration ............................................................................................................................ 4

1.5 Operating Conditions ............................................................................................................... 4

2 Keypad & Screen ........................................................................................... 5

2.1 Keypad Definitions ................................................................................................................... 5

3 Preparation ..................................................................................................... 6

3.1 Transducer Selection ............................................................................................................... 6

3.2 Condition and Preparation of Sur faces .................................................................................. 7

4 Operation ........................................................................................................ 8

4.1 Power On/Off ............................................................................................................................. 8

4.2 Setting the Measurement Mode .............................................................................................. 8

4.3 Perform Probe Zero .................................................................................................................. 8

4.4 Sound Velocity Calibration ...................................................................................................... 9

4.4.1 Calibration to a known thickness ................................................................................................ 9

4.4.2 Calibration to a known velocity ................................................................................................. 10

4.4.3 Two Point Calibration ............................................................................................................... 10

4.5 Performing Measurements .................................................................................................... 11

4.6 Scan mode .............................................................................................................................. 11

4.7 Changing Resolution ............................................................................................................. 12

4.8 Changing Units ....................................................................................................................... 12

4.9 Memory Management ............................................................................................................. 12

4.9.1 Storing a reading ...................................................................................................................... 12

4.9.2 Clearing selected file ................................................................................................................ 12

4.9.3 Viewing/deleting stored record ................................................................................................. 12

4.10 EL Backlight ............................................................................................................................ 13

4.11 Battery Information ................................................................................................................ 13

4.12 Auto Power Off ....................................................................................................................... 13

4.13 System Reset .......................................................................................................................... 13

4.14 Connecting to a Computer .................................................................................................... 13

5 Servicing ....................................................................................................... 13

6 Transport and Storage ................................................................................ 14

7 Declaration of Conformity ........................................................................... 16

2 TN_EE-BA-e-1410

Page 3

1 Overview

The model TN-EE is a multi-mode ultrasonic thickness gauge. Based on the same

operating principles as SONAR, the instrument is capable of measuring the thickness

of various materials with accuracy as high as 0.1/0.01 millimeters.

The multi-mode feature of the gauge allows the user to toggle between pulse-echo

mode and echo-echo mode (eliminating paint or coating thickness).

1.1 Product Specifications

There are two models available with the following measurement ranges:

-. TN 30-0.01EE

-. TN 60-0.01EE

1) Display:4.5 digits LCD with EL backlight.

2) Measurement Range: Pulse-Echo mode: (0.65~600)mm (in S teel), valid for both

models

Echo-Echo mode: (3~60) mm for TN 60-0.01EE.

Echo-Echo mode: (3~30) mm for TN 30-0.01EE

3) Sound Velocity Range: (1000~9999) m/s.

4) Resolution: 0.1mm/ 0.01mm

Accuracy: ±(0.5%Thickness+0.01)mm, depending on materials and conditions

5) Memory for up to 20 files (up to 99 values for each file) of stored values.

6) Power Source: Two “AA” size, 1.5 Volt alkaline batteries. 100 hours typical operating time (EL backlight off).

7) Communication:USB1.1.

8) Dimensions:150mm × 74mm × 32 mm.

9) Weight:245g

1.2 Main Functions

1) Multi-mode: Pulse-Echo mode and Echo-Echo mode.

2) Capable of performing measurements on a wide range of materials, including

metals, plastic, ceramics, composites, epoxies, glass and other ultrasonic wave

well-conductive materials.

3) Transducer models are available for special applications, including for coarse

grain material and high temperature applications.

4) Sensor Zero function, Soun d-Velocity-Calibration function

5) Two-Point- calibration function

6) Single point mode and Scan mode. Seven measurements readings per second in

single point mode, and sixteen per second in Scan Mode.

7) Coupling status indicator showing the coupling status.

8) Units: Metric/Imperial unit selectable.

9) Battery information indicates the rest capacity of the battery.

10) Auto sleep and auto power off function to conserve battery life.

11) Optional software to process the memory data on the PC.

