Kenmore 79680021900, 79680272900, 79690021900, 79690272900 Owner’s Manual

I I

Dryers

Use & Oa_e Guide and _nsta_ation _nst_uctions

Secadoras

Gu_ade uso y cuidado e mnstrucciones de instalaci6n

Models/Modelos

Electric / Electrico 796.8002#9## / 796.8027#9##

Gas / A Gas 796.9002#9## / 796.9027#9##

* = co,or number, n_mero de co,or

Protocol P154

Sanitization

Performanceof

Residetial Clothes dryer

Protocolo P154

Ejecucion de

Saneamiento en la zona

residencial Secadoras

Sears Brands Management Corporation, Hoffman Estates, IL 60179

3828EL3004U

I I

Sears Canada Inc., Toronto, Ontario, Canada M5B 2B8

www.seavs.cont

www.sears.ca

I I

IMPORTANT SAFETY INSTRUCTIONS

SAFETY MESSAGES .............................. 3

IMPORTANT SAFETY INSTRUCTIONS ............... 3-6

FEATURES AND BENEFITS

Key Parts and Components .......................... 7

INSTALLATION INSTRUCTIONS

Key Dimensions and Specifications .................... 8

Location Requirements .............................. 8

Choose the Proper Location .......................... 8

Clearances .............................. 8

Installation with Optional Pedestal Base or Stacking Kit..... 9

Optional Accessories .............................. 9

Gas Requirements .............................. 10

Connecting Gas Dryers ............................ 10,11

Electrical Requirements ............................. 12

Connecting Electric Dryers ......................... 12,13

Venting the Dryer .............................. 14,15

Leveling the Dryer.............................. 16

Reversing the Door Swing .......................... 16

Final Installation Check ............................. 17

HOW TO USE

Control Panel Features ............................. 18

Operating the Dryer ............................. 19

Cycle Guide ............................. 20

Sorting Loads ............................. 21

Loading the Dryer ............................. 21

Time and Status Display ............................ 22

Cycle Modifier Buttons ............................. 23

Cycle Options and Special Features ................... 24

Wrinkle Guard ............................. 24

Control Lock ............................. 24

Sanitize Cycle ............................. 24

USER MAINTENANCE INSTRUCTIONS

Regular Cleaning ............................. 25

Cleaning the Exterior ............................. 25

Cleaning the Interior ............................. 25

Maintaining the Ductwork ........................... 25

Cleaning the Lint Screen ............................ 25

TROUBLESHOOTING GUIDE

Before Calling Service ............................ 26-28

OPTIONAL ACCESSORIES

Optional Accessories ............................. 29

Stacking Kit Installation ............................. 29

Pedestal Installation ............................. 30

Side venting kit installation .......................... 31

WARRANTY ............................. 32

In the space below, record the date of purchase, model,

and serial number of your product. You will find the

model and serial number printed on an identification

plate located inside the dryer door. Have thesejtems

of information available whenever you contact Sears

concerning your product.

Model No.

Date of Purchase

Serial No.

Save these instructions and your sales receipt for

future reference.

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore <"_'product is designed and manufactured for

years of dependable operation. But like all products, it

may require preventive maintenance or repair from time

to time. That's when having a Master Protection Agreement

can save you money and aggravation.

The Master Protection Agreement also helps extend the

life of your new product. Here's what the Agreement*

includes:

, Parts and labor needed to help keep products oper-

ating properly under normal use, not just defects.

Our coverage goes well beyond the product war=

ranty. No deductible, no functional failure excluded

from coverage--real protection.

, Expert service by a force of more than 10,000

authorized Sears service technicians, which means

someone you can trust will be working on your prod-

uct.

, Unlimited service calls and nationwide service, as

often as you want us, whenever you want us.

, No-lemon guarantee--replacement of your covered

product if four or more product failures occur within

twelve months.

, Product replacement if your covered product can't

be fixed.

, Annual Preventive Maintenance Check at your

request--no extra charge.

, Fast help by phone--we call it Rapid Resolution.

Phone support from a Sears representative on all

products. Think of us as a t alking owner s manual.

, Power surge protection against electrical damage

due to power fluctuations.

, $250 food loss protection annually for any food

spoilage that is the result of mechanical failure of any

covered refrigerator or freezer.

, Rental reimbursement if repair of your covered

product takes longer than promised.

,10% discount off the regular price of any non-cov-

ered repair service and related installed parts.

Once you purchase the Agreement, a simple phone call

is all that it takes for you to schedule service. You can

call anytime day or night or schedule a service appoint-

ment online.

The Master Protection Agreement is a risk free pur-

chase. If you cancel for any reason during the product

warranty period, we will provide a full refund, or a pro-

rated refund anytime after the product warranty period

expires. Purchase your Master Protection Agreement

today!

Some limitations and exclusions apply.

For prices and additional information in the U.S.A.

call 1-800=827=6655.

*Coverage in Canada varies on some items.

For full details cail Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances,

garage door openers, water heaters, and other major

home items, in the U.S.A. or Canada, call

1-800-4-MY-HOM E_"_'.

2

I I

I I

Ri=AD ALL iNSTRUCTiONS BSFORS USE

•r..uWARNING oo,o,y,,.o,.,oratorio.mo.oo, bo,o,owo ,o

minimize the risk of fire or explosion, electric shock, or to prevent property damage, personal injury,

or loss of life.

f

Your Safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or WARNING.

These words mean:

DANGER: Youcanbe killed or seriously injured if you don't immediately follow instructions.

WARN|NG-" You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

Do not install a clothes dryer with flexible plastic venting materials, if flexible metal (foil type) duct

is installed, it must be of a specific type identified by the appliance manufacturer as suitable for

use with clothes dryers. Flexible venting materials are known to collapse, be easily crushed, and

trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this appliance

or any other appliances.

installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

install the clothes dryer according to the manufacturer's instructions and local codes.

* Save these instructions.

WHAT TO DO IF YOU SMELL GAS:

1. Do not try to light a match or cigarette, or turn on any gas or electrical appliance.

2. Do not touch any electrical switches. Do not use any phone in your building.

3. Clear the room, building, or area of all occupants.

4. Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions

carefully.

5. if you cannot reach your gas supplier, call the fire department.

I I

I I

BASIC SAFETY PRECAUTIONS

WARNING:

follow basic precautions, including the following:

• Read all instructions before using the dryer.

• Before use, the dryer must be properly installed as

described in this manual.

• Do not place items exposed to cooking oils in your

dryer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause a

load to catch fire.

• Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

• Do not reach into the dryer if the drum or any other

part is moving.

• Do not repair or replace any part of the dryer or

attempt any servicing unless specifically

recommended in this Use and Care Guide or in

published user-repair instructions that you understand

and have the skills to carry out.

• Do not tamper with controls.

• Before the dryer is removed from service or

discarded, remove the door to the drying

compartment.

To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

• Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

• Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of the

fabric softener or product.

• Do not use heat to dry articles containing foam rubber

or similarly textured rubber-like materials.

• Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint,

dust, and dirt.

• The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

• Do not install or store the dryer where it will be

exposed to the weather.

• Always check the inside of the dryer for foreign

objects.

• Clean lint screen before or after each load.

CALIFORNIA SAFE DRINKING WATER AND TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish a list of substances known to the state to cause cancer, birth defects,

or other reproductive harm and requires businesses to warn customers of potential exposure to such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide, formaldehyde,

and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be minimized further by

properly venting the dryer to the outdoors.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current. This appliance must be equipped with a cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

_=_ WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. Check with a qualified electrician or service person if you are in doubt as to whether the appliance is properly

grounded. Do not modify the plug provided with the appliance. If it will not fit the outlet, have a proper outlet installed by a

qualified electrician. This appliance must be connected to a grounded metal, permanent wiring system or an equipment

grounding conductor must be run with the circuit conductors and connected to the equipment grounding terminal or lead

on the appliance. Electrical shock can result if the dryer is not properly grounded.

4

I I

I I

SAFETY INSTRUCTIONS FOR INSTALLATION

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

Properly ground dryer to conform with all

governing codes and ordinances. Follow details in

the installation instructions. Electrical shock can result

if the dryer is not properly grounded.

Before use, the dryer must be properly installed

as described in this manual. Electrical shock can

result if the dryer is not properly grounded.

Install and store the dryer where it will not be

exposed to temperatures below freezing or

exposed to the weather.

All repairs and servicing must be performed by an

authorized servicer unless specifically

recommended in this Owner's Guide. Use only

authorized factory parts. Failure to follow this

warning can cause serious injury,fire, electrical

shock, or death.

To reduce the risk of electric shock, do not install

the dryer in humid spaces. Failure to follow this

warning can cause serious injury,fire, electrical

shock, or death.

Connect to a properly rated, protected, and sized

power circuit to avoid electrical overload. Improper

power circuit can melt, creating electrical shock

and/or fire hazard.

Remove all packing items and dispose of all

shipping materials properly. Failure to do so can

result in death, explosion, fire, or burns.

Place dryer at least 18 in. above the floor for a

garage installation. Failure to do so can result in

death, explosion, fire, or burns.

Keep all packaging from children. Packaging

material can be dangerous for children. There is a risk

of suffocation.

Do not install nearby heat item. Such as stove,

cooking oven. Failure to do so can cause deform,

smoke and fire.

Do not place candle and cigarettes on top of the

product. Failure to do so can cause deform, smoke

and fire.

Remove all protective vinyl film from the product.

Failure to do so can cause deform, smoke and fire.

Exhaust/Ducting"

Gas dryers MUST be exhausted to the outside.

Failure to follow these instructionscan result in fire or

death.

The dryer exhaust system must be exhausted to

the outside of the dwelling. If the dryer is not

exhausted outdoors, some fine lint and large

amounts of moisture will be expelled into the

laundry area. An accumulation of lint in any area of

the home can create a health and fire hazard.

Use only rigid metal or flexible metal 4-in.

diameter ductwork inside the dryer cabinet or for

exhausting to the outside. Use of plastic or other

combustible ductwork can cause a fire. Punctured

ductwork can cause a fire if itcollapses or becomes

otherwise restricted in use or during installation.

Ductwork is not provided with the dryer, and you

should obtain the necessary ductwork locally. The

end cap should have hinged dampers to prevent

backdraft when the dryer is not in use. Failure to

follow these instructions can result in fire or death.

Failure to do so can cause deform, smoke and fire.

The exhaust duct must be 4 in. (10.2 cm) in

diameter with no obstructions. The exhaust duct

should be kept as short as possible. Make sure to

clean any old ducts before installing your new

dryer. Failure to follow these instructionscan result in

fire or death.

Rigid or semi rigid metal ducting is recommended

for use between the dryer and the wall. In special

installations when it is impossible to make a

connection with the above recommendations, a

ULlisted flexible metal transition duct may be

used between the dryer and wall connection only.

The use of this ducting will affect drying time.

Failure to follow these instructions can result in fire or

death.

DO NOT use sheet metal screws or other

fasteners which extend into the duct that could

catch lint and reduce the efficiency of the exhaust

system. Secure all joints with duct tape. For complete

details, follow the Installation Instructions. Failure to

follow these instructions can result in fire or death.

I I

I I

SAFETY INSTRUCTIONS FOR CONNECTING ELECTRICITY

,re.EL]WARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

Do not, under any circumstances, cut or remove

the ground prong from the power cord. To prevent

personal injury or damage to the dryer, the electrical

power cord must be plugged into a properly grounded

outlet.

For personal safety, this dryer must be properly

grounded. Failure to do so can result in electrical

shock or injury.

Refer to the installation instructions in this

manual for specific electrical requirements for

your model. Failure to follow these instructions can

create an electrical shock hazard and/or a fire hazard.

This dryer must be plugged into a properly

grounded outlet. Electrical shock can result if the

dryer is not properly grounded. Have the wall

outlet and circuit checked by a qualified

electrician to make sure the outlet is properly

grounded. Failure to follow these instructions can

create an electrical shock hazard and/or a fire hazard.

The dryer should always be plugged into it's own

individual electrical outlet which has a voltage

rating that matches the rating plate. This provides

the best performance and also prevents overloading

house wiring circuits which could cause a fire hazard

from overheated wires.

Never unplug your dryer by pulling on the power

cord. Always grip plug firmly and pull straight out

from the outlet. The power cord can be damaged,

resulting in a risk of fire and electrical shock.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do

not use a cord that shows cracks or abrasion

damage along its length or at either end. The

power cord can melt, creating electrical shock and/or

fire hazard.

When installing or moving the dryer, be careful

not to pinch, crush, or damage the power cord.

This will prevent injury and prevent damage to the

dryer from fire and electrical shock.

