Page 1

INSTRUCTION MANUAL

KEPCO

An ISO 9001 Company.

BOP 1000W

Transition Circuit

KIT 219-0550

BOP 10-75MG

TRANSITION CIRCUIT KIT

1. DESCRIPTION

Kepco KIT 219-0550 contains components used for a field upgrade of BOP 10-75MG power supplies to allow

smoother transitions through zero power when driving inductive loads at low frequencies and/or at a low rate of

output power changes. This upgrade avoids possible faults under these conditions which can cause the unit to display an error and reduce output power to zero.

The Transition circuit detects when the voltage and the current at the BOP output have opposite signs, showing

that the unit is beginning to sink power. This turns on a preload placed between the Front End Module and the Output Module of the BOP. If the Sink power increases to the point that the Source-Recuperation Detector is triggered,

the Front End switches to Sink-Recuperation mode at an increased level of power, as the preload is turned off by

the Source-Recuperation Detector. This permits a sharper transition towards Sink-Recuperation mode. If the Front

End switches to Source mode, the preload is activated for a predetermined period of time in order to boost the

power requested from the Front End, resulting in a sharper transition towards the Source mode.

2. APPLICABILITY

This KIT applies only to BOP 10-75MG models. Contact Kepco for kits applicable to other models.

3. INSTALLATION INSTRUCTIONS

3.1 MATERIAL SUPPLIED (See Table 1.)

TABLE 1. MATERIAL SUPPLIED

MATERIAL KEPCO PART NUMBER QUANTITY

Transition Circuit assembly

• Printed Circuit Board assembly (A7A3)

• Heat Sink assembly

Screw, TPTH, 8-18 X 0.625 IN. 101-0328 1

Cable Assembly, A2A5 to A7A3J1 (5-Pin connector) 118-1265 1

Cable Assembly, A4A8 to A7A3J3 (4-Pin connector) 118-1266 1

Cable Assembly, A4A8 to A7A3J4 (3-Pin connector) 118-1267 1

Resistor, 150KOhms, 1%, 1/8W (R59) 115-2597 1

Resistor 200KOhms, 1%, 1/4W (R58, R70) 115-2809 2

Cable Tie 138-0076 5

Plastic Tie Mount 138-0084 1

Instruction Manual 228-1746 1

300-0515

236-2928

136-0476

1

1

1

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

©2012, KEPCO, INC 1

Data subject to change without notice 228-1746 REV 2

Page 2

3.2 COVER REMOVAL PROCEDURE

WARNING: Before installing the kit, unplug the BOP from a-c input source and disconnect the output

load!

1. Turn power off and disconnect the unit from source power and remove line cord, then disconnect the output

load.

NOTE: Retain all hardware for reassembly.

2. Remove the two mounting ears from the chassis by removing three screws from each.

CAUTION: The two screws at the top of the front panel must be removed first to avoid damage to the

!

3. Remove the top cover of the unit by removing 14 screws as follows: two at top of the front panel, four at each

side, (one towards the rear, three at the bottom) and four at the top of the rear panel.