TN_EE-BA-e-1410 3

Page 4

1.3 Measuring Principle

2

tv

H

×

=

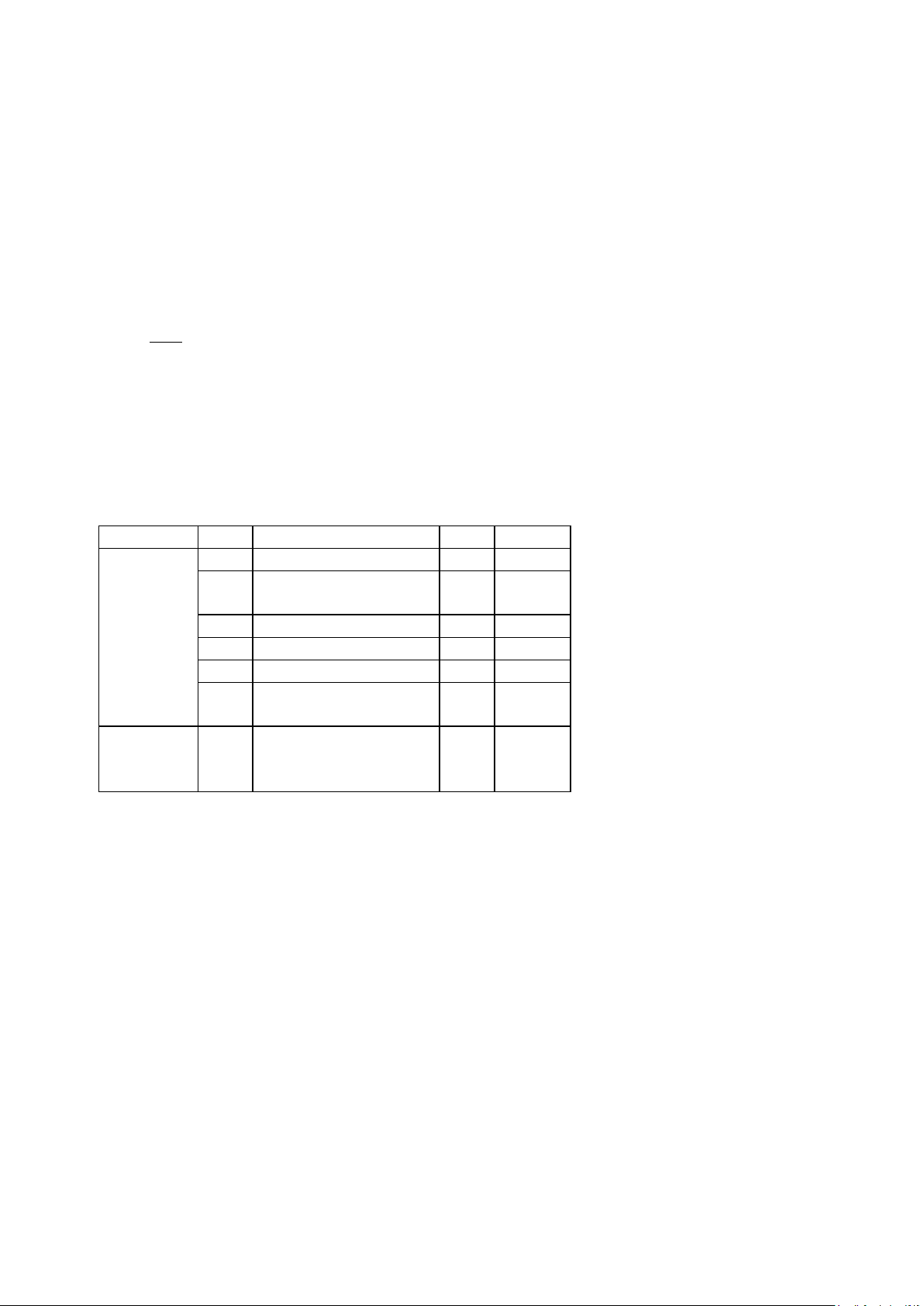

No

Item

Qty.

Note

Standard

1

Main body

1

2

Sensor P5EE,

10 MHz, Ø 10mm

1

3

Couplant

1 4

Transport Case

1 5

Instruction Manual

1

6

Alkaline battery

2

AA

size

Optional

ration

11

Data Software

1

The digital ultrasonic thickness gauge determines the thickness of a part or structure

by accurately measuring the time required for a short ultrasonic pulse generated by a

transducer to travel through the thickness of the material, reflect from the back or inside surface, and be returned to the transducer. The measured two-way transit time

is divided by two to account for the down-and-back travel path, and then multiplied by

the velocity of sound in the material. The result is expressed in the well-known

relationship:

Where: H-Thickness of the test piece.

v-Sound Velocity in the material.

t-The measured roun d-trip transit time.

1.4 Configuration

Table 1-1

Configuration

Configu-

(ATU-04)

1.5 Operating Conditions

Operating Temperature: -20℃~+60℃;

Storage Temperature :-30℃~+70℃

Relative Humidity: ≤90%

In the environment of usage vibrations, strong magnetic field, corrosive medium and

heavy dust should be avoided.

