T300

Body Builders’ Manual

BODY BUILDERS’ MANUAL

CONTENTS

SECTION 1 INTRODUCTION

SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SECTION 2 SAFETY AND COMPLIANCE

SAFETY SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Warnings, cautions, and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

FEDERAL MOTOR VEHICLE SAFETY STANDARDS (FMVSS) COMPLIANCE 2-1

Incomplete Vehicle Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SECTION 3 DIMENSIONS

ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

TURNING RADIUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

OVERALL DIMENSIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Side View — T300 with Single Rear Axle . . . . . . . . . . . . . . . . . . . . 3-2

Side View — T300 with Tandem Rear Axle . . . . . . . . . . . . . . . . . . 3-3

Front and Rear Views — T3 0 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

DETAIL VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Side View Detail — T300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Left Side: Step and Cab Floor Height — T300 . . . . . . . . . . . . . . . . 3-6

Right Side: Step and Cab Floor Height — T300 . . . . . . . . . . . . . . . 3-7

Crossmember Locations — T300 . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Fuel Tank Locations — T300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Frame Rail Configurations — T300 . . . . . . . . . . . . . . . . . . . . . . . 3-10

Battery Box and Air Tanks — T300 . . . . . . . . . . . . . . . . . . . . . . . 3-10

Fuel Tank and Exhaust — T300 . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

22-inch Fuel Tanks — T300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Horizontal Muffler-Vertical Tailpipe on Cab — T300 . . . . . . . . . . . 3-12

SECTION 4 BODY MOUNTING

CRITICAL CLEARANCES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Rear Wheels and Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chassis with Outserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

BODY MOUNTING US ING BR ACK ETS . . . . . . . . . . . . . . . . . . . . . . . 4-2

Frame Sill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -2

Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Frame Drilli ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Kenwo rth Truck Co. 6/99 I

BODY MOUNTING USING U–BOLTS. . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Rear Body Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

SECTION 5 FRAME MODIFICATIONS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

DRILLING RAILS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Loc a ti on and Hole Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

MODIFYING FRAME LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Frame Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Changing Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Crossmembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

WELDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

SECTION 6 ELECTRI CAL

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

ELECTRICAL CIRCUITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Prewired Body Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Fuse and Circuit Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Circuits Wired Through the Ignition . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Circuits Wired to Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

INSTALLING A THIRD BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

WIRING FOR A LIFTGATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Lift g a t e Power Sour c e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Connecting the Liftgate Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

APPENDIX A VEHICLE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . A-1

VIN Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Chassis Number Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

CERTIFICATION LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Components and Weights Label . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Tire/Rim and Weight Rating Data Label . . . . . . . . . . . . . . . . . . . . . A-2

Incomplete Vehicle Certification Label . . . . . . . . . . . . . . . . . . . . . . A-2

Noise Emission Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Paint Identification Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Engine Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Transmission Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Front Axle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Rear Axle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Kenwo rth Truck Co. 6/99 II

APPENDIX B WEIGHT DISTRIBUTION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

CALCULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Weight Distribution without Body . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Weight Distribution with Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

COMPLETE (LOADED) VEHICLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Water Level Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Body Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

INDEX

CONTENTS

Kenwo rth Truck Co. 6/99 III

CONTENTS

FIGURES

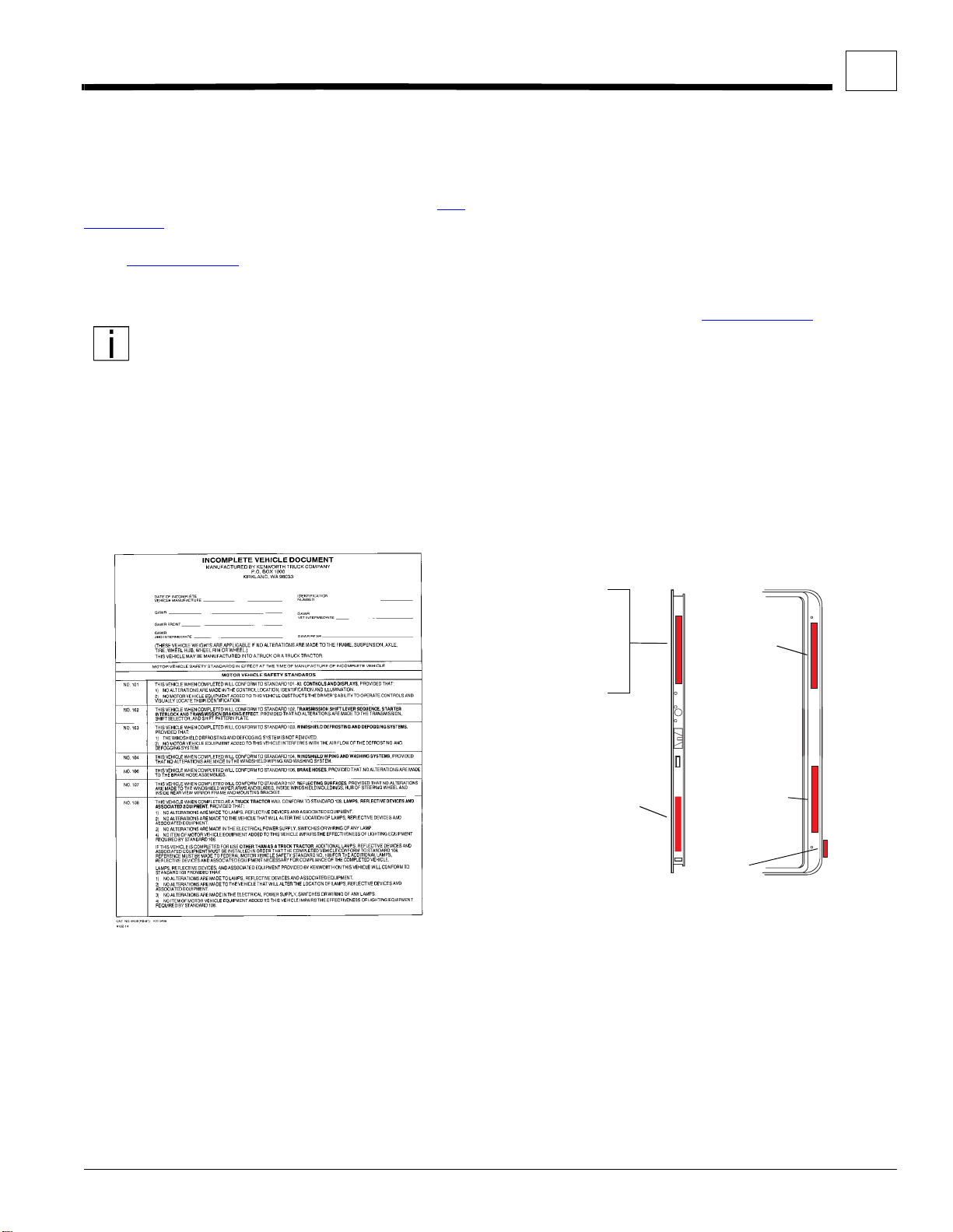

Figure 2–1. Incomplete Vehicle Certification Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

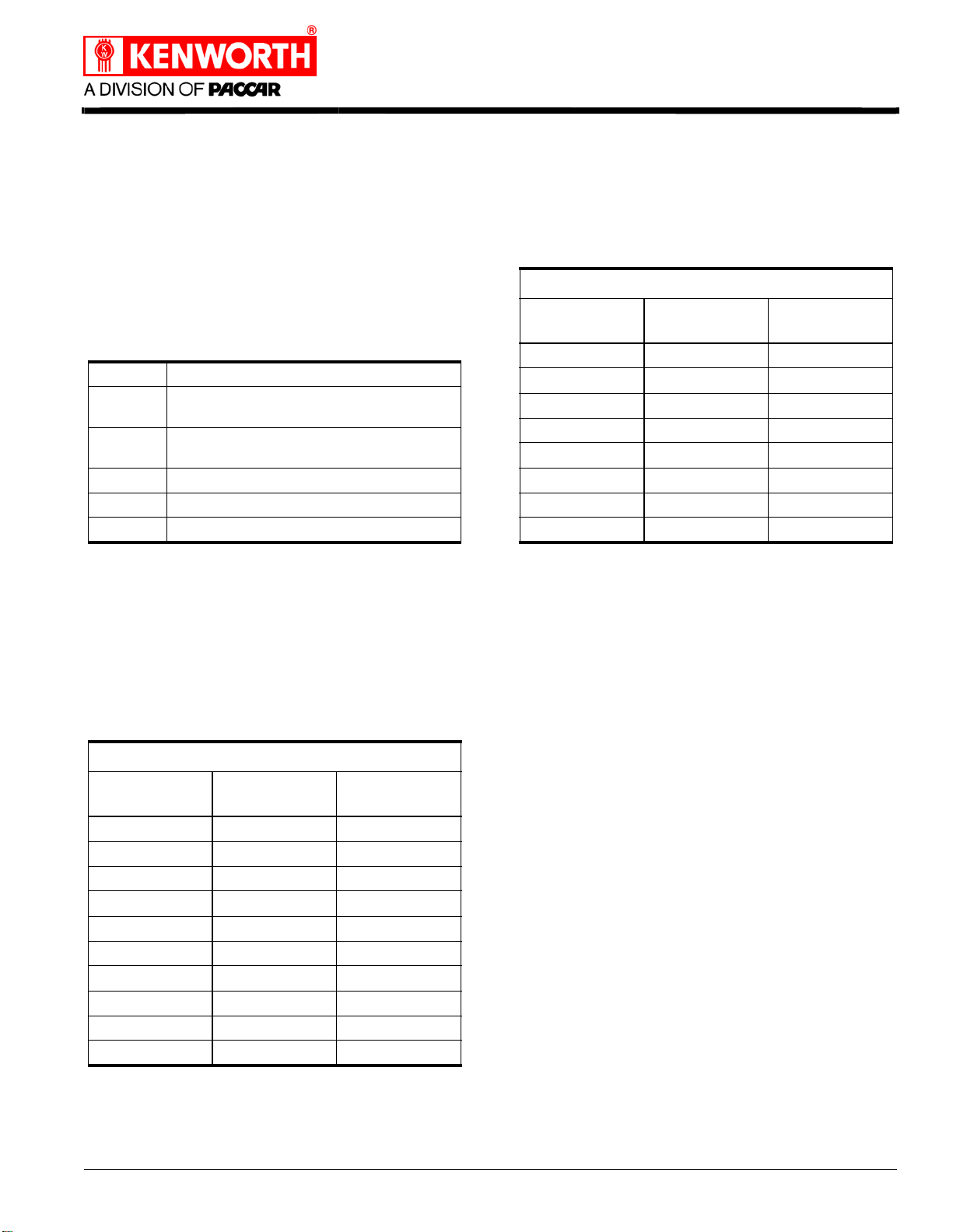

Figure 2–2. Location of Certification Labels - Driver’s Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