SAVE THESE INSTRUCTIONS

6

I I

I I

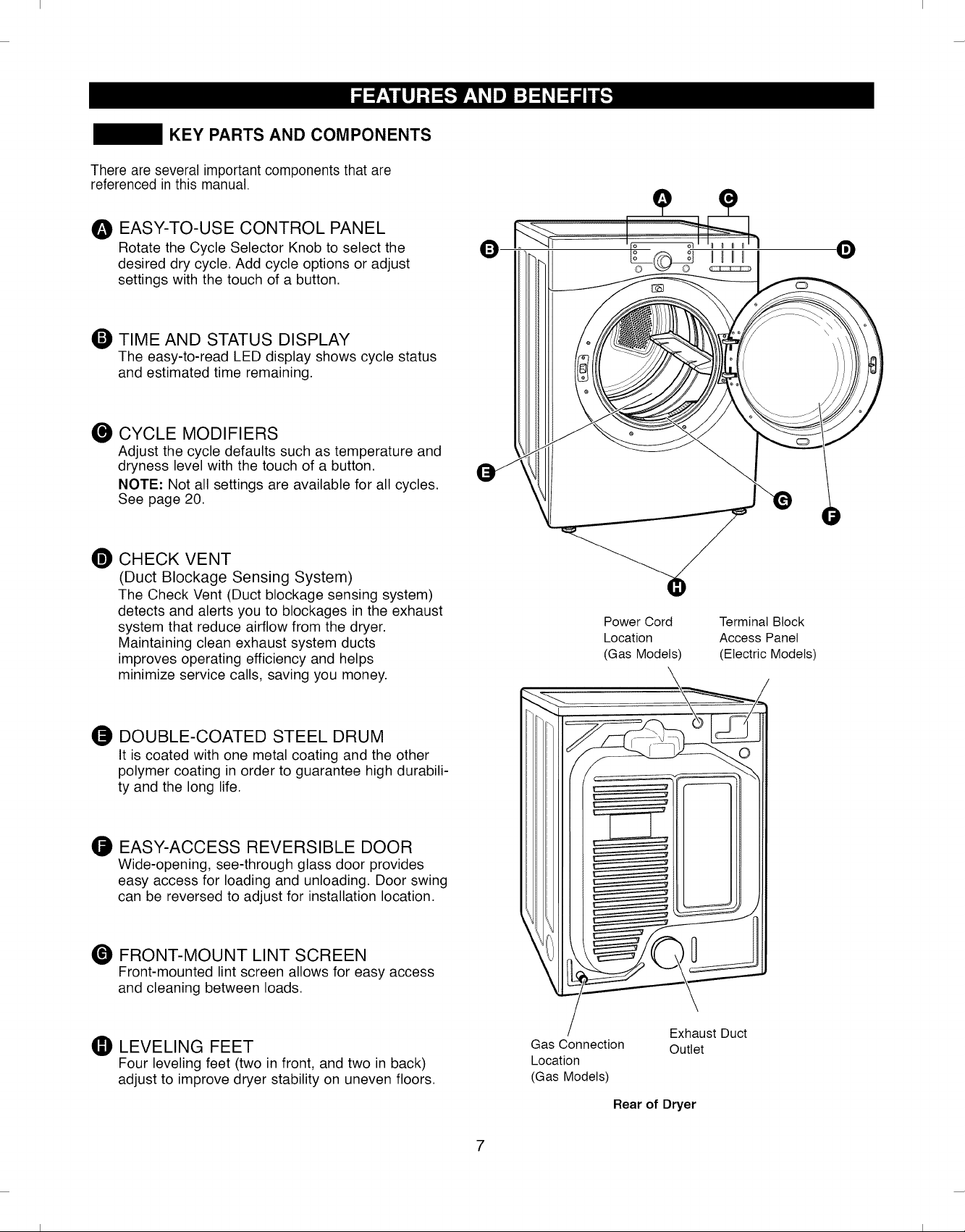

KEY PARTS AND COMPONENTS

There are several important components that are

referenced in this manual.

O EASY-TO-USE CONTROL PANEL

Rotate the Cycle Selector Knob to select the

desired dry cycle. Add cycle options or adjust

settings with the touch of a button.

O TIME AND STATUS DISPLAY

The easy-to-read LED display shows cycle status

and estimated time remaining.

e e

CYCLE MODIFIERS

Adjust the cycle defaults such as temperature and

dryness level with the touch of a button.

NOTE: Not all settings are available for all cycles.

See page 20.

CHECK VENT

(Duct Blockage Sensing System)

The Check Vent (Duct blockage sensing system)

detects and alerts you to blockages in the exhaust

system that reduce airflow from the dryer.

Maintaining clean exhaust system ducts

improves operating efficiency and helps

minimize service calls, saving you money.

DOUBLE-COATED STEEL DRUM

It is coated with one metal coating and the other

polymer coating in order to guarantee high durabili-

ty and the long life.

EASY-ACCESS REVERSIBLE DOOR

Wide-opening, see-through glass door provides

easy access for loading and unloading. Door swing

can be reversed to adjust for installation location.

Power Cord Terminal Block

Location Access Panel

(Gas Models) (Electric Models)

FRONT-MOUNT LINT SCREEN

Front-mounted lint screen allows for easy access

and cleaning between loads.

LEVELING FEET

Four leveling feet (two in front, and two in back)

adjust to improve dryer stability on uneven floors.

I I

Gas Connection

Location

(Gas Models)