4 TN_EE-BA-e-1410

Page 5

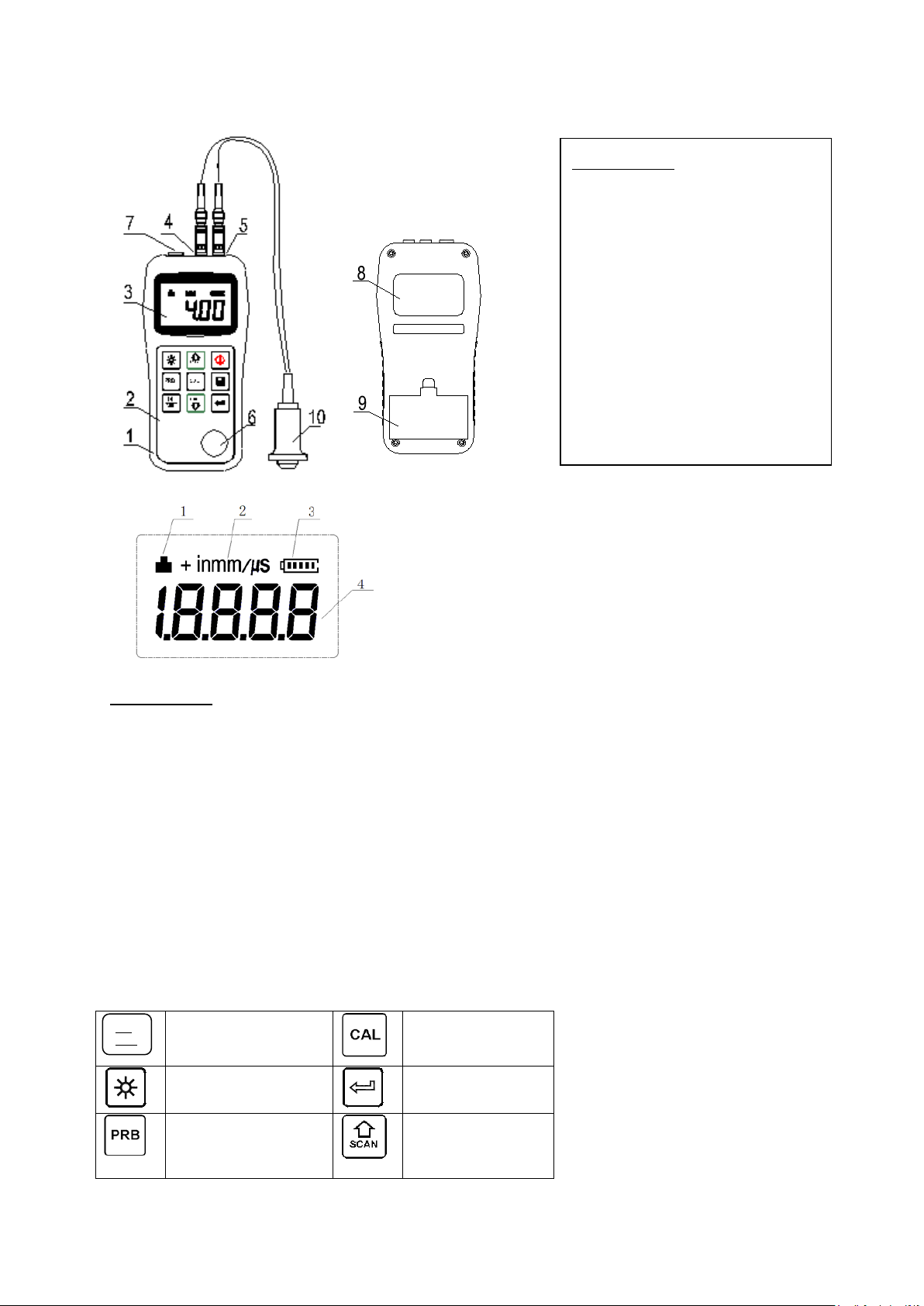

2 Keypad & Screen

ON

Turn the instru-

Sound velocity

Turn on/off the EL

Enter

Probe-Zero

Plus;

Turn on/off

Scan mode

1. 2.1 Main Screen

Explanation:

ULTRASONIC

THICKNESS GAUGE

SN:

POWER: 2 X 1.5V

Explanation:

1 The main body

2 Keypad

3 LCD display

4 Pulse socket

5 Receiver socket

6 Sensor zero disc

7 Communication port

8 Label

9 Battery cover

10 Measurement head

1. Coupling Status: Indicates the coupling status. While the gauge is taking a

measurement, the coupling status should be on. If it is not on or not stable, the

gauge is having difficulties in achieving a stable measurement, and the thickness value displayed will most likely be erroneous.

2. Unit: Current unit system. “mm” or “in” for thickness value. “m/s” or “in/μs” for

sound velocity.

3. B attery Information: Displays the rest capacity of the battery.

4. Information Display: Displays the measured thickness value, the sound

velocity and shows hints of current operation.

