Kenmore 79681382410, 79681383410, 79691382410, 79691383410 Owner’s Manual

Use & Care Guide

Manual de Uso y Cuidado

English / Espafiol

Model/Modelo: 796.8138 _, 796.9138 _

I<enmore

Drye

vapo_

s' ..............co/or numb÷_, nOmero de co/or

IIIIIIIIIIIIIIIIUIIll

MFL67731025

Sears Brands Management Corporation

Hofl:man Estates, IL60179 U.S.A.

www.kenmore.com

www.sears.com

IMPORTANT SAFETY INSTRUCTIONS .................... 3-6

GROUNDING REQUIREMENTS ................................... 4

FEATURES AND BENEFITS

Key Parts and Components ........................................ 7

INSTALLATION INSTRUCTIONS

Key Dimensions and Specifications .......................... 8

Location Requirements ................................................ 8

Choose the Proper Location ....................................... 8

Clearances .................................................................... 8

Installation with Optional Pedestal Base

or Stacking Kit ............................................................. 9

Optional Accessories .................................................. 9

Connecting Gas Dryers ............................................ 10

Gas Requirements (Gas Models Only) .............. 10-11

Electrical Requirements ..................................... 10&12

Connecting Electric Dryers ................................. 12-13

Venting the Dryer ................................................. 14-15

Leveling the Dryer ..................................................... 16

Reversing the Door Swing ........................................ 16

Final Installation Check ............................................ 17

HOW TO USE

Control Panel Features ............................................. 18

Operating the Dryer ................................................. 19

Cycle Guide ......................................................... 20-21

Sorting Loads ............................................................. 22

Loading the Dryer ..................................................... 22

Time and Status Display .......................................... 23

Cycle Modifier Buttons ............................................ 24

Cycle Options and Special Features ...................... 25

Wrinkle Guard .................................................... 25

Control Lock ........................................................ 25

My Cycle .............................................................. 25

Damp Dry Signal ................................................. 25

Installing and Using the Drying Rack ................ 25

Steam Features ................................................... 26-27

Important Notes About Steam Functions ....... 26

Using the STEAM REFRESH Cycle ................... 26

STATIC SHIELD ................................................... 26

IRON READY ....................................................... 26

Filling the Steam Feeder .................................. 27

Important Notes about Steam Cycles ............ 27

USER MAINTENANCE INSTRUCTIONS

Regular Cleaning ..................................................... 28

Cleaning the Exterior ......................................... 28

Cleaning the Interior .......................................... 28

Cleaning Around and Under the Dryer ........... 28

Cleaning the Lint Filter ...................................... 28

Maintaining the Exhaust System ............................. 29

KENMORE CONNECT ................................................. 30

TROUBLESHOOTING GUIDE

Before Calling for Service ................................. 31-33

WARRANTY ................................................................... 34

SERVICE .......................................................... Back Cover

In the space below, record the date of purchase, model,

and serial number of your product. You will find the

model and serial number printed on an identification

plate located inside the dryer door. Have these items of

information available whenever you contact Sears

concerning your product.

Model No.

Date of Purchase

Serial No.

Save these instructions and your sales receipt for future

reference.

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore ® product is designed and manufactured for

years of dependable operation. But like all products,

it may require preventive maintenance or repair from

time to time. That's when having a Master Protection

Agreement can save you money and aggravation.

The Master Protection Agreement also helps extend the

life of your new product. Here's what the Agreement*

includes:

• Parts and labor needed to help keep products

operating properly under normal use, not just defects.

Our coverage goes well beyond the product warranty.

No deductible, no functional failure excluded from

coverage - real protection.

• Expert service by a force of more than 10,000

authorized Sears service technicians, which means

someone you can trust will be working on your product.

• Unlimited service calls and nationwide service, as often

as you want us, whenever you want us.

• "No-lemon" guarantee - replacement of your

covered product if four or more product failures occur

within 12 months.

• Product replacement if your covered product can not

be fixed.

• Annual Preventive Maintenance Check at your request

- no extra charge.

• Fast help by phone - we call it Rapid Resolution.

Phone support from a Sears representative on all

products. Think of us as a "talking owner's manual."

• Power surge protection against electrical damage clue to

power fluctuations.

• $250 food loss protection annually for any food

spoilage that is the result of mechanical failure of any

covered refrigerator or freezer.

• Rental reimbursement if repair of your covered

product takes longer than promised.

o25% discount off: the regular price of any non-covered

repair service and related installed parts.

Once you purchase the Agreement, a simple phone call

is all that it takes for you to schedule service. You can

call at any time day or night or schedule a service

appointment online.

The Master Protection Agreement is a risk-free purchase.

If you cancel for any reason during the product warranty

period, we will provide a full refund, or a prorated refund

anytime after the product warranty period expires.

Purchase your Master Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information in the U.S.A.

call 1-800-827-6655.

*Coverage in Canada varies on some items.

For full details call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances,

garage door openers, water heaters, and other major

home items, in the U.S.A. or Canada call:

1-800-4-MY-HOME ®.

READ ALL INSTRUCTIONS BEFORE USE

f Yoursafety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read and

obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or WARNING.

These words mean:

DANGER: Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION • Indicates a hazardous situation which, if not avoided, could result in minor or

• moderate injury.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and

k,,tell you what can happen if the instructions are not followed.

^4L WARNING: For your safety, the information in this manual must be followed to

mnnimize the risk of fire or explosion, electric shock, or to prevent property damage, personal injury,

or loss of life.

• Do not install a clothes dryer with flexible plastic venting materials. If a flexible metal (foil type) duct is installed,

it must be of a specific type identified by the appliance manufacturer as suitable for use with clothes dryers.

Flexible venting materials are known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this appliance or any

other appliances.

• Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

• Install the clothes dryer according to the manufacturer's instructions and local codes.

• Save these instructions.

WHAT TO DO IF YOU SMELL GAS:

1. Do not try to light a match or cigarette, or turn on any gas or electrical appliance.

2. Do not touch any electrical switches. Do not use any phones in your building.

3. Clear the room, building, or area of all occupants.

4. Immediately call your gas supplier from a neighbor's phone. Carefully follow the gas supplier's instructions.

5. If you cannot reach your gas supplier, call the fire department.

SAVE THESE INSTRUCTIONS

BASIC SAFETY PRECAUTIONS

A WARN ING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

• Read all instructions before using the dryer.

• Before use, the dryer must be properly installed, as

described in this manual.

• Do not place items exposed to cooking oils in your

dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a

load to catch fire.

• Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, or other flammable or explosive

substances, as they give ofF vapors that could ignite

or explode.

• Do not reach into the dryer if the drum or any other

part is moving.

• Do not repair or replace any part of the dryer or

attempt any servicing unless specifically recommended

in this Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

• Do not tamper with controls.

• Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

CALIFORNIA SAFE DRINKING WATER AND

TOXIC ENFORCEMENT ACT

This act requires the Governor of California to publish

a list of substances known to the state to cause cancer,

birth defects, or other reproductive harm and requires

businesses to warn customers of potential exposure

to such substances. Gas appliances can cause minor

exposure to four of these substances, namely benzene,

carbon monoxide, formaldehyde, and soot, caused

primarily by the incomplete combustion of natural gas

or LP fuels.

Properly adjusted dryers will minimize incomplete

combustion. Exposure to these substances can be

minimized further by properly venting the dryer to the

outdoors.

• Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

• Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of the

fabric softener or product.

• Do not use heat to dry articles containing foam rubber

or similarly textured rubber-like materials.

• Keep the area around the exhaust opening and

adjacent surrounding areas free from the accumulation

of lint, dust, and dirt.

• The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

• Do not install or store the dryer where it will be

exposed to the weather.

• Always check the inside of the dryer for

foreign objects.

• Clean the lint filter before or after each load.

Warning: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm. Washhands after handling.

WARN ING: Improper connectionofthe

risk of electric shack. Check with a qualified electrician

or service person if you are in doubt as to whether the

appliance is properly grounded. Do not modify the plug

provided with the appliance. If it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

This appliance must be connected to a grounded metal,

permanent wiring system or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment grounding terminal or lead

on the appliance. Electric shock can result if the dryer is

not properly grounded.

equlpment-groundlng

conductor can result in a

GROUNDING REQUIREMENTS

This appliance must be grounded. In the event of

malfunction or breakdown, grounding will reduce

the risk of electric shock by providing a path of least

resistance for electric current. This appliance must be

equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

4

SAFETY INSTRUCTIONS FOR INSTALLATION

WARN ING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

• Properly ground the dryer to conform with all governing

codes and ordinances. Follow details in the installation

instructions. Electric shock can result if the dryer isnot

properly grounded.

• Before use, the dryer must be properly installed as

described in this manual. Electric shock can result if the

dryer is not properly grounded.

• Install and store the dryer where it will not be exposed

to temperatures below freezing or exposed to

the weather.

• All repairs and servicing must be performed by an

authorized service technician unless specifically

recommended in this Use & Care Guide. Use only

authorized factory parts. Failure to follow this warning

can cause serious injury, fire, electric shock, or death.

• To reduce the risk of electric shock, do not install the

dryer in humid spaces. Failure to follow this warning

can cause serious injury, fire, electric shock, or death.

• Connect to a properly rated, protected, and sized

power circuit to avoid electrical overload. Improper

power circuits can melt, creating risk of electric shock

and/or fire hazard.

Remove all packing items and dispose of all shipping

materials properly. Failure to do so can result in fire,

explosion, burns, or death.

Place the dryer at least 18 inches above the floor for

a garage installation. Failure to do so can result in fire,

explosion, burns, or death.

Keep all packaging from children. Packaging material

can be dangerous for children. There is a risk of

suffocation.

Do not install near items that produce heat or open

flame such as stoves or cooking ovens. Failure to follow

this warning can cause product deformation, smoke and

fire.

Do not place candles or cigarettes on top of the

product. Failure to follow this warning can cause

product deformation, smoke and fire.

Remove all protective vinyl film from the product.

Failure to do so can cause product deformation, smoke

and fire.

Exhaust/Ducting:

• Gas dryers MUST be exhausted to the outside. Failure

to follow these instructions can result in fire or death.

• The dryer exhaust system must be exhausted to the

outside of the dwelling. If the dryer is not exhausted

outdoors, some fine lint and large amounts of

moisture will be expelled into the laundry area. An

accumulation of lint in any area of the home can

create a health and fire hazard.

• Use only rigid metal or flexible metal 4 inch diameter

duct inside the dryer cabinet or for exhausting to the

outside. Use of plastic or other combustible ductwork

can cause a fire. Punctured ductwork can cause a fire

if it collapses or becomes otherwise restricted in use or

during installation.

• Ductwork is not provided with the dryer, and you

should obtain the necessary ductwork locally. The end

cap should have hinged dampers to prevent backdraft

when the dryer is not in use. Failure to follow these

instructions can result in fire or death.

The exhaust duct must be 4 inches (10.2 cm) in

diameter with no obstructions. The exhaust duct

should be kept as short as possible. Make sure to

clean any old ducts before installing your new dryer.

Failure to follow these instructions can result in fire or

death.

Rigid or semi-rigid metal ducting is recommended

for use between the dryer and the wall. In special

installations when it is impossible to make a

connection with the above recommendations, a UL

listed flexible metal transition duct may be used

between the dryer and wall connection only. The

use of this ducting will affect drying time. Failure to

follow these instructions can result in fire or death.

DO NOT use sheet metal screws or other fasteners

which extend into the duct that could catch lint and

reduce the efficiency of the exhaust system. Secure

all joints with duct tape. For complete details, follow

the Installation Instructions. Failure to follow these

instructions can result in fire or death.

SAFETY INSTRUCTIONS FOR STEAM FUNCTIONS

WARN ING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

• Do not open the dryer door during steam cycles.

Failure to follow these instructions can result in a

burn hazard.

• Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, or other flammable or explosive

substances, as they give off vapors that could ignite or

explode. Failure to follow these instructions can result in

fire or death.

Do not fill the steam feeder with gasoline, dry-

cleaning solvents, or other flammable or explosive

substances. Failure to follow these instructions can

result in fire or death.

Do not touch the steam nozzle in the drum during

or after the steam cycle. Failure to follow these

instructions can result in a burn hazard.

• Do not fill the steam feeder with hot water (over

86°F/30°C). Failure to follow these instructions can

result in a burn hazard.

SAFETY INSTRUCTIONS FOR CONNECTING ELECTRICITY

,/k WARN ING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

• Do not, under any circumstances, cut or remove

the ground prong from the power cord. To prevent

personal injury or damage to the dryer, the electrical

power cord must be plugged into a properly

grounded outlet.

• For personal safety, this dryer must be properly

grounded. Failure to do so can result in electric shock

or injury.

• Refer to the installation instructions in this manual

for specific electrical requirements for your model.

Failure to follow these instructions can create an

electric shock hazard and/or a fire hazard.

• This dryer must be plugged into a properly grounded

outlet. Electric shock can result if the dryer is not

properly grounded. Have the wall outlet and circuit

checked by a qualified electrician to make sure the

outlet is properly grounded. Failure to follow these

instructions can create an electric shock hazard

and/or a fire hazard.

• The dryer should always be plugged into its own

individual electrical outlet which has a voltage rating

that matches the rating plate. This provides the best

performance and also prevents overloading house

wiring circuits which could cause a fire hazard from

overheated wires.

Never unplug your dryer by pulling on the power

cord. Always grip the plug firmly and pull straight

out from the outlet. The power cord can be damaged,

resulting in a risk of fire and electric shock.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end. The power cord can

melt, creating an electric shock and/or fire hazard.

When installing or moving the dryer, be careful not

to pinch, crush, or damage the power cord. This will

prevent injury and prevent damage to the dryer from

fire and electric shock.

SAVE THESE INSTRUCTIONS

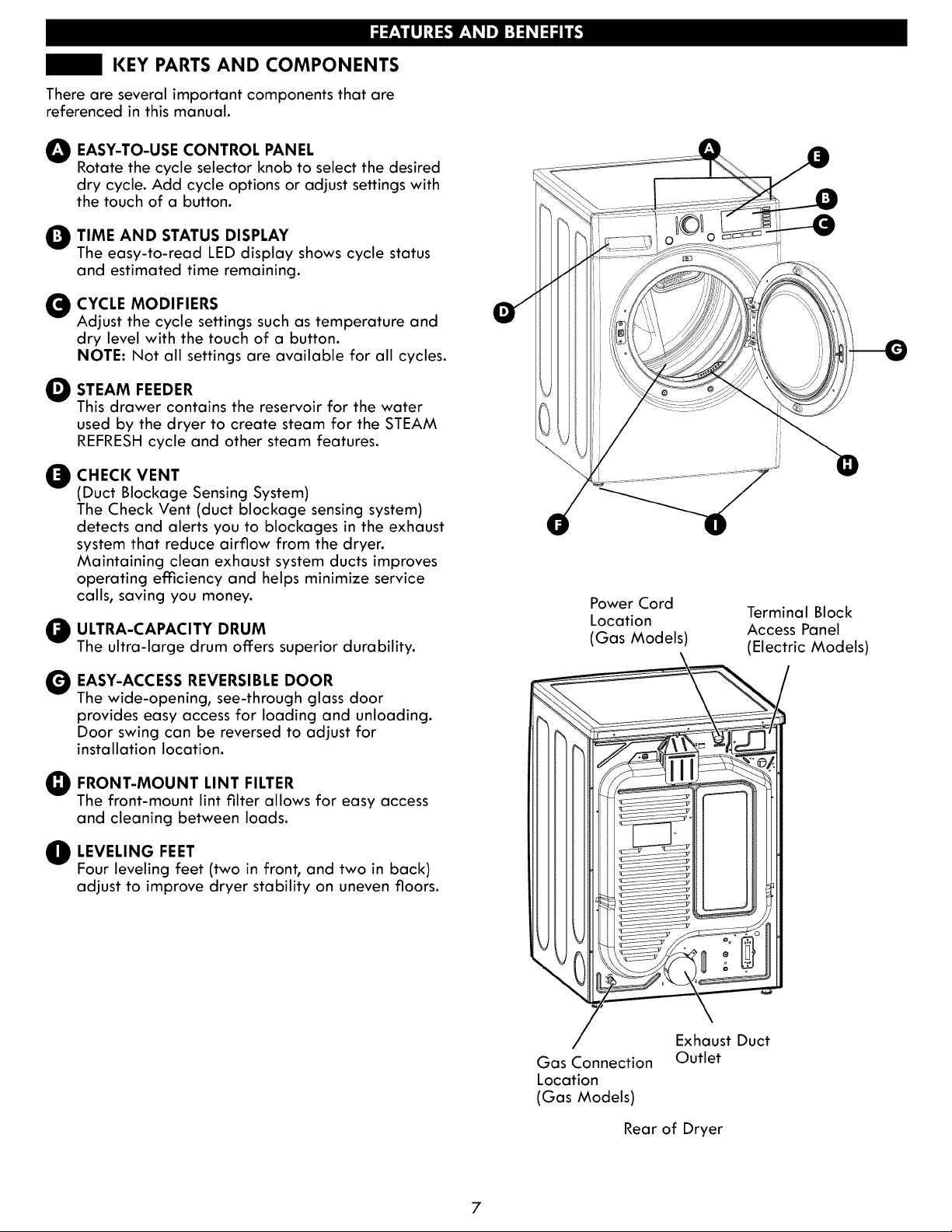

I KEY PARTS AND COMPONENTS

There are several important components that are

referenced in this manual.

O ASY-TO-USE CONTROL PANEL

Rotate the cycle selector knob to select the desired

city cycle. Adcl cycle options or adjust settings with

the touch of a button.

O IME AND STATUS DISPLAY

The easy-to-read LED display shows cycle status

ancl estimated time remaining.

O YCLE MODIFIERS

Adjust the cycle settings such as temperature and

dry level with the touch of a button.

NOTE: Not all settings are available for all cycles.

O TEAM FEEDER

This drawer contains the reservoir for the water

used by the dryer to create steam for the STEAM

REFRESH cycle and other steam features.

O HECI( VENT

(Duct Blockage Sensing System)

The Check Vent (duct blockage sensing system)

detects and alerts you to blockages in the exhaust

system that reduce airflow from the dryer.

Maintaining clean exhaust system ducts improves

operating emciency ancl helps minimize service

calls, saving you money.

O ULTRA-CAPACITY DRUM

The ultra-large drum offers superior durability.

O ASY-ACCESS REVERSIBLE DOOR

The wide-opening, see-through glass door

provides easy access for loading ancl unloading.

Door swing can be reversed to adjust for

installation location.

O RONT-MOUNT LINT FILTER

The front-mount lint filter allows for easy access

and cleaning between loads.

O EVELING FEET

Four leveling feet (two in front, and two in back)

adjust to improve dryer stability on uneven floors.

\

Power Cord

Location

(Gas Models)

Terminal Block

Access Panel

(Electric Models)

Exhaust Duct

Gas Connection

Outlet

Location

(Gas Models)

Rear of Dryer

7

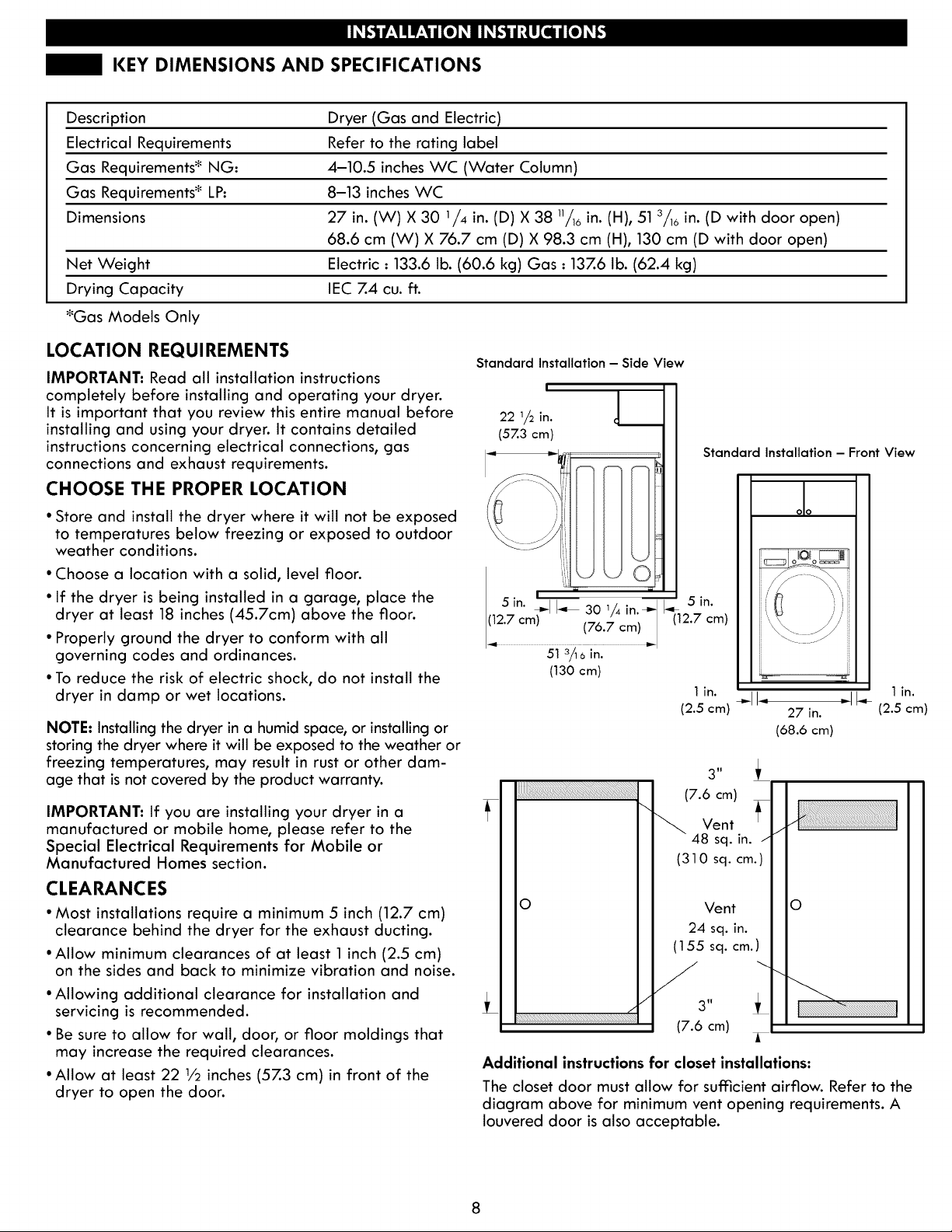

KEY DIMENSIONS AND SPECIFICATIONS

Description Dryer (Gas and Electric)

Electrical Requirements Refer to the rating label

Gas Requirements* NG. 4-10.5 inches WC (Water Column)

Gas Requirements* LP. 8-13 inches WC

Dimensions 27 in. (W) X 30 1/4 in. (D) X 38 11/16 in. (H), 51 3//16in. (D with door open)

68.6 cm (W) X 76.7 cm (D) X 98.3 cm (H), 130 cm (D with door open)

Net Weight Electric : 133.6 lb. (60.6 kg) Gas : 137.6 lb. (62.4 kg)

Drying Capacity IEC 7.4 cu. ft.

*Gas Models Only

LOCATION REQUIREMENTS

Standard Installation - Side View

IMPORTANT: Read all installation instructions

completely before installing and operating your dryer.

It is important that you review this entire manual before 22 1/2in.

installing and using your dryer. It contains detailed (57.3cm)

instructions concerning electrical connections, gas

connections and exhaust requirements.

CHOOSE THE PROPER LOCATION

•Store and install the dryer where it will not be exposed

to temperatures below freezing or exposed to outdoor

weather conditions.

•Choose a location with a solid, level floor.

• If the dryer is being installed in a garage, place the

dryer at least 18 inches (45.7cm) above the floor.

• Properly ground the dryer to conform with all

governing codes and ordinances.

•To reduce the risk of electric shock, do not install the

dryer in clamp or wet locations.

NOTE: Installing the dryer in a humid space, or installing or

storing the dryer where it will be exposed to the weather or

freezing temperatures, may result in rust or other dam-

age that is not covered by the product warranty.

IMPORTANT: If you are installing your dryer in a

manufactured or mobile home, please refer to the

Special Electrical Requirements for Mobile or

Manufactured Homes section.

CLEARANCES

•Most installations require a minimum 5 inch (12.7 cm)

clearance behind the dryer for the exhaust ducting.

•Allow minimum clearances of at least 1inch (2.5 cm)

on the sides and back to minimize vibration and noise.

•Allowing additional clearance for installation and

servicing is recommended.

• Be sure to allow for wall, door, or floor moldings that

may increase the required clearances.

•Allow at least 22 1/2inches (57.3 cm) in front of the

dryer to open the door.

O

Additional instructions for closet installations:

The closet door must allow for sufflcient airflow. Refer to the

diagram above for minimum vent opening requirements. A

Iouvered door is also acceptable.

Standard Installation - Front View

1in. --,.-I!-- --I_ 1in.

(2.5 cm) 27 in. (2.5 cm)

3"

(7.6 cm)

_ Vent

48 sq. in. --

(310 sq. cm.)

Vent

24 sq. in.

(155 sq. cm.)

f

/ 3" I_

(7.6 cm)

00

(68.6 cm)

O

i

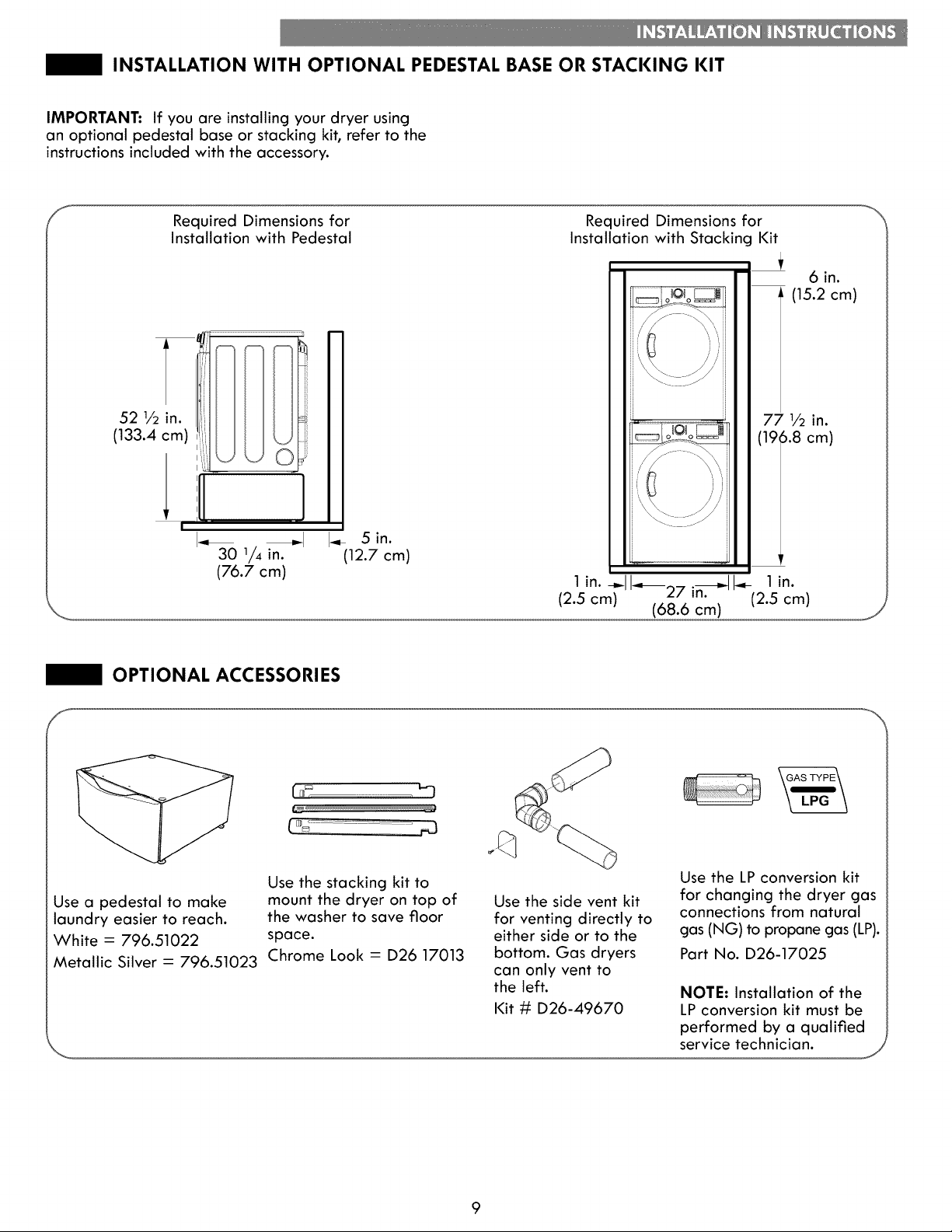

INSTALLATION WITH OPTIONAL PEDESTAL BASE OR STACKING KIT

IMPORTANT: If you are installing your dryer using

an optional pedestal base or stacking kit, refer to the

instructions included with the accessory.

f

52 1/2 in.

(133.4 cm)

Required Dimensions for

Installation with Pedestal

Required Dimensions for

Installation with Stacking Kit

6in.

(15.2 cm)

1

771/2 in.

(19 5.8 cm)

¸i

J

-., -,- I-* 5in.

30 1/4 in. (12.7 cm)

(76.7 cm)

1 in. --I I-.._27 i_l _ 1in.

(2.5 cm) (68.6 cm) (2.5 cm)

OPTIONAL ACCESSORIES

f

(md rd

Use the stacking kit to

Use a pedestal to make mount the dryer on top of

laundry easier to reach, the washer to save floor

White : 796.51022 space.

Metallic Silver : 796.51023 Chrome Look : D26 17013

Use the side vent kit

for venting directly to

either side or to the

bottom. Gas dryers

can only vent to

the left.

Kit # D26-49670

Use the LP conversion kit

for changing the dryer gas

connections from natural

gas (NG) to propane gas (LP).

Part No. D26-17025

NOTE: Installation of the

LP conversion kit must be

performed by a qualified

CONNECTING GAS DRYERS

GAS REQUIREMENTS (GAS MODELS ONLY)

WARNING: Toreducether skoffire,

electric shock, or injury to persons when using this

appliance, follow basic precautions, including

the following:

• Gas supply requirements: As shipped from the

factory, this dryer is configured for use with natural

gas (NG). It can be converted for use with propane

(LP) gas. Gas pressure must not exceed 8 inches

water column for (NG), or 13 inches water column for

(LP).

• A qualified service or gas company technician must

connect the dryer to the gas service. Failure to follow

these instructions can result in fire, explosion, or death.

• Isolate the dryer from the gas supply system by

closing its individual manual shutoff valve during any

pressure testing of the gas supply. Failure to do so can

result in fire, explosion, or death.

• Supply line requirements: Your laundry room must

have a rigid gas supply line to your dryer. In the

United States, an individual manual shutoff valve

MUST be installed within at least 6 ft. (1.8 m) of the

dryer, in accordance with the National Fuel Gas Code

ANSI Z223.1 or Canadian gas installation code CSA

B149.1. A _ inch NPT pipe plug must be installed.

Failure to do so can result in fire, explosion, or death.

• If using a rigid pipe, the rigid pipe should be 1½inch

IPS. If acceptable under local codes and ordinances

and when acceptable to your gas supplier, ¾ inch

approved tubing may be used where lengths are less

than 20 ft. (6.1 m). Larger tubing should be used for

lengths in excess of 20 ft. (6.1 m). Failure to do so can

result in fire, explosion, or death.

• Connect the dryer to the type of gas shown on

the nameplate. Failure to do so can result in fire,

explosion, or death.

• To prevent contamination of the gas valve, purge the

gas supply of air and sediment before connecting

the gas supply to the dryer. Before tightening the

connection between the gas supply and the dryer,

purge remaining air until the odor of gas is detected.

Failure to do so can result in fire, explosion, or death.

• DO NOT use an open flame to inspect for gas leaks.

Use a noncorrosive leak detection fluid. Failure to do

so can result in fire, explosion, or death.

• Use only a new AGA- or CSA-certified gas supply

line with flexible stainless steel connectors. Failure to

do so can result in fire, explosion, or death.

• Securely tighten all gas connections. Failure to do so

can result in fire, explosion, or death.

• Use Teflon tape or a pipe-joint compound that is

insoluble in propane (LP) gas on all pipe threads.

Failure to do so can result in fire, explosion,

or death.

• DO NOT attempt any disassembly of the dryer;

disassembly requires the attention and tools of

an authorized and qualified service technician or

company. Failure to follow this warning can result in fire,

explosion, or death.

ELECTRICAL REQUIREMENTS FOR

GAS MODELS ONLY

• Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord. Failure

to follow this warning can result in fire, explosion, or

death.

• For personal safety, this dryer must be properly

grounded. Failure to follow this warning can result in

fire, explosion, or death.

• The power cord of this dryer is equipped with

a 3-prong (grounding) plug which mates with a

standard 3-prong (grounding) wall outlet to minimize

the possibility of electric shock hazard from this

appliance. Failure to follow this warning can result in

fire, explosion, or death.

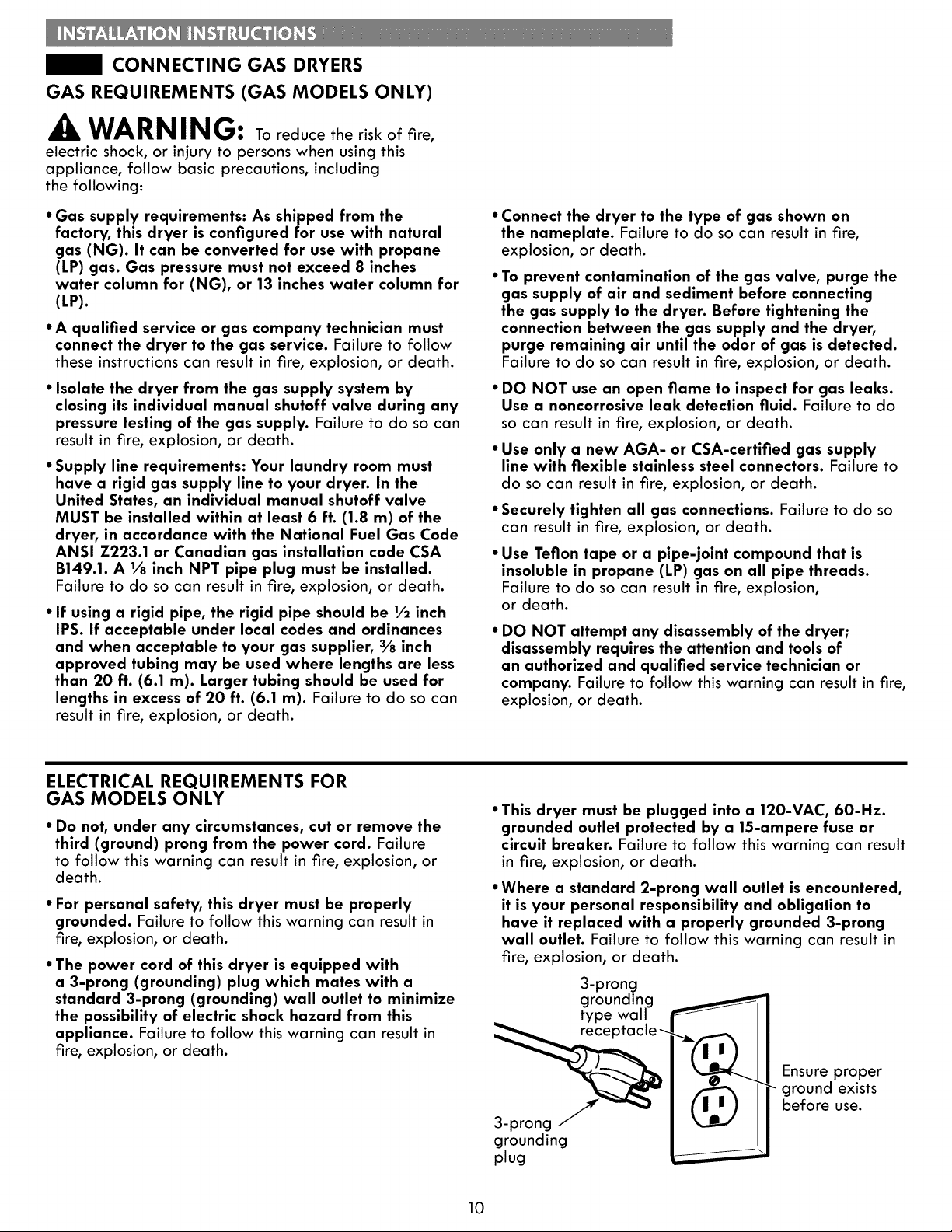

• This dryer must be plugged into a 120-VAC, 60-Hz.

grounded outlet protected by a 15-ampere fuse or

circuit breaker. Failure to follow this warning can result

in fire, explosion, or death.

• Where a standard 2-prong wall outlet is encountered,

it is your personal responsibility and obligation to

have it replaced with a properly grounded 3-prong

wall outlet. Failure to follow this warning can result in

fire, explosion, or death.

3-prong

grounding

type wall

Ensure proper

ground exists

before use.

grounding

plug

10

CONNECTING GAS DRYERS (continued)

A,,.WARNING: Toreducether skoffire,

electric shock, or injury to persons when using this

appliance, follow basic precautions, including

the following:

• Installation and service must be performed by a

qualified installer, service agency, or the gas supplier.

Failure to do so can result in fire, explosion, or death.

• Use only a new stainless steel flexible connector and

a new AGA-certified connector. Failure to do so can

result in fire, explosion, or death.

• A gas shutoff valve must be installed within 6 ft.

(1.8 m) of the dryer. Failure to do so can result in fire,

explosion, or death.

• The dryer is configured for natural gas when

shipped from the factory. Make sure that the dryer

is equipped with the correct burner nozzle for the

type of gas being used (natural gas or propane gas).

Failure to do so can result in fire, explosion, or death.

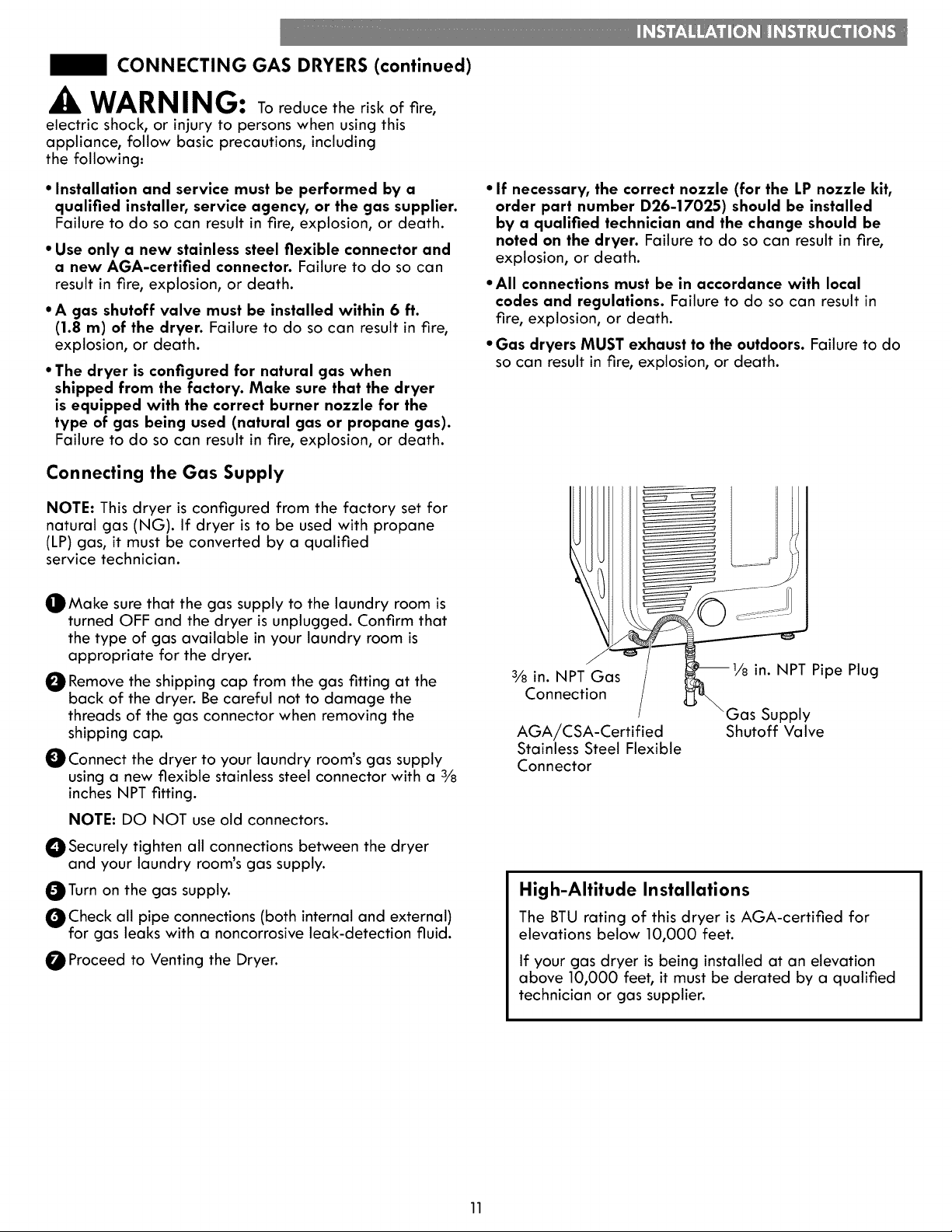

Connecting the Gas Supply

NOTE: This dryer is configured from the factory set for

natural gas (NG). If dryer is to be used with propane

(LP) gas, it must be converted by a qualified

service technician.

_lMake sure that the gas supply to the laundry room is

turned OFF and the dryer is unplugged. Confirm that

the type of gas available in your laundry room is

appropriate for the dryer.

O Remove the shipping cap from the gas fitting at the

back of the dryer. Be careful not to damage the

threads of the gas connector when removing the

shipping cap.

OConnect the dryer to your laundry room's gas supply

using a new flexible stainless steel connector with a 3/8

inches NPT fitting.

NOTE: DO NOT use old connectors.

• If necessary, the correct nozzle (for the LP nozzle kit,

order part number D26-17025) should be installed

by a qualified technician and the change should be

noted on the dryer. Failure to do so can result in fire,

explosion, or death.

• All connections must be in accordance with local

codes and regulations. Failure to do so can result in

fire, explosion, or death.

• Gas dryers MUST exhaust to the outdoors. Failure to do

so can result in fire, explosion, or death.

/

_ 11--J

•

3/8in. NPT Gas

Connection

/ _-_si_u_ily Pipe Plug

AGA/CSA-Certified Shutoff Valve

Stainless Steel Flexible

Connector

_Securely tighten all connections between the dryer

and your laundry room's gas supply.

Turn on the gas supply.

_Check all pipe connections (both internal and external)

for gas leaks with a noncorrosive leak-detection fluid.

Proceed to Venting the Dryer.

High-Altitude Installations

The BTU rating of this dryer is AGA-certified for

elevations below 10,000 feet.

If your gas dryer is being installed at an elevation

above 10,000 feet, it must be derated by a qualified

technician or gas supplier.

11

CONNECTING ELECTRIC DRYERS

ELECTRICAL REQUIREMENTS

WARNING: To help prevent fire, electric

shock, serious injury, or death, the wiring and grounding

must conform to the latest edition of the National

Electrical Code, ANSI/NFPA 70 and all applicable local

regulations. Please contact a qualified electrician to

check your home's wiring and fuses to ensure that your

home has adequate electrical power to operate the dryer.

A,.,WARNING: To reduce the risk of fire,

electric shock, or injury to persons when using this

appliance, follow basic precautions, including the

following:

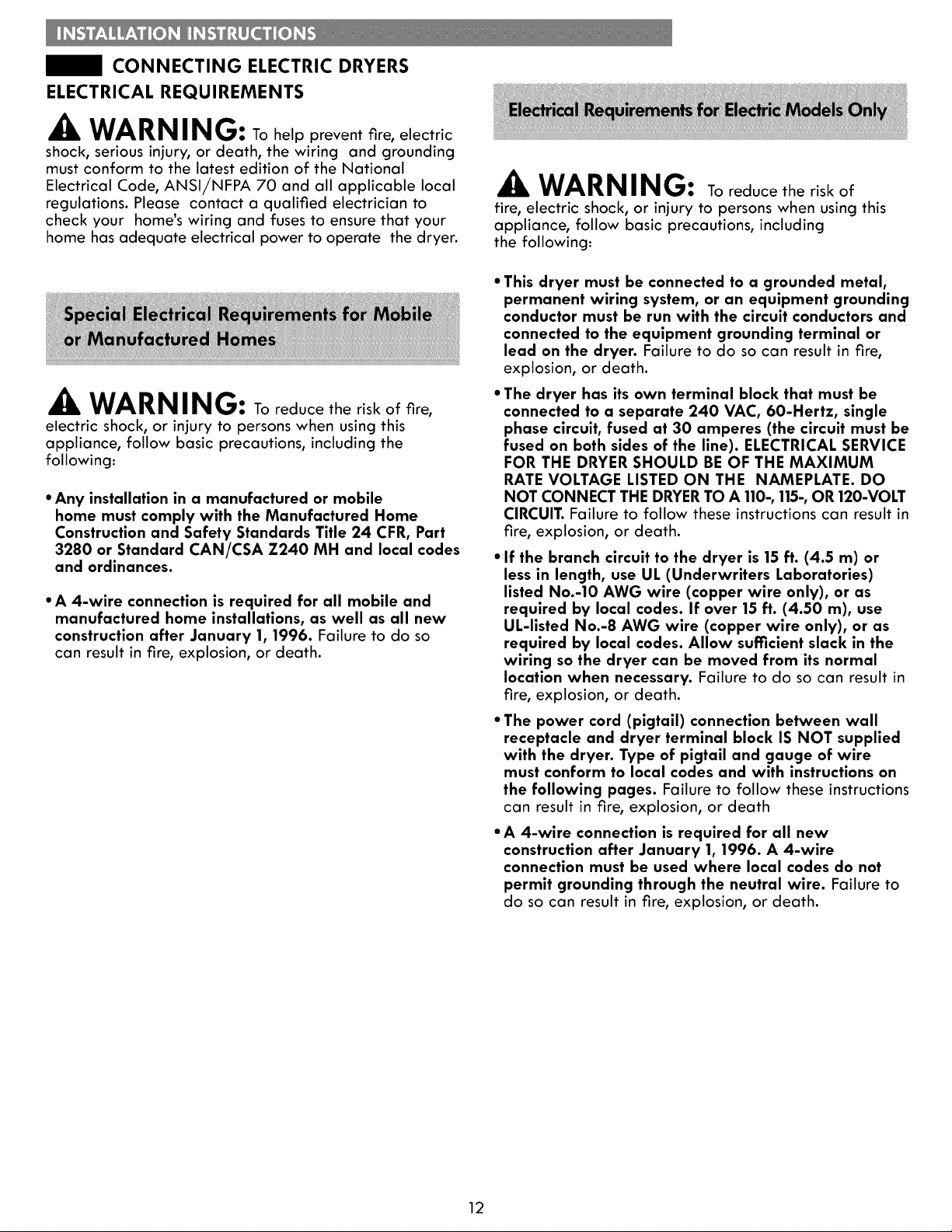

• Any installation in a manufactured or mobile

home must comply with the Manufactured Home

Construction and Safety Standards Title 24 CFR, Part

3280 or Standard CAN/CSA Z240 MH and local codes

and ordinances.

• A 4-wire connection is required for all mobile and

manufactured home installations, as well as all new

construction after January 1, 1996. Failure to do so

can result in fire, explosion, or death.

WARNING: To reduce the risk of

fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including

the following:

• This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment grounding terminal or

lead on the dryer. Failure to do so can result in fire,

explosion, or death.

• The dryer has its own terminal block that must be

connected to a separate 240 VAC, 60-Hertz, single

phase circuit, fused at 30 amperes (the circuit must be

fused an both sides of the line). ELECTRICAL SERVICE

FOR THE DRYER SHOULD BE OF THE MAXIMUM

RATE VOLTAGE LISTED ON THE NAMEPLATE. DO

NOT CONNECT THE DRYER TO A 110-, 115-,OR 120-VOLT

CIRCUIT. Failure to follow these instructions can result in

fire, explosion, or death.

• If the branch circuit to the dryer is 15 ft. (4.5 m) or

less in length, use UL (Underwriters Laboratories)

listed No.-10 AWG wire (copper wire only), or as

required by local codes. If over 15 ft. (4.50 m), use

UL-listed No.-8 AWG wire (copper wire only), or as

required by local codes. Allow sufficient slack in the

wiring so the dryer can be moved from its normal

location when necessary. Failure to do so can result in

fire, explosion, or death.

• The power cord (pigtail) connection between wall

receptacle and dryer terminal block IS NOT supplied

with the dryer. Type of pigtail and gauge of wire

must conform to local codes and with instructions on

the following pages. Failure to follow these instructions

can result in fire, explosion, or death

•A 4-wire connection is required for all new

construction after January 1, 1996. A 4-wire

connection must be used where local codes do not

permit grounding through the neutral wire. Failure to

do so can result in fire, explosion, or death.

12

CONNECTING ELECTRIC DRYERS (continued)

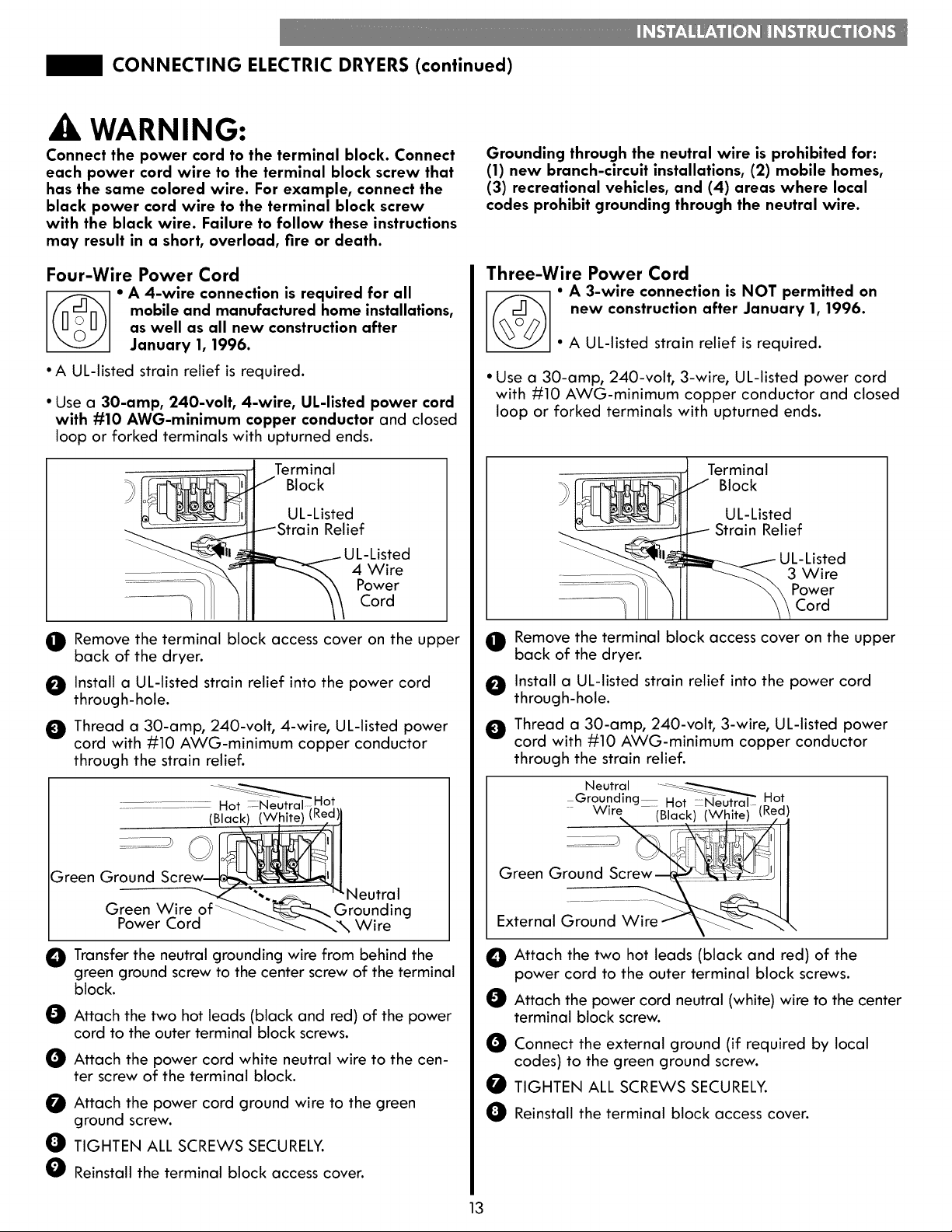

WARNING:

Connect the power cord to the terminal block. Connect

each power cord wire to the terminal block screw that

has the same colored wire. For example, connect the

black power cord wire to the terminal block screw

with the black wire. Failure to follow these instructions

may result in a short, overload, fire or death.

Grounding through the neutral wire is prohibited for:

(1) new branch-circuit installations, (2) mobile homes,

(3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral wire.

Four-Wire Power Cord

mobile and manufactured home installations,

as well as all new construction after

oA 4-wire connection is required for all

January 1, 1996.

• A UL-listed strain relief is required.

• Use a 30-amp, 240-volt, 4-wire, UL-listed power cord

with #10 AWG-minimum copper conductor and closed

loop or forked terminals with upturned ends.

Terminal

Block

UL-Listed

Relief

UL-Listed

4 Wire

Power

Cord

_t Remove the terminal block access cover on the upper

back of the dryer.

_I Install a UL-listed strain relief into the power cord

through-hole.

Three-Wire Power Cord

• A 3-wire connection is NOT permitted on

new construction after January 1, 1996.

• A UL-listed strain relief is required.

• Use a 30-amp, 240-volt, 3-wire, UL-listed power cord

with #10 AWG-minimum copper conductor and closed

loop or forked terminals with upturned ends.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

3 Wire

Power

Cord

_I Remove the terminal block access cover on the upper

back of the dryer.

O1 Install a UL-listed strain relief into the power cord

through-hole.

O Thread a 30-amp, 240-volt, 4-wire, UL-listed power

cord with #10 AWG-minimum copper conductor

through the strain relief.

(Black)

Green Ground

Neutral

Green Wire Grounding

Power Cord Wire

O Transfer the neutral grounding wire from behind the

green ground screw to the center screw of the terminal

block.

O1 Attach the two hot leads (black and red) of the power

cord to the outer terminal block screws.

_t Attach the power cord white neutral wire to the cen-

ter screw of the terminal block.

Attach the power cord ground wire to the green

ground screw.

_I TIGHTEN ALL SCREWS SECURELY.

_I Reinstall the terminal block access cover.

_I Thread a 30-amp, 240-volt, 3-wire, UL-listed power

cord with #10 AWG-minimum copper conductor

through the strain relief.

Neutral ......__

......Grounding_ Hot _Neut_al Hot

W,r_ (Black) (White) (Red!

Green G ]

External Ground Wire J _'__'_x

O Attach the two hot leads (black and red) of the

power cord to the outer terminal block screws.

O

Attach the power cord neutral (white) wire to the center

terminal block screw.

@

Connect the external ground (if required by local

codes) to the green ground screw.

@

TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access coven

O

13

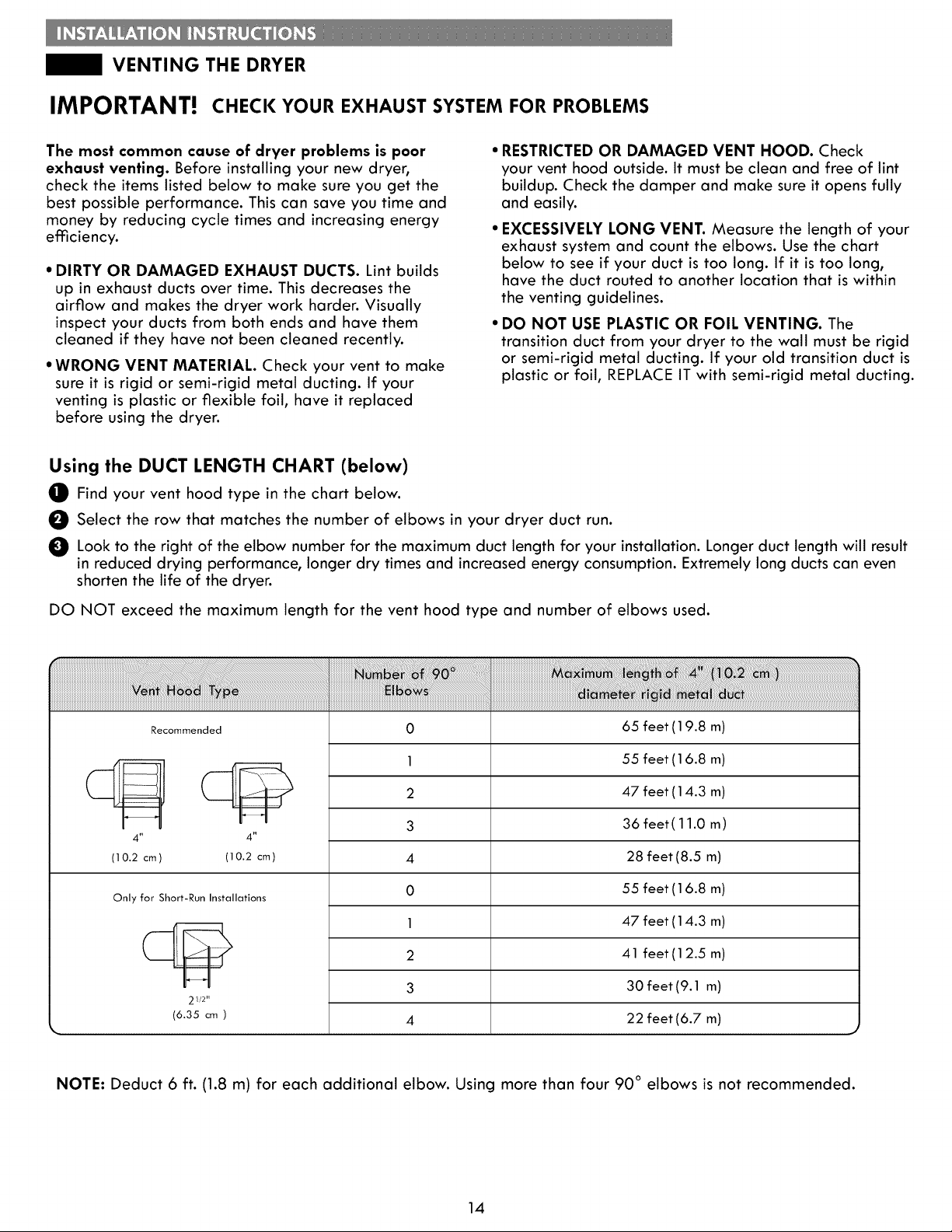

VENTING THE DRYER

IMPORTANT! CHECK YOUR EXHAUST SYSTEM FOR PROBLEMS

The most common cause of dryer problems is poor

exhaust venting. Before installing your new dryer,

check the items listed below to make sure you get the

best possible performance. This can save you time and

money by reducing cycle times and increasing energy

efficiency.

• DIRTY OR DAMAGED EXHAUST DUCTS. Lint builds

up in exhaust ducts over time. This decreases the

airflow and makes the dryer work harder. Visually

inspect your ducts from both ends and have them

cleaned if they have not been cleaned recently.

• WRONG VENT MATERIAL. Check your vent to make

sure it is rigid or semi-rigid metal ducting. If your

• RESTRICTED OR DAMAGED VENT HOOD. Check

your vent hood outside. It must be clean and free of lint

buildup. Check the damper and make sure it opens fully

and easily.

• EXCESSIVELY LONG VENT. Measure the length of your

exhaust system and count the elbows. Use the chart

below to see if your duct is too long. If it is too long,

have the duct routed to another location that iswithin

the venting guidelines.

• DO NOT USE PLASTIC OR FOIL VENTING. The

transition duct from your dryer to the wall must be rigid

or semi-rigid metal ducting. If your old transition duct is

plastic or foil, REPLACE IT with semi-rigid metal ducting.

venting is plastic or flexible foil, have it replaced

before using the dryer.

Using the DUCT LENGTH CHART (below)

_1 Find your vent hood type in the chart below.

O Select the row that matches the number of elbows in your dryer duct run.

Look to the right of the elbow number for the maximum duct length for your installation. Longer duct length will result

in reduced drying performance, longer dry times and increased energy consumption. Extremely long ducts can even

shorten the life of the dryer.

DO NOT exceed the maximum length for the vent hood type and number of elbows used.

(----I

1H

4"

(10.2 cm)

Only for Short-Run Installations

21/2"

(6.35 cm )

4"

(10.2 cm)

1

2

3

4

0

1

2

3

4

55 feet (16.8 m)

47 feet (14.3 m)

36 feet(11.0 m)

28 feet (8.5 m)

55 feet (16.8 m)

47 feet (14.3 m)

41 feet (12.5 m)

30 feet (9.1 m)

22 feet (6.7 m)

NOTE: Deduct 6 ft. (1.8 m) for each additional elbow. Using more than four 90 ° elbows is not recommended.

14

VENTING THE DRYER (continued)

Routing and Connecting Ductwork

Follow the guidelines below to maximize dryer

performance and reduce lint buildup and condensation

in the ductwork.

NOTE: Transition duct (from dryer to wall) and fittings

are NOT included and must be purchased separately.

• Use 4 inch (102mm) diameter rigid or semi-rigid

metal duct.

•The exhaust duct run should be as short as possible.

• Use as few elbow joints as possible.

•The male end of each section of exhaust duct must

point away from the dryer. See figure on lower right of

page.

• Use duct tape on all joints. Never use screws.

• Insulate ducts that run through unheated areas in order

to reduce condensation and lint buildup on

duct surfaces.

•The total length of semi-rigid metal transition duct

should not exceed 8 ft. (2.4 m).

Correct Venting

E

Incorrect Venting

A WARNING: Failure to follow these

guidelines will result in poor performance, product

failure, and/or result in fire or death.

IMPORTANT: Failure to exhaust the dryer, per the

guidelines included within these instructions, may

result in unsatisfactory dryer performance. All venting

and ductwork beyond the exterior of the dryer is the

responsibility of the consumer. Product failure, as a

result of improper venting, is not covered by the dryer

wa rra nty.

Connecting the Dryer Vent

O Verify all ducts and elbows are clean and free

from any blockages.

Measure duct length. DO NOT exceed the

maximum length listed in the Duct Length Chart.

Connect dryer exhaust to existing duct.

•Only use duct tape or clamps.

• DO NOT use screws to secure ductwork.

• Use rigid or semi-rigid metal ducts.

• DO NOT use plastic or thin metal foil tubing

for ductwork.

•The male end of each elbow must always point in

the direction of the airflow.

mAI

Male

Ends

!

1

O

15

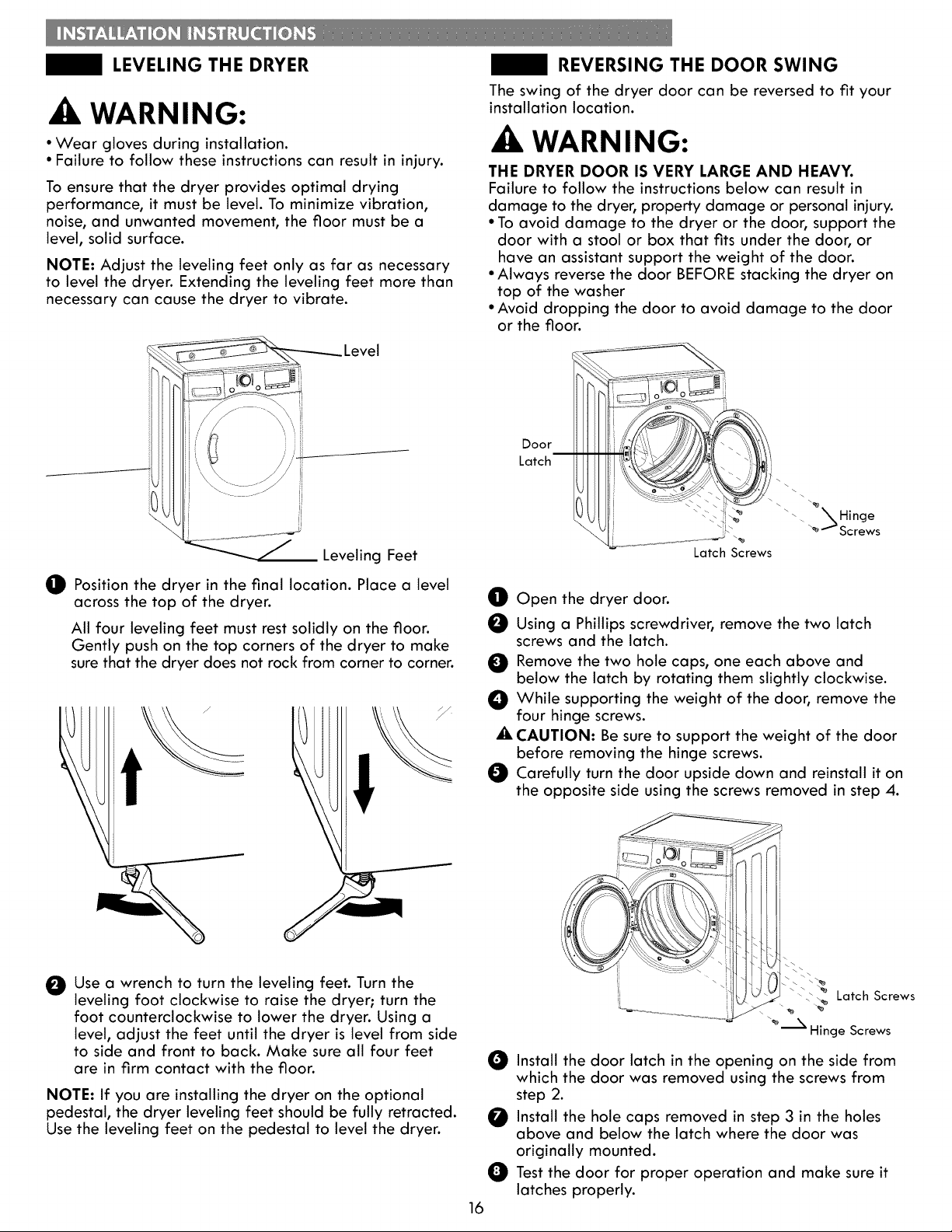

LEVELING THE DRYER _ REVERSING THE DOOR SWING

The swing of the dryer door can be reversed to fit your

WARNING:

installation location.

•Wear gloves during installation.

• Failure to follow these instructions can result in injury.

To ensure that the dryer provides optimal drying

performance, it must be level. To minimize vibration,

noise, and unwanted movement, the floor must be a

level, solid surface.

NOTE: Adjust the leveling feet only as far as necessary

to level the dryer. Extending the leveling feet more than

necessary can cause the dryer to vibrate.

Level

\

Leveling Feet

_11 Position the dryer in the final location. Place a level

across the top of the dryer.

All four leveling feet must rest solidly on the floor.

Gently push on the top corners of the dryer to make

sure that the dryer does not rock from corner to corner.

!

WARNING:

THE DRYER DOOR IS VERY LARGE AND HEAVY.

Failure to follow the instructions below can result in

damage to the dryer, property damage or personal injury.

• To avoid damage to the dryer or the door, support the

door with a stool or box that fits under the door, or

have an assistant support the weight of the door.

•Always reverse the door BEFORE stacking the dryer on

top of the washer

•Avoid dropping the door to avoid damage to the door

or the floor.

Door

Latch

O

Open the dryer door.

Using a Phillips screwdriver, remove the two latch

screws and the latch.

Remove the two hole caps, one each above and

below the latch by rotating them slightly clockwise.

While supporting the weight of the door, remove the

four hinge screws.

_, CAUTION: Be sure to support the weight of the door

before removing the hinge screws.

O1 Carefully turn the door upside down and reinstall it on

the opposite side using the screws removed in step 4.

Use a wrench to turn the leveling feet. Turn the

O

leveling foot clockwise to raise the dryer; turn the

foot counterclockwise to lower the dryer. Using a

level, adjust the feet until the dryer is level from side

to side and front to back. Make sure all four feet

are in firm contact with the floor.

NOTE: If you are installing the dryer on the optional

pedestal, the dryer leveling feet should be fully retracted.

Use the leveling feet on the pedestal to level the dryer.

16

_ Hinge Screws

Install the door latch in the opening on the side from

which the door was removed using the screws from

step 2.

Install the hole caps removed in step 3 in the holes

above and below the latch where the door was

originally mounted.

0

Test the door for proper operation and make sure it

latches properly.

Latch Screws

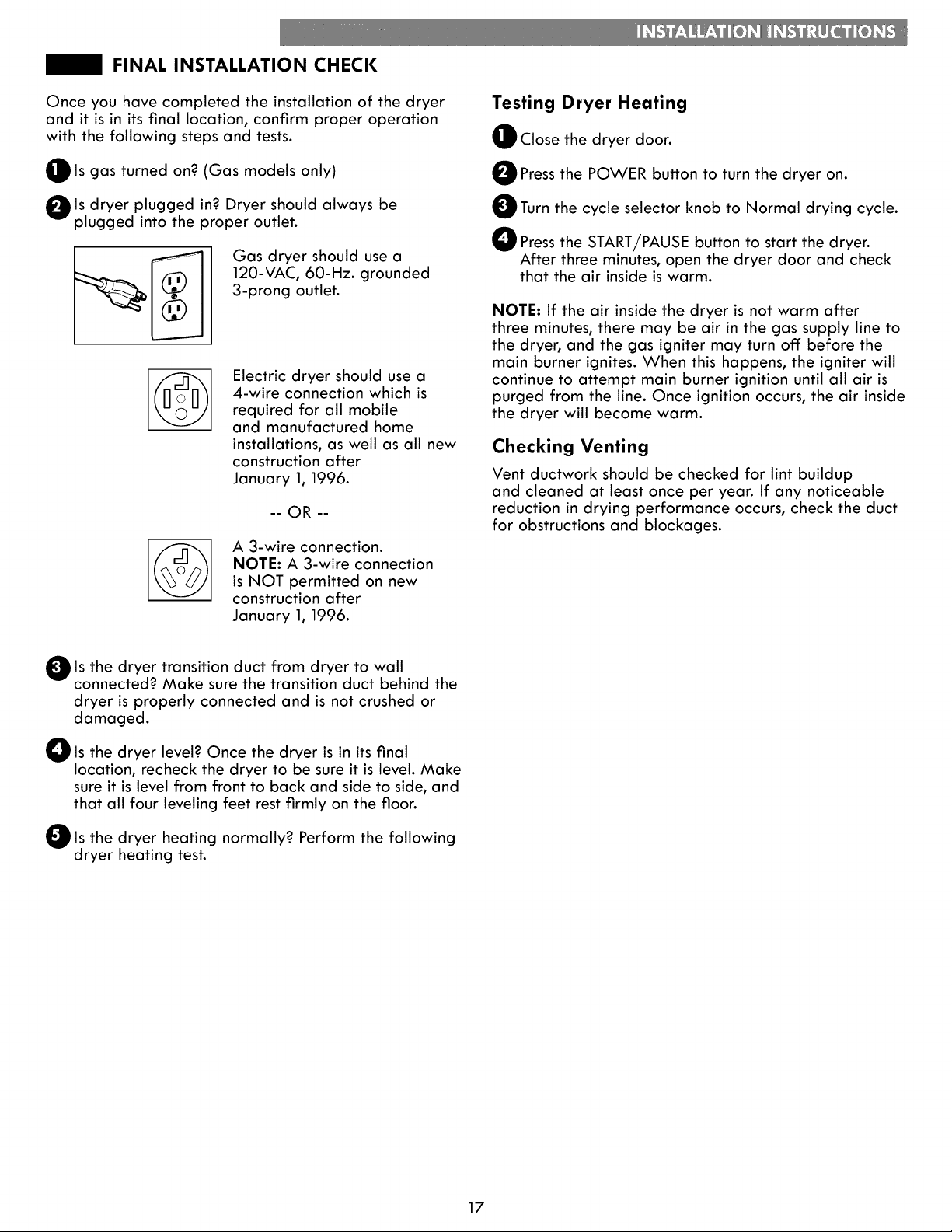

FINAL INSTALLATION CHECK

Once you have completed the installation of the dryer

and it is in its final location, confirm proper operation

with the following steps and tests.

_)ls gas turned on? (Gas models only)

O s dryer plugged in? Dryer should always be

plugged into the proper outlet.

Gas dryer should use a

120-VAC, 60-Hz. grounded

3-prong outlet.

Electric dryer should use a

4-wire connection which is

©

©

required for all mobile

and manufactured home

installations, as well as all new

construction after

January 1, 1996.

--OR --

A 3-wire connection.

NOTE: A 3-wire connection

is NOT permitted on new

construction after

January 1, 1996.

Testing Dryer Heating

_ICIose the dryer door.

O Press the POWER button to turn the dryer on.

OTurn the cycle selector knob to Normal drying cycle.

O Press the START/PAUSE button to start the dryer.

After three minutes, open the dryer door and check

that the air inside is warm.

NOTE: If the air inside the dryer is not warm after

three minutes, there may be air in the gas supply line to

the dryer, and the gas igniter may turn off before the

main burner ignites. When this happens, the igniter will

continue to attempt main burner ignition until all air is

purged from the line. Once ignition occurs, the air inside

the dryer will become warm.

Checking Venting

Vent ductwork should be checked for lint buildup

and cleaned at least once per year. If any noticeable

reduction in drying performance occurs, check the duct

for obstructions and blockages.

O s the dryer transition duct from dryer to wall

connected? Make sure the transition duct behind the

dryer is properly connected and is not crushed or

damaged.

O Is the dryer level? Once the dryer is in its final

location, recheck the dryer to be sure it is level. Make

sure it is level from front to back and side to side, and

that all four leveling feet rest firmly on the floor.

_)ls the dryer heating normally? Perform the following

dryer heating test.

17

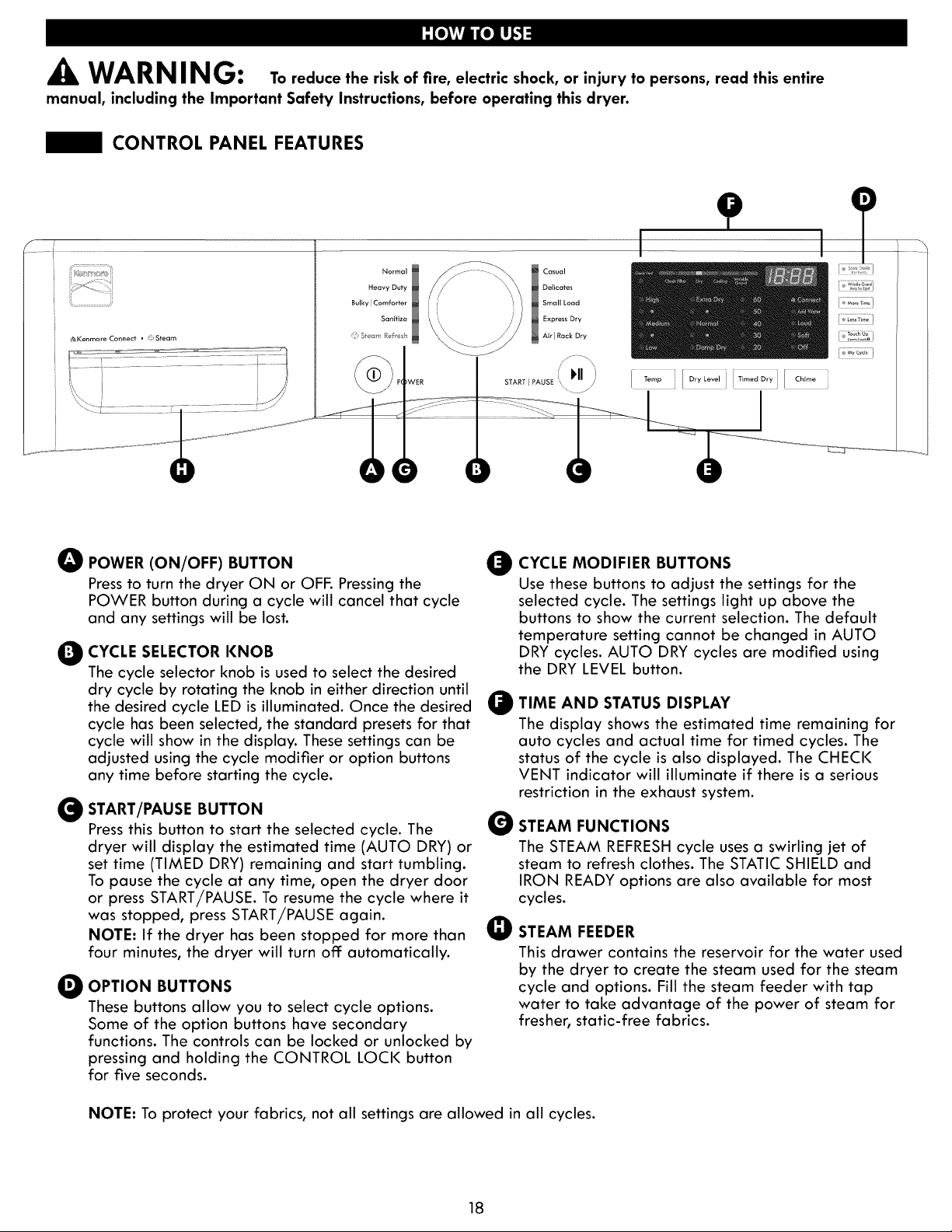

WARNING: To reduce the risk of fire, electric shock, or injury to persons, read this entire

manual, including the Important Safety Instructions, before operating this dryer.

CONTROL PANEL FEATURES

Casual

Delicates

_hKenmore Connect • d Steam

O POWER (ON/OFF) BUTTON

Pressto turn the dryer ON or OFF. Pressing the

POWER button during a cycle will cancel that cycle

and any settings will be lost.

CYCLE SELECTOR KNOB

O

The cycle selector knob is used to select the desired

dry cycle by rotating the knob in either direction until

the desired cycle LED is illuminated. Once the desired

cycle has been selected, the standard presets for that

cycle will show in the display. These settings can be

adjusted using the cycle modifier or option buttons

any time before starting the cycle.

_I START/PAUSE BUTTON

Press this button to start the selected cycle. The

dryer will display the estimated time (AUTO DRY) or

set time (TIMED DRY) remaining and start tumbling.

To pause the cycle at any time, open the dryer door

or press START/PAUSE. To resume the cycle where it

was stopped, press START/PAUSE again.

NOTE: If the dryer has been stopped for more than

four minutes, the dryer will turn off automatically.

OPTION BUTTONS

O

These buttons allow you to select cycle options.

Some of the option buttons have secondary

functions. The controls can be locked or unlocked by

pressing and holding the CONTROL LOCI( button

for five seconds.

,WER

STARTIPAUSE \ /

HI

\ /

i Temp [ !ii !iii! ] [ Timed DI;] [ !!!m i

I

CYCLE MODIFIER BUTTONS

O

Use these buttons to adjust the settings for the

selected cycle. The settings light up above the

buttons to show the current selection. The default

temperature setting cannot be changed in AUTO

DRY cycles. AUTO DRY cycles are modified using

the DRY LEVEL button.

TIME AND STATUS DISPLAY

O

The display shows the estimated time remaining for

auto cycles and actual time for timed cycles. The

status of the cycle is also displayed. The CHECK

VENT indicator will illuminate if there is a serious

restriction in the exhaust system.

STEAM FUNCTIONS

O

The STEAM REFRESH cycle uses a swirling jet of

steam to refresh clothes. The STATIC SHIELD and

IRON READY options are also available for most

cycles.

O

STEAM FEEDER

This drawer contains the reservoir for the water used

by the dryer to create the steam used for the steam

cycle and options. Fill the steam feeder with tap

water to take advantage of the power of steam for

fresher, static-free fabrics.

NOTE: To protect your fabrics, not all settings are allowed in all cycles.

18

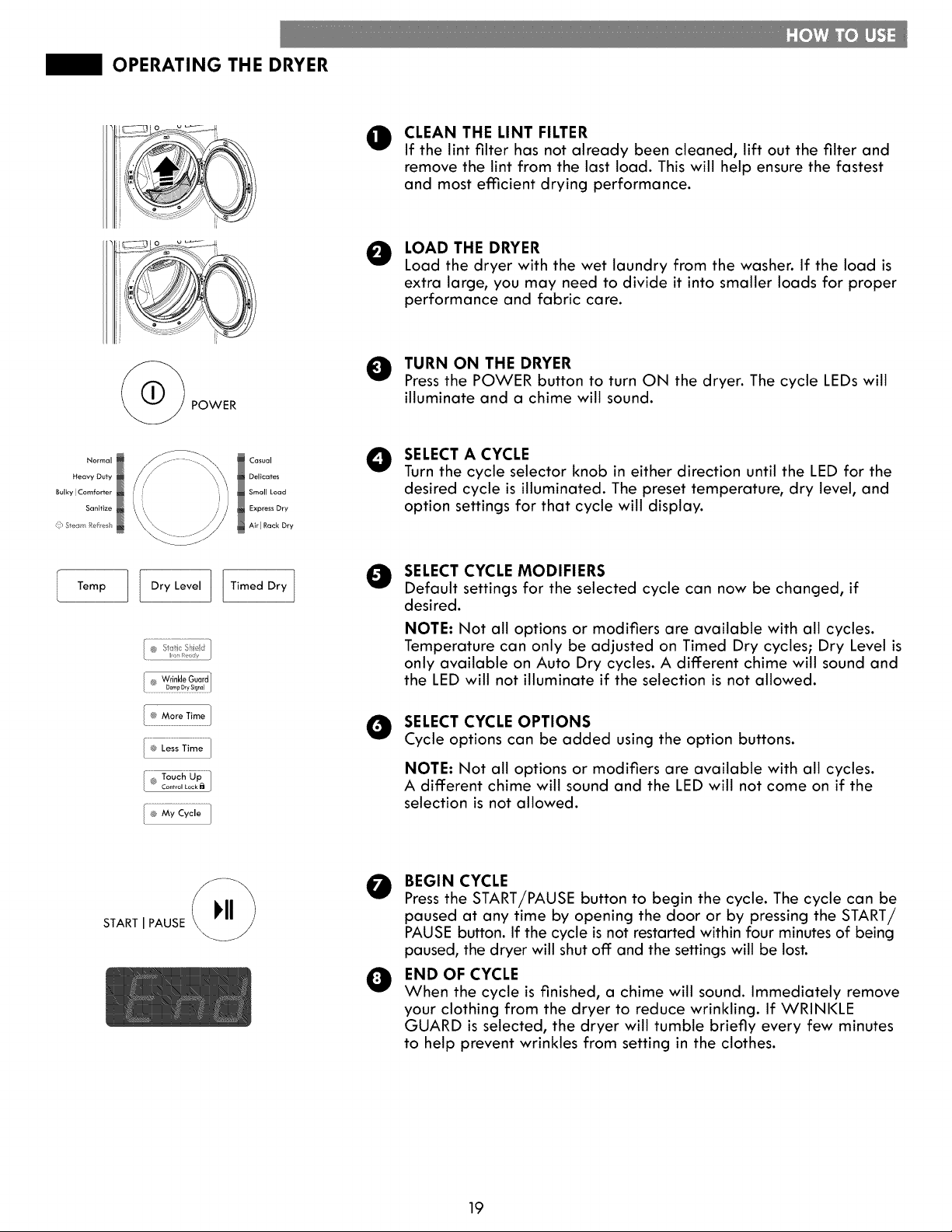

1 OPERATING THE DRYER

POWER

CLEAN THE LINT FILTER

e!

If the lint filter has not already been cleaned, lift out the filter and

remove the lint from the last load. This will help ensure the fastest

and most efficient drying performance.

LOAD THE DRYER

O

Load the dryer with the wet laundry from the washer. If the load is

extra large, you may need to divide it into smaller loads for proper

performance and fabric care.

O URN ON THE DRYER

Press the POWER button to turn ON the dryer. The cycle LEDs will

illuminate and a chime will sound.

Normal

Heavy Duty

Bulky JComforter

Sanitize

_b Steam Refresh

Temp

Dry Level J Timed Dry J

_ W_inkleGuard/

_ Control Lock_

START JPAUSE

Casual

Delicates

Small Load

Express Dry

Air J Rack Dry

SELECT A CYCLE

O

Turn the cycle selector knob in either direction until the LED for the

desired cycle is illuminated. The preset temperature, dry level, and

option settings for that cycle will display.

O1 ELECT CYCLE MODIFIERS

Default settings for the selected cycle can now be changed, if

desired.

NOTE: Not all options or modifiers are available with all cycles.

Temperature can only be adjusted on Timed Dry cycles; Dry Level is

only available on Auto Dry cycles. A different chime will sound and

the LED will not illuminate if the selection is not allowed.

SELECT CYCLE OPTIONS

O

Cycle options can be added using the option buttons.

NOTE: Not all options or modifiers are available with all cycles.

A different chime will sound and the LED will not come on if the

selection is not allowed.

BEGIN CYCLE

O

Press the START/PAUSE button to begin the cycle. The cycle can be

paused at any time by opening the door or by pressing the START/

PAUSE button. If the cycle is not restarted within four minutes of being

paused, the dryer will shut off and the settings will be lost.

END OF CYCLE

@

When the cycle is finished, a chime will sound. Immediately remove

your clothing from the dryer to reduce wrinkling. If WRINKLE

GUARD is selected, the dryer will tumble briefly every few minutes

to help prevent wrinkles from setting in the clothes.

19

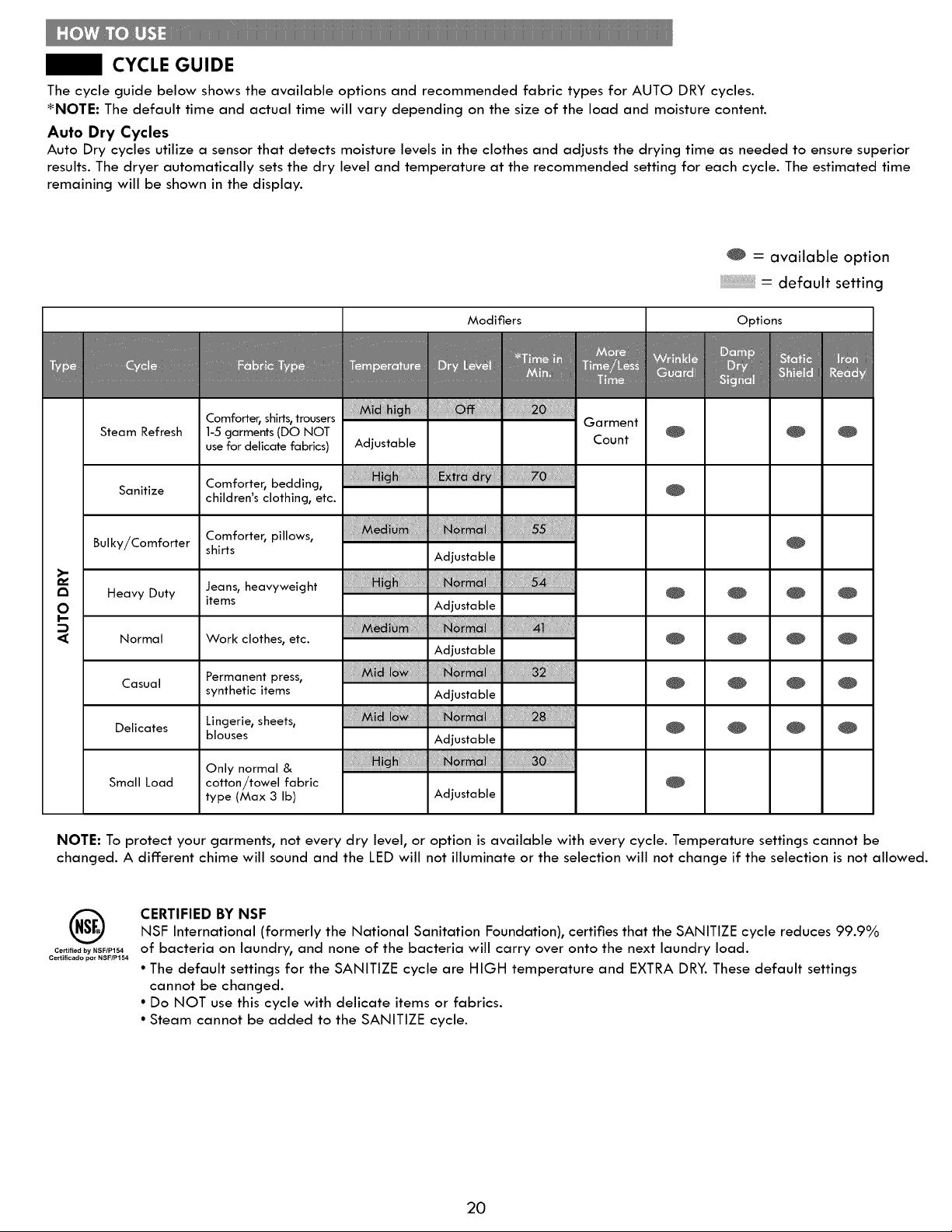

CYCLE GUIDE

The cycle guide below shows the available options and recommended fabric types for AUTO DRY cycles.

_NOTE: The default time and actual time will vary depending on the size of the load and moisture content.

Auto Dry Cycles

Auto Dry cycles utilize a sensor that detects moisture levels in the clothes and adjusts the drying time as needed to ensure superior

results. The dryer automatically sets the dry level and temperature at the recommended setting for each cycle. The estimated time

remaining will be shown in the display.

O = available option

= default setting

Steam Refresh

Sanitize

Bulky/Comforter

Heavy Duty

Normal

Casual

Delicates

Small Load

Comforter, shirts,trousers

1-5 garments (DO NOT

use for delicate fabrics)

Comforter, bedding,

children's clothing, etc.

Comforter, pillows,

shirts

Jeans, heavyweight

items

Work clothes, etc.

Permanent press,

synthetic items

Lingerie, sheets,

blouses

Only normal &

cotton/towel fabric

type (Max 3 Ib)

Adjustable

Modifiers

Adjustable

Adjustable

Adjustable

Adjustable

Adjustable

Adjustable

Options

Garment

Count

NOTE: To protect your garments, not every dry level, or option is available with every cycle. Temperature settings cannot be

changed. A different chime will sound and the LED will not illuminate or the selection will not change if the selection is not allowed.

CERTIFIED BY NSF

@

Certified by NSF/P154

Certificado pot NSFIP154

NSF International (formerly the National Sanitation Foundation), certifies that the SANITIZE cycle reduces 99.9%

of bacteria on laundry, and none of the bacteria will carry over onto the next laundry load.

• The default settings for the SANITIZE cycle are HIGH temperature and EXTRA DRY. These default settings

cannot be changed.

• Do NOT use this cycle with delicate items or fabrics.

• Steam cannot be added to the SANITIZE cycle.

2O

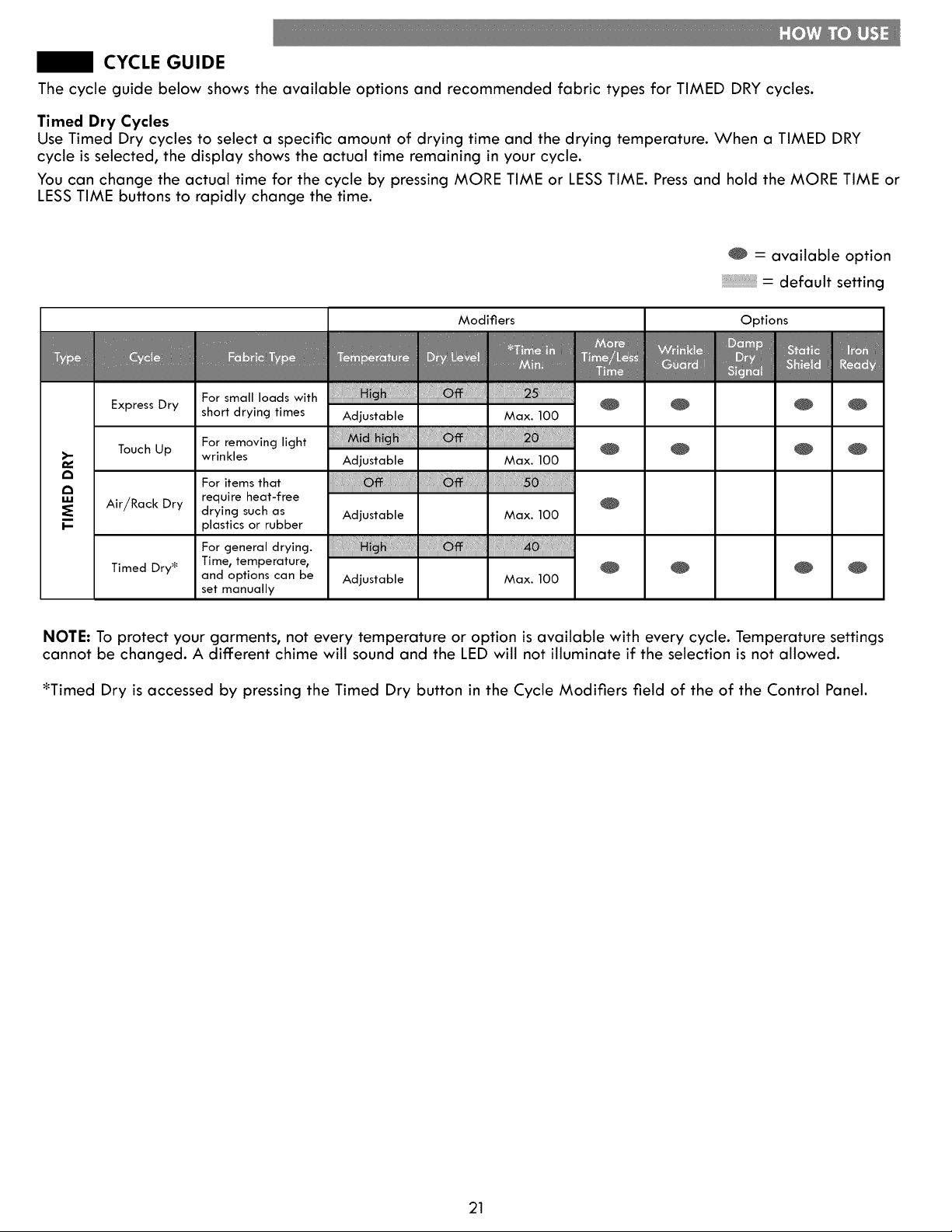

CYCLE GUIDE

The cycle guide below shows the available options and recommended fabric types for TIMED DRY cycles.

Timed Dry Cycles

Use Timed Dry cycles to select a specific amount of drying time and the drying temperature. When a TIMED DRY

cycle is selected, the display shows the actual time remaining in your cycle.

You can change the actual time for the cycle by pressing MORE TIME or LESSTIME. Press and hold the MORE TIME or

LESS TIME buttons to rapidly change the time.

O = available option

= default setting

Express Dry

Touch Up

Air/Rack Dry

Timed Dry _

For small loads with

short drying times

For removing light

wrinkles

For items that

require heat-free

drying such as

plastics or rubber

For general drying.

Time, temperature,

and options can be

set manually

Adjustable

Adjustable

Adjustable

Adjustable

Modifiers

Max. 100

Max. 100

Max. 100

Max. 100

Options

NOTE: To protect your garments, not every temperature or option is available with every cycle. Temperature settings

cannot be changed. A different chime will sound and the LED will not illuminate if the selection is not allowed.

_Timed Dry is accessed by pressing the Timed Dry button in the Cycle Modifiers field of the of the Control Panel.

21

WARN ING: To reduce the risk of fire, electric shock, or injury to persons, read this entire manual,

including the Important Safety Instructions, before operating this dryer.

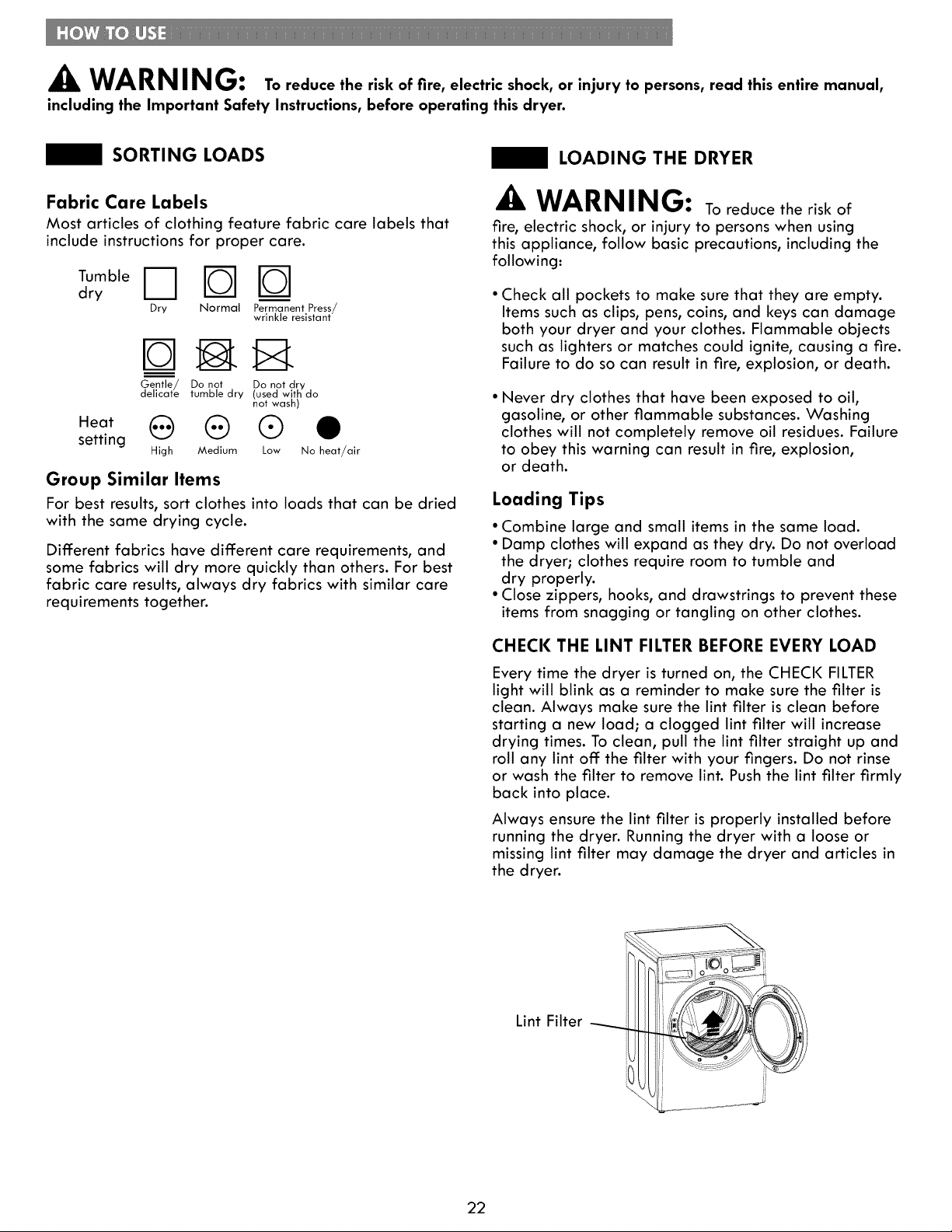

SORTING LOADS

Fabric Care Labels

Most articles of clothing feature fabric care labels that

include instructions for proper care.

Tumble D [O---] [O- 1

dry

Dry Normal Permanent Press/

Gentle/ Do not Do not dry

delicate tumble dry (used with do

wrinkle resistant

not wash)

Heat

setting

High Medium Low No heat/air

Group Similar Items

For best results, sort clothes into loads that can be dried

with the same drying cycle.

Different fabrics have different care requirements, and

some fabrics will dry more quickly than others. For best

fabric care results, always dry fabrics with similar care

requirements together.

LOADING THE DRYER

A WARNING: To reduce the risk of

fire, electric shock, or injury to persons when using

this appliance, follow basic precautions, including the

following:

• Check all pockets to make sure that they are empty.

Items such as clips, pens, coins, and keys can damage

both your dryer and your clothes. Flammable objects

such as lighters or matches could ignite, causing a fire.

Failure to do so can result in fire, explosion, or death.

• Never dry clothes that have been exposed to oil,

gasoline, or other flammable substances. Washing

clothes will not completely remove oil residues. Failure

to obey this warning can result in fire, explosion,

or death.

Loading Tips

• Combine large and small items in the same load.

• Damp clothes will expand as they dry. Do not overload

the dryer; clothes require room to tumble and

dry properly.

• Close zippers, hooks, and drawstrings to prevent these

items from snagging or tangling on other clothes.

CHECK THE LINT FILTER BEFORE EVERY LOAD

Every time the dryer is turned on, the CHECK FILTER

light will blink as a reminder to make sure the filter is

clean. Always make sure the lint filter is clean before

starting a new load; a clogged lint filter will increase

drying times. To clean, pull the lint filter straight up and

roll any lint off the filter with your fingers. Do not rinse

or wash the filter to remove lint. Push the lint filter firmly

back into place.

Always ensure the lint filter is properly installed before

running the dryer. Running the dryer with a loose or

missing lint filter may damage the dryer and articles in

the dryer.

Lint Filter

\

22

Loading...

Loading...