Page 1

OPERATOR’S MANUAL

KLN 750W

PROGRAMMABLE D-C POWER SUPPLY

1U HALF RACK

KEPCO INC.

An ISO 9001 Company.

POWER SUPPLY

ORDER NO.

IMPORTANT NOTES:

1) This manual is valid for the following Firmware Versions:

FIRMWARE VERSION NOTE.

1.60 and higher

2) A Change Page may be included at the end of the manual. All applicable changes and

revision number changes are documented with reference to the equipment serial numbers. Before using this Instruction Manual, check your equipment firmware version number to identify your model. If in doubt, contact your nearest Kepco Representative, or the

Kepco Documentation Office in New York, (718) 461-7000, requesting the correct revision

for your particular model and firmware version number.

3) The contents of this manual are protected by copyright. Reproduction of any part can be

made only with the specific written permission of Kepco, Inc.

Data subject to change without notice.

MODEL

KLN 750W

©2014, KEPCO, INC

P/N 243-1339-r4a

KEPCO, INC. ! 131-38 SANFORD AVENUE ! FLUSHING, NY. 11355 U.S.A. ! TEL (718) 461-7000 ! FAX (718) 767-1102

email: hq@kepcopower.com ! World Wide Web: http://www.kepcopower.com

KEPCO®

THE POWER SUPPLIER™

Page 2

Page 3

OPERATOR

SAFETY INSTRUCTIONS

Read these safety instructions, as well as the applicable installation and operating instructions contained in

this manual before using the power supply.

WARNING

Do not touch the output terminals. The output is dangerous. Electric shock can cause injury or death.

Do not remove the cover or disassemble the unit. There are no operator serviceable components or

adjustments inside the unit. High voltage components inside the unit can cause serious injury even with

input power disconnected.

Service must be referred to authorized personnel. Using the power supply in a manner not specified by

Kepco. Inc. may impair the protection provided by the power supply. Observe all safety precautions noted

throughout this manual. Table 1-5 lists symbols used on the power supply or in this manual where applicable.

KLN 750W/ 032614 A

Page 4

Page 5

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Specifications .......................................................................................................................................... 1-2

1.4 Local Control ........................................................................................................................................... 1-7

1.5 Remote Control ....................................................................................................................................... 1-7

1.6 Analog Control......................................................................................................................................... 1-8

1.7 Features .................................................................................................................................................. 1-8

1.7.1 Digital Calibration............................................................................................................................... 1-8

1.7.2 Protection........................................................................................................................................... 1-8

1.7.3 Saving and Recalling Settings........................................................................................................... 1-8

1.7.4 Parallel and Series Configurations .................................................................................................... 1-8

1.7.5 Miscellaneous Features..................................................................................................................... 1-8

1.8 Equipment Supplied ................................................................................................................................ 1-9

1.9 Accessories ............................................................................................................................................. 1-9

1.10 Safety ...................................................................................................................................................... 1-10

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection ....................................................................................................................... 2-1

2.2 Terminations and Controls ...................................................................................................................... 2-1

2.3 Preliminary Operational Check................................................................................................................ 2-4

2.4 Installation ............................................................................................................................................... 2-5

2.4.1 Rack Mounting................................................................................................................................... 2-5

2.4.1.1 Mounting One 1/2-rack Unit in 19-inch Rack ............................................................................... 2-5

2.4.1.2 Mounting Two 1/2-rack Units in 19-inch Rack ............................................................................. 2-6

2.5 Wiring Instructions................................................................................................................................... 2-6

2.5.1 Safety Grounding............................................................................................................................... 2-7

2.5.2 Source Power Connections ............................................................................................................... 2-7

2.5.3 D-C Output Grounding....................................................................................................................... 2-7

2.5.4 Power Supply/Load Interface............................................................................................................. 2-8

2.5.5 Load Connection - General................................................................................................................ 2-8

2.5.6 Load Connection Using Local Sensing.............................................................................................. 2-9

2.5.7 Load Connection Using Remote Sensing.......................................................................................... 2-10

2.6 Cooling .................................................................................................................................................... 2-11

2.7 Setting up the unit ................................................................................................................................... 2-11

2.7.1 Setup for Local Operation.................................................................................................................. 2-11

2.7.2 Setup for Remote Operation via RS-485........................................................................................... 2-11

2.7.3 Setup for Remote Operation via GPIB............................................................................................... 2-12

2.7.4 Setup for Remote Operation via LAN ................................................................................................ 2-12

2.8 Multiple Unit Configurations .................................................................................................................... 2-12

2.8.1 Series Connections............................................................................................................................ 2-13

2.8.1.1 Series Connections Using Optional Series Connection Kit.......................................................... 2-13

2.8.2 Parallel Connections.......................................................................................................................... 2-14

2.8.2.1 Parallel Connections Using Optional Parallel Connection Kit ...................................................... 2-15

SECTION 3 - OPERATION

3.1 General.................................................................................................................................................... 3-1

3.2 Power Supply Basics............................................................................................................................... 3-1

3.2.1 Turning the Power Supply On............................................................................................................ 3-3

3.2.2 Menu Structure .................................................................................................................................. 3-5

3.3 Local Mode Operation ............................................................................................................................. 3-5

3.3.1 Setting Local/Remote Mode .............................................................................................................. 3-5

3.3.1.1 Front Panel Lockout..................................................................................................................... 3-7

3.3.2 Set Voltage or Overvoltage Protection (OVP) ................................................................................... 3-7

3.3.3 Set Current or Overcurrent Protection (OCP).................................................................................... 3-7

3.3.4 OVP/OVC Operation and Recovery .................................................................................................. 3-7

KLN 750W 032614 i

Page 6

TABLE OF CONTENTS

SECTION PAGE

3.3.5 Enabling/Disabling DC Output Power ............................................................................................... 3-8

3.3.6 Storing Power Supply Output Settings.............................................................................................. 3-8

3.3.7 Recalling Power Supply Output Settings .......................................................................................... 3-8

3.3.8 Output Mode (Voltage Set: Direct or Enter) ...................................................................................... 3-9

3.3.9 Power On Setting.............................................................................................................................. 3-9

3.3.10 Rise Time (Ramp up)........................................................................................................................ 3-9

3.3.11 Fall Time (Ramp Down) .................................................................................................................... 3-10

3.3.12 Memory Flag ..................................................................................................................................... 3-10

3.3.13 Beep.................................................................................................................................................. 3-10

3.3.14 Display Brightness ............................................................................................................................ 3-11

3.3.15 I/O Select .......................................................................................................................................... 3-11

3.3.16 RS-485 Baud Rate............................................................................................................................ 3-11

3.3.17 GPIB Address (GPIB Interface Only)................................................................................................ 3-12

3.3.18 RS-485 Address................................................................................................................................ 3-12

3.3.19 DHCP Function On/Off Control (LAN Interface Only)....................................................................... 3-12

3.3.20 Set 1st Part of IP Address (LAN Interface Only)............................................................................... 3-13

3.3.21 Set 2nd Part of IP Address (LAN Interface Only).............................................................................. 3-13

3.3.22 Set 3rd Part of IP Address (LAN Interface Only) .............................................................................. 3-13

3.3.23 Set 4th Part of IP Address (LAN Interface Only)............................................................................... 3-14

3.3.24 Parallel/Serial Master/Slave Setup ................................................................................................... 3-14

3.3.25 External Control of Output On/Off..................................................................................................... 3-14

3.3.26 Enable Voltage Control via Programming Control Port..................................................................... 3-14

3.3.27 Enable Current Control via Programming Control Port..................................................................... 3-15

3.3.28 Calibration Access ............................................................................................................................ 3-15

3.3.29 View Serial Number .......................................................................................................................... 3-15

3.3.30 View Firmware Version..................................................................................................................... 3-16

3.3.31 View Hardware Version .................................................................................................................... 3-16

3.3.32 View 1st Part of IP Address (LAN Interface Only) ............................................................................ 3-16

3.3.33 View 2nd Part of IP Address (LAN Interface Only) ........................................................................... 3-16

3.3.34 View 3rd Part of IP Address (LAN Interface Only) ............................................................................ 3-17

3.3.35 View 4th Part of IP Address (LAN Interface Only) ............................................................................ 3-17

3.3.36 View 1st Part of Subnet Mask Address (LAN Interface Only)........................................................... 3-17

3.3.37 View 2nd Part of Subnet Mask Address (LAN Interface Only).......................................................... 3-18

3.3.38 View 3rd Part of Subnet Mask Address (LAN Interface Only) .......................................................... 3-18

3.3.39 View 4th Part of Subnet Mask Address (LAN Interface Only)........................................................... 3-18

3.3.40 View 1st Part of MAC Address (LAN Interface Only)........................................................................ 3-18

3.3.41 View 2nd Part of MAC Address (LAN Interface Only)....................................................................... 3-19

3.3.42 View 3rd Part of MAC Address (LAN Interface Only) ....................................................................... 3-19

3.3.43 Reset................................................................................................................................................. 3-19

3.3.44 IP Address Reset .............................................................................................................................. 3-20

3.3.45 Viewing Error Codes......................................................................................................................... 3-20

3.4 Series/Parallel Operation........................................................................................................................ 3-20

3.4.1 Series Operation ............................................................................................................................... 3-20

3.4.2 Discontinuing Series Operation ........................................................................................................ 3-21

3.4.3 Parallel Operation ............................................................................................................................. 3-21

3.4.4 Discontinuing Parallel Operation....................................................................................................... 3-22

3.5 Analog Remote Mode Programming ...................................................................................................... 3-22

3.5.1 Remote Output On/off....................................................................................................................... 3-22

3.5.2 Remote Emergency Shutdown ......................................................................................................... 3-23

3.5.3 Remote Control of Output Voltage Using an analog signal .............................................................. 3-23

3.5.4 Remote Control of Output Current Using an analog signal............................................................... 3-23

3.5.5 Recalling Previously Stored Setting Using Programming Control Port ............................................. 3-23

3.5.6 Monitoring Output Status Using Programming Control Port ............................................................. 3-23

3.5.6.1 Monitor Output Voltage or Current.............................................................................................. 3-24

3.5.6.2 Monitor Unit Status...................................................................................................................... 3-24

ii KLN 750W 032614

Page 7

TABLE OF CONTENTS

SECTION PAGE

3.6 Digital Remote Mode Programming ........................................................................................................ 3-24

3.6.1 RS-485 Operation.............................................................................................................................. 3-25

3.6.2 GPIB Operation (If Option Installed) .................................................................................................. 3-25

3.6.2.1 IEEE 488 (GPIB) Bus Protocol .................................................................................................... 3-25

3.6.3 LAN Operation (If Option Installed).................................................................................................... 3-26

3.6.3.1 LAN Connection........................................................................................................................... 3-27

3.7 SCPI Programming ................................................................................................................................. 3-30

3.7.1 SCPI Messages ................................................................................................................................. 3-30

3.7.2 Common Commands/Queries ........................................................................................................... 3-30

3.7.3 SCPI Subsystem Command/query Structure .................................................................................... 3-30

3.7.3.1 Calibrate Subsystem.................................................................................................................... 3-30

3.7.3.2 Display Subsystem ...................................................................................................................... 3-31

3.7.3.3 Fetch Subsystem ......................................................................................................................... 3-31

3.7.3.4 Output Subsystem ....................................................................................................................... 3-31

3.7.3.5 Source Subsystem....................................................................................................................... 3-31

3.7.3.6 System Subsystem ...................................................................................................................... 3-31

3.7.4 Understanding The Command Structure ........................................................................................... 3-31

SECTION 4 - CALIBRATION

4.1 General.................................................................................................................................................... 4-1

