Kenmore Elite 23351282710, 23351283710, 23351289710, 23351292710, 23351299710 Owner’s Manual

Use & Care / Installation Manual

Manual de Uso y Cuidado / Instalación

English / Español

Models/Modelos 51282*, 51283*, 51289*

51292*, 51299*, 51353*

Kenmore

®

Range Hood

Campana de cocina

* = color number, número de color

P/N 99045662-009A

Sears Brands Management Corporation,

Hoff man Estates, IL 60179 USA

www.kenmore.com

www.sears.com

TM

READ AND SAVE THESE INSTRUCTIONS

TABLE OF CONTENTS KENMORE LIMITED WARRANTY

SECTION ............................................................. PAGE

Warranty ............................................................................... 2

Safety Instructions ............................................................... 3

Operation .............................................................................. 4

Cleaning ................................................................................ 4

Parts Included With Hood ................................................. 5

Parts Not Included With Hood ......................................... 5

Tools Needed ....................................................................... 5

Equivalent Duct Length Chart ........................................... 6

Install Ductwork ................................................................. 7

Prepare The Hood ......................................................... 7-9

Prepare The Hood Location ....................................... 10-13

EZ1 One-Person Installation ............................... 10-11

Install The Hood (EZ-1 Brackets) ............................ 12

Standard Installation (without EZ1 Brackets) ....... 13

Install The Hood (Standard Installation) ............... 13

Connect The Wiring .......................................................... 14

Install The Light Bulbs ........................................................ 15

Install The Filters ............................................................... 15

Service Parts ...................................................................... 16

Master Protection Agreements ....................................... 17

When this appliance is installed, operated and maintained

according to all supplied instructions, the following warranty

coverage applies. To arrange for warranty service, call

1-800-4-MY-HOME® (1-800-469-4663).

• For one year from the date of purchase, any part of

this product that fails due to a defect in material or

workmanship will receive free repair or replacement if

repair proves impossible. The length of this coverage

does not apply to the fi nish of any painted or bright

metal part.

• For thirty days date of purchase, any painted or bright

metal part of this product will be replaced free of charge

if its fi nish is defective in material or workmanship.

All warranty coverage is void if this product is ever used for

other than private household purposes.

This warranty covers only defects in material and

workmanship, and will NOT pay for:

1. Consumable parts that can wear out from normal use,

including but not limited to fi lters, belts, light bulbs, and

bags.

2. A service technician to instruct the user in correct product

installation, operation or maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed,

operated or maintained according to the all instructions

supplied with the product.

5. Damage to or failure of this product resulting from

accident, abuse, misuse or use for other than its

intended purpose.

6. Damage to or failure of this product caused by the use

of detergents, cleaners, chemicals or utensils other than

those recommended in all instructions supplied with the

product.

7. Damage to or failure of parts or systems resulting from

unauthorized modifi cations made to this product.

Disclaimer of implied warranties; limitation of remedies

Customer’s sole and exclusive remedy under this limited

warranty shall be product repair as provided herein.

Implied warranties, including warranties of merchantability

or fi tness for a particular purpose, are limited to one

year or the shortest period allowed by law. Sears shall

not be liable for incidental or consequential damages.

Some states and provinces do not allow the exclusion

or limitation of incidental or consequential damages, or

limitation on the duration ofi mplied warranties of

merchantability or fi tness, so these exclusions or limitations

may not apply to you.

This warranty gives you specifi c legal rights, and you may

also have other rights which vary from state to state.

Sears Brands Management Corporation,

Hoff man Estates, IL 60179

2

SAFETY INSTRUCTIONS

!

!

!

INTENDED FOR DOMESTIC COOKING ONLY.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address listed in the warranty.

2. Before servicing or cleaning unit, switch power off

at service panel and lock the service disconnecting

means to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by

a qualifi ed person(s) in accordance with all applicable

codes and standards, including fi re-rated codes and

standards.

4. Suffi cient air is needed for proper combustion and

exhausting of gases through the fl ue (chimney) of fuel

burning equipment to prevent backdrafting. Follow

the heating equipment manufacturer’s guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. To reduce the risk of fi re or electric shock, do not

use this range hood with an additional speed control

device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fi re, use only metal ductwork.

9. This unit must be grounded.

Warranty Safety CleaningOperation Installation Service Parts

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that

may ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or

when cooking fl aming foods.

3. Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan or fi lter.

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fi tting lid, cookie

sheet, or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the fl ames do not

go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels - a violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and

you already know how to operate it.

B. The fi re is small and contained in the area where

it started.

C. The fi re department is being called.

D. You can fi ght the fi re with your back to an exit.

* Based on “Kitchen Fire safety Tips” published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/

or unbalanced impellers, keep drywall spray,

construction dust, etc. off power unit.

3. For best capture of cooking impurities, your range

hood should be mounted so that the top of the hood

is 18-24” above the cooking surface.

4. Use only with range hood cord-connection kits that

have been investigated and found acceptable for use

with this model range hood.

5. Please read specifi cation label on product for further

information and requirements.

NOTE

If hood is to be installed Non-Ducted:

Purchase non-ducted fi lters and attach them to the

aluminum mesh fi lters.

“Non-ducted Filters” available by calling Sears at

1-800-4-MY-HOME

3

®

CLEANINGOPERATION

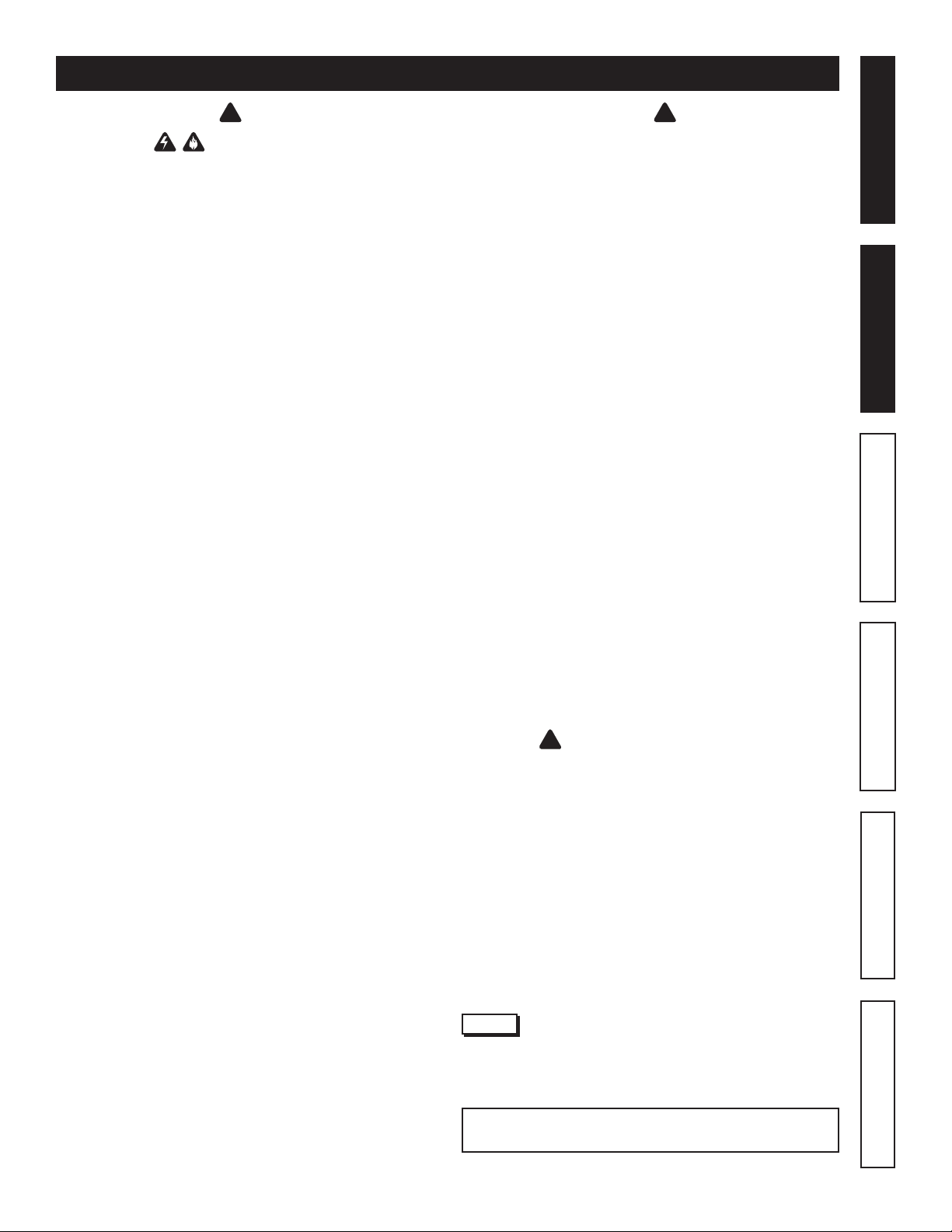

BLOWER SPEED LEVEL

PUSH BUTTONS

ON/OFF BLOWER

PUSH BUTTON

ON/OFF BLOWER PUSH BUTTON

When blower is OFF, push on this button to turn ON the

blower at the last selected speed. Push on this button

again to turn OFF the blower.

NOTE: If there is no speed selected (all blower

speed push buttons up), the blower will not turn

ON. In that case, press on the desired speed

level push button to activate the blower.

BLOWER SPEED LEVEL PUSH BUTTONS

When blower is ON, change the blower speed by

pressing on the push button corresponding to the

desired speed: one line for LOW, two lines for MEDIUM

and three lines for HIGH speed.

ON/OFF LIGHT PUSH BUTTON

When lights are OFF, push once on this button to turn

ON the lights at the last selected setting. Push on this

button again to turn OFF the lights.

LIGHT INTENSITY LEVELS PUSH BUTTON

Push on this button to change the light intensity (HIGH

or LOW).

LIGHT INTENSITY

LEVELS PUSH BUTTON

ON/OFF LIGHT

PUSH BUTTON

WARNING: To reduce the risk of electric shock,

disconnect from power supply before cleaning.

Micromesh fi lters

Clean frequently using hot water and a mild detergent

or in your dishwasher. The micromesh fi lters should be

washed approximately every month depending on the

amount of usage. Wash more often if your cooking style

generates greater grease - like frying foods or wok

cooking.

Non-ducted recirculation fi lters

(available separately - see page 5)

The non-ducted recirculation fi lters should be changed

every 3 to 6 months. Replace more often if your cooking

style generates extra grease, such as frying and wok

cooking. Refer to installation instructions included with

non-ducted recirculation fi lters.

Painted hood surfaces

Clean with warm water and mild detergent only. If

discoloration occurs, use a fi nish polish such as automotive

polish. (DO NOT use rough abrasive cleaner or porcelain

cleaner.)

Stainless steel hood surfaces

Do:

• Regularly wash with clean cloth or rag soaked

with warm water and mild soap or liquid dish

detergent.

• Always clean in the direction of original polish

lines.

• Always rinse well with clear water (2 or 3 times)

after cleaning. Wipe dry completely.

• You may also use a specialized household stainless

steel cleaner.

Don’t:

• Use any steel or stainless steel wool or any other

scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues

reach the hood. During construction/renovation,

cover the range hood to make sure no dust sticks

to the stainless steel surface.