Rear of Dryer

Exhaust Duct

Outlet

I I

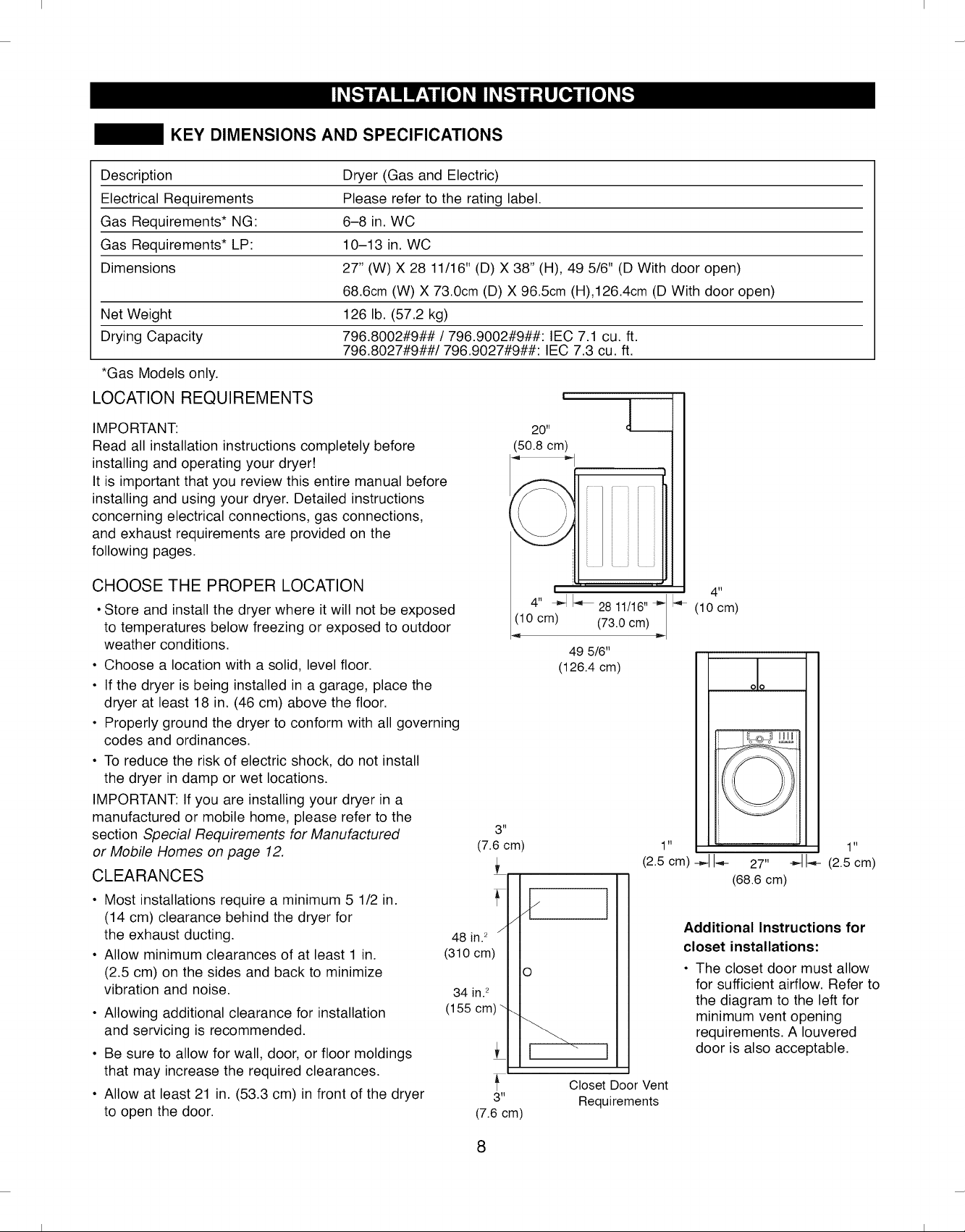

KEY DIMENSIONS AND SPECIFICATIONS

Description Dryer (Gas and Electric)

Electrical Requirements Please refer to the rating label.

Gas Requirements* NG: 6-8 in. WC

Gas Requirements* LP: 10-13 in. WC

Dimensions 27" (W) X 28 11/16" (D) X 38" (H), 49 5/6" (D With door open)

68.6cm (W) X 73.0cm (D) X 96.5cm (H),126.4cm (D With door open)

Net Weight 126 lb. (57.2 kg)

Drying Capacity 796.8002#9## / 796.9002#9##: IEC 7.1 cu. ft.

*Gas Models only.

LOCATION REQUIREMENTS

796.8027#9##/796.9027#9##: IEC 7.3 cu. ft.

!

IMPORTANT:

Read all installation instructions completely before

installing and operating your dryer!

It is important that you review this entire manual before

installing and using your dryer. Detailed instructions

concerning electrical connections, gas connections,

and exhaust requirements are provided on the

following pages.

CHOOSE THE PROPER LOCATION

•Store and install the dryer where it will not be exposed

to temperatures below freezing or exposed to outdoor

weather conditions.

• Choose a location with a solid, level floor.

• If the dryer is being installed in a garage, place the

dryer at least 18 in. (46 cm) above the floor.

• Properly ground the dryer to conform with all governing

codes and ordinances.

• To reduce the risk of electric shock, do not install

the dryer in damp or wet locations.

IMPORTANT: If you are installing your dryer in a

manufactured or mobile home, please refer to the

section Special Requirements for Manufactured

or Mobile Homes on page 12.

CLEARANCES

• Most installations require a minimum 5 1/2 in.

(14 cm) clearance behind the dryer for

the exhaust ducting.

• Allow minimum clearances of at least 1 in.

(2.5 cm) on the sides and back to minimize

vibration and noise.

• Allowing additional clearance for installation

and servicing is recommended.

• Be sure to allow for wall, door, or floor moldings

that may increase the required clearances.

• Allow at least 21 in. (53.3 cm) in front of the dryer

to open the door.

(7.6 cm)

48 in.2

(310 cm)

34 in. 2

(155 cm) \

(7.6 cm)

20"

(50.8 cm)

' ' ' ' ' _11

I

4" _11-_,_2811/16''-_ I-_

(10 cm) (73.0cm) _ (10 cm)

49 5/6"

(126.4 cm)

3 II

1 ii

i

(2.5 cm) -_11_

I

J

iO

Closet Door Vent

3" Requirements

oo

1 ii

27" _ _- (2.5 cm)

(68.6 cm)

Additional Instructions for

closet installations:

• The closet door must allow

for sufficient airflow. Refer to

the diagram to the left for

minimum vent opening

requirements. A Iouvered

door is also acceptable.

8

I I

I I

INSTALLATION WITH OPTIONAL

PEDESTAL BASE OR STACKING KIT

IMPORTANT: If you are installing your dryer using

an optional pedestal base or stacking kit, please refer

to the instructions for your pedestal or stacking kit

before proceeding with the installation.

f_

Required Dimensions for Installation

With Pedestal

Required Dimensions for Installation

With Stacking Kit

51 1/2"

(130.9 cm)

OPTIONAL ACCESSORIES

F_

Usea pedestalto make

laundryeasier to reach.

White = 796.51022

ChiliPepper= 796.51029

Ginger= 796.51028

(76.2 cm) (10 cm)

Usethe stackingkit to mountthe

dryeron top ofthe washerto

save floor space

D2617002(White)

D2617008(Ginger)

D2617009(ChiliPepper)

1,,-_11_ 27,,_ 1,,

(2.5 crn) (68.6 cm) (2.5 crn)

Use the side vent kitfor

ventingdirectlyon either

sideor on the bottom.

Kit# D26-49670

77½"

(190.5 cm)

Usethe LP CONVERSIONKIT

for changingthe dryergas

connectionsfrom NaturalGas

(NG)to LiquefiedPropaneGas

(LP)

383EEL3002A

NOTE:Installationofthe LP

conversionkit must be

performedby aqualified

serviceprofessional.

