Page 1

Service Manual for Electronic

Precision Balances series

434

Version 1.0 7/97

434-SH-e-9710

Page 2

Table of Contents

1 Specifications __________________________________________________________4

2 Introduction ___________________________________________________________5

3 Principles of operation ___________________________________________________5

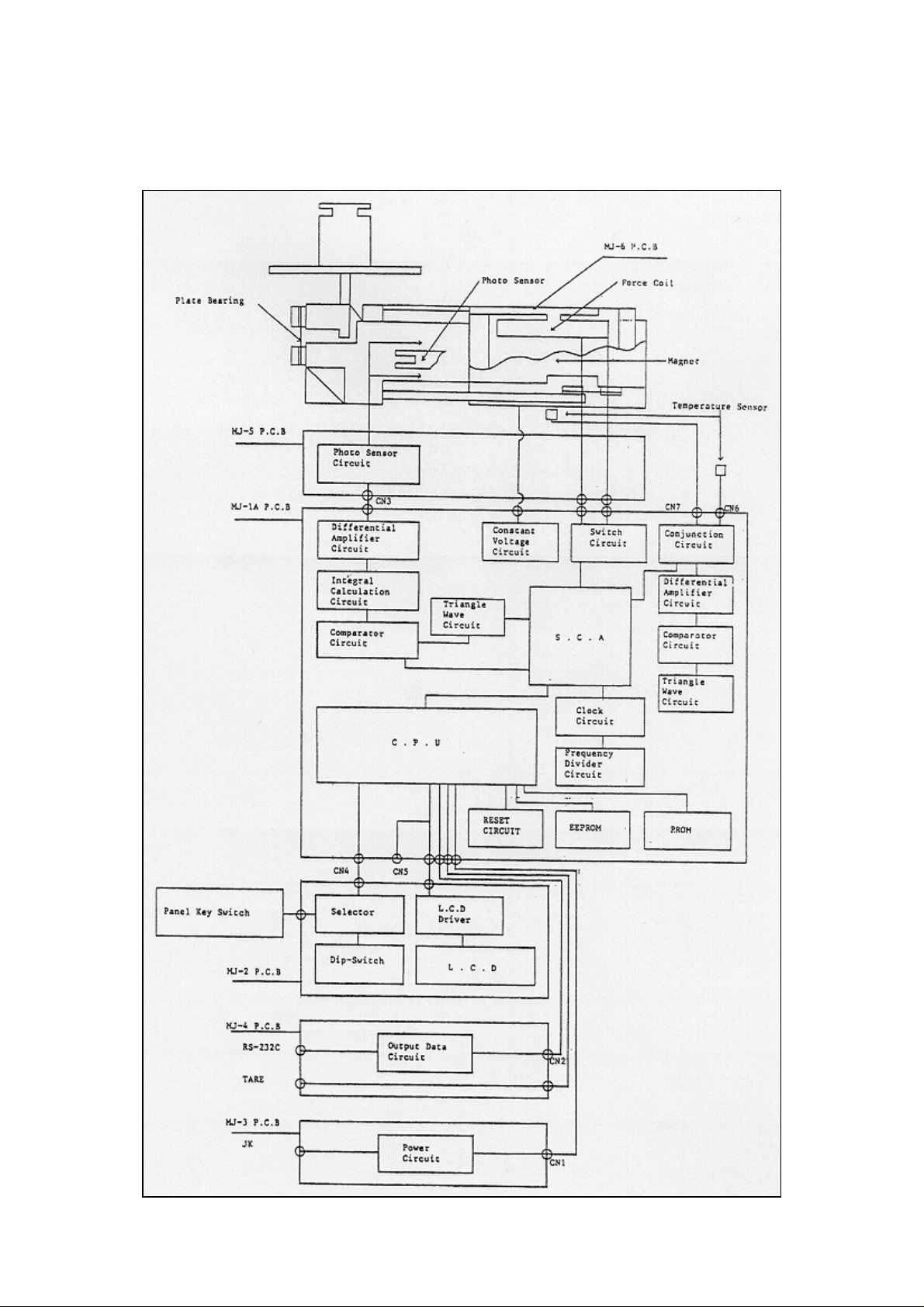

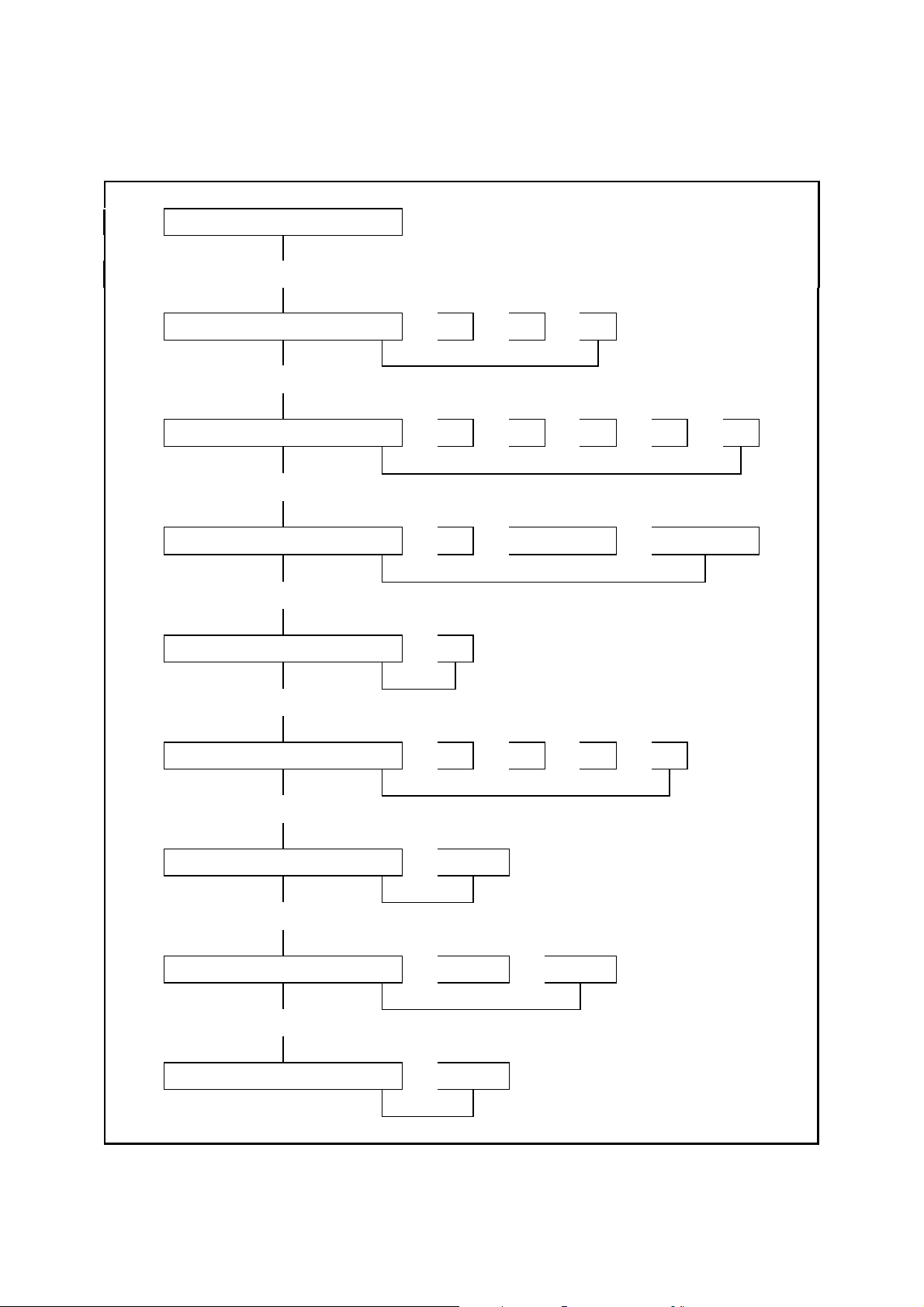

4 Block Diagram _________________________________________________________6

5 Best Conditions for Weighing _____________________________________________7

6 Balance Functions ______________________________________________________8

7 Description of Function Menu_____________________________________________9

8 Description of Functions ________________________________________________10

9 Weighing Unit Initialisation _____________________________________________11

9.1 Keyboard Method_________________________________________________________ 11

9.2 Parameter Number Chart __________________________________________________ 12

10 Piece Counting Mode ___________________________________________________13

10.1 Removing establishment of the standard unit weight for piece counting__________ 14

11 Percent Mode _________________________________________________________15

11.1 Weighing Mixture Mode _________________________________________________ 15

12 Adjusting Introduction__________________________________________________17

13 Inner A /D Counter Check Mode__________________________________________19

14 Disassembly / Assembly _________________________________________________21

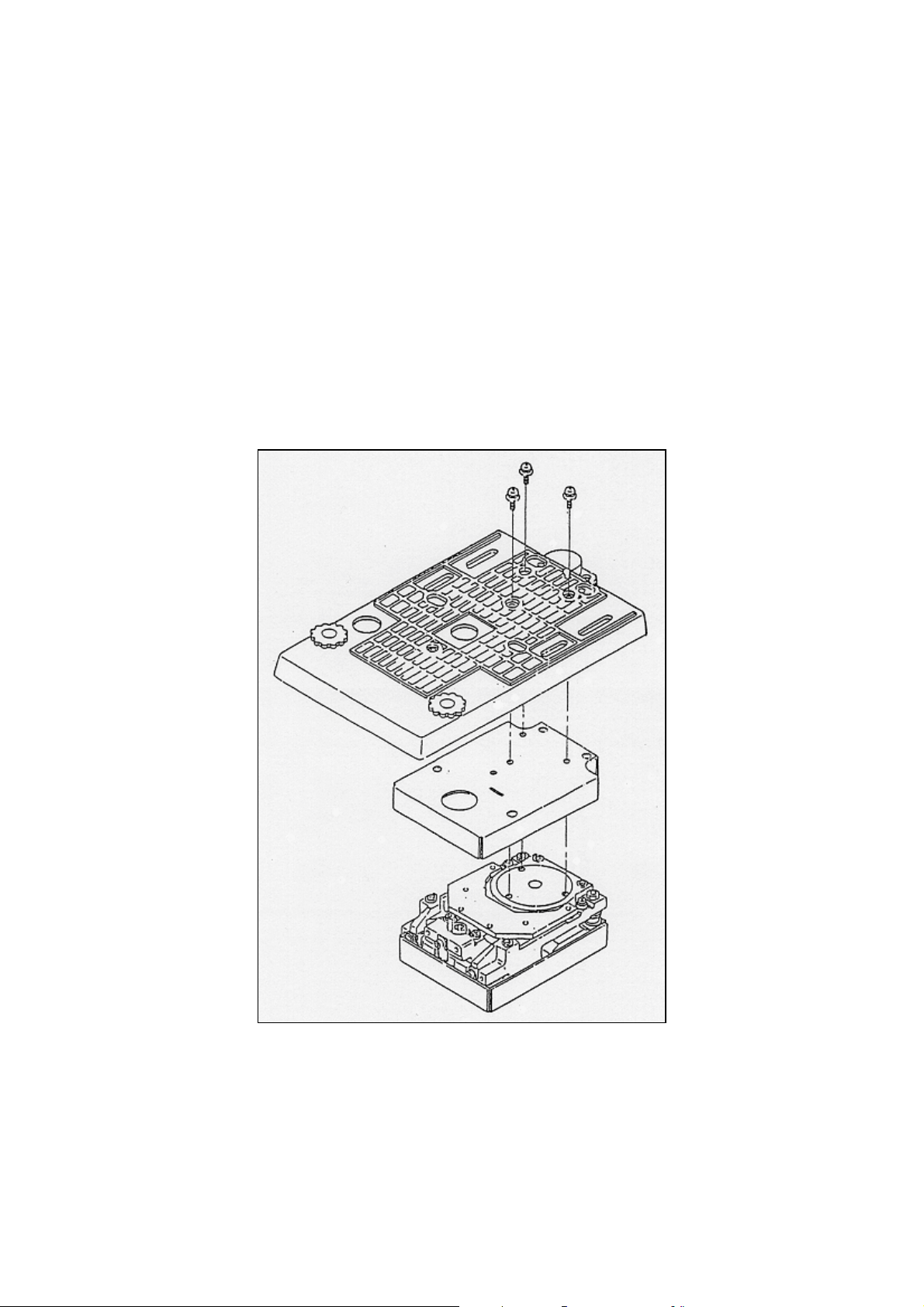

14.1 Removing the Top Case__________________________________________________ 21

14.2 Removing the Mechanical Unit____________________________________________ 22

14.3 Mechanical Unit Disassembly_____________________________________________ 23

14.4 Assembly ______________________________________________________________ 24

15 Jig Set _______________________________________________________________25

16 Additional Disassembly / Assembly ________________________________________26

16.1 Replacement of the Force Coil Bobbin _____________________________________ 26

16.2 Cleaning Inside the Magnet ______________________________________________ 26

16.3 Positioning Edge of the Beam Inside the Photo Sensor ________________________ 27

17 Primary Checking Procedure_____________________________________________28

18 Visual Check__________________________________________________________28

19 Mechanical Fault Finding_______________________________________________29

19.1 "+ / - .", "All Segment Lines" or No Display ________________________________ 29

