Kenwood DW-320-V Service manual

R

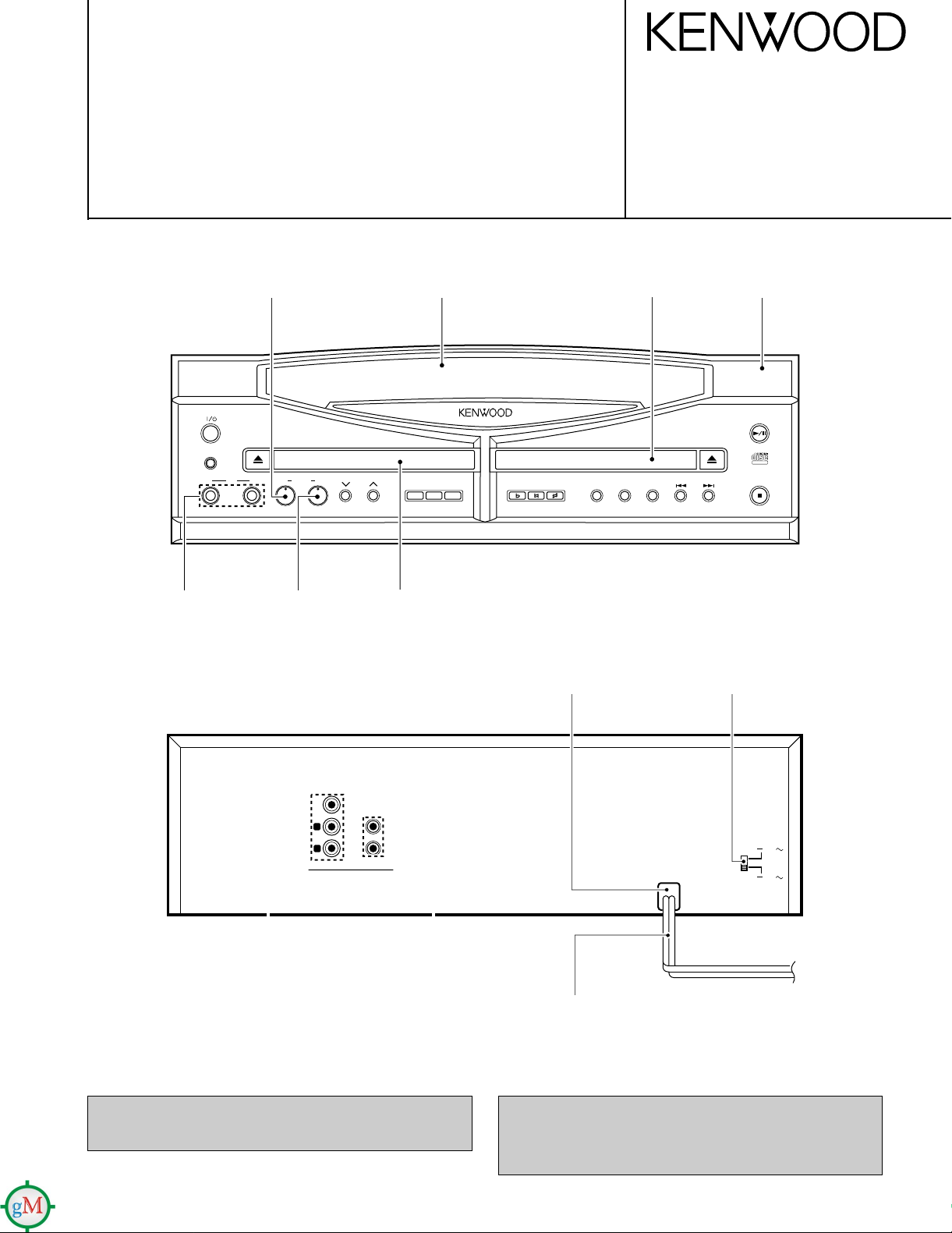

L

VIDEO OUTPUT

AUDIO OUTPUT

SYSTEM

CONTROL

AC 110 120V

AC 220 240V

2

1

DISC

SELECTOR

1 2KARAOKEKEY CONTROL

RANDOM REPEAT AUTO PAUSE

ECHO

LEVEL

MIC MIX 21MIC 21

ON SCREEN

DIGEST

ON/STANDBY

DIGITAL VIDEO

TWIN VIDEO CD PLAYER D-W320V

TWIN VIDEO CD PLAYER

D-W320V

SERVICE MANUAL

© 1997-11/B51-5389-00 (K/K) 405

Phone jack

(E11-0384-08)