I I

I I

GAS REQUIREMENTS (GAS MODELS ONLY)

CONNECTING GAS DRYERS

| VV/-_I-II_III_Ik._" TO reduce the risk of fire,

electric shock, or injury to persons when using

this appliance, follow basic precautions, including

the following:

• Gas supply requirements:

As shipped from the factory, this dryer is config-

ured for use with (NG) natural gas. It can be con-

verted for use with LP (Liquefied Propane) gas. Gas

pressure must not exceed 8-in. water column for

(NG), or 13-in. water column for (LP).

. A qualified service or gas company technician must

connect the dryer to the gas service. Failure to do so

can result in fire, explosion, or death.

• Isolate the dryer from the gas supply system by

closing its individual manual shutoff valve during

any pressure testing of the gas supply. Failure to do

so can result in fire, explosion, or death.

• Supply line requirements:

Your laundry room must have a rigid gas supply

line to your dryer. In the United States, an individ-

ual manual shutoff valve MUST be installed within

at least 6 ft. (1.8 m) of the dryer, in accordance with

the National Fuel Gas Code ANSI Z223.1. A 1/8-in.

NPT pipe plug must be installed. Failure to do so can

result in fire, explosion, or death.

• If using a rigid pipe, the rigid pipe should be 1/2-in.

IPS. If acceptable under local codes and ordinances

and when acceptable to your gas supplier, 3/8-in.

approved tubing may be used where lengths are

less than 20 ft. (6.1 m). Larger tubing should be

used for lengths in excess of 20 ft. (6.1 m). Failure

to do so can result in fire, explosion, or death.

Connect the dryer to the type of gas shown on the

nameplate. Failure to do so can result in fire, explo-

sion, or death.

• To prevent contamination of the gas valve, purge

the gas supply of air and sediment before connect-

ing the gas supply to the dryer. Before tightening

the connection between the gas supply and the

dryer, purge remaining air until the odor of gas is

detected. Failure to do so can result in fire, explosion,

or death.

• DO NOT use an open flame to inspect for gas leaks.

Use a noncorrosive leak detection fluid. Failure to do

so can result in fire, explosion, or death.

• Use only a new AGA- or CSA-certified gas supply

line with flexible stainless steel connectors. Failure

to do so can result in fire, explosion, or death.

• Securely tighten all gas connections. Failure to do

so can result in fire, explosion, or death.

• Use Teflon _"_tape or a pipe-joint compound that is

insoluble in Liquefied Petroleum (LP) gas on all

pipe threads. Failure to do so can result in fire, explo-

sion, or death.

• DO NOT attempt any disassembly of the dryer; any

disassembly requires the attention and tools of an

authorized and qualified service person or company.

Failure to do so can result in fire, explosion, or death.

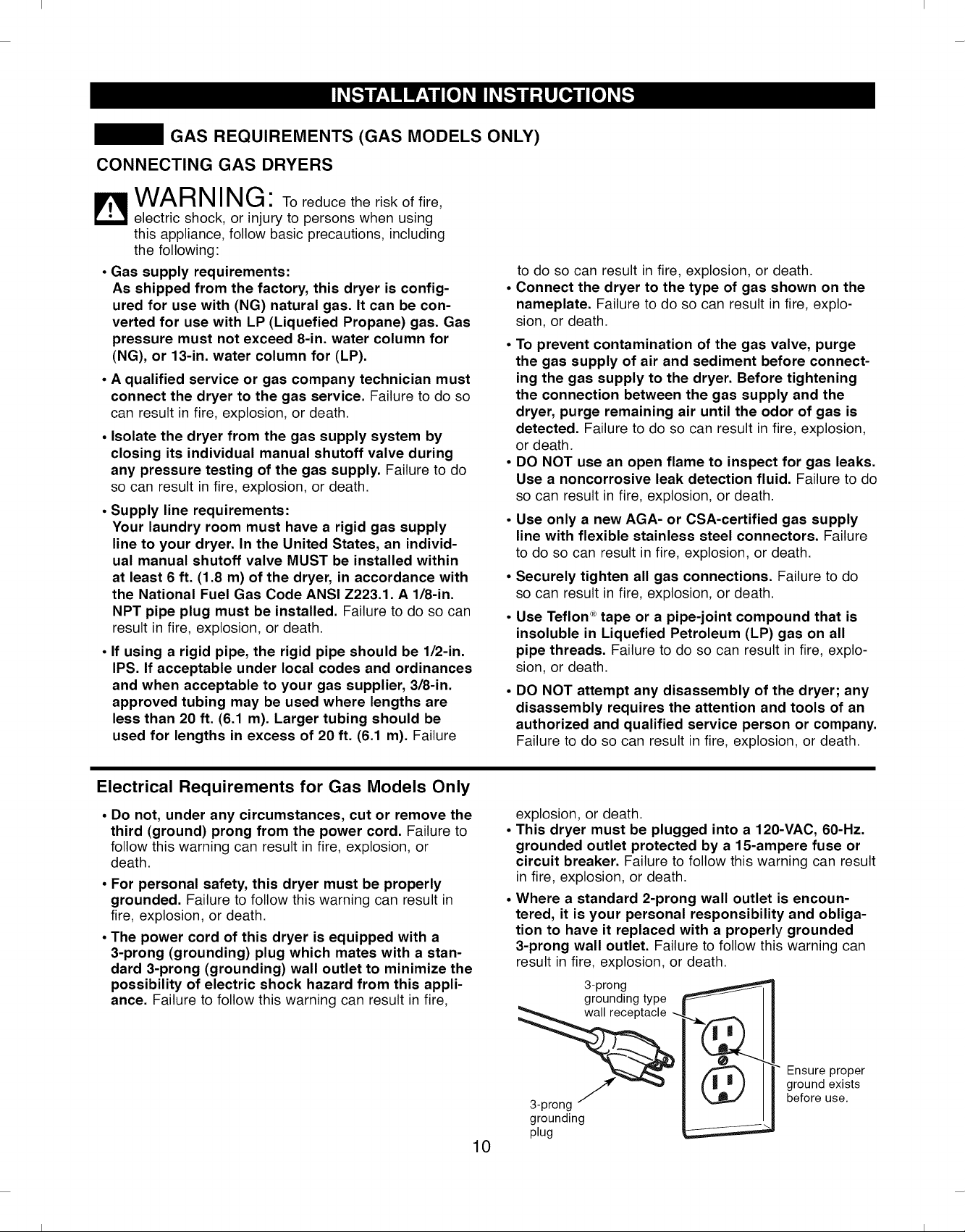

Electrical Requirements for Gas Models Only

• Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord. Failure to

follow this warning can result in fire, explosion, or

death.

