Use and Care Guide

Liquid Propane Gas (LPG)Grill

Model141.16674800

Natural Gas (NG)Grill

Model141.17674800

• Safety

• Assembly

• Use and Care

• Cooking Guide

• Frequently Asked Questions

®

Call us first if you have any problem with

this product. We can help you with ques-

tions about assembly and grill operation or

if there are damaged or missing parts

when you unpack this unit from the ship-

ping box. Please call before contacting

your local retailer.

1-888-317-7642

8am-8pm CST, Monday throu.qh Friday

• NOTE TO ASSEMBLER/INSTALLER:

Leave this Guide with the consumer.

• NOTETO CONSUMER:

Keep this Guide for future reference.

• RECORDYOURSERIAL#

(see silver CSA label on main body of grill)

• Failure to comply with these instructions could

result in a fire or explosion that could cause

serious bodily injury, death or property damage.

• Whether this grill was assembled by you or

someone else, you must read this entire manual

before using your grill to ensure the grill is

properly assembled, installed and maintained.

• Use your grill at least 3 feet away from any

wall or surface. Use your grill at least 3 feet

away from combustible objects that can melt or

catch fire such as vinyl or wood siding, fences

and overhangs or sources of ignition including

pilot lights on water heaters and live electrical

appliances.

• THIS GASAPPLIANCEIS DESIGNED FOROUT-

DOOR USE ONLY.

• Never use your gas grill in a garage, porch,

shed, breezeway or any other enclosed area.

• Never obstruct the flow of ventilation air

around your gas grill housing.

• Never disconnect the gas regulator or any gas

fitting while your grill is lit. A lit grill can ignite

leaking gas and cause a fire or explosion which

could result in property damage, personal injury

or death.

Sears, Roebuck and Co., Hoffman Estates, IL 60197, USA www.sears.com

Guide # P80103010H - Date:2007/12/20

Primary Safety Warnings ............................ 1-3

Warranty Terms and Conditions ................... 2

Pre-Assembly Instructions .............................. 3

Part Diagrams and Lists ........................... 4-9

Assembly Instructions ............................... 10-11

LP Gas Tank Installation ....................... 12-14

Natural Gas Connection .............................. 15

Use & Care Instructions:

• Lighting Instructions ................................. 16

• Troubleshooting ......................................... 17

• Rotisserie Instructions ......................... 18-20

Cleaning and Maintenance ...................... 21-22

Cooking Guide ........................................ A1-A6

Frequently Asked Questions .................. A8-A9

Repair Protection Agreements .................... A10

If you smell gas:

1. Shut off gas to the appliance.

2 Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from

the appliance and immediately call

your gas supplier or your fire

department.

Kenmore Elite Full Warranty

If this grill fails due to a defect in material or

workmanship within two years frown the date of

purchase, call 1-800-4-MY-HOME "_ to arrange for

free repair (or replacement if repair proves

impossible).

Limited Warranty on Stainless Steel Burners

Any stainless steel burner that ever rusts

through will be replaced free of charge. After

the second year from the date of purchase you

must pay the labor cost to have it installed.

Limited Warranty on Selected Grill Parts

For three years from the date of purchase, any

stainless or painted steel part will be replaced

free of charge if it rusts through. After the

second year from the date of purchase you

must pay the labor cost to have it installed.

All warranty coverage excludes ignitor batteries

and grill part paint loss or rusting, which are

either expendable parts that can wear out from

normal use in less than a year, or are condi-

tions that can be the result of normal use,

accident or improper maintenance.

All warranty coverage is void if this grill is ever

used for commercial or rental purposes.

All warranty coverage applies only if this grill is

used in the United States.

This warranty gives you specific legal rights,

and you may have other rights which vary from

sate to state.

Sears, Roebuck and Co., Hoffman Estates, IL

LPG models must be used with Liquid

Propane Gas and the regulator assembly

supplied. Natural Gas models must be used

with Natural Gas only.

Keep gas regulator hose away from hot grill

surfaces and dripping grease. Avoid unneces-

sary twisting of hose. Visually inspect hose

prior to each use for cuts, cracks, excessive

wear or other damage. If the hose appears

damaged do not use the gas grill. Call Sears

at 1-888-317-7642 for a certified replacement

hose.

California Proposition 65

Combustion byproducts produced when using

this product contain chemicals known to the

State of California to cause cancer, birth de-

fects, or other reproductive harm.

Brass components on the grill, such as hose

fittings, propane cylinder valves (sold sepa-

rately) and burner valve stems, contain lead

which is known to the State of California to

cause cancer, birth defects, or other reproduc-

tive harm.

Never use charcoal or lighter fluid in this gas

grill. Failure to comply with these instructions

could result in a grease fire or explosion that

could cause serious bodily injury, death or

propertydamage.

The Grease Draining Tray and Grease Recep-

tacle must be visually inspected before each

grill use. Remove any grease and wash Grease

Draining Tray and Grease Receptacle with a

mild soap and warm water solution. Failure to

comply with these instructions could re-

sult in a grease fire or explosion that could

cause serious bodilyinjury, death or prop-

erty damage.

© Sears Brands, LLC

To expedite the assembly process follow these

general guidelines:

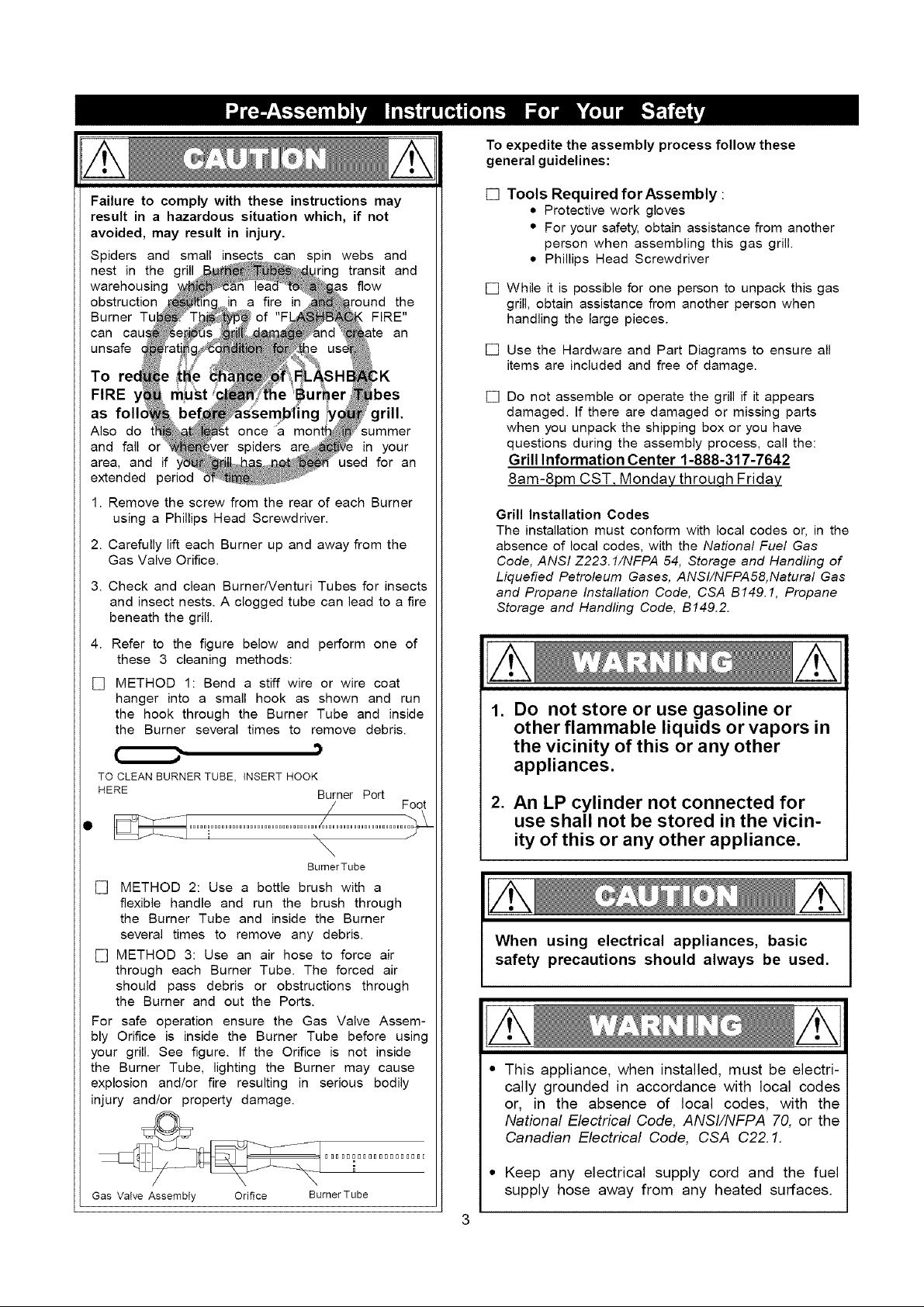

Failure to comply with these instructions may

result in a hazardous situation which, if not

avoided, may result in injury.

Spiders and small insects can spin webs and

nest in the grill "ing transit and

warehousing flow

obstruction round the

Burner T_ FIRE"

can cau_ an

unsafe €

To .'K

FIRE bes

as grill.

Also do summer

and fall or in your

area, and if used for an

extended period

1. Remove the screw from the rear of each Burner

using a Phillips Head Screwdriver.

2. Carefully lift each Burner up and away from the

Gas Valve Orifice.

3. Check and clean Burner/Venturi Tubes for insects

and insect nests. A clogged tube can lead to a fire

beneath the grill.

4. Refer to the figure below and perform one of

these 3 cleaning methods:

[] METHOD 1: Bend a stiff wire or wire coat

hanger into a small hook as shown and run

the hook through the Burner Tube and inside

the Burner several times to remove debris.

,)

TO CLEAN BURNER TUBE, INSERT HOOK

HERE Burner Port

\

Foot

\

BumerTube

[] METHOD 2: Use a bottle brush with a

flexible handle and run the brush through

the Burner Tube and inside the Burner

several times to remove any debris.

[] METHOD 3: Use an air hose to force air

through each Burner Tube. The forced air

should pass debris or obstructions through

the Burner and out the Ports.

For safe operation ensure the Gas Valve Assem-

bly Orifice is inside the Burner Tube before using

your grill. See figure. If the Orifice is not inside

the Burner Tube, lighting the Burner may cause

explosion and/or fire resulting in serious bodily

injury and/or property damage.

[] Tools Required forAssembly :

• Protective work gloves

• For your safety, obtain assistance from another

person when assembling this gas grill.

• Phillips Head Screwdriver

[] While it is possible for one person to unpack this gas

grill, obtain assistance from another person when

handling the large pieces.

[] Use the Hardware and Part Diagrams to ensure all

items are included and free of damage.

[] Do not assemble or operate the grill if it appears

damaged. If there are damaged or missing parts

when you unpack the shipping box or you have

questions during the assembly process, call the:

Grill Information Center 1-888-317-7642

8am-8pm CST, Monday throu.qh Friday

Grill Installation Codes

The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, Storage and Handling of

Liquefied Petroleum Gases, ANSI/NFPA58,Natural Gas

and Propane Installation Code, CSA B149.1, Propane

Storage and Handling Code, B149.2.

1. Do not store or use gasoline or

other flammable liquids or vapors in

the vicinity of this or any other

appliances.

2. An LP cylinder not connected for

use shall not be stored in the vicin-

ity of this or any other appliance.

When using electrical appliances, basic

safety precautions should always be used.

• This appliance, when installed, must be electri-

cally grounded in accordance with local codes

or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the

Canadian Electrical Code, CSA C22.1.

/

Gas Valve Assembly Orifice BurnerTube

• Keep any electrical supply cord and the fuel

supply hose away from any heated surfaces.

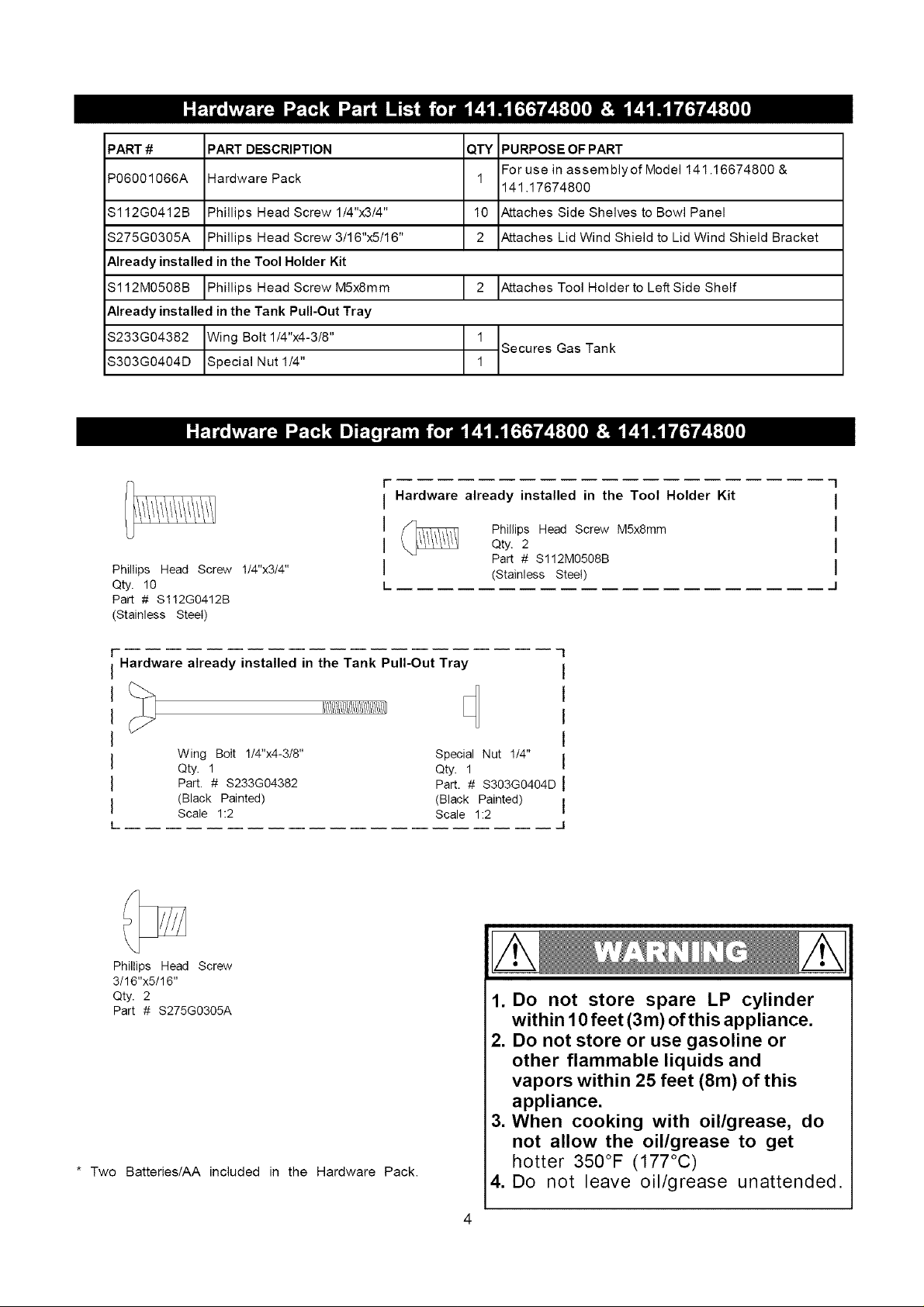

PART # PART DESCRIPTION

P06001066A Hardware Pack

S112G0412B Phillips Head Screw 1/4"x3/4"

S275G0305A Phillips Head Screw 3/16"x5/16"

Already installed in the Tool Holder Kit

S112M0508B Phillips Head Screw M5x8mm

Already installed in the Tank Pull-Out Tray

$233G04382 Wing Bolt 1/4"x4-3/8"

S303G0404D Special Nut 1/4"

QTY PURPOSE OF PART

For use in assemblyof Model 141.16674800 &

1

141.17674800

10 Attaches Side Shelves to Bowl Panel

2 Attaches Lid Wind Shield to Lid Wind Shield Bracket

2 Attaches Tool Holder to Left Side Shelf

1

Secures Gas Tank

1

r

i Hardware already installed in the Tool Holder Kit

] Phillips Head Screw M5x8mm

I Qty. 2

Phillips Head Screw 1/4"x3/4"

Qty. 10

Part # S112G0412B

(Stainless Steel)

Hardware already installed in the Tank Pull-Out Tray

Wing Bolt 1/4"x4-3/8"

Qty. 1

Part. # $233G04382

(Black Painted)

Scale 1:2

I (Stainless Steel)

L

Part # S112M0508B

Special Nut 1/4"

Qty. 1

Part. # S303G0404D

(Black Painted)

Scale 1:2

7

I

I

I

I

d

J

Phillips Head Screw

3/16"x5/16"

Qty. 2

Part # S275G0305A

* Two Batteries/AA included in the Hardware Pack.

1. Do not store spare LP cylinder

within 10 feet (3m) of this appliance.

2. Do not store or use gasoline or

other flammable liquids and

vapors within 25 feet (8m) of this

appliance.

