Kenwood D-40113205 Service manual

D40-1132-05

CASSETTE MECHANISM ASSY

SERVICE MANUAL

C

1999-5 PRINTED IN KOREA

B51-7505-00 (K) 482

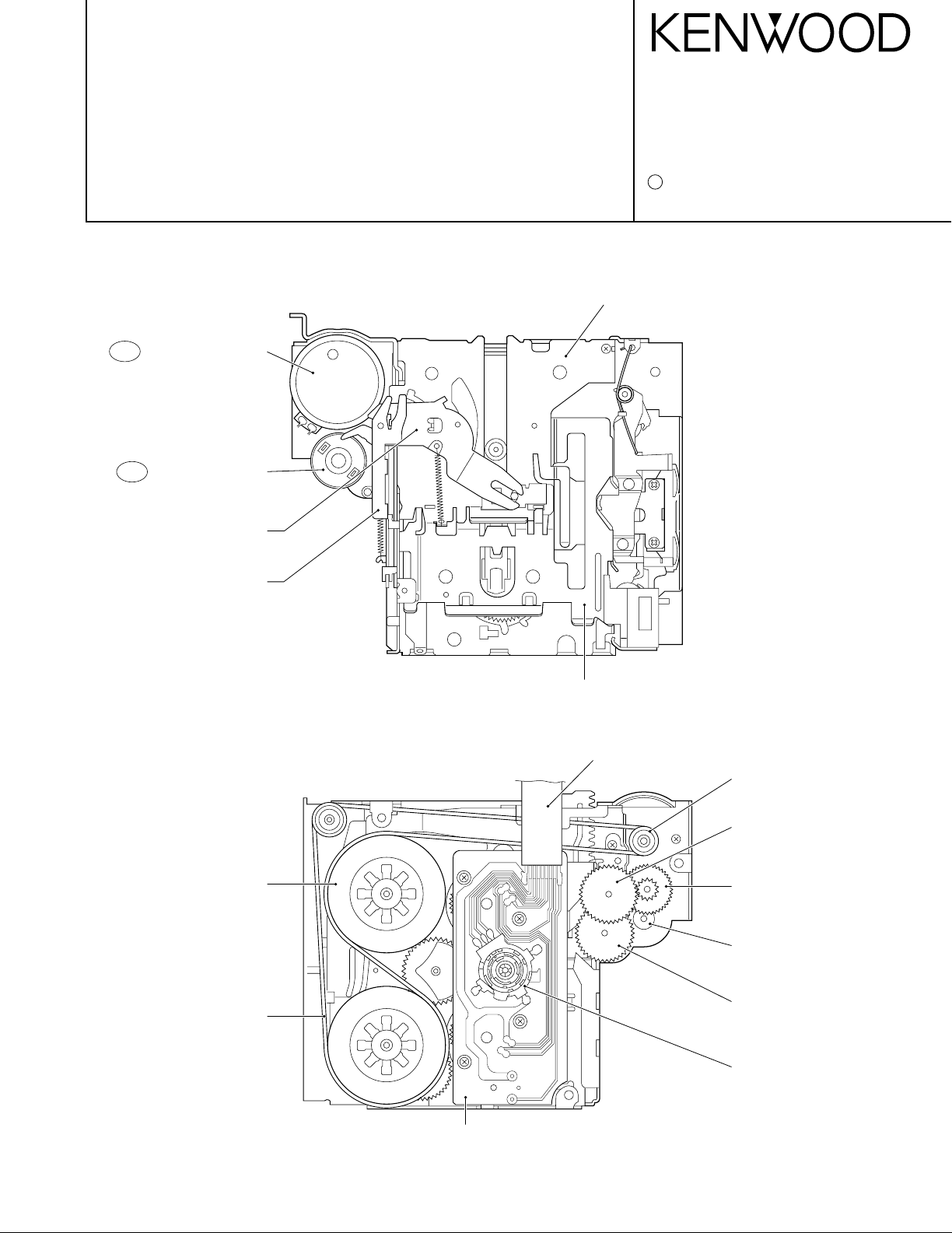

Top View

Bottom View

] CASE LIFTER

MOTOR PULLY

(MAIN MOTOR ASS'Y)

A GEAR

(SUB MOTOR ASS'Y)

FFC CABLE

7 C GEAR

5 B GEAR

6 D GEAR

MODE SW

REEL PWB

CM1 MAIN MOTOR ASS'Y

CM2 SUB MOTOR ASS'Y

| PS ACTUATOR PLATE

* EJECT LEVER

‚ FLY WHEEL

— MAIN BELT

\ CASSETTE CASE

D40-1132-05

CONTENTS / DISASSEMBLY FOR REPAIR

CONTENTS

CONTENTS / DISASSEMBLY FOR REPAIR.............2

MECHANISM DESCRIPTION ..................................13

ADJUSTMENT..........................................................19

DISASSEMBLY FOR REPAIR

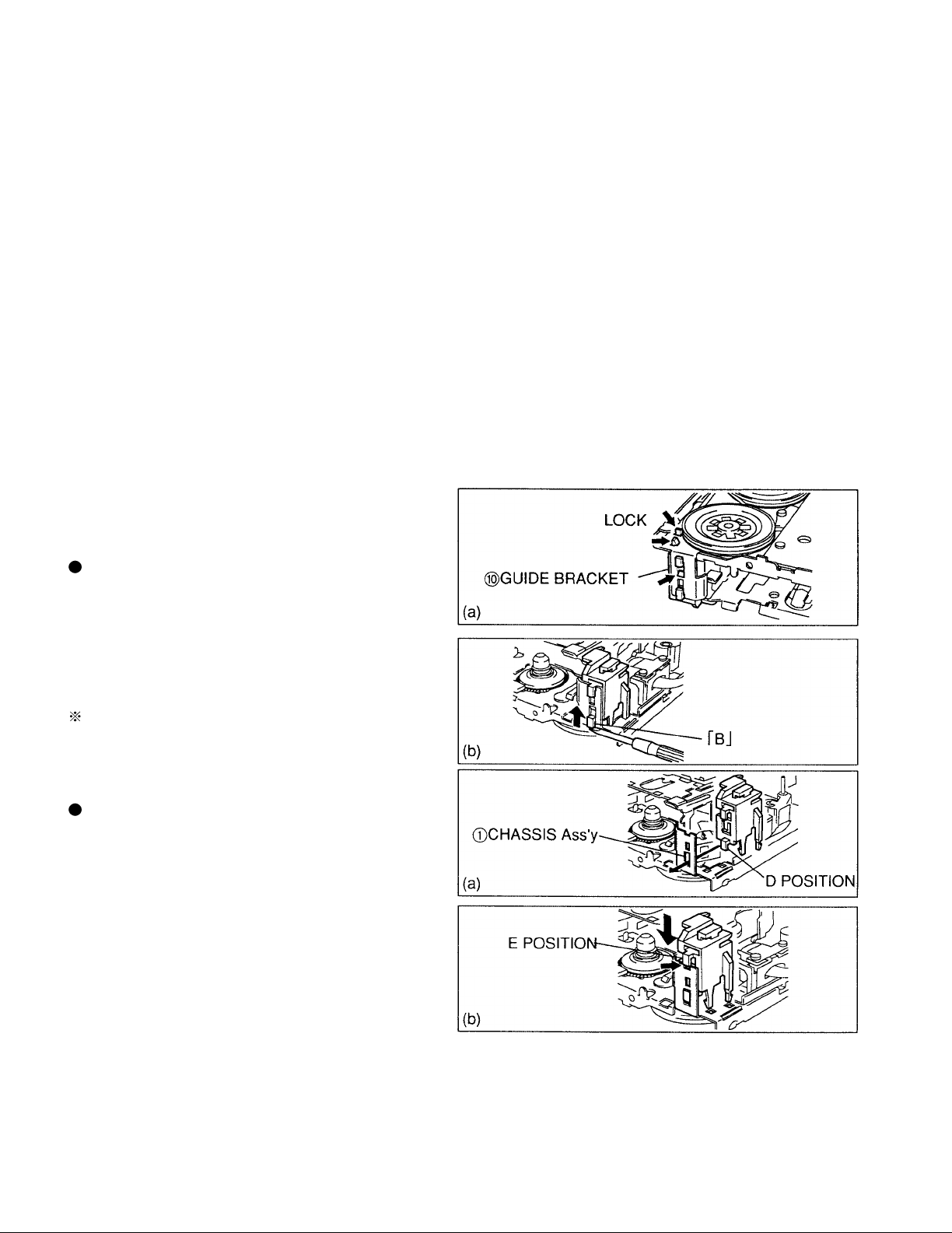

1.1. GUIDE BRACKET

CAUTION:

This part is damageable during disassembling, and it cannot

be reused.

Disassembling

(a) Note that 0GUIDE BRACKET is locked at three places

shown in figure.

EXPLODED VIEW....................................................20

PARTS LIST .............................................................21

(b) Set the mechanism in "R.PLAY" mode (see 2.1 Manual

Operation).

(c) Push "B" portion strongly upward with a proper tool, and

the Bracket will be unlocked at once.

If the above unlocking failed, break the lock with nippers

(In such a case, take care not to allow debris to enter the

deck.)

Reassembling

(a) From the side of PINCH ROLLER ARM Ass'y, first insert

"D" portion into a hole in 1CHASSIS Ass'y.

(b) Adjusting three locks and "E" portion, push the Bracket

down until it clicks.

(c) Make sure that the Bracket is locked at three places.

(hooks are engaged with the Chassis.)

2

(a)

(b)

(d)

(b)

(c)

(d)

‘PACK SLIDER

‘PACK SLIDER

‘PACK SLIDER

|PS ACTUATOR PLATE

|PS ACTUATOR PLATE

|PS ACTUATOR PLATE

]CASE LIFTER

]CASE LIFTER

“PS SPRING

B

A

C

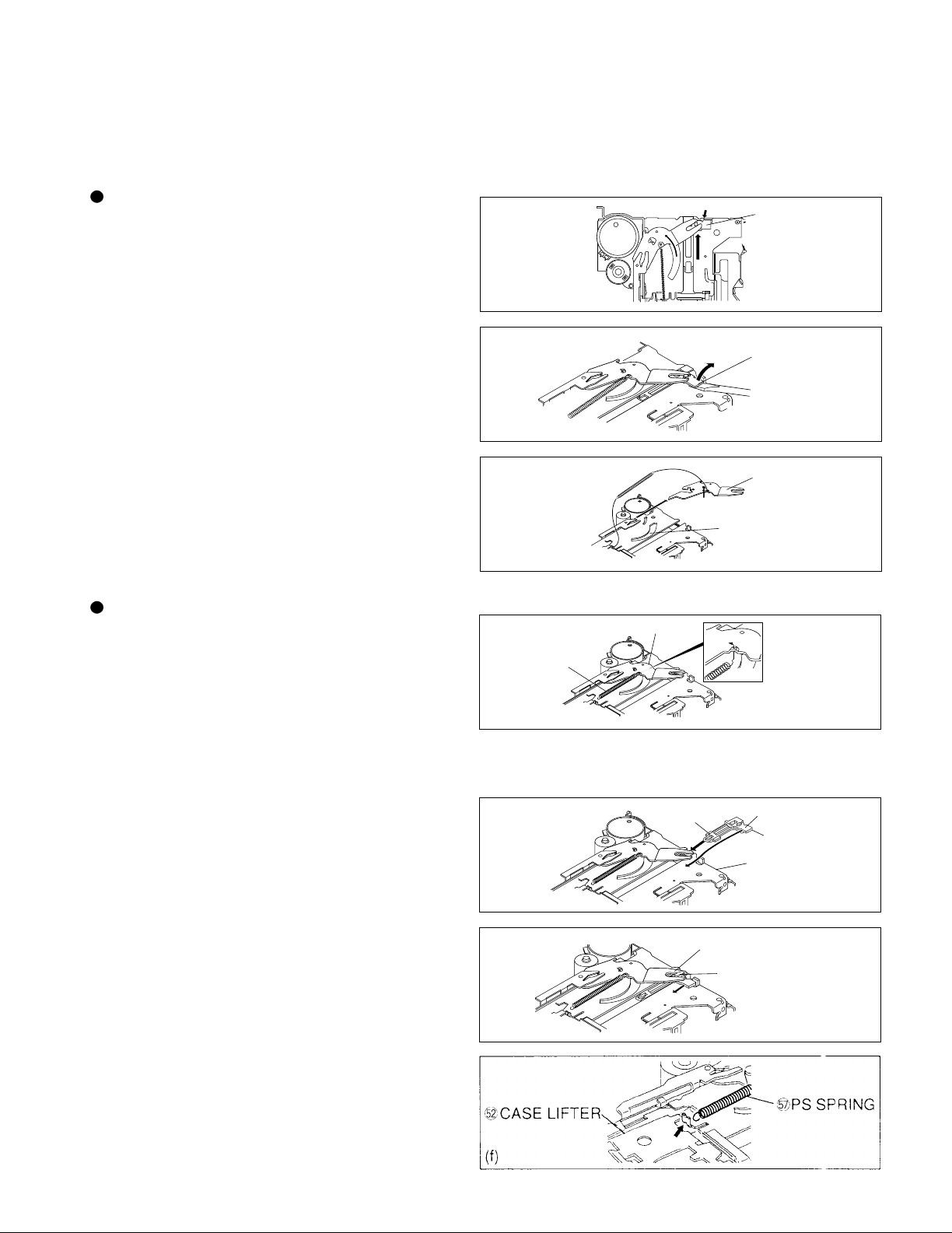

1.2. ‘PACK SLIDER/|PS ACTUATOR PLATE

CAUTION:

The PACK SLIDER is damageable during disassembling, and it cannot be reused. and it cannot be reused.

Disassembling

(a) Rotate 7D GEAR by hand until the position shown in fig-

ure where ‘PACK SLIDER gets stuck to the stopper.

-Position traveling over the PULL.E a little.-

(b) Raising the part shown in figure with a thin edge screw-

driver, push the ‘PACK SLIDER in arrow direction,

avoiding interference with the stopper.

(c) Disengage the boss from the PS ACTUATOR PLATE,

and the PACK SLIDER will be removed.

(d) Further turning CCW the |PS ACTUATOR PLATE,

raise the Guide shown with an arrow while meeting with

the hole in ]CASE LIFTER, and the PS ACTUATOR

PLATE can be removed.

(e) At the same time, remove “PS SPRING from the

]CASE LEFTER (if necessary), and from the | PS

ACTUATOR PLATE.

Reassembling

(a) Rotating 7D GEAR in the deck until the position where a

marker on OP PLATE Ass'y travels over the pulley a little.

(b) Hook “PS SPRING to the |PS ACTUATOR PLATE

from the bottom. Meeting the hole with the boss of

]CASE LIFTER, insert a bent portion into a sector hole

in the ]CASE LIFTER (step (b) in previous item).

D40-1132-05

DISASSEMBLY FOR REPAIR

(c) Under this condition, insert the ‘PACK SLIDER so that

its "A" and "B" portions come out under and above the

]CASE LIFTER respectively.

(d) Insert the boss into |PS ACTUATOR PLATE, and slide

toward the front.

(e) Rotate the D GEAR clockwise to set up the EJECT sta-

tus.

(f) Hook another end “PS SPRING to the ]CASE LIFTER.