4.2 Equipment Required................................................................................................................................ 4-1

4.3 Voltage Calibration Procedure ................................................................................................................ 4-1

4.4 Current Calibration Procedure................................................................................................................. 4-3

APPENDIX A - SCPI COMMON COMMAND/QUERY DEFINITIONS

A.2 *CLS — Clear Status Command ............................................................................................................ A-1

A.3 *IDN? — Identification Query ................................................................................................................. A-1

A.4 *OPC — Operation Complete Command............................................................................................... A-1

A.5 *OPC? — Operation Complete Query.................................................................................................... A-2

A.6 *RST — Reset Command ...................................................................................................................... A-2

A.7 *TST? — Self Test Query....................................................................................................................... A-2

APPENDIX B - SCPI COMMAND/QUERY DEFINITIONS

B.1 Introduction............................................................................................................................................. B-1

B.2 Numerical Values ................................................................................................................................... B-1

B.3 DISP:CONT

B.4 DISP:CONTrast? Query ........................................................................................................................ B-1

B.5 FETCh? Query ....................................................................................................................................... B-2

B.6 OUTP

B.7 OUTPut? Query ..................................................................................................................................... B-2

B.8 OUTP

B.9 OUTP

B.10 SOURce:CURRent Command .............................................................................................................. B-3

B.11 SOUR

B.12 SOUR

B.13 SOURce:CURRent:PROtection:LEVel? Query.................................................................................... B-3

B.14 SOUR

B.15 SOUR

B.16 SOUR

B.17 SOUR

B.18 SOURce:MEMory:CLS Command ........................................................................................................ B-4

B.19 SOUR

B.20 SOUR

rast Command.................................................................................................................... B-1

ut Command................................................................................................................................. B-2

ut:PON Command........................................................................................................................ B-2

ut:PON? Query............................................................................................................................. B-2

ce:CURRent? Query................................................................................................................... B-3

ce:CURRent:PROtection:LEVel Command ............................................................................... B-3

ce:LIST:DTIMe Command........................................................................................................... B-3

ce:LIST:DTIMe? Query ............................................................................................................... B-3

ce:LIST:RTIMe Command........................................................................................................... B-4

ce:LIST:RTIMe? Query ............................................................................................................... B-4

ce:MEMory:CURRent:X Command............................................................................................ B-4

ce:MEMory:CURRent:X? Query ................................................................................................ B-4

KLN 750W 032614 iii

Page 8

TABLE OF CONTENTS

SECTION PAGE

B.21 SOURce:MEMory:LIST:X? Query ......................................................................................................... B-4

B.22 SOURce:MEMory:RECall:X Command ................................................................................................ B-4

B.23 SOURce:MEMory:VOLTage:X Command ............................................................................................ B-5

B.24 SOUR

B.25 SOURce:VOLTage Command ............................................................................................................... B-5

B.26 SOURce:VOLTage? Query ................................................................................................................... B-5

B.27 SOUR

B.28 SOURce:VOLTage:LIMit:LOW? Query ................................................................................................. B-5

B.29 SOUR

B.30 SOURce:VOLTage:PROtection:LEVel? Query.................................................................................... B-6

B.31 SYSTem:BEEP Command ..................................................................................................................... B-6

B.32 SYST

B.33 SYSTem:COMMunicate:LAN:DHCP Command ................................................................................... B-6

B.34 SYSTem:COMMunicate:LAN:DHCP? Query........................................................................................ B-6

B.35 SYST

B.36 SYSTem:COMMunicate:LAN:GATEway? Query................................................................................. B-7

B.37 SYSTem:COMMunicate:LAN:IP Command.......................................................................................... B-7

B.38 SYST

B.39 SYSTem:COMMunicate:LAN:IPADdress Command........................................................................... B-7

B.40 SYSTem:COMMunicate:LAN:IPADdress? Query................................................................................ B-7

B.41 SYST

B.42 SYSTem:COMMunicate:LAN:MAC? Query.......................................................................................... B-8

B.43 SYSTem:COMMunicate:LAN:RESet Command .................................................................................. B-8

B.44 SYST

B.45 SYSTem:COMMunicate:LAN:SMAS? Query........................................................................................ B-8

B.46 SYSTem:COMMunicate:LAN:TELnet:PORT Command...................................................................... B-8

B.47 SYST

B.48 SYSTem:ERRor? Query ........................................................................................................................ B-9

B.49 SYSTem:KLOCk Command................................................................................................................... B-10

B.50 SYST

B.51 SYSTem:LOCal Command .................................................................................................................... B-10

B.52 SYSTem:REMote Command ................................................................................................................. B-10

B.53 SYST

ce:MEMory:VOLTage:X? Query ................................................................................................. B-5

ce:VOLTage:LIMit:LOW Command............................................................................................. B-5

ce:VOLTage:PROtection:LEVel Command................................................................................ B-6

em:BEEP? Query.......................................................................................................................... B-6

em:COMMunicate:LAN:GATEway Command ............................................................................ B-7

em:COMMunicate:LAN:IP? Query .............................................................................................. B-7

em:COMMunicate:LAN:MAC Command ..................................................................................... B-8

em:COMMunicate:LAN:SMAS Command ................................................................................... B-8

em:COMMunicate:LAN:TELnet:PORT? Query........................................................................... B-9

em:KLOCk? Query ....................................................................................................................... B-10

em:VERSion? Query .................................................................................................................... B-11

iv KLN 750W 032614

Page 9

LIST OF FIGURES

FIGURE TITLE PAGE

1-1 KLN 750W Power Supply, Automatic Crossover Characteristics ............................................................... 1-1

1-2 KLN 750W Power Supply, Outline Drawing (two units Mounted in Rack) .................................................. 1-6

2-1 KLN 750W Series Rear Panel .................................................................................................................... 2-1

2-2 RS-485 Port ................................................................................................................................................ 2-2

2-3 Programming Control Port .......................................................................................................................... 2-3

2-4 Mounting One KLN 750W Unit in 19-inch Rack .......................................................................................... 2-6

2-5 Load Connection Terminals for 6V - 150V Models ..................................................................................... 2-9

2-6 Load Connections, Local Sensing .............................................................................................................. 2-9

2-7 Load Wire Voltage Drop, Equivalent Schematic Diagram........................................................................... 2-10

2-8 Load Connections, Remote Sensing .......................................................................................................... 2-11

2-9 RS-485 Connections................................................................................................................................... 2-12

2-10 Series Connections Without Remote Sensing ............................................................................................ 2-13

2-11 Series Connections with Remote Sensing .................................................................................................. 2-13

2-12 Optional Series Connection Kit ................................................................................................................... 2-14

2-13 Parallel Connections Without Remote Sensing .......................................................................................... 2-14

2-14 Parallel Connections with Remote Sensing ................................................................................................ 2-15

2-15 Programming Control Port Connections for Parallel Operation .................................................................. 2-15

2-16 Optional Parallel Connector Board ............................................................................................................. 2-15

3-1 KLN 750W Series Front Panel.................................................................................................................... 3-1

3-2 7-Segment Display Characters ................................................................................................................... 3-3

3-3 Remote Control Using Programming Control Port and Optocoupler or Relay ............................................ 3-23

3-4 Programming Control Port Status Monitoring ............................................................................................. 3-24

3-5 Instrument Home page ............................................................................................................................... 3-27

3-6 IP Configuration .......................................................................................................................................... 3-28

3-7 Open HyperTerminal Connection ............................................................................................................... 3-28

3-8 Hyper terminal Properties ........................................................................................................................... 3-29

3-9 Hyper terminal ASCII Setup........................................................................................................................ 3-29

3-10 Tree Diagram of SCPI Commands Used with KLN 750W Power Supply ................................................... 3-32

4-1 Calibration Setup ........................................................................................................................................ 4-2

KLN 750W 032614

v

Page 10

LIST OF TABLES

TABLE TITLE PAGE

1-1 KLN 750 Watt Model Parameters ............................................................................................................... 1-2

1-2 KLN 750W General Specifications ............................................................................................................. 1-3

1-3 Equipment Supplied ................................................................................................................................... 1-9

1-4 Accessories ................................................................................................................................................ 1-9

1-5 Safety Symbols .......................................................................................................................................... 1-10

2-1 Rear Panel Connector Functions ............................................................................................................... 2-1

2-2 RS-485 Port Input/Output Pin Assignments ............................................................................................... 2-2

2-3 GPIB (IEEE 488) Port Input/Output Pin Assignments ................................................................................ 2-2

2-4 Programming Control Port I/O Pin Assignments ........................................................................................ 2-3

2-5 Maximum Load Wire Length for Voltage drop less than 1V ....................................................................... 2-10

3-1 Front Panel Controls and Indicators ........................................................................................................... 3-2

3-2 Factory Defaults ......................................................................................................................................... 3-4

3-3 Menu Functions .......................................................................................................................................... 3-6

3-4 IEEE 488 (GPIB) Bus Interface Functions ................................................................................................. 3-25

3-5 IEEE 488 (GPIB) Bus Command Mode Messages .................................................................................... 3-26

3-6 IEEE 488 (GPIB) Bus Data Mode Messages ............................................................................................. 3-26

3-7 VISA Resource String Corresponding to Interface ..................................................................................... 3-30

A-1 IEEE 488.2 Command/query Index ............................................................................................................A-1

B-1 SCPI Subsystem Command/query Index ...................................................................................................B-1

B-2 Error Codes ................................................................................................................................................B-9

vi KLN 750W SVC 032614

Page 11

1.1 SCOPE OF MANUAL

This manual contains instructions for the installation and operation of the KLN series of 750

Watt programmable, voltage and current stabilized d-c power supplies, hereafter referred to as

KLN 750W, from Kepco, Inc., Flushing, New York, U.S.A.

1.2 GENERAL DESCRIPTION

The KLN 750W power supply is a voltage and current stabilized d-c source with a sharp crossover between the constant voltage and constant current mode of operation. Eleven models are

offered, with rated d-c output voltage ranging from 6V to 600V and rated d-c output current ranging from 1.25A to 100A (see Table 1-1).

KLN 750W switching power supplies operate from wide range 100-240V a-c, 50/60 Hz input

source power and employ active power factor correction (PFC). Since there are no internal

adjustments, KLN 750W Power Supplies offer excellent output voltage/current stability and easy

calibration.

Output voltage and current are displayed on independent LED displays. Control of the KLN

750W can be either local, via the front panel controls and displays, or remote, using 1) either

analog signals (applied to the Programming Control Port), or 2) digital programming. Digital programming of standard models is via RS-485 communication bus. Optional IEEE 488.2 (GPIB)

and LAN interfaces are also available.

SECTION 1 - INTRODUCTION

KLN 750W output and readback are high resolution: 16 bits D/A to set output voltage and current, 24 bits A/D for readback of output voltage and current. These units feature a low temperature coefficient: Constant Voltage mode: 100ppm/°C, Constant Current mode: 300ppm/°C, and

built-in remote sensing with a maximum compensation of 5V.

The KLN 750W series is suitable for ATE automatic test, burn- in test and other applications that

require lots of testing power.