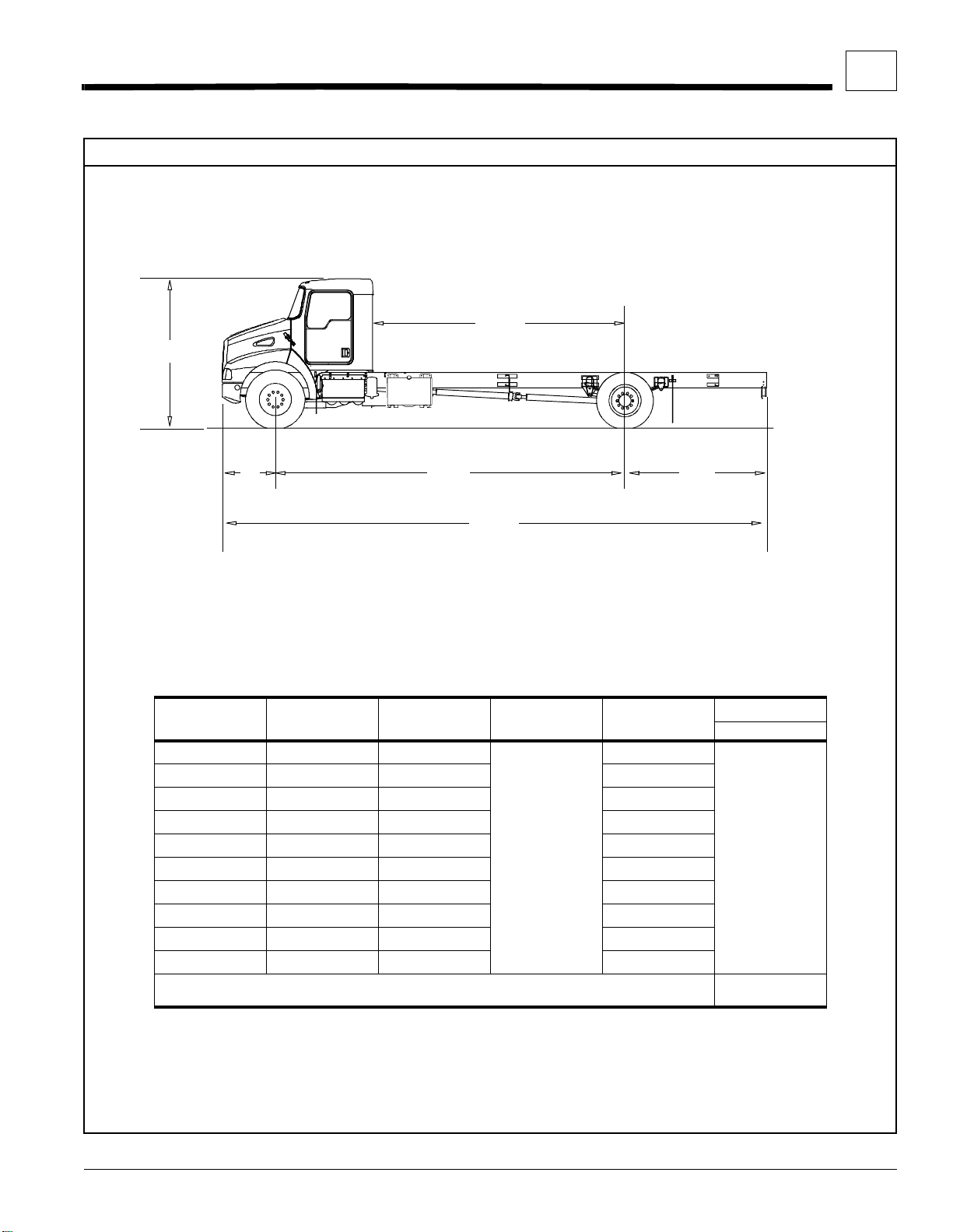

Figure 3–1. T300 W/ Single Rear Axle: Height and Length Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

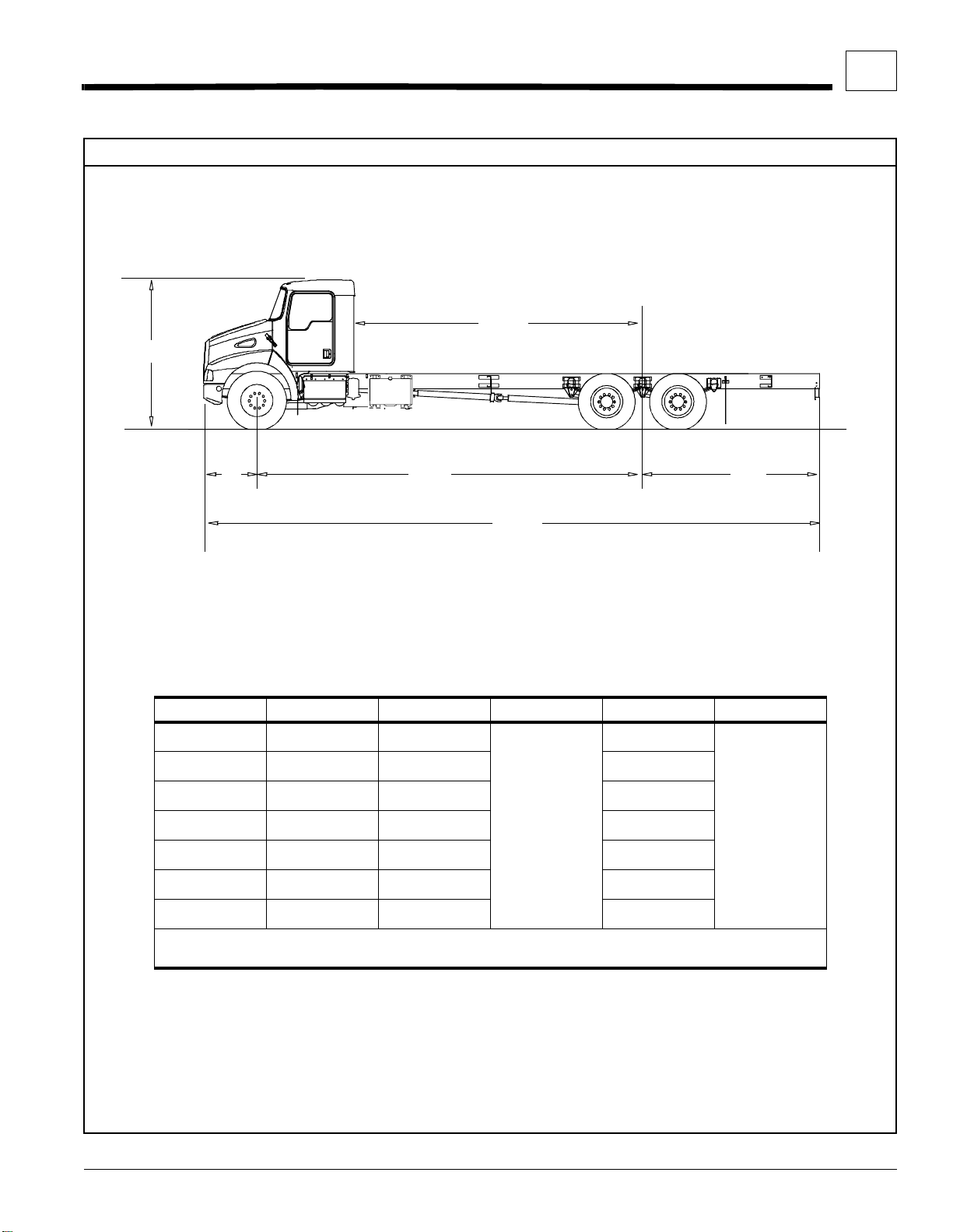

Figure 3–2. T300 W/ Tandem Rear Axle: Height and Length Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

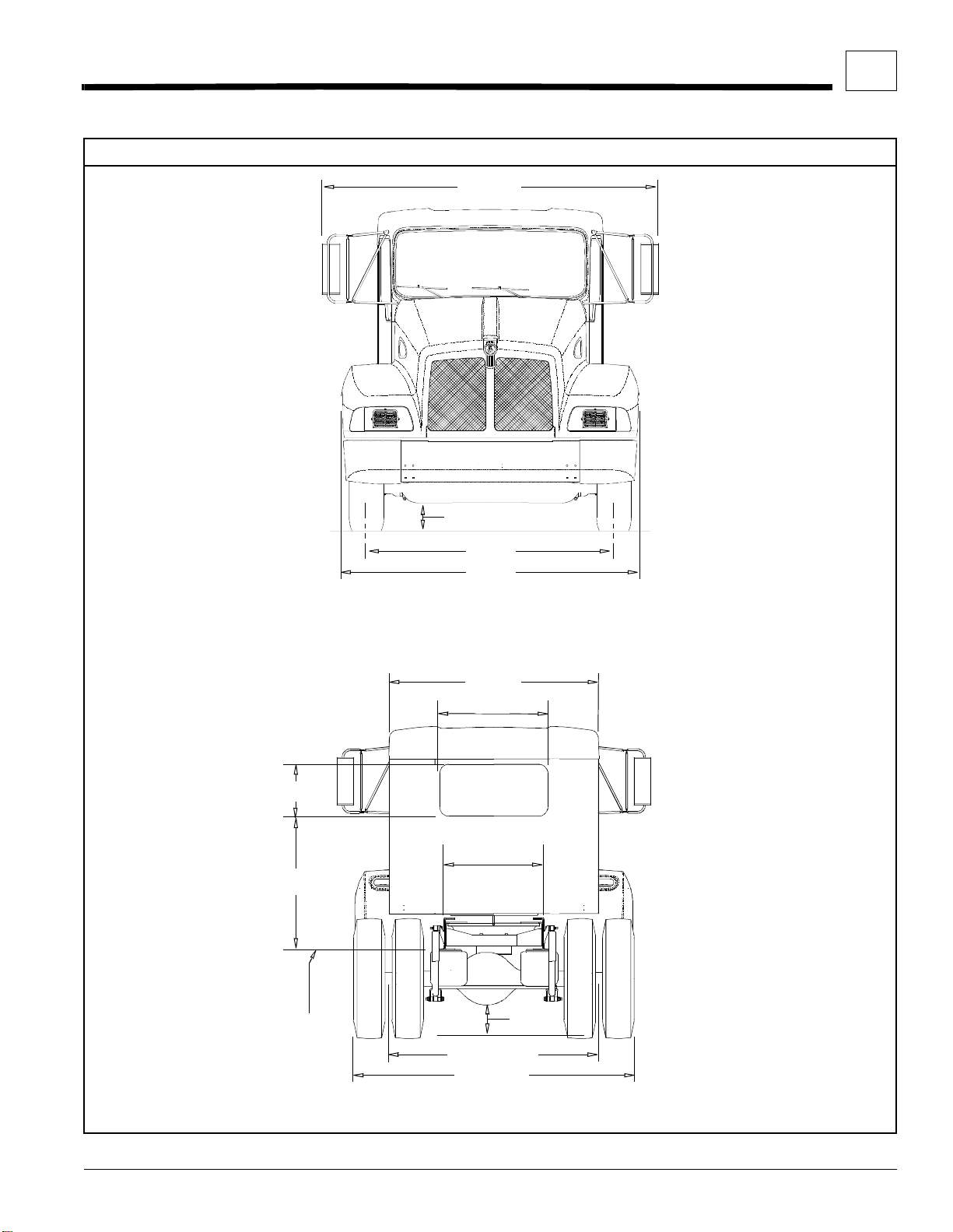

Figure 3–3. T300 Front View: Width and Ground Clearance Measurements [inches (mm)]. . . . . . . . . . . . . . . . . .3-4