2.1 Keypad Definitions

ON

OFF

OFF

ment on/off

backlight

operation

calibration

TN_EE-BA-e-1410 5

Page 6

Unit switch be-

Minus;

Switch between

echo and

mode

Data Save or Da-

3 Preparation

3.1 Transducer Selection

The gauge is inherently capable of performing measurements on a wide range of materials, from various metals to glass and plastics. Different types of material, however,

will require the use of different transducers. Choosing the correct transducer for an

application is much important to perform easily accurate and reliable measurements.

The following paragraphs highlight the important properties of transducers, which

should be considered when selecting a transducer for a specific application.

Generally speaking, the best transducer for an application is one that sends sufficient

ultrasonic energy into the material being measured in the way that a strong, stable

echo is received by the gauge. Several factors affect the strength of ultrasound as it

travels. These are outlined bel ow:

Initial Signal Strength: The stronger a signal is to begin with, the stronger its return

echo will be. Initial signal strength is largely a factor of the size of the ultrasound

emitter in the transducer. A large emitting area will send more energy into the material being measured than a small emitting area. Thus, a so-called “1/2 inch” transducer

will emit a stronger signal than a “1/4 inch” transducer.

Absorption and Scattering: As ultrasound travels through any material, it is partly absorbed. If the material through which the sound travels has any grain structure, the

sound waves will experience scattering. Both of these effects reduce the strength of

the waves, and thus, the gauge’s ability to detect the returning echo. Higher frequency ultrasound is absorbed and scattered more than ultrasound of a lower frequency.

While it may seem that using a lower frequency transducer might be better in every

instance, low frequencies are less directional than high frequencies. Thus, a higher

frequency transducer would be a better choice for detecting the exact location of

small pits or flaws in the material being measured.

Geometry of the transducer: The physical constraints of the measuring environment

sometimes determine a transducer’s suitability for a given job. Some transducers

may simply be too large to be used in tightly confined areas. Also, the surface area

available for contacting with the transducer may be limited, requiring the use of a

transducer with a small bearing face. Measuring on a curved surface, such as an engine cylinder wall, may require the use of a transducer with a matching curved bearing face.

Temperature of the material: When it is necessary to measure on surfaces that are

exceedingly hot, high temperature transducers must be used. These transducers are

built using special materials and techniques that allow them to withstand high temperatures without damage. Additionally, care must be taken when performing a “Sensor-Zeroing” or “Calibration to Known Thickness” with a high temperature transducer.

Selection of the proper transducer is often a matter of tradeoffs between various

characteristics. It may be necessary to experiment with a variety of transducers in

order to find one that works well for a given application.

6 TN_EE-BA-e-1410

tween Metric and

Imperial system

ta Delete

pulseecho-echo

Page 7

The transducer is the “business end” of the instrument. It transmits and receives ul-

Model

Frequence

MHz

Φmm

Measurement

range

Lower limit

Annotation

P5EE

5

10

P-E: 2~600 mm

E-E:3~30/60 mm

Φ20 mm×3,0 mm

Standard

measurement

trasonic sound waves that the instrument uses to calculate the thickness of the material being measured. The transducer connects to the instrument via the attached cable, and two coaxial connectors. When using transducers, the orientation of the dual

coaxial connectors is not critical: either plug may be fitted to either socket in the instrument.

The transducer must be used correctly in order for the instrument to produce accurate, reliable measurements. Below is a short description of the transducer, followed

by instructions for its use.

Left figure is a bottom view of a typical transducer. The two semicircles of the bearing

face are visible, as is the barrier separating them. One of the semicircles is responsible for conducting ultrasonic sound into the material being measured, and the other

semicircle is responsible for conducting the echoed sound back into the transducer.

When the transducer is placed against the material being measured, it is the area

directly beneath the center of the bearing face that is being measured.

Right figure is a top view of a typical transducer. Press against the top with the thumb

or index finger to hold the transducer in place. Moderate pressure is sufficient, as it is

only necessary to keep the transducer stationary, and the bearing face seated flat

against the surface of the material being measured.

Tabelle Nr. 3-1 Suitable Measurement head

3.2 Condition and Preparation of Surfaces

In any ultrasonic measurement scenario, the shape and roughness of the test surface are of paramount importance. Rough, uneven surfaces may limit the penetration

of ultrasound through the material, and result in unstable, and therefore unreliable,

measurements. The surface being measured should be clean, and free of any small

particulate matter, rust, or scale. The presence of such obstructions will prevent the

transducer from seating properly against the surface. Often, a wire brush or scraper

will be helpful in cleaning surfaces. In more extreme cases, rotary sanders or grinding wheels may be used, though care must be taken to prevent surface gouging,

which will inhibit proper transducer coupling.