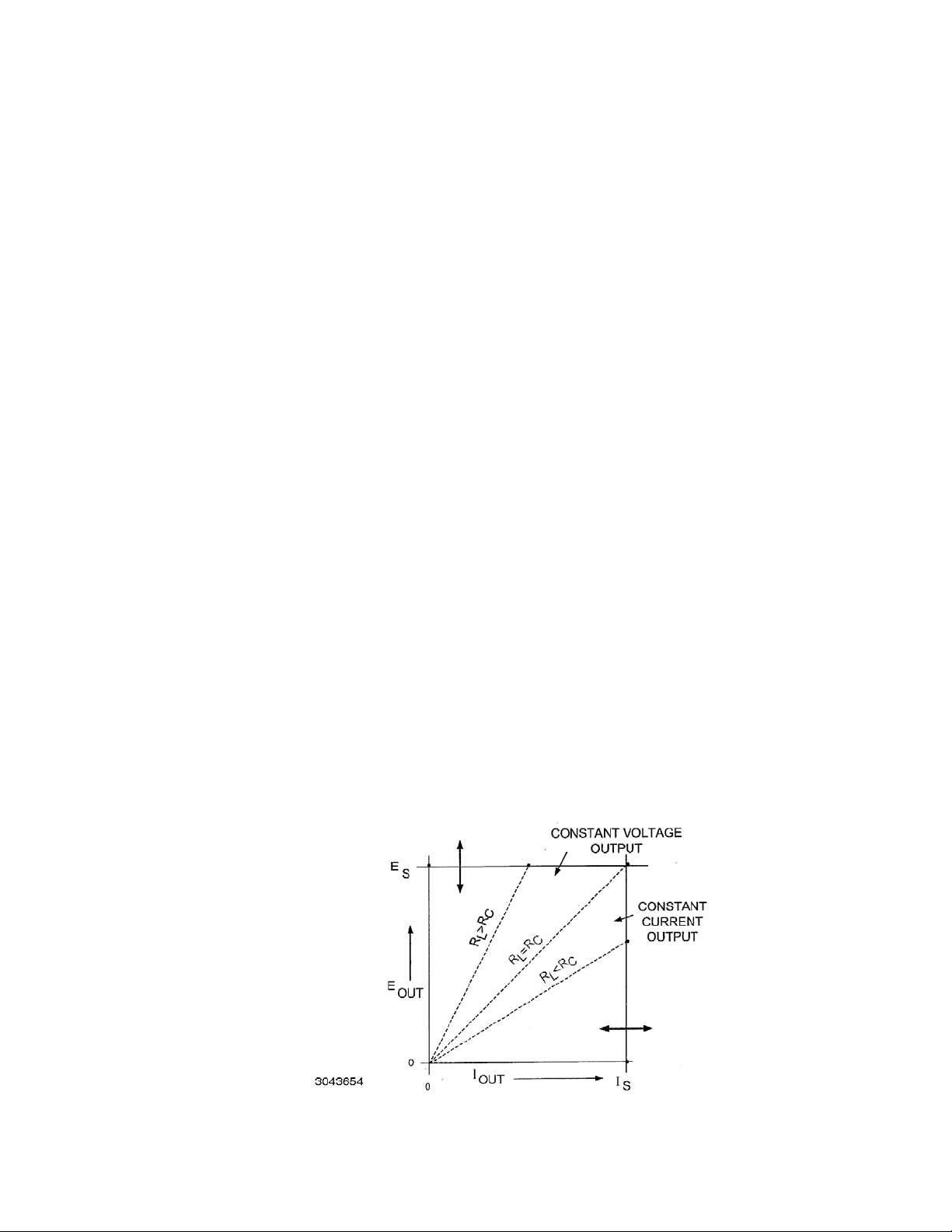

The KLN 750W power supply acts as a constant voltage source for comparatively large values

of load resistance, and as a constant current source for comparatively small values of load

resistance. The transition between these two modes of operation occurs automatically at a “critical” or “crossover” value of load resistance Rc = Es/Is, where Es is the voltage control setting

and Is is the current control setting (see Figure 1-1).

FIGURE 1-1. KLN 750W POWER SUPPLY, AUTOMATIC CROSSOVER CHARACTERISTICS

KLN 750W 032614 1-1

Page 12

1.3 SPECIFICATIONS

Table 1-1 below indicates parameters that vary for different KLN 750W models; Table 1-2 lists

general specifications that apply to all KLN 750W models.

TABLE 1-1. KLN 750 WATT MODEL PARAMETERS

d-c Output Range

Constant

Model

(8)(9)(11)(12)

KLN 6-100 0 to 6 0 to 100 10 180 2.8 11 2.8 23 0.08 0.05 0.6 1

KLN 8-90 0 to 8 0 to 90 10 180 2.8 11 2.8 23 0.08 0.05 0.6 1

KLN 20-38 0 to 20 0 to 38 10 76 4 5.8 4 12.6 0.08 0.05 0.8 1

KLN 30-25 0 to 30 0 to 25 10 63 5 4.5 5 10 0.08 0.08 0.9 1.5

KLN 40-19 0 to 40 0 to 19 10 48 6 3.9 6 8.8 0.08 0.08 1 2

KLN 60-12.5 0 to 60 0 to 12.5 10 38 8 3.25 8 7.5 0.08 0.08 1.1 3

KLN 80-9.5 0 to 80 0 to 9.5 10 29 10 2.95 10 6.9 0.15 0.15 1.2 4

KLN 100-7.5 0 to 100 0 to 7.5 10 23 12 2.75 12 6.5 0.15 0.15 1.5 5

KLN 150-5 0 to 150 0 to 5 16 18 17 2.5 17 6 0.15 0.15 2 5

KLN 300-2.5 0 to 300 0 to 2.5 25 13 32 2.25 32 5.5 0.15 0.15 3 5

KLN 600-1.25 0 to 600 0 to 1.25 75 8 62 2.13 62 5.26 0.25 0.3 4 5

NOTES:

1. Actual output voltage should be

2. Actual output current should be

3. Measured when output is within 10%-100% of rated value; ripple bandwidth: 300kHz (rms), noise bandwidth: <20MHz (p-p).

4. For 6V model: measured when output voltage 2-6V and rated current; all other models measured when output 10-100% of rated voltage and rated

current.

5. Input voltage 100-240V a-c, 50/60Hz.

6. Constant input voltage and output from 10% of loading to full load.

7. With rated input, resistive load.

8. Rated power output with input 115V or 230V a-c

9. Specifications met after 30 minutes of operation, ambient temperature 23±5°C, humidity under 80% R. H, a-c input voltage ±5% of nominal, THD

≤2%, not using the remote compensation, not operating in series or parallel.

10. For example, the spec for KLN 6-100 line regulation and load regulation in CV mode is 0.05% + 2.8mV (or 6 x 0.0005 = ±3mV +2.8mV =5.8mV), so

line and load regulation are within 0.2mV to 5.8mV for the 6V model.

11. Add G suffix for models with optional GPIB interface, add E suffix for optional LAN interface.

12. Specifications subject to change without notice.

Vol tag e

(CV)

V d-c A d-c

Constant

Current

(1)

(CC)

(2)

≤0.1% of rated voltage when output voltage is set to zero.

≤0.1% of the rated current when output current is set to zero (resistive load).

Ripple

CV

mV

rms

(3)

Line Regulation

(4)

CC

mA

rms

CV CC

0.05%mV0.1%mV0.05%mV0.1%

(5)

Load Regulation

(6)

CV

CC

mV

(10)

Response Time

Full

(6)

Full

Load

Load

Up

Down

Sec Sec Sec V

(7)

No

Load

Down

Remote

Sense

Voltage

drop

(max.)

1-2 KLN 750W 032614

Page 13

TABLE 1-2. KLN 750W GENERAL SPECIFICATIONS

SPECIFICATION RATING/DESCRIPTION

INPUT CHARACTERISTICS

Input voltage 100~240Vac, 50/60Hz

127~373V d-c

Input current (Full load) 115Vac - 8.1A; 230V a-c - 4.1A

Inrush current 230Vac - 12.5A

Power Factor (PF) 0.99 (at 115V a-c, rated output)

(1)

OUTPUT CHARACTERISTICS

Type of Stabilizer Constant Voltage (CV)/Constant Current (CC),

Adjustment Range Voltage:

Current:

Protective functions Programmable overvoltage (OVP),

Protection setting range Overvoltage:

Overcurrent:

Remote Error Sense Compensation 5V max. (See Table 1-1.)

Parallel Operation Up to 5 units maximum, automatic load sharing

Series Operation 2 units maximum (total voltage must not exceed 600V)

Temperature. Coefficient Constant Voltage Mode,

Constant Current Mode:

automatic crossover

0 to 100% of rated voltage

0 to 100% of rated current

Programmable overcurrent (OCP),

Overtemperature (OTP),

Fuse blown

0% to 110% of rated voltage

10% to 110% of rated current

100ppm/°C of rated output voltage or current, after 30 minute warm-up

Temperature. Drift Constant Voltage Mode,

Constant Current Mode:

Transient response time Constant Voltage mode: 20V and under:

Efficiency 76% – 87%

Power Factor (PF) 0.99 (at 155/230 V a-c, rated output)

Isolation Voltage Input - Outputs:

Input - Ground:

Output - Ground (6V-150V)

Output - Ground (300V-600V)

0.05% of rated output voltage or current over 8hrs interval

following 30 minutes warm-up. Constant line, load and temperature.

≤1.5ms;

30V~100V:

150V~600V:

2000V a-c: 1 minute

2000V a-c: 1 minute

500V d-c, leakage current: 100

1200V d-c, leakage current: 100

≤1ms

≤2ms

µA

µA

PROGRAMMING CHARACTERISTICS - LOCAL

Display resolution Voltage and Current: 4 digits (setting and display)

Display setting accuracy Voltage:

Current:

Display reading accuracy Voltage:

Current:

(1) Connect (+) to L and (–) to N. Safety agency approvals apply to a-c input operation only.

(2) C = 1 count of the last displayed digit.

±0.1% ± 3C

±0.5% ± 3C

±0.2% ± 3C

±0.5% ± 3C

(2)

at rated voltage

(2)

at rated current

(2)

at rated voltage

(2)