19.2 Unstable Weighing Results Adjustment ____________________________________ 30

20 Mechanical Fault Finding Chart _________________________________________32

21 Short Wire Check ______________________________________________________33

22 Connecting Cable Check ________________________________________________34

434-SH-e-97102

Page 3

23 Plate Bearing / Coupling Link Check ______________________________________35

24 Beam Stopper Adjustment _______________________________________________36

25 A / D Converter Check __________________________________________________38

26 Initialisation of EEPROM _______________________________________________39

27 Linearity Adjusting_____________________________________________________40

27.1 Linearity Adjusting Procedure____________________________________________ 40

27.2 Adjusting Masses Chart _________________________________________________ 41

28 Span Adjusting ________________________________________________________42

28.1 Adjusting Masses Chart _________________________________________________ 42

28.2 Adjusting Mass Tolerance Collection ______________________________________ 44

28.3 Disable the Span Adjusting Function_______________________________________ 46

29 Cornerload Adjustment _________________________________________________46

29.1 Cornerload Adjustment Masses ___________________________________________ 46

30 Electronic Fault Finding ________________________________________________48

30.1 Power Check___________________________________________________________ 48

30.2 EEPROM Check _______________________________________________________ 48

30.3 Voltage Check__________________________________________________________ 49

31 Electronic Fault Finding Charts __________________________________________50

32 Wave Form Check _____________________________________________________55

33 RS-232 C Interface_____________________________________________________57

33.1 Interface Specifications __________________________________________________ 57

33.2 Output Format _________________________________________________________ 59

33.3 Output Data Mode ______________________________________________________ 60

33.4 External Control Commands _____________________________________________ 61

33.5 Cabling Diagrams_______________________________________________________ 62

34 Installation of the Air Shield Case (OMJ-2 Option)___________________________63

35 Troubleshooting _______________________________________________________64

36 KERN 434 Series Parts List ______________________________________________68

37 Balance drawings ____________________________ Fehler! Textmarke nicht definiert.

434-SH-e-9710 3

Page 4

1 Specifications

Model KERN 434-23 KERN 434-33 KERN 434-37

Gram

Ounce

Pound

Carat

Pennyweight

Troy Ounce

Grain

Momme

Tael (Hong Kong)

Tael (Singapore)

Tael (Taiwan)

Linearity

Readability

Stabilization time

Span drift (15° C - 30°C)

310 x 0.001 510 x 0.001 3100 x 0.001

10 x 0.0005 18 x 0.0005 109 x 0.0005

0.6 x 0.000005 1.1 x 0.000005 6.8 x 0.000005

1550 x 0.005 2550 x 0.005 15500 x 0.005

199 x 0.001 327 x 0.001 1993 x 0.001

9.9 x 0.00005 16 x 0.00005 99 x 0.00005

4784. x 0.02 7870. x 0.02 47840. x 0.02

82 x 0.0005 136 x 0.0005 826 x 0.0005

8 x 0.00005 13 x 0.00005 82 x 0.00005

8 x 0.00005 13 x 0.00005 82 x 0.00005

8 x 0.00005 13 x 0.00005 82 x 0.00005

±

0.002 g

0.001 g 0.01 g

2.3 sec

±

5 ppm/° C

±

0.02 g

±

3 ppm/° C

Operation temperature

Pan size

Total min. weight of

percent display

Min. percent display

Total min. weight of

piece counting

Max. piece counting

display

Sampling number of

piece counting

Data output

Power supply

Dimensions

Options: Auxiliary display (OMK-0), Underweighing hook (OMJ-1), Air shield case (OMJ-2)

Animal weighing pan (OMJ-3), Small animal weighing pan (OMJ-4), Auxiliary display base

stand (OMJ-10), Dust cover (O MJ- 11), Auxiliary display stand pole (OMJ-12)

31000 pcs 51000 pcs 31000 pcs

RS-232C bi-direction (standard accessory)

AC Adapter 220 V, 110 V or other (+10 V, 015 V)

135 mm

∅

0.01 g 0.1 g

50/60 Hz Output AC19V 200 mA

194 (W) x 334 (D) x 81 (H) mm

10° C - 40° C

160 x 160 mm

1 g 10 g

0.01 %

5, 20, 100 or 100 pcs

434-SH-e-97104

Page 5

2 Introduction

This Maintenance Manual covers three models from the KERN 434 series, the

KERN 434-23, KERN 434-33 and KERN 434-37. Please read this Maintenance

Manual and the owner’s Instruction Manual fully before beginning any

maintenance work.

The KERN 434 series precision balances are the products of years of research,

development, design and in-field testing. They incorporate the latest advances

in mechanical and electronic engineering and offer the highest standard of

reliability, easy to use functions and rugged durability.

3 Principles of operation

The KERN 434 series precision balances work on the principle of "Force

Compensation". Any change in the load on the weighing pan causes the Beam to

pivot on fulcrum Plate Bearings (see Block Diagram page 4). Attached to this Beam

is a coil wound with fine wire, called the "Force Coil Bobbin", which floats in a

permanent magnet. At the end of the Beam there is a small notch which allows light

from a Light-Emitting Diode (LED) to pass through to a Photo Sensor (Light

Measuring Diode). At zero weight, the light detected by the Photo Sensor is exactly

equal to the light emitted by the LED.

When the end of the beam is forced up by the leverage exerted from a mass placed

on the weighing pan, the Photo Sensor detects a change in the position of the beam

and the attached Force Coil Bobbin, because the light reaching the Photo Sensor

has become less than that emitted by the LED. The balance then feeds the Force

Coil Bobbin with more voltage, which increases the magnetic power and pulls the

Bobbin downward until the light reaching the Photo Sensor is once again equal to

the light emitted by the LED. This is accomplished by a Differential Amplifier, a filter

and an Analogue/Digital (A/D) Converter receiving photo current from the Photo

Sensor, converting it to voltage and boosting it back to the Force Coil Bobbin.

The electrical current flowing through the Force Coil Bobbin generates a voltage

proportional to the load weight on the pan. This is read back through the Differential

Amplifier and filter, then the A/D Converter digitalises this voltage. The resulting

value is then counted and fed to the microprocessor (CPU). The CPU performs a

multitude of commands and mathematical operations in conjunction with parameter

and adjusting information stored in Random Access Memory (RAM). Finally, the

results are displayed on the Liquid Crystal Display (LCD) or sent to the RS-232 C

Interface.

434-SH-e-9710 5

Page 6

4 Block Diagram

434-SH-e-97106

Page 7

5 Best Conditions for Weighing

1. Never turn off the power switch or disconnect the AC adapter when in use.

2. When making a measurement, always place the sample in the centre of the

weighing pan. Slight errors may result if the sample is not near the centre of

the pan.

3. Make sure the balance is level by using the level vial and the adjustable feet

on the bottom.

4. Install the balance in a controlled environment.

A) The weighing room should be kept clean, dry and free of cigarette

smoke.

B) Protect the balance from drafts (air currents). Use a draft shield if

necessary.

C) Maintain the ambient temperature to

D) Maintain the ambient humidity to

E) If larger changes in temperature or humidity occur, re-calibrate the

balance.

F) The balance table should be level and free from excessive vibration.

Corners of rooms are less prone to vibration.

G) Do not expose the balance to direct sunlight or radiated heat. Keep away

from windows, heaters, hot plates, flames, fans, air conditioners, etc.

H) Allow hot or cold sample containers to come to ambient temperature

before weighing.

I) Discharge any statically charged sample before weighing.

J) Do not expose the balance to corrosive gases.

±±±±

10 %.

±±±±

3° C.

5. Magnetised samples cannot be weighed accurately on an electronic

balance. Keep equipment containing magnets away from the balance.

6. Make certain that the AC power supply is free from electrical disturbances.

7. Clean the balance with a damp cloth only (no solvents).

8. Always warm-up the balance before use or leave on Stand-by (display off)

overnight.

9. Always handle the balance with care during use or when moving or storing.

434-SH-e-9710 7

Page 8

6 Balance Functions

Sampling Time Function (SAP):

The

the surrounding environmental conditions. The

function allows the balance to adapt to

SAP

should be adjusted to a small

SAP

value for corresponds to the "integration time" in seconds that the balance is using to

display readings.

Stability Indicator Function (STb):

All KERN 434 series balances use the star (Η)

symbol to indicate stability. When the Η appears on the display, the balance has not

yet stabilised. When the Η disappears from the display, the balance is stable. The

weight reading should be made only after the Η has disappeared from the display

and the indicator on the display for different sample types and weighing conditions.

Small values fo r

require very stable conditions before the Η disappears from the

STb

display and large values allow the Η to disappear under more reliable conditions

such as animal weighing.

Adjusting (Cal):

The

function is used to perform a Span Adjusting on the

Cal

balance. See Span Adjusting page 35 for the steps required for this procedure.

Weighing Unit Selection (Uni):

different weighing units.

between units.

Uni-2

allows the user to switch from grams to another unit by pushing

Uni-1

locks in grams or another unit and prevents switching

The

function is used to select and lock in

Uni

the U key. See Weighing Unit Initialisation page 9 to select or change the available

weighing units.

Output Data Mode (oUT):

The

function is used to change the output data

oUT

mode when using the RS-232 C interface. See RS-232 C Interface page 54.

RS-232 C Mode (rS):

The rS function allows you to switch between 8 bit non-parity

(8N1) and 7 bit even-parity (7E1)when using the RS-232 C Interface. See RS-232 C

Interface page 58 - 63

Baud Rate Speed (rSS):

The

function changes the baud rate speed when using

rSS

the RS-232 C Interface. See RS-232 C Interface page 8 for the steps required for

this procedure.

Auto-Start Mode (AST-ON):

If

auto-start mode

position immediately without pressing the

ON/S

is on, the balance will be weighing

key.

TBY

434-SH-e-97108

Page 9

7 Description of Function Menu

0.000g

⇓→

Press the F key.

⇓

Press the

!

Press the U key.

T

ARE

key.

SAP 1

⇓

Stb 1

⇓

CAL

⇓

Un i 1

⇓

OUT 1

!

!

!

!

"

!

!

2

"

!

2

!

3

3

!

A

H1

!

H2

!

H3

⇐

!

0

Full Point Value

Second Point Value

→

⇐

2

!

2

3

"

!

!

4

5

⇓

rS 8 n 1

!

"

7 E 1

⇓

r S S 1 . 2

!

2 . 4

"

!

4 . 8

⇓

AST ON

The display returns to the weighing mode if no operation is made for 3 sec. See the appropriate section

for further explanation of individual function

!

"

OFF

434-SH-e-9710 9

Page 10

8 Description of Functions

Display Command Selectable Setting Factory Set ting Remarks

1 Very steady

Range of 2 Normal

SAP

STb

CAL

Uni

OUT

rS

rSS

AST

Vibration 3 Unstable 2 Note 1

Adapter A Extremely unstable

1 Limited

Range of 2 Standard

Stability 3 Extensive 2 Note 1

H1 HOLD - Limited

H2 HOLD - Standard

H3 HOLD - Extensive

Adjusting See the adjusting section (page 11). Note 2

Unit Locking the key.

Selection Release the lock. 2 Note 3

Output upon print

1 com m and m ade

only after the balance

has stabilised.

After print command

2 made, output as

soon as balance

has stabilised.

Data Output upon print

Transmission 3 command regard- Note 4

Mode less of stability.

Automatic output as

4 soon as balance

has stabilised.

Automatic output

5 regardless of

stability.

RS-232 C 8N1 8 bit Non-parity

Interface 7E1 7 bit Even-parity 8N1 Note 5

Mode

RS-232 C 1.2 1200 BPS

Interface 2.4 2400 BPS 1.2 Note 5

Speed Mode 4.8 4800 BPS

Auto-Start ON Auto-start is on.

Mode OFF Auto-start is off. OFF Note 6

434-SH-e-971010

Page 11

9 Weighing Unit Initialisation

9.1 Keyboard Method

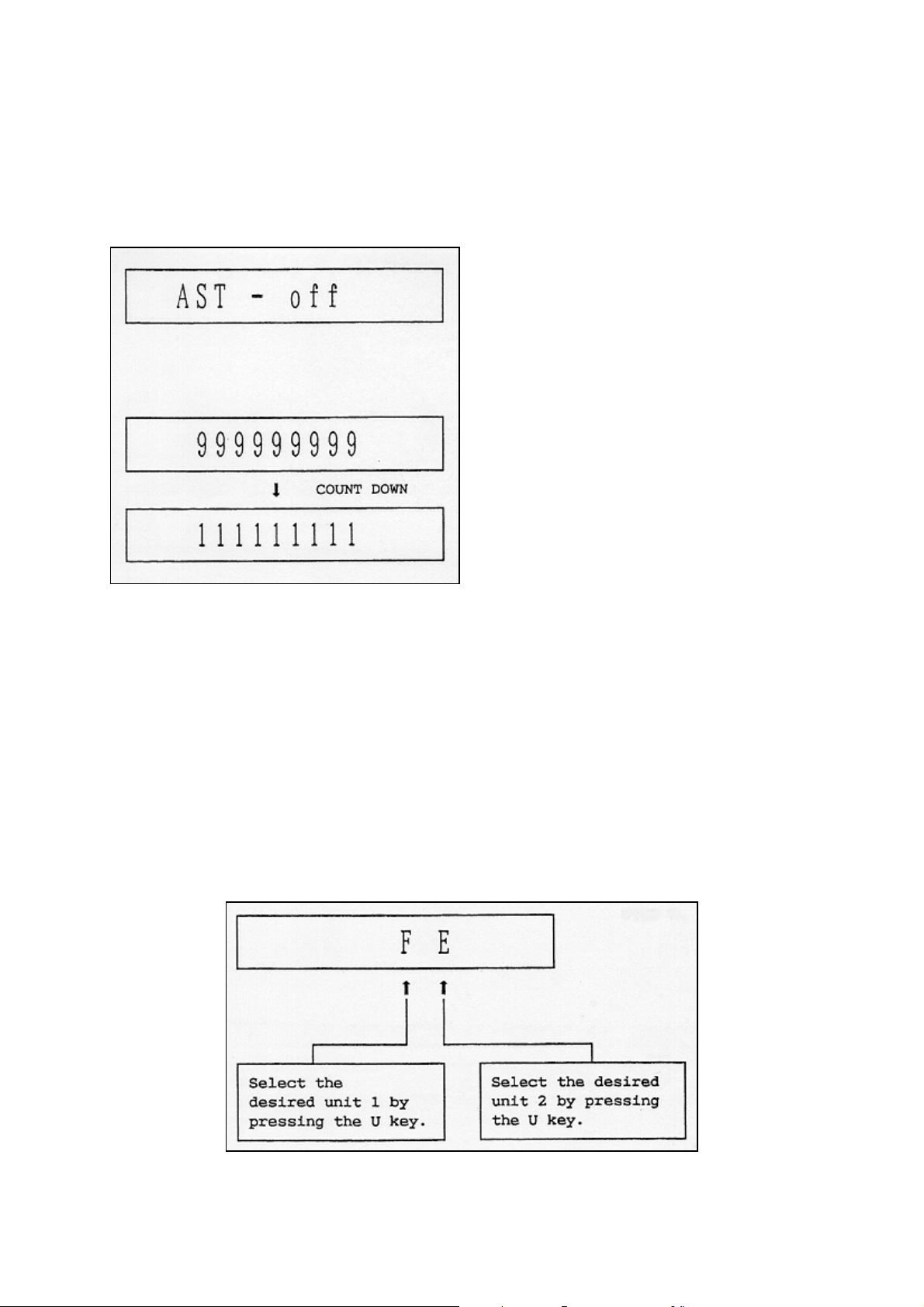

Step 1:

Make certain that AST function

mode (Automatic start) is off.