Extremely rough surfaces, such as the pebble-like finish of some cast iron , will prove

most difficult to measure. These kinds of surfaces act on the sound beam like frosted

glass on light, the beam becomes diffused and scattered in all directions.

In addition to posing obstacles to measurement, rough surfaces contribute to excessive wear of the transducer, particularly in situations where the transducer is

“scrubbed” along the surface. Transducers should be inspected on a regular basis,

for signs of uneven wear of the bearing face. If the bearing face is worn on one side

more than another, the sound beam penetrating the test material may no longer be

TN_EE-BA-e-1410 7

Page 8

perpendicular to the material surface. In this case, it will be difficult to exactly locate

tiny irregularities in the material being measured, as the focus of the sound beam no

longer lies directly beneath the transducer.

4 Operation

4.1 Power On/Off

The instrument is turned on by pressing the key. When the gauge is turned on, it

will first perform a brief display test by illuminating all of the segments in the display.

After one second, the gauge will display the sound velocity now used, indicating the

gauge is ready for use.

The gauge can be turned off by pressing the key. The tool has a special memory

that retains all of its settings even when the power is off. The gauge also features an

auto-power down mode designed to conserve battery life. If the gauge is idle for 5

minutes, it will turn itself off.

4.2 Setting the Measurement Mode

Often time users and inspectors in the field are faced with coated materials such as

pipes and tanks. Typically inspectors will need to remove the paint or coating prior to

measuring, or allow for some fixed amount of error introduced by the paint or coating

thickness and velocit y .

The error can be eliminated with this gauge by using a special echo-echo mode to

perform measurements for applications such as this. The gauge gives you this feature in a simple way, one button toggle, eliminating the need to remove the paint or

coating.

To switch between pulse-echo mode and echo-echo mode, simply press the key.

4.3 Perform Probe Zero

Note: The Probe Zero operation is onl y to be applied in Pulse-Echo mode, not

in Echo-Echo mode.

The key is used to “zero” the instrument in much the same way that a mechanical

micrometer is zeroed. If the gauge is not zeroed correctly, all the measurements that

the gauge makes may be in error by some fixed value. When the instrument is “zeroed”, this fixed error value is measured and automatically corrected for all subsequent measurements. The instrument may be “zeroed” by performing the following

procedure:

1) Plug the transducer into the instrument. Make sure that the connectors are fully

engaged. Check that the bearing face of the transducer is clean and free of any

debris.

2) Press the key to activate the zero mode.

8 TN_EE-BA-e-1410

Page 9

3) Use the key and the key to scroll to the probe model currently being used.

Be sure to set the right probe model to the instrument. Otherwise, there will be errors or deviations.

4) Apply a single droplet of ultrasonic couplant to the face of the metal probe disc.

5) Press the transducer against the probe disc, making sure that the transducer sits

flat against the surface.

6) Remove the transducer from the probe disc.

At this point, the instrument has successfully calculated its internal error factor, and

will compensate for this value in any subsequent measurements. When performing

an “instrument zero”, the instrument will always use the sound velocity value of the

built-in probe disc, even if some other velocity value has been entered for making

actual measurements. Though the instrument will remember the last “probe zero”

performed, it is generally a good idea to perform an “probe zero” whenever the gauge

is turned on, as well as any time a different transducer is used. This will ensure that

the instrument is always correctly zeroed.

Press while in probe zero mode will stop current probe zero operation

and return to the meas ur em ent mo de.

4.4 Sound Velocity Calibration

In order for the gauge to make accurate measurements, it must be set to the correct

sound velocity for the material being measured. Different types of material have different inherent sound velocities. If the gauge is not set to the correct sound velocity,

all of the measurements the gauge makes will be erroneous by some fixed percentage. The One-Point calibration is the simplest and most commonly used calibration

procedure optimizing linearity over large ranges. The Two-point calibration allows for

greater accuracy over small ranges by calculating the probe zero and velocity.

Note: One and Two point calibrations must be performed on material with the paint

or coating removed. Failure to remove the paint or coating prior to calibration will result in a multi material velocity calculation that may be different from the actual material velocity intended to be measured.

4.4.1 Calibration to a known thickness

Note: This procedure requires a sample piece of the specific material to be measured, the exact thickness of which is known, e.g. from having been measured by

some other means.

1) Perform a Probe-Zero.

2) Apply couplant to the sample piece.

3) Press the transducer against the sample piece, making sure that the transducer

sits flat against the surface of the sample. The display should show some thickness value, and the coupling status indicator should appear steadily.

4) Having achieved a stable reading, remove the transducer. If the displayed thickness changes from the value shown while the transducer was coupled, repeat

step 3.

5) Press the key to activate the calibration mode. The MM (or IN) symbol should

begin flashing.

