Page 1

GB

KERN 572/573/KB/DS

Version 4.10 12/2004

Operating Instructions

Electronic Precision and Platform Balances

Table of contents:

1 MODE - MENUE __________________________________________________________ 26

2 Technical data_____________________________________________________________ 27

2.1 KERN 572 __________________________________________________________________ 27

2.2 KERN 573 __________________________________________________________________ 28

2.3 KERN KB __________________________________________________________________ 29

2.4 KERN DS___________________________________________________________________ 29

3 Fundamental information (general) ___________________________________________ 30

3.1 Intended use_________________________________________________________________ 30

3.2 Inappropriate use ____________________________________________________________ 30

3.3 Guarantee __________________________________________________________________ 30

3.4 Monitoring the test substances__________________________________________________ 30

4 Fundamental safety information ______________________________________________ 30

4.1 Observe the information in the operating instructions ______________________________ 30

4.2 Staff training ________________________________________________________________ 30

5 Transport and storage_______________________________________________________ 30

5.1 Acceptance check ____________________________________________________________ 30

5.2 Packaging___________________________________________________________________ 31

6 Unpacking, installation and commissioning _____________________________________ 31

6.1 Place of installation, place of use ________________________________________________ 31

6.2 Unpacking __________________________________________________________________ 31

6.2.1 Installation _______________________________________________________________________ 31

6.3 Mains supply ________________________________________________________________ 31

6.4 Connecting peripheral equipment_______________________________________________ 31

6.5 Initial start-up _______________________________________________________________ 31

6.6 Adjustment _________________________________________________________________ 32

6.7 Adjusting ___________________________________________________________________ 32

6.7.1 Adjusting for verification (KERN 573) _________________________________________________ 32

6.8 Verification _________________________________________________________________ 32

24

572/573/KB/DS-BA-defsi-04410

Page 2

7 Operation_________________________________________________________________ 33

7.1 Display control panel _______________________________________________________ 33

7.2 Operation___________________________________________________________________ 34

7.3 Interface RS 232 C ___________________________________________________________ 38

RS 232 C Data output via interface RS 232 C _____________________________________ 38