Knob

(K29-6973-08)

Knob

(K29-6974-08)

Front glass

(B10-2467-08)

Tray panel

(A21-3663-08)

Tray panel

(A21-3664-08)

Power cord bushing

(J42-0083-05)

Panel assy

(A60-1413-08)

Slide switch

(S90-0125-08)

Phono jack

(E63-1036-08)

In compliance with Federal Regulations, following are reproductions of labels on, or inside the product relating to laser product

Miniature phone jack

(E11-0188-05)

safety.

AC power cord *

(E30-)

* Refer to parts list on page 24.

KENWOOD-Crop. certifies this equipment conforms to DHHS

Regulations No. 21 DFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM

D-W320V

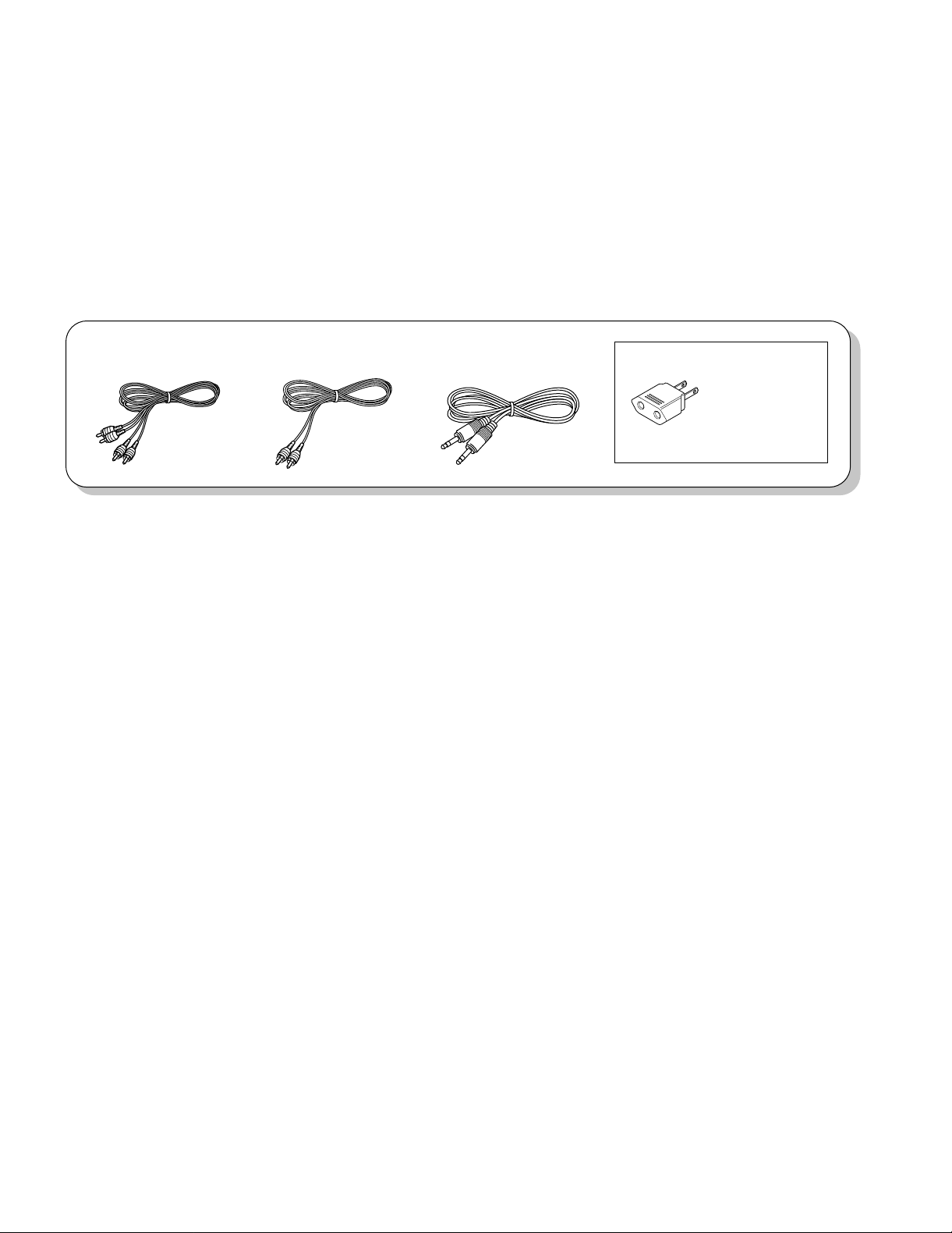

CONTENTS / ACCESSORIES

CONTENTS

CONTENTS .................................................................2

DISASSEMBLY FOR REPAIR.....................................3

CIRCUIT DESCRIPTION.............................................4

ADJUSTMENT...........................................................10

PC BOARD ................................................................11

Accessories

SCHEMATIC DIAGRAM............................................15

EXPLODED VIEW .....................................................22

PARTS LIST...............................................................24

SPECIFICATIONS .......................................Back cover

Audio cord...................(1)

(E30-0505-05)

Video cord...................(1)

(E30-1427-05)

System control cord....(2)

(E30-2733-05)

AC plug adapter.........(1)

(E03-0115-05)

Use to adapt the

plug on the power

cord to the shape of

the wall outlet.

(Accessory only for regions where use

is necessary.)

2

DISASSEMBLY FOR REPAIR

5

3

7

1

4

2

6

1

x4

Fig.1

5

1

2

1

2

3

1

4

6

CHASSIS

CD MECHANISM HOLDER

(SUB CHASSIS)

CLAMPER

GUIDE

SLIDER

Fig.2

1

2

C

B

A

2

4

5

3

2

TRAY(A)

TRAY(B)

Fig.3

short-land

7

2

4

44

3

3

5

1

7

8

9

6

x4

DRIVE GEAR