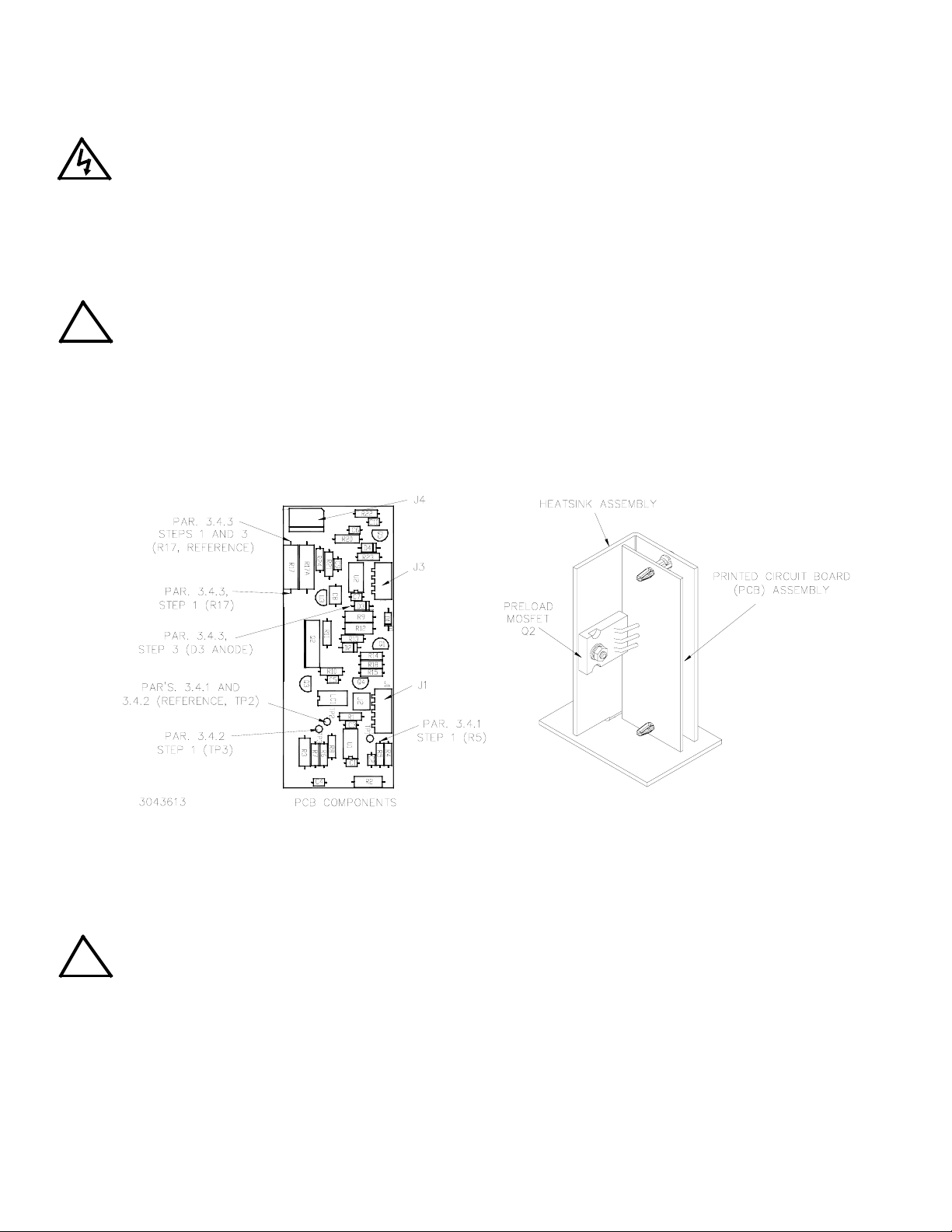

3.3 PRINTED CIRCUIT BOARD AND HEAT SINK INSTALLATION PROCEDURE

The Transition Circuit assembly Printed Circuit Board (PCB) is shipped assembled to the Heatsink with the preload-MOSFET mounted directly on the heatsink (Figure 1).

front panel.

FIGURE 1. TRANSITION CIRCUIT ASSEMBLY, COMPONENT LOCATIONS

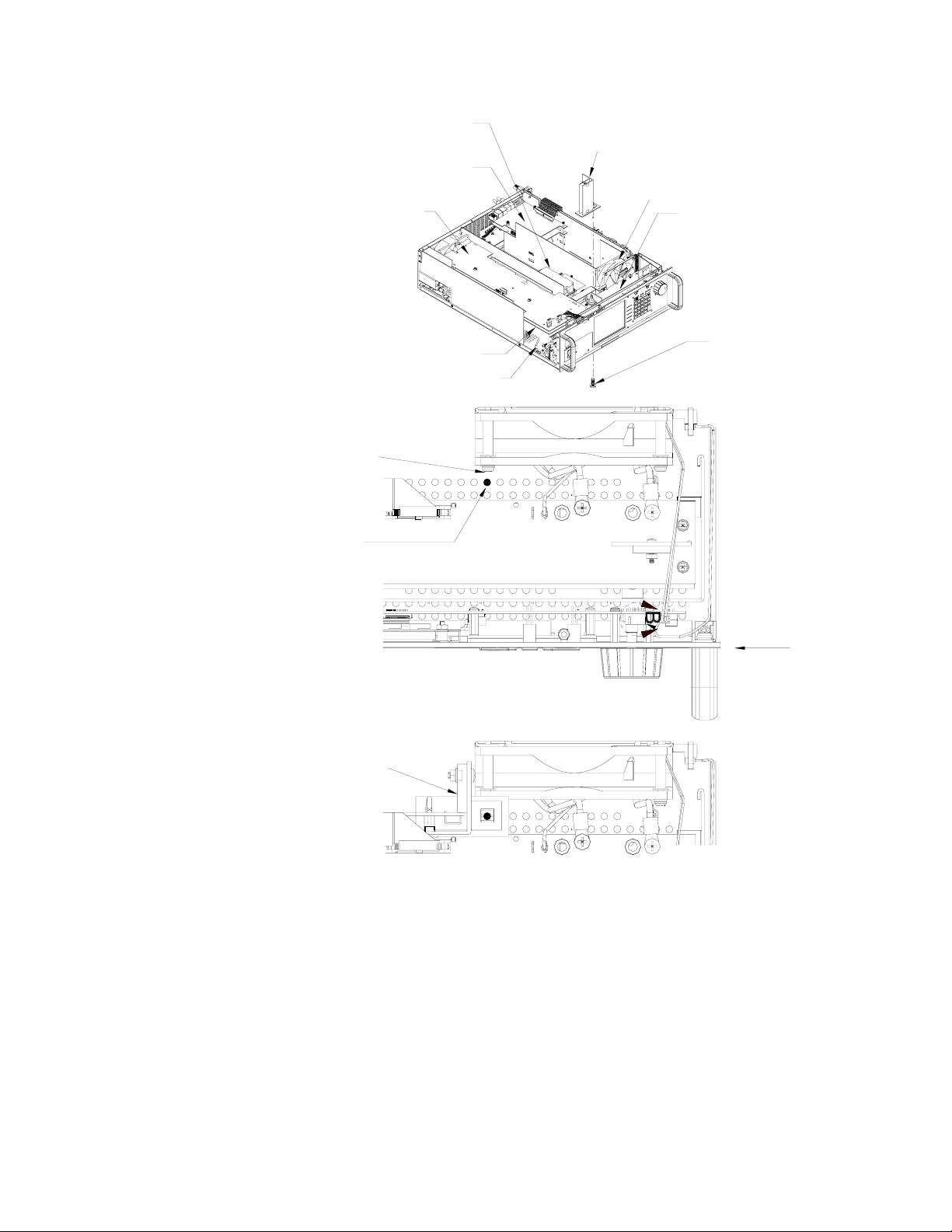

1. Install the Transition Circuit assembly as shown in Figure 2 using the ventilation hole identified in the figure

and the screw provided in this kit. The screw is inserted up through the bottom of the chassis into the plastic

grommet of the heatsink. The plastic grommet keeps the Transition Circuit assembly electrically isolated from

the chassis.

CAUTION: When routing cables, ensure that the cables stay clear of the Output Module (A2) Fan and

!

2. Cable assembly P/N 118-1267 (provided in the Kit) has a 3-pin connector with two wires, each having non-isolated ring lugs. Remove the screws and lockwashers from J4M and J2M on A4A8, then add the wires from the

cable assembly to the wires already connected to J4M and J2M as follows (see Figure 2 for the location of

A4A8 in the chassis, Figure 3 for location of J4M and J2M and Figure 6 for cable routing):

• red/white wire to A4A8- J4M

• black/white wire to A4A8- J2M

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

2 228-1746 REV 2 071812

Auxiliary Power Supply (A5).

http://www.kepcopower.com email: hq@kepcopower.com

Page 3

AUXILIARY

POWER SUPPLY A5

TRANSITION CIRCUIT

ASSEMBLY A7A3

(SEE DETAILS "A" AND "B")

A2A5 ASSEMBLY

(SEE FIGURE 5.)

A4A3 ASSEMBLY

(SEE FIGURE 6,)

A4A1 ASSEMBLY

CHASSIS GROUND CONNECTION

FAN MOUNTING

SCREW

INSERT SCREW IN THIS

VENTILATION HOLE (IN LINE

WITH FAN MOUNTING SCREW)

TO MOUNT TRANSITION

CIRCUIT ASSEMBLY A7A3.

OUTPUT MODULE

(A2) FAN)

A4A8 ASSEMBLY

(SEE FIGURE 4.)