7.4

7.4.1 There are 4 methods for the data output via RS 232 C______________________________________ 38

7.4.2 Description of the data transfer________________________________________________________ 39

7.5 Printer _____________________________________________________________________ 39

7.6 Underfloor weighing __________________________________________________________ 39

8 Maintenance, upkeep, disposal________________________________________________ 40

8.1 Cleaning ____________________________________________________________________ 40

8.2 Maintenance, upkeep _________________________________________________________ 40

8.3 Disposal ____________________________________________________________________ 40

9 Troubleshooting ___________________________________________________________ 40

10 Declaration of conformity__________________________________________________ 41

572/573/KB/DS-BA-defsi-04410

25

Page 3

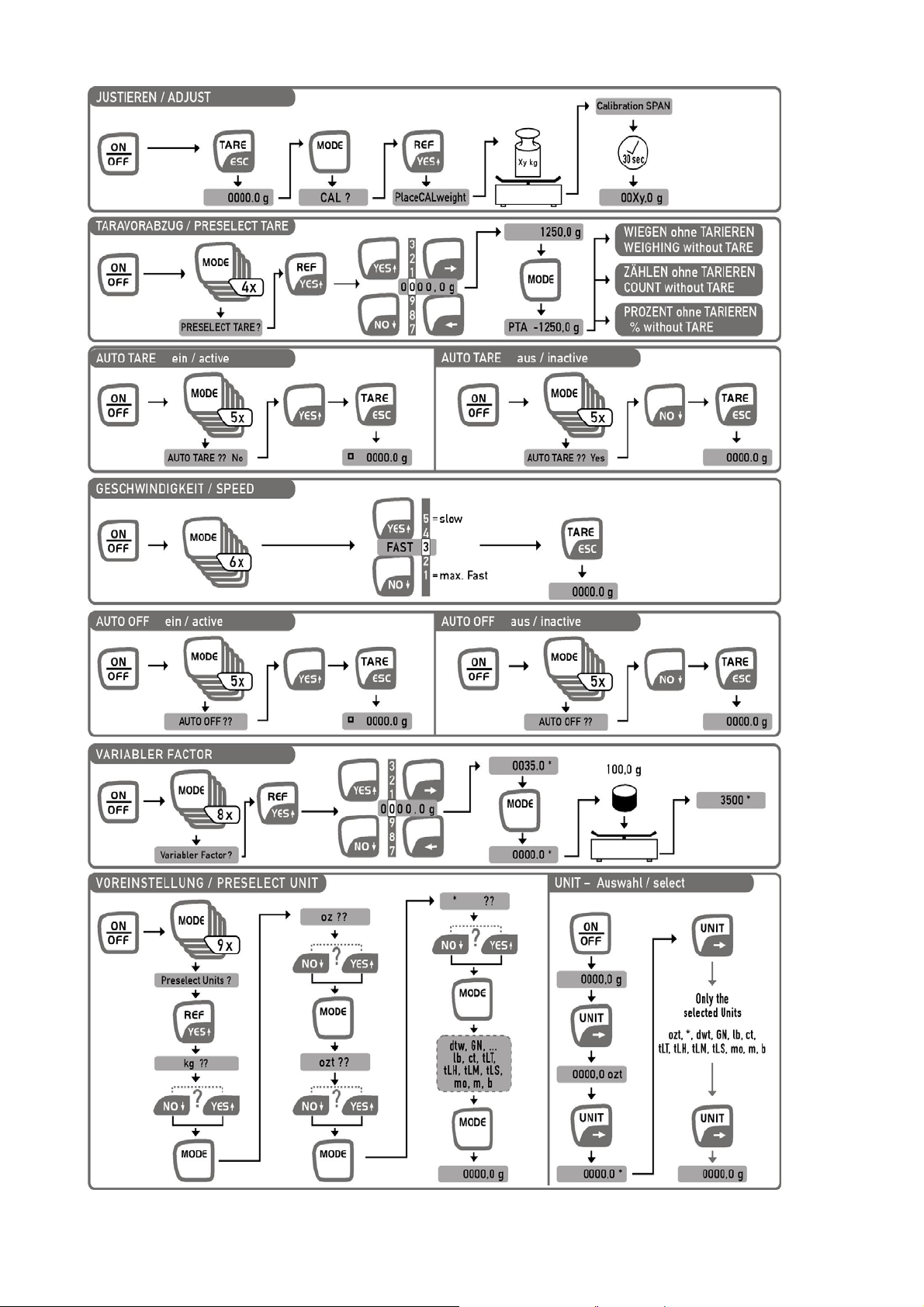

1 MODE - MENUE

MO DE

CAL?

Mod e

COUNT?

% ?

AUTOTARE?

FAST 3

AUTO OFF?

Variable Factor ?

Presel ect Un i ts ?

N/Y

Mod e

N/Y

Mod e

Presel ect Tare?

Mod e

N/Y

Mod e

Mod e

N/Y

Mod e

Mod e

Mod e

Y

PLACE CAL

WEIGHT

REF=1

Y

Mode Esc

REF = 5

Mode Esc

REF=10

Mode Esc

REF=20

Mode Esc

Y

1 l 0.000g

Y N - -

1 l 0.000g

Y

Y N - -

g

Y

Mode Esc

N/Y

N/Y

N/Y

N/Y

Mode

Mode

N/Y

Manufactur Setting:

Count?: YES

REF10: YES

9600bd: YES

Preselect

Units?: g/kg

Autotare: YES

Fast: 3

PRINTER?

Mod e

g, kg, oz, ozt,

mo, m, b,

b

N/Y

Mode Esc

2400Bd

Y

Mode Esc

4800Bd

Mode Esc

9600Bd

Mode Esc

19200Bd

Mode Esc

Numerator

Mode Esc

AUTOPRINT

Mode Esc

AUTOP RT P C

Mode Esc

*, dwt, GN,

lb, ct, tLT,

tLH, tLM,

tLS, tL, t,

N/Y

N/Y

N/Y

N/Y

N/Y

o,

N/Y

N/Y

26

weighing

572/573/KB/DS-BA-defsi-04410

Page 4

2 Technical data

2.1 KERN 572

KERN 572-33 572-35 572-45 572-49 572-57

Readout 0,01 g 0,01 g 0,1 g 0,1 g 0,2 g

Weighing range 1.010 g 1210 g 10.100 g 12.100 g 20.100 g

Taring range (subtractive) 1.010 g 1210 g 10.100 g 12.100 g 20.100 g

Reproducibility 0,01 g 0,01 g 0,1 g 0,1 g 0,2g

Linearity ±0,03 g ±0,03 g ±0,3 g ±0,3 g ± 0,6 g

Minimum weight for counting parts 0,03 g 0,03 g 0,3 g 0,3 g 0,6 g

Test weight (included)

tolerance as per M1

Recommended adjusting weight M1 1 kg 1 kg 10 kg 10 kg 10 kg

Verifiable No No No No No

Stabilisation time (typical) 2 sec.