Figure 3–4. T300 Rear View: Width and Ground Clearance Measurements [inches (mm)]. . . . . . . . . . . . . . . . . .3-4

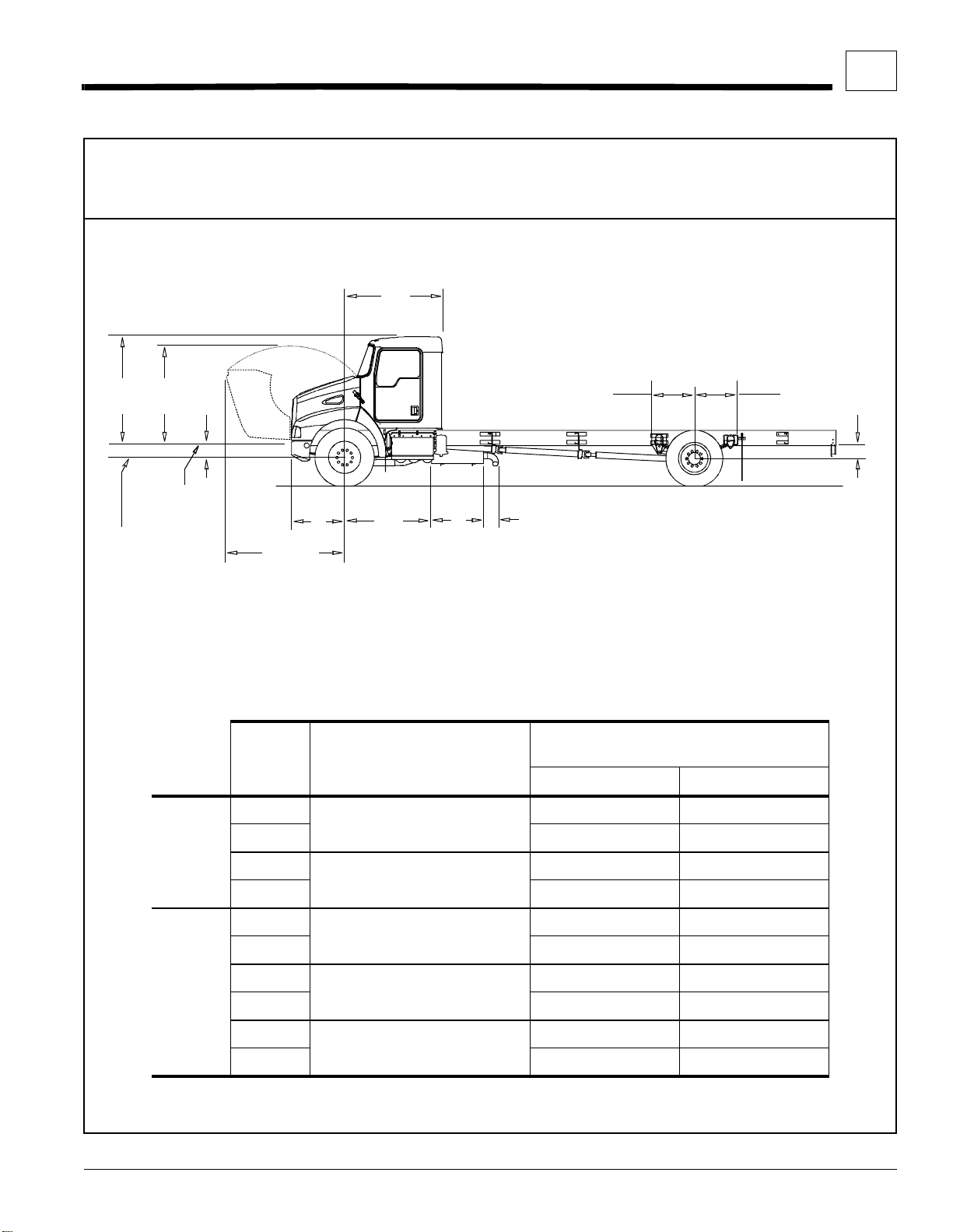

Figure 3–5. T300 Detailed Side View: Specific Measurements [inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Figure 3–6. T300 Battery Box Step and Cab Floor: side view, left side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3–7. T300 Fuel Tank Step and Cab Floor: side view, right side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3–8. T300 Crossmember Location and Overall Width with Doors Open. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3–9. T300 Fuel Tank Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Figure 3–10. T300 10.5 and 10.62–Inch Rail Measurements [Inches (mm)] and Strength Characteristics. . . . . . 3-10

Figure 3–11. T300 Battery Box and Air Tank Measurements [Inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3–12. T300 Standard Fuel Tank and Exhaust Measurements [Inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3–13. T300 Optional 22-inch Fuel Tank Mounting Measurements [Inches (mm)]. . . . . . . . . . . . . . . . . . . . 3-11

Figure 3–14. T300 Vertical Tailpipe on Side of Cab [Inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Figure 3–15. T300 Vertical Tailpipe on Back of Cab [Inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 4–1. Minimum Clearance Between Top of Rear Tires and Body Structure Overhang. . . . . . . . . . . . . . . . .4-1

Figure 4–2. Minimum Back–of–Cab Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4–3. Air Gap with Frame Rail with Outsert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Figure 4–4. Spacer Between Frame Sill and Body Rail — Rubber or Plastic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4–5. High Compression Spring Between the Mounting Bolt and Upper Bracket. . . . . . . . . . . . . . . . . . . . .4-3

Figure 4–6. Rubber Spacer Between Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4–7. Hole Location Guidelines for Frame Rail and Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Figure 4–8. Crossmember–Gusset Hole Pattern Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Figure 4–9. Acceptable U–Bolt Mounting with Wood and Fabricated Spacers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4–10. Clearance Space for Air Lines and Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Figure 4–11. Example of Fishplate Bracket at Rear End of Body, used with U–Bolts. . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 5–1. Detail of Frame Extensions and Joint Welding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -2

Figure 5–2. Frame Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Figure 5–3. Comparison of Original, Shortened, and Extended Wheelbases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5–4. Crossmember Added When Distance Exceeds 60 Inches (1524mm). . . . . . . . . . . . . . . . . . . . . . . . .5-4

Figure 6–1. Location of Prewired Body Harness Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Figure 6–2. Prewired Truck and Body Harness (before 4/98) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Figure 6–3. Prewired Truck and Body Harness (after 3/98) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Figure 6–4. Adding a Third Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Figure 6–5. Liftgate Circuit Breaker Inside Battery Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure A–1. Vehicle Identification Number (VIN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Figure A–2. Driver’s Door and Door Frame Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Figure A–3. Cummins Identification Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Figure A–4. Front Axle Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Figure A–5. Rear Axle Identification Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Figure B–1. Balanced Load: CGf 100 in. from front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Figure B–2. Unbalanced Load: CGf 133 in. from front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Figure B–3. Balanced Body Unloaded: CGf 156 in. (3962 mm) from front axle. . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Figure B–4. Liftgate Example: CGf 246 in. (6248 mm) from front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

Figure B–5. Loaded Vehicle Example: CGf 156 in. (3962 mm) from front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Kenwo rth Truck Co. 6/99 IV

CONTENTS

TABLES

TABLE 3-1. Abbreviations Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

TABLE 3-2. Turning Radius-T300 w/single rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

TABLE 3-3. Turning Radius-T300 w/tandem rear axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

TABLE 3-4. T300 w/ Single Rear Axle: Overall Dimensions [inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

TABLE 3-5. T300 w/ Tandem Rear Axle: Overall Dimensions [inches (mm)]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

TABLE 3-6. T300 Front and Rear Suspension (FS/RS) Centerline (C/L) to Rail Measurements. . . . . . . . . . . . . . . . . . 3-5

TABLE 3-7. T300 Battery Box Step and Cab Floor Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

TABLE 3-8. T300 Fuel Tank Step and Cab Floor Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

TABLE 3-9. T300 Crossmember Locations: measured from front axle centerline [inches (mm)]. . . . . . . . . . . . . . . . . .3-8

TABLE 3-10.T300 Fuel Tank Locations for Standard Wheelbase Configurations [inches (mm)]. . . . . . . . . . . . . . . . . . .3-9

TABLE 6-1. Third Battery Installation Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

TABLE A-1. Model Year Letter (CODE) Designations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

TABLE B-1. T300 Single Rear Axle “Bare” Chassis Tare Weights (no driver, no fuel), lb (kg). . . . . . . . . . . . . . . . . . . .B-3

TABLE B-2. T300 Tandem Rear Axle “Bare” Chassis Tare Weights (no driver, no fuel), lb (kg). . . . . . . . . . . . . . . . . . .B-4

TABLE B-3. T300 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

TABLE B-4. T300 Weight distribution and chassis rating calculation (sample) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

TABLE B-5. Recommended T300 Body Lengths (Single Rear Axle). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

TABLE B-6. Recommended T300 Body Lengths (Tandem Rear Axle). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Kenwo rth Truck Co. 6/99 V

SECTION 1 INTRODUCTION

SCOPE

This manual was created to provide body builders with

appropriate information and guidelines useful in the

body planning and installation process. This information

will be helpful when installing bodies or other associated equipment.

This manual contains appropriate dime nsional information, guidelines for mounting bodies, guidelines for

modifying frames, electrical wiring information, and

other information useful in the body installation process.

The intended primary users of this manual are body

builders who install bodies and associated equipment

on Kenworth T300 Medium Duty vehicles. Dealers who

sell and service the vehicle will also find this information

useful.

This Body Builders’ Manual can be very useful when

specifying a vehicle, particularly when th e body builder

is involved in the vehicle definition and ordering pro-

cess. Early in the process, professional body builders

can often contribute valuable information that reduces

the ultimate cost of the body installation.

This manual is not a maintenance manual or an

operation manual.

• For chassis maintenance and repair information

consult the

Manual

selling dealer or you can order your own copy of the

maintenance manual from your local dealer.

• For chassis operating information consult the

ator’s Manual

also be ordered from your local dealer.

Kenworth Medium Duty Maintenance

available in the Service Departmen t of the

Oper-

, included with each vehicle. They can

1–1 6/99 Body Builders’ Ma nual

SECTION 2 SAFETY AND COMPLIANCE

SAFETY SIGNALS

We’ve put a number of alerting mess ages in this book.

Please read and follow them. They are there for your

protection and information. These alerting messages

can help you avoid injury to yourself or others and help

prevent costly damage to the vehicle.

Key symbols and “signal words” are used to indicate

what kind of message is going to follow. Pay special

attention to comments prefaced by “WARNING”, “CAUTION”, and “NOTE.” Please don't ignore any of these

alerts.

Warnings, cautions, and notes

WARNING

When you see th is word and symbol, the message that follows is especially vital. It signals a

potent ially hazardou s situatio n which, if not

avoided, could result in death or serious injury.

This m essage wil l tell you what the haza rd is,

what can happen if you don’t heed the warning,

and how to avoid it.

Example:

WARNING! Be sure to use a circuit breaker

designed to meet liftgate am p erage req ui rements. An incorrectly specified circuit

breaker could result in a electrical overload

or fire situation. Follow the liftgate installation instructions and use a circuit breaker

with the recommeded capacity.

CAUTIO N

Signals a potentially hazardous situation

which, if not avoi ded, could r esult i n minor or moderate injury or damage to the vehicle.

Example:

CAUTION:

in the rail. Use the appropriate drill bit.