Avoid when choosing a detergent:

• Any cleaners that contain bleach will attack stainless steel.

• Any products containing: chloride, fl uoride, iodide,

bromide will deteriorate surfaces rapidly.

• Any combustible products used for cleaning such as

acetone, alcohol, ether, benzol, etc., are highly

explosive and should never be used close to a range.

Fan assembly

The fan blade should be cleaned frequently. Use a clean

cloth soaked with warm detergent solution.

The motor is permanently lubricated and never needs

oiling. If the motor bearings make excessive or unusual

noise, replace the motor with the exact service motor.

The fan blade should also be replaced.

4

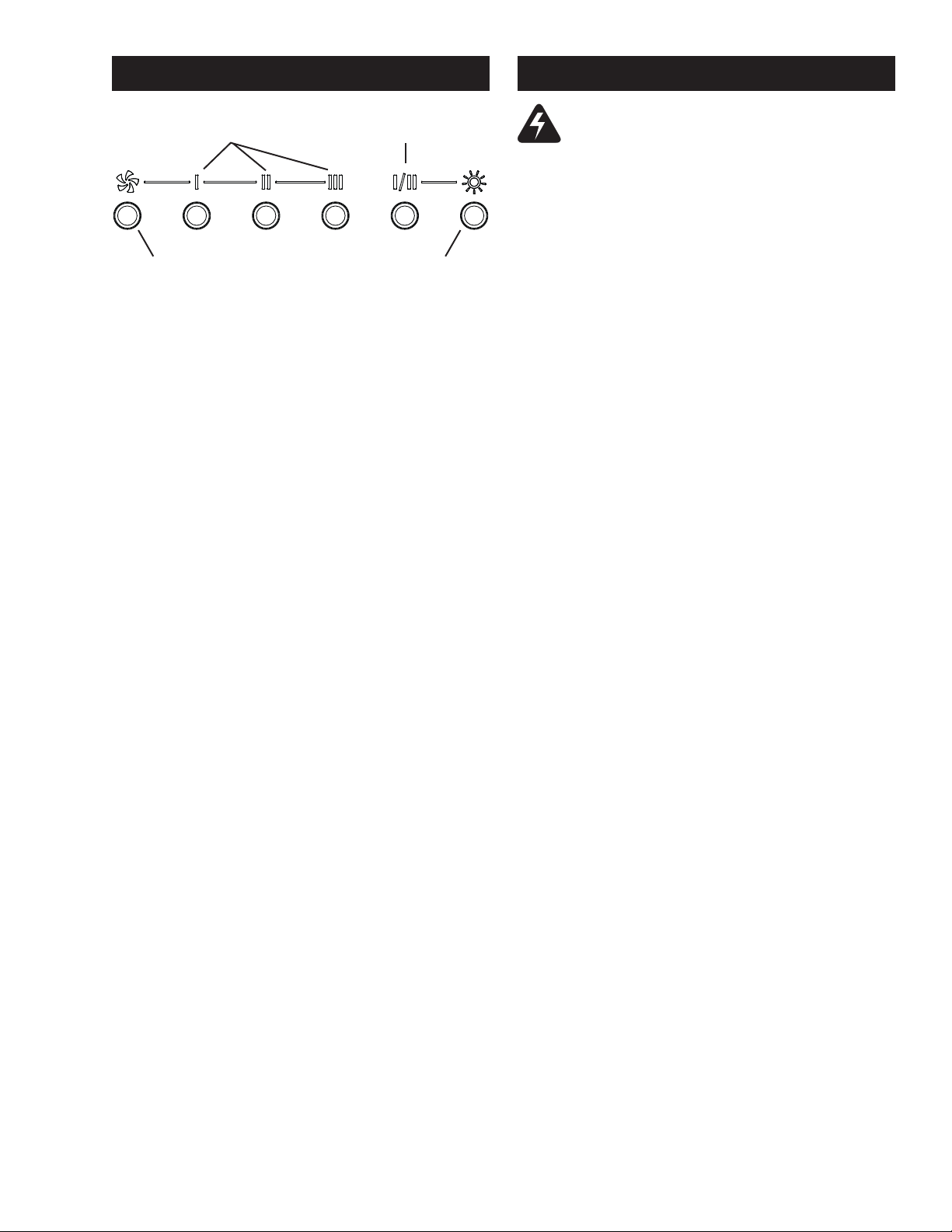

PARTS INCLUDED WITH HOOD

C

L

AB

Apoyar este borde contra la pared de atrásPlace this edge against back wall

VERTICAL EXHAUST

= 3¼” x 10”

= 3¼” x 14”

RECTANGULAR DUCTING7” ROUND DUCTING

OR

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

= 3¼ po x 10 po

= 3¼ po x 14 po

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

CONDUCTO RECTANGULARCONDUCTO REDONDO

DE

7 PULG.

O

Appuyer ce bord au mur arrière

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BETRANSLATED IN SPANISH

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

4¼”

10½”

14½”

8”

7½”

C

C

C

Bend template along graduated

scale when installing to framed

cabinet.

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

conséquence.

To be translated in Spanish.

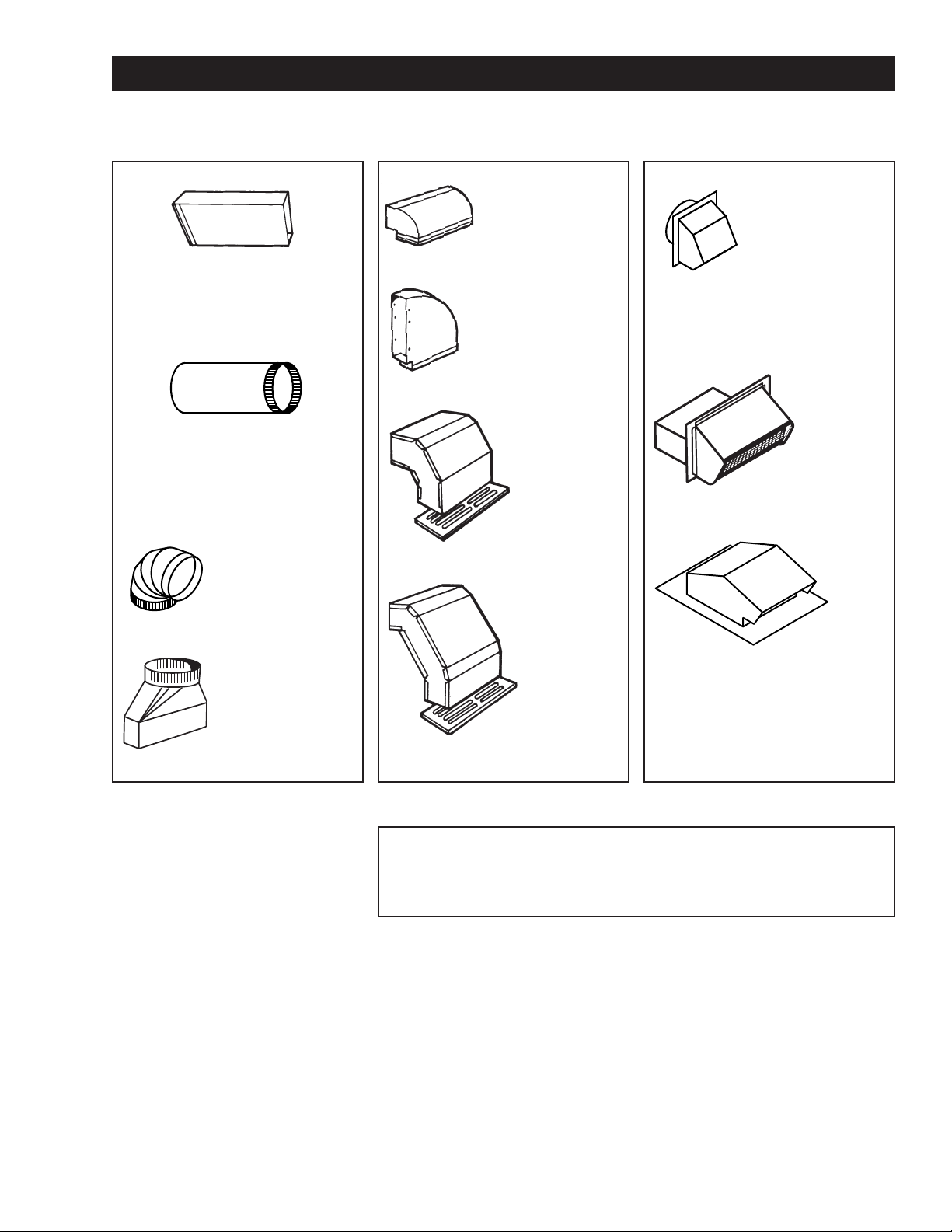

PARTS NOT INCLUDED WITH HOOD*

Micromesh Grease Filters

(2 per hood)

3¼” x 10”

Damper / Duct

Connector

EZ-1 One person Installation Kit

(including template for

ducting, printed both sides,

and installation brackets)

Shielded Halogen Bulbs

(120 V, 50 W max., MR16 or

PAR16 with GU10 base)

(2 per hood)

7” Round

Duct Connector

OPTIONAL PARTS (purchase separately)

Non-Ducted Recirculation Filters

(Non-ducted hoods only)

(2 per hood)

Part Nos.:

S97020466 (30-in. width hoods)

S97020467 (36-in. width hoods)

7-inch Round Damper

(For use with 7-inch Round Duct)

Sears Part No. 59183

Warranty Safety CleaningOperation Installation Service Parts

Parts Bag

(4 no. 8-18 x 1/2" metal screws,

4 washers, 6 no. 8 x 5/8" round head

wood screws, 6 no. 8 x 1/2" countersunk

wood screws, 1 suction cup tool)

TOOLS NEEDED FOR HOOD INSTALLATION

Screwdriver

(Flat & Phillips no. 2)

Pencil

Ducting Accessories

(See “Equivalent Duct Length Chart” on page 6 for

Ducting Accessory Model Nos.)

“Parts Not Included With Hood” available by calling

Drill

(with 1/8" and

7/64" drill bits,

and 1½" hole saw)

Tape

Measure

Sears at 1-800-4-MY-HOME

Long Nose

Pliers

-orKeyhole

Sabre Saw

Saw

®

Metal Foil

Duct Tape

Sheet Metal

Shears

Wire

Stripper

5

EQUIVALENT DUCT LENGTH CHART

Kenmore range hoods are designed to perform effi ciently when attached to long runs of duct. As a point of reference,

this hood will function at approximately 80% of its rated air fl ow when 25 equivalent feet of 7" round ductwork is

attached. Use this chart to calculate the equivalent duct length of your system.

Broan Model 401

Straight Duct

3¼-in. x 10-in. x 2-ft. long

Equivalent length

2 ft.

Broan Model 407

Straight Duct

7-in. round x 2-ft. long

Equivalent length

2 ft.

Broan Model 415

7-in. Round Elbow

Equivalent length

8 ft.

Broan Model 412H

3¼-in. x 10-in. to

7-in. Round

Transition

Equivalent length

5.5 ft.

Broan Model 428

3¼-in. x 10-in.

Right-angle Elbow

Equivalent length

8.5 ft.

