Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operating manual

Analytical balance

KERN ABP

Version 1.0

2018-08

GB

ABP-BA-e-1810

Page 2

2 ABP-BA-e-1810

GB

KERN ABP

Version 1.0 2018-08

Operating manual

Analytical balance

Contents

1 Technical data ................................................................................................ 5

2 Declaration of conformity ............................................................................. 7

3 Appliance overview ....................................................................................... 8

3.1 Components .............................................................................................................................. 8

3.2 Keyboard ................................................................................................................................. 10

3.2.1 Numeric entry ........................................................................................................................... 11

3.3 Display ..................................................................................................................................... 12

4 Basic Information (General ) ........................................................................ 15

4.1 Proper use ............................................................................................................................... 15

4.2 Improper Use .......................................................................................................................... 15

4.3 Warranty .................................................................................................................................. 15

4.4 Monitoring of Test Resources ............................................................................................... 16

5 Basic Safety Precauti on s ............................................................................ 16

5.1 Pay attention to the instructions in the Operation Manual ................................................ 16

5.2 Personnel training .................................................................................................................. 16

6 Transport and storage ................................................................................. 16

6.1 Testing upon acceptance ...................................................................................................... 16

6.2 Packaging / return transport ................................................................................................. 17

7 Unpacking, Setup and Commissioning ..................................................... 19

7.1 Installation Site, Location of Us e .......................................................................................... 19

7.2 Unpacking and checking ....................................................................................................... 19

7.2.1 Placing ...................................................................................................................................... 21

7.3 Mains connection ................................................................................................................... 24

7.3.1 Turning On the Power .............................................................................................................. 25

7.4 Initial Commissioning ............................................................................................................ 25

7.5 Connection of peripheral devices ......................................................................................... 26

8 Adjustment ................................................................................................... 26

8.1 Automatic adjustment via PSC function .............................................................................. 26

8.2 Time-controlled automatic adjustment ................................................................................ 28

8.3 Manual adjustment via key [CAL-key] .................................................................................. 29

8.3.1 Setting adjustment function for CAL-key .................................................................................. 29

8.3.2 Adjustment with internal weight ................................................................................................ 29

8.3.3 Adjustment test with internal weight ......................................................................................... 30

8.3.4 Adjustment with external weight ............................................................................................... 30

8.3.5 Adjustment test with external weight ........................................................................................ 31

8.4 Adjustment log ....................................................................................................................... 32

8.5 Regular inspections ............................................................................................................... 33

9 Verification ................................................................................................... 35

Page 3

ABP-BA-e-1810 3

10 Basic Operation ........................................................................................... 36

10.1 Activate standard weighing mode ........................................................................................ 36

10.2 Simple weighing ..................................................................................................................... 36

10.3 Taring ....................................................................................................................................... 37

10.4 Underfloor weighing ............................................................................................................... 38

10.5 Switch off the balance............................................................................................................ 39

10.6 Switch-over weighing unit ..................................................................................................... 39

10.7 Change readability (1D/10D) (not availab le for verified models) ....................................... 39

10.8 Display Tare / Net / Gross ...................................................................................................... 40

10.9 Display decimal dot as point or comma............................................................................... 41

11 Menu ............................................................................................................. 42

11.1 Navigation in the menu .......................................................................................................... 42

11.1.1 Standard weighing mode ..................................................................................................... 43

11.1.2 Weighing settings ................................................................................................................. 44

11.1.3 System Settings ................................................................................................................... 46

11.1.4 Application settings .............................................................................................................. 48

11.2 Menu overview ........................................................................................................................ 48

11.3 Resetting the menu ................................................................................................................ 49

11.4 Menu Lock ............................................................................................................................... 50

11.5 Log menu settings .................................................................................................................. 51

11.6 Menu history ........................................................................................................................... 52

12 Description of individual functions ............................................................ 53

12.1 Zero setting and tare function ............................................................................................... 53

12.2 Zero tracking function............................................................................................................ 53

12.3 Auto Tare function .................................................................................................................. 54

12.4 Settings for Stability and Response ..................................................................................... 55

12.4.1 Stability and reaction settings via „Smart Setting display“ (without invoking menu) ............ 55

12.5 Dosing...................................................................................................................................... 56

12.5.1 Standstill width ..................................................................................................................... 57

12.6 Weighing Units ....................................................................................................................... 58

12.7 User administration log-in function ...................................................................................... 58

13 Balance settings .......................................................................................... 65

13.1 Screen saver ........................................................................................................................... 65

13.2 Display settings in operating mode ...................................................................................... 65

13.3 Balance identification no. ...................................................................................................... 66

13.4 Entering date and time ........................................................................................................... 66

13.5 Date format .............................................................................................................................. 66

13.6 Brightness of display ............................................................................................................. 67

13.7 Audio signal on pressing key or display of stability .......................................................... 67

13.8 User language ......................................................................................................................... 67

14 Application Functions ................................................................................. 68

14.1 Parts counting ........................................................................................................................ 69

14.1.1 Settings ................................................................................................................................ 69

14.1.2 Setting the display ................................................................................................................ 71

14.1.3 Part counting ........................................................................................................................ 71

14.1.4 Change settings ................................................................................................................... 72

14.1.5 Switching between counting and weighing mode ................................................................ 72

14.2 Percent determination............................................................................................................ 73

14.2.1 Settings ................................................................................................................................ 73

14.2.2 Setting the display ................................................................................................................ 75

14.2.3 Performing calculation of percentage .................................................................................. 76

14.2.4 Change settings ................................................................................................................... 76

14.2.5 Switching between percentage and weighing mode ............................................................ 77

Page 4

4 ABP-BA-e-1810

14.3 Determining the density of solid matter and fluids ............................................................ 77

14.4 Totalization .............................................................................................................................. 78

14.5 Formulation ............................................................................................................................. 81

14.5.1 Free formulating ................................................................................................................... 81

14.5.2 Define and process formulations ......................................................................................... 84

14.5.3 Change recipe ...................................................................................................................... 88

14.5.4 Sample log (KERN YKB-01N): ............................................................................................. 89

14.6 Preparing buffer solutions..................................................................................................... 90

14.7 Sample preparation ................................................................................................................ 93

14.7.1 Changing saved samples ..................................................................................................... 95

14.8 Statistics .................................................................................................................................. 96

14.9 Control weighing and target weighing ................................................................................. 98

14.9.1 Target weighing .................................................................................................................... 98

14.10 Control weighing (Pass / Fail evaluation) ...................................................................... 100

14.11 Minimum sample weight .................................................................................................. 102

15 Interfaces .................................................................................................... 103

15.1 Connect printer ..................................................................................................................... 103

15.2 Connect PC ........................................................................................................................... 103

15.3 Connect serial devices / connect programmable controller (SPS / PLC) ....................... 104

15.4 Interface cable (RS232) ........................................................................................................ 104

15.5 Data transmission format .................................................................................................... 105

15.6 Interface commands............................................................................................................. 106

15.7 Communication parameters ................................................................................................ 110

15.7.1 Select standard setting ....................................................................................................... 110

15.7.2 User defined settings (display example for KERN YKB-01N ............................................. 111

15.8 Issue functions ..................................................................................................................... 113

15.8.1 Automatic data output / Auto Print function ........................................................................ 113

15.8.2 Continuous data output ...................................................................................................... 114

15.8.3 GLP Output Function ......................................................................................................... 116

15.8.4 Defining output details ........................................................................................................ 117

15.10 USB connection ............................................................................................................... 118

15.10.1 Edit weighing data, adjustment logs and screenshots to USB medium ............................ 119

15.10.2 Data transfer by means of barcode reader ........................................................................ 122

16 Servicing, maintenance, disposal ............................................................ 123

16.1 Cleaning ................................................................................................................................ 123

16.2 Servicing, maintenance ....................................................................................................... 124

16.3 Disposal ................................................................................................................................. 125

17 Instant help ................................................................................................. 125

18 Ionizer (factory option) .............................................................................. 126

18.1 General .................................................................................................................................. 126

18.2 Basic Safety Precautions .................................................................................................... 126

18.3 Technical Data ...................................................................................................................... 128

18.4 Commissioning ..................................................................................................................... 128

18.5 Maintenance and cleaning ................................................................................................... 130

Page 5

ABP-BA-e-1810 5

1 Technical data

KERN ABP 100-4M ABP 100-5DM

Item no./ Type TABP 100-4M-A TABP 100-5DM-A

Readability (d) 0.0001 g 0.00001 g / 0.0001 g

Weighing range (max) 120 g 52 g / 120 g

Minimum load (Min) 0.01 g 0.001 g

Verification value (e) 0.001 g 0.001 g

Verification class I I

Reproducibility 0.0001 g 0.00002 g / 0.0001 g

Linearity ± 0.0002 g ± 0.00005 g / 0.0002 g

Stabilization time 2 s 2 s / 8 s

Adjustment weight internal

Warm-up time 8 h

Weighing Units mg, g, ct (unverified)

g, ct (verified)

Smallest component weight

for part counting

1mg (under lab conditions*)

10 mg (under normal conditions**)

Reference quantities at

piece counting

1 - 100

Weighing plate, stainless steel ø 91mm

Dimensions caisse

(l x L x h) [mm]

212 x 367 x 345 212 x 411 x 345

Dimensions

Glass wind screen [mm]

170 x 165 x 220 mm (weighing space)

Net weight (kg) 7 8

Permissible

ambient condition

+5° C to +40° C

Humidity of air 20 ~ 85 % relative (not condensing)

Power pack

Input voltage

AC 100 -240 V, 300 mA 50/60Hz

or

AC 100 -240 V, 320 – 190 mA 50/60Hz

Weighing scales

Input voltage

DC 12 V, 1,0 A

Degree of pollution 2

Overvoltage category Category II

Metres in height Up to 2000 m

Place of installation In sealed rooms only

Interfaces RS-232, USB (type B, PC connection), USB host (type A)

Page 6

6 ABP-BA-e-1810

KERN ABP 200-4M ABP 200-5DM ABP 300-4M

Item no./ Type TABP 200-4M-A TABP 200-5DM-A TABP 300-4M-A

Readability (d) 0.0001 g 0.00001 g / 0.0001 g 0.0001 g

Weighing range (max) 220 g 102 g / 220 g 320 g

Minimum load (Min) 0.01 g 0.001 g 0.01 g

Verification value (e) 0.001 g 0.001 g 0.001 g

Verification class I I I

Reproducibility 0.0001 g 0.00005 g / 0.0001 g 0.00015 g

Linearity ± 0.0002 g ± 0.0001 g / 0.0002 g ± 0.0003 g

Stabilization time 2 s 2 s / 8 s 2 s

Adjustment weight internal

Warm-up time 8 h

Weighing Units mg, g, ct (unverified)

g, ct (verified)

Smallest component weight

for part counting

1mg (under lab conditions*)

10 mg (under normal conditions**)

Reference quantities at

piece counting

1 - 100

Weighing plate, stainless steel ø 91mm

Dimensions caisse

(l x L x h) [mm]

212 x 367 x 345 212 x 411 x 345 212 x 367 x 345

Dimensions

Glass wind screen [mm]

170 x 165 x 220 mm (weighing space)

Net weight (kg) 7 8 7

Permissible

ambient condition

+5° C to +40° C

Humidity of air 20 ~ 85 % relative (not condensing)

Power pack

Input voltage

AC 100 -240 V, 300 mA 50/60Hz

or

AC 100 -240 V, 320 – 190 mA 50/60Hz

Weighing scales

Input voltage

DC 12 V, 1,0 A

Degree of pollution 2

Overvoltage category Category II

Metres in height Up to 2000 m

Place of installation In sealed rooms only

Interfaces RS-232, USB (type B, PC connection), USB host (type A)

Page 7

ABP-BA-e-1810 7

* Smallest component weight for part counting - under lab conditions:

There are ideal ambient conditions for high-resolution counting

The parts to be counted are not scattered

** Smallest component part for part counting – under normal conditions:

There are unsteady ambient conditions (draft, vibrations)

The parts to be counted are being scattered

2 Declaration of conformity

The current EC/EU Conformity declaration can be found online in:

www.kern-sohn.com/ce

For verified weighing scales (= weighing scales assessed for

conformity) a declaration of

conformity is included in the scope of

delivery.

Page 8

8 ABP-BA-e-1810

3 Appliance overview

3.1 Components

Models d = 0.0001 g Mode. d = 0.00001 g/0.0001 g

Pos. Description

1 Keyboard

2 Bubble level

3 Display

4 Windshield

5 Weighing pan

6 Fastening point ionizer (optional)

7 Glass wind screen

8 USB host port

9 Levelling screw

Page 9

ABP-BA-e-1810 9

Rear view:

Models d = 0.0001 g Models d = 0.00001 g/0.0001 g

Pos. Description

10 Serial interface (RS232)

11 USB device

12 Port for ionizer

13 Connector for AC adapter

14 Fastening point for anti-theft device

16 Fastening lug for anti-theft chain or wire

17 Port for power pack

18 External electronics box

Page 10

10 ABP-BA-e-1810

3.2 Keyboard

Button Description

Function

Short key pressing

Long key pressing

In menu

[ON/OFF]

Switching between

operating and

standby mode

-

Return to

weighing mode

[1d/10d]

Readability

change

[CAL]

Start adjustment

Call setup menu

"Adjustment"

-

[PRINT]

Data output to

external device

(weighing mode)

Call setup menu

"Print"

[TARE]

Taring

Zeroing

Call setup "Zero

Setting / Taring"

[MENU]

• Call up menu

• Call application

specific settings

• Call Statistics

[Ionizer]

Ionizer on/off

(Factory option)

Call Setup Menu

Ionizer

(Factory option)

[OK] - -

Confirm

input

Page 11

ABP-BA-e-1810 11

[R]

Change reaction

setting for display

Select menu

item.

Navigation button

[UNIT]

Weighing mode:

Switch-over weighing

unit.

Counting mode:

Display single weight

Calculate

percentage:

Display reference

weight

Call setup menu

"Units"

Scroll forward in

menu

Navigation button

[F]

Switch over

weighing mode /

application mode

Scroll

backwards in

menu

Navigation button

[S]

Change stability

setting of display

Select menu

item.

Navigation button

3.2.1 Numeric entry

Button

Description

Function

Navigation button

Flashing digit (0 – 9) or

increase character (, [blank], -, A – Z)

Navigation button

Flashing digit (0 – 9) or

reduce character (, [blank], -, A – Z)

Navigation button

Digit selection to the right

Navigation button

Digit selection to the left

Navigation button

Confirm entry

ESC Cancel input

Page 12

12 ABP-BA-e-1810

3.3 Display

Apart from the display of the weighing result, all functions of the menu may be

accessed from here. The display will vary, depending on the weighing scale being

either in operating or setting mode.

Special keys (e.g. CAL-, TARE-, PRINT-key) provide fast and purposeful access to

the individual setup menu. The navigation keys allow intuitive control.

Display example operating mode:

The display is sub-divided into four areas.

No.

Status Description

1 Operating

mode

Current application

2 User field Display of logged-in user and current time

Data output to external devices

USB-storage medium is connected

Menu Lock

3 Measuring

Value

Display of weighing result in current weighing unit

Stability display

Net weight

Tare weight

Gross weight

Hold function enabled

Zero indicator

Negative weighed value

Net weight during formulating

Tolerance marker

Capacity display

The non-verified value is given in

brackets in verified scales.

Page 13

ABP-BA-e-1810 13

4

Status display

Current settings

Minimum initial weight

Settings for Stability and Response

Printer settings

Auto Print function active

Flashing during automatic Output

continuous output enabled

Flashing during continuous Output

Weighing settings

Dispensing mode

Zero tracking (Autom. zero point

correction)

Statistics

Error reports

Adjustment required (PSC-function)

Inadequate power supply

Defective USB-connection

Display example setting mode:

After pressing the MENU-key in weighing mode the display will change to setting

mode.

Example of illustration: For calling system settings see chap. 11.1.3

Page 14

14 ABP-BA-e-1810

Symbol Description Application icons

Level 1

Selecting an

application

Weighing mode

Parts counting

Percent determination

Density determination <Solid matter>

Density determination <Fluids>

Totalization

Formulation

Autom. Processing a recipe

Produce a buffer solution

Produce an analysis sample

Symbol Description Application icons

Level 2

Icon of selected

application

Available settings will be shown on level 1.

Level 1

Weighing settings

Dosing

Zero tracking

Level 1

System Settings

System Settings

Settings <Print>

Settings <Save data>

Settings <Communication>

Settings <Adjustment>

Settings <User>

Level 1

History

The last 10 menu steps will be displayed.