at rated current

KLN 750W 032614 1-3

Page 14

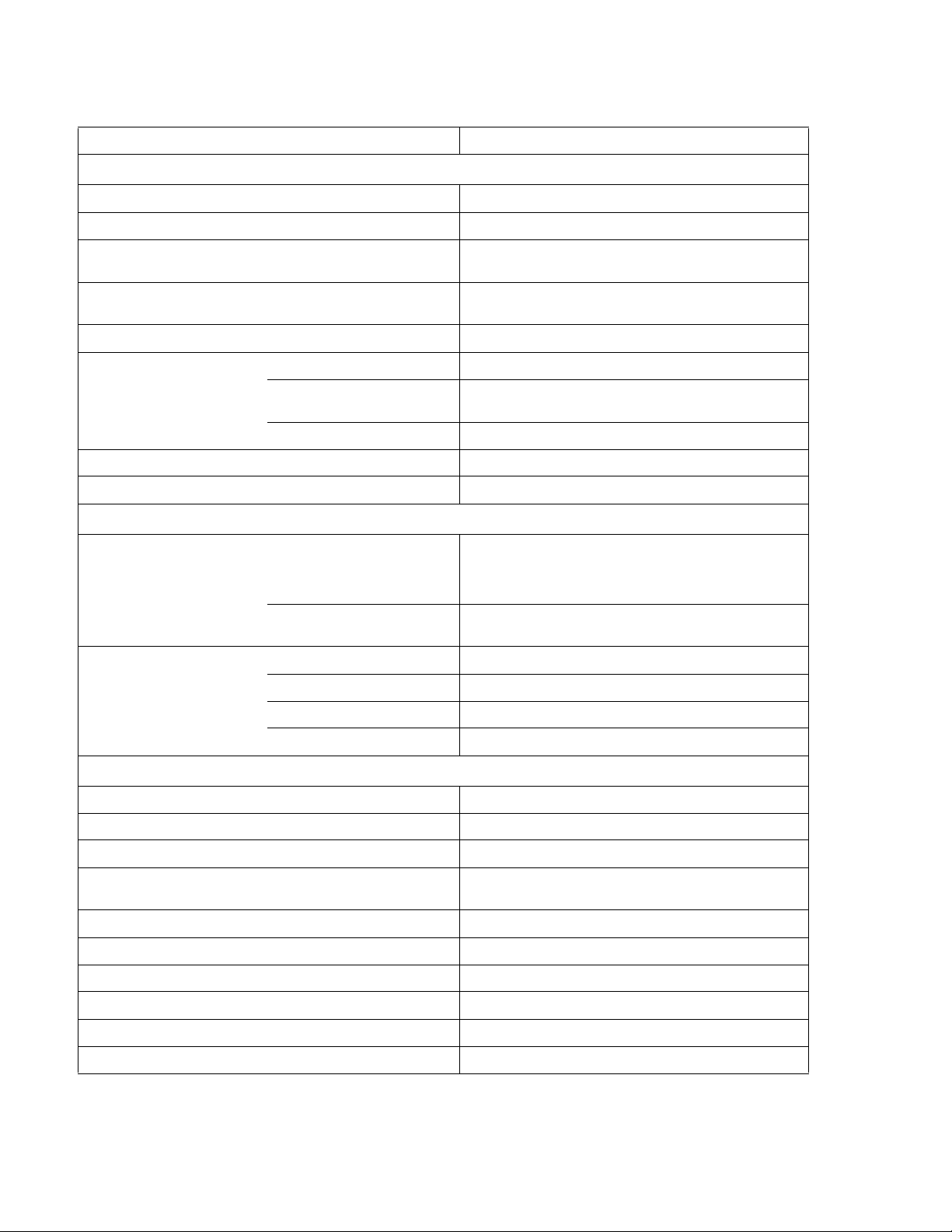

TABLE 1-2. KLN 750W GENERAL SPECIFICATIONS (CONTINUED)

SPECIFICATION RATING/DESCRIPTION

PROGRAMMING CHARACTERISTICS - DIGITAL

Command setting resolution ±0.002% of full scale

Command reading resolution ±0.002% of full scale

Command and D/A

setting accuracy

Command and A/D

Measurement accuracy

Command response time

Voltage:

Current:

Voltage:

Current:

±0.1% ± 3C

±0.5% ± 3C

±0.2% ± 2C

±0.5% ± 3C

≤20ms (After received)

(1)

at rated voltage

(1)

at rated current

(1)

at rated voltage (Average Measurement)

(1)

at rated current (Average Measurement)

(2)

RS-485 Digital Interface

(standard)

Max. effective control distance: 1000 meters.

GPIB Digital Interface Optional

LAN Digital Interface Optional

Max baud rate: 115,200

Max number of units

connected to bus:

254

PROGRAMMING CHARACTERISTICS - ANALOG

Analog setting accuracy

Constant Voltage mode (CV): Voltage:

Current:

Constant Current mode (CC): Voltage:

Current:

Analog monitor accuracy Rated voltage output: 10.00V ± 0.25V

Zero voltage output: 0.00V ± 0.25V

Rated current output: 10.00V ± 0.25V

Zero current output: 0.00V ± 0.25V

± 5%

± 5%

± 5%

± 5%

PHYSICAL CHARACTERISTICS

Weight Less than 11.2 lbs (5.1 Kg)

Dimensions W x H x D: 8.46" x 1.73" x 18.5" (215mm x 44mm x 470mm)

Source Power Connector IEC 320 inlet

Load Connections 6V to 100V models:

150V to 600V models:

Programming Control port 26-pin connector

SER IN port 2-position Euroblock (mating connector supplied)

Sense port 3-position Euroblock (mating connector supplied)

RS-485 port 3-position Euroblock (mating connector supplied)

LAN port (optional) RJ 45 connector

GPIB port (optional) Standard IEEE 488.2 GPIB connector

(1) C = 1 count of the last displayed digit.

(2) Programming time = Command response time + Output response time. The output response time differs for different models,

from 30mS ~ 200mS

± bus bars with protective cover

5-position Euroblock

1-4 KLN 750W 032614

Page 15

TABLE 1-2. KLN 750W GENERAL SPECIFICATIONS (CONTINUED)

SPECIFICATION RATING/DESCRIPTION

GENERAL (ENVIRONMENTAL) SPECIFICATIONS

Temperature Operating:

Storage:

Humidity Operating:

Storage:

Altitude 3000m max

Cooling Speed-Controlled Fan

Noise <70 dB (A)

EMC Standard EN 61326-1:2006

EMC Emissions (EN 61326-1) Conducted Disturbance: EN 55011:2007 +A2:2007 Class B

Radiated Disturbance: EN 55011:2007 +A2:2007 Class B

Harmonic Distortion: EN 61000-3-2:2006 Class A

Voltage Fluctuations

and Flicker:

EMC Immunity (EN 61326-1) Electrostatic Discharge (ESD): EN 61000-4-2:2009 Class B

Radiated RF Magnetic Field: EN 61000-4-3:2006 + A1:2008 + A2:2010 Class A

Electrical Fast Transients and

Bursts:

Surge: EN 61000-4-5:2006 Class B

Conducted Disturbance

Induced by RF Fields:

0 to 50°C (indoor use)

-20 to 70°C

30%~90% RH (no condensation)

10%~90% RH (no condensation)

EN 61000-3-3:2008 Section 5

EN 61000-4-4:2004 + A1:2010 Class B

EN 61000-4-6:2009, Class A

Voltage Dips and Short

Interruptions:

NOTE:

All specifications apply after power on for 30 minutes, ambient temperature: 23±5°C, Humidity: under 80% RH, AC Voltage: ±5%,

Frequency: ±5%.

EN 61000-4-11:2004, Class C

KLN 750W 032614 1-5

Page 16

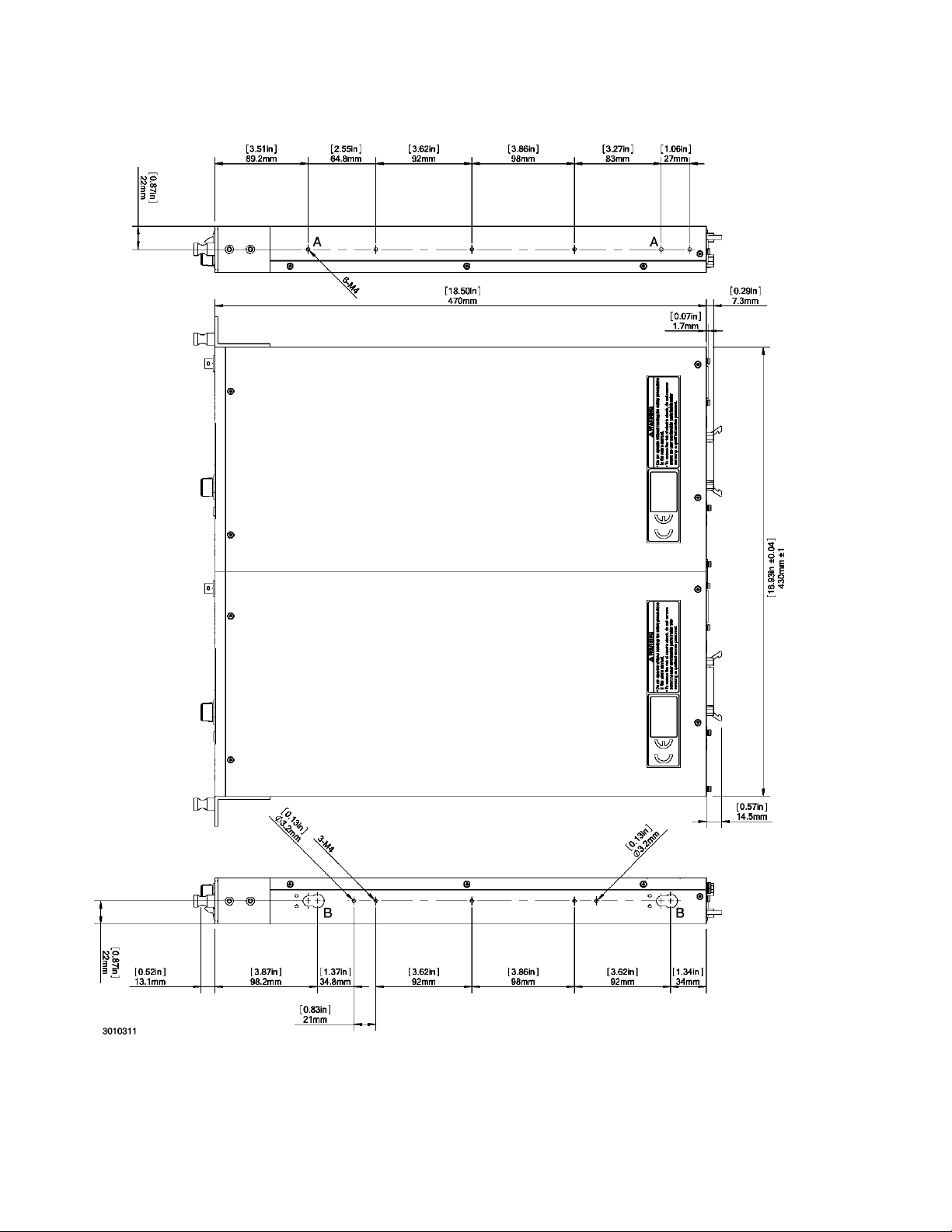

FIGURE 1-2. KLN 750W POWER SUPPLY, OUTLINE DRAWING (TWO UNITS MOUNTED IN RACK)

(SHEET 1 OF 2)

1-6 KLN 750W 032614

Page 17

FIGURE 1-2. KLN 750W POWER SUPPLY, OUTLINE DRAWING (SHEET 2 OF 2)

1.4 LOCAL CONTROL

The front panel encoder can set and adjust output voltage and current under local control. The

display uses two 4-digit LED displays to provide a digital readout of output voltage and current.

1.5 REMOTE CONTROL

The KLN 750W Power Supply can be remotely controlled directly via the built-in RS-485 interface using SCPI commands (see Appendix A and B). Most features available in local mode can

also be accessed remotely via the RS-485 (standard), and GPIB (optional) or LAN (optional)

KLN 750W 032614 1-7

Page 18

digital interfaces. The transmission rate of RS-485 can be up to 115.2K bps. The RS-485 interface can be used to connect multiple power supplies, up to a maximum of 254 units. The maximum effective control distance can be up to 1000m.

Digital remote control is also available via optional GPIB (suffix G) and LAN (suffix E) interfaces.

1.6 ANALOG CONTROL

External reference signals, provided through the Programming Control port (see Table 2-4), can

be used to control the output voltage and current of the KLN 750W. The Programming Control

port allows control of output on/off and permits emergency shutdown of the output. Output signals allow remote monitoring of whether the unit is powered on, output on/off, alarm condition,

output voltage and current, and operating mode: Constant Current (CC) or Constant Voltage

(CV). Refer to PAR. 3.5 for further details on using external signals to control and monitor the

output.

1.7 FEATURES

1.7.1 DIGITAL CALIBRATION

The KLN 750W Power Supply features high stability and long intervals between calibration. The

unit contains no user-required internal adjustments. Calibration is done by means of software

(see Section 4).

1.7.2 PROTECTION

The following protection is provided: OVP (Overvoltage protection), OCP (overcurrent protection), OTP, (overtemperature protection) and blown fuse.

1.7.3 SAVING AND RECALLING SETTINGS

The KLN 750W offers 16 memory locations accessible from the front panel that can be used to

store a set of operating parameters for later use. For each location, the user can store voltage

and current values. The stored settings can then be recalled to quickly program the unit to the

predetermined setting. Refer to PAR. 3.3.6 and 3.3.7 for further details.

1.7.4 PARALLEL AND SERIES CONFIGURATIONS

Identical KLN 750W units may be configured in series (up to two units including master) or parallel (up to five units including master) configurations. Parallel configurations provide for automatic current sharing (see PAR. 2.8 for details).

1.7.5 MISCELLANEOUS FEATURES

• Both positive and negative output ramps can be independently programmed (see PAR’s.

3.3.10 and 3.3.11).

• Last setting is automatically restored upon power-up. Output can be programmed to be

either on or off upon power-up (see PAR’s. 3.3.9).

• One key recall of up to 16 memory locations storing voltage and current settings (see

PAR’s. 3.3.26 and 3.3.7).

• Variable speed fan reduces noise and extends fan life.

• Non-gap stacking; No ventilation holes at top or bottom.

1-8 KLN 750W 032614

Page 19

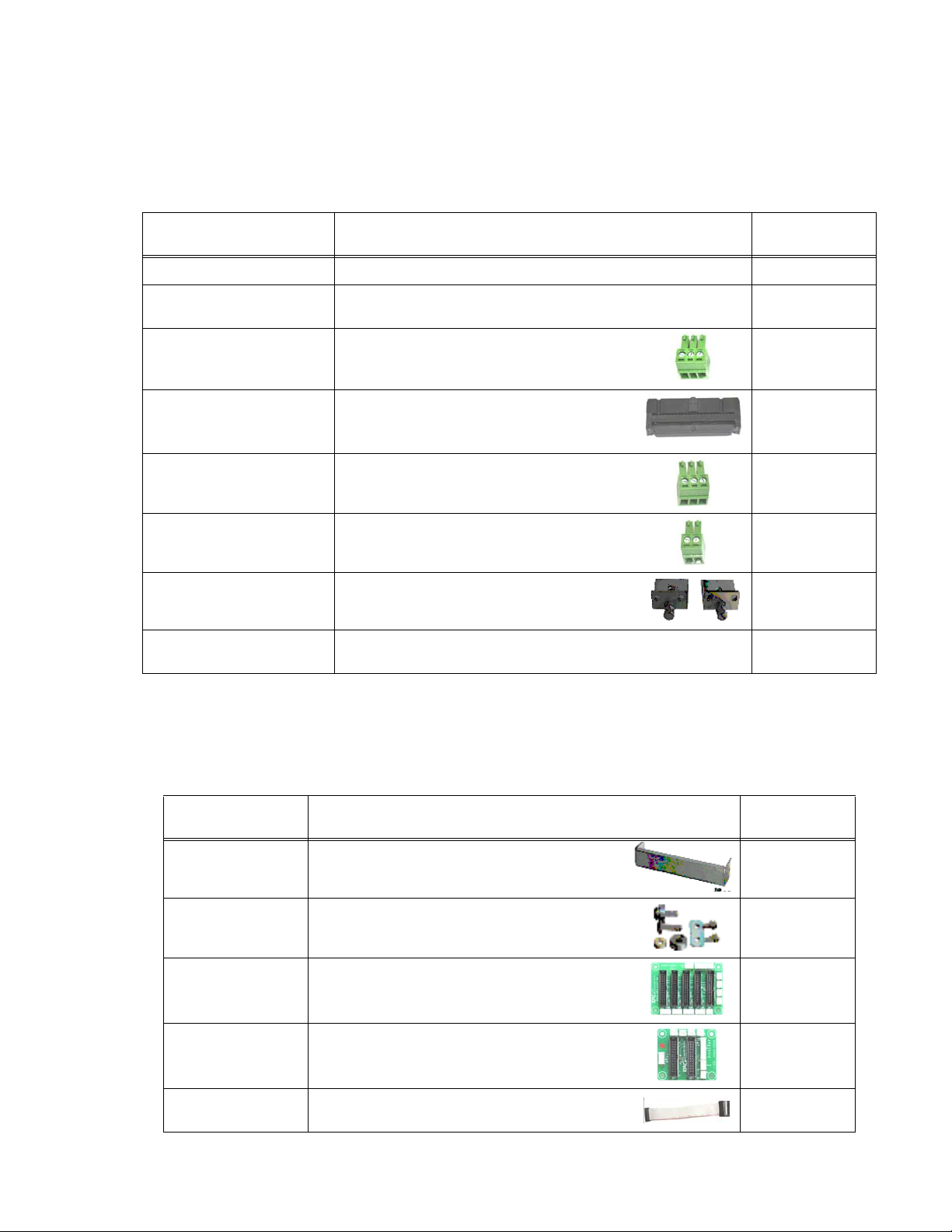

1.8 EQUIPMENT SUPPLIED

Equipment supplied with the KLN 750W power supply is listed in Table 1-3.

TABLE 1-3. EQUIPMENT SUPPLIED

ITEM DESCRIPTION

Power Cable, (125V/15A) Connects unit to 115V a-c source power. 118-1136

Sense wires: Red, black Used to connect output to local sensing

RS-485 Mating connector Supplied installed on RS-485 port to allow access

Programming Control Port

Mating connector

Sense Mating Connector Supplied installed on Sense connector to provide

SER IN mating connector Supplied installed on SER IN connector to allow

L-type Brackets (2) with

mounting screws (4)

Output Protective Cover Supplied with 6V through 100V models only; used

connections: red: (+) to +S, black: (–) to –S

to RS 485 interface.

Supplied installed on Programming Control port to

allow access to pins for analog control and

monitoring.

access to sense connections used to compensate

for voltage drop on load connections

series connection of two units.

Used with optional rack mounting Kits RA 81-1 or

RA 81-2 to install one or two units in 19-inch rack.

to cover output terminals

KEPCO PART

NUMBER

N/A

542-0037

143-0394

542-0035

542-0036

N/A

N/A

1.9 ACCESSORIES

Accessories (not supplied) for the KLN 750W Power Supply are listed in Table 1-4.

TABLE 1-4. ACCESSORIES

ITEM FUNCTION

Rack Mount Kit Allows mounting of one half-rack KLN 750W unit in

standard 19-inch rack (L-type brackets supplied with

unit, not included in Kit).

Rack Mount Kit Allows mounting of two half-rack KLN 750W units

side-by-side in standard 19-inch rack (L-type brackets

supplied with unit, not included in Kit).

Parallel Socket Board Provides convenient connections for parallel

Series Socket Board Provides convenient connections for series operation

Programming Port

Cable

operation of up to five units

of two units.

Provides connections between two programming

ports for parallel and series operation.

KEPCO

PART NUMBER

RA 81-1

RA 81-2

536-0129

536-0130

518-0119

KLN 750W 032614 1-9

Page 20

1.10 SAFETY

Service must be referred to authorized personnel. Using the power supply in a manner not

specified by Kepco. Inc. may impair the protection provided by the power supply. Observe all

safety precautions noted throughout this manual (see listing on Safety page A, preceding the

Table of Contents). Table 1-5 lists symbols used on the power supply or in this manual where

applicable.

TABLE 1-5. SAFETY SYMBOLS

SYMBOL Meaning

WARNING! RISK OF ELECTRIC SHOCK!

CAUTION: REFER TO REFERENCED PROCEDURE.

!

FRAME OR CHASIS TERMINAL

GROUND TERMINAL

PROTECTIVE GROUND CONDUCTOR TERMINAL

WARNING

CAUTION

INDICATES THE POSSIBILITY OF BODILY INJURY

OR DEATH.

INDICATES THE POSSIBILITY OF EQUIPMENT

DAMAGE.

1-10 KLN 750W 032614

Page 21

SECTION 2 - INSTALLATION

2.1 UNPACKING AND INSPECTION

This instrument has been thoroughly inspected and tested prior to packing and is ready for

operation. After careful unpacking, inspect for shipping damage before attempting to operate.

Perform the preliminary operational check as outlined in PAR. 2.3. If any indication of damage is

found, file an immediate claim with the responsible transport service.

2.2 TERMINATIONS AND CONTROLS

a) Front Panel: Refer to Figure 3-1 and Table 3-1.

b) Rear Panel: Refer to Figure 2-1 and Table 2-1.

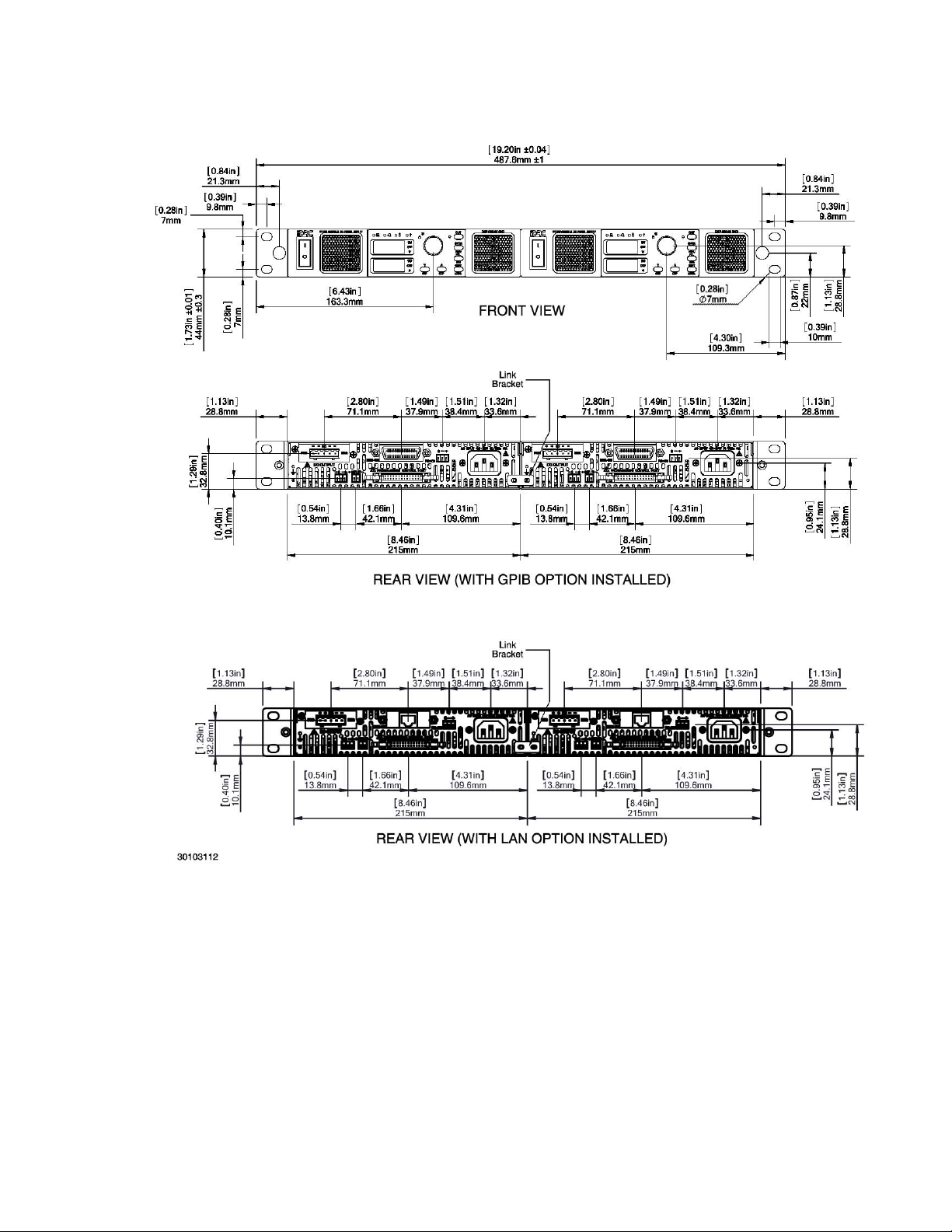

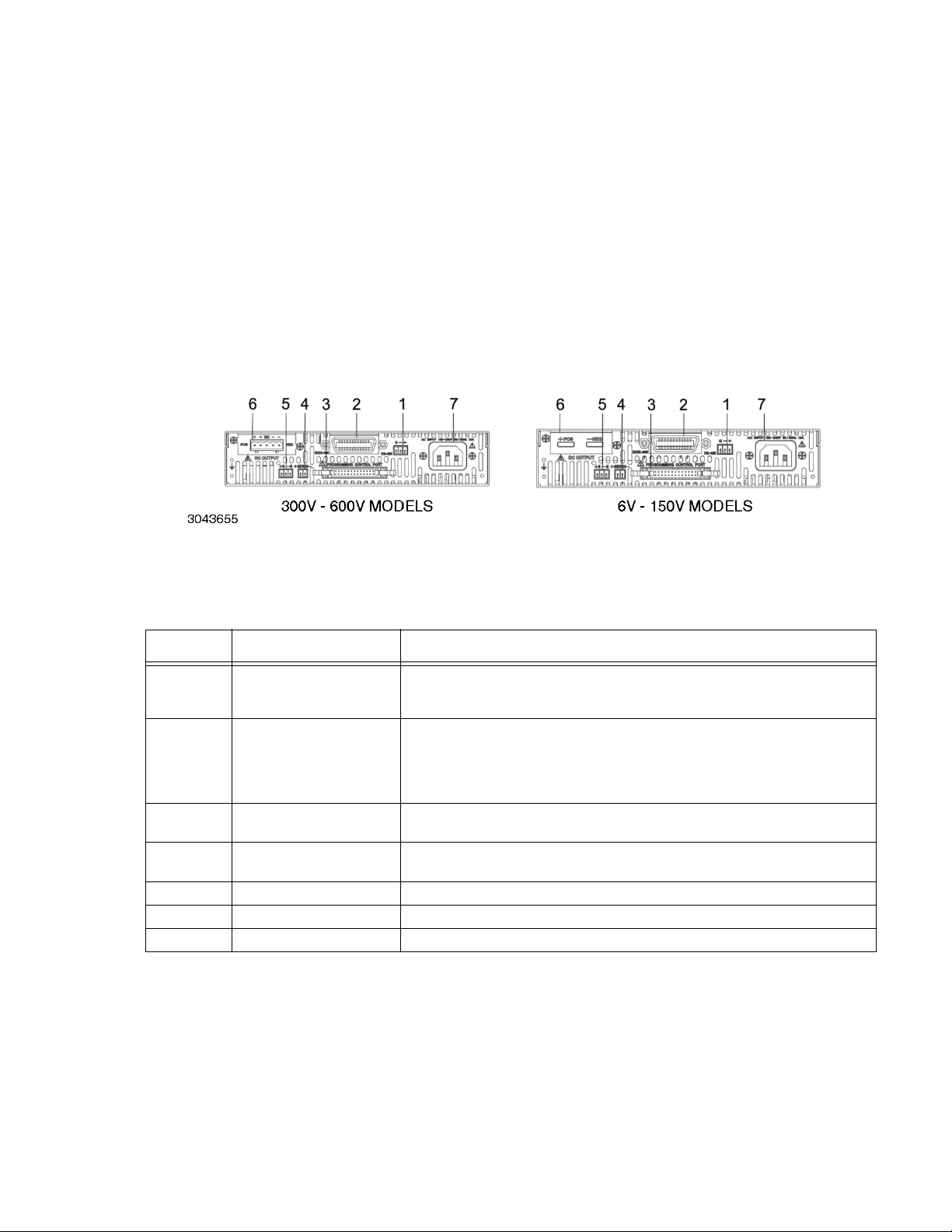

FIGURE 2-1. KLN 750W SERIES REAR PANEL

TABLE 2-1. REAR PANEL CONNECTOR FUNCTIONS

NUMBER

(FIGURE 2-1)

1

2

3 Programming Control Port

4 SER IN

5 +S, –S Remote sensing voltage compensation.

6 DC Output Allows connection to load.

7 AC input Allows connection to mains supply using power cord supplied.

CONNECTOR/TERMINAL FUNCTION

RS-485

3-pin pluggable terminal

block

Optional:

either 24-pin GPIB

connector (shown)

or LAN ethernet connector

(not shown)

Allows connection to RS-485 bus. See Table 2-2 for details.

Allows connection to GPIB bus or LAN (optional) when installed. See Table 2-3 for

GPIB connector details.

Allows access to analog input/output signals that allow monitoring and control of the

power supply by analog means. See Table 2-4 for pin assignments.

Provides output voltage reference from master to slave to ensure voltage slave

matches the master when two units connected in series.

KLN 750W 032614 2-1

Page 22

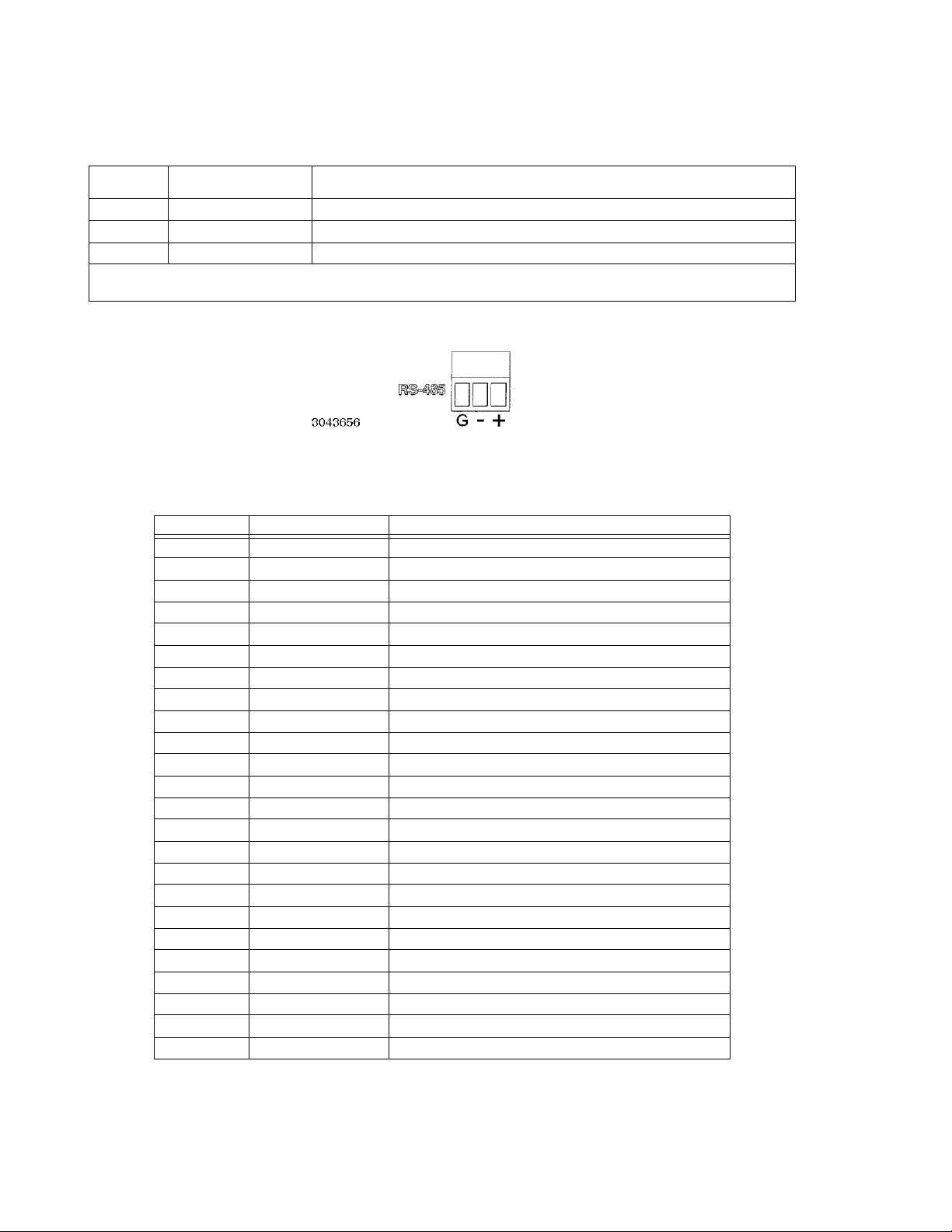

TABLE 2-2. RS-485 PORT INPUT/OUTPUT PIN ASSIGNMENTS

PIN

(FIGURE 2-2)

G Ground Reduce external interference

+ +RX Connect to +TX of computer and/or +RX of next unit on RS-485 bus (see Figure 2-9).

– –RX Connect to –TX of computer and/or –RX of next unit on RS-485 bus (see Figure 2-9).

NOTE: Connect 120 Ohm termination resistor across + and – of last unit connected to RS-485 bus (furthest from computer)

See PAR. 2.7.2.