Step 2:

To have the count-down display,

once disconnect the AC adapter cord and

reconnect it again.

Step 3:

keys at the same time when

F

“

111111111

Step 4:

Press and hold the

“ appears.

Release the keys when the „All

T

ARE

, U and

Segment“ line appears.

Step 5:

Parameter number will appear

after „All Segment“ line has stopped

flashing.

Step 6:

Two units in addition to grams can be selected and programmed into

memory. Grams will automatically be in memory and does not need to be selected in

this procedure. Unit 1 is selected by pressing the U key until the unit code place. Unit

2 is selected by pressing the

key until the unit does appear on the display in

T

ARE

the Unit 2 digit place. For example, if you select Units F and E as shown below the

balance will show weighing results in Piece Counting and Percent.

Step 7:

Press the F key to store your selections. Check to make certain the desired

units have been stored by pressing the U key. When the unit selection (Uni) is set at

Uni-2 you can switch between units by pressing the U key. The Uni-1 setting locks in

one unit and switching to another unit is not possible.

434-SH-e-9710 11

Page 12

Step 8:

Press the F key to complete the Unit Selection procedure.

Display Circular

(# Press the U key)

Gram display

$%

9.2 Parameter Number Chart

0 Gram g 9 Carat C.M

1 Cancel last digit g A Momme mom

2 Kilogram kg B Taiwan Tael tl

3 Pound lb C Singapore Tael tl

4 Ounce oz D Hongkong Tael tl

5 Troy ounce ozt E

6Grain gr F

#

Unit 1

#

Unit 2

Η

Η

#

Percent %

Piece counting pcs

Gram display

7 Pennyweight dwt

8 Carat ct

Factory setting

Η

434-SH-e-971012

Page 13

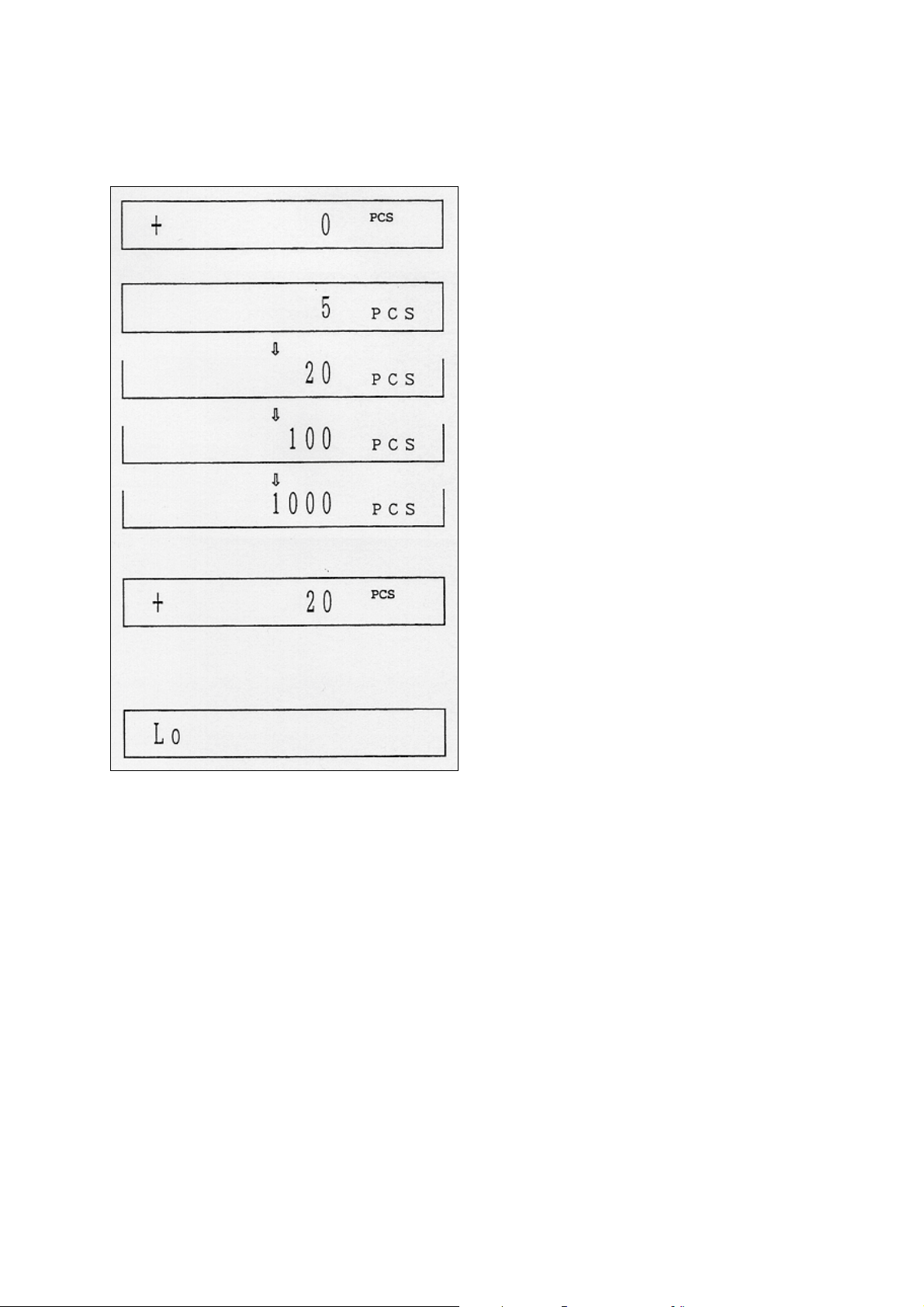

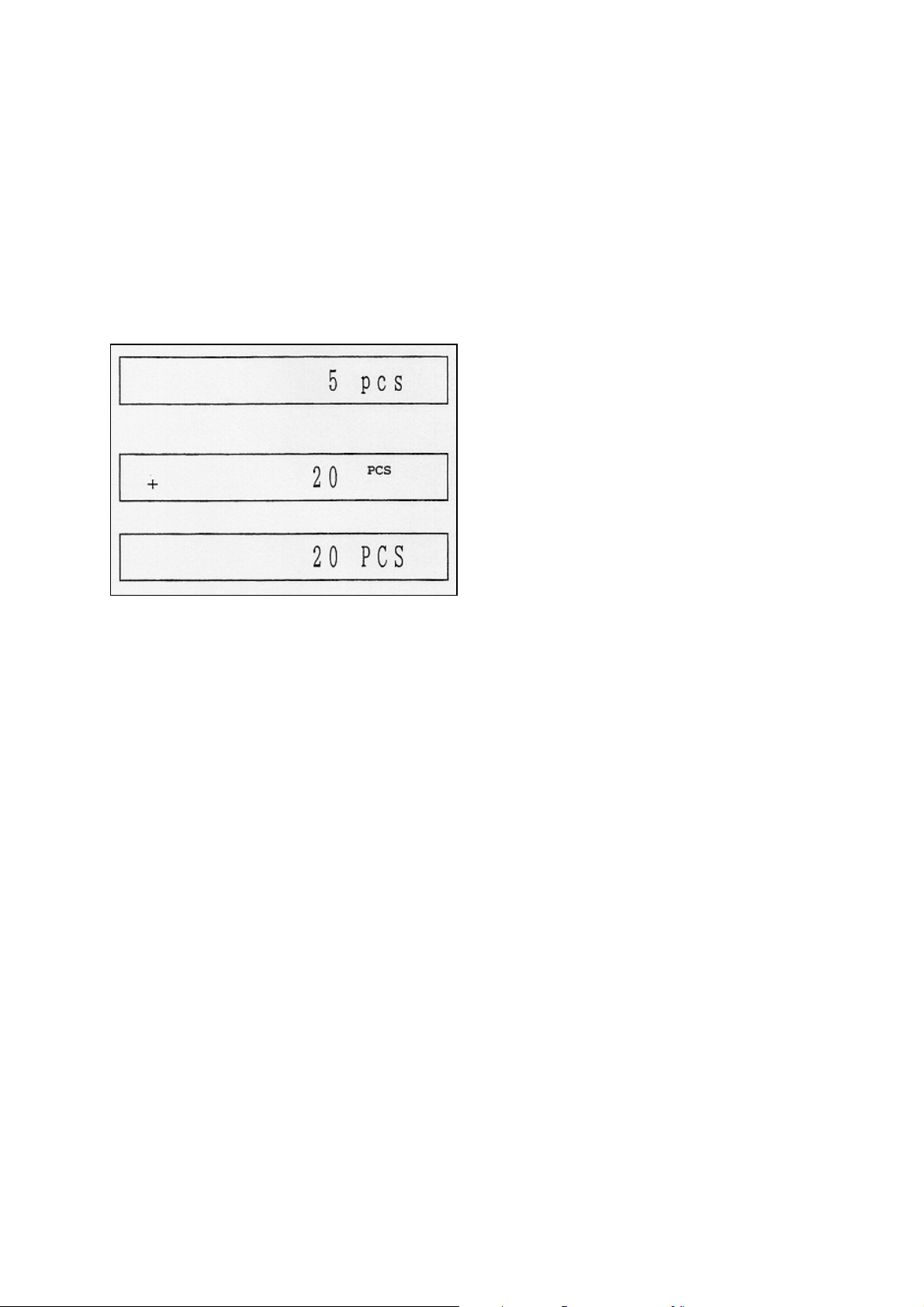

10 Piece Counting Mode

Step 1:

Press the U key to switch the

display to Piece Counting Mode (see

Weighing Unit Initialisation page 11).

Step 2:

Press the F key until the desired

count value is displayed, 5, 20, 100 or

1000 pcs.

Step 3:

Count out the same number of

sample pieces as you selected in Step 2,

and place them on the weighing pan.

Step 4:

Press the

key to memorise

T

ARE

the number of sample pieces and their

unit weight. The display will flash until the

balance has memorised this data.

Step 5:

Proceed with piece counting.

Step 6:

message when pressing the

If the display shows a

T

ARE

"Lo"

key,

the unit weight of the sample pieces is

less than the balance can detect.

The minimum weight of each sample piece required to establish piece counting is as

follows:

KERN 434-23

KERN 434-33

KERN 434-37

⇑

⇑

⇑

0.01 g

0.01 g

0.1 g

434-SH-e-9710 13

Page 14

10.1 Removing establishment of the standard unit weight for piece counting

This unique function of the KERN 434 series is used to easily increase the number of

pieces of sample used as your piece counting standard without taking the time to

count out each standard sample separately. This is important because the greater

the number of sample pieces used to set your standard, the more accurate an

precise your piece counting will be.

Step 1:

sample pieces and unit weight at 5 PCS, f or

example, by following the procedure on the

previous page.

Step 2:

weighing pan. The display will show that

there are 20 pieces on the pan.

Step 3:

pan and press the F key until 20 PCS

appears on the display.

Step 4:

new number of sample pieces and the new

unit weight.

Step 5:

increase the standard to 100 or 1000 pieces.

Establish the standard number of

Place 15 more sample pieces on the

Leave the 20 pieces on the weighing

Press the

Follow the same procedure to

key to memorise the

Tare

Note: The key is to let the balance do the counting for you when establishing

the standard. For example, count out 20 pieces by yourself and set the

standard at 20 pieces. Use the piece counting mode to count up to 100 pieces

and set the new standard at 100 pieces. Then use the piece counting mode

again to count up to 1000 pieces and set the new standard again at 1000

pieces.

434-SH-e-971014

Page 15

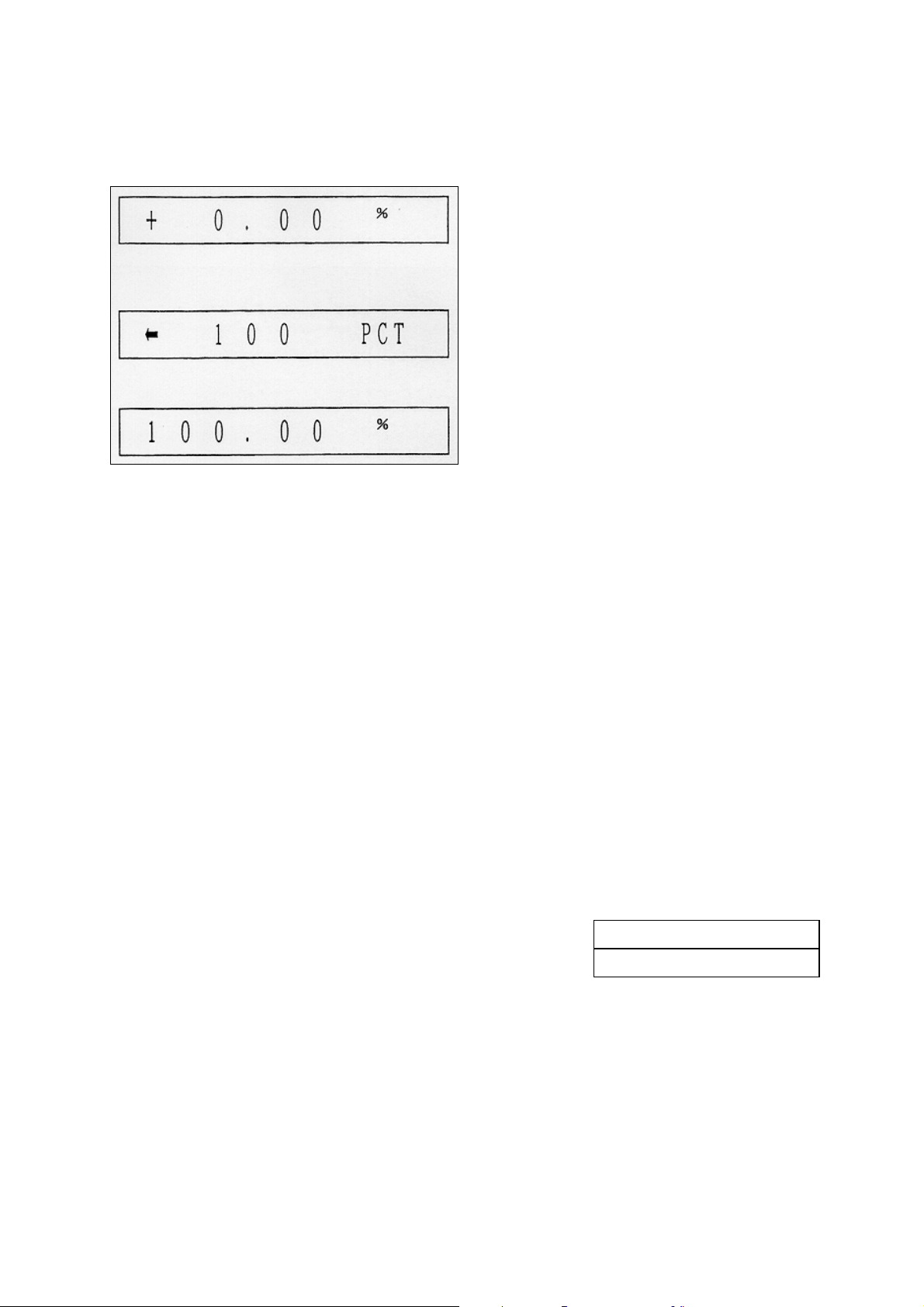

11 Percent Mode

Target weight:

Step 1:

"%" appears.