3. When cooking with oil/grease, do

not allow the oil/grease to get

hotter 350°F (177°C)

4. Do not leave oil/grease unattended.

3

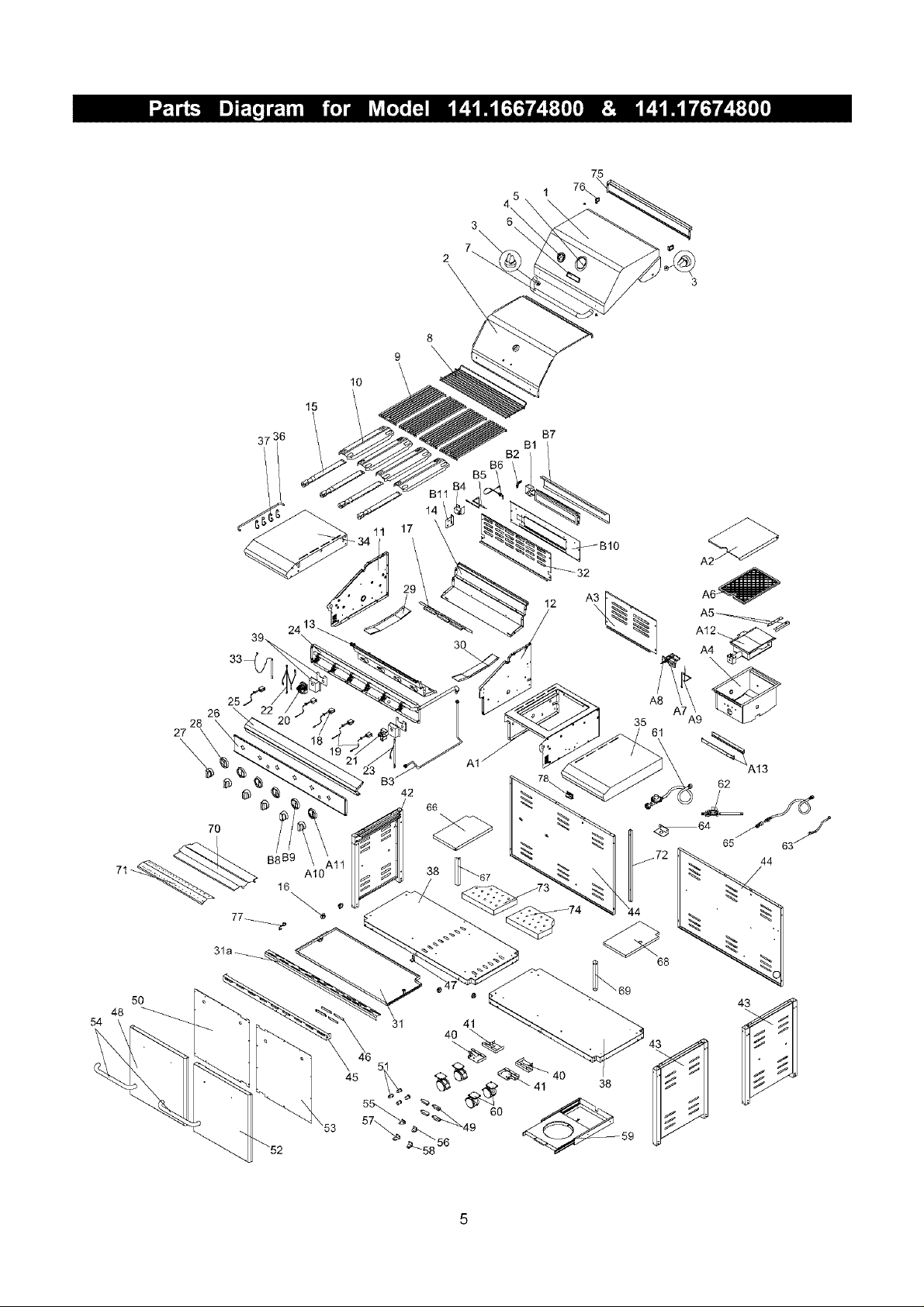

2 7_

8

9

lO

15

B7

B1

B2

B6

B5

11 17

12

3O

28

27

\

42

66

7O

68

50

48

54

45

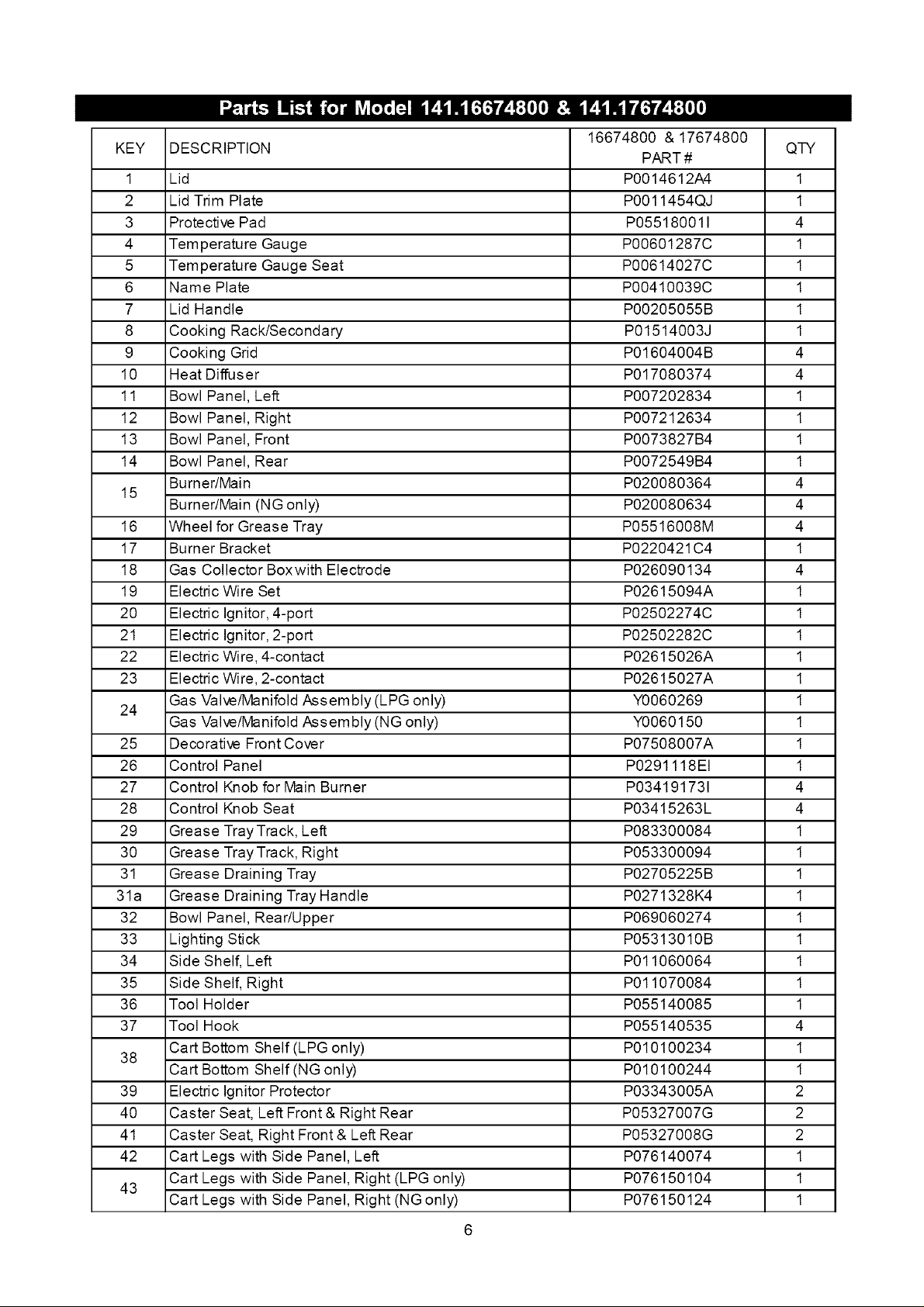

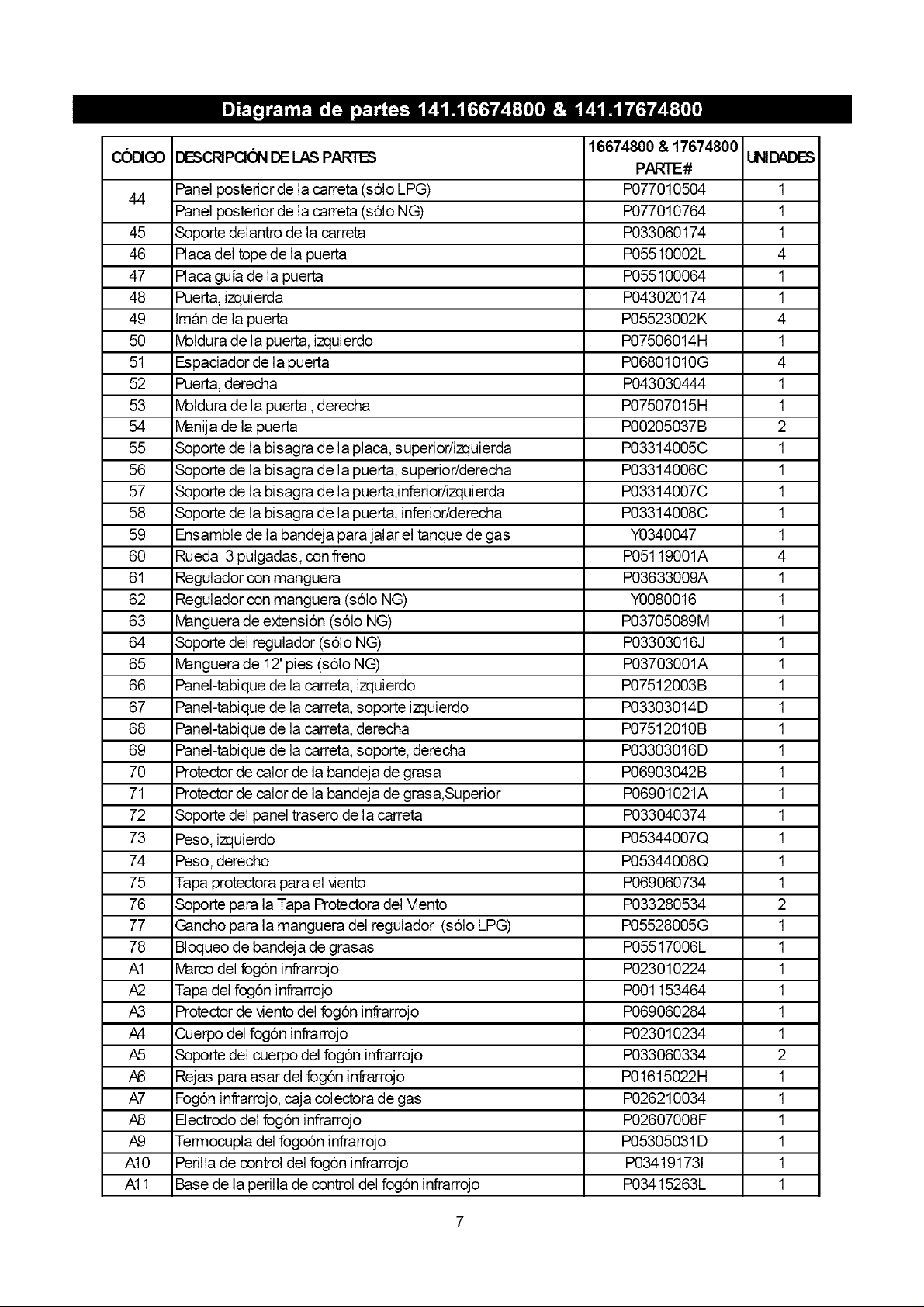

KEY DESCRIPTION 16674800 & 17674800 QTY

1 Lid P0014612A4 1

2 Lid Trim Plate P0011454QJ 1

3 Protective Pad P055180011 4

4 Temperature Gauge P00601287C 1

5 Temperature Gauge Seat P00614027C 1

6 Name Plate P00410039C 1

7 Lid Handle P00205055B 1

8 Cooking Rack/Secondary P01514003J 1

9 Cooking Grid P01604004B 4

10 Heat Diffuser P017080374 4

11 Bowl Panel, Left P007202834 1

12 Bowl Panel, Right P007212634 1

13 Bowl Panel, Front P0073827B4 1

14 Bowl Panel, Rear P0072549B4 1

15

16 Wheel for Grease Tray P05516008M 4

17 Burner Bracket P0220421 C4 1

18 Gas Collector Boxwith Electrode P026090134 4

19 Electric Wire Set P02615094A 1

20 Electric Ignitor, 4-port P02502274C 1

21 Electric Ignitor, 2-port P02502282C 1

22 Electric Wire, 4-contact P02615026A 1

23 Electric Wire, 2-contact P02615027A 1

24

25 Decorative Front Cover P07508007A 1

26 Control Panel P0291118EI 1

27 Control Knob for Main Burner P034191731 4

28 Control Knob Seat P03415263L 4

29 Grease Tray Track, Left P083300084 1

30 Grease Tray Track, Right P053300094 1

31 Grease Draining Tray P02705225B 1

31a Grease Draining Tray Handle P0271328K4 1

32 Bowl Panel, Rear/Upper P069060274 1

33 Lighting Stick P05313010B 1

34 Side Shelf, Left P011060064 1

35 Side Shelf, Right P011070084 1

36 Tool Holder P055140085 1

37 Tool Hook P055140535 4

38

39 Electric Ignitor Protector P03343005A 2

40 Caster Seat, Left Front & Right Rear P05327007G 2

41 Caster Seat, Right Front & Left Rear P05327008G 2

42 Cart Legs with Side Panel, Left P076140074 1

Burner/Main P020080364 4

Burner/Main (NG only) P020080634 4

Gas Valve/Manifold Assembly (LPG only) Y0060269 1

Gas Valve/Manifold Assembly (NG only) Y0060150 1

Cart Bottom Shelf (LPG only) P010100234 1

Cart Bottom Shelf (NG only) P010100244 1

PART #

43 Cart Legs with Side Panel, Right (LPG only) P076150104 1

Cart Legs with Side Panel, Right (NG only) P076150124 1

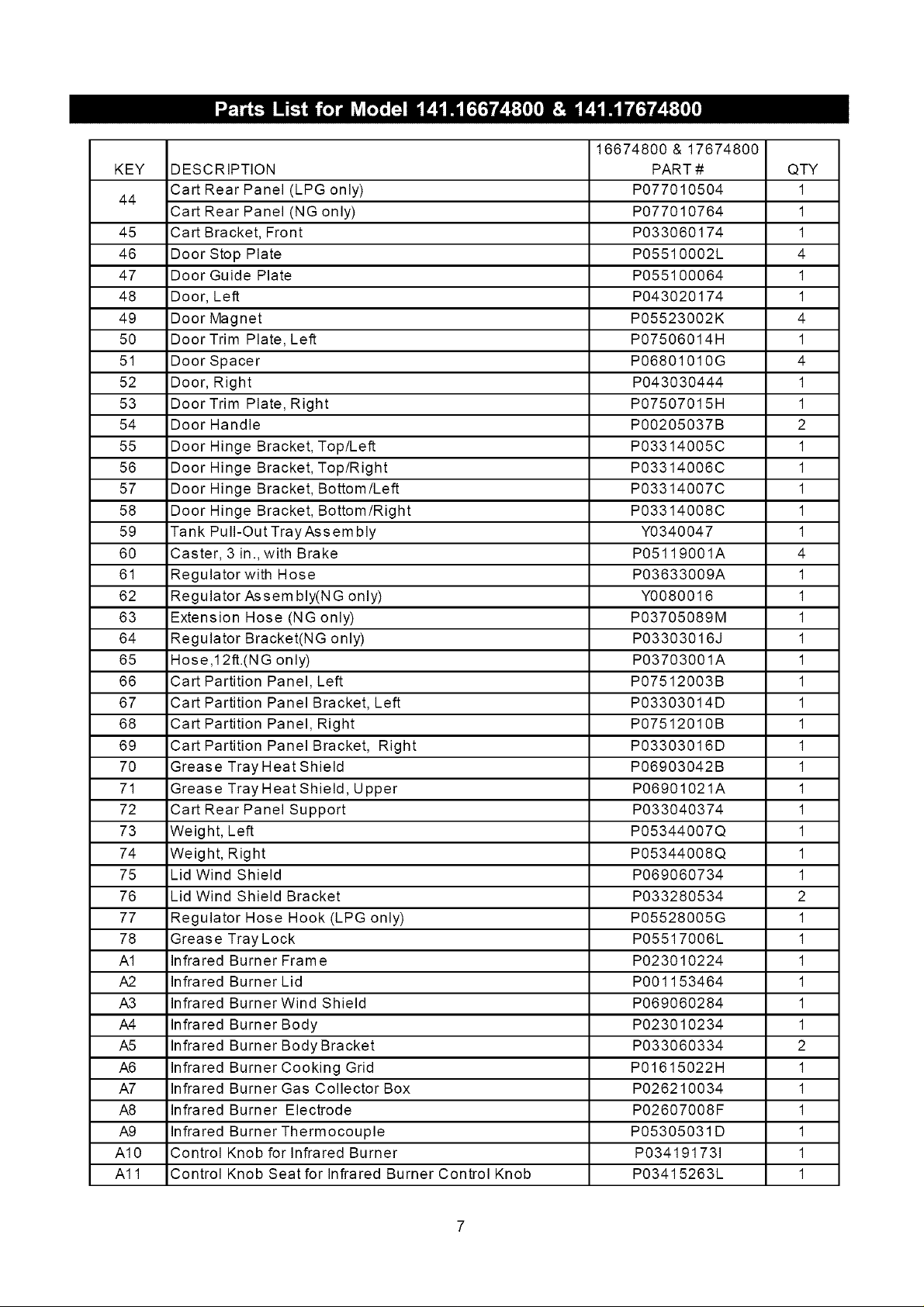

16674800&17674800

KEY DESCRIPTION PART# QTY

44

45 CartBracket,Front P033060174 1

46 DoorStopPlate P05510002L 4

47 DoorGuidePlate P055100064 1

48 Door,Left P043020174 1

49 DoorMagnet P05523002K 4

50 DoorTrimPlate,Left P07506014H 1

51 DoorSpacer P06801010G 4

52 Door,Right P043030444 1

53 DoorTrimPlate,Right P07507015H 1

54 DoorHandle P00205037B 2

55 DoorHingeBracket,Top/Left P03314005C 1

56 DoorHingeBracket,Top/Right P03314006C 1

57 DoorHingeBracket,Bottom/Left P03314007C 1

58 DoorHingeBracket,Bottom/Right P03314008C 1

59 TankPull-OutTrayAssembly Y0340047 1

60 Caster,3in.,withBrake P05119001A 4

61 RegulatorwithHose P03633009A 1

62 RegulatorAssembly(NGonly) Y0080016 1

63 ExtensionHose(NGonly) P03705089M 1

64 RegulatorBracket(NGonly) P03303016J 1

65 Hose,12ft.(NGonly) P03703001A 1

66 CartPartitionPanel,Left P07512003B 1

67 CartPartitionPanelBracket,Left P03303014D 1

68 CartPartitionPanel,Right P07512010B 1

69 CartPartitionPanelBracket,Right P03303016D 1

70 GreaseTrayHeatShield P06903042B 1

71 GreaseTrayHeatShield,Upper P06901021A 1

72 CartRearPanelSupport P033040374 1

73 Weight,Left P05344007Q 1

74 Weight,Right P05344008Q 1

75 LidWindShield P069060734 1

76 LidWindShieldBracket P033280534 2

