Kenwood RXDM-57 Service manual

COMPACT Hi-Fi COMPONENT SYSTEM

70%

RXD-M57MP-H/M57MP-S

SERVICE MANUAL

(HM-537MP)

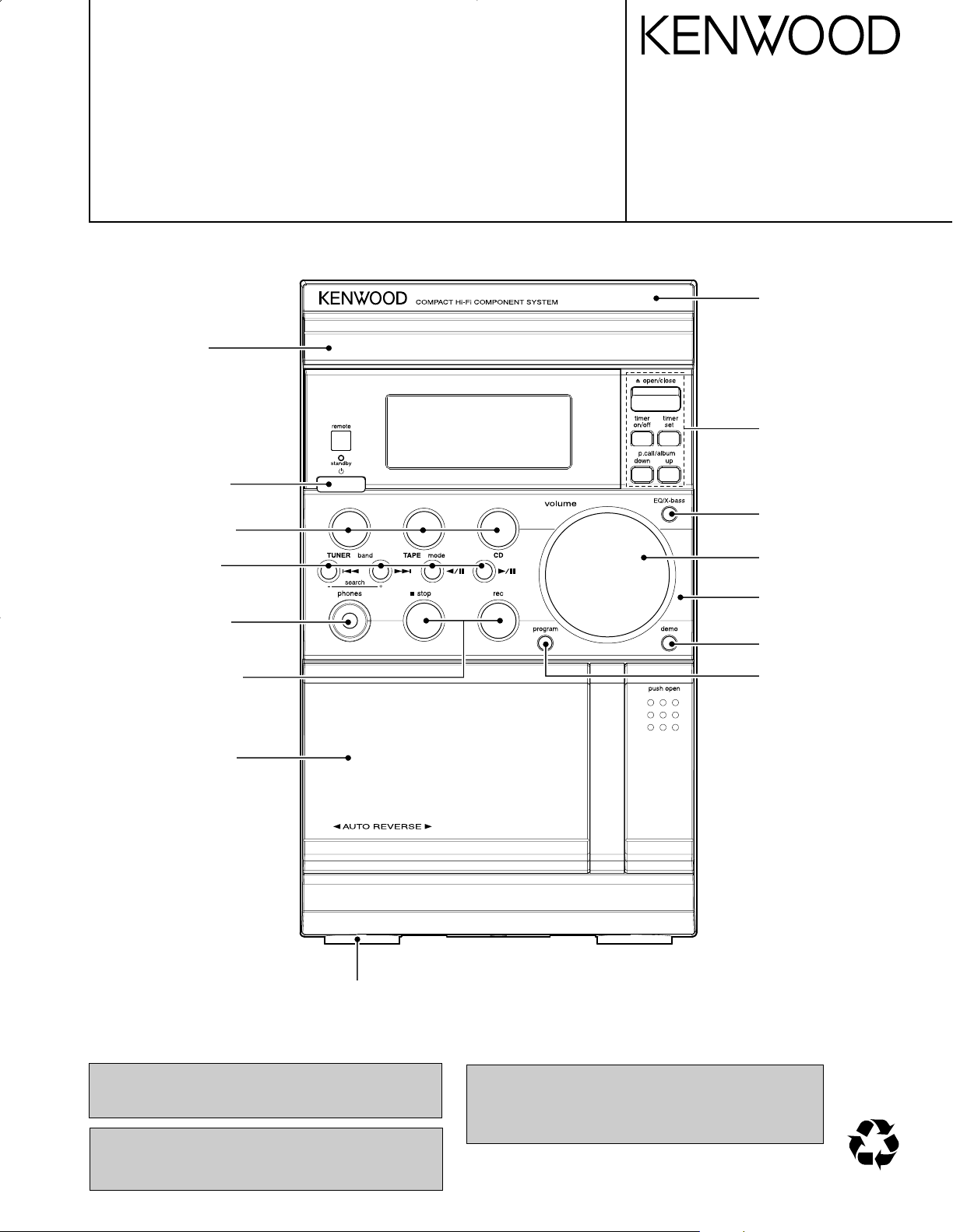

CD Door *

(A29-)

Knob(Power)

(K29-8417-08)

Knob(Function)

(K29-8414-08)

Knob(Play) *

(K29-)

Phone jack

(E11-0981-08)

Knob(Stop/REC)

(K29-8415-08)

© 2004-8 PRINTED IN KOREA

B51-5923-00 (K/K) 339

Front cabinet ass’y *

(A60-)

Knob(Open/Close)

(K29-8416-08)

Knob(EQ/Bass) *

(K29-)

Knob(Volume)

(K29-8413-08)

Control panel *

(A21-)

Knob(Demo) *

(K29-)

Knob(Prog) *

(K29-)

Cass lid ass’y *

(A53-)

Rubber foot

(G11-2961-08)

* Refer to parts list on page 20.

In compliance with Federal Regulations, following are reproduction of labels on, or inside the product relating to laser

product safety.

Caution : No connection of ground line if disassemble

the unit. Please connect the ground line on

rear panel, PCBs, Chassis and some others.

KENWOOD Corp. certifies this equipment conforms to DHHS

Regulations No.21 CFR 1040. 10, Chapter 1, subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM.

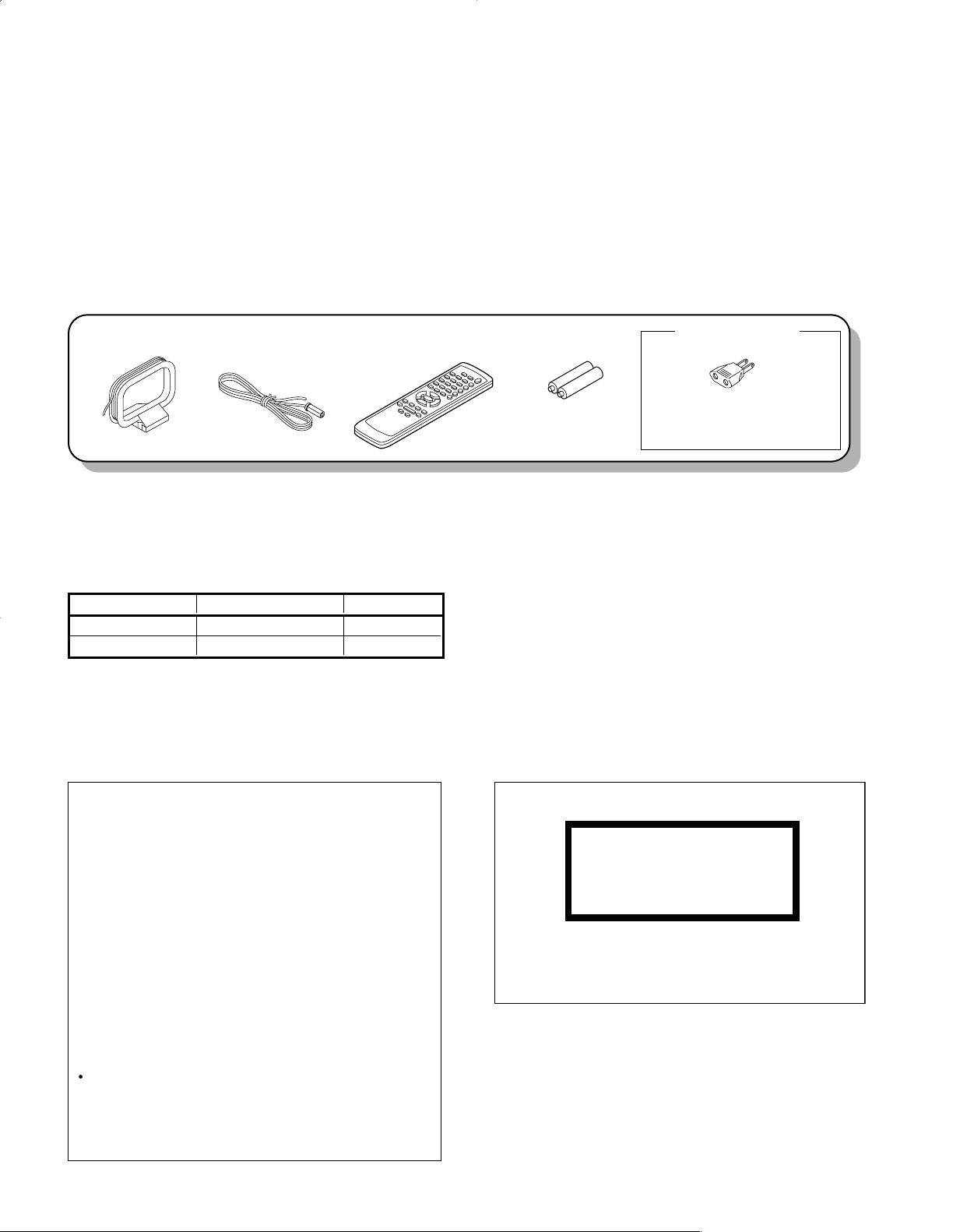

Remote control unit (1)

(A70-1688-08)

AM loop antenna (1)

(T90-0908-08)

FM ANT Wire (1)

(T90-0918-08)

Batteries (R6/AA) (2)

AC plug adapter (1)

(E03-0115-05)

Use to adapt the plug on the power

cord to the shape of the wall outlet.

(Accessory only for regions where

use is necessary.)

RXD-M57MP

CLASS 1 LASER PRODUCT

LASER KLASSE 1

APPAREIL A LASER DE CLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

The marking this product has been classified as Class 1.

It means that there is no danger of hazardous radiation

outside the product.

Location: Bottom

Resetting the Microcomputer

The microcomputer may malfunction (unit cannot be operated, or shows an erroneous display) if the power cord is unplugged while the

power is ON, or due to some other external

factor. If this happens, execute the following

procedure to reset the microcomputer and

return the unit to its normal operating condition.

Plug in the AC power cord to the wall outlet,

and within 5 seconds, press and hold down

the

7

button and press CD button.

Please note that resetting the microcomputer

will clear the contents of the memory and

return the unit to the state it was in when it

left the factory .

SYSTEM RECEIVER SPEAKERS

HM-537MP-H RXD-M57MP-H LS-M57-H

HM-537MP-S RXD-M57MP-S LS-M57-S

CONTENTS / ACCESSORIES / CAUTIONS

CONTENTS

CONTENTS / ACCESSORIES / CAUTIONS...............2

EXTERNAL VIEW ........................................................3

ADJUSTMENT .............................................................4

PC BOARD ..................................................................8

ACCESSORIES

SCHEMATIC DIAGRAM ............................................13

EXPLODED VIEW .....................................................19

PARTS LIST...............................................................20

SPECIFICATIONS..................................BACK COVER

SYSTEM CONFIGURATION

CAUTIONS

2

220-240V

110-120V

VOLTAGE

SELECTOR

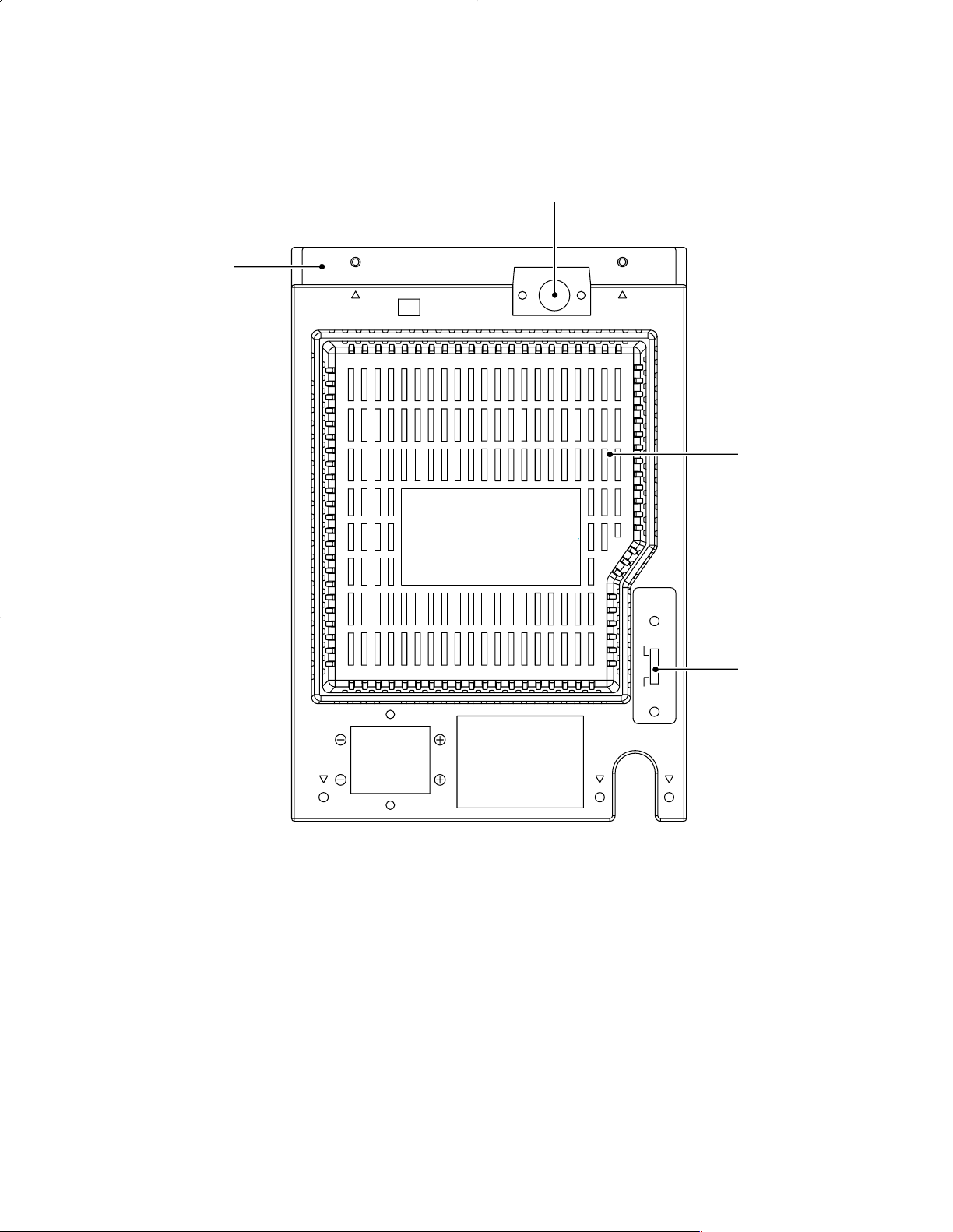

Top cabinet

(A01-3943-08)

RXD-M57MP

EXTERNAL VIEW

FM 75 ohm Ant.

(E70-0200-08)

Rear cabinet

(A80-4494-08)

* Refer to parts list on page 20.

Voltage SW. *

(S62-0124-08)

3

RXD-M57MP

SERVICE ADJUSTMENT

Lubrication

The mechanical parts are factory coated with a thin coat of light grease and should not require further

lubrication. If a light grease is applied, be careful not to get any grease on the play/record head or erase

head, hubs, pulleys, tapes reels, drive belts, or switches. Use a good lubricant such as Silicon Lube G322L

or Lubricate.

Service Check

Before aligning the mechanism, wipe off any accumulated dirt with denatured alcohol. Wipe around parts

where the tape contacts and around all rotating parts. Drive belts are specially processed. Do not clean

them with alcohol.

Mechanical Torque

Use a cassette type torque gauge and check the tape mechanism.

Take-up torque 35 to 70 g-cm

Rewind torque 50 g-cm min.

Fast forward torque 50 g-cm min.

Pinch Wheel Pressure

No adjustment to the pinch roller spring is necessary. It should be sufficient to give at least 40 g-cm pull

force.

Tape Head Servicing

Each time the unit is serviced, the face of all heads should be thoroughly cleaned with denatured alcohol or

commercial head cleaning solution. The playback head should be demagnetized with a commercial

demagnetizer. Accumulation of tape oxide during normal operations can cause problems, including loss of

high frequencies and wow and flutter.

Erase Head

The erase head is properly aligned when the tape rides directly between the tape guide on the head without

crinkling the tape.

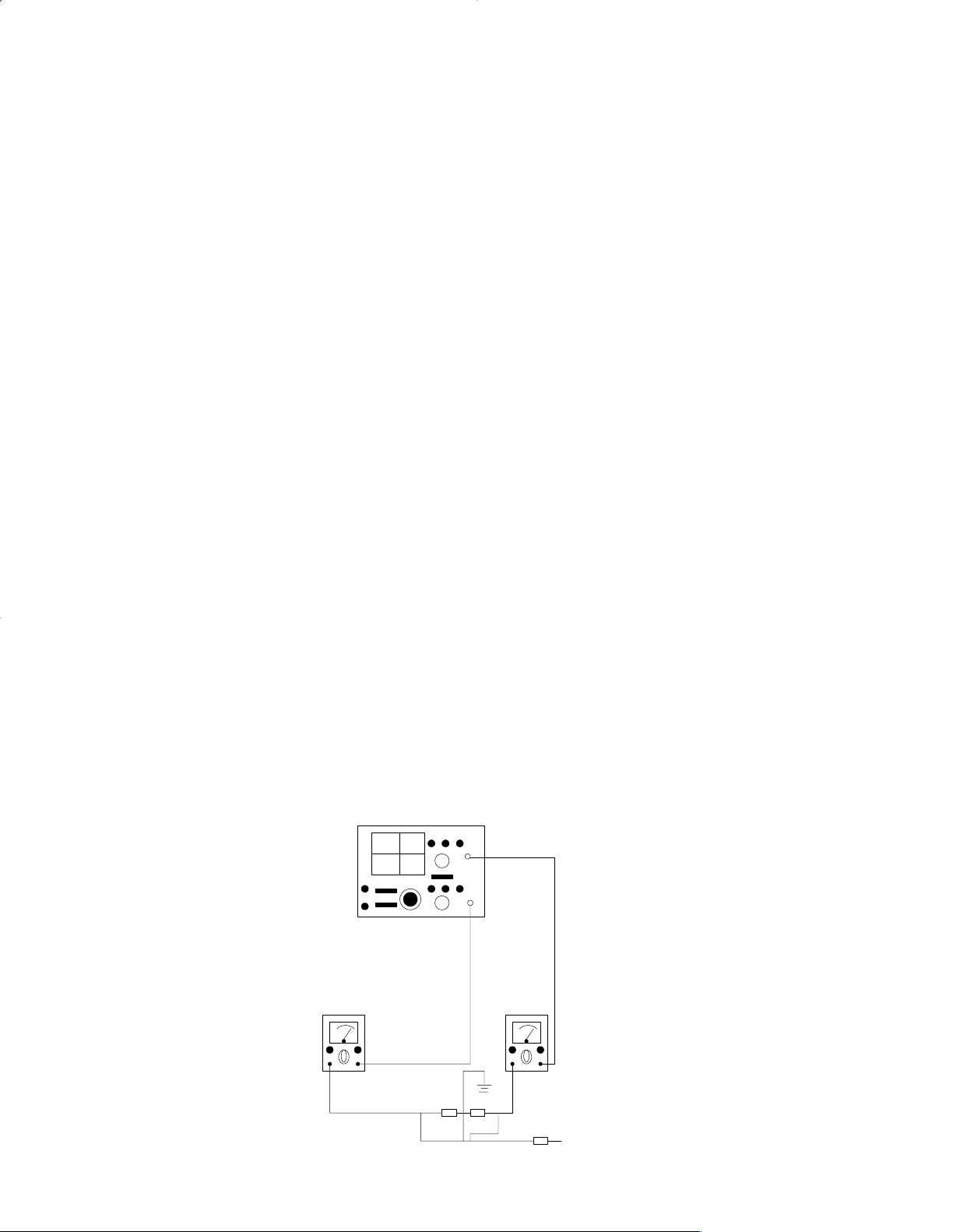

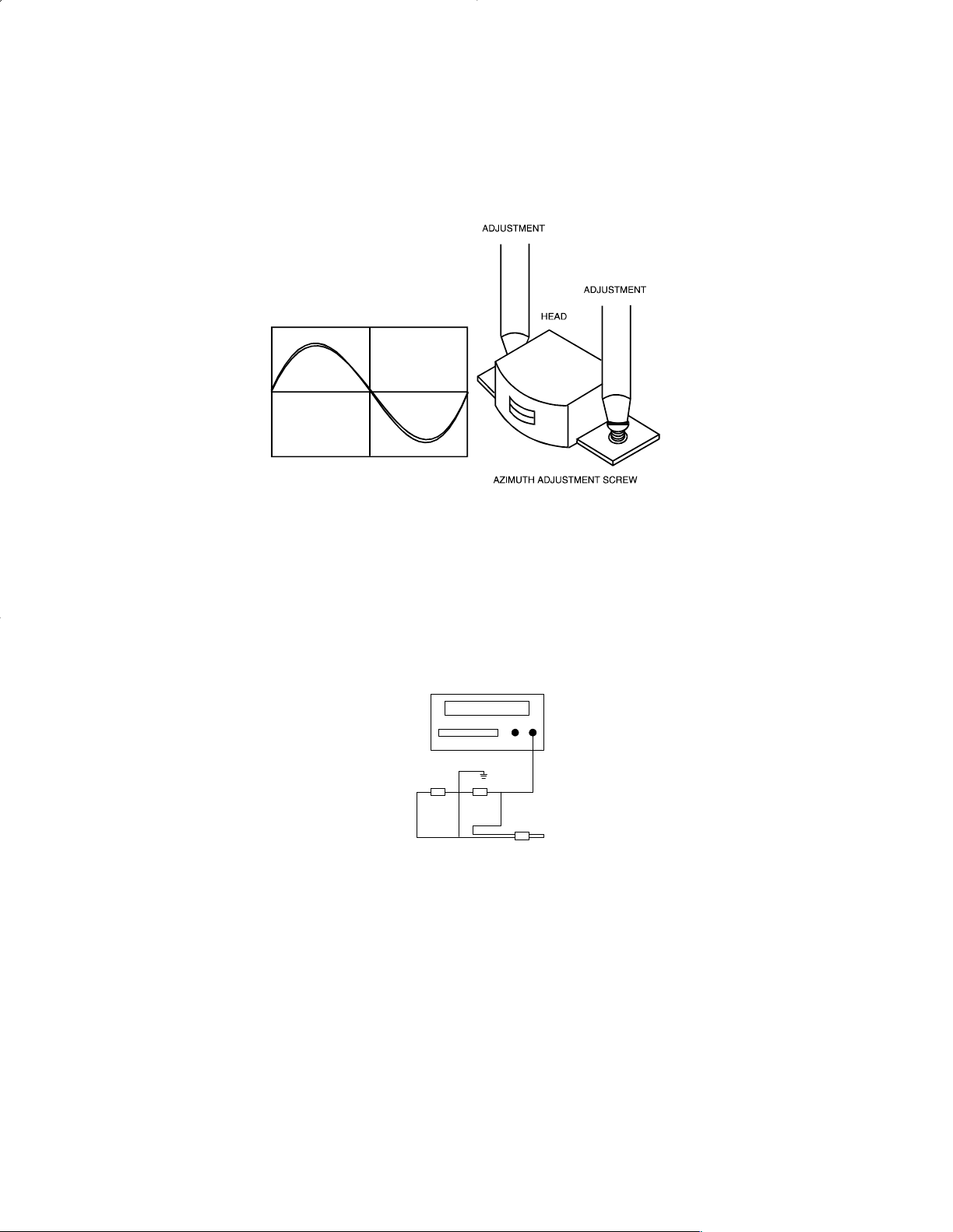

Play/Record and Playback Head Azimuth Adjustment

To adjust the play/record and playback head azimuth screw:

1. Connect two (2) VTVMs and a dual trace scope to the stereo headphone jack (as shown) with a 32

ohm dummy load. (See Figure 1.)

VTVM VTVM

DUMMY LOAD

JK400

SCOPE

CH1

CH2

Figure 1. Azimuth Adjustment

ADJUSTMENT

4

ADJUSTMENT

2. Insert a 10 kHz test tape (Teac MTT-1141V or Equivalent) into the tape mechanism and play it back.

3. While playing back the test tape, slowly turn the azimuth adjusting screw until the amplitude of both

channel output waveforms is maximum and in phase. Note: Reiteration adjusting Right, lift the screw,

until the amplitude of both channel output waveform is maximum. (See Figure 2.)

4. Secure the azimuth screw in place with glue or paint after making the adjustment.

Figure 2. Head Output Signal

Tape Speed Adjustment

1. Set the function switch to TAPE.

2. Connect a frequency counter with a 32 ohm dummy load to the stereo headphone jack. (See Figure 3.)

FREQUENCY COUNTER

DUMMY LOAD

JK400

Figure 3. Tape Speed Adjustment

3. Insert and play back a 3 kHz test tape (Teac MTT-111 or Equivalent) into the tape mechanism.

4. Insert an insulated alignment tool and adjust the tape speed potentiometer (MOTOR) until the

frequency counter indicates 2940 Hz to 3090 Hz.

Bias Oscillator Frequency and Level Adjustment

1. Set the function switch to TAPE and the record and play tape mechanism to RECORD.

2. Connect a VTVM and frequency counter to test point R/P HEAD.

3. Adjust bias oscillator coil L203 until the frequency counter indicates 67 kHz ± 0.5 kHz.

RXD-M57MP

5

RXD-M57MP

TUNER ALIGNMENT PROCEDURE

Equipment needed:

1. AM Signal generator

2. FM Signal generator

3. DC Voltage meter

4. Oscilloscope

5. Output meter (VTVM)

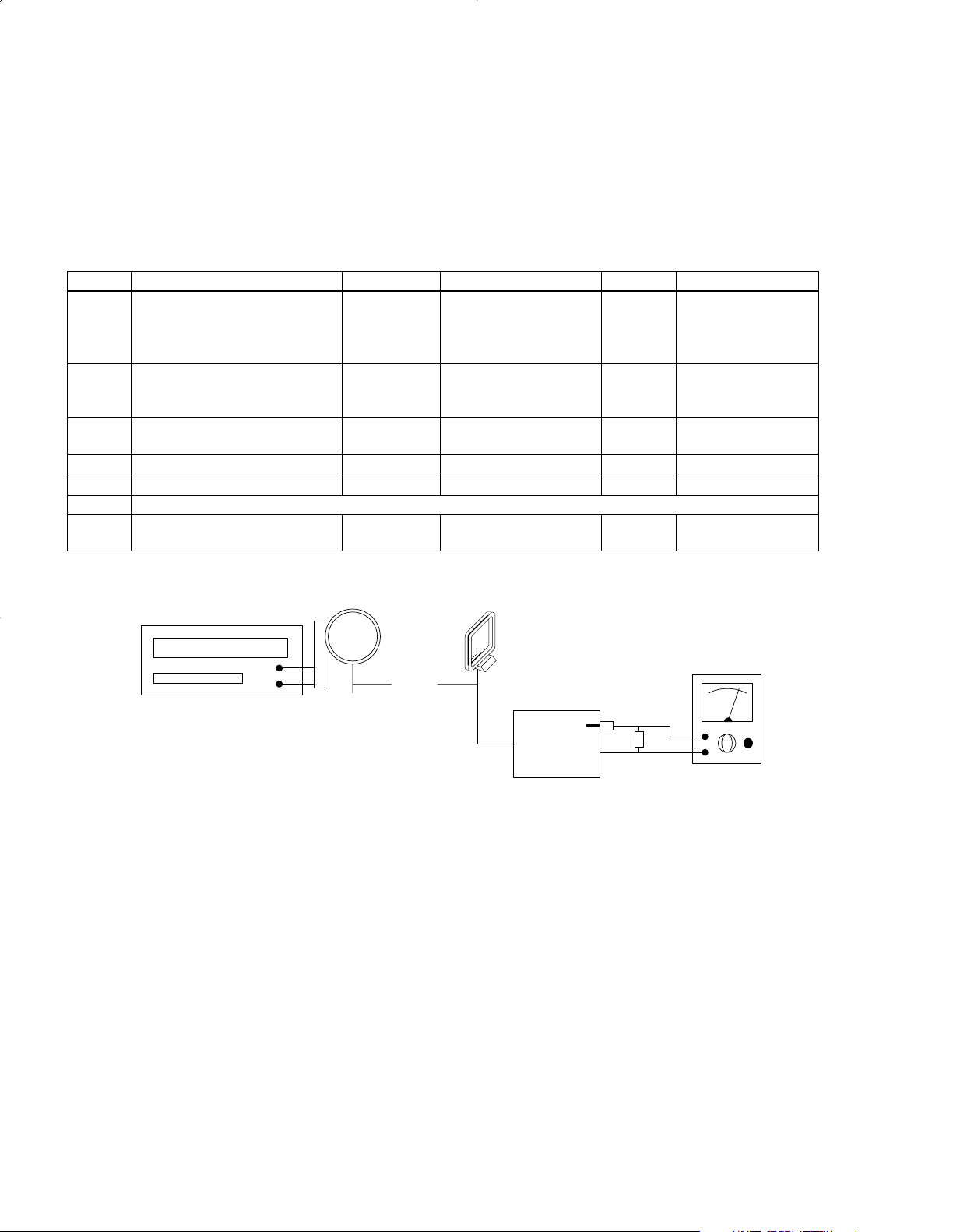

AM Alignment

Step S/G Frequency Dial Setting Indicator Adjust Remarks

1 450 kHz (1 kHz 30% mod.) 612 kHz Connect

oscilloscope or

VTVM to speaker

jack

T101 Adjust for

maximum

output

2 531 kHz (1 kHz 30% mod.) Low end Connect DC voltage

meter to test point Vt

and ground

L102 Adjust until

Vt equal to

1.5 – 0.05V

3 1602 kHz (1 kHz 30% mod.) High end Same as step 2 Confirm Vt:

6.5~8.5V

4 612 kHz (1 kHz 30% mod.) 612 kHz Same as step 1 L103 Maximum output

5 1404 kHz (1 kHz 30% mod.) 1404 kHz Same as step 1 TC101 Maximum output

6 Repeat steps 4 and 5 to minimize tracking error

7 999 kHz

(1 kHz 30%mod.)

999 kHz

Same as step 1 Offset is less than

6 dB.

60 cm

AM SIGNAL GENERATOR

AM LOOP ANT

AM LOOP

ANTENNA

DUMMY LOA D

VTVM

TEST UNIT

Figure 4. AM IF/RF Tracking

ADJUSTMENT

6

ADJUSTMENT

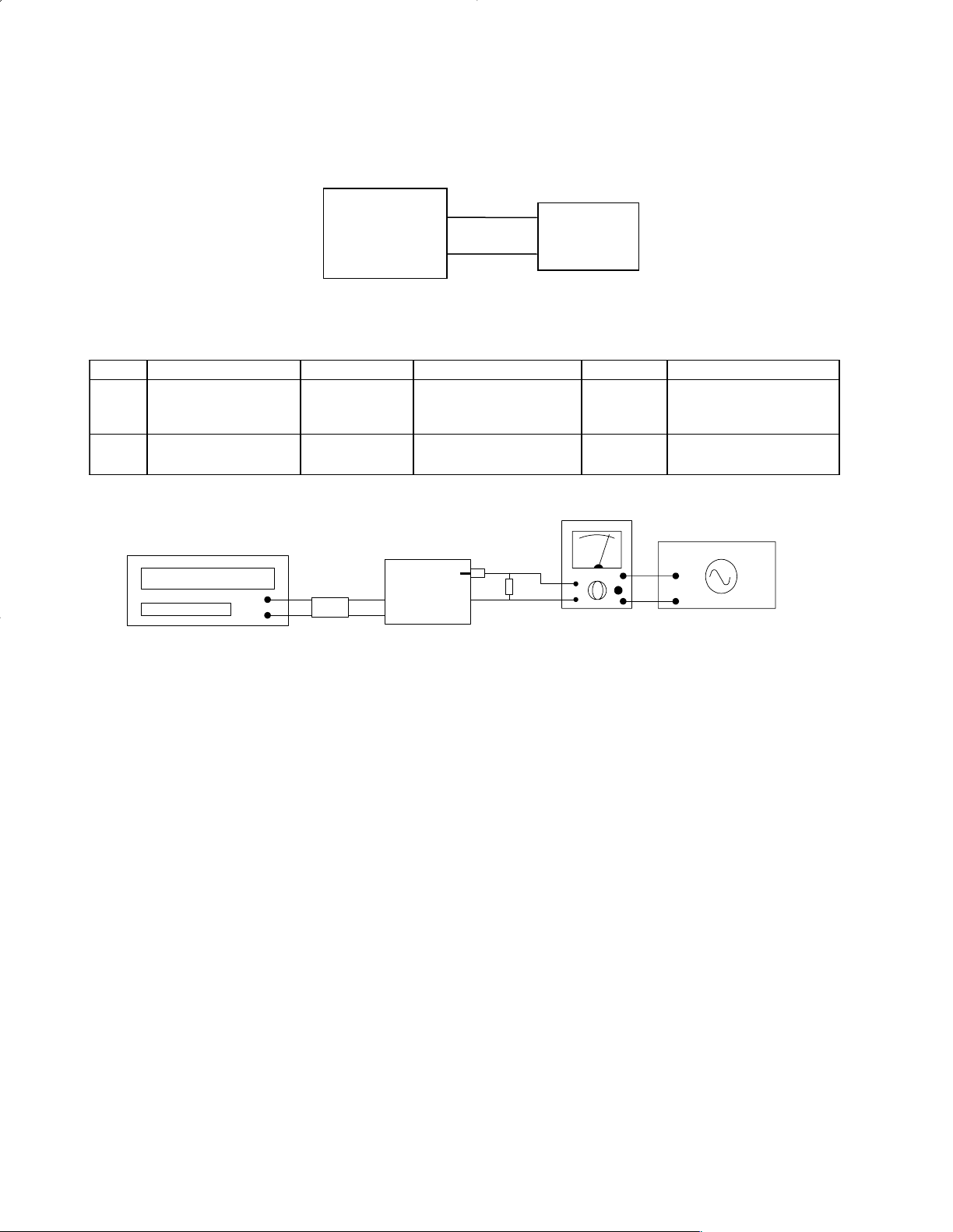

FM Alignment:

TEST UNIT

Figure 5. FM Band Frequency Coverage Alignment

Connect FM S/G to ANT inputs (mod 1 kHz 22.5kHz dev.)

Step S/G Frequency Dial Setting Indicator Adjust Remarks

1 87.5 MHz Low end Connect DC Voltage

meter to test point Vt

and ground

Confirm Vt:

1.7 ± 0.2V

2 108 MHz High end Same as step 1 Confirm Vt:

8.5 ± 1V

Figure 6. FM Band/Tracking

FM GENERATOR

DUMMY

ANTENNA

TP1

TEST UNIT

DUMMY

LOAD

VTVM

OSCILLOSCOPE

Vt

GROUND

DC

RXD-M57MP

7

Loading...

Loading...