KEPCO P/N 101-0328

SCREW, TPTH,

8-18 X 0.625 IN.

NOTE: For flush mounting of

chassis in rack,

contact Kepco

(See Note)

FRONT

PANEL

3043609

DETAIL "A"

(PARTIAL TOP VIEW)

A7A3 SCREW LOCATION

TRANSITION

CIRCUIT

A7A3

DETAIL "B"

(PARTIAL TOP VIEW)

A7A3 INSTALLED

FIGURE 2. BOP 1KW COMPONENT LOCATIONS

3. Install the 4-pin cable assembly (P/N 118-1266) on Transition Circuit A7A3J3 of the PCB (see Figure 1). Route

the cables as shown by Figure 6. This cable has three (3) unterminated wires. Determine the needed length,

cut the wire and remove the insulated sleeving (approximately 0.15"), then solder each wire to the indicated

point (see Figure 3 for A4A8 component locations and Figure 6 for cable routing):

• red wire to A4A8D1 Cathode

• black wire to A4A8D1 Anode

• white wire to A4A8TP2

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

071812 228-1746 REV 2 3

Page 4

FIGURE 3. A4A8 COMPONENT LOCATION/WIRING

4. Install the 5-pin cable assembly (P/N 118-1265) on Transition Circuit A7A3J1 (see Figure 1) of the PCB. Route

the cables as shown by Figure 6. This cable assembly has a 5-pin connector with five (5) unterminated wires.

Determine the needed length, cut the wire and remove the insulated sleeving (approximately 0.15"), then solder each wire to the indicated point of assembly A2A5 (see Figure 4 for location of wire attachment points and

Figure 6 for cable routing):

• white/yellow wire to A2A5D26 Anode

• white/blue wire to junction of A2A5R40 and J3, pin 6

• black wire to A2A5TP1

• red wire to A2A5TP7

• white wire to A2A5TP8

FIGURE 4. A2A5 COMPONENT LOCATION

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

4 228-1746 REV 2 071812

Page 5

5. To gain access to the components of A4A3 in order to replace R58, R59 and R70, first remove A4A3 from the

chassis as follows:

a. At top of A4A3 disconnect nine cables from J1 through J9 of A4A3 (Figure 5).

b. Remove four screws attaching A4 assembly to the chassis.

c. Remove five screws and five washers attaching A4A3 board to A4A1 board and remove A4A3 board.

6. Unsolder and remove the following three resistors from A4A3 and replace with the resistors supplied as follows (see Figure 5 for location of A4A3 components):

• Install and solder replacement R59 supplied: P/N 115-2597 (150K Ohms, 1%, 0.125W)

• Install and solder replacement R58 and R70 supplied: P/N 115-2809 (200K Ohms, 1%, 0.25W)

FIGURE 5. A4A3 COMPONENT LOCATIONS

7. Reinstall A4A3 by following the reverse of step 5 above.

8. Perform visual inspection of transition circuit installation.

CAUTION: After installing all components and wiring as described above, perform the following

!

• Verify that cable wires are connected properly and to the correct termination

• Check for unintentional short-circuits between the wire connections and adjacent components, pads and

traces.

• Use an ohmmeter to verify that the Transition Circuit heatsink is isolated (more than 1Megohm resistance)

from the BOP chassis.

• Verify that the Transition Circuit is securely attached to the BOP chassis.

• Verify that the Transition circuit cables are clear of the Output Module (A2) Fan and Auxiliary Power Supply

(A5).

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

071812 228-1746 REV 2 5

checklist to verify that installation has been done correctly.

http://www.kepcopower.com email: hq@kepcopower.com

Page 6

FIGURE 6. TRANSITION CIRCUIT ASSEMBLY, CABLE ROUTING

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

6 228-1746 REV 2 071812

Page 7

3.4 VERIFICATION MEASUREMENTS

Prior to shipping, the Transition Circuit has been tested in a BOP 1KW. The following measurements can be used

to ensure that the Transition circuit has been installed correctly, or for debugging. Table 2 lists the test equipment

needed to perform these measurements.