SIGNAL NAME FUNCTION

FIGURE 2-2. RS-485 PORT

TABLE 2-3. GPIB (IEEE 488) PORT INPUT/OUTPUT PIN ASSIGNMENTS

PIN SIGNAL NAME FUNCTION

1DI01 I/O Line

2D

3D

4D

5 EOI End or Identify

6 D AV Da ta Vali d

7 NRFD Not Ready for Data

8 NDAC Not Data Accepted

9 IFC Interface Clear

10 SRQ Service Request

11 ATN Attention

12 SHIELD Shield

13 D

14 D

15 D

16 D

17 REN Remote Enable

18 GND Ground (signal common)

19 GND Ground (signal common)

20 GND Ground (signal common)

21 GND Ground (signal common)

22 GND Ground (signal common)

23 GND Ground (signal common)

24 LOGIC GND Logic Ground

I02 I/O Line

I03 I/O Line

I04 I/O Line

I05 I/O Line

I06 I/O Line

I07 I/O Line

I08 I/O Line

2-2 KLN 750W 032614

Page 23

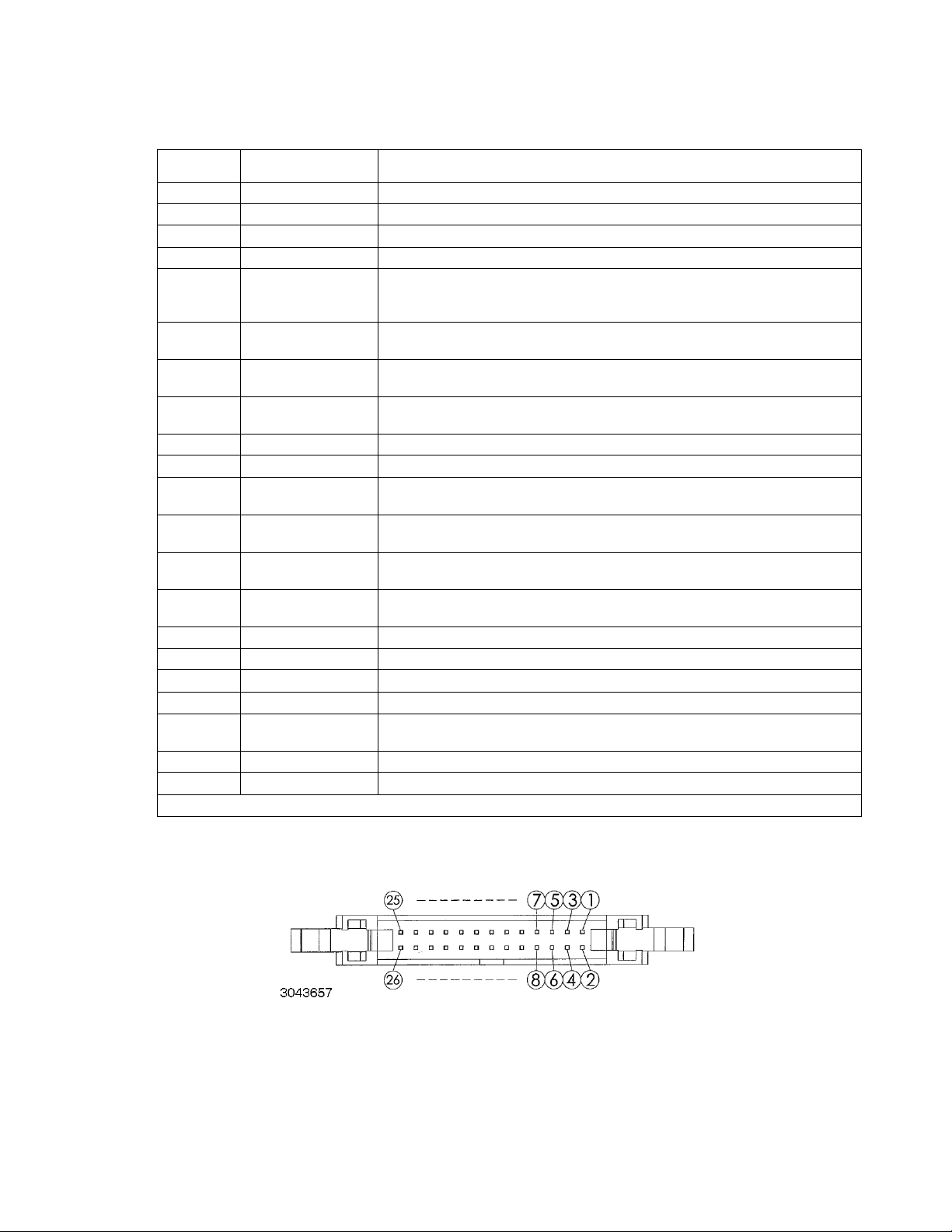

TABLE 2-4. PROGRAMMING CONTROL PORT I/O PIN ASSIGNMENTS

PIN

(FIGURE 2-3)

1, 2 RECALL External recall control (dry contact). Same function as RCL key on front panel.

3, 4, 5, 6 --- Not used

7 Power on/off status Output signal. Active (low between pin 7 and pin 8) to indicate unit is turned on.

8 Status common Common for Status signal pins 7, 9, 10, 11 and 12

9 Alarm status

10 On/off status

11 CC status

12 CV status

13 EXT 5V input+ Input signal. Used to supply +5V for the relay providing remote output on/off function.

14 EXT V input common Common for Pin 13 (remote output on/off function).

15 PRL IN+

16 EXT CV

17 PRL OUT+

18 EXT CC

19 PRL IN–/OUT– V common for pins 15 and 17.

20 V Monitor Output signal. Zero to 10V d-c corresponds to zero to full scale voltage,

21 ON/OFF Control Input Signal. Used to power unit on (short) or off (open). Dry contact.

22 A Monitor Output signal. Zero to 10V d-c corresponds to zero to full scale current.

23 Shutdown

24, 26 Analog Common Analog signal control ground, connected to pin 19.

25 Digital Common Digital signal control ground.

(1) Open collector output: maximum voltage 30V, maximum current 8mA; Low: <0.4V.

SIGNAL NAME FUNCTION

Output signal. Active (low between pin 9 and pin 8) to indicate whether alarm (OVP or

OCP trips or shutdown signal applied to pin 23) has occurred. (open collector via optocoupler).

Output signal. Active (low between pin 10 and pin 8) to indicate output is on (open collector by optocoupler).

Output signal. Active (low between pin 11 and pin 8) to indicate unit is in constant current mode (open collector by optocoupler).

Output signal. Active (low between pin 12 and pin 8) to indicate unit is in constant voltage mode (open collector by optocoupler).

(1)

(1)

(See PAR. 3.3.25 to enable.)

(1)

(1)

Input signal. For units operating in parallel, used for signal input into MASTER of current sharing between MASTER and SLAVE(s) (see PAR. 2.8.2.1).

Input signal. External voltage to control output voltage of unit. 0 to 10V d-c corresponds to zero to full scale output voltage (see PAR. 3.3.26 to enable).

Output signal. For units operating in parallel, used for signal output of current sharing

from SLAVE to MASTER (see PAR. 2.8.2.1).

Input signal. External voltage to control output current of unit. 0 to 10V d-c corresponds to zero to full scale output current (see PAR. 3.3.27 to enable).

Short between pin 23 and analog ground (pins 24 or 26) causes emergency shutdown

of unit.

(1)

(1)

FIGURE 2-3. PROGRAMMING CONTROL PORT

KLN 750W 032614 2-3

Page 24

2.3 PRELIMINARY OPERATIONAL CHECK

A simple operational check after unpacking and before equipment installation is advisable to

ascertain whether the power supply has suffered damage resulting from shipping.

Refer to Figures 2-1 and 3-1 for location of operating controls and electrical connections. Tables

3-1 and 3-2 explain the functions of operating controls/indicators and keypad keys, respectively.

Refer to PAR. 3.2 for a description of basic operating techniques.

1. With power supply disconnected from source power verify that sense connections are correct: +S is connected to +POS and –S is connected to –NEG (see PAR. 2-6).

2. With front panel power circuit breaker to OFF position, connect the power supply to source

power (see PAR. 2.5.2).

3. With no load connected, set power circuit breaker to ON. Each time the unit is turned on it

beeps and an internal self-test is performed (see PAR 3.2.1). After the test has been successfully completed, the 4-digit Voltage Display and Current Display show the last programmed voltage and current values, respectively, in Volts and Amperes.

4. Press SHIFT/LOCAL key. Verify blue LED goes on. Press V/OVP key: Least significant

digit of Voltage Display and integral red OVP LED at the right of the display blink. Verify

blue LED goes off.

5. Rotate encoder to change the digits for adjustment. Turn clockwise to increase the value,

counterclockwise to decrease the value. Tap encoder to move to the next digit. Continue until

the maximum OVP value is displayed (e.g., 33.00 for 30V model).

6. Press ENTER key to accept programmed OVP value.

7. Press SHIFT/LOCAL key. Verify blue LED goes on. Press A/OCP. Least significant digit

of Current Display and integral red OCP LED at the right of the display blink. Verify

blue LED goes off.

8. Rotate encoder to change the digits for adjustment. Turn clockwise to increase the value,

counterclockwise to decrease the value. Tap encoder to move to the next digit. Continue until

the maximum OCP value is displayed (e.g., 26.25 for 25 Ampere model).

9. Press ENTER key to accept programmed OCP value.

10.Press V/OVP key. Least significant digit of Voltage Display blinks.

11. Rotate encoder to change the digits for adjustment. Turn clockwise to increase the value,

counterclockwise to decrease the value. Tap encoder to move to the next digit. Continue until

the rated output voltage value (e.g., 30.00 for 30V model) is displayed.

12.Press ENTER key to accept programmed voltage value.

13.Press A/OCP key. Least significant digit of Current Display blinks.

14.Rotate encoder to change the digits for adjustment. Turn clockwise to increase the value,

counterclockwise to decrease the value. Tap encoder to move to the next digit. Continue until

a value of several Amperes of output current is displayed.

2-4 KLN 750W 032614

Page 25

15.Connect a digital voltmeter (DVM) to the (+S) and (-S) terminals on the rear panel. Verify that

DVM shows there is no output voltage from the power supply.

16.Press red OUT key. Verify that red LED at left of OUT key goes on.

17.Compare the programmed output voltage value (e.g., 30.00V for 30V model per step 11) with

the voltage reading of the DVM; Verify that the difference between the two does not exceed

±0.1% ± 3C

(*)

.

18.Compare the voltage reading of Voltage Display with that of the DVM; Verify that the difference between the two does not exceed ±0.2% ± 3C

19.Disable the output by pressing the OUT key; verify front panel Voltage and Current displays

show programmed values of Voltage and Current, respectively and DVM reads 0V.

20.Set power switch to OFF. The unit issues a long beep as it powers down. Disconnect unit

from source power, then disconnect test equipment.

(*) C = 1 count of the last displayed digit.

2.4 INSTALLATION

2.4.1 RACK MOUNTING

One or two (side by side) KLN 750W units can be mounted in a standard 19-inch rack. The units

are 1U high and do not require any gaps between equipment above and below. Airflow is front

to back only. Use the RA 81-1 Mounting Kit (see Table 1-4) to mount a single unit. Use Mounting

Kit RA 81-2 (optional, see Table 1-4) to mount two half-rack units side by side in a 19-inch rack.

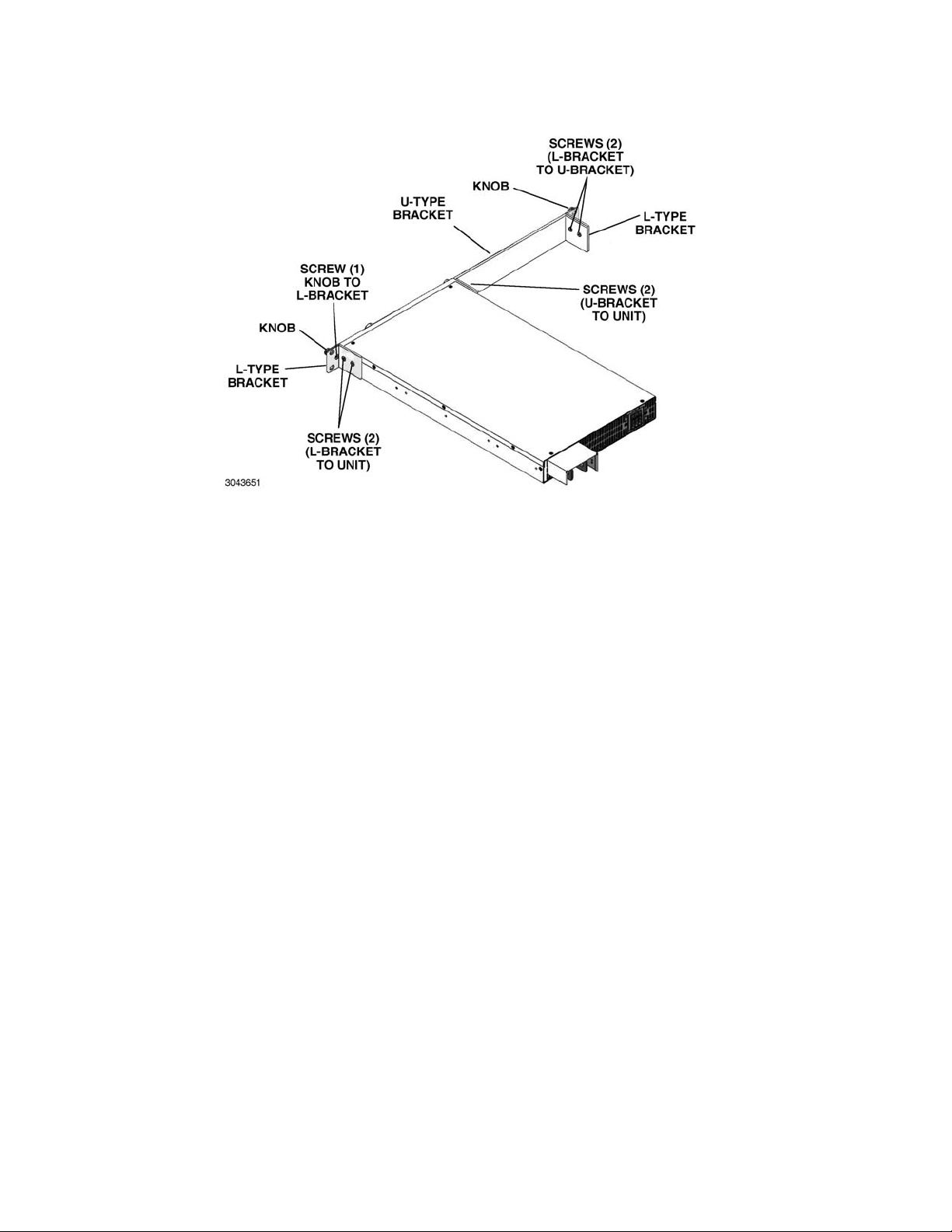

2.4.1.1 MOUNTING ONE 1/2-RACK UNIT IN 19-INCH RACK

1. On one side of the unit, mount one L-type bracket with knob (supplied with unit) to the unit

using two screws supplied with unit.

(*)

.

2. Mount the U-type bracket supplied in the Kit to the other side of the unit using two screws

supplied in Kit.

3. Mount the other L-type bracket with knob (supplied with unit) to the end of the U-type bracket

using two screws supplied with unit. The knobs can now be used to support the assembled

unit while installing in a 19-inch rack.

KLN 750W 032614 2-5

Page 26

FIGURE 2-4. MOUNTING ONE KLN 750W UNIT IN 19-INCH RACK

2.4.1.2 MOUNTING TWO 1/2-RACK UNITS IN 19-INCH RACK

To mount two KLN 750W units side-by-side in a 19 inch rack, use the RA 81-2 mounting kit (not

supplied, see Accessories, Table 1-4).

1. Place the two units side by side as they would be installed in the rack. On the outer side of

each unit (not facing the other unit), mount one L-type bracket with knob (supplied with unit)

to each unit using two screws supplied with unit for each (see Figure 1-2).

2. Separate the two units. Install two shoulder screws, flat washers and lockwashers (supplied

with Kit) at two locations on one unit (two threaded holes, A, Figure 1-2).

3. Move the two units together and insert the shoulder screws into the keyhole-shaped opening

in the other unit (two holes, B, Figure 1-2). Then slide the unit with the shoulder screws forward until the front panels of both units are flush.

4. Connect the two units at the rear using linking bracket (see Figure 1-2, sheet 2) and two

screws supplied with Kit. The two units can now be handled as an assembly and can be

installed directly into a 19-inch rack.

2.5 WIRING INSTRUCTIONS

Interconnections between an a-c power source and a power supply, and between the power

supply and its load are as critical as the interface between other types of electronic equipment.

If optimum performance is expected, certain rules for the interconnection of source, power supply and load must be observed by the user. These rules are described in detail in the following

paragraphs.

2-6 KLN 750W 032614

Page 27

CAUTION: WHEN WORKING WITH ACTIVE LOADS, THE VOLTAGE OR CURRENT OF

THE ACTIVE LOAD MUST NOT EXCEED THE MAXIMUM VOLTAGE OR CURRENT RATING OF THE KLN 750W. OTHERWISE THE OVERVOLTAGE OR

OVERCURRENT PROTECTION WILL SHUT DOWN THE POWER SUPPLY.

2.5.1 SAFETY GROUNDING

To minimize shock hazard, the product chassis must be connected to an electrical ground. The

product must be connected to the AC power supply mains through a three-conductor power

cable, with the ground wire firmly connected to an electrical ground (safety ground) at the power

outlet.

Local, national and international safety rules dictate the grounding of the metal cover and case

of any instrument connected to the a-c power source, when such grounding is an intrinsic part of

the safety aspect of the instrument. The ground terminal of the source power connector (Figure

2-1) is connected to the chassis and the instructions below suggest wiring methods which comply with these safety requirements. In the event that the specific installation for the power system is different from the recommended wiring, it is the customer's responsibility to ensure that

all applicable electric codes for safety grounding requirements are met. As a precaution, always

connect the screw marked at the rear panel to proper earth ground.

2.5.2 SOURCE POWER CONNECTIONS

Source power is connected to the power supply via three-wire input power using the source

power cable supplied (see Table 1-3). See Table 1-2 for source power specifications. This power

supply operates from single phase a-c mains power (or between two phases of 3-phase a-c

mains power) over the specified voltage and frequency ranges (Table 1-2) without any need for

range selection.

CAUTION: DO NOT USE AC SUPPLY WHICH EXCEEDS THE INPUT VOLTAGE AND FRE-

QUENCY RATING OF THIS INSTRUMENT. THE INPUT VOLTAGE AND FREQUENCY RATING OF THE POWER SUPPLY ARE SHOWN IN TABLE 1-2. FOR

SAFETY REASONS, THE MAINS SUPPLY VOLTAGE FLUCTUATIONS MUST

NOT EXCEED ±10% OF NOMINAL VOLTAGE.

2.5.3 D-C OUTPUT GROUNDING

Connections between the power supply and the load and sensing connections may, despite all

precautions such as shielding, twisting of wire pairs, etc., be influenced by radiated noise, or

“noise pick-up”. To minimize the effects of this radiated noise the user should consider grounding one side of the power supply/load circuit. The success of d-c grounding requires careful

analysis of each specific application, however, this recommendation can only serve as a general

guideline.

One of the most important considerations in establishing a successful grounding scheme is to

avoid GROUND LOOPS. Ground loops are created when two or more points are grounded at

different physical locations along the output circuit. Due to the interconnection impedance

between the separated grounding points, a difference voltage and resultant current flow is

superimposed on the load. The effect of this ground loop can be anything from an undesirable

increase in output noise to disruption of power supply and/or load operation. The only way to

avoid ground loops is to ensure that the entire output/load circuit is fully isolated from ground,

and only then establish a single point along the output/load circuit as the single-wire ground

point.

KLN 750W 032614 2-7

Page 28

The exact location of the “best” d-c ground point is entirely dependent upon the specific application, and its selection requires a combination of analysis, good judgement and some amount of

empirical testing. If there is a choice in selecting either the OUTPUT or COMMON output terminals of the power supply for the d-c ground point, both sides should be tried, and preference

given to the ground point producing the least noise. For single, isolated loads the d-c ground

point is often best located directly at one of the output terminals of the power supply; when

remote error sensing is employed, d-c ground may be established at the point of sense lead

attachment. In the specific case of an internally-grounded load, the d-c ground point is automatically established at the load.

The (+) and (–) terminals of KLN 750W power supplies are d-c isolated (“floating”) from the

chassis in order to permit the user maximum flexibility in selecting the best single point ground

location. Care must be taken in measuring the ripple and noise at the power supply: measuring

devices which are a-c line operated can often introduce additional ripple and noise into the circuit.

There is, unfortunately, no “best” method for interconnecting the load and power supply. Individual applications, location and nature of the load require careful analysis in each case. Grounding a single point in the output circuit can be of great importance. It is hoped that the preceding

paragraphs will be of some assistance in most cases. For help in special applications or difficult

problems, consult directly with Kepco's Application Engineering Department.

2.5.4 POWER SUPPLY/LOAD INTERFACE

The general function of a voltage- or current-stabilized power supply is to deliver the rated output quantities to the connected load. The load may have any conceivable characteristic: it may

be fixed or variable, it may have predominantly resistive, capacitive or inductive parameters; it

may be located very close to the power supply output terminals or it may be a considerable distance away. The perfect interface between a power supply and its load would mean that the

specified performance at the output terminals would be transferred without impairment to any

load, regardless of electrical characteristics or proximity to each other.

The stabilized d-c power supply is definitely not an ideal voltage or current source, and practical

interfaces definitely fall short of the ideal. All voltage-stabilized power supplies have a finite

source impedance which increases with frequency, and all current-stabilized power supplies

have a finite shunt impedance which decreases with frequency. The method of interface

between the power supply output and the load must, therefore, take into account not only the

size with regard to minimum voltage drop, but the configuration with regard to minimizing the

impedance introduced by practical interconnection techniques (wire, bus bars, etc.). The series

inductance of the load wire must be as small as possible as compared to the source inductance

of the power supply: although the error sensing connection to the load compensates for the d-c

voltage drop in the power leads, it cannot compensate for the undesirable output effects of the

power lead inductance. These lead impedances (both power and sensing leads) are especially

important if the load: is constantly modulated or step-programmed; has primarily reactive characteristics; or where the dynamic output response of the power supply is critical to load performance.

2.5.5 LOAD CONNECTION - GENERAL

Power connections to the load are achieved via the +POS and –NEG DC OUTPUT terminals

located on the rear panel. Terminal connections for low voltage models (6V to 150V) are shown

in Figure 2-5. The 300V and 600V models employ Euroblock-style terminal blocks that accept

bare wire ends.

2-8 KLN 750W 032614

Page 29

FIGURE 2-5. LOAD CONNECTION TERMINALS FOR 6V - 150V MODELS

Kepco strongly recommends the use of stranded (not solid) wire with (+) and (–) wires tightly

twisted to reduce self-inductance; wire end ferrules are suggested to prevent fraying of the

strands.

NOTE REGARDLESS OF OUTPUT CONFIGURATION, EITHER LOCAL OR REMOTE OUT-

PUT SENSE LINES SHOULD BE CONNECTED FOR OPTIMUM OPERATION.

• OBSERVE POLARITIES: The +S sensing wire must be connected to the (+) load wire,

and the –S sensing wire must be connected to the (–) load wire.

• IF LOCAL SENSING IS USED: Install red and black sense leads supplied (see Figure 2-

6).

2.5.6 LOAD CONNECTION USING LOCAL SENSING

Figure 2-6 shows a typical configuration using local sensing. Local sensing is recommended for

a high noise or switching mode load such as d-c to d-c or d-c to a-c.

CAUTION: CONNECT +S ONLY TO + AND –S ONLY TO –. CONNECTING +S TO –S, +V

TO –S, OR –V TO +S WILL DAMAGE THE UNIT.

FIGURE 2-6. LOAD CONNECTIONS, LOCAL SENSING

KLN 750W 032614 2-9

Page 30

Use the following formula and Figure 2-7 to calculate the voltage drop based on expected current and wire resistance. Refer to Table 2-5 for wire resistance for standard AWG sizes, as well

as maximum recommended length of load wires for a voltage drop of less than 1V with expected

load current of 5, 10, 20, 50 or 150 Amperes.

V

= (I x r1) + (I x r2)

DROP

where r1 and r2 is the load wire resistance

I is output current

Voltage across Load RL = Voltage (displayed on front panel display) – V

DROP

FIGURE 2-7. LOAD WIRE VOLTAGE DROP, EQUIVALENT SCHEMATIC DIAGRAM

TABLE 2-5. MAXIMUM LOAD WIRE LENGTH FOR VOLTAGE DROP LESS THAN 1V

AWG

SIZE

14 2 0.8 24.4m 12.2m 6.1m 2.4m 0.6m

12 3.5 0.5 36.6m 18.3m 9.1m 3.7m 1.0m

10 5.5 0.3 61.0m 30.5m 15.2m 6.1m 1.8m

8 8 0.2 97.5m 48.8m 24.4m 9.8m 3.0m

6 14 0.1 152.4m 61m 38.1m 15.2m 4.9m