Kenwood KMD-300, KMD-300GD2 Service Manual

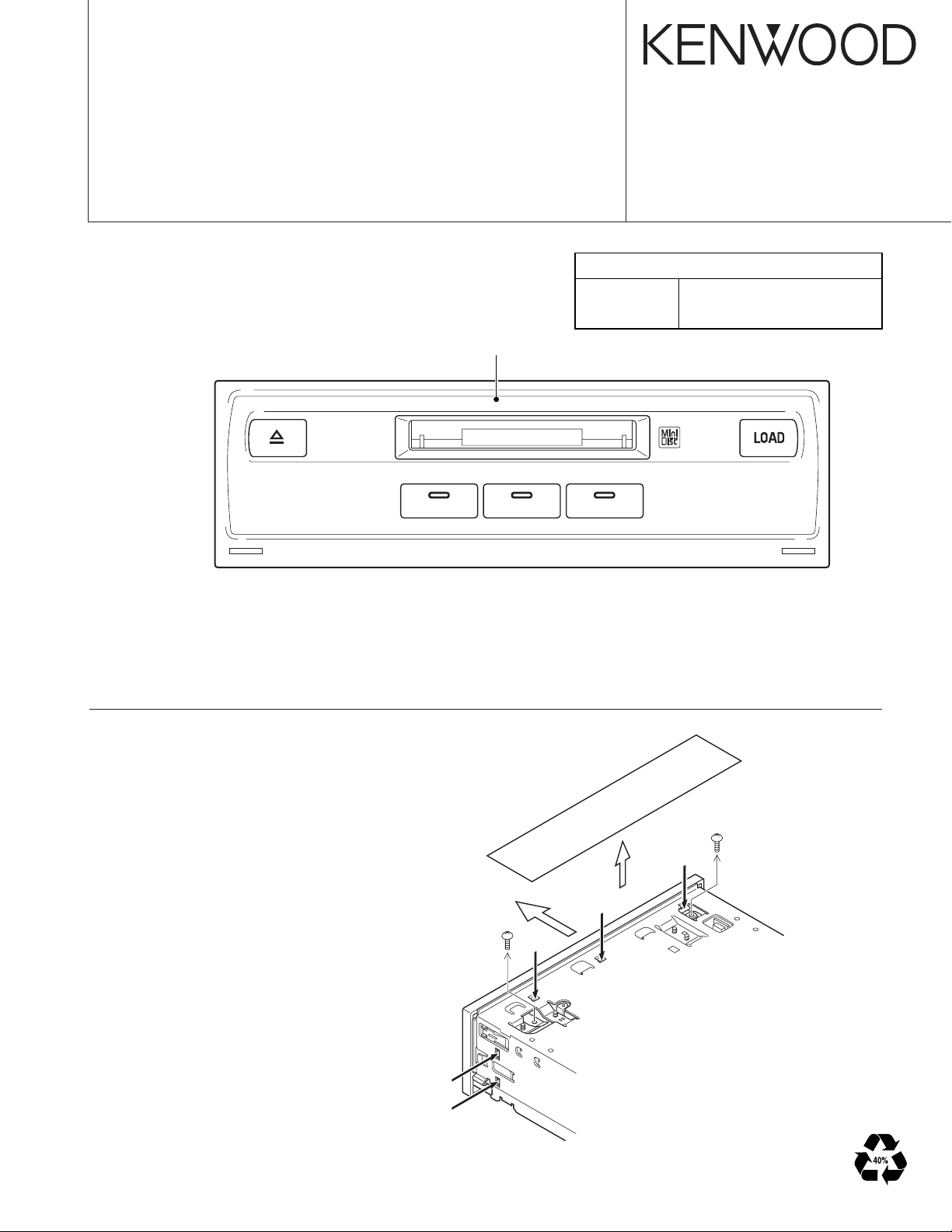

MD CHANGER

KMD-300/GD2

SERVICE MANUAL

© 2003-11 CREATED IN JAPAN

B53-0110-00 (N) 0

Audi GENUINE

Panel assy

(A64-2691-12)

Audi md changer

GENUINE PARTS No.

Hardware 4E0 035 121 41

Software 4E0 910 121 0001 300

How to Take the Panel Assembly Off

1) Take the sheet (A) off.

2) Remove screw (B).

3) While pressing on the hook (C), take the panel

assembly off.

A

C

B

C

BOTTOM

C

C

B

C

C

2

G&H

6.5V

IC3

IC2

5V DIG.

5V CONT.

IC1

BU. DET.