Broan Model 429

3¼-in. x 10-in.

Right-angle Flat Elbow

Equivalent length

24 ft.

Broan Model 430

3¼-in. x 10-in.

Right-angle

Short

Eave Elbow

Equivalent length

15 ft.

Broan Model 431

3¼-in. x 10-in.

Right-angle

Long

Eave Elbow

Equivalent length

15 ft.

Broan Model 647

7-in. Round

Wall Cap

Equivalent length

34 ft.

(6-ft. w/o damper)

Sears Model

59391

3¼-in. x

10-in.

Wall Cap

Equivalent

length

45 ft.

(7-ft. w/o

damper)

Sears

Model 59091

Roof Cap

(accepts 7-in. round

or 3¼-in. x 10-in. duct)

Equivalent length

30 ft. (7-ft. w/o damper)

Sears Model “Ducting Accessories” available by calling:

Sears at 1-800-4-MY-HOME

®

Broan Model “Ducting Accessories” available by calling:

1-800-558-1711.

6

SOFFIT

18" MIN - 24" MAX

ABOVE

COOKING SURFACE

CABINET

3¼" X 10" DUCT

(FOR HORIZONTAL DISCHARGE)

WALL CAP

ROOF CAP

3¼" X 10" OR

7" ROUND DUCT

(FOR VERTICAL

DISCHARGE

)

HOUSE WIRING

(TOP OR BACK OF HOOD)

HOOD

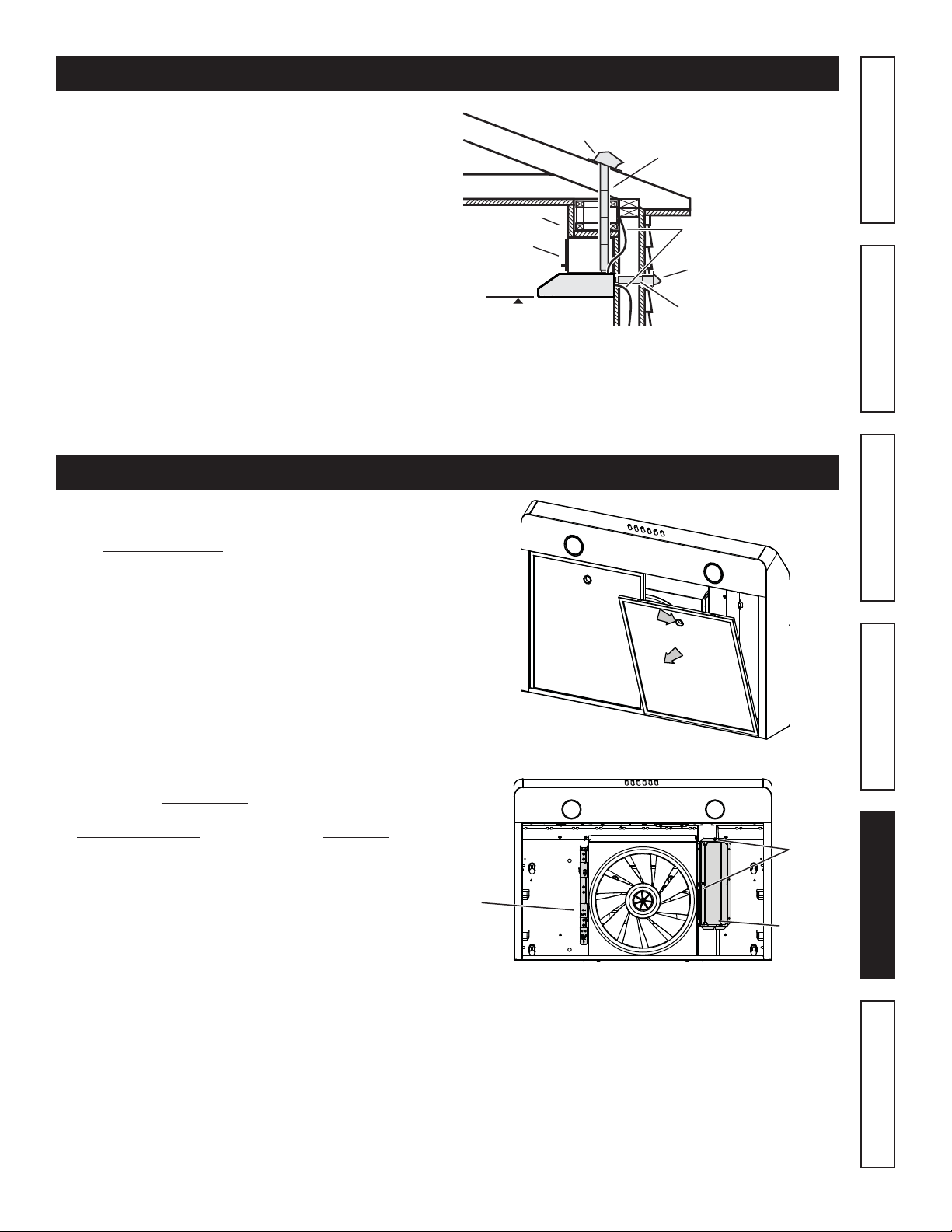

INSTALL DUCTWORK (DUCTED INSTALLATION ONLY)

B

C

1. Determine whether hood will discharge vertically

(3¼” x 10” or 7” Round) or horizontally (3¼” x 10”

only).

2. Run ductwork between the hood location and a roof

cap or wall cap.

3. Choose a straight, short duct run to allow the hood to

perform most effi ciently. Long duct runs, elbows and

transitions will reduce the performance of the hood.

Use as few of them as possible. When possible, use

at least 2 foot straight runs before any turns. Larger

ductwork may be required for best performance with

longer duct runs.

4. Install wall cap or roof cap (sold separately); ensure

there is no leak in hoiouse insulation. Connect metal

ductwork to cap and work back towards the hood

location. Use 2” metal foil duct tape to seal the joints

between ductwork sections.

PREPARE THE HOOD

1. If present, remove all protective polyfi lm from the

hood and/or parts. Using the fi nger cup, remove

the Micromesh Filters from the hood by pushing

down and tilting fi lters out.

Warranty Safety CleaningOperation Installation Service Parts

NOTE: Distances over 24” are at the installer and user

discretion.

2. Remove the EZ1 brackets from inside the hood by

cutting off the tie wrap. Remove both screws holding

damper assembly to hood. Remove parts bag

(captured behind the damper assembly). Remove

damper assembly from inside the hood and keep

the screws for further use.

BRACKETS

SCREWS

EZ1

DAMPER

ASSEMBLY

7

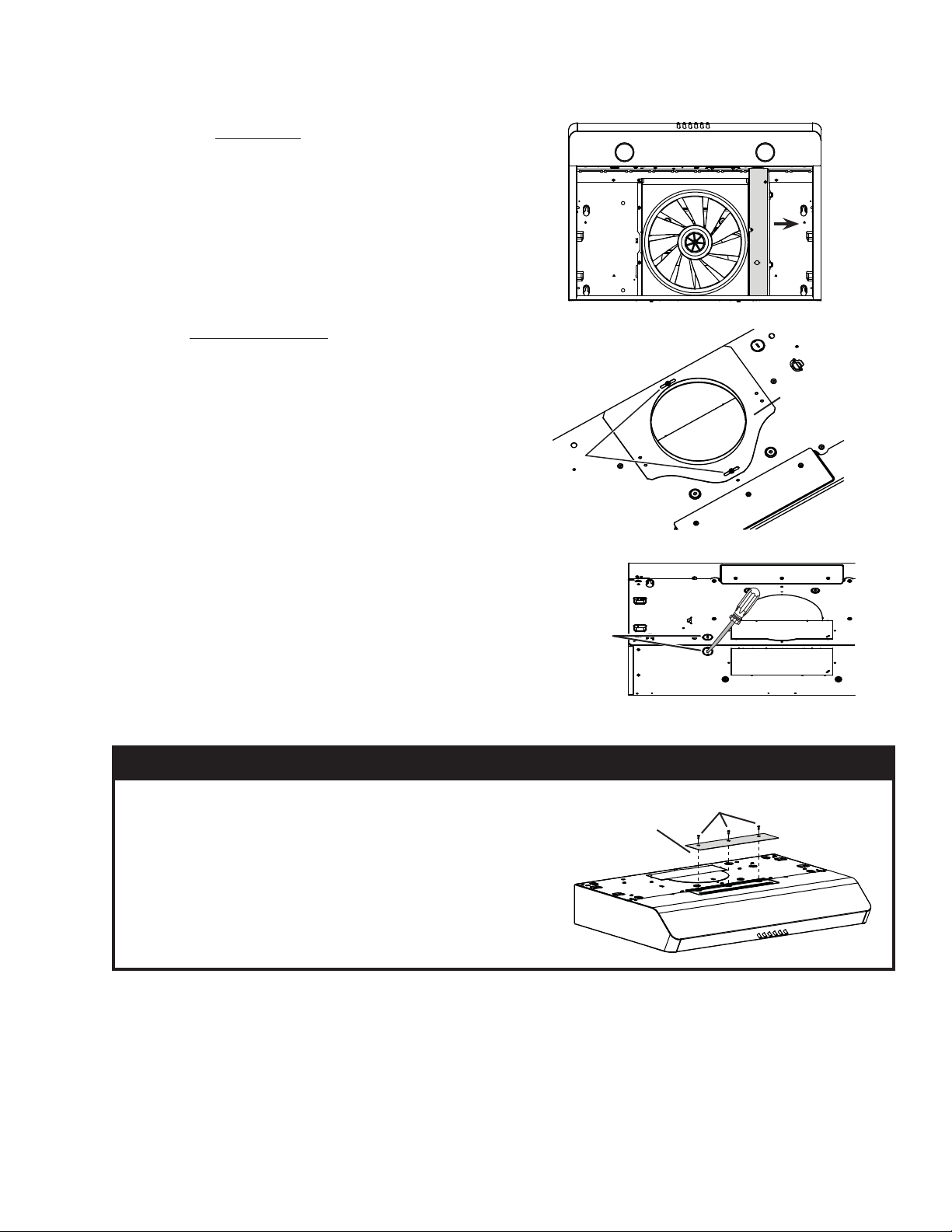

3. Remove the wiring cover (shaded part on illustration

beside) by sliding it out from the hood and set it

aside.

4. Remove 7” Round Duct Plate from top/back of hood

(see illustration beside).

5. Remove Electrical Power Cable Knockout from top

(vertical exhaust) or back (horizontal exhaust) of

hood. Install an appropriate strain relief, 1/2” diameter

(not included).

7” ROUND

DUCT PLATE

2 SCREWS

ELECTRICAL

POWER CABLE

KNOCKOUT

NON-DUCTED INSTALLATIONS ONLY

6. Remove 3 screws retaining the recirculation cover

plate (shaded part in illustration beside) to the hood.

Discard this plate with its screws.