Step 2:

weight on the weighing pan.

Step 3:

100% weight. Make certain that """ sign

appears when entering a sample. Press the

T

ARE

Step 4:

when "100.00%" appears. Proceed with

percent weighing by placing a new sample on

the weighing pan. Percentage display is

100.00& for KERN 434-23, KERN 434-33

and KERN 434-37.

Continuously press the U key until

Place a sample of the ideal 100%

Press the F key to memorise the

key if the """ sign does not appear.

Percent mode procedure is complete

The minimum weight of the 100% sample required to establish percent weighing is

as follows:

KERN 434-23

KERN 434-33

KERN 434-37

⇑

⇑

⇑

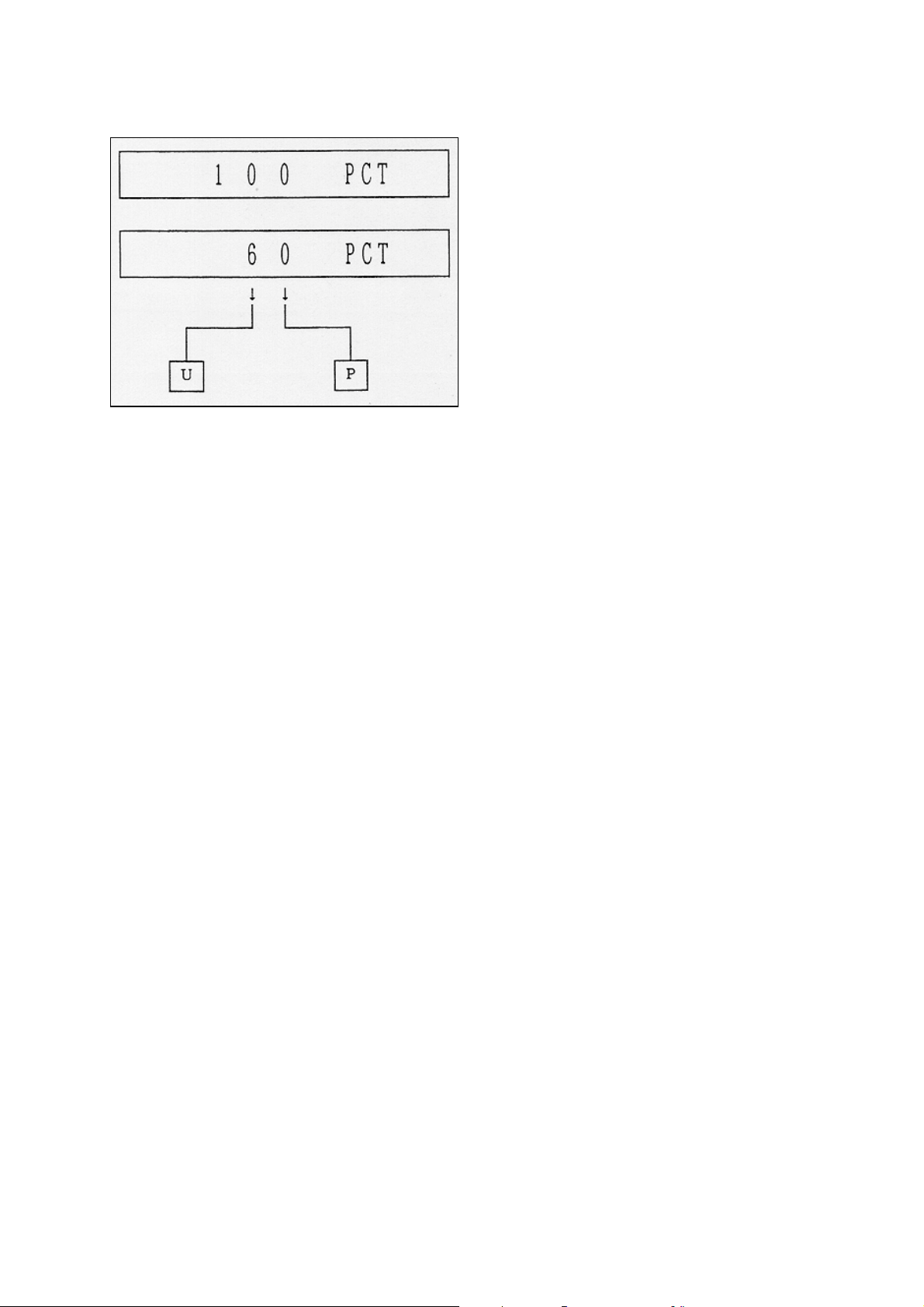

11.1 Weighing Mixture Mode

This mode is used when you want to mix two

sample together. For instance when you add

sample B to sample A to make a 100%

mixture sample.

1 g

1 g

10 g

Sample B 40 %

Sample A 60 %

434-SH-e-9710 15

Page 16

Step 1:

the 100 % weight by using the percent

mode procedure above.

First, memorise sample A to be

Step 2:

by pressing the U and P keys.

Step 3:

the 100 % weight is reached.

Reset sample A at 60 % weight

Add sample B to sample A until

434-SH-e-971016

Page 17

12 Adjusting Introduction

Adjusting of KERN 434 series precision balances is required at initial installation, any

time the balance is moved or bumped, whenever the ambient temperature changes

by more than 3° C, and additionally every 30 days or so. Adjusting is necessary for

two main reasons. First, with time and use, mechanical deviations can occur.

Secondly, the weight of a mass in one location or under a certain set of conditions

will not always be the same at a different location or under a different set of

conditions.

There are a number of adjusting procedures that will need to be done during the life

of a KERN 434 series balance. They are briefly explained below. The actual

adjusting procedures are contained throughout this manual (see Table of Contents

page 2).

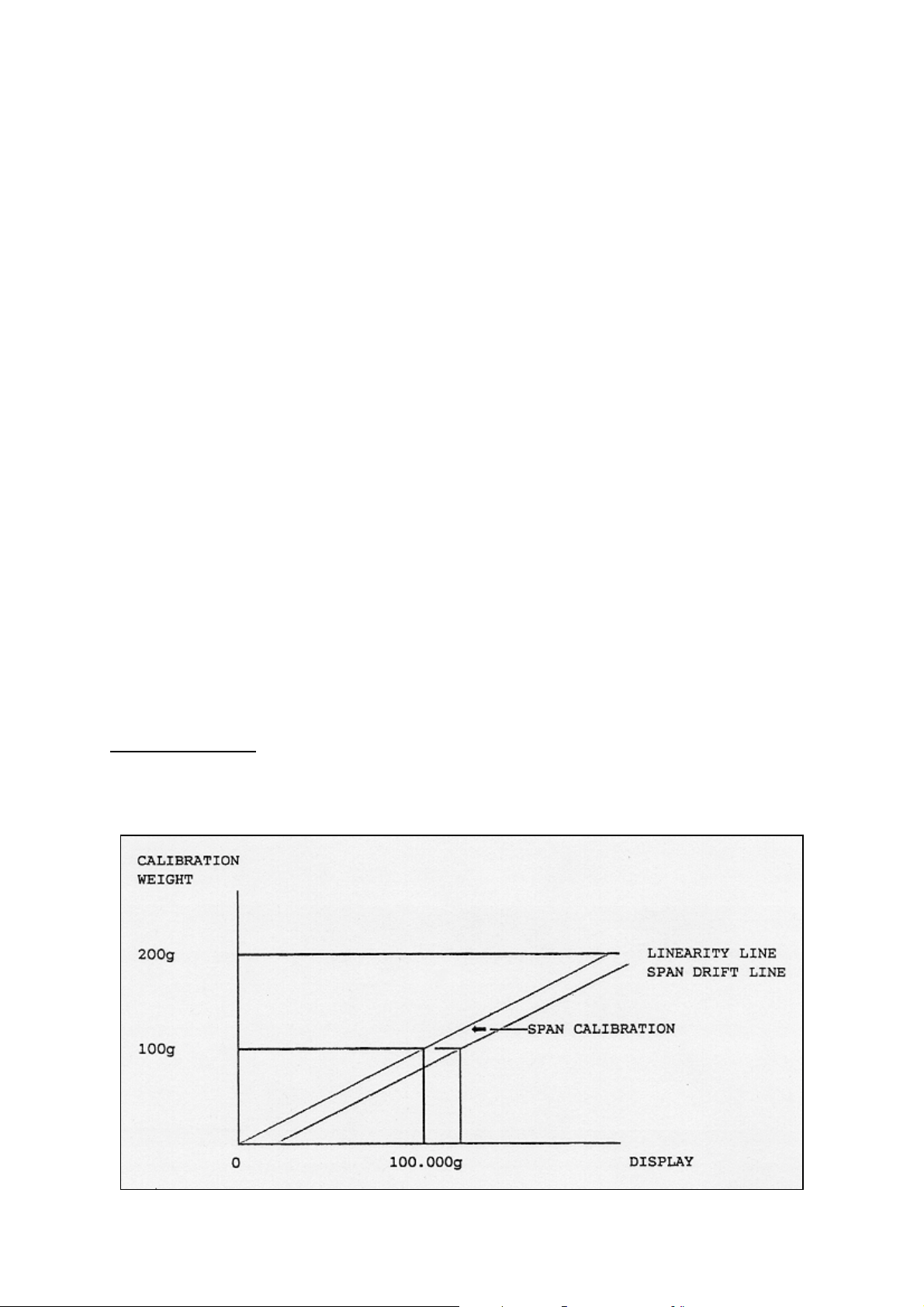

Linearity Adjusting: The purpose of Linearity Adjusting is to create a straight line

from Zero to the Full Capacity Scale Value to that the balance will display accurate

weighing results at all values in between. On the graph below, the Y-axis represents

the "true weight" of a mass on the weighing pan and the X-axis represents the

weight displayed by the balance. An accurate mass of any weight value will be

plotted on a linear (straight line) path from zero to the maximum capacity. However,

although a straight line will be generated by Linear Adjusting, this line must be

correctly placed by the balance during Span Adjusting (see Linearity Adjusting page

41).

Span Adjusting: With Span Adjusting, we are shifting the straight line generated

during Linearity Adjusting by giving it the Zero Load Value and the full capacity

adjusting mass value as reference points (see Span Adjusting page 43).

434-SH-e-9710 17

Page 18

Temperature Compensation Adjusting: The KERN 434 Mechanical Unit operates

by a force coil moving inside a permanent magnet. A change in ambient temperature

causes a change in the temperature of the Mechanical Unit, in turn altering the

characteristics of the magnet. Unless this is compensated for, it will cause sensitivity

drift problems. KERN 434 balances use a transistor temperature sensor in the

Mechanical Unit to detect changes in temperature. The temperature compensation

settings, which match the temperature characteristics of the Mechanical Unit sensor,

are stored in Electronic Erasable Programmable Read Only Memory (EEPROM).

All KERN 434 series balances undergo a Temperature Compensation Adjusting at

the factory before shipment. At that time all temperature compensations settings are

programmed into EEPROM. Therefore, it is not necessary to perform this adjusting

regularly to avoid sensitivity drift problems.

EEPROM: If the EEPROM is lost due to a component replacement or short circuit, all

adjusting data is cleared. If this happens, the EEPROM must be reinitialised.

Reinitialisations of the EEPROM must always be followed by Linearity and Span

Adjustings. Depending the user’s needs, a Temperature Compensation Adjusting

may also be necessary (see Initialisation of EEPROM, page 39).

