Kenworth HVAC Service Manual

Kenworth HVAC Systems

Mobile Air Conditioning Society Worldwide

2017 Convention

1

Topics

• Introductions

• System Components

• Kenworth Electrical

• Truck System Information

• B-Cab

• T2000/T700

• NGP 680/880

• Testing/Troubleshooting

• Scan Tool

• K Series Medium Duty

• T Series Medium Duty

• KIMS

2

Who is PACCAR/Kenworth

PACCAR is the corporate umbrella for truck, and supply related manufacturing

companies, headquartered in Bellevue, Washington. Initially manufactured

railroad cars and logging equipment, starting in 1905.

Heavy-duty truck manufacturing market segments:

• Kenworth Motor Truck Company, USA, in 1945

• Peterbilt Motors Company, USA, in 1958

• Dart Truck Company, USA, in 1958

• Foden Trucks UK in 1981

• DAF Trucks N.V. in 1996

• Leyland Trucks UK in 1998

Truck Subsidiaries:

• Kenworth Mexicana VILPAC 1966

• Kenworth Australia, in 1970

• Paccar Engine Manufacturing NA, in 2010

3

Kenworth Models

Class 8 – Heavy Duty, Off Highway

+80,000# GVWR

2.3m (Wide Cab)

• T2000 - > T700: No longer produced

1.9m B-Cabs

• T800, W900, T600 -> T660, C500, C550,

T440, 963

2.1m Next Generation Product (NGP)

• Kenworth: T680, T880

• Peterbilt: 579, 567

COE

• K500: Off highway ONLY

• K100: No longer produced

MONSTER TRUCK: up to 400,000# GVWR

• 963/965: Off highway ONLY – modified B-Cab electrics

4

Kenworth Models

Class 7, 6 & 5 – Medium Duty

33,000# – 16,001# GVWR

• T370, T270, T170

Conventional Cab,

Built in Saint Therese, Canada

• T370 Class 7: 26,001 - 33,000# GVWR

• T270 Class 6: 19,501 - 26,000# GVWR

• T170 Class 5: 16,001 – 19,500# GVWR

• K370, K270 (LFNA: LF North America)

COE, Cab built in Holland,

Assembled onto chassis in Mexico

• K370 Class 7: 26,001 - 33,000# GVWR

• K270 Class 6: 19,501 - 26,000# GVWR

S i m p l i f i e d

B - C a b

E l e c t r i c a l

S ystem

• Use DAVIE 4 to service cab’s electrical

24VDC– Cab

12VDC– C h a s s i s

5

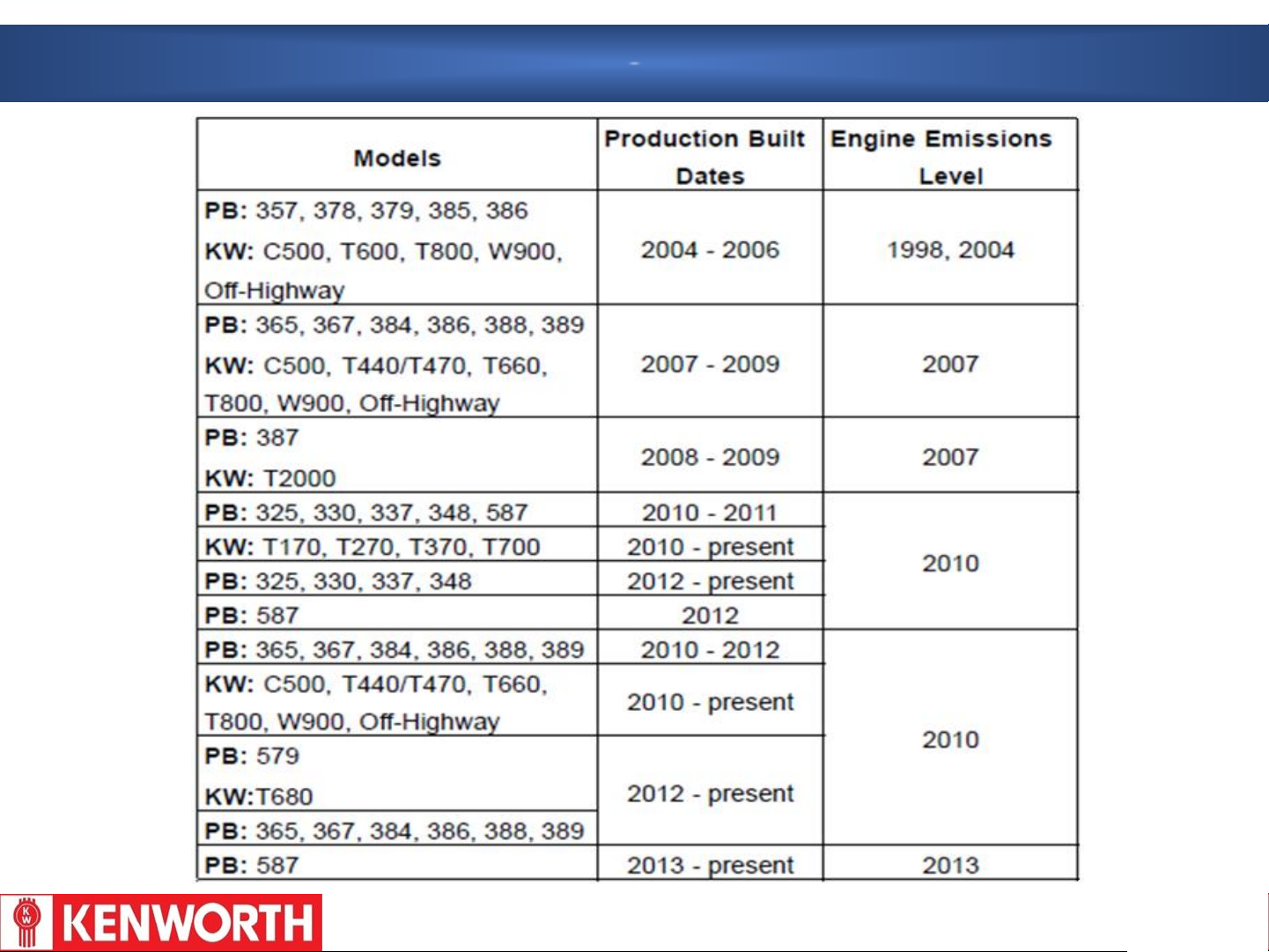

Kenworth/Peterbilt Model Comparison

6

System Components

7

Mechanical Components

Most current applications use Sanden, compressors.

SD5H14 and SD7H15

8

Mechanical Components

Condenser, sized per application parameters.