8

RECIRCULATION

COVER PLATE

SCREWS

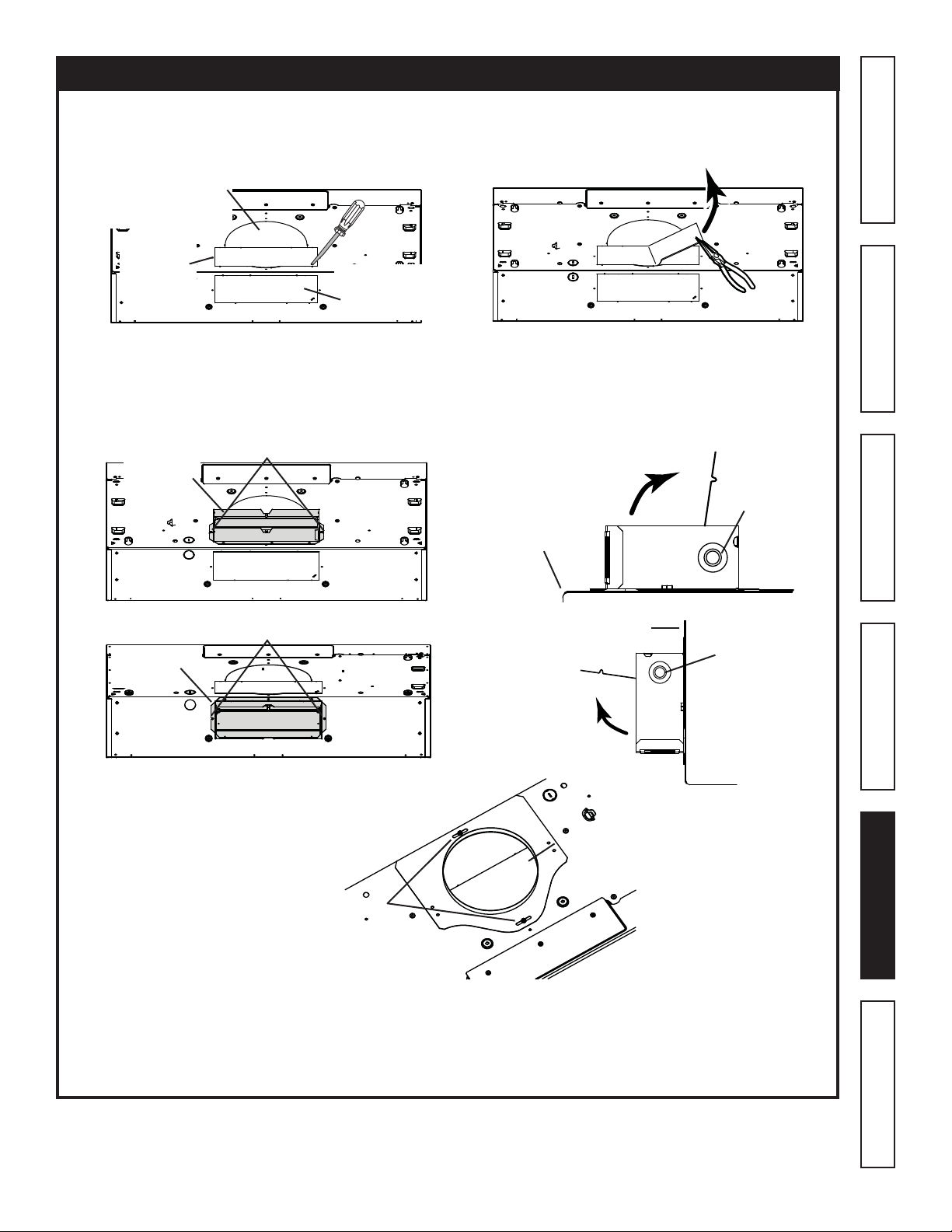

DUCTED INSTALLATIONS ONLY

7. Remove 3¼” x 10” vertical, 3¼” x 10” horizontal, or 7-inch round knockout plate as appropriate for your

ducting method (see FIGURES 1 A and 1 B).

FIGURE 1 A FIGURE 1 B

7” ROUND

KNOCKOUT PLATE

(ALSO REMOVE VERTICAL

KNOCKOUT PLATE)

3¼” X 10”

VERTICAL

KNOCKOUT

PLATE

8. Attach 3¼” x 10” Damper Assembly on top OR back of hood (if using 3¼” x 10” duct; shaded part in F

3¼” X 10”

HORIZONTAL

KNOCKOUT

PLATE

IGURE 2 A)

or 7” Round Duct Plate (if using 7-inch round duct, FIGURE 3) over the knockout opening. When installed, the

3¼” x 10” damper assembly must open as shown in F

FIGURE 2 A

SCREWS

3¼” X 10”

DAMPER

ASSEMBLY

IGURE 2 B.

FIGURE 2 B

TOP/BACK

EDGE OF

DAMPER

FLAP

PIVOT

HOOD

Warranty Safety CleaningOperation Installation Service Parts

BACK OF

SCREWS

3¼” X 10”

DAMPER

ASSEMBLY

HOOD

DAMPER

FLAP

PIVOT

FIGURE 3

7” ROUND

DUCT

PLATE

SCREWS

NOTE: To accommodate off -center ductwork, the 7” round duct plate can be installed up to 1/2” on either

side of the hood center.

TIP: Insert a small length of duct over the 3¼” x 10” damper assembly (for rectangular ducting) or 7” round (for

round ducting) and seal the joint using aluminum foil duct tape to ease connection with the house ductwork.

9

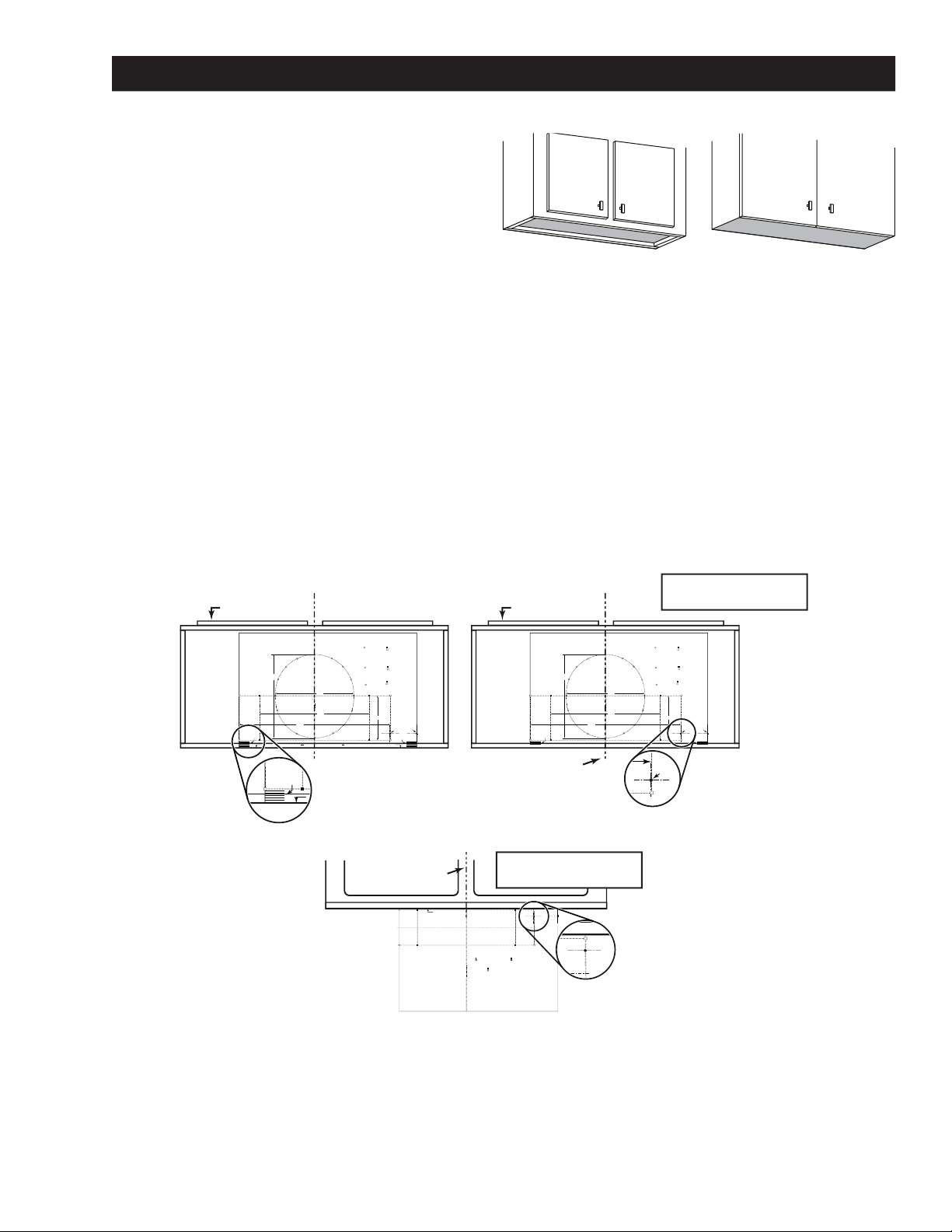

PREPARE THE HOOD LOCATION

VERTICAL EXHAUST

VERTICAL EXHAUST

NOTE: Before starting installation, read all the steps

FRAMED CABINET FRAMELESS CABINET

of these instructions.

Use the illustration beside to identify your kitchen

cabinet type.

This manual covers 2 kinds of installation: the standard

(without EZ1 brackets) and the EZ1 one-person

installation system (using included template and

brackets). For the standard installation, go to page 14.

EZ1 One-person installation system

EZ1 installation is designed for use with kitchen cabinets that have the same width designation as the range hood

width. If the cabinet is greater than 1/2” wider than the range hood width, please use the standard installation

method.

1. Use the proper template for vertical OR horizontal

disharge (included) for placement of ductwork and

electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole, only cut

the hole for electrical wiring. If replacing a hood and

plan to use the existing duct and electrical, steps 2 to

5 may not be necessary. If so, skip to step 6.

2. Measure and mark the hood center line on cabinet

bottom.

3. Align the center line on template with the hood

center line marked on the bottom of the cabinet,

placing the edge (where indicated) of the template

against back wall. When using with framed cabinet

for vertical exhaust installation, fold over rear edge

of template equal to the depth of the cabinet frame

at the wall (use graduations on template, C locations

on template). Tape the template in place.

NOTE: When facing the installation, A and B (on

template) must be at right.

CABINET FRONT

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

14½”

C

C

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

DE

C

L

Appuyer ce bord au mur arrière

7 PULG.

= 3¼ pulg. x 14 pulg.

4¼”

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

AB

C

7½”

10½”

Apoyar este borde contra la pared de atrásPlace this edge against back wall

FOLD TEMPLATE ALONG GRADUATED

SCALE

WHEN INSTALLING TO FRAMED

P

CABINET

.

CENTER LINE

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Place this edge against

cabinet bottom.

Appuyer ce bord contre le bas

de l’armoire.

Apoyar este borde contra

la base del armario.

CABINET FRONT

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

conséquence.

To be translated in Spanish.

C

CENTER LINE

HORIZONTAL

EXHAUST DUCTING

AB

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRE

= 3¼ po x 10 po

= 3¼ po x 14 po

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

ELECTRICAL

ACCESS HOLE

LOCATION (A)

C

L

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING

= 3¼” x 10”

= 3¼” x 14”

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULAR

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

8”

IN WALL)

(

14½”

A

Electrical access hol

A = single blower ho

B = double blower

Centre du tr

d’alim

VERTICAL

EXHAUST DUCTING

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

DE

C

L

7 PULG.

= 3¼ pulg. x 14 pulg.