TABLE 2. TEST EQUIPMENT REQUIRED

Test Equipment Requirement

Digital Voltmeter (DVM) Voltage measurements (d-c)

Resistive Load (RL) Value (Ohms) = 200 x Nominal Output Voltage / Nominal Output Current

Variable Power Supply (PS) Unipolar, adjustable, able to deliver Nominal Output Voltage of 10V with an adjust-

(RL = 25 Ohms, 10 Watts).

able current limit having a maximum value of at least 12A.

3.4.1 A7A3R5 Measurement

1. With the unit turned off, connect a DVM (set for DC voltage measurements) to Transition Circuit A7A3R5 (end

closest to A7A3J1; see Figure 1), referenced to TP2.

2. Install the power cord and connect the BOP to source power.

3. With no load connected, turn on the unit, then set the BOP to voltage mode, enable the output and program

the output voltage to positive full scale (10V).

4. Set the current limit to the full scale value (75A).

5. Verify that the DVM measures –10V ±0.5V.

6. Set the output voltage to negative full scale and verify that the DVM measures +10V ±0.5V. Turn off the unit.

3.4.2 A7A3TP3 Measurement

1. With the unit turned off, connect the DVM to Transition Circuit A7A3TP3, referenced to TP2.

2. Install a short-circuit across the BOP output.

3. Turn on the unit, then set the BOP to current mode, enable the output and program the output current to positive full scale (75A).

4. Set the voltage limit to the full scale value (10V).

5. Verify that the DVM measures +10V ±0.1V.

6. Set the output current to negative full scale. Verify the DVM measures –10V ±0.1V, then turn off the unit

3.4.3 A7A3R17 Measurement

1. With the unit turned off, connect the DVM across A7A3R17 (reference lead connected to the resistor end nearest to A7A3J4).

2. Disconnect the short-circuit from the output and connect a resistive load RL (see Table 2) across the output.

Turn on the unit, set voltage mode, enable the output and program the output voltage to positive full scale. Set

the current limit to the full scale value. The DVM should measure 0V ±10mV. Turn off the unit.

3. With the unit turned off, leave the DVM across A7A3R17 and connect a digital scope probe to A7A3D3 anode

(referenced to the end of resistor A7A3R17 nearest to A7A3J4). Set the digital scope for 1V/div, 5ms/div, normal triggering (positive edge, single).

4. Disconnect the load from the output and connect a variable power supply PS (see Table 2) to the BOP with PS

positive terminal to BOP OUT terminal and PS negative terminal to BOP COM terminal. Set the PS for to the

nominal output voltage of the BOP (10V), and set PS current limit value to minimum (zero).

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

071812 228-1746 REV 2 7

Page 8

5. Turn on the BOP, set voltage mode, enable the output and program a positive output voltage of +9V value and

set the current limit to full scale (75A).

6. Gradually increase the PS current, monitoring the DVM/ digital scope and the BOP front panel display and/or

the internal LED indicators DS3 and DS2 on A3A4 (see Figure 5 for location of LEDs). DS3 is green and goes

on when the Front End Module is in source mode of operation. DS2 is yellow and goes on when the Front End

Module is in sink (recuperation) mode of operation.

7. When PS current reaches approximately 0.075 ±0.025A, note that the DVM indication jumps from zero to

+1.24V ±0.3V.

8. When PS current reaches approximately 8.9A ±1.3A, green LED indicator A4A3DS3 goes off, yellow LED

A4A3DS2 goes on, the BOP display changes the message flag from “SOURCE” to “SINK” and the DVM jumps

from +1.24V to zero.

9. Gradually decrease PS current. When PS current reaches approximately 2.8A ±0.4A, green LED indicator

A4A3DS3 goes on, yellow LED A4A3DS2 goes off, the BOP display changes the message flag from “SINK” to

“SOURCE” and the digital scope will show a 15V, 5mS positive pulse.

10. Turn off the unit and disconnect all the test equipment from the BOP. Unplug the unit from the a-c input source.

3.5 REASSEMBLY PROCEDURE

CAUTION: The two screws at the top of the front panel must be installed last to avoid damage to the

!

1. Attach the cover to the chassis using 14 screws.

2. Attach the two mounting ears to the chassis using three screws for each.

front panel.

3. Install the power cord and connect the unit to source power.

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: hq@kepcopower.com

8 228-1746 REV 2 071812

Loading...

Loading...