434-SH-e-971018

Page 19

13 Inner A /D Counter Check Mode

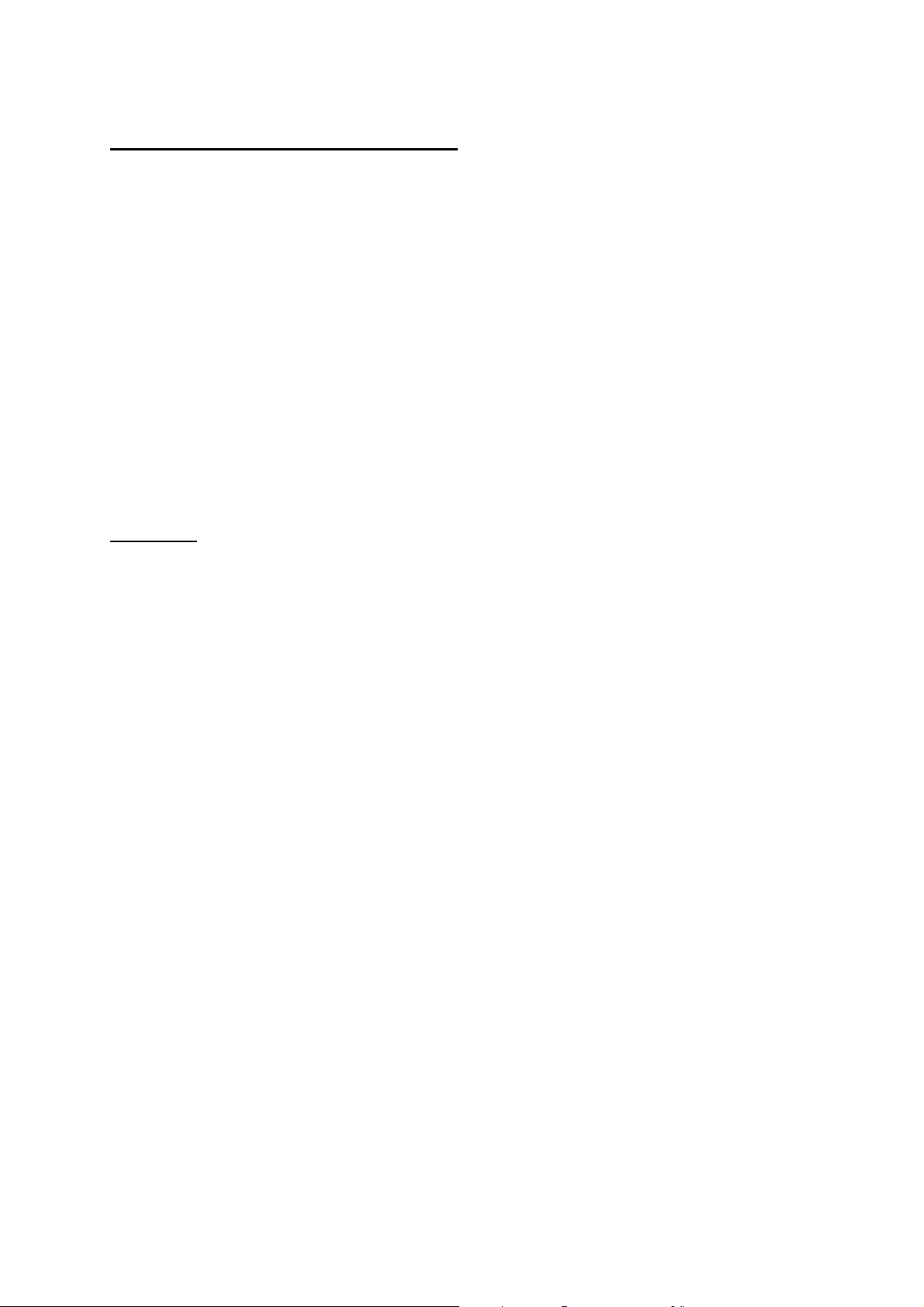

Many of the maintenance procedures contained in this manual require adjustments

to the Inner A / D Counter Dip Switch, hereby referred to as Dip Switch, located on

the Display P.C.B. (MJ-1A).

The Check Modes needed to perform the repair procedures contained in this manual

are found below. When a Dip Switch adjustment is required, simply flip the switches

so that they correspond to the appropriate Modes below.

1234

Check 0 Mode

(Normal Weighing)

νννν

Off

On

1234

Check 1 Mode

(A/D Count Data)

(A/D Counter Range 0000000 - 3884160)

ννν

ν

Off

On

434-SH-e-9710 19

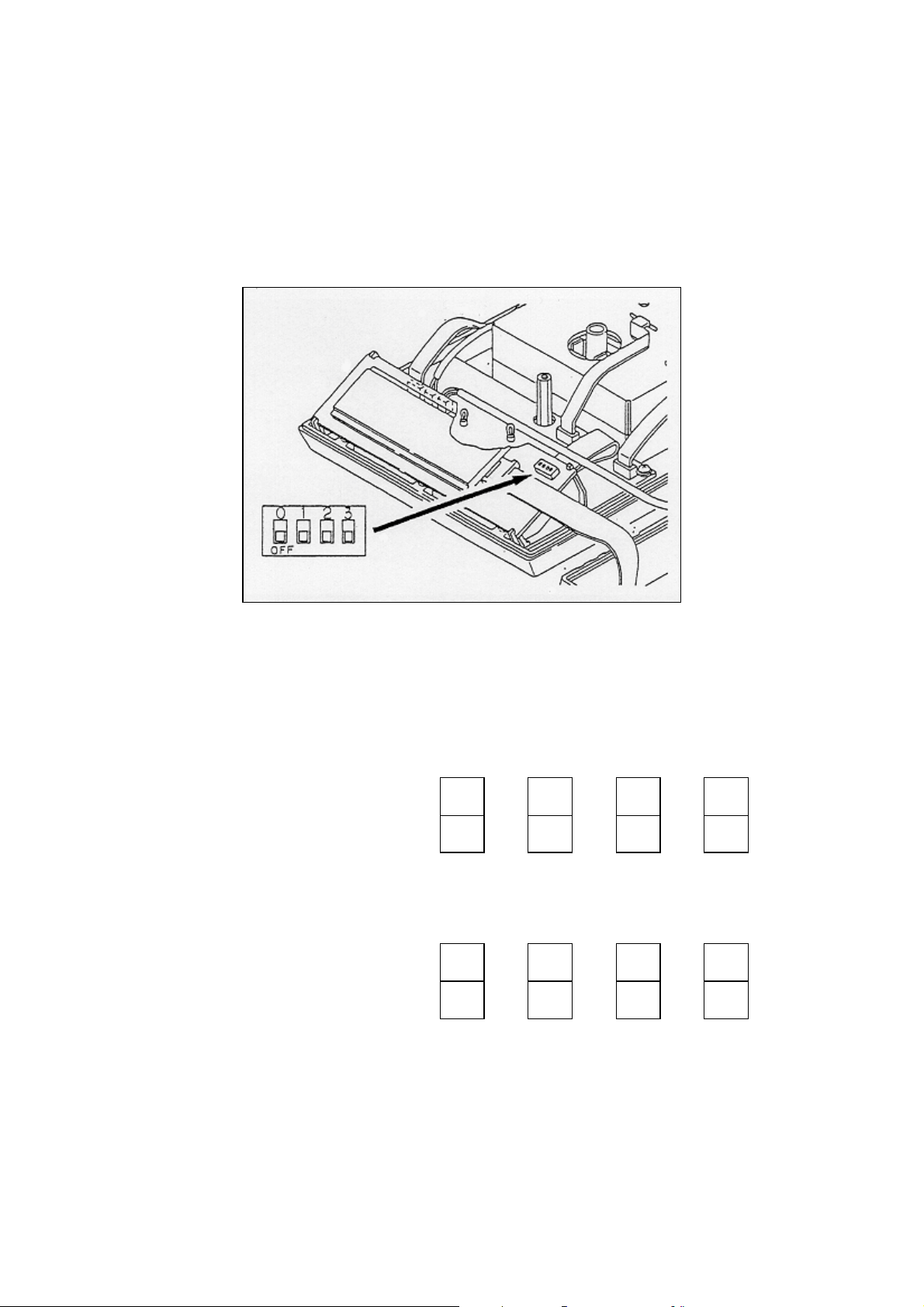

Page 20

1234

Check 2 Mode

(Temperature Compensation Data)

(A/D Counter Range 180000 - 220000)

Check 3 Mode

(Linearity Data)

(A/D Counter Range 0000000 - 3884160)

νν ν

ν

12

34

νν

νν

Off

On

Off

On

434-SH-e-971020

Page 21

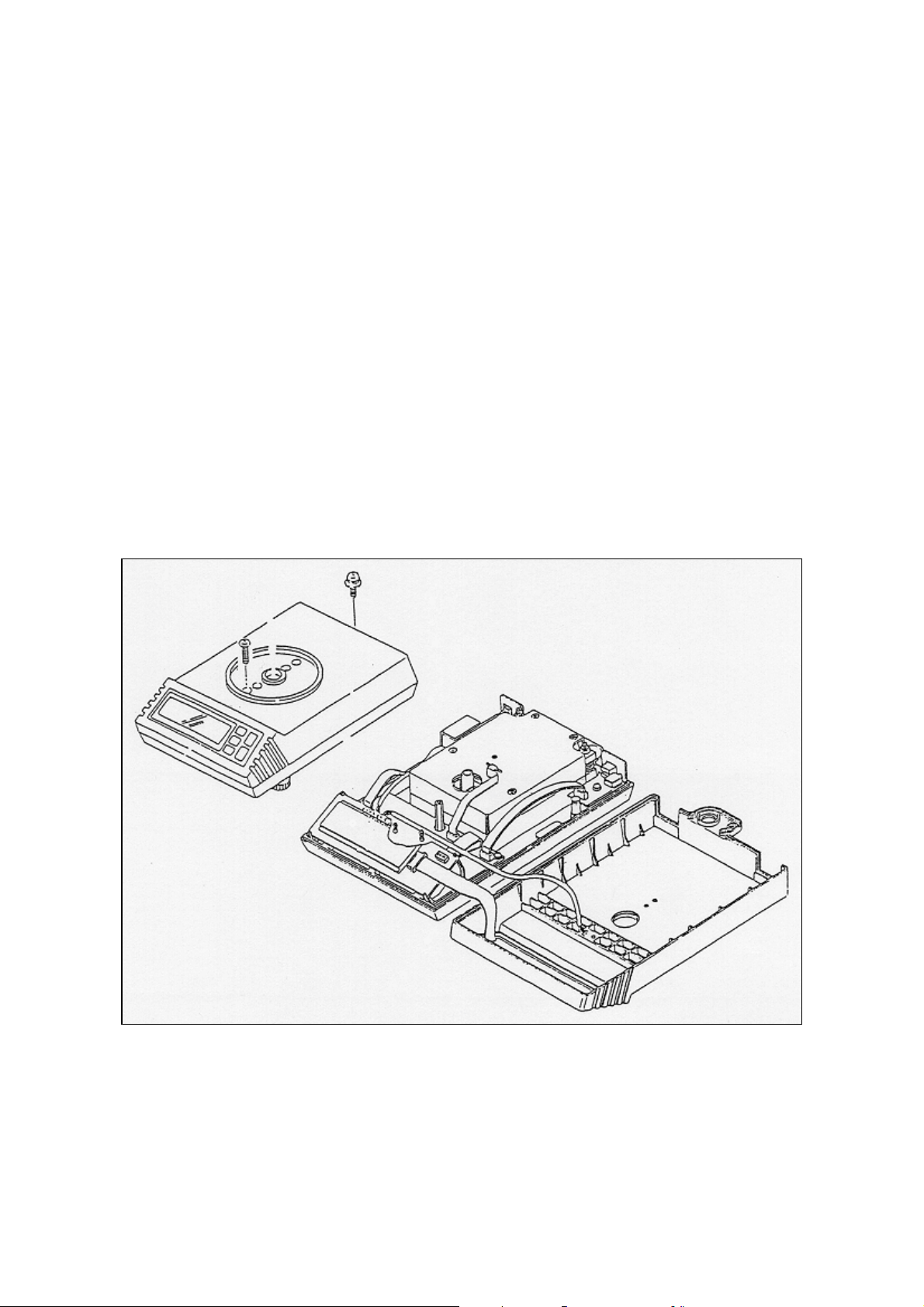

14 Disassembly / Assembly

14.1 Removing the Top Case

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Unplug the AC adapter from the balance.

Remove the weighing pan and the pan support.

Loosen a forehead screw toward the display keyboard and screws on rear

side of the balance.

Gently lift off the top cover, flipping it to the right.

Do not jerk the connecting cable.

Disconnect all cables inside the balance.

434-SH-e-9710 21

Page 22

14.2 Removing the Mechanical Unit

Step 1:

Step 2:

Step 3:

Step 4:

Loosen 3 screws on the bottom of the balance.

Gently lift the Mechanical Unit box from the bottom case.

Slowly place this Mechanical Unit box a flat surface and loosen 4 screws

on top of this box.

Open this box, then the Mechanical Unit will be exposed.

434-SH-e-971022

Page 23

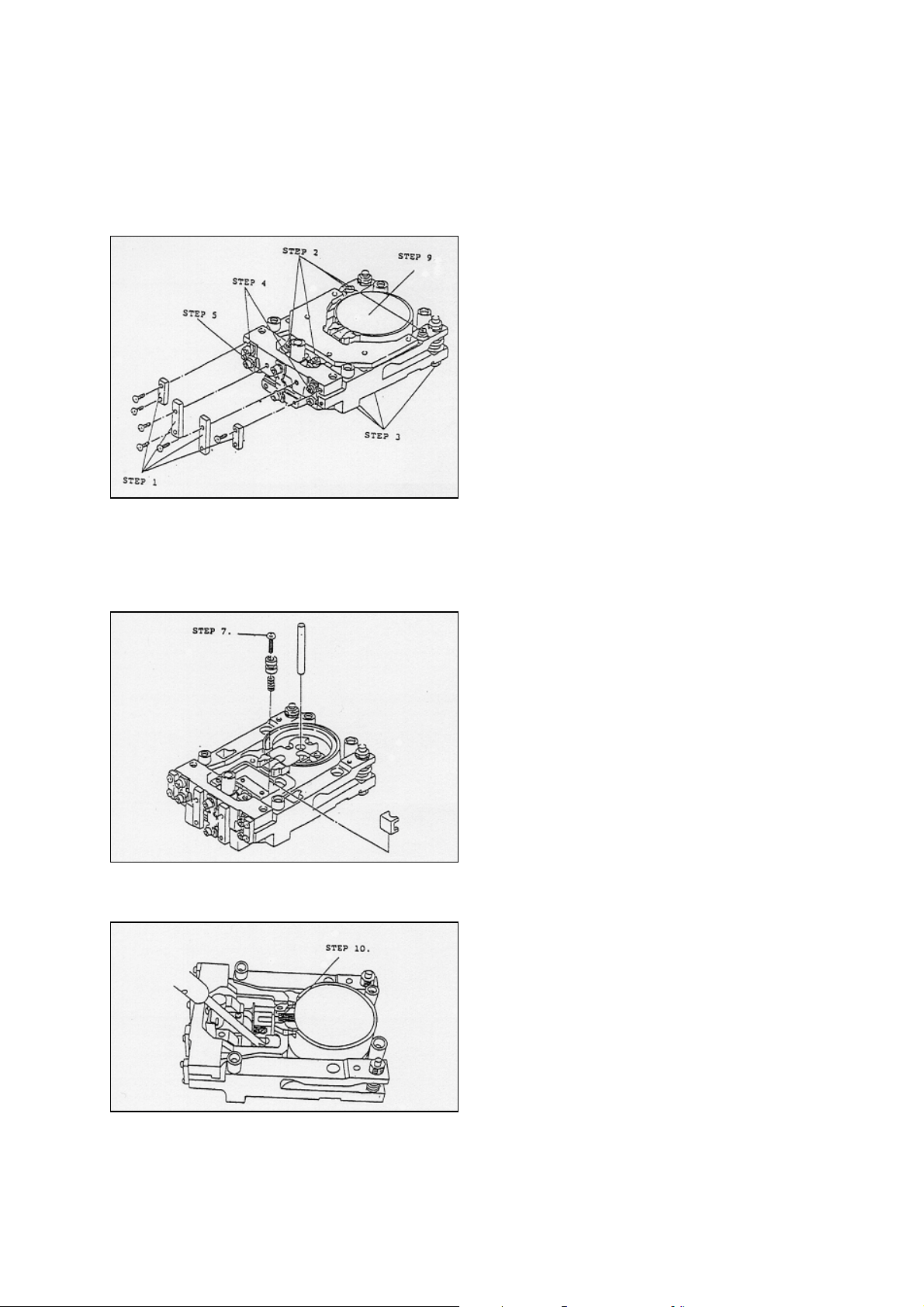

14.3 Mechanical Unit Disassembly

Step 1:

Jig Set (the beam Jig and the beamsuspension Jig) - see the Jig Set page

21.