7½”

10½”

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

4¼”

A = single blower hood

B = double blower hood

AB

A

C

C

ELECTRICAL

ACCESS HOLE

LOCATION (A)

IN CABINET BOTTOM)

(

10

4. Drill a 1/8” dia. pilot hole for house wiring,

at A location on template.

5. Use a sharp pencil or 1/8” drill bit to mark the

locations for the appropriate duct access holes

(16 locations for 7” round duct, or 4 corner locations

for rectangular duct). Remove the template.

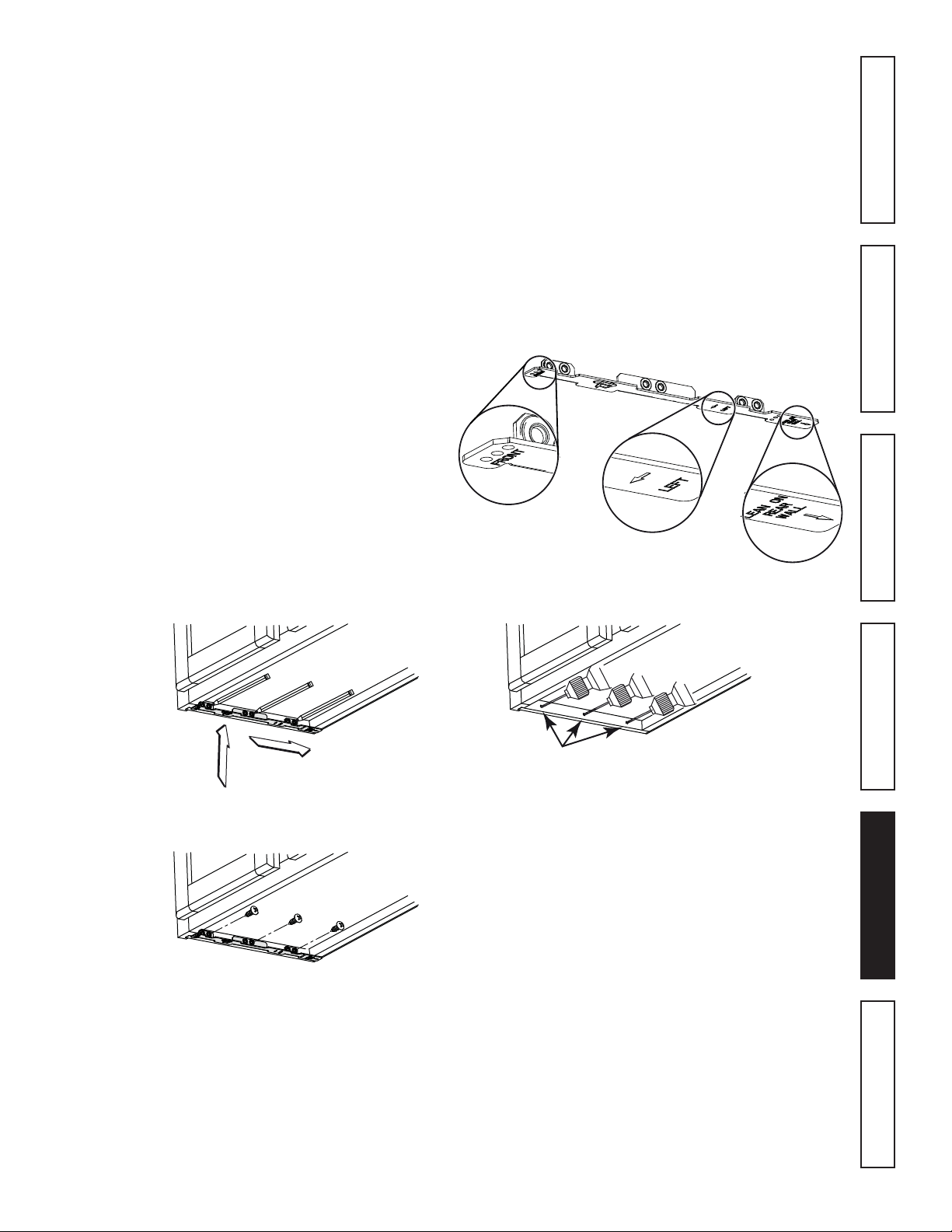

FRAMED CABINET

Refer to the marking on the brackets to determine

the correct installation side and orientation.

Warranty Safety CleaningOperation Installation Service Parts

6. Draw the border for the exhaust ducting by linking its

marks (16 for round duct and 4 for rectangular duct),

then cut the opening in the cabinet bottom (vertical

exhaust) or in the wall (horizontal exhaust). Drill the

house wiring hole by using a 1½” hole saw centered

with the pilot hole previously made in 4.

7. Install the proper installation brackets according to

the type of cabinet (framed or frameless). See below.

XY

Z

Mate the corresponding bracket to the cabinet

side frame, while placing rear end of bracket

against the wall. Use a pencil to mark 3 holes

(there are 6 holes but only 3 are necessary).

7/64”

Assemble the bracket to the side frame using a

Phillips screwdriver and 3 provided no. 8 x 5/8”

wood screws. Repeat for the other side frame.

Remove the bracket. Using a 7/64” drill bit,

drill 3 holes where marked.

11

FRAMELESS CABINET

Refer to the marking on the brackets to determine

the correct installation side and orientation.

X

3 X

Y

[ \

7/64”

Align the corresponding bracket to the cabinet

side, while placing rear end of bracket against

the wall. Draw a line on the outer edge of the

bracket (as shown).

Slide the bracket towards the center of cabinet

and align the outside edge of the bracket with the

marked line, keeping the rear end edge leaning

on the wall.

Z

Use a pencil to mark 3 holes.

Remove the bracket. Using a 7/64” drill bit,

drill 3 holes where marked.

Assemble the bracket to the cabinet bottom using

a Phillips screwdriver and 3 provided countersunk

wood screws. Repeat for the other cabinet side

.

12

Install the hood (EZ1 brackets)

NOTE: The following procedure applies to both

framed or frameless cabinet installations.

Warranty Safety CleaningOperation Installation Service Parts

1. Run house power cable between service panel and

hood location.

2. There are 2 pairs of recessed holes on each side

of the top of the hood (on rear: A and B, on front

C and D on illustration below); these holes allow

the range hood to hang on the brackets (previously

installed).

HORIZONTAL EXHAUST INSTALLATION ONLY

3. Temporarily hang the hood on the brackets using its

2 recessed REAR HOLES (A and B). While holding

the hood, run the house power cable into the hood

through the strain relief previously installed i

n step 5

on page 8.

4. Unhook the rear holes from the brackets and hang

the hood using its 2 recessed FRONT HOLES (C and

D). While holding the hood, attach the power cable

to the hood using the strain relief.

VERTICAL EXHAUST INSTALLATION ONLY

A

C

D

B

A

B

5. Hang the hood on the brackets using the 2 recessed

FRONT HOLES (C and D). While holding the hood,

run the house power cable into the hood through

the strain relief previously installed in step 5 on

page 8. Attach power cable to the hood.

DUCTED INSTALLATIONS ONLY

6. Connect the ductwork to the hood and use metal foil duct tape to make joints secure and air-tight. Make sure

the damper assembly (or round duct plate) enters the ductwork and that the damper opens and closes freely.

7. For framed cabinet, secure the hood to the EZ1

brackets using 4 no. 8-18 x 1/2” metal screws with

washers (screws and washers included in parts

bag). Insert 2 screws and washers per side, in the

slots (as shown in inset on illustration beside).

8. For frameless cabinet, secure the hood to the

cabinet using 4 no. 8 x 5/8” round head wood

screws (screws and washers included in parts bag).

Insert 2 screws and washers per side, in the slots (as

shown in inset on illustration beside).

FRAMED CABINET FRAMELESS CABINET

13

METAL

SCREWS

OOD

W

SCREWS

Standard Installation (without EZ1 brackets)

VERTICAL DUCT

ACCESS HOLE

1015/16"

5¼"

5¼"

CENTER

LINE

HOOD MOUNTING SCREWS (4)

ELECTRICAL

ACCESS HOLE

(

IN CABINET BOTTOM)

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

CABINET FRONT

3/4"

1⅜"

1½"

7³/16"

12⅞" (30" HOOD)

15⅞" (36"

HOOD)

47/16"

CABINET

BOTTOM

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

CABINET

BOTTOM

CABINET FRONT

HORIZONTAL DUCT

ACCESS HOLE

HOOD

MOUNTING

SCREWS (4)

ELECTRICAL

ACCESS HOLE

(

IN WALL)

3⅞"

CENTER

LINE

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

13/16"

3/16"

5¼"

5¼"

12⅞" (30" HOOD)

15⅞" (36"

HOOD)

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

7³/

16"

7-IN. ROUND

DUCT

ACCESS

HOLE

1. Use these diagrams for proper placement of ductwork

and electrical cutout in cabinet or wall.

For a non-ducted installation, DO NOT cut a duct

access hole, only cut the hole for electrical wiring

7” ROUND

VERTICAL DUCTING

HOOD MOUNTING SCREWS (4)

12⅞" (30"

15⅞" (36"

WOOD SHIMS

RECESSED-BOTTOM

(

CABINETS

ONLY)

HOOD)

HOOD)

4¹¹/16"

7-IN. ROUND

7-IN. ROUND

DUCT

DUCT

ACCESS

ACCESS

HOLE

HOLE

12⅞" (30"

15⅞" (36"

7³/

HOOD)

HOOD)

16"

8" DIA.

HOLE

1⅜"

ELECTRICAL

ACCESS HOLE

IN CABINET BOTTOM)

(

1½"

10

15

/16"

3¼” x 10”

VERTICAL DUCTING

3¼” x 10”

HORIZONTAL DUCTING

2. Install part-way four (4) ROUND HEAD no. 8 x 5/8”

mounting screws into shims/cabinet, according to

the proper diagram above. (Mounting screws are

included in parts bag, but wood shims and shim

mounting screws are not included)

NOTE: Two installers are recommended because of the weight of this hood.

1. Run house power cable between service panel and

hood location. Run the house power cable into the

hood through the strain relief previously installed in

step 5 on page 8.

2. Hang hood from (4) mounting screws previously installed.

Slide hood back towards wall until mounting screw

heads are engaged in narrow end of keyhole slots in

top of hood. Tighten screws securely. Attach power

cable to the hood using the strain relief.

3. Connect the ductwork to the hood and use metal foil duct tape to make joints secure and air-tight. Make sure

the damper assembly (or round duct plate) enters the ductwork and that the damper opens and closes freely.

Install the Hood (Standard Installation)

DUCTED INSTALLATIONS ONLY

14

CONNECT THE WIRING

!

WARNING: Risk of electric shock. Electrical

wiring must be done by qualifi ed personnel

in accordance with all applicable codes and

standards. Before connecting wires, switch

power off at service panel and lock service

disconnecting means to prevent power from

being switched on accidentally.

1. Connect House Power Cable to range hood wiring:

BLACK to BLACK, WHITE to WHITE and GREEN or

bare wire under GREEN ground screw.

2. Reinstall wiring cover and attach it to the hood using

its retaining screw.

CAUTION: Ensure both tabs on inner top of

hood are engaged in their corresponding slots in

wiring cover. Also, take care not to pinch wires

while reinstalling wiring cover.

HOUSE

POWER

CABLE

SCREW

Warranty Safety CleaningOperation Installation Service Parts

MOTOR

GROUND

WIRE

GROUND

SCREW

TABS ON

INNER TOP

OF HOOD

ENGAGED IN

WIRING

COVER SLOTS.

15

!

INSTALL THE LIGHT BULBS

This range hood requires two shielded Halogen Bulbs (120 V, 50 W max., MR16 or PAR16 with GU10 base).

WARNING: Do not touch lamps during or soon

after operation. Burns may occur. In order to

prevent the risk of personal injury, only install

shielded halogen lamps. Also, never install a

cool beam, a dichroic lamp, a lamp not suitable

for use in recessed luminaires or identifi ed for

use in enclosed fi xtures.

BULB

LEADS

BULB LEAD

GROOVES

(IN SOCKET)

INDENT

SUCTION

CUP TOOL

1. Align the bulb leads with the small indentations located

on the border of the lamp location on hood (see inset

above), then install the bulbs by placing the bulb leads

into their grooves in the socket.

NOTE: The Suction Cup Tool (included with hood) can be used to install and remove light bulbs. Press suction cup

tool on bulb and rotate counterclockwise to remove bulb or clockwise to install bulb.

CAUTION: Most GU10 LED replacement bulbs

commonly found in the market are not designed

for use in a cooking environment and might not

perform as advertised. Their usage with this

product is not recommended.

2. Gently push upwards and turn clockwise until secure.

INSTALL THE FILTERS

Ducted Installation Only:

Re-install grease fi lters removed in step 1 on page 7,

under “Prepare the Hood”.

Non-ducted Installation Only:

Purchase two non-ducted fi lters (see part number in

Service parts list). Attach the non-ducted fi lters following

instructions packed with the non-ducted fi lters.

16

“Non-ducted Filters” available by calling Sears at

1-800-4-MY-HOME

®

3

5

SERVICE PARTS

4

6

7

2

8

Warranty Safety CleaningOperation Service PartsInstallation

1

9

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains

in good working condition,

you must use the manufacturer

genuine replacement parts

only. The manufacturer genuine

replacement parts are specially

designed for each unit and are

manufactured to comply with

all the applicable certifi cation

standards and maintain a high

standard of safety. Any third

party replacement part used

may cause serious damage

and drastically reduce the

performance level of your unit,

which will result in premature

failing. The manufacturer

recommends to contact a

certifi ed service depot for all

replacement parts and repairs.

KEY NO. PART NO. DESCRIPTION

S97020030 R

1

S97020031 R

S97020029 R

2 SR680508 7'' R

3 S97020534 3¼”

4 S97020409 B

5 S97020407 F

6 SR99420635 C

S99010434-002 G

7

S99010434-003 G

8 S97020427 M

9 SV05921 S

* S97020450 W

* S98011637 W

* S97020292

ECIRCULATION COVER PLATE, WHITE (INCL. SCREWS)1 1

ECIRCULATION COVER PLATE, STAINLESS STEEL (INCL. SCREWS)1 1

ECIRCULATION COVER PLATE, BLACK (INCL. SCREWS)11

OUND DUCT PLATE (INCLUDING SCREWS) 111111

X 10” DAMPER ASSEMBLY (INCLUDING SCREWS)111111

LOWER MOTOR (INCL. 4 SCREWS AND 1 CAPACITOR)111111

ANPELLER (INCLUDING ITEM 6) 111111

LIP FOR FANPELLER 111111

REASE FILTER - MICRO MESH - TYPE C1 (SET OF 2) 1 1 1

REASE FILTER - MICRO MESH - TYPE D1 (SET OF 2) 1 1 1

ECHANICAL PUSH-BUTTON CONTROL (6 BUTTONS) 111111

HIELDED HALOGEN BULB 50 W, GU10 222222

IRE HARNESS 111111

IRING COVER 111111

ARTS BAG INCLUDING: 4 WASHERS, 1 SUCTION CUP TOOL,

P

4 METAL SCREWS NO. 8-18 X 1/2”,

6 ROUND HEAD NO. 8 X 5/8” WOOD SCREWS,

6 NO. 8 X 1/2” COUNTERSUNK WOOD SCREWS

ON-DUCTED FILTER - TYPE XC (SET OF 2)

* S97020466

* S97020467

* S99527587 N

* S97020470 E

N

(NON-DUCTED INSTALLATION ONLY)

N

ON-DUCTED FILTER - TYPE XD (SET OF 2)

(NON-DUCTED INSTALLATION ONLY)

ON-DUCTED FILTER CLIP KIT (INCLUDES 4 CLIPS) 111111

ASY INSTALL KIT (INCLUDING HARDWARE) 111111

Order replacement parts by PART NO. - not by KEY NO.

* Not illustrated

QUANTITY

51282 51283 51289 51292 51353 51299

111111

111

111

17

MASTER PROTECTION AGREEMENTS

Congratulations on making a smart purchase. Your new

Kenmore® product is designed and manufactured for

years of dependable operation. But like all products, it

may require preventive maintenance or repair from time

to time. That’s when having a Master Protection

Agreement can save you money and aggravation.

The Master Protection Agreement also helps extend the

life of your new product. Here’s what the Agreement*

includes:

Parts and labor needed to help keep products

operating properly under normal use, not just defects. Our coverage goes well beyond the

product warranty. No deductibles, no functional

failure excluded from coverage - real protection.

Expert service by a force of more than 10,000

authorized Sears service technicians, which means

someone you can trust will be working on your product.

Unlimited service calls and nationwide service, as

often as you want us, whenever you want us.

“No-lemon” guarantee – replacement of your

covered product if four or more product failures occur

within twelve months.

Product replacement if your covered product can’t be

fi xed.

Annual Preventive Maintenance Check at your

request – no extra charge.

Fast help by phone – we call it Rapid Resolution –

phone support from a Sears representative on all

products. Think of us as a “talking owner’s manual.”

Power surge protection against electrical damage

due to power fl uctuations.

$250 Food Loss Protection annually for any food

spoilage that is the result of mechanical failure of any

covered refrigerator or freezer.

Rental reimbursement if repair of your covered

product takes longer than promised.

10% discount off the regular price of any non-covered

repair service and related installed parts.

Once you purchase the Agreement, a simple phone call is

all that it takes for you to schedule service. You can call

anytime day or night, or schedule a service appointment

online.

The Master Protection Agreement is a risk free purchase.

If you can-cel for any reason during the product warranty

period, we will provide a full refund. Or, a prorated refund

anytime after the product warranty period expires.

Purchase your Master Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information in the U.S.A. call 1-800-827-6655. *

Sears Installation Service

For Sears professional installation of home appliances,

garage door openers, water heaters, and other major

home items, in the U.S.A. call 1-800-4-MY-HOME

®

.

18

LEA Y CONSERVE ESTAS INSTRUCCIONES

TABLA DE CONTENIDO GARANTÍA LIMITADA DE KENMORE

GARANTÍA LIMITADA DE KENMORE

Garantía Seguridad LimpiezaOperación

SECCIÓN .........................................................PÁGINA

Garantía .............................................................................. 19

Instrucciones de seguridad ............................................. 20

Operación ........................................................................... 21

Limpieza .............................................................................. 21

Piezas incluidas con la campana .................................. 22

Piezas no incluidas con la campana ............................ 22

Herramientas necesarias ................................................. 22

Cuadro de largo equivalentes de conducto ................ 23

Instale los conductos ........................................................ 24

Prepare la campana ................................................. 24-26

Prepare la ubicación para la campana .................. 27-31

Instalación EZ1 por una persona ...................... 27-29

Instale la campana (Soportes EZ1) ....................... 30

Instalación normal (Sin soportes EZ1) ................... 31

Instale la campana (Instalación normal) .............. 31

Conecte el cableado ....................................................... 32

Instale las bombillas.......................................................... 33

Instale los fi ltros ................................................................. 33

Piezas de servicio ............................................................. 34

Acuerdos de Protección Maestros ................................. 35

Si se instala, opera y mantiene este electrodoméstico

conforme a todas las instrucciones suministradas, se

aplica la siguiente cobertura de garantía.

Para disponer servicio bajo garantía, llame al

1-800-4-MY-HOME® (1-800-469-4663).

• Durante un año desde la fecha de compra, cualquier

parte de este producto que falle debido a un defecto

en material o mano de obra recibirá reparación o

sustitución gratuita si se hace imposible repararlo. La

duración de esta cobertura no es aplicable al acabado

de ninguna pieza de metal brillante o pintada.

• Durante treinta días desde la fecha de compra, se

reemplazará sin cargo toda parte de metal brillante

o pintada de este producto si está defectuoso su

acabado en cuanto a material o mano de obra.

Toda cobertura de garantía queda nula si se utiliza

este producto para otro fi n que no sea su uso en una

casa particular.

Esta garantía cubre solamente defectos en material

y mano de obra, y NO abarca:

1. Piezas consumibles que pueden desgastarse por

el uso normal, como fi ltros, correas, bombillas y

bolsas, entre otras.

2. Un técnico de servicio para indicar al usuario la

instalación, operación o el mantenimiento correcto

del producto.

3. Un técnico de servicio para estar a cargo de la

limpieza y el mantenimiento de este producto.

4. Daños o fallas de este producto si no se instala, opera o mantiene conforme a todas las instrucciones

entregadas con el producto.

5. Daños o fallas de este producto resultantes de

accidente, maltrato, uso indebido o utilización

distinta del propósito del producto.

6. Daño o avería de este producto causada por el uso

de detergentes, limpiadores, agentes químicos o

utensilios que no sean los recomendados en todas

las instrucciones entregadas con el producto.

7. Daño o falla de piezas o sistemas resultante de

modifi caciones no autorizadas realizadas a este producto.

Limitación de garantías implícitas; limitación de remedios

El único y exclusivo remedio del cliente conforme a

esta garantía limitada será la reparación del producto

como se indica aquí. Las garantías implícitas, como

garantías de comerciabilidad o idoneidad para un fi n

particular, se limitan a un año o el menor periodo que

permita la ley. Sears no será responsable de daños

fortuitos o consecuentes. Algunos estados y provincias

no permiten excluir o limitar daños fortuitos o consecuentes,

ni limitar la duración de garantáis implícitas de

comerciabilidad o idoneidad, de tal modo que

es posible que estas exclusiones o limitaciones no

correspondan a su caso.

Esta garantía le concede derechos legales específi cos,

y usted puede tener también otros derechos que

varían de un estado a otro.

Sears Brands Management Corporation, Hoff man

Estates, Illinois 60179

Instalación

Piezas de servicio

19

INSTRUCCIONES DE SEGURIDAD

!

!

PREVISTO PARA COCINAR DOMÉSTICO SOLAMENTE.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, CHOQUE

ELÉCTRICO, O LESIÓN A PERSONAS, OBSERVE LO

SIGUIENTE:

1. Utilice esta unidad sólo en la manera prescrita

por el fabricante. Si tiene usted alguna pregunta,

comuniqúese con el fabricante a la dirección o al

télefono indicados en la garantía.

2. Antes de efectuar algún servicio o limpieza, se debe

desconectar la corriente eléctrica en el armario de

circuitos y asegurarlo con llave para evitar que la

corriente sea conectada accidentalmente. Cuando

el medio de desconexión del servicio no puede ser

trabado, sujete un dispositivo de advertencia evidente,

tal como una etiqueta, al panel de servicio.

3. Todo trabajo do instalación y cableado eléctrico

debe ser realizado por personal califi cado y de

acuerdo con todos los códigos y normas pertinentes,

incluyendo los códigos y normas relacionados con

construcción clasifi cada para incendio.

4. Aire suficiente es necesario para facilitar la

combustión adecuada y la salida apropiada de gases

por la chimenea de la unidad y para evitar corrientes

de aire invertidas. Siga las instrucciones y medidas

de seguridad del fabricante del equipo y de las

sociedades profesionales de equipos do calentadores

y los reglamentos de seguridad locales.

5. Al cortar o perforar la pared o el techo, no dañe el

cableado eléctrico y otros servicios públicos ocultos.

6. Para reducir el riesgo de incendio o de descarga

eléctrica, no utilice esta campana con un dispositivo

de control de velocidad adicional.

7. Los ventiladores con conducto deberán siempre tener

una salida hacia el exterior.

8. Para reducir el riesgo de incendio, use sólo conductos

de metal.

9. Esta unidad se debe instalar con conexión a tierra.

PARA REDUCIR EL RIESGO DE UN INCENDIO POR

GRASA EN LA ESTUFA:

1. Nunca deje las unidades de superfi cie sin supervisión

cuando tengan ajustes altos. Los reboses pueden

provocar humo y derrames grasosos que se pueden

incendiar. Caliente lentamente el aceite en un ajuste

bajo o medio.

2. Siempre ENCIENDA la campana cuando cocine con

alta temperatura o cuando cocine alimentos que se

puedan incendiar.

3. Limpie con frecuencia los ventiladores. No debe

permitir que la grasa se acumule en el ventilador ni

en el fi ltro.

4. Utilice un sartén de tamaño adecuado. Siempre utilice

el utensilio adecuado al tamaño del elemento do

superfi cie.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES A PER-

SONAS EN CASO DE INCENDIO DE GRASA EN LA

ESTUFA, OBSERVE LO SIGUIENTE:*

1. APAGUE LAS LLAMAS con una tapa ajustada,

plancha para galletitas o charola decorativa, y

luego apague la hornilla. TENGA CUIDADO DE

EVITAR QUEMADURAS. Si las llamas no se apagan

de inmediato, EVACÚE EL LUGAR Y LLAME AL

DEPARTAMENTO DE BOMBEROS.

2. NUNCA LEVANTE UNA SARTEN QUE ESTÉ EN

LLAMAS - Usted se podrá quemar.

3. NO UTILICE AGUA, incluyendo toallas de cocina

mojadas - puede resultar una explosión de vapor

violenta.

4. Utilice un extintor SOLAMENTE si:

A. Usted sabe que tiene un extintor de clase ABC y

ya sabe utilizarlo.

B. El incendio es pequeño y contenido dentro del área

donde se inició.

C. Los bomberos han sido avisados.

D. Usted puede combatir el incendio con una salida

a su espalda.

* Basado en las recomendaciones para “Seguridad en

la Cocina” publicadas por NFPA de los EE.UU.

PRECAUCIÓN

1. Solamente para uso general de ventilación. No utilice

para descargar materiales peligrosos o materiales y

vapores explosivos.

2. Para evitar daños al cojinete del motor y evitar que

las paletas del ventilador emitan mucho ruido o estén

fuera de equilibrio, mantenga el motor libre de pelusa,

polvo, etc.

3. Para obtener mejores resultados en la captura de

impurezas, la parte superior de la campana debe

estar montada de forma tal que la campana quede

de 18-24” de distancia de la superfi cie de la estufa.

4. Use sólo kits de cable de conexión para campana de

cocina cuyo uso ya se haya estudiado y aprobado

para este modelo de campana.

5. Por favor, lea la etiqueta de especificaciones

del producto para mayores informaciones y

requerimientos.

NOTA

Si se instalará la campana en un sistema sin conductos:

• Compre dos fi ltros de recirculación y Instale los

fi ltros de recirculación siguiendo las instrucciones

que vienen con los fi ltros.

“Filtros de recirculación”

!

disponibles llamando a:

Sears en 1-800-4-MY HOME®

20

LIMPIEZAOPERACIÓN

BOTONES PULSADORES

DE LAS VELOCIDADES

DEL VENTILADOR

BOTÓN PULSADOR

ENCENDIDO/

APAGADO DEL

VENTILADOR

BOTÓN PULSADOR ENCENDIDO/APAGADO DEL

VENTILADOR

Cuando el ventilador impelente esté APAGADO, pulse

este botón pulsador para ENCENDER el ventilador

impelente en la última velocidad seleccionada. Pulsa de

nuevo este botón pulsador para apagar el ventilador.

NOTA: Si no hay una velocidad seleccionada (todos los

botónes pulsadores de las velocidades del

ventilador hacia arriba), el ventilador no se

encenderá. En este caso, pulsa el botón pulsador de

la velocidad deseada para encender el ventilador.

BOTONES PULSADORES DE LAS VELOCIDADES

DEL VENTILADOR

Cuando el ventilador impelente esté ENCENDIDO,

cambia la velocidad del ventilador al pulsar el botón

pulsador correspondiente a la velocidad deseada: una

lìnea para BAJA, dos lìneas para MEDIA y tres lìneas

para ALTA.

BOTÓN PULSADOR ENCENDIDO/APAGADO DE LA LUZ

Cuando las luces estén apagadas, pulsa este botón

pulsador para ENCENDER las luces en la última

intencidad seleccionada. Pulsa de nuevo este botón

para APAGAR las luces.

BOTÓN PULSADOR DE LA INTENSIDAD DE LA LUZ

Pulsa este botón para cambiar la intensidad de la luz

(ALTA o BAJA).

BOTÓN PULSADOR

DE LA INTENSIDAD

DE LA LUZ

BOTÓN PULSADOR

ENCENDIDO/

APAGADO

DE LA LUZ

ADVERTENCIA: Para reducir el riesgo de una

descarga eléctrica, desconecte el suministro

eléctrico antes de limpiar la unidad.

Filtros de microfi ltración

Limpie frecuentemente los fi ltros con agua caliente

y un detergente suave. Los fi ltros se pueden lavar en

lavaplatos. Se debe lavar los fi ltros de malla de aluminio

aproximadamente cada mes, dependiendo de su uso.

Lávelos con mayor frecuencia si su forma de cocinar

genera más grasa - como, por ejemplo, frituras o ‘wok’.

Filtros de recirculación

(disponibles por separado – ver página 20)

Los fi ltros de recirculación deberían cambiarse cada

3 a 6 meses. Sustitúyalo con mayor frecuencia si su

tipo de cocina genera más grasa, por ejemplo si

fríe o cocina con wok. Consulte las instrucciones de

instalación que vienen con el fi ltro de recirculación.

Superfi cies pintadas de la campana

Limpie con agua tibia y un detergente suave únicamente.

Si la superfi cie se descolora, use una cera para acabados,

como una cera para automóviles. (NO use productos

limpiadores duros o abrasivos ni limpiadores para porcelana.)

Superfi cies de acero inoxidable de la campana

A hacer:

• Lávelo regularmente con un trapo limpio empapado

con una disolución de agua tibia y jabón suave o

detergente para lavar vajillas.

• Limpie siempre en la dirección de las líneas de pulido.

• Enjuague siempre bien con agua limpia (2 o 3 veces)

después de limpiar. Séquelo completamente.

• También puede usar un producto limpiador

doméstico para acero inoxidable.

A no hacer:

• Usar lana de acero o de acero inoxidable o un

rascador para quitar la suciedad más incrustada.

• Usar productos limpiadores agresivos o abrasivos.

• Dejar que se acumule la suciedad.

• Permitir que el polvo de yeso u otros residuos de

construcción entren en contacto con la campana.

Durante los trabajos de construcción o renovación,

cubra la campana para evitar que el polvo se

adhiera a las superfi cies de acero inoxidable.

Al elegir un detergente, evite:

• Los productos limpiadores que contengan blanqueador

(lejía) ya que dañarán el acero inoxidable.

• Los productos que contengan: cloruro,

yoduro, bromuro, ya que deteriorarán las

superfi cies rápidamente.

• Los productos combustibles que se usan para

limpiar, tales como: acetona, alcohol, éter, benzol,

etc., ya que son muy explosivos y no deberían

usarse nunca cerca de una cocina.

Montaje del ventilador

El motor está lubricado permanentemente y no necesita

engrase nunca. Si los rodamientos del motor hacen un

ruido excesivo o no habitual, sustituya el motor por otro

idéntico. También se debería sustituir la hélice.

21

fl uoruro,

Garantía

Seguridad LimpiezaOperación Instalación

Piezas de servicio

PIEZAS INCLUIDAS CON LA CAMPANA

C

L

AB

Apoyar este borde contra la pared de atrásPlace this edge against back wall

VERTICAL EXHAUST

= 3¼” x 10”

= 3¼” x 14”

RECTANGULAR DUCTING7” ROUND DUCTING

OR

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

= 3¼ po x 10 po

= 3¼ po x 14 po

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

CONDUCTO RECTANGULARCONDUCTO REDONDO

DE

7 PULG.

O

Appuyer ce bord au mur arrière

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BETRANSLATED IN SPANISH

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

4¼”

10½”

14½”

8”

7½”

C

C

C

Bend template along graduated

scale when installing to framed

cabinet.

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

conséquence.

To be translated in Spanish.

Bombillas halógenas

Filtros de grasa

de microfi ltración

(2 por campana)

Conjunto de la

clapeta de retención

3¼” x 10”

MR16 o PAR16 con base GU10)

Sistema de instalación EZ1

por una persona

(incluso plantilla para

instalación de conductos,

impresa por ambos lados,

y soportes de instalación)

con pantalla

(120 V, 50 W max.,

(2 por campana)

Conector de

conducto

redondo de 7”

PIEZAS NO INCLUIDAS CON LA CAMPANA*

PIEZAS OPTATIVAS (compra separada)

Filtros de recirculación

(Campana sin conducto

unicamente)

(2 por campana)

Pieza Sears N.° S97020466

Regulador de tiro

redondo de 7"

(Para uso con conducto

redondo de 7"

Pieza Sears N.° 59183

Accesorios para conductos

Bolsa de piezas

(4 tornillos para metal n.° 8-18 x 1/2",

4 arandelas, 6 tornillos de cabeza redonda

(Vea el “Cuadro de largo equivalente de conducto”

de la página 21 para obtener los Nos. de Modelos de

Accesorios para Conductos).

para madera n.° 8 x 5/8", 6 tornillos

embuditos para madera n.° 8 x 1/2",

1 ventosa para bombillas)

Las “Piezas no incluidas con la campana” están

disponibles llamando a Sears al 1-800-4-MY-HOME

HERRAMIENTAS NECESARIAS PARA LA INSTALACIÓN DE LA CAMPANA

Perforadora

Destornillador

(chato y Phillips)

Lápiz

(con broca de 1/8",

broca de 7/64", y

serrucho de calar

de 1½")

Cinta métrica

Pinzas de

punta

Sierra

de punta

-o-

Cinta adhesiva

metálica

para conductos

Serrucho

de punta

®

Tijera para

hojalatero

22

Pelador de

cable

CUADRO DE LARGO EQUIVALENTE DE CONDUCTO

Las campanas de cocina Kenmore fueron diseñadas para su desempeño efi ciente cuando se las sujeta a largos

recorridos de conducto. Como punto de referencia, esta campana funcionará a aproximadamente el 80% de su

fl ujo de aire nominal cuando se le sujeta 25 pies equivalentes de conducto redondo de 7". Utilice esta cuadro para

calcular el largo equivalente de conducto de su sistema.

Modelo Broan 647

7-pulg. Tapón de

pared redondo

Largo equivalente

34 pies

(6 pies sin regulador

de tiro)

Modelo Sears 59391

3¼-pulg. x

10-pulg.

Tapón de

pared

Largo

equivalente

45 pies

(7 pies sin

regulador de tiro)

Modelo Sears 59091

Tapón de techo

equivalente 30 pies

Modelo Broan 401

Conducto recto

3¼-pulg. x 10-pulg. x 2-pies

de largo. Largo equivalente

2 pies

Modelo Broan 407

Conducto recto

7-pulg. alrededor x 2 pies

de largo. Largo equivalente

2 pies

Modelo Broan 415

Acodado redondo

de 7 pulg.

Largo equivalente

8 pies

Modelo Broan 412H

3¼-pulg. x 10-pulg.

a 7-pulg.

Transición redondo

Largo equivalente

5.5 pies

Modelo Broan 428

3¼-pulg. x 10-pulg.

Acodado con

ángulo recto

Largo equivalente

8.5 pies

Modelo Broan 429

3¼-pulg. x 10-pulg.

Acodado plano con

ángulo recto

Largo equivalente

24 pies

Modelo Broan 430

3¼-pulg. x 10-pulg.

Acodado

con alero corto

y ángulo recto.

Largo equivalente

15 pies

Modelo Broan 431

3¼-pulg. x 10-pulg.

Acodado

con alero largo

y ángulo recto

Largo equivalente

15 pies

(acepta ducto de 7-pulg. redondo

o de 3¼-pulg. x 10-pulg.). Largo

(7 pies] sin regulador de tiro)

Garantía Seguridad Operación Instalación

Limpieza

“Accesorios para conductos” modelo Sears disponibles llamando a:

Sears en 1-800-4-MY HOME®

“Accesorios para conductos” modelo Broan disponibles llamando a:

1-800-558-1711.

23

Piezas de servicio

INTRADÓS

18” MÍN - 24” MÁX POR ENCIMA

DE

LA SUPERFICIE DE LA COCINA

ARMARIO

CONDUCTO DE 3¼” X 10”

(PARA EVACUACIÓN HORIZONTAL)

CAPUCHÓN MURAL

CAPUCHÓN PARA TEJADO

CONDUCTO DE 3¼” X 10”

O 7” REDONDO

(PARA EVACUACIÓN VERTICAL)

CABLEADO DE LA VIVIENDA

(PARTE SUPERIOR OR TRASERA

DE

LA CAMPANA)

CAMPANA

INSTALE LOS CONDUCTOS (iNSTALACIONES CANALIZADAS ÚNICAMENTE)

B

C

1. Determine si la campana evacuará verticalmente

(conducto redondo de 3¼” x 10” o 7”) u horizontalmente

(conducto de 3¼” x 10” únicamente).

2. Decida por dónde pasarán los conductos entre la

campana y el exterior.

3. Elija un paso recto y corto para que la campana funcione

de la forma más efi caz. Los recorridos largos, los

codos y las transiciones reducen el desempeño de

la campana. Use los menos posible. Cuando pueda,

prevea al menos 2 pies de conducto recto antes de

cualquier giro. Pueden ser necesarios conductos más

anchos para lograr mejor desempeño cuando los

conductos más largos giran.

4. Instale un capuchón mural o un capuchón para tejado

(se venden por separado). Conecte el conducto metálico

al capuchón y vuelva al lugar donde se encuentra la

campana. Use cinta adhesiva metálica de 2” para

sellar las juntas entre los tramos de los conductos.

NOTA: Las distancias superiores a 24” son a discreción

del instalador y del usuario.

PREPARE LA CAMPANA

1. De haberla, retire de la campana y de todas las piezas

la película protectora. Use el orifi cio de agarre para

retirar de la campana los fi ltros de microfi ltración

empujando hacia abajo e inclinando los fi ltros hacia

fuera.

2. Retire los soportes EZ1 del interior de la campana

cortando la tira de amarre. Retire ambos tornillos

que sujetan el conjunto de la clapeta a la campana.

Retire la bolsa de piezas que viene en la campana

(sujeta detrás del conjunto de la clapeta). Retire el

conjunto de la clapeta del interior de la campana y

conserve los tornillos para usarlos posteriormente.

TORNILLOS

SOPORTES

EZ1

24

CONJUNTO

DE LA

CLAPETA

3. Retire la tapa del cableado (parte sombreada de

la ilustración de abajo) deslizándola fuera de la

campana; póngala a un lado.

4. Retire la placa para conducto redondo de 7” de

la parte superior trasera de la campana (véase la

ilustración de la derecha).

Garantía Seguridad LimpiezaOperación Instalación

PLACA PARA

CONDUCTO

REDONDO

DE 7”

2 TORNILLOS

5. Retire la parte punzonada para el cable de

alimentación eléctrica desde la parte superior (salida

vertical) o desde la parte trasera (salida horizontal)

de la campana. Instale una descarga de presión

adecuada de 1/2” de diámetro (no incluida).

INSTALACIÓN SIN CONDUCTOS ÚNICAMENTE

6. Retire los 3 tornillos que sujetan la placa de cubierta

de recirculación (parte sombreada de la ilustración

de la derecha) a la campana. Deseche esta placa y

los tornillos.

PARTE

PUNZONADA

PARA EL

CABLE DE

ALIMENTACIÓN

ELÉCTRICA

PLACA DE

CUBIERTA DE

RECIRCULACIÓN

TORNILLOS

Piezas de servicio

25

INSTALACIÓN CON CONDUCTOS ÚNICAMENTE

7. Retire la placa punzonada vertical de 3¼” x 10”, la placa punzonada horizontal de 3¼” x 10” o la placa

punzonada redonda de 7 pulgadas, según el modo de evacuación elegido (véanse las FIGURAS 1 A y 1 B).

FIGURA 1 A FIGURA 1 B

PLACA PUNZONADA

REDONDA DE 7”

(RETIRE TAMBIÉN LA PLACA

PUNZONADA VERTICAL)

PLACA

PUNZONADA

VERTICAL

DE 3¼” X 10”

8. Instale el conjunto de la clapeta de 3¼” x 10” en la parte superior O en la parte trasera de la campana

(si se usa el conducto de 3¼” x 10”; parte sombreada de la

redondo de 7” (si se usa el conducto redondo de 7 pulgadas, FIGURE 3) por encima de la abertura punzonada.

Una vez instalado, el conjunto de la clapeta de 3¼” x 10” debe abrirse como se ve en la F

PLACA

PUNZONADA

HORIZONTAL

DE 3¼” X 10”

FIGURA 2 A de abajo) o la placa para conducto

IGURA 2 B.

FIGURA 2 A

CONJUTO DE

LA CLAPETA

DE 3¼” X 10”

CONJUTO DE

LA CLAPETA

DE 3¼” X 10”

TORNILLOS

TORNILLOS

FIGURA 3

FIGURA 2 B

BORDE

SUPERIOR

TRASERO DE

LA CAMPANA

PIVOTE DE LA

COMPUERTA

PARTE TRASERA

DE LA CAMPANA

PIVOTE DE LA

COMPUERTA

PLACA PARA

CONDUCTO

REDONDO

DE 7”

TORNILLOS

NOTA: Para adaptarse a un conducto descentrado, la placa para conducto redondo de 7” puede instalarse

hasta 1/2” de cada lado del centro de la campana.

CONSEJO: Introduzca una pequeña longitud de conducto en el conjunto de la clapeta de 3¼” x 10” (para un

conducto rectangular) o en la placa para conducto redondo de 7” (para un conducto redondo) y selle

la junta con cinta adhesiva de aluminio para facilitar la conexión con los conductos de la vivienda.

26

PREPARE LA UBICACIÓN DE LA CAMPANA

VERTICAL EXHAUST

NOTA: Antes de empezar la instalación, lea todas las

ARMARIO CON ARMAZÓN ARMARIO SIN ARMAZÓN

etapas de estas instrucciones.

Use la ilustración de la derecha para reconocer su tipo

de armario de cocina.

Este manual cubre 2 tipos de instalación: la normal

(sin soportes EZ1) y la instalación EZ1 por una persona

(usando la plantilla y los soporte provistos). Para la

instalación normal, vaya a la página 31.

Sistema de instalación EZ1 por una persona

La instalación EZ1 está pensada para armarios de cocina que tienen la misma anchura que la de la campana. Si

el armario es 1/2” más ancho que la campana, use el modo de instalación normal.

1. Use la plantilla adecuada para la evacuación vertical

U horizontal (incluidas) para colocar los conductos y la

alimentación eléctrica en el armario o en la pared.

Para una instalación sin conductos, NO corte el orifi cio

de acceso al conducto; corte sólo el orifi cio para el

cableado eléctrico. Si sustituye una campana y prevé

usar el conducto y la alimentación eléctrica existentes,

puede que las etapas 2 a 5 no sean necesarias. De

ser el caso, pase a la etapa 6.

2. Mida y marque la línea central de la campana en la

parte inferior del armario.

3. Alinee la línea central de la plantilla con la línea

central de la campana marcada en la parte inferior

del armario, colocando el borde (donde se indica)

de la plantilla contra la pared trasera. Cuando se

use un armario con armazón para una instalación

con salida vertical, pliegue hacia atrás el borde de

la plantilla en una medida equivalente a la profundidad del armazón del armario en la pared (use las

graduaciones de la plantilla, puntos C de la plantilla).

Sujete la plantilla con cinta adhesiva.

NOTA: Si se sitúa frente a la instalación, A y B (en

la plantilla) deben estar a la derecha.

Garantía Seguridad LimpiezaOperación Instalación

DELANTERA

DEL ARMARIO

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

C

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

DE

C

14½”

Appuyer ce bord au mur arrière

L

7 PULG.

= 3¼ pulg. x 14 pulg.

4¼”

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

AB

C

7½”

10½”

Apoyar este borde contra la pared de atrásPlace this edge against back wall

DOBLE LA PLANTILLA A LO LARGO DE LA

ESCALA GRADUADA AL INSTALAR LA CAMPANA

P

EN

UN ARMARIO CON ARMAZÓN.

LÍNEA

CENTRAL

Place this edge against

cabinet bottom.

Appuyer ce bord contre le bas

de l’armoire.

Apoyar este borde contra

la base del armario.

C

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

L

DELANTERA

DEL ARMARIO

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas