Kenmore 9113651190 Owner’s Manual

SEARS

Kenmore OWNER'S MANUAL

GAS SLIDE-IN RANGE

models 36511, 36519

MNM127(346435)-2

CONTENTS

NOTICES

................................................................................................... 2

INSTALLATION

................................................................................ 3-10

USEAND CARE

Important Instructions for Your Safety ........................................................................... 11. 12

Your Range and Its Features ....................................................................................... 13

Burner Ignition ............................................................................................................... 15

Oven Vent ...................................................................................................................... 15

Electronic Range Control ................................................................................................. 14

Oven Cooking ............................................................................................. 16, 17

Broiling ......................................................................................................... 18

The Self-Glean cycle ..................................................................................... 19, 20

Cleaning Tips .............................................................................. 21, 22

Removable Range Parts ............................................ 23, 24

SERVICE

Replacing Oven Light Bulb (some models) ................................................. 22

What to Do before Calring for Service ................................................ 25, 26

Adjusting Oven Temperature .................................................. 26

REPAIR PARTS LIST

How Io Order ........................................ 27

WARRANTY

GCO064

f

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

\

f

f

,_ FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

.J

_,_ L.P. Burner

Adjustments

The adjustments in the Instal-

lation Section must be made

before you trytouseyour range.

If you are using Llquified Pe-

troleum Gas (bottled gas) all

L.P adjustments in the Instal-

lation Section must be made

before use.

If your oven is not properly ad-

justed, flames may be too high,

orthe oven may use foe much

fuel, release toxic fumes or cook

poorly.

To insure safety for

yourself and your

home, please read

your Owner's Manual

carefully. Keep it

handy for quick, easy

reference.

Pay close attention to

the safety sections of

your manual. You can

recognize the safety

sections by looking for

the _, symbol or the

word "Safety".

f

,_ WARNING:

Improper Installation,

alteration, service or

maintenance can cause

Injury or properly dam-

age. Refer to this man-

ual. For assistance or

additional information

consult a qualified In-

staller, service agency,

manufacturer (dealer)

or the gas supplier.

J

J

2 GNOT16-1

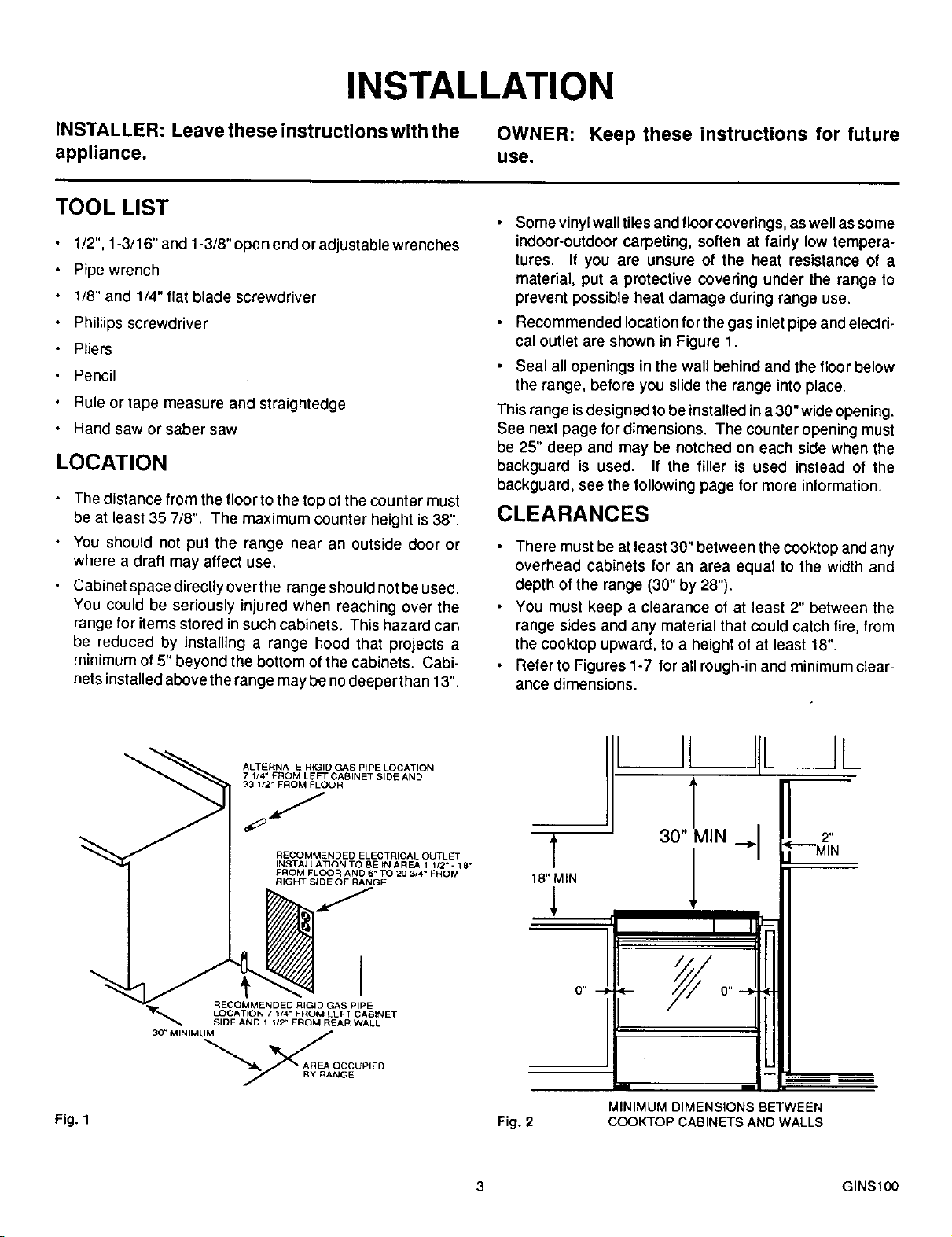

INSTALLATION

INSTALLER: Leavetheseinstructionswiththe OWNER: Keep these instructions for future

appliance, use.

TOOL LIST

Some vinylwall tiles and floorcoverings, as well as some

1/2", 1-3/16" and 1-3/8" open end or adjustable wrenches

Pipe wrench

1/8" and 1/4" flat blade screwdriver

Phillips screwdriver

Pliers

Pencil

Rule or tape measure and straightedge

Hand saw or saber saw

LOCATION

• Thedistance from the floor to the top of the counter must

be at least 35 7/8". The maximum counter height is 38".

• You should not put the range near an outside door or

where a draft may affect use.

Cabinet space directly over the range should not be used.

You could be seriously injured when reaching over the

range for items stored in such cabinets. This hazard can

be reduced by installing a range hood that projects a

minimum of 5" beyond the bottom of the cabinets. Cabi-

nets installed above the range may be no deeper than 13".

indoor-outdoor carpeting, soften at fairly low tempera-

tures. If you are unsure of the heat resistance of a

material, put a protective covering under the range to

prevent possible heat damage during range use.

Recommended location for the gas inlet pipe and electri-

cal outlet are shown in Figure 1.

• Seal all openings in the wall behind and the floor below

the range, before you slide the range into place.

This range is designedto be installed in a30"wide opening.