Permissible ambient temperature +10 °C ... + 40 °C

Casing (W x H x D) mm 180 x 310 x 90

Weighing plate mm Ø 150 Ø 150 160 x 200

Net weight kg 4

Interface Yes (RS232)

500 g 500 g 5.000 g 5.000g 5.000 g

572/573/KB/DS-BA-defsi-04410

27

Page 5

2.2 KERN 573

KERN 573-46 573-52

Class of accuracy II II

Readout (d) 0,1 g 0,2 g

Verification value (e) 1g 2g

Weighing range (max.) 6500 g 13000 g

Minimum load (Min) 5g 10g

Taring range (subtractive) 6500 g 13000 g

Reproducibility 0,1 g 0,2 g

Linearity ±0,2 g ±0,4 g

Minimum weight for counting parts 0,3 g 0,6 g

Test weight (included) tolerance as per M1 5000 g 5000 g

Recommended adjusting weight M1 5 kg 10 kg

Verifiable Yes Yes

Air humidity max. 80 % relative (not condensing)

Stabilization time 2 sec.

Permissible ambient temperature 0° C to + 50° C

Temperature range for verifiable applications +10 °C ... + 40 °C

Casing (W x H x D) mm 180 x 310 x 90

Weighing plate mm 160 x 200 160 x 200

Data interface Yes (RS232)

Weighing units g, kg

Vibratory filter Yes

Net weight (kg) 4

28

572/573/KB/DS-BA-defsi-04410

Page 6

2.3 KERN KB

8

6

6

6

KERN KB800-2 KB8000-1

Readout 0,01 g 0,1 g

Weighing range 810 g 8.100 g

Taring range (subtractive) 810 g 8.100 g

Reproducibility 0,01 g 0,1 g

Linearity ±0,03 g ±0,3 g

Minimum weight for counting parts 0,03 g 0,3 g

Test weight (included) tolerance as per M1 200 g 1.000 g

Adjusting weight (not included)tolerance as per M1 500 g 5.000 g

Verifiable No

Stabilisation time (typical) 2 sec.

Permissible ambient temperature 0° C to + 50° C

Casing (W x H x D) mm 165 x 230 x 85

Weighing plate mm 130 x 130 150 x 170

Net weight kg 1,8 2,7

Data interface Yes (RS232)

2.4 KERN DS

KERN

Readout 0,05 g 0,1 g 0,2 g 0,5 g 0,5 g 1g 1g 2g

Weighing range 3.100 g 8.100 g 16.100 g 36.100 g 36.100 g 65.100g 101.000g 151.000

Taring range (subtractive) 3.100 g 8.100 g 16.100 g 36.100 g 36.100 g 65.100g 101.000g 151.000

Reproducibility 0,05 g 0,1 g 0,2 g 0,5 g 0,5 g 1g 1g 2g

Linearity ± 0,15

Minimum weight for

counting parts

Adjusting weight (not included)tolerance as per

M1

Verifiable No No No No No No No No

Stabilisation time (typical) 3 sec.

Permissible ambient

temperature

Casing (W x H x D) mm

Net weight kg 8 12,5

Data interface Yes (RS232)

DS3

K0.05

g

0,15 g 0,3 g 0,6 g 1,5 g 1,5 g 3g 3g 6g

2 kg 5 kg 10 kg 10 kg 20 kg 50 kg 50 kg 50 kg

DS

K0.1

± 0,3 g ± 0,6 g ± 1,5 g ± 1,5 g ± 3 g ± 3 g ± 6 g

Platform 310 x 310 x 70

Terminal 200 x 100 x 55

DS1

K0.2

DS3

K0.5

0° C to + 50° C

DS3

K0.5L

DS65

K1

Platform 350 x 450 x 115

Terminal 200 x 100 x 55

DS100

K1

DS150

K2

g

g

572/573/KB/DS-BA-defsi-04410

29

Page 7

3 Fundamental information (general)

It is essential to read through and observe the complete operating instructions before installing and commissioning.