Never use a torch to m ake a h ole

NOTE

Provides general infor mation: for example, the

note could warn you on how to avoid damaging

your vehicle or how to drive the vehicle more efficiently.

Example:

NOTE:

to the battery box and fuel tank fill neck.

Please take the time to read these mes-

sages when you see them, and remember:

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

seri o us inj u ry.

CAUTION

Signals a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury or damage to the vehicle.

NOTE

Useful information that is related to the topic

being discussed.

Be sure to provide maintenanc e access

FEDERAL MOT OR VEHICLE SAFETY STANDARDS (FMVSS) COMPLIANCE

As an Original Equipment Manufacturer (OEM), Kenworth Truck Co. ensures that our products comply with

all applicable Federal Motor Vehicle Safety Standards

(FMVSS). However, the fact that this vehicle has no

fifth–wheel and that a Body Builder (Final Stage M anufacturer) will be doing additional modifications means

that the vehicle was incomplete when it left the build

plant. See page 2–2

information.

and Appendix A for additional

Kenwo rth Truck Co. 6/99 2–1

SAFETY AND COMPLIANCE

Figure 2–1. Inco mp le te Vehicle Ce rtifica tion

Document.

01476

2

Incomplete Vehicle Certification

An Incomplete Vehicle Document is shipped with the

vehicle, certifying that the vehicle is no t complete. Se e

Figure 2–1. In addition, affixed to th e driver's side d oor

frame or edge is an Incomplete Vehicle Certification

label. See Figure 2–2.

cle Certification and Identification, see APPENDIX A

“VEHICLE IDENTIFICATION.”

NOTE: These documents list the FMVSS regulations that the vehicle complied with when it

left the build plant. You should be aware that if

you modify or alter any of the components or

systems covered by these FMVSS regulations, it is your responsibility as the Final

Stage Manufacturer to ensure that the complete vehicle maintains compliance with the

particular FMVSS regulations whe n you complete your modifications.

. For further information on Vehi-

As the Final Stage Manufacturer, you should retain the

Incomplete Vehicle Document for your records. In addition, you should record and retain the manufacturer and

serial number of the tires on the vehicle. Upon completion of the vehicle (installation of the body and any other

modifications), you should affix your certification label

to the vehicle as required by Federal law. This tag identifies you as the “Final Stage Manufacturer” and certifies that the vehicle complies with Federal Motor

Vehicle Safety Standards. (See Figure 2–2.

DOOR EDGE

DOOR

)

FRAME

TIRE,RIM,CERTIFICATION

AND WEIGHT LABEL

(TRACTOR)

OR INCOMPLETE

VEHICLE

CERTIFICATION

LABEL (TRUCK)

MAJOR

COMPONENTS

AND WEIGHTS

LABEL (TRUCK

OR TRACTOR)

FINAL STAGE MAN-

UFA CTURER LABEL

(STAMPED)

Figure 2–2. Location of Certification

Labels - Driver’s Door

TIRE, RIM,

AND WEIGHT

RATING DATA

LABEL

(TRUCK)

(TO BE INSTALLED

BY FINAL STAGE

MANUFACTURER

(TRUCK ONLY)

CHASSIS

NUMBER

02378

Kenwo rth Truck Co. 6/99 2–2

SECTION 3 DIMENSIONS

ABBREVIATIONS

Throughout this section and in other sections as well,

abbreviations are used to describe cer tain characteristics on your vehicle. The char t below lists the abbreviated terms used.

T ABLE 3-1. Abbreviation s Used.

A OVERALL VEHIC LE LENGTH

AF

B

CA BACK OF CAB TO REAR AXLE LENGTH

D CAB HEIGHT

WB WHEELBASE LENGTH

FRAME RAIL OVERHANG LENGTH

BEHIND REAR AXLE

FRONT BUMPER TO FRONT AXLE

LENGTH

TURNING RADIUS

Approximate turning radius specifications for the T300

are listed (by wheelbase) in the following tables. Tables

3-2 and 3-3 list turn radius information for chassis with

standard components. Optional components may give

different results.

T ABLE 3-2.

T300 W/SINGLE REAR AXLE

WHEELBASE

Turning Radius-T300 w/single rear axle

CURB TO

(IN.)

145 20 23

150 21 24

160 22 25

185 25 28

200 27 30

215 29 32

230 31 34

245 32 35

260 34 37

280 36 39

CURB (FT.)

WALL T O W ALL

(FT.)

T ABLE 3-3. Turning Radius-T300 w/tandem rear

axles

T300 W/TANDEM REAR AXLES

WHEELBASE

(IN.)

165 24 28

175 26 29

190 27 30

205 29 32

220 31 34

235 33 36

250 35 38

260 36 39

CURB TO

CURB (FT.)

WALL T O W ALL

(FT.)

OVERALL DIMENSIONS

This section includes drawings and char ts of the standard T300 vehicle, including a 10,000 lb. front suspension, a 20,000 lb. rear suspension, and R250F

295/75R22.5 tires. Use these drawings to plan overall

vehicle configurations.

On the pages t hat follow, detail drawings show particular views of each vehicle component. They illustrate

important m easurements critica l to designing bodies of

all types. See the “Contents” at the beginning of the

manual to locate the drawing you need.

Kenwo rth Truck Co. 3–1

Side View — T300 with Single Rear Axle

D

CA

DIMENSIONS

OVERALL DIMENSIONS — T300

3

B

WB

A

Figure 3–1. T300 W/ Single Rear Axle: Height and Length Measurements.

T ABLE 3-4. T300 w/ Single Rear Axle: Overall Dimensions [inches (mm)].

WB A AF B CA *

145 (3683) 237.2 (6025) 55 (1397)

150 (3810) 237.2 (6025) 50 (1270) 82 (2083)

160 (4064) 261.2 (6634) 64 (1626) 92 (2337)

185 (4699) 285.2 (7244) 63 (1600) 117 (2972)

200 (5080) 309.2 (7854) 72 (1829) 132 (3353)

215 (5461) 333.2 (8463) 81 (2057) 147 (3734)

230 (5842) 357.2 (9073) 90 (2286) 162 (4115)

245 (6223) 381.2 (9682) 99 (2515) 177 (4496)

260 (6604 ) 405.2 (10292) 108 (2743 ) 192 (4877 )

280 (7112 ) 429.2 (10902) 112 (2845 ) 212 (5385 )

*

CA measured from true back of cab to rear axle centerline

** Determined with Front Tire Bridgestone R250F 295/75R22.5

37.2 (945)

AF

03008

UNLADEN

D **

77 (1956)

104.9 (26 64)

Kenwo rth Truck Co. 3–2

Side View — T300 with Tandem Rear Axle

D

CA

DIMENSIONS

OVERALL DIMENSIONS — T300

3

B

WB

A

Figure 3–2. T300 W/ Tandem Rear Axle: Height and Length Measurements.

T ABLE 3-5. T300 w/ Tandem Rear Axle: Overall Dimensions [inches (mm)].

WB A AF B CA * D **

175 (4445) 283.2 (7193) 71 (1803)

190 (4826) 307.2 (7803) 80 (2032) 122 (3099)

205 (5207) 331.2 (8412) 89 (2261) 137 (3480)

220 (5588) 355.2 (9022) 98 (2489) 152 (3861)

235 (5969 ) 379.2 (96 32) 107 (2718) 167 (4242)

250 (6350 ) 403.2 (10241) 116 (2946 ) 182 (4623 )

260 (6604 ) 427.2 (10851) 130 (3302 ) 192 (4877 )

*

CA measured from true back of cab to rear axle centerline

** Determined with Front Tire Bridgestone R250F 295/75R22.5

37.2 (945)

AF

03008T

107 (2718 )

104.9 (26 64)

Kenwo rth Truck Co. 3–3

Front and Rear Views — T300

107.7

(2735)

DIMENSIONS

OVERALL DIMENSIONS — T300

3

8.9

(226)

79.1

(2019)

95.3

(2421)

Figure 3–3. T300 Front View: Width and Ground Clearance Measurements [inches (mm)].

71.8

(1824)

36

(914)

17 (432)

34

46.3 (1177)

(864)

02389

BOTTOM

FRAME

FLANGE

Figure 3–4. T300 Rear View: Width and Ground Clearance Measurements [inches (mm)].

Kenwo rth Truck Co. 3–4

71.9 (1827)

96 (2440)

9.7

(248)

03005A

Side View Detail — T300

76.7

(1948)

66.9

(1699)

FS RS

DETAI L VI EWS

68

(1727)

DIMENSIONS

OVERALL DIMENSIONS — T300

29.8

(757)

(762)

3

30

BOTTOM

FLANGE

AXLE C / L

Figure 3–5. T300 Detailed Side View: Specific Measurements [inches (mm)].

T ABLE 3-6. T300 Front and Rear Suspension (FS/RS) Centerline (C/L) to Rail Measurements.

LOAD REAR SUSPENSION

UNLADEN

LADEN 6.6 (168) 6.6 (168)

SINGLE

UNLADEN

REAR AXLE

LADEN 6.6 (168) 7.8 (198)

UNLADEN

LADEN 6.6 (168) 7.2 (183)

37.2

(945)

82.8

(2102)

REYCO 79KB

HENDRICKSON

HAS 210L /230L

REYCO 102

61

(1550)

36

(914)

10.5

(267)

CENTERLINE OF AXLE TO BOTTOM

03008

FLANGE OF RAIL [IN. (MM)]

FS RS

8.4 (213) 9.0 (229)

8.4 (213) 7.8 (198)

8.4 (213) 8.5 (216)

UNLADEN

TANDEM

Kenwo rth Truck Co. 3–5

LADEN 6.6 (168) 7.8 (198)

REAR AXLE

UNLADEN

LADEN 6.6 (168) 7.6 (193)

HENDRICKSON

HAS 402

HENDRICKSON

RT2-400

8.4 (213) 7.8 (198)

8.4 (213) 8.6 (218)

Left Side: Step and Ca b Floor Height — T300

DIMENSIONS

OVERALL DIMENSIONS — T300

3

Figure 3–6. T300 Battery Box Step and Cab Floor: side view, left side.

T ABLE 3-7. T300 Battery Box Step and Cab Floor Measurements.