• For personal safety, this dryer must be properly

grounded. Failure to follow this warning can result in

fire, explosion, or death.

• The power cord of this dryer is equipped with a

3-prong (grounding) plug which mates with a stan-

dard 3-prong (grounding) wall outlet to minimize the

possibility of electric shock hazard from this appli-

ance. Failure to follow this warning can result in fire,

explosion, or death.

This dryer must be plugged into a 120-VAC, 60-Hz.

grounded outlet protected by a 15-ampere fuse or

circuit breaker. Failure to follow this warning can result

in fire, explosion, or death.

Where a standard 2-prong wall outlet is encoun-

tered, it is your personal responsibility and obliga-

tion to have it replaced with a properly grounded

3-prong wall outlet. Failure to follow this warning can

result in fire, explosion, or death.

3-prong

grounding type

a-prong

grounding

plug

10

Ensure proper

ground exists

before use.

I I

I I

CONNECTING GAS DRYERS (cont.)

VV/_I-II_I II_lk._" TOreduce the risk of fire,

electric shock, or injury to persons when using

this appliance, follow basic precautions, including

the following:

• Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier. Failure to do so can result in fire, explosion,

or death.

• Use only a new stainless steel flexible connector

and a new AGA-certified connector. Failure to do

so can result in fire, explosion, or death.

• A gas shutoff valve must be installed within 6 ft.

(1.8 m) of the dryer. Failure to do so can result in fire,

explosion, or death.

• The dryer is configured for Natural Gas when

shipped from the factory. Make sure that the dryer

is equipped with the correct burner nozzle for the

type of gas being used (Natural Gas or Liquefied

Petroleum). Failure to do so can result in fire,

explosion, or death.

• If necessary, the correct nozzle (for the LP nozzle

kit, order part number 4948EL4002B) should be

installed by a qualified technician and the change

should be noted on the dryer. Failure to do so can

result in fire, explosion, or death.

• All connections must be in accordance with local

codes and regulations. Failure to do so can result

in fire, explosion, or death.

• Gas dryers MUST exhaust to the outdoors. Failure

to do so can result in fire, explosion, or death.

Connecting the Gas Supply

NOTE: This dryer is configured from the factory set for

Natural Gas (NG). If dryer is to be used with LP gas,

it must be converted by a qualified service technician.

O Make sure that the gas supply to the laundry room is

turned OFF and the dryer is unplugged. Confirm that

the type of gas available in your laundry room is

appropriate for the dryer.

Remove the shipping cap from the gas fitting at the

back of the dryer. Be careful not to damage the threads

of the gas connector when removing the shipping cap.

O Connect the dryer to your laundry room's gas supply

using a new flexible stainless steel connector with a

3/8-in. NPT fitting.

NOTE: DO NOT use old connectors.

O Securely tighten all connections between the dryer

and your laundry room's gas supply.

(}Turn on your laundry room's gas supply.

(_ Check all pipe connections (both internal and external)

for gas leaks with a noncorrosive leak-detection fluid.

O Proceed to Venting Requirements on page 14.

3/8" NPT Gas

Connection

AGA/CSA-Certified

Stainless Steel

Flexible Connector

1/8" NPT Pipe Plug

Gas Supply

Shutoff Valve

High-Altitude Installations

The BTU rating of this dryer is AGA-certified for

elevations below 10,000 feet.

If your gas dryer is being installed at an elevation

above 10,000 feet, it must be derated by a qualified

technician or gas supplier.

11

I I

I I

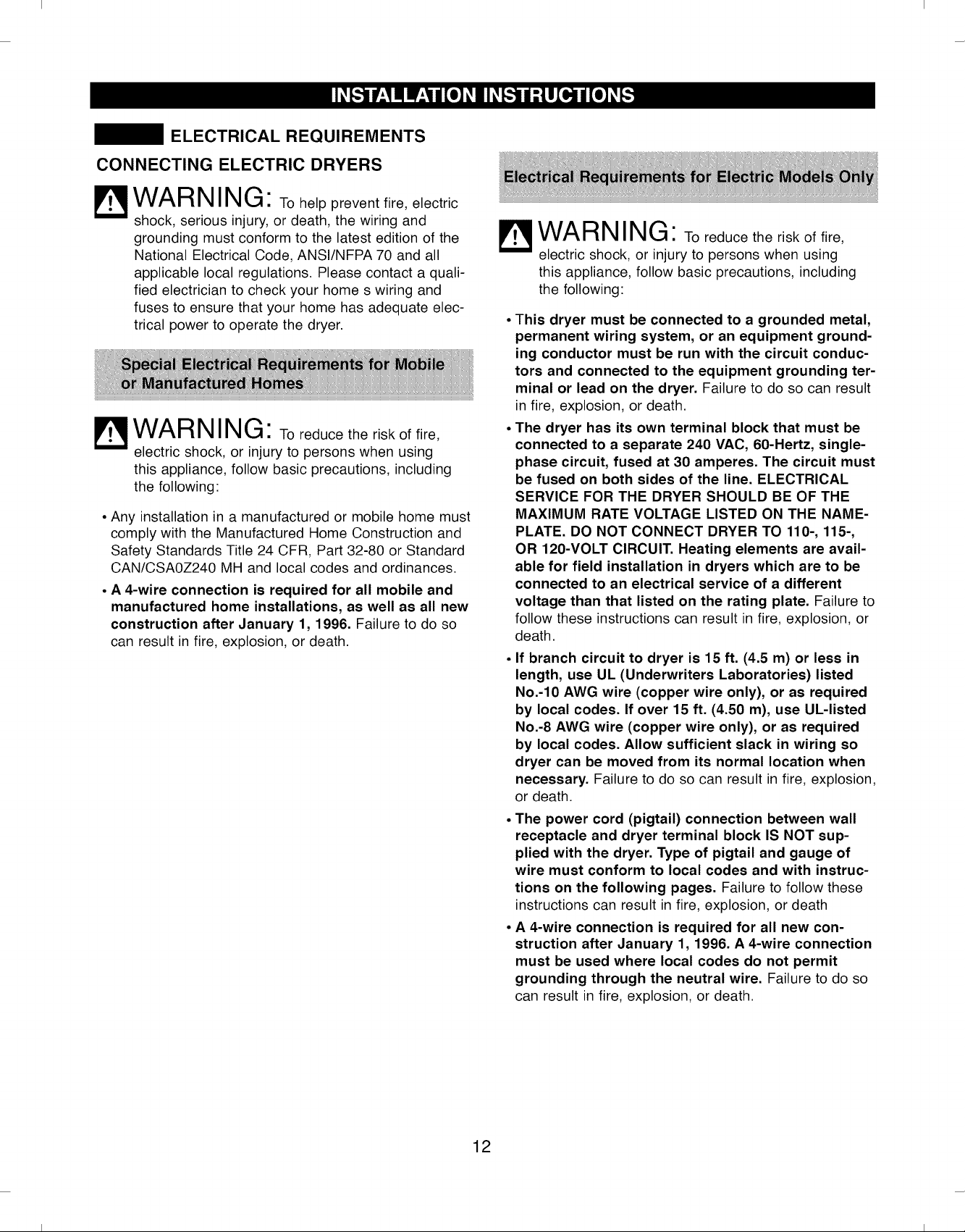

ELECTRICAL REQUIREMENTS

CONNECTING ELECTRIC DRYERS

_A/ADM I M('__

VV/-_,FII _111_11L.,1"TOhelp prevent fire, electric

shock, serious injury, or death, the wiring and

grounding must conform to the latest edition of the

National Electrical Code, ANSI/NFPA 70 and all

applicable local regulations. Please contact a quali-

fied electrician to check your home s wiring and

fuses to ensure that your home has adequate elec-

trical power to operate the dryer. "

_A/ADM IMt__

VV/-_,FII _111_11b_.,1"To reduce the risk of fire,

electric shock, or injury to persons when using

this appliance, follow basic precautions, including

the following:

• Any installation in a manufactured or mobile home must

comply with the Manufactured Home Construction and

Safety Standards Title 24 CFR, Part 32-80 or Standard

CAN/CSAOZ240 MH and local codes and ordinances.

• A 4-wire connection is required for all mobile and

manufactured home installations, as well as all new

construction after January 1, 1996. Failure to do so

can result in fire, explosion, or death.

WARN

electric shock, or injury to persons when using

this appliance, follow basic precautions, including

the following:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment ground-

ing conductor must be run with the circuit conduc-

tors and connected to the equipment grounding ter-

minal or lead on the dryer. Failure to do so can result

in fire, explosion, or death.

The dryer has its own terminal block that must be

connected to a separate 240 VAC, 60-Hertz, single-

phase circuit, fused at 30 amperes. The circuit must

be fused on both sides of the line. ELECTRICAL

SERVICE FOR THE DRYER SHOULD BE OF THE

MAXIMUM RATE VOLTAGE LISTED ON THE NAME-

PLATE. DO NOT CONNECT DRYER TO 110-, 115-,

OR 120-VOLT CIRCUIT. Heating elements are avail-

able for field installation in dryers which are to be

connected to an electrical service of a different

voltage than that listed on the rating plate. Failure to

follow these instructions can result in fire, explosion, or

death.

If branch circuit to dryer is 15 ft. (4.5 m) or less in

length, use UL (Underwriters Laboratories) listed

No.-10 AWG wire (copper wire only), or as required

by local codes. If over 15 ft. (4.50 m), use UL-listed

No.-8 AWG wire (copper wire only), or as required

by local codes. Allow sufficient slack in wiring so

dryer can be moved from its normal location when

necessary. Failure to do so can result in fire, explosion,

or death.

• The power cord (pigtail) connection between wall

receptacle and dryer terminal block IS NOT sup-

plied with the dryer. Type of pigtail and gauge of

wire must conform to local codes and with instruc-

tions on the following pages. Failure to follow these

instructions can result in fire, explosion, or death

• A 4-wire connection is required for all new con-

struction after January 1, 1996. A 4-wire connection

must be used where local codes do not permit

grounding through the neutral wire. Failure to do so

can result in fire, explosion, or death.