IC30

SW to

IC31

Q41-43

DIAG

CIRCUIT

POW

POWER

ON

IC32-34

LOGIC

LED DRIVER

Q60-66

MECHA CONNECTOR

IC70

KEY

HOLD

IC1

3.3V

WDTIMER

IC90

EEPROM

IC91

IC30

H8S2626

u-COM

IC151

OS8104

MOST

TRANCEIVER

DIR

IC150

PIGTAIL

MOST

OPT ATT.

J1

CN100

J180

1

2

3

4

5

6

7

8

GND

BU+12V

ID-X

ID-Y

S +6.5V

M-BU+5V

D+5V

A+5V

BU+5V

DIAG

PON

LEV6V

SW to POW

STATUS

HOLD

DIAG IN

DIAG OUT

PINX

PINY

LED EJECT

LED DISC1

LED DISC2

LED DISC3

LED GUIDE

LED LOAD

SW DISC1

SW DISC2

SW DISC3

SW EJECT

SW LOAD

30 29

28

27

26 25

24

23

22

21

20

19

18

17

16

15 14

13 12

11

10

9

8

7

6

5

4

3

2

1

SW EJECT

SW LOAD

SW DISC1

SW DISC2

SW DISC3

SW EJECT

SW LOAD

CLEAR

OPT ATT

LEV16V

10

6

5

LED LOAD

LED GUIDE

LED DISC3

LED DISC2

LED DISC1

LED EJECT

HOLD

DIAGOUT

PINX

PINY

DIAGIN

STATUS

LEV16V

PON

SW to PWR

LEV6V

WDTN

RESET

DATA IN

8

7

6

5

4

3

2

1

RX

STATUS

GND

BU+5V

ATT

D+5V

GND

TX

STATUS

LRC IN

C IN

CL

LRCL

MCLK(22.5792MHz)

D.AUDIO(IEC60958)

D+5V

BU+5V

(X14-6912-70) (A/2)

(X14- ) (B/2)

(X25-9252-70)