POSITION

A FIRST

STEP

B SECOND

STEP

C CAB

FLOOR

UNLADEN

IN. (MM)

21.3 (540) 18.9 (481)

37.0 (940) 34.7 (881)

44.6 (1133) 42 (1069)

LADEN

IN. (MM)

C

B

A

03012

Kenwo rth Truck Co. 3–6

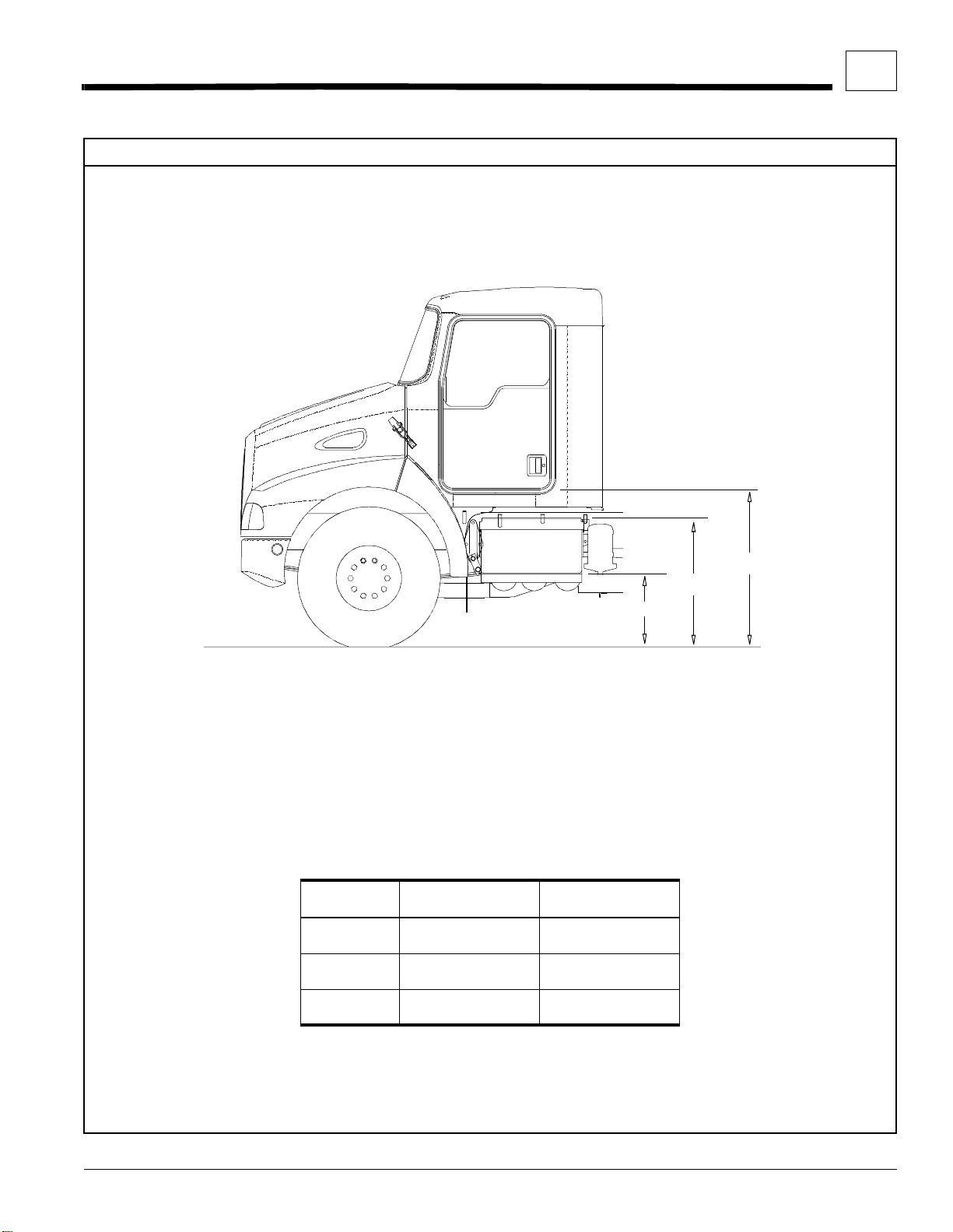

Right Side: Step and Cab Floor Height — T300

DIMENSIONS

OVERALL DIMENSIONS — T300

3

C

B

A

Figure 3–7. T300 Fuel Tank Step and Cab Floor: side view, right side.

T ABLE 3-8. T300 Fuel Tank Step and Cab Floor Measurements.

POSITION

A FIRST

STEP

B SECOND

STEP

C CAB

FLOOR

UNLADEN

IN. (MM)

23.3 (592) 21.0 (533)

38.1 (967) 35.8 (908)

44.6 (1133) 42 (1069)

9707211

LADEN

IN. (MM)

Kenwo rth Truck Co. 3–7

Crossmember Locations — T300

118

(2997)

50°–55°

A

B

DIMENSIONS

OVERALL DIMENSIONS — T300

3

C

D

E

Figure 3–8. T300 Crossmember Location and Overall Width with Doors Open.

TABLE 3-9. T300 Crossmember Locations: measured from front axle centerline [inches (mm)].

WHEELBASE A CB B CB C CB D E

145

146 - 150

151 - 160

161 - 185

186 - 200

201 - 215

216 - 230

231 - 245

246 - 260

261 - 280

157 - 177

178 - 193

194 - 217

218 - 231

232 - 247

248 - 256

257 - 262

90.7 (2305)

79.7 (2025)

90.7 (2305)

101.7 (2585)

101.7 (2585)

90.7 (2305)

101.7 (2585)

101.7 (2585)

101.7 (2585)

101.7 (2585)

90.7 (2305)

90.7 (2305)

101.7 (2585)

101.7 (2585)

90.7 (2305)

101.7 (2585)

101.7 (2585)

✓ Driveline centerbearing (CB) mounted on this crossmember

➀ Dimensions noted are based on the use of the standard T300 transmission, rear axle, and driveline.

— ➀ ————— —

✓ ➀ ————— —

✓ ————— —

✓ ————— —

—

✓

✓

✓

✓

✓

140.3 (3565)

118.3 (3005)

162.4 (4125)

162.4 (4125)

162.4 (4125)

140.3 (3565)

———— —

✓

156.9 (3985)

✓ ———

✓ ———

✓

—

201 (5105)

178.9 (4545)

——

——

✓

217.5 (5525) 344.4 (8748)

279.4 (7097)

294.4 (7478)

309.4 (7859)

324.4 (8240)

T ANDEM REAR AXLES

—————— —

✓ ————— —

✓ ————— —

—

✓

✓

✓

140.3 (3565)

118.3 (3005)

151.4 (3845)

156.9 (3985)

———— —

✓

156.9 (3985)

✓ ———

✓ ———

——

325.4 (8265)

340.4 (8646)

350.4 (8900)

03009

Kenwo rth Truck Co. 3–8

Fuel Tank Locations — T300

A B

A

DIMENSIONS

OVERALL DIMENSIONS — T300

3

Figure 3–9. T300 Fuel Tank Locations.

TABLE 3-10. T300 Fuel Tank Locations for Standard Wheelbase Configurations [inches (mm)].

FUEL T ANK A * B

RH Under Cab

Rectangular Steel 50 Gal

Round 22” Aluminum

LH Behind Cab

Rectangular Steel

Round 22” Aluminum **

* Measured from centerline of front axle

** Also RH Behind Cab.

B

56 Gal 35.6 (904)

75 Gal 47.3 (1201)

100 Gal 62.2 (15 80)

120 Gal 74.3 (18 87)

50 Gal 78.3 (1989) 30.5 (775)

70 Gal 77.7 (1974) 42.6 (1082)

56 Gal

75 Gal 47.3 (1201)

100 Gal 62.2 (15 80)

32.8 (833)

77.3 (1963)

03011

33.5 (851)

35.6 (904)

Kenwo rth Truck Co. 3–9

Frame Rail Configurations — T300

COMPONENTS

DIMENSIONS

OVERALL DIMENSIONS — T300

3

10.5–INCH RAIL

YIELD: 80,000 psi

SECTION MODULUS:

16.75 cu in.

RBM: 1,340,000 lb. in.

01162-1

.5

(12.7)

10.5

(266.7)

.25

(6.35)

Figure 3–10. T300 10.5 and 10.62–Inch Rail Measurements

10

(254)

3.5

(88.9)

[Inches (mm)] and Strength Characteristics.

Battery Box and Air Tanks — T300

10.62–INCH RAIL

3.74

HEAT TREATED

(95)

YIELD: 110,00 0 ps i

SECTION MODULUS:

14.8 cu in.

10.24

(260)

ST ANDARD BATTER Y

BOX WITH AIR TANKS

RBM: 1,628,000 lb. in.

.25

(6.35)

.31

(7.94)

3.46

(87.8)

10

(254)

10.62

(269.9)

01161-1

33

(838)

8.7

(220)

7.2

12.6

(319)

Figure 3–11. T300 Battery Box and Air Tank Measurements

Kenwo rth Truck Co. 3–10

(184)

REAR VIEW

[Inches (mm)].

13.6 (346)

15.9 (404) UNLADEN

GROUND

LADEN

03006-1

Fuel Tank and Exhaust — T300

DIMENSIONS

OVERALL DIMENSIONS — T300

3

03006-2

13.2

(334)

(44)

STANDARD FUEL TANK MOUNTING

26.2

(665)

1.8

23

(583)

REAR VIEW

Figure 3–12. T300 Standard Fuel Tank and Exhaust

EXHAUST / MUFFLER MOUNTING

2.5

(63)

6.8

(172)

13.0 (331) LADEN

15.3 (389) UNLADEN

GROUND

Meas u remen t s [Inche s (mm)] .

HORIZONTAL

FROM OUTSIDE

OF RAIL

1.3

(32)

12.2

(309)

REAR VIEW

13.8

(351)

FROM OUTSIDE

OF RAIL

03007

22-inch Fuel Tanks — T300

REAR VIEW

Figure 3–13. T300 Optional 22-inch Fuel Tank Mounting Measurement s [I nches (mm)].

11.0

(279)

16.3

(414)

9.9 (251) LADEN

12.2 (310) UNLADEN

GROUND

25.9

(658)

REAR VIEW

RIGHT SIDE UNDER CABLEFT SIDE BEHIND CAB

Kenwo rth Truck Co. 3–11

Horizontal Muffler-Vertical Tailpipe on Cab — T300

7.3 (185)

7 (178)

DIMENSIONS

OVERALL DIMENSIONS — T300

3

Figure 3–14. T300 Vertical Tailpipe on Side of Cab [Inches (mm)].

CENTERLINE OF CAB

25 (635)

MUFFLER

8 (203)

29

(736.6)

BACK OF CAB

Figure 3–15. T300 Vertical Tailpipe on Back of Cab [Inches (mm)].

Kenwo rth Truck Co. 3–12

SECTION 4 BOD Y MOUNTING

CRITICAL CLEARANCES

Rear Wheels and Cab

CAUTION: Insufficient clearance between

rear tires and body structure could cause

damage to the body during suspension

movement. Allow at least 8 inches clear-

ance (See Figure 4–1.)

Normal suspension movement could cause contact

between the tires and the body. To prevent this, mount

the body so that the m inimum clearance between the

top of the tire and the bottom of the body is 8 inches

(203mm). This should be measured with the body

empty. See Figure 4–1.

8 in.

(203mm)

72 in.

(1829 mm)

MINIMUM

4 in.

03008-4

Figure 4–2. Minimum Back–of–Cab Clearance.

a minimum of 4 inches (102 mm) behind the cab. The

result is a minimum back–of–cab clearance of 72

inches (1829 mm) from the front axle to the leading

edge of the body.

• See SECTION 3 “DIMENSIONS” for further

details on dimensions and clearances.

• Also, se e APPENDI X B “WEIGH T DISTRI BUTION” for explanation of back–of–cab (BOC) /

CA calculations.

02866

Figure 4–1. Minimum Clearance Between Top

of Rear Tires and Body Structure

Overhang.

CAUTION: Maintain adequate clearance

between back of cab and the front (leading

edge) of mounted body . See Figure 4–2.

NOTE: Be sure to provide maintenance

access to battery box and fuel tank fill neck.

The true distance from the centerline of the front axle to

the back of the cab is 68 inches (1727 mm). It is recommended that the leading edge of the body be mo unted

Kenwo rth Truck Co. 4–1

BODY

BODY MOUNTING

4

12.7 mm (½ in.)