3

D40-1132-05

DISASSEMBLY FOR REPAIR

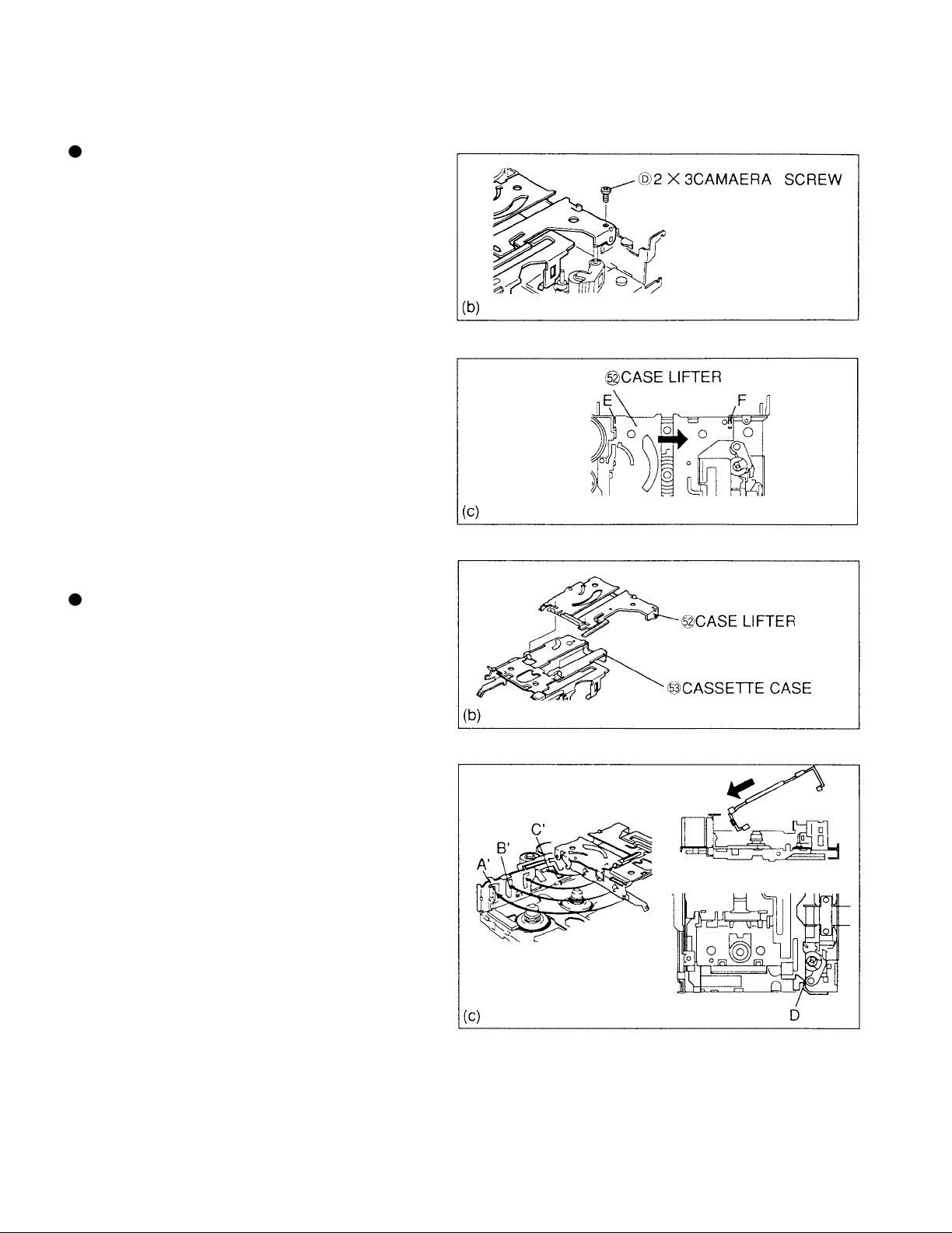

1.3. \CASSETTE CASE/]CASE LIFTER

Disassembling

(a) Set the mechanism in EJECT POSITION.

(b) Remove D2x3 CAMERA SCREW.

(c) Push ]CASE LIFTER in arrow direction so that "E" and

"F" portions are disengaged.

Reassembling

(a) Confirm that the mechanism is at EJECT position.

(b) Meeting the holes in ]CASE LIFTER with the holes in

\CASSETTE CASE as shown in figure, assemble these

parts.

(c) Meeting A, B, C with A', B', C' respectively, insert the

Cassette Case obliquely. (Note that "D" portion may get

stuck.)

(d) When the Cassette Case becomes horizontal, confirm that A, B, C are engaged, then adjust fitting at E and F portions in

Fig.(c) in previous item, and insert the Case completely. (Step (c) in previous item) (Fitting is over when no gap is found.)

(e) Tighten 2x3 SCREW.