77 RegulatorHoseHook(LPGonly) P05528005G 1

78 GreaseTrayLock P05517006L 1

A1 InfraredBurnerFrame P023010224 1

A2 InfraredBurnerLid P001153464 1

A3 InfraredBurnerWindShield P069060284 1

A4 InfraredBurnerBody P023010234 1

A5 InfraredBurnerBodyBracket P033060334 2

A6 InfraredBurnerCookingGrid P01615022H 1

A7 InfraredBurnerGasCollectorBox P026210034 1

A8 InfraredBurnerElectrode P02607008F 1

A9 InfraredBurnerThermocouple P05305031D 1

A10 ControlKnobforInfraredBurner P034191731 1

A11 ControlKnobSeatforInfraredBurnerControlKnob P03415263L 1

CartRearPanel(LPGonly) P077010504 1

CartRearPanel(NGonly) P077010764 1

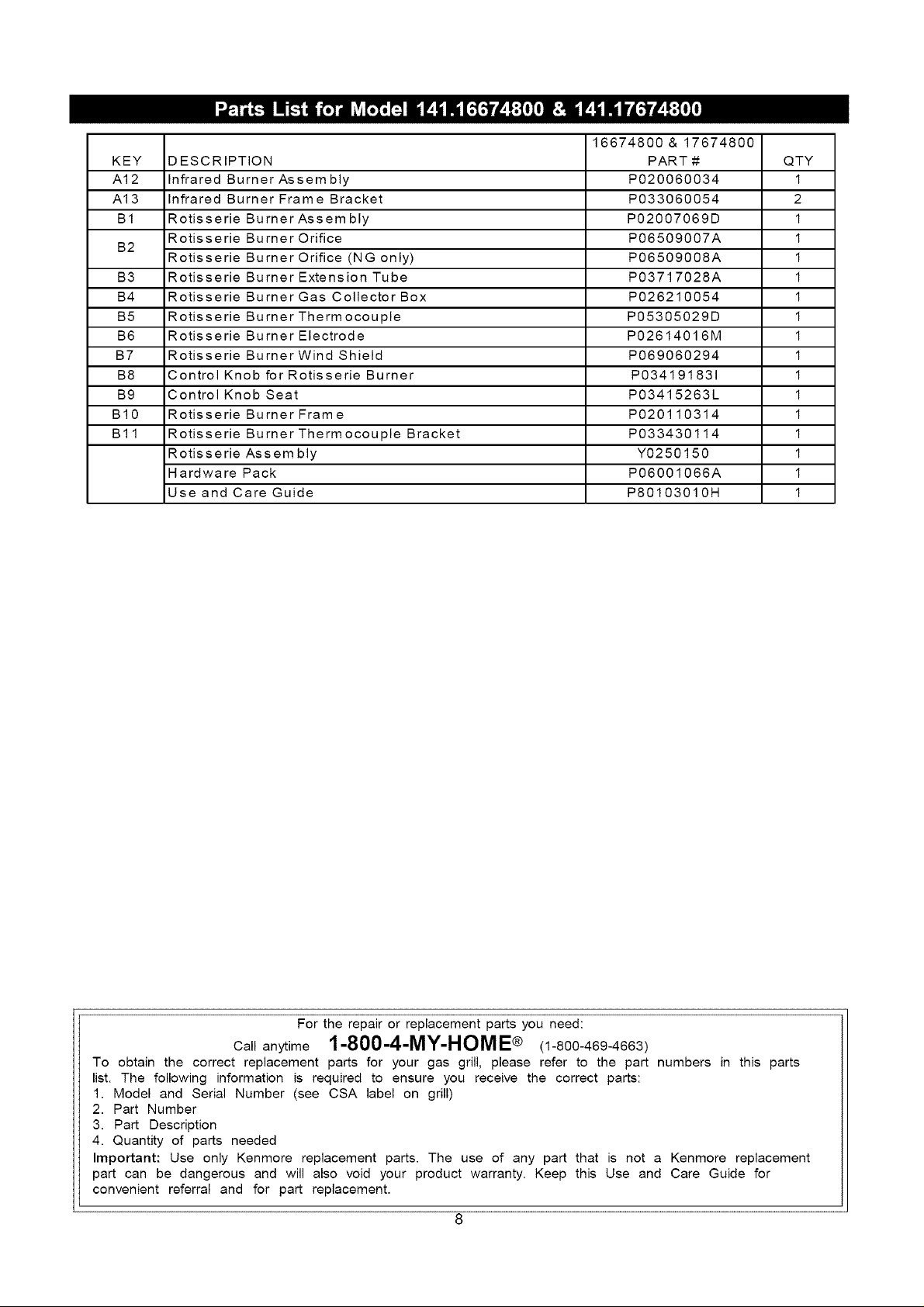

16674800& 17674800

KEY DESCRIPTION PART# QTY

A12 Infrared Burner Assembly P020060034 1

A13 Infrared Burner Frame Bracket P033060054 2

B1 Rotisserie Burner Assembly P02007069D 1

B2

B3 Rotisserie Burner Extension Tube P03717028A 1

B4 Rotisserie Burner Gas Collector Box P026210054 1

B5 Rotisserie Burner Therm ocouple P05305029D 1

B6 Rotisserie Burner Electrode P02614016M 1

B7 Rotisserie Burner Wind Shield P069060294 1

B8 ControIKnob for Rotisserie Burner P034191831 1

B9 ControIKnob Seat P03415263L 1

B10 Rotisserie Burner Frame P020110314 1

Bll Rotisserie Burner Thermocouple Bracket P033430114 1

Rotisserie Burner Orifice P06509007A 1

Rotisserie Burner Orifice (NG only) P06509008A 1

Rotisserie Assem bly Y0250150 1

Hardware Pack P06001066A 1

Use and Care Guide P80103010H 1

For the repair or replacement parts you need:

Call anytime 1-800-4-MY-HOME® (1-800-469-4663)

To obtain the correct replacement parts for your gas grill, please refer to the part numbers in this parts

list. The following information is required to ensure you receive the correct parts:

1. Model and Serial Number (see CSA label on grill)

2. Part Number

3. Part Description

4. Quantity of parts needed

Important: Use only Kenmore replacement parts. The use of any part that is not a Kenmore replacement

part can be dangerous and will also void your product warranty. Keep this Use and Care Guide for

convenient referral and for part replacement.

6

11

9

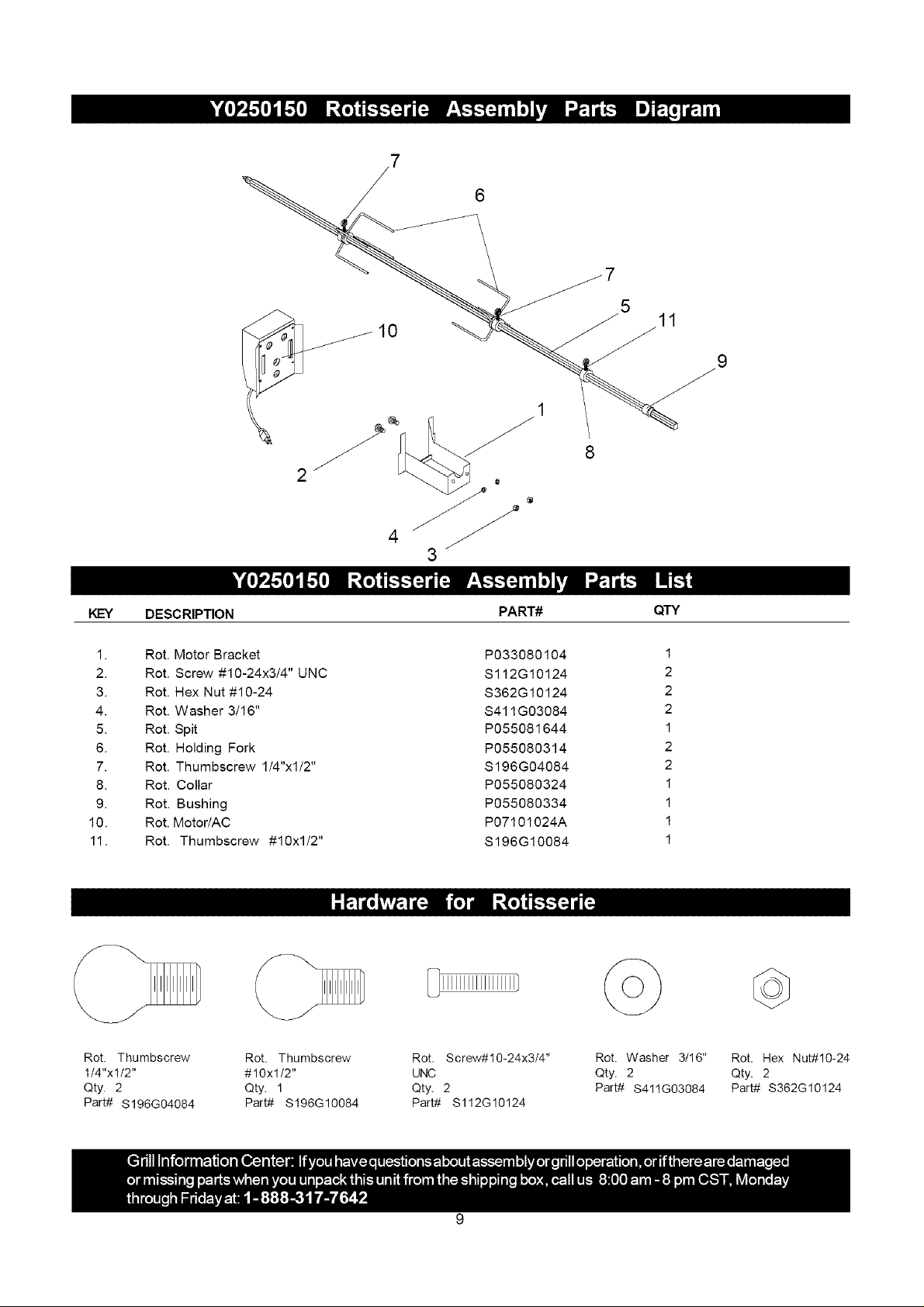

KEY DESCRIPTION

1. Rot. Motor Bracket

2. Rot. Screw #10-24x3/4" UNC

3. Rot. Hex Nut #10-24

4. Rot. Washer 3/16"

5. Rot. Spit

6. Rot. Holding Fork

7. Rot. Thumbscrew 1/4"x1/2"

8. Rot. Collar

9. Rot. Bushing

10. Rot. Motor/AC

11. Rot. Thumbscrew #10x1/2"

PART#

P033080104

Sl12G10124

S362G10124

S411G03084

P055081644

P055080314

S196G04084

P055080324

P055080334

P07101024A

S196G10084

QTY

1

2

2

2

1

2

2

1

1

1

1

111111111111111111]

Rot. Thumbscrew Rot. Thumbscrew Rot. Screw#10-24x3/4" Rot. Washer 3/16"

1/4"x1/2" #10x1/2" UNC Qty. 2

Qty. 2 Qty. 1 Qty. 2 Part# $411G03084

Part# $196G04084 Part# S196G10084 Part# $112G10124

Rot. Hex Nut#10-24

Qty. 2

Part# $362G10124

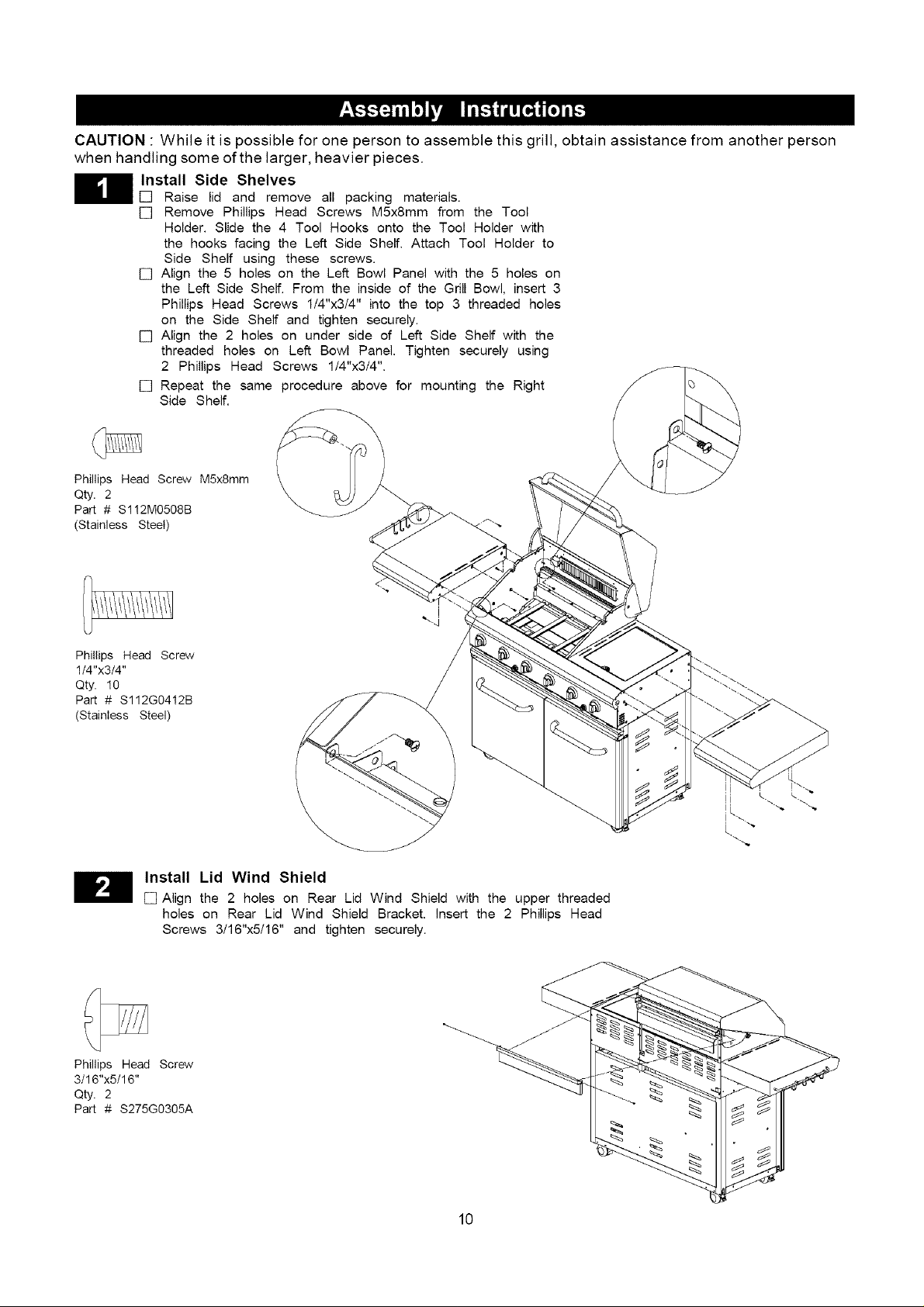

CAUTION " While it is possible for one person to assemble this grill, obtain assistance from another person

when handling some of the larger, heavier pieces.

H nstall Side Shelves

[] Raise lid and remove all packing materials.

[] Remove Phillips Head Screws M5x8mm from the Tool

Holder. Slide the 4 Tool Hooks onto the Tool Holder with

the hooks facing the Left Side Shelf. Attach Tool Holder to

Side Shelf using these screws.

[] Align the 5 holes on the Left Bowl Panel with the 5 holes on

the Left Side Shelf. From the inside of the Grill Bowl, insert 3

Phillips Head Screws 1/4"x3/4" into the top 3 threaded holes

on the Side Shelf and tighten securely.

[] Align the 2 holes on under side of Left Side Shelf with the

threaded holes on Left Bowl Panel. Tighten securely using

2 Phillips Head Screws 1/4"x3/4".

[] Repeat the same procedure above for mounting the Right

Side Shelf.

Phillips Head Screw M5x8mm

Qty. 2

Part # Sl!2M0508B

(Stainless Steel)

Phillips Head Screw

1/4"x3/4"

Qty. 10

Part # S112G0412B

(Stainless Steel)

Install Lid Wind Shield

[] Align the 2 holes on Rear Lid Wind Shield with the upper threaded

holes on Rear Lid Wind Shield Bracket. Insert the 2 Phillips Head

Screws 3/16"x5/16" and tighten securely.

Phillips Head Screw

3/16"x5/16"

Qty. 2

Part # S275G0305A

10

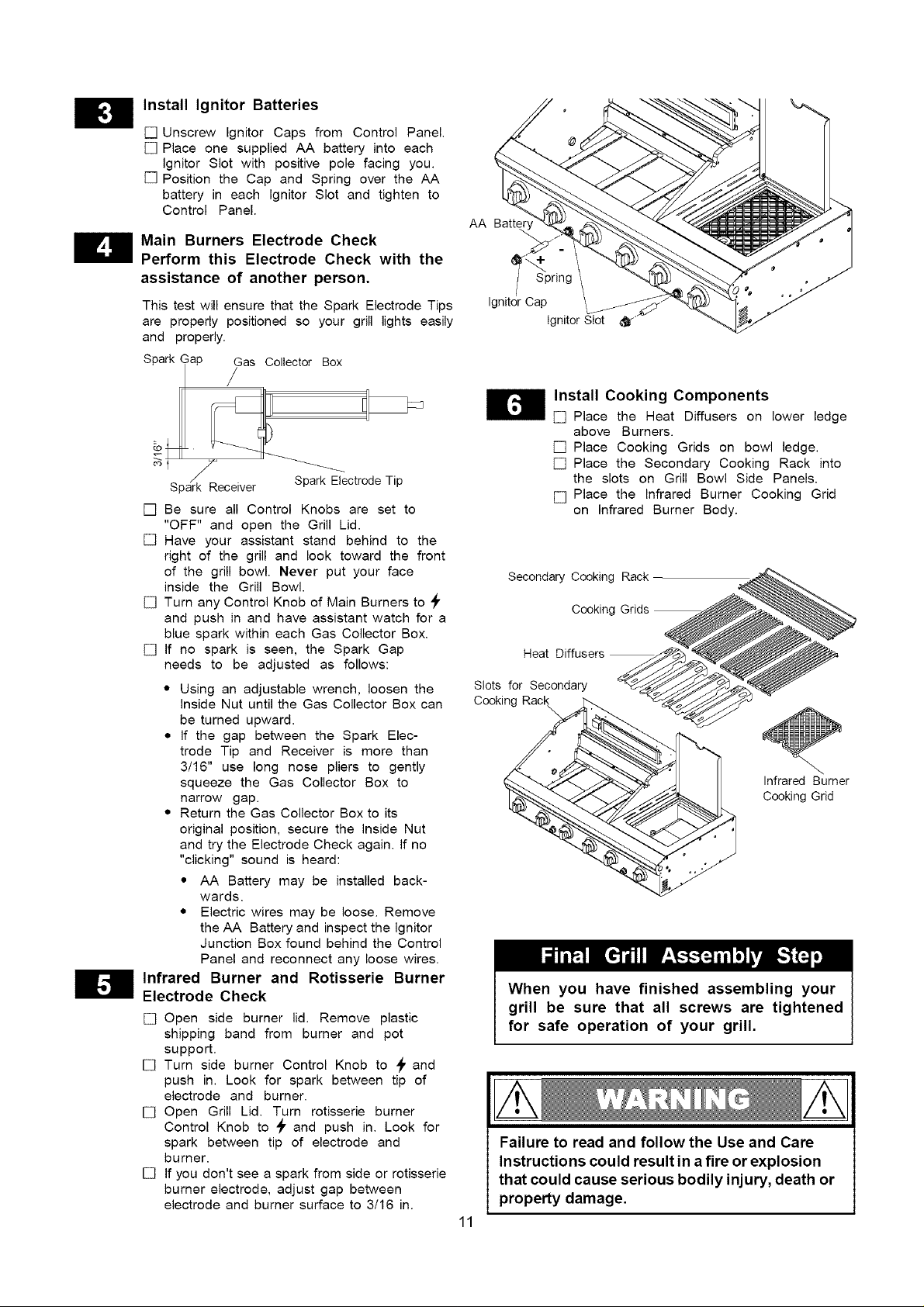

H Install Ignitor Batteries

[] Unscrew Ignitor Caps from Control Panel.

[] Place one supplied AA battery into each

ignitor Slot with positive pole facing you.

[] Position the Cap and Spring over the AA

battery in each Ignitor Slot and tighten to

Control Panel.

Main Burners Electrode Check

Perform this Electrode Check with the

assistance of another person.

This test will ensure that the Spark Electrode Tips

are properly positioned so your grill lights easily

and properly.

Spark Gap Gas Collector Box

Spark Receiver p ctrode Tip

[] Be sure all Control Knobs are set to

"OFF" and open the Grill Lid.

[] Have your assistant stand behind to the

right of the grill and look toward the front

of the grill bowl. Never put your face

inside the Grill Bowl.

[] Turn any Control Knob of Main Burners to _I,

and push in and have assistant watch for a

blue spark within each Gas Collector Box.

[] If no spark is seen, the Spark Gap

needs to be adjusted as follows:

• Using an adjustable wrench, loosen the

inside Nut until the Gas Collector Box can

be turned upward.

• If the gap between the Spark Elec-

trode Tip and Receiver is more than

3/16" use long nose pliers to gently

squeeze the Gas Collector Box to

narrow gap.

• Return the Gas Collector Box to its

original position, secure the inside Nut

and try the Electrode Check again. If no

"clicking" sound is heard:

• AA Battery may be installed back-

wards.

• Electric wires may be loose. Remove

the AA Battery and inspect the ignitor

Junction Box found behind the Control

Panel and reconnect any loose wires.

AA Batte£

Ignitor Cap

Ignitor Slot _

Install Cooking Components

[] Place the Heat Diffusers on lower ledge

above Burners.

[] Place Cooking Grids on bowl ledge.

[] Place the Secondary Cooking Rack into

the slots on Grill Bowl Side Panels.

[] Place the Infrared Burner Cooking Grid

on Infrared Burner Body.

Secondary Cooking Rack

Cooking

Heat Diffusers

Slots for Secondary

Cooking Rack

Infrared Burner

Cooking Grid

H nfrared Burner and Rotisserie Burner

Electrode Check

[] Open side burner lid. Remove plastic

shipping band from burner and pot

support.

[] Turn side burner Control Knob to _' and

push in. Look for spark between tip of

electrode and burner.

[] Open Grill Lid. Turn rotisserie burner

Control Knob to _I, and push in. Look for

spark between tip of electrode and

burner.

[] If you don't see a spark from side or rotisserie

burner electrode, adjust gap between

electrode and burner surface to 3/16 in.

When you have finished assembling your

grill be sure that all screws are tightened

for safe operation of your grill.

Failure to read and follow the Use and Care

Instructions could result in a fire or explosion

that could cause serious bodily injury, death or

property damage.

11

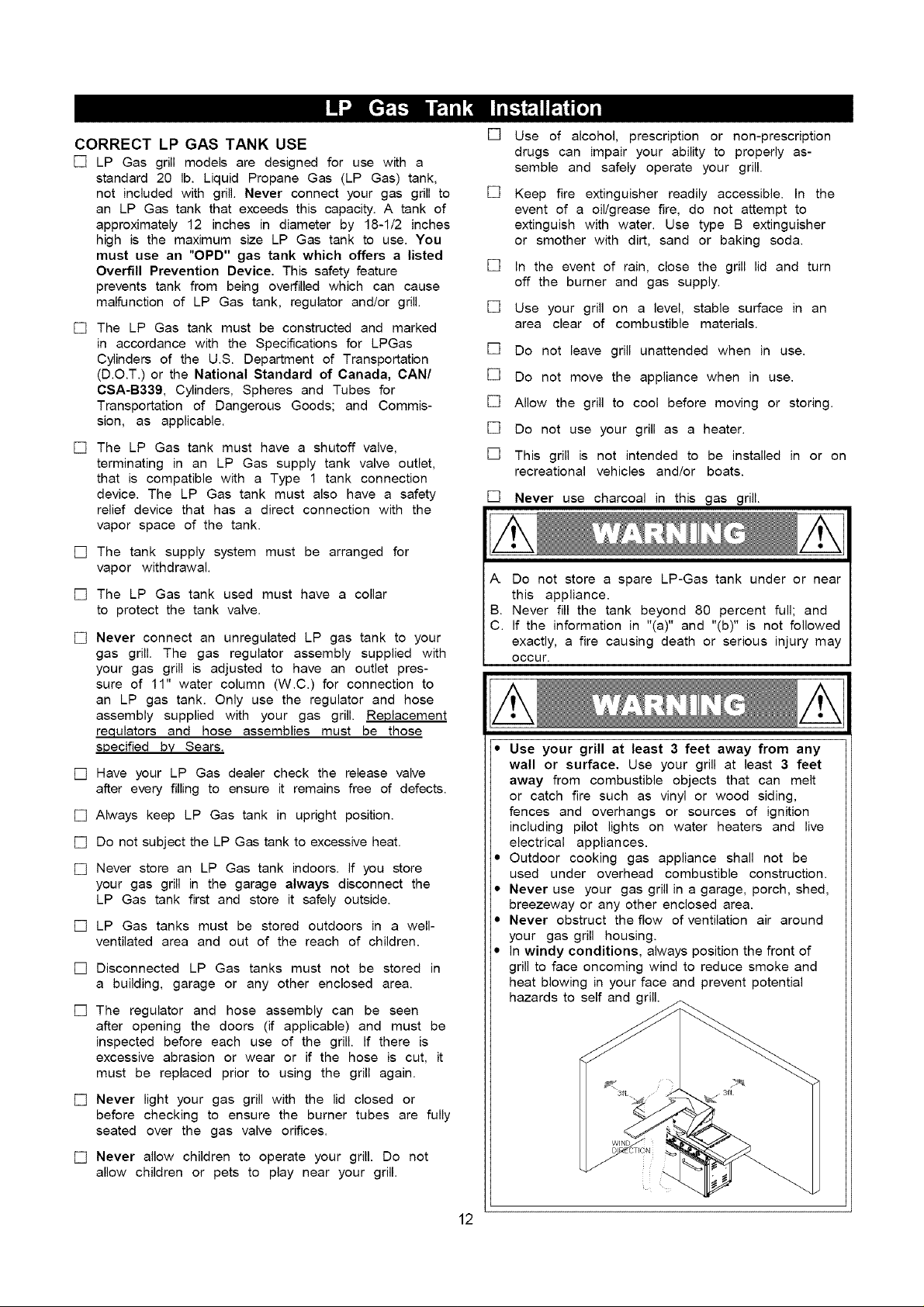

CORRECT LP GAS TANK USE

[] LP Gas grill models are designed for use with a

standard 20 lb. Liquid Propane Gas (LP Gas) tank,

not included with grill. Never connect your gas grill to

an LP Gas tank that exceeds this capacity. A tank of

approximately 12 inches in diameter by 18-1/2 inches

high is the maximum size LP Gas tank to use. You

must use an "OPD" gas tank which offers a listed

Overfill Prevention Device. This safety feature

prevents tank from being overfilled which can cause

malfunction of LP Gas tank, regulator and/or grill.

[] The LP Gas tank must be constructed and marked

in accordance with the Specifications for LPGas

Cylinders of the U.S. Department of Transportation

(D.O.T.) or the National Standard of Canada, CAN/

CSA-B339, Cylinders, Spheres and Tubes for

Transportation of Dangerous Goods; and Commis-

sion, as applicable.

[] The LP Gas tank must have a shutoff valve,

terminating in an LP Gas supply tank valve outlet,

that is compatible with a Type 1 tank connection

device. The LP Gas tank must also have a safety

relief device that has a direct connection with the

vapor space of the tank.

[] The tank supply system must be arranged for

vapor withdrawal.

[] The LP Gas tank used must have a collar

to protect the tank valve.

[] Never connect an unregulated LP gas tank to your

gas grill. The gas regulator assembly supplied with

your gas grill is adjusted to have an outlet pres-

sure of 11" water column (W.C.) for connection to

an LP gas tank. Only use the regulator and hose

assembly supplied with your gas grill. Replacement

requlators and hose assemblies must be those

specified by Sears.

[] Have your LP Gas dealer check the release valve

after every filling to ensure it remains free of defects.

[] Always keep LP Gas tank in upright position.

[] Do not subject the LP Gas tank to excessive heat.

[] Never store an LP Gas tank indoors. If you store

your gas grill in the garage always disconnect the

LP Gas tank first and store it safely outside.

[] LP Gas tanks must be stored outdoors in a well-

ventilated area and out of the reach of children.

[] Disconnected LP Gas tanks must not be stored in

a building, garage or any other enclosed area.

[] The regulator and hose assembly can be seen

after opening the doors (if applicable) and must be

inspected before each use of the grill. If there is

excessive abrasion or wear or if the hose is cut, it

must be replaced prior to using the grill again.

[] Never light your gas grill with the lid closed or

before checking to ensure the burner tubes are fully

seated over the gas valve orifices.

[] Never allow children to operate your grill. Do not

allow children or pets to play near your grill.

[] Use of alcohol, prescription or non-prescription

drugs can impair your ability to properly as-

semble and safely operate your grill.

[] Keep fire extinguisher readily accessible. In the

event of a oil/grease fire, do not attempt to

extinguish with water. Use type B extinguisher

or smother with dirt, sand or baking soda.

[] In the event of rain, close the grill lid and turn

off the burner and gas supply.

[] Use your grill on a level, stable surface in an

area clear of combustible materials.

[] Do not leave grill unattended when in use.

[] Do not move the appliance when in use.

[] Allow the grill to cool before moving or storing.

[] Do not use your grill as a heater.

[] This grill is not intended to be installed in or on

recreational vehicles and/or boats.

[] Never use charcoal in this gas grill.

this appliance.

Never fill the tank beyond 80 percent full; and

". If the information in "(a)" and "(b)" is not followed

[_ o not store a spare LP-Gas tank under or near

exactly, a fire causing death or serious injury may

occur.

• Use your grill at least 3 feet away from any

wall or surface. Use your grill at least 3 feet

away from combustible objects that can melt

or catch fire such as vinyl or wood siding,

fences and overhangs or sources of ignition

including pilot lights on water heaters and live

electrical appliances.

• Outdoor cooking gas appliance shall not be

used under overhead combustible construction.

• Never use your gas grill in a garage, porch, shed,

breezeway or any other enclosed area.

• Never obstruct the flow of ventilation air around

your gas grill housing.

• In windy conditions, always position the front of

grill to face oncoming wind to reduce smoke and

heat blowing in your face and prevent potential

hazards to

3ft. /

12

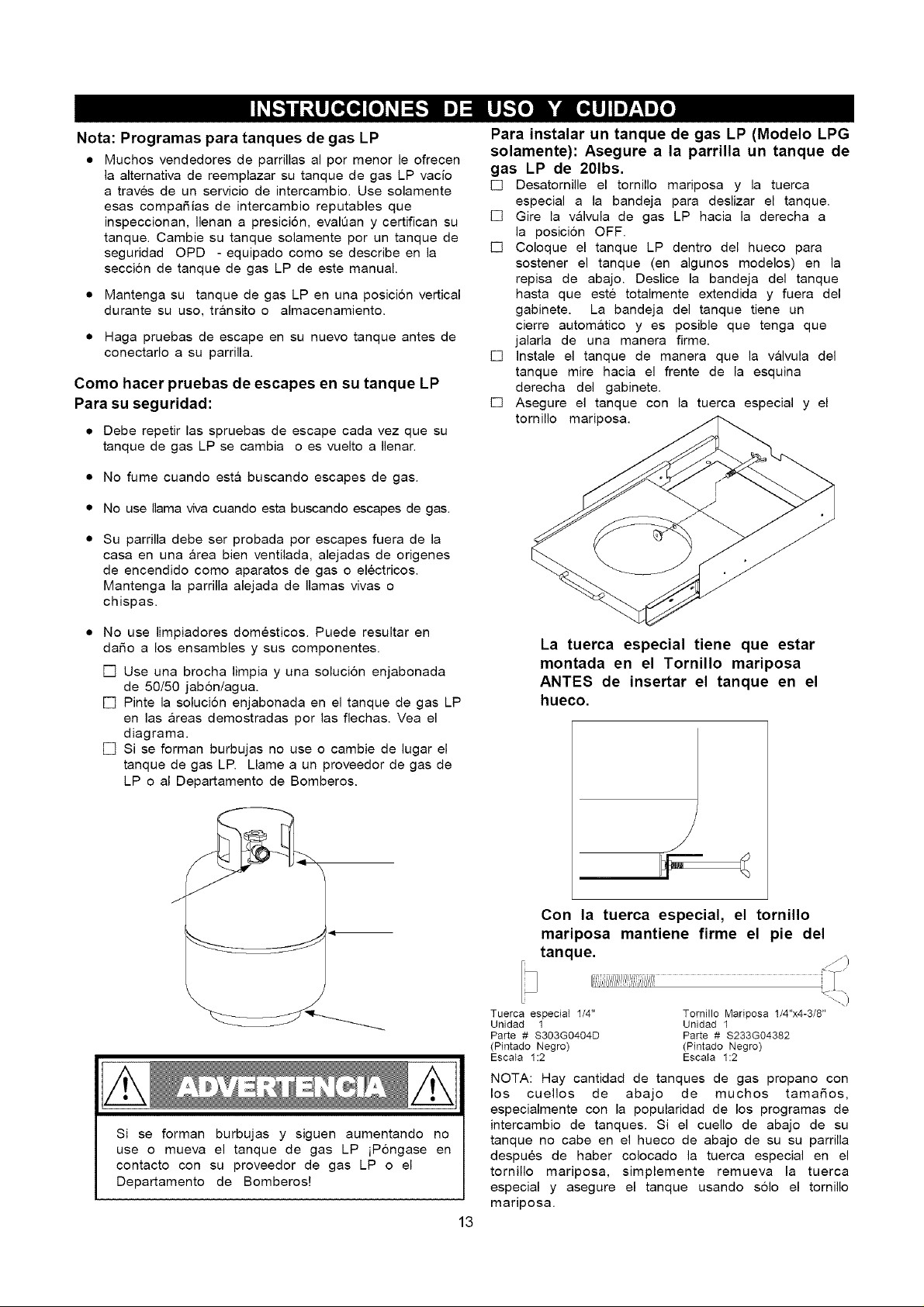

NOTE about LP Gas Tank Exchange Programs

• Many retailers that sell grills offer you the option of

replacing your empty LP Gas tank through an ex-

change service. Use only those reputable exchange

companies that inspect, precision fill, test and certify

their tanks. Exchange your tank only for an OPD safety

feature-equipped tank as described in the LP Gas tank

section of this Guide.

• Always keep new and exchanged LP Gas tanks in an

upright position during use, transit or storage.

• Leak test new and exchanged LP Gas tanks BEFORE

connecting one to your grill.

How to Leak Test your LP Gas Tank

For you r safety:

• All leak tests must be repeated each time your LP Gas

tank is exchanged or refilled.

• When checking for gas leaks do not smoke.

• Do not use an open flame to check for gas leaks.

• Your grill must be leak tested outdoors in a well-

ventilated area, away from ignition sources such as

gas fired or electrical appliances. During the leak test,

keep your grill away from open flames or sparks.

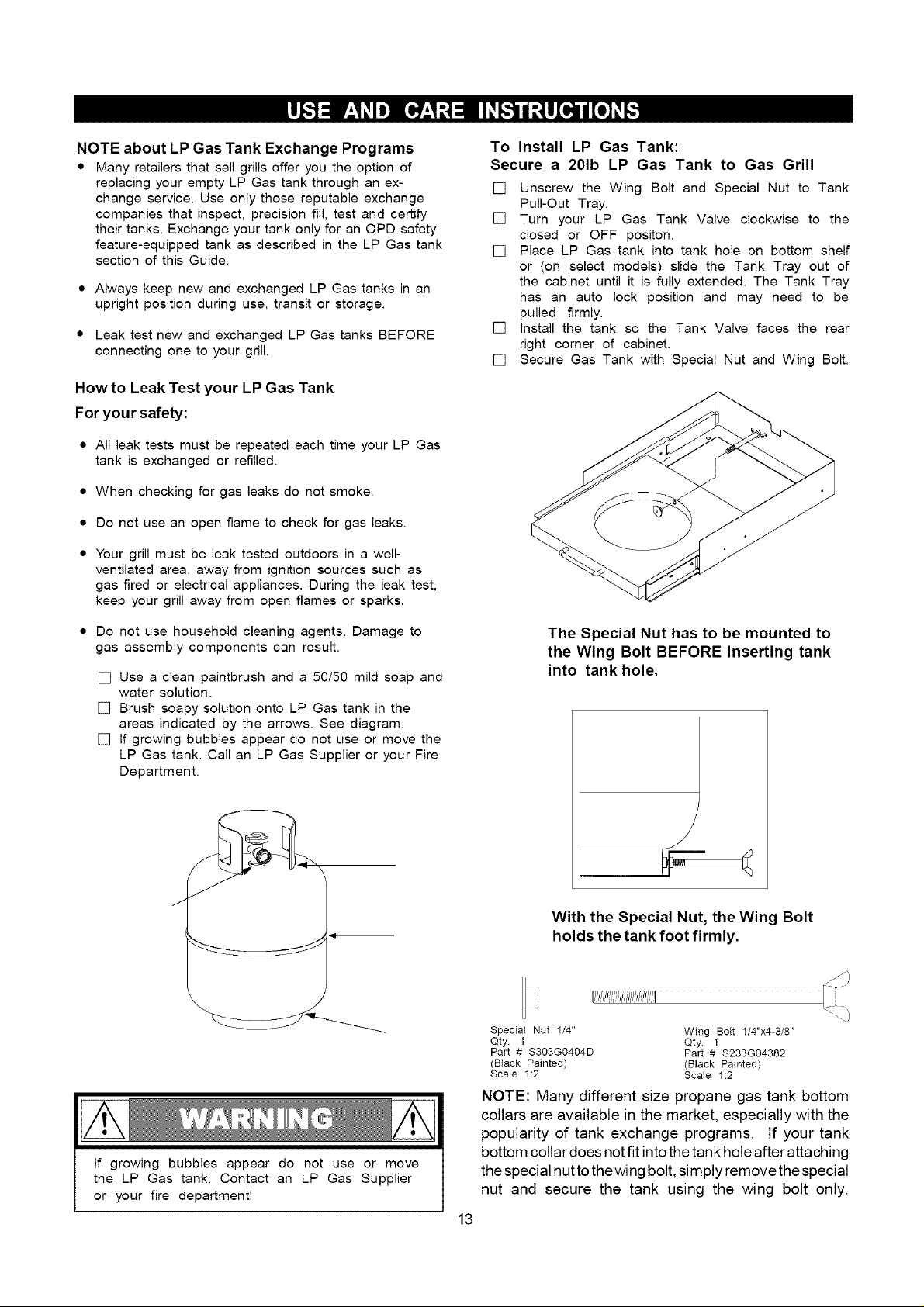

To Install LP Gas Tank:

Secure a 201b LP Gas Tank to Gas Grill

[] Unscrew the Wing Bolt and Special Nut to Tank

Pull-Out Tray.

[] Turn your LP Gas Tank Valve clockwise to the

closed or OFF positon.

[] Place LP Gas tank into tank hole on bottom shelf

or (on select models) slide the Tank Tray out of

the cabinet until it is fully extended. The Tank Tray

has an auto lock position and may need to be

pulled firmly.

[] install the tank so the Tank Valve faces the rear

right corner of cabinet.

[] Secure Gas Tank with Special Nut and Wing Bolt.

• Do not use household cleaning agents. Damage to

gas assembly components can result.

[] Use a clean paintbrush and a 50/50 mild soap and

water solution.

[] Brush soapy solution onto LP Gas tank in the

areas indicated by the arrows. See diagram.

[] If growing bubbles appear do not use or move the

LP Gas tank. Call an LP Gas Supplier or your Fire

Department.

J

If growing bubbles appear do not use or move

the LP Gas tank. Contact an LP Gas Supplier

or your fire department!

The Special Nut has to be mounted to

the Wing Bolt BEFORE inserting tank

into tank hole.

With the Special Nut, the Wing Bolt

holds the tank foot firmly.

[I/////1'/,']llJ//f//<<"l

Speciat Nut 1/4" Wing BoIt 1/4"x4-3/8"

Qty. 1 Qty. 1

Part # S303G0404D Part # $233G04382

(Btack Painted) (Black Painted)

Scale 1:2 Scale 1:2

NOTE: Many different size propane gas tank bottom

collars are available in the market, especially with the

popularity of tank exchange programs. If your tank

bottom collar does notfit into the tank hole after attaching

the special nut to thewing bolt, simply remove the special

nut and secure the tank using the wing bolt only.

13

-..)

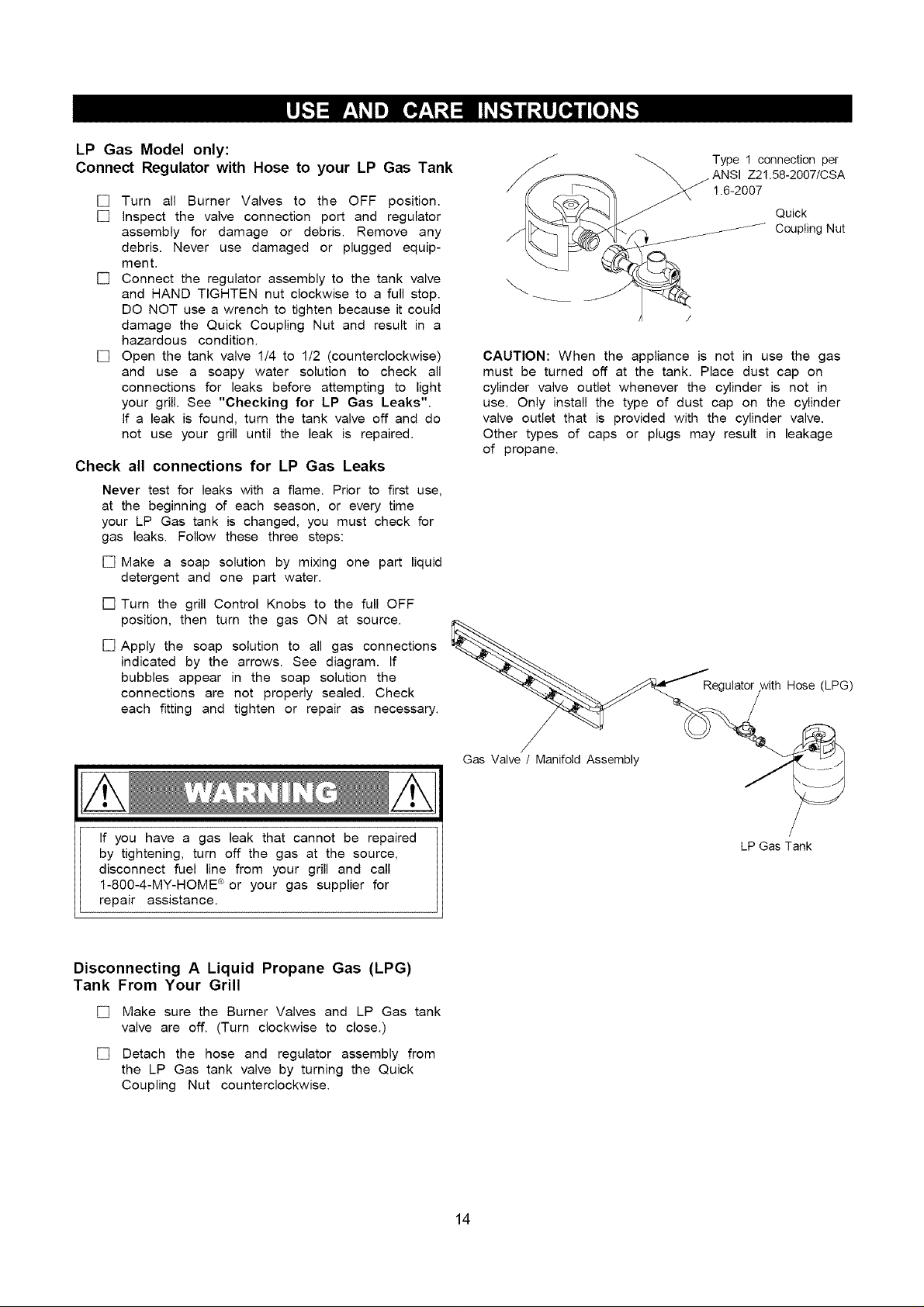

LP Gas Model only:

Connect Regulator with Hose to your LP Gas Tank

[] Turn all Burner Valves to the OFF position.

[] inspect the valve connection port and regulator

assembly for damage or debris. Remove any

debris. Never use damaged or plugged equip-

ment.

[] Connect the regulator assembly to the tank valve

and HAND TIGHTEN nut clockwise to a full stop.

DO NOT use a wrench to tighten because it could

damage the Quick Coupling Nut and result in a

hazardous condition.

[] Open the tank valve 1/4 to 1/2 (counterclockwise)

and use a soapy water solution to check all

connections for leaks before attempting to light

your grill. See "Checking for LP Gas Leaks".

If a leak is found, turn the tank valve off and do

not use your grill until the leak is repaired.

Check all connections for LP Gas Leaks

Never test for leaks with a flame. Prior to first use,

at the beginning of each season, or every time

your LP Gas tank is changed, you must check for

gas leaks. Follow these three steps:

[] Make a soap solution by mixing one part liquid

detergent and one part water.

[] Turn the grill Control Knobs to the full OFF

position, then turn the gas ON at source.

[] Apply the soap solution to all gas connections

indicated by the arrows. See diagram. If

bubbles appear in the soap solution the

connections are not properly sealed. Check

each fitting and tighten or repair as necessary.

Type 1 connection per

ANSI Z21.58-2007/CSA

1.6-2007 Quick

Couphng Nut

CAUTION: When the appliance is not in use the gas

must be turned off at the tank. Place dust cap on

cylinder valve outlet whenever the cylinder is not in

use. Only install the type of dust cap on the cylinder

valve outlet that is provided with the cylinder valve.

Other types of caps or plugs may result in leakage

of propane.

Regulator with Hose (LPG)

If you have a gas leak that cannot be repaired

by tightening, turn off the gas at the source,

disconnect fuel line from your grill and call

1-800-4-MY-HOME _ or your gas supplier for

repair assistance.

Disconnecting A Liquid Propane Gas (LPG)

Tank From Your Grill

[] Make sure the Burner Valves and LP Gas tank

valve are off. (Turn clockwise to close.)

[] Detach the hose and regulator assembly from

the LP Gas tank valve by turning the Quick

Coupling Nut counterclockwise.

Gas Valve / Manifold Assembly

LP Gas Tank

14

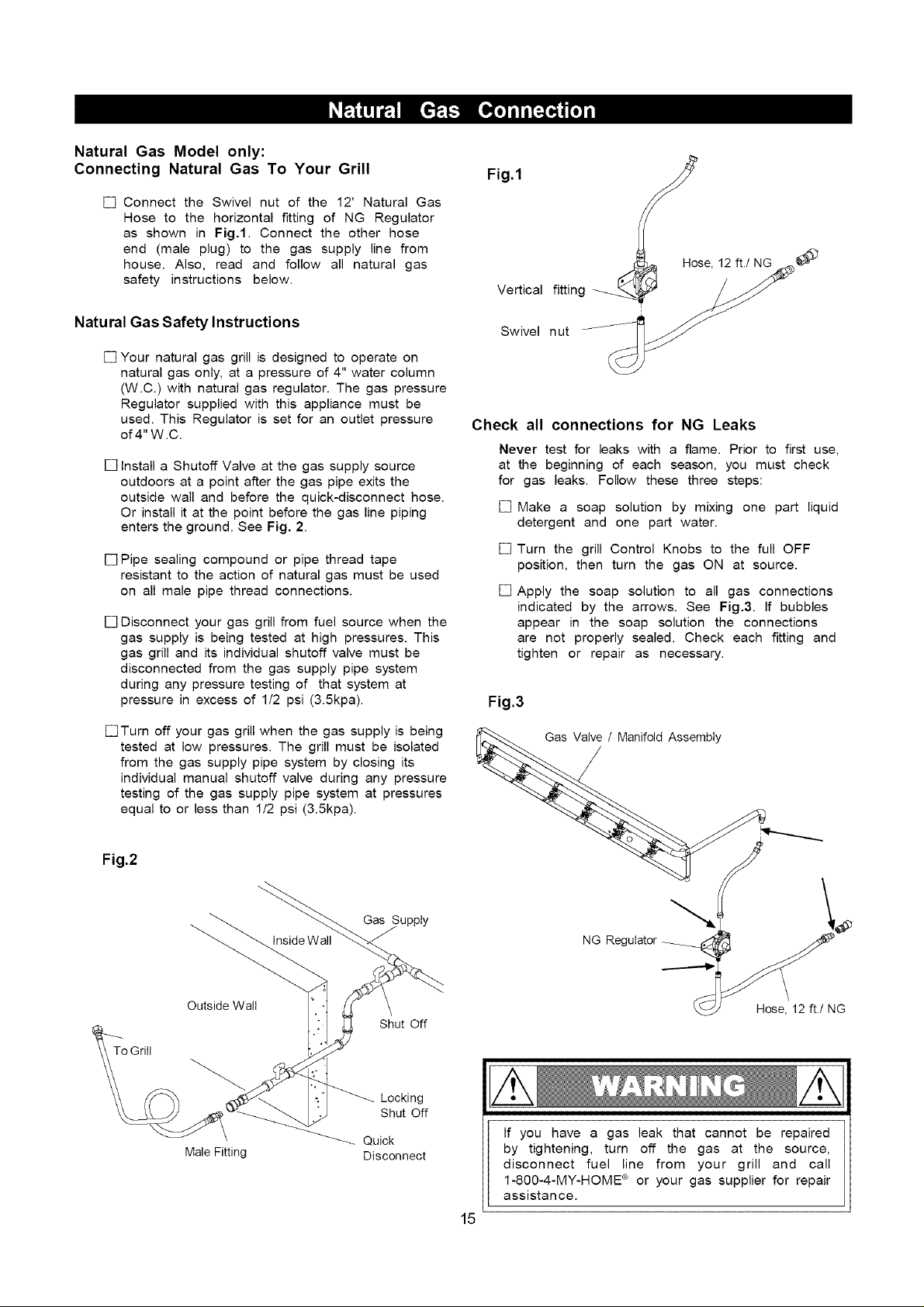

Natural Gas Model only:

Connecting Natural Gas To Your Grill

[] Connect the Swivel nut of the 12' Natural Gas

Hose to the horizontal fitting of NG Regulator

as shown in Fig.l. Connect the other hose

end (male plug) to the gas supply line from

house. Also, read and follow all natural gas

safety instructions below.

Fig.1

• ,_se, 12 ft./NG

Natural Gas Safety Instructions

[] Your natural gas grill is designed to operate on

natural gas only, at a pressure of 4" water column

(W.C.) with natural gas regulator. The gas pressure

Regulator supplied with this appliance must be

used. This Regulator is set for an outlet pressure

of 4"W.C.

[] Install a Shutoff Valve at the gas supply source

outdoors at a point after the gas pipe exits the

outside wall and before the quick-disconnect hose.

Or install it at the point before the gas line piping

enters the ground. See Fig. 2.

[] Pipe sealing compound or pipe thread tape

resistant to the action of natural gas must be used

on all male pipe thread connections.

[] Disconnect your gas grill from fuel source when the

gas supply is being tested at high pressures. This

gas grill and its individual shutoff valve must be

disconnected from the gas supply pipe system

during any pressure testing of that system at

pressure in excess of 1/2 psi (3.5kpa).

DTurn off your gas grill when the gas supply is being

tested at low pressures. The grill must be isolated

from the gas supply pipe system by closing its

individual manual shutoff valve during any pressure

testing of the gas supply pipe system at pressures

equal to or less than 1/2 psi (3.5kpa).

Swivel nut

Vertical fitting_

Check all connections for NG Leaks

Never test for leaks with a flame. Prior to first use,

at the beginning of each season, you must check

for gas leaks. Follow these three steps:

[] Make a soap solution by mixing one part liquid

detergent and one part water.

[] Turn the grill Control Knobs to the full OFF

position, then turn the gas ON at source.

[] Apply the soap solution to all gas connections

indicated by the arrows. See Fig.3. If bubbles

appear in the soap solution the connections

are not properly sealed. Check each fitting and

tighten or repair as necessary.

Fig.3

Fig.2

To Grill

Gas }uppty

Inside Wall

Outside Wall

Shut Off

Locking

Shut Off

Quick

Male Fitting Disconnect

NG Regulator _ ;

Hose, 12 ft./NG

If you have a gas leak that cannot be repaired

by tightening, turn off the gas at the source,

disconnect fuel line from your grill and call

1-800-4-MY-HOME ® or your gas supplier for repair

assistance.

15

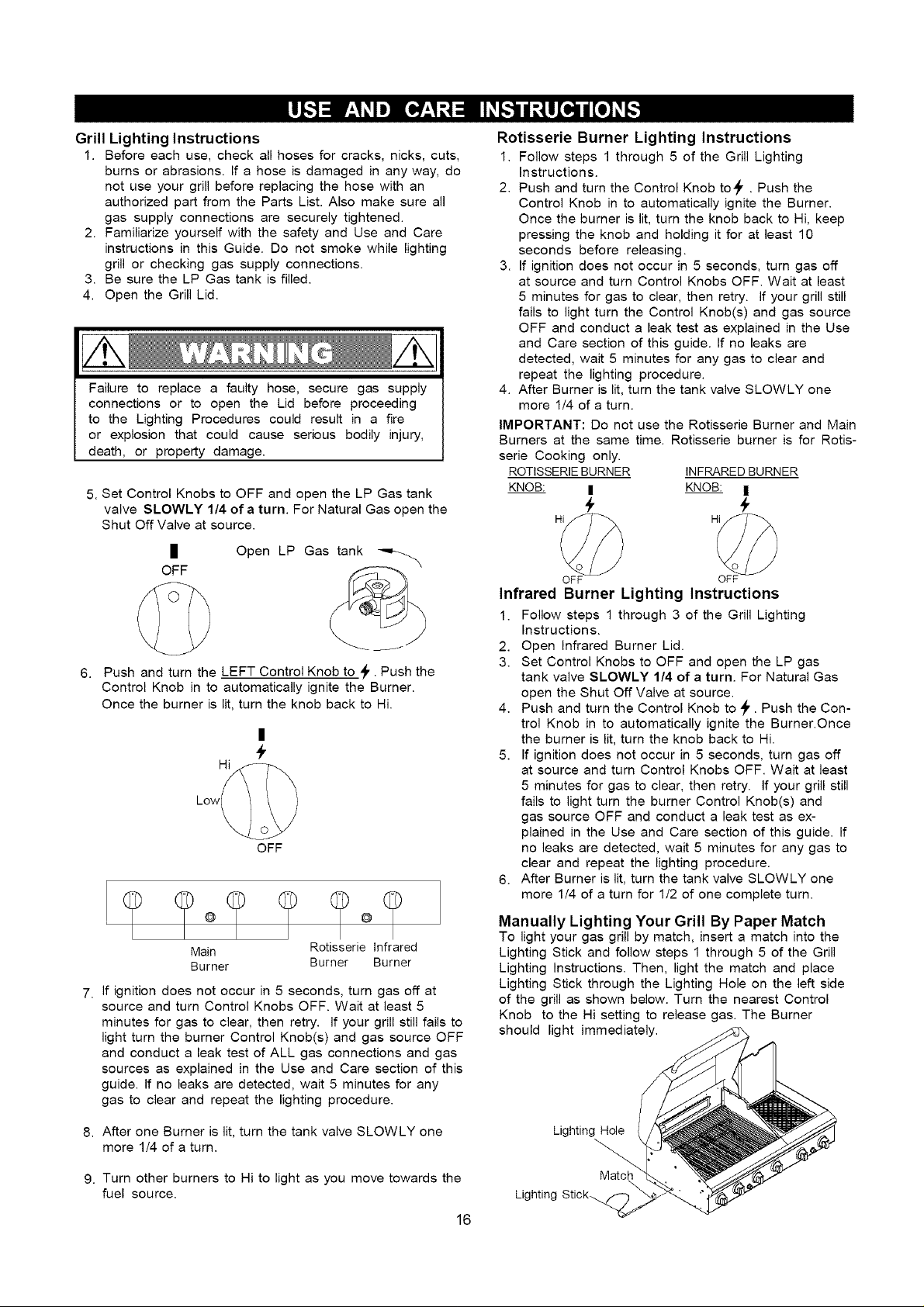

Grill Lighting Instructions

1. Before each use, check all hoses for cracks, nicks, cuts,

burns or abrasions. If a hose is damaged in any way, do

not use your grill before replacing the hose with an

authorized part from the Parts List. Also make sure all

gas supply connections are securely tightened.

2. Familiarize yourself with the safety and Use and Care

instructions in this Guide. Do not smoke while lighting

grill or checking gas supply connections.

3. Be sure the LP Gas tank is filled.

4. Open the Grill Lid.

Failure to replace a faulty hose, secure gas supply

connections or to open the Lid before proceeding

to the Lighting Procedures could result in a fire

or explosion that could cause serious bodily injury,

death, or property damage.

5. Set Control Knobs to OFF and open the LP Gas tank

valve SLOWLY 1/4 of a turn. For Natural Gas open the

Shut Off Valve at source.

Open LP Gas tank

OFF

6.

Push and turn the LEFT Control Knob to._l,. Push the

Control Knob in to automatically ignite the Burner.

Once the burner is lit, turn the knob back to Hi.

I

Low_

OFF

Rotisserie Burner Lighting Instructions

1. Follow steps 1 through 5 of the Grill Lighting

Instructions.

2. Push and turn the Control Knob to_' . Push the

Control Knob in to automatically ignite the Burner.

Once the burner is lit, turn the knob back to Hi, keep

pressing the knob and holding it for at least 10

seconds before releasing.

3. If ignition does not occur in 5 seconds, turn gas off

at source and turn Control Knobs OFF. Wait at least

5 minutes for gas to clear, then retry. If your grill still

fails to light turn the Control Knob(s) and gas source

OFF and conduct a leak test as explained in the Use

and Care section of this guide. If no leaks are

detected, wait 5 minutes for any gas to clear and

repeat the lighting procedure.

4. After Burner is lit, turn the tank valve SLOWLY one

more 1/4 of a turn.

IMPORTANT: Do not use the Rotisserie Burner and Main

Burners at the same time. Rotisserie burner is for Rotis-

serie Cooking only.

ROTISSERIE BURNER INFRARED BURNER

KNOB: I KNOB: I

÷ +

Infrared Burner Lighting Instructions

1. Follow steps 1 through 3 of the Grill Lighting

Instructions.

2. Open Infrared Burner Lid.

3. Set Control Knobs to OFF and open the LP gas

tank valve SLOWLY 1/4 of a turn. For Natural Gas

open the Shut Off Valve at source.

4. Push and turn the Control Knob to _'. Push the Con-

trol Knob in to automatically ignite the Burner.Once

the burner is lit, turn the knob back to Hi.

5. If ignition does not occur in 5 seconds, turn gas off

at source and turn Control Knobs OFF. Wait at least

5 minutes for gas to clear, then retry. If your grill still

fails to light turn the burner Control Knob(s) and

gas source OFF and conduct a leak test as ex-

plained in the Use and Care section of this guide. If

no leaks are detected, wait 5 minutes for any gas to

clear and repeat the lighting procedure.

6. After Burner is lit, turn the tank valve SLOWLY one

more 1/4 of a turn for 1/2 of one complete turn.

? t ?-t

Main Rotisserie Infrared

Burner Burner Burner

7. If ignition does not occur in 5 seconds, turn gas off at

source and turn Control Knobs OFF. Wait at least 5

minutes for gas to clear, then retry. If your grill still fails to

light turn the burner Control Knob(s) and gas source OFF

and conduct a leak test of ALL gas connections and gas

sources as explained in the Use and Care section of this

guide. If no leaks are detected, wait 5 minutes for any

gas to clear and repeat the lighting procedure.

8. After one Burner is lit, turn the tank valve SLOWLY one

more 1/4 of a turn.

9. Turn other burners to Hi to light as you move towards the

fuel source.

Manually Lighting Your Grill By Paper Match

To light your gas grill by match, insert a match into the

Lighting Stick and follow steps 1 through 5 of the Grill

Lighting Instructions. Then, light the match and place

Lighting Stick through the Lighting Hole on the left side

of the grill as shown below. Turn the nearest Control

Knob to the Hi setting to release gas. The Burner

should light immediately.

Lighting Hole

Match

Lighting

16

Troubleshooting

If the grill fails to light :

1. Turn gas off at source and turn Control Knobs to

OFF. Wait at least 5 minutes for gas to clear, then

retry.

2. if your grill still fails to light, check gas supply

and connections.

3. Repeat lighting procedure, if your grill still fails

to operate, turn the gas off at source, turn the

Control Knobs to OFF, then check the following:

[] Misalignment of Burner Tubes over Orifices

Correction: Reposition Burner Tubes over Orifices.

[]

Obstruction in gas line

Correction: Remove fuel line from grill. Do not

smoke! Open gas supply for one second to clear

any obstruction from fuel line. Close off gas supply

at source and reconnect fuel line to grill.

[]

Plugged Orifice

Correction: Remove Burners from grill by remov-

ing the screw from the rear of each Burner using a

Phillips Head Screwdriver. Carefully lift each

Burner up and away from gas valve Orifice.

Remove the Orifice from gas valve and gently clear

any obstruction with a fine wire. Then reinstall all

Orifices, Burners, Cotter Pins and cooking

components.

[]

If an obstruction is suspected in Gas Valves or

Manifold, call the Grill Information Center.

Obstruction in Burner Tubes

[]

Correction: Follow the Burner Tube cleaning

procedure on page 22 of this Use and Care

Guide.

Misalignment of ignitor on Burner

[]

Correction: Check for proper position of the

Electrode Tip as shown in step 4 page 11. The

gap between the Spark Electrode Tip and Spark

Receiver should be approximately 3/16". Adjust

if necessary. With the gas supply closed, turn any

Main Burner Control Knob to _, then push in and

watch for the presence of a spark at the Elec-

trode.

Disconnected Electric Wires

[]

Correction: Inspect the Electric Ignitor (see Parts

List) found behind the Control Panel. Connect loose

Electric wires to Junction Box and try to light the grill.

[] WeakAA battery

Correction: Unscrew the ignitor Cap and replace

the battery.

[] If the grill still does not light you may need to

purge air from the gas line or reset the

regulator excess gas flow device. Note: This

procedure should be done every time a new

LP Gas tank is connected to your grill.

To purge air from your gas line and/or reset

the regulator excess gas flow device:

[] Turn Control Knobs to the OFF position.

[] Turn off the gas at the tank valve.

For Natural Gas shut off NG valve.

[] Disconnect regulator from LP Gas tank.

For Natural Gas disconnect regulator from 12 ft.

Natural Gas Hose.

[] Let unit stand 5 minutes to allow air to purge.

[] Reconnect regulator to the LP Gas tank.

For Natural Gas reconnect regulator to 12 ft.

Natural Gas Hose.

[] Turn tank valve on SLOWLY 1/4 of a turn.

For Natural Gas open Shut Off valve.

[] Open the Grill Lid.

[] Push and turn the LEFT Main Burner Control

Knob to _'. Push the Control Knob in to

automatically ignite the Burner.

Should a FLASHBACK fire occur in or around

the Burner Tubes, follow the instructions below.

Failure to comply with these instructions could

result in a fire or explosion that could cause

serious bodily injury, death, or property damage.

• Shut off gas supply to the gas grill.

• Turn the Control Knobs to OFF position.

• Open the Grill Lid.

• Put out any flame with a Class B fire

extinguisher.

• Once the grill has cooled down, clean

the Burner Tubes and Burners according

to the cleaning instructions in this Use

and Care Guide.

Never lean over the grill cooking area while lighting

your gas grill. Keep your face and body a safe

distance (at least 18 inches) from the Lighting Hole

or Burners when lighting your grill by match.

GRILL INFORMATION CENTER

Call 8am to 8pm CST 1-888-317-7642 Monday through Friday

17

CORRECT ROTISSERIE USE

Read all instructions before initial use.

IMPORTANT: When using electrical appliances, basic

safety precautions should always be used.

The Rotisserie Motor is set for 120V, 60Hz AC current.

The Rotisserie is for outdoor use only.

Do not let children operate or play nearby your grill or

Rotisserie.

Connecting Rotisserie

Always attach the assembled Rotisserie to your grill first

and then plug the Cord into an outlet.

Operating Rotisserie

Do not operate the Rotisserie if the cord or plug be-

comes damaged, or if the Rotisserie malfunctions or

has been damaged in any manner.

The use of accessory attachments is not recommeded

by the manufacturer and may cause injuries. Do not use

this Rotisserie other than for its intended use.

Do not immerse Electrical Cord, Plug or Motor in water

or expose to rain, as this may result in an electrical

shock.

Disconnect Rotisserie

Careful as all surfaces will be hot, both grill and Rotis-

serie parts. Use protective mitts to handle the Rotis-

serie.

Unplug the Rotisserie from electrical outlet when not in

use and before cleaning. Allow to cool before adding or

removing parts.

When Roitsserie cooking place a Cooking Pan under

the food to be cooked as this will capture the drippings

and keep your grill clean of excess grease which could

cause a fire.

CAUTION: Handle with care when moving a Cooking

Pan with hot oils

Should a grease fire occur, turn the burners and gas off

and leave the grill lid Closed until the fire is out.

Store the Rotisserie indoors

When Rotisserie is not in use, store it indoors in a dry

place.

To protect against electrical shock, do not immerse

electrical cord, plugs or motor in water or expose to

rain. Protect electrical elements from burners, hot

grill surfaces and grease.

To protect against shock hazard risk, connect only

to properly Grounded Outlet.

ELECTRICAL EQUIPMENT USE

.

To protect against electric shock, do not immerse

cord or plugs in water or other liquid.

2.

Unplug from the outlet when not in use and before

cleaning. Allow to cool before putting on or taking

off parts.

3. Do not operate any outdoor cooking gas appliance

with a damaged cord, plug, or after the appliance

malfunctions or has been damaged in any manner.

Contact the manufacturer for repair.

4. Do not let the cord hang over the edge of a table or

touch hot surfaces.

5. Do not use an outdoor cooking gas appliance for

purposes other than intended.

6. When connecting, first connect plug to the outdoor

cooking gas appliance then plug appliance into the

outlet.

7. Use only a Ground Fault Interrupter (GFI)

protected circuit with this outdoor cooking gas

appliance.

.

Never remove the grounding plug or use with an

adapter of 2 prongs.

9.

Use only extension cords with a 3 prong grounding

plug, rated for the power of the equipment, and

approved for outdoor use with a W-A marking.

18

.

Remove all components from the carton.

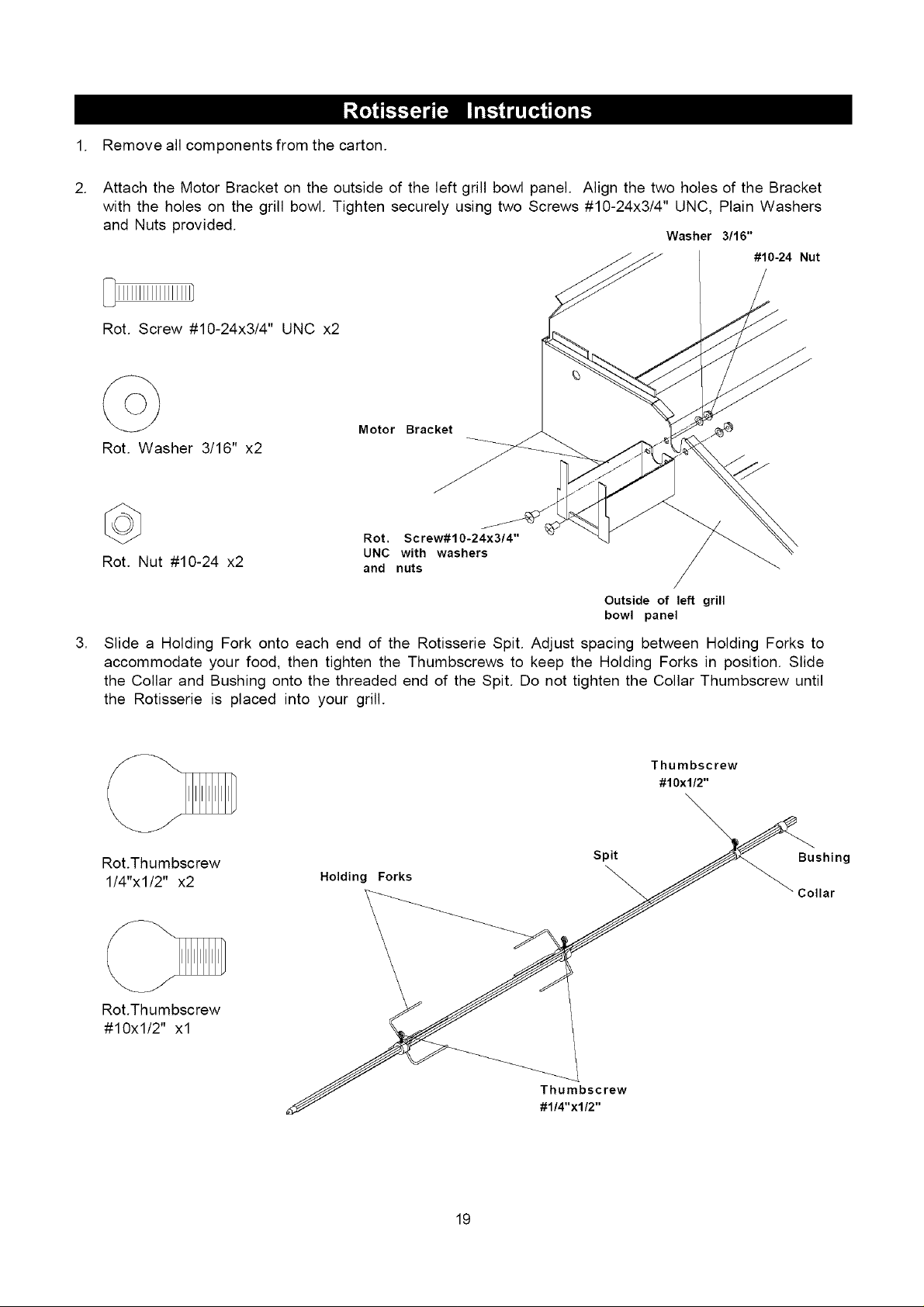

2.

Attach the Motor Bracket on the outside of the left grill bowl panel. Align the two holes of the Bracket

with the holes on the grill bowl. Tighten securely using two Screws #10-24x3/4" UNC, Plain Washers

and Nuts provided. Washer 3/16"

[ 1111111111111111111

Rot. Screw #10-24x3/4" UNC x2

#10-24 Nut

©

Motor Bracket

Rot. Washer 3/16" x2

Rot, Screw#10-24x3/4"

Rot. Nut #10-24 x2

.

Slide a Holding Fork onto each end of the Rotisserie Spit. Adjust spacing between Holding Forks to

accommodate your food, then tighten the Thumbscrews to keep the Holding Forks in position. Slide

the Collar and Bushing onto the threaded end of the Spit. Do not tighten the Collar Thumbscrew until

the Rotisserie is placed into your grill.

Rot.Thumbscrew Spit Bushing

1/4"xl/2" x2 Holding Forks

UNC with washers

and nuts

Outside of left grill

bowl panel

Thumbscrew

#10x1/2"

Collar

Rot.Thumbscrew

#10xl/2" xl

Thumbscrew

#1/4"x1/2"

19

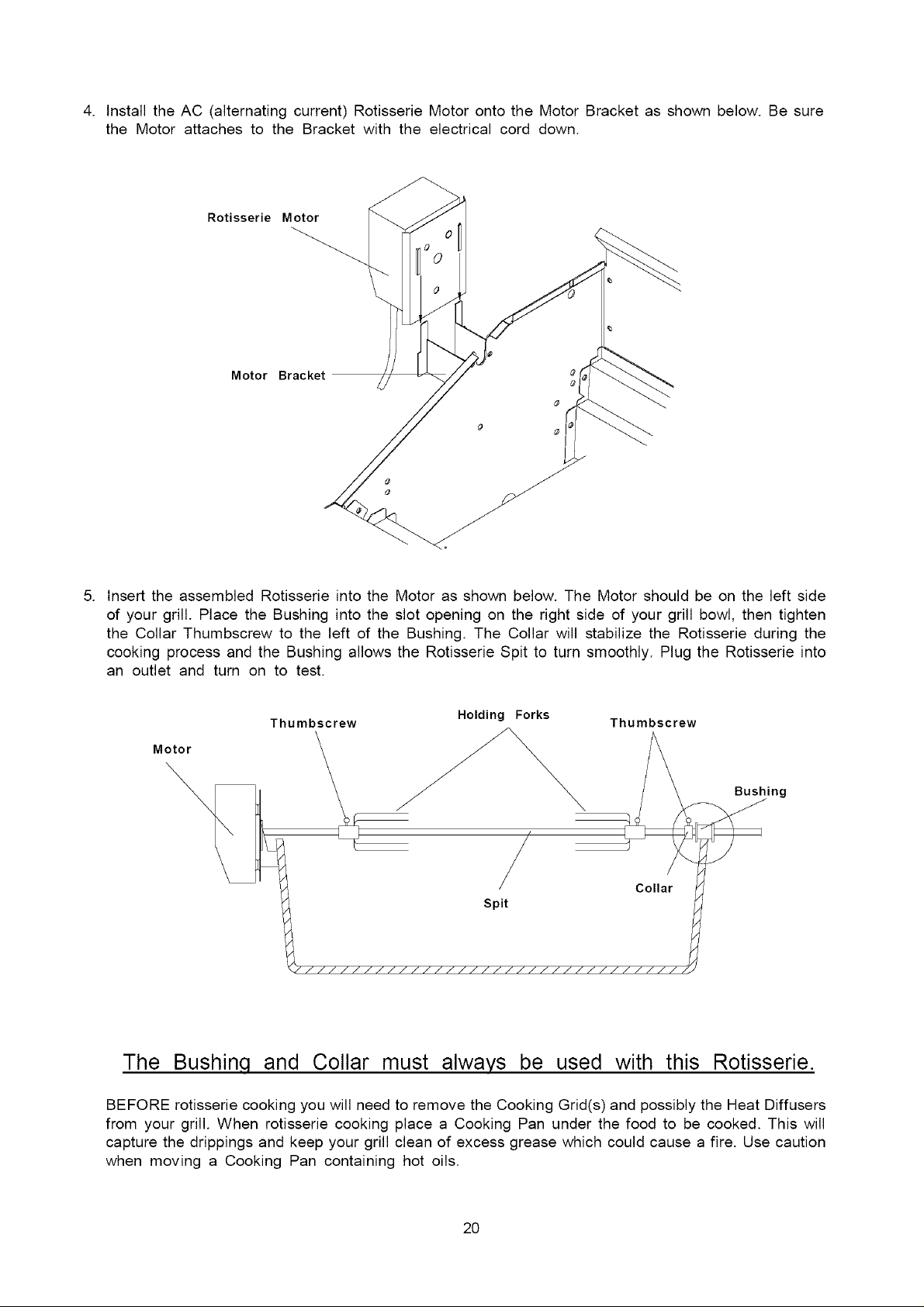

4. InstalltheAC (alternatingcurrent)RotisserieMotorontotheMotorBracketasshownbelow.Besure

the Motorattachesto the Bracketwiththe electricalcorddown.

Rotisserie Motor

Motor Bracket

. Insert the assembled Rotisserie into the Motor as shown below. The Motor should be on the left side

of your grill. Place the Bushing into the slot opening on the right side of your grill bowl, then tighten

the Collar Thumbscrew to the left of the Bushing. The Collar will stabilize the Rotisserie during the

cooking process and the Bushing allows the Rotisserie Spit to turn smoothly. Plug the Rotisserie into

an outlet and turn on to test.

Thumbscrew Holding Forks Thumbscrew

Bushing

J

Motor_ _

/

Collar

Spit

The Bushin.q and Collar must always be used with this Rotisserie.

BEFORE rotisserie cooking you will need to remove the Cooking Grid(s) and possibly the Heat Diffusers

from your grill. When rotisserie cooking place a Cooking Pan under the food to be cooked. This will

capture the drippings and keep your grill clean of excess grease which could cause a fire. Use caution

when moving a Cooking Pan containing hot oils.

2O

Proper care and maintenance will keep your grill in top

operating condition and prolong its life. Follow these

cleaning procedures on a timely basis and your grill will

stay clean and operate with minimum effort.

CAUTION: Be sure your grill is OFF and cool before cleaning.

Cleaning The Cooking Grids

[] Before initial use, and periodically, wash your

Cooking Grids in a mild soap and warm water

solution. You can use a wash cloth or vegetable

brush to clean your Cooking Grids.

Cleaning Heat diffusers

[] Periodically you should wash Heat Diffusers in a

soap and warm water solution. Use a vegetable brush

to remove stubborn burnt-on cooking residue. Dry the

Heat Diffuser thoroughly before you reinstall them

into the cooking bowl.

Cleaning The Grease Tray

[] To reduce the chance of fire, the Grease Draining

Tray should be visually inspected before each grill

use. Remove any grease and wash Grease Tray

with a mild soap and warm water solution.

Cleaning the Inside of the Grill Lid

[] Grease can have a tendency to build up on the

inside of the Grill Lid and could drip onto deck or

patio when the lid is opened. Visually inspect the

inside of the Grill Lid before each grill use. Remove

any grease and wash with a mild soap and warm

water solution.

Routine Cleaning of The Grill Interior

[] Burning-off excess food after every cookout will keep it

ready for instant use. However,at least every 3 months

you must give the entire grill a thorough cleaning to

minimize your risk of grease fire and keep the grill in

top shape. Follow these steps:

1. Turn all Burner Valves to the full OFF position.

2. Turn the LP gas tank valve to the full OFF position.

For Natural Gas shut off valve.

3. Disconnect the regulator from the gas tank. Inspect the

hose with regulator assembly for cracking, cuts or any

other damage, and replace as neccessary. Refer to the

Parts List in this Operator's Guide.

4. Remove and clean the Heat Diffuser, Cooking Grids,

5. Cooking Rack and Grill Burners.

6. Cover each Gas Valve Orifice with aluminum foil.

7. Brush the inside and bottom of the grill with a fiber pad

or nylon brush and wash with a mild soap and warm

water solution. Rinse thoroughly and let dry.

8. Remove aluminum foil from Orifices and check each

Orifice for obstruction.

9. Check each Spark Electrode, adjusting as needed. The

space between the Spark Electrode Tip and Spark

Receiver should be approximately 3/16".

10. Replace the Burners and adjust the Gas

Collector Box. The edge of the collector box should be

overlapping the Burner Port.

11. Replace Heat Diffusers and Cooking Grids.

Reconnect the gas source and observe the

Burner flame for correct operation.

Cleaning Exterior Stainless Steel Surfaces:

[] Routine care and maintenance is required to preserve

the appearance and corrosion resistance of stainless

steel. The fact is stainless steel can corrode, rust and

discolor under certain conditions. Rust is caused

when regular steel particles in the atmosphere

become attached to the stainless steel surface. Steel

particles can also become attached to your grill if you

use steel wool or stiff wire brushes to clean the grill

instead of non-abrasive cloth, sponge or nylon

cleaning tools. In coastal areas rust pits can develop

on stainless surfaces that cannot be fully removed.

Bleach and other chlorine based solutions used for

household and pool cleaning can also cause corro-

sion to stainless steel. Weathering, extreme heat,

smoke from cooking and machine oils used in the

manufacturing process of stainless steel can cause

stainless steel to turn tan in color. Although there are

many factors which can affect the surface appearance

of stainless steel, they do not affect the integrity of the

steel or the performance of the grill.

[] To help maintain the finish of stainless steel follow

these cleaning procedures for the best results:

1. After every use (after your grill has cooled down), wipe

stainless surfaces with a soft, soapy cloth or sponge

then rinse with water. Be sure to remove all food

particles, sauces or marinades from stainless steel

because these can be highly acidic and damaging to

stainless surfaces.

2. Never use abrasive cleaners, scrubbers or stiff wire

brushes of any type on your grill.

3. Use a heat resistant Stainless Steel Cleaner and rub

or wipe in the direction of the stainless steel grain or

polish lines NOT against the grain.

Failure to comply with these instructions could

result in a fire or explosion that could cause

serious bodilyinjury, death or propertydamage.

Keep grill area clear and free from combustible

materials, gasoline and other flammable vapors

and liquids.

Do not obstruct the flow of air for combustion

and ventilation.

Keep the ventilation openings of the tank enclosure

cabinet free and clear of debris.

Visually check burner flames occasionally to

ensure proper flame pattern as shown below.

Cleaning Exterior painted Surfaces:

Before initial use, and periodically thereafter, we

suggest you wash your grill using a mild soap and

warm water solution. You can use a wash cloth or

sponge for this process. Do not use a stiff wire or

brass brush. These will scratch stainless steel and

chip painted surfaces (varies by model) during the

cleaning process.

THROUGH

HOLE

21

ToreducethechanceofFLASHBACKFIRE you must

clean the Burner Tubes as follows at least once a month

in summer and fall or whenever spiders are active in your

area, and if your grill has not been used for an extended

period of time.

1. Turn all Burner Valves to the full OFF position.

2. Turn the LP Gas tank valve to the full OFF position.

For Natural Gas shut off NG valve.

3. Detach the LP Gas regulator assembly from your

gas grill. For Natural Gas detach NG regulator from

your grill.

4. Remove the Cooking Grids and Heat Diffuser from

your grill.

5. Remove the screws from the rear of each Burner

using a Phillips Head Screwdriver.

6. Carefully lift each Burner up and away from the

Gas Valve Orifice.

7. Check and clean burner/venturi tubes for insect

and insect nests. A clogged tube can lead to a fire

beneath the grill.

8. Refer to Figure I and perform one of these

three cleaning methods:

[] METHOD 1: Bend a stiff wire or wire coat

hanger into a small hook as shown and

run the hook through the Burner Tube and

inside the Burner several times to remove

debris.

,1

Regardless of which Burner cleaning procedure you

use, we recommend you also complete the following

steps to help prolong Burner life.

1. Use a fiber pad or nylon brush to clean the entire

outer surface of each Burner until free of food

residue and dirt.

2. Clean any clogged ports with a stiff wire, such as

an open paper clip.

.

Inspect each Burner for damage (cracks or

holes) and if such damage is found, order and

install a new Burner. After installation, check

to ensure that the Gas Valve Orifices are

correctly placed inside the ends of the Burner

Tubes. Also check the position of your Spark

Electrode.

For safe operation ensure the Gas Valve

Assembly Orifice is inside the Burner Tube

before using your grill. See figure. If the Orifice

is not inside the Burner Tube, lighting the

Burner may cause explosion and/or fire result-

ing in serious bodily injury and/or property

damage.

Tube Burner

[] METHOD 2: Use a bottle brush with a

flexible handle and run the brush through

the Burner Tube and inside the Burner

several times to remove any debris.

[] METHOD 3: Use an air hose to force air

through each Burner Tube. The forced air

should pass debris or obstructions through

the Burner and out the Ports.