(DISC MOTOR A`ssy)

Fig.4

1. HOW TO REMOVE THE TRAYS.

1. Push the on / standby key.

2. Push the open / close key (DISC 1).

3. Remove the left tray panel.

4. Push the open / close key (DISC 2).

5. Remove the right tray panel.

6. Push the open / close key (DISC 2).

7. Turn the AC power off.

8. Remove 5 screws (

9. Turn the tray drive gear to clockwise (2) to remove right

tray.

10. Remove the hook (3) and then pull out the right tray.

11. Turn the tray drive gear to counterclockwise (4).

(Pickup down (5)

î Left tray comes out (7))

12. Remove the hook (same as 3) and then pull out the left

tray.

2. HOW TO REMOVE THE CD MECHANISM HOLDER

1. Remove 3 screws (1).

2. Remove the clamper guide to arrow mark (2).

3. To down the CD mechanism holder, set the slider to arrow

mark (4) by turning the tray drive gear (5).

4. Remove the CD mechanism holder to arrow mark (3).

1) and front panel.

î CD mecha moves (6) î Pickup up

D-W320V

3. HOW TO MOUNT THE CD MECHANISM HOLDER

1. Set the slider to arrow mark (4) by turning the tray drive

gear (5).

2. Inset the CD mechanism holder into the hole of slider (6).

4. HOW TO MOUNT THE TRAYS.

1. Mount the clamper guide (1).

2. Fix 3 screws (2).

3. Set the slider to arrow mark (A, B) by turning the tray

drive gear.

4. Insert the tray (A) to guide (B) on slider (3).

5. Turning the tray drive gear to clockwise (4) set the slider

to arrow mark (C).

6. Insert the tray (B) to guide (C) on slider (5).

5. HOW TO REPLACE THE PICKUP

1. Remove 4 screws (1) and turn over the CD mechanism

assy.

★ Short the short-land of the pickup before the following pro-

cedures (2)

2. Remove 3 connectors (3) and 3 screws (4).

3. Remove the disc motor ass'y (5).

4. Remove washer and gear (6).

5. Remove 2 screws (7) and rod (8).

6. Remove the pickup ass'y (9).

Note : When mounting the pickup, in the reverse order of dis-

assembly. Unsolder the short land after connecting

the connectors.