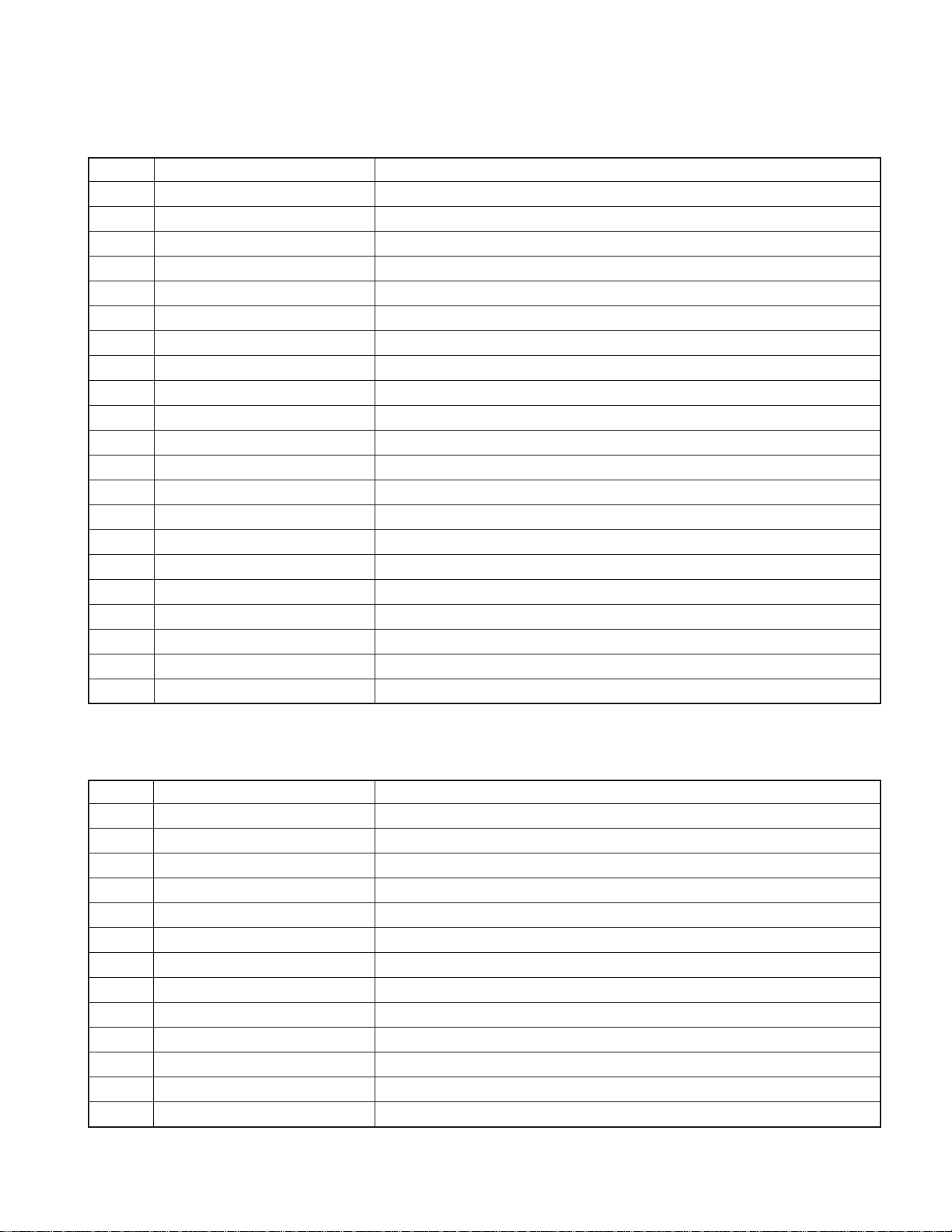

KMD-300/GD2

BLOCK DIAGRAM

KMD-300/GD2

COMPONENTS DESCRIPTION

● DISPLAY UNIT (X14-6912-70)

Ref. No. Application/Function Operation /Condition/Compatibility

IC1 Stabilized power supply Supplies Bu +5V to IC30, IC31, IC32, IC33, IC34, etc.

IC2 Stabilized power supply Supplies D.+5V to X25 board

IC3 Stabilized power supply Supplies +6.5V to mechanism X33

IC30 Reset IC OUT=H when BU+5V is above 4.2V

IC31 1 pulse oscillation Oscillates 1 pulse at rise of BU

IC32 NOT circuit ((~STATUS | | DIAG | | Sw to Pow) &&-LEV6) | | HOLD=H, then D.+5V ON

IC33 OR circuit ((~STATUS | | DIAG | | Sw to Pow) &&-LEV6) | | HOLD=H, then D.+5V ON

IC34 D flip-flop Detects downward slope of J1 DIAG

Q1 Switch Q1 base =L, then LEV16=12V

Q2 NOT circuit Q2 base =H, then Q1 base =L

Q40 NOT circuit J1 DIAG=L, then IC33 A3 input=H

Q41 NOT circuit CN1 DIAGOUT=H, then J1 DIAG=L

Q42 Excess current protection Limit Q41 emitter current

Q43 NOT circuit J1 DIAG=L, then CN1 DIAGIN=H

Q60 Switch CN2 LED1=H, then D60 lights up.

Q61 Switch CN2 LED2=H, then D61 lights up.

Q62 Switch CN2 LED3=H, then D62 lights up.

Q63 Switch CN2 LED4=H, then D63 lights up.

Q64 Switch CN2 LED5=H, then D64 lights up.

Q65 Switch CN2 LED6=H, then D65 lights up.

Q66 Switch CN2 LED6=H, then D66 lights up.

● ELECTRIC UNIT (X25-9252-70)

Ref. No. Application/Function Operation /Condition/Compatibility

IC1 Stabilized power supply Supplies 3.3V to IC30 and IC150.

IC30 µ-com Controls various sections of the set.

IC70 D flip-flop Detects rise of key input for LOAD/EJECT

IC71 NAND circuit IC70 CLR=~ (IC90 RESET&&IC30 CLEAR)

IC90 RESET IC D+5V is above 4.2V, then RESET=H.

IC91 EEPROM Saves backup data.

IC150 DIR Converts IEC60958 (SPDIF) signal to 3-line serial.

IC151 MOST transceiver Signal processing IC for optical input/output

Q30 Switch PF3=L, then AVREF ON.

Q70 NOT circuit CN70 EJECT=H, then IC30 EJECT=L

Q71 NOT circuit CN70 LOAD=H, then IC30 LOAD=L

Q180 NOT circuit MOST ATT=H, then Q181 base=L

Q181 Switch MOST ATT=H, then increase optical output.