4

D40-1132-05

DISASSEMBLY FOR REPAIR

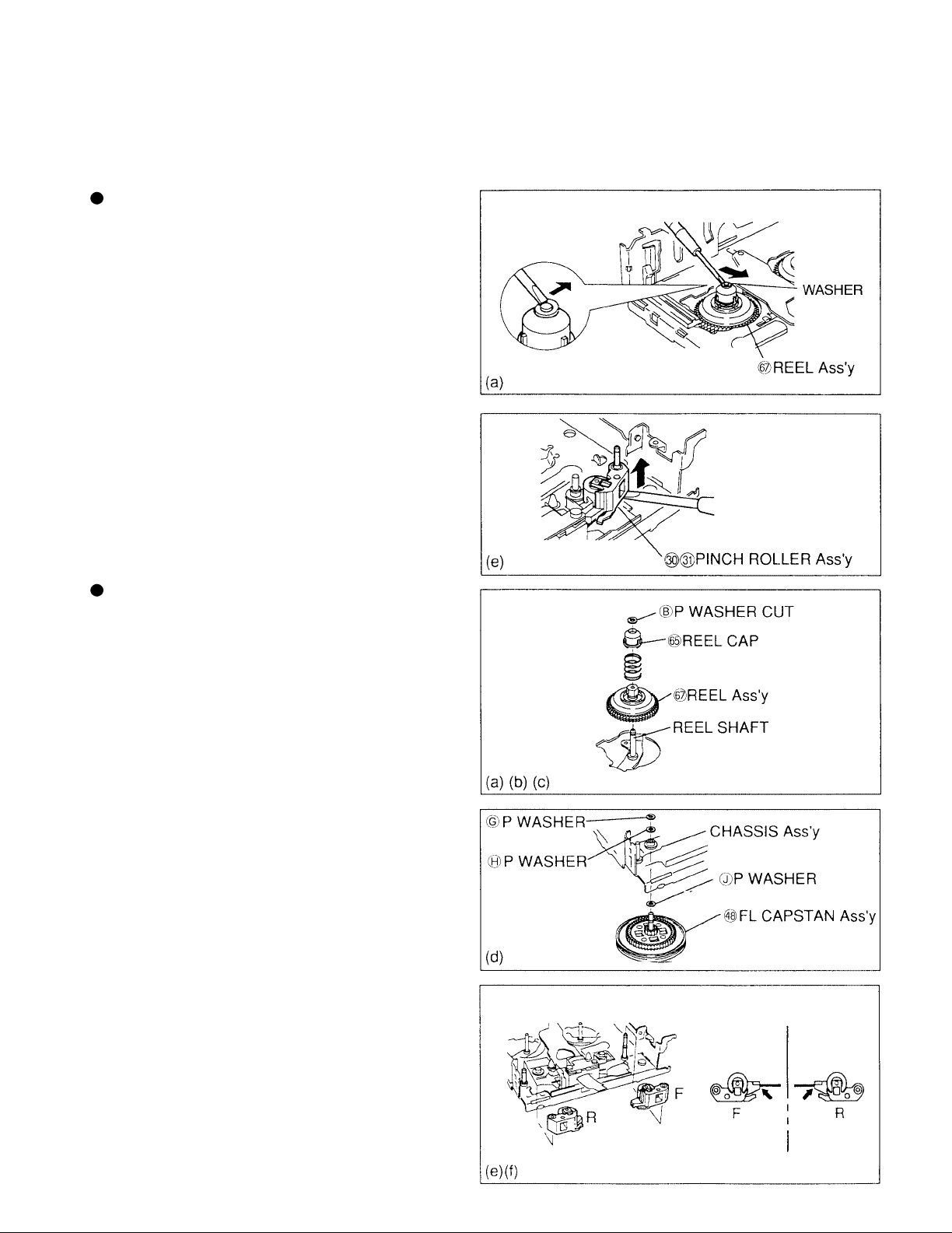

1.4. –REEL Ass'y/‚FL CAPSTAN Ass'y/∞§PINCH ROLLER Ass'y

CAUTION:

As :REEL CAP/∞§PINCH ROLLER Ass'y are damageable during disassembling, they cannot be reused.

Disassembling

(a) Open and remove the Washer at the lead edge of

…REEL Ass'y as shown in figure. (The washer is damageable, and it cannot be reused.)

(b) Raise and remove :REEL CAP/REEL Ass'y.

(c) For ‚FL CAPSTAN Ass'y, open and remove the Washer

in the same manner.

(d) Remove the FL CAPSTAN Ass'y from the bottom (In

such a case, HJP WASHERS may stay on the Chassis,

and take care not to allow them to enter the deck.) (See

Fig.(d) in next item)

(e) Insert a flat-head screwdriver into ∞§PINCH ROLLER

Ass'y as shown in figure, and raise the Ass'y until it

clicks. Thus, it will be unlocked.

(f) Then, remove the Pinch Roller Ass'y by hand.

Reassembling

(a) Insert the …REEL Ass'y into the REEL SHAFT.

(b) Insert "REEL WING SPRING, then a :REEL CAP on

it, and push them until they pass through the REEL

SHAFT.

(c) Under this condition, insert BP WASHER CUT.

(d) Insert the ‚FL CAPSTAN Ass'y into the CHASSIS Ass'y

and lock with GP WASHER (At this time, don't forget to

insert HJP WASHERS.)

(e) The PINCH ROLLER Ass'y is designed so as to be fit by

a force, and therefore insert it into the SHAFT of

1CHASSIS Ass'y at portions F and R.

(f) The PINCH ROLLER Ass'y is designed so as to be fit by

a force, and therefore insert it into the SHAFT of

1CHASSIS Ass'y at portions F and R. Next, press to fit

the Springs attaching to @HEAD PANEL Ass'y at both F

and R in the same manner.

5

D40-1132-05

DISASSEMBLY FOR REPAIR

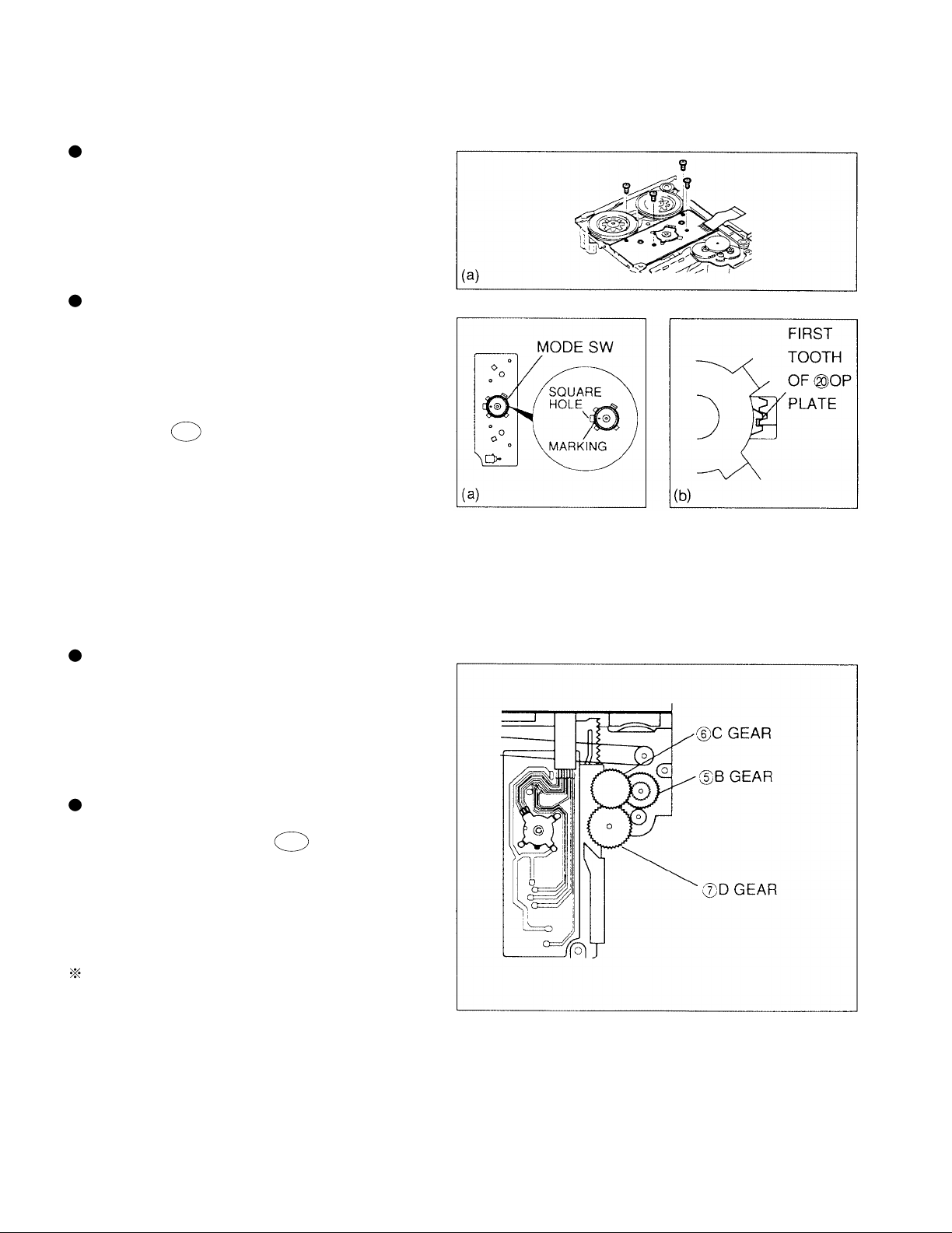

1.5. ’REEL PWB Ass'y/»CR DETECTIVE PLATE

Disassembling

(a) Remove four screws as shown in figure.

Remove the REEL PWB Ass'y, can be removed.

Reassembling

(a) Align the marking of the MODE SW on he REEL PWB

Ass'y with a square hole, as shown in fig(a).

(b) IN reassembling, adjust the REEL PWB Ass'y so that the

first tooth of &OP PLATE gear enters between two pro-

trusions that can be seen through a window, then adjust

four screw positions.

(c) Tighten four 200 2 X 2.2CAMERA SCREW. (previous

Fig.(a))

1.6. 5B GEAR/6C GEAR/7D GEAR

Disassembling

(a) As these Gears are fit forcibly, to remove the Gears.

raise them from the bottom with a flathead screw driver

while taking care not to damage other parts.

(b) As for the disassembling order, first remove 6C GEAR,

then

5B GEAR or 7D GEAR. (Removed parts cannot

be reused.)

Reassembling

(a) Fit the B GEAR forcibly with a small gear side facing up

while meshing with A GEAR ( CM2 SUB MOTOR Ass'y).

(b) Fit the D GEAR forcibly with a small gear side facing

down while meshing a small gear with the gear of

PLATE Ass'y.

(c) Fit the C GEAR forcibly with a small gear side facing

down while meshing a small gear with D GEAR and also

a large gear with B GEAR.

In any case after fitting, confirm that the Gears rotate

smoothly.

&OP

6

DISASSEMBLY FOR REPAIR

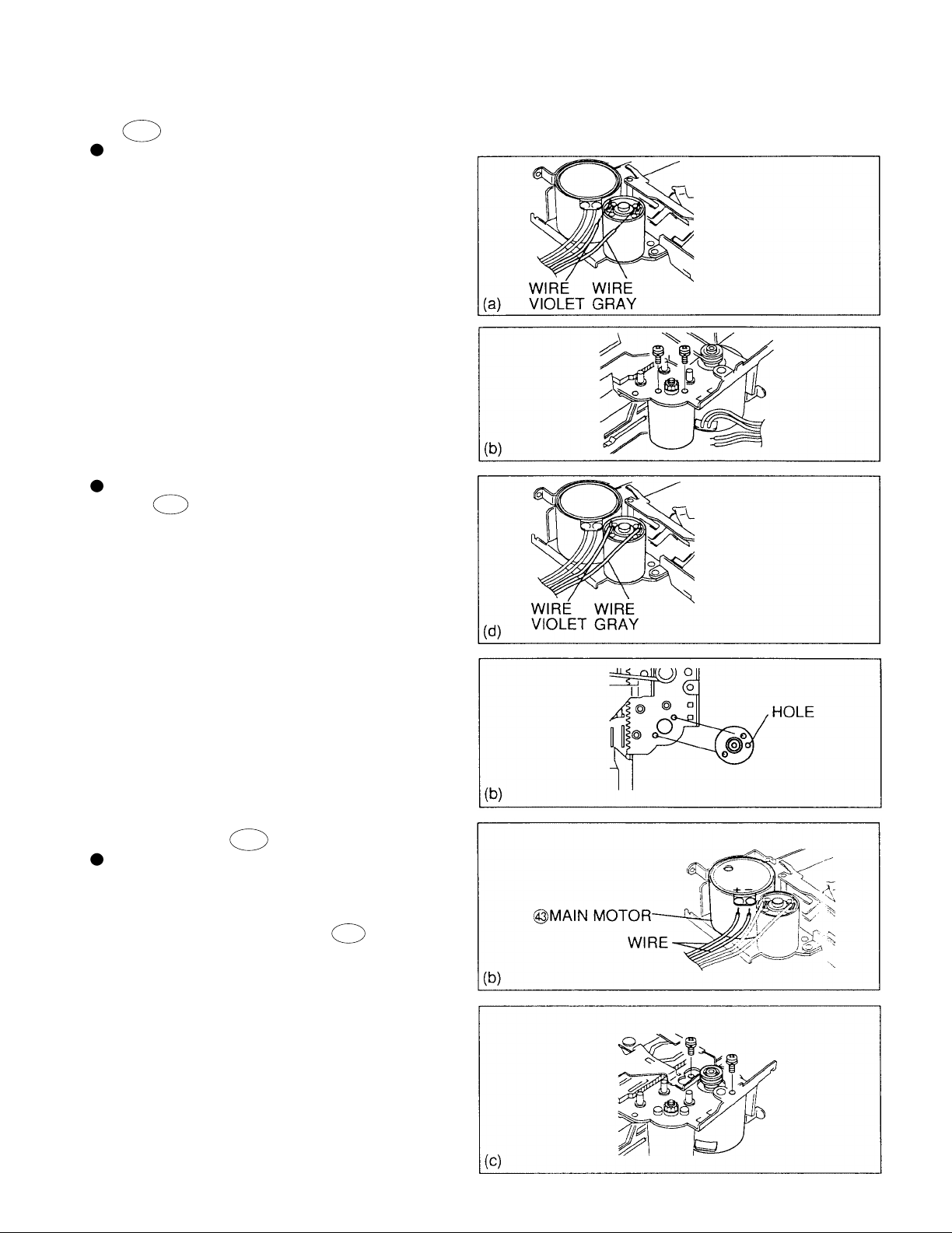

1.7. CM2 SUB MOTOR Ass'y

Disassembling

(a) Break the solders of two wires (violet and gray) of M

CONNECTOR WIRE.

(b) Remove two screws. (Assume that the GEARS were

already removed.)

Reassembling

(a) Insert CM2 SUB MOTOR while taking care not to allow

A GEAR to interfere with the edge of

(b) In such a case, meet screw holes with holes in the

CHASSIS as shown in figure.

(c) Tighten

(d) Solder lead wires of M CONNECTOR Ass'y.

E42 X 3 TAMS SCREW.

1CHASSIS Ass'y.

D40-1132-05

1.8. —MAIN BELT/ CM1 MAIN MOTOR

Disassembling

(a) Disengage

age the back of Belt.

(b) Break the solders of two wires (red and brown) of M

CONNECTOR WIRE connected to CM1 MAIN MOTOR.

(c) Remove two screws. (Assume that the GEARS were

already removed.)

—MAIN BELT while :taking care not to dam-

7

Loading...

Loading...