3

D-W320V

CIRCUIT DESCRIPTION

1. System u-COM IC701 (MN1872423 KEN)

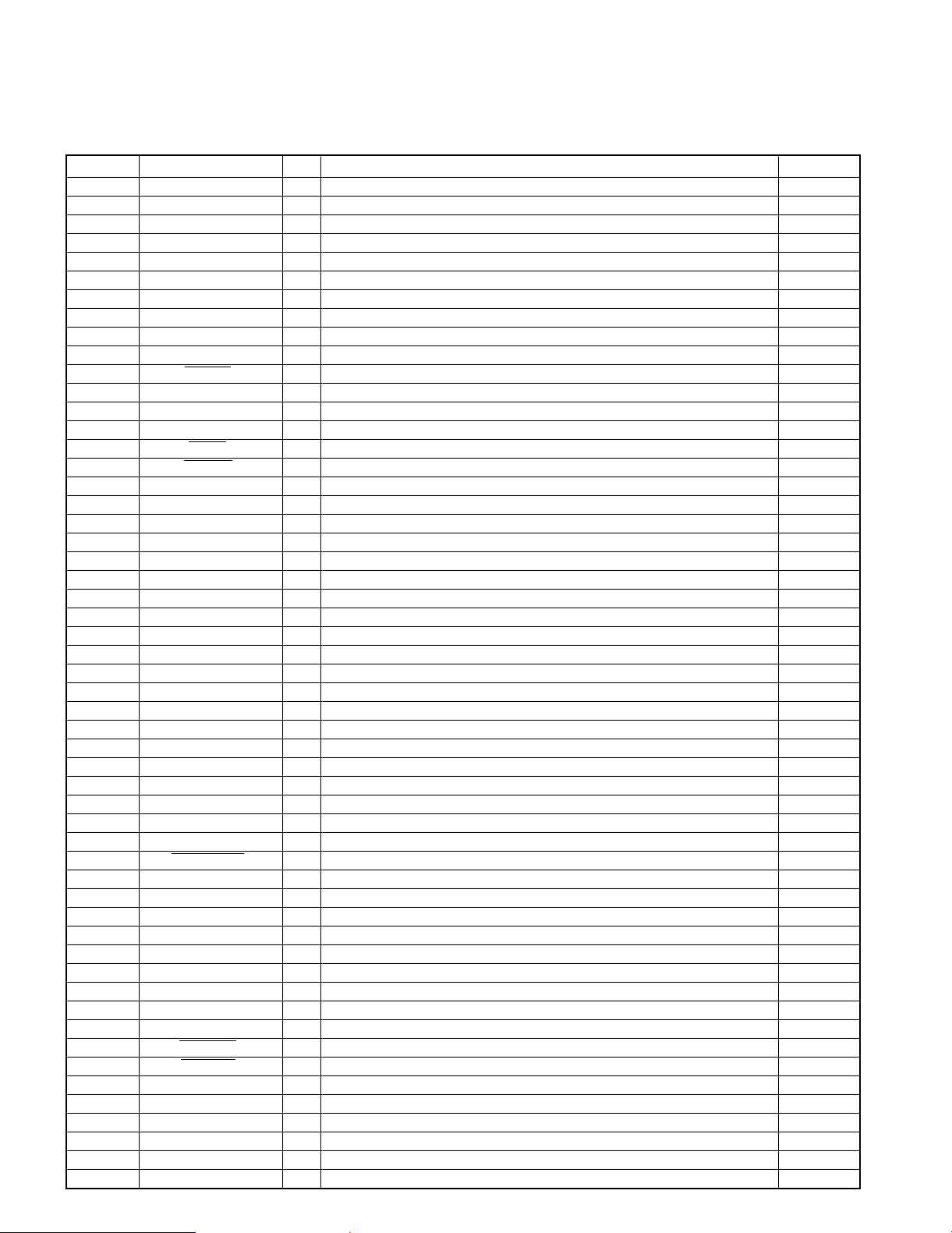

Pin description.

PIN NO. TERMINAL NAME I/O FUNCTION ACT

1~7 7~1G O FL grid drive –

8 VDD – VDD +5V –

9 P/N I O PAL/NTSC INPUT H : PAL H

10 P/N O I PAL/NTSC OUTPUT H : PAL H

11 M/A O PAL/NTSC MANUAL/AUTO SELECT H : MANUAL H

12 POWER O POWER ON / OFF H : ON H

13 C-BUSY O VIDEO CD DATA STATUS H : BUSY H

14 CLOCK I VIDEO CD DATA CLOCK H/L

15 C-DATA – DATA SIGNAL to MPEG BOARD H/L

16 M-DATA – DATA SIGNAL from MPEG BOARD H/L

17 RESET – HARD RESET L

18 TR+ – TRAY MOTOR CONTROL H : OPEN H

19 TR- – TRAY MOTOR CONTROL H : CLOSE H

20, 21 AVSS – GND –

22 PU IN – PICK UP LOCATION L : INSIDE L

23 UP SW – MECHA POSITION L : DISC1 & UP L

24 TRSW2 – DISC2 TRAY SW L : CLOSE H : OPEN –

24, 25 TRSW2, 1 I DISC2 TRAY SW L : CLOSE H : OPEN A/D

26~28 KEY3~1 I KEY INPUT A/D

29 AVDD – AVDD +5V –

30 AVREF – AVREF +5V –

31, 32 XT1, 2 – NC –

33 VSS – GND –

34 X1 – X-TAL IN 4.19 MHz –

35 X2 – X-TAL OUT 4.19 MHz –

36 WRQ I WRITE REQUEST H

37 COIN O COMMAND DATA TO CD DSP H/L

38 IFL O KARAOKE IC DATA H/L

39 IFS O KARAOKE IC CLOCK H/L

40 IFD O KARAOKE IC LATCH H

41 CQCK O CLOCK TO CD DSP H/L

42 SQOUT I SQ DATA FROM CD DSP H/L

43 RWC O READ/WRITE CONTROL H

44 M-BUSY O MAIN MICOM STATUS H : BUSY H

45 SBUSY I/O SYSTEM CONTROL DATA H/L

46 SDATA I/O SYSTEM CONTROL STATUS H

47 REMOCON I REMOCON INPUT L

48 VPP – GND –

49 SP CONT O TRAY MOTOR SPEED CONTROL H : HIGH SPEED H

50 SL- O SLED MOTOR REVERSE H

51 SL+ O SLED MOTOR FORWARD H

52 VDD – VDD +5V –

53 FLAT O KEY CON LED NATURAL H : ON H

54 SHARP O KEY CON LED SHARP H : ON H

55 MATURAL O KEY CON LED FLAT : H : ON H

56 C-RESET O CD DSP, MPEG BOARD, MPEG MICOM RESET H

57 M-MUTE O MIC MUTE L : ON L

58 S-MUTE O SYSTEM MUTE L : ON L

59 NC O NOT USED L

60 DRF I CD FOCUS OK SIG. H : OK H

61~70 P16~7 O FL SEGMENT DRIVE –

71 VLOAD – VLOAD - 32V –

72~77 P6~P1 O FL SEGMENT DRIVE –

78~80 10~8G O FL GRID DRIVE –

4

CIRCUIT DESCRIPTION

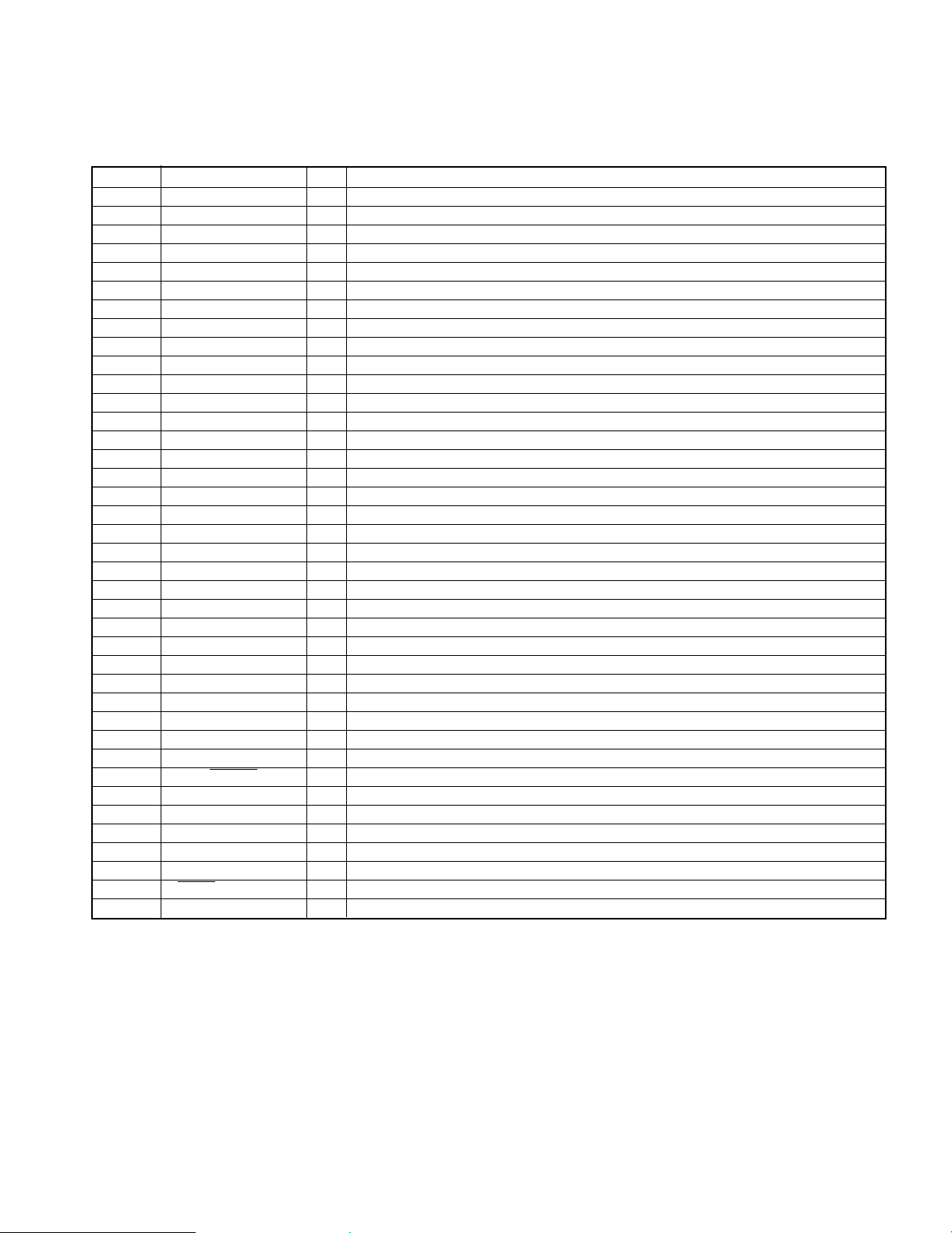

2. KARAOKE IC/DAC IC 201 (TC9409 BF)

Pin description

Pin No. Terminal Name I/O Function

1 VDA1 – ADC power supply

2 MICI I LPF input for Mic input

3 LPFO1 O LPF output for Mic input

4 VRA1 – ADC reference voltage

5 AIL I Line input (Lch)

6 LPFO2 O Not used

7 VRA2 – ADC reference voltage

8 AIR I Line input (Rch)

9 LPFO3 O Not used

10 GNDA1 – ADC ground

11 LI I Lch analog add input

12 LZ O Not used

13 GNDA2 – DAC ground

14 AOL O DAC output (Lch)

15 VR2 – DAC reference voltage

16 AOR O DAC out put (Rch)

17 VDA2 – DAC power SUPPLY

18 RZ O Not used

19 RI I Rch analog add input

20 VDX – X-TAL power supply

21 XI I X-TAL in (16.9344 MHz)

22 XO O X-TAL out

23 GNDX – Ground

24, 25 VDD1, CKS – Digital power supply

26 MCK2 O Not used

27 MCK1 O Clock output

28~30 SDO/BCKO/LRCKO – Not used

31 SDI I Digital audio data input

32 BCKI – Bit clock input

33 LRCKI – Channel clock input

34 GNDD – Digital ground

35 RESET I Reset

36 IFD I U-com I/F data input

37 IFS I U-com I/F data shift clock input

38 IFL I U-com I/F latch pulse input

39 EMP I DE-emphasis setting (H = DE-emphasis filter on)

40 EXTO O Not used

41~43 TEST/VDD2/VDL – Digital power supply

44 GNDL – Digital ground for DRAM

D-W320V

5

D-W320V

R+5V

DGND

R+5V

DGND

R+5V

DGND AGND

2MDRAM

CD I/F

Subcode I/F

Host I/F

D+3.3V

A+3.3V

S Video Out

Video Out

Audio Out

4MDRAM

1chip

MPEG

Decoder

LPF

CIRCUIT DESCRIPTUON

3. Connection terminal (CN P401) specification for MPEG board

No Terminal I/O Specification

1 A+3.3V – +3.3V power supply for analog video

2 CVOUT O Composite video output

3, 4 N/C O Not used

5.6 VGND – Analog video ground

7 R+5V – Digital +5V power supply

8, 9 D+3.3V – Digital +3.3V power supply

10, 11 DGND – Digital ground

12 CD CLK I Audio external frequency clock (384 FS)

13 EMPH O Audio emphasis output (High Active)

14 DILRCK O Audio left right clock

15 HRDY – Host data ready

16 DISCK O Audio bit clock

17 DIDATA O Audio data serial bus

18 HINT O Host interrupt

19 N/C O Not used

20 VRST I Hardware reset (Low Active)

21 HCK I Host clock

22 HDIO I/O Host serial data bus

23 CDSCK I CD bit clock

24 CDDATA I CD data input

25 CDLRCK I CD left right clock input

26 IPFLG I CD data error flag (C2P0)

27 HSEL I Host address / data select

28~30 DATA/SFSY/SBSY I Not used

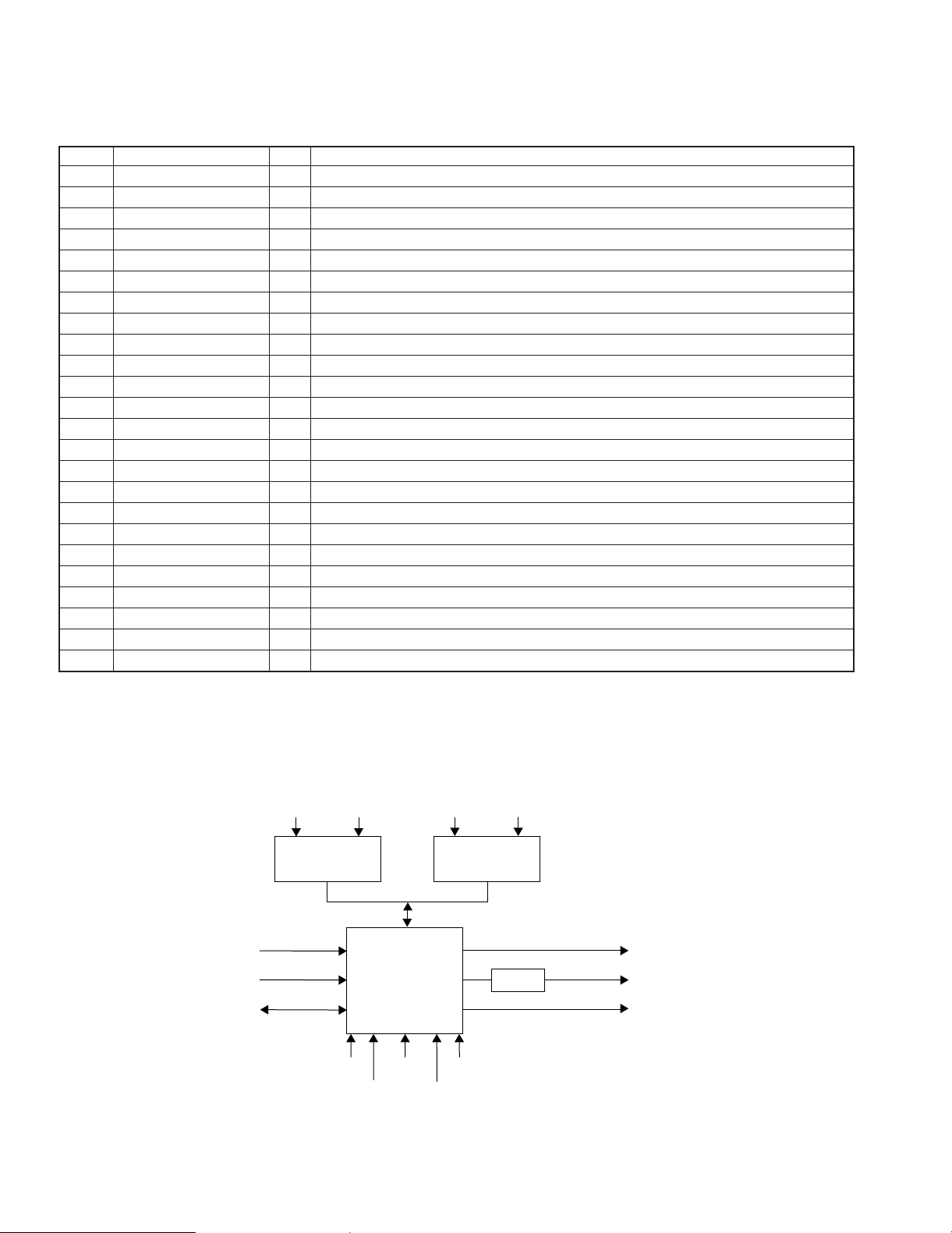

4. MPEG board block diagram

6

CIRCUIT DESCRIPTION

D-W320V

5. Input / Output port

5-1 A / D input port key table

Pin No. : IC701(MN 1872423KEN)

A/D VOLTAGE

PIN No. PIN NAME

26 ANI2 TRAY1 O/C TRAY2 O/C ON/STANDBY

27 ANI1 KARAOKE SHARP NATURAL

28 ANI0 FF REV –

A/D VOLTAGE

PIN No.PIN NAME

26 ANI2 PLAY STOP DIGEST

27 ANI1 FLAT AUTO PAUSE ECHO UP ECHO DOWN

28 ANI0 DISC2 DISC1 REPEAT RANDOM

5-2 Motor driver I/O condition

IC4 (TA7291S)

INPUT OUTPUT

TR+ (PIN 1) TR- (PIN9) OUT (PIN7) OUT2 (PIN3)

L L OPEN OPEN STOP

H L H L TRAY1OPEN

L H L H TRAY2 OPEN

H H L L BREAK

5-3 Motor speed control

IC701(MN1872423KEN)

PIN49 H L

SPEED HIGH LOW