3

KMD-300/GD2

MICROCOMPUTER’S TERMINAL DESCRIPTION

● MICROCOMPUTER : HD64F2626FA20I (X25 : IC30)

Pin No. Pin Name I/O Application

1ATT O MOST TX attenuate

2 MOST_INT I MOST data reception interrupt

3 BEEP O BEEP output

4 ERROR I MOST error signal

5 DIR_CS O DIR CS

6 VCC1

7 HTxD

8 VSS1

9 HRxD

10 MMUTE I Mechanism mute detection

11 SS1_SW I Stock1 Detection of disk/No disk SW

12 SS2_SW I Stock2 Detection of disk/No disk SW

13 SS3_SW I Stock3 Detection of disk/No disk SW

14 MS_SW I EJECT complete detection SW

15 VSS2

16 FS_SW I LOAD start detection SW

17 PVCC1

18 OS_SW I Wrong direction detection SW

19 NC

20 MSTOP O Mechanism control Wake Up

21 MRST O Mechanism control RESET

22 M0 O M1, M2, M3 control output

23 M1 O LO/EJ control output

24 M2 O Mechanism roller attach control output

25 M3 O Mechanism rising order control output

26 NC

27 NC

28 MSDA I/O Mechanism I2C data

29 MSCL I/O Mechanism I2C clock

30 DIR_ERR I DIR error

31 DIR_TX O DIR control output

32 DIR_RX I DIR control input

33 DIR_CLK O DIR clock

34 SDA I/O MOST I2C data

35 SCL I/O MOST I2C clock

36 LED1 O MD1 eject SW LED

37 VSS3

38 LED2 O MD2 eject SW LED

39 PVCC2

40 LED3 O MD3 eject SW LED

41 LED4 O Load SW LED

42 LED5 O Eject SW LED

43 LED6 O Insert slot LED

44 CLEAR O Hard key buffer clear

45 MOST_WRITE

46 NC

47 TXD O Flash writer data output

48 RXD I Flash writer data input

49 NC

50 OSC1

4

KMD-300/GD2

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Application

51 OSC2

52 PVCC3

53 MD0

54 VSS4

55 MD1 I µ-com mode switching

56 MD2 I µ-com mode switching

57 PLLVSS

58 PLLCAP

59 PLLVCC

60 RES I µ-com resetting

61 NMI

62 STBY

63 VCC2

64 XTAL

65 VSS5

66 EXTAL

67 FEW I Flash write enable

68 NC

69 PON O Peripheral circuit power supply control

70 SA_SW O SA switch

71 HOLD_SW O SD switch

72 LPSCO O Vref control

73 WDT_OFF O Watch dog timer count output

74 DIAG_OUT O DIAG output

75 DIAG_IN I DIAG input

76 AVCC

77 Vref I Reference voltage input

78 MLPS I Mechanism location position detection

79 PS_SW I Play position detection of disk/No disk SW

80 LS_SW I Load complete SW

81 CS_SW I roller attach/detach SW

82 BU_DET I Power supply +B input

83 LEV16 I Power supply voltage detection

84 NC

85 LEV_6 I Power supply voltage <6V

86 DISK1 I MD1 select SW

87 DISK2 I MD2 select SW

88 DISK3 I MD3 select SW

89 LOAD I LOAD SW

90 EJECT I Eject SW

91 SW_TO_PW I Power supply control

92 ID-X I Unit position detection

93 ID-Y I Unit position detection

94 AVSS

95 VSS6

96 WDTOVFA

97 PVCC4

