Kenwood TK-5210 Service manual

VHF APCO P25 TRANSCEIVER

TK-5210

SERVICE MANUAL

© 2004-11 PRINTED IN JAPAN

B51-8703-00 (S) 658

Helical Antenna

(KRA-22: Option)

Knob (Volume)

(K29-9322-03)

Knob (PTT)

(K29-9328-02)

Main cabinet

(A02-3875-01)

Knob (16CH)

(K29-9323-03)

Helical Antenna

(KRA-22: Option)

Knob (Volume)

(K29-9322-03)

Key top

(EMG)

(K29-9319-03)

Knob (PTT)

(K29-9328-02)

Main cabinet

(4key)

(A02-3877-01)

Knob (16CH)

(K29-9323-03)

Knob (Volume)

(K29-9322-03)

Key top

(EMG)

(K29-9319-03)

Knob (PTT)

(K29-9328-02)

Key top

(4key)

(K29-9320-03)

Main cabinet

(DTMF)

(A02-3879-01)

Helical Antenna

(KRA-22: Option)

Knob (16CH)

(K29-9323-03)

Key top

(EMG)

(K29-9319-03)

Key top

(DTMF)

(K29-9321-13)

TK-5210 K TK-5210 K2 TK-5210 K3

Does not come with antenna. Antenna is available as an option.

CONTENTS

GENERAL ............................................................... 2

SYSTEM SET-UP ................................................... 2

REALIGNMENT ...................................................... 3

DISASSEMBLY FOR REPAIR ................................ 8

CIRCUIT DESCRIPTION ....................................... 13

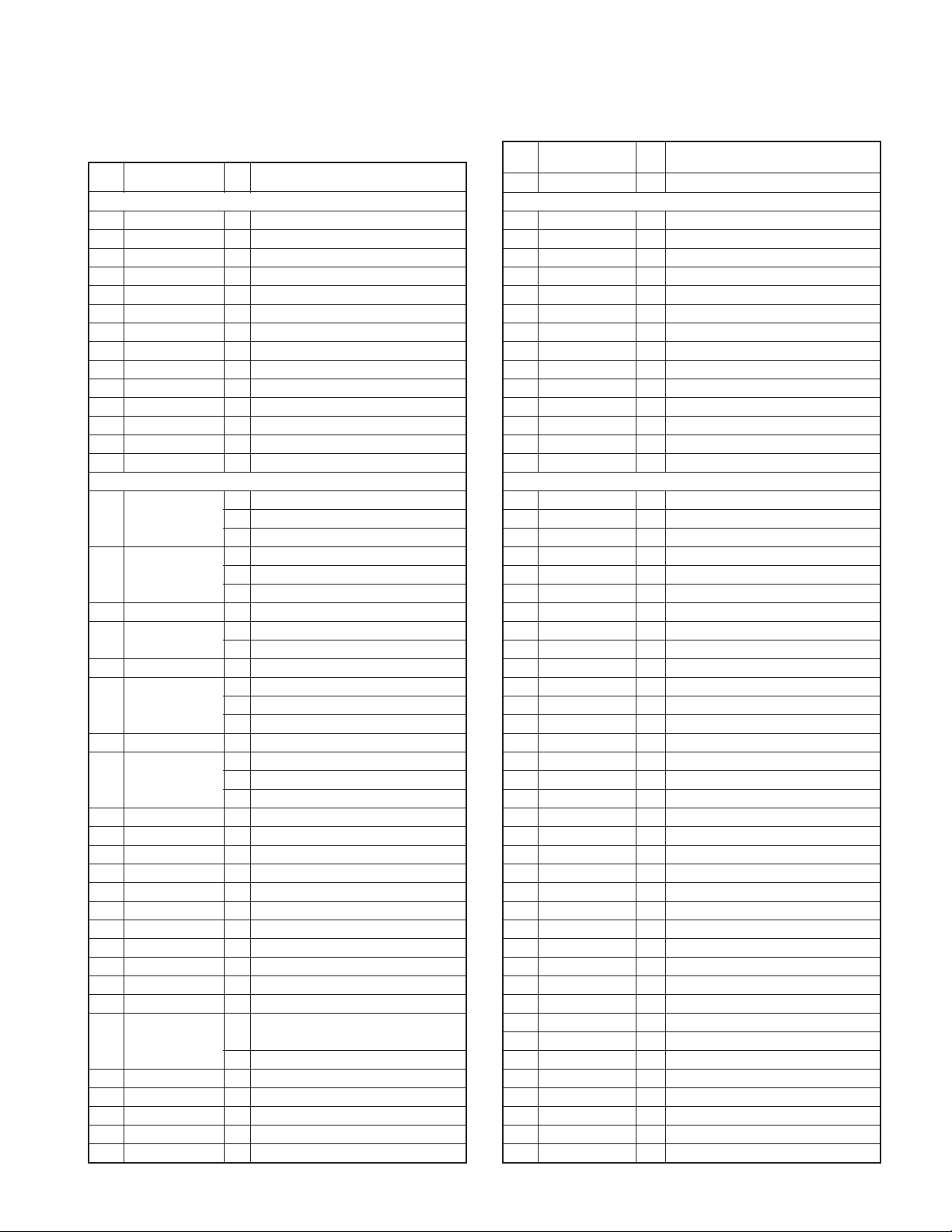

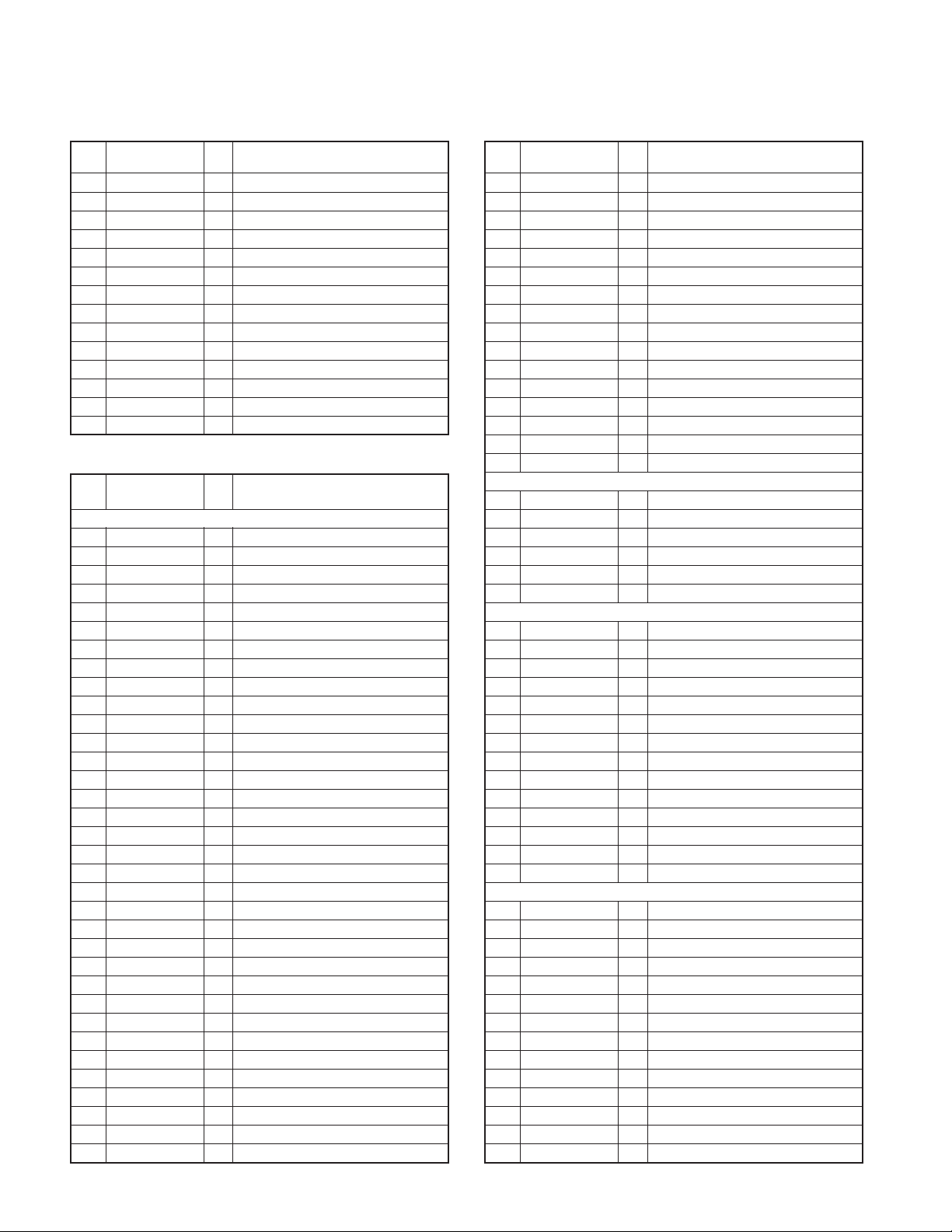

TERMINAL FUNCTION ........................................ 19

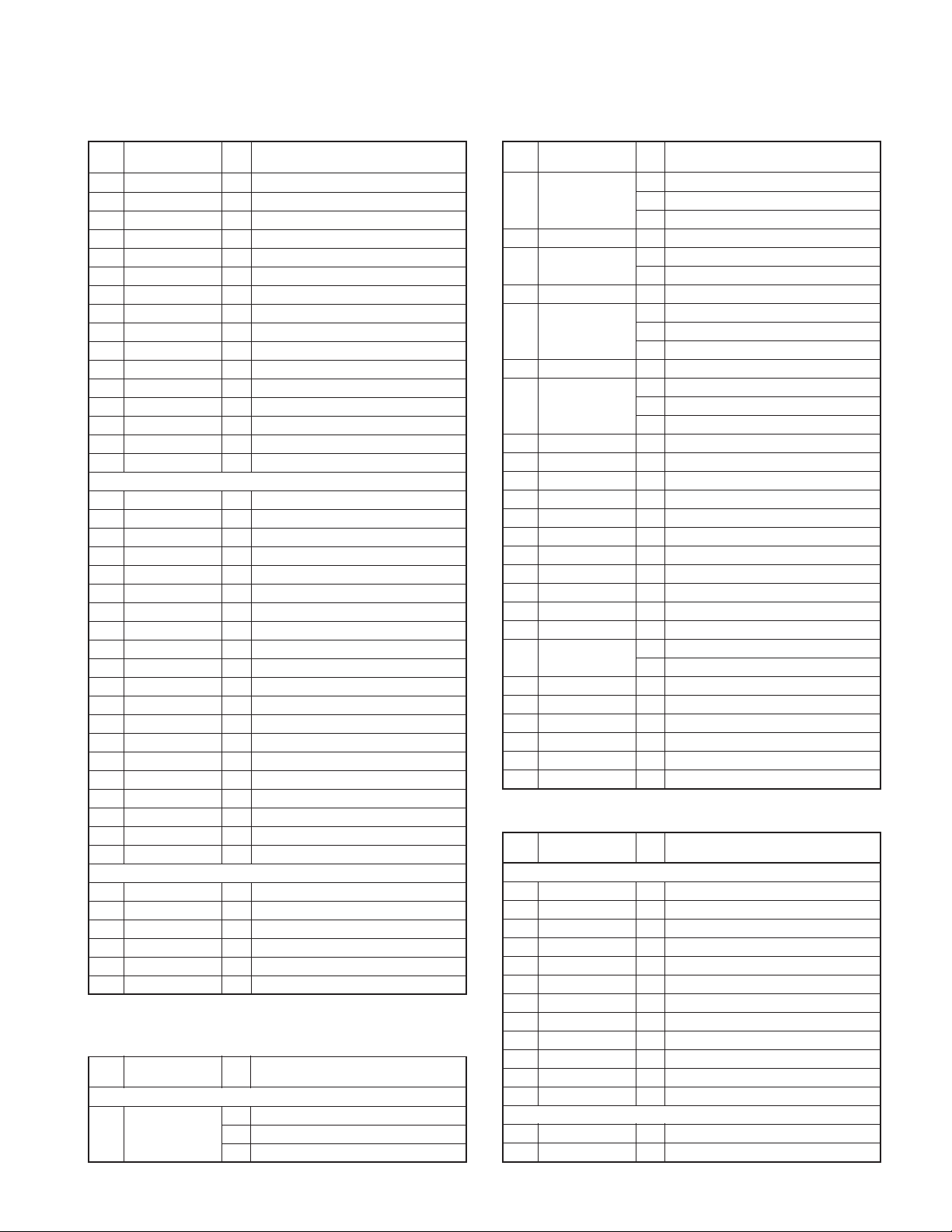

SEMICONDUCTOR DATA ................................... 23

COMPONENTS DESCRIPTION ........................... 25

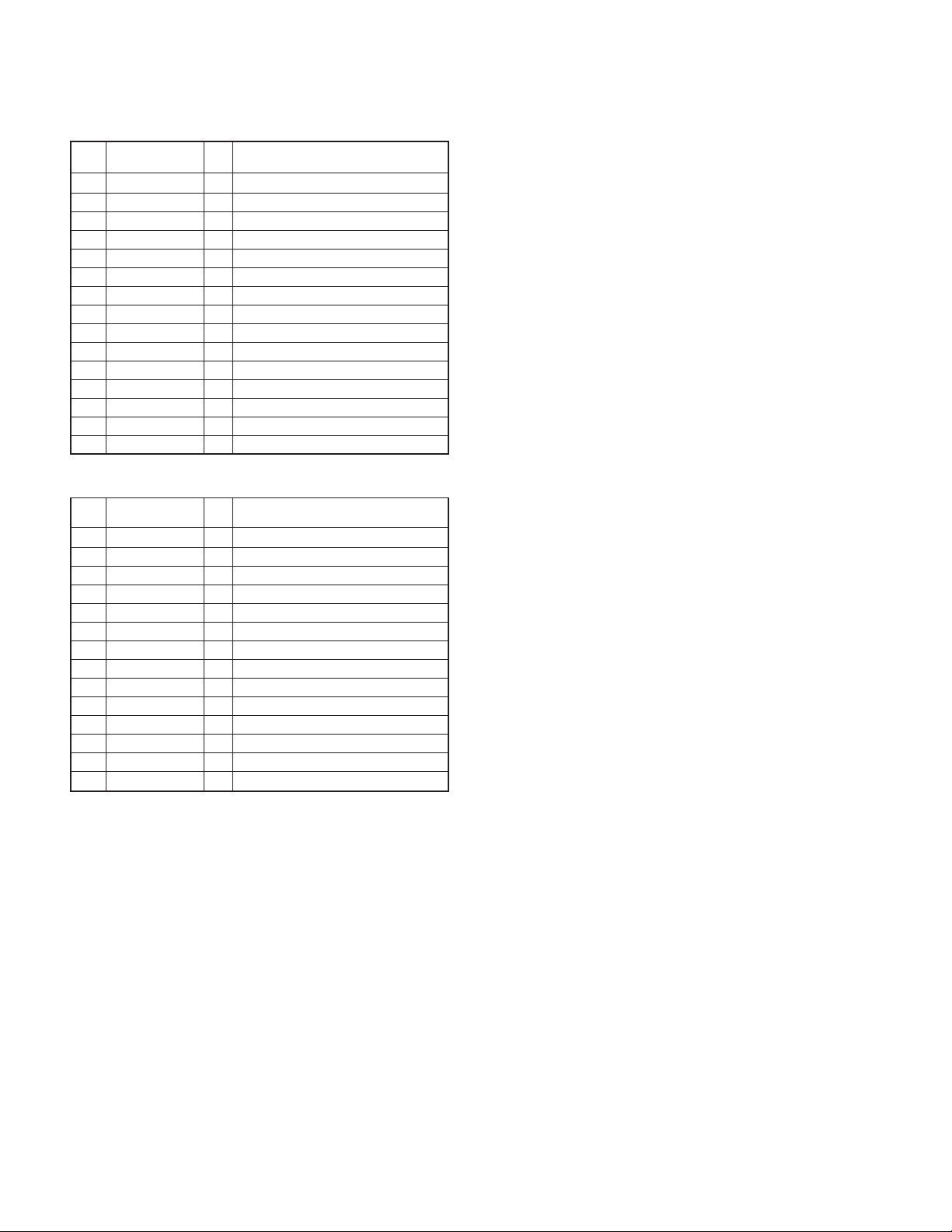

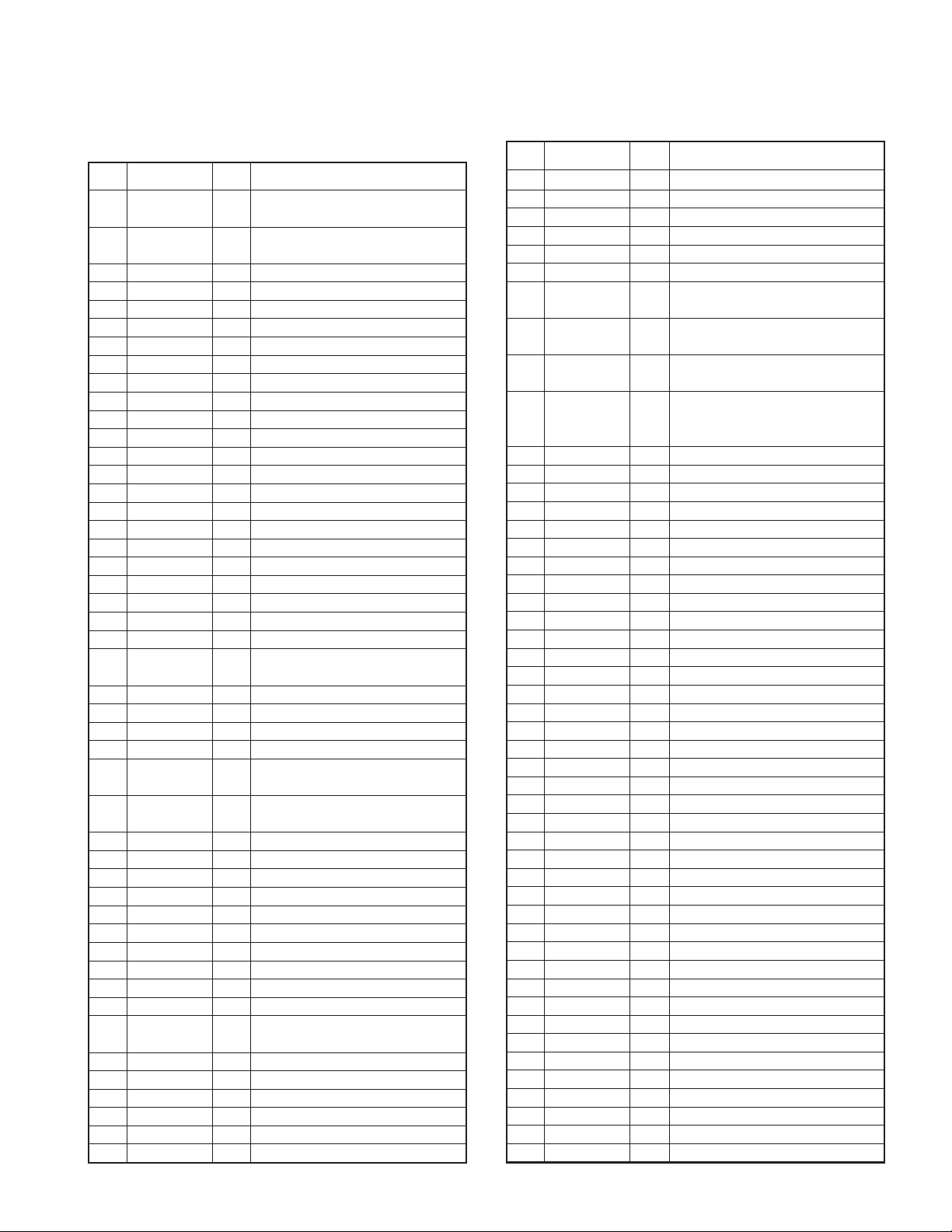

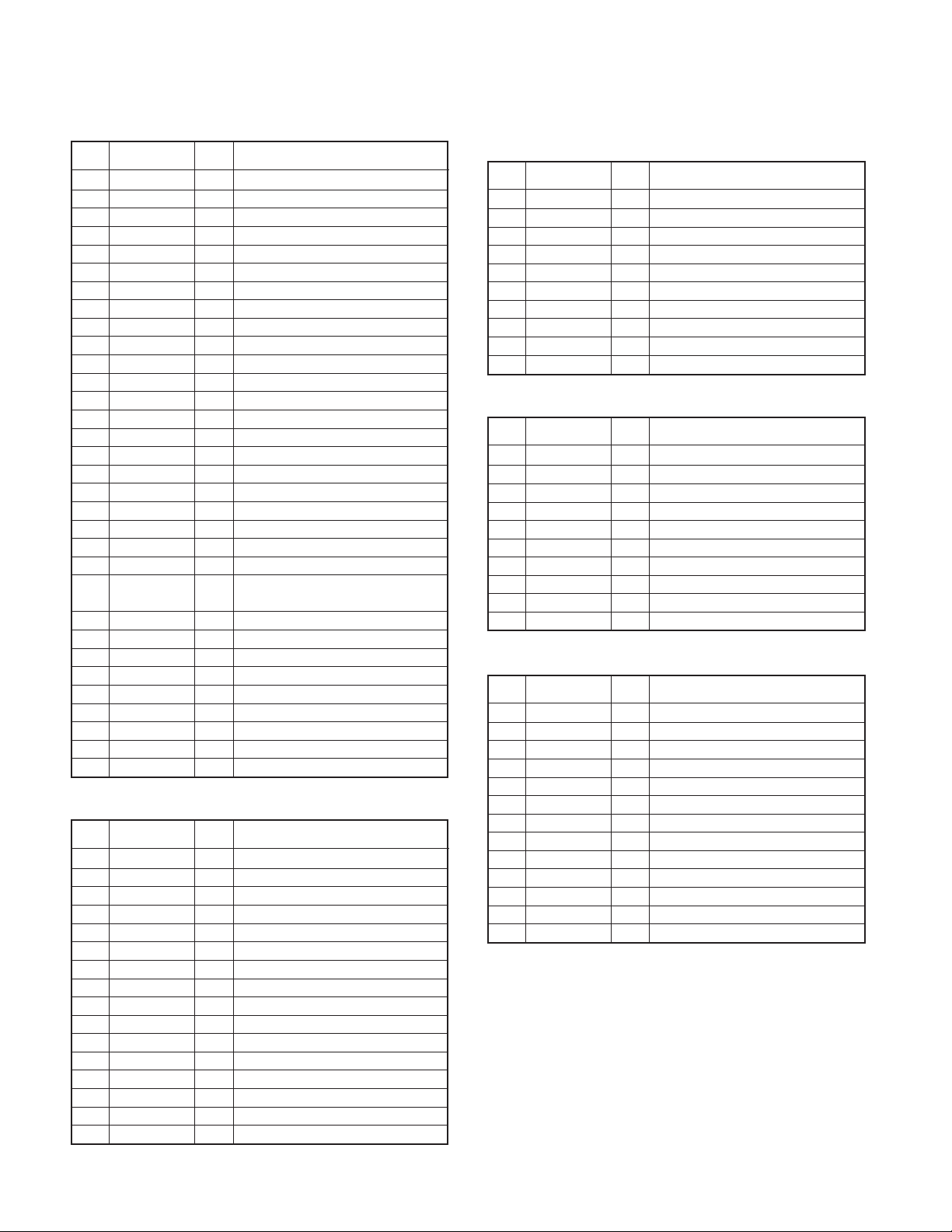

PARTS LIST .......................................................... 27

EXPLODED VIEW................................................. 37

PACKING ..............................................................39

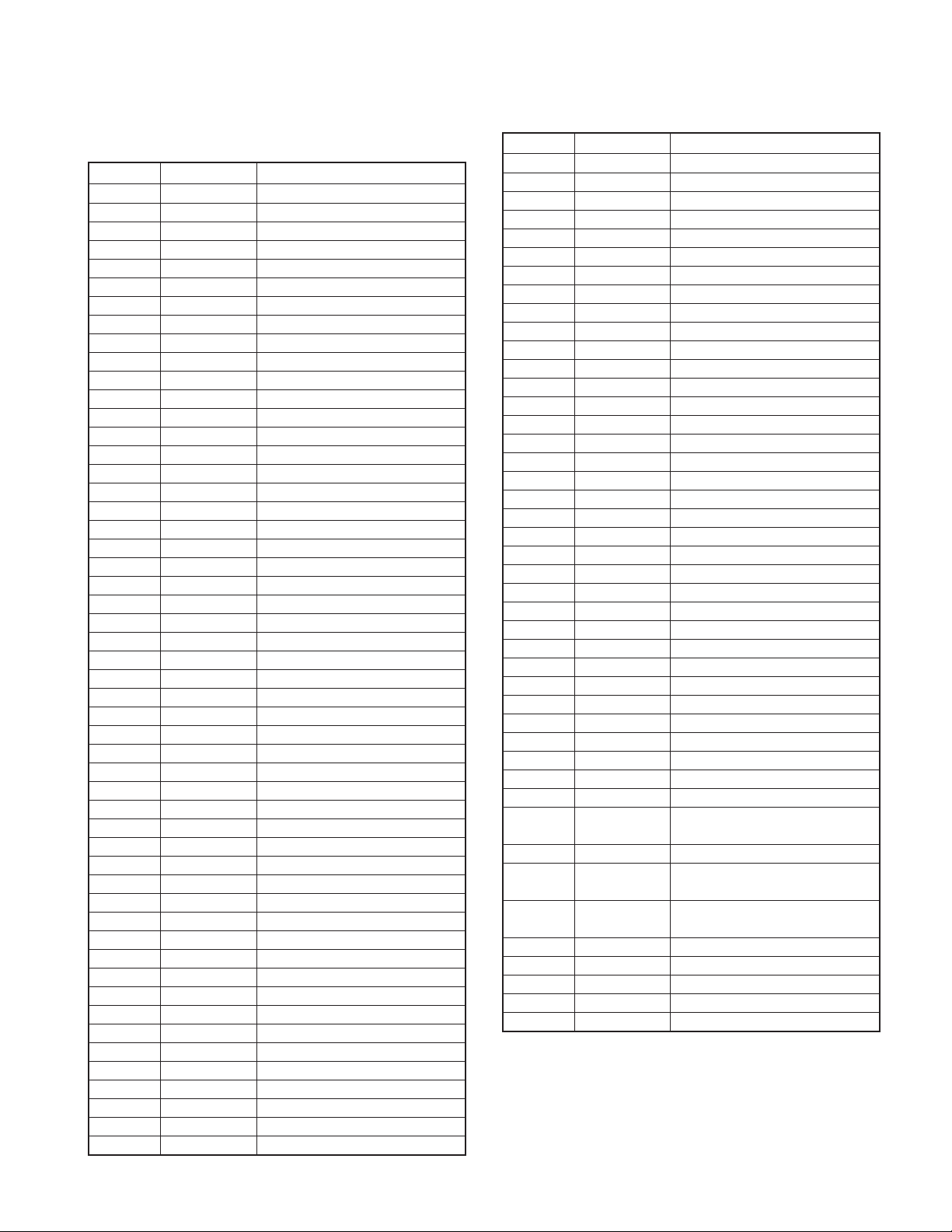

ADJUSTMENT ..................................................... 40

PC BOARD

TX-RX UNIT (X57-6820-XX) ........................... 54

SCHEMATIC DIAGRAM....................................... 62

INTERCONNECTION DIAGRAM ......................... 74

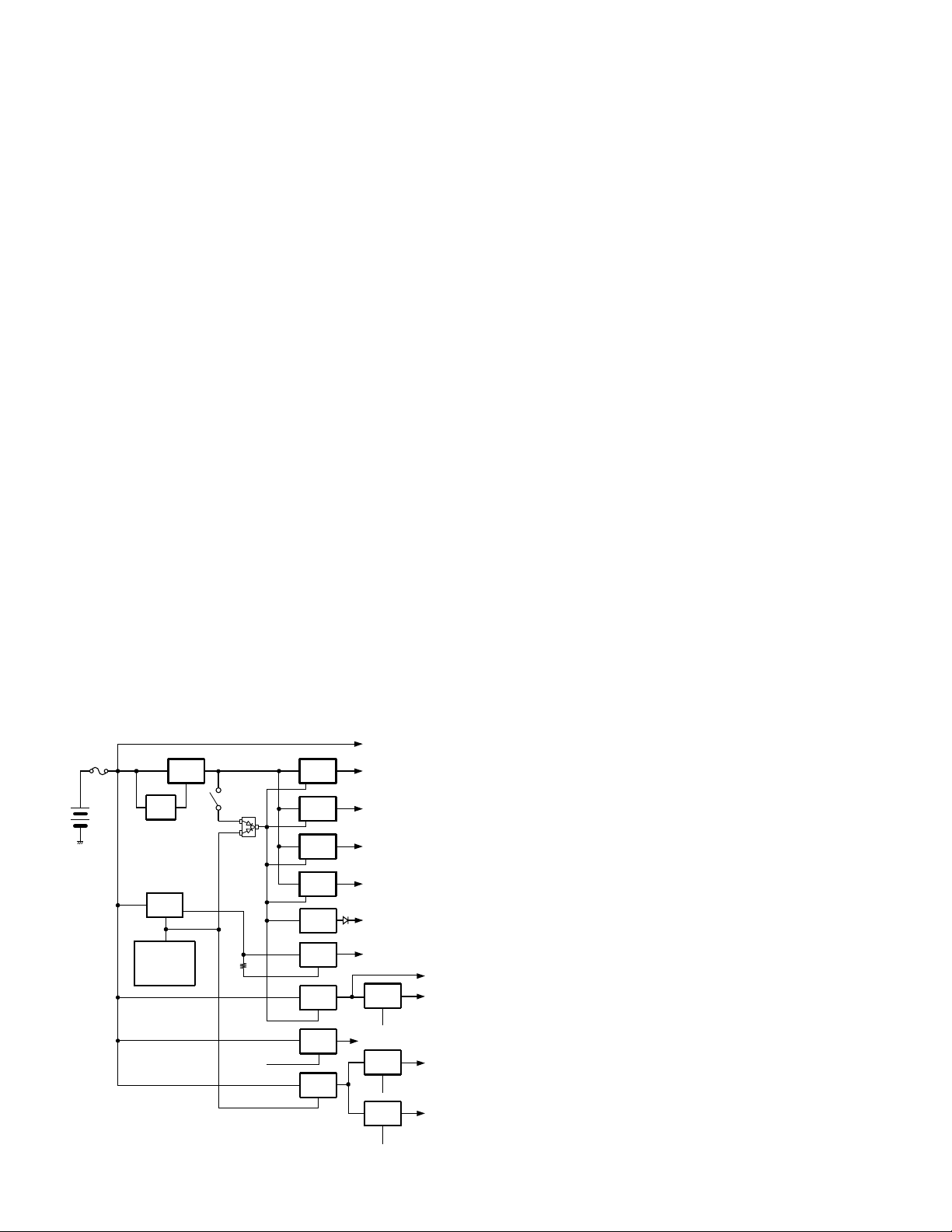

BLOCK DIAGRAM ................................................ 75

LEVEL DIAGRAM ................................................. 78

OPTIONAL ACCESSORIES

KNB-31A/32N/33L .......................................... 79

KSC-32 ............................................................. 79

SPECIFICATIONS .............................. BACK COVER

TK-5210

GENERAL / SYSTEM SET-UP

INTRODUCTION

SCOPE OF THIS MANUAL

This manual is intended for use by experienced technicians familiar with similar types of commercial grade communications equipment. It contains all required service information for the equipment and is current as of the publication

date. Changes which may occur after publication are covered

by either Service Bulletins or Manual Revisions. These are

issued as required.

ORDERING REPLACEMENT PARTS

When ordering replacement parts or equipment information, the full part identification number should be included.

This applies to all parts : components, kits, or chassis. If the

part number is not known, include the chassis or kit number

of which it is a part, and a sufficient description of the required component for proper identification.

Model &

Destination (Market code)

TK-5210 K2 ✓ 136~174 MHz

Unit X57-682X-XX

0-10 0-11 0-12

K ✓

K3 ✓✓✓✓

Frequency range Remarks LCD 4-key

PERSONNEL SAFETY

The following precautions are recommended for person-

nel safety:

• DO NOT transmit until all RF connectors are verified secure and any open connectors are properly terminated.

•SHUT OFF and DO NOT operate this equipment near electrical blasting caps or in an explosive atmosphere.

• This equipment should be serviced by a qualified technician only.

SERVICE

This transceiver is designed for easy servicing. Refer to

the schematic diagrams, printed circuit board views, and

alignment procedures contained within.

DTMF

keypad

1st IF:49.95MHz

LOC:50.4MHz

---

✓✓

-

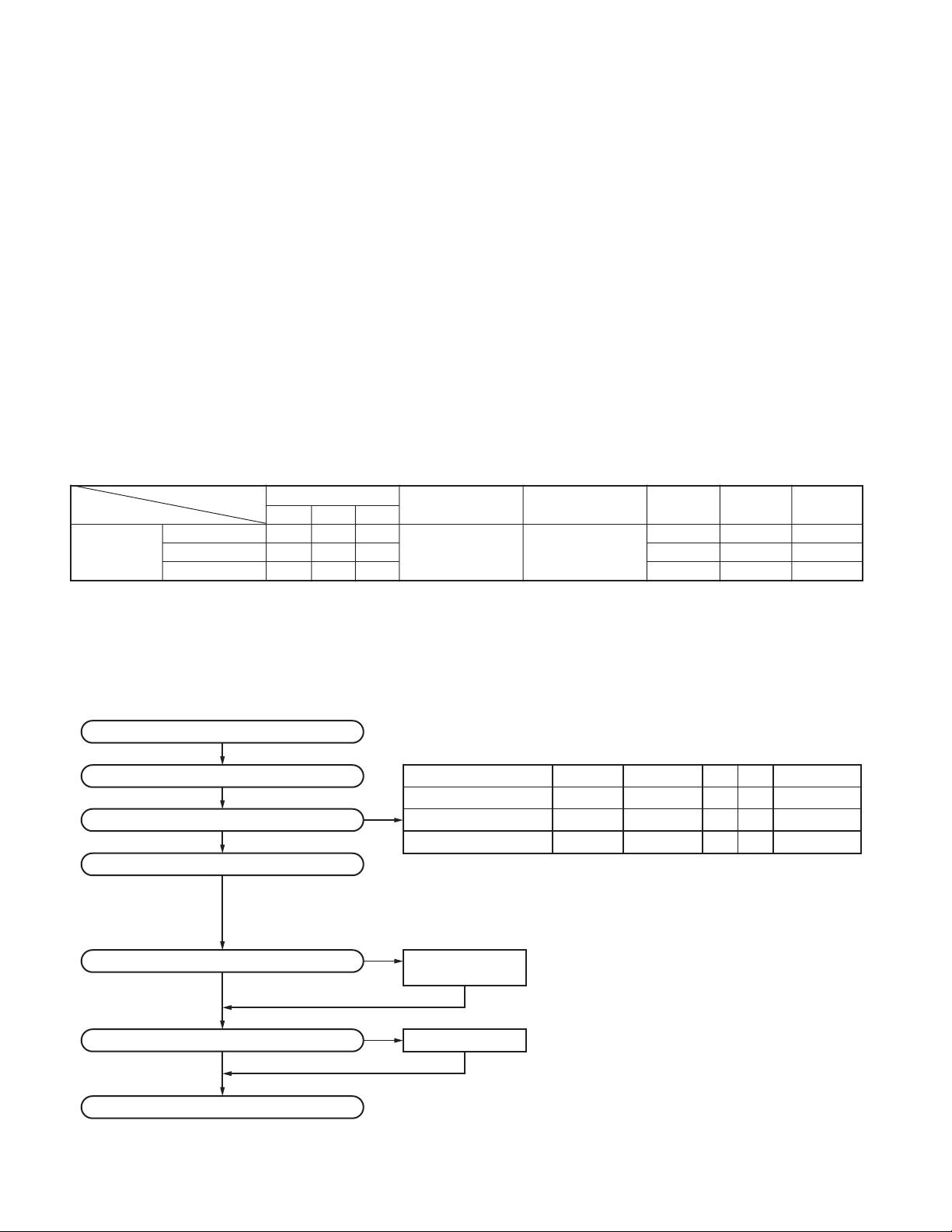

SYSTEM SET-UP

Merchandise received

License and frequency allocated by FCC

Choose the type of transceiver

Transceiver programming

Are you using the optional antenna?

NO

Are you using the speaker microphone?

NO

Delivery

Frequency range (MHz) RF power Type LCD 4-key

TX/RX 136~174 5W TK-5120 K No No No

TX/RX 136~174 5W TK-5120 K2 Yes Yes

TX/RX 136~174 5W TK-5120 K3 Yes Yes Yes

A personal computer (IBM PC or compatible), programming

interface (KPG-36), and programming software (KPG-95D)

are required for programming.

(The frequency, and signaling data are programmed for the

transceiver.)

YES

KRA-22 or KRA-26

Helical antenna

(Option)

YES

KMC-25

(Option)

DTMF keypad

No

2

TK-5210

REALIGNMENT

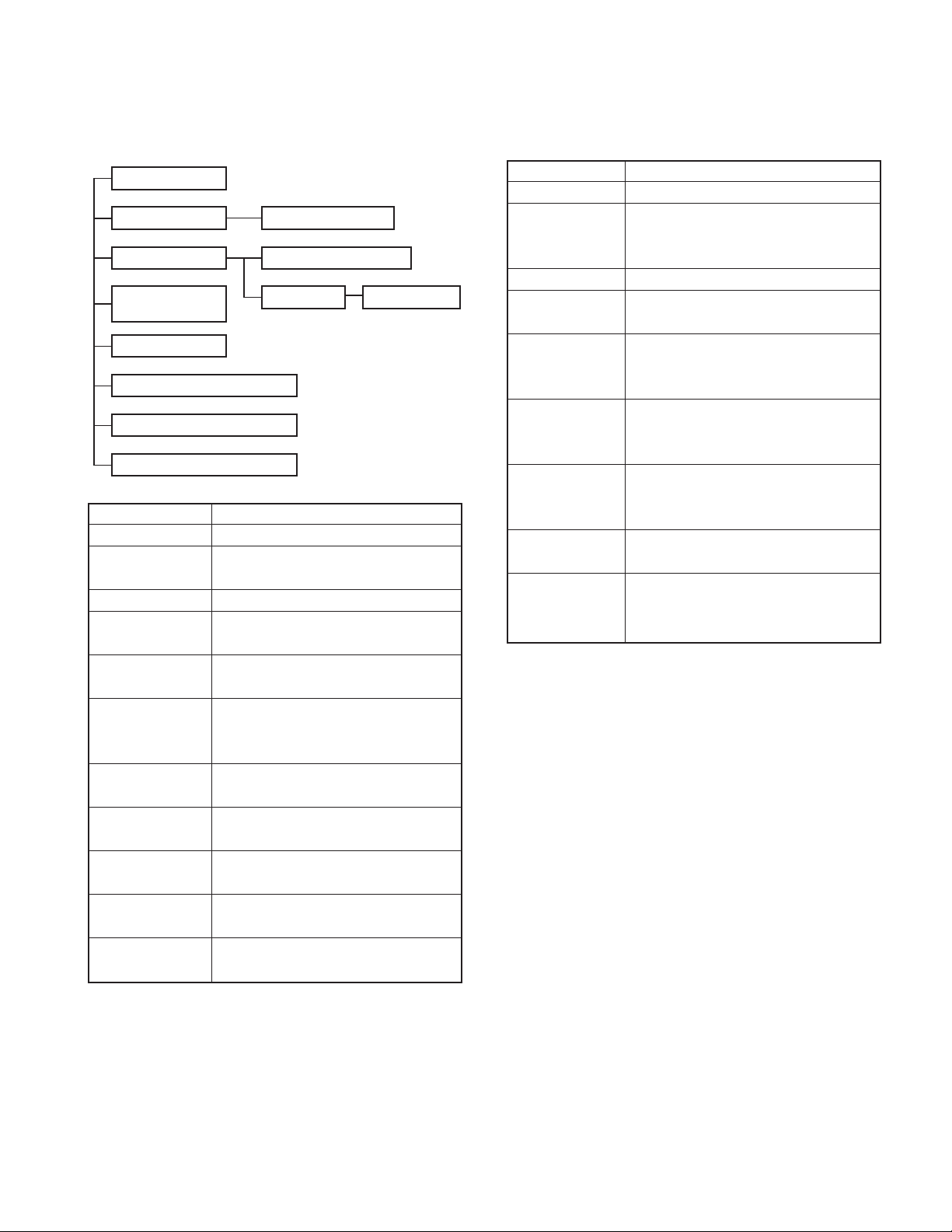

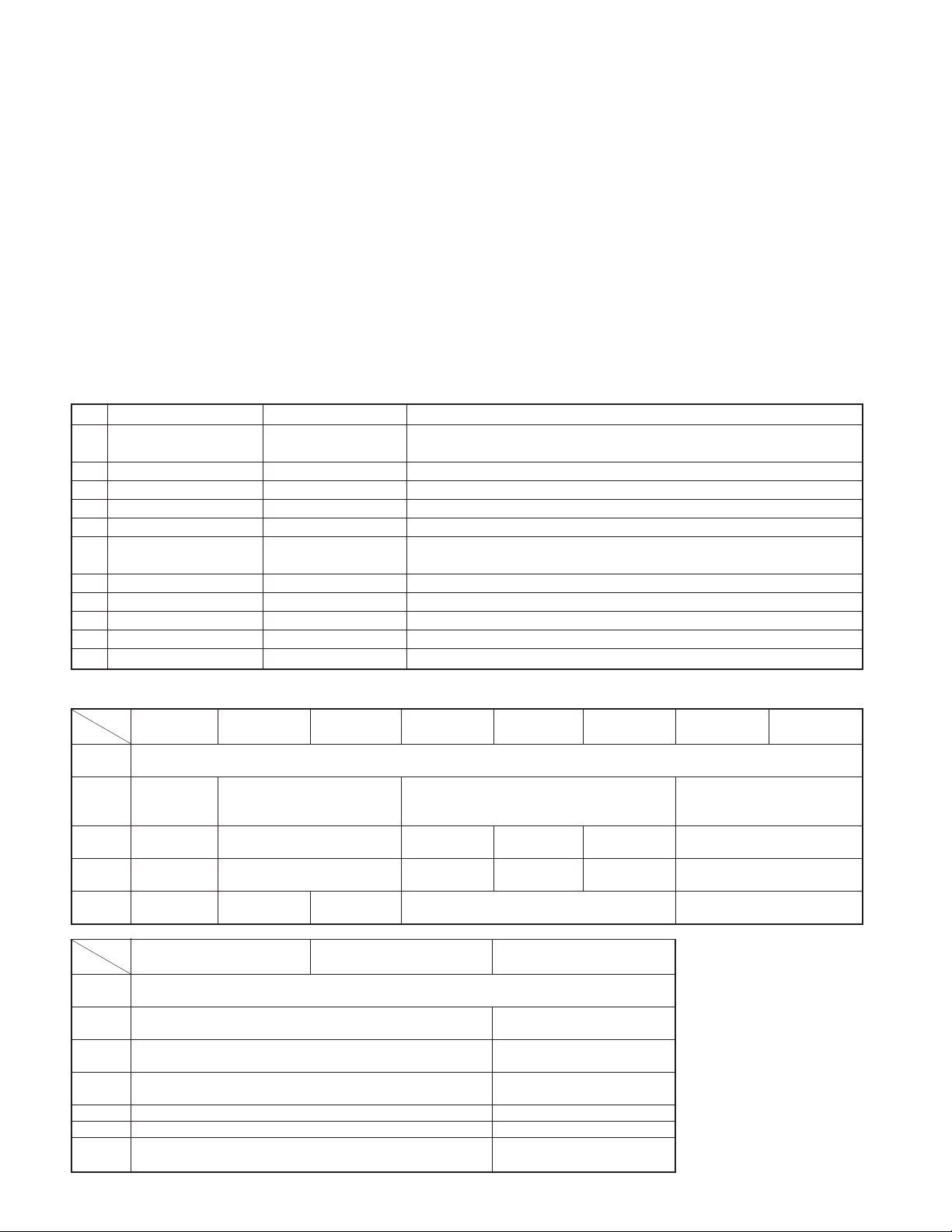

1. Modes 2. How to Enter Each Mode

User mode

Panel test mode

PC mode

Firmware

programming mode

Clone mode ∗1

Self programming mode ∗1

Firmware version information

Clock adjustment mode ∗1

Mode Function

User mode For normal use.

Panel test mode ∗1 Used by the dealer to check the fundamen-

Panel tuning mode ∗1

PC mode Used for communication between the

Data programming Used to read and write frequency data and

mode other features to and from the transceiver.

PC test mode Used to check the transceiver using the PC.

Firmware Used when changing the main program of

programming mode the flash memory.

Clone mode ∗1 Used to transfer programming data from

Self programming Frequency, signaling and features write to

mode ∗1 the transceiver.

Firmware version Used to confirm the internal firmware

information ∗1 version.

Clock adjustment Used by the dealer to adjust date and time.

mode ∗1

∗

1 : K2 and K3 models only

∗

1

tal characteristics.

Used by the dealer to tune the transceiver.

transceiver and PC (IBM compatible).

This feature is included in the FPU.

See panel tuning.

one transceiver to another.

Panel tuning mode ∗1

Data programming mode

PC test mode

∗

1

PC tuning mode

Mode Operation

User mode Power ON

Panel test mode ∗2 Press and hold the [Side3] and [PTT] keys

while turning the transceiver power on and

then release the [PTT] key first.

PC mode Received commands from PC

Panel tuning Press the [Side3] key, in Panel test mode

mode ∗2

Firmware

programming mode

Clone mode ∗2 Press and hold the [Side2] and [PTT] keys

Self

programming

mode ∗2 while turning the transceiver power on and

Firmware version

information ∗2 while turning the transceiver power on.

Clock adjustment Press and hold the [Orange] and [PTT] keys

mode ∗2 while turning the transceiver power on and

∗

2 : K2 and K3 models only

Press and hold the [Side3] and [PTT] keys

while turning the transceiver power on and

then release the [Side3] key first.

while turning the transceiver power on and

then release the [Side2] key first.

Press and hold the [Side2] and [PTT] keys

then release the [PTT] key first.

Press and hold the [Side3] key

then release the [Orange] key first.

3. Panel Test Mode (K2 and K3 models only)

Setting method refer to ADJUSTMENT.

4. Panel Tuning Mode (K2 and K3 models only)

Setting method refer to ADJUSTMENT.

3

TK-5210

REALIGNMENT

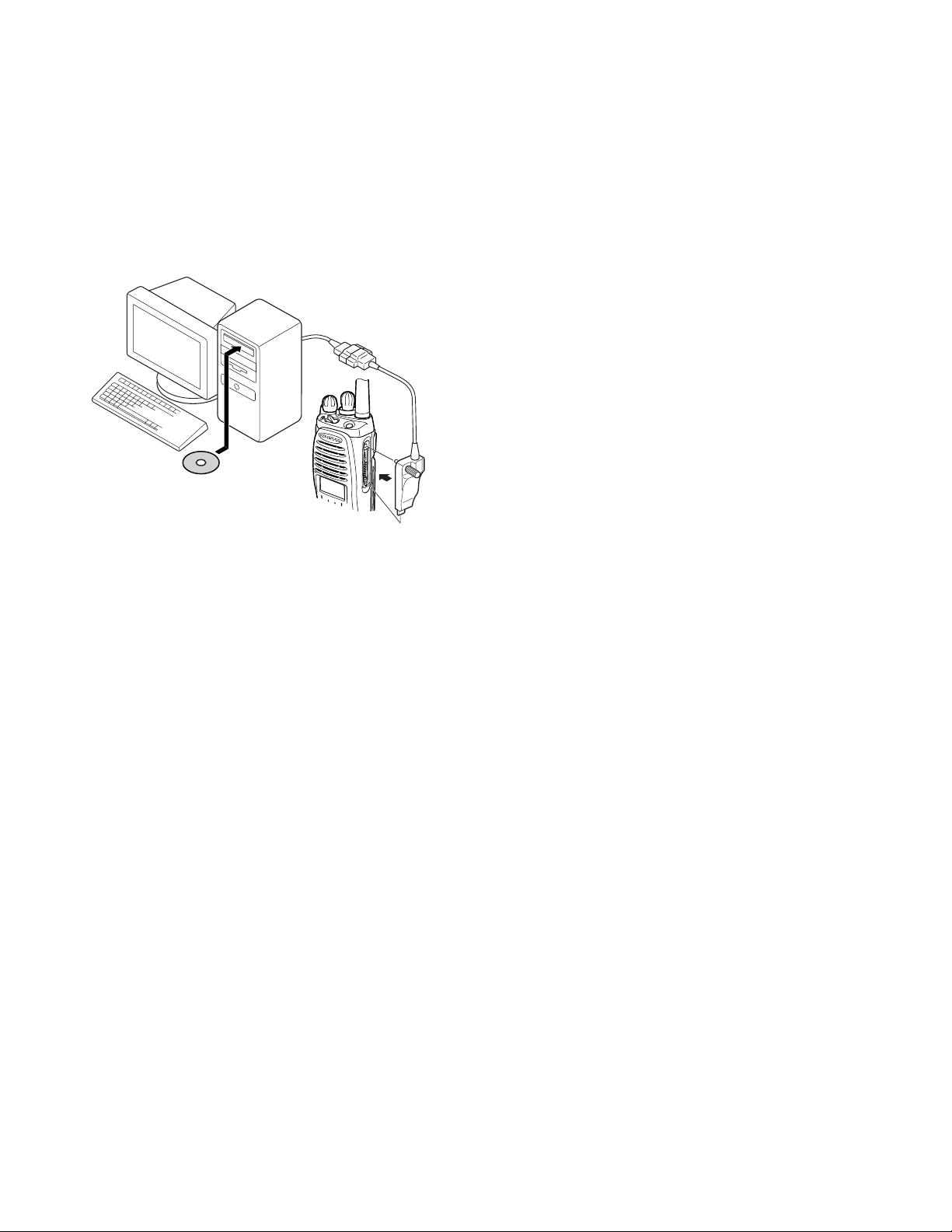

5. PC Mode

5-1. Preface

The transceiver is programmed by using a personal computer, programming interface (KPG-36) and programming

software (KPG-95D).

The programming software can be used with an IBM PC

or compatible. Figure 1 shows the setup of an IBM PC for

programming.

IBM-PC

KPG-36

KPG-95D

Fig. 1

5-2. Connection procedure

1. Connect the transceiver to the personal computer with

the interface cable.

2. When the POWER switch on, user mode can be entered

immediately. When PC sends command the transceiver

enter PC mode, and “PROGRAM” is displayed on the

LCD.

When data transmitting from transceiver, the red LED is

lights.

When data receiving to transceiver, the green LED is

lights.

6. Firmware Programming Mode

6-1. Preface

Flash memory is mounted on the transceiver. This allows

the transceiver to be upgraded when new features are released in the future. (For details on how to obtain the firmware, contact Customer Service.)

6-2. Connection procedure

Connect the transceiver to the personal computer (IBM

PC or compatible) with the interface cable (KPG-36). (Connection is the same as in the PC Mode.)

6-3. Programming

1. Start up the firmware programming software (Fpro.exe).

2. Set the communications speed (normally, 115200 bps)

and communications port in the configuration item.

3. Set the firmware to be updated by File name item.

4. Press and hold the [Side3] and [PTT] keys while turning

the transceiver power on and then release the [Side3] key

first. Then, the orange LED on the transceiver lights and

the baud rate is displayed as follows according to the posi-

tion of the Concentric switch.

A: PROGRAM 115200 bps

B: PROGRAM 57600 bps

C: PROGRAM 19200 bps

Since the baud rate is normally set to 115200 bps, change

the Concentric switch to "A".

5. Check the connection between the transceiver and the

personal computer, and make sure that the transceiver is

in the Program mode.

6. Press “write” button in the window. When the transceiver starts to receive data, the [PG] display lights.

7. If writing ends successfully, the checksum is calculated

and a result is displayed.

8. If you want to continue programming other transceivers,

repeat steps 4 to 7.

Notes:

• The text message are displayed for K2 and K3 models

only.

• The data stored in the personal computer must match

"Model Name and Market Code", when it is written into

the EEPROM and flash memory.

5-3. KPG-36 description

(PC programming interface cable: Option)

The KPG-36 is required to interface the transceiver to the

computer. It has a circuit in its D-sub connector (25-pin) case

that converts the RS-232C logic level to the TTL level.

The KPG-36 connects the universal connector of the trans-

ceiver to the computers RS-232C serial port.

5-4. Programming software KPG-95D description

The KPG-95D is the programming software for the trans-

ceiver supplied on a CD-ROM. This software runs under MSWindows 98, ME, Windows 2000 or XP on an IBM-PC or

compatible machine.

The data can be input to or read from the transceiver and

edited on the screen. The programmed or edited data can be

printed out. It is also possible to tune the transceiver.

4

Notes:

• This mode cannot be entered if the Firmware Programming mode is set to Disable in the Programming software.

• The text message are displayed for K2 and K3 models

only.

6-4. Baud rate change

1. Change baud rate by changing the Concentric switch position. The baud rates are assigned to positions of the Concentric switch as follows:

A: PROGRAM 115200 bps

B: PROGRAM 57600 bps

C: PROGRAM 19200 bps

2. If you press the [Side1] switch (top of left side) while the

baud rate (such as “PROGRAM 115200 bps") is displayed,

the checksum is calculated, and a result is displayed. If

you press the [Side1] switch again while the checksum is

displayed, the baud rate (such as “PROGRAM 115200

bps") is redisplayed.

Notes:

• Normally, write in the high-speed mode.

• The text message are displayed for K2 and K3 models

only.

REALIGNMENT

TK-5210

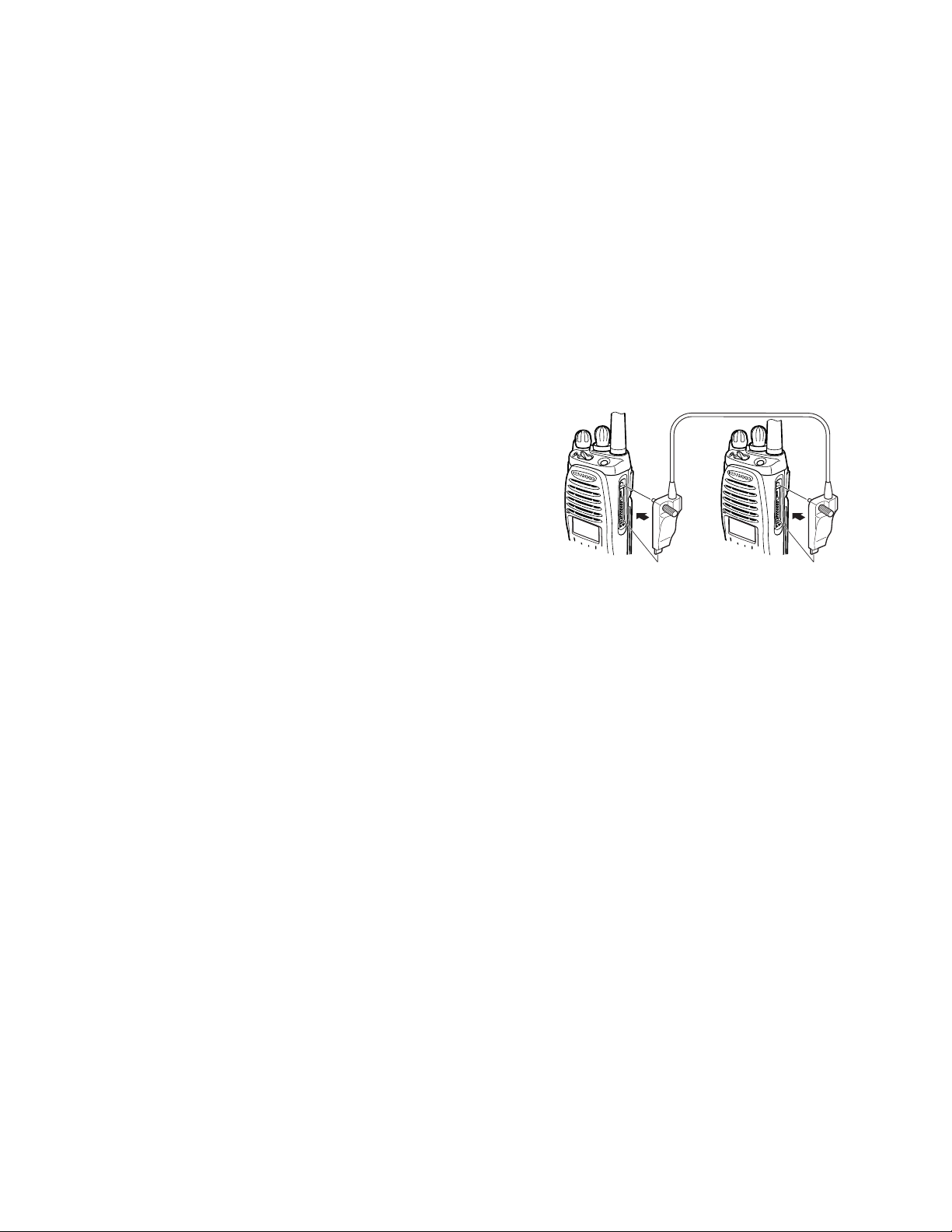

7. Clone Mode (K2 and K3 models only)

Programming data can be transferred from one transceiver to another by connecting them via their external universal connectors. The operation is as follows (the transmit

transceiver is the master and the receive transceiver is a

slave).

The following data cannot be cloned.

• Tuning data

• Embedded message with password

• Model name data

• ESN data

Key guide on the "INPUT PASSWORD" display.

• CNF([A] key): The password confirmation

• DEL([B] key): Delete the least digit from the current pass-

word number

• SET([D] key): Determine the least digit of the password

number

1. Press and hold the [Side2] and [PTT] keys while turning

the transceiver power on and then release the [Side2] key

first. If the Read authorization password is set to the trans-

ceiver, the transceiver displays “CLONE LOCK”. If the

password is not set, the transceiver displays “CLONE

MODE”.

2. When you enter the correct password, and “CLONE

MODE” is displayed, the transceiver can be used as the

cloning master. The following describes how to enter the

password.

3.

• How to enter the password using the keypad (K3 model

only);

If the [D] key is pressed while "CLONE LOCK" is displayed,

the Read authorization password input screen (INPUT

PASSWORD) is displayd.

If one of keys 0 to 9 is pressed while "INPUT PASSWORD"

is displayed, the pressed number is displayed on the LCD.

Each press of the key shifts the display in order to the left.

When you enter the password and press the [A] or [✳]

key, “CLONE MODE” is displayed if the entered pass-

word is correct. If the password is incorrect, “CLONE

LOCK” is redisplayed.

• How to enter the password using the [Side2] and [Side3]

keys (K2 and K3 models);

If the [D] key is pressed while "CLONE LOCK" is displayed,

the Read authorization password input screen (INPUT

PASSWORD) is displayd.

If the [Side2] key or [Side3] key is pressed while "INPUT

PASSWORD" is displayed, the number (0 to 9) flashes on

the LCD. When you press the [D] key, the currently

selected number is determined. If you press the [A] key

after entering the password in this procedure, “CLONE

MODE” is displayed if the entered password is correct. If

the password is incorrect, “CLONE LOCK” is redisplayed.

4. Power on the slave transceiver.

5. Connect the cloning cable (part No. E30-3325-05) to the

universal connectors on the master and slave.

6. Press the [Side1] or [A] key on the master while the mas-

ter displays “CLONE MODE”. The data of the master is

sent to the slave. While the slave is receiving the data,

“PROGRAM” is displayed. When cloning of data is com-

pleted, the master displays “END”, and the slave automatically operates in the User mode. The slave can then

be operated by the same program as the master.

7. The other slave can be continuously cloned. When the

[Side1] or [A] key on the master is pressed while the master displays “END”, the master displays “CLONE

MODE”. Carry out the operation in step 4 to 6.

Notes:

• Can not be cloned if the password (over write password)

is programmed to the slave.

•"Model Name and Market Code" must be same to clone

the transceiver. However, it may be unable to clone the

transceiver depending on the enhanced features settings.

(Refer to the FPU for the enhanced features details.)

Cloning cable

(E30-3325-05)

Fig. 2

8. Self Programming Mode

(K2 and K3 models only)

Write mode for frequency data and signaling etc. To be

used ONLY by the authorized service person maintaining the

user's equipment. After programming, reset the FPU to the

"Self- Programming" disabled mode. Transceivers CANNOT

be delivered to the end-user in the self-programming mode.

The following setup items in the channels programmed by

the FPU can be changed using the self-programming mode.

The addition of new channel and the deletion of channel that

has already been programmed by the FPU cannot be

performed using the self-programming mode.

• RX frequency

• TX frequency

• Channel type

• TX mode (When the channel type is selected "MIXED".)

• Channel spacing

• RX signaling

• TX signaling

• RX NAC

• TX NAC

• Talkgroup list number

Note:

The personality will be also changed when the abovementioned items is changed. (Refer to the FPU for the

personality details.)

Key guide on the "INPUT PASSWORD" display.

• CNF([A] key): The password confirmation

• DEL([B] key): Delete the least digit from the current pass-

word number

5

TK-5210

REALIGNMENT

• SET([D] key): Determine the least digit of the password

number

MODE" is displayed on the LCD when you enter the correct

password while "INPUT PASSWORD" is displayed.

For the password input method, see "7.Clone Mode”

8-1. Enter to the self programming mode

Press and hold the [Side2] and [PTT] keys while turning

the transceiver power on and then release the [PTT] key first.

Ignoring whether the Read authorization password is set or

not, "INPUT PASSWORD" appears.

step 3 described on page 5.

Note :

This mode (self programming mode) cannot be set when

it has been disabled with the FPU.

If the Read authorization password is not set to the transceiver, "SELF PROG MODE" is displayed on the LCD when

the [A] key is pressed while "INPUT PASSWORD" is displayed.

If the password is set to the transceiver, "SELF PROG

8-2. Data Writing

If the [Side3] key is pressed while Zone/Channel mode is

displayd, new data is written into memory. "Writing" is displayed while the transceiver is writing data.

The setup items for self programming mode are as follows.

No. Setup item Display Remarks

1 Select ZONE [**] -CH *** Zone : 1~50

Zone/Channel ZONE ** -CH [***] CH : 1~250

2 RX frequency RX Freq Receive frequency

3 TX frequency TX Freq Transmit frequency

4 Channel type CH Type ANALOG/APCO/MIXED

5 TX mode TX Mode ANALOG/APCO

6Channel spacing CH Space 25.0kHz/12.5kHz

APCO 12.5kHz/12.5kHz (When the Channel type is selected "APCO".)

7 RX Signaling RX Sig Receive QT/DQT

8 TX Signaling TX Sig Transmit QT/DQT

9 RX NAC RX NAC *** 000~FFF (Hexadecimal)

10 TX NAC TX NAC *** 000~FFF (Hexadecimal)

11 Talkgroup list number TG List No. *** 1~250

(When the Channel type is selected "ANALOG" or "MIXED".)

Key operation

Item

Key

[Side3]

Item

Key

[Side2] Increment a number in the specified digit Unused

[Side3] Decrement a number in the specified digit Unused

Keypad Add a digit to the

(K3 model only)

6

Zone-Channel RX Frequency TX Frequency Channel Type TX Mode Channel Spacing RX Signaling TX Signaling

[A] Go to the next item

Zone/ Channel

[B]

[C]

[D]

[A] Go to the next item

[B]

[C] Unused

[D] Determine the least digit

switching

Zone/ Channel

down switching(Back) switching(Back) switching(Back)

Zone/ Channel

up

Data

writing switching switching

RX NAC TX NAC TG List No.

Delete the least digit from the current number

2.5kHz/5kHz/6.25kHz/

7.5kHz/1MHz Unused

step switching

1 step down

1 step up

Unused

(Press and hold to delete all numbers.)

current number

ON/OFF

ANALOG/APCO/MIXED

ANALOG/APCO/MIXED

switching(Forward) switching(Forward) switching(Forward)

ANALOG/APCO Channel spacing

ANALOG/APCO Channel spacing

Unused

number down

QT/DQT(N)/DQT(I)/OFF

switching

Signaling down

Signaling up

1 step/Standard

Unused

TG List

TG List

number up

Unused

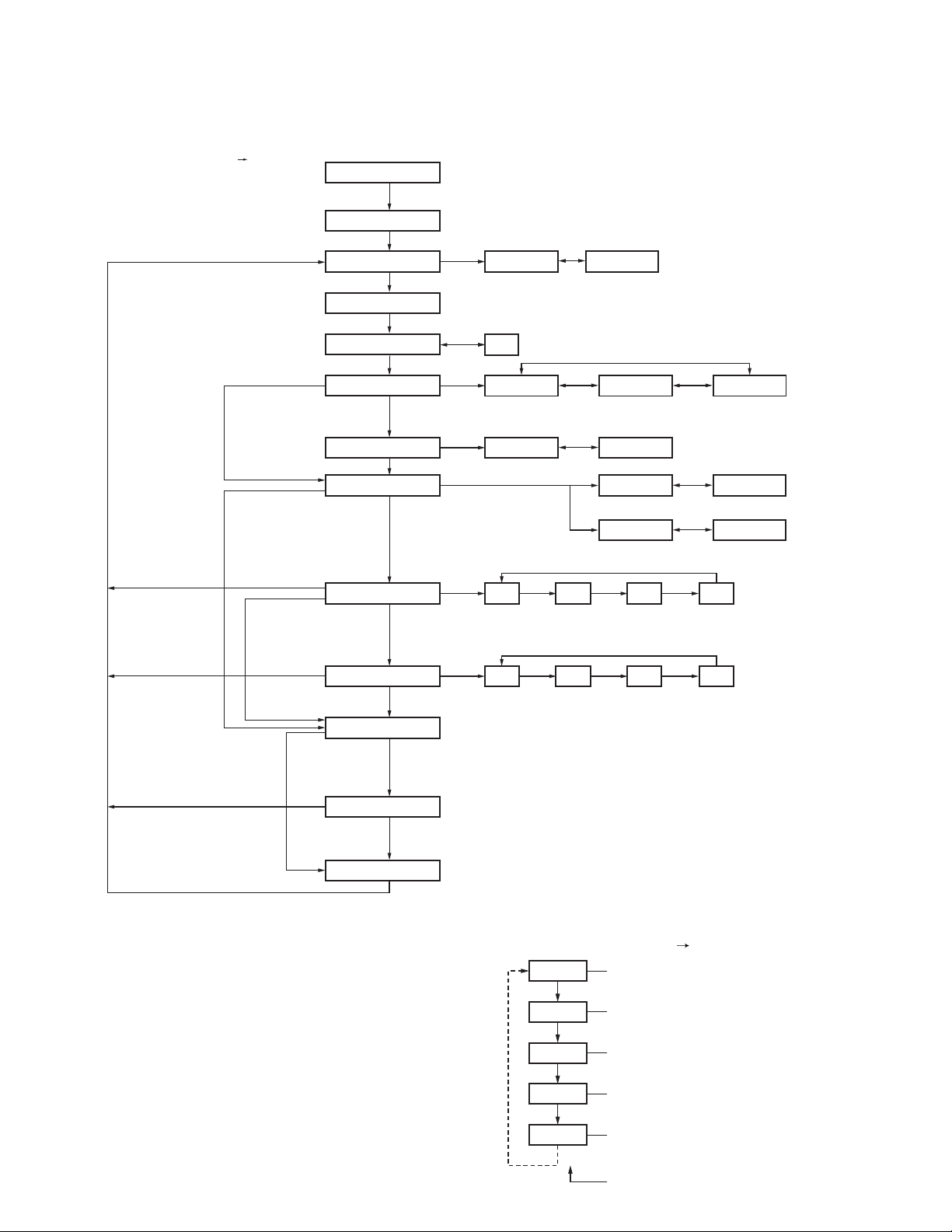

●

Self programming mode flow chart

[Side2] + [PTT] + POWER ON Release [PTT]

[A] [A]

[TX frequency] : "OFF"

[Channel type] : "ANALOG" or "APCO"

[A]

[Channel type] : "APCO"

REALIGNMENT

Input Password

Read authorization password entry (6 digits)

[A]

Self programming mode

[A]

Zone/Channel

[A] When the [Side3] key is pressed, new data is written into memory.

RX frequency

[A]

TX frequency

[A]

Channel type

[TX frequency] : Other than "OFF"

[Channel type] : "MIXED"

TX mode

[A]

Channel spacing

[A]

[Channel type] : "ANALOG" or "MIXED"

[Side 3]

Zone selection

OFF

ANALOG

[B]

Channel selection

[C]/[D]

[C]/[D]

[C]/[D]

*1

*2

APCO

APCOANALOG

*1 [Channel type] : "ANALOG" or "MIXED"

APCO 12.5kHz

*2 [Channel type] : "APCO"

[B]

[C]/[D]

[C]/[D]

[C]/[D]

TK-5210

MIXED

12.5kHz25.0kHz

12.5kHz

[A]

[TX frequency] : "OFF"

[Channel type] : "ANALOG"

[A]

[Channel type] : "ANALOG"

[A]

Talkgroup ID List Amount : 0

[A]

[TX frequency] : "OFF"

[Channel type] : "APCO" or "MIXED"

[A]

[TX frequency] : "OFF"

RX signaling

[A]

[TX frequency] : Other than "OFF"

[Channel type] : "ANALOG" or "MIXED"

[TX mode] : "ANALOG"

TX signaling

[A]

[Channel type] : "APCO" or "MIXED"

RX NAC

[A]

[TX frequency] : Other than "OFF"

[Channel type] : "APCO" or "MIXED"

If [Channel type] is set to "MIXED", [TX mode] must be set to "APCO".

TX NAC

[A]

[Channel type] : "APCO" or "MIXED"

Talkgroup ID List Amount must not be 0.

Talkgroup list number

[A]

9. Firmware Information Mode

(K2 and K3 models only)

Turn the transceiver ON with the [Side3] key held down.

Then, the version is displayed during holding the [Side3] key.

10.Clock Adjustment Mode

(K2 and K3 models only)

10-1. Flow chart of operation

OFF QT

[B] [B] [B]

OFF QT DQT N

[B]

DQT N

[B]

[B]

DQT I

DQT I

[B]

[Orange] + [PTT] + Power ON Release [Orange]

YEAR

[Side2] and [Side3] keys or [C] and [D] keys

[A]

MONTH

[Side2] and [Side3] keys or [C] and [D] keys

[A]

DAY

[Side2] and [Side3] keys or [C] and [D] keys

[A]

HOUR

[Side2] and [Side3] keys or [C] and [D] keys

[A]

MINUTE

[Side2] and [Side3] keys or [C] and [D] keys

[A]

Completion

7

TK-5210

DISASSEMBLY FOR REPAIR

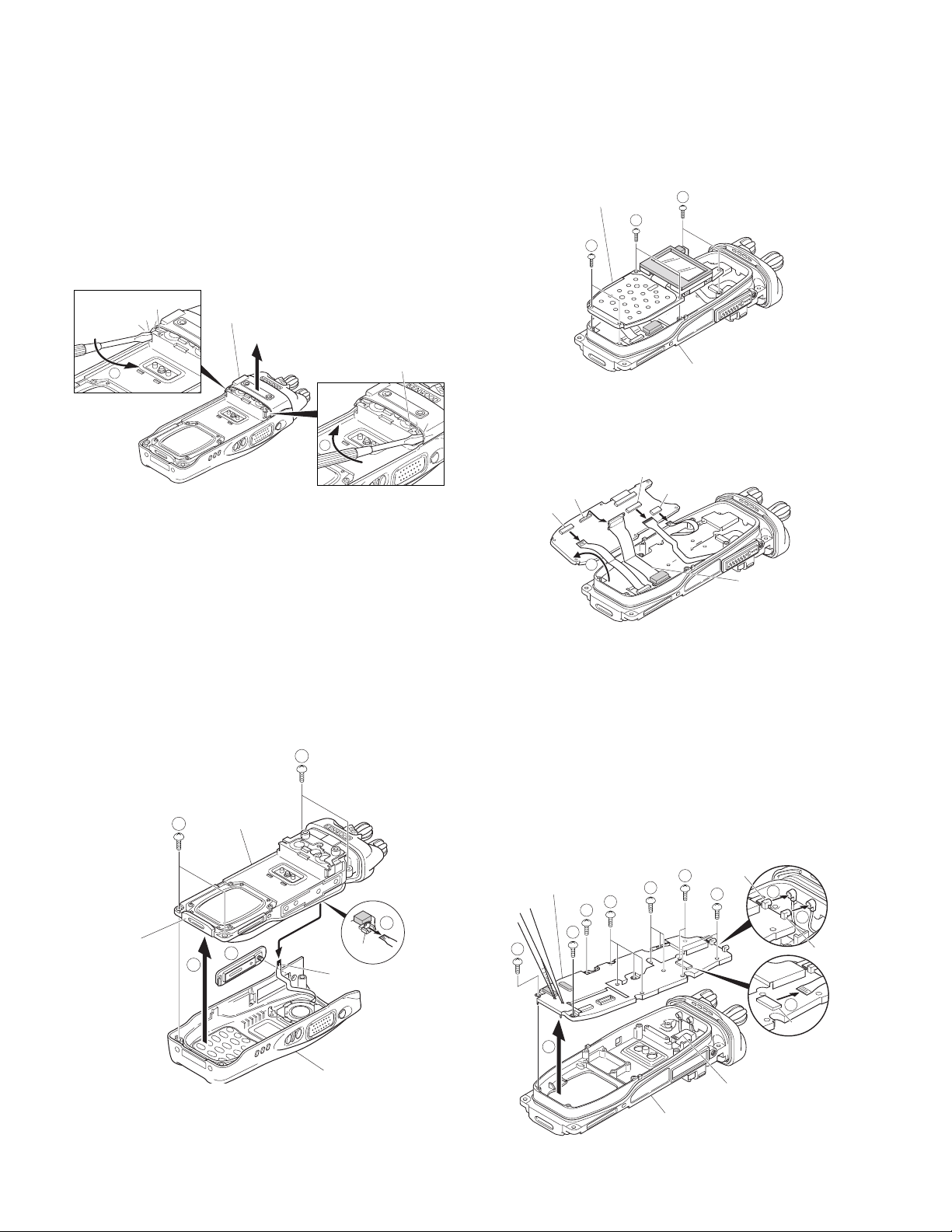

Disassembly Procedure

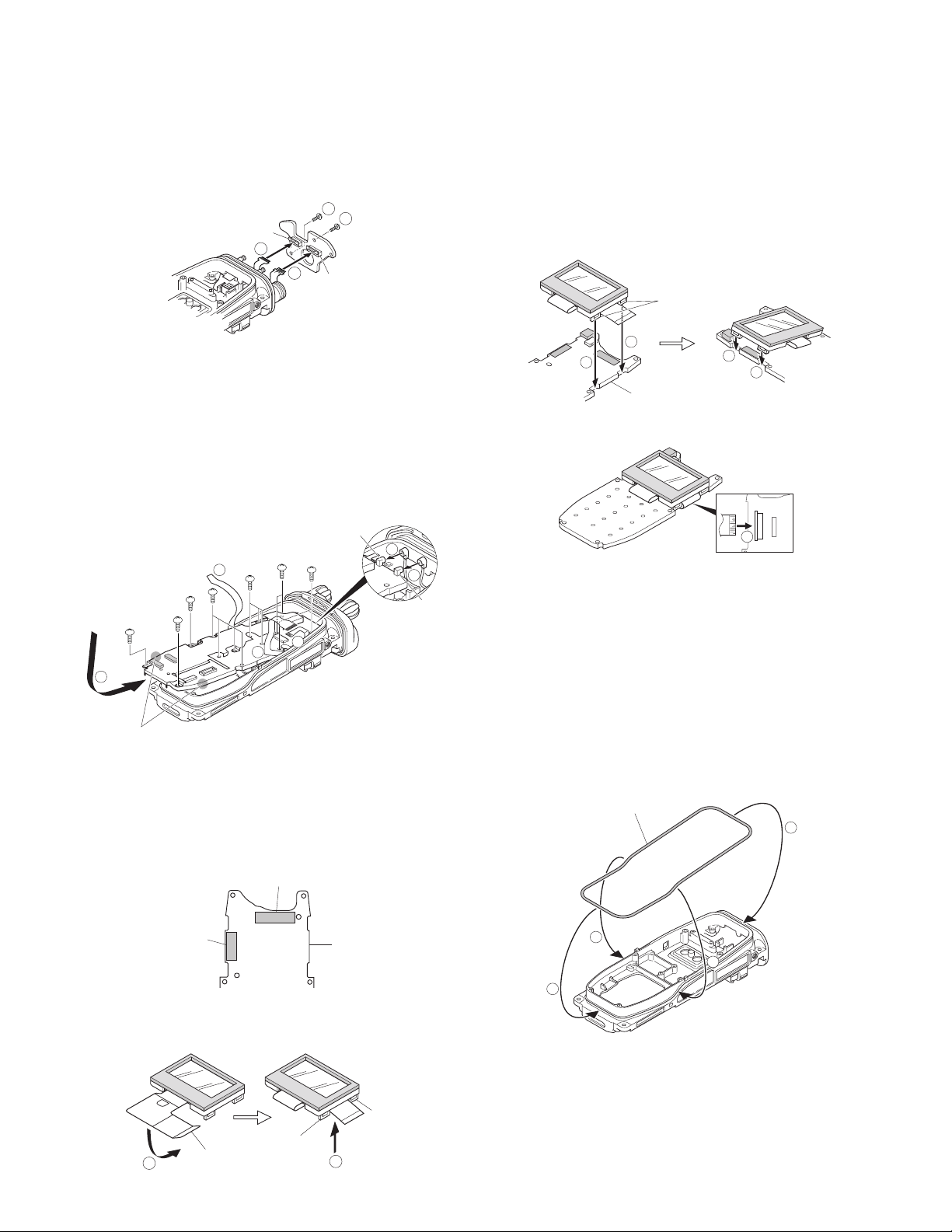

■ Removing the front case from the chassis.

1. Remove the rear panel with a flat-head screwdriver.

Insert the screwdriver between the rear panel (right side)

and the chassis (the place next to the """ mark shown on

the chassis), push it in the direction of the arrow

remove the right side of the rear panel. Repeat the above

action for the left side of the rear panel 2.

""" mark

2

Rear panel

1

2. Remove the four screws 3 and universal connector cap

4.

3. Lift the battery pack release latch on the bottom of the

chassis

Notes:

• Lift the chassis from the front case slowly and carefully. If

the chassis is lifted suddenly, the SP/MIC FPC may be

pulled and the connector may become damaged.

• Handle the main packing with care. It is likely to collect

dust and dirt.

4. Remove the SP/MIC FPC from the CONTROL PCB connector (CN603).

Battery pack

release latch

5 and remove the chassis from the front case.

6

3

Chassis

3

4

5

CN603

SP/MIC FPC

1, and

""" mark

6

■ Removing the CONTROL PCB (X57-682 B/5)

from the chassis.

1. Remove the six screws 7.

CONTROL PCB

7

2. On the reverse side of the CONTROL PCB

7

7

Chassis

8, remove the

cord ASSY and each FPC from the connectors (CN601,

CN604 (K2 and K3 models only), CN752, CN753) of the

CONTROL PCB.

CN752

CN601

CN604

8

CN753

Cord ASSY

■ Removing the TX-RX PCB (X57-682 A/5) from

the chassis.

1. Remove the 14 screws 9.

2. Remove the universal connector FPC from the TX-RX PCB

connector (CN7) 0.

3. Insert the two tips of a pair of tweezers into the two holes

in the bottom of the shield plate of the TX-RX PCB, firmly

squeeze the tweezers to hold the shield plate, then

remove the TX-RX PCB

4. Remove the coaxial cables from the two connectors

(MAIN (CN101), UNIV (CN102)) of the TX-RX PCB @.

TX-RX PCB

9

9

9

9

!.

UNIV

(CN102)

9

9

9

12

12

MAIN

(CN101)

10

CN7

11

Front case

Chassis

Universal

connector FPC

8

DISASSEMBLY FOR REPAIR

TK-5210

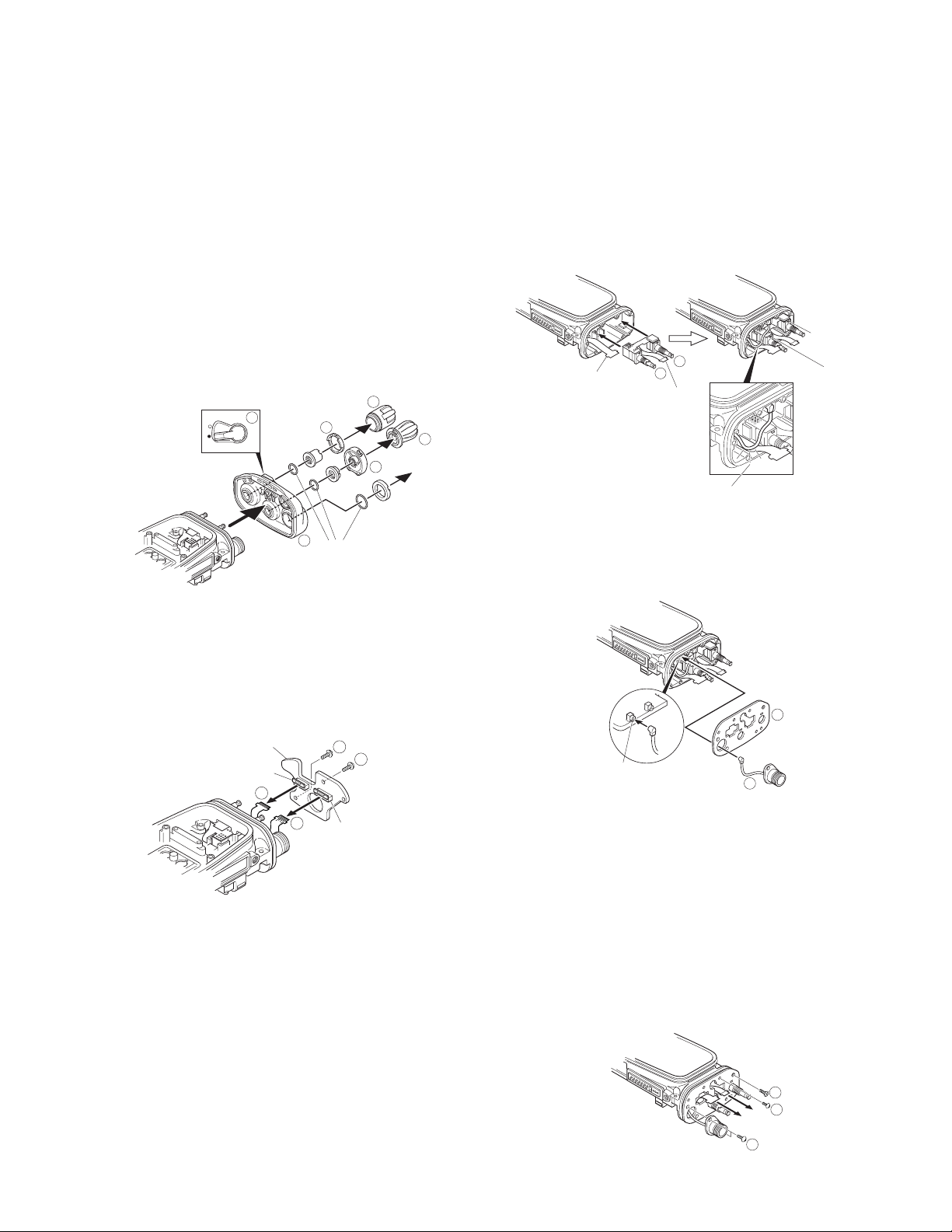

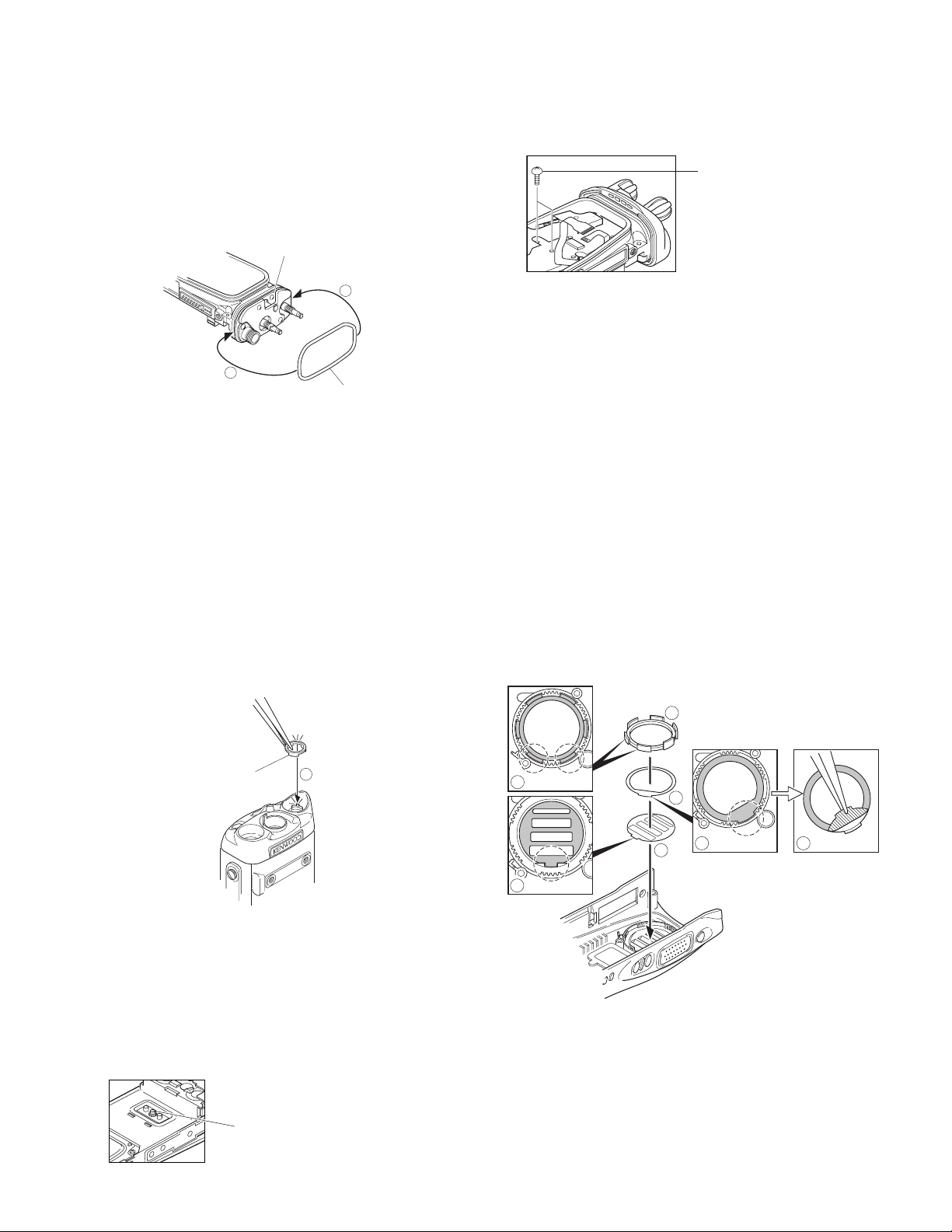

■ Removing the top panel from the chassis.

1. Remove the volume knob # and channel knob $.

2. Remove the concentric switch knob

3. Remove the volume torque-up packing

tweezers.

4. Remove the nuts from the volume knob, channel knob

and antenna receptacle.

5. Remove the top panel

&.

Notes:

•Before removing the top panel, set the lever switch to the

"-" position (circle painted in white)

• Each of the volume knob, channel knob and antenna receptacle on the top panel has an O-ring. Take care not to

lose them after removing the panel.

18

%.

^ using a pair of

*.

13

16

15

17

O-ring

14

Precautions for Reassembly

■ Installing the VOL/CH FPC and CONTROL-TOP

FPC on the TOP PCB

1. Remove the volume 1 and channel switch 2 from the

chassis.

2. Position the coaxial cable connecting the ANT PCB and

TX-RX PCB as shown in the figure below.

The projection

of the volume

1

CONTROL-TOP

FPC

3. Pass the coaxial cable

2

VOL/CH FPC

Aline the coaxial cable

connecting the ANT PCB and

TX-RX PCB as shown in the figure.

3 of the antenna receptacle

through the round hole of the hardware fixture

insert it into the coaxial connector (MAIN (CN101)) of the

TX-RX PCB.

pedestal

The projection of

the channel

switch pedestal

4, then

■ Removing the TOP PCB (X57-682 C/5) from the

chassis.

1. Remove the two screws (.

2. Lift the TOP PCB and remove the VOL/CH FPC

CONTROL-TOP FPC

⁄ from the two connectors (CN902,

CN903) of the TOP PCB.

TOP PCB

CN902

20

19

19

21

CN903

) and

4

MAIN

(CN101)

3

4. Pass the volume, channel switch, VOL/CH FPC and

CONTROL-TOP FPC through hardware fixture holes, then

bring the hardware fixture into contact with the chassis

and fix it with a screw

5.

Note:

The projections of the volume and channel switch pedestals must protrude from the square holes of the hardware

fixture.

5. Fix the antenna receptacle with the two screws 6.

6. Fix the hardware fixture with a screw

7.

5

7

6

9

TK-5210

3

3

tab

CONTROL PCB

DISASSEMBLY FOR REPAIR

7. Insert the VOL/CH FPC 8 and the CONTROL-TOP FPC 9

into the connectors (CN902, CN903) of the TOP PCB.

8. Fix the TOP PCB with a screw

9. Fix the TOP PCB with a screw

CN902

8

0.

!.

10

11

9

CN903

■ TX-RX PCB Installation Procedure

1. Insert the coaxial cable of the antenna receptacle into the

coaxial connector (CN101) of the TX-RX PCB

1 and the

coaxial cable of the ANT PCB into the coaxial connector

(CN102) of the TX-RX PCB

2.

2. Grasp both sides of the lower part of the TX-RX PCB, tilt

the TX-RX PCB and install the chassis so that the PTT FPC

3, CONTROL-TOP FPC 4 and universal connector FPC

5 are not caught 6.

3. Fix the TX-RX PCB with the 14 screws.

3

6

Grasp both sides of the lower part

of the TX-RX PCB

CN102

5

4

2

1

CN101

■ LCD ASSY Installation Procedure (K2 and K3

models only)

1. Remove the two adhesive sheets attached to the

CONTROL PCB, and attach the new adhesive sheets to

the location as shown in the following figure.

Adhesive sheet

(J99-0393-04)

3. Fit the two tabs on the right side of the holder 3 and the

two tabs on the left side of the holder

4 into the

CONTROL PCB.

Note:

Take care that the FPC is not caught when fitting the two

tabs on the right side of the holder.

4

4

4. Insert the FPC into the CONTROL PCB connector (CN751)

5.

CN751

5

■

Main Packing (G53-1637-04) Installation Procedure

1. Hook the packing (coated with silicon oil) in the upper

groove of the chassis

lower groove of the chassis

Note:

Ensure that the chassis grooves and packing are free from

dirt and dust.

2. Fit the packing into the grooves on both sides of the

chassis 3. (Fit the packing into the groove in the chassis

by tracing it lightly with your fingers.)

Main packing

1, then fit the packing into the

2.

1

Adhesive sheet

(J99-0394-04)

CONTROL PCB

2. Fold the LCD ASSY FPC to the back of the holder

that the FPC is between the two tabs on the right side of

2.

tab

2

1

LCD ASSY FPC

10

the holder

tab

3

3

2

1 so

Note:

To remove the packing from the chassis groove, use a

resin adjustment bar or other such device. If the packing

is pried with a sharp metallic tool, such as tweezers, the

packing may become damaged.

3. Verify that the packing fits snuggly into the groove of the

chassis.

DISASSEMBLY FOR REPAIR

TK-5210

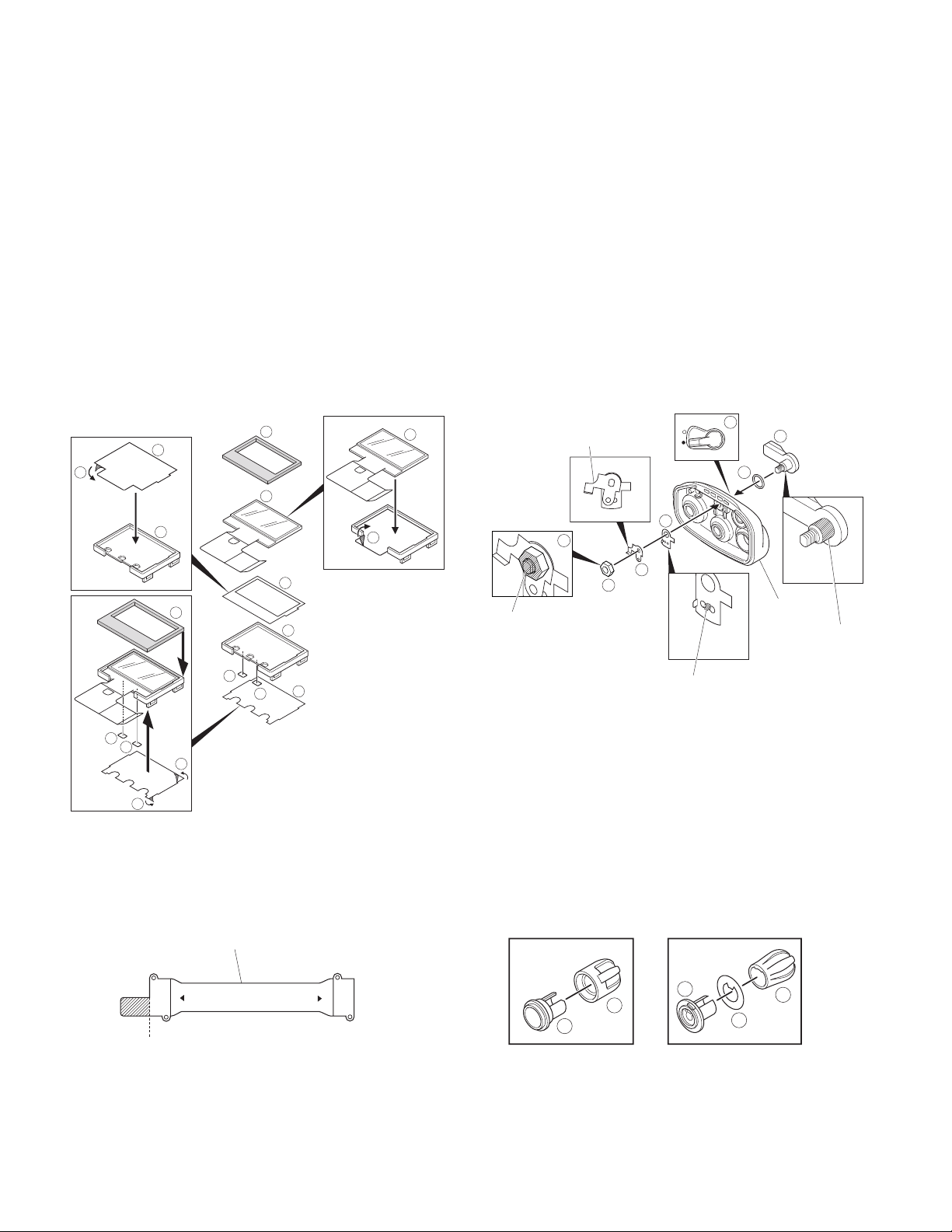

■ Top Packing (G53-1638-04) Installation Procedure

1. Ensure that the hardware fixture is first secured to the

chassis.

2. Hook the packing (coated with silicon oil) in the upper left

groove of the chassis

groove of the chassis.

Notes:

• Verify that the chassis grooves and packing are free from

dirt and dust.

• To remove the packing from the chassis groove, use a

resin adjustment bar or other such device. If the packing

is pried with a sharp metallic tool, such as tweezers, the

packing may become damaged.

3. Verify that the packing fits snuggly into the groove of the

chassis.

1, then fit the packing into the right

2

Hardware fixture

1

2

Top packing

2. Tighten the two screws from the TX-RX PCB side.

Two s crews

3. Firmly tighten the hexagon screws of the GND terminal.

Installation Procedure during Parts Replacement

■ Attaching the Sheet (G10-1338-04, J99-0383-14)

to the Front Case Speaker and Installation of

the Packing (G53-1633-04)

1. Attach a new fiber sheet 1 (G10-1338-04) so that its

convex fits the hollow of the front case

2. Attach a new pressure sensitive adhesive sheet

0383-14) so that its convex fits the hollow of the front

case 4.

3. Remove the separation sheet from the pressure sensitive

adhesive sheet with a pair of tweezers 5.

4. Fit the packing

speaker.

6 (G53-1633-04) into the front case

2.

3 (J99-

■ Volume Torque-up Packing (G53-1628-04)

Installation Procedure

Insert the packing using a pair of tweezers so that the

hollow of the packing fits the convex of the panel

Volume torque-up packing

1

1.

■ Screw sequence for mounting the battery

terminal block to the chassis.

Attach the battery terminal block to the chassis as

described in the following procedure.

1. Loosely fix the hexagon screws of the GND terminal to

the chassis (enough so that the hexagon screws do not

move).

Note:

Fit the packing into the hollow of the case so that the two

low-height places in the convex of the packing are positioned on the lower side

7

2

5. Verify that the packing does not ride on the rib of the case.

7.

6

3

4 5

1

GND terminal

11

TK-5210

DISASSEMBLY FOR REPAIR

■ Installing a new LCD ASSY to the holder (K2

and K3 models only)

1. Remove the separation paper (brown) from the new sheet

1 2, and attach the sheet to the surface of the holder 3.

2. Remove the protection sheets attached to both sides of

the new LCD ASSY.

3. Remove the separation paper (white) from the sheet in

4, then attach the LCD ASSY 5 to the sheet.

step 1

4. Attach two pieces of double-sided adhesive tape

back of the holder and remove the separation paper.

5. Remove the protection sheet (transparent) attached to

one side of the new filter

sheet (yellow) from the other side

7 8 and remove the protection

9.

6. Attach the filter from step 5 to the back of the holder.

7. Attach the new cushion 0 so that it fits to the corner of

the holder convex.

10

1

2

5

3

1

10

3

6

7

6

6 to the

5

4

■ Procedures when Replacing the Top Panel

1. Insert the O-ring 1 into the lever switch part of the new

top panel.

2. Apply grease to the base of the shaft of the lever knob 2

and install the lever knob so that it is in the "-" position

(circle painted in white) on the top panel

3. Pass the hardware fixture

4 through the shaft and install

it onto the top panel.

4. Apply grease to between the two holes in the hardware

4.

fixture

5. Install the hardware fixture

5 so that it is inserted into the

hole on the left side of the hardware fixture

6. Fix the two hardware fixtures with the hexagon nut

7. Apply bond (Three Bond 1401C) to the tip of the lever

knob shaft and the surface of the hexagon nut

Inserted into the hole

on the left side of the

hardware fixture.

4

7

5

6

Apply bond (Three Bond 1401C)

to the tip of the lever knob shaft

and the surface of the hexagon

nut.

Apply grease to between

the two holes in

the hardware fixture.

3.

4.

6.

7.

3

2

1

Top panel

Apply grease to the

base of the shaft of

the lever knob.

6

6

8

9

■ Preparation when Replacing the Cord ASSY

(X42-3270-10)

Cut the tip of the FPC on the side on which "TX-RX" is

stamped when replacing the cord ASSY.

Cord Assy(X42-3270-10)

TX-RX

CUT

12

CONT

■ Volume Knob and Channel Knob Parts Replacement

Since the volume knob consists of two components, a

1 and a spacer 2, replace and reinstall these two

knob

parts at the same time.

Since the channel knob consists of three components, a

3, a 16CH display seal 4 and a spacer 5, replace

knob

and reinstall these three parts at the same time.

Volume Knob Channel Knob

5

1

2

3

4

CIRCUIT DESCRIPTION

TK-5210

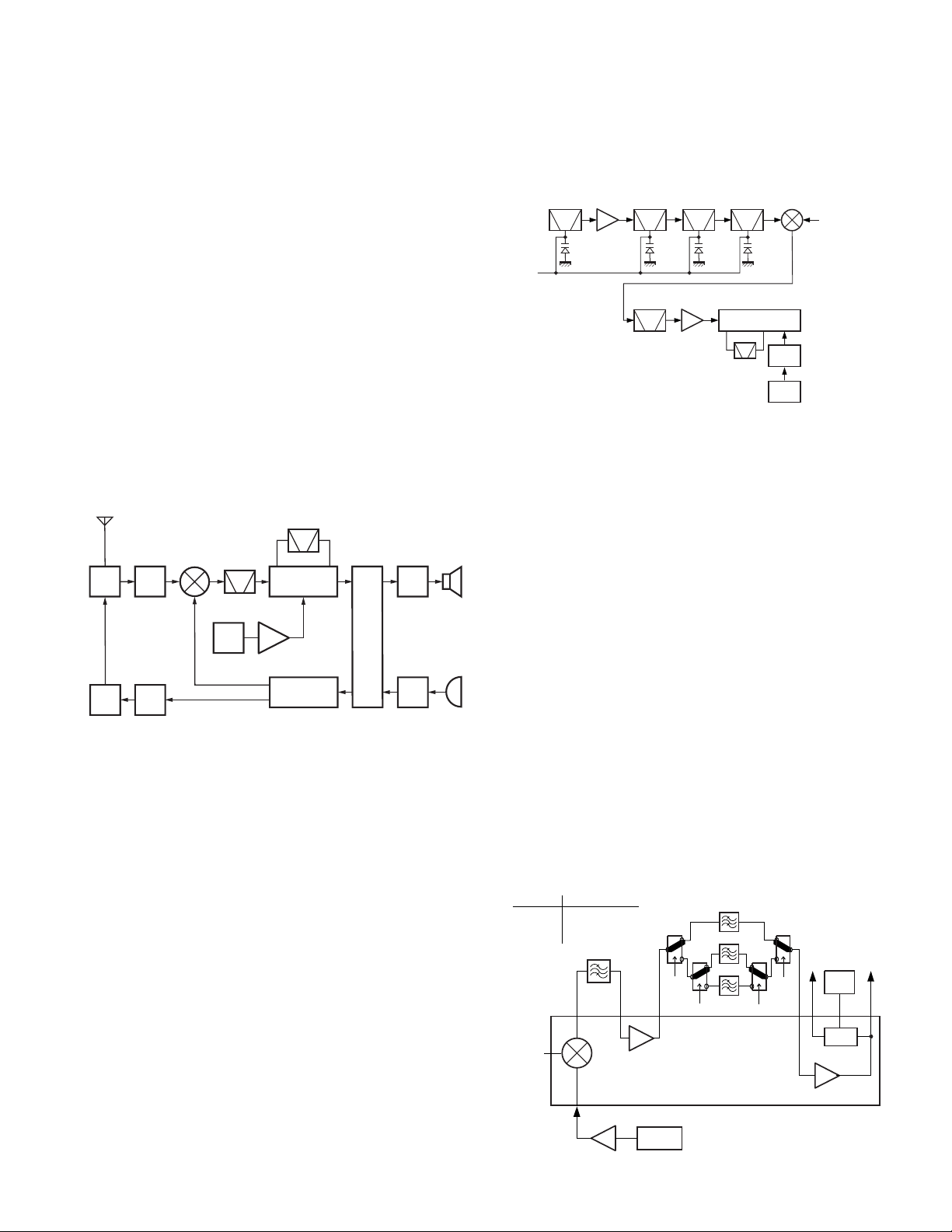

1. Overview

This transceiver is a VHF/FM/APCO portable transceiver

designed to operate in the frequency range of 136 to

174MHz.

The unit consists of receiver, transmitter, phase-locked

loop (PLL) frequency synthesizer, base band parts, power

supply, and control circuits.

2. Frequency Configuration

The receiver is a double-conversion superheterodyne

using first intermediate frequency (IF) of 49.95MHz and

second IF of 450kHz. Incoming signals from the antenna are

mixed with the local signal from the PLL circuit to produce

the first IF of 49.95MHz.

This is then mixed with the 50.4MHz second local

oscillator output to produce the 450kHz second IF. This

signal is detected to give the demodulated signal in the DSP.

The transmit signal frequency is generated by the PLL

VCO, and modulated by the signal from the DSP. It is then

amplified and fed to the antenna.

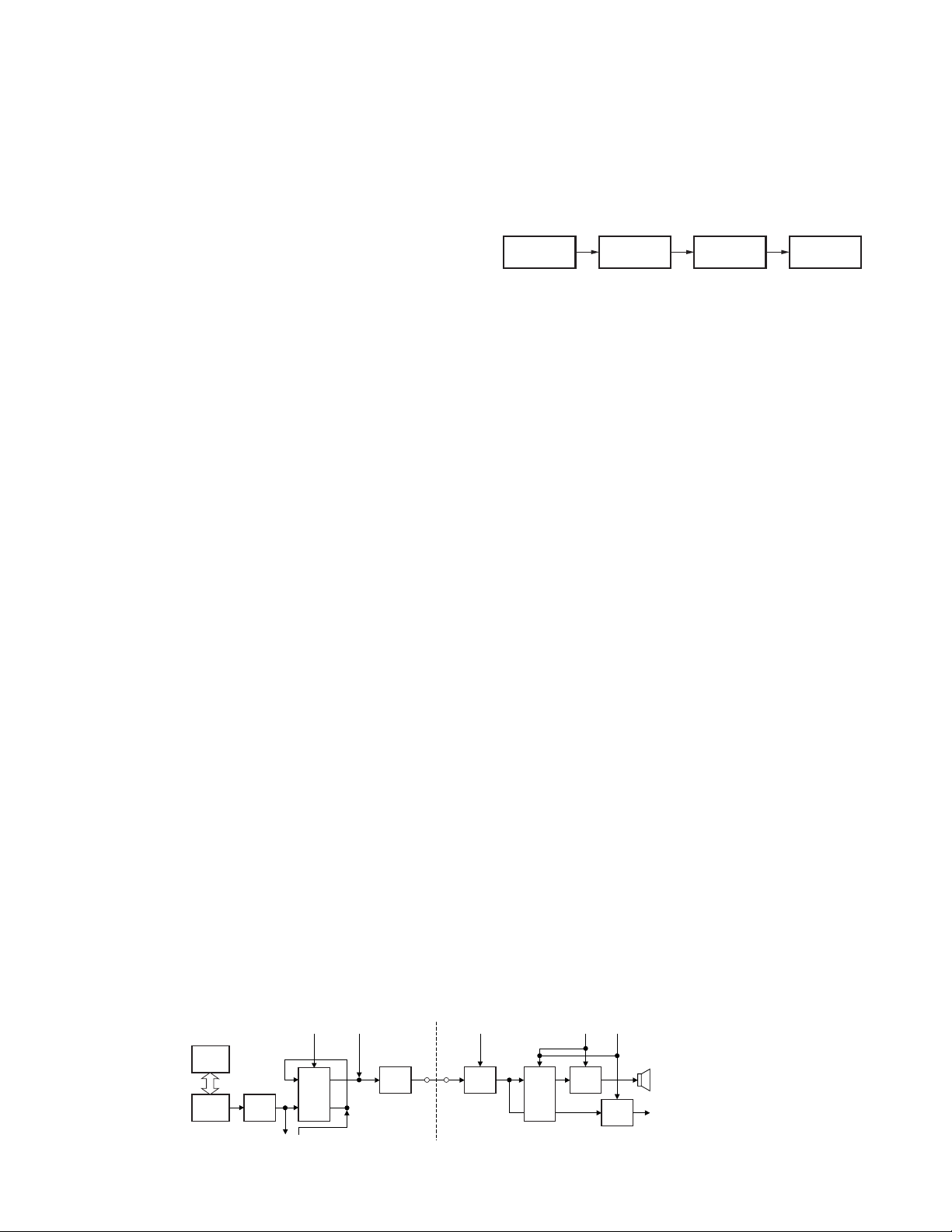

ANT

TX/RX : 136~174MHz

PA

RF

AMP

TX

AMP

ANT

SW

AMP

1st MIX

49.95MHz

16.8MHz

VCXO

185.95~

223.95MHz

136~174MHz

MCF

450kHz

IF AMP

x3

50.4MHz

CF

MIX

PLL

VCO

FPGA

A/D

D/A

DSP

AF

AMP

MIC

AMP

SP

MIC

Fig. 1 Frequency configuration

3. Receiver System

3-1. Front-end RF Amplifier

The signal is passed through an antenna matching coil,

where the high-frequency components are amplified by a

GaAs FET(Q202). The signals are then fed into band-pass

filter that uses varactor diode tuning to reject unwanted

signal components, and is fed to the 1st mixer.

3-2. 1st Mixer

The 1st mixer uses the GaAs IC (IC202). The 1st mixer

mixes the signal with the 1st local oscillator frequency from

the VCO, and converts it to the 1st IF (49.95MHz).

The signal then passes through monolithic crystal filter

(XF201) to remove unnecessary nearby frequency

components. The signal from the MCF is used as the 1st IF

signal.

2nd IF of 450KHz. The 450KHz signal is then passed through

a ceramic filter (CF201) and fed back into IC204 for additional

amplification.

L202

TUNE

Q202L201

BPF BPF BPF

LNA MIXER

XF201

MCF

49.95MHz

L204 L205 IC202

BPF

Q204

IF AMP

CF201

IC204

FM IC

1st

Tripler

VCXO

2nd Local OSC

Q205

X3

X201

16.8MHz

1st Local OSC

Fig. 2 Receiver section

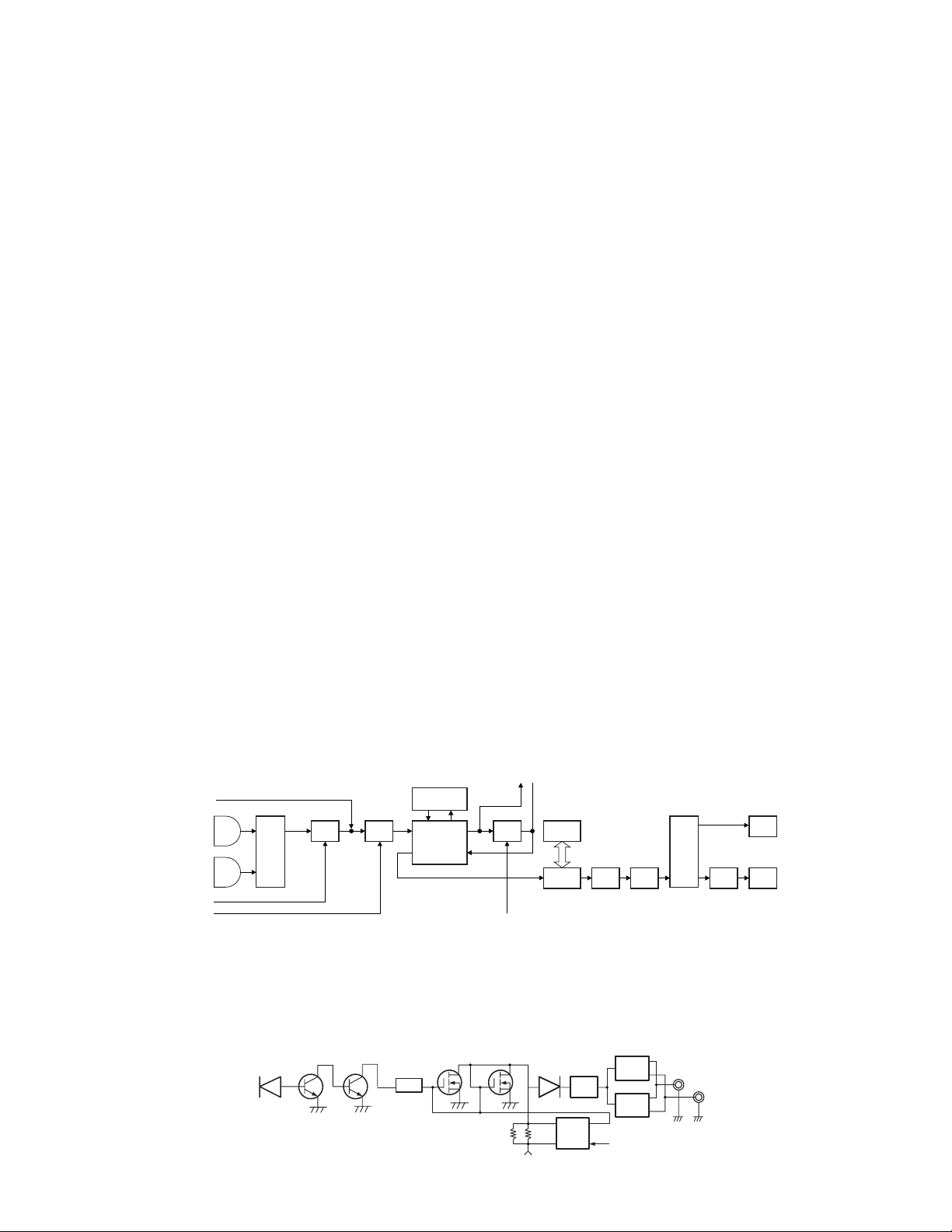

3-4. Wide/ Narrow/ APCO Switching Circuit

Narrow and Wide and APCO settings can be made for

each channel by switching the ceramic filters CF203 (Wide),

CF204 (Narrow), CF202 (APCO).

The Wide and Narrow and APCO data is output from pin54

(WN) and pin55 (VN) of CPU (IC5).

When a Wide data (VN : low level, WN : high level) is

received, the 450KHz signal is passed through a ceramic filter

(CF203). When a Narrow data (VN : low level, WN : low level)

is received, the 450KHz signal is passed through a ceramic

filter (CF204). When a APCO data (VN : high level, WN : high

level) is received, the 450KHz signal is passed through a

ceramic filter (CF202).

If the 450kHz signal is a FM signal(Wide, Narrow), the

signal is detected by a ceramic discriminator (CD201). AF

signal is fed to CODEC(IC406), the AF level is adjusted and it

is output from 15pin of IC406. Q209 turns on/off with the

Wide/Narrow data and the IC204 detector output level is

changed to maintain a constant output level during Wide or

Narrow signals.

If the 450kHz signal is an APCO signal, the signal is

prepared by the buffer amplifier (IC208) and fed to FPGA

(IC13). The APCO signal is A/D-converted by the FPGA and

DSP (IC8), and is performed APCO demodulation.

The AF signal is output from 15pin of CODEC (IC406).

VN WN

HH

L

L

49.95MHz

Filter

APCO

HLWide

Narrow

450kHz

IC203

CF201

CF202

APCO

CF204

IC204

FM IC

Narrow

CF203

Wide

IC206

WN WN

IC207

IC205

VNVN

CD201

AF

APCO

CD

DET

3-3. IF Amplifier

The 1st IF signal is amplified by the IF amplifier (Q204) and

fed into the FM IC (IC204). The IF signal is then mixed with

the 2nd local oscillator frequency of 50.4MHz to generate the

50.4MHz

Q205

x3

X201

VCXO

16.8MHz

Fig. 3 Wide/Narrow/APCO switching circuit

13

TK-5210

CIRCUIT DESCRIPTION

3-5. Audio Amplifier Circuit

• AF signal

The AF signal from CODEC (IC406) is amplified by IC407

and goes through IC408.

The AF signal goes through a DAC (IC411), an AF amplifier

(IC603), and an AF switch (IC604), and is routed to audio

power amplifier (IC601), where the signal is amplified and

output to the internal speaker.

•Audio circuit

CODEC (IC406) extracts the audio signal from the receive

signal in the detection circuit in FM mode. The signal is then

deemphasized and output as a decoded audio signal in APCO

mode.

LPF (IC407) removes quantization noise from the audio

signal output of the CODEC.

The switch (IC408) stops the audio signal of the CODEC to

prevent the mixing of BEEP, voice announcement and audio

signal when the BEEP or voice announcement is output from

the CPU. If an optional scrambler board is installed, the audio

path is adjusted so that the audio signal goes through the

scrambler board.

DAC (IC411) controls the voltage amplitude level of the

audio signal according to the volume position of the

transceiver. This determines the volume level output from

the speaker.

The amplifier (IC603) amplifies the audio signal so that the

audio signal level at the final stage amplifier is appropriate.

The volume levels of the 8Ω internal speaker and 16Ω

external speaker are matched using the EXT AFC.

The switch (IC604) adjusts the signal path so that the

audio signal is output to the audio amplifier (IC602) for

external speakers when optional external speakers are

connected. If no external speakers are connected, the audio

signal is output to the audio amplifier (IC601) for the internal

speaker.

IC601 and IC602 output is BTL (Bridge Tied Load).

• AF control

Speaker switching is performed by the CPU (IC5) using

INT AFC or EXT AFC. First, the logic level at the speakers

switching terminal (SSW) on the universal connector is fed to

the CPU. The CPU then outputs data based on this input.

When there is no SP-MIC installed, this logic level

becomes high. When the INT AFC is high, the EXT AFC goes

low, so the AF signal is only fed to the amplifier for the

internal speaker (INT SP) of IC601.

However, when a SP-MIC has been connected, this logic

level becomes low, so the INT AFC goes low and the EXT

AFC goes high. In this case, the AF signal is fed only to

amplifier for the external speaker (EXT SP) of IC602.

3-6. Squelch Circuit

It amplifies the demodulated noise signal from FM IC

(IC204) after filtering through BPF circuit. Then, the amplified

signal is converted to DC signal by the detection circuit. The

converted signal is fed to the CPU (IC5).

IC403

LPF AMP

Q412

Noise AMP

D404

DET

IC5

CPU

Fig. 5 Squelch circuit

4. Transmitter System

4-1. Audio Band Circuit

The audio band circuit of the transmitter system consists

of the following:

• Microphone (Main)

• Microphone (Sub)

• N/C amplifier (Noise canceling mic amplifier) (IC603)

• Switch (Int/ext) (Q410)

• Switch (Mic mute) (Q406)

• AGC (IC405, D402, D403)

• Switch (Scrambler board) (Q407)

This transceiver has two types of microphones: main and

sub. The main microphone is located at the front of the

cabinet and the sub microphone is located at the rear of the

cabinet. The audio signal input from these microphones is

synthesized by the N/C amplifier (IC603). The audio signal

from the main microphone is synthesized in normal phase

and the audio signal from the sub microphone is synthesized

in opposite phase. So if the same audio signal is applied in the

same phase to the main and sub microphones, it is cancelled

by the N/C amplifier. If audio signal is input to only the main or

sub microphone, it is not cancelled, but output from the N/C

amplifier.

This prevents ambient noise from entering the audio band

circuit at the next or subsequent stages.

When an optional external speaker microphone is

installed, the Int/ext switch (Q410) cuts off the audio signal

from the main and sub microphones and sends only the audio

signal from the external microphone to the next stage.

The microphone mute switch (Q406) cuts off audio

signals from the main, sub and external microphones.

AGC (IC405, D402, D403) is an amplifier that reduces gain

automatically by greatly increasing the attenuation when the

audio signal of a certain level or higher is present. It controls

the gain so that the audio signal input to the CODEC (IC406)

is not clipped.

If an optional scrambler board is installed, the switch

14

IC8

DSP

IC406

CODEC

TX-RX (X57-682 A/5) CONTROL (X57-682 B/5)

IC407

LPF

Scrambler board

IC408

SW

BEEPS/

SCSW

BEEP/

voice announce

IC411

DAC

EXT AFC EXT AFC

IC603

AMP

IC604

SW

INT AFC

IC601

AMP

Fig. 4 Audio circuit diagram

IC602

AMP

INT SP

universal connector

EXT SP

CIRCUIT DESCRIPTION

TK-5210

(Q407) adjusts the signal path so that the audio signal is input

to the CODEC through the scrambler board.

The audio signal is input to the CODEC (base band circuit)

through the above path.

4-2. Base Band Circuit

The base band circuit of the transmitter system consists

of the following:

• CODEC (IC406)

• DSP (IC411)

• LPF (IC407)

• Buffer (IC409)

• DAC (IC411)

•Amplifier (IC412)

The audio signal output from the base band circuit is

converted to digital data of a sampling frequency of 48 kHz

and a quantization resolution of 16 bits by the CODEC

(IC406). This digital data is sent to the DSP (IC8), and voice

signals of 300 Hz or lower and frequencies of 3 kHz or higher

are cut off and an audio range 300 Hz to 3 kHz is extracted.

The audio signal is then pre-emphasized in FM mode and

synthesized with the signals, such as QT and DQT, as

required, and is then output from the CODEC. In APCO

mode, the audio signal is converted to the C4FM base band

signal and output from the CODEC. The DTMF and MSK base

band signals are also generated by the DSP and output by the

CODEC.

LPF (IC407) removes quantization noise from the base

band signal output from the CODEC.

The buffer (IC409) sets the base band signal level to the

DAC input range.

The DAC (IC411) assigns the base band signal to the VCO

(Q311) and VCXO (X301).

At this time, the level output according to the transmit

carrier is fine-adjusted according to the modulation method

of FM Wide, FM Narrow and APCO.

EXT.MIC

MIC(MAIN)

MIC(SUB)

MSW/CTS

MM

IC603

N/C

AMP

MIC

Q410

SW

Q406

SW

D402,D403

DET

AGC-AMP

IC405

LPF

4-3. Transmit Signal Amplification Circuit

(From T/R switch to Final amplifier)

The transmit signal passing through the T/R switch

(D101) is amplified to approx. 50 mW by the two transistor

amplification circuits (Q101, Q102). The transmit signal

output from Q102 passes through a 3dB attenuator to

improve high-frequency signal matching is amplified by the

drive amplifier (Q103) and applied to the final amplifier

(Q105). The signal applied to the final amplifier is amplified by

the final amplifier so that the antenna output is 5 W (1 W for

Low Power).

4-4. High-Frequency Signal Switch Circuit

(From Antenna switch to ANT output)

The transmit signal output from the final amplifier (Q105)

passes through the antenna switch (D106, D107) and LPF,

and goes into the SPDT switch (IC102, IC103) which changes

the antenna connector (CN101) and the universal connector

(CN102).

The transmit signal passing through the output change

switch passes through the surge protection HPF and

spurious removing LPF and then goes to the antenna

connector (CN101) or the universal connector (CN102),

specified by the SPDT switch (IC102, IC103).

4-5. APC Circuit

The APC circuit detects the current of the drive amplifier

(Q103) and final amplifier (Q105) during transmission and

controls the output power by controlling the current.

It detects the current using R119 and R120 and applies a

drop voltage between both resistors during transmission to

APC (IC101). It controls the transmission current of the drive

amplifier and final amplifier so that it is constant by

comparing this current with the reference voltage output

from pin 7 of IC104. The reference voltage input to pin 5 of

IC104 is output from the DAC (IC411). High/Low power

output is set according to the DAC output voltage.

Scrambler board

IC412

AMP

Q311

VCO

X301

VCXO

Q407SWIC8

SCSW

DSP

IC406

CODEC

IC407

LPF

IC409

BUFF

IC411

DAC

Fig. 6 Audio band and Base band circuit

4-6. Temperature Protection Circuit

The temperature protection circuit reduces the APC

voltage when the temperature of Q105 rises, to prevent

thermal destruction of the final amplifier (Q105). The CPU

D101

T/R SW

Q101

Pre Pre

Drive Amp

Q102

Pre

Drive Amp

3dB

Attenuator

Q103

Drive Amp

Fig. 7 Transmitter circuit

(IC5) detects the temperature with a thermistor (TH101) to

control the reference voltage to the APC circuit.

LPF

IC102,IC103

SPDT

APC SW

CN101

CN102

Q105

Final Amp

D106,D107

R119+BR120

ANT SW

IC101

APC

15

TK-5210

T/R

IC414

V-assist

TX: 272~348MHz

RX: 371.9~447.9MHz

RHE

PCS

DAT

CLK

LE

DAT

CLK

IC304 Q314 D101

to pre-pre-drive

LPF VCO

1/2 BUFF SW

UL CV

IC5

IC303 Q312 D210

to 1st mixer

(Q101)

(IC202)

CPU

PLL

LPF

BUFF SW

MOD

X301 IC411

VCXO DAC

CIRCUIT DESCRIPTION

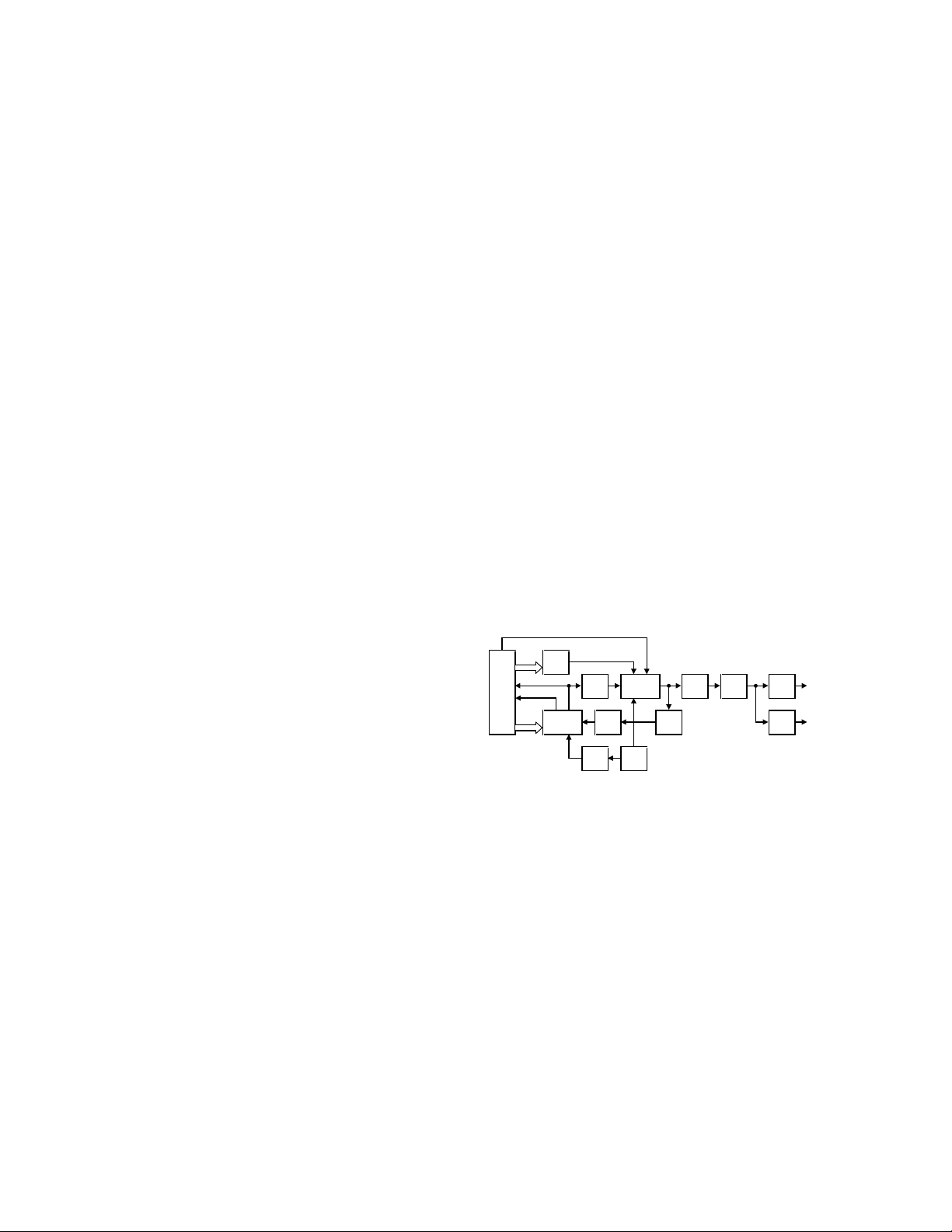

5. PLL Frequency Synthesizer

The PLL Frequency Synthesizer consists of the following

components:

• VCXO (X301)

• VCO (Q310, Q311)

• Rheostat (IC414)

• PLL IC (IC303)

• 1/2 divider (IC304)

• Local switch (D101, D210)

5-1. VCXO (X301)

VCXO (X301) generates a reference frequency of 16.8

MHz for the PLL frequency synthesizer. This reference

frequency is applied to pin 8 of the PLL IC (IC303).

The VCXO oscillation frequency is fine-adjusted by

controlling the voltage applied to pin 1 of the VCXO with DAC

(IC411). It is also controlled with pin 1 of the VCXO if the

output from VCXO is modulated.

5-2. VCO

There is a RX VCO and a TX VCO.

The TX VCO (Q311) generates a transmit carrier and the

RX VCO (Q310) generates a 1st local receive signal.

For the VCO oscillation frequency, the transmit carrier is

272 to 348 MHz and the 1st local receive signal is 371.9 to

447.9 MHz.

The VCO oscillation frequency is determined by one

system of operation switching terminal "T/R" and two

systems of voltage control terminals "C/V" and "V-assist".

The operation switching terminal, "T/R", is controlled by

the control line (T/R) output from the CPU (IC5). When the T/

R logic is low, the VCO outputs the transmit carrier and when

it is high, it outputs a 1st local receive signal.

The voltage control terminals, "CV" and "V-assist", are

controlled by the PLL IC (IC303) and rheostat (IC414) and the

output frequency changes continuously according to the

applied voltage. For the modulation input terminal, "MOD",

the output frequency changes according to the applied

voltage. This is used to modulate the VCO output. "MOD"

works only when "T/R" is low.

difference increases when the set frequency is changed. To

supplement this, the rheostat is used before control by the

PLL IC to bring the VCO oscillation frequency close to the

desired frequency. As a result, the VCO CV voltage does not

change and is always stable at approx. 2 V.

The desired frequency is set for the PLL IC by the CPU

(IC5) through the 3-line "LE", "DAT", "CLK" serial bus. Whether

the PLL IC is locked or not is monitored by the CPU through

the “UL” signal line. If the VCO is not the desired frequency

(unlock), the "UL" logic is low.

5-5. 1/2 divider (IC304)

The 1/2 divider (IC304) inputs the transmit carrier and the

1st local receive signal output from the VCO and divides each

frequency by 1/2. The frequency divided by 1/2 becomes a

carrier that is actually sent and a 1st local receive signal that is

actually input to a mixer. (Both the VCO and the PLL IC

operate with double frequencies in phase locked loops.)

5-6. Local Switch (D101, D210)

The connection destination of the signal output from the

1/2 divider (IC304) is changed with the diode switch (D101)

that is controlled by the transmission power supply, 5T, and

the diode switch (D210) that is controlled by the receive

power supply, 5R.

If the 5T logic is high, it is connected to a send-side prepre-drive (Q101). If the 5T logic is low, it is connected to a

receive-side mixer (IC202).

Fig. 8 PLL block diagram

5-3. Rheostat (IC414)

The rheostat (IC414) is connected to the VCO voltage

control terminal, "V-assist", and quickly controls the VCO

oscillation frequency. However, its accuracy is low and the

VCO frequency cannot be matched accurately with the

desired transmit carrier or the 1st local receive signal.

The rheostat is controlled by the CPU (IC5) through the 3line "PCS", "DAT", "CLK" serial bus.

6. Control Circuit

The control circuit consists of CPU (IC5) and its peripheral

circuits. It controls the TX-RX unit and transfers data to the

Control unit. IC5 mainly performs the following;

1) Switching between transmission and reception by PTT

signal input.

2) Reading system, zone, frequency, and program data from

the memory circuit.

5-4. PLL IC (IC303)

PLL IC compares the differences in phases of the VCO

oscillation frequency and the VCXO reference frequency,

returns the difference to the VCO CV terminal and realizes

the "Phase Locked Loop" for the return control. This allows

the VCO oscillation frequency to accurately match (lock) the

desired frequency.

When the frequency is controlled by the PLL, the

frequency convergence time increases as the frequency

16

3) Sending frequency program data to the PLL.

4) Controlling squelch on/off by the DC voltage from the

squelch circuit.

5) Controlling the audio mute circuit by decode data input.

6) Transmitting tone and encode data.

6-1. Memory Circuit

Memory circuit consists of the CPU (IC5) and a flash

memory (IC6). A flash memory has a capacity of 16M bits and

CIRCUIT DESCRIPTION

TK-5210

contains the transceiver control program for the CPU. It also

stores the data for transceiver channels and operating parameter that are written by the FPU. This program can be easily

written from an external devices.

The EEPROM (IC2) stores the last channel data, the scan

on status, and other parameters.

■ Flash memory

Note : The flash memory stores the data that is written by

the FPU (KPG-95D), and firmware program (User mode, Test

mode, Tuning mode, etc.). This data must be rewritten when

replacing the flash memory.

■ EEPROM

Note : The EEPROM stores tuning data (Deviation, Squelch,

etc.).

Realign the transceiver after replacing the EEPROM.

■ Real-time clock

The clock function is based on real-time clock IC (IC1).

When the power supply is off, it is backed up by an internal

secondary lithium battery

IC5

CPU

FLASH

IC6

IC2

EEPROM

Fig. 9 Memory circuit

IC5

CPU

IC8

DSP

IC13

FPGA

IC406

CODEC

9.216MHz

9.216MHz

IC14

(2/3,3/3)

18.432MHz

18.432MHz

IC12

IC14

(1/3)

X2

VCXO

18.432MHz

Fig. 10 Clock diagram

6-2. LCD (K2 and K3 models only)

The LCD is controlled using the bus lines on the connector

(CN604) of the control unit (X57 B/5).

It corrects the LCD contrast voltage using IC704. The

voltage corresponding to the temperature is sent to pin 3 of

IC704 from the CPU (IC5) according to the temperature

measurement results using a temperature IC (IC4).

6-3. Temperature Detection Circuit

The temperature detection circuit detects the

temperature using a temperature IC (IC4) and corrects the

thermal characteristic change of the squelch or LCD.

6-4. Key Detection Circuit

Keys are detected using three shift registers (IC701,

IC702, IC703).

The KIN signal that is normally pulled down goes high

when any key is pressed.

6-5. Low Battery Warning

The battery voltage is divided using R15 and R16 and is

detected by the CPU (IC5). When the battery voltage falls

below the voltage set by the Low battery warning

adjustment, the red LED blinks to notify the operator that it is

time to replace the battery. If the battery voltage falls even

more (approx. 5.8V), a beep sounds and transmission stops.

Low battery warning Battery condition

The red LED blinks during The battery voltage is low but

transmission. the transceiver is still usable.

The red LED blinks and The battery voltage is low and

the warning tone beeps while the transceiver is not usable to

the PTT switch is pressed. make calls.

6-6. VOX

The VOX function can be used only with an external

microphone.

The VOX (Voice Operated Transmission) function detects

voice input to the microphone and automatically switches

between transmission and reception. However, if a

scrambler board is installed (Extended Function Voice

Scrambler is selected with FPU), VOX does not operate.

If the microphone input exceeds a certain level,

transmission automatically begins. If the input falls below a

certain level, the transceiver automatically returns to receive

mode.

The TK-5210 realizes this function using DSP (IC8).

6-7. DSP

The DSP circuit consists of a DSP (IC8), a CODEC (IC406)

and processes the base band signal. The DSP operates on an

external clock of 9.216MHz (the same as the CPU), the I/O

section operates at 3.3V and the core section operates at

1.5V. The DSP carries out the following processes:

• C4FM encoding

• Analog FM pre-emphasis/de-emphasis

• Vocoder (IMBE) processing between audio codec and

modulation/demodulation

• CAI processing, such as error correction encoding

• QT/DQT encoding/decoding

• DTMF encoding/decoding

• MSK encoding/decoding

• 2-tone decoding

• Compressor/expander processing

• Transmit/receive audio filtering processing

• VOX processing

• Microphone amplifier AGC processing

• Audio mute processing

•Modulation level processing

17

TK-5210

CIRCUIT DESCRIPTION

6-8. FPGA

The FPGA(IC13) I/O section operates at 3.3V. and the core

section operates at 2.5V. The FPGA has the following function.

• Demodulation (C4FM,CQPSK)

• Shift register(8CH)

• Level convert Buffer amplifier(5V➝3.3V)(9CH)

• Generates 1.536MHz for the demodulation and CODEC.

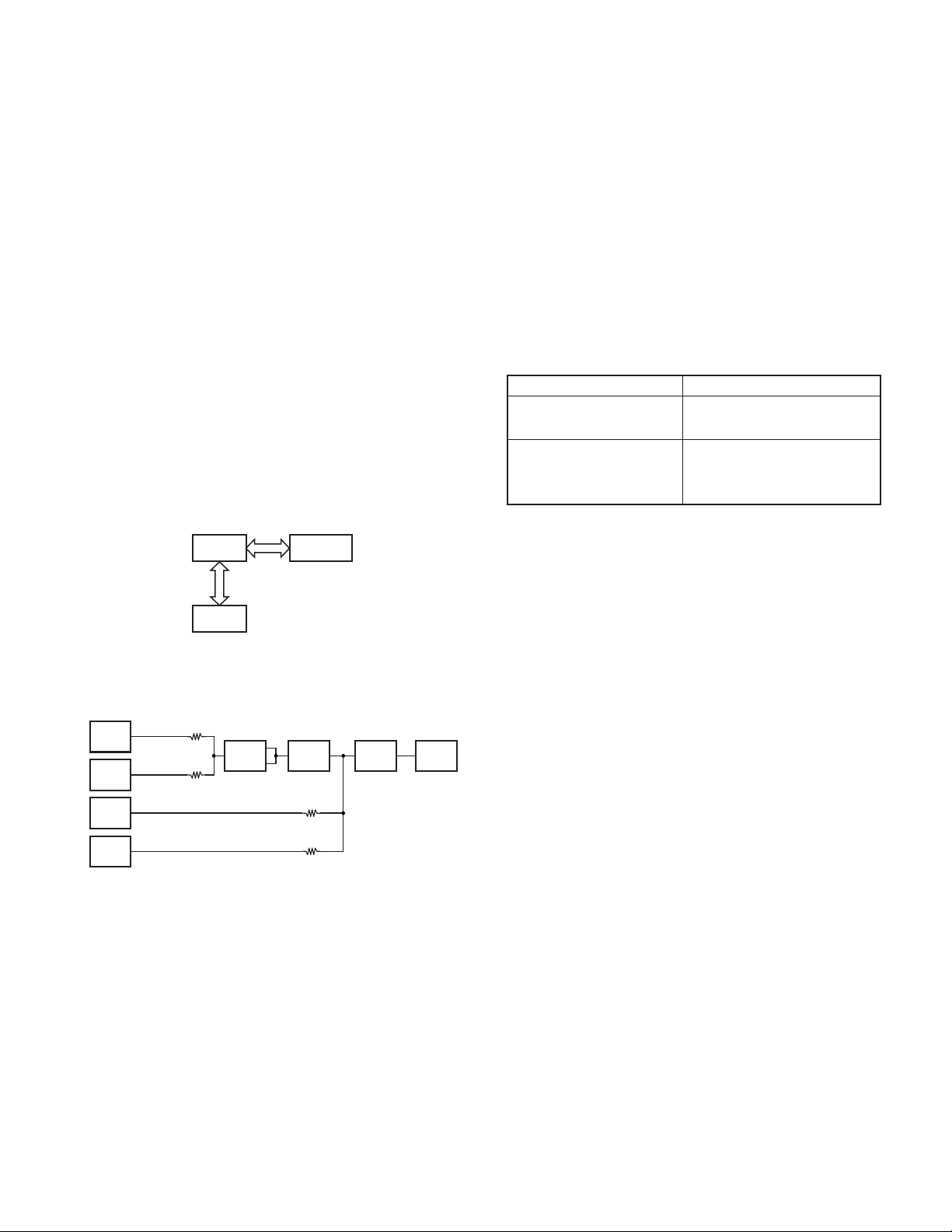

7. Power Supply Circuit

The battery voltage (+B) is provided from the battery

terminal on the TX-RX unit (X57 A/5).

The battery voltage passes through a 3A fuse (F401) and

goes to the VDD terminal of the DC/DC converter (IC805).

The +B voltage is detected by the voltage detection IC

(IC804). If the voltage is 5.6 V or higher, the IC805 CE pin

becomes high and the DC/DC converter begins.

The IC805 output voltage (3.6V) becomes a power supply

for five regulators (IC801, IC802, IC803, IC806, IC807).

The output from IC805 controls the CE pin of IC801,

IC802, IC803, IC806, IC807 by turning the VOL SW ON/OFF.

The CPU, DSP and FPGA start with the above five

regulators. After the CPU starts, two regulators (IC401,

IC402) begin operating with the PWR and 5CC signals output

from the CPU.

When the Power SW (Q415) is turned ON by the PWR

signal, the 15V DC/DC converter (IC808) is activated. IC807,

IC402, IC401 VDD is provided by +B.

The output from IC401 is switched to 5R that is turned ON

in receive mode and 5T that is turned ON in transmit mode

via CPU control. Output from IC807 includes two voltages:

5M that is always 5 V and 5MCS that is turned ON when an

option is installed on the universal connector.

8. Signaling Circuit

8-1. Encode (QT/DQT/DTMF/MSK)

Each signaling data signal of QT, DQT, DTMF and MSK is

generated by the DSP circuit, superposed on a modulation

signal and output from pin 16 of the CODEC (IC406).

The modulation balance of the QT/DQT signal is adjusted

by the D/A converter(IC411) and the resulting signal is routed

to the modulation input of the VCO and VCXO (X301).

The each deviation of the TX QT, DQT, DTMF and MSK

tone is adjusted by changing the output level of the CODEC

and the resulting signal is routed to VCO and VCXO. The RX

DTMF tone is output from pin 15 of the CODEC, passes

through the receive audio signal system, and is output from

the speaker.

8-2. Decode (QT/DQT/DTMF/2-tone/MSK)

The audio signal is removed from the FM detection signal

sent to the DSP circuit and the resulting signal is decoded.

9. Compander Circuit

The term “compander” means compressor and expander.

The compander reduces noise by utilizing a compressor and

an expander.

The TK-5210 contains DSP(IC8) to perform this operation.

The TK-5210 compander can be turned on or off using the

FPU.

18

3A Fuse

Batt

Drive, Final AMP

+B

+B

IC804

Detect

Q415

Power

SW

IC5

CPU

IC805

DC/DC

CE

S36M

PWR

PWR

PWR

3.6V

VOL

SW

SB

5CC

+B

IC801

AVR IC

CE

IC802

AVR IC

CE

IC803

AVR IC

CE

IC806

AVR IC

CE

IC606

AVR IC

IC808

DC/DC

CE

IC807

AVR IC

CE

IC402

AVR IC

CE

IC401

AVR IC

CE

CPU, FlashROM,

33M

EEPROM, VCXO,

33A

15D

2.5D

28M

15V

Q402

5R SW

CE

5MC

5C

Q402

5R SW

CE

5RC

Q401

5T SW

CE

5TC

DC/DC, AVR

FPGA (I/O)

DSP (I/O)

DSP Core

FPGA Core

RTC

LCD

VCO

5M

5MCS

5R

5T

Fig. 11

TERMINAL FUNCTION

TK-5210

TX-RX unit (X57-6820-XX A/5)

Pin

No.

1 DSR I Data set ready

2E -GND

3 RXD I Serial data input

4 TXD O Serial data Output

55M -5V

6 RTS1 O Request to Send

7 REM I Programmable function key input

8 PTT I External PTT input

9MICE - External MIC GND

10 EMC I External MIC input

11 MSW/CTS I EXT/INT MIC switch input

12 SP- O BTL output - for external speaker

13 SP+ O BTL output + for external speaker

14 SSW I EXT/INT speaker switch input

1 OPT1 O

2 OPT3 O

3 RXD1 I Serial data intput(VGS-1)

4 TXD1 O PTT (Scrambler board)

5NC-No connection

6 OPT4 I/O Echo PTT (Scrambler board)

7 USEL - GND

8 OPT5 O

9 DGND - GND

10 AGND - GND

11 AI I VGS Audio Input (VGS-1)

12 AO O VGS Audio Output (VGS-1)

13 AGND - GND

14 5A - 5V

15 STON I Side tone input(ANI board)

16 DI/ANI I Data input (ANI board)

17 TCONT I Speaker mute signal (ANI board)

18 MAN DOWN O Man-down output (ANI board)

19 INH I MIC mute signal input (ANI board)

20 OPT2 O Scrambler control signal output

21 TXO O MIC signal output (Scrambler board)

22 RXEO O Audio signal output (Scrambler board)

23 RXEI I Audio signal input (Scrambler board)

24 TXI I MIC signal input (Scrambler board)

25 OPT6 O

Name I/O Function

CN7

CN14

Scramble code output 1 (Scrambler board)

O Channel busy (ANI board)

I Busy (VGS-1)

Scramble code output 2 (Scrambler board)

I Key (ANI board)

I Play (VGS-1)

O Serial data output (VGS-1)

O PTT (ANI board)

O Enable (VGS-1)

Scramble code output 4 (Scrambler board)

O Emergency (ANI board)

O Reset output(VGS-1)

(Scrambler board)

I Emergency signal input (ANI board)

Scramble code output 3 (Scrambler board)

Pin

No.

26 SB2 O Switched B output

1 LCS O LCD chip select

2 GND - GND

3D0 I/O Data bus 0

4D1 I/O Data bus 1

5D2 I/O Data bus 2

6D3 I/O Data bus 3

7D4 I/O Data bus 4

8D5 I/O Data bus 5

9D6 I/O Data bus 6

10 D7 I/O Data bus 7

11 RD - No connection

12 WR O WR bus

13 GND - GND

14 A0 O Address bus 0

1 GND - GND

2 GND - GND

3 MIC I External MIC input

4MICE - External MIC GND

5 SP+ I BTL output + for external speaker

6 PWR O Power control output

7 SP+ I BTL output + for external speaker

8 15V - 15V

9 SP- I BTL output - for external speaker

10 SB1 I Battery level input

11 SP- I BTL output - for external speaker

12 +B -

13 AF O Audio Output

14 +B -

15 VOL I Volume level input

16 +B -

17 CLK O Clock data output

18 +B -

19 GND - GND

20 LRST O LCD reset output

21 KIN I Key input

22 28M - 2.8V

23 EXAFC O External AF output

24 PSW I Power input after power switch

25 KES O Key counter clear to send

26 INAFC O Internal AF output

27 DAT O Data output

28 ECSW O Echo cancel MIC switch

29 TGL0 I Lever switch input 0

30 33M - 3.3V

31 TGL2 I Concentric switch input 2

32 33M - 3.3V

33 TGL1 I Concentric switch input 1

34 33A - 3.3V

35 CH_A I Rotary switch input 1

36 33A - 3.3V

Name I/O Function

CN19 (K2 and K3 models only)

CN408

Power input after passing through the fuse

Power input after passing through the fuse

Power input after passing through the fuse

Power input after passing through the fuse

19

TK-5210

TERMINAL FUNCTION

Pin

No.

37 CH_B I Rotary switch input 2

38 25D - 2.5V

39 CH_C I Rotary switch input 3

40 15D - 1.5V

41 CH_D I Rotary switch input 4

42 15D - 1.5V

43 PTT I PTT input

44 5M - 5V

45 NC - No connection

46 5M - 5V

47 oE O Shift register OE

48 LCDV - LCD contrast control voltage

49 DGND - GND

50 DGND - GND

Name I/O Function

Control unit (X57-6820-XX B/5)

Pin

No.

1 GND - GND

2 GND - GND

3 MIC O External MIC output

4MICE - External MIC GND

5 SP+ O BTL output + for external speaker

6 PWR I Power control input

7 SP+ O BTL output + for external speaker

8 15V - 15V

9 SP- O BTL output - for external speaker

10 SB1 O Battery Level output

11 SP- O BTL output - for external speaker

12 +B -

13 AF I Audio input

14 +B -

15 VOL O Volume level output

16 +B -

17 CLK I Clock data input

18 +B -

19 GND - GND

20 LRST I LCD reset input

21 KIN O Key output

22 28M - 2.8V

23 EXAFC I External AF input

24 PSW O Power output after power switch

25 KES I Key counter clear to send

26 INAFC I Internal AF input

27 DAT I Data input

28 ECSW I Echo cancel MIC switch

29 TGL0 O Lever switch output 0

30 33M - 3.3V

31 TGL2 O Concentric switch output 2

32 33M - 3.3V

33 TGL1 O Concentric switch output 1

34 33A - 3.3V

Name I/O Function

CN601

Power input after passing through the fuse

Power input after passing through the fuse

Power input after passing through the fuse

Power input after passing through the fuse

Pin

No.

35 CH_A O Rotary switch output 1

36 33A - 3.3V

37 CH_B O Rotary switch output 2

38 25D - 2.5V

39 CH_C O Rotary switch output 3

40 15D - 1.5V

41 CH_D O Rotary switch output 4

42 15D - 1.5V

43 PTT O PTT output

44 5M - 5V

45 NC - No connection

46 5M - 5V

47 oE I Shift register OE

48 LCDV - LCD contrast control voltage

49 DGND - GND

50 DGND - GND

1 INT SP- O BTL output - for internal speaker

2 INT SP- O BTL output - for internal speaker

3 INT SP+ O BTL output + for internal speaker

4 INT SP+ O BTL output + for internal speaker

5 INT MIC+ I Internal MIC input

6 INT MIC- - Internal MIC GND

1A0IAdrress bus 0

2 GND - GND

3WR IWR bus

4RD-No connection

5D7 I/O Data bus 7

6D6 I/O Data bus 6

7D5 I/O Data bus 5

8D4 I/O Data bus 4

9D3 I/O Data bus 3

10 D2 I/O Data bus 2

11 D1 I/O Data bus 1

12 D0 I/O Data bus 0

13 GND - GND

14 LCS I LCD chip select

1V4-LCD drive power supply

2V3-LCD drive power supply

3V2-LCD drive power supply

4V1-LCD drive power supply

5V0-LCD drive power supply

6VR-V0 voltage adjustment terminal

7NC-No connection

8NC-No connection

9NC-No connection

10 NC - No connection

11 NC - No connection

12 NC - No connection

13 Vout - Raising voltage output

14 VDD - 3.3V

Name I/O Function

CN603

CN604 (K2 and K3 models only)

CN751 (K2 and K3 models only)

20

TERMINAL FUNCTION

TK-5210

Pin

No.

15 NC - No connection

16 GND - GND

17 GND - GND

18 D7 I/O Data bus 7

19 D6 I/O Data bus 6

20 D5 I/O Data bus 5

21 D4 I/O Data bus 4

22 D3 I/O Data bus 3

23 D2 I/O Data bus 2

24 D1 I/O Data bus 1

25 D0 I/O Data bus 0

26 E/RD I RD bus

27 WR O WR bus

28 A0 O Adrress bus 0

29 LRST O LCD reset output

30 LCS O LCD chip select

1NC-No connection

2 L_MIC I Noise canceler MIC

3MICE - MIC GND

4 GND - GND

5 CH_A I Rotary switch input 1

6 CH_B I Rotary switch input 2

7 CH_C I Rotary switch input 3

8 CH_D I Rotary switch input 4

9 36M - 3.6V

10 S36M - 3.6V

11 33M - 3.3V

12 TGL0 I Lever switch input 0

13 TGL1 I Concentric switch input 1

14 TGL2 I Concentric switch input 2

15 BLED - Busy LED control

16 TXLED - TX LED control

17 ORG O Key scan signal output

18 VOL I Volume level input

19 L_KEY1 O Key scan signal output

20 GND - GND

1 PF2 O Key output (Side2 Key)

2 PF3 O Key output (Side3 Key)

3 L_KEY1 I Key input

4 L_PTTG I PTT GND

5 L_PTT I PTT input

6 PF1 O Key output (Side1 Key)

Name I/O Function

CN752

CN753

Option board unit (X57-6820-XX D/5)

Pin

No.

1 OPT1 I

Name I/O Function

CN901

Scramble code input 1 (Scrambler board)

I Channel busy (ANI board)

O Busy (VGS-1)

Pin

No.

2 OPT3 I

3 RXD1 O Serial Data output(VGS-1)

4 TXD1 I PTT (Scrambler board)

5NC-No connection

6 OPT4 I/O Echo PTT (Scrambler board)

7NC-No connection

8 OPT5 I

9 DGND - DGND

10 AGND - GND

11 NC - No connection

12 NC - No connection

13 AGND - GND

14 5A - 5V

15 STON O Side tone output(ANI board)

16 DI/ANI O Data output (ANI board)

17 TCONT O Speaker mute signal (ANI board)

18 MAN DOWN I Man-down input (ANI board)

19 INH O MIC mute signal output (ANI board)

20 OPT2 I

21 TXO I MIC signal input (Scrambler board)

22 RXEO I Audio signal input (Scrambler board)

23 RXEI O Audio signal output (Scrambler board)

24 TXI O MIC signal output (Scrambler board)

25 C3 I

26 SB2 I Switched B input

Name I/O Function

Scramble code input 2 (Scrambler board)

O Key (ANI board)

O Play (VGS-1)

I Serial Data input (VGS-1)

I PTT (ANI board)

I Enable (VGS-1)

Scramble code input 4 (Scrambler board)

I Emergency (ANI board)

I Reset input(VGS-1)

Scrambler control signal input (Scrambler board)

O Emergency signal output (ANI board)

Scramble code input 3 (Scrambler board)

Top panel unit (X57-6820-XX C/5)

Pin

No.

1 36M - 3.6V

2 S36M - 3.6V

3 GND - GND

4 VOL I Volume level input

5 33M - 3.3V

6 CH_A I Rotary switch input 1

7 TGL2 I Concentric switch input 2

8 TGL1 I Concentric switch input 1

9C -GND

10 CH_B I Rotary switch input 2

11 CH_D I Rotary switch input 4

12 CH_C I Rotary switch input 3

1 GND - GND

2 CH_A O Rotary switch output 1

Name I/O Function

CN902

CN903

21

TK-5210

TERMINAL FUNCTION

Pin

No.

3 CH_B O Rotary switch output 2

4 CH_C O Rotary switch output 3

5 CH_D O Rotary switch output 4

6 36M - 3.6V

7 S36M - 3.6V

8 33M - 3.3V

9 TGL0 O Lever switch output 0

10 TGL1 O Concentric switch output 1

11 TGL2 O Concentric switch output 2

12 BLED - Busy LED control

13 TXLED - TX LED control

14 ORG I Key scan signal input

15 VOL O Volume Level output

16 KIN I Key scan signal input

17 GND - GND

Name I/O Function

Universal connector

Pin

No.

1 SSW I EXT/INT speaker switch input

2 SP+ O BTL output + for external speaker

3SP− O BTL output − for external speaker

4 MSW I EXT/INT MIC switch input

5 EMC I External MIC input

6ME-External MIC GND

7 PTT I External PTT input

8PFIProgrammable function key input

9 OPT - No connection

10 E - GND

11 5M - 5V

12 TXD O Serial data output

13 RXD I Serial data input

14 NC(E) - Not used (GND)

Name I/O Function

22

SEMICONDUCTOR DATA

TK-5210

CPU:30625MGP193GP (TX-RX unit: IC5)

Pin

Port Name I/O Function

No.

1 VREF - A/D converter reference voltage input

terminal

2 AVCC - A/D converter power supply input

terminal

3 T/R O TX/RX switch (L:TX, H:RX)

4 BATT DET I(A/D) Battery detection terminal

5 NC(ANEX0) I NC (For expansion A/D)

6 LCDV O

7 VOICE O

8 SOE O Shift register OE

9ULIPLL unlock input

10 DAT O Common data

11 CLK O Common clock

12 SDA I/O EEPROM data

13 BYTE I Use as 8bit data bus (Vcc)

14 CNVSS I Use as memory expansion mode (Vss)

15 PCS O Potentiometer CS

16 NC - No connection

17 RESET I Reset input

18 XOUT - No connection

19 VSS1 - Power supply input

20 XIN - Clock input, 9.216MHz(18.432MHz/2)

21 VCC1 - Power supply input

22 NMI I NC