3.1 Intended use

The balance you have acquired serves to determine the weighing value of the material to be weighed. It is

intended to be used as a “non-automatic“ balance, i.e. the material to be weighed is manually and carefully

placed in the centre of the weighing plate. The weighing value can be read off after a stable weighing value

has been obtained.

3.2 Inappropriate use

Do not use the balance for dynamic weighing. In the event that small quantities are removed or added to the

material to be weighed, incorrect weighing results can be displayed due to the “stability compensation“ in the

balance. (Example: Slowly draining fluids from a container on the balance.)

Do not leave a permanent load on the weighing plate. This can damage the measuring equipment.

Be sure to avoid impact shock and overloading the balance in excess of the prescribed maximum load rating

(max.), minus any possible tare weight that is already present. This could cause damage to the balance.

Never operate the balance in hazardous locations. The series design is not explosion-proof.

Structural alterations may not be made to the balance. This can lead to incorrect weighing results, faults

concerning safety regulations as well as to destruction of the balance.

The balance may only be used in compliance with the described guidelines. Varying areas of application/planned use must be approved by KERN in writing.

3.3 Guarantee

The guarantee is not valid following

- non-observation of our guidelines in the operating instructions

- use outside the described applications

- alteration to or opening of the device

- mechanical damage and damage caused by media, liquids

- natural wear and tear

- inappropriate erection or electric installation

- overloading of the measuring equipment

3.4 Monitoring the test substances

The metrology features of the balance and any possible available adjusting weight must be checked at regular intervals within the scope of quality assurance. For this purpose, the answerable user must define a suitable interval as well as the nature and scope of this check. Information is available on KERN’s home page

(www.kern-sohn.com

for this. Test weights and balances can be adjusted quickly and at a reasonable price in KERN’s accredited

DKD calibration laboratory (return to national normal).

) with regard to the monitoring of balance test substances and the test weights required

4 Fundamental safety information

4.1 Observe the information in the operating instructions

Please read the operating instructions carefully before erecting and commissioning, even if you already have

experience with KERN balances.

4.2 Staff training

The device may only be operated and looked after by trained members of staff.

5 Transport and storage

5.1 Acceptance check

Please check the packaging immediately upon delivery and the device during unpacking for any visible signs

of external damage.

In the case of visible damages please obtain a signature from the bearer to serve as confirmation of damage. Do not make alterations to the goods and packaging, do not remove any consignment parts. Report

the damage to the parcel service immediately in writing ( within 24 hours).

30

572/573/KB/DS-BA-defsi-04410

Page 8

5.2 Packaging

Please retain all parts of the original packaging in case it should be necessary to return items at any time.

Only the original packaging should be used for return consignments.

Before despatch, disconnect all attached cables and loose/movable parts, remove weighing plate.

Apply any intended transport security devices. Secure all parts, e.g. glass windshield, weighing plate, power

unit etc., to prevent slipping and damage.

6 Unpacking, installation and commissioning

6.1 Place of installation, place of use

The balance is constructed in such a way that reliable weighing results can be achieved under normal application conditions.

By selecting the correct location for your balance, you will be able to work quickly and precisely.

Therefore please observe the following at the place of installation:

- Place the balance on a firm, level surface;

- Avoid extreme heat as well as temperature fluctuation caused by installing next to a radiator or in the

direct sunlight;

- Protect the balance against direct draughts due to open windows and doors;

- Avoid jarring during weighing;

- Protect the balance against high humidity, vapours and dust;

- Do not expose the device to extreme dampness for longer periods of time. Inadmissible bedewing

(condensation of air moisture on the device) can occur if a cold device is taken into a significantly

warmer environment. In this case, please acclimatise the device for approx. 2 hours at room temperature after it has been disconnected from the mains.

- Avoid static charging of the material to be weighed, weighing container and windshield.

Major display deviations (incorrect weighing results) are possible if electromagnetic fields occur as well as

due to static charging and instable power supply. It is then necessary to change the location.

6.2 Unpacking

Carefully remove the balance from its packaging, remove the plastic wrapping and position the balance in its

intended working location.

6.2.1 Installation

Install the balance in such a fashion that the weighing plate is absolutely horizonta

6.3 Mains supply

Electric power supply is by means of the external mains supply circuit. The printed voltage level must comply

with the local voltage.

Only use original KERN mains supply circuits. The use of other makes is subject to approval by Kern.