See next page for dimensions. The counter opening must

be 25" deep and may be notched on each side when the

backguard is used. If the filler is used instead of the

backguard, see the following page for more information.

CLEARANCES

There must be at least 30" between the cooktop and any

overhead cabinets for an area equal to the width and

depth of the range (30" by 28").

You must keep a clearance of at least 2" between the

range sides and any material that could catch fire, from

the cooktop upward, to a height of at least 18".

Refer to Figures 1-7 for all rough-in and minimum clear-

ance dimensions.

Fig 1

ALTERNATE R_GID GAS PiPE LOCATION

7 1/4" FROM LEFT CABINET SIDE AND

33 1/2" FROM FLOOR

RECOMMENDED ELECTRICAL OUTLET

INSTALLATION TO BE IN AREA 1 1/2" - 18"

FROM FLOOR AND 6" TO 20 3/4" FROM

RIGHT S/DE OF RANGE

J

I

RECOMMENDED RIGID GAS PIPE

LOCATION 7 1/4" FROM LEFT CABINET

SIDE AND 1 I/2" FROM REAR WALL

oc .uo, o

J BY RANGE

MINIMUM DIMENSIONS BETWEEN

Fig. 2

3 GINS100

COOK'FOP CABINETS AND WALLS

PREPARING THE COUNTER

Ifyou have an existing 30" wide cutout that goes all the way

to the wall you may want to buy a Main Top Filler Kit No,

80279 or a 4" Backguard Kit No. 80509. These will fill in the

space between the back of the range and the wall. The kits

are available from Sears general catalog and may be or-

dered at any Sears catalog outlet or the catalog desk at any

Sears Retail Store. If this existing cutout is in a counter that

has a backsplash (postformed top) we recommend that you

use the 4'* Backguard.

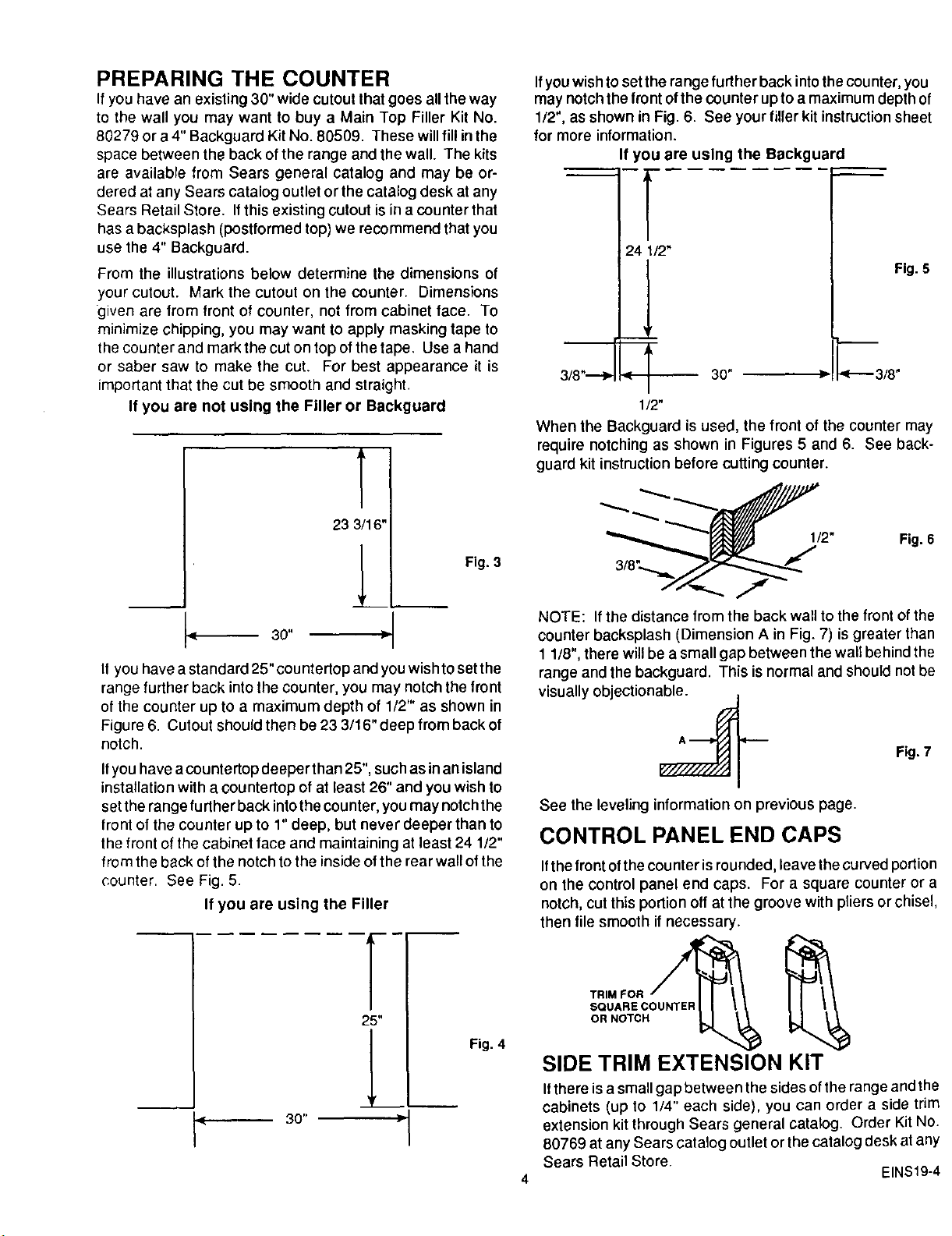

From the illustrations below determine the dimensions of

your cutout. Mark the cutout on the counter. Dimensions

given are from front of counter, not from cabinet face. To

minimize chipping, you may want to apply masking tape to

the counter and mark the cut on top of the tape. Use a hand

or saber saw to make the cut. For best appearance it is

important that the cut be smooth and straight.

If you are not using the Filler or Backguard

23 3/16"

Fig. 3

Ifyou wishto set the range further back into the counter, you

may notch the front of the counter up to a maximum depth of

1/2", as shown in Fig. 6. See your filler kit instructionsheet

for more information.

you are using the Beckguard

---I

24 1/2"

Fig.5

,1

3/8"----> _ _ 30" • 1----3/8"

When the Backguard is used, the front of the counter may

require notching as shown in Figures 5 and 6. See back-

guard kit instruction before cuffing counter.

/

1/2"

1/2" Fig. 6

If you have a standard 25" countertop and you wish to set the

range further back into the counter, you may notch the front

of the counter up to a maximum depth of 1/2'" as shown in

Figure 6. Cutout should then be 23 3/16" deep from back of

notch.

Ifyou have a countertop deeper than 25", such as in an island

installation with a countertop of at least 26" and you wish to

set the range further back into the counter, you may notch the

front of the counter up to 1" deep, but never deeper than to

the front of the cabinet face and maintaining at least 24 1/2"

from the back of the notch to the inside of the rear wall of the

counter. See Fig. 5.

If you are using the Filler

.[

25"

Fig. 4

l

30" _'

NOTE: If the distance from the back wall to the front of the

counter backsplash (Dimension A in Fig. 7) is greater than

1 1/8", there will be a small gap between the wall behind the

range and the backguard. This is normal and should not be

visually objectionable.