98 NC

99 STATUS MOST status

100 MOST_RST MOST reset

5

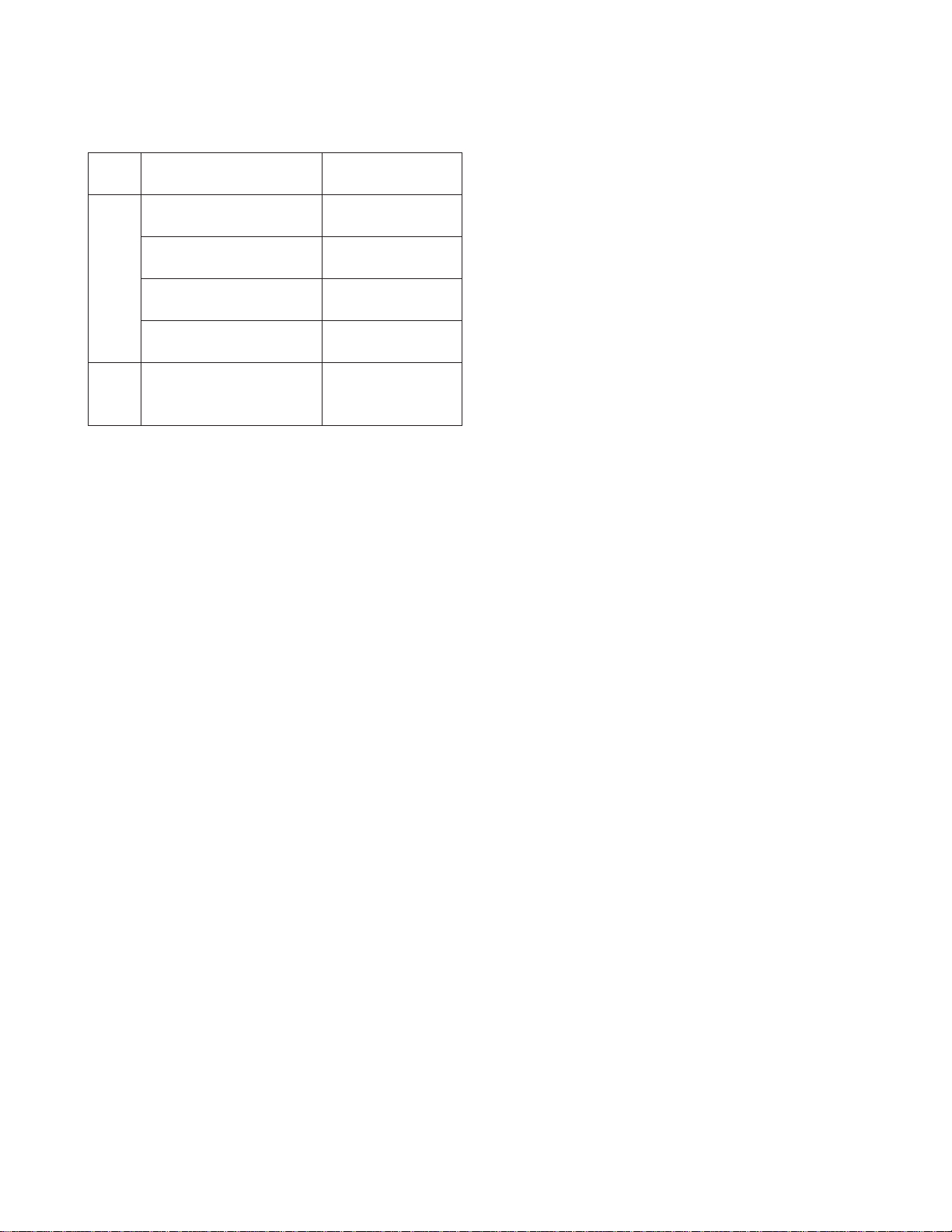

KMD-300/GD2

TEST MODE

1. TEST MODE

MDC possesses test mode functions for production purposes.

There are three test modes: production line test mode, mechanism operation test mode, and shipping mode. As shown in

Figure 1, it is possible by using the keys to shift to each of

these modes.

Automatic

mechanism

mode

Normal

Operation

Mode

Start

q+e

Figure 1 Test Mode conditioned flowchart

e, w, q

Test Mode

selection

mode

q, q, q

1.1. Test Mode selection mode

In this unit, there are but five ke ys: LOAD , UNLO AD, q (DISC

SELECT LEFT KEY), w (DISC SELECT CENTER KEY), and

e (DISC SELECT RIGHT KEY). After installation of the unit

by the user, if direct switching to the Test Mode were enabled

by combining these five keys, it is possible to shift accidentally

into the Test Mode. This is because of the simplicity of the

input method.

To avoid this problem, use Test Mode selection. This mode

condition is achieved by enabling key input during the Test

Mode. In other words, no direct switching to the Test Mode is

done. This Test Mode selection mode prevents the user from

entering the Test Mode inadvertently.

1.1.1 How to enter the Test Mode selection mode

With the MOST Tx Output (Light) on, b y sim ultaneously depressing the q and e keys and by resetting or turning the

power on, Test Mode selection mode is achieved.

Or with the MOST Tx Output (Light) off, by simultaneously

depressing the q, e, and LO AD ke ys and resetting or turning the power on, the Test Mode selection mode is also

achieved.

q, w,

e

Test mode

for

mechanism

operation

Production

line

Test Mode

Shipping

mode

Manual

mechanism

mode

1.1.2 How to exit the Test Mode selection mode

The following are ways to move out of the Test Mode selection mode. The operation after exiting the mode will be the

same as after hardware resetting. The unit must be reset in

the final stage of the Test Mode.

1. By resetting the system

2. By changing MOST Tx=On to MOST Tx=Off

3. By a momentary power outage

4. After entering this mode, when there is no effective key

input for ten or more seconds

5. After entering this mode, when there is no ineff ective key

input

1.1.3 Initial condition after entering the Test Mode

The q, w, e, LOAD, and UNLOAD keys have LED’s (red

and red only) installed.

Also, one LED (red and red only) is placed on each side of

the disk insertion slot.

When the Test Mode selection mode is entered, all LED’s

light up.