6.4 Connecting peripheral equipment

The balance must be disconnected from the mains before connecting or disconnecting additional equipment

(printer, PC) to or from the data interface.

Only use KERN accessories and peripheral equipment with your balance. These have been ideally coordinated to your balance.

6.5 Initial start-up

A warm-up time of 15 minutes stabilises the measured values after switching on.

The accuracy of the balance depends on the local acceleration of the fall.

Please be sure to observe the information in the chapter on adjusting.

572/573/KB/DS-BA-defsi-04410

31

Page 9

6.6 Adjustment

As the acceleration value due to gravity is not the same at every location on earth, each balance must be

coordinated – in compliance with the underlying physical weighing principle - to the existing acceleration

due to gravity at its place of location ( only if the balance has not already been adjusted to the location in the

factory). This adjustment process must be carried out during the initial start-up, after change in location and

variation of surrounding temperature. It is also recommendable to adjust the balance periodically during

weighing operation in order to obtain exact measured values.

6.7 Adjusting

Using a precision weight, the accuracy of the balance can be checked at any time and adjusted.

Warning:

With verified balances, this precision adjustment is not possible

Adjustment procedure:

Check that the surrounding conditions are stable.

A short warm-up time of about 15 minutes is recommended for stabilisation.

6.7.1 Adjusting for verification (KERN 573)

General Information:

Prior to the procedure of verification the balance has to be adjusted.

Remark: The adjusting is only possible when not being blocked by the adjusting switch.

The switch for this step is located at the bottom of the housing between the two turning feet.

Switch to the right

This setting has to be selected before starting the adjusting.

Executing the adjusting according to chapter 7.2 “Operation“.

After the adjusting has been completed successfully it is nec-

Switch to the left

Adjusting function is released.

essary to turn the adjusting switch to the left for blocking.

Adjusting function is blocked.

After the adjusting has been completed successfully the ad-

justing has to be blocked by switching to the left.

The balance is now prepared for the procedure of verification.

After the verification the adjusting switch has to be secured by

a verification mark against access.

6.8 Verification

General:

According to the EU guideline 90/384/EEC balances must be verified officially if they are to be used as follows (legally regulated area):

a) For commercial transactions if the price of goods is determined by weighing

b) For the production of medines in pharmacies as well as for analyses in the medical and pharmaceu-

tical laboratory

c) For official purposes

d) For the production of finished packages

In case of doubt, please contact your local office of weights and measures.

Verification information

An EU qualification approval is available for those balances marked as appropriate for verification in the

technical data. In the event that the balance is applied in an area subject to verification as described above,

it must be officially verified and re-verified at regular intervals.

Re-verification of a balance is carried out in compliance with the respective legal provisions of the states.

The term of verification validity for balances in Germany, for example, is normally 2 years.

The legal provisions of the country of use are to be observed.

32

572/573/KB/DS-BA-defsi-04410

Page 10

7 Operation

7.1 Display control panel

Keyboard

Display-Symbol Meaning

==OVERLOAD==

= ============

<< .

.

PTA .

D .

Net .

SUM .

Æ .

Overload: Weighing range has been exceeded

Underload: Weighing range has been fallen short of

In counting and % mode: part too light

Automatic tare active

Preselect tare Tare pre-selection active

Difference in % during percentage weighing

Net weight of the components during formula preparation

Gross weight of several components during formula preparation

Balance is in counting mode and currently displaying the

weight value of the counting amount

ON / OFF

Print weighing result

in MODE: No / descending

in % and counting mode:

Form reference

in MODE: Yes / ascending

MODE configuration

(see mode structure diagram page 2)

Formula weighing

in MODE: to left

Change g-pieces

Unit changeover

in MODE: to right

Tare

in MODE: back in weighing operation

572/573/KB/DS-BA-defsi-04410

33

Page 11

7.2 Operation

WIEGEN mit TARIEREN/WEIGHING with TARE

During weighing in a certain weight amount of a product is to be filled into a weighing container without the tare weight of the container being weighed. The weighing container is excluded from consideration by using TARE and thus only the measured value of the product is indicated. The maximum

weighing range is reduced by the value of the tare weighing container – tare is therefore classed as

being subtractive. Wait until the g or kg unit symbol appears on the display. The weighing result is

now stable.