GAP

OUTSERT

Figure 4–3. Air Gap with Frame Rail with Outsert

Chassis with Outserts

A 10½-inch non-heat treated frame rail with an outsert

will have an air gap of approximately 6.4 mm (¼ inch)

between the bottom of the out sert flange and the to p of

the frame rail flange. This gap is for manufacturing tolerance purposes and guarantees that the outsert will fit

over the frame rail.

WARNING! If the frame rail flanges are

modified or damaged, the rail could fail

prematurely and cause an accid ent. When

mounting a body to the chassis, DO NOT

drill holes in the upper or lower flange of

the fram e rail. Mount the body usi ng body

mounting brackets or U–bolts.

Install a 12.7 mm (½ inch) thick spacer on the frame rail

aft of the outsert to suppor t the body. The purpose of

the spacer is to fill the "gap" See Figure 4–3. above.

OUTSERT

BODY

FRAME

RAIL

BOD Y MOUNTING USING

BRACKETS

CAUTION: Always install a spacer between

the body subframe and the top flange of

the frame rail.

Installation of a spacer between the body subframe and

the top flange of the frame rail will he lp prevent premature wear of the components due t o chafing or corrosion.

Frame Sill

If the body is mounted to the frame with brackets, we

recommend that the frame sill spacer be made from a

strip of rubber or plastic (delrin or nylon). These materials will not undergo large dimensional changes during

periods of high or low humidity. The strip will be less

likely to fall out during extreme relative motion between

body and chassis. See Figure 4–4.

Kenwo rth Truck Co. 4–2

BOD Y

SUBFRAME

(RAIL)

CHASSIS FRAME

(RAIL) SILL

SPACER

Figure 4–4. Spacer Between Frame Sil l and

Body Rail — Rubber or Plastic.

01016

BODY MOUNTING

4

RUBBER

SPACER

01445

Figure 4–6. Rubber Spacer Between Brackets.

These designs will allow relative movement between

the body and t he chassis during extreme f rame racking

situations. Extreme frame racking, and mountings that

are too rigid, could caus e damage to the body. This is

particularly true with tanker installations.

Brackets

When mounting a body to the chassis with brackets, we

recommend designs that offer limited amount of relative

movement, bolted securely but not too rigid. Brackets

should allow for slight movement between the body and

the chassis. For instance, Figure 4–5 shows a high

compression spring between the bolt and the bracket.

SPRING

01446

Figure 4–5. High Compression Spring Between

the Mounting Bolt and Upper

Bracket.

Another possibility is mounting a rubber spacer

between the brackets. See Figure 4–6.

Mounting Holes

When installing the lower bracket on frame rails the

mounting holes in the chassis fram e bracket and frame

rail must comply with th e general spacing an d location

guidelines illustrated in Figure 4–7. The hole diameter

should not exceed the bolt diamet er by more than .0 60

inches (1.5mm).

A or B EQUAL TO OR GREATER THAN 2 in. (50mm)

UPPER FRAME

FLANGE

LOWER FRAME

FLANGE

01023

Figure 4–7. Hole Location Guidelines for Fr am e Rail

and Bracket.

Kenwo rth Truck Co. 4–3

BODY MOUNTING

4

4 HOLES

.5 IN. DIA.

(12.7mm)

5.63

(143mm)

2.0

(50mm)

5.5

(140mm)

Figure 4–8. Crossmember–Gusset Hole P attern Requirements.

Frame Drilling

WARNING!

chassis, DO NOT drill holes in the upper or

lower flange of th e frame rail. If the frame

rail flanges are modified or damaged, the

rail could fail prematurely and cause an

accident. Mount the body using body

mounting brackets or U–bolts.

When mounting a body to the

6 HOLES

.5 IN. DIA.

(12.7mm)

5.63

(143mm)

2.0

(50mm)

5.5

(140mm)

11.0

(279mm)

01022-01

Hole Location Guidelines

Holes must be located from th e flange as indicated in

Figure 4–7. They must be no closer than 2 inches

(50mm) to each other.

NOTE: If your design permits placement of

body mounting brackets at crossmember locations, you can use the crossmember gusset

bolt holes for body mounting. See Figure 4–8.

BODY MOUNTING USING U–BOLTS

Spacers

If the body is mounted to the frame with U–bolts, use a

hardwood sill (minimum 1/2 inch (12 mm) thick)

between the frame rail and body frame to protect the

WARNING! Do not drill new holes any

closer than 2 inches (50mm) to existing

holes. Frame drilling affects the strength of

the rails.

Kenwo rth Truck Co. 4–4

top surface of the rail flange.

CAUTION: Use care when drilling the

frame web so the wires and air lines routed

inside the rail are not damaged.

BODY MOUNTING

Figure 4–9. Acceptable U–Bolt Moun ti ng wit h Wood

and Fabricated Spacers.

BODY

STRUCTURE

TRUCK FRAME

WOOD SILL

½ in. (12mm)

U–BOLT

FRAME RAIL

SPACER

(FABRICATED

STEEL OR

HARDWOOD)

U–BOLT

SPACER

(HARDWOOD)

01018

MINIMUM

4

WARNING! Do not allow the frame rails or

flanges to deform when tightening the

U–bolts. It will weaken the frame and cou ld

cause an accident. Use suitable spacers

made of steel or hardwood on the inside of

the frame rail to prevent collapse of the

frame flanges.

• Use a hardwood spacer between the bottom

flange and the U–bolt to prevent the U–bolt

from notching the frame flange. See Figure 4–9.

FRAME

RAIL

AIR LINES

AND WIRING

HARNESSES

CHECK

CLEARANCE

SPACE FOR AIR

LINES AND

WIRING

Figure 4–10. Clearance Space for Air Lines and

Cables.

U–BOLT

FRAME RAIL

SPACER

(HARDWOOD

OR STEEL)

U–BOLT

SPACER

WARNING! Do not notch frame rail flanges

to force a U–bolt fit. Notched or damaged

frame flanges could result in premature

frame failure. Use a larger size U–bolt.

01027

WARNING! Do not allow spacers and other

body mounting parts to interfere with

brake lines, fuel lines, or wiring har nesses

routed inside the frame rail. Crimped or

damaged brake lines, fuel lines, or wiring

could result in loss of braking, fuel leaks,

electrical overload or a fire. Carefully

inspect the installation to ensure adequ ate

Kenwo rth Truck Co. 4–5

clearances for air brake lines, fuel lines,

and wiring. See Figure 4–10.

CAUTION: Mount U–bolts so they do not

chafe on frame rail.

Rear Body Mount

When U–bolts are used to mount a body we recommend that the last body attachment be made with a

“fishplate” bracket. See Figure 4–11. This provides a

firm attaching poin t and helps prevent any relative fore

or aft movement between the body and frame.

BODY

STRUCTURE

FRAME

RAIL

Figure 4–11. Example of Fishplate Br ack et at Rear End

of Body, used with U–Bolts.

SECTION 5 FRAME MODIFICATIONS

INTRODUCTION

There are ten standard wheelbase choices for the T300

with a single rear axle (145 to 280 inches) and seven

choices available with tandem rear axles. In addition,

the T300 offers customer specified wheelbases. So, in

most cases frame modifications to produce a certain

wheelbase should not be necessary.

However, some installations may require slight modifications, while other installations will require extensive

modifications. Sometimes an existing dealer stock

chassis may need to have the wheelbase changed to

better fit a customer’s application. The modifications

may be as simple as shortening or lengthening the

frame cutoff, or they may be as complex as changing

the wheelbase.

DRILLING RAILS

Location and Hole Pattern

If holes need to be drilled t o attach a nything to th e rail,

see SECTION 4 “BODY MOUNTING” for more information. Follow the general spacing and hole location

guidelines on Page 4–3, Figure 4-6.

WARNING!

chassis, DO NOT drill holes in the upper or

lower flange of th e frame rail. If the frame

rail flanges are modified or damaged, the

rail could fail prematurely and cause an

accident. Mount the body using body

mounting brackets or U–bolts.

When mounting a body to the

WARNING! Do not drill new holes any

closer than 2 inches (50mm) to existing

holes. Frame drilling affects the strength of

the rails.

CAUTION: Use care when drilling the

frame web so the wires and air lines routed

inside the rail are not damaged.

• Never use a torch to make a hole in the rail. Use

the appropriate diameter drill bit.

Hole pattern dimensions for crossmember designs are

illustrated in Page 4–3, Figure 4-7.

Hole diameter should not exceed the bolt diam eter by

more than .060 inches (1.5 mm).

MODIFYING FRAME LENGTH

The frame cutoff after the rear axle can be shortene d to

match a particular body leng th. Using a torch is acceptable; however, heat from a torch will affect the material

characteristics of the frame rail. The affected material

will normally be confined to within 1 to 2 inches (25 to

50mm) of the flame cut and may not adversely affect

the strength of the chassis or body installation.

The frame cutoff can be lengthened by adding frame

extenders.

When extending the rails, the additional sections can

typically be welded to the existing rails. The joint should

be welded and reinforced as illustrated in Figure 5–1.

NOTE: See page 5–4 for more information on

welding frames.

Frame Insert

A frame insert must be added after welding a frame rail

to compensate for lost strength. The insert should be of

the same material as the frame member, or of steel,

and at least equal to the frame rail in thickness.

Attachment of the insert to the frame should be made

with Ream-Fit heat-treated bolts, 5/8 in. (16 mm) dia. or

the next larger size. Both the reinforcement and frame

Kenwo rth Truck Co. 5–1

FRAME MODIFICATIONS

(

6

1

0

m

m

)

2

4

i

n

.

m

i

n

5

holes should be reamed to provide a fit of from .001 in.

to .003 in. (.025 to .076 mm) clearance. Do not weld

reinforcing members. The insert should span a distance

of at least 24 in. (610 mm) on either side of the crack to

insure an even distribution of stresses. Cut the end s of

the insert at 45° as shown in Figure 5–2 unless the

insert extends to the end of the frame.

8.1 in

(205 mm)

7.9 in

(200 mm)

2.4 in

(62 mm)

Where possible, use existing bolt holes to attach the

insert to the frame. Bolt holes must not be located

closer to the frame flanges than the present bolt pattern .

If the insert is placed in a section of the main frame

where few bolts are located, additional bolts are

required. Use the following guideline for locating additional bolt holes.

.15 IN (4 mm)

Figure 5–1. Detail of Frame Extensions and Joint Welding.

Figure 5–2. Frame Insert

WELD FRAME RAILS ON

THE OUTSIDE ONLY

45°

01019

Changing Wheelbase

We do not recommend modifying the wheelbase. Occasionally, however, a chassis wheelbase will need to be

reduced or lengthened. When this needs to be done

there are a few guidelines that should to be considered.

WARNING! When c hanging the wheelbase,

be sure to follow the driveline manufac-

turer’s recommendations for driveline

length or angle changes . Incorrectly modified drivelines can fail prematurely due to

excessive vibration. This can cause an

accident.

Before changing the wheelbase the driveline angles of

the proposed wheelbase need to be examined to

ensure that no har mful vibrations are created. Cons ult

the driveline manufacturer for appropriate recommendations.

Kenwo rth Truck Co. 5–2

FRAME MODIFICATIONS

5

WARNING! Do not drill new holes any

closer than 2 inches (50mm) to existing

holes. Frame drilling affects the strength of

the rails.

Before the rear suspension is relocated, check the new

location of the spring hanger brackets. The new holes

for the spring hanger brackets must not overlap existing

holes and should not come any closer than 2 inches

(50mm) to existing holes in the frame.

WARNING! When relocating a suspension

bracket, do not mount it on the extended

(added) section of a frame rail. The suspension loading could re sult in prematur e

failure of the added section splice. This

could cause an accident. Use care when

planning the wheelbase so that the rear

suspension bracket is a lways mounted on

the original rail section. See Figure 5–3.

If you are extending the wheelbase, you may also have

to extend the frame length to accommodate a body.

When you reposition the rear suspension spring hangers, do not mount them on the a dded extended por tion

of the rail. The relocated rear suspension bracket

should be located o n the original frame rails. See Fig-

ure 5–3.

Before the rear suspension is relocated, check the new

location of the spring hanger brackets. The new holes

for the spring hanger brackets must not overlap existing

holes and should not come any closer than 2 inches

(50mm) to existing holes.

MOUNT THE SUSPENSION

BRACKETS ON THE

ORIGINAL RAIL

EXTENDED WHEELBASE

DO NOT MOUNT THE

SUSPENSION BRACKET ON

THE ADDED FRAME RAIL

When reducing the wheelbase, we recommend that the

suspension be moved forward and relocated on the

original rail. The rail behind the suspension can then be

cut to achieve the desired frame cutoff. See Figure 5–3.

WARNING! Do not drill new holes any

closer than 2 inches (50mm) to existing

holes. Frame drilling affects the strength of

the rails.

ORIGINAL WHEELBASE

RELOCATED REAR

SUSPENSION

SHORTENED WHEELBASE

CUT F RAME AT REAR TO

OBTAIN DESIRED CUTOFF

03008-1

Figure 5–3. Comparison of Original, Shortened,

and Extended Wheelbases.

Kenwo rth Truck Co. 5–3

FRAME MODIFICATIONS

Figure 5–4. Crossmember Added When Distance

Exceeds 60 Inches (1524m m ).

00627B

ADDITIONAL CROSSMEMBER

BEFORE WHEELBASE IS LENGTHENED

GREATER

THAN 60 IN

.

LESS THAN

60 IN.

5

Crossmembers

After changing a wheelbase, an additional crossmember may be required to maintain the original frame

strength.

• The maximum allowable distance between adjacent

crossmembers is 60 inches (1524 mm). If the distance between adjacent crossmembers exceeds

this dimension, add a cros smember between them.

See Figure 5–4.

WELDING

The 10.5 inch frame rail on the T300 is non–heat

treated steel and can be welded using the following precautions. However, the 10.62 inch rail is heat treated;

therefore, it is not weldable.

Precautions

CAUTION: Before welding, disconnect the

negative terminal battery cable.

• Disconnect alternator terminals to avoid potential damage to the voltage regulator and/or

alternator.

CAUTION: The 10.62 (10 5/8) inch rail is

heat treated; therefore, it is not weldable.

The 10.5 inch frame is n on-heat treated VAN 80 High

Strength Low Alloy (HSLA) steel. Use the following

guidelines when welding this material.

• Due to low carbon and alloy contents, VAN steels

possess good characteristics for welding and are

resistant to hot and cold cracking. Preheating a nd

postheating is not required when welding VAN

steels. Even with high heat inputs, joint efficiencies

(strength of weld compared to that of base metal) of

95 to 100 percent can be obtained.

1

Kenwo rth Truck Co. 5–4

• For best results when arc welding, use a E 10018

(low hydrogen) electrode. Along with shielded arc

welding, VAN steels can be readily welded with gas

metal arc (manual or semi-automatic) or submerged arc welding techniques. For details concerning specific welding techniques refer to welding

wire manufacturers for recommendations.

1. Welding Guidelines: Jones & Lauglin “VAN STEEL” Data

Sheet.

SECTION 6 ELECTRICAL

INTRODUCTION

Electrical wiring can sometimes be very frustrating.

This is especially true when adding circuits to an existing setup. Through the use of a prewired body harness,

we have tried to reduce the com plexity associated with

adding common circuits to a body installation.

NOTE: The most common circuits that body

builders may need are preconnected to this

wiring harness.

The new body related circuits can be added by connecting the added circuit wires to the ap propriate wires

in this harness.

ELECTRICAL CIRCUITS

Capacity

WARNING! Do not install an electrical circuit that requires more amperage (electrical capacity) than wh at is available in the

specific chassis circuit. An overloa ded circuit could cause a fire. Compare the

amperage requirem ents of the new circuit

to the electrical current capacity of the

existing chassis circuit before adding the

body or othe r equ ip m e nt.

When adding an electrical circuit, you must know the

current capacity (amperes) of each circuit.

The capacity of the existing system in the chassis must

be enough to power the additional circuit. The new circuit will require a ce rtain amou nt of power to o perate;

so, the existing (battery or alternator) power source

must have the capacity to provide additional power or

the new circuit will not function properly.

than the demand of the added circuit otherwise these

components may not work properly. See Ta ble 6–2 on

page 6–2 for relevant circuit information.

Prewired Body Harness

The prewired body harness can be connected to the

chassis harness throu gh a connector mounted on the

left hand frame rail directly behind the battery box.

See Figure 6–1.

TRUCK BODY CONNECTOR

TO CHASSIS HARNESS

LEFT RAIL

PREWIRED BODY

HARNESS WITH

PLUG

001041

Figure 6–1. Loc a t ion of Prewire d Body H arnes s

Connection.

For shipping purposes the body harnes s is coiled and

mounted to the crossmember. The body harness wire

ends are tagged with circuit markers, identifying the

connecting circuit. See Figure 6–2 and 6–3 o n the next

pages.

Check the current (ampere) demand of the circuit to be

added. Compare it to the current capacity of the circuit

you are connecting into. The current carrying capacity

of the wires, controls, switches, and circuit breakers that

provide current to the circuit must be equal to or greater

Kenwo rth Truck Co. 6–1

Fuse and Circuit Identification

ELECTRICAL

6

Fuses protect each wire (see CAPACITY in Figures 6-1

and 6-2 for capacity of each circuit). These are sepa-

P4

L2

STC

BLANK

L3

MLB

L33

LT

TR

T

S

Z

Y

U

R

W

X

L79

BL

rate circuits; so by connecting to them, you will not

affect the existing circuit in the chassis.

GND

10

L1

V

TL

L34

RT

(For chassis built prior to

First Quarter 1998)

WIRE

DESCRIPTION FUNCTION PIN CIRCUIT

BACKUP LP

RH TURN

LH TURN

AUX PWR

CLEARANCE LP

STOP LP BRAKE LAMP S L2STC RED 15 1 10

TAIL LP TAIL LAMP V L1TL BROWN 10 5 12

GND GROUND U GND WHITE 10

BACKUP

LAMP/ ALARM

RIGHT TURN

SIGNAL LAMP

LEFT TURN

SIGNAL LAMP

AUXILIARY

POWER,

BODY OR

TRAILER

MARKER/

CLEARANCE

LAMPS

XL79BL

WL34RT

YL33LT

T P4TR BLUE 10 14 12

Z L3MLB BLACK 15 6 12

WIRE

COLOR

PINK /

WHITE

GREEN /

BLACK

YELLOW

/ BLA CK

CAPACITY

(AMPERES)

10 29 12

15 1 14

15 1 14

FUSE

NUMBER

Figure 6–2. Prewired Truck and Body Harness (before 4/98)

WIRE

GAUGE

Kenwo rth Truck Co. 6–2

ELECTRICAL

6

BLANK

P4

TRC

T

S

Z

Y

U

R

V

W

(For chassis built after

First Quarter 1998)

L2

STC

GND

W

L3

MLB

X

L33

LT

L34

RT

L79

BL

WIRE

DESCRIPTION FUNCTION PIN CIRCUIT

BACKUP LP

RH TURN

LH TURN

AUX PWR

CLEARANCE LP

STOP LP BRAKE LAMP S L2STC RED 20 1 8

TAIL LP TAIL LAMP V L1TL BROWN 15 5 12

GND GROUND R GND WHITE 6

BACKUP

LAMP/ ALARM

RIGHT TURN

SIGNAL LAMP

LEFT TURN

SIGNAL LAMP

AUXILIARY

POWER,

BODY OR

TRAILER

MARKER/

CLEARANCE

LAMPS

XL79BL

WL34RT

YL33LT

U P4TRC BLUE

Z L3MLB BLACK 15 6 12

WIRE

COLOR

PINK /

WHITE

GREEN /

BLACK

YELLOW

/ BLA CK

CAPACITY

(AMPERES)

10 29 12

20 1 12

20 1 12

STD Config - IGN power

15 37

Optional config - BAT power

10 14

FUSE

NUMBER

L1

TL

WIRE

GAUGE

8

Figure 6–3. Prewired Truck and Body Harness (after 3/98)

Kenwo rth Truck Co. 6–3

ELECTRICAL

6

Circuits Wired Through the Ignition

The following circuits are powered on when the ignition

key is turned to the ON position.

Right and Left Turn Signal

Backup Lamp

After the connections are made by splicing into the

prewired body har nes s, the body componen ts will have

power when the similar chassis components receive

power.

For instance, when the right hand turn signal is activated and the right hand t ur n s igna l light flashes on th e

cab, the right hand turn signal light on the installed body

will also flash.

Connecting I gnition Circuits

Ignition circuits are tagged as follows:

Righ t Turn Signal

The right tur n signal wire is tagged RH TURN an d

is green/black.

Left Turn Signal

The left turn signal wire is tagge d LH TURN and is

yellow / black.

Auxiliary Power (Standard in chassis built prior to

first qtr , 98; optional in later chassis, if t here are

no trailer connections.)

Brake Lamp

Tail Lamp

Clearance Lamps

When the prewired body harness is properly connected, the similar circuit in the body will also have

power. If the chassis clearance lamps are activated, the

body clearance lamps will also be activated.

Auxiliary Power in Battery Circuit

The auxiliary power circuit is a 10 ampere capacity circuit connected, with a 10 ampere fuse, directly to the

battery. Use this circuit whenever you need power for

auxiliary equipment. There is continuous power to this

circuit (when the batteries are charged) even when the

engine is off.

For example, if the van body has interior lights or floodlights, these can be wired to the auxiliary p ower circuit

and switched ON from inside the van.

Connecting Battery Circuits

Battery circuits are tagged as follows:

Auxiliar y Pow er (optional w/o TRLR connections)

Backup Lamp

The backup lamp wire is tagged BACKUP LP and is

pink/white.

Ground

The ground wire is tagged GND and is white.

Auxiliary Power — (Standard config for chassis built

after first quarter, 1998)

The auxiliary power circuit wire is tagged AUX PWR

and is blue. Used for TRLR ABS if there is a trailer.

This aux power circuit is a 15 ampere capacity circuit, connected with a 15 ampere fuse, in the ignition circuit. This aux power circuit can be used only

when the ignition switch is ON.

Circu i ts Wir ed to Battery

The following circuits are wired directly to the battery

through a fuse and switch.

The auxiliary power circuit wire is tagged AUX PWR

and is blue.