1.2. Shipping Mode

When transporting MD Changer units, their mechanisms are

subject to vibrations and shocks. These could damage the MD

Changer mechanisms (including the servo system and pickup).

Therefore, before tr ansporting the units, it is necessary to place

the mechanisms in positions that are most vibration and shock

resistant. The Shipping Mode causes the mechanism to shift

into ideal, optimally robust shipping positions.

1.2.1 How to enter the Shipping Mode

In the Test Mode selection mode with no disk in the unit, the

selection mode can be entered by pressing the q key three

times.

1.2.2 How to exit the Shipping Mode

By resetting the system or by turning on the power, the Shipping Mode is released and the mechanism returns to its

initial position.

Accordingly, after confirming that the mechanism has entered the Shipping Mode, the power should be turned off.

Table 1 MD Changer (Shipping Mode) Key description

Key Mode Description

#1 #1 #1 MD Changer Mechanism are put into shipping

position.

6

TEST MODE

KMD-300/GD2

Table 2 Flow of MD Changer Conditions (Shipping Position)

Disk

Condition

Out Receiving signal to shift #1 blinks with 500ms

In Ineffective (any one of the

MD Changer Condition Display

to shipping position interval

Shifting #1 blinks with 500ms

interval

Shifting successfully #1 lights up

completed.

Shifting unsuccessful #1, #2, and #3 blink

at 500ms intervals

switches of the mechanism

is on).

1.3. Production Line Test Mode

1.3.1 How to enter the production line Test Mode

In the Test Mode selection mode, with LED’s for the q, w,

and e keys alight, it is possible to enter the production line

Test Mode by consecutively pressing the q, w, and e keys.

As these inputs are made, each LED on these keys lights

up, enabling k e y input confirmation. Also, when the production line Test Mode is entered by eff ective k ey input, the LED’ s

that had remained unlit light up.

If incorrect keys were pressed or no eff ectiv e k e y input were

made for ten consecutive seconds , the Test Mode selection

mode is released. In this case the T est Mode selection mode

must be reentered to enable Test Mode entry.

1.3.2 How to enter the production line Test Mode

The following are ways to release the production line Test

Mode selection mode. Ideally, the condition after exiting the

Test Mode should be the same as after resetting the hardware by means of the program. This, however, cannot always be achieved at present.

Accordingly, it is necessary to reset the system in the final

process of the Test Mode. (This excludes the case of setting

the mechanism to transport position.)

1. By resetting the system

2. By changing MOST Tx=On to MOST Tx=Off

3. After entering the Test Mode, when an ineff ectiv e ke y was

pressed

1.3.3 Initial condition in the production line Test Mode

In the Test Mode, there is no special initial setting. (This is

other than the initial setting of normal units.) To indicate,

howev er, that the Test Mode has been entered, all LED’s on

the q, w, and e keys will light up.

1.3.4 Display (LED)

LED installation on the q, w, and e keys can be check ed.

With all disks removed, press any of the q, w, or e keys

and lift your finger within one second. This causes the LED

corresponding to the pressed key to go from “off” to “lighting

up” to “blinking,” and to “off.”

When and if a disk or disks are present, the LED will light up

according to the disk condition. (The condition according to

normal operational specifications will follow.)

Inasmuch as the LED’s are also used for judging key input,

no judgment results when there is a key-input problem.

Accordingly, if no judgment were possible, a disk must be

inserted into the desired position and appropriate key input

made. Confirm that disk ejection is possible.

1.3.5 Keys

To ensure that the conductance of the q, w, e, LOAD, and

UNLOAD keys is satisfactory, with all disks removed, press

any of the q, w, e, LO AD, and UNLOAD keys and lift y our

finger within one second. Then confirm that the LED corresponding to the pressed key will proceed from “off” to “lighting up” to “blinking,” and to “off.”

Inasmuch as this is the same as evaluating the display

(LED’s), if a problem exists with the LED, no evaluation can

be conducted.

Accordingly, if no evaluation were possible, a disk must be

placed into the desired position and appropriate key input

made. Be sure that the disk can be ejected.

When and if the q, w, and e ke ys are depressed f or more

than one second, the Stock and Stock Position Confirmation Modes will be entered, as described below.

1.3.6 MD servo

After disk-loading, playing starts at Track No. 7.

The following ke y oper ations are begun by commands from

the control unit and are conducted only when the source is

the MD Changer.

Even when the playing track number is changed other than

by the keys (commands) described below, the playing condition will persist.

1.3.7 Mechanism transport position

Refer to “1.2 Shipping Mode.”

To enter this mode, press the q key and hold it do wn one or

more seconds.

7

KMD-300/GD2

TEST MODE

1.4 Test mode for MD Changer mechanism operation

1.4.1 How to enter the Test Mode for MD Changer mecha-

nism operation

After selecting the Test Mode selection mode, while the LED’ s

for the q, w, and e keys are lighting up, consecutively press

the q, w, and e keys. The Test Mode for MD Changer

mechanism operation can then be entered.

During key input, the LED corresponding to the key goes

out, enabling key input confirmation.

After effective key input, when the Test Mode for the MD

Changer mechanism operation is entered, all unlit LED’s

will light up.

In case of an error in key input, or no effective key input

were conducted for ten or more consecutive seconds, the

Test Mode selection mode is released. It is then necessary

to restart from the setting for the Test Mode selection mode.

Table 3 Test Mode input procedure for MD Changer mecha-

nism operation

Procedure

and result

1 In Test Mode selection mode

2 e key input

3 w key input

4 q key input

5

6Elapse of ten seconds

7

Status and Operation LED (● light up)

Test Mode for MD Changer - - mechanism operation ●●●

Release of the Test Mode - - selection mode KKK

Key (result) /

qwe

---

●●●

773

●●K

747

● KK

577

KKK

777

KKK

1.4.2 Releasing the T est Mode for MD Changer mechanism

operation

The following methods release the Test Mode for MD

Changer mechanism operation. Ideally, the condition after

exiting the Test Mode should be the same as after resetting

the hardware by means of the program. This, however, cannot always be achieved at present Below are ways to release the production line Test Mode selection mode.

The system must always be reset after the final process in

the Test Mode. When, however, desiring to enter the transport position, simply shut off the power after confirming that

the mechanism will shift into the transport position. Remember that, when resetting after shifting into the transport position, the unit will return to the initial position.

1. By resetting the system

2. After setting this mode, no effective key input is made for

ten seconds.

3. After entering the Test Mode, an ineffective key was

pressed.

1.4.3 Initial condition of the Test Mode for MD Changer

mechanism operation

There is no special initial setting in the Test Mode. Nevertheless, to indicate that the Test Mode has been entered, all

LED's installed on the q, w, and e keys will light up.

8

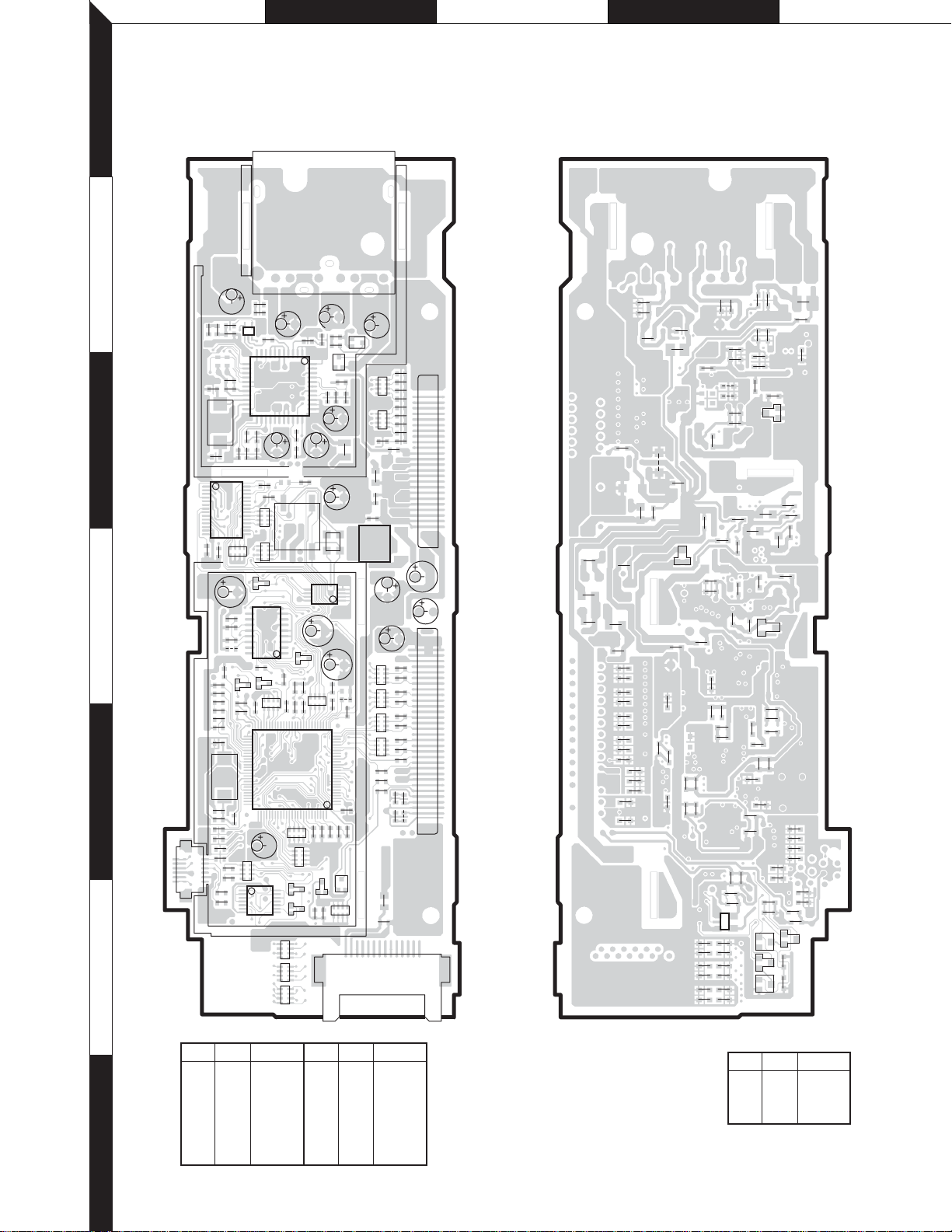

A B C D E

KMD-300/GD2

1

PC BOARD

(COMPONENT SIDE VIEW) (FOIL SIDE VIEW)

ELECTRIC UNIT X25-9252-70 (J74-1528-12)

2

C185

R158

C165

IC152

L154

C166

C167

C169

C168

X150

3

4

5

C170

1

14

R150

R151

CP150

C93

R91

R92

W90

R43

R44

R45

C44

R46

C46

R48

C49

X30

C50

R52

R131

R133

R135

R130

1

212

C131

C133

11

CN130

R132

R134

6

8

L157

R172

45

L153

1

3

C187

11

12

IC151

22 34

C173

C90

28

15

16 9

50

R165

C174

R153

CP151

L151

D31

R41

CP31

R154

D91

IC90

R54

L150

8

D34

1

R40

R167

C38

R163

IC150

C94

D30

R47

C45

51

C172

R164

IC30

75

76

R51

CP34

C53

CP32

D32

CP130

148

IC70

71

R155

3323

C178

C159

R38

D72

L71

L72

L73

C181

1

44

IC91

85

C30

L30

C37

R36

R57

D33

R56

C177

26

100

C54

R180

R181

L152

R171

R168

L155

R35

R58

CP33

R169

C160

C31

25

1

R59

Q30

J180

EB

W31

R34

R62

R60

EB

R170

4

1

R61

EB

Q180

L156

C6

G

R33

C182

Q181

CP2

CP1

C2

IC1

CP103

CP102

CP101

CP100

R102

R101

R100

CN70

1

CN1

C7

C8

C9

248

C10

C11

C12

C13

C14

R1

C15

L3

L1

C1

O

47 1

C19

I

C17

C100

C102

C125

C123

C121

C119

C117

C115

C113

C111

R103

C105

L103

159

260

L102

CN100

W100

L70

C82

141

ELECTRIC UNIT X25-9252-70 (J74-1528-12)

L183

C164

R157

R156

R162

C150

R49

R55

R93

C48

C171

D150

D90

C42

C43

R71

C86

C186

C163

R42

R50

C47

C132

C134

EB

B

E

C151

C153

R90

C157

C154

C139

C137

C135

C140

L130

C130

R182

C138

C136

D70

R70

C83

L182

R159

C18

L100

C101

L101

C103

C3

C16

C126

C124

C122

C120

C118

C116

C114

C112

C110

C106

C104

C109

C108

C107

C184

C183

L2

L181

C189

C32

C55

C188

C161

C162

R173

W154

W152

C175

C176

R166

L160

R2

C156

L159

D1

R31

C33

C56

C80

C78

C76

C74

C73

C70

C95

C96

C41

R37

1

3

IC71

C39

C40

C81

C79

C77

C75

C72

C71

R39

C88

C87

R53

C84

C91

5

4

L158

R94

C92

C52

C51

C85

Q70

D71

Q71

C180

L180

W2

C5

C4

R30

C36

C35

C34

R32

X25-9252-70

IC Q Address

14B

30 5B

70 6A

90 4B

7

91 4B

150 3A

IC Q Address

151 3B

152 2A

30 5B

180 3B

181 2B

Refer to the schematic diagram for the values of resistors and capacitors.

X25-9252-70

IC Q Address

71 6D

70 6D

71 6D

9

Loading...

Loading...