9

Mechanical Components

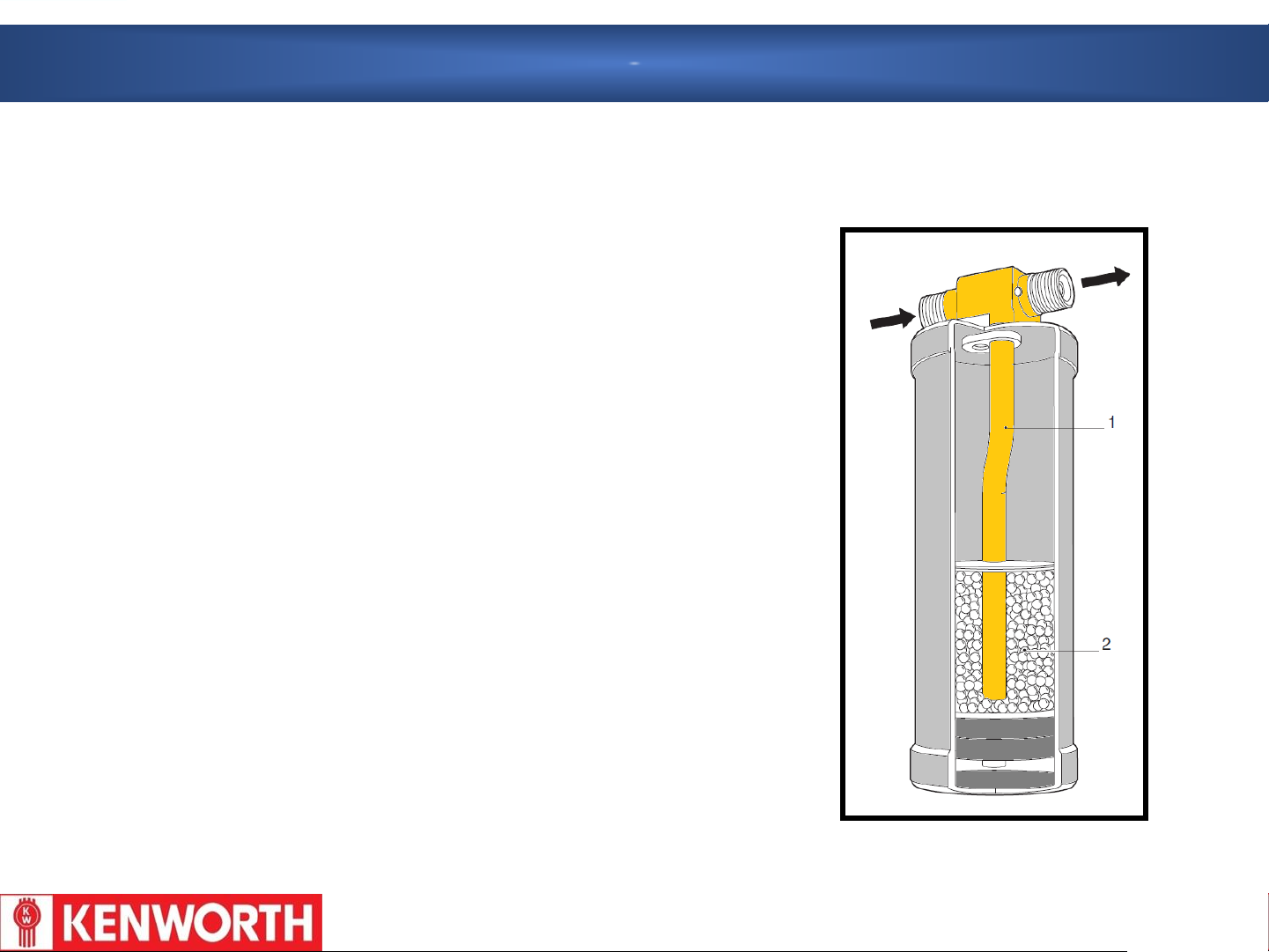

Receiver-Drier:

Normal application, absorbs

system moisture and also filters

and stores the liquid coolant

Uses either XH7 or XH9 desiccant

package.

10

Mechanical Components

Expansion Valve

11

Mechanical Components

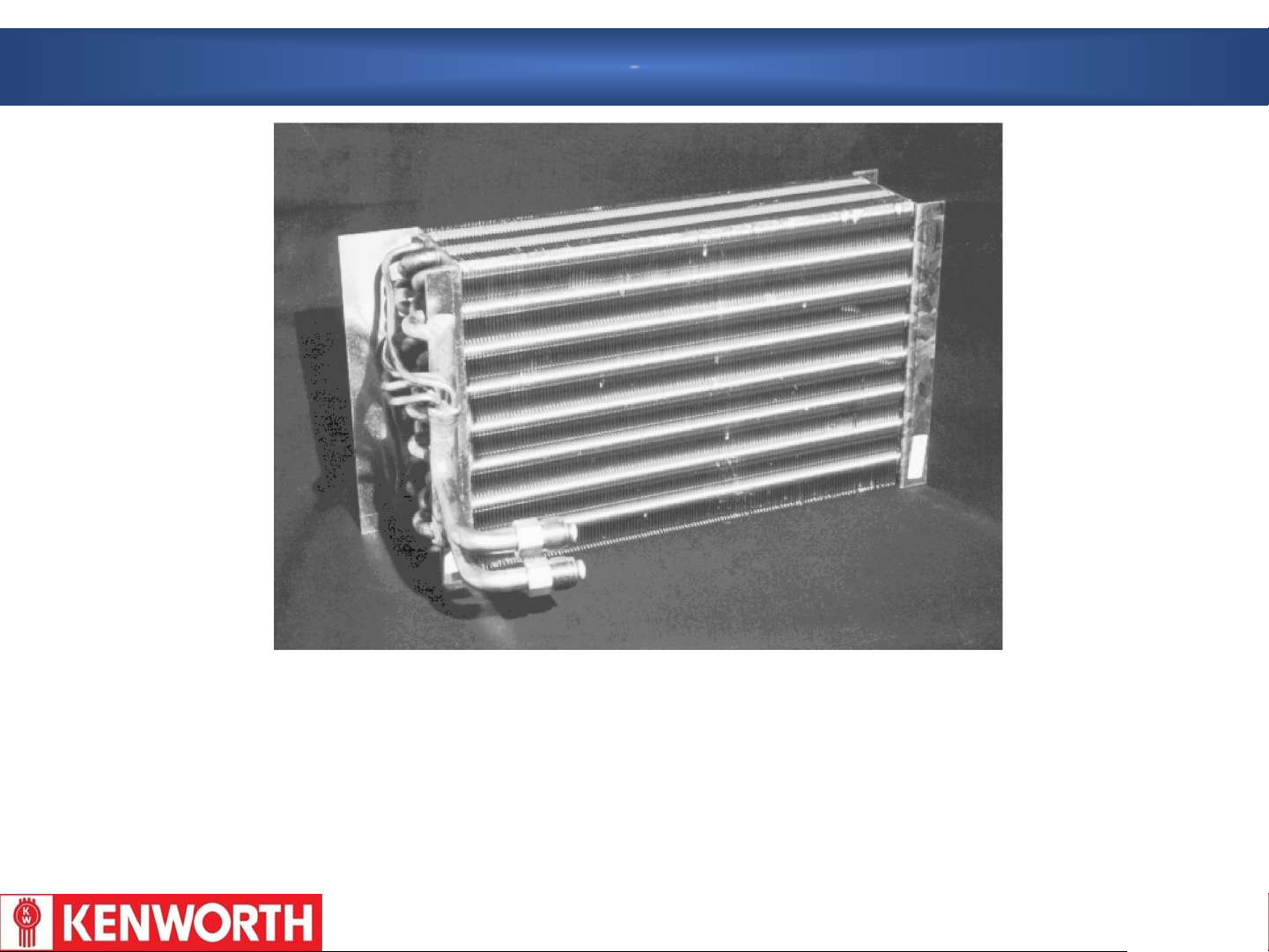

Evaporator:

• Changes low pressure liquid into a low pressure

gas by absorbing heat from cab air

12

Mechanical Components

13

Mechanical Components

14

Electrical

Electrical Systems

15

Electrical

CAN Electrical Systems Definitions

Definitions

Instrumentation Control Unit (ICU) – 1st generation Instrumentation-only Multiplex

Cab Electronic Control Unit (CECU) – 2nd generation Multiplex, includes systems other than

instrumentation. CECU’s variants relate to vehicle model and the engine emissions standard.

Identifying which CECU in the vehicle helps determine what features are present and also aids

in troubleshooting.

North American MultipleXing (NAMUX) - The CAN electrical architecture used by Kenworth

and Peterbilt Divisions.

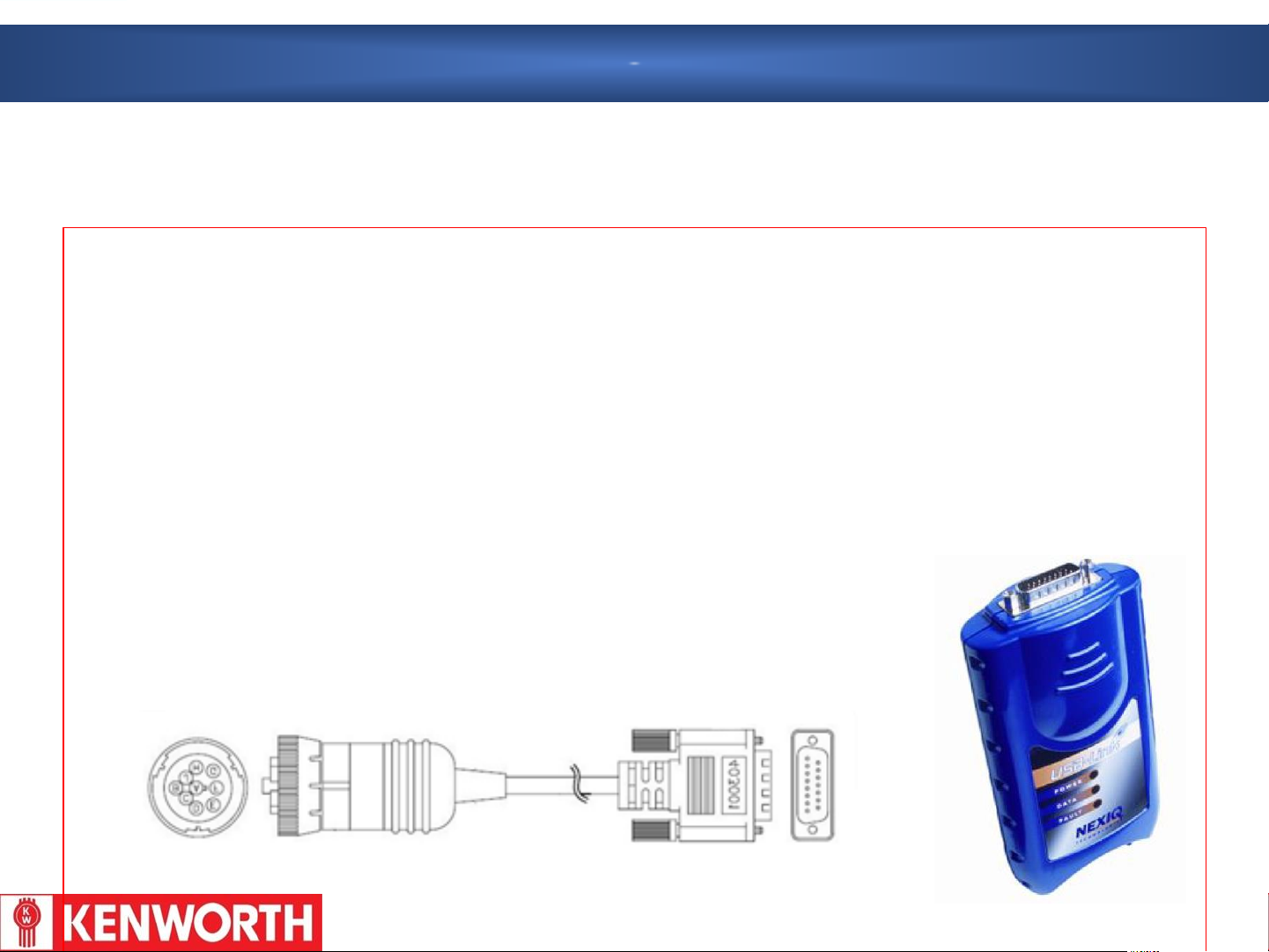

Electronic Service Analyst (ESA) - Software Program

needed for all CAN system malfunction code reading and service related

operations. NEXIQ scan tool used with ESA software.

16

Electrical

Kenworth Electrical Systems – 2 Iterations

• Traditional Electrical Systems:

• (Legacy - thru - 2004) – KM815001

• CAN Based Instrumentation:

• ICU – NAMUX (2005-2007) – KM815054/PM819010

• CECU – NAMUX2 (2007-2010) – KM815054/PM819010

• Service manual change, see page 38/39

• CECU3 – NAMUX3/ NAMUX4 (2010 – Present) w/Chassis Node

B-Cab = NAMUX 3 – KM815056 (includes DTC codes)

NGP = NAMUX 4 - KM815057 (includes DTC codes)

17

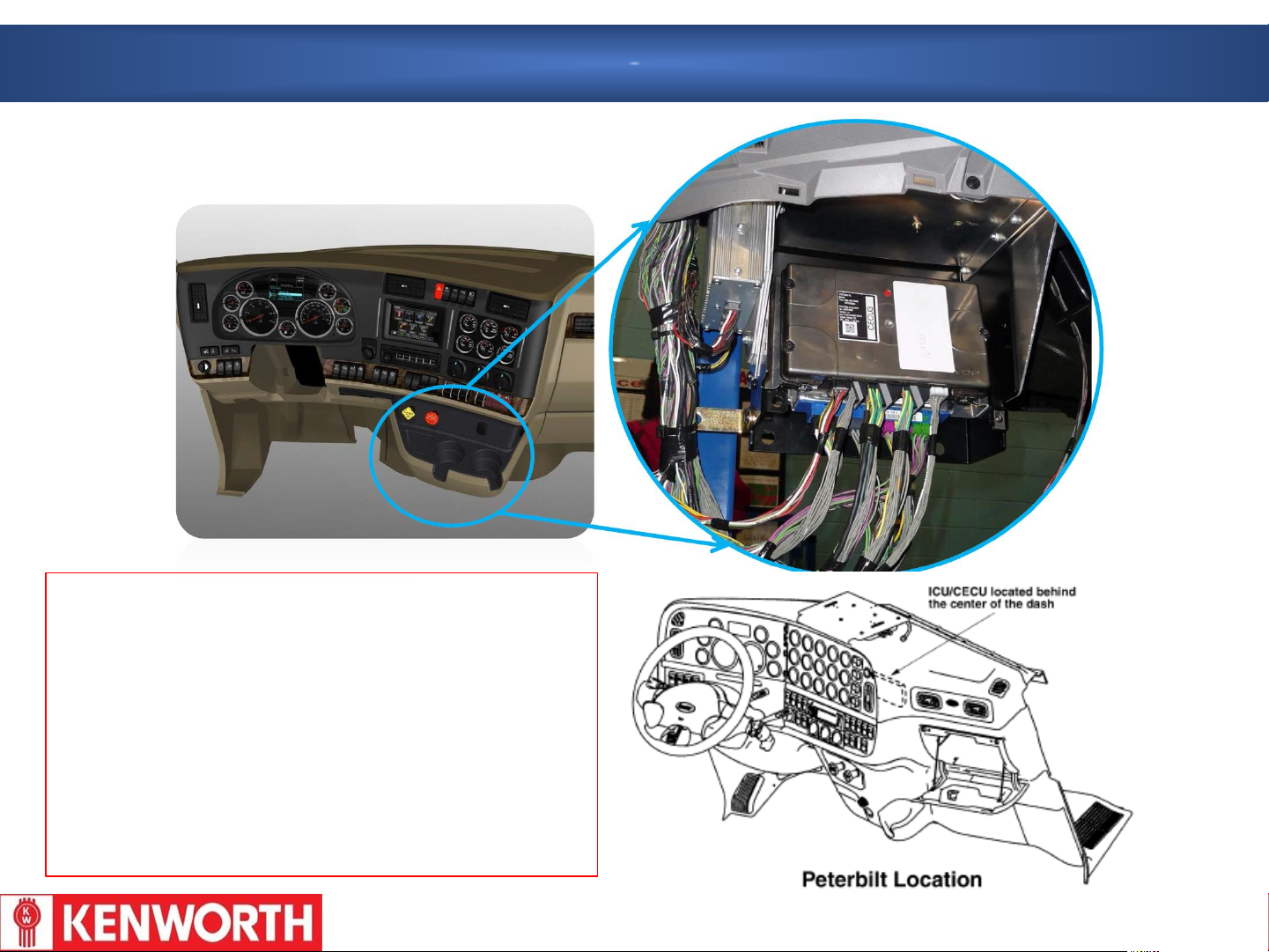

Electrical - Typical ICU/CECU Locations

Note: T2000 and T700 is at the front

of the passenger footwell.

2010 emissions compliantT170, T270,

T370 medium duty, is behind the lower

center of the dash panel. Peterbilt

versions, behind the top center of the

dash panel.

18

Electrical - 1st Iteration

Standard Electrical Systems – 1st Iteration

Original Circuit Wiring Key for production prior to phase out for CAN

thru 2004

Brief Examples of Each Category Definition

320

10

Models Covered by Elect Wiring Key—T2000, T6/T8/T4, W900B,C500B, K100E

Service Manual KM815001

247

19

Electrical - 1st Iteration

20

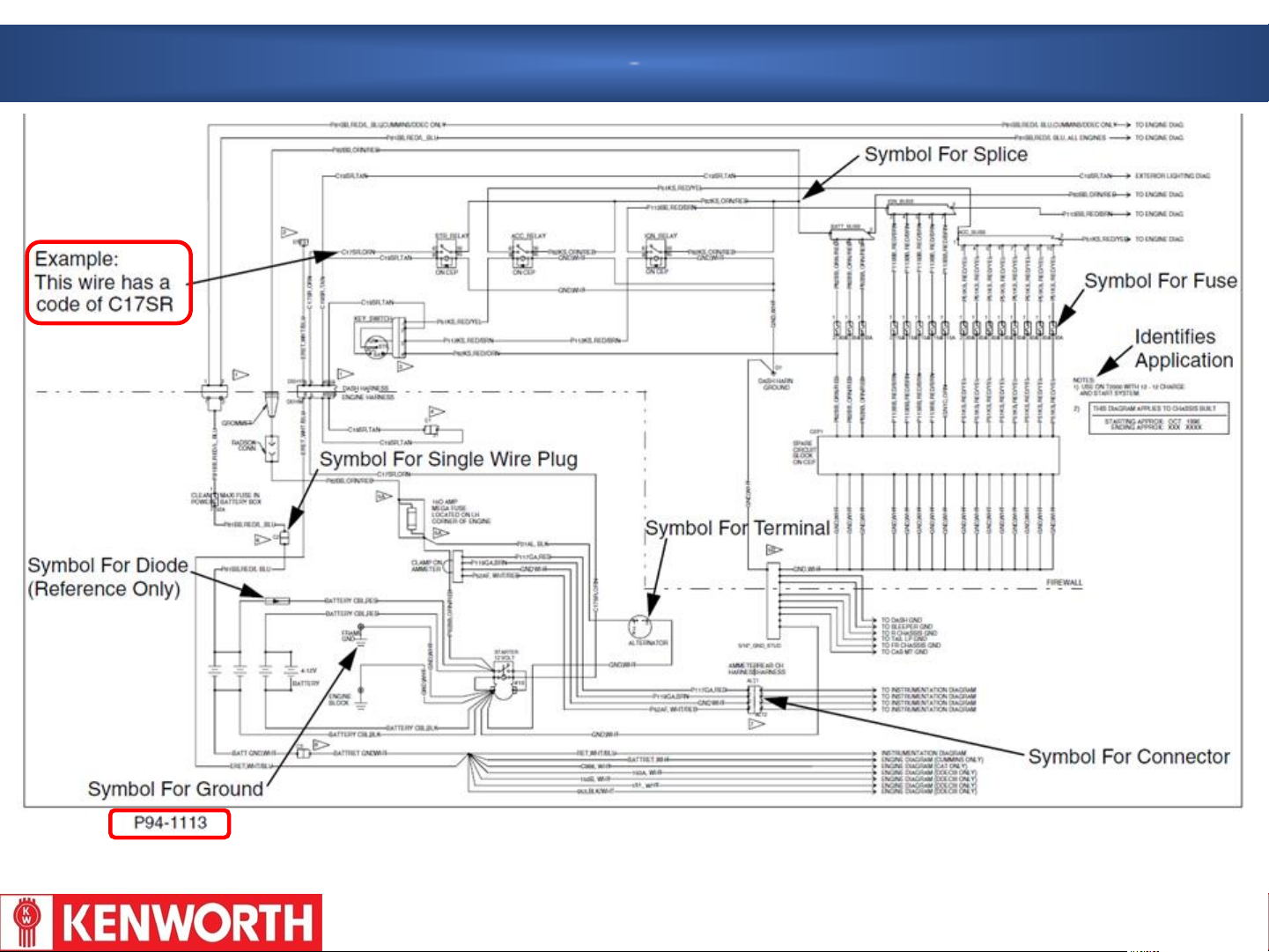

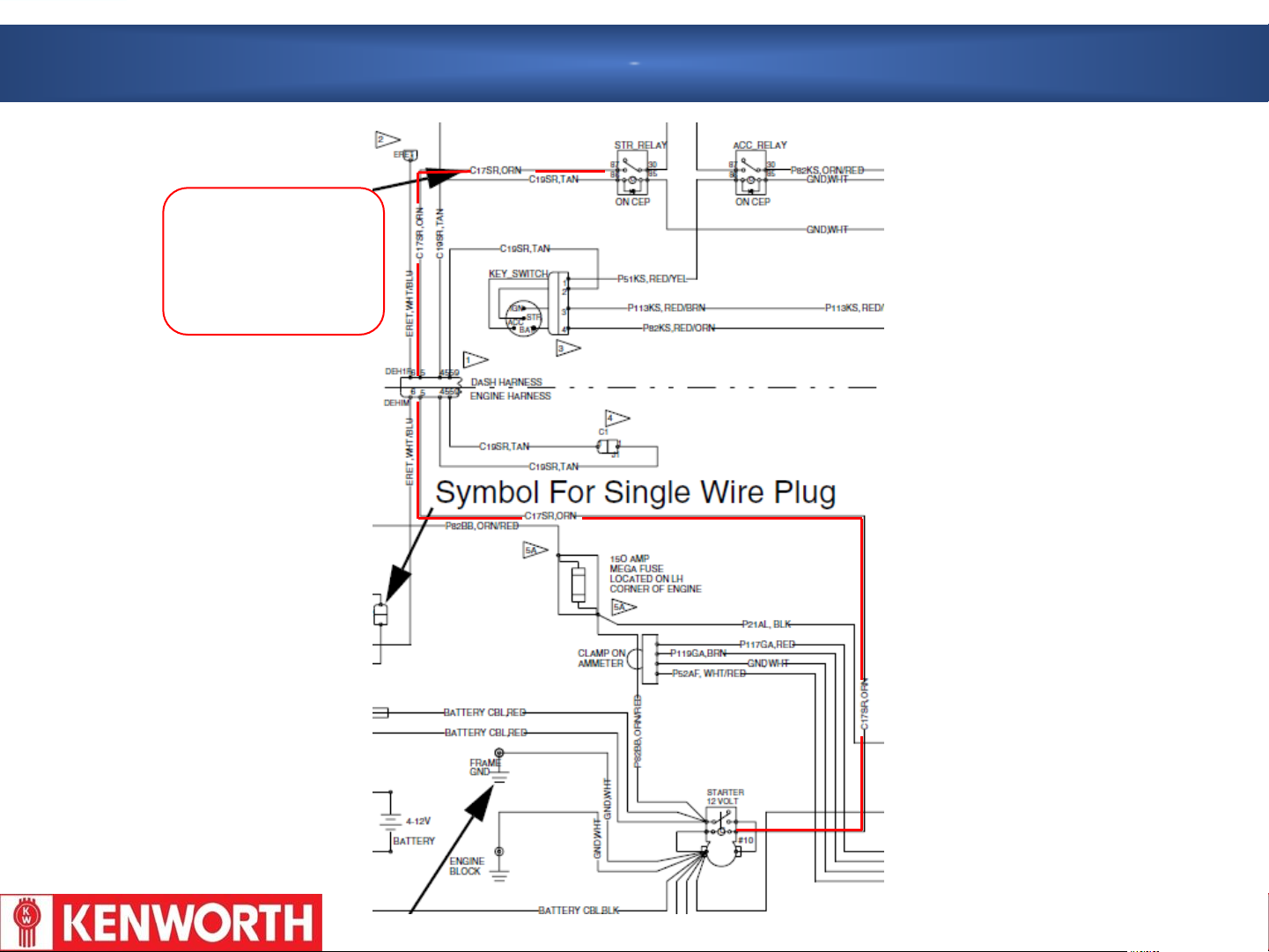

Electrical - 1st Iteration

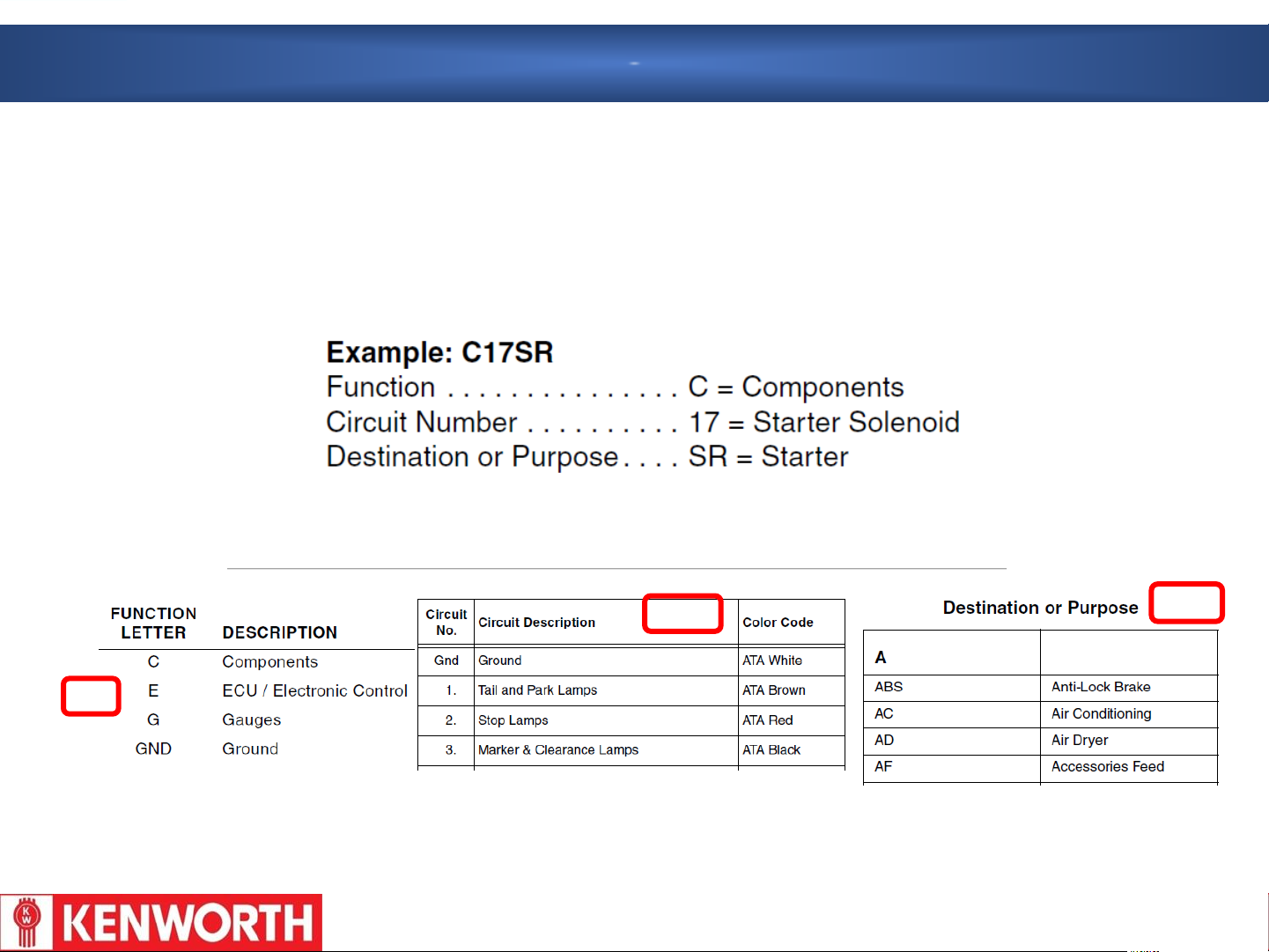

Example: this

wire has a code

of C17SR, ORN

21

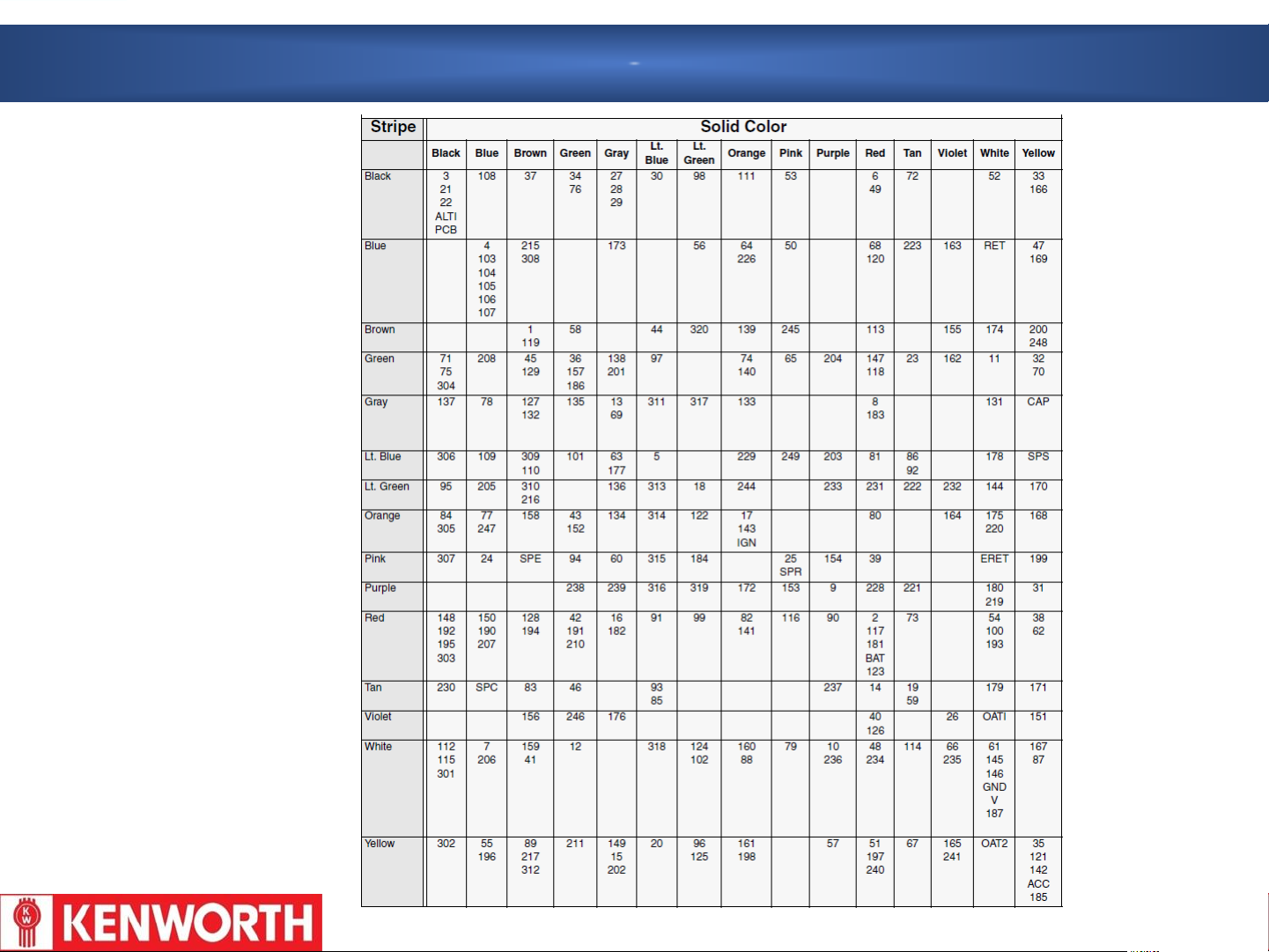

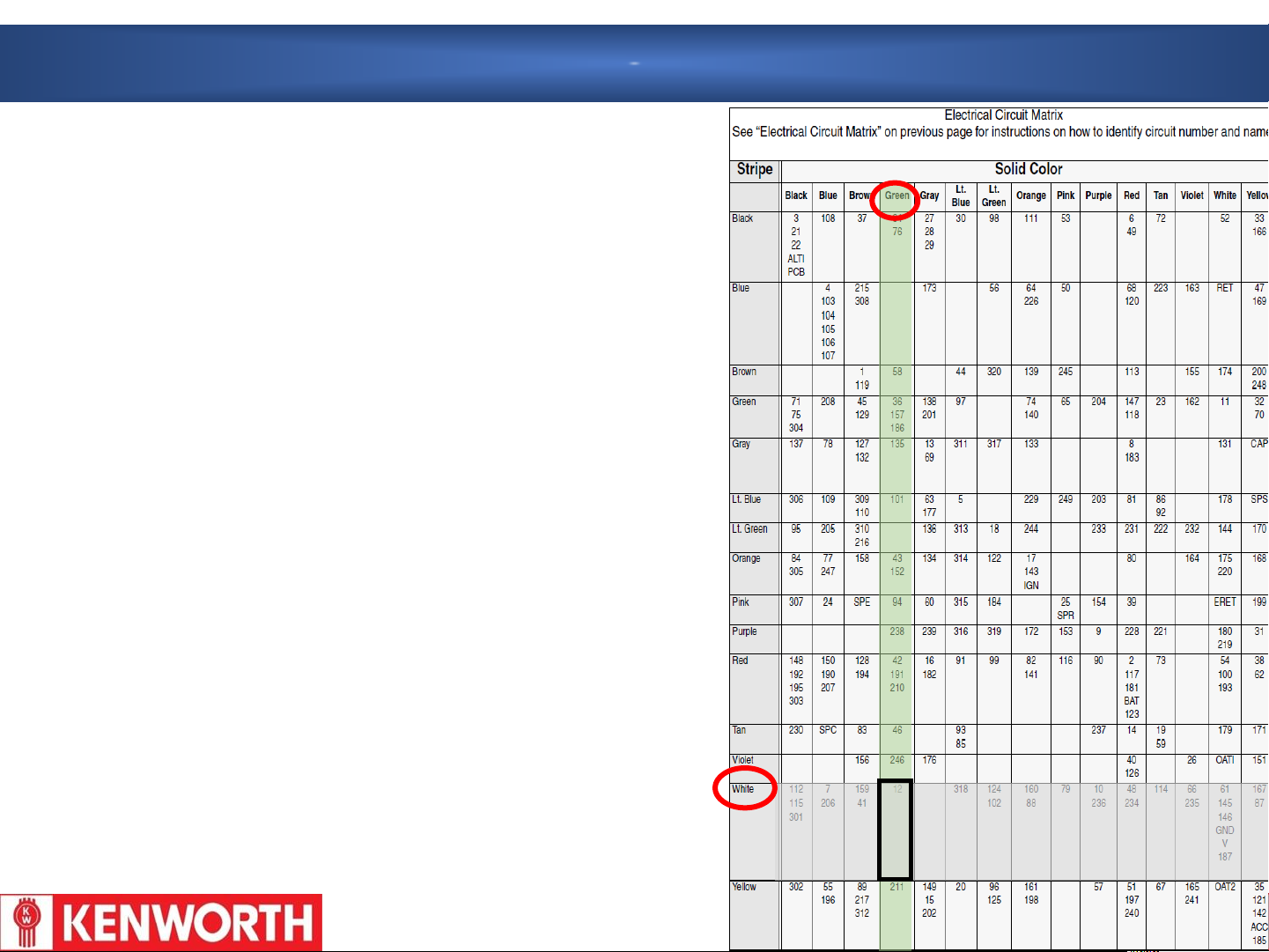

Electrical

Circuit

Matrix

See “Electrical

Circuit Matrix” on

previous page for

Electrical - 1st Iteration

instructions on

how to identify

circuit number

and name.

22

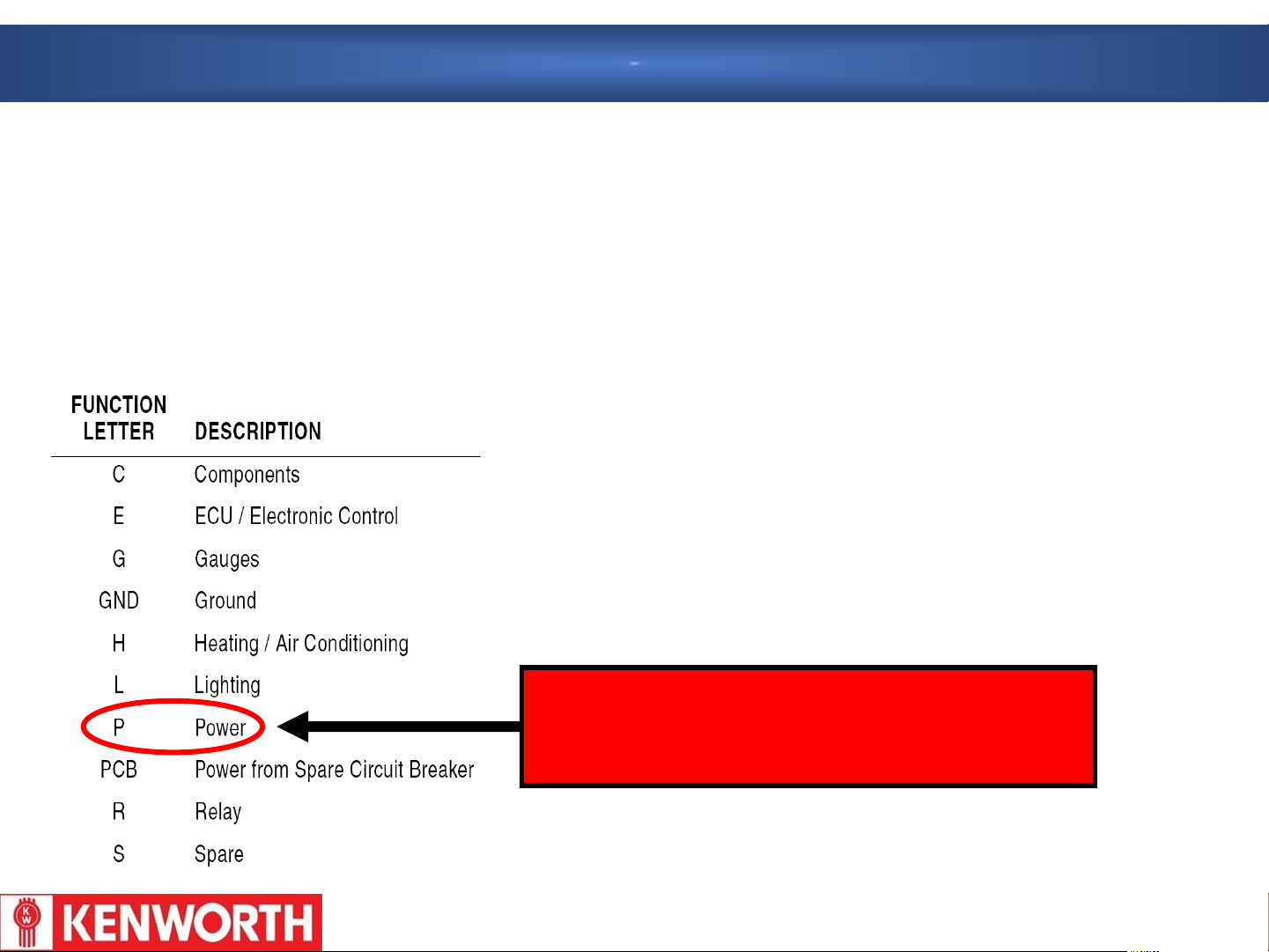

Kenworth Wire Numbering System

P12HN – Kenworth Circuit Code

Circuit function - P

Circuit number

Color of the wire

Destination of circuit or purpose of the circuit

Using Electrical Circuit Matrix

23

Kenworth Wire Numbering System

Example: P12HN

Circuit function - P

P - identifies circuit

function: Power

24

Kenworth Wire Numbering System

Example: P12HN

Circuit function

Circuit number - 12

Color of the wire

Destination of the circuit or purpose of the circuit

Using Electrical Circuit Matrix

25

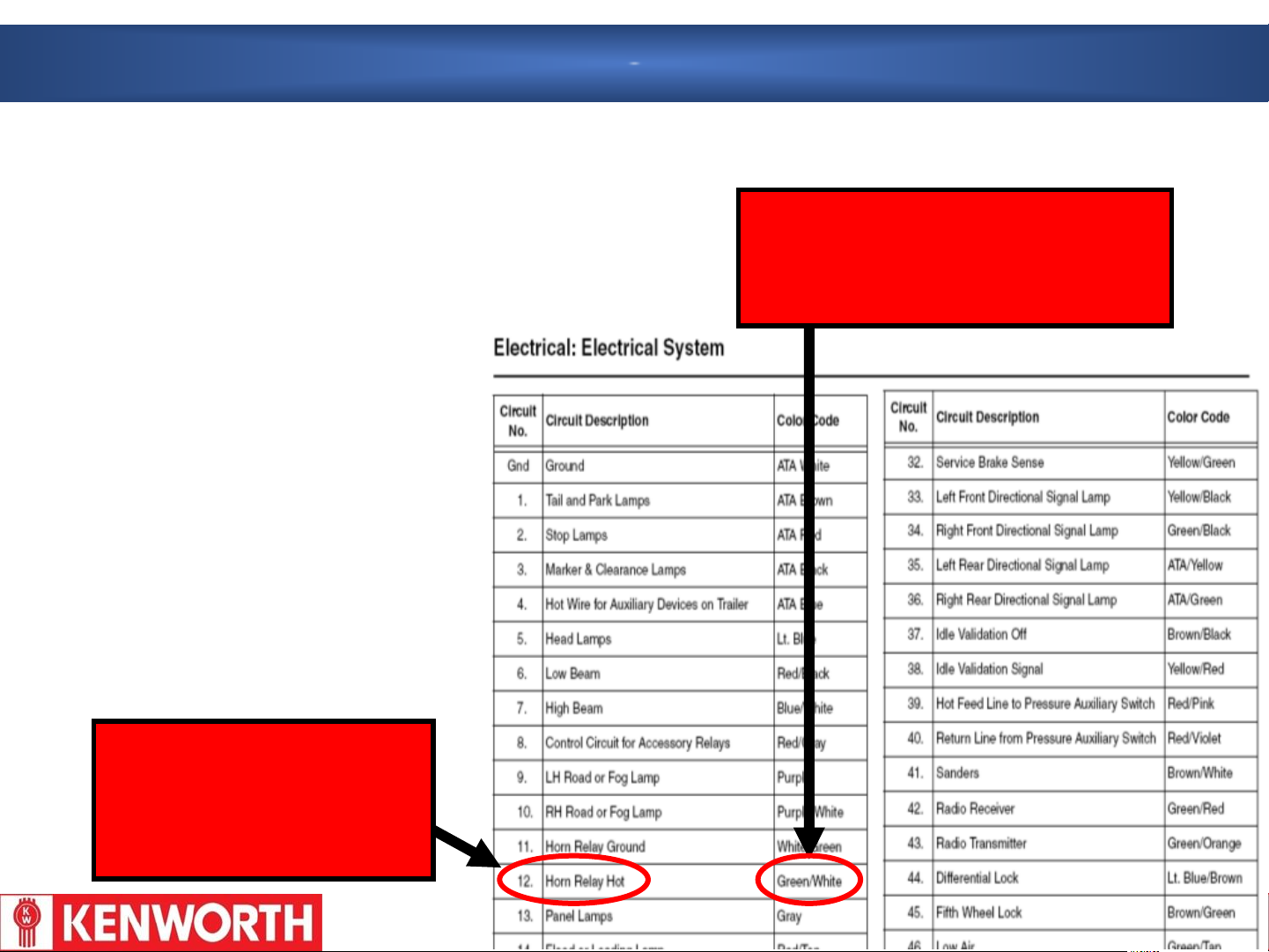

Kenworth Wire Numbering System

Example: P12HN

Circuit number -

Color of the wire

12 - Identifies circuit color:

Green/White

12 - Identifies circuit

description:

Horn Relay Hot

26

Kenworth Wire Numbering System

Example: P12HN

Circuit function

Circuit number

Color of the wire

Destination of the circuit or purpose of the circuit -

HN

Using Electrical Circuit Matrix

27

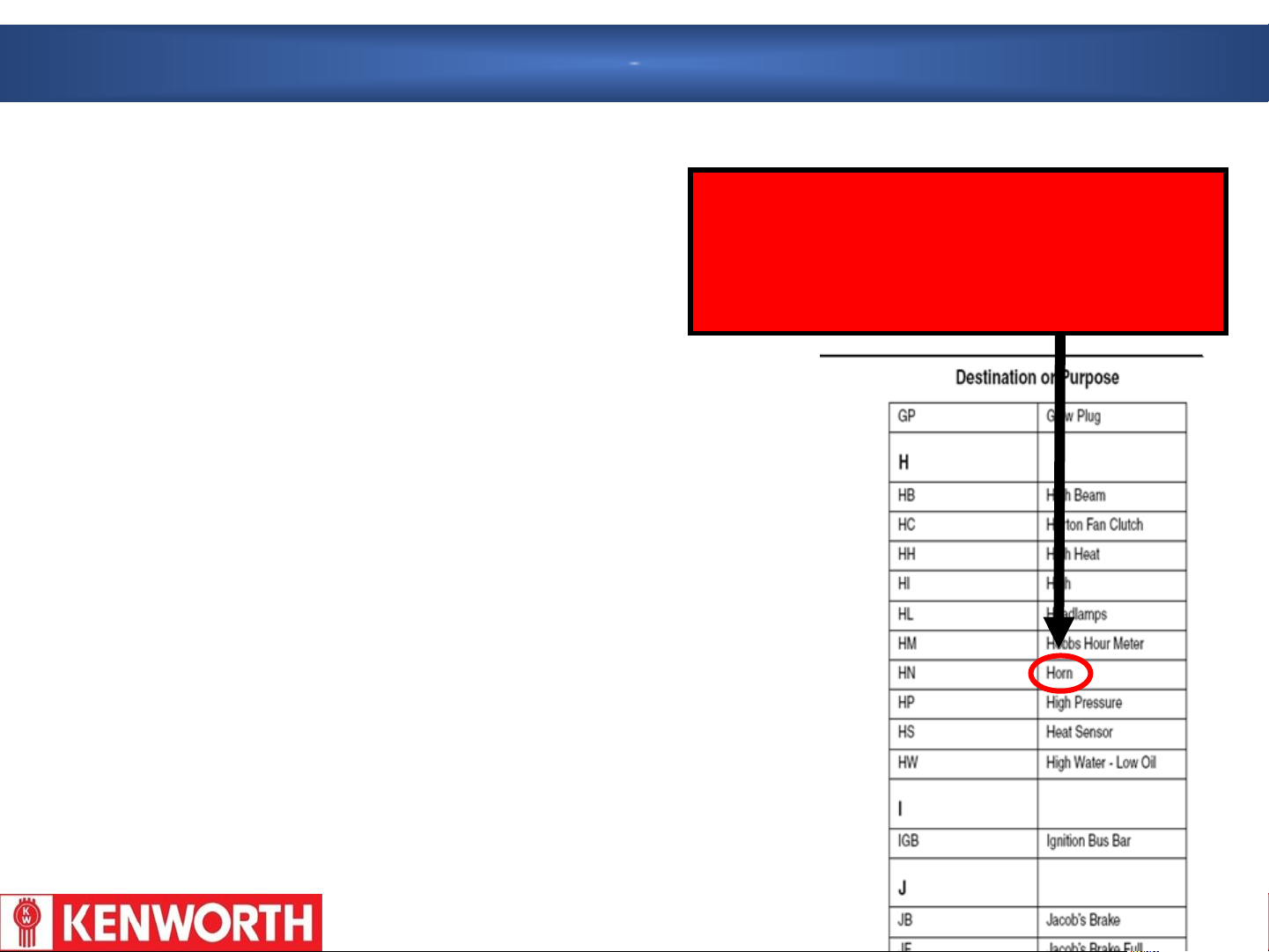

Kenworth Wire Numbering System

HN - identifies circuit destination

Example: P12HN

Circuit purpose – HN

or purpose:

Horn

28

Kenworth Wire Numbering System

Example: GREEN / WHITE

Circuit function

Circuit number

Color of the wire

Destination of the circuit or purpose of the circuit

Using Electrical Circuit Matrix

12

29

Electrical – CAN Code Designations

• Multiplex migration began in 2004 in models T600, T660, T800, W900,

C500 and Off-Highway models with instrumentation.

• Crossover trucks use a mixture of original circuit designations for existing

electrical truck and chassis components, while “phasing” in the PACCAR

circuit numbering system to support the multiplexed instrumentation

• Circuits numbers and alpha characters used to identify each circuit are much

different than in our legacy circuit wiring key

Service Manual KM815052

30

Loading...

Loading...