Figure 1

TO CLEAN BURNER TUBE,

INSERT HOOK AS INDICATED BY THE ARROW

Gas Valve Assembly Orifice BurnerTube

22

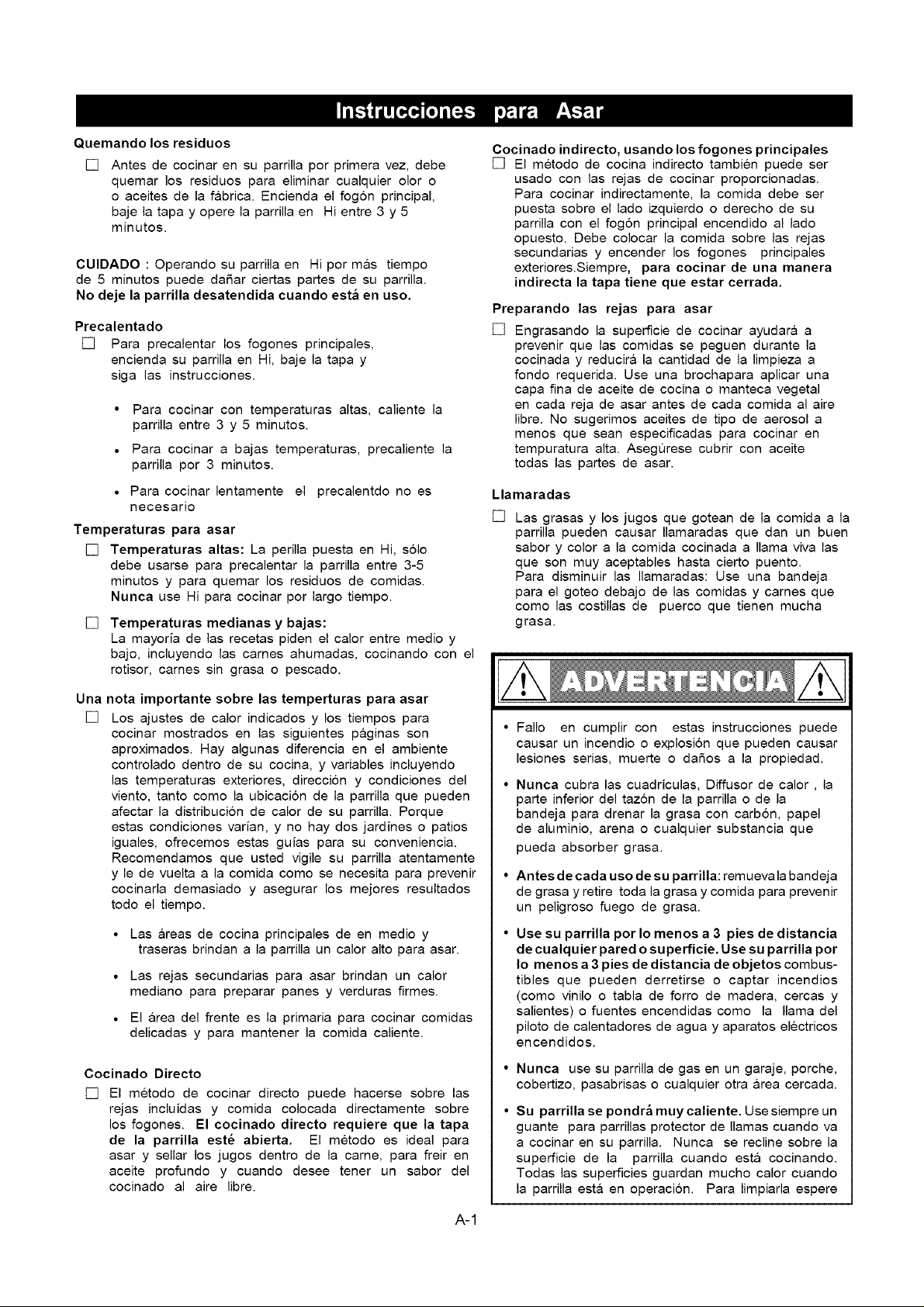

Burn-Off

[] Before cooking on your gas grill for the first time, you

should "burn off" the grill to eliminate any odor or

foreign matter. Ignite the burners, lower the Lid, and

operate grill on Hi setting for 3 to 5 minutes.

CAUTION: Operating ALL main burners on Hi

setting for longer than five minutes may damage

certain parts of your grill. Do not leave your grill

unattended when in use.

Preheating

[] To preheat, light your grill on Hi, lower the Lid

and follow this timetable:

• For high temperature cooking, preheat grill 3 to 5

minutes.

• For low temperature cooking, preheat grill 3 minutes.

• To slow cook, preheating is not necessary.

Cooking Temperatures

[] High setting: The Hi Control Knob setting should

only be used to pre-heat your grill the first 3-5 minutes

and for burning food residue off the grill for 3-5 minutes

after cooking is complete.

CAUTION: Operating ALL main burners on Hi setting for

longer than five minutes may damage certain parts of

your grill. Do not leave your grill unattended when in

use.

Indirect Cooking

[] The indirect cooking method can also be used with

the supplied Cooking Grids. To cook indirectly, the

food should be placed on the left or right side of your

grill with the Burner lit on the opposite side. Or place

your food on the Secondary Cooking Rack and light

the outer grill Burners. Either way, indirect cooking

must be done with the Lid down.

Prepare Cooking Grids for Grilling

[] Greasing the cooking surface will help keep foods

from sticking during the cookout and reduces the

amount of cleanup required. Use a brush to apply a

thin layer of cooking oil or vegetable shortening onto

each Cooking Grid before each cookout. We do not

suggest spray type oils unless they are specified for

high-temperature cooking. Be sure to coat the entire

cooking surface including edges and any areas with

chipped porcelain.

Flare-Ups

[] The fats and juices dripping from grilled food can

cause flare-ups. Since flare-ups impart a favorably,

distinctive taste and color to food cooked over an

open flame, they should be accepted up to a point.

To minimize flare-ups use a drip pan under foods

that produce a lot of grease, like ribs.

[] Medium to Low Settings: Most recipes specify

medium to low settings, including all smoking,

rotisserie cooking and cooking lean cuts such as fish.

An Important Note About Cooking Temperatures

[] The suggested heat settings and cooking times

shown in the following pages are approximate.

Unlike the controlled environment inside your kitchen,

variables including outside temperatures, direction

and conditions of wind, as well as grill location will

affect your grill's heat distribution. Because these

condition vary, and no two backyards are alike, we

offer this guide as a convenience. We recommend

you monitor your grill closely and rotate foods as

needed to prevent overcooking and ensure the most

delicious results every time.

• The middle and back primary cooking areas offer the

highest heat for searing and grilling.

• The Secondary Cooking Rack offers medium heat for

preparing breads and firm vegetables like potatoes

and corn.

• The front primary cooking area offers less heat and is

ideal for preparing delicate foods and for keeping

cooked foods warm.

DirectCooking

[] The direct cooking method can be used with the

supplied Cooking Grids and food placed directly over

the lit grill Burners. Direct Cooking requires the Grill

Lid to be open. This method is ideal for searing,

grilling, deep frying and whenever you want foods to

have an open-flame barbecued taste.

Failure to comply with these instructions could

result in a fire or explosion that could cause

serious bodily injury, death or property damage.

Never cover the cooking grids, Heat Diffusers,

bottom of grill bowl or Grease Draining Tray with

charcoal, aluminum foil, sand or any substance that

can absorb grease.

Before each use of your grill: Pull out the Grease

Tray and remove all grease and food debris to

prevent grease fire hazard.

Use your grill at least 3 feet away from any

wall or surface. Use your grill at least 3 feet

away from combustible objects that can melt or

catch fire (such as vinyl or wood siding, fences

and overhangs) or sources of ignition including

pilot lights on water heaters and live electrical

appliances.

Never use your gas grill in a garage, porch, shed,

breezeway or any other enclosed area.

Your grill will get very hot. Always wear a flame

retardant BBQ Mitt when cooking on your grill.

Never lean over cooking areas while using grill.

Do not touch cooking surfaces, Lid, grill housing

or other parts while grill is in operation, or until

the grill has cooled down after use.

A-1

Grilling Steak and Ribs

Turn the grill Burners on Hi, close the Lid and preheat

your grill 3 to 5 minutes. Open Lid and place the meat on

the Cooking Grid directly above the lit Burners. Cook the

meat on both sides until seared. Reduce the heat to

MEDIUM and cook meat until done. Grilling times will vary

according to meat thickness.

Grilling Hamburgers and Sausages

Turn the grill Burners on Hi, close Lid and preheat your

grill 3 to 5 minutes. Open Lid and place the meat on the

Cooking Grid directly above the lit Burners. Cook the meat

on both sides until seared. Reduce the heat to MEDIUM

and cook the meat until done. Grilling times will vary

according to meat thickness.

Grilling Poultry

Turn the grill Burners on Hi, close Lid and preheat your

grill 2 to 3 minutes. Then raise the Lid, reduce heat to

MEDIUM and cook poultry directly over lit Burners until

done. Poultry skin is fatty so you should expect some

flare-ups when using this direct method.

To minimize flare-ups, try grilling poultry using the indirect

method. Place the poultry on one side of the grill with the

opposing Burners on MEDIUM heat, and lower the grill

Lid. Grilling times will vary based on the size of your

poultry.

Cut of Meat

T-bone steak

Sirloin steak

Beef spare ribs

Porterhouse steak

New York strip steak

Hamburgers

Sausages

Chicken breast

(cook with bone down)

Chicken wings

Drumsticks

Whole bird

(cook with breast up)

Approximate Cooking Times

a_e: 4-8 minutes

Medium: 10-14 minutes

Well done: 15-20 minutes

Rare: 4-6 minutes

Medium: 8-10 minutes

Well done: 10-15 minutes

Direct method:

approximately 15 minutes

indirect method:

up to 30 minutes

indirect method:

approximately 1 hour

Grilling Pork

Turn Burners on Hi, and preheat your grill 3 to 5 minutes

with the Lid closed. Raise Lid, place pork on Cooking Grid

and cook until seared. Reduce heat to MEDIUM and cook

until done. Grilling times will vary according to meat

thickness.

Whole Fish and Whole Fillets

Preheat your grill on Hi for 2-3 minutes with the Lid down.

Raise lid and turn Burners to MEDIUM heat. Place fish

(skin down) on grill and cook over direct heat until done.

Use cooking time as a guide or until fish is opaque but

still moist.

Smaller Fish Fillets and Cubes

Follow the directions from above, using approximate

cooking times shown at right. Place a small piece of

aluminum foil on the Cooking Grids if the fish pieces are

small enough to drop between the Cooking Grids.

Vegetables and Fruit

Prepare your fruit or vegetables and brush with butter or

basting sauce if desired. To cook indirectly, the food

should be placed on the left or right side of your grill with

the Burner lit on the opposite side and the grill lid down.

Or center your food on the Secondary Cooking Rack and

light the outer grill Burners. Either way, indirect cooking

must be done with the Lid down.

In some instances, you may want to grill vegetables and

fruit directly over the heat, using the supplied Cooking

Grids. Foods that work best with direct heat are relatively

soft and require a short cooking time: mushrooms,

zucchini, tomatoes and skewered fruit such as apricots,

peaches, pineapple, strawberries and kiwis. Remember

the Grill Lid must remain up when cooking directly.

Chops

Loins

Medium: 10-14 minutes

Well done: 15-20 minutes

Cutlets

Whole fish

Whole fish fillets

Fish fillets

Boneless cubes

For very firm vegetables--particularly potatoes and yams,

we recommend that you partially boil until almost cooked,

before placing them on the grill. Cooking times using the

indirect method with the lid down will be similar to those

for your kitchen oven. However, there are many factors

such as outside temperature, wind conditions and

location of grill that affect your grill performance so we

suggest you watch the temperature gauge and adjust the

heat accordingly.

Cooking times for foods prepared with the direct method

will be much shorter mainly because of the direct heat

source and softness of the food. Timing will be compa-

rable to normal pan frying or grilling.

10 - 12 minutes per pound or

until fish is opaque

4 - 5 minutes each side

or until fish is opaque

A-2

important notes about using the infrared Burner

Whether you are a seasoned chef or a newcomer to gas

grilling, infrared cooking is quite different than grilling over

a traditional burner. Although the primary grill burners will

also sear meat, the Infrared Burner produces a more

intense and concentrated heat that sears the meat more

quickly. This quick searing produces a crisp and flavorful

outer crust and locks in the meat's natural flavor and

juices.

Follow the cooking guidelines provided. Then take some

time to experiment with your Infrared cooking zone. Also,

read the Cooking instructions on page A-1 so you

understand the importance of pre-heating, cooking

temperatures and safety warnings.

• The Lid must always be open when the Infrared

Burner is lit.

• Infrared cooking times will be much shorter than

traditional grilling so do not leave the grill unattended.

Once lit, leave the infrared Burner on High and sear

both sides of meat using the guidelines below.

Once seared, adjust the Infrared Burner to Low and

continue cooking until desired doneness. You can

also move the seared meat to the primary grilling area

to finish cooking. This method allows you to sear and

prepare larger amounts of meat.

NEVER attempt to douse a flare-up with water which

can damage the Burner. To control flare-ups:

• Trim excess fat from meats and poultry.

• Preheat the Burner properly.

• Clean the Burner regularly to remove food and

grease build-up. See Burner Tube cleaning

instructions in this manual.

• Reposition your food often and consider moving the

seared meat to the primary grilling area to finish

cooking.

Searing Steak and Ribs

Turn the Infrared Burner on Hi and preheat for 3 to 5

minutes with the Lid open. Then place the meat on the

Cooking Grid and sear each side for approximately 2

minutes. Reduce the Infrared Burner to LOW or move

meat to the primary grilling area and finish cooking.

Grilling times will vary according to meat thickness.

Searing Hamburgers and Sausages

Turn the Infrared Burner on Hi and preheat for 3 to 5

minutes with the Lid open. Then place the meat on the

Cooking Grid and sear each side for approximately 2

minutes. Reduce the infrared Burner to LOW or move food

to the primary grilling area and finish cooking. Grilling

times will vary according to meat thickness.

Hamburgers and sausages are fatty so you should expect

some flare-ups when cooking these foods.

To minimize flare-ups follow the instructions on page A-1.

You may also consider grilling these and other fatty foods

using the primary grill area and the indirect cooking

method.

Cut of Meat

T-bone steak

Sirloin steak

Beef spare ribs

Porterhouse steak

New York strip steak

Hamburgers

Sausages

Approximate Total Cooking

Time

Rare: 4 minutes

Medium: 6-7 minutes

Well done: 8-10 minutes

Rare: 4 minutes

Medium: 5 minutes

Well done: 6-7 minutes

A-3

An Important Note About Heat Settings

The suggested heat settings shown are approximate.

There are many factors such as outside temperature,

wind conditions and grill location that affect your grill

performance. We offer these cooking times as a conve-

nience, but suggest you watch the temperature gauge and

adjust the heat accordingly.

Preparing to Roast

Roasting uses the indirect cooking method. Therefore, the

food should be placed on the left or right side of your grill

with the Burner lit on the opposite side. You can also use

the supplied Cooking Grid with an aluminum drip pan

underneath allowing you to collect juices for making

gravies. Remember, indirect cooking requires the Lid of

your grill to be down.

Preheating your grill is not required for slow cooking

methods such as roasting. If you do choose to preheat your

grill before roasting, turn the Burners on Hi and close Lid for

approximately 2-3 minutes.

Type of Food HowCooked Approximate Cooking Times

Beef Rare 18 minutes per pound

Food preparation

Trim meat of excess fat. Truss meat and poultry with

cooking string to retain shape if desired. Bacon strips can

be used to cover the outside surface of lean meat and

poultry to help prevent it from drying out. Another method

for keeping food moist during roasting is to put water in a

cooking pan, then cover with foil. The foil should be

removed for the first or the last part of the cooking time to

ensure proper browning.

Tips for roasting

Except when roasting with water in a roasting pan, the

juices that collect in the pan can be used as the base for a

tasty sauce or gravy. Place a cooking pan directly over the

heat, add extra butter if needed, then add several spoon-

fuls of flour to thicken sauce. Finally, add sufficient chicken

or beef stock to obtain the desired consistency.

Once the meat is cooked, remove it from your grill and

cover with a piece of foil. Allow it to stand for 10-15

minutes which allows the juices to settle. This will make

carving easier and ensure a tender, juicy roast.

Medium 23 minutes per pound

Well done 27 minutes per pound

Lamb Medium 18 minutes per pound

Well done 23 minutes per pound

Veal 27 minutes per pound

Pork 30-33 minutes per pound

Chicken 20-25 minutes per pound

Duck 25 minutes per pound

Fish 10 minutes per pound

Turkey, under 16 pounds 20-25 per pound + 30 minutes

Turkey, over 16 pounds 18-23 per pound + 15 minutes

BAKING TECHNIQUES

From casseroles and combread to delicious desserts like

fondue fruit skewers or crumb cake, baking on the grill is as

easy as baking in the kitchen.

Preparing to Bake

To bake in your new grill you'll need a baking dish or cast-

iron cooking pan, and a pair of flame retardant BBQ Mitts. If

the cooking pan is cast-iron be sure to season the pan

before use.

Preheat your grill 3-5 minutes, then lower heat to achieve

the baking temperature desired. Baking uses the indirect

cooking method. Therefore, your cooking pan should be

Oven Temperature

Slow 300 ° - 340 ° F

Moderate 355 ° - 390 ° F

High 410 ° - 480 ° F

placed on the left or right side of your grill with the burner lit

on the opposite side.

Tips for Baking

Prepare your favorite recipe as you would in the kitchen.

Foods cooked in the grill for long periods of time should

always be covered in aluminum foil to retain moisture. You

will need to stir the food several times as it bakes, and add

additional liquid if required.

Watch the temperature, and adjust to cook according to

your recipe directions.

Recommended Grill Setting

Both outside Burners on LOW

1 outside Burner on Hi and 1 outside Burner on LOW

Both outside Burners on Hi

A-4

Slow Cooking with a Rotisserie

A Rotisserie Kit is made to fit your grill model. Rotis-

serie cooking produces foods that are moist, flavorful

and attractive. The optional rotisserie system is most

commonly used for cooking meat or poultry and is

designed to cook food slowly. You can place a cooking

pan beneath the food to collect juices for basting and

gravy. To flavor the contents of the cooking pan you

may add herbs, onions, or other spices of your choice.

The cooking times on a rotisserie will be approximately