Kenmore 91132359590, 91132355590, 91132356590 Installation Guide

INSTALLATION INSTRUCTIONS FOR YOUR NEW

30"SEALEDGASCOOKTOPS

Before you begin: Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector's use.

;IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

INSTALLER: Be sure to leave these instructions with the Consumer.

CONSUMER: Keep these instructions with your Use and Care Book for future

reference.

This appliance must be properly grounded.

Installation of this cooktop must conform with

local codes or in the absence of local codes

with the National Fuel Gas Code, ANSI Z223

1-Latest edition.

_ WARNING!!If theinformation in i!i

_ _ this manual is not followed i_;_

exactly, a fire, explosion,orgas iii_:

leakmayresult causlngproperty ii_iiii

damage, personal injury, or ilii

death, ii_i

Be sure your cooktop is installed properly by a

qualified installer or service technician.

Do not store items of interest tochildren in cabinets

above the cooktop. They could be seriously

bumed climbing on the cooktop to reach them.

To eliminate reaching over surface burners,

cabinet storage above bumer should be avoided.

Adjust surface bumer flame size so it does not

extend beyond the edge of the cooking utensil.

Do not install the unit near an outside door or

where a draft may affect its use.

This cooktop has been design certified by the

American Gas Association. You'll find safety

precautions in your Use and Care book. Read

them carefully.

SR10275

22sc4053P040.3

• 1/8" drill bit

• Electric or hand drill

• No. 1 or No. 2 Phillips

screwdriver

• Pencil

• Rulerandstraightedge

ADDITIONAL MATERIAL YOU MAY NEED:

• Gas line shut-off valve

• Pipe joint sealant

• 1/2"pipenipple

For flexible connection where local codes

permit:

• Coated and approved flexible metal tubing

(same 3/4" or 1/2" LD. as gas supply line)

• Adaptor or connector

For rigid connection:

• Pipe fittings or union as required

• Hand or saber saw

• Pipe wrench

• Adjustable wrench

• 3/16"hexsocket

driver

• 12" spirit level

1

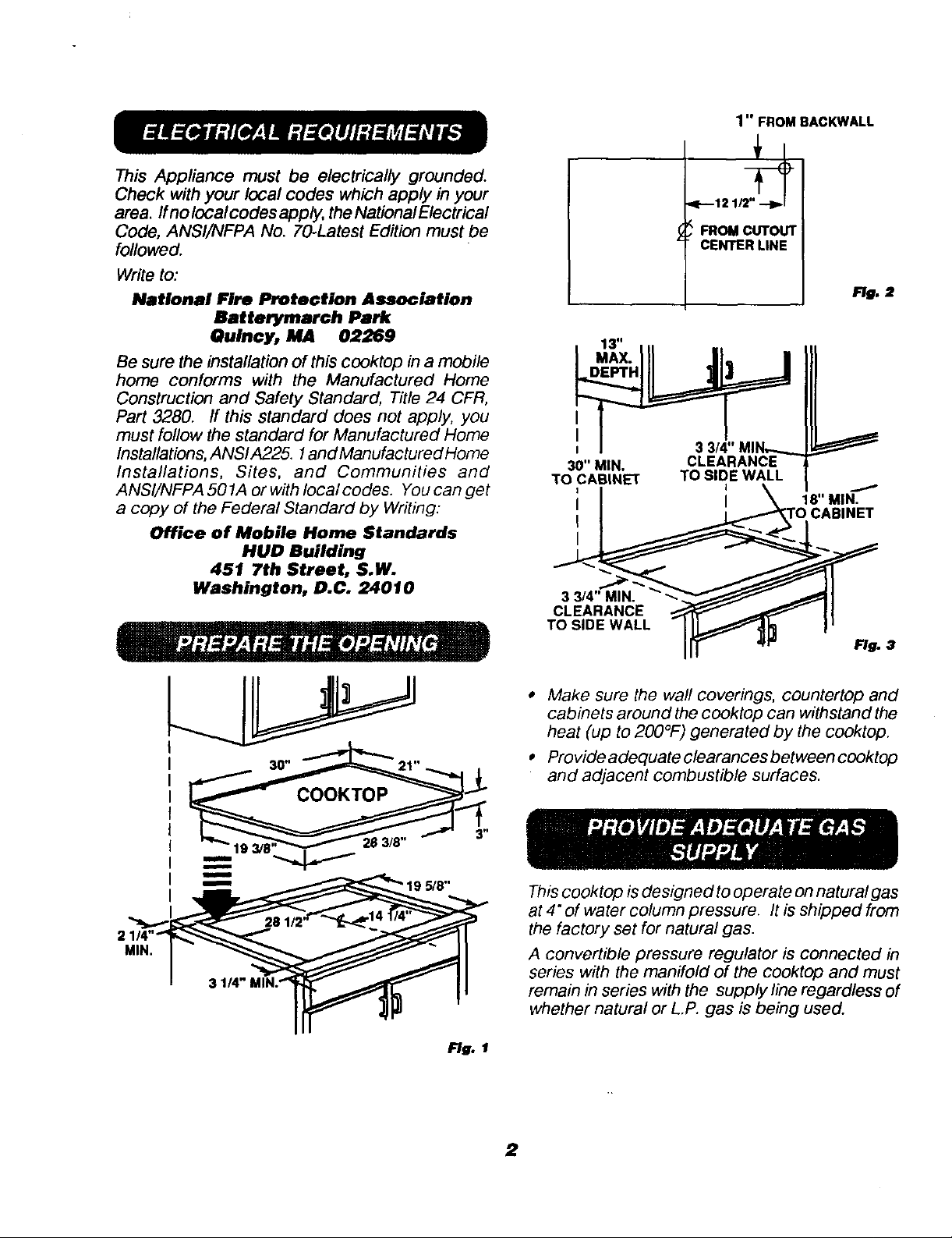

1" FROMBACKWALL

ThisAppliance must be electrically grounded.

Checkwithyourlocalcodeswhichapply inyour

area.ffnoIocalcodesapply,theNationalElectrical

Code,ANSl/NFPANo.70-LatestEditionmustbe

followed.

Writeto:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Be sure the installation of this cooktop in a mobile

home conforms with the Manufactured Home

Construction and Safety Standard, Title 24 CFR,

Part 3280. If this standard does not apply, you

must follow the standard for Manufactured Home

Installations, ANSI A225. l and Manufactured Home

Installations, Sites, and Communities and

ANSI/NFPA 501A or with Iocal codes. You can get

a copy of the Federal Standard by Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

I

I

I

30" MIN.

TO CABINET

3 3/4" MIN.

CLEARANCE

TO SIDE WALL

,_---12 1F_"_

_.•_FROMCUTOUT

CENTERLINE

Fig. 2

3 3/4" MII_

CLEARANCE

TO SIDE WALL

I 18" MIN,

INET

Fig. 3

2 1/4""

MIN.

• Make sure the wall coverings, countertop and

cabinets around the cooktop can withstand the

heat (up to 200°F) generated by the cooktop.

• Provideadequateolearancesbetweencooktop

and adjacent combustible surfaces.

This cooktop is designed to operate on natural gas

at 4" of water column pressure. It is shipped from

the factory set for natural gas.

A convertible pressure regulator is connected in

series with the manifold of the cooktop and must

remain in series with the supply line regardless of

whether natural or L.P. gas is being used.

Fig. 1

2

FOR PROPER OPERA TION, THE MAXIMUM

INLET PRESSURE TO THE REGULATOR

MUST BE NO MORE THAN 14" OF WA TIER

COLUMN PRESSURE.

For checking the regulator, the inlet pressure must

be at least 1"(or3.4 KPA ) greater than the regulator

output setting, ff the regulator is set for 4" of water

column pressure, the inlet pressure must be at

least 5" If the regulator is set for 10; the inlet

pressure must be at least 11"

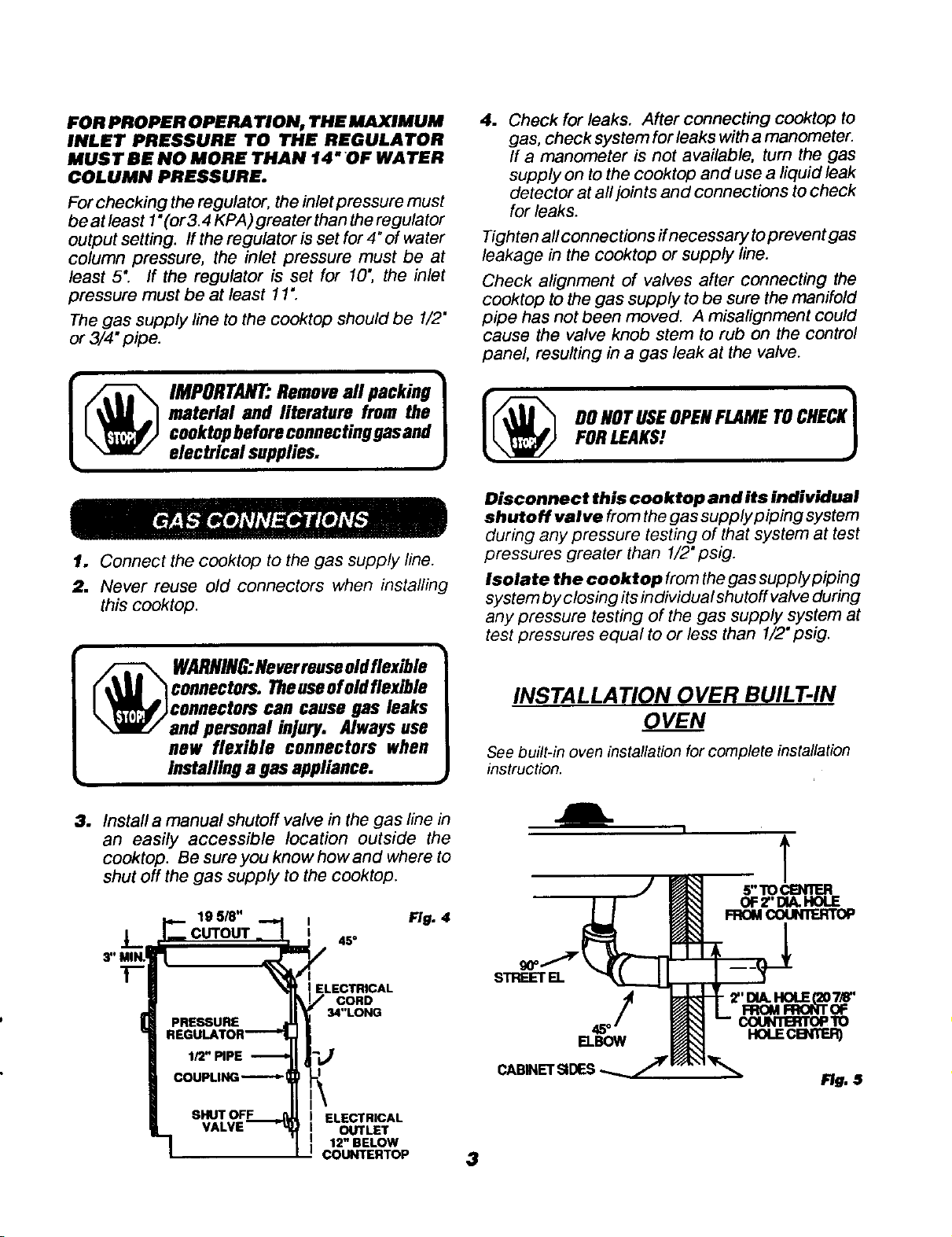

The gas supply line to the cooktop should be 1/2"

or 3/4" pipe.

material and literature from the | DO NOT USE OPEN FLAME TO CHECK!

cooktopbeforec.onnectiuggasand | FOR LEAKS! J

electrical supplies. J

1. Connect the cooktop to the gas supply line.

2. Never reuse old connectors when installing

this cooktop.

4. Check for leaks. After connecting cooktop to

gas, check system for leaks with a manometer.

If a manometer is not available, turn the gas

supply on to the cooktop and use a liquid leak

detector at all joints and connections to check

for leaks.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of valves after connecting the

cooktop to the gas supply to be sure the manifold

pipe has not been moved. A misalignment could

cause the valve knob stem to rub on the control

panel, resulting in a gas leak at the valve.

Disconnect this cooktop and its individual

shutoff valve from the gas supply piping system

during any pressure testing of that system at test

pressures greater than 1/2" psig.

Isolate the cooktop from the gas supply piping

system by closing its individual shutoff valve during

any pressure testing of the gas supply system at

test pressures equal to or less than 1/2" psig.

_UJ __connectors.Theuseofoldflexible

L._f _connectors can causegas leaks

andpersonal injury, Alwaysuse

( ./'_'-_ WARNING:Neverreuseoldflexible

new flexible connectors when

installinga gas appliance.

3. Install a manual shutoff valve in the gas line in

an easily accessible location outside the

cooktop. Be sure you know how and where to

shut off the gas supply to the cooktop.

__ 195/8" .._

.L.

3" MIN.

_ CUTOUT _

45° Fi u. 4

I-

ELECTRICAL

/ .C,,.ORD

PRESSURE

REGULATOR_

1/2" PIPE

COUPLING

SHUTOFF f

VALVE--_

34 LONG

Y

ELECTRICAL

OUTLET

12" BELOW

COUNTERTOP

INSTALLATION OVER BUILT-IN

OVEN

See built-in oven installation for complete installation

instruction.

I

5"TOCIES_/TER

OF2"DIA,HOLE

STREETEL

2"DULHOLE(207/8"

FROMFRONTOF

_TO

ELBOW

CABINETSIDES _ .7

3

HOLECB_._)

F/e. S

Loading...

Loading...