Page 1

Kenworth Heavy Duty

Body Builder Manual

2017

®

Page 2

This page intentionally left blank.

Page 3

Kenworth Heavy Duty

2.1m Cab

Body Builder Manual

®

Page 4

Body Builder Manual

Contents

SECTION 1: INTRODUCTION 1-1

SECTION 2: SAFETY & COMPLIANCE 2-1

SAFETY SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

FEDERAL MOTOR VEHICLE SAFETY

STANDARDS COMPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

SECTION 3: DIMENSIONS 3-1

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

TURNING RADIUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

T680 STANDARD HOOD DAYCAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

T680 MX (SHORT) HOOD DAYCAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

T880 STANDARD HOOD DAYCAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

T880S SFFA (SHORT) HOOD DAYCAB . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

T680 STANDARD HOOD 40” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

T680 MX (SHORT) HOOD 40” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

T880 STANDARD HOOD 40” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

T880S SFFA (SHORT) HOOD 40” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . . .3-13

T680 STANDARD HOOD 52” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

T680 MX (SHORT) HOOD 52” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

T880 STANDARD HOOD WITH 52” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . .3-16

T880 MX (SHORT) HOOD WITH 52” SLEEPER . . . . . . . . . . . . . . . . . . . . . . . 3-17

T680 STANDARD HOOD WITH 76” HIGH-ROOF SLEEPER . . . . . . . . . . . . . . . . .3-18

T680 MX (SHORT) HOOD WITH 76” HIGH-ROOF SLEEPER . . . . . . . . . . . . . . . .3-19

T680 STANDARD HOOD WITH 76” MID-ROOF SLEEPER . . . . . . . . . . . . . . . . . 3-20

T680 MX (SHORT) HOOD WITH 76” MID-ROOF SLEEPER . . . . . . . . . . . . . . . . . 3-21

T880 STANDARD HOOD WITH 76” MID-ROOF SLEEPER . . . . . . . . . . . . . . . . . 3-22

T880 MX (SHORT) HOOD WITH 76” MID-ROOF SLEEPER . . . . . . . . . . . . . . . . . 3-23

RIDE HEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

REAR SUSPENSION LAYOUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

AG400L TANDEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

AG400 OR AG460 TANDEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

AG460 TANDEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

AG690 TRIDEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

REYCO 79KB SINGLE REAR AXLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

REYCO 102 TANDEM REAR AXLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

NEWAY ADZ 123 SINGLE REAR AXLE. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

NEWAY ADZ 246 TANDEM SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

NEWAY ADZ 369 TRIDEM SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

HENDRICKSON PRIMAAX EX TANDEM SUSPENSION . . . . . . . . . . . . . . . . . . .3-36

HENDRICKSON PRIMAAX EX TRIDEM SUSPENSION . . . . . . . . . . . . . . . . . . . 3-37

HENDRICKSON UMX TANDEM SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . 3-38

HENDRICKSON RT TANDEM SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . . .3-39

CHALMERS 856-46 TANDEM SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . . .3-40

LIFT AXLES (PUSHERS AND TAGS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

AXLE TRACK AND TIRE WIDTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

2/17

ii

Page 5

Body Builder Manual

Contents

SECTION 4: PTO MOUNTING & PROGRAMMING 4-1

4-1. PTO MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2. PTO TELLTALE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PTO WIRING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-3. PTO CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-4. T680/880 TRANSMISSION PTO APPLICATION GUIDE . . . . . . . . . . . . . . . . . 4-10

4.5 PTO CONTROLS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-6. ELECTRIC OVER AIR SYSTEM INTERLOCKING . . . . . . . . . . . . . . . . . . . .4-22

4-7. PACCAR MX ENGINES - PTO PROGRAMMING: . . . . . . . . . . . . . . . . . . . . 4-25

SECTION 5: EXHAUST & AFTERTREATMENT 5-1

EXHAUST AND AFTER-TREATMENT INFORMATION . . . . . . . . . . . . . . . . . . . . 5-1

GENERAL GUIDELINES FOR DEF SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 5-3

GENERAL EXHAUST INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

SECTION 6: FRAME LAYOUTS 6-1

FRAME LAYOUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

COMMON OPTIONAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

FRAME LAYOUT INDEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

SECTION 7: BODY MOUNTING 7-1

FRAME INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

CRITICAL CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

BODY MOUNTING USING BRACKETS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

MOUNTING HOLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

BODY MOUNTING USING U–BOLTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

SECTION 8: FRAME MODIFICATIONS 8-1

FRAME MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

DRILLING RAILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MODIFYING FRAME LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

CHANGING WHEELBASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

CROSSMEMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

WELDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

TORQUE REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

SECTION 9: ELECTRICAL 9-1

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

BODY BUILDER CONNECTION POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

LIFT AXLES (PUSHERS & TAG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

SECTION 10: ROUTING 10-1

ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

ROUTING REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

APPENDIX A: VEHICLE IDENTIFICATION 1

VEHICLE IDENTIFICATION LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

iii

2/17

Page 6

2/17

Figures

FIGURE 2-1. Incomplete Vehicle Certication Document . . . . . . . . . . . . . . . . . . . 2-2

FIGURE 2-2. Locations Of Certication Labels - Driver’s Door And Frame . . . . . . . . . . 2-2

FIGURE 2-3: Aerodynamic Mirror Oat Sensor Location. . . . . . . . . . . . . . . . . . . . 2-8

FIGURE 2-4: Instrument Cluster For T680/T880 . . . . . . . . . . . . . . . . . . . . . . . 2-8

FIGURE 3-1. Prospecter Turn Circle Analysis . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

FIGURE 4-1. Medium Duty Manual Transmission Ptos . . . . . . . . . . . . . . . . . . . . 4-1

FIGURE 4-2. Heavy Duty Manual Transmission Ptos . . . . . . . . . . . . . . . . . . . . . 4-1

FIGURE 4-3. Thru-Shaft Pto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

FIGURE 4-4. Allison 4000 Series Transmission Pto Locations . . . . . . . . . . . . . . . . 4-2

FIGURE 4-5. Allison 3000 Series Transmission Pto Locations . . . . . . . . . . . . . . . . 4-2

FIGURE 4-6. Repto Location Shown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

FIGURE 4-7. Pto Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

FIGURE 4-8. Pto Telltale Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

FIGURE 4-9. Relay Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

FIGURE 4-10. 2013+ Mx-11 And Mx-13 Pin-Out . . . . . . . . . . . . . . . . . . . . . . . 4-5

FIGURE 4-11. 2013+ Isx15, Isx12, Px-9 Pin-Out . . . . . . . . . . . . . . . . . . . . . . . 4-5

FIGURE 4-12. Pto Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

FIGURE 4-13. Single Acting And Dual Acting Ptos . . . . . . . . . . . . . . . . . . . . . . 4-15

FIGURE 4-14. Single-Acting Eaton Pto . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

FIGURE 4-15. Double-Acting Eaton Pto. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

FIGURE 4-16. Allison Transmission-Mounted Ptos . . . . . . . . . . . . . . . . . . . . . . 4-18

FIGURE 4-17. Auto Susp Dump W/ Allison Mtd Pto. . . . . . . . . . . . . . . . . . . . . .4-19

FIGURE 4-18. Eoa Reversible Pto Example. . . . . . . . . . . . . . . . . . . . . . . . . .4-20

FIGURE 4-19. Air Actuated Pto (No Interlock). . . . . . . . . . . . . . . . . . . . . . . . .4-20

FIGURE 4-20. Rear Axle Declutch Telltale. . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

FIGURE 4-21. Split Shaft Pto Example #1. . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

FIGURE 4-22. Pump Mode Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

FIGURE 4-23. Sample Chassis Node And Eoa Manifold.. . . . . . . . . . . . . . . . . . .4-23

FIGURE 4-24. Wiring Diagram For Chassis Node, Cab Switches, And Eoa Manifold. . . . .4-24

FIGURE 4-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

FIGURE 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

FIGURE 4-27. In-Cab Pto Control For T680/T880. . . . . . . . . . . . . . . . . . . . . . .4-29

FIGURE 4-28. In-Cab Pto Control – Esa Settings For T680/T880. . . . . . . . . . . . . . .4-30

FIGURE 4-29. Hard-Wired Remote Pto Control . . . . . . . . . . . . . . . . . . . . . . . .4-31

FIGURE 4-30. Hardwired Remote Pto Control – Esa Settings For T680/T880 . . . . . . . . 4-33

FIGURE 4-31. Remote Pto Control Over Bcan With Pto On/Off Switch Hardwired To Cecu . 4-34

FIGURE 4-32. Remote Pto Control Over Bcan With Hardwired Pto Engagement Feedback

To Engine– Esa Settings T680/T880 . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

FIGURE 4-33. Remote Pto Control Over Bcan With Hardwired Pto Engagement Feedback

To Engine – Esa Settings T680/T880 . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

FIGURE 4-34. Remote Pto Control Over Bcan With Pto On/Off Switch Signal Over Bcan . . 4-38

FIGURE 4-35. Remote Pto Control Over Bcan With Pto On/Off Switch Signal Over Bcan –

Esa Settings For T680/T880 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

FIGURE 4-36. Remote Pto Control Over Bcan With Pto On/Off Switch Signal Over Bcan –

Esa Settings For T680/T880 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

FIGURE 4-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

FIGURE 4-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

FIGURE 5-1. Routing Def And Coolant Lines . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

FIGURE 5-2. Supply Module Allowed Clocking Angle Limit Scribes A 90° Inverted Cone. . . 5-6

FIGURE 5-3. Isometric View Of Right Hand Under Dpf/Scr With Single Side Of Cab Tailpipe 5-8

FIGURE 5-4. Isometric View Of Right Hand Under Dpf/Scr With Single Side Of Cab Tailpipe 5-8

FIGURE 5-5. Right View Of Right Hand Under Dpf/Scr With Single Side Of Cab Tailpipe . . 5-9

FIGURE 5-6. Back View Of Right Hand Under Dpf/Scr With Single Side Of Cab Tailpipe. . . 5-9

FIGURE 5-7. Isometric View Of Right Hand Under Dpf/Scr With Dual Side Of Cab Tailpipe . 5-10

FIGURE 5-8. Isometric View Of Right Hand Under Dpf/Scr With Dual Side Of Cab Tailpipe 5-10

iv

Page 7

Figures

FIGURE 5-9. Right View Of Right Hand Under Dpf/Scr With Dual Side Of Cab Tailpipe . . . 5-11

FIGURE 5-10. Back View Of Right Hand Under Dpf/Scr With Dual Side Of Cab Tailpipe . . .5-11

FIGURE 5-11. Isometric View Of Right Hand Under Dpf/Scr With Single

Back Of Cab Tailpipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

FIGURE 5-12. Isometric View Of Right Hand Under Dpf/Scr With Single

Back Of Cab Tailpipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

FIGURE 5-13. Right View Of Right Hand Under Dpf/Scr With Single Back Of Cab Tailpipe . 5-13

FIGURE 5-14. Back View Of Right Hand Under Dpf/Scr With Single Back Of Cab Tailpipe . .5-13

FIGURE 5-15. Isometric View Of Right Hand Under Dpf/Scr With Ground-Dump Tailpipe . . 5-14

FIGURE 5-16. Isometric View Of Right Hand Under Dpf/Scr With Ground-Dump Tailpipe . . 5-14

FIGURE 5-17. Right View Of Right Hand Under Dpf/Scr With Ground-Dump Tailpipe . . . . 5-15

FIGURE 5-18. Back View Of Right Hand Under Dpf/Scr With Ground-Dump Tailpipe . . . . 5-15

FIGURE 5-19. Isometric View Of Independent Back Of Cab Dpf/Scr With

Back Of Cab Tailpipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

FIGURE 5-20. Isometric View Of Independent Back Of Cab Dpf/Scr With

Back Of Cab Tailpipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

FIGURE 5-21. Right View Of Independent Back Of Cab Dpf/Scr With Back Of Cab Tailpipe 5-17

FIGURE 5-22. Back View Of Independent Back Of Cab Dpf/Scr With Back Of Cab Tailpipe 5-17

FIGURE 5-23. Isometric View Of Horizontal Dpf/Scr With Ground-Dump Tailpipe . . . . . . 5-18

FIGURE 5-24. Isometric View Of Horizontal Dpf/Scr With Ground-Dump Tailpipe . . . . . . 5-18

FIGURE 5-25. Right View Of Horizontal Dpf/Scr With Ground-Dump Tailpipe. . . . . . . . .5-19

FIGURE 5-26. Back View Of Horizontal Dpf/Scr With Ground-Dump Tailpipe . . . . . . . . .5-19

FIGURE 5-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

FIGURE 5-28. Dimension A = Top Of Rail Frame Height From Prospector – Frame Depth. . 5-21

FIGURE 6-1. Def Tank Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

FIGURE 7-1. Minimum Clearance Between Top Of Rear Tires And Body Structure Overhang. 7-2

FIGURE 7-2. Minimum Back Of Cab Clearance . . . . . . . . . . . . . . . . . . . . . . . . 7-3

FIGURE 7-3. Spacer Between Frame Sill And Body Rail - Rubber Or Plastic. . . . . . . . . 7-4

FIGURE 7-4. High Compression Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

FIGURE 7-5. Rubber Spacer Between BracketsBetween The Mounting Bolt

And Upper Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

FIGURE 7-6. Crossmember-Gusset Hole Pattern Requirements. [Inch (Mm)] . . . . . . . . 7-5

FIGURE 7-7. Acceptable U-Bolt Mounting With Wood And Fabricated Spacers [Inch (Mm)] . 7-6

FIGURE 7-8. Clearance Space For Air Lines And Cables. . . . . . . . . . . . . . . . . . . 7-7

FIGURE 7-9. Example Of Fishplate Bracket At Rear End Of Body, Used With U-Bolts . . . . 7-8

FIGURE 8-1. Detail Of Frame Extension And Joint Welding. . . . . . . . . . . . . . . . . . 8-2

FIGURE 8-2. Frame Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

FIGURE 8-3. Comparison Of Original, Shortened, And Extended Wheelbases. . . . . . . . 8-4

FIGURE 8-4. Crossmember Added When Distance Exceeds 60 Inches (1524 Mm) . . . . . 8-5

FIGURE 9-1. Namux 4 System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

FIGURE 9-2. Diagnostic Connector Comparison . . . . . . . . . . . . . . . . . . . . . . . 9-2

FIGURE 9-3. 2016+ Service Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

FIGURE 9-4. 12 Pin Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

FIGURE 9-5. Spare Circuit Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

FIGURE 9-6. Grounding Buss Bar Design. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

FIGURE 9-7. Grounding Point - Cab Interior Behind Driver’s Side Kick Panel . . . . . . . . 9-4

FIGURE 9-8. Grounding Point - Cab Exterior Lh Side Of Firewall. . . . . . . . . . . . . . . 9-4

TABLE 9-1. Wire Number General Categories . . . . . . . . . . . . . . . . . . . . . . . . 9-5

FIGURE 9-9. Spare Circuit Location Under-Dash (P096) . . . . . . . . . . . . . . . . . . . 9-6

FIGURE 9-10. Spare Circuit Location On Power Distribution Center (Dash-Side, P001) . . . 9-7

FIGURE 9-11. Spare Circuit Diagram (P001 And P096) . . . . . . . . . . . . . . . . . . . 9-8

FIGURE 9-12. Electric Engaged Equipment Connector . . . . . . . . . . . . . . . . . . . . 9-9

FIGURE 9-13. Air Solenoid Bank And Chassis Node . . . . . . . . . . . . . . . . . . . . . 9-9

FIGURE 9-14. Rear Axle Controls And Sensors Connector. . . . . . . . . . . . . . . . . .9-10

FIGURE 9-15. B-Can Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-11

v

2/17

Page 8

Figures

Figures

FIGURE 9-16. Chassis Harness From Cab Mount To Front Of Frame . . . . . . . . . . . . 9-11

FIGURE 9-17. Chassis Harness From Cab Mount To Boc . . . . . . . . . . . . . . . . . . 9-12

FIGURE 9-18. Connectors Near Front Cab Mount . . . . . . . . . . . . . . . . . . . . . . 9-12

FIGURE 9-19. Connector Near Boc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

FIGURE 9-20. Vcan Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-13

FIGURE 9-21. Firewall Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

FIGURE 9-22. Chassis Node And Electric Over Air Solenoid Bank . . . . . . . . . . . . . .9-14

FIGURE 9-23. Installing Additional Switches Onto The Chassis Side . . . . . . . . . . . . .9-15

FIGURE 9-24. Installing Additional Gauges On The Dash. . . . . . . . . . . . . . . . . . .9-16

FIGURE 9-25. Installing Sensors On The Chassis Side For Gauges . . . . . . . . . . . . . 9-17

FIGURE 9-26. Typical Installation Of Sensors Diagram . . . . . . . . . . . . . . . . . . . . 9-18

FIGURE 9-27. Spare Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

FIGURE 9-28. Truck Lift Axles (Separate Switches). . . . . . . . . . . . . . . . . . . . . .9-19

FIGURE 9-29. Truck Lift Axles (Single Switch) . . . . . . . . . . . . . . . . . . . . . . . . 9-19

FIGURE 9-30. Eoa Trailer Lift Axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

FIGURE 9-31. Mx-13 Connection Location. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

FIGURE 9-32. Mx-11 Connection Location. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

FIGURE 9-33. Isx15 Connection Location. . . . . . . . . . . . . . . . . . . . . . . . . . .9-23

FIGURE 9-34. Isx12 Connection Location. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

FIGURE 9-35. Mating Connector: Packard Pn 12020786 . . . . . . . . . . . . . . . . . . . 9-30

FIGURE 9-36. Junction Box Boc Or Eof . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-30

FIGURE 9-37. Dash Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-31

FIGURE 9-38. Engine Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

FIGURE 9-39. J1939 Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

FIGURE 9-40. J1939 Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

FIGURE 9-41. J1939 Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

FIGURE 9-42. Trim Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

FIGURE 9-43. Gauge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

FIGURE 9-44. Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

FIGURE 9-45. Cluster Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

FIGURE 9-46. Telltale Installation Diagnostics & Service Tool Connection . . . . . . . . . . 9-36

FIGURE 10-1. Clamp And Buttery Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

FIGURE 10-2. Buttery Tie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

FIGURE 10-3. Tie Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

FIGURE 10-4. Heavy Duty (Hd) Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

FIGURE 10-5. Denition Of Measurements.. . . . . . . . . . . . . . . . . . . . . . . . . .10-4

2/17

vi

Page 9

Tables

TABLE 3-1. Abbreviations Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

TABLE 3-2. Turning Radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

TABLE 3-3. Ride Heights. To calculate the frame height use the following formulas: . . . . .3-24

TABLE 3-4. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

TABLE 3-5. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

TABLE 3-6. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

TABLE 3-7. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

TABLE 3-8. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

TABLE 3-9. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

TABLE 3-10. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

TABLE 3-11. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

TABLE 3-12. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

TABLE 3-13. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

TABLE 3-14. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

TABLE 3-15. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

TABLE 3-16. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

TABLE 3-17. Rear Suspension Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

TABLE 3-18. Axle Width Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

TABLE 3-19. Ground Clearance for Fuel Tanks . . . . . . . . . . . . . . . . . . . . . . . . 3-47

TABLE 3-20. Ground Clearance for Battery Boxes . . . . . . . . . . . . . . . . . . . . . . 3-48

TABLE 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

TABLE 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

TABLE 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

TABLE 4-4. Current single-acting PTOs include: . . . . . . . . . . . . . . . . . . . . . . . 4-16

TABLE 4-6. Reversible PTO States to Ports. . . . . . . . . . . . . . . . . . . . . . . . . .4-20

TABLE 4-7. PACCAR PTO TSC1 Message Requirements . . . . . . . . . . . . . . . . . .4-26

TABLE 4-8. In cab PTO Control – ESA Settings for T680/T880 . . . . . . . . . . . . . . . .4-29

TABLE 4-9. In-Cab PTO Control – PEP Settings . . . . . . . . . . . . . . . . . . . . . . . 4-31

TABLE 4-10. J1939 signals from CECU (SA 0x31) to Engine over VCAN . . . . . . . . . . 4-32

TABLE 4-11. Hard-wired Remote PTO Control – ESA Settings for T680/T880 . . . . . . . . 4-32

TABLE 4-12. Hardwired Remote PTO Control – PEP Settings . . . . . . . . . . . . . . . . 4-34

TABLE 4-13. J1939 signals from CECU (SA 0x31) to Engine over VCAN . . . . . . . . . . 4-35

TABLE 4-14. Engine Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

TABLE 4-15. Remote PTO Control over BCAN with hardwired PTO Engagement

Feedback to Engine– ESA Settings T680/T880 . . . . . . . . . . . . . . . . . . . . . 4-35

TABLE 4-16. Hardwired Remote PTO Control – PEP Settings . . . . . . . . . . . . . . . . 4-37

TABLE 4-17. J1939 signals from CECU (SA 0x31) to Engine over VCAN . . . . . . . . . . 4-39

TABLE 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

TABLE 4-19. Remote PTO Control over BCAN with PTO ON/OFF Switch Signal over

BCAN – ESA Settings for T680/T880. . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

TABLE 4-20. Hardwired Remote PTO Control – PEP Settings . . . . . . . . . . . . . . . . 4-44

TABLE 4-21. PACCAR BCAN Message Requirements . . . . . . . . . . . . . . . . . . . . 4-44

TABLE 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

TABLE 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

TABLE 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

TABLE 6-2. Fuel Tank Overall Length (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

TABLE 6-3. Battery Box Centerframe Lengths (in) . . . . . . . . . . . . . . . . . . . . . . 6-2

TABLE 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

TABLE 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

TABLE 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

TABLE 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

TABLE 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

TABLE 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

TABLE 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

TABLE 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

vii

2/17

Page 10

Figures

Tables

TABLE 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

TABLE 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

TABLE 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

TABLE 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

TABLE 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

TABLE 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

TABLE 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

TABLE 7-1. Single Steel Rails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

TABLE 7-2. Inserted Steel Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

TABLE 8-1. Customary Grade 8 UNF or UNC. . . . . . . . . . . . . . . . . . . . . . . . . 8-7

TABLE 8-2. U.S. Customary – Grade 8. Metric Class 10.9 . . . . . . . . . . . . . . . . . . 8-7

TABLE 9-2. Truck Lift Axle Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

TABLE 9-3. Air Solenoid Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

TABLE 9-4. MX engine (P111C/J111C) . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-21

TABLE 9-5. ISX Remote Throttle/PTO Connector P111A/J111A: . . . . . . . . . . . . . . .9-23

TABLE 9-6. EoA Chassis Node Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

TABLE 9-7. EoA CECU Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-24

TABLE 9-8. CECU Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

TABLE 9-9. Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

TABLE 10-1. Exhaust – System Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

2/17

viii

Page 11

Section 1

Introduction

This manual was created to provide body builders with appropriate information and guidelines

useful in the body planning and installation process. This information will be helpful when installing

bodies or other associated equipment.

This manual contains appropriate dimensional information, guidelines for mounting bodies, guidelines for modifying frames, electrical wiring information, and other information useful in the body

installation process. This manual is specic to chassis with 2017 EPA emissions engines.

The Body Builder Manual can be very useful when specifying a vehicle, particularly when the body

builder is involved in the vehicle denition and ordering process. Early in the process, professional

body builders can often contribute valuable information that reduces the ultimate cost of the body

installation.

In the interest of continuing product development, Kenworth reserves the right to change specications or products at any time without prior notice. It is the responsibility of the user to ensure

that he is working with the latest released information. Check Kenworth.com for the latest released

version.

If you require additional information or reference materials, please contact your local Kenworth

dealer.

1-1

2/17

Page 12

This page intentionally left blank.

Page 13

Section 2

Safety & Compliance

SAFETY SIGNALS

We’ve put a number of alerting messages in this book. Please read and follow them. They are there for your protection

and information. These alerting messages can help you avoid injury to yourself or others and help prevent costly damage to the vehicle.

Key symbols and “signal words” are used to indicate what kind of message is going to follow. Pay special attention to

comments prefaced by “WARNING”, “CAUTION”, and “NOTE.” Please don’t ignore any of these alerts.

Warnings, cautions, and notes

WARNING

Example:

WARNING! Be sure to use a circuit breaker designed to meet liftgate amperage requirements. An incor-

rectly specied circuit breaker could result in a electrical overload or re situation. Follow the liftgate

installation instructions and use a circuit breaker with the recommended capacity.

CAUTION

Example:

CAUTION: Never use a torch to make a hole in the rail. Use the appropriate drill bit.

NOTE

When you see this word and symbol, the message that follows is especially vital. It signals a

potentially hazardous situation which, if not avoided, could result in death or serious injury.

This message will tell you what the hazard is, what can happen if you don’t heed the warning,

and how to avoid it.

Signals a potentially hazardous situation which, if not avoided, could result in minor or moderate injury or damage to the vehicle.

Provides general information: for example, the note could warn you on how to avoid damaging

your vehicle or how to drive the vehicle more efciently.

Example:

Note: Be sure to provide maintenance access to the battery box and fuel tank ll neck.

Please take the time to read these messages when you see them, and remember:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Signals a potentially hazardous situation which, if not avoided, could result in minor or moderate

injury or damage to the vehicle.

NOTE

Useful information that is related to the topic being discussed.

2-1

2/17

Page 14

Section 2

Safety & Compliance

FEDERAL MOTOR VEHICLE SAFETY

STANDARDS COMPLIANCE

As an Original Equipment Manufacturer (OEM), Kenworth Truck Co. ensures that our products comply with all applicable

U.S. or Canadian Federal Motor Vehicle Safety Standards. However, the fact that this vehicle has no fth wheel and that a

Body Builder (Intermediate or Final Stage Manufacturer) will be doing additional modications means that the vehicle was

incomplete when it left the build plant. See next section and Appendix A for additional information.

Incomplete Vehicle Certication

An Incomplete Vehicle Document is shipped with the vehicle, certifying that the vehicle is not complete. See Figure 2–1.

In addition, afxed to the driver’s side door frame or edge is an Incomplete Vehicle Certication label. See Figure 2–2. For

further information on Vehicle Certication and Identication, see APPENDIX A “VEHICLE IDENTIFICATION.”

NOTE

These documents list the U.S. or Canadian Federal Motor Vehicle Safety Standard regulations that the

vehicle complied with when it left the build plant. You should be aware that if you add, modify or alter any

of the components or systems covered by these regulations, it is your responsibility as the Intermediate or

Final Stage Manufacturer to ensure that the complete vehicle is in compliance with the particular regula-

tions upon completion of the modications.

U.S. EPA Noise Label (U.S. registered vehicles only)

Final Stage Manufacturer

Label to be Installed by

Final Stage Manufacturer

Chassis Serial

Number

Vehicle Emission Control

Information Label

FIGURE 2-1. Incomplete Ve-

hicle Certication Document

Tire, Rim and

Weight Rating

Data label

Safety Mark (Canadian

Registry Only)

Incomplete Vehicle

Certication Label

Major Components and

Weights Label

FIGURE 2-2. Locations of Certica-

tion Labels - Driver’s Door and Frame

As the Intermediate or Final Stage Manufacturer, you should retain the Incomplete Vehicle Document for your records. In

addition, you should record and retain the manufacturer and serial number of the tires on the vehicle. Upon completion

of the vehicle (installation of the body and any other modications), you should afx your certication label to the vehicle

as required by Federal law. This tag identies you as the “Intermediate or Final Stage Manufacturer” and certies that the

vehicle complies with Federal Motor Vehicle Safety Standards. (See Figure 2–2.) Be advised that regulations affecting the

intermediate and nal stage manufacturer may change without notice. Ensure you are referencing the most updated copy

of the regulation during the certication and documentation processes.

In part, if the nal stage manufacturer can complete and certify the vehicle within the instruction in the incomplete vehicle

document (IVD) the certication label would need a statement that reads, “This vehicle has been completed in accordance

with the prior manufacturers‚ IVD where applicable. This vehicle conforms to all applicable Federal Motor Vehicle Safety

Standards [and Bumper and Theft Prevention Standards if applicable] in effect in (month, year).”

However, if the vehicle can not be completed and certied with in the guidance provided in the IVD, the nal stage manufacturer must ensure the vehicle conforms to all applicable Federal Motor Vehicle Safety Standards (FMVSS). The nal

stage manufactures certication label would need a statement that reads, “This vehicle conforms to all applicable Federal

Motor Vehicle Safety Standards [and Bumper and Theft Prevention Standards if applicable] in effect in (month, year).”

2/17

2-2

Page 15

Section 2

Safety & Compliance

These statements are just part of the changes to the new certication regulation. Please refer to the Feb 15, 2005 nal

rule for all of the details related to this regulation. You can contact NTEA Technical Services Department at 1-800-441NTEA for a copy of the nal rule (DocID 101760).

For Canadian nal stage manufacturers see:

http://www.gazette.gc.ca/index-eng.html; and

http://www.tc.gc.ca/eng/acts-regulations/menu.htm for the regulations.

Or contact:

Transport Canada

Tower C, Place de Ville, 330 Sparks Street

Ottawa, Ontario K1A 0N5

(613) 990-2309

TTY: 1-888-675-6863

Noise and Emissions Requirements

NOTE

This truck may be equipped with specic emissions control components/systems* in order to

meet applicable Federal and California noise and exhaust emissions requirements. Tampering

with these emissions control components/systems* is against the rules that are established by the

U.S Code of Federal Regulations, Environment Canada Regulations and California Air Resources

Board (CARB). These emissions control components/systems* may only be replaced with original

equipment parts.

Additionally, most vehicles in North America will be equipped with a Greenhouse Gas (GHG)

“Vehicle Emission Control Information” door label indicating its certied conguration. The vehicle

components listed on this label are considered emission control devices.

Modifying (i.e. altering, substituting, relocating) any of the emissions control components/sys-

tems dened above will affect the noise and emissions performance/certication. Modications

that alter the overall shape and aerodynamic performance of a tractor will also affect the emis-

sion certication. If modications are required, they must rst be approved by the manufacturer.

Unapproved modications could negatively affect emissions performance/certication. There is no

guarantee that proposed modications will be approved.

Tires may be substituted provided the new tires possess a Coefcient of rolling resistance (Crr)

equal to or lower than Crr of the original tires. Consult with your tire supplier(s) for appropriate

replacement tires.

Contact the engine manufacturer for any requirements and restrictions prior to any modications.

• For Cummins Contact 1-800-DIESELS or your local Cummins distributor. Reference AEB 21.102.

It is possible to relocate the DEF tank, however the relocation requirements need to be followed. Any variance from the

relocation requirements may cause the emissions control components/systems to operate improperly potentially resulting

in engine de-rate. See page 4-3 for relocation requirements.

NOTE

All 2017 engine emissions certied vehicles will be equipped with an On-Board Diagnostics

(OBD) system. The OBD system is designed to detect malfunctions of any engine or vehicle component that may increase exhaust emissions or interfere with the proper performance of the OBD

system itself.

2-3

2/17

Page 16

Section 2

Safety & Compliance

All diesel engines will be equipped with an On-Board Diagnostics (OBD) system. The OBD

system consists of computer program on one or more of the vehicle’s Electronic Control Units

(ECUs). This program uses information from the control system and from additional sensors to

detect malfunctions. When a malfunction is detected, information is stored in the ECU(s) for diagnostic purposes. A Malfunction Indicator Light (MIL) is illuminated in the dash to alert the driver of

the need for service of an emission-related component or system.

To ensure compliance to emissions regulations, the nal conguration of certain features of the completed vehicle

must meet specic requirements. This section describes requirements relevant for only the most common or critical modications done by body builders. For a complete description of acceptable modications, see the application

guidance available from the manufacturer of the engine installed in the chassis.

Fuel System

The following are highlights of some of the more common or critical aspects of this system.

The overall system restriction may not exceed the restriction limitations set forth by the engine manufacturer for both

supply and return.

• Ensure that fuel lines are not pinched or can potentially be damaged when installed between body and frame

• Fuel lines must be routed and secured without dips or sags

• There must be easy access to lter(s) and ll cap

• The tank vent may not obstructed

• Added accessories (heaters, generators) cannot introduce air into system

• Fuel tank must be located so that the full level is not above cylinder head

• “Ultra Low Sulfur Fuel Only” labels must be present on the dash and fuel ll

• Modication of the pressure side secondary lter and plumbing is not allowed without engine manufacturer

approval

• Body installation of fuel tank or routing of lines must not cause signicant increase in fuel temperature

• Fuel hoses shall meet or exceed OEM supplied hose material construction specications

• Formed nylon fuel lines with quick-connects are installed underneath the cab and hood along the frame rail.

Behind the cab from the fuel tee to tanks are wirebraid-reinforced rubber lines. Supply and return ttings are

poka-yoked to prevent incorrect assembly.

2/17

Nylon

Wirebraid-reinforced rubber

2-4

Page 17

Section 2

Safety & Compliance

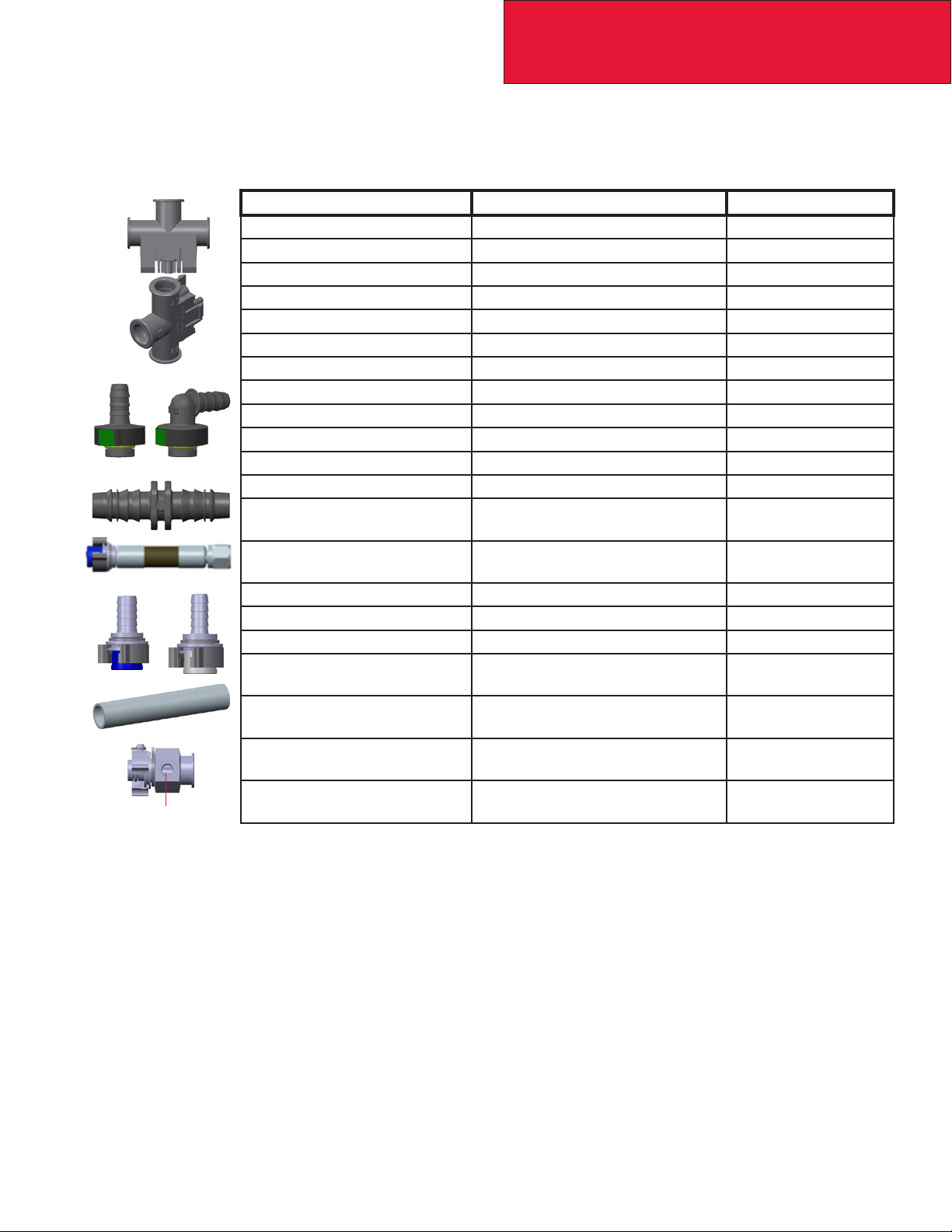

PARTS

Replacement nylon fuel line assemblies are available based on individual chassis and fuel system hardware.

For other chassis changes, individual parts are listed below.

DESCRIPTION USE PART NO.

Supply Tee – All ports open Dual LH and RH fuel tanks K38-1057

Supply Tee – RH port closed Only LH fuel tank(s) K38-1058

Supply Tee – LH port closed Only RH fuel tank(s) K38-1059

Return Tee – All ports open Dual LH and RH fuel tanks K38-1060

Return Tee – RH port closed Only LH fuel tank(s) K38-1061

Return Tee – LH port closed Only RH fuel tank(s) K38-1062

Supply Fitting – Straight Nylon line assemblies K38-1069-001

Supply Fitting – 90˚ Nylon line assemblies K38-1069-002

Return Fitting – Straight Nylon line assemblies K38-1069-003

Return Fitting – 90˚ Nylon line assemblies K38-1069-004

Supply Union Short-term repair, 12mm ID K38-1069-010

Return Union Short-term repair, 10mm ID K38-1069-009

¼” NPT Port

Supply Rubber Line Assembly Fuel tee to fuel tank lines, xxx in

inches

Return Rubber Line Assembly Fuel tee to fuel tank lines, xxx in

inches

Supply Steel Fitting – Straight Rubber line assemblies, 1/2” barb K38-1069-007

Return Steel Fitting – Straight Rubber line assemblies, 3/8” barb K38-1069-008

Retaining Clip Collar on steel rubber hose ttings K38-1069-015

Bulk Supply Nylon Line Short-term repair, 12mm ID, xxxx

in mm

Bulk Return Nylon Line Short-term repair, 10mm ID, xxxx

in mm

Supply APU Fitting Additional fuel-powered unit, install

in-line at tee

Return APU Fitting Additional fuel-powered unit, install

in-line at tee

V50-14860082111xxx

V50-14860063111xxx

V50-1178-1xxxx

V50-1178-2xxxx

K38-1055

K38-1056

Compressed Air System

The following are highlights of some of the more common or critical aspects of this system.

• Air system modication must meet applicable FMVSS regulations

• Compressed Air tank may not be modied (exception – addition or removal of ttings or relocation of the tank)

• Added devices or bodywork may not interfere with or rub air lines

• Air supply to the engine doser may not be restricted or disconnected

• Air lines should be routed, protected from heat, and properly secured to prevent damage from other

components

• Care should be taken so that air lines do not rub against other components

• Care should be taken to protect the air system from heat sources.

2-5

2/17

Page 18

Section 2

Safety & Compliance

Exhaust and Exhaust After-treatment System

The following are highlights of some of the more common or critical aspects of this system.

• The following after-treatment and exhaust system components may not be modied:

• DPF assembly

• SCR Catalyst assembly

• Exhaust pipes between the engine and after-treatment devices (DPF, SCR Catalyst) and between

after-treatment devices

• NOx Sensors

• PM Sensor

• The following modications may only be done within the guidelines of the “DEF System Relocation Guide.”

• Modications to Diesel Exhaust Fluid (DEF) throttle, suction, or pressure lines

• Modication or relocation of the DEF tank

• Modication of coolant lines to and from the DEF tank

• All DEF and coolant lines should be routed, protected, and properly secured to prevent damage during vehicle

operation or other components

• If relocation of the DCU or ACM is necessary, use existing frame brackets and mount inside of frame anges

where necessary. Do not extend the harnesses

• The DPF, the SCR catalyst, or their mounting may not be modied

• The NOx sensor may not be relocated or altered in any way; this includes re-clocking the aftertreatement

canister or reorienting the sensor(s)

• Exhaust pipes used for tailpipes/stacks must be properly sized, and must prevent water from entering

• Ensure adequate clearance between the exhaust and body panels, hoses, and wire harnesses

• The body in the vicinity of the DPF must be able to withstand temperatures up to 400°C (750°F)

• Do not add thermal insulation to the external surface of the DPF

• The SCR water drain hole may not be blocked

• Allow adequate clearance (25mm (1 inch)) for servicing the DPF sensors, wiring, and clamped joints

• Drainage may not come in contact with the DPF, SCR catalyst, sensors or wiring

• Allow sufcient clearance for removing sensors from DPF. Thermistors require four inches. Other sensors

require one inch

• Wiring should be routed, protected from heat, and properly secured to prevent damage from

other components

• The exhaust system from an auxiliary power unit (APU) must not be connected to any part of the vehicle

after-treatment system or vehicle tail pipe.

Cooling System

The following are highlights of some of the more common or critical aspects of this system.

• Modications to the design or locations of ll or vent lines, heater or defroster core, and surge tank are not

recommended

• Additional accessories plumbed into the engine cooling system are not permitted, at the risk of voiding vehicle

warranty

• Coolant level sensor tampering will void warranty

2/17

2-6

Page 19

Section 2

Safety & Compliance

• When installing auxiliary equipment in front of the vehicle, or additional heat exchangers, ensure that

adequate air ow is available to the vehicle cooling system. Refer to engine manufacturer application guidelines for further detail

• When installing FEPTO drivelines, the lower radiator anti-recirculation seal must be retained with FEPTO

driveline clearance modication only

• Changes made to cooling fan circuit and controls are not allowed, with the exception of AC minimum fan on

time parameter

• See owner’s manual for appropriate winter front usage

Electrical System

The following are highlights of some of the more common or critical aspects of this system.

• Electrical harnesses providing battery power and electronic control signals to engine and emissions control/

vehicle OBD components including datalinks may not be spliced. These emissions control/vehicle OBD

components include the following:

• throttle pedal

• vehicle speed sensor

• after-treatment wiring

• 9-pin OBD Connector

• CAN Communication / OBD Diagnostic wiring

• If the alternator or battery is substituted, it must meet the requirements of the engine manufacture’s guidelines. This includes alternator ground voltage drop and alternator ground cable effectiveness. See the engine

manufacture’s guidelines for recommended test procedure. Additionally the maximum voltage differential and

the peak-peak voltage differential between the engine ECM block ground stud and battery negative terminal

may not exceed 500 mV under any combination of loads or operating conditions.

• Only an OBD compliant battery disconnect switch may be installed on vehicles equipped EPA 2013 and

beyond compliant diesel engines. An OBD compliant switch and harness, even in the off position, supply a

small amount of power to the engine controller and enable certain emissions critical functions (e.g. DEF line

purge). Any modications to the electrical system which interrupt this power supply will cause OBD fault codes

and illumination of the MIL. In addition, such a modication will render the engine non-compliant with certain

emission regulations. As a general rule of thumb, you can remove and replace a battery disconnect switch on

a truck equipped with a battery disconnect switch at the factory. However, if a battery disconnect switch was

not installed in the factory a signicant harness modication is required before a battery disconnect switch can

be added.

• Installation of aftermarket transfer-cases must address the vehicle speed sensor position. The standard position of the speed sensor is at the transmission tail shaft. When a transfer-case is added it is best to relocate

the sensor to the axle side output shaft of the transfer-case. This is typically accomplished by adding a tone

wheel into the driveline yoke assembly.

• Wiring extensions for the after-treatment wiring are available for relocating the DEF tank from your dealer via

Paccar Parts. For relocation of DEF tank, refer to the after-treatment section of this manual.

• The emission system requires an accurate Outside Air Temperature (OAT) reading in order to properly run

its control algorithms. The OAT sensor is located in the driver’s side mirror assembly on Kenworth trucks and

is shown in the gures below. If the body builder needs to modify the mirror assembly in any way, it is important the OAT sensor stay positioned on the mirror assembly. Running the vehicle without the OAT sensor

connected will cause the MIL lamp to illuminate. If needed, a replacement sensor can be ordered from your

Kenworth dealer.

2-7

2/17

Page 20

Section 2

Safety & Compliance

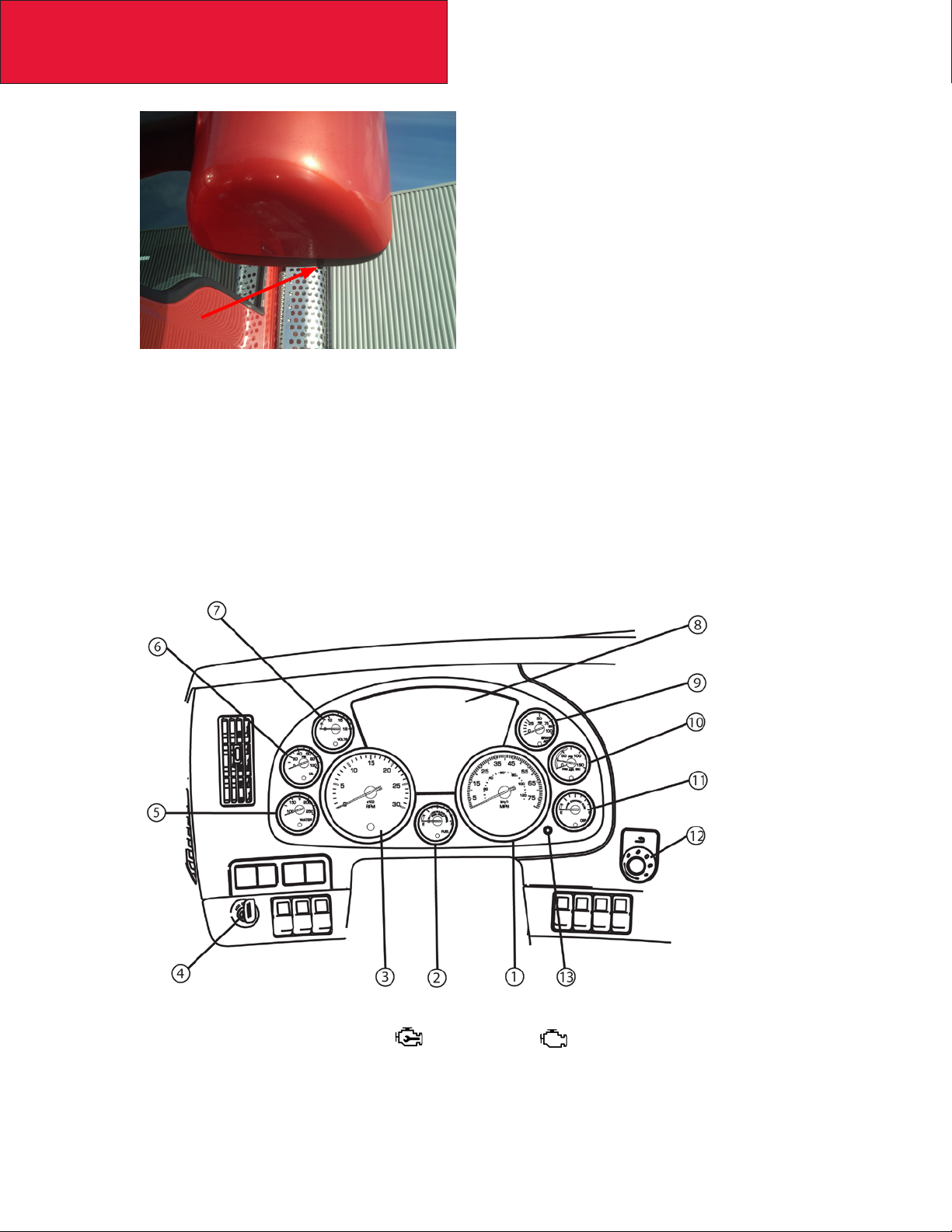

FIGURE 2-3: Aerodynamic Mirror OAT Sensor Location

• Coolant Sensor considerations are given in the Cooling section above

• The OBD/Diagnostic connector port is located below the dash to the left of the steering wheel. This connector

and its location may not be changed.

• All vehicles equipped with EPA 2013 compliant diesel and bi-fueled engines must be equipped with a Malfunc-

tion Indicator Lamp (MIL) lamp. This lamp is required to be an engine outline symbol as dened by ISO (International Standards Organization). The gure below shows the instrument cluster and MIL lamp position. Note

this lamp location is xed with respect to the controls and its location may not be changed if you are updating

the warning lamp cards.

2/17

FIGURE 2-4: Instrument Cluster for T680/T880 used with EPA 2013 Emission compliant

engines. The Check Engine lamp and/or the MIL will appear in the Driver Performance

Center (#8). See T680/T880 Operator’s Manual for more information.

• In addition to the sensors and lamps above, the emission system also depends on signals from the exhaust

DPF (Diesel Particulate Filter), SCR (Selective Catalytic Reduction), and NOx sensor. Wiring between these

devices, the Dosing Control Unit (DCU) and engine ECM should not be tampered with or altered in any way.

2-8

Page 21

Section 2

Safety & Compliance

Air Intake System

The following are highlights of some of the more common or critical aspects of this system.

• The air intake screen may not be blocked, either fully or partially

• Modication to the air intake system may not restrict airow. For example, pipe diameter may not be reduced

• All sensors must be retained in existing locations

• To retain system seal, proper clamp torque must be used. Refer to service manual for proper clamp torque

Charge Air Cooler System

The following are highlights of some of the more common or critical aspects of this system.

• The Charge Air Cooler may not be modied

• The installation of engine overspeed shutdown devices must not introduce restriction in the intake system

• All plumbing associated with the charge air cooler may not be modied

2-9

2/17

Page 22

This page intentionally left blank.

Page 23

Section 3

Dimensions

DIMENSIONS

This section has been designed to provide enough information to successfully layout chassis in the body planning

process. Optional equipment may not be depicted. Please contact your local Kenworth dealer if more dimensional

information is desired.

ABBREVIATIONS

Throughout this section, and in other sections as well, abbreviations are used to describe certain characteristics on your

vehicle. The chart below lists the abbreviated terms used.

TABLE 3-1. Abbreviations Used

CA BACK OF CAB TO CENTERLINE OF REAR AXLE OR CENTERLINE OF TANDEMS ON TANDEM SUSPENSION

EOF FRAME RAIL OVERHANG BEHIND REAR AXLE – MEASURED FROM THE CENTERLINE OF TANDEMS

FS FRONT SUSPENSION HEIGHT

RS REAR SUSPENSION HEIGHT

WB WHEELBASE

SOC SIDE OF CAB

BOC BACK OF CAB

TURNING RADIUS

Approximate turning radius specications are listed in the following tables as a general guide. It is important to note that

optional components may alter the results.

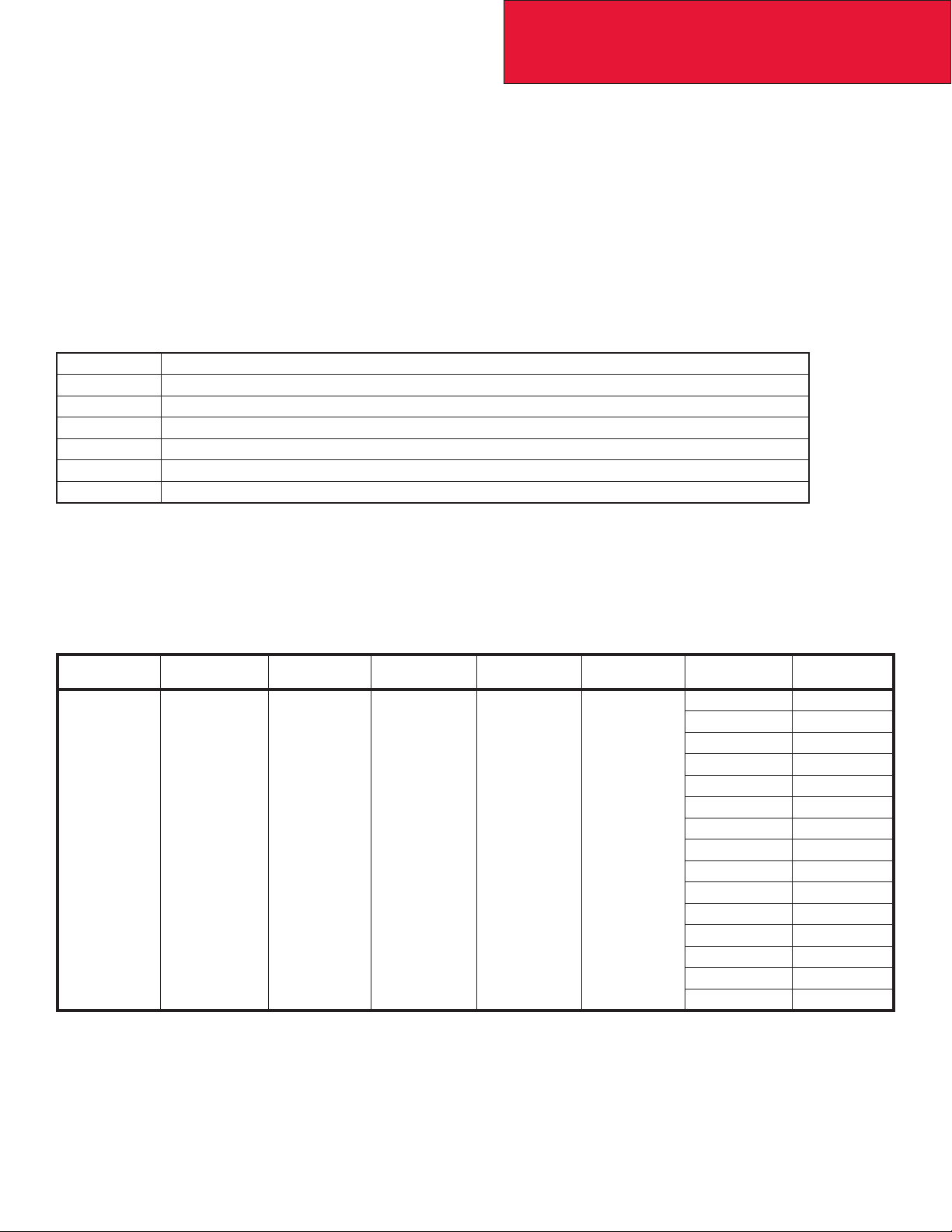

TABLE 3-2. Turning Radius

Model Steering Gear Front Axle Front Wheel Front Tire

T680/T880

Single Gear

HD94 or

THP60

Dana Spicer

E-1202I 12K or

E13221 13.2K

Accuride 50487

or Alcoa 88367

22.5 X 8.25

295/75R22.5

Rear

Suspension

Tandem

52” Axle

Spacing

Wheel Base

(in.)

181 26.7

193 26.9

201 28.0

213 29.7

220 30.6

232 32.3

240 33.4

252 35.0

260 36.1

272 37.7

280 38.8

291 40.4

303 42.0

323 44.7

331 45.8

Turning

Radius (ft)

3-1

TABLE 3-2 CONTINUES ON NEXT PAGE…

2/17

Page 24

Section 3

Dimensions

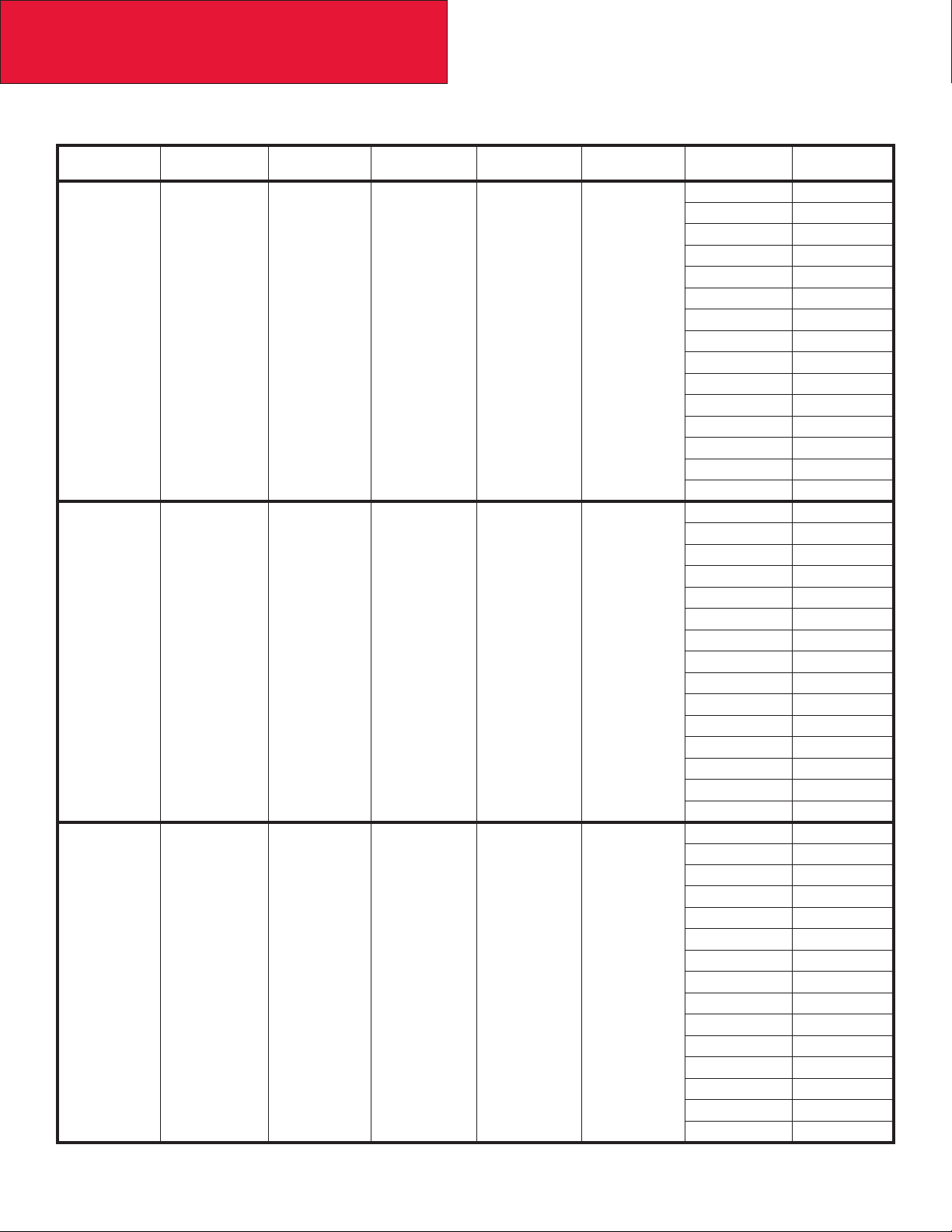

TABLE 3-2 CONTINUED

Model Steering Gear Front Axle Front Wheel Front Tire

Meritor

MFS12 or

MFS13

Dana Spicer

E-12021 12K or

E-13221 13.2K

Meritor

MFS14

Dana Spicer

E-14621

Meritor

MFS20

Standard Track

Dana Spicer

D2000 20K

Standard Track

Accuride 50487

or Alcoa 88367

22.5 X 8.25

Alcoa 89365

22.5 X 9

Alcoa 89365

22.5 X 9

11R22.5

315/80R22.5

315/80R22.5

T680/T880

T880

T880

Single Gear

HD94 or

THP60

Single Gear

SD110 or

TAS85

Dual Gears

HD94 or

THP60

Rear

Suspension

Tandem

52” Axle

Spacing

Tandem

52” Axle

Spacing

Tandem

52” Axle

Spacing

Wheel Base

(in.)

181 26.9

193 27.4

201 28.5

213 30.2

220 31.2

232 32.9

240 34.0

252 35.7

260 36.8

272 38.4

280 39.6

291 41.1

303 42.8

323 45.6

331 46.7

181 26.9

193 26.9

201 27.9

213 29.6

220 30.5

232 32.2

240 33.2

252 34.0

260 35.1

272 36.7

280 37.8

291 39.2

303 40.8

323 43.4

331 44.5

181 28.1

193 28.6

201 29.7

213 31.5

220 32.5

232 34.2

240 35.3

252 35.2

260 36.3

272 38.0

280 39.1

291 40.6

303 42.2

323 45.0

331 46.0

Turning

Radius (ft)

2/17

TABLE 3-2 CONTINUES ON NEXT PAGE…

3-2

Page 25

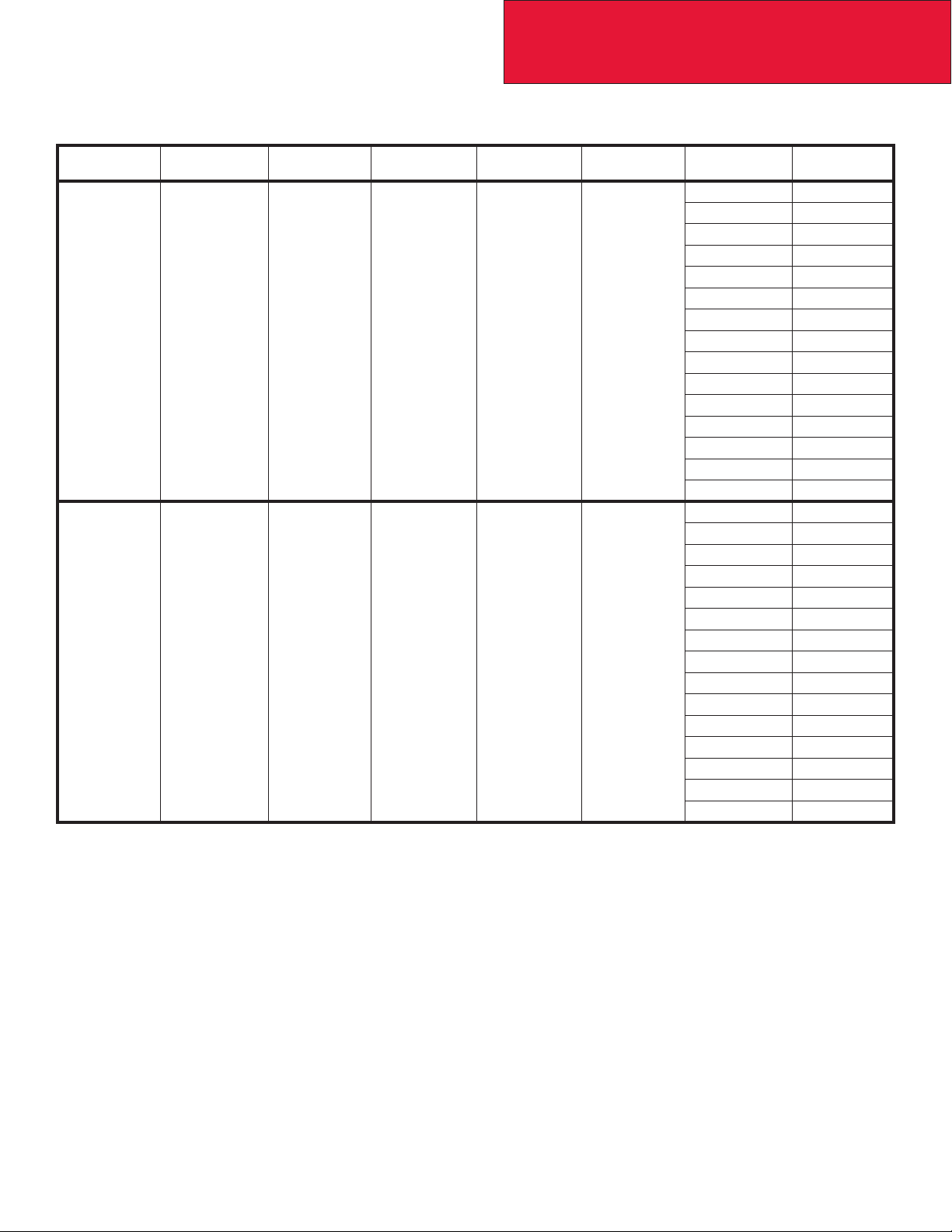

TABLE 3-2 CONTINUED

Section 3

Dimensions

Model Steering Gear Front Axle Front Wheel Front Tire

Meritor

MFS20

Standard Track

Dana Spicer

D2000 20K

Standard Track

Meritor

MFS20

Standard Track

Dana Spicer

D2000 20K

Standard Track

Alcoa 82362

22.5 X 12.25

Alcoa 82362

22.5 X 12.25

385/65R22.5

425/65R22.5

T880

T880

Dual Gears

HD94 or

THP60

Dual Gears

HD94 or

THP60

Rear

Suspension

Tandem

52” Axle

Spacing

Tandem

52” Axle

Spacing

Wheel Base

(in.)

181 28.1

193 28.6

201 29.8

213 31.5

220 32.5

232 34.2

240 35.4

252 35.3

260 36.4

272 38.0

280 39.1

291 40.6

303 42.2

323 45.0

331 46.1

181 28.1

193 28.6

201 29.8

213 31.5

220 32.5

232 34.2

240 35.4

252 36.7

260 37.8

272 39.5

280 40.7

291 42.2

303 43.9

323 46.8

331 47.9

Turning

Radius (ft)

3-3

2/17

Page 26

Section 3

Dimensions

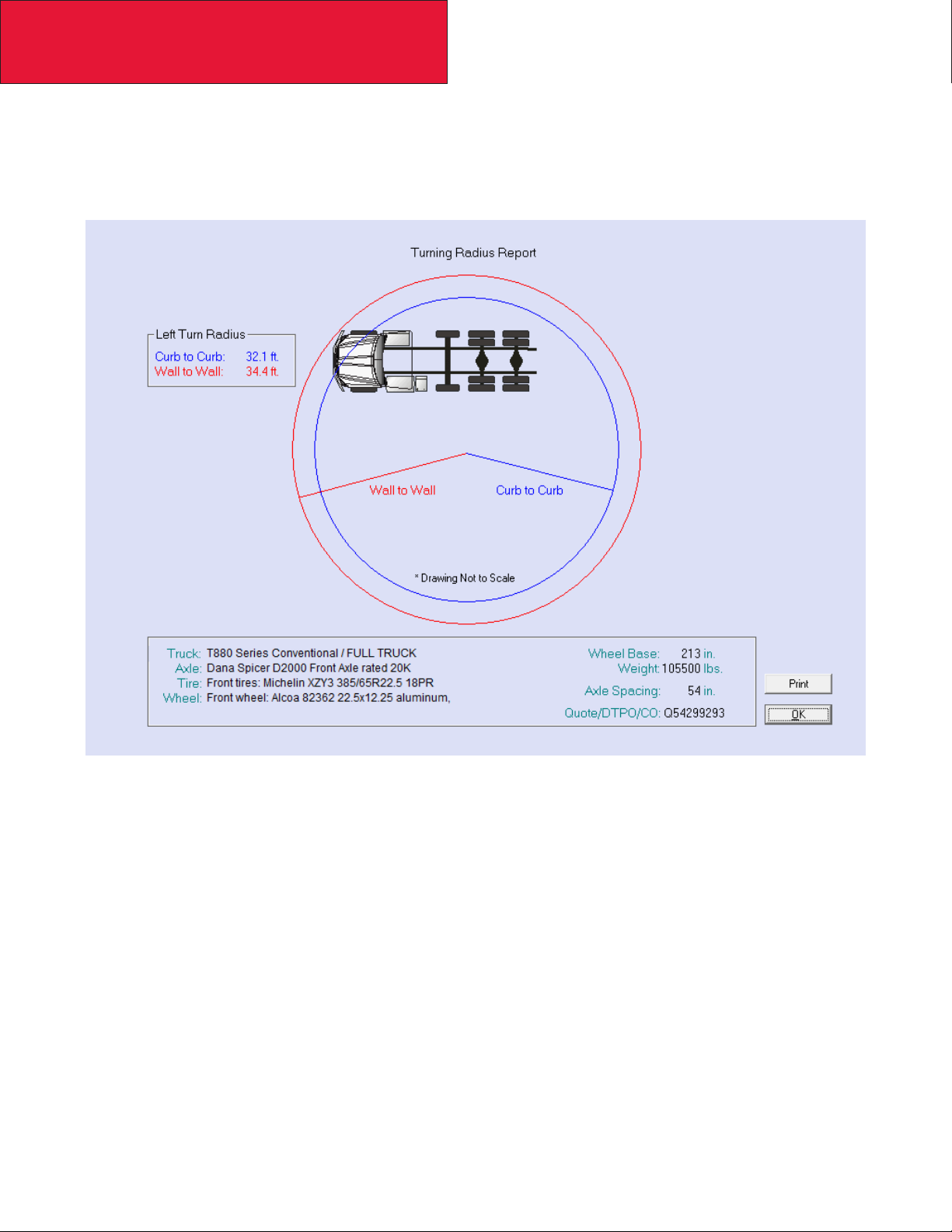

Prospector Turn Circle Analysis:

Please see Figure 3-2 as an example of Kenworth’s turn circle calculation made in Prospector for your specic chassis.

Your local Kenworth dealer can provide this information to you.

FIGURE 3-1. Prospecter Turn Circle Analysis

Please consult your local Kenworth Dealer for this information, as it is chassis specic.

2/17

3-4

Page 27

Section 3

Dimensions

OVERALL DIMENSIONS

This section includes drawings and charts of the following Class 8 models: T680 and T880, including 40”, 52”, and

76” sleepers

On the pages that follow, detail drawings show particular views of each vehicle, all dimensions are in inches (in). They

illustrate important measurements critical to designing bodies of all types. See the “Contents” at the beginning of the

manual to locate the drawing that you need.

Note: To determine overall height please locate the chart Table 3-3 on page 3-12 and add that value to the height. All

heights are given from the bottom of the frame rail.

Kenworth also offers .dxf les and frame layouts of ordered chassis four weeks prior to build. Please speak with your

salesman to request this feature when specifying your chassis.

3-5

2/17

Page 28

Section 3

Dimensions

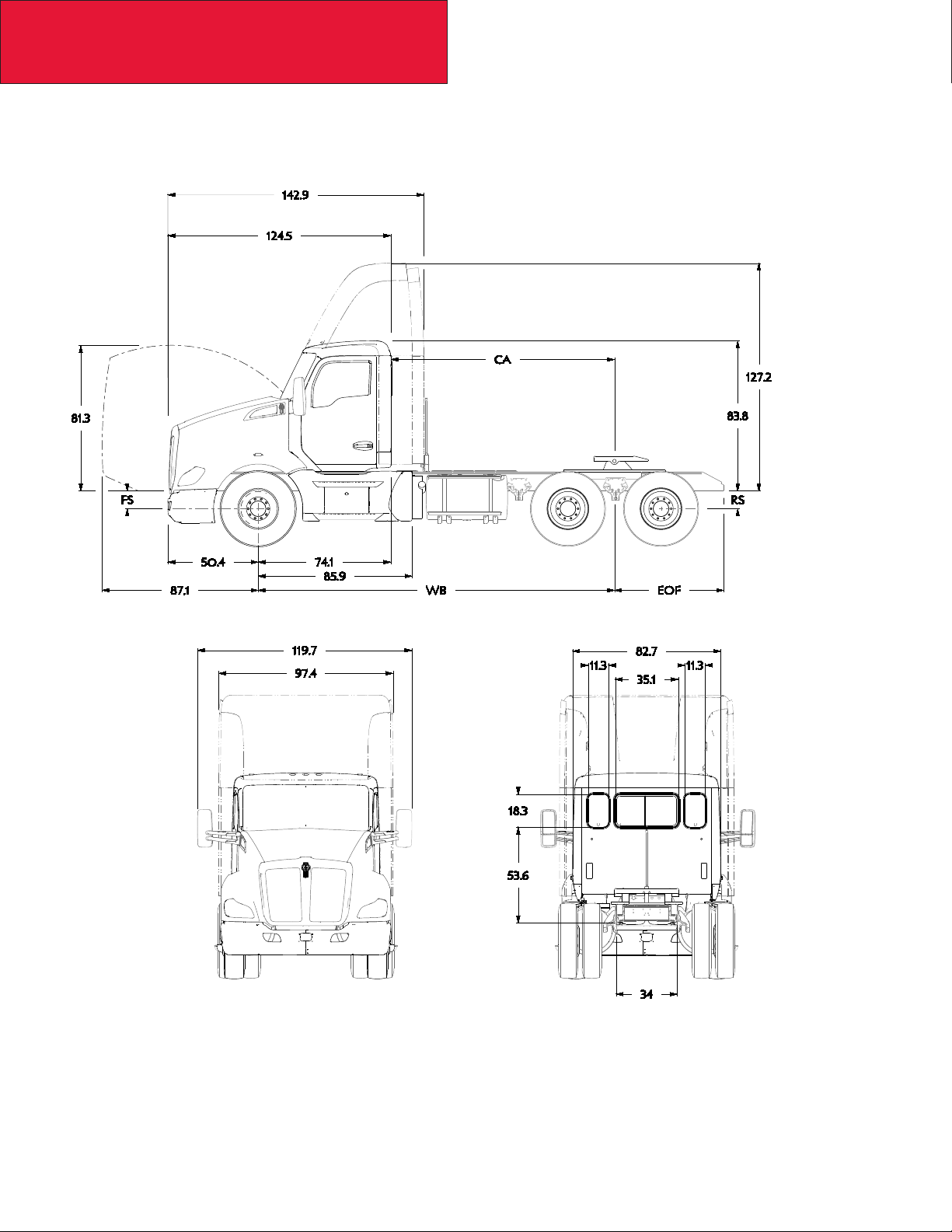

T680 STANDARD HOOD DAYCAB

The following drawings are of a standard T680 Standard Hood Daycab, shown with standard chassis components.

2/17

3-6

Page 29

Section 3

Dimensions

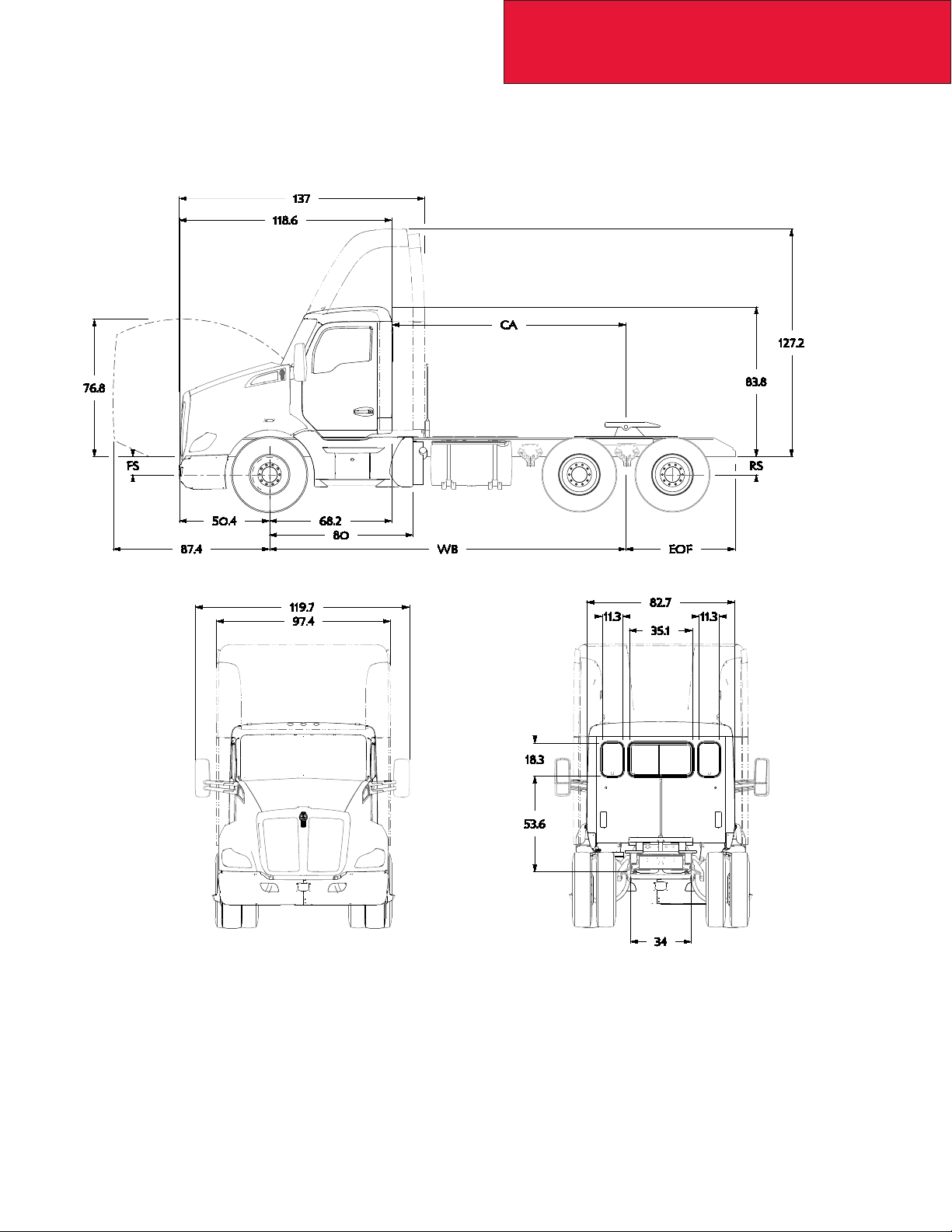

T680 MX (SHORT) HOOD DAYCAB

The following drawings are of a standard T680 MX (Short) Hood Daycab, shown with standard chassis components.

3-7

2/17

Page 30

Section 3

Dimensions

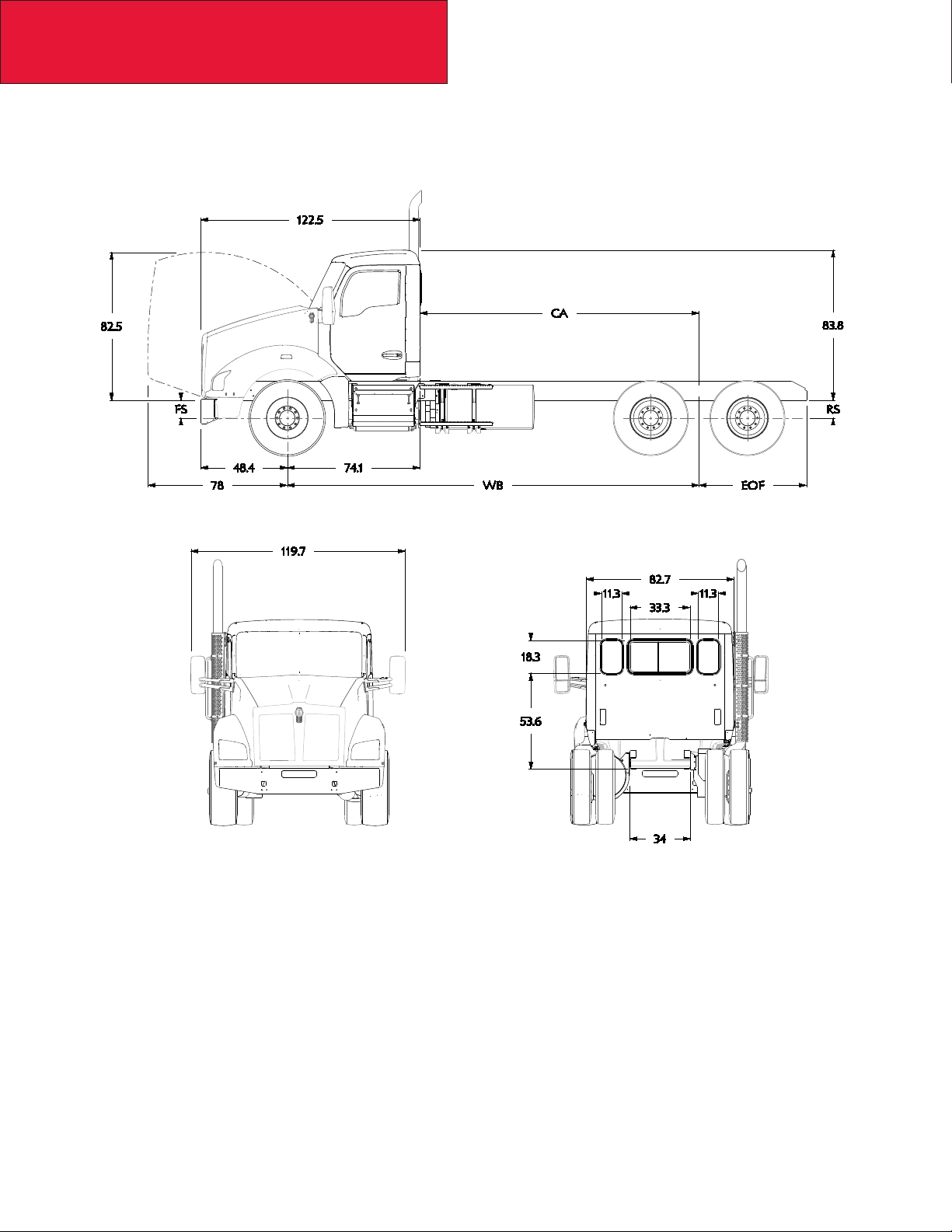

T880 STANDARD HOOD DAYCAB

The following drawings are of a standard T880 Standard Hood Daycab, shown with standard chassis components.

2/17

3-8

Page 31

Section 3

Dimensions

T880S SFFA (SHORT) HOOD DAYCAB

The following drawings are of a standard T880S SFFA (Short) Hood Daycab, shown with standard chassis components.

BBC

CA

77.1

FS

BS 86.2

61.4

37.3

119.7

WB EOF

11.3

18.3

53.6

82.7

33.3

11.3

83.8

RS

3-9

34

2/17

Page 32

Section 3

Dimensions

T680 STANDARD HOOD 40” SLEEPER

The following drawings are of a standard T680 Standard Hood 40” Sleeper, shown with standard chassis components.

2/17

3-10

Page 33

Section 3

Dimensions

T680 MX (SHORT) HOOD 40” SLEEPER

The following drawings are of a standard T680 MX (Short) Hood 40” Sleeper, shown with standard chassis components.

3-11

2/17

Page 34

Section 3

Dimensions

T880 STANDARD HOOD 40” SLEEPER

The following drawings are of a standard T880 Standard Hood 40” Sleeper, shown with standard chassis components.

2/17

3-12

Page 35

Section 3

Dimensions

T880S SFFA (SHORT) HOOD 40” SLEEPER

The following drawings are of a standard T880S SFFA (Short) Hood 40” Sleeper, shown with standard chassis components.

77.1

FS

61.4

BS

37.2

119.7

BBS

115.7

WB

18.2

CA

11.1

94.7

35

87.2

RS

EOF

11.1

18.1

51

34

3-13

2/17

Page 36

Section 3

Dimensions

T680 STANDARD HOOD 52” SLEEPER

The following drawings are of a standard T680 Standard Hood 52” Sleeper, shown with standard chassis components.

2/17

3-14

Page 37

Section 3

Dimensions

T680 MX (SHORT) HOOD 52” SLEEPER

The following drawings are of a standard T880 MX (Short) Hood 52” Sleeper, shown with standard chassis components.

3-15

2/17

Page 38

Section 3

Dimensions

T880 STANDARD HOOD WITH 52” SLEEPER

The following drawings are of a standard T880 Standard Hood with 52” Sleeper, shown with standard chassis components.

2/17

3-16

Page 39

Section 3

Dimensions

T880 MX (SHORT) HOOD WITH 52” SLEEPER

The following drawings are of a standard T880 MX (Short) hood with 52” Sleeper, shown with standard chassis components.

3-17

2/17

Page 40

Section 3

Dimensions

T680 STANDARD HOOD WITH 76” HIGH-ROOF SLEEPER

The following drawings are of a standard T680 Standard Hood with 76” High-Roof Sleeper, shown with standard chassis

components.

2/17

3-18

Page 41

Section 3

Dimensions

T680 MX (SHORT) HOOD WITH 76” HIGH-ROOF SLEEPER

The following drawings are of a standard T680 MX (Short) hood with 76” High-Roof Sleeper, shown with standard chassis

components.

3-19

2/17

Page 42

Section 3

Dimensions

T680 STANDARD HOOD WITH 76” MID-ROOF SLEEPER

The following drawings are of a standard T680 Standard Hood with 76” Mid-Roof Sleeper, shown with standard chassis

components.

2/17

3-20

Page 43

Section 3

Dimensions

T680 MX (SHORT) HOOD WITH 76” MID-ROOF SLEEPER

The following drawings are of a standard T680 MX (Short) hood with 76” Mid-Roof Sleeper, shown with standard chassis

components.

3-21

2/17

Page 44

Section 3

Dimensions

T880 STANDARD HOOD WITH 76” MID-ROOF SLEEPER

The following drawings are of a standard T880 Standard Hood with 76” Mid-Roof Sleeper, shown with standard chassis

components.

2/17

3-22

Page 45

Section 3

Dimensions

T880 MX (SHORT) HOOD WITH 76” MID-ROOF SLEEPER

The following drawings are of a standard T880 MX (Short) hood with 76” Mid-Roof Sleeper, shown with standard chassis

components.

3-23

2/17

Page 46

Section 3

Dimensions

RIDE HEIGHTS

The front (FS) and rear (RS) suspension ride heights are provided as a basic tool to determine the overall height of the

cab, height of exhaust components, and frame heights. The heights are all calculated from the centerlines of the axles,

please be sure to include the tire radius dimension to determine overall height. Note: the frame rail height itself will not

affect the overall height as all components are located from the bottom of the frame rail.

82.5

TABLE 3-3. Ride Heights. To calculate the frame height use the following formulas:

Front Frame Height = FS + 1/2 Front Tire Diameter

Rear Frame Height = RS + 1/2 Rear Tire Diameter

Front Suspension (T680/T880)

Front Suspension (FS) Laden: Unladen:

12K Taperleaf 10.3” 11.5”

13.2K Taperleaf 10.3” 11.5”

14.6K Taperleaf 10.3” 11.7”

16K Taperleaf 10.6” 12.3”

20K Taperleaf 10.4” 11.9”

22K Multi-stage Taperleaf 10.7” 12.7”

RSFS

2/17

3-24

Page 47

Section 3

Dimensions

Rear Suspension (All Models). Common Rear Suspensions are shown here, for detailed

suspensions please use the Rear suspension layouts on pages 3-18 to 3-33.

Rear Suspension Laden: Unladen:

Kenworth AG400L 8.5” 8.5”

Kenworth AG400 9” 9”

Kenworth AG460 10.5” 10.5”

Kenworth AG690 Tridem 10.5” 10.5”

Reyco 79KB 23K Rating 8.3” 10.8”

Reyco 102 38K Rating 9.2” 10.8”

Chalmers 854-40-L-HS 40K Rating 9.6” 11”

Chalmers 854-46-H 46K Rating 10.1” 12.4”

Chalmers 854-50-H-HS 50K Rating 10.8” 12.5”

Chalmers 865-65-XL 65K Rating 13” 15.7”

Hend HMX400 16.5” Saddle 9.5” 10.6”

Hend HMX400 17.5” Saddle 10.5” 11.6”

Hend HMX460 46K 16.5” Saddle 9.5” 10.6”

Hend HMX460 46K 17.5” Saddle 10.5” 11.6”

Hendrickson Primaax EX 46K Rating 10” 10”

Hendrickson RT463 6” Saddle

46K Rating

Hendrickson RT463 7.19” Saddle

46K Rating

Hend RT523 52K 6” Saddle 9.9” 11”

Neway ADZ246 46K Rating 10” or 12” 10” or 12”

Neway ADZ252 52K Rating 10” or 12” 10” or 12”

Neway ADZ369 69K Tridem 10” or 12” 10” or 12”

Neway ADZ378 78K Tridem 10” 10”

10” 11.1”

11.2” 12.5”

3-25

2/17

Page 48

Section 3

Dimensions

REAR SUSPENSION LAYOUTS

The rear suspension layouts are provided as a tool to help layout bodies prior to arrival. The applicable dimensions are

shown. Be sure to check the axle spacing that is shown, as alternate spacings may exist and could change some of the

dimensions. The dimensions shown below are the most typical installations, in special cases some hole locations will

move. If you are planning on using the holes shown for your body installation, please conrm with your local KW dealer

that the drawing below will be the installation used on your specic truck. Ensure that proper torque is used to reinstall any

suspension components. See Tables 7-1 and 7-2 on page 7-7.

It would be a good idea in this case to order the frame layout of your chassis along with your truck order. This can be done

on any Kenworth truck, and will be provided 4 weeks ahead of the build schedule.

If there are hole locations that are not detailed please work with your local Kenworth Dealer to request that information.

Additionally optional axle spacings are shown in the charts, if you would like details on the frame drilling with optional

spacings, please contact your local Kenworth dealer.

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

2/17

3-26

Page 49

AG400L TANDEM

Section 3

Dimensions

59.4

58.3

53.8

AG400L Suspensions

56.9

54.7

8.5

Axle Spacing

Note: “54” Axle Spacing dmensions shown

TABLE 3-4. Rear Suspension Options

Suspension Type Rating Axle Spacing

AG400L Tandem 40K 52" 8.5" 8.5"

AG400L Tandem 40K 54" 8.5" 8.5"

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

Laden Ride

Height

Unladen Ride

Height

3-27

2/17

Page 50

Section 3

Dimensions

AG400 OR AG460 TANDEM

60.6

AG400 Suspensions

58.5

48.0

45.9

Ride

Height

Axle Spacing

TABLE 3-5. Rear Suspension Options

Suspension Type Rating Axle Spacing

AG400 Tandem 40K 52" 9" 9"

AG400 Tandem 40K 54" 9" 9"

AG460 Tandem 46K 54” 10.5” 10.5”

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

Laden Ride

Height

Unladen Ride

Height

2/17

3-28

Page 51

AG460 TANDEM

Section 3

Dimensions

67.7

65.8

AG460 Suspensions

52.0

49.9

10.5

60.0

TABLE 3-6. Rear Suspension Options

Suspension Type Rating Axle Spacing

AG460 Tandem 60" Spacing 46K 60" 10.5" 10.5"

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

Laden Ride

Height

Unladen Ride

Height

3-29

2/17

Page 52

Section 3

Dimensions

AG690 TRIDEM

87.6

85.5

54.0

AG690 Tridem Suspension

TABLE 3-7. Rear Suspension Options

Suspension Type Rating Axle Spacing

76.0

73.9

54.0

Laden Ride

Height

10.5

Unladen Ride

Height

AG690 Tridem 69K 108" (54" + 54") 10.5" 10.5"

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

2/17

3-30

Page 53

REYCO 79KB SINGLE REAR AXLE

30.2 30.1

28.7 29.0

Section 3

Dimensions

Ride Height

Optional Reyco 79KB Suspensions

TABLE 3-8. Rear Suspension Options

Suspension Type Rating Axle Spacing

Reyco 79KB single 20K - 8.3” 10.8”

Reyco 79KB single 23K - 8.3” 10.8”

Reyco 79KB single 26K - 8.2” 11.3”

Reyco 79KB single 31K - 9.6” 12.2”

Laden Ride

Height

Unladen Ride

Height

3-31

2/17

Page 54

Section 3

Dimensions

REYCO 102 TANDEM REAR AXLE

Shown with a 52” Axle Spacing

Reyco 102 Suspension Data

TABLE 3-9. Rear Suspension Options

Suspension Type Rating Axle Spacing Laden Ride Height

Reyco 102 Tandem 38K 52” 9.2” 10.8”

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

Unladen Ride

Height

2/17

3-32

Page 55

NEWAY ADZ 123 SINGLE REAR AXLE

30.8

29.8

27.8

Section 3

Dimensions

18.0

16.0

2.1

8.0

2.7

4.6

Optional Neway ADZ Single Suspensions

TABLE 3-10. Rear Suspension Options

18.8

26.4

24.3

RIDE

HEIGHT

5.9

2.4

Suspension Type Rating Axle Spacing

Neway ADZ123 single 23K - 10” 10”

Neway ADZ126 single 26K - 10” 10”

Laden Ride

Height

Unladen Ride

Height

3-33

2/17

Page 56

Section 3

Dimensions

NEWAY ADZ 246 TANDEM SUSPENSION

Shown with a 54” Axle Spacing

57.7

56.7

54.7

44.9

42.9

52.1

50.7

2.7

4.6

8.0

AXLE SPACING

Optional Neway ADZ Tandem Suspensions

TABLE 3-11. Rear Suspension Options

Suspension Type Rating Axle Spacing

Neway ADZ246 tandem 46K 54” 10” 10”

Neway ADZ246 tandem 46K 60” 10” 10”

Laden Ride

Height

Unladen Ride

Height

RIDE

HEIGHT

Neway ADZ246 tandem 46K 72” 10” 10”

Neway ADZ252 tandem 52K 54” 10” 10”

Neway ADZ252 tandem 52K 54” 12” 12”

Neway ADZ252 tandem 52K 60” 10” 10”

Neway ADZ252 tandem 52K 60” 12” 12”

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

2/17

3-34

Page 57

NEWAY ADZ 369 TRIDEM SUSPENSION

Shown with 54” Axle Spacings

84.7

83.7

81.7

71.9

69.9

Section 3

Dimensions

79.1

77.7

72.9

5.4

2.4

2.7

4.6

8.0

AXLE SPACING

AXLE SPACING

Optional Neway ADZ Tridem Suspensions

TABLE 3-12. Rear Suspension Options

Suspension Type Rating Axle Spacing

Laden Ride

Height

Neway ADZ369 tridem 69K 54” 10” 10”

Neway ADZ369 tridem 69K 54” 12” 12”

Unladen Ride

Height

RIDE

HEIGHT

Neway ADZ369 tridem 69K 60” 12” 12”

Neway ADZ378 tridem 78K 54” 10” 10”

Neway AD378 tridem 78K 60” 10” 10”

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

3-35

2/17

Page 58

Section 3

Dimensions

HENDRICKSON PRIMAAX EX TANDEM SUSPENSION

Shown with 54” Axle Spacings

Optional Hendrickson Primaax EX Tandem Suspensions

TABLE 3-13. Rear Suspension Options

Suspension Type Rating Axle Spacing

Hendrickson Primaax Tandem 46K 54” 10” 10”

Hendrickson Primaax Tandem 46K 60” 10” 10”

Hendrickson Primaax Tandem 46K 72” 10” 10”

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

Laden Ride

Height

Unladen Ride

Height

2/17

3-36

Page 59

Section 3

Dimensions

HENDRICKSON PRIMAAX EX TRIDEM SUSPENSION

Shown with 54” Axle Spacings

Optional Hendrickson Primaax EX Tridem Suspensions

TABLE 3-14. Rear Suspension Options

Suspension Type Rating Axle Spacing

Hendrickson Primaax Tridem 69K 54” 10” 10”

Hendrickson Primaax Tridem 69K 60” 10” 10”

NOTE: Actual axle spacing can depart from nominal due to axle slant requirements. Final axle spacing can vary by more

than an inch from nominal in some cases. If precise axle spacing is critical due to body installation or state/local regulatory

requirements please contact Kenworth Applications/technical Support for assistance.

Laden Ride

Height

Unladen Ride

Height

3-37

2/17

Page 60

Section 3

Dimensions

HENDRICKSON UMX TANDEM SUSPENSION

Shown with 54” Axle Spacing

Optional Hendrickson HMX Tandem Suspensions

TABLE 3-15. Rear Suspension Options

Suspension Type Rating Axle Spacing

Hendrickson ULTIMAAX 460 17.5” Saddle Height 46K 54” 11” 12.5”

Hendrickson ULTIMAAX 460 18.25” Saddle Height 46K 54” 11” 12.5”