6) Use the key and the key to adjust the displayed thickness up or down, until

it matches the thickness of the sample piece.

TN_EE-BA-e-1410 9

Page 10

7) Press the key again. The M/S (or IN/μS) symbols should begin flashing. The

gauge is now displaying the sound velocity value it has calculated based on the

thickness value that was entered.

8) Press the key once again to exit the calibration mode and return to the measurement mode. The gauge is now ready to perform measurements.

4.4.2 Calibration to a known velocity

Note: This procedure requires that the operator knows the sound velocity of the material to be measured. A table of common materials and their sound velocities can be

found in Appendix B of this manual.

1) Press the key to activate the calibration mode. The MM (or IN) symbol should

begin flashing.

2) Press the key again, so that The M/S (or IN/μS) symbols are flashing.

3) Use the key and the key to adjust the sound velocity value up or down, until

it matches the sound velocity of the material to be measured. You can also press

the key to switch among the preset commonly using velocities.

4) Press the key to exit from the calibration mode. The gauge is now ready to

perform measurements.

To achieve the most accurate measurements possible, it is generally advisable to

always calibrate the gauge to a sample piece of known thickness. Material composition (and thus, its sound velocity) sometimes varies from lot to lot and from manufacturer to manufacturer. Calibration to a sample of known thickness will ensure that the

gauge is set as closely as possible to the sound velocity of the material to be measured.

4.4.3 Two Point Calibration

Note: This procedure requires that the operator has two known thickness points on

the test piece that are representative of the range to be measured.

1) Probe-Zero has to be performed fir st.

2) Apply couplant to the sample piece.

3) Press the transducer against the sample piece, at the first/second calibration

point, making sure that the transducer sits flat against the surface of the sample.

The display should show some (probably incorrect) thickness value, and the coupling status indicator should appear steadily.

4) Having achieved a stable reading, remove the transducer. If the displayed thickness changes from the value shown while the transducer was coupled, repeat

step 3.

5) Press the key. The MM (or IN) symbol should begin flashing .

6) Use the key and the key to adjust the displayed thickness up or down, until

it matches the thickness of the sample piece.

7) Press the key. The display will flash 1OF2. Repeat steps 3 through 6 on the

second calibration point.

8) Press the key, so that The M/S (or IN/μS) symbols are flashing. The gauge will

now display the sound velocity value it has calculated based on the thickness values that were entered in step 6.

9) Press the key once more to exit the calibration mode. The gauge is now ready

to perform measurements within this range.

10 TN_EE-BA-e-1410

Page 11

4.5 Performing Measurements

When the instrument is displaying thickness measurements, the display will hold the

last value measured, until a new measurement is made.

In order for the transducer to do its job, there must be no air gaps between the wearface and the surface of the material being measured. This is accomplished with the

use of a “coupling” fluid, commonly called “couplant”. This fluid serves to “couple”, or

transfer, the ultrasonic sound waves from the transducer, into the material, and back

again. Before attempting to make a measurement, a small amount of couplant should

be applied to the surface of the material being measured. Typically, a single droplet

of couplant is sufficient.

After applying couplant, press the transducer (bearing face down) firmly against the

area to be measured. The coupling status indicator should appear, and a digit number should appear in the display. If the instrument has been properly “zeroed” and set

to the correct sound velocity, the number in the display will indicate the actual thickness of the material directly beneath the transducer.

If the coupling status indicator does not appear, not stable, or the numbers on the

display seem erratic, firstly check to make sure that there is an adequate film of

couplant beneath the transducer, and that the transducer is seated flat against the

material. If the condition persists, it may be necessary to select a different transducer

(size or frequency) for the material being measured.

While the transducer is in contact with the material that is being measured, the instrument will perform four measurements every second, updating its display as it

does so. When the transducer is removed from the surface, the display will hold the

last measurement mad e.

Note:Occasionally, a small film of couplant will be drawn out between the transducer and the surface as the transducer is removed. When this happens, the gauge may

perform a measurement through this couplant film, resulting in a measurement that is

larger or smaller than it should be. This phenomenon is obvious when one thickness

value is observed while the transducer is in place, and another value is observed after the transducer is removed. In addition, measurements through very thick paint or

coatings may result in the paint or coating being measured rather than the actual material intended. The responsibility for proper use of the instrument, and recognition of

these types of phenomenon, rests solely with the user of the instrument.

4.6 Scan mode

While the gauge excels at making single point measurements, it is sometimes desirable to examine a larger region, searching for the thinnest point. The gauge includes

a feature, called Scan Mode, which allows it to do just that.

In normal operation, the gauge performs and displays four measurements every second, which is quite adequate for single measurements. In Scan Mode, however, the

gauge performs ten measurements every second, and displays the readings while

scanning. While the transducer is in contact with the material being measured, the

gauge is keeping track of the lowest measurement it finds. The transducer may be

“scrubbed” across a surface, and any brief interruptions in the signal will be ignored.

When the transducer loses contact with the surface for more than two seconds, the

gauge will display the smallest measurement it found. When the transducer is removed from the material being scanned, the gauge will display the smallest measurement it found.

TN_EE-BA-e-1410 11

Page 12

When the scan mode is turned off, the single point mode will be automatically turned

on. Turn on/off the scan mode by the following steps:

Press the key to switch the scan mode on and off. It will display the current condition of the scan mode on the main screen.

4.7 Changing Resolution

The gauge has selectable display resolution, which is 0.1mm and 0.01mm.

Press down the key while turning on the gauge will switch the resolution between

“High” and “Low”.

4.8 Changing Units

On the measurement mode, press the key to switch back and forth between imperial and metric units.

4.9 Memory Management

4.9.1 Storing a reading

There are twenty files (F00-F19) that can be used to store the measurement values

inside the gauge. At most 100 records (thickness values) can be stored to each file.

By simply pressing the key after a new measurement reading appears, the measured thickness value will be saved to current file. It is added as the last record of the

file. To change the destination file to store the measured values, follow the steps:

1) Press the key to activate the data logging functions. It will display the current

file name and the total record count o f the file .

2) Use the key and the key to select the desired file to set as current file.

3) Press the key to exit the data logging functions at any time.

4.9.2 Clearing selected file

The user may require the contents of an entire file be completely cleared of all measurements. This would allow the user to start a new list of measurements starting at

storage location L00. The procedure is outlined in the following steps.

1. Press the key to activate the data logging functions. It will display the current

file name and the total record count o f the file .

2. Use the key and the key to scroll to the file that will be cleared of all meas-

urements.

3. Press the key on the desired file. It will automatically clear the file, and display

“-DEL”.

4. Press the key, at any time, to exit the data logging functions and return to

measurement mode.

4.9.3 Viewing/deleting stored record

This function provides the user with the ability to view/delete a record in a desired file

previously saved in memory. Following is the steps:

1. Press the key to activate the data logging functions. It will display the current

file name and the total record count o f the file .

2. Use the key and the key to select the desired file.

12 TN_EE-BA-e-1410

Page 13

3. Press the key to enter the selected file. It will display the current record num-

ber (for example, L012) and the record content.

4. Use the key and the key to select the desired record.

5. Press the key on the desired record. It will automatically delete this record,

and display “-DEL”.

6. Press the key to exit the data logging functions and return to measurement

mode.

4.10 EL Backlight

With the background light, it is convenient to work in the dark condition. Press key

to switch on or switch off the background light at any moment as you need after power on. Since the EL light will consume much power, turn on it only when necessary.

4.11 Battery Information

Two AA size alkaline batteries are needed as the power source. After several hours’

usage of the preset batteries, the battery symbol on the screen will be shown as

. The more of dark part indicates the more close to fill. When the battery capacity runs out, the battery symbol will be shown as and will begin to flash.

When this occurs, the batteries should be replaced.

Please take out the batteries when not working during a long period of time.

4.12 Auto Power Off

The instrument features an auto power off function designed to conserve battery life.

If the tool is idle for 5 minutes, it will turn itself off. While the voltage of the battery is

too low this function will also work.

4.13 System Reset

Press down the key while powering on the instrument will restore factory defaults.

All the memory data will be cleared during system reset. The only time this might

possibly helpful is if the parameter in the gauge was somehow corrupted.

4.14 Connecting to a Computer

The gauge is equipped with a USB port. Using the accessory cable, the gauge has

the ability to be connected to a computer, or external storage device. Measurement

data stored in the memory of the gauge can be transferred to the computer through

the USB port. Detailed information of the communication software and its usage refer

to the software manual.

5 Servicing

When the tester appears some other abnormal phenomena, please do not dismantle

or adjust any fixed assembled parts. Just contact us by e-mail or phone and the follow-up for a (warranty) service can be initiated.

TN_EE-BA-e-1410 13

Page 14

6 T ransport and Storage

Keep it away from vibration, strong magnetic field, corrosive medium and dust.

Storage in ordinary temperature.

Appendix A: Applications Notes

Measuring pipes and tubes

When measuring a piece of pipe to determine the thickness of the pipe wall, orientation of the transducers is important. If the diameter of the pipe is larger than approximately 4 inches, measurements should be made with the transducer oriented so that

the gap in the bearing face is perpendicular (at right angle) to the long axis of the

pipe. For smaller pipe diameters, two measurements should be performed, one with

the bearing face gap perpendicular, another with the gap parallel to the long axis of

the pipe. The smaller of the two displayed values should then be taken as the thickness at that point.

Measuring laminated mat er ial s

Laminated materials are unique in that their density (and therefore sound-velocity)

may vary considerably from one piece to another. Some laminated materials may

even exhibit noticeable changes in sound-velocity across a single surface. The only

way to reliably measure such materials is by performing a calibration procedure on a

sample piece of known thickness. Ideally, this sample material should be a part of the

same piece being measured, or at least from the same lamination batch. By calibrating to each test piece individually, the effects of variation of sound-velocity will be

minimized.

An additional important consideration when measuring laminates, is that any included

air gaps or pockets will cause an early reflection of the ultrasound beam. This effect

will be noticed as a sudden decrease in thickness in an otherwise regular surface.

While this may impede accurate measurement of total material thickness, it does

provide the user with positive indication of air gaps in the laminate.

Measuring through paint & coatings

Measuring through paints and coatings are also unique, in that the velocity of the

paint/ coating will be significantly different form the actual material being measured. A

perfect example of this would be a mild steel pipe with approximately 0.6mm of coating on the surface. Where the velocity of the pipe is 5920m/s, and the velocity of the

paint is 2300m/s. If the user is calibrated for mild steel pipe and measures through

both materials, the actual coating thickness will appear to be 2.5 times thicker than it

actually is, as a result of the differences in velocity. This error can be eliminated by

using a special echo-echo mode to perform measurements for applications such as

14 TN_EE-BA-e-1410

Page 15

these. In echo-echo mode, the paint/ coating thickness will be eliminated entirely and

the steel will be the only material measured.

Suitability of materials

Ultrasonic thickness measurements rely on passing a sound wave through the material being measured. Not all materials are good at transmitting sound. Ultrasonic

thickness measurement is practical in a wide variety of materials including metals,

plastics, and glass. Materials that are difficult include some cast materials, concrete,

wood, fiberglass, and some rubber.

Couplants

All ultrasonic applications require some medium to couple the sound from the transducer to the test piece. Typically a high viscosity liquid is used as the medium. The

sound used in ultrasonic thickness measurement does not travel through air efficiently.

A wide variety of couplant materials may be used in ultrasonic gauging. Propylene

glycol is suitable for most applications. In difficult applications where maximum transfer of sound energy is required, glycerin is recommended. However, on some metals

glycerin can promote corrosion by means of water absorption and thus may be undesirable. Other suitable couplants for measurements at normal temperatures may include water, various oils and greases, gels, and silicone fluids. Measurements at elevated temperatures will require specially formulated high temperature couplants.

Inherent in ultrasonic thickness measurement is the possibility that the instrument will

use the second rather than the first echo from the back surface of the material being

measured while in standard pulse-echo mode. This may result in a thickness reading

that is TWICE what it should be. The Responsibility for proper use of the instrument

and recognition of these types of phenomenon rests solely with the user of the instrument.

TN_EE-BA-e-1410 15

Page 16

7 Declaration of Conformity

Sauter GmbH

Ziegelei 1

Ziegelei 1

Manifestamos en la presente que el producto al que se refiere esta

Signature

Datum

07.04.2009

Ort der Ausstellung

72336 Balingen

Albert Sauter

SAUTER GmbH

Geschäftsführer

Managing director

SAUTER GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-199

Fax +49-[0]7433/9933-149, E-Mail: info@sauter.eu, Inter net: www .sauter.eu

D-72336 Balingen

E-Mail: info@sauter.eu

D-72336 Balingen

E-Mail: info@sauter.eu

Konformitätserklärung

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con marca CE

Dichiarazione di conformità per apparecchi contrassegnati con la marcatura CE

D

GB

E

F

I

Konformitätserklärung

Declaration of

conformity

Declaración de

conformidad

Déclaration de

conformité

Dichiarazione di

conformità

Wir erklären hierm it, dass das Produkt, auf das sich diese Erk lärung bezieht,

mit den nachstehenden Normen übereinstimmt.

We hereby declare that the produc t to which this declaration refer s conforms

with the following standards.

declaración está de acuerdo con las normas siguientes

Nous déclarons avec cela res ponsabilité que l e produit, auquel se r apporte la

présente déclaration, est conforme aux normes citées ci-après.

Dichiariamo con ciò che il prodott o al quale la presente dichiara zione si riferi-

sce è conforme alle norme di seguito citate.

Ultrasonic Thickn ess Gauge: TN-EE

EU Directive Standards

98/37 EC EN 50081-2

2005 / 95 EN 50082-2

2004 / 108 EC

Date

Place of issue

Signatur

16 TN_EE-BA-e-1410

Loading...

Loading...