Brake Lamp

The brake lamp wire is tagged ST OP LP and is red.

Tail Lamp

The tail lamp wire is tagged TAIL LP and is brown.

Clearance Lamps

The clearance lamp wire is tagged CLEARANCE

LP and is black.

Kenwo rth Truck Co. 6–4

INSTALLING A THIRD BATTERY

TABLE 6-1. Third Battery Installation Parts

QTY. ITEM P ART NUMBER

1

BATTERY GRP 31 W/

THREADED POSTS

K306–11–1

1

HOLDDOWN K144–282

1

TRAY K032–3424

1

JUMPER CABLE K396–1010–008

1

JUMPER CABLE K396–1020–008

2

NUTS K169–111

ELECTRICAL

6

A third battery is a published option and can be ordered

with your vehicle. If this was not done, use Figure 6–4

as a guide for installing a third battery.

You will need the following additional par ts to install th e

third battery:

WIRING FOR A LIFTGATE

K396–1020–008

BATTERY JUMPER

Figure 6–4. Adding a Third Battery

K396–1010–008

BATTERY JUMPER

THIRD BATTERY

(OPTIONAL)

03018

CAUTION: Consult the liftgate manufac-

turer’s installation instructions for details

concerning wiring for their product and

specific model.

A liftgate w ill us ually requi re cur rent much greater tha n

10 amperes. Typically, 100 to 150 amperes is required

and some models require more than 150 a mperes. For

a liftgate installation a third battery is required for adequate power.

NOTE: A liftgate installation must have a dedicated circuit to distribute power to the liftgate.

Liftgate Power Source

Liftgate motors will typically use DC power. A conve-

nient power source is the battery. Use Figure 6–5 as a

guide. Install the circuit breaker inside the bat tery box

on the rear panel.

Kenwo rth Truck Co. 6–5

WARNING! DO NOT use a circuit breaker

of lower capacity than the liftgate amperage requireme nts. If you do, i t could r esult

in an electrical overload or fire. Follow the liftgate

installation instructions and use a circuit breaker

with the recommended capacity.

A 200 ampere circuit breaker is available from PACCAR

Parts. This should be adequate for most installations.

However, the liftgate manufacturer’s recommendation

should determine the actual circuit breaker used.

200 Ampere Circuit Breaker Part Number :

7855–7–200

ELECTRICAL

6

Connecting the Liftgate Power

Follow these instructions to connect the liftgate to the

third battery. See Figure 6–5.

a. Connect the liftgate power cable to one termi-

nal of the circuit breaker.

b. Connect one end of the circuit breaker cable to

the other terminal of the circuit breaker.

c. Install the third battery.

LIFTGATE

POWER

7855-7-200

CIRCUIT BREAKER

CABLE

d. Connect the remaining end of the circuit

breaker cable to the positive terminal of the

third battery.

The cable used to connect the circuit breaker to the battery is availa ble from PACCAR Parts.

Circuit Breaker Cable Part Number:

K396–1C91F014

The remainder of the wiring installation should be in

accordance with the liftgate m anufacturer’s installation

instructions.

MOUNT CIRCUIT

BREAKER ON

THIS PANEL

CONNECT K396-1C91F014

CIRCUIT BREAKER CABLE

TO BATTERY POSITIVE TERMINAL

Figure 6–5. Liftgate Circuit Breaker Inside Battery Box.

Kenwo rth Truck Co. 6–6

01048

BODY BUILDERS’ MANUAL

APPENDICES

APPENDIX A VEHICLE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . A-1

VIN Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Chassis Number Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

CERTIFICATION LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Components and Weights Label . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Tire and Rim Data Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Incomplete Vehicle Certification Label . . . . . . . . . . . . . . . . . . . . . . A-2

Noise Emission Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Paint Identification Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

COMPONENT IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Engine Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Transmission Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Front Axle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Rear Axle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

APPENDIX B WEIGHT DISTRIBUTION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

CALCULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Weight Distribution without Body . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Weight Distribution with Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Chassis Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Option Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Rear Liftgate Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

COMPLETE (LOADED) VEHICLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Water Level Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Weight Distribution Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Body Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Kenworth Truck Co.

APPENDIX A VEHICLE IDENTIFICATION

Figure 1–1. Veh icle Identificatio n Numbe r (VI N).

02377

TABLE A-1. Model Year Letter (CODE) Designations.

CODE YEAR

T 1996

V 1997

W 1998

X 1999

Y 2000

VEHICLE IDENTIFICATION NUMBER

A 17–character number (numeral and letter combination) forms the Vehicle Identification Number (VIN) and

Chassis Number. It contains among other information,

the model year (4), assembly plant (5), and vehicle

serial number (6). See Figure 1–1.

The model year (4) is designated by a letter code in the

tenth character position in the VIN. See Table A-1 and

Figure 1–1.

Chassis Number Locations

The Chass is N umb er com pr ise s the last six ch ara cter s

of the VIN.

The T300 chassis number is shown in six places:

• Right frame rail, top flange, about 3 ft. from the

front end: stamped.

• Left side of cab, lower right corner of door

frame: stamped plate.

• Tire, Rim, and Weight Rating Data label (truck).

• Components and Weights label.

• Noise E missio n label.

• Paint Identification label.

CERTIFICATION LABELS

Components and Weights Label

The Major Components and Weights Label is located

on either the driver’s side door edge or on the door

frame. See Figure 1–2. It includes: c hassis weight and

gross weight; plus, model and serial numbers for the

vehicle, engine, transmission, and axles.

DOOR EDGE

DOOR

FRAME

VIN Location

The VIN is ma rked on t he Inc om plete Vehicle Certification Label (on trucks) or on the Tire, Rim, Cert ification

and Weight Rating Data Label (on tractors). Both labels

are located either on the driver’s door edge or door

frame. See Figure 1–2.

Kenwo rth Truck Co. A–1

TIRE,RIM,CERTIFICATION

AND WEIGHT LABEL

Figure 1–2. Driver’s Door and Door Frame Labels

(TRACTOR)

OR INCOMPLETE

VEHICLE

CERTIFICATION

LABEL (TRUCK)

MAJOR

COMPONENTS

AND WEIGHTS

LABEL (TRUCK

OR TRACTOR)

TIRE, RIM,

AND WEIGHT

RATING DATA

LABEL

(TRUCK)

FINAL STAGE MAN-

UFA CTURER LABEL

(TO BE INSTALLED

BY FINAL STAGE

MANUFACTURER

(TRUCK ONLY)

CHASSIS

NUMBER

(STAMPED)

02378

VEHICLE IDENTIFICATION

A

Tire/R im and Weight Rating Data Label

The Tire/Rim and Weight Rating Data Label is located

on the driver’s side door edge, below the door latch.

See Figure 1–2. It contains the following information:

• GVWR — Gross Vehicle Weight Rating

• GAWR FRONT and REAR — Gross Axle

Weight Ratings for Front and Rear Axle

• TIRE/RIM SIZES AND INFLATION PRESSURES — Tire/Rim Sizes and Cold Pressure

Minimu ms

• Chass is (Serial) Number

NOTE: GVWR is the TOTAL WEIGHT the

vehicle is designed to carry. This includes the

weight of the empty vehicle, loading platform,

occupants, fuel, and any load. Axle weight rat-

ings are listed on the edge of the driver’s door.

Incomplete Vehicle Certification Label

The Incomplete Vehicle Certification Label (for trucks)

is located on the driver’s side door edge. See Figure

1–2. It contains the following information:

• DATE OF MANUFACTURE

• VIN — V ehicle Identification Number

• LISTING OF APPLICABLE FEDERAL M OTOR

VEHICLE SAFETY STANDARDS

Engine Identification

The engine serial number is stamped on a plate located

on the either the left front side (for Cummins) or right

rear of the engine, depend ing on engine model (Cummins or Caterpillar). For further information, please

refer to the Engine Operation and Maintenance Manual

(included in the glove compartment of each vehicle).

01054

Figure 1–3. Cummins Identification Plate.

Transmission Identification

The transmission identification num ber is stamped on a

tag affixed to the right rear side of the transmission

case. It includes amon g other specifications the transmission number, serial, and part number.

Front Axle Identification

Noise Emission Label

The front axle serial number is stamped on a plate

The Noise Emission Label is located on the left side of

the steering column support. It contains information

regarding U.S. noise emission regulations, chassis

number, and date of manufacture.

located on the front axle beam.

Paint Identification Label

The Paint Identification Label contains the paint colors

used by the factory to paint your truck/tractor. It lists

frame, wheels, cab interior and exterior colors. This

label is located next to the Noise Emission Label on the

steering column support.

COMPONENT I DENTIFICATION

Each of the following components has their own identification label.

Kenwo rth Truck Co. A–2

Figure 1–4. Front Axle Identification.

Rear Axle Identification

Figure 1–5. Rear Axle Identification Labels.

2

3

1

01053

The rear axle identification numberi ng system includes

three labels or stamps.

1. Axle Specification Number, stamped on the right

rear side of the axle housing. This num ber identifies the complete axle.

2. Axle Housing Number Tag, located on the left forward side of the hous ing ar m. T his tag identifies

the axle housing.

3. Axle Differential Carrier Identification, located on

the top side of the differential carrier. The following

information is either stamped, or marked with a

metal tag: Model N o., Production Assembly No.,

Serial No., Gear Ratio, and Part Number.

VEHICLE IDENTIFICATION

A

NOTE: Illustrated identification tag locations

are typical. Actual locations may vary by axle

manufacturer and with single versus tandem

axles.

Kenwo rth Truck Co. A–3

APPENDIX B WEIGHT DISTRIBUTION

INTRODUCTION

In the Medium Duty truck market, matching the wheelbase to the body spe cification is extremely impor tant.

Selection of the wrong wheelba se may lead to premature component failure, poor performance, and ultimately a dissatisfied customer. Before selecting the

proper wheelbase, it is important to have a basic understanding of weight distribution.

Abbreviations

Throughout this section, abbreviations are used to

describe cer tain features and requirement s of the vehicle (see the list below). Review this list frequently so

you know what the abbreviations mean.

AF = Frame rail overhang length – behind the

rear axle

BL = Body Length

CA = Back of cab to centerline of rear axle

NOTE: The T300 CA figures are measured

from the true back of cab to the centerline of

the rear axle. To obtain a usable CA the body

builder must subract any required space

behind the cab, which may be needed for

other equipment.

CG = Center of gravity: the balance point or cen-

ter of a load. It is us ual ly ide ntified by a circle with alternati ng black and white

quarters.

CGf = Distance from the centerline of the front

axle to the center of gra v ity of the load (L).

The load ca n be an y load s uch as a fuel

tank, a body, or the payload.

FA = Front Axle

GVW = Gross Vehicle Weight

L = Load: the we ight that is carried. This coul d

be the body, the payload or any item that

has its weight distributed between the two

axles.

Lf = Portion of load (L) carried by front axle

Lr = Portion of load (L) carried by rear axle

RA = Rear Axle

WB = Whee lbase Length

Kenwo rth Truck Co. B–1

WEIGHT DISTRIBUTION

Figure 2–1. Balanced Load: CGf 100 in. from

front axle.

100 in.

200 in.

FRONT AXLE

100 lb

B

CALCULATIONS

Weight Distribution without Body

There are two primar y equations used in weight distribution calculations: