Page 1

6

7

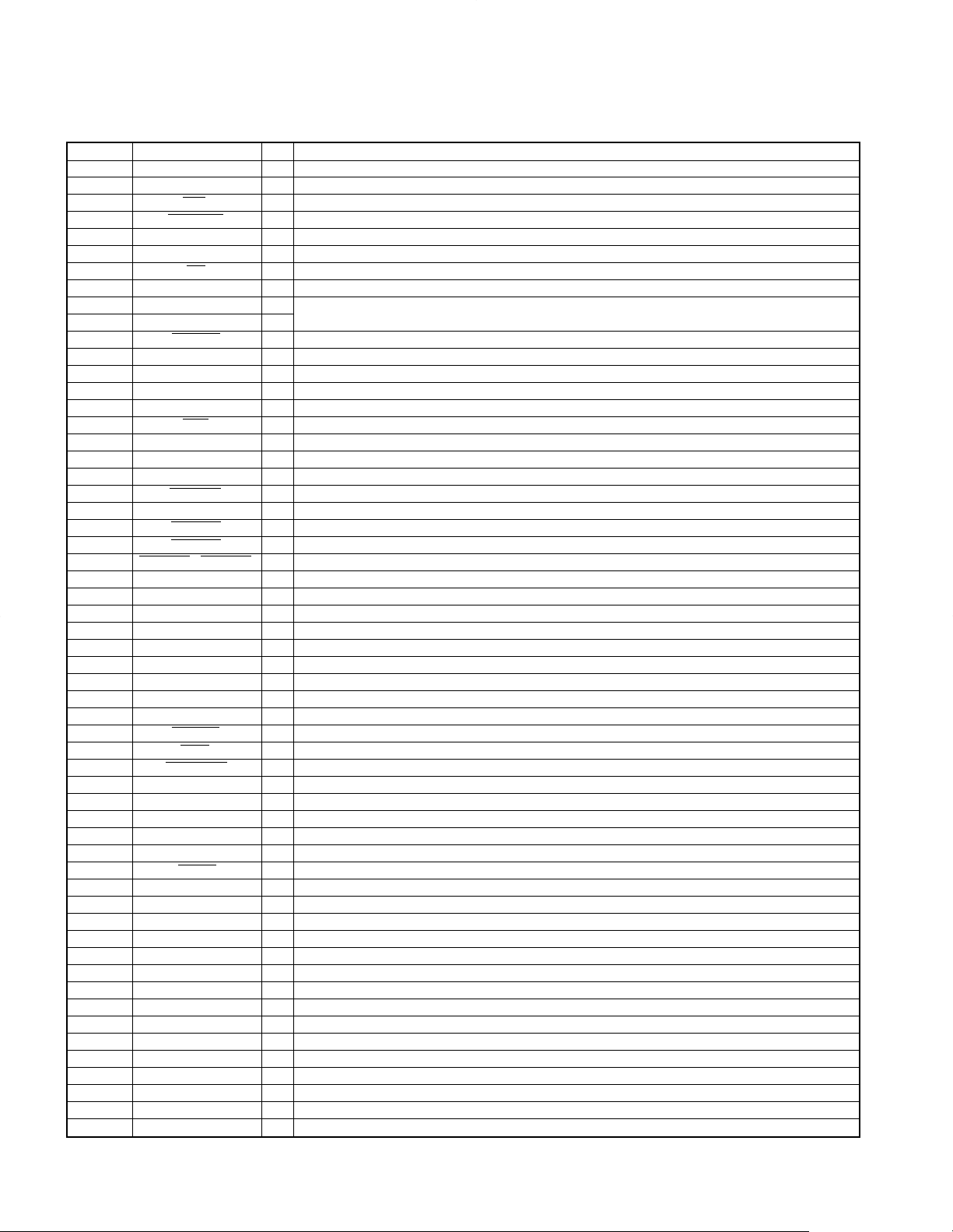

3DISC

QUICK

MOVE

TITLE

INPUT

TITLE

SEARCH

MULTI JOG

UP

DOWN

DELETE

PUSH

OPEN

TWIN

REC

O.T.E.

3D / O.T.T.

ON/STANDBY

PHONES

DISC

changer

EQUALIZER

DOLBY NR

DISPLAY

/DEMO

REC

¶

0

0

6

7

4

1¡

7¶

32

REPEAT

BEST HITS

O.T.E. TRACK EDIT

DISC LOADING MECHANISM

INPUT

SELECT

REV.MODE

REC INPUT

SELECT

CYBER

TITLER

TUNER/BAND

EX.BASS

MODE

EQUALIZER

DOLBY NR

MULTI CONTROL

/VOLUME

OPEN/CLOSE

DIGITAL AUDIO

COMPACT

D

I

S

C

1

D

I

S

C

2

D

I

S

C

3

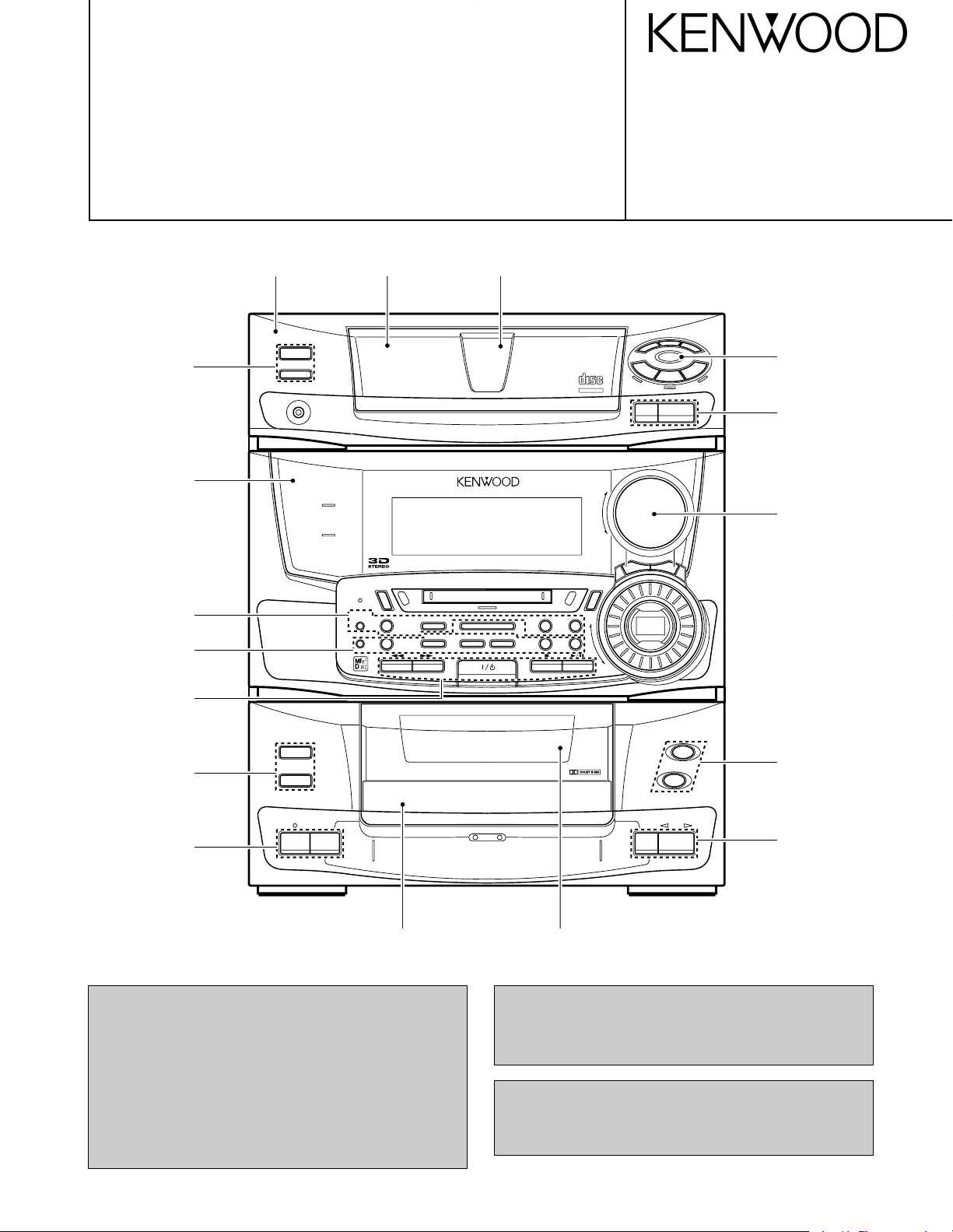

MINI HiFi COMPONENT SYSTEM

¢

E

N

T

E

R

S

E

T

0

3

0

2

0

1

3

TEXT

AUTO REVERSE

MINI HIFI COMPONENT SYSTEM

RXD-981MD

SERVICE MANUAL

(XD-981MD)

© 1997-12/B51-5402-00 (K/K) 2157

Knob

(K29-6811-13)

Front glass

(B10-2398-12)

Knob

(K29-6808-12)

Knob

(K29-6809-13)

Knob

(K29-6808-12)

Panel

(A60-1342-11)

Panel (CD)

(A29-0887-12)

Front glass (CD)

(B10-2399-03)

Knob

(K29-6813-13)

Knob

(K29-6810-12)

Knob

(K29-6823-04)

Knob

(K29-6811-13)

Knob

(K29-6810-12)

Cassette holder

(A53-2017-12)

• Refer to DM-3090 service manual(B51-5396-00), if

require the following items in detail.

1) MD mechanism(MDM-97) disassembly for repair

(page5,6)

2) Semiconductor description

IC1101:RF signal control(page9)

IC1201:ENDEC/ATRAC(page10,11)

IC1401:system microcomputer(page 12,13)

3) Trouble shooting(page19~23)

• Refer to RXD-980MD service manual(B51-5299-00), if

require the MD error message in detail.(page14)

Front glass

(B10-2400-03)

* Refer to parts list on page 65.

Caution : No connection of ground line if disassemble the

KENWOOD-Crop. certifies this equipment conforms to DHHS

Regulations No. 21 DFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM

unit.

Please connect the ground line on rear panel,

PCBs, Chassis and some others.

Knob

(K29-6813-13)

Knob

(K29-6810-12)

Page 2

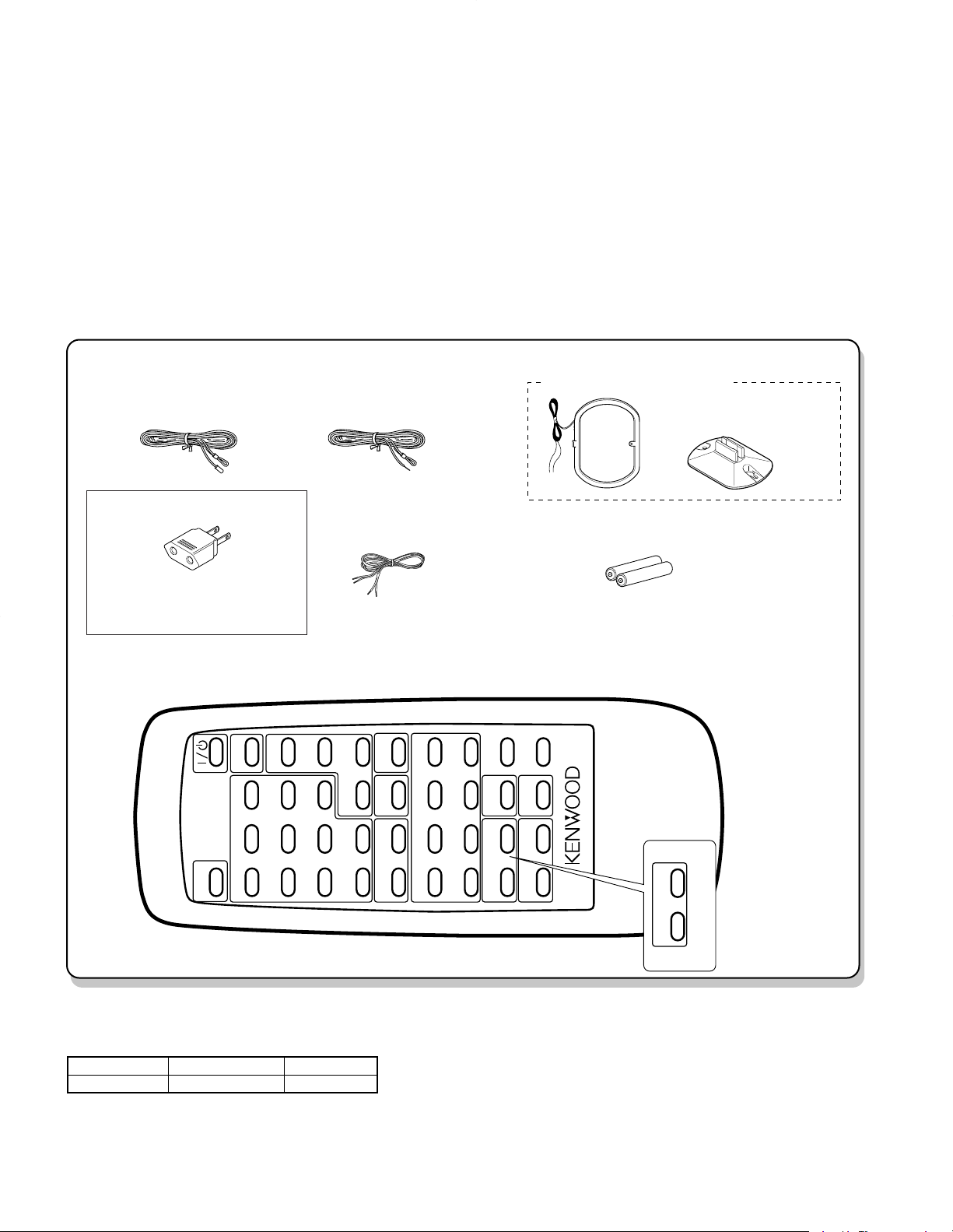

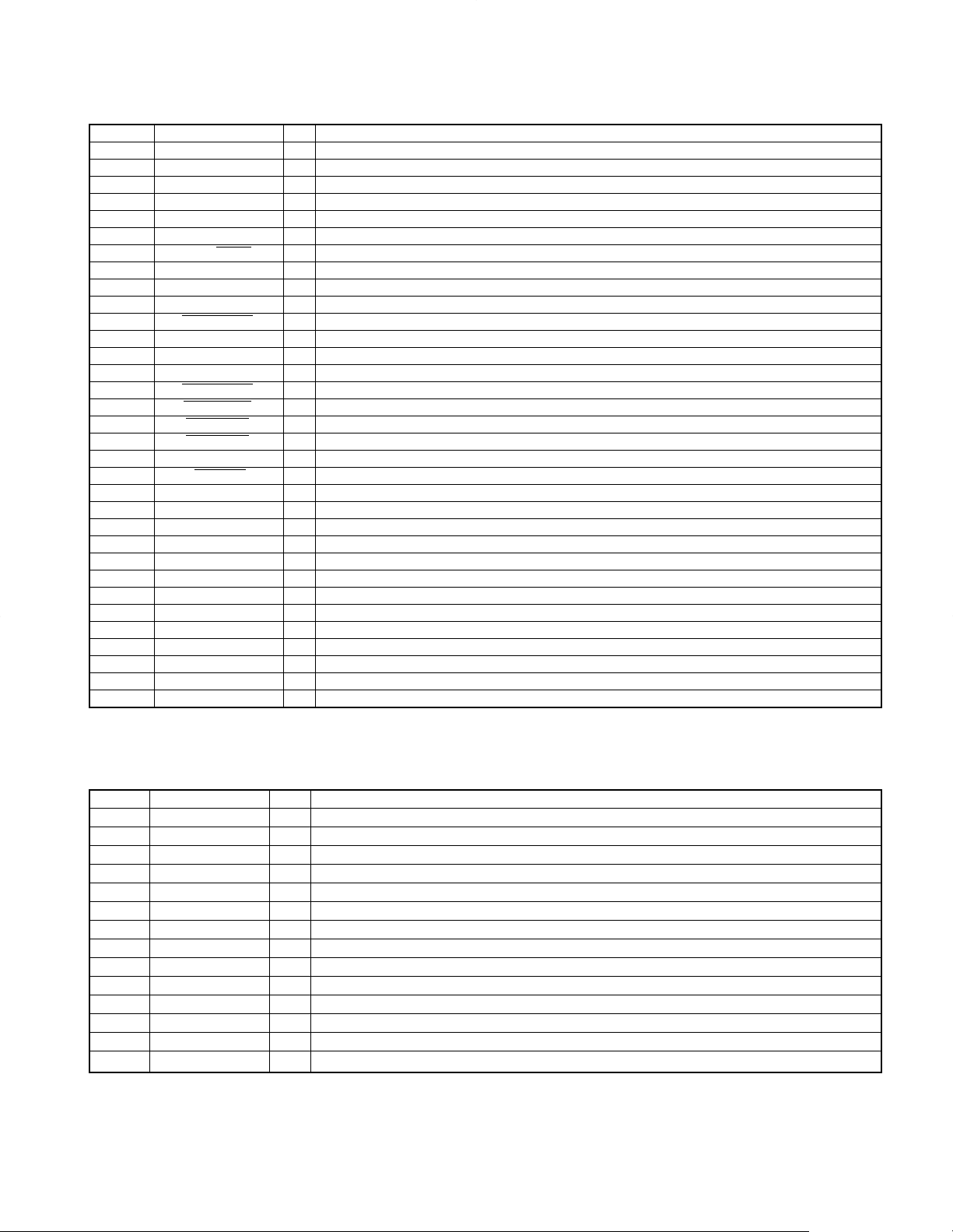

Batteries (R6/AA) (2)

Other countries

Remote

Battery cover (A09-0384-08)

control unit (1)

AM loop antenna stand (1)

Speaker cords (2)

Loop antenna (1) (T90-0833-05)

Please confirm that the following accessories are present.

FM indoor antenna (1)

Europe and U.K.

AC plug adapter (1)

Use to adapt the plug on the power

cord to the shape of the wall outlet.

(Accessory only for regions where

use is necessary.

1

32

N.B.

456

REPEAT

789

RANDOM

+10 0

PGM

CLEAR

O.T.E.

TAPE

O.T.E.

MD

AUX

MUTE

ENTER

DISC

SELECTOR

1

¡

4¢

2 3

7

%

fi

TITLE

SEARCH

TUNER

BAND

VOLUME

CONTROL

DOT

DISPLAY

TIME

DISPLAY

36

SLEEP

REMOTE CONTROL UNIT

RC-M1MD

TAPE MD C D

P.CALL

PTY

TA/

NEWS/INFO

REMOTE CONTROL UNIT

RC-981MD

(T90-0810-05): TE

(E03-0115-05)

(E30-5474-08)

(A70-1178-05) : RC-M1MD.......MH

(A70-1179-05) : RC-981MD.......TE

(T90-0801-05): MH

(J19-3645-05))

RXD-981MD

CONTENTS / ACCESSORIES

Contents

CONTENTS / ACCESSORIES ....................................2

EXTERNAL VIEW........................................................3

DISASSEMBLY FOR REPAIR.....................................4

CD MECHANISM DESCRIPTION ...............................5

CIRCUIT DESCRIPTION...........................................12

ADJUSTMENT.......................................................... 26

WIRING DIAGRAM....................................................29

Accessories

PC BOARD ................................................................30

SCHEMATIC DIAGRAM............................................39

EXPLODED VIEW .....................................................61

PARTS LIST...............................................................65

PARTS DESCRIPTIONS...........................................77

SPECIFICATIONS .......................................Back cover

System configuration

SYSTEM MAIN UNIT SPEAKER

XD-981MD RXD-981MD LS-N651

2

Page 3

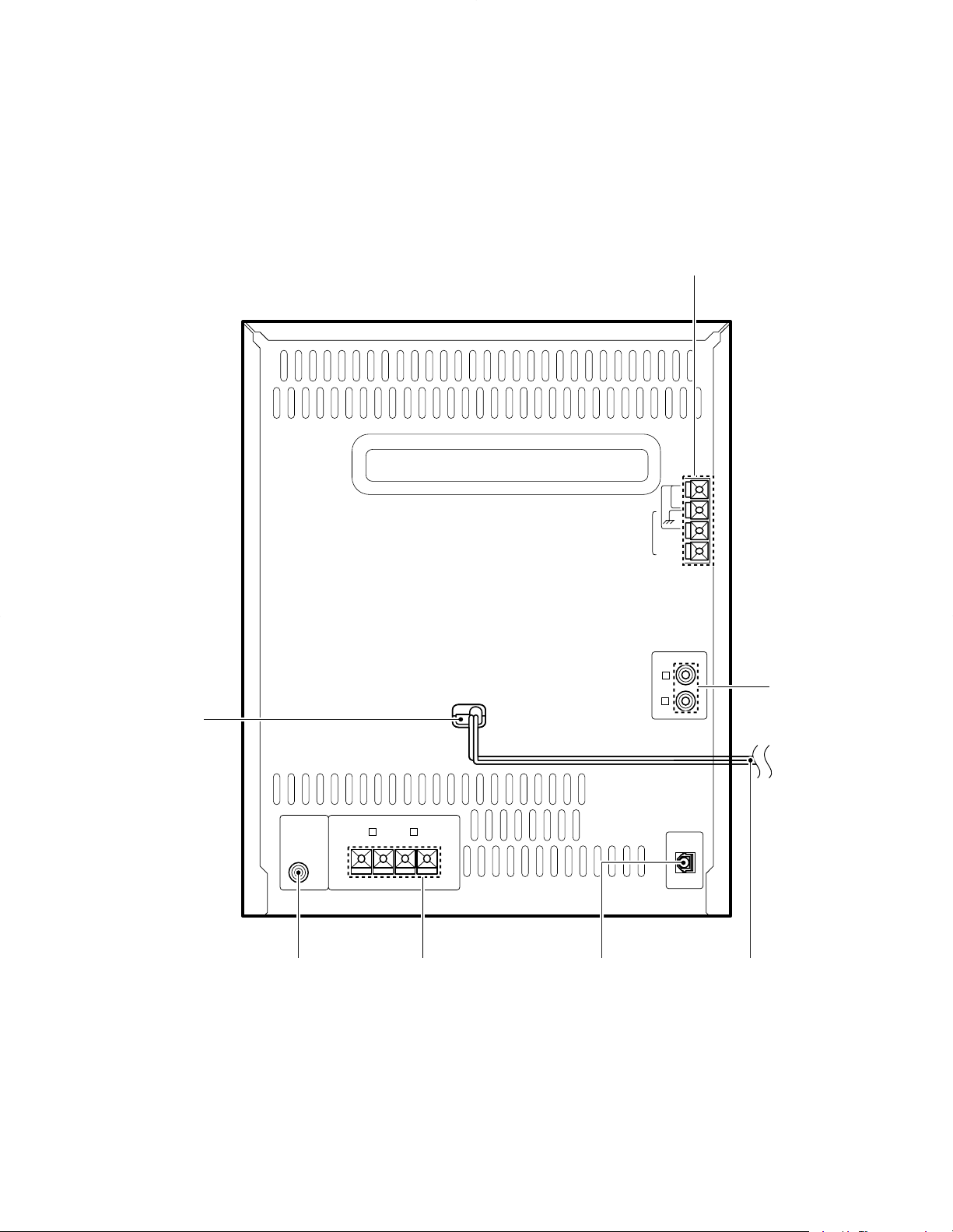

EXTERNAL VIEW

ANTENNA

AM FM

300Ω

FM

75Ω

GND

SUPER

WOOFER

PRE OUT

SPEAKERS

i6-16‰ j

RR LL

+

--

+

RR

LL

AUX INPUT

DIGITAL

INPUT

OPTICAL

RXD-981MD

Lock terminal board *

(E70-)

Power cord bushing

(J42-0083-05)

Phono jack

(E63-0164-05)

Lock terminal board

(E70-0057-05)

Optic receiving module

(W02-1181-05)

Phono jack

(E63-1024-05)

AC power cord *

(E30-)

* Refer to parts list on page 65.

3

Page 4

RXD-981MD

1

7

2

3

4

4

5

6

8

9

11

12

13

14

15

17

18

19

20

20

20

20

20

16

10

TOP

(Fig: a) (Fig: b)

TOP

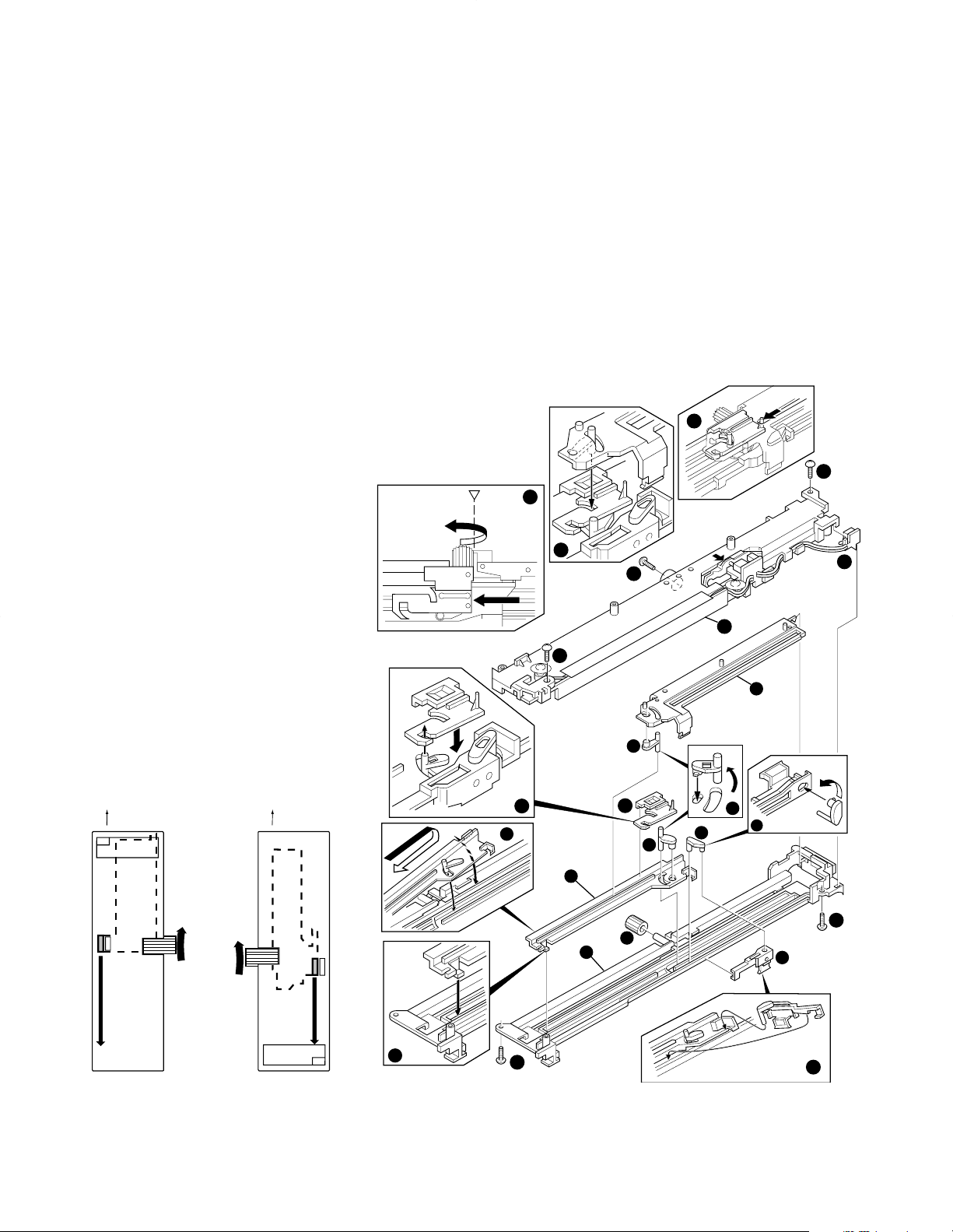

DISASSEMBLY FOR REPAIR

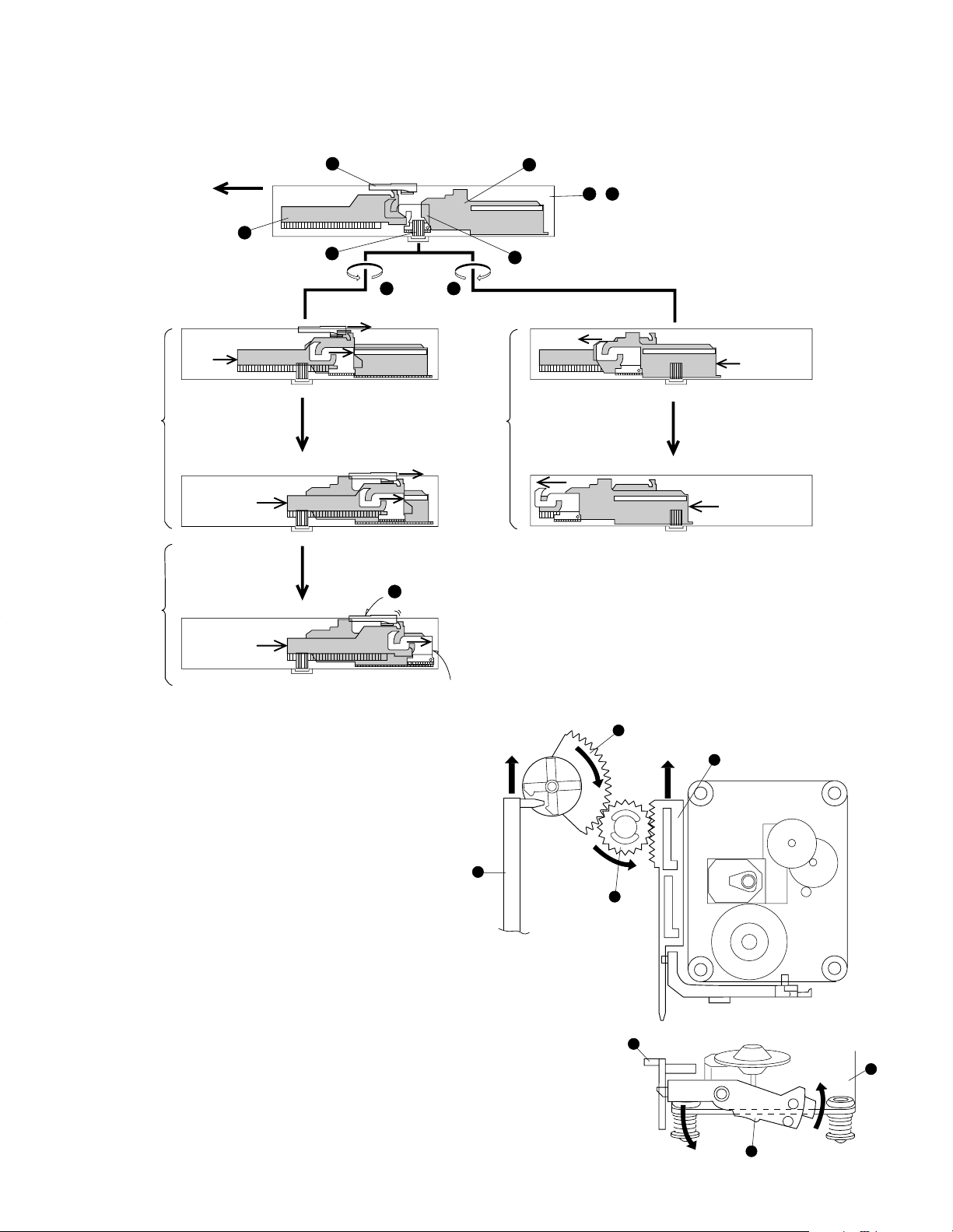

How to Assemble the Slider Ass'y in the

CD Mechanism

1. Mount the black lever1to the tray slider2 and assemble

them3.

2. Mount the white lever4 to the load slider5 and the open

slider6, and assemble them7.

3. Insert the gear9 to the groove of the holder8.

4. Insert the L shaped part of the load slider5 to the groove

of the holder8 and assemble them0.

5. Slide the load slider5 with lifting the edge of it rightwards.

Next insert the hook of the load slider5 and the boss of

the white lever4 to the groove of holder8. Then slide

the load slider5 to the fully leftward!.

6. Mount the tray slider 2 to the holder8 and assemble

them @.(note:Mount the tray slider2 to the wall of the

holder8)

7. Mount the slit of the center slider# to the boss of the

white lever4 and assemble them$.

How to Check the Slider Ass'y

After Assembly

Stand upright the slider ass'y before check

8. Slide the center slider# leftwards and position the right

edge of the gear9 to the right edge of center slider#.

Refer to %.

9. Position the boss of the open slider6 to the square hole

of the holder8 and slide the open slider6 fully rightwards. Mount the boss of the white lever4 assembled

with the open slider6 to the groove of the center

slider#.

Refer to ^.

10. Slide the center slider6 fully rightwards and slide the

boss of the center slider#.

Refer to &.

11. Mount the boss of the SW pcb to the slit of the holder8

and do holder* to the holder8. Then fix with screw).

Fig a: Turn the gear9 upwards and the tray

slider goes downwards smoothly. The

tray slider drops on the way.

Fig b: Turn the gear9 upwards and the open

slider goes downwards smoothly.

4

Page 5

CD MECHANISM DESCRIPTION

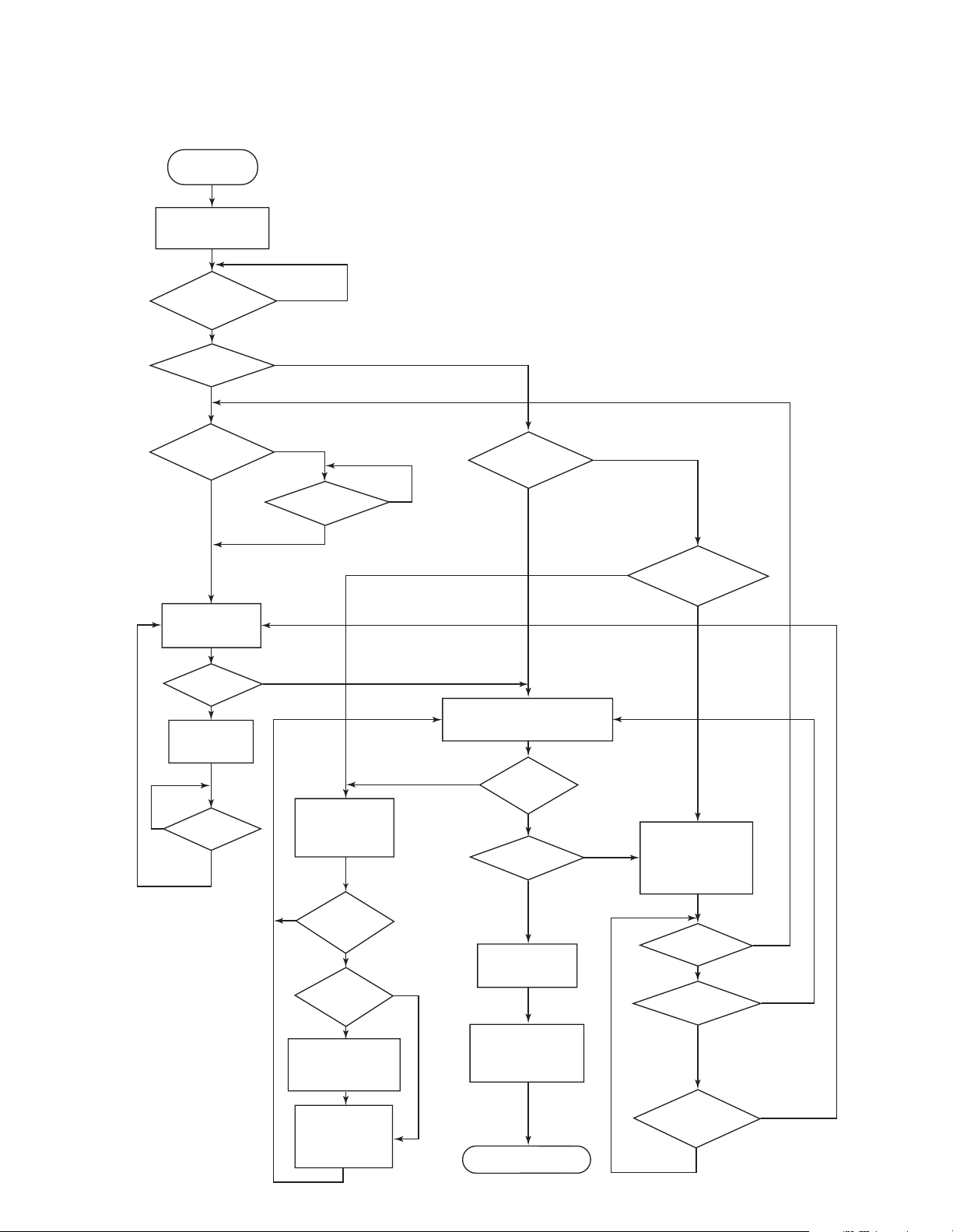

START

Pickup moves

inwards

Pickup

position is at the

full inside?

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Close ok

Open

position?

Top

position of

the holder?

Motor works

for close

Close ok?

Motor works

for open

Open ok?

Key pressed?

Motor works

for load and

load the holder

Top

position of

the holder

Clamp?

Meet with the

height of t.u

ass'y and

the holder

Motor works

for store and

return to

close position

Clamp with no disc

Clamp with no disc

Load or close

position?

Reset home position

of holder from bottom

In clamping?

Close

position?

t.u. ass'y

moves full

bottom

Reset home

position of holder

from bottom

Initial end

Slider position is poor

Clamp hoder

at top holder

position?

Motor works

for open and

set timer

to detect

"open error".

Open

position?

Close

position?

Motor start

time is over?

CD INITIALIZE FLOWCHART

RXD-981MD

5

Page 6

RXD-981MD

UP

DOWN

LIFT

1

2

3

a

b

b

c

b

a

c

b

CLOSE

OPEN

LOAD

UNLOAD(STORE)

a

b

c

OPEN WAIT

(RIGHT SIDE VIEW)

(TOP VIEW)

(FRONT VIEW)

CLAMP UNCLAMP

(RIGHT SIDE VIEW)

(SIDE VIEW of TU ass'y)

LOAD

Slider ASS'Y

PLAY

Hook of slider

TRAY

TRAY NO.

TRAVERSE UNIT ASS'Y

(T.U. ass'y)

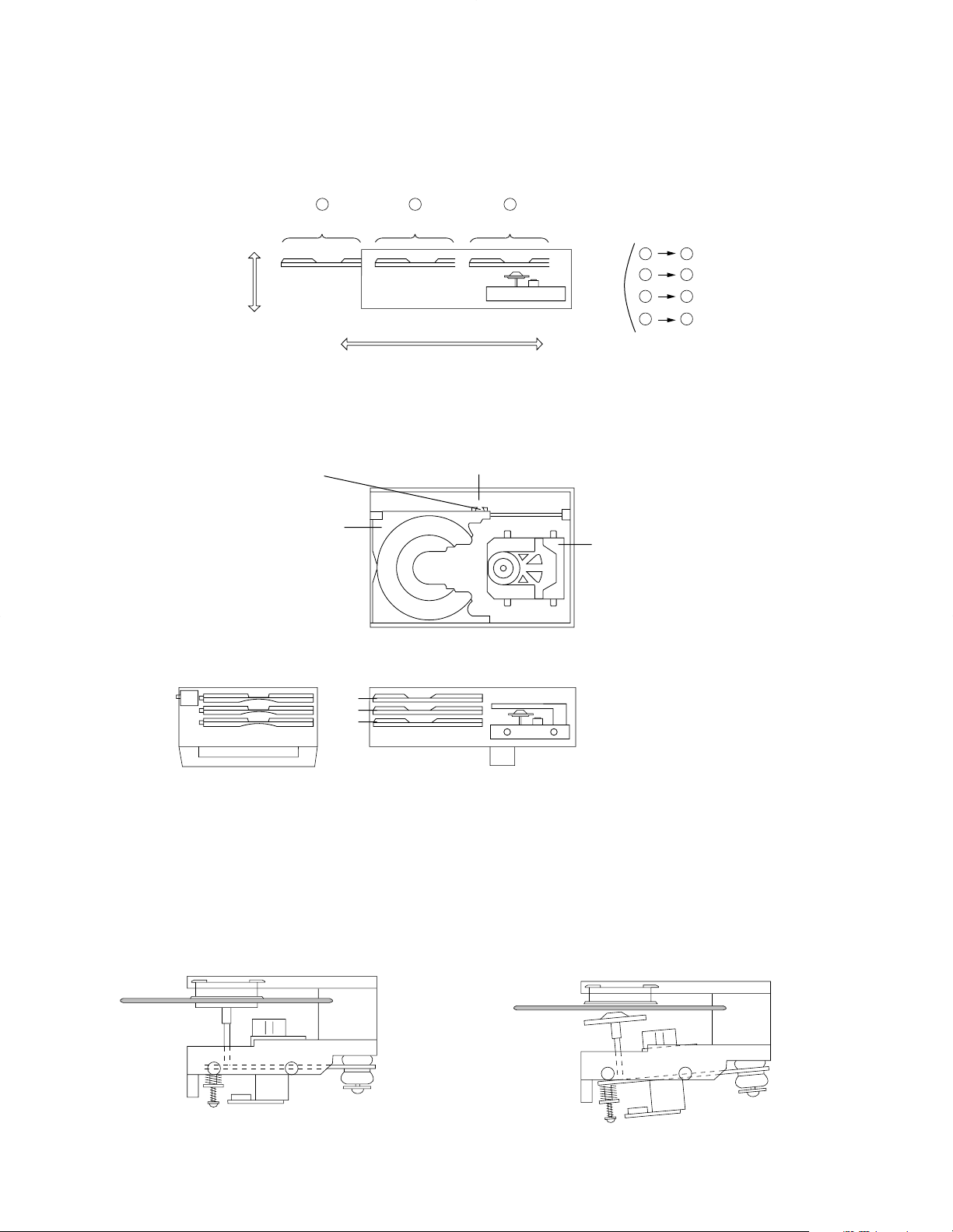

CD MECHANISM DESCRIPTION

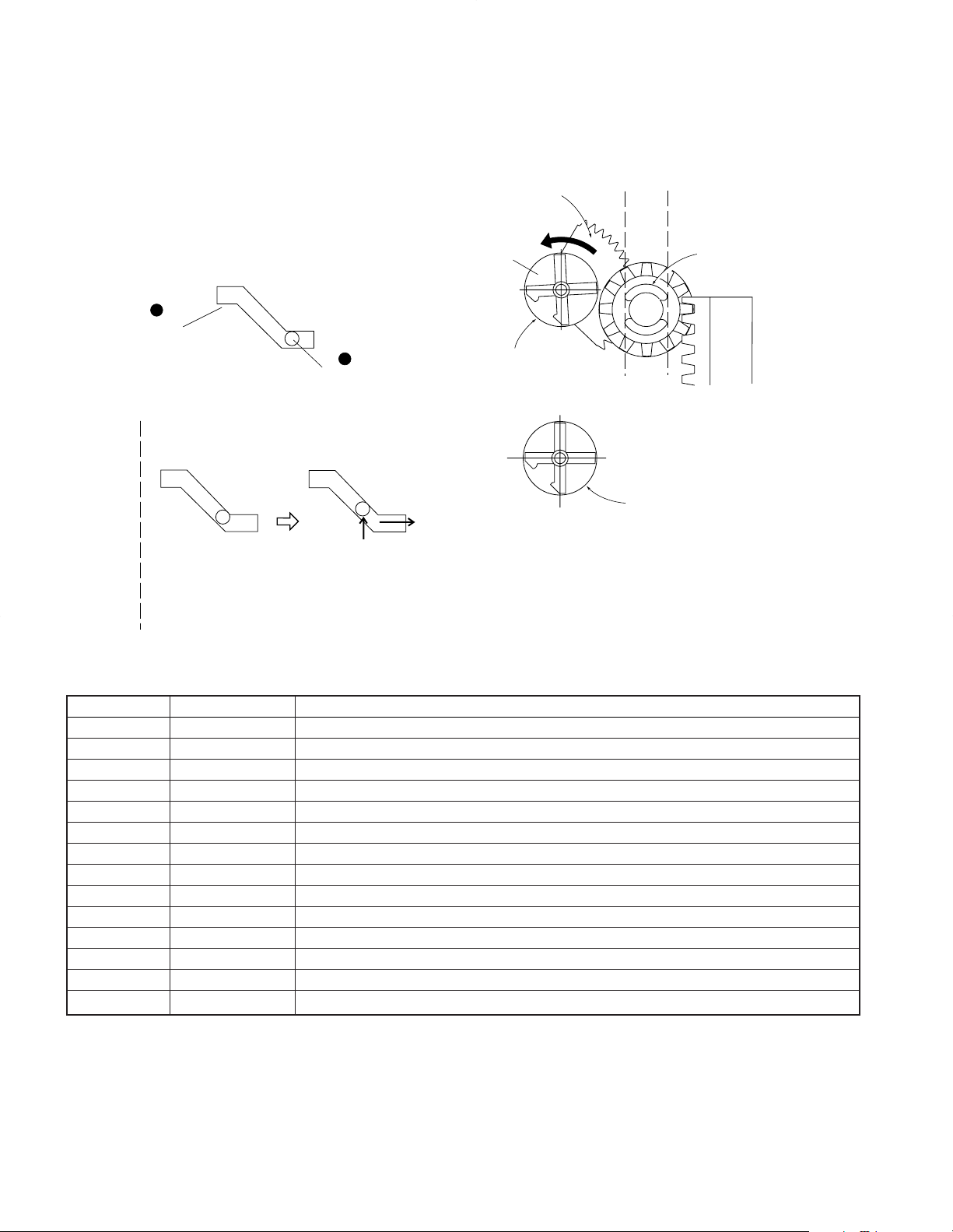

1. CD BANK MECHANISM

1-1 Function of Item Word

Function word is available in the figure.

1-2 Function of Parts

Tray... .........Each tray works in load mode only

Slider ass'y ... Lift mode(7 steps linked height). Hook of the slider ass'y in the load mode

T.U. ass'y.......Lift mode(3-steps linked the tray)

1-3 Clamp/Unclamp

6

Page 7

1

2

3

Hook of

OPEN @

TRAVELING

AREA of OPEN hook

TRAVELING

AREA of LOAD hook

Hook of

LOAD !

TRAY NO

(FRONT VIEW) (RIGHT SIDE VIEW)

FRONT REAR

LIFT MOTOR LOADING MOTOR

(TOP VIEW)

< PARTS LOCATION >

RXD-981MD

CD MECHANISM DESCRIPTION

1-4 Function of Lift and Load Mode

Ex: Disc-2 Playback from The Tray Open.

• Close the tray-2(loading)

• Lift the slider ass'y(lifting)--- To lift the T.U.

• Lift the T.U.ass'y(lifting)

• Move the slider ass'y downwards(lifting)----To meet the height of the slider ass'y with the tray-2.

• Load the tray-2.

• Clamp the CD disc on the tray-2(loading)

• Lift the holder ass'y up(lifting)----- To return in home position(HP)

• Move the slider ass'y from playback to waiting position.

• End.

1-5 Home Position(HP)

• Figure shows parts location at the home position.

• Each part in the home position

• Tray ---- Waiting

• Slider ass'y ----- Top

• Hook of sliders ------ Center

• T.U. ass'y ------ Bottom(Tray-3),unclamp

2. Motor Function

7

Page 8

RXD-981MD

21

b

b

a

a

< LOAD FUNCTION >

26

32

2

25

20

8

23

46

48

a

a

b

b

< LIFT FUNCTION >

Hook of OPEN

Hook of LOAD

TRAY 1

H.P. (no disc) (7th step)

< 7STEPS VS SLIDER ASS'Y >

1 LOAD/UNLOAD (6th step)

1 OPEN/CLOSE (5th step)

2 LOAD/UNLOAD (4th step)

3 LOAD/UNLOAD (2nd step)

2 OPEN/CLOSE (3rd step)

3 OPEN/CLOSE (1st step)

TRAY 2

TRAY 3

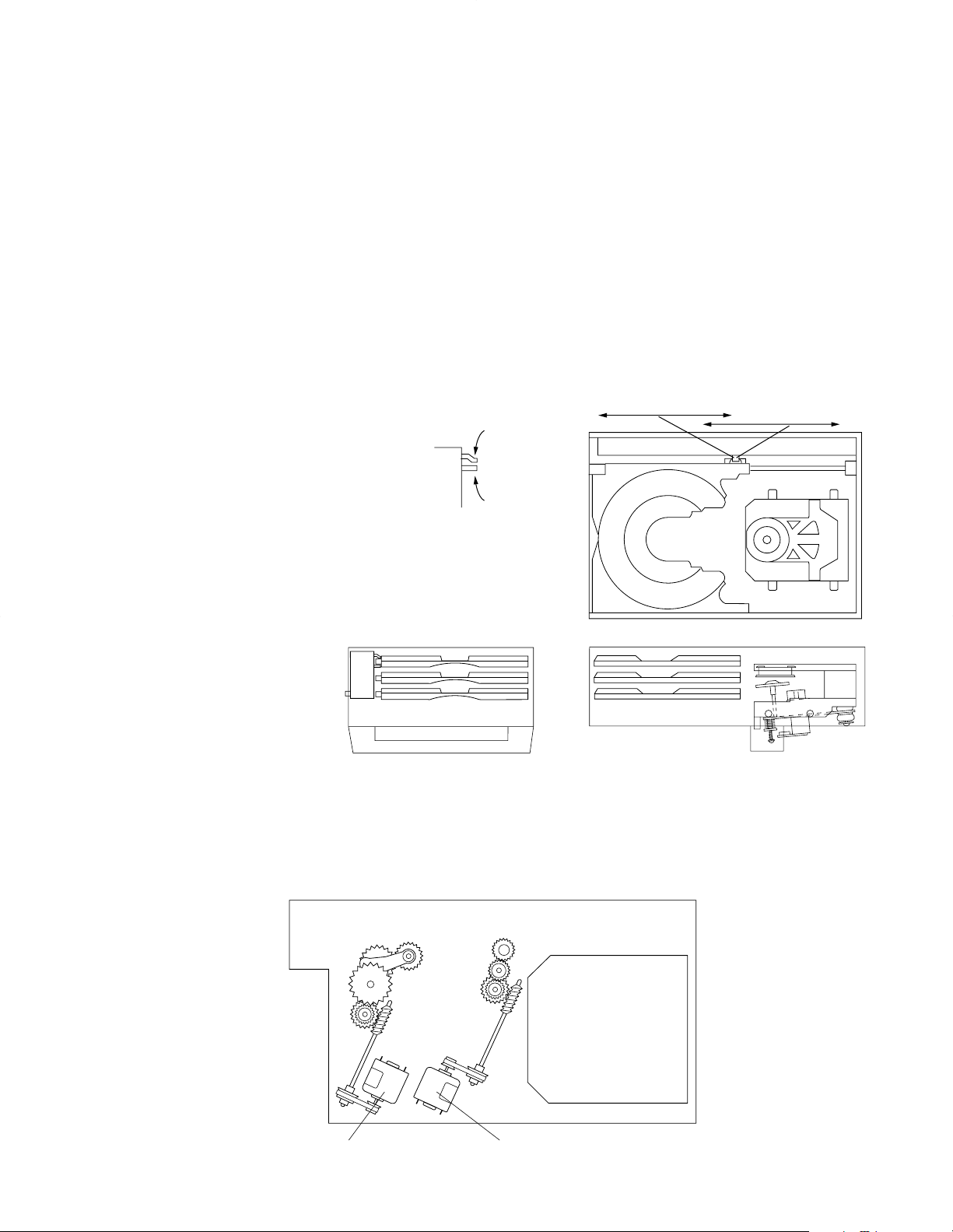

CD MECHANISM DESCRIPTION

• The lift motor turns counterclockwise a and the friction

arm¤ moves leftwards. The arm meet with the J shaped

rack gear of the lift-L slider. The slider moves backwards

The slider has 7 steps cam and it makes up or down

mode.

• The lift motor turns clockwise b and the slider2 moves

frontwards. The slider ass'y moves upwards.

• The gear§ separates from the J shaped rack gear and

gears into the gear∞. The gear∞ linked with the gear)

turn counterclockwise and T.U. ass'y move upwards.

• Namely up and down modes repeat.

• The friction arm¤ is the free position in the home position. T.U.ass'y moves upwards if the lift motor turns

counterclockwise.

8

Slider ass'y vs Height(7 steps)

2-1 Load Function

2-1-1 The slider of the slider ass'y backwards if the loading

motor turns counterclockwise(UNLOAD,OPEN MODE)

2-1-2 The slider of the slider ass'y frontwards if the loading

motor turns clockwise(LOAD,CLOSE MODE)

Page 9

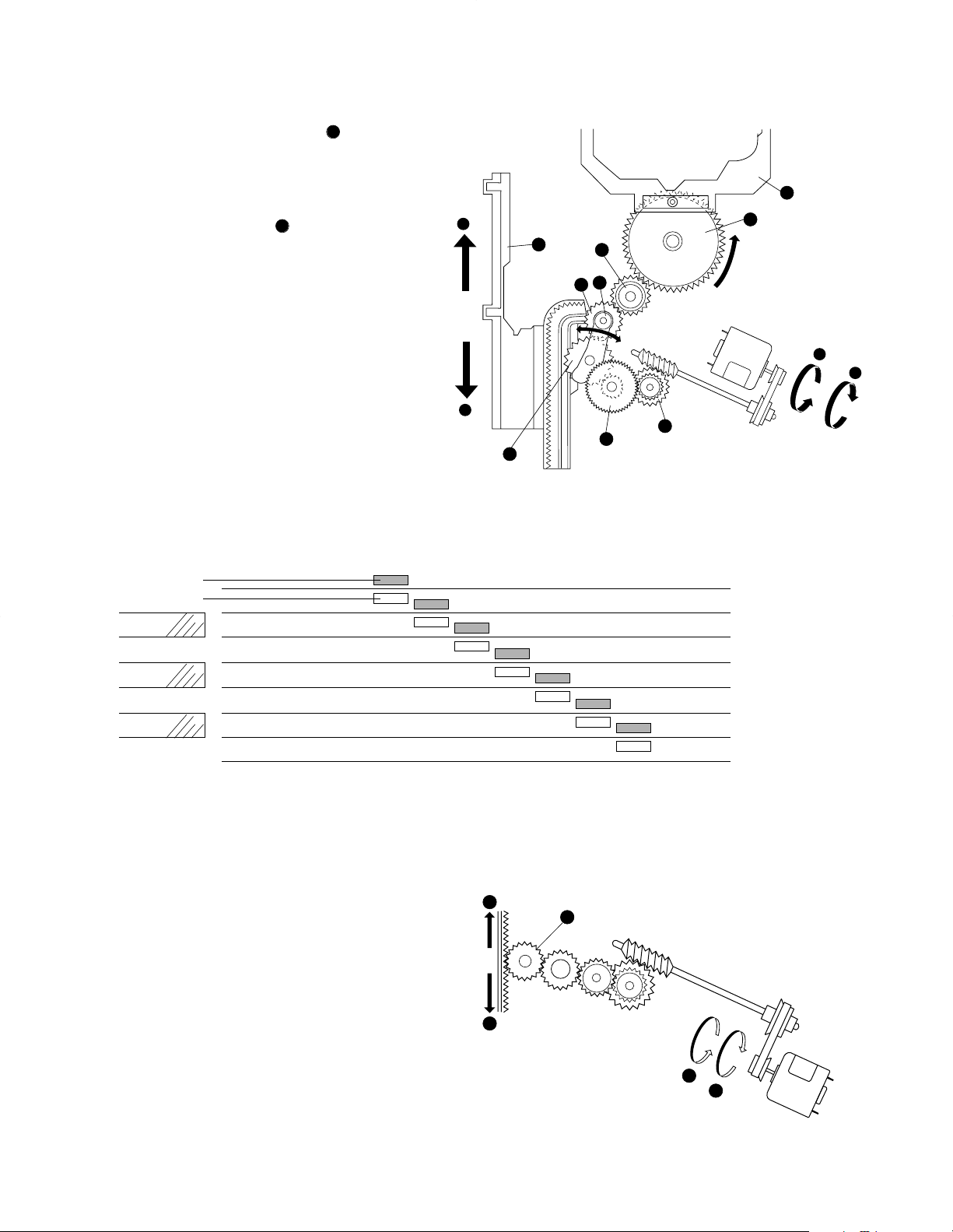

CD MECHANISM DESCRIPTION

15

4 5

33

36

21

a

b

14

36

OPEN

LOAD

CLAMP

,

Home

position

Slider (tray) ass'y

OPEN

Slider (open)

Slider (load)

Slider (center)

stops

continue to move

14

30

13

13

16

78

29

< CLAMP, UNCLAMP >

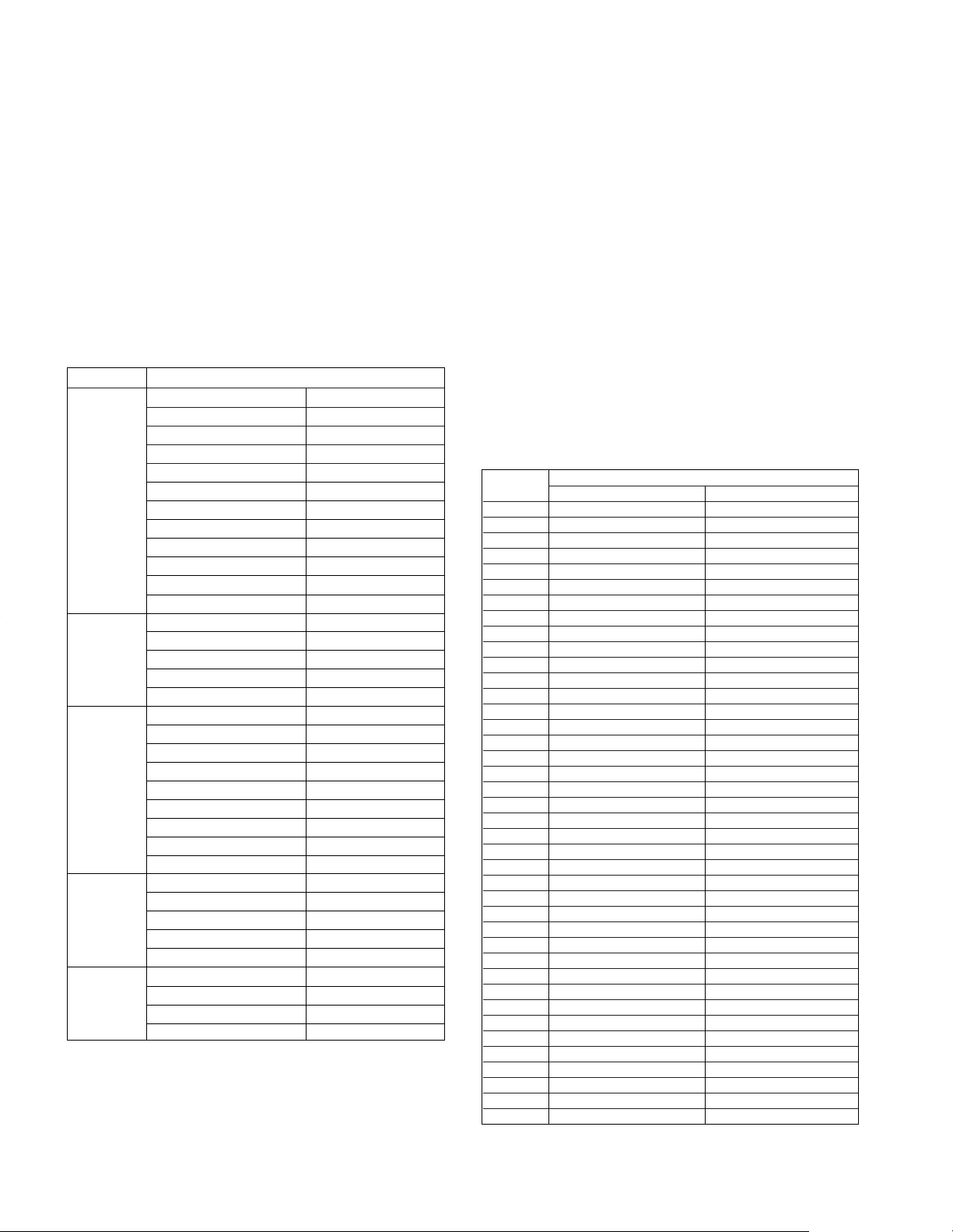

2-2 Each Slider Function in Slider Ass'y

RXD-981MD

The sliders(‹,$,fl) moves to LOAD if turn the gear¡

counterclockwise in the home position. The sliders separates and the sliders($ and ‹) moves more rightwards and the clamp mode starts after LOAD is over.

2-3 Clamp/Unclamp Function

The slider$ kicks the cross part of the gearº by load

mode. The gearª turns and moves the slider lack

gear# to LOAD by the door of the tray. Then the

slider# pushes the lever^ and T.U. ass'y moves

upwards. The clamp function starts by lifting the

T.U.ass'y.

The slider‹ moves to leftwards if the gear¡ turns clockwise in the home position. Then the open mode straits by

the sliders%,‹.

9

Page 10

full counter

clock wise

like time 8:27

TU Gear

(Ribs make a right angle)

Right angle is NG.

(out of 1 tooth)

zeneba gear

RXD-981MD

slider (CLAMP)

out of 1tooth

Boss of LEVER

(CLAMP)

< GOOD >

< NO GOOD >

13

16

CD MECHANISM DESCRIPTION

How to Assemble the Gear (zeneba)

The zeneba gearº has to meet the timing.

The T.U. ass'y doesn't work the clamp if the zeneba gear is

1 tooth out of the right position.

FUNCTION of SWITCH and MOTOR

Ref No. Parts Name Description

LM tray motor The motor for the slider(open,close load store)

LFTM lift motor The motor for the lift(holder up/down, T.U.height)

S1 open sw The switch for the position detector in the slider-open(Low active)

S2 close sw The switch for the position detector in the slider-close(Low active)

S3 load clamp sw The switch for the position detector in the slider-load(Low active)

S4 unclamp sw The switch for the position detector in the disc unclamp of the T.U.(Low active)

S5 tu height a sw The switch A for the height detector in the T.U.(Low active)

S6 tu height b sw The switch B for the height detector in the T.U.(Low active)

S7 home position sw The switch for the home position detector in the slider(Low active)

S8 count sw The switch for the height detector in the holder(Low active)

S9 center boss sw The switch for the disc position detector in the stocker(Low active)

PTR1 disc sensor The switch for the disc detector in the close mode(Low active)

SLT.SW start limit sw The switch for the most inner position detector of the pickup.

IC208(X09) LM speed control To control the speed of the tray motor.(L:speed down)

10

Page 11

RXD-981MD

CD MECHANISM DESCRIPTION

ACTUAL OPERATIONS (Refer page 8)

EX 1: Playback the Disc-1 in the All Discs Load

Load the disc-1 The slider ass'y moves

down by 2 steps (the 5th step)

ó

The tray-1 opens

ó ....................Load the disc

The tray-1 closes

ó

The slider ass'y moves

up by 2 steps (the H.P.)

ó

Load the disc-2 The slider ass'y moves

down by 4 steps(the 3rd step)

ó

The tray-2 opens

ó ....................Load the disc

The tray-2 closes

ó

The slider ass'y moves

up by 4 steps(the H.P.)

Load the disc-3 The slider ass'y moves

down by 6 steps(the 1st step)

ó

The tray-3 opens

ó ....................Load the disc

The tray-3 closes

ó

The slider ass'y moves

up by 6 steps (the H.P.)

ó

Playback the disc-1 The T.U. ass'y moves

up by 2 steps (tray-1 height)

ó

The slider ass'y moves

down by 1 step(the 6th step)

ó

Clamp the disc-1

ó

The slider ass'y moves

down by 1 step(the H.P.)

ó

Load the tray-1 of the no disc.

ó

Playback the disc

EX 2: Change to the Disc-3 in Playbacking

the Disc-1(There are discs on the tray1 and 2)

Unload the tray-1 Load the tray-1 of the no disc.

ó

The slider ass'y moves

down by 1 step(the 6th steps)

ó

Unclamp the tray-1

ó

The slider ass'y moves

up by 1 step(the H.P.)

ó

Playback the tray-3 The T.U. ass'y moves

down by 2 steps(tray-3 height)

ó

The slider ass'y moves

down by 5 steps(the 2nd steps)

ó

Load the tray-3 and

clamp the disc-3

ó

The slider ass'y moves

up by 5 steps(the H.P.)

ó

Load the tray-3 of the no disc.

ó

Playback the disc-3

EX 3: Change to the Disc-2 and Playback it in Playbacking the Disc-1

Open the tray-2 The slider ass'y moves

down by 4 steps(the 3rd steps)

ó

Open the tray-2

ó ....................Change the disc

Close the tray-2

ó

The slider ass'y moves

up by 4 steps(the H.P.)

Unload the tray-1 ó

Load the tray-1 of the no disc.

ó

The slider ass'y moves

down by 1 step(the 6th steps)

ó

Unclamp the tray-3

ó

The slider ass'y moves

up by 1 step(the H.P.)

Playback the tray-2 ó

Change the height

of the T.U. ass'y

(3î1î2/down-up*) ...*1skip the 2nd

step if down

ó mode.

The slider ass'y moves

down by 5 steps(the 2nd step)

ó

Clamp the disc-3

ó

The slider ass'y moves

down by 5 step(the H.P.)

ó

Load the tray-2 of the no disc.

ó

Playback the disc-2

11

Page 12

RXD-981MD

CIRCUIT DESCRIPTION

1. Initialization

1-1 Setting of initial conditions

While pressing the [ENTER] key, plug the AC power cord

into an AC power outlet.

1-2 Initializing operation

• A microcomputer is initialized for start when the AC

power is turned on while pressing the [ENTER] key. At

that time, CD mechanism, MD mechanism and CASSETTE mechanism are also initialized.

• During the initial operation, the display shows “INITIALIZE” and after that the clock blinks up on display.

1-3 Initial items and back up data

ITEMS

✣ POWER OFF

✣ VOLUME 15

✣ BALANCE CENTER

✣ MUTING OFF

✣ EQ OFF

✣ EQ. MANU FLAT

AMP ✣ EX. BASS ON

✣ SURROUND OFF

✣ INPUT SEL TUNER

✣ AUX INPUT 0 (-6dB)

✣ N. B. OFF

✣ DEMO OFF

✣ BAND FM

✣ LAST f LIMIT

TUNER ✣ LAST Pch ——

✣ AUTO/MONO AUTO

✣ Pch TEST f

✣ CLOCK AM 12 : 00

✣ PROG ON AM 12 : 00

CLOCK ✣ PROG OFF AM 12 : 00

TIMER ✣ PRO MODE PLAY

✣ SOURCE TUNER

✣ Pch 1

✣ EXE OFF

✣ OTT OFF

SLEEP OFF

PLAY MODE TRACK

REPEAT OFF

CD RANDOM OFF

PLAY MODE STOP

TIME SINGLE

✣ DIRECTION FORWARD

DECK ✣ RVS MODE p

✣ DOLBY NR OFF

OPERATION MODE STOP

✣ back up data

1-4 Mechanism initialization

1-4-1 CD mechanism

• If a mechanism error occurs, “C” is indicated on the

display.

1-4-2 MD mechanism

• The MD ON code is input within 4 seconds after turned

the power port on, the MD initial code (D122H) is output.

If the MD on code is not input, the error indication is

displayed as "M" on the display.

1-4-3 CASSETTE mechanism

• If a mechanism error occurs, "X" is indicated on the display.

1-5 All RAM clear

While pressing [SET] key, plug the AC power cord into

an AC power outlet, the all RAM cleared.

2. TUNER preset frequency

ch

1 FM 97.50MHz FM 97.50MHz

2 FM 108.00MHz FM 108.00MHz

3 AM 630kHz AM 630kHz

4 AM 1000kHz AM 999kHz

5 AM 1440kHz AM 1440kHz

6 AM 1610kHz AM 1602kHz

7 FM 87.50MHz FM 87.50MHz

8 FM 87.50MHz FM 87.50MHz

9 FM 87.50MHz FM 87.50MHz

10 FM 89.10MHz FM 89.10MHz

11 FM 87.50MHz FM 87.50MHz

12 FM 90.00MHz FM 90.00MHz

13 FM 106.00MHz FM 106.00MHz

14 AM 530kHz AM 531kHz

15 FM 87.50MHz FM 87.50MHz

16 FM 98.00MHz FM 98.00MHz

17 FM 98.50MHz FM 98.50MHz

18 FM 87.50MHz FM 87.50MHz

19 AM 990kHz AM 990kHz

20 FM 97.40MHz FM 97.40MHz

21 FM 87.50MHz FM 87.50MHz

22 FM 87.50MHz FM 87.50MHz

23 FM 87.50MHz FM 87.50MHz

24 FM 87.50MHz FM 87.50MHz

25 FM 87.50MHz FM 87.50MHz

26 FM 87.50MHz FM 87.50MHz

27 FM 87.50MHz FM 87.50MHz

28 FM 87.50MHz FM 87.50MHz

29 FM 87.50MHz FM 87.50MHz

30 FM 87.50MHz FM 87.50MHz

31 FM 87.50MHz FM 87.50MHz

32 FM 87.50MHz FM 87.50MHz

33 FM 87.50MHz FM 87.50MHz

34 FM 87.50MHz FM 87.50MHz

35 FM 87.50MHz FM 87.50MHz

36 FM 87.50MHz FM 87.50MHz

37 FM 87.50MHz FM 87.50MHz

38 FM 87.50MHz FM 87.50MHz

39 FM 87.50MHz FM 87.50MHz

40 FM 87.50MHz FM 87.50MHz

K2 E1/E2/H

Destination

12

Page 13

RXD-981MD

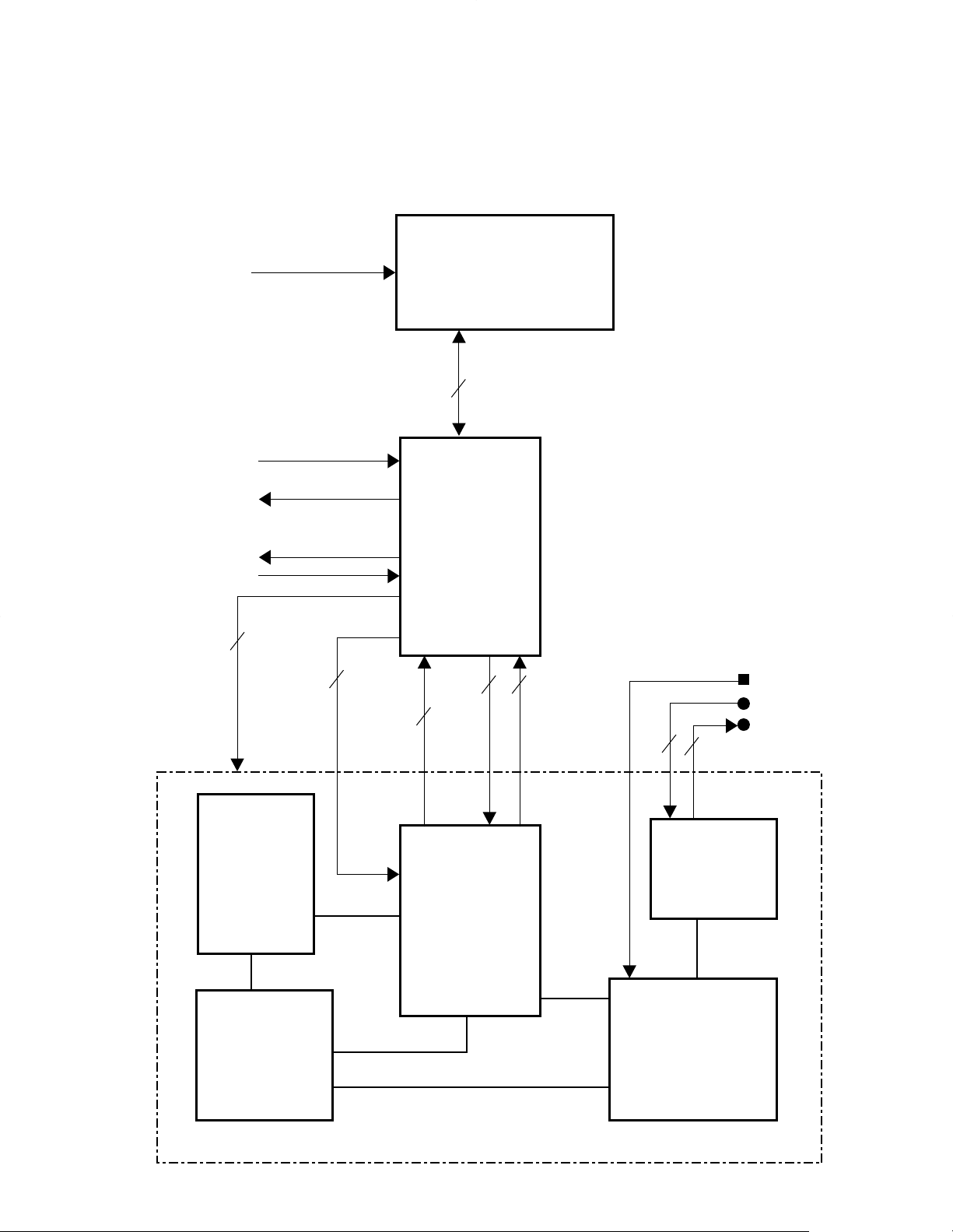

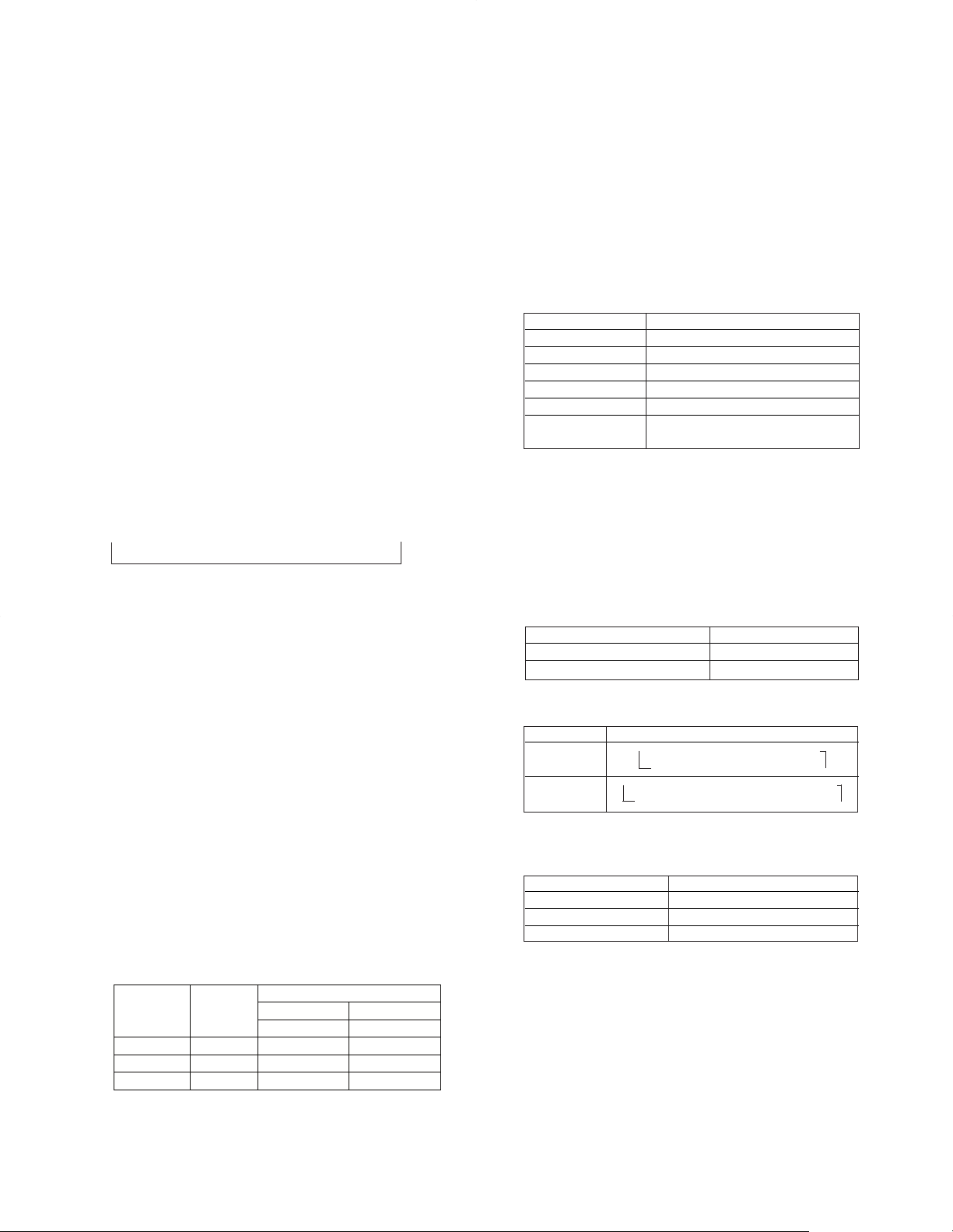

GC-E6003

X09, IC2

X14, IC1

X14, IC2

X09

IC61

X09

IC203

X09

IC402

X09

IC403

X14

IC3

E TYPE

ONLY

X09, IC7

CD mechanism

Mechanism

control

circuit

Mechanism

control

circuit

Auto reverse

cassette

mechanism

Head amp

dolby B

HA12209F

CXD2587Q

TUNER

PLL IC

LC72131

AUDIO

AMP SYSTEM IC

(LC75396)

MD

MDM-97A

LCD

LED

X14 ED1

FL

BJ573GK

Key matrix

encoder

remocon

RDS

demodulator

DOT driver

LC75710NE

E ONLY

BU2090

LED ariver

BU2090

M30612MA-306

FP

u-COM

CIRCUIT DESCRIPTION

3. Destination list of TUNER

Desti- U-COM Discrimination Receiving frequency Channel PORT

nation Desti- DSW1 DSW0 Band range space IF RF 92

– – K2 – – FM 87.5MHz~108.0MHz 100kHz +10.7MHz 25kHz 1

H, X H 1 0 FM 87.5MHz~108.0MHz 50kHz +10.7MHz 25kHz 0

Y, M, I E1 0 1 FM 87.5MHz~108.0MHz 50kHz +10.7MHz 25kHz 0

C, V AM 531kHz~1602kHz 9kHz +450kHz 9kHz 0

E, T E1 1 1 FM 87.5MHz~108.0MHz 50kHz +10.7MHz 25kHz 0

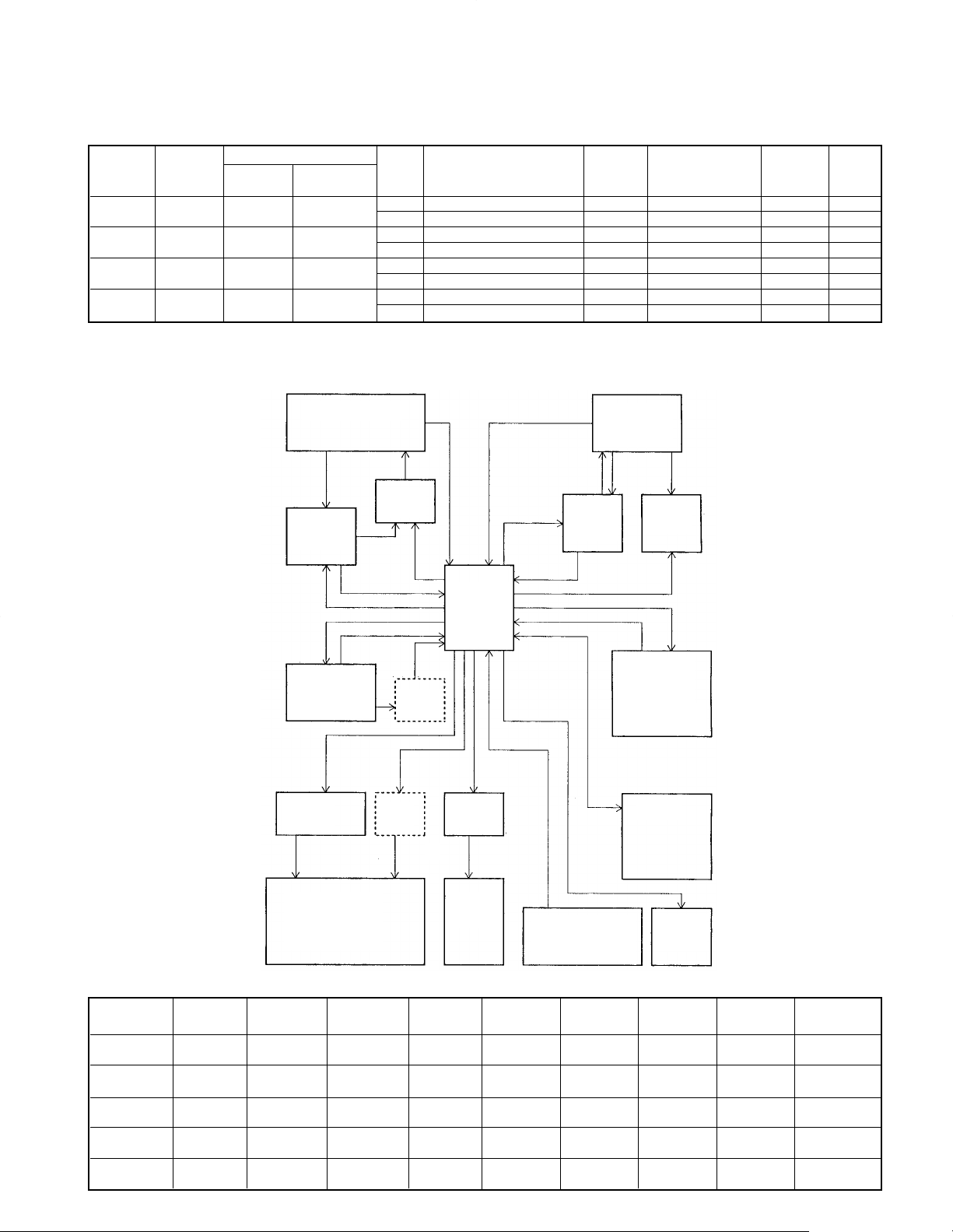

4. Composition

4-1 Microprocessor periphery block diagram

nation (65pin) (66pin)

AM 530kHz~1610kHz 10kHz +450kHz 10kHz 0

AM 531kHz~1602kHz 9kHz +450kHz 9kHz 0

RDS AM 531kHz~1602kHz 9kHz +450kHz 9kHz 0

0=(input low) 1=(input high)

4-2 Key matrix

REFERENCE VOLTAGE (5V)

Voltage 0.45 < 0.96 < 1.41< 1.85 < 2.29 < 2.74 < 3.20 < 3.64 < 4.10 <

<

0.96

KEY0 MODE EQ./ TAPE DOLBY TAPE TAPE TWIN TAPE KEY

94PIN BEATC. REC NR STOP PLAY REC O.T.E. OFF

KEY1 REW FF POWER MD MD MD QUICK T.EDIT/ KEY

93PIN 1¡ STOP 6 DELETE MOVE ADJ. OFF

=

KEY2 REPEAT SURRO- MD OTE TITLE TITLE MD SET ENTER KEY

<

=

1.41

<

1.85

=

<

=

2.29

<

=

2.74

<

=

3.20

<

=

3.64

<

4.10 210 <

=

92PIN /PROG. UND/OTT /EXE. INPUT SEARCH EJECT OFF

KEY3 DISPLAY RVS INPUT BEST REC MD EXBASS TUNER KEY

91PIN MODE SELECT HITS INPUT REC /A.P.S BAND OFF

KEY4 CD CD CD_3 CD_2 CD_1 CD_1 CD_2 CD_3 KEY

90PIN STOP 6 OPEN OPEN OPEN OFF

13

Page 14

RXD-981MD

CIRCUIT DESCRIPTION

4-3 Pin description of main microprocessor: M30612MA-306FP(X09: IC7)

Pin No. Name I/O Description

1 CE O PLL/system IC(chip enable)

2 PLL-DO I PLL(LC 72131)data input

3 SD I Tuner SD detector input H: NO tuned L: tuned

4 STEREO I Stereo(tuner) detector input H: MONO L: STEREO

5 EMPHASIS O Emphasis change-over(M type only) H: 100K L: 50K

6 RDS-DATA I RDS data signal input(E type only)

7 CE I Power failure input H: AC ON L: AC OFF

8,9 BYTE,CNVSS I No used

10 XCIN I

11 XCOUT O

12 RESET I Reset H: Normal L: Reset

13 XOUT O Main clock output(10MHz)

14 VSS – GND

15 XIN I Main clock input(10MHz)

16 VCC – u-com power supply

17 NMI I +5V(VCC terminal)

18 REMOCON I Remote control input

19 RDS-CLK I RDS IC clock

20 SCOR I Sub code synchronism signal(CXD2587Q)

21 CD SW3 I CD mecha. SW3 H: OFF L: ON

22 LCD DATA/CLOCK O LCD DATA/CLOCK

23 CD SW1 I CD mecha. SW1 H: OFF L: ON

24 CD SW2 I CD mecha. SW H: OFF L: ON

25~27 CD SW5~CD SW7 I CD mecha. SW5~7 H: OFF L: ON

28 SQCK O Sub code clock(CXD2587Q)

29 SUBQ I Sub code data

30 N.C. – No used

31 FL DATA O FL driver data output(LC75710NE)

32 SW8 I CD mecha. SW8 H: OFF L: ON

33 FL CLK O Clock output for FL driver(LC75710NE)

34 FL CE O Chip enable output for FL driver(LC75710NE)

35 MD TX O TX data output to MD

36 MD RX I RX data input from MD

37 FL RST O Reset output for FL driver(LC75710NE) H: normal L: reset

38 LDC O CD laser control output H: OFF L: ON

39 CD MUTE I CD zero mute input H: OFF L: ON

40 SLCK O CD sense data read clock(CXD2587Q)

41 SENSE I CD sense input(CXD2587Q)

42 CD-CLK O CD DSP clock(CXD2587Q)

43 XLAT O CD latch output(CXD2587Q)

44 CD-DATA O CD DSP data(CXD2587Q)

45 XRST O CD DSP reset output(CXD2587Q) H: normal L: reset

46 DC OFF O CD DSP power supply H: ON L: OFF

47 DREC SEL O MD digital input selector H: digital in L: others

48 SENSOR I CD mecha. sensor H: OFF L: ON

49 M UP O CD mecha. up H: ON L: OFF

50 M OPEN O CD mecha. open H: ON L: OFF

51 TMC O CD mecha. speed control H: slow L: fast

52 M CLOSE O CD mecha. close H: ON L: OFF

53 M DOWN O CD mecha. down H: ON L: OFF

54 CD SW4 I CD mecha. SW4 input(unclamp) H: OFF L: ON

55 CD BOS I CD mecha. bos sensor input H: OFF L: ON

56 ENC4 I Rotary encoder4/Vol. input A

57 ENC3 I Rotary encoder3/Vol. input B

58 ENC2 I Rotary encoder2/Jog input A

59 ENC1 I Rotary encoder1/Jog input B

60 LED CLK O Clock output for LED driver

Timer clock input/output(32.768kHz)

14

Page 15

RXD-981MD

CIRCUIT DESCRIPTION

Pin No. Name I/O Description

61 RES/FL DATA O Reset for FL driver

62 VCC – +5V(VCC terminal)

63 LED DATA O LED driver DATA output (BU2090)

64 VSS – GND

65,66 DSW1, DSW0 I Model discrimination

67 CD SW11 I CD mecha. load on sensor input H: OFF L: ON

68 REC/PLAY O Deck REC/PLAY change-over H: REC L: PLAY

69 BEAT C O Deck beat cancel H: ON L: OFF

70 SOL O Deck solenoid control H: ON L: OFF

71 CPM O Deck motor control H: ON L: OFF

72 REC MUTE O Deck rec mute control H: OFF L: ON

73 BIAS O Deck bias control H: ON L: OFF

74 DOLBY O Deck dolby control H: ON L: OFF

75 DPSS I Deck DPSS detection input L: ON music signal

76 REC R SW I Reverse rec detection SW L: inhibited

77 REC F SW I Forward rec detection SW L: inhibited

78 PACK SW I Deck pack SW input H: OFF L: ON

79 PLAY SW I Deck play SW input H: OFF L: ON

80 CLK O Clock output to LC75396/LC72131

81 A-MUTE O Mute control H: ON L: OFF

82 VOL ATT O Vol attenuation H: ON L: OFF

83 POWER O Power control H: ON L: OFF

84 PROTECT I Protection input H: Protect L: Normal

85 SP RELAY O Speaker relay control

86~88 SSELA~SSELC O Speana band selection(A,B,C)

89 BP IN I Speana input

90~94 KEY4~KEY0 O A/D input for keys(KEY4~KEY0)

95 RDS S LEVEL I RDS signal level

96 AVSS – A/D GND

97 PHOTO O Reel pulse input

98 VREF – A/D reference voltage

99 AVCC – +5V(VCC terminal)

100 DATA O Data for LC75396E/LC72131

4-4 Pin description of expander IC: BU2090 (X14, IC2)

Pin No. Name I/O Description

1 VSS – GND

2 DATA I DATA INPUT TERMINAL

3 CLOCK I CLOCK TERMINAL

4 TAPE_REC O TAPE REC LED H=OFF L=ON

5 TAPE_RVS O TAPE RVS LED H=OFF L=ON

6 TAPE_FWD O TAPE FWD LED H=OFF L=ON

7~9 DISC3~1 O CD DISC3~1 LED H=OFF L=ON

10 EQ O EQ LED H=OFF L=ON

11 TAPE_DOLBY O TAPE DOLBY LED H=OFF L=ON

12 MD_REC O MD REC LED H=OFF L=ON

13 POWER O STANDBY LED H=OFF L=ON

14 SURROUND O SURROUND LED H=OFF L=ON

15 MD_SLOT O MD SLOT LED H=OFF L=ON

16 VDD – POWER SUPPLY

15

Page 16

RXD-981MD

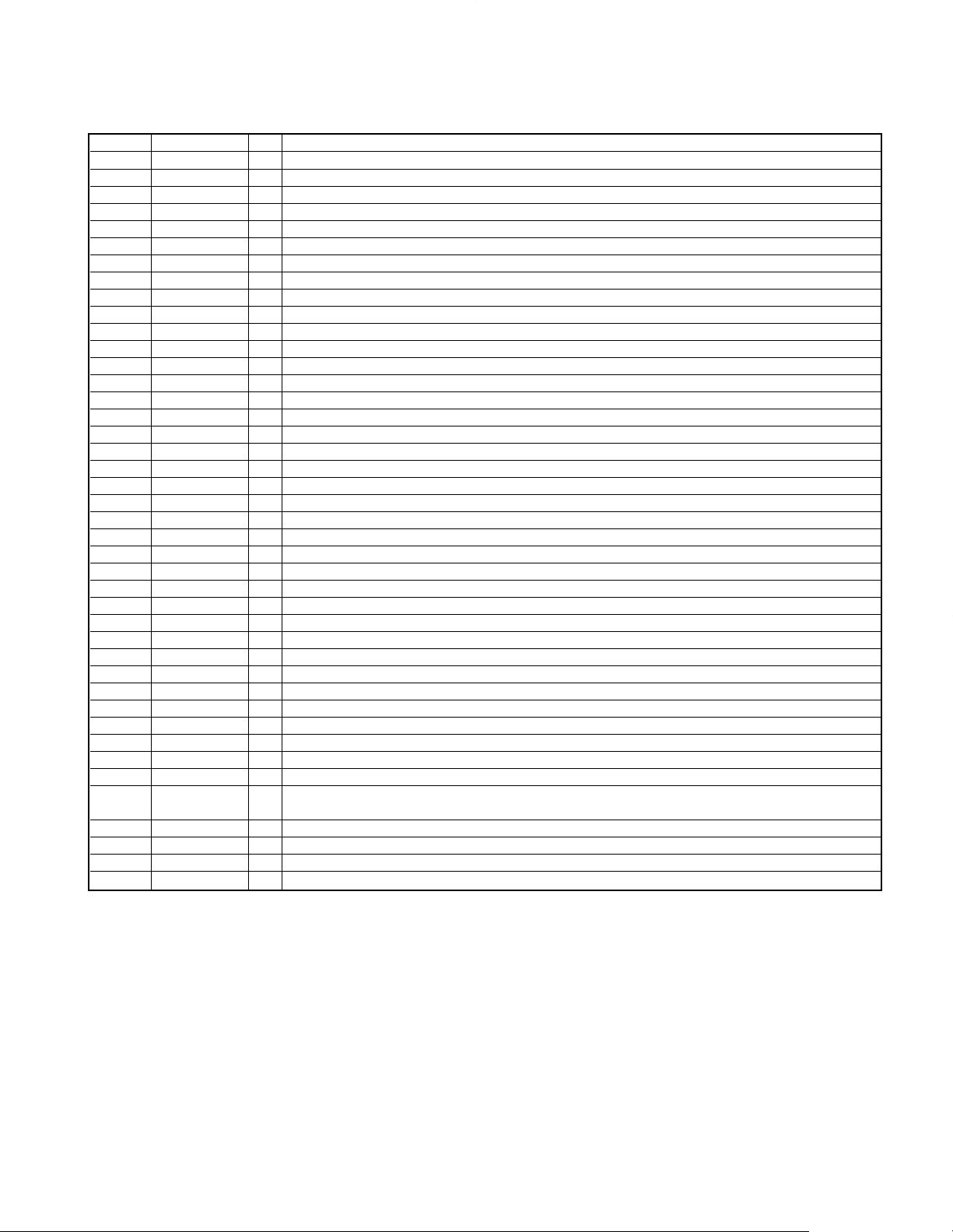

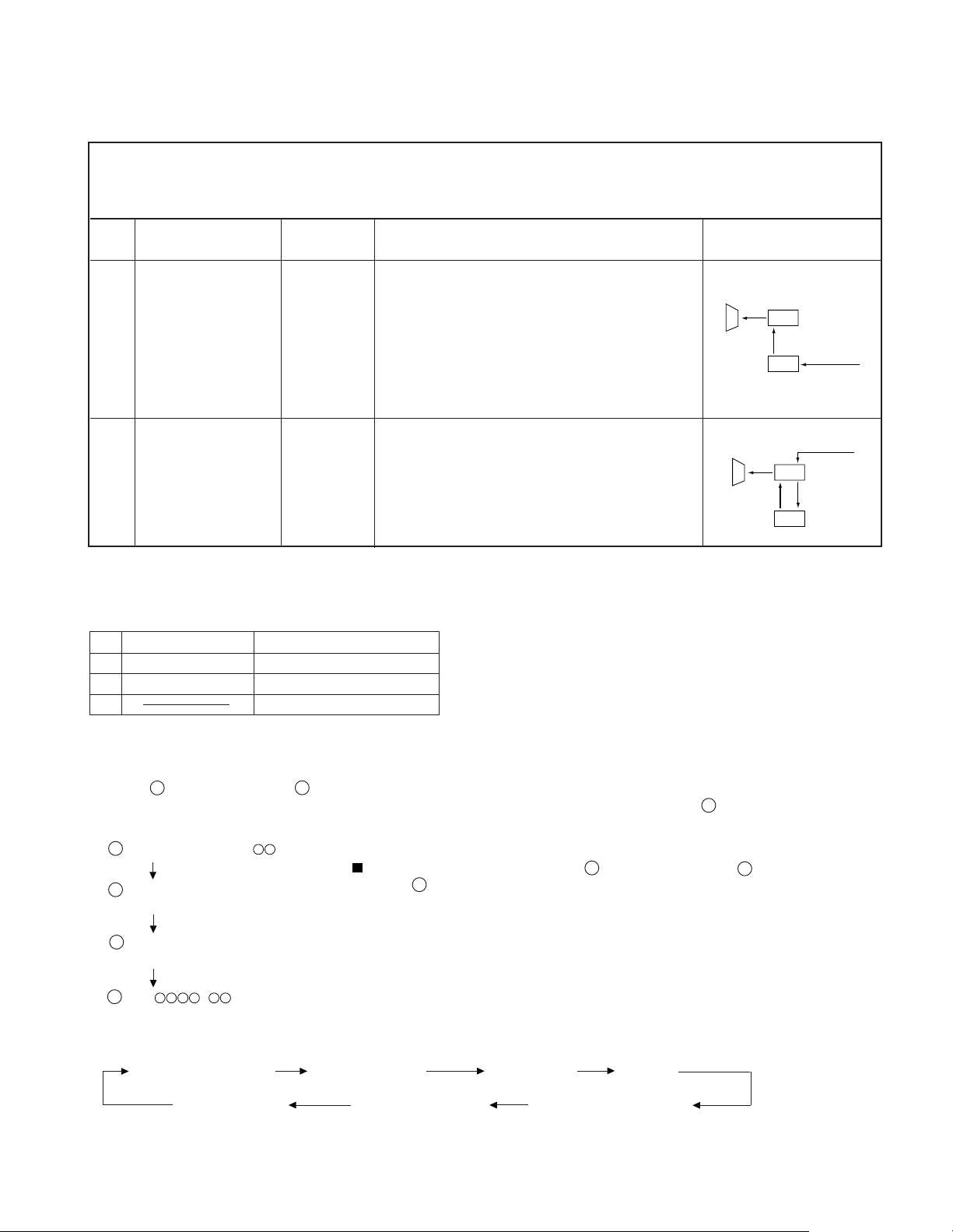

Back up power

supply (+5V)

X09, IC7

X09, IC8

MAIN u-COM

M30612MA-306FP

ENG_KANA

MD_MUTE

MUTE AND OR

(MAIN u-COM)

back up sw

MD SUPPLY VOLTAGE

CHANGE-OVER

TERMINAL

MD_RESET

MD-ST

SEARCH

LOAD_IN

DSCK

K_DATA

DSTB

MD_DATA

uart

rxd

txd

digital in

analog L/R in

analog L/R out

AD / DA

CONVERTER

MD

CONTROL

u-COM

DRIVE

UNIT

MD u-DOM

RF AMP

ENDEC / ATRAC

MD mecha. unit (MDM-97A)

2

22

2

2

1

3

1

uPD78058GC-A59

• DISPLAY CONTROL

• RF AMP CONTROL

• SIGNAL PROCESSING IC

CONTROL (TUNER)

• VOLUME, MUTE CONTROL

• INPUT SELECTOR CONTROL

back up voltage detection

5. Composition (MD section)

5-1 Microprocessor periphery block diagram

CIRCUIT DESCRIPTION

16

Page 17

RXD-981MD

CIRCUIT DESCRIPTION

5-2 Pin description of MD u-COM: uPD78058GC-A59

Pin No Name I/O Description

1 PDOWN O MDM-97 POWER DOWN DETECTOR

2 SEARCH O CD SEARCH OUTPUT

3 LOAD IN I LOAD SWITCH INPUT

4 Avss – A/D POWER SUPPLY (CONNECTED TO GND)

5,6 – – NO USED

7 Avref1 – D/A REFERENCE VOLTAGE(+5V)

8 RXD I COMMUNICATION FROM MAIN u-COM (UART RXD)

9 TXD O COMMUNICATION TO MAIN u-COM (UART TXD)

10 – – NO USED

11 MD_DATA I MD IC IN DATA (MDM-97 IN DATA)

12 K_DATA O MD IC OUT DATA (MDM-97 OUT DATA)

13 DSCK O MD IC CK (MDM-97 CLOCK)

14 DSTB I MD IC STB (MDM-97 STB)

15 COMM_ANS I NO USED

16 COMM_DIN I NO USED

17 COMM_DOUT O NO USED

18 COMM_CLK I/O NO USED

19 COMM_REQ O NO USED

20~31 – – NO USED

32 MD VLOAD O MD LOAD VOLTAGE CHANGE-OVER DISC LOAD/EJECT : H OTHER : L

33 Vss – u-COM(CONNECTED TO GND)

34~43 – – NO USED

44 INISW I INITIAL SW (H : RXD-981MD L : J TYPE)

45~58 – – NO USED

59 SRESET O NO USED

60 RESET I u-COM RESET

61 REMOCON I REMOCON INPUT (NO USED)

62~66 – – NO USED

67 CE I u-COM CE

68 Vdd – u-COM POWER SUPPLY

69 X2 – 5MHz OSCILLATOR

70 X1 I 5MHz OSCILLATOR

71 IC – IC TERMINAL(CONNECTED TO GND)

72 XT2 – NO USED (OPEN)

73 XT1 I NO USED (CONNECTED TO GND)

74 Avdd – A/D POWER SUPPLY

75 Avref0 I A/D REFERENCE VOLTAGE

76 BACKUP I

77 AMUTE O ANALOG MUTE H : MUTE ON L : MUTE OFF

78 BACKUPSW O BACKUP DETECTOR SW H:ON(IN CASE of CE : HIGH) L:OFF(IN CASE of CE LOW)

79 MD_RESET O MD u-COM RESET H : NORMAL L : MD u-COM RESET (LOW EDGE)

80 MD_ST O MD ON/CD SYNC H : MD ON L : BACKUP MODE

BACKUP DETECTOR(A/D)

BACK UP : MORE THAN2.2V NO BACKUP:LESS THAN2.2V

6. Test mode

6-1 Test mode of the receiver

(1) Setting of the test mode

While pressing the [INPUT] key or [Band] key, plug the

AC power cord into an AC power outlet.

(2) Canceling of the test mode

Unplug an AC power cord.

(3) Condition in test mode

POWER • • • • • • ON

SELECTOR • • • AUX (in case of [INPUT] key)

TUNER (in case of [BAND] key)

FL, LED • • • • • • All the fluorescent display indicate and

LEDs light. (The all illuminated state is

cleared by pressing any main unit key

or remocon key.

EX. BASS • • • • • OFF

(4) Basic operation in test mode.

1 The muting during mode selection is not controlled in

the test mode.

2 The test mode is cancelled when the AC power is

turned OFF.

3 The operation of the keys in the test mode, as follows.

(5) The operation of the keys in the test mode.

1 DISP key

When this key is pressed in the test mode, all the fluorescent light off and normal display are indicated

cyclically. (FL, LED, LCD)

17

Page 18

RXD-981MD

KEY

INDICATION

OF VOL.

VALUE

Press mode key in the AUX mode

1 time

2 times

BALANCE

INPUT LEVEL

TRACK EDIT1L

-6

DELETE

44 (MID)

CENTER

0

QUICK MOVE

86 (MAX)R+3

CIRCUIT DESCRIPTION

2 REPEAT key

If this key is pressed when setting the test mode, the

RDS indication is available on the display with the

selector on TUNER.

3 DISC 1~3 keys

With the selector on AUX, when the DISC 1~3 keys

are operated, the surround level settings can be

made as follows.

1 DISC 1 • • • • SURROUND level -10 (Min)

2 DISC 2 • • • • SURROUND level 0 (Center)

3 DISC 3 • • • • SURROUND level +10 (Max)

4 REC INPUT key

With the selector on TUNER, the fluorescent changes

cyclically as follows by pressing the REC INPUT key.

• ATT is switched OFF. “ATT OFF XX”

• ATT is switched ON. “ATT ON XX”

• ATT is switched OFF. Normal display

XX means A/D value (HEX) of S.

5 CD STOP key

With the selector on TUNER, when the [CD STOP]

key operated, the preset memory can be changed as

10 steps.

î10

– –

î 20

– –

î 30

– –

î 40

– –

î 01 ì

6 TITLE INPUT/TITLE SEARCH/TWIN REC keys

With the selector on something other than TUNER,

the E.Q (Flat, Min, Max) settings can be made by

pressing the TITLE INPUT/TITLE SEARCH/TWIN

REC keys.

TWIN REC key E.Q Flat

TITLE INPUT key E.Q Min

TITLE SEARCH key E.Q Max

7 JOG DIAL key

With the selector on TUNER, the P. CALL is operated

by turning the JOG DIAL key.

JOG DIAL(CW) P.CALL up

JOG DIAL(CCW) P. CALL down

8 CD DISC1 OPEN/CLOSE key

With the selector on TUNER, the channel space settings can be made cyclically by pressing the DISC

OPEN/CLOSE key with E1 version.

9 Other keys

During the test mode, it can be operated in a special

manner that is different from an ordinary operation by

using the keys on the main body, specifically as

shown in the following table.

6-2 Test mode of DECK section

(1) Setting

While pressing the PLAY key(DECK), plug the AC

power cord into an AC power outlet.

(2) Resetting

• Disconnect the AC power cord from an AC power outlet or press the [ON/STANDBY] key.

(3) Operation in TEST mode

(a) Initial condition

Item Condition

Power ON

Selector TAPE

Main VOL. -63dB(VOL.17)

Input level(AUX) -6dB(Input0)

EX. bass OFF

FL, LED, LCD All the FLs, LEDs,

and LCDs are turned on

(b) 4-sec REC

If the REC key is pushed, the system record for 4sec.

Then, it rewinds to the REC starting position and

plays back automatically.

If the REC key is pushed during the 4-sec REC operation, the system records further for 4-sec, then

returns to the starting position of the first 4-sec REC

operation and plays back.

(c) Mechanism SW detection

SW Display

FWD REC Inhibit SW Calendar-1

RVS REC Inhibit SW Calendar-2

(d) O.T.E / TWIN REC indication

The LCD changes cyclically as follows.

Keys Indication of LCD

O.T.E. î TAPE, O.T.E. (light ON) î

TAPE, O.T.E. (light OFF) í

TWIN REC î TWIN REC, O.T.E. (light ON) î

TWIN REC, O.T.E. (light OFF) í

(e) AUX input level

The AUX input level settings can be made as follows

by pressing keys.

Keys Input level

TRACK EDIT Min (-6)

DELETE Initial value (0)

QUICK MOVE Max (+3)

(f) REC PAUSE

When the REV. MODE key is pressed, the REC

PAUSE is entered during the REC operation.

18

Page 19

RXD-981MD

SEL.

MD

(PAUSE)

CD

DIGITAL

SP

SEL.

MD

(PAUSE)

AUX IN

(ANALOG)

REC IN

SP

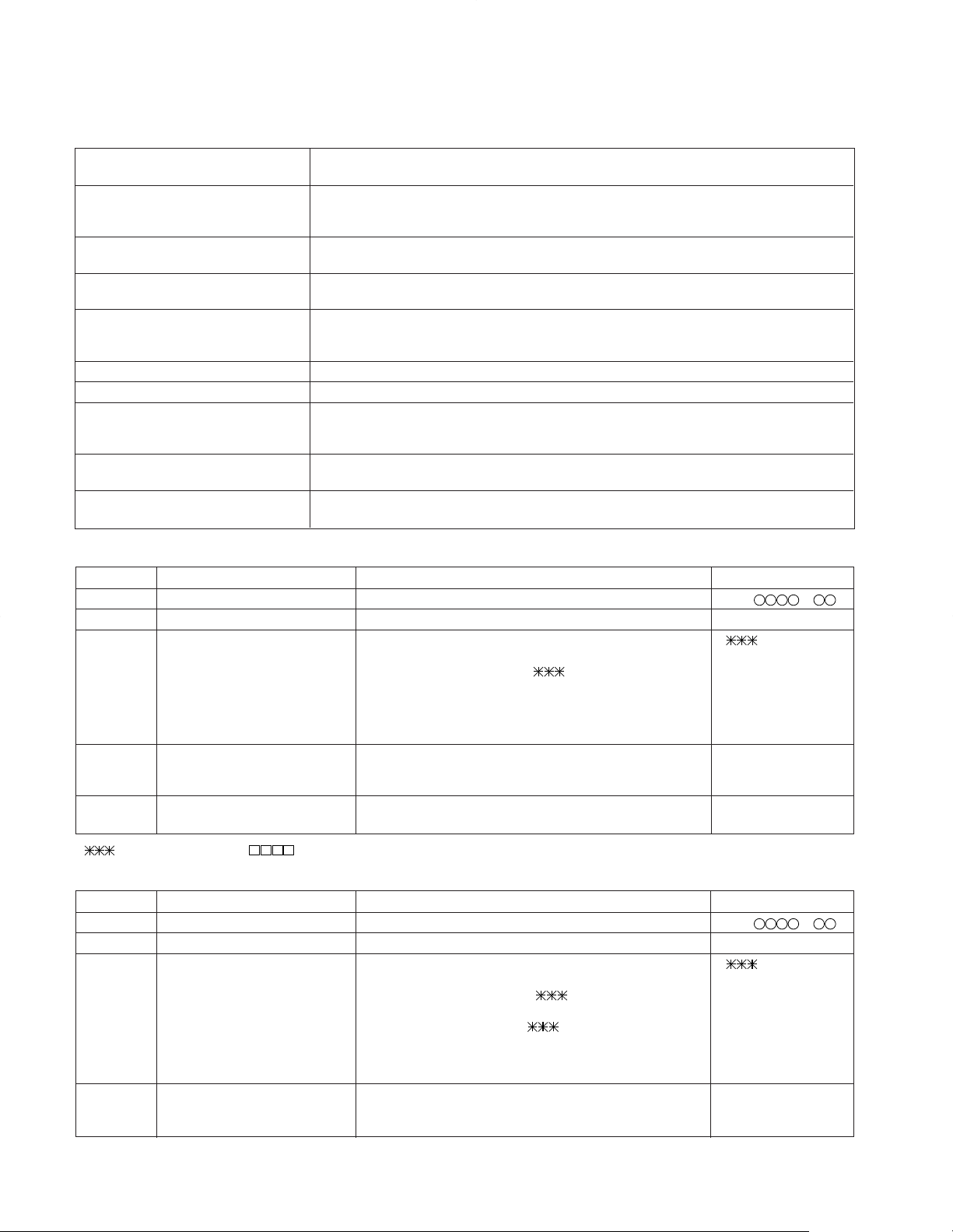

1. Preparation for adjustment Test disc

6-3-2 MD TEST mode for adjustment

Type Test disc

1 High reflection disc TGYS1 (SONY)

2 Low reflection disc Recording minidisc

3 Head Adjusting transparent

2. Test mode Test mode setting method

1. While pressing the [TRACK EDIT] key, plug the AC power cord into an AC power outlet.

(State A is changed to state B .)

2. Insert the playback disc 1 (high reflection disc) or recording disc 2 (low reflection disc). (State C is set.)

Thus, the test mode state is set.

A MD

represents version of MD microcomputer.

(When the MD (STOP) button is pressed in the C state,

is restored. To restore C again,

press

the

B EJECT

TEST

C AUTO

TEST

Entering the specific mode

Whenever the [MD REC] button is pressed, the mode is changed.

AUTO pre-adjustment AUTO adjustment RESULT SUB RESULT

EEPROM setting MANUAL adjustment MANUAL pre-adjustment

(AUTO YOBI) (AUTO AJST) (RST YOBI) (RESULT)

(EEPROM SET) (MNU AJST) (MNU YOBI)

the indication D

[MD REC] button.)

D tsm

e : TEST MODE

TEST STOP state

• Canceling the test mode

When the POWER button is pressed, the test mode is canceled, and the POWER OFF state is set.

CIRCUIT DESCRIPTION

6-3 Test mode of MD player

6-3-1 Inspection mode

Setting : While pressing the [QUICK MOVE] Key, plug the AC power cord into an AC power outlet.

The "INSPECTION" shows on the display.

Cancellation : Unplug the AC power cord from an AC power outlet.

No.

1 Digital through TITLE INPUT

2 Analog through TITLE

Contents of

TEST mode

test mode

test mode SEARCH

Keys Operation & Indication RemarKs

• The "DIGITAL1" is indicated on the display for a

second. "DIGITAL1"îCD input

• The "DIGITAL 2" is indicated on the display for

a second. "DIGITAL 2"îExternal digital input

• The "DIGITAL1" and "DIGITAL 2" can be

changed cyclically by pressing the [TITLE

INPUT] Key.

• Source indicator (MD) is blinked.

• The "ANALOG" is indicated on the display for a

second.

• AUX input levelîMID

• Source indicator (AUX) is turned ON .

19

Page 20

RXD-981MD

2. AUTO adjustment mode

Step No.

Setting Method

Remarks Display

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the

MD REC button two times.

AUTO adjustment menu [ A U T O _ A J S T _ ]

Step 3 Press once the MD PLAY button. The slide moves to the innermost periphery, and automatic [ : _ _ _ _ _ _ ]

adjustment is started.

• In case of high reflection disc changes as follows.

PEG→HAG

•In case of low reflection disc changes as follows.

PEG→LAG→GCG→GEG→LAG

End of adjustment If adjustment is OK, Step 4.

If adjustment is NG, Step 7.

Step 4 Adjustment value output [ _ C O M P L E T E _ ]

Press the MD PLAY button. STEP 5

Press the MD STOP button. STEP 2

1. AUTO pre-adjustment mode (Low reflection disc only)

Step No.

Setting Method

Remarks Display

Step 1 Testmode STOP state [ t s m e ]

Step 2 Press once the MD REC button. AUTO pre-adjustment menu [ A U T O ]

Step 3 Press once the MD PLAY button. The slide moves to the innermost periphery, and automatic [ : _ _ _ _ _ _ ]

pre-adjustment is started.

• During automatic adjustment changes as follows.

HAo→RFg→SAg→SBg→PTG→PCH→GTG→GCH→RCG→

SEG→RFG→SAG→HAO→HEO→TCO→LAO

End of adjustment If adjustment is OK, Step 4.

If adjustment is NG, Step 5.

Step 4 Grating adjustment, [ _ C O M P L E T E _ ]

adjustment value output

Press once the MD STOP button. STEP 2

Step 5 Adjustment value output [ A U T Y O B I ]

Press once the MD STOP button. STEP 2 AUTO pre-adjustment menu

• : Adjustment name, : Address

• Test Mode

1. AUTO pre-adjustment mode • Automatic pre-adjustment is performed. (After adjustment the grating adjustment mode is set.)

• The adjustment value is output with the aid of system controller interface.

2. AUTO adjustment mode • Automatic adjustment is performed.

• The adjustment value is output with the aid of system controller interface.

• Continuous playback is performed. (Error rate indication, jump test)

3. RESULT sub-mode • The measurement value, set value and calculated value are indicated.

• The set value is changed manually (in servo OFF state).

4. RESULT mode (final adjustment) • The set value (after calculation) is indicated.

• The set value is changed manually (in servo OFF state).

5. MANUAL pre-adjustment mode • RF side manual adjustment is performed.

• Focus and tracking signal ATT manual adjustment is performed.

• Focus and tracking signal offset setting is performed.

6. MANUAL adjustment mode • Focus and tracking signal ATT manual adjustment is performed.

7. EEPROM setting mode

8. TEST-PLAY mode • Continuous playback from the specified address is performed.

• • C1 error rate measurement,

This mode is not used for service.

•

This mode is not used for service.

•

This mode is not used for service.

9. TEST-REC mode • Continuous recording from the specified address is performed.

• Change of record laser output (servo gain is also changed according to laser output)

10. EJECT mode • TEMP setting (of EEPROM setting)

CIRCUIT DESCRIPTION

20

Page 21

RXD-981MD

Step 11 Press once the

MD REC

button. Indication of measurement value [ S E G : _ _ _ ]

Step 12 Press once the

MD REC

button. Indication of measurement value [ S F G : _ _ _ ]

Step 13 Press once the

MD REC

button. Indication of measurement value [ H A O : _ _ _]

Step 14 Press once the

MD REC

button. Indication of measurement value [ H B O : _ _ _]

Step 15 Press once the

MD REC

button. Indication of measurement value [ H E O : _ _ _]

Step 16 Press once the

MD REC

button. Indication of measurement value [ H F O : _ _ _]

Step 17 Press once the

MD REC

button. Indication of measurement value [ L A O : _ _ _]

Step 18 Press once the

MD REC

button. Indication of measurement value [ L B O : _ _ _]

Step 19 Press once the

MD REC

button. Indication of measurement value [ L E O : _ _ _]

Step 20 Press once the

MD REC

button. Indication of measurement value [ L F O : _ _ _]

Step 21 Press once the

MD REC

button. Indication of measurement value [ T C O : _ _ _ _]

Step 22 Press once the

MD REC

button. Indication of adjustment error sequence No. [ Y O B : _ _ _ _]

Step 23 Press once the

MD REC

button. Indication of adjustment status [ D I F : _ _ _ _]

Step 24 Press once the

MD REC

button. Indication of pre-adjustment not completed (00)/completed (4B) [ A D J : _ _ _ _]

Step 25 Press once the MD STOP button. RESULT sub-menu state [ _ R S T _ Y O B I _ ]

• : Measurement value, : Adjustment value, : Other various informations

• Pressing the REC button causes reversing.

• When the FF (⁄) key is pressed while the setting is displayed, the setting increases, and a new setting is stored in RAM.

• When the FB (!) key is pressed while the setting is displayed, the setting increases, and a new setting is stored in RAM.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the MD REC button four times.

RESULT menu [ _ R S T U L T _ _ _ ]

Step 3 Press once the MD PLAY button. Indication of set value [ H A G : _ _ _ ]

Step 4 Press once the

MD REC

button. Indication of set value [ H B G : _ _ _ ]

Step 5 Press once the

MD REC

button. Indication of set value [ L A G : _ _ _ ]

Step 6 Press once the

MD REC

button. Indication of set value [ L B G : _ _ _ ]

Step 7 Press once the

MD REC

button. Indication of set value [ P E G : _ _ _ ]

Step 8 Press once the

MD REC

button. Indication of set value [ P F G : _ _ _ ]

Step 9 Press once the

MD REC

button. Indication of set value [ G E G : _ _ _ ]

Step 10 Press once the

MD REC

button. Indication of set value [ G F G : _ _ _ ]

Step 11 Press once the

MD REC

button. Indication of set value [ G C G : _ _ _ _ ]

Step 12 Press once the MD STOP button. RESULT menu state [ _ R E S U L T _ _ _ ]

4. RESULT mode (final adjustment)

Step No.

Setting Method

Remarks Display

Step 5

Continuous playback (groove section)

[ a c ]

Step 6 Press the MD STOP button. STEP 2 AUTO adjustment menu

Step 7 Adjustment value output [ C a n ' t _ A D J . ]

Press the MD STOP button. STEP 2 AUTO adjustment menu

• : Adjustment name, : Measurement value, : Address

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the MD REC button three times.

RESULT sub-menu [ _ R S T _ Y O B I _ ]

Step 3 Press once the MD PLAY button. Indication of measurement value [ R F G : _ _ _ ]

Step 4 Press once the

MD REC

button. Indication of measurement value [ R C G : _ _ _ ]

Step 5 Press once the

MD REC

button. Indication of measurement value [ R T G : _ _ _ _ _ ]

Step 6 Press once the

MD REC

button. Indication of measurement value [ G T G : _ _ _ _ _ ]

Step 7 Press once the

MD REC

button. Indication of measurement value [ P C H : _ _ _ _ ]

Step 8 Press once the

MD REC

button. Indication of measurement value [ G C H : _ _ _ _ ]

Step 9 Press once the

MD REC

button. Indication of measurement value [ S A G : _ _ _ ]

Step 10 Press once the

MD REC

button. Indication of measurement value [ S B G : _ _ _ ]

3. RESULT sub-mode

Step No.

Setting Method

Remarks Display

Step No.

Setting Method

Remarks Display

CIRCUIT DESCRIPTION

21

Page 22

Step 11 Press once the

MD REC

button. Focus ATT (B signal) tentative setting [ S B g : ]

Step 12 Press once the

MD REC

button. RF side pit section TG adjustment [ P T G : _ _ ]

Step 13 Press once the

MD REC

button. Pit section COUT level setting [ P C H : _ ]

Step 14 Press once the

MD REC

button. Outer periphery move → RF side groove TG adjustment [ G T G : _ _ ]

Step 15 Press once the

MD REC

button. Groove section COUT level setting [ G C H : _ ]

Step 16 Press once the

MD REC

button. RF side TCRS adjustment [ R C G : _ _ ]

Step 17 Press once the

MD REC

button. Tracking ATT (A signal) setting [ S E G : ]

Step 18 Press once the

MD REC

button. Tracking ATT (B signal) setting [ S F G : ]

Step 19 Press once the

MD REC

button. Indication of tracking EFMIO measurement [ g M I : _ _ _ ]

Step 20 Press once the

MD REC

button. RF side pit section FG adjustment [R F G : _ _ ]

Step 21 Press once the

MD REC

button. Focus ATT (A signal) setting [ S A G : ]

Step 22 Press once the

MD REC

button. Focus ATT (B signal) setting [ S B G : ]

Step 23 Press once the

MD REC

button. Offset "0" setting → A signal offset measurement [ H A O : _ _ _ ]

Step 24 Press once the

MD REC

button. B signal offset measurement [ H B O : _ _ _ ]

Step 25 Press once the

MD REC

button. E signal offset measurement [ H E O : _ _ _ ]

Step 26 Press once the

MD REC

button. F signal offset measurement [ H F O : _ _ _ ]

Step 27 Press once the

MD REC

button. TCRS signal offset measurement [ T C O : _ _ _ ]

Step 28 Press once the

MD REC

button. A signal offset measurement [ L A O : _ _ _ ]

Step 29 Press once the

MD REC

button. B signal offset measurement [ L B O : _ _ _ ]

Step 30 Press once the

MD REC

button. E signal offset measurement [ L E O : _ _ _ ]

Step 31 Press once the

MD REC

button. F signal offset measurement [ L F O : _ _ _ ]

• : Measurement value, : Set value, : Account value

• If the FF (⁄) or FB (!) key is pressed is pressed during setting indication, the setting increases/decreases, and the new setting is stored

in RAM.

If the measurement value is within the OK range, "

" appears on the 8th character.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the MD REC button six times.

MANUAL adjustment menu [ _ M N U _ A J S T _ ]

Step 3 Press once the MD PLAY button. Initial setting → Temperature measuring mode [ T M P : _ _ _ _ ]

Step 4 Press once the MD REC button. Laser ON [ L O N : _ _ _ _ _ _ ]

Step 5 Press once the MD REC button. Innermost periphery move → Tracking ATT (E signal) setting [ P E G : ]

Step 6 Press once the MD REC button. Tracking ATT (F signal) setting [ P F G : ]

6. MANUAL adjustment mode High reflection disc

Step No.

Setting Method

Remarks Display

•

: Measurement value

• Pressing the REC button causes reversing.

• When the FF(⁄) key is pressed while the setting is displayed, the setting increases, and a new setting is stored in RAM.

• When the FB(!) key is pressed while the setting is displayed, the setting increases, and a new setting is stored in RAM.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the

MD REC button five times.

MANUAL auxiliary adjustment mode [ _ M N U _ Y O B I _ ]

Step 3 Press once the MD PLAY button. Initial setting → Temperature measuring mode [ T M P : _ _ _ _ ]

Step 4 Press once the

MD REC

button. Offset "0" setting → A signal offset tentative measurement [ H A o : _ _ _ ]

Step 5 Press once the

MD REC

button. B signal offset tentative measurement [ H B o : _ _ _ ]

Step 6 Press once the

MD REC

button. E signal offset tentative measurement [ H E o : _ _ _ ]

Step 7 Press once the

MD REC

button. F signal offset tentative measurement [ H F o : _ _ _ ]

Step 8 Press once the

MD REC

button. Offset tentative measurement → Laser ON [ L O N : _ _ _ _ _ _ ]

Step 9 Press once the

MD REC

button. Innermost periphery move → RF side FG rough adjustment [ R F g : _ _ ]

Step 10 Press once the

MD REC

button. Focus ATT (A signal) tentative setting [ S A g : ]

5. MANUAL auxiliary adjustment mode (only low reflection disc)

Step No.

Setting Method

Remarks Display

RXD-981MD

CIRCUIT DESCRIPTION

22

Page 23

RXD-981MD

Step 11 Press once the MD REC button. Tracking ATT (E signal) setting [ G E G : ]

Step 12 Press once the MD REC button. Tracking ATT (F signal) setting [ P F G : ]

Step 13 Press once the MD REC button. Indication of tracking EFMIO measurement (groove section) [ G M I : _ _ _ ]

Step 14 Press once the MD REC button. Focus ATT (A signal) setting [ L A G : ]

Step 15 Press once the MD REC button. Focus ATT (B signal) setting [ L B G : ]

• If the MD STOP button is pressed while the MANUAL adjustment menu is displayed, the state is changed to the TEST mode STOP

state.

• This mode is not used for service.

7. EEPROM setting mode

8. TEST-PLAY mode

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the MD O.T.E. button.

TEST-PLAY menu [ T E S T _ P L A Y _ ]

Step 3 Press once the MD PLAY button. During search the search output pin 11 is set to "H", and it is

returned to "L" when continuous playback is started.

Step 4

Continuous playback (groove section)

(Address + C1 error indication) [a c ]

Step 5 Press once the MD STOP button. TEST-PLAY menu [ T E S T _ P L A Y _ ]

Step No.

Setting Method

Remarks Display

• If the MD STOP button is pressed while the TEST-PLAY menu is displayed, TEST mode STOP state is set.

• If the MD PLAY button is pressed while the TEST-PLAY menu is displayed, continuous playback is started from the current pickup position.

•

: Adress, : Error late

9. TEST-REC mode

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the MD O.T.E. button.

TEST-REC menu [ T E S T _ R E C _ _ ]

Step 3 Press once the MD PLAY button. During search the search output pin 11 is set to "H", and it is

(returned on "L" when continuous playback is started.Address +

C1 error indication) Continuous recording [ a

p w ]

Step 4 Press once the MD STOP button. TEST-REC menu [ T E S T _ R E C _ _ ]

Step No.

Setting Method

Remarks Display

• If the MD STOP button is pressed while the TEST-PLAY menu is displayed, TEST mode STOP state is set.

• If the MD PLAY button is pressed while the TEST-REC menu is displayed, continuous record is started from the current pickup position.

• If the FF(⁄) or FB(!) button is pressed in TEST-REC mode and continuous record mode, the laser record power changes.

(Servo gain changes also according to the record power.)

•

: Adress, : Laser power cord

Step 7 Press once the MD REC button. Indication of tracking EFMIO measurement [ P M I : _ _ _ ]

Step 8 Press once the MD REC button. Focus ATT (A signal) setting [ H A G : ]

Step 9 Press once the MD REC button. Focus ATT (B signal) setting [ H B G : ]

Step No.

Setting Method

Remarks Display

• If the MD STOP button is pressed while the MANUAL adjustment menu is displayed, the state is changed to the TEST mode STOP

state.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Press the MD REC button six times.

MANUAL adjustment menu [ _ M N U _ A J S T _ ]

Step 3 Press once the MD PLAY button. Initial setting → Temperature measuring mode [ T M P : _ _ _ _ ]

Step 4 Press once the MD REC button. Laser ON [ L O N : _ _ _ _ _ _ ]

Step 5 Press once the MD REC button. Innermost periphery move → Tracking ATT (E signal) setting [ P E G : ]

Step 6 Press once the MD REC button. Tracking ATT (F signal) setting [ P F G : ]

Step 7 Press once the MD REC button. Indication of tracking EFMIO measurement (pit section) [ P M I : _ _ _ ]

Step 8 Press once the MD REC button. Focus ATT (A signal) setting [ L A g : ]

Step 9 Press once the MD REC button. Focus ATT (B signal) setting [ L B g : ]

Step 10 Press once the MD REC button. Outside periphery move → Track closs setting [ G C G :

]

High reflection disc

Step No.

Setting Method

Remarks Display

CIRCUIT DESCRIPTION

23

Page 24

RXD-981MD

CIRCUIT DESCRIPTION

Laser record power list

Indica- Recommended Output (25˚C)

tion TOC laser power Output setting Output voltage

value value

00H 2.50 mW 6E H 1.354 V

01H 2.60 mW 74 H 1.427 V

02H 2.70 mW 7B H 1.513 V

03H 2.85 mW 83 H 1.612 V

04H 3.00 mW 8A H 1.698 V

05H 3.15 mW 93 H 1.809 V

06H 3.30 mW 93 H 1.809 V

07H 3.45 mW 9C H 1.920 V

10. EJECT mode

Step No.

Step 1 Testmode EJECT state [ _ _ E J E C T _ _ _ ]

Step 2 Press oncethe DELETE button. TEMP setting [ T E M P ]

Step 3 Press once the STOP button. [ _ _ E J E C T _ _ ]

• : Measurement value, : Adjustment value

• When the FF (⁄) key is pressed while the TEMP setting is displayed, the setting increases, and a new setting is stored in RAM.

• When the FB (!) key is pressed while the TEMP setting is displayed, the setting decreases, and a new setting is stored in RAM.

Setting Method

Indica- Recommended Output (25˚C)

tion TOC laser power Output setting Output voltage

value value

08H 3.60 mW A6 H 2.043 V

09H 3.75 mW AE H 2.141 V

0AH 3.95 mW B9 H 2.289 V

0BH 4.15 mW B9 H 2.289 V

0CH 4.35 mW C4 H 2.412 V

0DH 4.55 mW CF H 2.547 V

0EH 4.75 mW DB H 2.695 V

0FH 5.00 mW DB H 2.695 V

Remarks Display

Mechanism Adjustment

1. Optical pickup grating inspecting method

43 pin of IC 1101

GND

26 pin of IC 1101

EOUT

25 pin of IC 1101

FOUT

100K

470p

470p

100K

OSILLOSCOPE

GND CH1 CH2

XY

LISSAJOUS'S WAVEFORM

b

Less thana:b = 3:1

a

Figure 1-1 Optical Pickup Grating Deviation

Measuring Method

After the automatic adjustment is performed in the AUTO

mode (test mode) with the aid of high refection MD disc

("COMPLATE" is displayed), the Lissajous's waveform (x-y) is

adjusted.

1. Slightly loosen the 3 screws of spindle moto, and maken an

adjustment, observing the Lissajous's waveform.

2. After adjustment tighten the screw in arder of 1 , 2 , 3 .

2. Jitter adjustment and checking method

jitter Meter

Spindle Motor

Adjusting hole

1

1

3

Spindle motor

adjusting

hole

2

3

2

Check the Lissajou's waveform,

shifting the mounting position with

a screwdriver (to be fitted into the

disc motor adjusting hole).

Figure 1-2

3pin of IC 1201 (TP1274)

EFMMON

13 pin of IC 1201 (TP1275)

GND

Figure 1-3 Jitter connection diagram

After performing automatic adjustment in AUTO mode of

TEST mode using the low reflection MD disc, check this jitter

in pit continuous playback and groove continuous playback

mode.

24

Page 25

RXD-981MD

Figure 1-4

5P extension flat cable

2P extension connector

CN1601(Bottom side)

CN1602

CN1252

CN1603

CN1604(Bottom side)

CNP1101

MD Main PWB

6P-2P extension connector

28Pextension flat cable

Extension PWB for service

Fit the extension PWB for service to the mechanism

From Optical

Pickup Unit

From Magnetic Head

From

motor

From mechanism switch

PWB

CIRCUIT DESCRIPTION

6-4 Test mode of CD player

6-4-1 Main unit

(1) Setting of the test mode

While pressing the [DISC3 PLAY] key, plug the AC

power cord into an AC outlet.

(2) Canceling of the test mode.

Unplug the AC power corde from AC power outlet or

press the [SET] key.

(3) Operation

KEY

[DISC3 PLAY]

+AC

STOP CD 5 01 STOP

PLAY/PAUSE

PAUSE

óï

PLAY

(Cyclically

changed)

FF

FB

BEST

HITS

DISPLAY OPERATION

POWER ON, SEL CD

CD 5 01

CD 5 05

PLAY MARK

ON ‰

CD 5 03

PAUSE MARK

ON 8

CD 5 01

CD 5 01

CD 5

Mecha. initialization

Tray 3 opens

05 MODE

TRAY CLOSE/DISC CLAMP

03 MODE

(TRACKING SERVO OFF)

Pick manual feed (INîOUT)

(Stop mode only)

Pick manual feed (OUTîIN)

(Stop mode only)

Indication

: Adjustment value/Mean

value (stop mode only)/HEX

DOT TNO SEC.

section section section

TB/FB TB value FB value

TG/FG TG value FG value

FE/RF FE value RF value

TE/VC TE value VC value

6-4-2 Mecha. manual mode

(1) Setting

While pressing the [DISC 1 PLAY] Key, plug the AC

power cord into an AC outlet.

(2) Cancelling

Press the [ON/STAND BY] Key.

(3) Operation

KEYS INDICATION OPERATION

FF CD MANUAL LIFT MOTOR UP

FB CD MANUAL LIFT MOTOR DOWN

DISC 2 CD MANUAL LOAD MOTOR OPEN

DISC 3 CD MANUAL LOAD MOTOR CLOSE

25

Page 26

RXD-981MD

Adjustment of CD player

ADJUSTMENT

No.

TEST MODE : While pressing the [DISC 3 PLAY] key, plug the AC power cord into the AC outlet.

1

2

Note:

Type 4disc :SONY YEDS-18 Test Disc or equivalent.

LPF : Around 47kΩ + 390pF or so.

ITEM

LASER

POWER

FOCUS

ERROR

BIAS

INPUT

SETTING

Set the senor section of

–

Connect an oscilloscope

Test disc

Type 4

(a) Laser Power

0.05~0.15 mW

OUTPUT

SETTING

the optical power meter

on the pickup lens.

as follows.

(+)side : RF(CN1-1)

GND : VC (CN1, 4)

PLAYER

SETTING

Press the"PLAY"key

to check that the

display is "03".

Press the "PLAY"

key. Confirm that

the display is”05”

(b)

RF signal : AC coupled

ALIGNMENT

POINT

–

VR1

Optimum eye pattern

ALIGN FOR

On the power

from.0.05 to

0.15mw. when the

diffraction grating is

correctly aligned

with the RF level of

0.8Vp-p or more

FIG.

(a)

(b)

Pickup

Optical power meter

¶ RF signal in test mode (PLAY).

¶ Perform the tangential and focusing offset are focused

into one point on the display. The crossing points above

and below the center shall also be looked clearly.

★ The MD Adjustment is listed on page 19 through p25.

26

Page 27

(A)

(C)

(B)

(D)

FM-MPX-SG

FM-MPX-SGPOLAR SG

AM-SG

AC voltmeter

Oscilloscope

Distortion meter

Dummy antenna

ANTENNA

AM FM

300Ω

FM

75Ω

GND

SUPER

WOOFER

PRE OUT

SPEAKERS

i6-16‰ j

RR LL

+

--

+

RR

LL

AUX INPUT

DIGITAL

INPUT

OPTICAL

Tuner adjustment

No.

ITEM

FM SECTION BAND : FM

1

DISCRIMINATOR

(E TYPE ONLY)

ADJUSTMENT

INPUT SETTING

(A)

CARRIER FREQ. : 98.0MHz

MOD FREQ. : 1kHz

DEVIATION : ±75kHz

SELECTOR : MONO

ANT INPUT LEVEL

: 70dBf

OUTPUT

SETTING

Connect a

DC

voltmeter to

CN401 of

X09.

TUNER

SETTING

MONO

98.0MHz

RXD-981MD

ALIGNMENT

POINTS

L405

ALIGN FOR

0V

FIG.

2

TUNED LEVEL

3

DISTORTION

(STEREO)

(A)

CARRIER FREQ. : 98.0MHz

MOD FREQ. : 1kHz

DEVIATION : ±75kHz

SELECTOR : MONO

ANT INPUT LEVEL

:

32.2dBf±10dB

(A)

CARRIER FREQ. : 98MHz

MOD FREQ. : 1kHz

DEVIATION : ±67.5kHz

PILOT : ±7.5kHz

SELECTOR : L or R

ANT INPUT LEVEL

: 70dBf

(B)

(B)

MONO

98.0MHz

AUTO

98.0MHz

Adjust VR401

and stop at the

VR401

point where

EDI (TUNED)

goes ON.

A401

Minimum

distortion.

27

Page 28

SUPER

WOOFER

PRE OUT

SPEAKERS

i6-16‰ j

RR LL

+

--

+

RR

LL

AUX INPUT

DIGITAL

INPUT

OPTICAL

AG

{

(A)(B)

AC voltmeter

AC voltmeter

Oscilloscope

Frequency counter

X09 CN202

1

2

3

4

5

PLAY (L)

REC (L)

GND

PLAY (R)

REC (R)

RXD-981MD

RVS FWD

NO. ITEM

INPUT

SETTING

OUTPUT

SETTING

CASSETTE TAPE

DECK SETTING

ALIGNMENT

POINTS

ALIGN FOR FIG.

Unless otherwise specified, set the respective switches as follows: 0dBs = 0.775V

TAPE : NORMAL DOLBY : OFF

I Cassette mechanism unit (Adjustment of the REC / PLAY head)

(1)

Demagnetization

and cleaning

——

Power : OFF

Demagnetization,

cleaning, PLAY

Recording

head, erase

head, capstan

pinch roller

Demagnetize the REC / PLAY head

with the head eraser. Clean the REC/

PLAY head, erase head, capstan and

pinch roller using a cotton swab slightly

damped with alcohol.

(2)

Azimuth of the

REC / PLAY

head

SCC-1727

TCC-153

MTT-114

10kHz, -10dB

(B) PLAY

Adjust the output to maximum and

adjust the azimuth adjustment screw

for the Lissajours waveform pattern of

the oscilloscope to become close to a

45˚ straight ling.

II PC BOARD ADJUSTMENT

(1)

TAPE SPEED

(NORMAL)

TCC-110

MTT-111

SCC-1727

3kHZ

(B) PLAY VR205

Adjust the tape speed so that 3kHz is

obtained at the center of the tape.

III PC board adjustment.

(1)

PLAYBACK

LEVEL

MTT-150

400Hz

(B) PLAY

VR201(L)

VR202(R)

Adjust the playback output to –2.5dBs.

MTT-256, SCC-1727

315Hz

Adjust the playback output to –5.5dBs.

MTT-256U, TCC-120

315 Hz

Adjust the playback output to –1.5 dBs.

(2)

BIAS

CURRENT

(A)

Adjust the AG for the

output of the DECK to

become 12.5KHz –20dBs.

400Hz / 12.5kHz

(AC-224)

(B) REC PLAY

VR203(L)

VR204(R)

Record 400Hz and 12.5kHz alternately,

and adjust the bias current adjustment

potentiometer for the playback levels to

become the same.

ADJUSTMENT

28

Page 29

DISPLAY UNIT

POWER AMP UNIT

AUDIO UNIT

(X07-) (D/4)

PRIMARY UNIT

PRIMARY UNIT

PRIMARY UNIT

SECONDARY UNIT

(X07- ) (C/4)

(X07-) (B/4)

(X14- ) (F/6)

(X14- ) (B/6)

(X14-468X-XX) (A/6)

RXD-981MD (M,T,E,H)

(X09-485X-XX)

EXCEPT for (J) TYPE

USED (J) TYPE

(X14-) (E/6)

USED (M) TYPE

(X14-) (D/6)

(X07-) (D/4)

USED (T,E,H) TYPE

(X14- ) (C/6)

(X07-295X-XX) (A/4)

HEADPHONE

(T,E) TYPE

(J,M,H) TYPE

CASSETTE

MECHANISM

(D40-1579-X5)

(D40-1567-X5)

MD MECHANISM

(D40-1586-X5)

CD MECHANISM

CN1902

CN1904

CN3

CN6

CN1

E4

E2

WH2

E3

WH1

E1

0-21

2-71

0-00

4-11

RXD-M1MD

RXD-981MD (T,E) :

(M) :

(J) :

(H) :

CN1CN9

CN2C11

0-21

4-11

0-00

2-71RXD-981MD

RXD-M1MD

(H) :

(J) :

(M) :

(T,E) :

CN11

CN11

S101

CN10

WH4 WH3

CN12

WH1

E1E2

CN11

(T,E) :

(M) :

2-71

0-21

(J) : 0-00

4-11(H) :

RXD-981MD

RXD-M1MD

J3

PHONES

P4

SUPER

1 Lch

2 Rch

J2

WOOFER

PRE OUT

-

+

SP OUTPUT

J1

( 6-16

-

+

)

E4

WH2

E3

E6

WH6

CN14

E5

WH5

CN13

OPTICAL

DIGITAL IN

A1

INPUT

J601

Lch

AUX

Rch

J401

AM ANT

GND

FM75 Ω

300Ω

FM

J401

FM

75Ω

GND

AM ANT

E35-2015-X5

E35-2094-X5

CN201

CN7

E35-1980-X5

E35-1979-X5

CN5

E35-1978-X5

CN4

CN6

CN2

CN10

CN3

CN203

CN8

Ω

F5

F4

F3

3

1

6

1

3

1

6

1

11

12112

1

1212

1

2

HOT

COLD

2

1

AC100V

50/60Hz

2

1

AC220-240V

AC110-120V

AC110-120V/

50/60Hz

220-240V~

: AC230V~ 50Hz

: AC240V~ 50Hz

WH12 (WHT)

WH11 (BRN)

WH14 (YEL)

WH13 (RED)

F2

HOT

COLD

F1

HOT

COLD

F1

(T,E)

(H)

3

1

1

3

11

1515

1

1

4

4

11

99

1

1

7

7

1

11

1

11

1

13

1

1

4

1

4

1

2

2

WHT/WHT

1

RED/BLK

1

2

22

11

2

1

11

1616

1

5

1

1

5

16

161

13

1

7

6

1

1

24

24

1

V

VV

V

V

V

V

V

V

V

V

V

V

V

VV

V

V

V

V

V

V

VV

V

V

V

V

V

VV

V

V

V

V

V

V

V

V

29

WIRING DIAGRAM

RXD-981MD

Page 30

CN1902

Q1820

Q1251

L1251

D1251

CN1252

C1252

R1251

C1251

Q1252

D1252

CN1602

C1700

R1702

R1714

C1702

R1713

R1701

C1701

C1711

IC1701

L1702

L1701

C1717

C1720

R1715

Q1701

R1717

R1711

R1710

R1712

R1807

C1716

C1709

C1810

R1806

Q1804

R1811

R1810

Q1806

C1704

C1460

R1735

R1734

R1707

R1708

R1733

R1731

R1994

R1995

CJ172

C1729

C1724

C1722

L1950

LR190

R1461

R1463

C1425

R1459

Q1822

R1939

R1827

R1466

R1464

R1462

R1460

R1458

R1454

R1452

R1456

C1904

Q1451

Q1821

Q1404

Q1403

C1927

J1921

IC1251

R1252

Q1254

Q1253

R1253

C1255

C1254

R1223

R1967

R1969

R1968

R1964

IC1916

IC1202

C1206

IC1906

IC1907

C1964

C1958

R1965

C1951

R1971

R1409

IC1990

C1954

R1963

R1962

C1955

C1990

D1990

C1953

C1992

R1961

C1952

CN1603

L1601

R1668

R1669

R1617

Q1601

R1609

R1612

R1611

C1604

R1610

R1614

R1613

C1610

XL1201

C1207

RC120

C1203

R1202

C1205

R1201

C1204

R1261

R1262

R1263

R1266

R1255

R1221

R1269

C1210

L1203

R1471

C1424

R1107

C1101

R1106

C1145

R1166

C1211

C1202

R1100

L1102

L1201

C1209

R1210

R1211

C1208

CN1101

IC1201

MD MAIN PWB – A (TOP VIEW)

1

24

28

15

14

105

20

25

1

17

8

14

1

2

1

7

8

14

1

8

916

1

7

8

14

1

3

4

5

1

5

6

10

11

15

16

20

1

28

1

5

10

15

20

25

26

30

35

40

45

50

51

55

60

65

70

75

76

80

85

90

95

100

1

2

1

2

A BDCE

PC BOARD(Component side view)

1

2

3

4

5

6

7

30

Refer to the schematic diagram for the value of resistors and capacitors.

Page 31

F GIHJ

PC BOARD(Component side view)

1

TP1524

JC170

TP1523

TP1511

TP1522

TP1520

TP1521

JC196

C1802

TP1519

TP1518

JC171

TP1801

TP1516

TP1517

Q1801

R1801

C1801

2

TP1515

C1715

TP1803

TP1701

TP1990

C1657

TP1610

C1710

TP1710

CN1601

TP1616

R1664

TP1611

5

4

3

2

1

C1605

C1655

3

4

5

6

CN1604

TP1711

TP1603

TP1602

TP1604

TP1605

TP1609

R1660

2

1

C1707

C1712C1714

TP1608

C1713

TP1713

TP1712

R1427

R1426

C1422

C1421

R1662

C1656

C1602

R1658

C1609

C1743

R1620

C1654

C1706

IC1802

R1716

R1425

TP1607

R1428

TP1606

42

22

TP1702

TP1601

30

25

TP1414

C1405

TP1454

TP1280

40

35

TP1102

TP1101

TP1504

TP1512

Q1803

C1703

1

8

R1416

R1666

IC1601

TP1103

C1803

IC1402

TP1279

TP1104

JC121

R1802

R1473

R1414

R1667

5

10

15

20

TP1217

TP1502

TP1503

R1805

3

R1804

1

Q1802

TP1509

TP1510

TP1416

TP1415

5

1

21

TP1218

TP1501

TP1505

R1478

4

C1631

R1947

IC1801

C1805

TP1508

TP1506

TP1413

R1476

R1475

R1474

TP1212

TP1214

TP1213

C1653

C1601

C1651

R1650

TP1129

4

5

R1820

TP1507

TP1216

Q1807

R1821

R1418

C1406

TP1215

R1656

R1254

R1652

C1650

R1809

C1807

TP1278

80

51

TP1273

C1661

R1808

R1424

81

75

70

65

60

55

50

R1655

C1652

TP1275

TP1908

C1806

TP1802

TP1456

R1423

TP1457

R1654

R1281

TP1220

TP1274

TP1907

85

45

R1663

R1665

R1657

TP1111

TP1612

TP1252

TP1901

C1913

TP1455

R1661

TP1204

TP1106

R1927

TP1260

TP1404

R1422

90

IC1401

40

R1651

C1114

TP1905

R1430

R1659

R1653

TP1120

C1116

C1115

R1153

C1113

TP1128

TP1255

R1429

R1401

95

TP1210

TP1123

TP1137

R1154

TP1135

R1152

R1151

TP1133

CN1904

1

TP1405

R1404

35

TP1109

TP1139

R1102

TP1136

TP1134

C1112

TP1902

100

5

10

15

20

25

TP1458

TP1107

C1106

R1155

TP1138

R1150

TP1132

C1402

R1472

31

C1107

TP1140

36

25

TP1127

4

TP1904

TP1412

1

30

TP1105

37

35

30

24

TP1130

TP1906

R1974

R1420

C1423

C1401

R1415

J1405

R1407

TP1150

TP1142

40

IC1101

TP1131

R1973

TP1911

TP1119

R1412

R1413

C1412

C1109

20

C1105

R1406

R1408

C1403

45

15

C1957

C1407

TP1122

C1121

TP1108

C1110

48

5

10

TP1115

13

TP1910