5-4 CD changer I/O

IC701

0 V 0.65 V 1.23 V

1.9 V 2.45 V 3.10 V 3.64 V

OPERATION

6. CD CHANGER CONTROL FUNCTION

6-1 Mechanism Control I/O Port

6-1-1 Input Port

TRSW1 and TRSW2 will detect mechanism operation mode.

Refer to 5. I/O port UPSW detects tray position in tray 1 or 2

mode. L : UPSW = on, H : UPSW = off

6-1-2 Output Port

TR+, TR- and SP CONT control evry motor in the mechanism. Refer to 5. I/O port

6-2 Mechanism Control Specifications

6-2-1 Motor Operation vs Output Port

TR+ TR-

Normal turn H L

Reverse turn L H

Stop H H

Brake H H

6-2-2 Brake Operation Specifications

Brake works before motor will change turning direction.

Brake period is 500msec.

6-2-3 Initial Operation

Mechanism will fix to model 1 or 2 when turn on after hard

reset mode.

1) Pickup will travel inwards

2) Mechanism will select turning direction of motor and model

1 or 2.

In power on / standby operation, mechanism will select

model 1 to mode 4 so it will not have initial operation.

PIN No. PORT NAME T. NAME FUNCTION

24 ANI4 TRSW2 TRAY1 POSITION DETECT

25 ANI3 TRSW1 TRAY2 POSITION DETECT

5-5 TRSW A/D data

IC 701

A/D VOLTAGE 0V 2.5V 5.0V

TRSW2 (PIN24) CLOSE OPEN OFF

TRSW (PIN25) CLOSE OPEN OFF

SYMBOL L M H

6-2-4 Mechanism error Message

detect sw wait period condition error no.

PU IN 4 sec only initial operation 4

TRSW1M 8 sec in tray open mode, TRSW1

TRSW2M or will not have 2.5voltage (M)

UPSW 8 sec in mechanism initial mode,

UPSW will not sense voltage

TRSW1L 8 sec in changing disc, TRSW1 or

TRSE2L TRSW2 will not have 3

Ovoltage (L)

Error message will erase when power is off (standby).

1

2

7

Loading...

Loading...