Fig. 7

See the leveling information on previous page.

CONTROL PANEL END CAPS

Ifthe frontof the counter is rounded, leave thecurved portion

on the control panel end caps. For a square counter or a

notch, cut this portion off at the groove with pliers or chisel,

then file smooth if necessary.

TRIM f

SQUARE COUNTER

OR NOTCH

SIDE TRIM EXTENSION KIT

If there is a small gap between the sides of the range and the

cabinets (up to 1/4" each side), you can order a side trim

extension kit through Sears general catalog. Order Kit No.

80769 at any Sears catalog outlet or the catalog desk at any

Sears Retail Store.

EINS19-4

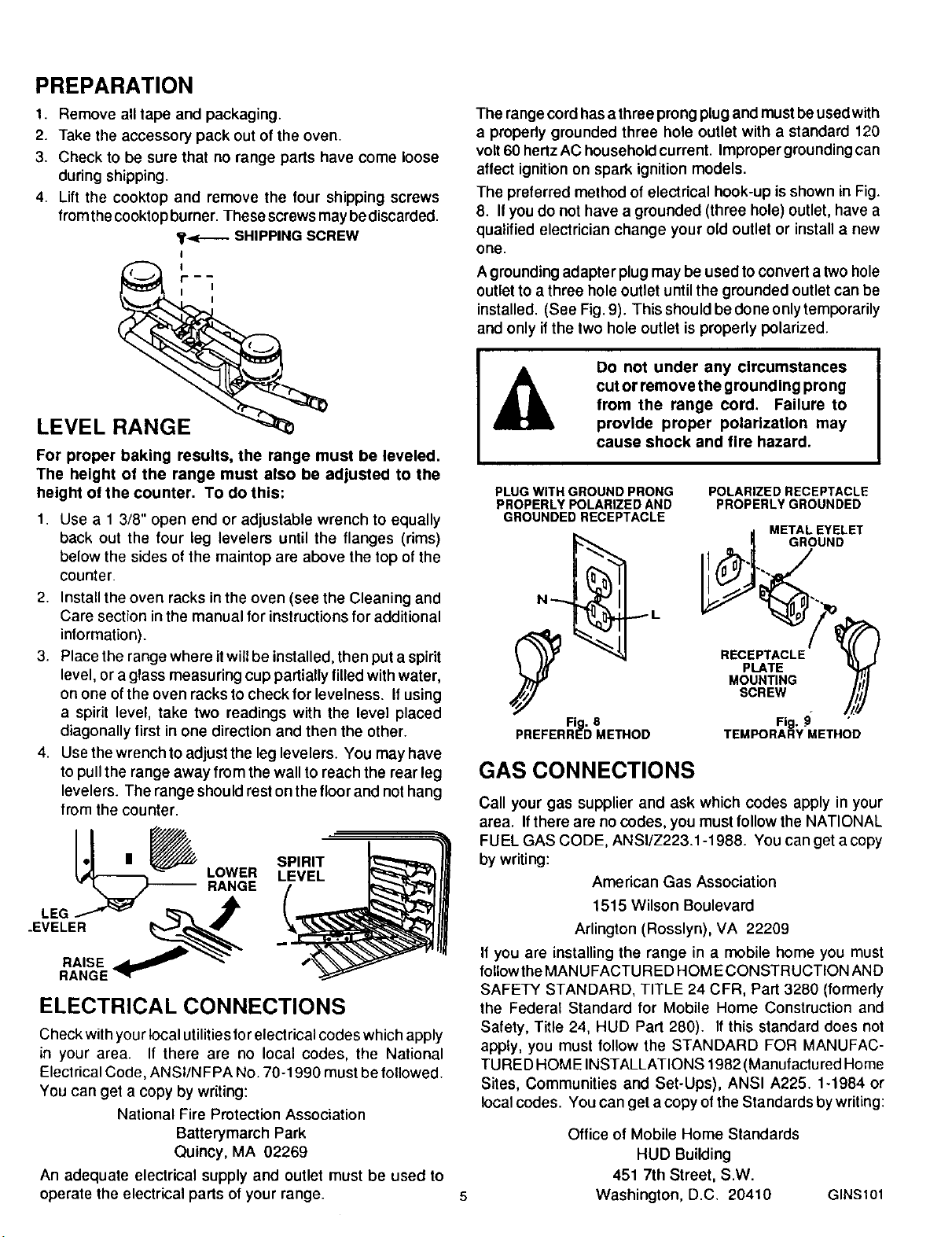

PREPARATION

1. Remove all tape and packaging.

2. Take the accessory pack out of the oven.

3. Check to be sure that no range parts have come loose

during shipping.

4. Lift the cooktop and remove the four shipping screws

from the cooktop burner. These screws may be discarded.

'it'<'----- SHIPPING SCREW

I

LEVEL

For proper baking results, the range must be leveled.

The height of the range must also be adjusted to the

height of the counter, To do this:

1. Use a 13/8" open end or adjustable wrench to equally

back out the four leg levelers until the flanges (rims)

below the sides of the maintop are above the top of the

counter.

2. Install the oven racks in the oven (see the Cleaning and

Care section inthe manual for instructions for additional

information).

3. Place the range where it will be installed, then put a spirit

level, or a glass measuring cup partially filled with water,

on one of the oven racks to check for levelness. It using

a spirit level, take two readings with the level placed

diagonally first in one direction and then the other.

4. Usethewrenchtoadjusttheleglevelers. Youmayhave

to pull the range away from the wall to reach the rear leg

levelers. The range should rest on the floor and not hang

from the counter.

SPIRIT

LEVEL

ELECTRICAL CONNECTIONS

Check with your local utilities torelectrical codes which apply

in your area. It there are no local codes, the National

Electrical Code, ANSI/NFPA No. 70-1990 must be followed.

You can get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

An adequate electrical supply and outlet must be used to

operate the electrical parts of your range.

The range cord has a three prong plug and must be usedwith

a properly grounded three hole outlet with a standard 120

volt 60 hertz AC household current. Improper grounding can

affect ignition on spark ignition models.

The preferred method of electrical hook-up is shown in Fig.

8. If you do not have a grounded (three hole) outlet, have a

qualified electrician change your old outlet or install a new

one.

Agrounding adapter plug may be used to convert a two hole

outletto a three hole outlet until the grounded outlet can be

installed. (See Fig.9). This shouldbedone onlytemporarily

and only it the two hole outlet is properly polarized.

Do not under any circumstances

cut or remove the grounding pro ng

from the range cord. Failure to

provide proper polarization may

cause shock and fire hazard.

PLUG WITH GROUND PRONG

PROPERLY POLARIZED AND

GROUNDED RECEPTACLE

POLARIZED RECEPTACLE

PROPERLY GROUNDED

i_ METALEYELET

GROUND

RECEPTACLE _

L

PL.ATE _"

MOUNTING Ilil

SCREW . ._//_/_

PREFERRED METHOD

Fig. 8

TEMPORARY METHOD

Fig. 9

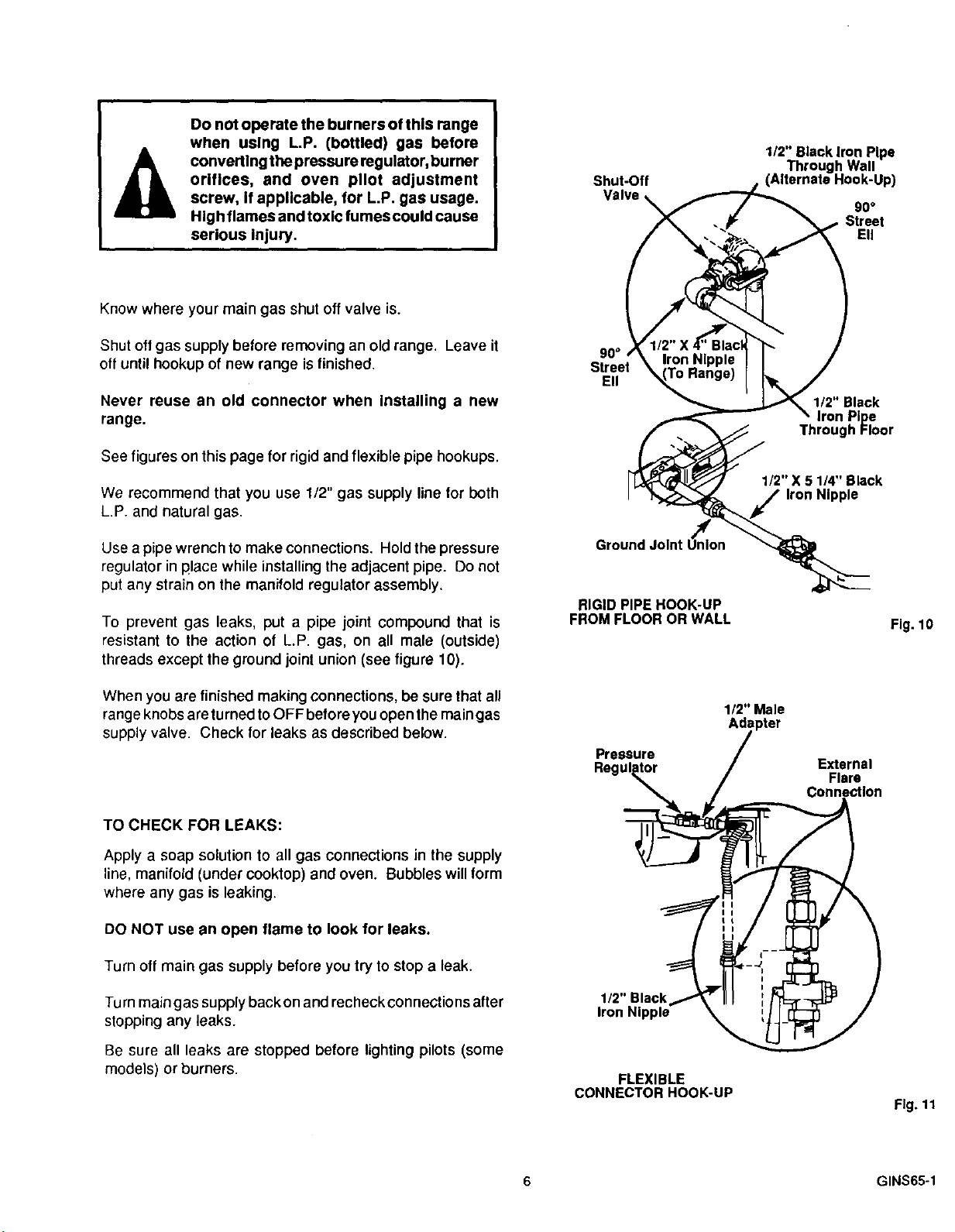

GAS CONNECTIONS

Call your gas supplier and ask which codes apply in your

area. If there are no codes, you must follow the NATIONAL

FUEL GAS CODE, ANSI/Z223.1-1988. You can get a copy

by writing:

American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

It you are installing the range in a mobile home you must

followthe MANUFACTURED HOME CONSTRUCTION AND

SAFETY STANDARD, TITLE 24 CFR, Part 3280 (formerly

the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280). Ifthis standard does not

apply, you must follow the STANDARD FOR MANUFAC-

TURED HOME INSTALLATIONS 1982 (Manufactured Home

Sites, Communities and Set-Ups), ANSI A225. 1-1984 or

local codes. You can get a copy of the Standards by writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 20410

GINS1Ol

Do not operate the burners of this range

when using LP. (bottled) gas before

converting the pressure regulator, burner

orifices, and oven pilot adjustment

A

Know where your main gas shut off valve is.

screw, If applicable, for L.P. gas usage.

HIghflames and toxic fumes could cause

serious Injury.

Shut-Off

Valve

1/2" Black Iron Pipe

look-Up)

90°

Street

Ell

Shut off gas supply before removing an old range. Leave it

off until hookup of new range is finished,

Never reuse an old connector when installing a new

range.

See figures on this page for rigid and flexible pipe hookups.

We recommend that you use 1/2" gas supply line for both

L.P. and natural gas,

Use a pipe wrench to make connections. Hold the pressure

regulator in place while installing the adjacent pipe. Do not

put any strain on the manifold regulator assembly.

To prevent gas leaks, put a pipe joint compound that is

resistant to the action of L.P. gas, on all male (outside)

threads except the ground joint union (see figure 10).

When you are finished making connections, be sure that all

range knobs are turned to OFF before you open lhe main gas

supply valve. Check forleaks as described below.

90°

Stree

Ell

Ground Joint

RIGID PIPEHOOK-UP

FROM FLOOR OR WALL

Pressure

Regu

1/2" Black

Iron Pipe

Through Floor

1/2" X 5 114" BLack

Iron Nipple

Fig. 10

1/2" Male

External

Flare

Connection

TO CHECK FOR LEAKS:

Apply a soap solution to all gas connections in the supply

line, manifold (under cooktop) and oven. Bubbles will form

where any gas is leaking.

OO NOT use an open flame to look for leaks.

Turn off main gas supply before you try to stop a leak.

Turn main gas supply back on and recheck connections after

stopping any leaks.

Be sure all leaks are stopped before lighting pilots (some

models) or burners.

1/2" Black

Iron N

FLEXIBLE

CONNECTOR HOOK-UP

Fig. 11

6 GINS65-1

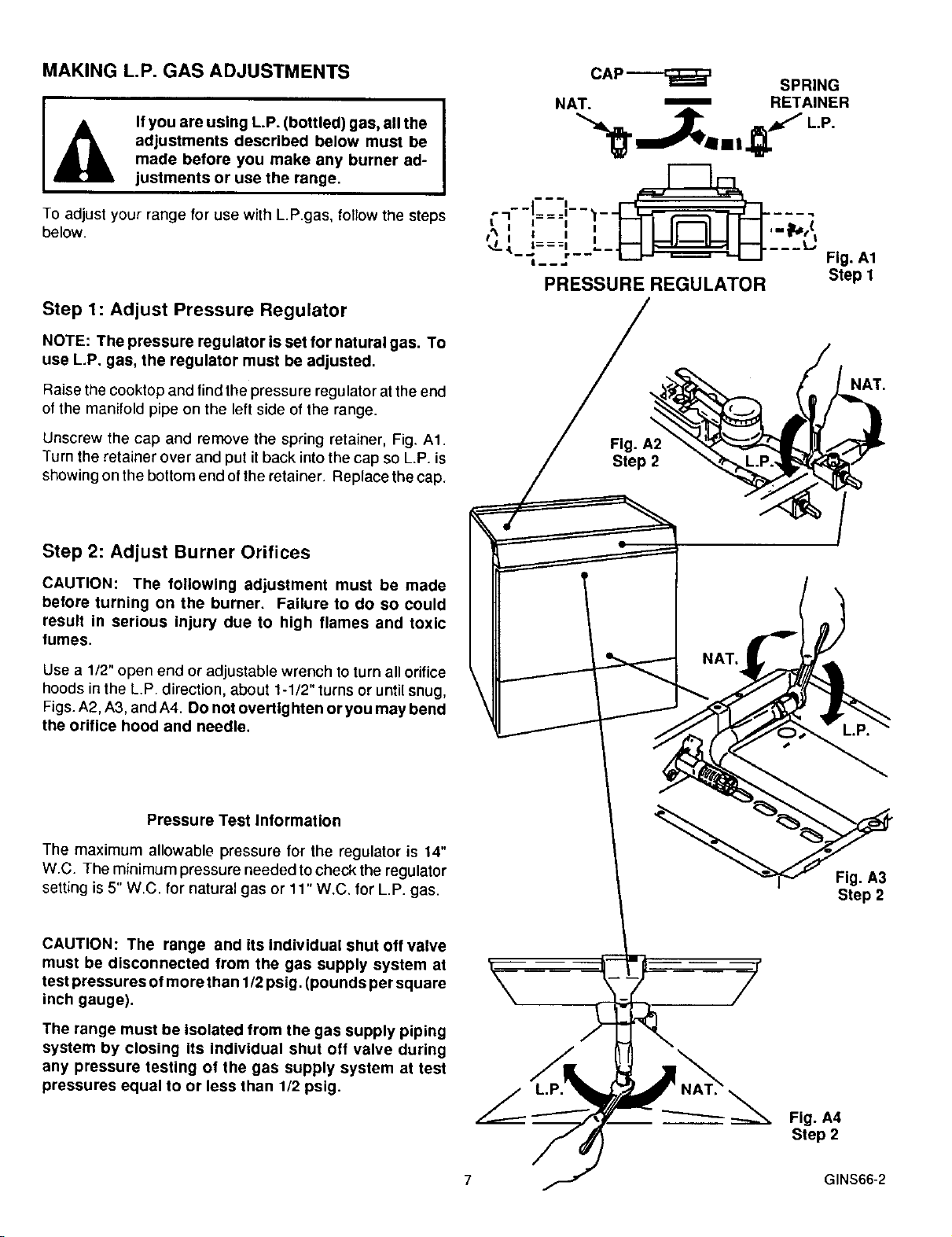

MAKING L.P. GAS ADJUSTMENTS

If you are using L.P. (bottled) gas, all the

adjustments described below must be

made before you make any burner ad-

justments or use the range.

To adjust your range for use with L.P.gas, follow the steps

below.

Step 1: Adjust Pressure Regulator

NOTE: The pressure regulator is set for natural gas. To

use L.P. gas, the regulator must be adjusted.

Raise the cooktop and find the pressure regulator at the end

of the manifold pipe on the left side of the range.

CAP

NAT.

RETAINER

F-7

....

t = l I = _ I Iml I _,.Lt,=.(

PRESSURE REGULATOR

SPRING

Fig. A1

Step 1

NAT.

Unscrew the cap and remove the spring retainer, Fig. A1.

Turn the retainer over and put it back into the cap so L.P. is

showing on the bottom end of the retainer. Replace the cap.

Step 2: Adjust Burner Orifices

CAUTION: The following adjustment must be made

before turning on the burner. Failure to do so could

result in serious injury due to high flames and toxic

tumes.

Use a 1/2" open end or adjustable wrench to turn all orifice

hoods in the L.P. direction, about 1-1/2" turns or until snug,

Figs. A2, A3, and A4. Do not overtlg hten or you may bend

the orifice hood and needle.

Pressure Test Information

The maximum allowable pressure for the regulator is 14"

W.C. The minimum pressure needed to check the regulator

setting is 5" W.C. for natural gas or 11" W.C. for L.P. gas.

Fig. A2

Step 2

NAT.

Fig. A3

Step 2

CAUTION: The range and its Individual shut off valve

must be disconnected from the gas supply system at

test pressures of more than 1/2 psig. (pounds per square

inch gauge).

The range must be isolated from the gas supply piping

system by closing its individual shut off valve during

any pressure testing of the gas supply system at test

pressures equal to or less than 1/2 psig.

\

Fig. A4

Step 2

7 GINS66-2

MAKING BURNER ADJUSTMENTS

If you are using LP. (bottled) gas, all the

adjustments described below muSt be

made before you make any burner ad-

justments or use the range.

All ranges are factory adjusted forusewiththe most common

type of natural gas. The gas used in some parts of the

country may be different. Inorder to assure safe and energy

efficient operation of this appliance, you should check all

adjustments described below and onthe next page. Ifyou

are using L.P. gas, all the adjustments must be made.

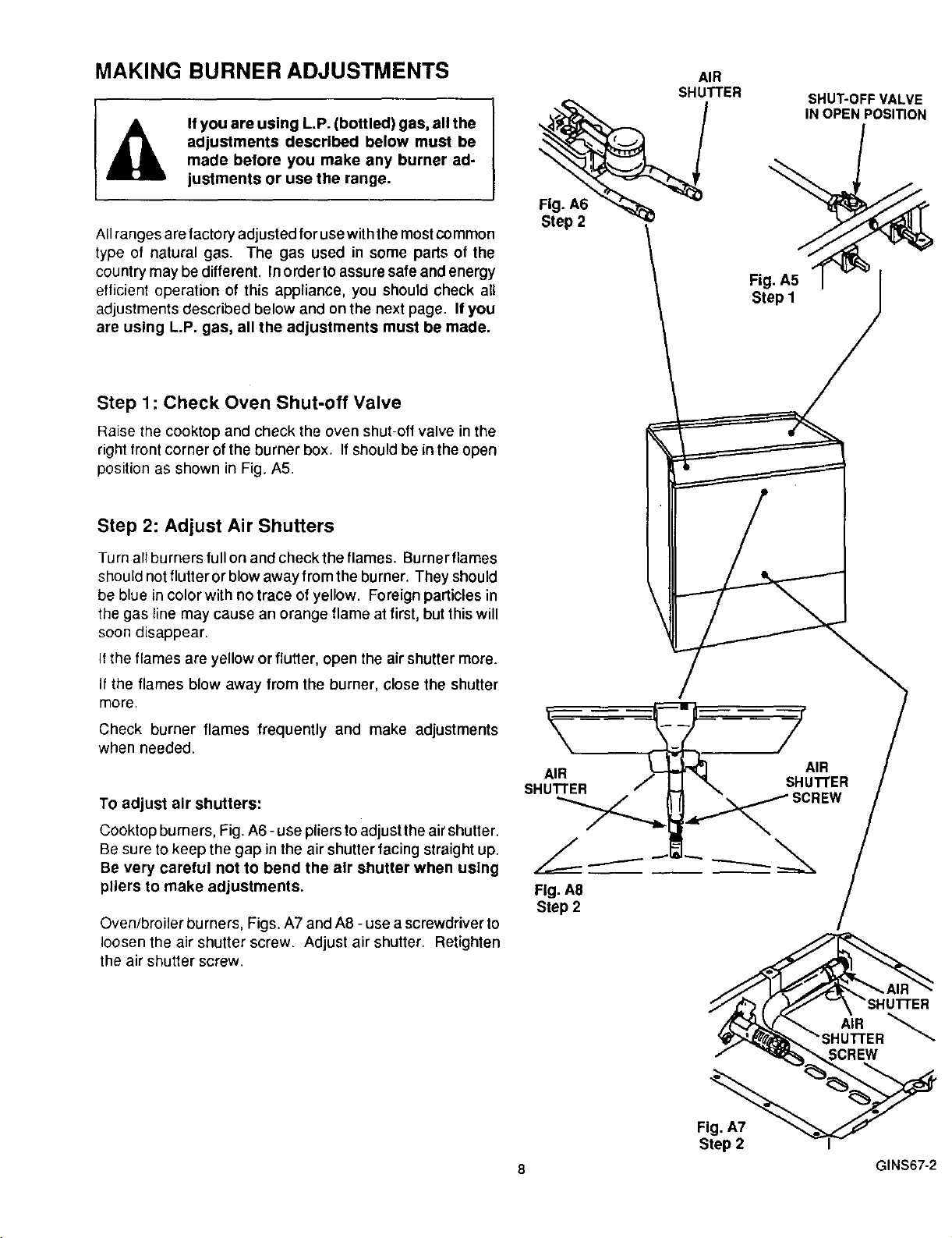

Step 1 : Check Oven Shut-off Valve

Raise the cooktop and check the oven shut-off valve in the

right front corner of the burner box, If should be in the open

position as shown in Fig. A5.

AIR

SHUTTER

SHUT-OFFVALVE

IN OPEN POSITION

Fig. A5

Step I

Step 2: Adjust Air Shutters

Turn all burners full on and checkthe flames. Burner flames

should not flutter or blow away from the burner. They should

be blue in color with no trace of yellow. Foreign particles in

the gas line may cause an orange flame at first, but this will

soon disappear.

If the flames are yellow or flutter, open the air shutter more.

if the flames blow away from the burner, close the shutter

more.

Check burner flames frequently and make adjustments

when needed.

To adjust air shutters:

Cooktop burners, Fig. A6 -use pliers to adjust the air shutter.

Be sure to keep the gap in the air shutter facing straight up.

Be very careful not to bend the air shutter when using

pliers to make adjustments.

Oven/broiler burners, Figs. A7 and A8 - use a screwdriver to

loosen the air shutter screw. Adjust air shutter. Retighten

the air shutter screw.

AIR

SHUTTER

Fig. A8

Step 2

U'I-rER

AIR

Fig. A7

Step 2

8 GINS67-2

MAKING BURNER ADJUSTMENTS

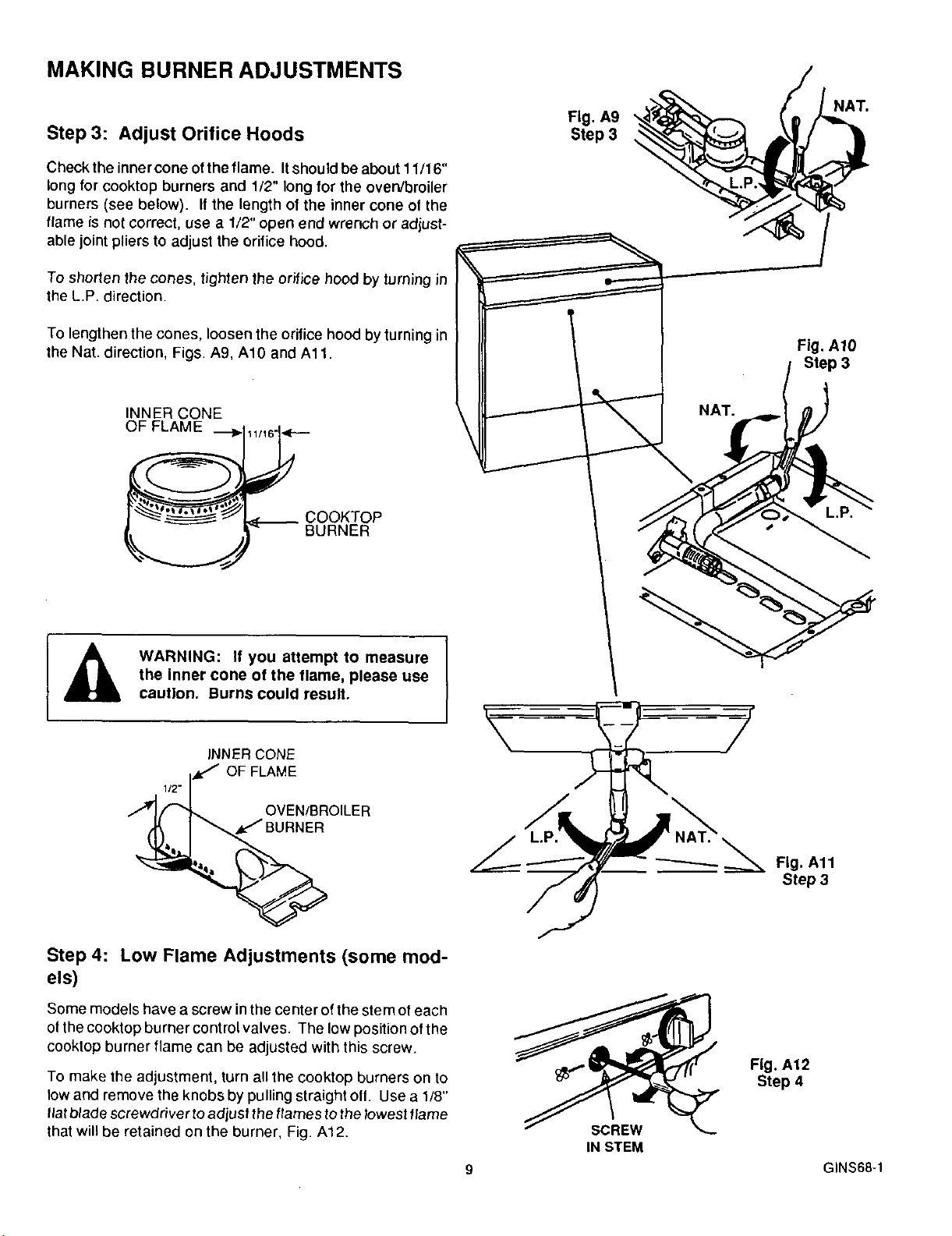

Step 3: Adjust Orifice Hoods

Check the inner cone ofthe flame. Itshould be about 11/16"

long for cooktop burners and 1/2" long for the oven/broiler

burners (see below). If the length of the inner cone ol the

flame is not correct, use a 1/2" open end wrench or adjust-

able joint pliers to adjust the orifice hood.

To shorten the cones, tighten the orifice hood by turning in

the L.P. direction.

To lengthen the cones, loosen the orifice hood by turning in

the Nat. direction, Figs. A9, A10 and A11.

INNER CONE

OF FLAME

__ COOKTOP

BURNER

Fig. A9

NAT.

Step 3

Fig. A10

Step 3

NAT.

WARNING: if you attempt to measure

the inner cone of the flame, please use

caution. Burns could result.

INNER CONE

OF FLAME

112"

OVEN/BROILER

Step 4: Low Flame Adjustments (some mod-

els)

Some models have a screw in the center of the stem of each

of the cooktop burner control valves. The low position of the

cooktop burner flame can be adjusted with this screw.

To make the adjustment, turn all the cooktop burners on to

low and remove the knobs by pulling straight oil. Use a 1/8"

tlat blade screwdriver to adjust the flames tothe lowest flame

that will be retained on the burner, Fig. A12.

\

Fig. A12

Step 4

SCREW

IN STEM

9

GINS68-1

KIT PART NO. (KIT 045) 344119

A WARNING:

• ALL RANGES CAN TIP

• INJURY COULD RESULT

• INSTALL ANTI-TIP DEVICE

PACKED WITH RANGE

• SEE INSTRUCTIONS

GAS RANGE STABILITY DEVICE

INSTALLATION INSTRUCTIONS

REMOVE ALL PARTS FROM THE PLASTIC BAG

ATTACHED TO THE BACK OF THE RANGE

AND SAVE PACKAGING TAPE.

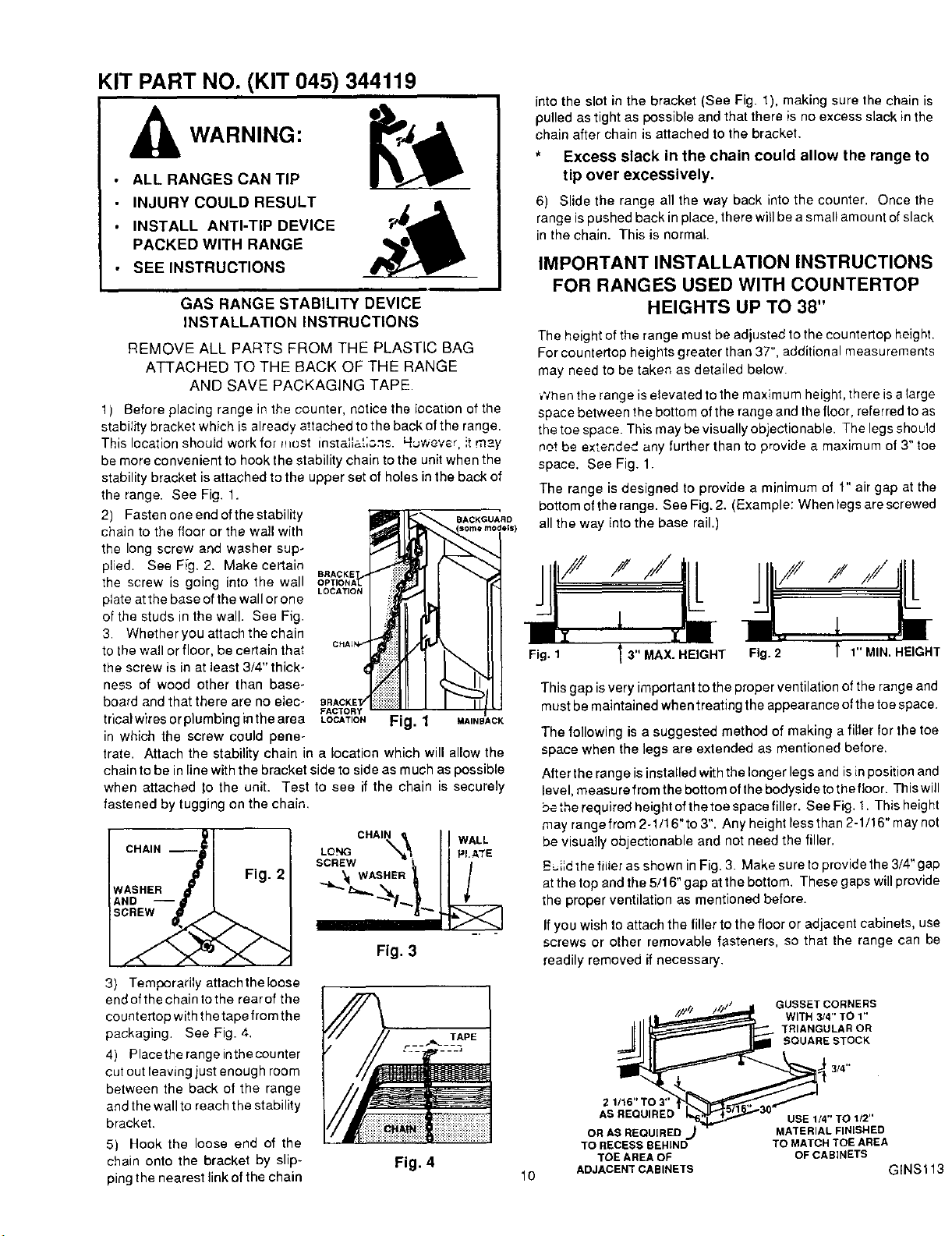

1) Before placing range in the counter, notice the Iocation of the

stability bracket which is already attached to the back of the range.

This location should work for r_ost instali_[;_,=s. H:_wew.r, it m_y

be more convenient to hook the stability chain to the unit when the

stability bracket is attached to the upper set of holes in the back of

the range. See Fig. 1.

2) Fasten one end of the stability

chain to the floar or the wall with

the long screw and washer sup-

plied. See Ftg. 2. Make certain

the screw is going into the wall

plate at the base of the wall or one

of the studs in the wall. See Fig.

3. Whether you attach the chain

to the wall or floor, be certain that

the screw is in at least 3/4" thick-

ness of wood other than base-

board and that there are no elec-

tricalwiresorplumbinginthearea =.OCATION Fig. 1 MAINEIACK

in which the screw could pene-

trate. Attach the stability chain in a location which will allow the

chain to be in line with the bracket side to side as much as possible

when attached _o the unit. Test to see if the chain is securely

fastened by tugging on the chain,

CHAIN

Fig. 2

WASHER

AND

3) Temporarily attach the loose

end of the chain to the rear of the

countertop with the tape from the

packaging, See Fig. 4,

4) Placethe range inthe counter

cut out leaving just enough room

between the back of the range

and tile wall to reach the stability

bracket.

5) Hook the loose end of the

chain onto the bracket by slip-

ping the nearest link of the chain

OPTIONA

LOCATION

CHAJ

BRACKE_

BRACK

FACTORY

Fig. 3

Fig. 4

into the slot in the bracket (See Fig. 1), making sure the chain is

pulled as tight as possible and that there is no excess slack in the

chain after chain is attached to the bracket.

* Excess slack in the chain could allow the range to

tip over excessively.

6) Slide the range all the way back into the counter. Once the

range ispushed back in place, there will be a small amount of slack

in the chain. This is normal.

IMPORTANT INSTALLATION INSTRUCTIONS

FOR RANGES USED WITH COUNTERTOP

HEIGHTS UP TO 38"

The height of the range must be adjusted tothe countertop height.

For countertop heights greater than 37", additional measurements

may need to be taken as detailed below.

WRen the range isetevated to the maximum height, there is a Iarge

space between the bottom of the range and the floor, referred to as

the toe space. This may be visually objectionable. The legs should

not be extended any further than to provide a maximum of 3" toe

space. See Fig. 1.

The range is designed to provide a minimum of 1" air gap at the

bottom of the range. See Fig. 2. (Example: When legs are screwed

all the way into the base rail.)

Fig. 1

This gap is very important to the proper ventilation of the range and

must be maintained when treating the appearance of the toe space.

The following is a suggested method of making a filler for the toe

space when the legs are extended as mentioned before.

After the range is installed with the longer legs and isin position and

level, measu refrom the bottom of the bodyside to the floor. This will

bethe required height of the toe space filler. See Fig. 1, This height

may range from 2-1/16" to 3". Any height less than 2-1/16" may not

be visually objectionable and not need the filler.

B_.:,=,d',hefiiier as shown inFig. 3. Make sure to provide the 3/4" gap

at the top and the 5/16" gap at the bottom. These gaps will provide

the proper ventilation as mentioned before.

Ifyou wish to attach the filler to the floor Dr adjacent cabinets, use

screws or other removable fasteners, so that the range can be

readily removed if necessary.

GUSSETCORNERS

WITH _4"TO 1"

TRIANGULAR OR

SQUARESTOCK

3/4"

10

AS REQUIRED

OR AS REQUIRED

TO RECESS BEHIND

TOE A REA OF

ADJACENT CABINETS

USE 1/4" TO 1/2"

MATERIAL FINtSHED

TO MATCH TOE AREA

OF CABINETS

GINS113

IMPORTANT INSTRUCTIONS FOR YOUR SAFETY

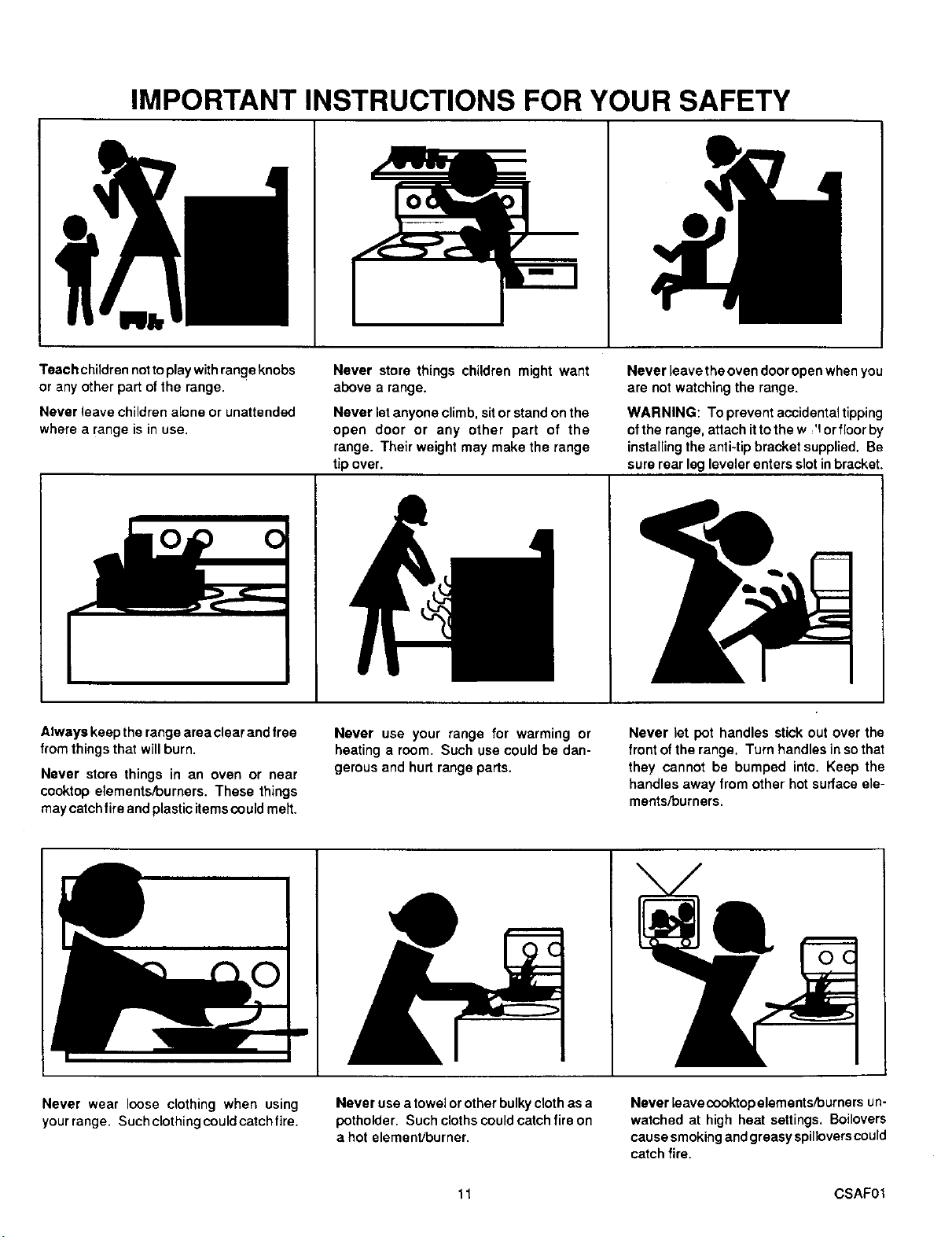

Teach childrennotto play withrange knobs

or any other part of the range.

Never leave children alone or unattended

where a range is in use.

Always keep the range area clear and free

from things that will burn.

Never store things in an oven or near

cooktop elements/burners. These things

may catch fire and plastic itemscouldmelt.

Never store things children might want

above a range.

Never let anyone climb, sitor stand onthe

open door or any other part of the

range. Their weight may make the range

tip over.

Never use your range for warming or

heating a room. Such use could be dan-

gerous and hurt range parts.

Never leave the oven door open when you

are not watching the range.

WARNING: To prevent accidental tipping

ofthe range, attach ittothe w 'tor floor by

installingthe anti-tip bracket supplied. Be

sure rear leg leveler enters slot inbracket.

Never let pot handles stick out over the

front of the range. Turn handles in so that

they cannot be bumped into. Keep the

handles away from other hot surface ele-

ments/burners.

Never wear loose clothing when using

your range. Such clothing could catch fire.

Never use a towelor other bulky cloth as a

potholdsr. Such clothscould catch fire on

a hot element/burner.

11 CSAF01

Never leavecooktopelementsiburners un-

watched at high heat settings. Boilovers

cause smoking and greasy spilloverscould

catch fire.

Loading...

Loading...