For further information about the operation of the display, see chap. 11.1

The icon for the

application selected

will be shown

Page 15

ABP-BA-e-1810 15

4 Basic Information (General)

4.1 Proper use

The balance you purchased is intended to determine the weighing value of material

to be weighed. It is intended to be used as a “non-automatic balance”, i.e. the

material to be weighed is manually and carefully placed in the centre of the weighing

pan. As soon as a stable weighing value is reached the weighing value can be read.

4.2 Improper Use

Do not use balance for dynamic add-on weighing procedures, if small amounts of

goods to be weighed are removed or added. The “stability compensation“ installed in

the balance may result in displaying an incorrect measuring value! (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the balance,

minus a possibly existing tare load, must be strictly avoided. Balance may be

damage by this.

Never operate balance in explosive environment. The serial version is not explosion

protected.

The structure of the balance may not be modified. This may lead to incorrect

weighing results, safety-related faults and destruction of the balance.

The balance may only be used according to the described conditions. Other areas of

use must be released by KERN in writing.

4.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

Page 16

16 ABP-BA-e-1810

4.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the

balance and, if applicable, the testing weight, must be checked regularly. The

responsible user must define a suitable interval as well as type and scope of this test.

Information is available on KERN’s home page (www.kern-sohn.com with regard to

the monitoring of balance test substances and the test weights required for this. In

KERN's accredited DKD calibration laboratory test weights and balances may be

calibrated (return to the national standard) fast and at moderate cost.

5 Basic Safety Precautions

5.1 Pay attention to the instructions in the Opera tion Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN balances.

All language versions contain a non-binding translation.

The original German is binding.

5.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

6 T ransport and storage

6.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

Page 17

ABP-BA-e-1810 17

6.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Illustration example models d = 0.0001 g

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the

weighing platform, power unit etc. against shifting and

damage.

Put network adapter and accessories in the small box

Lift scale with both hands

Page 18

18 ABP-BA-e-1810

Page 19

ABP-BA-e-1810 19

7 Unpacking, Setup and Commissioning

7.1 Installation Site, Location of Use

The balances are designed in a way that reliable weighing results are achieved in

common conditions of use.

You will work accurately and fast, if you select the right location for your balance.

Therefore, observe the following for the installation site:

• Place the balance on a firm, level surface;

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the balance against direct draughts due to open windows and doors;

• Avoid jarring during weighing;

• Protect the balance against high humidity, vapours and dust;

• Do not expose the device to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the appliance)

may occur if a cold appliance is taken to a considerably warmer environment.

In this case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature.

• Avoid static charge of weighed items or weighing container.

If electro-magnetic fields or static charge occur, or if the power supply is unstable

major deviations on the display (incorrect weighing results) are possible. In that case,

the location must be changed.

7.2 Unpacking and checking

Remove device and accessories carefully from packaging, remove packaging

material and place device at the planned work place. Check if that there has been no

damage and that all packing items are present.

Page 20

20 ABP-BA-e-1810

Scope of delivery / serial accessories

Pos. Description

1 Balance

2 Weighing pan

3 Carrier weighing pan

4 Centring ring (Models d = 0.0001 g only)

5 Protective cover

6 Mains adapter

7 Holder for adapter cable (Models d = 0.0001 g only)

8 Operating manual

9 External electronics box

10 Guard plate

11 Windshield

12 Multi-function weighing platform

13 Support multi-function weighing platform

Models d = 0.00001 g/0.0001 g only:

Page 21

ABP-BA-e-1810 21

7.2.1 Placing

The right place is decisive for the accuracy of the weighing results of highresolution precision balances (see chap. 7.1).

1. Attach holder for adapter cable (Models d = 0.0001 g only)

Pull off protective film and attach as shown on image.

2. Installation of weighing plate

Models d = 0.0001 g

Attach centering ring, carrier of weighing plate and weighing plate in order.

Attach the safety hood

Page 22

22 ABP-BA-e-1810

Mode. d = 0.00001 g/0.0001 g

Attach centering ring, carrier of weighing plate and weighing plate in order.

Attach the safety hood

Place the guard plate carefully in the weighing chamber

Page 23

ABP-BA-e-1810 23

3. Install the multi-function weighing platform (Models = 0.00001 g/0.0001 g

only)

Disconnect scale from power

supply.

Remove standard weighing plate as

shown on image.

Install multi-function weighing

platform together with the support.

Pay due attention to centring!

Application examples:

Adjustment will be required after exchanging the weighing platform, for

instructions see chap. 8

Standard weighing platform Support multi-function weighing platform

Page 24

24 ABP-BA-e-1810

4. Levelling

Level balance with foot screws until the air bubble of the water balance is in the

prescribed circle.

Check levelling regularly

7.3 Mains connection

Select a country-specific power plug and insert it in the mains adapter.

Check, whether the voltage acceptance on the scales is set correctly.

Do not connect the scales to the power mains unless the information on

the scales (sticker) matches the local mains voltage.

Only use KERN original mains adapter. Using other makes requires

consent by KERN.

Important:

Before starting your weighing balance, check the mains cable for

damage.

Ensure that the power unit does not come into contact with liquids.

Ensure access to mains plug at all times.

Page 25

ABP-BA-e-1810 25

7.3.1 Turning On the Power

Models d = 0.0001 g Mode. d = 0.00001 g/0.0001 g

Supply power to balance via mains

adapter. The display lights up and the

balance carries out a selftest. Internal

adjustment will be started automatically

(See chap.8.3.2). The motor noise of the

loading system for the internal

adjustment weight will be audible.

You can cancel the adjustment by

pressing the ON/OFF key.

The selftest is completed when „OFF“

appears on the display. From that point

onwards the weighing scale will be in

standby mode. The weighing balance will

remain switched on as long as it is

connected to the power supply.

To turn the display on/off, press the

ON/OFF key.

When the log-in function is enabled, use

the navigation keys to select the

respective user and enter password, see

chap. 12.7

7.4 Initial Commissioning

In order to obtain exact results with the electronic balances, your balance must have

reached the operating temperature (see warming up time chap.1). During this

warming up time the balance must be connected to the power supply (mains,

accumulator or battery). The accuracy of the balance depends on the local

acceleration of gravity. Strictly observe hints in chapter Adjustment.

Page 26

26 ABP-BA-e-1810

7.5 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data

interface, always disconnect the balance from the power supply.

With your balance, only use accessories and peripheral devices by KERN, as they

are ideally tuned to your balance.

8 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each balance must be coordinated - in compliance with the underlying physical

weighing principle - to the existing acceleration due to gravity at its place of location

(only if the balance has not already been adjusted to the location in the factory). This

adjustment process must be carried out for the first commissioning, after each

change of location as well as in case of fluctuating environment temperature. To

receive accurate measuring values it is also recommended to adjust the balance

periodically in weighing operation.

•

Observe stable environmental conditions. A warming up time

(see chapter 1) is required for stabilization.

• Ensure that there are no objects on the weighing pan.

• Avoid vibration and air flow.

• Always carry out adjustment with the standard weighing platform in place.

• To cancel internal adjustment, press the ON/OFF key.

•

When an optional printer is connected and the GLP function is connected,

the adjustment log will be edited, see chap. 8.4

8.1 Automatic adjustment via PSC function

Force-compensated scales react sensitively to changes in temperature. The higher

the sensitivity of the scale, the more pronounced the effect. The temperature

controlled PSC function enables the scale to automatically correct this effect.

PSC stands for Perfect Self Calibration and facilitates fully automatic internal scale

adjustment by means of an internal weight, based on time and/or temperature

criteria.

Adjustment in weighing mode is carried out automatically under the following

conditions:

(1) If there is a change in ambient temperature (∆t 1°C)

(2) When about four hours has passed since the previous calibration.

(3) When the balance is switched from standby status to weighing mode

and condition (1) or (2) has been met.

Page 27

ABP-BA-e-1810 27

If one of the above conditions was met in

weighing mode, the weight symbol

flashes for about two minutes in order to

notify the pending adjustment; During

operation, the display will automatically

change and the motor sound of the weight

loading system is heard. In order to ensure

proper PSC operation, prevent vibrations and

air flow.

• The PSC function will be enabled throughout in verified models.

• Also, no measurements can be made during automatic adjustment.

• When the weight symbol

starts flashing while the weighing platform is

loaded the following message will appear

Unload weighing plate

• In order to prevent that adjustment is starting during a measuring

sequence, press the ON/OFF key immediately when the following display

appears.

This will cancel the adjustment and you can proceed with the measuring

sequence.

Sometime later adjustment will be requested again by the flashing weight

symbol .

Page 28

28 ABP-BA-e-1810

8.2 Time-controlled automatic adjustment

With the help of its internal adjusting weight and integrated clock the balance can be

set to carry out automatic adjustment at set times (up to three times daily). This

function is a very convenient function, when adjustment reports are desired to be

made for regular adjustments, or when wishing span adjustments during break times

to avoid interruption of measurement work.

The weight symbol blinks for about two minutes as notification of span calibration

before it begins. Automatic adjustment can be stopped by actuating the [ON/OFF]

key during this message.

Parameter setting:

Press and hold the CAL-key for approx.

3 sec. and the menu for <CAL key>

setting will be displayed.

Use the navigation keys to select <Timer

CAL> and confirm using the OK-key.

Select first time <Timer 1> and confirm

using the OK-key.

Select setting [on] or [off] and confirm

using the OK-key.

Select [Setting] to enter time.

Use the navigation keys to enter time

and confirm using the OK-key.

Repeat these operating steps to set the

time for <Timer 2> / <Timer 3>.

Page 29

ABP-BA-e-1810 29

8.3 Manual adjustment via key [CAL-key]

8.3.1 Setting adjustment function for CAL-key

It is possible to start the preset adjustment method without having to access the

menu. The Set Adjustment Procedure may be set by simply pressing the [CAL]-key

when in weighing mode.

Press and hold the CAL-key for approx. 3

sec until the <CAL key> setting menu

appears.

Confirm using the OK-key and the available

settings will be displayed.

Adjustment with internal weight, see chap. 8.3.2

For adjustment test using internal weight,

see chap. 8.3.3

Adjustment using external weight, see chap. 8.3.4

Adjustment test with external weight,

see chap. 8.3.5

Select Settings with the help of the navigation

keys and confirm using the OK-key.

Use the ON/OFF button to return into

weighing mode

8.3.2 Adjustment with internal weight

Ensure that the CAL-key is assigned to the <Internal Weight Calibration> function,

see chap. 8.3.1.

Press CAL key, adjustment is started.

After successful adjustment the balance

automatically returns to weighing mode.

In case of an adjustment error (e.g. objects

on the weighing plate) the display will show

an error message, repeat adjustment.

Page 30

30 ABP-BA-e-1810

8.3.3 Adjustment test with internal weight

During adjustment tests the balance automatically compares the saved value of the

adjustment weight with the actual value. This is only a check, i.e. no values are

changed.

Ensure that the CAL-key is assigned to the <Internal Weight Test> function, see

chap. 8.3.1.

To start the test, press the CAL-key.

The difference to the previous adjustment will

be displayed.

8.3.4 Adjustment with external weight

Ensure that the CAL-key is assigned to the <External Weight Calibration> function,

see chap. 8.3.1.

Press the CAL-key and the weight value for

the adjustment weight will be flashing on the

display. (To change the weight value, follow

the instruction on the display*).

Put the required adjustment weight carefully

in the centre of the weighing pan. Close wind

screen doors completely. Wait until the

request for removing the adjustment weight is

displayed.

Take away adjustment weight.

*The adjustment weight to be used depends on the capacity of the scale.

Carry out adjustment as near as possible to the balance’s maximum weight

(recommended adjustment weight see chap. 1). Weights of different nominal

values may be used for adjustment but are not optimal for technical

measuring. Info about test weights can be found on the Internet at:

http://www.kern-sohn.com

Page 31

ABP-BA-e-1810 31

8.3.5 Adjustment test with exter nal weight

Ensure that the CAL-key is assigned to the <External Weight Test> function,

see chap. 8.3.1.

Press the CAL-key and the weight value for

the adjustment weight will be flashing on the

display. (To change the weight value, follow

the instruction on the display).

Put the required adjustment weight carefully

in the centre of the weighing pan. Close wind

screen doors completely. Wait until the

request for removing the adjustment weight is

displayed.

The difference to the previous adjustment will

be displayed.

Page 32

32 ABP-BA-e-1810

8.4 Adjustment log

If an optional printer is connected and the GLP function enabled, this will be followed

by automatic log output after every adjustment.

Printout example (KERN YKB-01N):

CAL –INTERNAL

Mode of adjustment

KERN & Sohn GmbH

Company

TYPE

ABP 300-4M

Model

SN

D319300002

Serial no.

BALID

1234

Balance identification no

DATE

2018 Aug. 17

Date

TIME

09.14.21

Time

REF

200.0000g

Used adjustment weight

BFR

200.0001g

Before adjustment

AFT

200.0000g

After adjustment

-COMPLETE

-SIGNATURE-

Prepared by

+ For enabling / defining GLP-function see chap. 15.8.3

Page 33

ABP-BA-e-1810 33

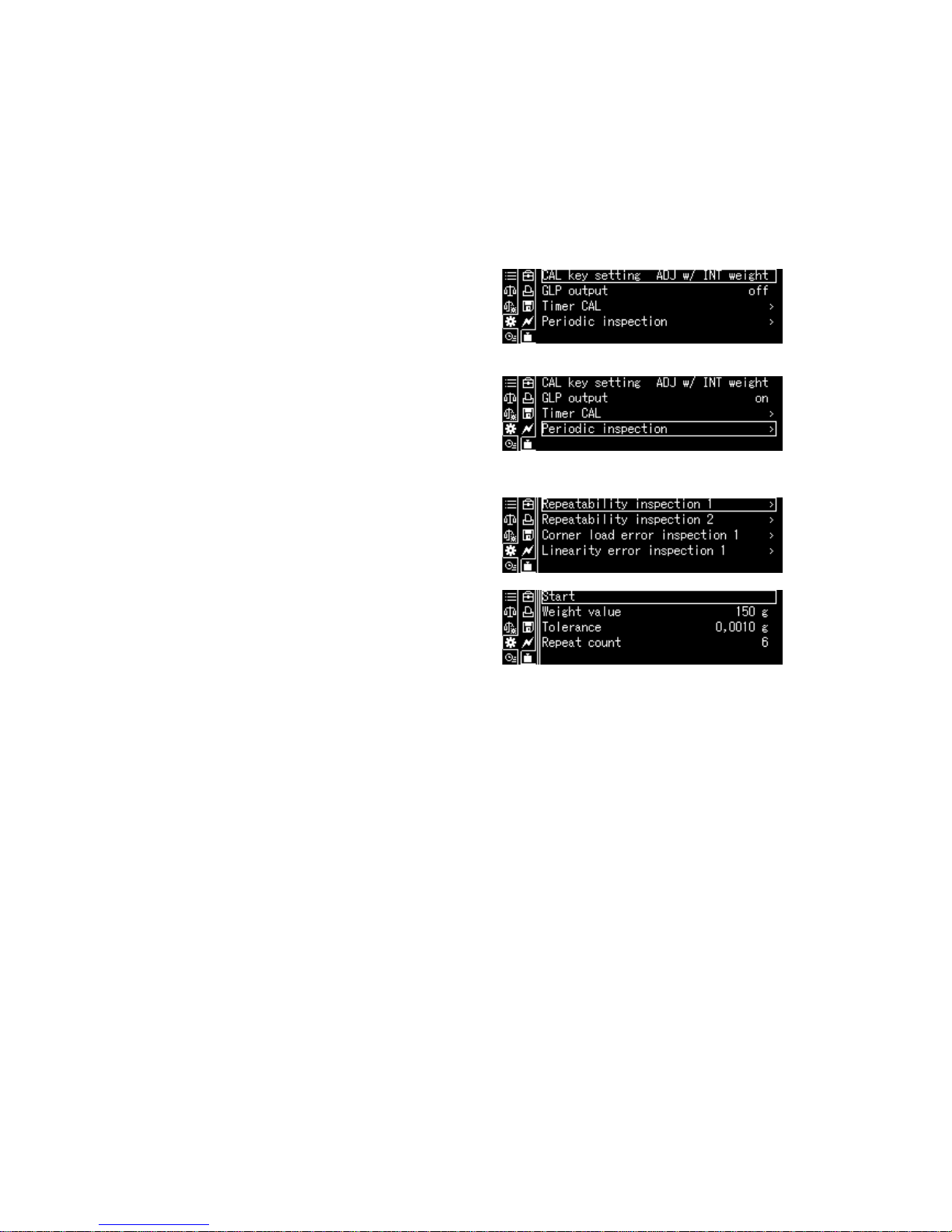

8.5 Regular i nspections

The ABP series supports regular inspection of your scale. This function may be used

to check repeatability, off-centre stress (off-centre load errors) and linearity. The

instructions on the display support the implementation of individual steps.

Parameter setting:

Call up menu:

Press and hold the CAL-key for approx.

3 sec. and the menu for <CAL key>

setting will be displayed.

Use the navigation keys to select

<Periodic inspection> and confirm

using the OK-key.

1. Settings Repeatability

Select <Repeatability insp. 1> and

confirm using the OK-key.

Select desired setting and confirm using

the OK-key.

To enter the weight value for the test

weight, select <Weight value> and

confirm using the OK-key.

Use the navigation keys to enter the

value and confirm using the OK-key.

Repeat these operating steps to set all

other settings for

<Tolerance> / <Repeat Counts>.

Return to menu by .

2. Settings off-centre

load

Repeat these operating steps for

Settings as shown for "Item 1

Repeatability".

Page 34

34 ABP-BA-e-1810

3. Settings linearization

Repeat these operating steps for

Settings as shown for "Item 1

Repeatability".

Performing test sequen ce :

Call up menu:

Press and hold the CAL-key for approx.

3 sec, the <CAL key> setting menu will

appear.

Use the navigation keys to select

<Periodic inspection> and confirm

using the OK-key.

Select desired test and confirm using the

OK-key.

Select <Start> and confirm using the

OK-key.

Follow the instructions on the display.

Page 35

ABP-BA-e-1810 35

9 Verification

General introduction:

According to EU directive 2014/31/EC balances must be officially verified if they are

used as follows (legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory.

c) For official purposes

d) For manufacturing final packages

In cases of doubt, please contact your local trade in standard.

Verification notes:

An EU type approval exists for balances described in their technical data as

verifiable. If a balance is used where obligation to verify exists as described above, it

must be verified and re-verified at regular intervals.

Re-verification of a balance is carried out according to the respective national

regulations. The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

Verification of the balance is invalid without the seal.

The seal marks attached on verified balances point out that the balance may

only be opened and serviced by trained and authorised specialist staff. If the

seal mark is destroyed, verification looses its validity. Please observe all

national laws and legal regulations. In Germany a re-verification will be

necessary.

Position of the official seals

Page 36

36 ABP-BA-e-1810

10 Basic Operation

10.1 Activate standard weighing mode

Status balance Action

The balance is now in stand-by

mode

Press the ON/OFF button.

Scale is in a different

operating mode

Press F -key

or

[ ] [ ]

Balance is in menu Press the ON/OFF key

After numeric input Repeatedly press the ON/OFF key.

10.2 Simple weighing

A warm-up time is required for stabilisation (see chap. 1).

Wait for zero display, reset to zero using TARE.

Place the goods to be weighed and close the wind screen doors

Wait until the stability display appears ( ).

Read weighing result.

When an optional printer is connected, the weighing value can be edited.

Print-out example with enabled GLP function (see chap. 15.8.3):

KERN & Sohn GmbH

Company

TYPE

ABP 300-4M

Model

SN

D319300002

Serial no.

BALID

1234

Balance identification no. (see chap. 13.3)

DATE

2018 Aug. 17

Date

TIME

09.14.21

Time

19.999[8] g

Measuring Value

-SIGNATURE-

prepared by

Page 37

ABP-BA-e-1810 37

Print-out example with disabled GLP function (see chap. 15.8.3):

19.999[8] g

Measuring Value

10.3 Taring

The dead weight of any weighing container may be tared away by pressing a button,

so that the following weighing procedures show the net weight of the goods to be

weighed.

Put vessel of goods to be weighed on weighing plate and close the wind

screen doors.

Wait until the stability display appears ( ), then press TARE. The weight of

the container is now internally saved.

Weigh the goods to be weighed and close the wind screen doors.

Wait until the stability display appears ( ).

Read net weight.

Note:

• The balance is able to only store one taring value at a time.

• When the balance is unloaded the

saved taring value is displayed with

negative sign.

•

To delete the stored tare value, remove load from weighing pan and

press TARE.

•

The taring process can be repeated any number of times. The limit is

reached when the whole weighing range is exhausted.

Page 38

38 ABP-BA-e-1810

10.4 Underfloor weighing

Objects unsuitable for placing on the weighing scale due to size or shape may be

weighed with the help of the flush-mounted platform.

Proceed as follows:

Switch off the balance.

Open closing cover (1) at the balance bottom.

Place weighing balance over an opening.

Attach weighed good to hook and carry out weighing procedure.

Fig.1: Underfloor weighing device

CAUTION

• Always ensure that all suspended objects are stable enough to hold the desired

goods to be weighed safely (danger of breaking).

• Never suspend loads that exceed the stated maximum load (max) (danger of

breaking)

Always ensure that there are no persons, an

imals or objects that might be damaged

underneath the load.

NOTICE

After completing the underfloor weighing the opening on the bottom of the balance

must always be closed (dust protection).

!

(1)

Page 39

ABP-BA-e-1810 39

10.5 Switch off the balance

Press the ON/OFF button. The balance is in standby

mode, that means that the balance is now in state readyfor-operation. Immediately after switching-on it is ready

for operation (press any key) without warm-up time.

To switch-off the balance completely, separate balance

from power supply.

When you see messages such as [Communication] do not disconnect scale

from power supply.

10.6 Switch-over weighing unit

To return the display to the units previously

enabled in the menu press the UNIT-key,

see chap. 12.6.

When switching-

on the balance, the unit in which the balance has been

switched off, will be displayed.

10.7 Change readability (1D/10D) (not av ailab le f o r veri fi ed mod els)

1d Display

10d Display

Page 40

40 ABP-BA-e-1810

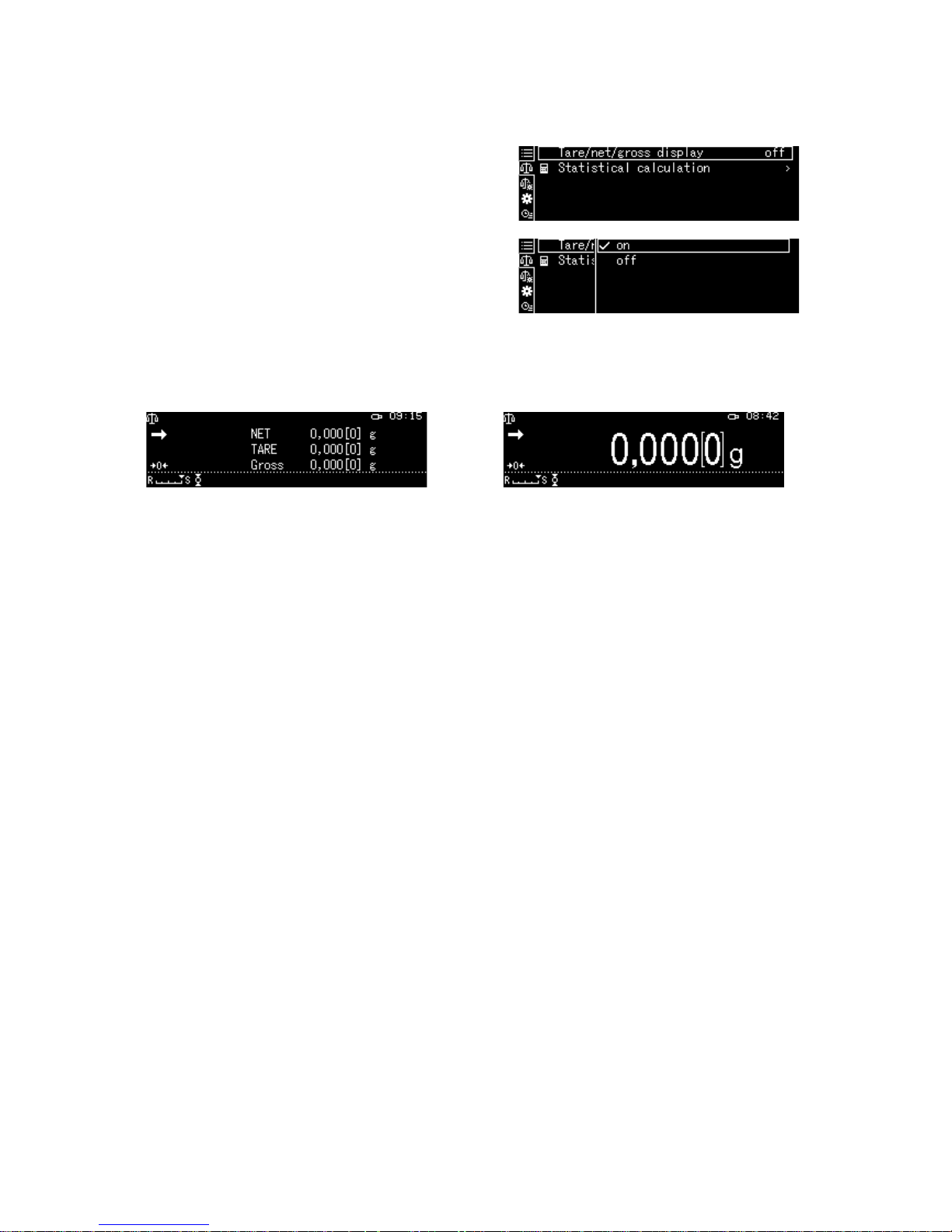

10.8 Display Tare / Net / Gross

In weighing mode press MENU button.

Select <Tare/net/gross display> and

confirm using the OK-key.

To display "Tara / Net / Gross"

Select <on> setting and confirm using the

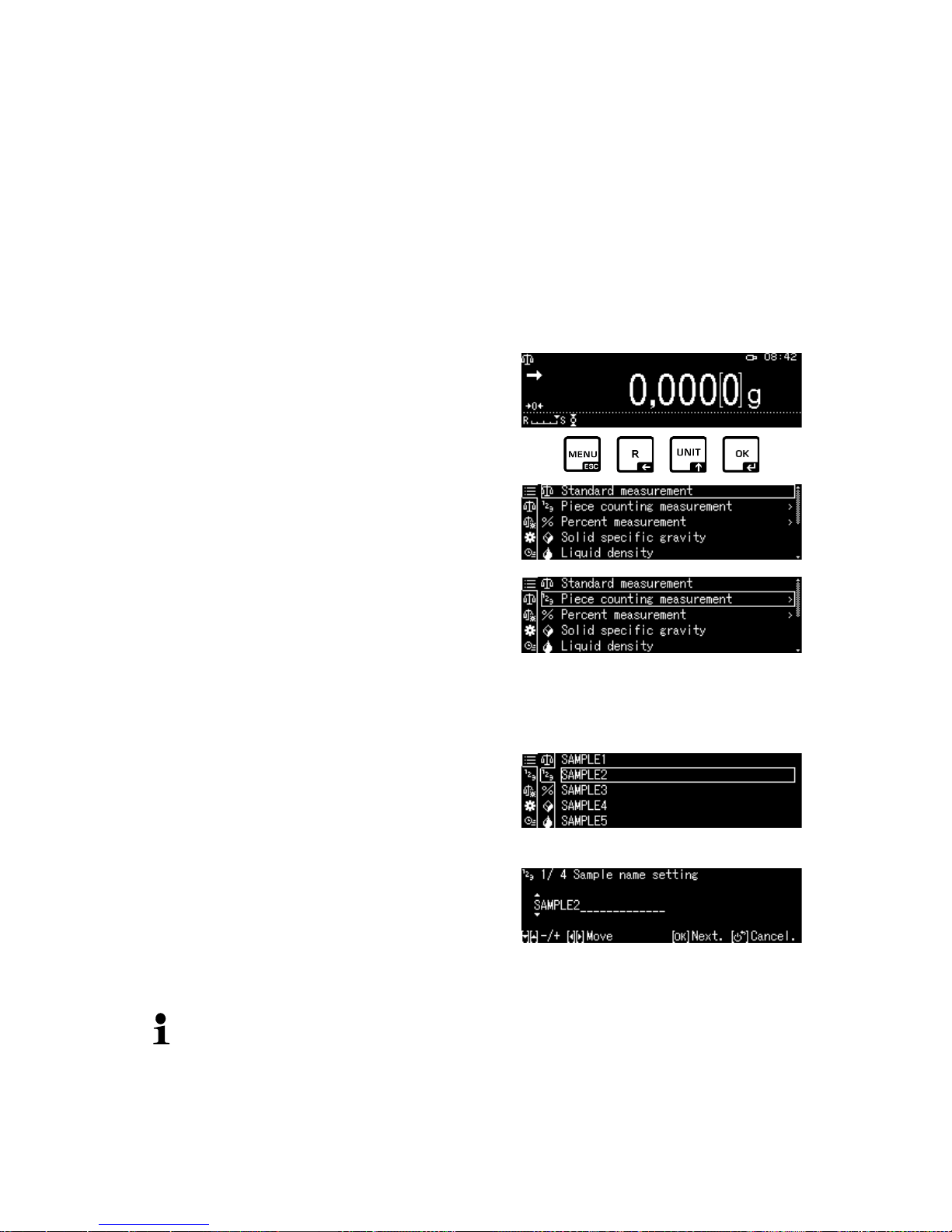

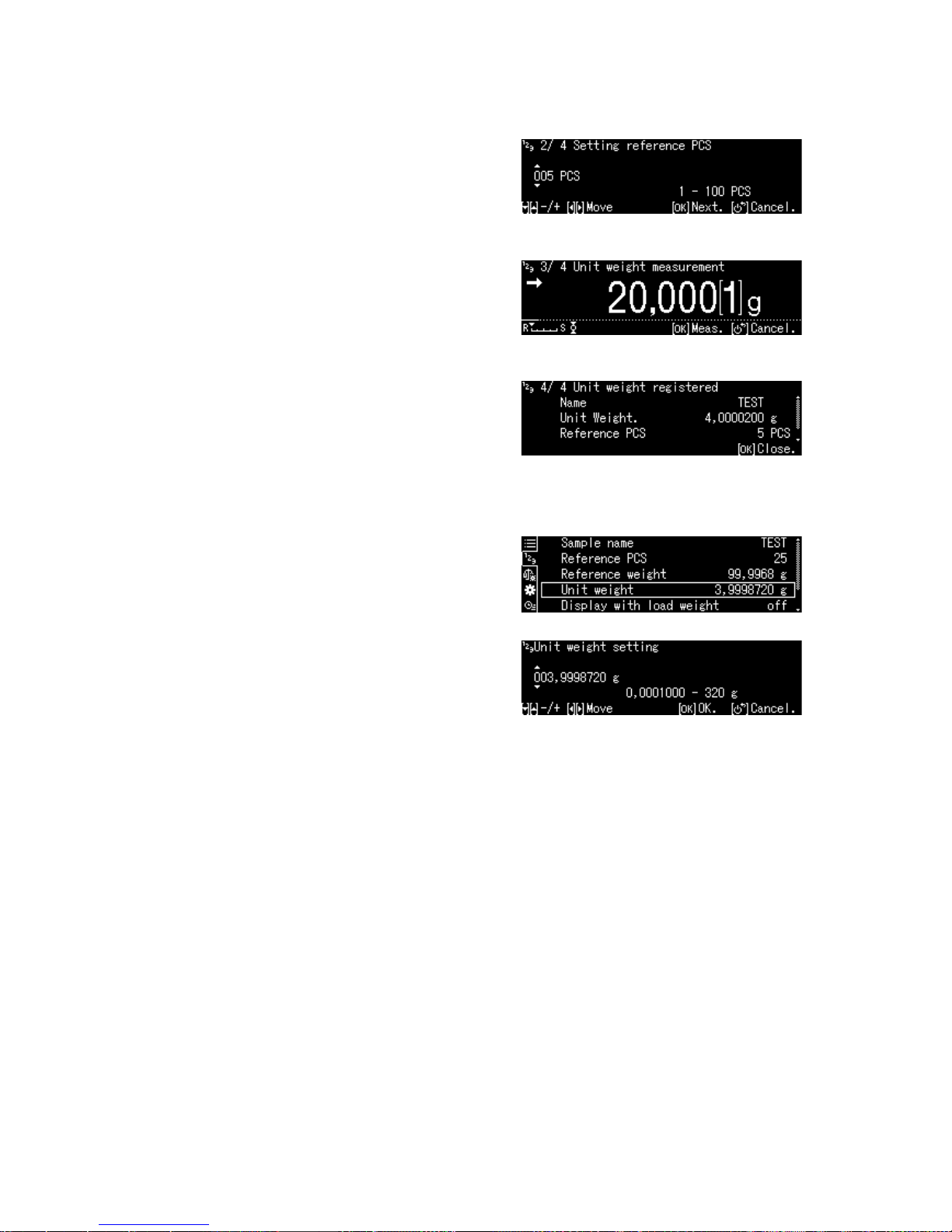

OK-key.

Setting <on> Setting <off>

Page 41

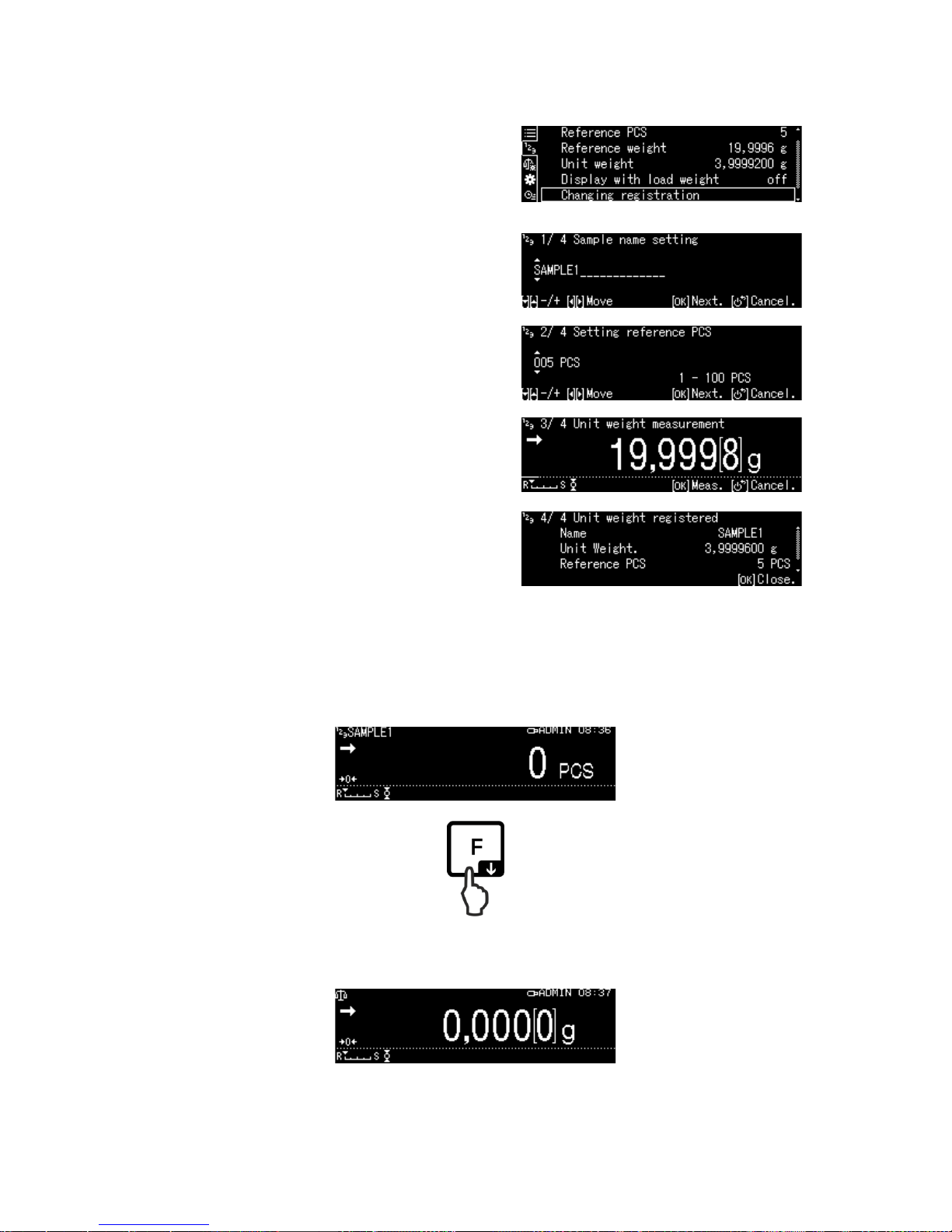

ABP-BA-e-1810 41

10.9 Display decimal dot as point or comma

Select System Settings and confirm using the

OK-key.

Select <Decimal point setting> and confirm

using the OK-key.

Select desired setting [Period] or [Comma]

and confirm using the OK-key.

Use the ON/OFF button to return into

weighing mode

Page 42

42 ABP-BA-e-1810

11 Menu

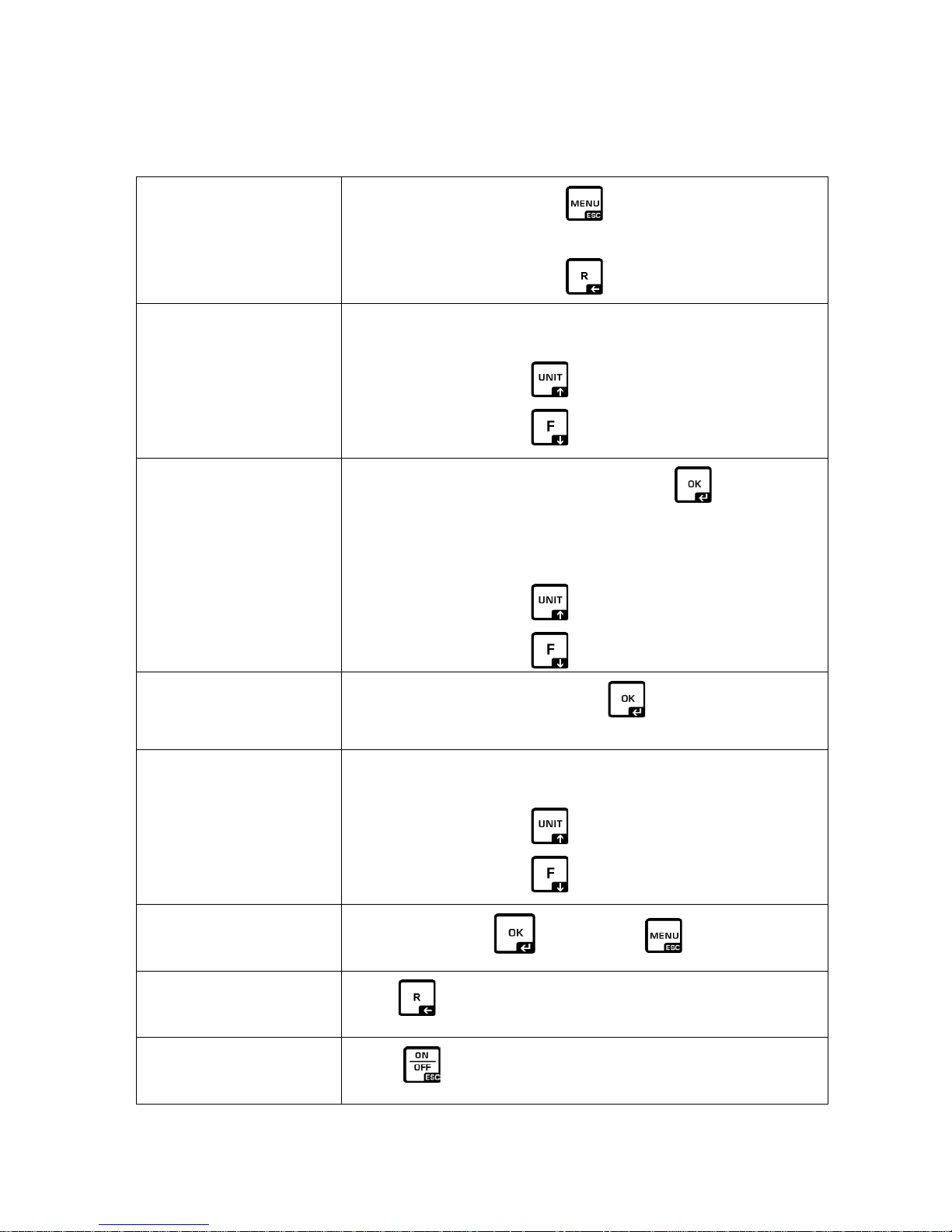

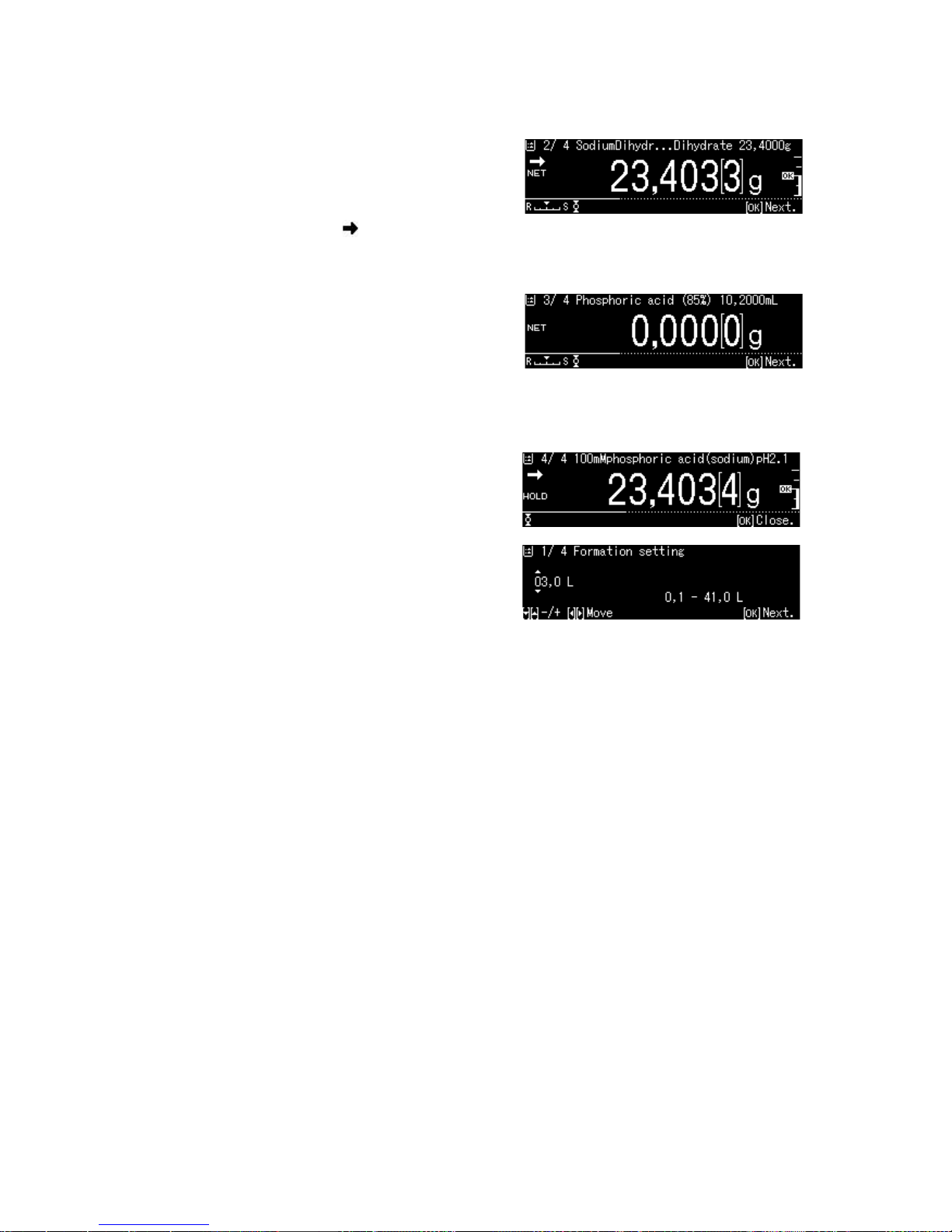

11.1 Navigation in the menu

Call up menu

Select menu block Use the navigation buttons to select the individual menu

blocks one by one.

Use the navigation key to scroll down.

Use the navigation key to scroll up.

Select menu item

Confirm selected menu block by pressing . The first

menu item of the selected menu block will be shown.

Use the navigation buttons to select the individual menu

items one by one.

Use the navigation key to scroll down.

Use the navigation key to scroll up.

Select setting

Confirm selected menu item with and the current

setting will be shown.

Change settings Use the navigation keys to switch over into the available

settings.

Use the navigation key to scroll down.

Use the navigation key to scroll up.

Confirm setting

Acknowledge with or reject with

Return to previous

menu

Press

Return to weighing

mode

Press

Page 43

ABP-BA-e-1810 43

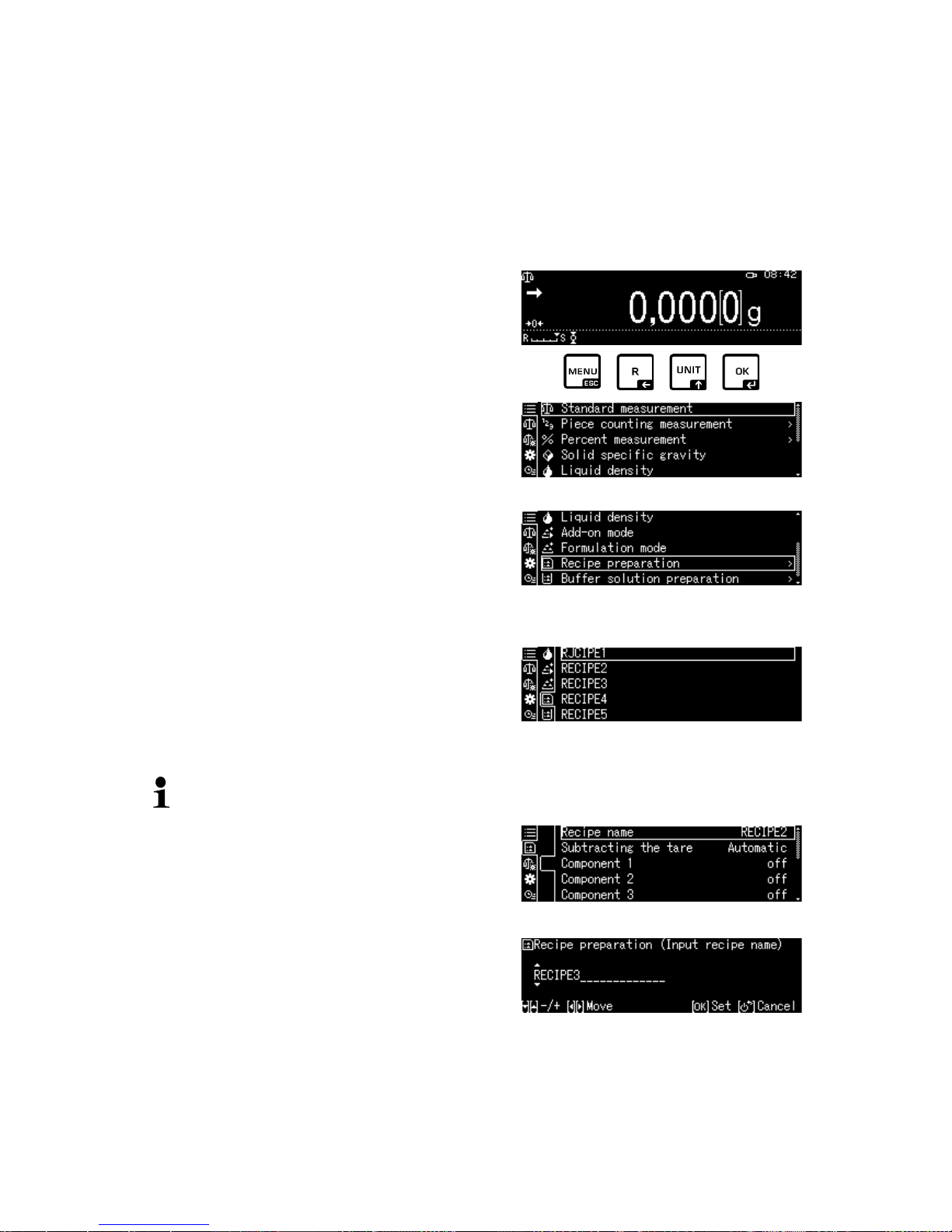

Display examples:

General navigation:

All selectable functions and settings may be accessed by navigating the arrow keys [,

,,] and confirming by pressing the OK-key.

The framing will indicate the current

selection.

When the icon is displayed you can press the S-key to access a submenu.

If a scroll bar is shown, further parameters may be displayed by using the

navigation keys , .

Menu settings surrounded by square brackets are not available.

To return to the previous menu, press the R-key

Numerical input, see chap. 3.2.1.

11.1.1 Standard weighing mode

The list of available settings will be displayed

How to change settings

1. Tare/net/gross display

Use the navigation keys to select the desired

settings

, and confirm using the OK-key.

Page 44

44 ABP-BA-e-1810

2. Statistical calculation

A submenu will be available by pressing

if the icon is displayed.

Use the navigation keys to select the desired

setting

, and confirm using the

OK-key.

Use to return to the previous menu

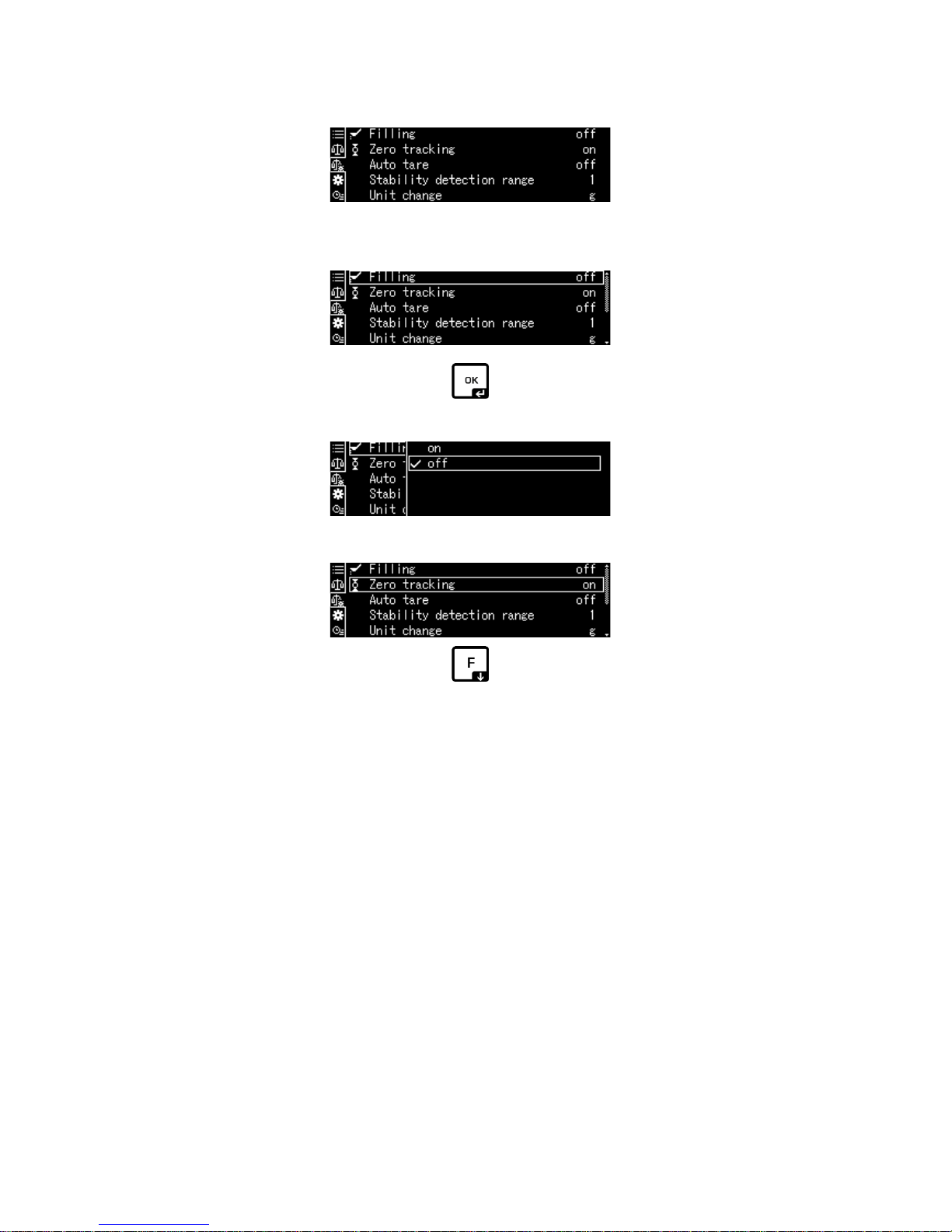

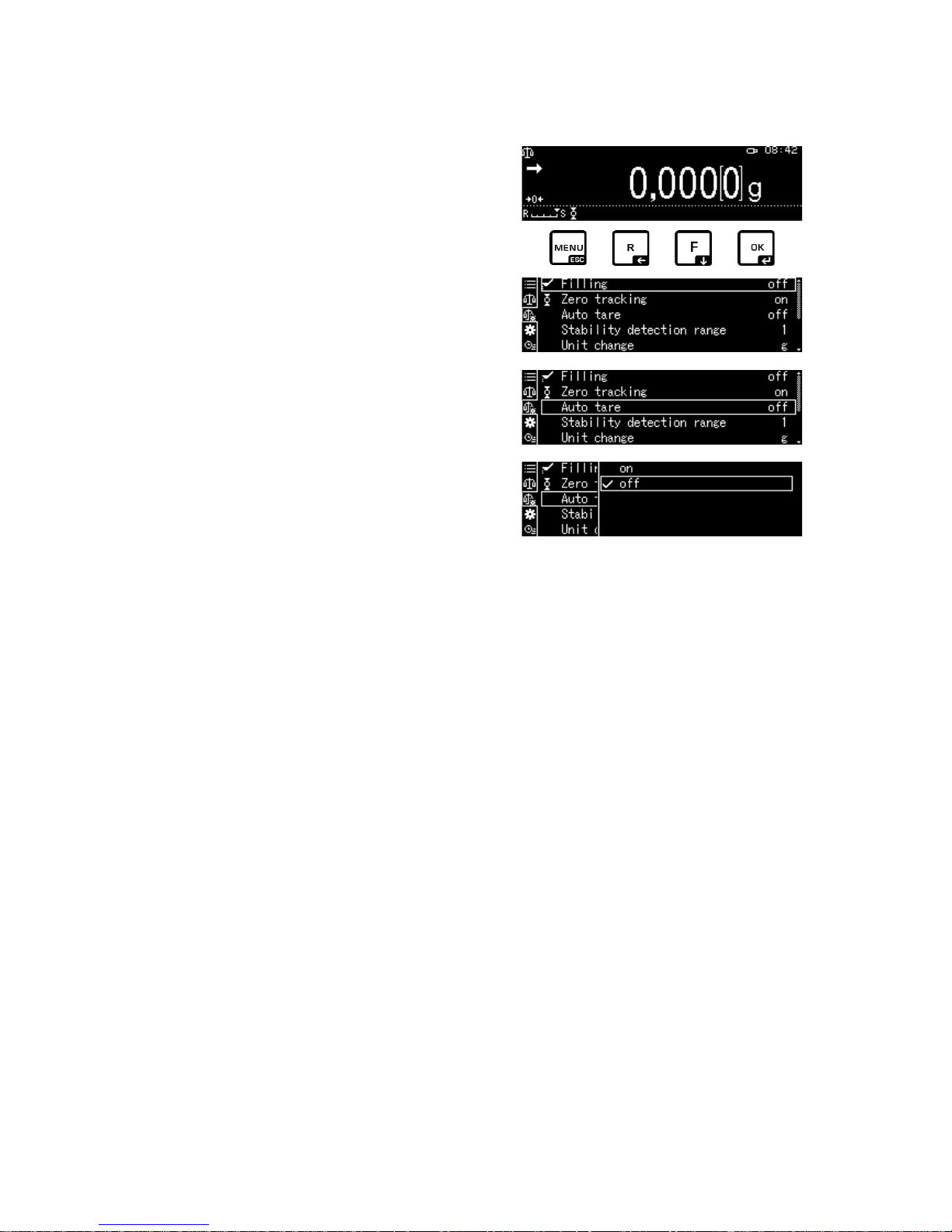

11.1.2 Weighing settings

Page 45

ABP-BA-e-1810 45

The list of available settings will be displayed.

Confirm using the OK-key. The framing will indicate the current selection.

Select the desired settings using the F-key.

To change your selection, press the OK-key.

Use the navigation keys

, to select the desired settings and confirm using the OK-key.

Press the F-key to select additional settings and make changes as described above.

Page 46

46 ABP-BA-e-1810

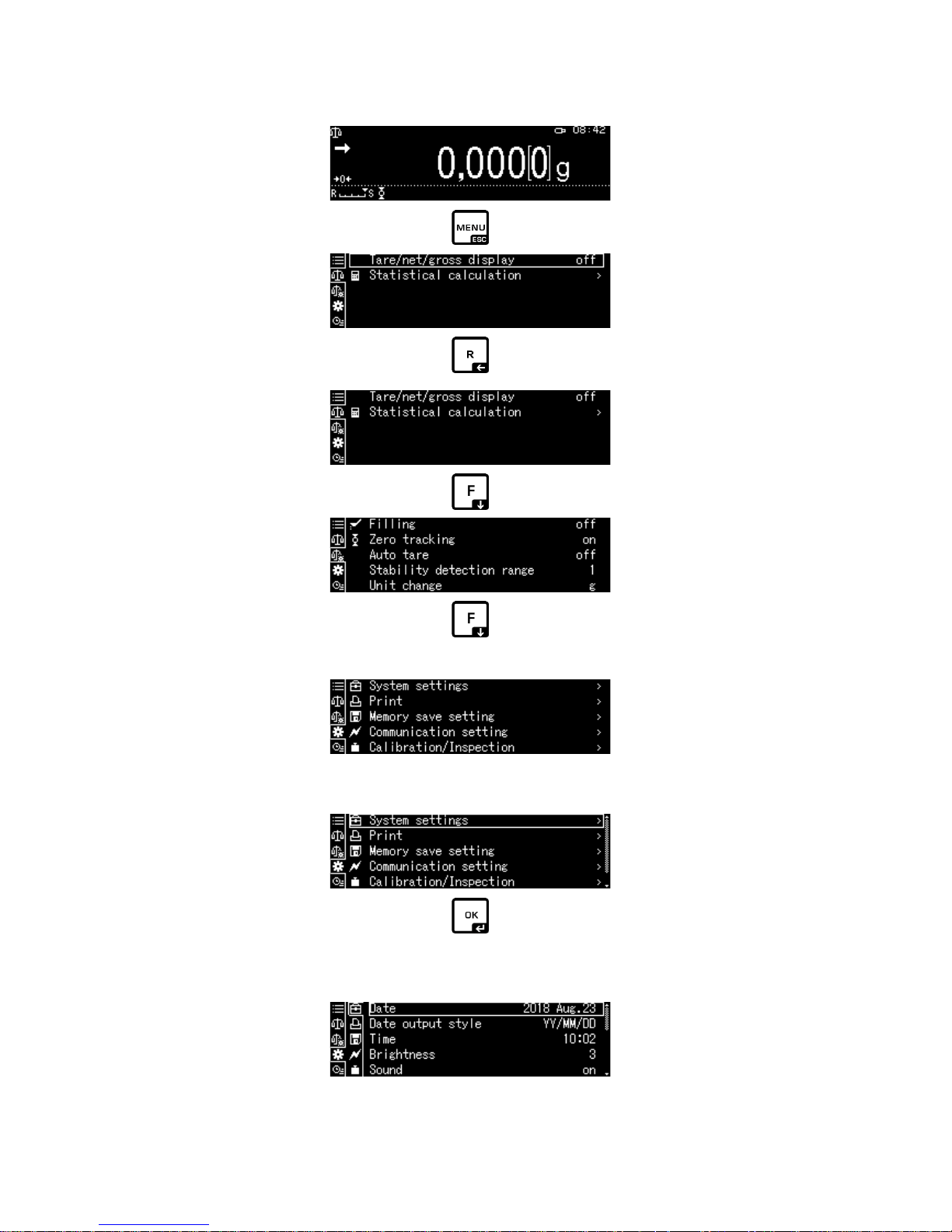

11.1.3 System Settings

The list of available menu blocks will be displayed.

Confirm using the OK-key. The framing will indicate the current selection. Use the navigation

keys , to select the desired menu block (such as system settings).

Confirm selection by pressing the OK-key.

The list of available settings will be displayed.

Page 47

ABP-BA-e-1810 47

Use the navigation keys , to select the desired setting (such aus brightness).

To change your selection, press the OK-key.

Use the navigation keys

, to select the desired setting and confirm using the OK-key.

Press the F-key to select additional settings and make changes as described above.

Page 48

48 ABP-BA-e-1810

11.1.4 Application settings

The available applications will be displayed.

Press the S-key and use the navigation keys , to select the desired application, such as

part counting. The framing will indicate the current selection.

Confirm using the OK-key and the application specific settings will be displayed.

The application specific settings are described in the respective chapters, see chap. 14

11.2 Menu overview

The menu overview is part of the scale’s scope of delivery and supplied in

the form of a separate document.

Page 49

ABP-BA-e-1810 49

11.3 Resetting the menu

The <Menu reset> menu may be used to reset all scale settings to default settings.

• Factory settings are marked by a “*” in the menu oversight.

• If user management is enabled, menu resetting may only be made by

an authorised user.

1. Call System Settings

see chap. 11.1.3.

2. Enable/disable function

Confirm using the OK-key.

Use the navigation keys , to select

<Menu reset> and confirm using the OK-key.

Password prompt will be displayed. For how

to enter a password, see chap. 3.2.1

"Numeric input" and confirm using the OK-

key.

Either

Enter user-defined password

or

Enter standard password [9999] (default

setting)

Confirm query by pressing the OK-key

The balance returns automatically into

weighing mode. All user and application

specific settings will be reset to default setting.

Page 50

50 ABP-BA-e-1810

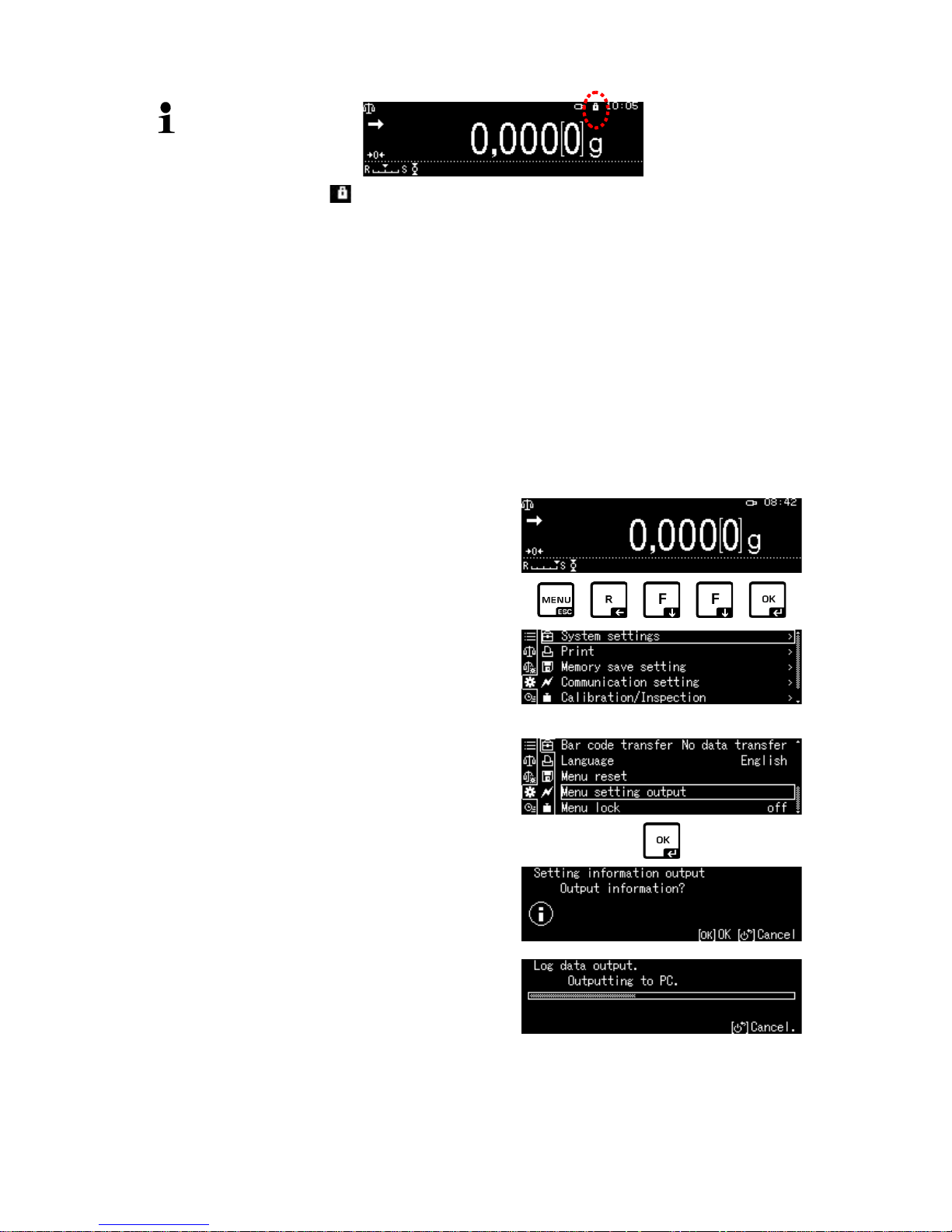

11.4 Menu Loc k

The menu setting operations can be locked so that the settings cannot be

inadvertently changed. This menu lock is set with the following procedure.

1. Call System Settings

see chap. 11.1.3.

2. Enable/disable function

Confirm using the OK-key.

Use the navigation keys , , select <Menu

lock> and confirm using the OK-key.

Password prompt will be displayed. For how

to enter a password, see chap. 3.2.1

"Numeric input" and confirm using the OK-

key.

Either

Enter user-defined password

or

Enter standard password [9999] (default

setting)

Confirm query by pressing the OK-key

Use the navigation keys , to enable (on) /

disable (off) the function and confirm using the

OK-key.

3. Return to weighing mode

Press the ON/OFF key

Page 51

ABP-BA-e-1810 51

• The icon will be displayed while the function is enabled.

• Weighing and adjustment can take place despite menu lock.

• Authorisation for performing this function may be allocated to any

user.

• If a menu item selection is attempted in locked status, the message

“LOCKED” appears and the menu selection is not allowed. To disable

the menu block, select Settings [off].

11.5 Log menu settings

When an optional printer is connected, a list of the current menu settings can be

printed out.

1. Call System Settings

see chap. 11.1.3.

2. Activate function

Confirm using the OK-key.

Use the navigation keys , to select

<Menu setting output> and confirm using the

OK-key.

Confirm request by pressing the OK-key and

printing will start.

The balance returns automatically into

weighing mode.

Page 52

52 ABP-BA-e-1810

11.6 Menu history

This function is applied to display the last 10 menu steps.

Use the navigation keys , to select

< > and the last 10 menu steps will be

displayed.

Page 53

ABP-BA-e-1810 53

12 Description of individual funct ions

12.1 Zero setting and tare function

Selectable functions:

Description

1. Zero tracking function

+ see chap. 12.2.

This function is used to correct automatically small

weight variations which appear directly after

switching-on.

In the event that small quantities are removed or added

to the material to be weighed, incorrect weighing results

can be displayed due to the “stability compensation“.

(e.g. slow flow of liquids from a container placed on the

balance, evaporating processes).

When apportioning involves small variations of weight, it

is advisable to switch off this function.

2. Auto tare function

+

see chap. 12.3.

After data output an automatic taring is carried out

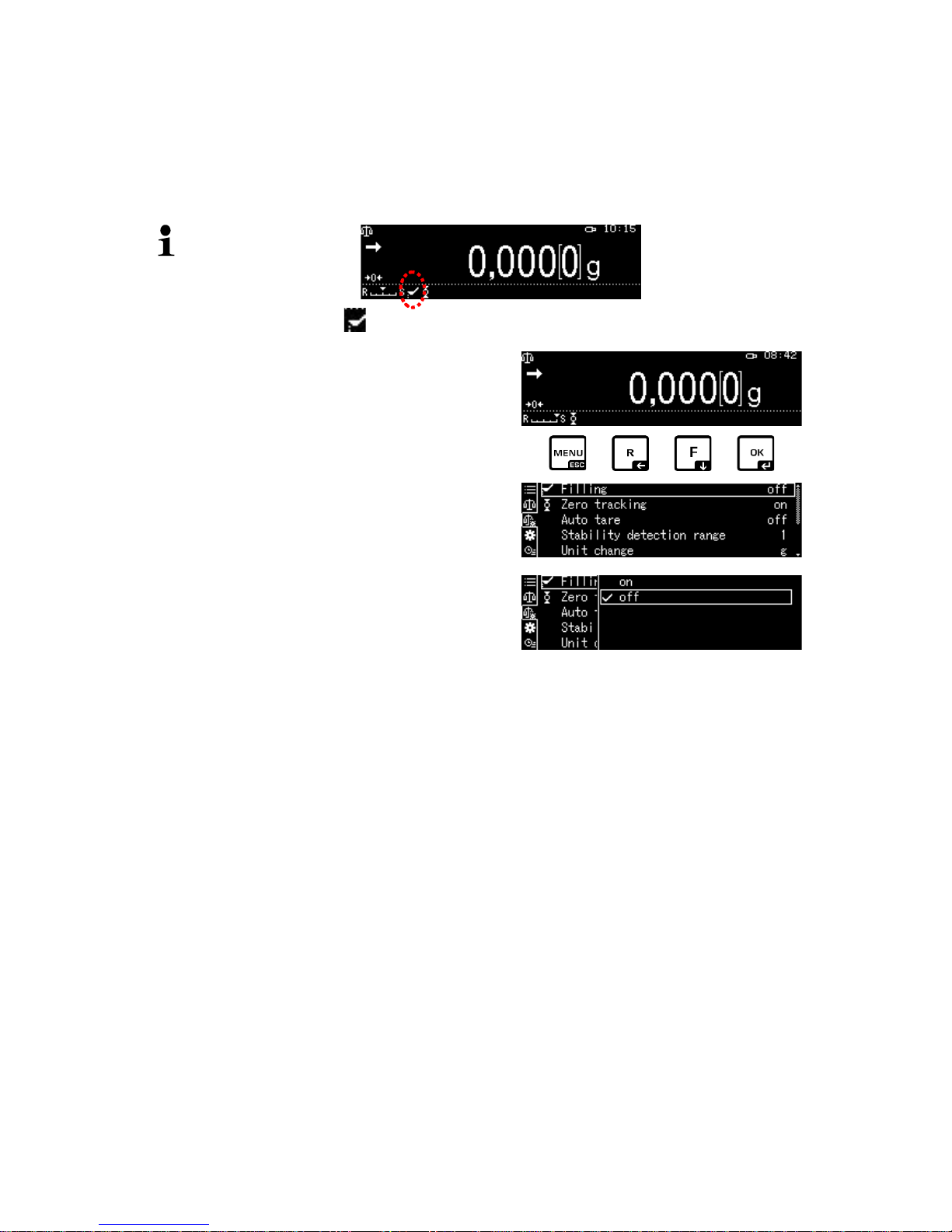

12.2 Zero tracking function

The icon will be displayed while the zero tracking function is enabled.

1. Call function

see chap. 11.1.2.

or

Press and hold the TARE-key for a long time

Use the navigation keys , to select <Zero

tracking> and confirm using the OK-key.

2. Enable/disable function

Use the navigation keys , to enable (on) /

disable (off) the function and confirm using the

OK-key.

3. Return to weighing mode

Press the ON/OFF key

Page 54

54 ABP-BA-e-1810

12.3 Auto Tare function

1. Call function

see chap. 11.1.2.

Use the navigation keys , to select

<Auto tare> and confirm using the OK-key.

2. Enable/disable function

Use the navigation keys , to enable (on) /

disable (off) the function and confirm using the

OK-key.

3. Return to weighing mode

Press the ON/OFF key

Page 55

ABP-BA-e-1810 55

Smart setting display

12.4 Settings for Stability and Response

Exists the possibility to tune the stability of the display and the degree of reaction of

the balance to the requirements of certain applications or the environmental

conditions.

Most measurements may be carried out by using default settings. In standard

weighing mode, stability and reaction have the same priority. For certain applications

such as e.g. dosage do use the dosing mode. In dosing mode the reaction degree

has the higher priority.

Beside the selection standard / dosing mode the stability of the display and the

reaction degree of the balance can additionally adapted in the menu.

Please note that in general slowing down reaction times result in higher stability of

the set data handling, while speeding up reaction times have an influence on the

stability deterioration.

12.4.1 Stability and reaction settings via „Smart Setting display“ (without

invoking menu)

If there is a change in ambient conditions the responding qualities or the stability of

the scale may be optimised – even during weighing – by simply pressing the key.

In weighing mode press for Reaction Settings or for Stability

Settings.

Priority on reaction

Priority on stability

Smart setting display

Operation

Every time the key is

pressed, the priority for the

reaction will be increased.

The icon will be moving in

the direction of <R>.

Every time the key is

pressed the priority for the

stability will be increased.

The icon will be moving

in the direction of <S>.

Page 56

56 ABP-BA-e-1810

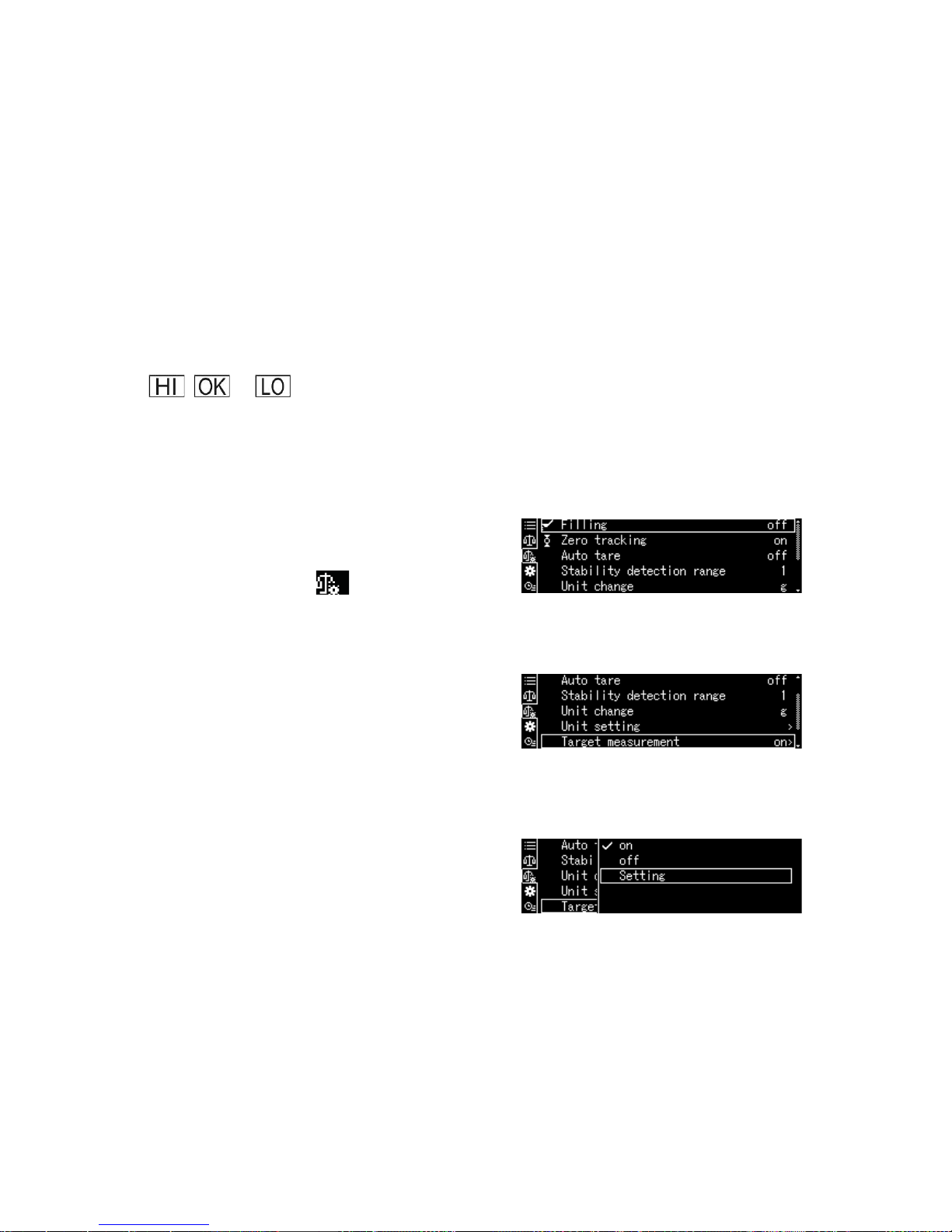

12.5 Dosing

Use this function if you wish to increase display speed, e.g. during apportioning.

However, please note that the balance is very susceptible to ambience conditions.

The icon will be displayed while the function is enabled.

1. Call function

see chap. 11.1.2.

Select<Filling> and confirm using the OK-key.

2. Enable/disable function

Use the navigation keys , to enable (on) /

disable (off) the function and confirm using the

OK-key.

3. Return to weighing mode

Press the ON/OFF key

Page 57

ABP-BA-e-1810 57

12.5.1 Standstill width

If the stability display lights up ( ), the weighing result will be stable within the range

indicated by the standstill width.

Set range for stability determination:

1. Call function

see chap. 11.1.2.

Use the navigation keys , to select

<Stability detection range> and confirm using

the OK-key.

2. Set range for stability determination

Use the navigation keys , to select

Setting and confirm using the OK-key.

0.5d Stability display ( ) very quiet environment

1000d Stability display ( ) busy environment

3. Return to weighing mode

Press the ON/OFF key

Page 58

58 ABP-BA-e-1810

12.6 Weighing Units

The <Unit setting> menu is used to define which weighing units you wish to apply.

By pressing the UNIT key, the display can be switched over to the units enabled

before in the menu.

Scales with type approval allow you to change to the following units:

[g] → [mg] → [ct]

1. Call function

Go to weighing mode and press and hold the

UNIT-key for approx. 3 sec until the

<Unit setting > menu is displayed.

Confirm using the OK-key and the available

units will be displayed.

Use the navigation keys to , select the

unit and confirm using the OK-key.

2. Enable/disable units

Use the navigation keys , to enable (on) /

disable (off) the function and confirm using the

OK-key.

3. Return to weighing mode

Press the ON/OFF key

12.7 User administration log-in function

The scale has a user administration where individual access rights for administrator

and user levels may be defined. The input of a user name and password is required

for access.

The administrator can use all the functions and has all rights. Only the administrator

is authorised to create new user profiles and to grant access rights.

A user on the other hand may not have access to all functions. He/she has limited

rights that are defined in the user profile. The maximum of users is limited to 10.

Page 59

ABP-BA-e-1810 59

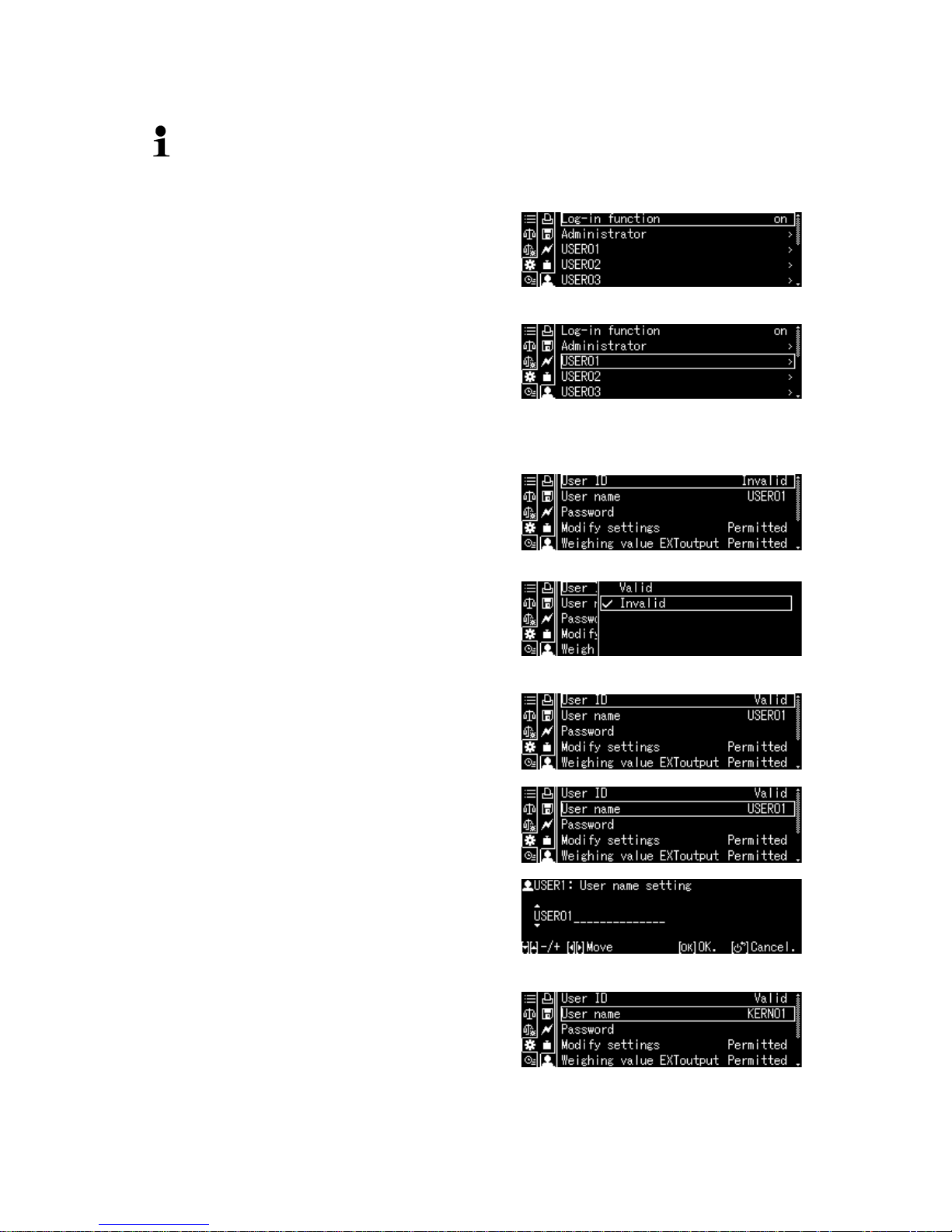

a) Enable/disable function

Login function [off] Login function [on]

All users have administrator rights and

full access (default setting).

There is only one administrator and

maximal 10 users.

1. Call System Settings

see chap. 11.1.3.

Use the navigation keys , to select

<User settings> and confirm using the OKkey.

2. Enable/disable function

Use the navigation keys , to enable (on) /

disable (off) the function and confirm using the

OK-key.

Weighing balance returns to menu.

From this point onwards you will be logged-in

as administrator and authorised to change

settings.

Page 60

60 ABP-BA-e-1810

b) Creat ing a user profile

Only the administrator may create new user profiles and grant access rights.

Changes to a user profile, too, may only be made by the administrator.

1. Select administrator or user

Use the navigation keys to , select

Administrator or User <Administrator or User

01 - 10> and confirm using the OK-key.

2. Define user selection to be displayed

on log-in

Use the navigation keys , to select

<User ID> and confirm using the OK-key.

Use the navigation keys , to select

<valid> or <invalid> and confirm using the

OK-key.

When selecting <valid> continue with input as

described in the next step.

When selecting <invalid> use the ON/OFF-

key to return to weighing mode.

3. Changing user name (ID)

Use the navigation keys to , select

<User name> and confirm using the OK-key.

Enter desired user name (For numeric input

see chap.3.2.1)

Confirm selection by pressing the OK-key.

Weighing balance returns to menu.

Here you may change settings as described

below.

Page 61

ABP-BA-e-1810 61

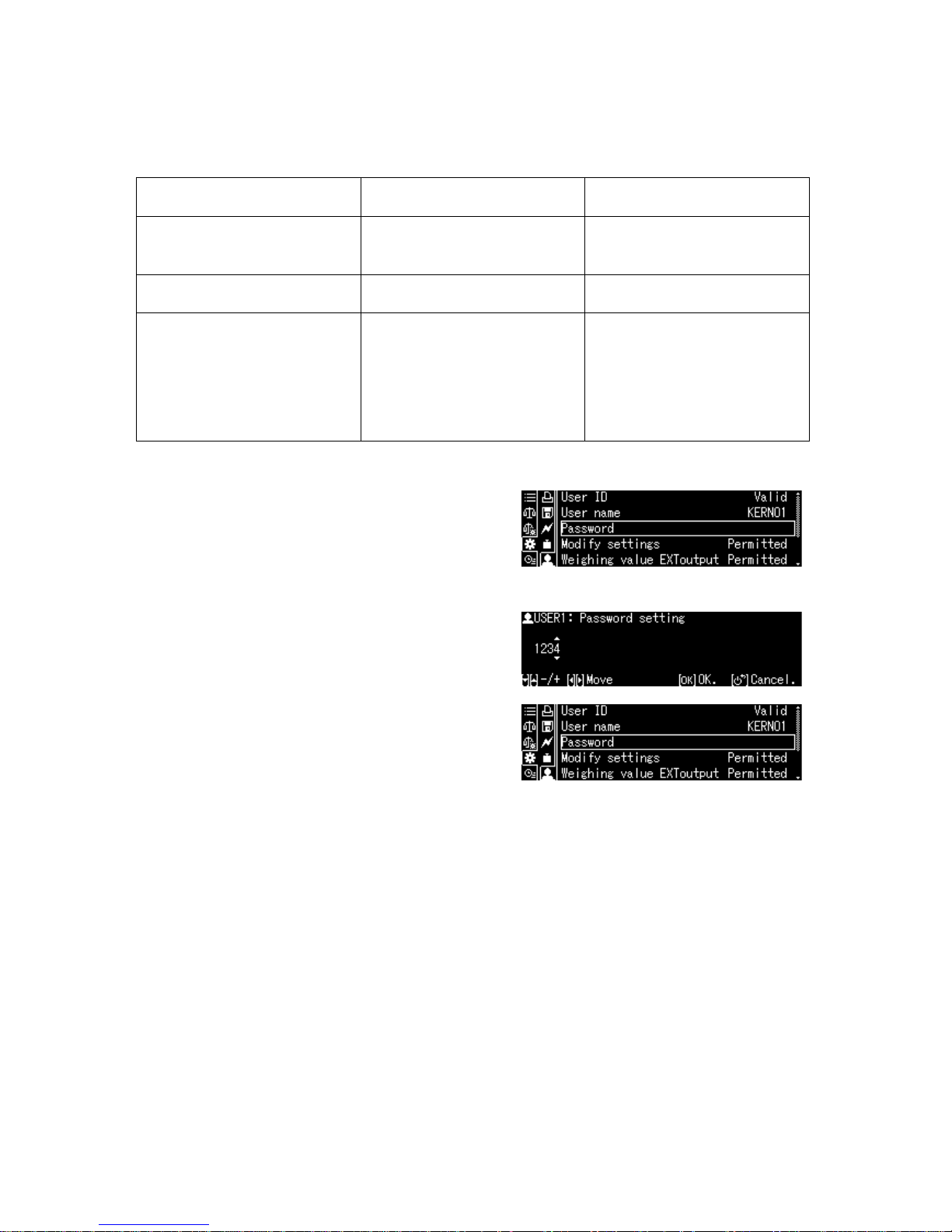

c) Define password

Different passwords are required according to user or administrator.

Type Administrator password User Password

Default setting for

password

9999 0000

Log-in Administrator ID User ID

Access rights All functions and rights Limited rights defined in

user profile.

No password will be

required if default setting

[0000] is used.

Use the navigation keys , to select

<Password > and confirm using the OK-key.

Enter password

(For numeric input see chap. 3.2.1

Confirm selection by pressing the OK-key.

Weighing balance returns to menu.

Here you may change settings as described

below.

Page 62

62 ABP-BA-e-1810

d) Gra nt ing user rights

The administrator defines which of the following activities may be performed by the

user.

Modify settings Make settings in menu

Weighing value

External output

Data output to external devices

Using USB flash

drive

Access to USB storage space

Adjustment Change adjustment settings

Test For performing regular inspections see chap. 8.2

Use the navigation keys , to select

activity such as <Modify setting>, to which

access rights are to be granted or refused.

Confirm selection by pressing the OK-key.

Use the navigation keys , to select the

desired setting and confirm using the OK-key.

Weighing balance returns to menu.

Use the navigation keys , to select the

next menu item such as <Weighing value

EXToutp.> and change settings as described

above.

Repeat this sequence of operations for all five

menu items.

Return to weighing mode:

Press the ON/OFF key

Page 63

ABP-BA-e-1810 63

e) Change user name

Use the navigation keys to , select

<User name> and confirm using the OK-key.

Enter desired user name (For numeric entry

see chap. 3.2.1)

Confirm selection by pressing the OK-key.

Weighing balance returns to menu.

Here you may change settings as described

below.

The user name will be displayed on the top right of the display during

operation and as long as the respective user profile is enabled.

Page 64

64 ABP-BA-e-1810

f) Login

When the log-in function is enabled, the list of

users will be displayed on log-in.

Use the navigation keys , to select User

and confirm using the OK-key.

Password prompt will be displayed.

Enter password and confirm using the OK-key

(For numeric entry see chap. 3.2.1).

When a user logs in using the standard password [0000] no password query

will be made.

The display will change into operating mode,

the selected user will be enabled and will be

shown at the top of the display.

• Apart from administrator or user it is also possible to log-in as "Guest".

• A logged-in guest may merely perform weighing.

Sequence of operations:

Press the ON/OFF-key when list of

users is displayed

The display will then change to

operating mode, the selected user

<GUEST> will be enabled and shown

on the top of the display.

Page 65

ABP-BA-e-1810 65

13 Balance settings

13.1 Screen saver

While this function is enabled the scale will automatically change to standby mode

after a defined time without a change in load or conditions. You can turn off the

function [off] or define a time after which the scale is to change into standby mode.

To restart press the ON/OFF-key.

Call System settings (see chap. 11.1.3).

Use the navigation keys , to select

<Screen saver> and confirm using the OKkey.

Use the navigation keys , to select

switch off time and confirm using the OK-key.

Options: off, 5, 10, 15, 20, 30 min.

Use the ON/OFF button to return into

weighing mode

13.2 Display settings in operating mode

For calling system settings see chap. 11.1.3.

Use the navigation keys , to select

<OP mode setting> and confirm using the

OK-key.

Use the navigation keys , to select

the desired setting and confirm using the OKkey.

Use the ON/OFF button to return into

weighing mode

Page 66

66 ABP-BA-e-1810

13.3 Balance identification no.

This setting is for the balance ID number that is output along with the adjustment

report.

For calling system settings see chap. 11.1.3.

Use the navigation keys , to select

<Balance ID> and confirm using the OK-key.

Use the navigation keys , to enter name

(max. 16 characters ) and confirm using the

OK-key.

Numerical input, see chap. 3.2.1.

Use the ON/OFF button to return into

weighing mode

13.4 Entering date and time

For calling system settings see chap. 11.1.3.

Use the navigation keys , to select

<Date> or <Time> and confirm using the OKkey.

Use the navigation keys , to enter

date or time and confirm using the OK-key.

Numerical input, see chap. 3.2.1.

Use the ON/OFF button to return into

weighing mode

13.5 Date format

For calling system settings see chap. 11.1.3.

Use the navigation keys , to

select <Date output style> and confirm using

the OK-key.

Use the navigation keys , to set the

display format and confirm using the OK-key.

Use the ON/OFF button to return into

weighing mode

Page 67

ABP-BA-e-1810 67

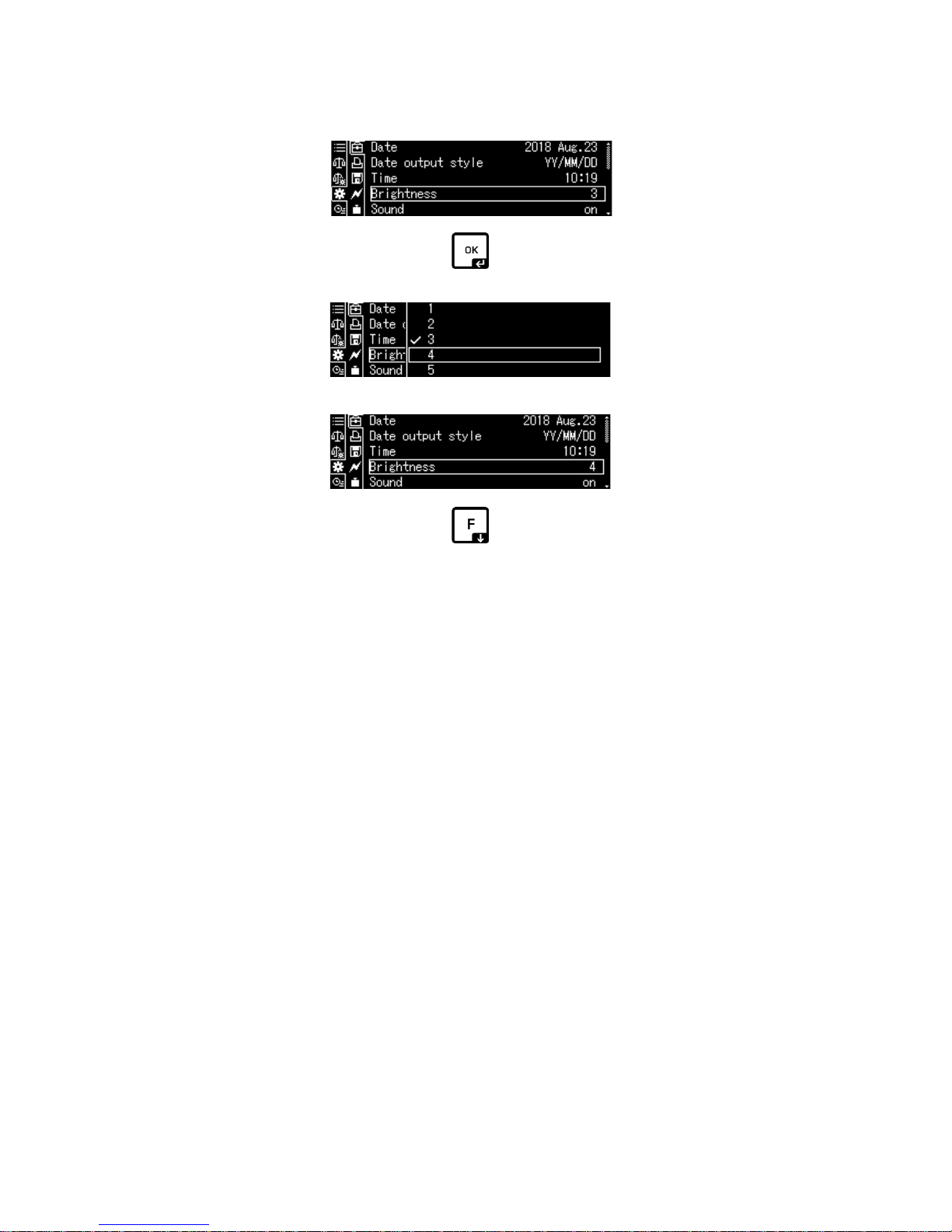

13.6 Brightness of display

For calling system settings see chap. 11.1.3.

Use the navigation keys , to select

<Brightness> and confirm using the OK-key.

Use the navigation keys , to

set brightness and confirm using the OK-key

Use the ON/OFF button to return into

weighing mode

13.7 Audio signal on pressing key or display of stability

For calling system settings see chap. 11.1.3.

Use the navigation keys , to select

<Sound> and confirm using the OK-key.

Use the navigation keys , to select

setting [on] or [off] and confirm using the OKkey

Use the ON/OFF button to return into

weighing mode

13.8 User language

For calling system settings see chap. 11.1.3.

Use the navigation keys , to select

<Language> and confirm using the OK-key.

Use the navigation keys , to select

language and confirm using the OK-key

Use the ON/OFF button to return into

weighing mode

Page 68

68 ABP-BA-e-1810

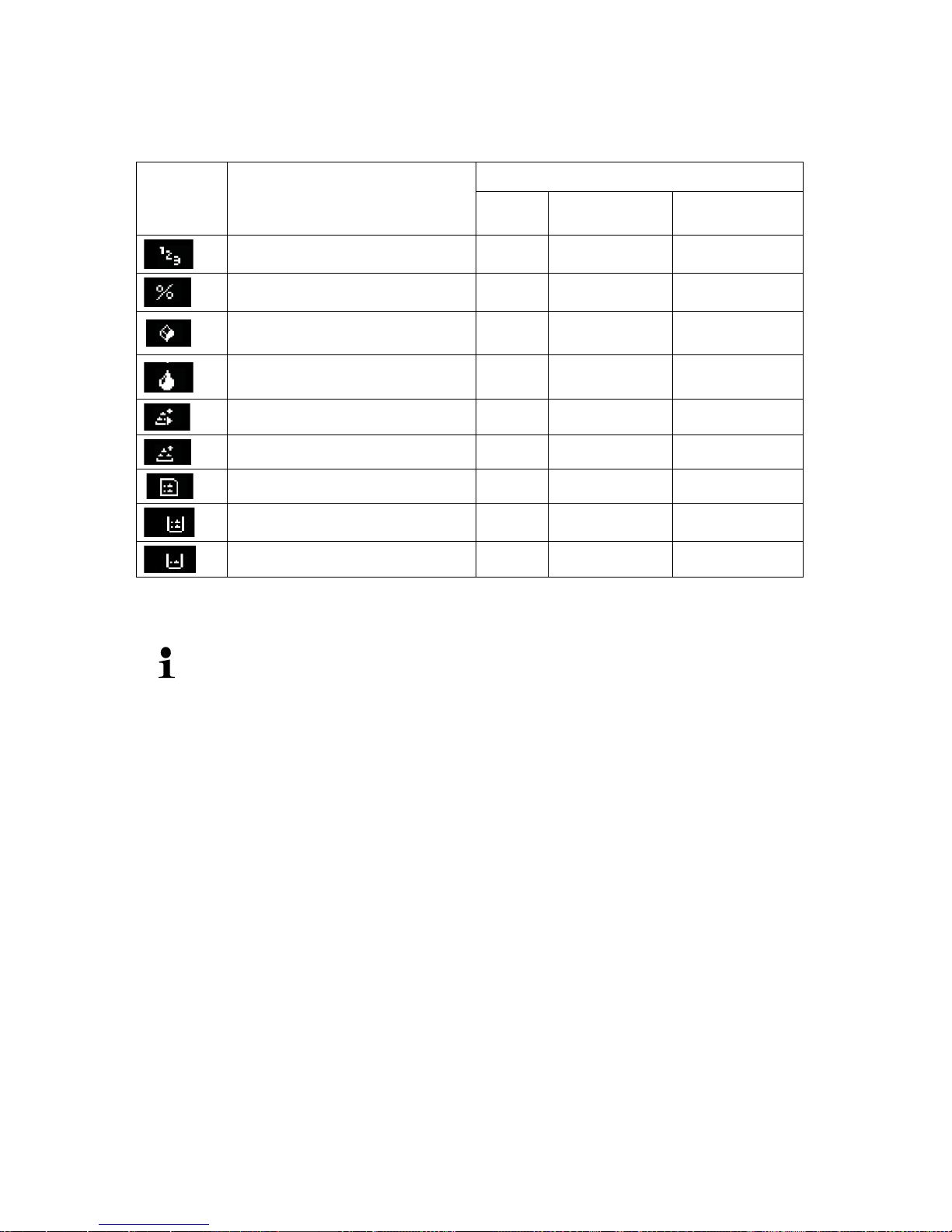

14 Application Functions

Overview of available applications:

Symbol Function

Combinable functions

Statistics Check weighing Minimum initial

weight

Parts counting

Percent determination

Density determination <Solid

matter>

Density determination

<Fluids>

Totalization

- -

Free formulating

- -

Autom. processing a recipe

- -

Produce a buffer solution

- -

Produce an analysis sample

- -

• The balance starts in the mode, in which it has been switched off.

• To switch between application and weighing mode press the F-key

(not available for statistics, check weighing, minimal weight)

Page 69

ABP-BA-e-1810 69

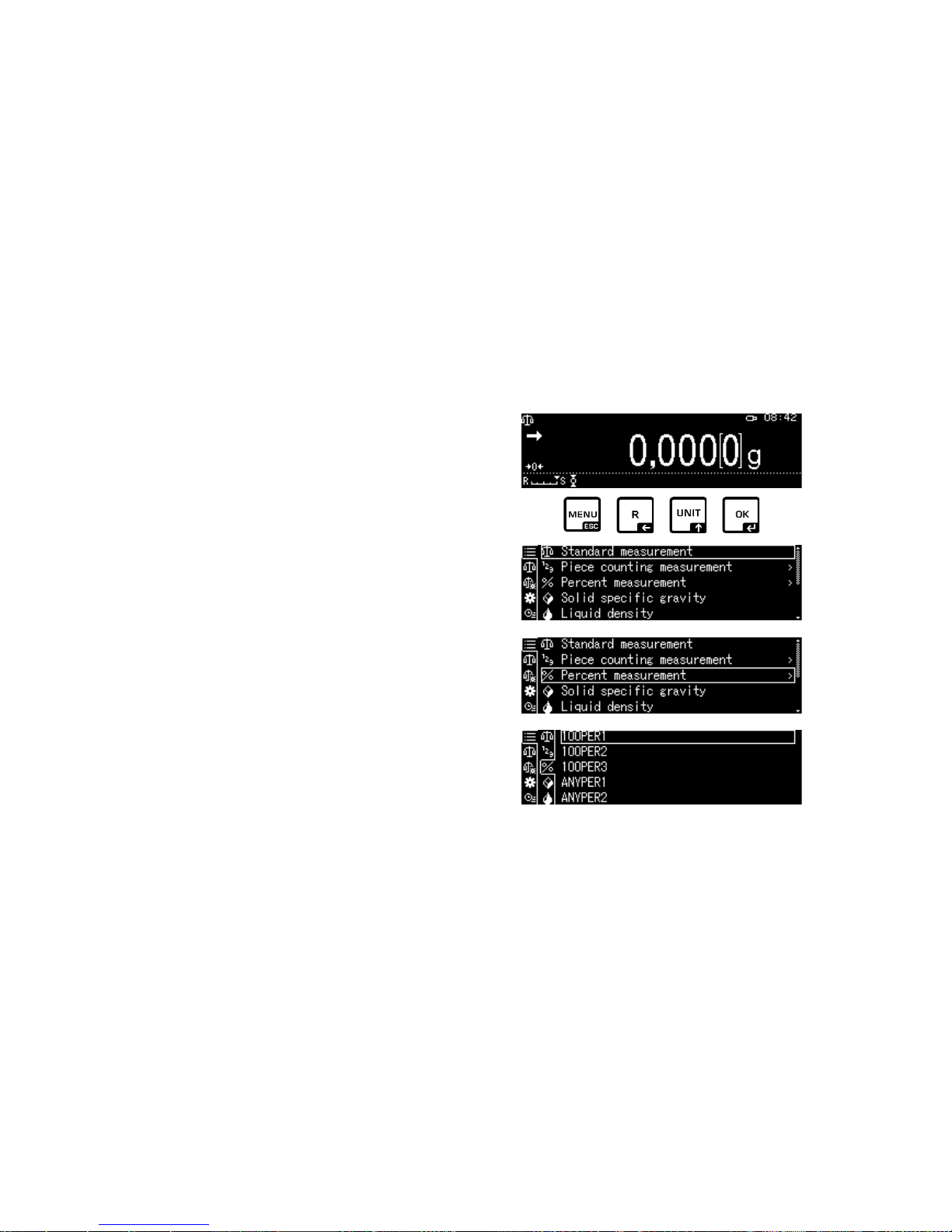

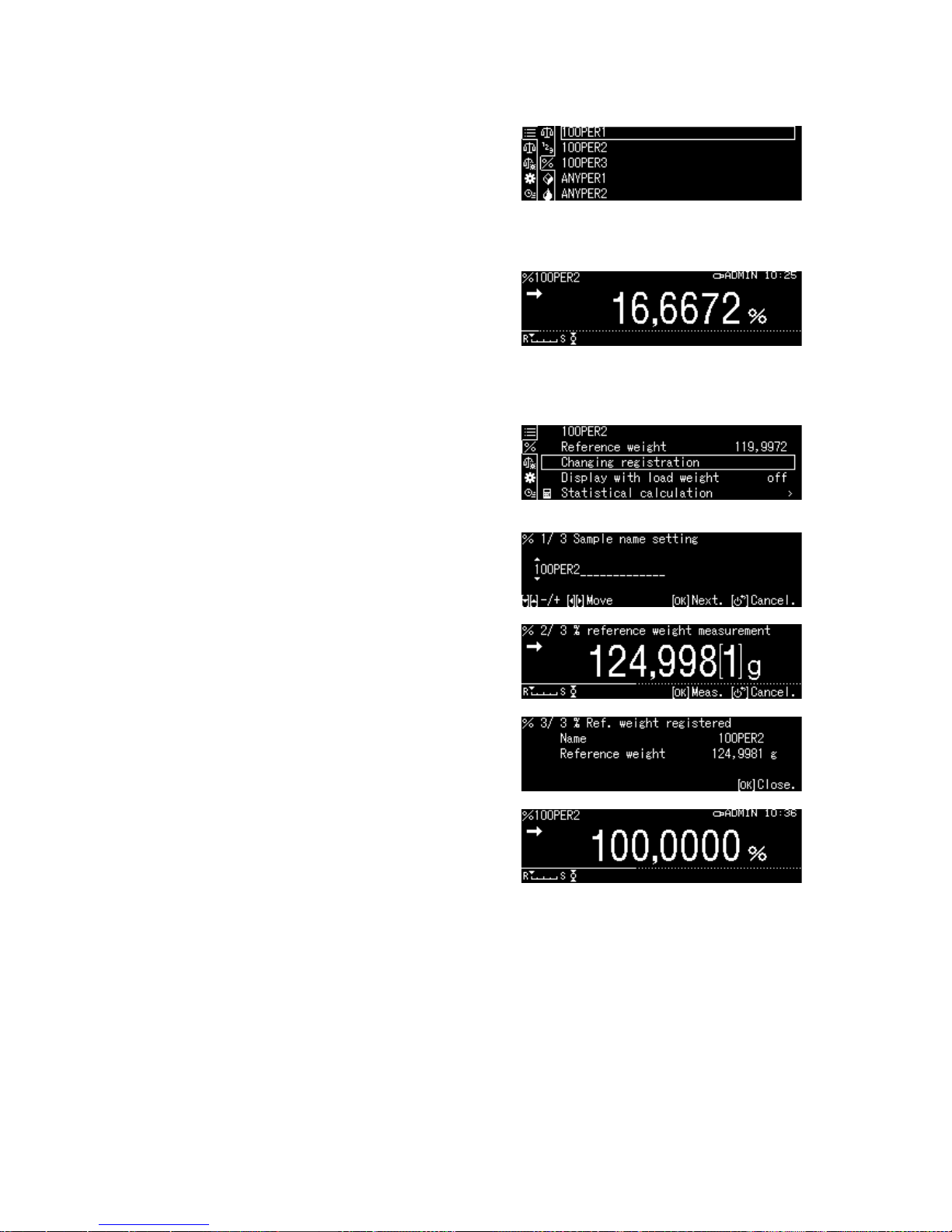

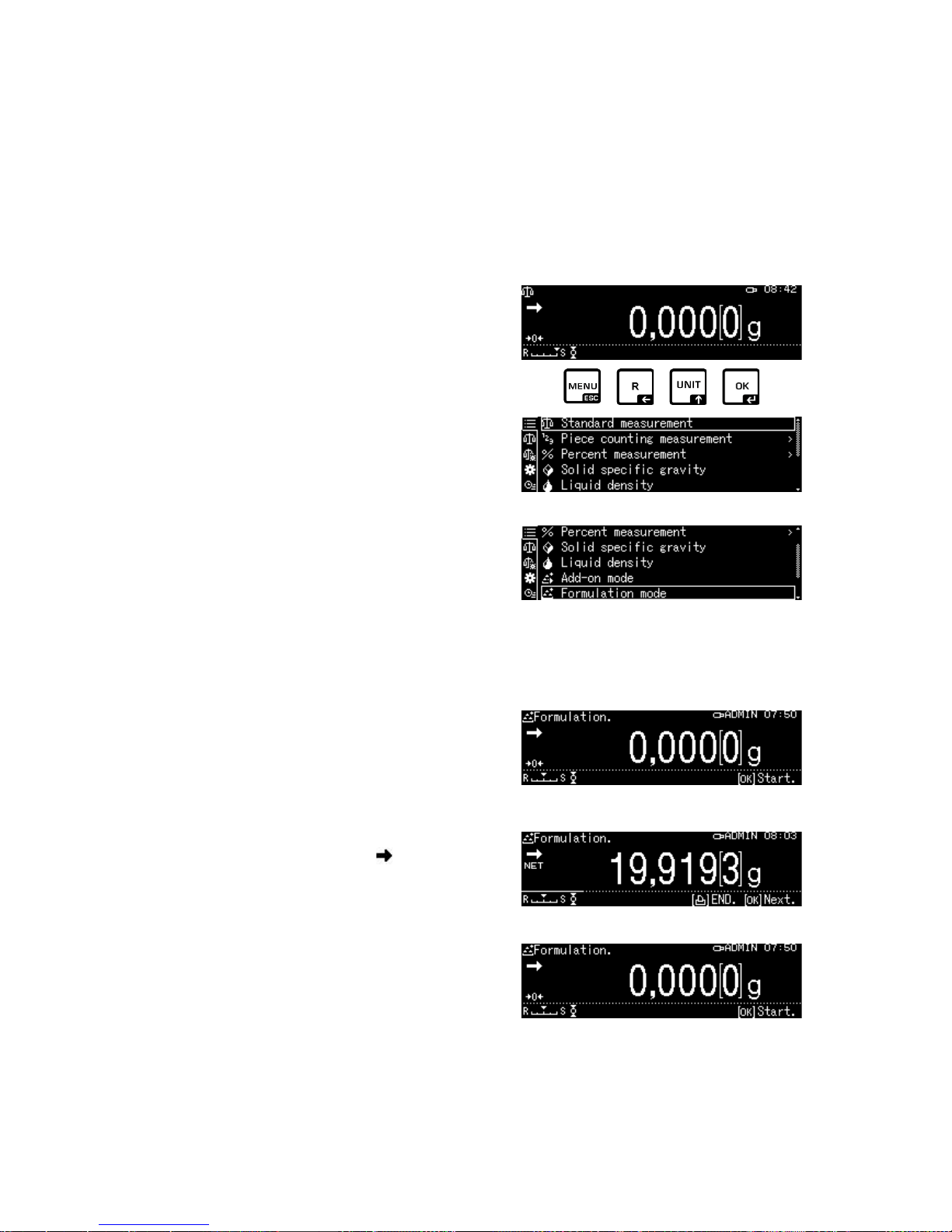

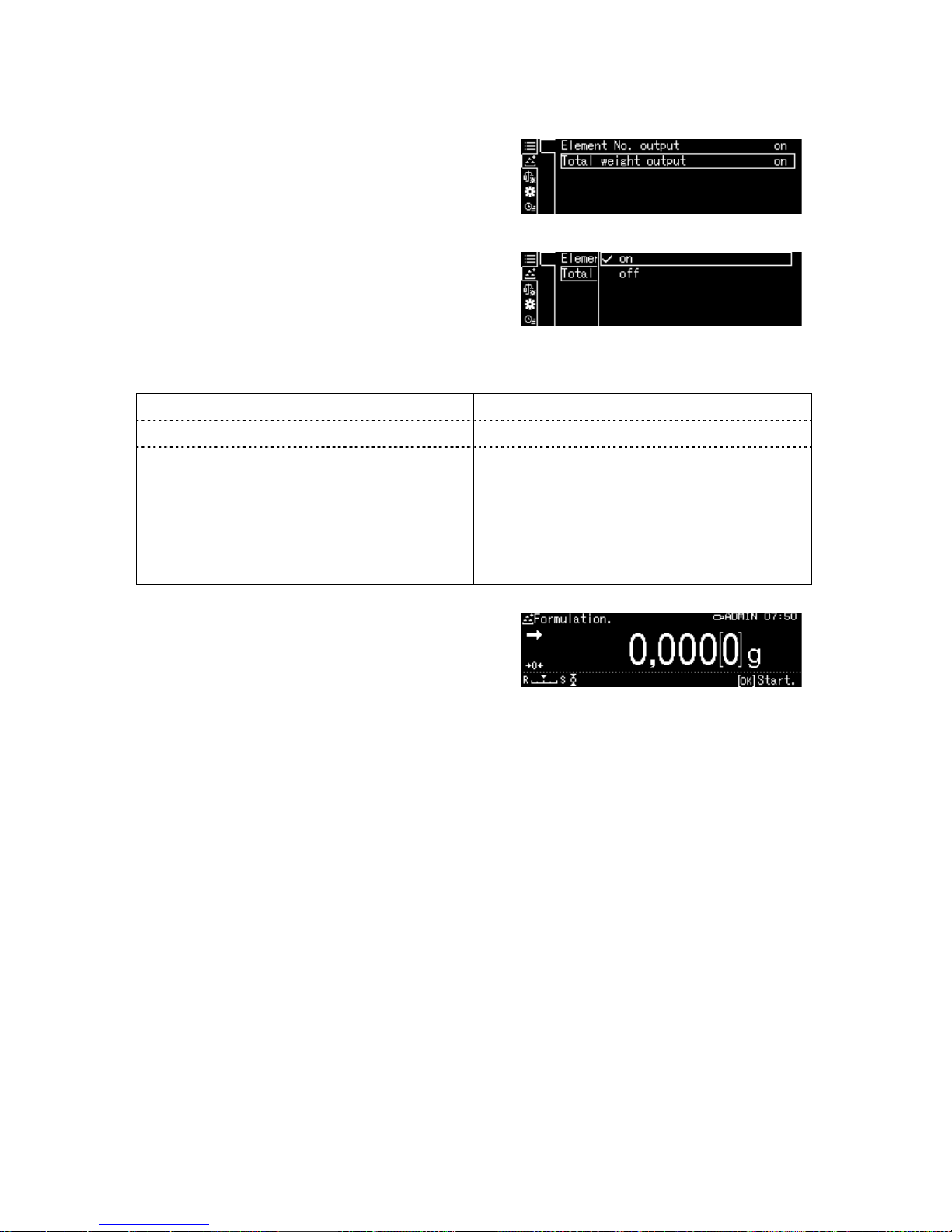

14.1 Parts counting