ZÄHLEN-Referenzstück auswählen/COUNT-Selection reference piece

In order to be able to count a larger quantity of parts it is necessary to determine the average weight

of each part using a small quantity (reference piece number).

The greater the reference piece number, the greater the counting accuracy.

In the case of small or very varied parts, a particularly high reference piece number must be selected.

ZÄHLEN/COUNT

Commence by applying the number of parts of the determined reference piece number.

Using the automatic reference optimization (OPT) the counting accuracy is automatically increased

when applying up to 100 items.

Now apply the quantity to be counted.

PERCENT/ %

When using percentage weighing it is possible to remove partial amounts from the weighing container.

Instead of the manual withdrawal there can also, for example, the evaporated amount of moisture

during a drying sequence be displayed as a percentage.

To begin with the percentage of the removed parts is displayed.

The remaining amount in the container is shown as a percentage by operating the REZ key.

REZEPTURWÄGUNG/FORMULA WEIGHING

The formula weighing function makes it possible to weigh in several components ( K1, K2, ...,Kn ) in

succession and subsequently determine the total weight of the components.

Return to weighing mode by pressing the ESC key.

PLUS-MINUS-WÄGUNG/Tolerance weighing

When using tolerance weighing the parts to be checked are compared with a target value and the

divergence displayed as a plus or minus value when compared to the target value.

34

572/573/KB/DS-BA-defsi-04410

Page 12

572/573/KB/DS-BA-defsi-04410

35

Page 13

JUSTIEREN/ADJUST

The balance must be adjusted at its place of installation before initial use and at regular

intervals.

Please observe the warm-up time referred to in the chapter on ”Commissioning”.

It is essential to avoid jarring and disturbances during the adjusting procedure.

TARAVORABZUG/PRESELECT TARE

The known tare value of a weighing container can be “deducted” by entering its weight as

preselect tare. In this way only the net weight of the goods to be weighed is displayed during subsequent weighings. PTA will be seen on the display.

Manual tare may not be carried out using the TARE key.

AUTO TARE ein/active

Auto tare activation serves to stabilize the zero point of the balance. Minor changes in weight in the

zero point range are tared automatically, i.e. the displayed figure remains at zero.

GESCHWINDIGKEIT/Filter/SPEED

The balance can be adapted in stages to its location from 1 – 5.

Stage 1 = good installation conditions, fast display / low filter effect (e.g. proportioning)

Stage 5 = poor installation conditions, slow display / high filter effect (restless environment)

e.g. proportion weighing requires a greater display speed and this can be adjusted by selecting ”Fast"

in the MODE program.

AUTO OFF ein/active

The auto-off function inactivates the balance after approx. 60 seconds if it is not in use.

VARIABLER FACTOR/VARIABLE FACTOR

The weighing value in grams is automatically multiplied by the set variable factor and the result (in-

cluding the unit *) shown on the display.

Example:

A sheet of paper sized 10 x 10cm weighs 0,6 g. In order to determine the weight g/1m², the factor has

to be at 100. The display value is 0,6g x 100 = 60,0*, thus 60,0 g/m².

VOREINSTELLUNG/PRESELECT UNIT

All selected units checked YES in Preselect Units are offered on the UNIT key in weighing mode

for unit changeover.

Recommendation

Each time the UNIT key is pressed, the next preselected unit (using Preselect Units) is selected.

: Only preselect the units that are actually required.

AUTO TARE aus/inactive

AUTO OFF aus/inactive

UNIT-Auswahl/select

36

572/573/KB/DS-BA-defsi-04410

Page 14

572/573/KB/DS-BA-defsi-04410

37

Page 15

7.3 Interface RS 232 C

Technical Data

8-bit ASCII Code

1 start bit, 8 data bits, 1 stop bits, no parity bit

Baud rate adjustable to 2400, 4800 and 9600 baud (default), 19200 baud

Sup-D- 9 pol. is necessary .

When working with an interface correct operation is secured only if the corresponding KERN-interface-

cable (max. 2m) is used.

Description of the jack

Sup-D- 9 pol.

5 1

Pin 2: Transmit data

Pin 3: Receive data

Pin 5: Signal ground

9 6

Baudrate

The Baud rate for the data transfer is adjusted with the MODE-key. The following example demonstrates

how to set the Baud rate 4800.

Select Baud rate Display

1. Press MODE-key repeatedly until "PRINTER" is displayed.

2. Press YES-key.

3. Press MODE-key repeatedly until the desired Baud rate appears (for

instance 4800 Baud).

4. Press YES-key to select 4800 Baud. The tick-mark (X) confirms the new

setting.

5. Press MODE-key repeatedly until the balance displays in grams again,

or press tare key.

2400 Baud

4800 Baud

PRINTER?

4800 Baud X

0,0 g

7.4 RS 232 C Data output via interface RS 232 C

RS 232 C Data output via interface RS 232 C

General information

As a condition for the data transfer between the balance and a peripheral device (for instance printer, PC ...)

both devise have to be set on the same interface parameter (for instance baud rate, parity ...).

7.4.1 There are 4 methods for the data output via RS 232 C

Data output via PRINT-Key

The printing process can be released by the PRINT-key. In this case the settings AUTOPRINT and AUTPRINT PC should be deselected.

AUTOPRINT (Data output, after having loaded the balance)

The setting AUTOPRINT is in the PRINTER-routine, and there it can be selected or deselected. When

AUTOPRINT is active the actual weighing value will be sent via the RS 232 interface when the balance has

been unloaded and then loaded after having achieved the stability.

AUTOPRINT PC (Continuous data output)

The setting AUTPRINT PC is in the PRINTER-routine, and there it can be selected or deselected. When

AUTOPRINT PC is active the actual weighing values will be sent continuously via the RS 232 interface.

Data output by transfer of remote controls

The following functions can be released by the remote controls that will be transferred as ASCII signs to the

balance.

t Tare.

w a weighing value (or unstable) is sent via RS 232 interface.

s a stable weighing value is sent via RS 232 interface.

If the balance receives the command w or s, it acts without printing delay.

38

572/573/KB/DS-BA-defsi-04410

Page 16

7.4.2 Description of the data transfer

Structure of each data transfer:

Without Numerator:

Bit-Nr. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

.

B B B B B B B B 0

0 B g B B CR LF

B*

B*: = Blank or % in the range of zero point.

.

, g: = Blank or weighing value with unit, depending on the load on the weighing plate.

B, 0,

CR: = Carriage Return

LF: = Line Feed

With Enumerator:

Bit.Nr. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

.

N N N B* B B B B B B B 0

0 B G B B CR LF

N: = Enumerator

7.5 Printer

With the serial data output RS 232 a printer can be connected.

The printout shows the weight in grams. When the counting mode is selected the number of pieces or the

weight is printed. When the percent mode is selected, the percentage or the weight will be printed. Press

The PRINT-key to print weighing results. Select the enumerator to number the weighing continuously. Turn

off the balance or use the CLEAR function to Reset the enumerator to (000).

7.6 Underfloor weighing

Objects which, because of their size or shape, cannot be put on the scale, can be weighed by means of underfloor weighing.

Proceed as follows:

• Switch off the balance.

• Turn the balance over,

without loading the balance plate.

• Open the cover plate on the base of the balance.

• Hang on the hook for underfloor weighing .

• Place the balance over an opening.

• Hang the item to be weighed on the hook and carry out weighing.

! CAUTION !

Take care that the hooks used for the underfloor weighing are stable enough to hold the goods

which you wish to weigh (risk of breakage).

Always make sure that there are no living beings or materials below the load that could be injured or

damaged.

! NOTE !

After completing the underfloor weighing, the opening in the floor of the balance must be closed

again (dust protection).

572/573/KB/DS-BA-defsi-04410

39

Page 17

8 Maintenance, upkeep, disposal

8.1 Cleaning

Please disconnect the device from the operating voltage before cleaning.

Only use a cloth dampened with mild suds and not aggressive cleaning agents (solvents or similar). Please

ensure that fluids are not able to get into the device and rub off using a clean, soft cloth.

Loose sample residue/powder can be removed carefully using a brush or hand vacuum cleaner.

Remove any spilt material to be weighed immediately.

8.2 Maintenance, upkeep

The device may only be opened by trained service engineers authorised by KERN.

Disconnect from the mains supply before opening.

8.3 Disposal

The operating company shall dispose of the packaging and the device in compliance with the valid national

or regional law of the operating location.

9 Troubleshooting

The balance should be switched off for a short time following an interruption in the programme sequence

and disconnected from the mains supply. It is then necessary to repeat the weighing process from the beginning.

Help:

Interruption Possible cause

Weight display is not illuminated.

The weight display changes continually

The weighing result is obviously incorrect

Switch the balance off if other error messages should appear and then switch on again. Contact the manufacturer if the error message does not disappear.

• The balance is not switched on.

• The mains supply connection has been interrupted

(mains cable not plugged in/faulty).

• Power supply interrupted. .

• Draught/air movement

• Table/floor vibrations

• The weighing plate is in contact with foreign mat-

ter.

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

possible)

• The balance display is not set to zero

• Adjustment is no longer correct.

• Great fluctuations in temperature.

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

possible)

40

572/573/KB/DS-BA-defsi-04410

Page 18

10 Declaration of conformity

Declaration of conformity

The electronic precision and platform balances

Type: KERN 572-33

KERN 572-35

KERN 572-45

KERN 572-49

KERN 572-57

KERN KB800-2

KERN KB8000-1

Correspond to the production model described in the EC type-approval certificate

and to the requirements of the following EC directives:

EC EMC directive Version 89/336/ECC

Applied harmonised norms, in particular

EN 61326: 1997

+ A1: 1998

+A2:2001

EN 61000-3-2: 1995

+ A1/A2 1998

+ A14 2000

If a change is made to the above mentioned appliances without consulting KERN

this declaration will become invalid.

Date: 07/01/2004 Signature:

Gottl. KERN & Sohn GmbH

Management

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72322 Balingen-Frommern, Tel. +49-07433/9933-0, Fax +49-07433/9933-149

KERN DS3K0.05

KERN DS8K0.1

KERN DS16K0.2

KERN DS36K0.5 + L

KERN DS65K1

KERN DS100K1

KERN DS150K2

EN 61000-3-3: 1995

572/573/KB/DS-BA-defsi-04410

41

Page 19

Dichiarazione di cofnromitá per apparecchi contrassegnati con la marcatura CE

English

Deutsch

Français

Español

Italiano

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Postfach 4052

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Konformitätserklärungen

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con disitintivo CE

We hereby declare that the product to which this declaration refers conforms with the following standards.

Wir erklären hiermit, daß das Produkt, auf das sich diese Erklärung bezieht, mit den nachstehenden Normen übereinstimmt.

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente

déclaration, est conforme aux normes citées ci-après.

Manifestamos en la presente que el producto al que se refiere esta declaración est´´a de

acuerdo con las normas siguientes

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è conforme alle norme di seguito citate.

Balance lines: 573

Mark applied EU Directive Standards

89/336EEC EMC EN45501

EN55022

Date: 03.06.2004

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-07433/9933-0,Fax +49-074433/9933-149

Signature:

Gottl. KERN & Sohn GmbH

Management

42

572/573/KB/DS-BA-defsi-04410

Page 20

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Postfach 4052

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Konformitätserklärungen

Declaration of conformity for apparatus with CE mark

Konformitätserklärung für Geräte mit CE-Zeichen

Déclaration de conformité pour appareils portant la marque CE

Declaración de conformidad para aparatos con disitintivo CE

Dichiarazione di cofnromitá per apparecchi contrassegnati con la marcatura CE

English

Deutsch

Français

Español

Italiano

Model: 573

EU Directive Standards

90/384/EEC EN45501 D04-09-019 PTB

Date: 03.06.2004

Gottl. KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-07433/9933-0,Fax +49-074433/9933-149

We hereby declare that the product to which this declaration refers conforms with the following standards.

This declaration is only valid with the certificate of conformity by a notified body.

Wir erklären hiermit, daß das Produkt, auf das sich diese Erklärung bezieht, mit den nachstehenden Normen übereinstimmt.

Diese Erklärung gilt nur in Verbindung mit der Konformitätsbescheinigung einer

benannten Stelle.

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la présente

déclaration, est conforme aux normes citées ci-après.

Cette déclaration est valide seulement avec un certificat de conformité dún organisme notifié.

Manifestamos en la presente que el producto al que se refiere esta declaración est´´a de

acuerdo con las normas siguientes.

Esta declaratión solo será válida acompañada del certificado de conformidad de

conformidad de la parte nominal.

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si riferisce è conforme alle norme di seguito citate.

Questa dichiarazione sarà valida solo se accompagnata dal certificato di conformità

della parte nominale.

EC-type-approval

certificate no.

Signature:

Issued by

Gottl. KERN & Sohn GmbH

Management

572/573/KB/DS-BA-defsi-04410

43

Loading...

Loading...