Step 2:

plate bearing assembly and remove it.

Step 3:

plate bearing assembly and remove it.

Step 4:

vertical plate springs.

Step 5:

the balance weight and remove it.

Step 6:

coupling link.

Attach the appropriate KERN 434

Loosen 4 screws on the upper

Loosen 4 screws on the lower

Loosen 4 screws for removing

Loosen 2 screws on bottom of

Loosen 4 screws for removing a

Step 7:

beam positioning and remove it.

Step 8:

assembly, the suspension assembly and

the mechanical unit base will be

disassembled separately.

Step 9:

Step 10:

attached on the beam

Step 11:

from the beam. We recommend that you

should wear gloves when handling the

Force Coil Bobbin.

Loosen a screw on top of the

Make certain that the beam

Remove the magnet lid.

Unsolder the short wire

Remove the Force Coil Bobbin

434-SH-e-9710 23

Page 24

14.4 Assembly

Step 1:

force coil bobbin attached to the beam .

Step 2:

force coil bobbin is attached to the beam.

Step 3:

positioning jigs in the mechanical unit base.

Step 4:

the right and left posit ioning jigs.

Step 5:

the mechanical unit.

Step 6:

force coil bobbin.

Step 7:

bobbin is completely positioned to have an

even space between outer rim of the bobbin

and the magnet inside. Then tighten the

screws for fixing in between the force coil

bobbin and the beam

And an edge of the beam will be positioned in

right space inside the photo sensor.

Note that the beam assembly is the

Slightly loosen the screws where the

Be laid and insert the right and left

Mount the suspension assembly on

Gently mount the beam assembly on

Insert the force coil bobbin j ig into the

Make certain that the force coil

Step 8:

suspension jigs by tightening the screws.

Step 9:

tighten the beam stopper with the beam

stopper jig.

Step 10:

that the beam stopper will be installed at an

proper height with the beam stopper jig.

Step 11:

then removing the mechanical unit and then

removing the top case in reverse order to be

complete.

Reattach the beam and the

Resolder the short wire and insert to

Make certain to tighten the screws

Proceed steps of the disassembly,

434-SH-e-971024

Page 25

15 Jig Set

You should never attempt to replace Plate Bearings or disassemble the

Mechanical Unit without first attaching the appropriate KERN 434 Jig Set. Even

slight movements or shifts in the Mechanical Unit components can seriously

hamper the performance and accuracy of the balance. The Jig Set’s primary

purpose, therefore, is to secure the Mechanical Unit to prevent such

movements.

434-SH-e-9710 25

Page 26

16 Additional Disassembly / Assembly

16.1 Replacement of the Force Coil Bobbin

Step 1:

orders of the Disassembly / Assembly

section page 21).

Step 2:

toward the force coil bobbin on the MJ-6

P.C.B. (Allow this small P.C.B. was

attached on center of the beam).

Step 3:

from the beam by loosening the screws.

Allow counter weight(s) is also mounted

on one or two of the same screw holes.

Step 4:

were always isolated and attached in

order on a new force coil bobbin.

Step 5:

reattaching the new force coil bobbin

below the beam.

Completely follow all procedure

Solder to release 4 lead wires

Remove the force coil bobbin

Make certain that 4 lead wires

Slightly tighten the screws when

16.2 Cleaning Inside the Magnet

Step 6:

have to be resoldered exactly in order to

the MJ-6 P.C.B.

Step 1:

attaching inside the magnet.

Step 2:

the magnet by air or adhesive tape.

make certain that 4 lead wires

Make certain that any dust is

Always blow out or clean inside

434-SH-e-971026

Page 27

16.3 Positioning Edge of the Beam Inside the Photo Sensor

Edge of the have has to be positioned 1

or 1.5 mm space inside the photo sensor.

434-SH-e-9710 27

Page 28

17 Primary Checking Procedure

When checking a damaged balance, there are primarily 3 major checking procedures

that should be followed in order until the damage is detected and corrected.

1. Visual Check (page 28)

2. Mechanical Fault Finding (page 29)

3. Electronic Fault Finding (page 49)

Most repair problems that you will encounter will be a result of damage to the

Mechanical unit during transport or rough usage. Occasionally you will also

encounter problems resulting from damage to the Electronic Unit. Please carefully

read the Disassembly / Assembly section on page 21 - 24 before going through the

repair procedure.

18 Visual Check

A careful Visual Check should always be performed before attempting further

repairs. If damage is detected during the Visual Check, replace the damaged unit.

Step 1:

Step 2:

Step 3:

Step 4:

Balance Case and Chassis - There should be no cracks or gaps in the

balance housing. Check that all housing screws are in place.

Keyboard - They keyboard pad should be free of cracks or tears.

Weighing Pan - The weighing pan and pan support should be free of dents

or bends and should be parallel to the balance case.

Level Vial - The level should be filled with fluid and the leveling bubble

should be within the circle at the top. Use the adjustable feet to level the

balance.

Step 5:

RS-232C Interface - Check for any damage, including dirt in the

connectors.

434-SH-e-971028

Page 29

19 Mechanical Fault Finding

This section provides a simple fault finding method when checking a balance

for Mechanical Unit damage. When mechanical damage is present, there are

two major problems that can occur when the power switch is turned on. First,

the display may show only a decimal point with a polarity sign (+ / -), "all

segment lines" message or no display at all. The second problem is when the

display shows and unstable weighing result.

19.1 "+ / - .", "All Segment Lines" or No Display

The procedure below is designed to fix a balance that shows the following displays

when the power switch is turned on.

(Only a decimal point and + or - sign)

Step 1:

Step 2:

Step 3:

Step 4:

(All Segment Lines)

(No Display)

Make certain that the Short Wires are correctly soldered (page 33) .

Make certain that all Connecting Cabl es are completel y connected ( page 21) .

Make certain that all Plate Bearings and the Coupling Link are not damaged,

twisted or broken (page 35) .

Reprogram the Linearity into EEPROM by doing a Linearity Adjusting (page

41).

434-SH-e-9710 29

Page 30

Step 5:

Return to the normal weighi ng mode by setting Dip Swit ch 2 to Check 0 Mode,

and make certain that the three error messages above are gone and that the

balance shows a correct weig hing di splay . If not, check all circui t boards.

Step 6:

Step 7:

19.2 Unstable Weighing Results Adjustment

The procedure below is designed to fix a balance that shows unstable

weighing results after the power switch has been turned on. Fox example,

when a 100 g sample is placed on the KERN 434-23 and the display shows a

reading that rapidly shifts from one reading to another the following

adjustment must be made to bring the display back to a stable reading of

100.00 g.

If the display shows an unstable weighing result, proceed to the Unstable

Weighing Results Adjustment procedure on page 30.

If the display shows a stable weighing reading, the problem has been

corrected. Do a Span Adjusting (page 43) before beginni ng to w eig h.

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Make certain that all Plate Bearings and the Coupling Link are not

damaged, twisted or broken (page 35).

Adjust the Inner A / D Counter (page 19).

Adjust the corner error by doing a Cornerload Adjustment (page 47 - 48).

Reprogram the Linearity into EEPROM by doing a Li nearity Adj usting (pag e 41).

Do a Span Adjusting (page 43).

434-SH-e-971030

Page 31

Step 6:

If the problem has been corrected, the balance will display a "

Pass

"

message. If a "

" message does not appear, check all circuit boards.

Pass

434-SH-e-9710 31

Page 32

20 Mechanical Fault Finding Chart

434-SH-e-971032

Page 33

21 Short Wire Check

The Short Wire (two wires) is used to conduct electronic current from the

Photo Sensor to the Force Coil Bobbin. The voltage that reaches the Bobbin

via the Short Wires provides the magnetic power required for the Beam to

reach equilibrium when a sample is placed on the Weighing Pan.

Step 1:

Step 2:

Step 3:

Remove the top cover (see Disassembly / Assembly page 21).

Check the Short Wire to make sure that it is securely soldered.

If the Short Wire is disconnected, then resolder. When resoldering,

maintain contact with the soldering iron for only 1 second to avoid melting

the wire.

434-SH-e-9710 33

Page 34

22 Connecting Cable Check

Step 1:

Step 2:

Step 3:

Remove the top cover (see Disassembly / Assembly page 21).

Check all Cables for damage. Take special notice of all bending parts and

Cable Connectors.

Make certain that all Connecting Cables are properly connected. Cables

should be checked in the order given in the illustration below.

434-SH-e-971034

Page 35

23 Plate Bearing / Coupling Link Check

To replace Plate Bearings or Coupling Links you must have the Jig Set used

exclusively on KERN 434 series balances. Do not attempt to disassemble the

Mechanical Unit or replace Plate Bearings without the appropriate Jig Set.

Please read the Disassembly / Assembly and Jig Set sections (page 25) before

attempting the steps below.

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Step 6:

Remove the Mechanical Unit from the base unit.

Check all Plate Bearings and the Coupling Link for bending, breakage or

other damage.

If replacement is required, install the appropriate KERN 434 Jig Set on the

Mechanical Unit. Make certain that the Jig Set has been properly attached.

Remove the damaged part from the Mechanical Unit.

Replace the Plate Bearing or Coupling Link. Visually check to be sure the

new part is perfectly straight and even.

Remove Jig Set and return Mechanical Unit to the balance housing.

434-SH-e-9710 35

Page 36

Remark: When reattaching plate bearing(s), then your tightening torgue has to be

exactly the same compared to other tightening torgues.

KERN 434-23, 434-33

KERN 434-37

1 Nm (10 kgfcm)

1.8 Nm (18 kgfcm)

24 Beam Stopper Adjustment

This procedure is required to adjust the up-down movement range of the Beam

in order to get a proper analogue count. The Photo Sensor will catch the updown movement of the Beam and determine the proper supply of electronic

current sent to the magnet.

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Remove the Balance Case (see Assembly / Disassembly page 21 - 24-).

Make certain that the beam stopper has to be set at exact height by using

the beam stopper jig.

Reassemble the scale as sh own in the illustration. And make certain that

all connecting cables have to be set completely.

Re-plug AC adapter cord to the balance.

Contact a Digital Tester to Ground and Contact Point TP 2 on the MJ-1

P.C.B.

434-SH-e-971036

Page 37

Step 6:

Allow an adjustment hole right behind the pan suspension.

Step 7:

Step 8:

&

&

Insert a screw driver in the hole and screw up or down the extension piece

space until the acceptable voltage + 3 V appears on the Tester.

Absolute voltage has to be ± 3 V even comparing No Load and Full Load.

- Contact Pin to GND

+ Contact Point to TP 2

Acceptable Voltage Range

No Load

Full Load

+ 3 V ± 1 V

- 3 V ± 1 V

434-SH-e-9710 37

Page 38

25 A / D Converter Check

When checking the A / D Converter you will be looking at the inner A / C count

from the Mechanical Unit. Three weighing conditions will be tested and at the

appropriate step you will be reading a number on the display and comparing it

to Table A below.

Table A

Model Adjusting Masses A / D Count Value

No Load A B

138720 - 971040

KERN 434-23

KERN 434-33

KERN 434-37

Step 1:

Set the balance to Check 3 Mode (see Inner A / D Counter Check Modes

page 19).

Step 2:

Turn the power switch

0 g 250 g 300 g 1720128 - 2164032

1803360 - 2635680

138720 - 971040

0 g 250 g 500 g 1720128 - 2164032

2913120 - 3745440

138720 - 971040

0 g 1500 g 3000 g 1720128 - 2164032

2913120 - 3745440

.

O

N

Step 3:

Step 4:

Make certain the balance has no load on the pan. Check to make certain

that A / D count value will be appeared within the correct range.

Continuously place different adjusting masses A & B in accordance with

Table A. And make certain that A / D count values are displayed as same

as the Table A shows. If wrong A / D count value appears, then you must

readjust to replace counter weight(s) on the force coil bobbin.

434-SH-e-971038

Page 39

Step 5:

Remove to readjust the counter weight if attached for having the correct

value. If not attached, then reattach the weight.

26 Initialisation of EEPROM

This procedure is necessary only when a complete loss of memory has

occurred. A loss of memory can occur from a component replacement, short

circuit or other electronic problem. To successfully complete this procedure

you will need to initialise the RAM, do a Linearity Adjusting and a Span

Adjusting. You may also need to do a Temperature Compensation Adjusting.

Step 1:

Step 2:

Readjust the Linearity Adjusting (see Linearity Adjusting page 41).

Readjust the Span Adjusting (see Span Adjusting page 43).

434-SH-e-9710 39

Page 40

27 Linearity Adjusting

The purpose of Linearity Adjusting is to create a straight line from Zero to the

Full Capacity Scale Value so that the balance will display accurate weighing

results at all values in between. For this adjusting procedure, please use a

high quality, non-magnetic-metric, stainless steel „Standard Mass“ that is

OIML Class F2 or better. Whenever Linearity Adjusting is performed on the

balance, it must be followed by a Span Adjusting.

27.1 Linearity Adjusting Procedure

Step 1:

The balance should be fully

warmed-up (plugged in for 30 minutes)

and all of the Best Conditions for

Weighing (page 7) should be met.

Step 2:

With the power switch

O

, reset

FF

Dip-Switch 2 & 3 to the Check 3 Mode.

Step 3:

Turn the power switch

O

while

N

pressing the F key. The current A / D

convert value will appear on the display.

Step 4:

Press the

T

ARE

key for

proceeding the procedure steps. Allow

that "

Lin CAL

Step 5:

Press the

" appears on the display.

key. Allow that

T

ARE

"

Step 6:

"

Step 7:

" appears on the display.

ZEro

Press the

HALF

" appears on the display.

Carefully place an adequate size

key. Allow that

T

ARE

of the adjusting weight A on the weighing

pan. See the Adjusting Masses Chart.

434-SH-e-971040

Page 41

27.2 Adjusting Masses Chart

Model Adjusting Mass Size

A - Half Size B - Full Size

KERN 434-23

KERN 434-33

KERN 434-37

150 g 300 g

250 g 500 g

1500 g 3000 g

Step 8:

"

FULL

" appears on the display.

Step 9:

Press the

Carefully place an adequate size

key. Allow that

T

ARE

of the adjusting mass B on the weighing

pan. See the Adjusting Masses Chart.

Step 10:

"

PASS

" appears on the display.

Press the

key. Allow that

T

ARE

The above procedure is successfully

completed.

If "

CAL Err

" appears, then check to make

certain the procedure was followed

correctly including proper size adjusting

mass.

434-SH-e-9710 41

Page 42

28 Span Adjusting

The balance should be adjusted for span when it is first installed, any time it is

moved or bumped, whenever the ambient temperature changes by more than

3° C, and additionally every 30 days or so. For this adjusting procedure, please

use a high quality, non-magnetic, metric, stainless steel "Standard Mass" that

is OIML Class F2 or better.

28.1 Adjusting Masses Chart

Model Adjusting Masses

A B

KERN 434-23

KERN 434-33

KERN 434-37

300 g 200 g

500 g 300 g

3000 g 2000 g

Step 1:

The balance should be fully

warmed-up (plugged in for 30 minutes)

and all of the Best Conditions for

Weighing (page 7) should be met.

Step 2:

Reset Dip Switch 2 to the Check

0 Mode (normal weighing).

Step 3:

until

Step 4:

Continuously press the F key

"CAL"

appears on the display.

Press the

key. Allow that

T

ARE

"CAL 0"

Step 5:

appears on the display.

Press the

key. The balance

T

ARE

automatically sets Zero.

Do not disturb the balance when pressing

T

ARE

key.

the

434-SH-e-971042

Page 43

(In case of KERN 434-37)

Step 6:

the appropriate size adjusting masses.

Carefully place the adjusting masses on

the weighing pan.

Step 7:

Step 8:

adjusting mass A size as same as a full

capacity value. However, if unfortunately

you have limited numbers of the adjusting

mass, then choose this secondary

procedure as follows the adjusting mass

B size.

The balanced will then request

Press the U key.

It is better to place an adequate

Step 9: "PASS"

when adjusting is complete.

appears on the display

434-SH-e-9710 43

Page 44

28.2 Adjusting Mass Tolerance Collection

If users desire to request for you to readjust KERN 434 balances by standard

masses, it is common to know that Standard Masses have always been

certified with an exact tolerance by your local Measurement Authority, then

readjust the span of the KERN 434 balances with this exact tolerance as

follows the below additional procedures.

Step 1:

until

Step 2:

Continuously press the F key

"CAL"

appears on the display.

Press the U key. Allow the

deviation number appear on the display.

Proceed to readjust a deviation value as

calculation of programmed adjusting

value - true value of the standard mass.

For instance, in case of KERN 434-37,

programmed adjusting value is 2000.00 g

and true value of the standard mass is

1999.85 g (you have to round off the

numeric figures below than 1 mg

readings). The deviation is + 0.15 g equal

to programmed deviation 15.

Step 3:

Press continuously the U key for

resetting the deviation value. Maximum

setting value is up to ± 25 deviation value.

Step 4:

If setting value is - 15, then press

the P key. Minus polarity will appear on

the display for resetting negative values.

Step 5:

Press the

setting. Allow

"CAL 0"

key for this

T

ARE

to appear on the

display. Then this procedure is complete.

Follow the same steps of the span

adjusting procedure.

434-SH-e-971044

Page 45

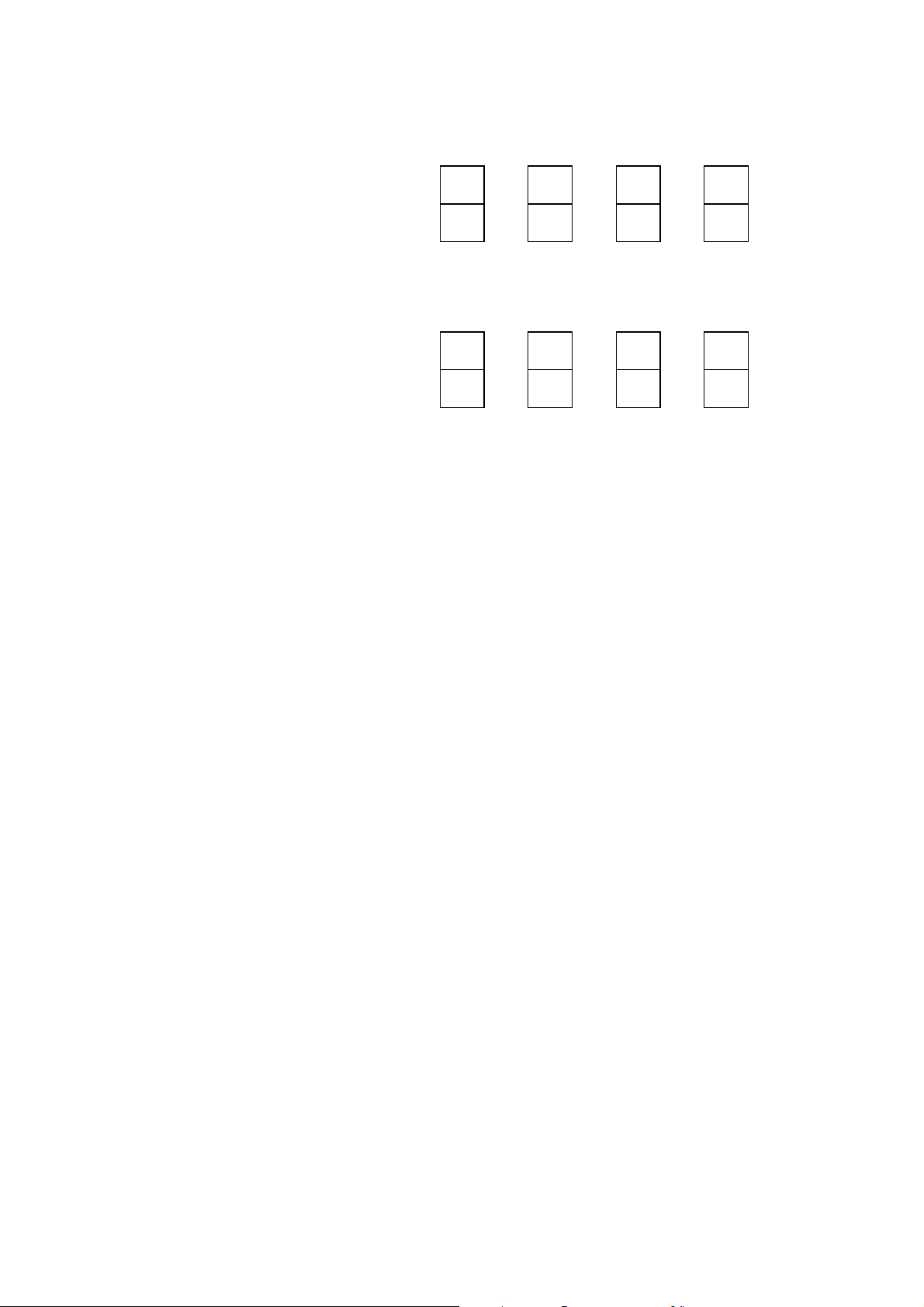

28.3 Disable the Span Adjusting Function

If the user does not require to have the adjusting function on KERN 434

balances, then simply reset a combination of the dip switches to disable this

function.

Dip Switch

1234

Step 1:

Step 2:

ννν

Off

On

ν

Open the top case, and allow A / D counter has been set to be Check 0

Mode (see Inner A / C Counter Check Mode, page 19).

Reset No. 4 of the dip switch has to be

O

.

N

434-SH-e-9710 45

Page 46

29 Cornerload Adjustment

Since the weighing pan is connected to the balance through one central point,

as you move away from the centre toward the outer rim of the pan, mechanical

distortions can occur, thus reducing the balance’s accuracy. Cornerload

Adjustment is performed to compensate for the problem.

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Step 6:

Step 7:

The balance must be fully warmed-up (plugged in for 30 minutes) before

starting.

Remove the top case (see Disassembly / Assembly page 21 - 24).

Replace the weighing pan.

Make certain that the balance is level.

Plug the AC adapter into the power source.

Press the

ON/O

key to get a normal weighing display (Check 0 Mode).

FF

Place the appropriate Cornerload Adjustment Mass in the centre of the

weighing pan (Point '). Place it around the pan. When using the draft

shield, make certain that it does not touch the pan.

29.1 Cornerload Adjustment Masses

Model Masses

KERN 434-23

KERN 434-33

KERN 434-37

Step 8:

Step 9:

Press the

Move the Cornerload Mass to Point ( and make a note of the display

T

ARE

key.

150 g

250 g

1500 g

reading.

434-SH-e-971046

Page 47

Step 11:

Move the Cornerload Mass to

Point ) and make a note of the display

reading.

Step 12:

Compare the absolute values

(ignore "+" or "-" signs) of the display

readings at Point ( and Point ) and

determine which is the greater deviation

from zero. The side that is greater must

be adjusted first. For example, if you get

results similar to those left, then Point

(

must be adjusted.

Step 13:

Make the adjustment by slightly

turning the appropriate Adjustment Screw

shown left with a box driver (Screw B to

adjust Point ) result and Screw A to

adjust Point ( result). When the result is

positive, "+", like the Point ( above, turn

the screw counter-clockwise. When

negative, "-", turn clockwise.

Step 14:

Repeat Steps 7 to 13 until both

Point ( and ) display zero ± 3

deviations.

Step 15:

push the

Place the mass at Point ' and

key. Check Points ( to

T

ARE

*

and ) to + as diagonal to be certain that

they are all at Zero ± 3 deviations.

434-SH-e-9710 47

Page 48

30 Electronic Fault Finding

The following procedures are used to detect and repair damage to the

Electronic Unit. Before proceeding with any of the repair procedures below, it

is advisable to make a thorough visual check of the Electronic Unit. Look for

dirt or other foreign objects throughout the balance. Check for objects

touching the circuitry, broken circuit paths, grounding, solder dry joints or any

other damage to the P.C. Boards.

30.1 Power Check

Fuse:

for touching objects. Also check the power supply electronics.

AD Adapter:

before shipment. If you find that the AC adapter is providing too little voltage or that it

generates irregular heat, check the attached voltage label to make sure the proper

voltage for your local power.

30.2 EEPROM Check

If the EEPROM (Electronic Erasable Programmable Read Only Memory) has

been lost, the balance will not show the normal weighing display when the

power switch is turned on. One of the following three messages will appear:

If the fuse (0.5 AMP) keeps blowing, there is a short circuit. Check the circuitry

The proper voltage AC adapter for your local power supply is provided

434-SH-e-971048

Page 49

Step 1:

Attempt to restore the linearity program into EEPROM by using the

procedures given in the Linearity Adjusting section on page 41.

Step 2:

30.3 Voltage Check

There are a number of voltage checks that can be carried out on the P.C.

Boards for pinpointing faulty electronics. The main checking points (1A, 2A,

3A, 4A, 5A) are on the power circuit MJ-3. Always check the voltage range first.

Other points are followed by listed numbers on the Electronic Fault Finding

Chart (page 47) and attached Circuit Diagrams (hereafter).

If the above procedure does not solve the problem, then replace the

EEPROM IC chip (IC 8).

434-SH-e-9710 49

Page 50

31 Electronic Fault Finding Charts

434-SH-e-971050

Page 51

434-SH-e-9710 51

Page 52

434-SH-e-971052

Page 53

434-SH-e-9710 53

Page 54

434-SH-e-971054

Page 55

32 Wave Form Check

If everything is correct in the Electronic Fault Finding Chart but the displayed

value is still incorrect, then either the CPU, the EEPROM or the SCA is at fault.

We will be able to tell by the wave form that is generated during testing. See

the Wave Form Table for the testing points. If an incorrect wave form is found,

then replace the unit that is the generator of the signal.

We recommend to use an oscilloscope (measuring capacity more than DC 100

MHz) and a digital tester (readability is 0.1

µµµµ

A).

P.C.B. No. Location Pinpoint No. Wave Form

1D

2D

3D

4D

5D

1C

2C

3C

9C

10C

MJ-1

MJ-1

IC 10 pin 3

IC 10 pin 5

CN 4 pin 12

CN 4 pin13

CN 4 pin 11

IC 11 pin 4

IC 11 pin 3

IC 11 pin 2

Resistor 37

Resistor 38

MJ-1 IC 13 pin 2 4C

MJ-1 Transistor 14 11C

434-SH-e-9710 55

Page 56

P.C.B. No. Location Pinpoint No. Wave Form

IC 13 pin 3

MJ-1

MJ-3 IC 1 1A

IC 12 pin 7

IC 12 pin 14

IC 12 pin 8

IC 11 pin 1 12C

Condenser 6 2A

5C

6C

7C

8C

Condenser

73A

Diode 1

Diode 2

4A

5A

434-SH-e-971056

Page 57

33 RS-232 C Interface

The data transmission RS-232 C Interface allows the user to use KERN 434

balances in conjunction with a computer, printer or other peripheral device.

The Interface circuit is already mounted in the balance as a standard

accessory.

Please read the following section and the instruction manuals of related

equipment before using this device. The RS-232 C Interface is designed for

exclusive use on KERN Balances and peripheral equipment designed by or

recommended by KERN & Sohn GmbH. Use of this Interface with any other

type of equipment is solely the responsibility of the user.

33.1 Interface Specifications

Type

Method

Speed

System

Signal

RS-232 C

Half Duplex Transmission

1200, 2400, 4800 BPS

Asynchronous system

8 bit length, non-parity, 1 Start bit, 1 Stop bit

7 bit length, even-parity, 1 Start bit, 1 Stop bit

434-SH-e-9710 57

Page 58

Configuration of Receptacle pins

Plug: Circle Type

Miniature connector

TCP8580 Type

Receptacle: Circle Type

Miniature connector

TCS75850-01-101

434-SH-e-971058

Page 59

33.2 Output Format

1. Method

±±±±

9 characters decimal point inclusive

Polarity Unit

Total:

Unit I:

Unit II:

g:

14 characters

Space or unit

Non-stable data

Gram & other units

IIICRLF

2. Example, data output

Gram weighing

+ 3000.00 gCRLF

Percent weighing

+ 100.00 %CRLF

Piece counting

+100PCCRLF

434-SH-e-9710 59

Page 60

3. Example, data output

Gram weighing

+.CRLF

The other weighing units

+CRLF

4. There will be no output when the balance is under following conditions:

The function data is being displayed.

Π

"All segments" display is on.

Π

The adjusting mark is being displayed.

Π

The stand-by mark is being displayed.

Π

The piece counting & percent weighing marks are being displayed.

Π

33.3 Output Data Mode

(Out 1)

(Out 2)

Transmits one data upon the print command when the balance is

stabilised.

Step 1:

Step 2:

Step 3:

Transmits one data upon the print command as soon as the balance has

stabilised.

Step 1:

Step 2:

Place a sample on the weighing pan.

Allow reading to stabilise.

Press the P key. The balance will output one data.

Place a sample on the weighing pan.

Press the P key. The balance will output one data as soon as the

reading has stabilised.

434-SH-e-971060

Page 61

(Out 3)

Transmits one data upon the print command even if the balance has not

stabilised.

(Out 4)

(Out 5)

Step 1:

Step 2:

Place a sample on the weighing pan.

Press the P key. The balance will output one data even if the

reading has not stabilised.

Automatically transmits one data when the balance has stabilised.

Step 1:

Step 2:

Place a sample on the weighing pan.

When the reading stabilises the balance will automatically output

one data without pressing the P key.

Step 3:

Step 4:

Remove the sample and place another sample on the pan.

The balance will automatically output another data after the

reading has stabilised.

Automatically transmits all data regardless of whether the balance has

stabilised or not.

Step 1:

Place a sample on the weighing pan. The balance will

automatically output all data.

33.4 External Control Commands

The command (ASCII) will be transmitted into the balance through the miniature

connector No.3 pin when pressing the appropriate code on the peripheral keyboard.

Command (ASCII) Functions

"D"

"Z"

"R"

"F"

Functions the same as pressing the P key.

Functions the same as pressing the T

ARE

Functions the same as pressing the U key.

Functions the same as pressing the F key.

key.

434-SH-e-9710 61

Page 62

33.5 Cabling Diagrams

For connecting a computer or a peripheral device to the balance.

434-SH-e-971062

Page 63

34 Installation of the Air Shield Case (OMJ-2 Option)

We recommend the installation of an air shield case whenever your operation

will be held under unstable weighing conditions.

Remove the weighing pan and the pan

support from the balance.

Loosen the 4 screws on top of the

balance case.

Remove the dust ring from the top case.

Install the Air Shield Case by placing it

squarely on the top of the balance.

Replace the dust ring on top of the air

shield under panel.

Replace only the 2 outside screws and

tighten them snugly into place.

Replace the weighing pan and the pan

support.

434-SH-e-9710 63

Page 64

35 Troubleshooting

Problem Research Cause Possible Solution

A) No display when

plug AC adapter into

power.

B) No display after

count display when

plug AC adapter into

power.

C) Error message

display "Error 3"

when plug AC

adapter into power.

(1) Problem with check

point 4A, 5A voltage

on MJ-3 P.C.B.

Before checkin g mu st

disconnect CN 1

connector.

(2) Problem with check

point 1A, 2A, 3A when

correct voltage on

check point 4A, 5A on

MJ-3 P.C.B. Before

checking must

disconnect CN 1

connector.

(3) No display when

check mode 1.

(4) Problem with check

point 1D on MJ-1

P.C.B.

(5) Problem with check

point 2D on MJ-1

P.C.B.

(6) No signal at check

point 3D, 4D on MJ-1

P.C.B.

(7) No signal at check

point 5D on MJ-1

P.C.B.

(1) No display of co rrect

data when check

mode 1.

(1) Correct display when

re-plug into power.

(2) Always error message

display "Erro r 3".

AC adapter malfunction.

Blown fuse.

Power Jack (JK)

malfunction.

MJ-3 P.C.B. malfunction.

IC 1, IC 2, IC 3

malfunction. C 5, C6, C7

malfunction or D3, D4,

D5 malfunction on MJ-3

P.C.B.

Power cable malfunction.

Disconnect power cable.

Disconnect display cable.

Quarts malfunction. Replace the defective

IC 10 malfunction. Replace the defective

IC 5 malfunction. Replace the defective

IC 6 malfunction. Replace the defective

IC 6 malfunction on MJ-1

P.C.B.

IC 9 malfunction on MJ-1

P.C.B.

IC 8 malfunction on MJ-1

P.C.B.

Replace the defective

parts.

Replace the defective

parts.

Replace the new parts.

Re-plug the power cable.

Re-plug the display cable.

parts.

parts.

parts.

parts.

Replace the defective

parts.

Replace the defective

parts.

Replace the defective

parts.

434-SH-e-971064

Page 65

Problem Research Cause Possible Solution

D) Continuous flashing

display after all

segment line when

plug into power

E) "+." or "-." appears

after all segment line

when AC adapter

was plugged.

(3) No continuous error

message.

(1) Check whether zero

display is unsteady

after pushing down

the weighing pan to

end.

(2) Problem with check

point 2A, 3A on MJ-3

P.C.B.

(3) No signal at check

point 5B.

(4) No triangle wave at

check point 4B.

(1) Problem with voltage

at check point 2A, 3A

on MJ-3 P.C.B.

(2) Cable disconnection. Disconnect Photo sensor

(3) "CAL Err" appears A / D count value is

(4) Visual check. Object attaching weighing

(5) Problem with voltage

at check point 1B, 2B

or 3B on MJ-1 P.C.B.

Caused by electronic

noise.

Program data is unstable

by draft, vibration, etc.

Dust cover attach ing

weighing pan.

Power supply is

fluctuated.

AC adapter malfunction.

IC 2, IC 3 malfunction on

MJ-3 P.C.B.

D1, D2 malfunction on

MJ-3 P.C.B.

C3, C4 malfunction on

MJ-3 P.C.B.

IC 6 (SCA) malfunction

on MJ-1 P.C.B.

Tr 7, Tr8, C 13

malfunction on MJ-1.

Same as D) 2. Same as D) 2.

cable.

wrong.

Linearity program is

wrong.

pan.

Defective plate bearing or

coupling link.

ZD, IC 1, IC 2, Tr 1, Tr 2

malfunction.

Attach a win d shi el d case

on the balance.

Install the balance on an

anti-vibration table.

Set up the dust cover

again.

Replace AC adapter.

Replace the defective

parts.

Replace the defective

parts.

Replace the defective

parts.

Reconnect the cable

again.

Recheck the A / D count

value.

Restore the correct

linearity program.

Clean around the

weighing pan.

Replace the defective

parts.

Replace the defective

parts.

434-SH-e-9710 65

Page 66

Problem Research Cause Possible Solution

F) Irregular span

adjusting.

(6) A / D count value at

Check 3 Mode is

"0000000" or

"3884160"

(7) Problem with TP 1,

TP 2.

(1) Problem with A / D

count value at Check

2 Mode.

(2) No signal at check

point 11C.

(3) Problem with signal at

check point 1C, 2C,

3C.

Defective plate bearings

or coupling link.

Broken wire of force coil.

Defective photo sensor.

IC 3 malfunction on MJ-1

P.C.B.

IC 4 malfunction on MJ-1

P.C.B.

Broken wire of

temperature sensor or

disconnecting the

connector.

Problem with IC 10 on

MJ-1 P.C.B.

Problem with IC 11, IC

13.

Replace the defective

parts.

Replace the defective

parts.

Replace the defective

parts.

Resolder the wire or

reconnecting the

connector.

G) When increasing

load on the weighing

pan, display does

not allow the

corresponding

results in half way.

H) No corresponding

results when

loading on the

weighing pan.

(4) Problem with voltage

at check point 5C, 6C,

7C, 8C.

(5) Problem with voltage

at check point 4C.

(6) Recheck plate

bearings or coupling

link.

(1) No electricity into forth

coil wire.

(1) Problem with AC

adapter.

Problem with IC 12, Tr

11, Tr 12.

Problem with Tr 13, Tr

14, Tr 15.

Problem with plate

bearings or coupling link.

Broken wire of the forth

coil.

Problem with Tr 3, Tr 4,

Tr 5, Tr 6.

Misuse of the wrong

voltage AC adapter.

Replace the defective

parts.

Replace the defective

parts.

Replace the defective

parts.

Replace a new AC

adapter.

434-SH-e-971066

Page 67

Problem Research Cause Possible Solution

I) Very poor

reproducibility.

(1) Recheck weighing

condition for effection

of any vibration or air

draft.

(2) Unstable installation

of the balance.

Air draft (by air condition

or by vibration which

caused by somebody

walking near the

balance).

Vibration (caused by

machine operation or car

moving outside).

Surface of the balance

table is not completely

flat.

Attach Air Shield Case on

the balance.

Replace the balance

somewhere in stable

condition and on antivibration table.

434-SH-e-9710 67

Page 68

36 KERN 434 Series Parts List

No. Description Qty 434-23 434-33 434-37

101 Pan holder (type 1) 1 325013 325013 - 102 Packing cushion (left) 1 325010 325010 325010

103 Outer packing case 1 325009 325009 325009

104 Packing cushion (right) 1 325011 325011 325011

105 Shipping lock spacer 1 211013 211013 - 106 Shipping lock 1 240232 240232 240232

108 Pan holder (type 2) 1 - - - - 325014

109 AC adapter box 1 325012 325012 325012

111 AC adapter (220 – 240 V) 1 122107 122107 122107

201 Weighing pan 1 230205 230205 - 203 Pan support 1 240210 240210 - 204 Pan support peg 1 240405 240405 - 205 Weighing pan 1 - - - - 210202

207 Pan support 1 - - - - 240246

208 Pan support peg 1 - - - - 240406

211 Dust ring 1 240238 240238 240238

212 Dust cover 1 210906 210906 210906

213 Hook connection 1 210712 210712 210712

214 Underweighing hook 1 210712 210712 210712

301 Panel keyboard 1 121945 121945 121945

302 Temperature sensor cable 1 123015 123015 123015

303 Power cable 1 123009 123009 123009

304 Display board 1 130109-2 130110-2 130111-2

305 Display board guide 2 210815 210815 210815

306 Display board cable 1 123010 123010 123010

307 Photo sensor cable 1 123011 123011 123011

308 Main circuit board 1 130109-1 130110-1 130111-1

310 Case shaft 1 210463 210463 210463

311 Bed 1 240103 240103 240103

312 Adjustable legs 2 210809 210809 210809

434-SH-e-971068

Page 69

No. Description Qty 434-23 434-33 434-37

315 Underweighing cap 2 210813 210813 210813

317 Circuit board stand (A) 2 210464 210464 210464

318 Circuit board stand (B) 2 210465 210465 210465

319 Spirit level washer 1 211106 211106 211106

320 Spirit level 1 211121 211121 211121

322 Data output board 1 130109-4 130110-4 130111-4

323 Rear socket plate (right) 1 210329 210329 210329

325 Data output cable 1 123009 123009 123009

326 Power circuit board 1 130109-3 130110-3 130111-3

327 Rear socket plate (left) 1 210330 210330 210330

329 Top case 1 210812 210812 210812

330 Spirit level window 1 211010 211010 211010

402 Transducer shield (upper) 1 210328 210328 210328

403 Magnet cover 1 240332 240332 240332

404 Upper parallel guide 1 210506 210506 210508

405 Parallel plate bearing 8 211214 211214 211215

407 Force coil board 1 120114 120114 120114

409 Beam plate bearing 2 2112166 2112166 211214

414 Beam extension piece 1 210239 210239 210239

415 Extension piece spacer 1 210470 210470 210470

419 Short wire (silver) 3 113107 113107 113107

420 Photo sensor board 1 120113 120113 120113

429 Suspension spring 1 210717 210717 210718

431 Coupling link 1 211204 211204 211205

432 Lower parallel guide 1 210507 210507 210509

434 Corner adjustment spring 2 210715 210715 210715

435 Corner adjust screw (B) 2 210467 210467 210467

436 Corner adjust screw (A) 2 210466 210466 210466

437 Beam stopper spring 1 210716 210716 210716

438 Beam stopper 1 241011 241011 241011

440 Force coil bobbin 1 251506 251506 251506

441 Beam counter weight 0-3 210473 210473 210473

444 Plate bearing spacer 16 - - - - 210472

434-SH-e-9710 69

Page 70

No. Description Qty 434-23 434-33 434-37

447 Temperature sensor cable 1 123015 123015 123015

448 Balance weight 1 211634 211634 211634

451 Coupling link spacer 2 210398 210398 210398

453 Transducer shield (lower) 1 240397 240397 240397

500 434 series complete jig set 1 310102 310102 310102

501 Force co il jig 1 - - - - - 502 Beam jig 2 - - - - - 503 Suspension jig 2 - - - - - 505 Left positioning jig 1 - - - - - 506 Right positioning jig 1 - - - - - 507 Beam stopper jig 1 - - - - - -

434-SH-e-971070

Page 71

37 Balance drawings

434-SH-e-9710 71

Page 72

434-SH-e-971072

Page 73

434-SH-e-9710 73

Page 74

434-SH-e-971074

Page 75

434-SH-e-9710 75

Loading...

Loading...