IMt__

ii _11b_.,1"To reduce the risk of fire,

12

I I

I I

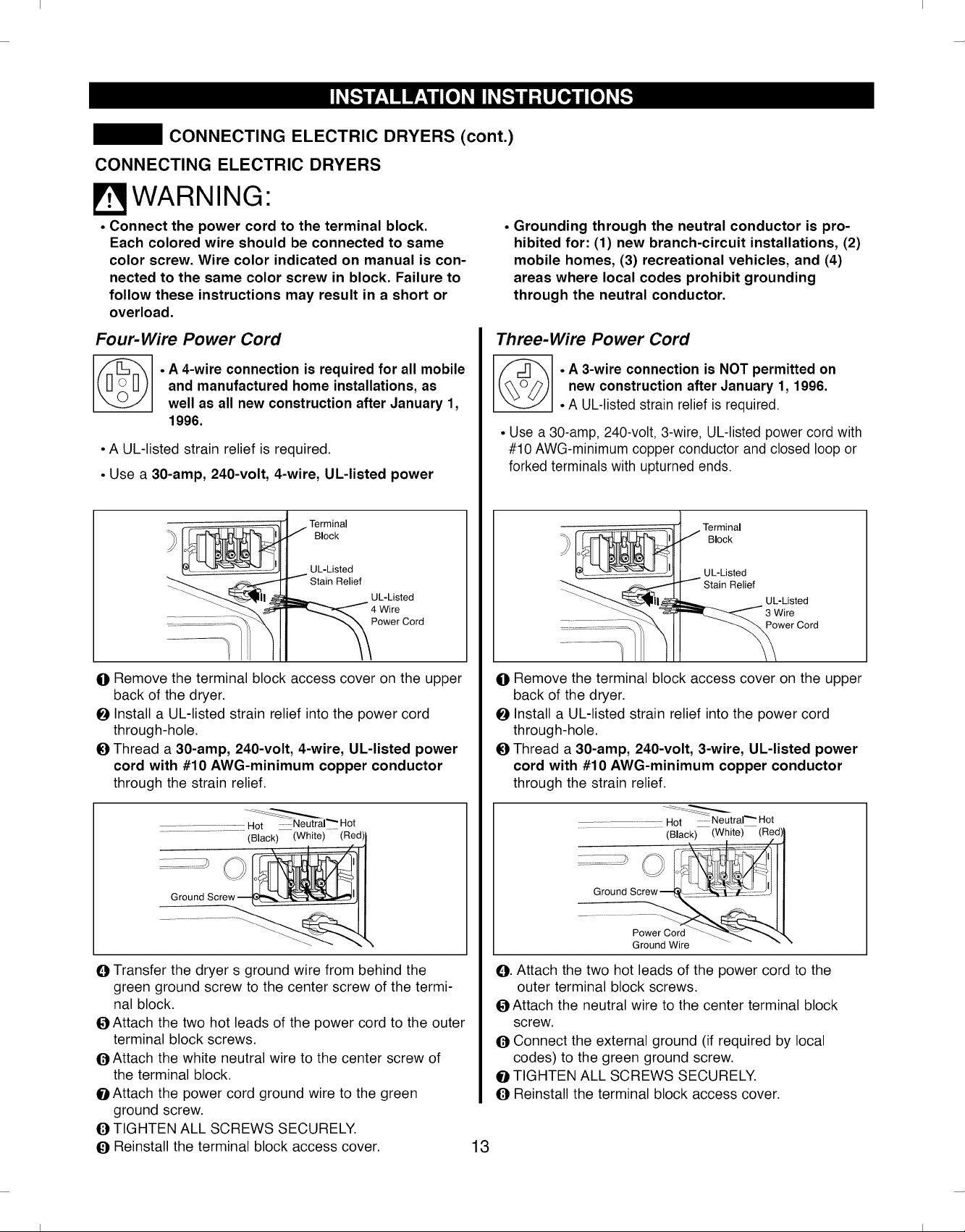

CONNECTING ELECTRIC DRYERS (cont.)

CONNECTING ELECTRIC DRYERS

WARNING"

. Connect the power cord to the terminal block.

Each colored wire should be connected to same

color screw. Wire color indicated on manual is con-

nected to the same color screw in block. Failure to

follow these instructions may result in a short or

overload.

° Grounding through the neutral conductor is pro-

hibited for: (1) new branch-circuit installations, (2)

mobile homes, (3) recreational vehicles, and (4)

areas where local codes prohibit grounding

through the neutral conductor.

Four-Wire Power Cord

• A 4-wire connection is required for all mobile

©

• A UL-listed strain relief is required.

° Use a 30-amp, 240-volt, 4-wire, UL-listed power

O Remove the terminal block access cover on the upper

back of the dryer.

O Install a UL-listed strain relief into the power cord

through-hole.

O Thread a 30-amp, 240-volt, 4-wire, UL-listed power

cord with #10 AWG-minimum copper conductor

through the strain relief.

and manufactured home installations, as

well as all new construction after January 1,

1996.

Terminal

Block

UL-Listed

Relief

UL-Listed

Power Cord

Three-Wire Power Cord

• A 3-wire connection is NOT permitted on

©

• Use a 30-amp, 240-volt, 3-wire, UL-listed power cord with

#10 AWG-minimum copper conductor and closed loop or

forked terminals with upturned ends.

O Remove the terminal block access cover on the upper

back of the dryer.

O Install a UL-listed strain relief into the power cord

through-hole.

O Thread a 30-amp, 240-volt, 3-wire, UL-listed power

cord with #10 AWG-minimum copper conductor

through the strain relief.

new construction after January 1, 1996.

• A UL-listed strain relief is required.

Terminal

Block

UL-Listed

Stain Relief

UL-Listed

3 Wire

Power Cord

Hot ............Neutral"" Hot

(Black) (White) (Red)

........................................(Black) (White)-- (Red)}

Hot ..........Neutral"" Hot

ii s02............o ........ t

Ground Wire - - " "

O Transfer the dryer s ground wire from behind the

green ground screw to the center screw of the termi-

nal block.

OAttach the two hot leads of the power cord to the outer

terminal block screws.

O Attach the white neutral wire to the center screw of

the terminal block.

O Attach the power cord ground wire to the green

ground screw.

O TIGHTEN ALL SCREWS SECURELY.

O Reinstall the terminal block access cover.

I I

O. Attach the two hot leads of the power cord to the

outer terminal block screws.

O Attach the neutral wire to the center terminal block

screw.

O Connect the external ground (if required by local

codes) to the green ground screw.

O TIGHTEN ALL SCREWS SECURELY.

O Reinstall the terminal block access cover.

13

I I

VENTING THE DRYER

CHECK YOUR EXHAUST SYSTEM FOR

PROBLEMS

The most common cause of dryer problems is poor exhaust venting. Before you install your new dryer, check the

items listed below to make sure you get the best possible performance. This can save you time and money by reducing

cycle times and increasing energy efficiency.

@ DIRTY OR DAMAGED EXHAUST DUCTS. Lint builds up in exhaust ducts over time. This decreases the airflow and

makes the dryer work harder. Visually inspect your ducts from both ends and have them cleaned ifthey have not

been cleaned recently.

O WRONG VENT MATERIAL. Check your vent to make sure it is rigid or semi-rigid metal ducting. If your venting is

plastic flexible foil, have it replace before using the dryer.

O RESTRICTED OR DAMAGED VENT HOOD. Check your vent hood outside. It must be clean and free of lint buildup.

Check the damper and make sure it opens fully and easily.

O EXESSIVEL¥ LONG VENT. Measure the length of your exhaust system and count the elbows. Use the chart of page

14 to see if your duct is too long. If it is too long, have the duct routed to another location that is within the venting

guidelines.

O DO NOT USE PLASTIC OR FOIL VENTING. The transition duct from your dryer to the wall must be rigid or

semi-rigid metal ducting. If your old transition duct is plastic or foil, REPLACE IT with semi-rigid metal ducting.

Using the Duct Requirements Chart (below)

O Select the type of wall cap.

O Select row that matches the number of elbows required in the dryer duct run.

O Select the duct type. The length shown in the chart at this point is the maximum allowable duct length for your instal-

lation. Longer duct length will result in reduced

drying performance, longer dry times and increased energy consumption.

DO NOT exceed maximum length for the duct type and number of elbows used.

Selecting and Verifying Duct Length Chart

Recommended 0 65 feet (19.8 m)

4" 4"

(10,2 cm) (10,2 cm)

Only for Short-Run Installations

1

2

3

4

0

1

55 feet (16.8 m)

47 feet (13.7 m)

36 feet (11.0 m)

28 feet (8.5 m)

55 feet (16.8 m)

47 feet (13.7 m)

2-1/2"

(6,35 cm)

2

3

4

41 feet (12.5 m)

30 feet (9.1 m)

22 feet (6.7 m)

NOTE: Deduct 6 ft. (1.8 m) for each additional elbow. It is not recommended to use more than four 906elbows.

14

I I

I I

VENTING THE DRYER (cont.)

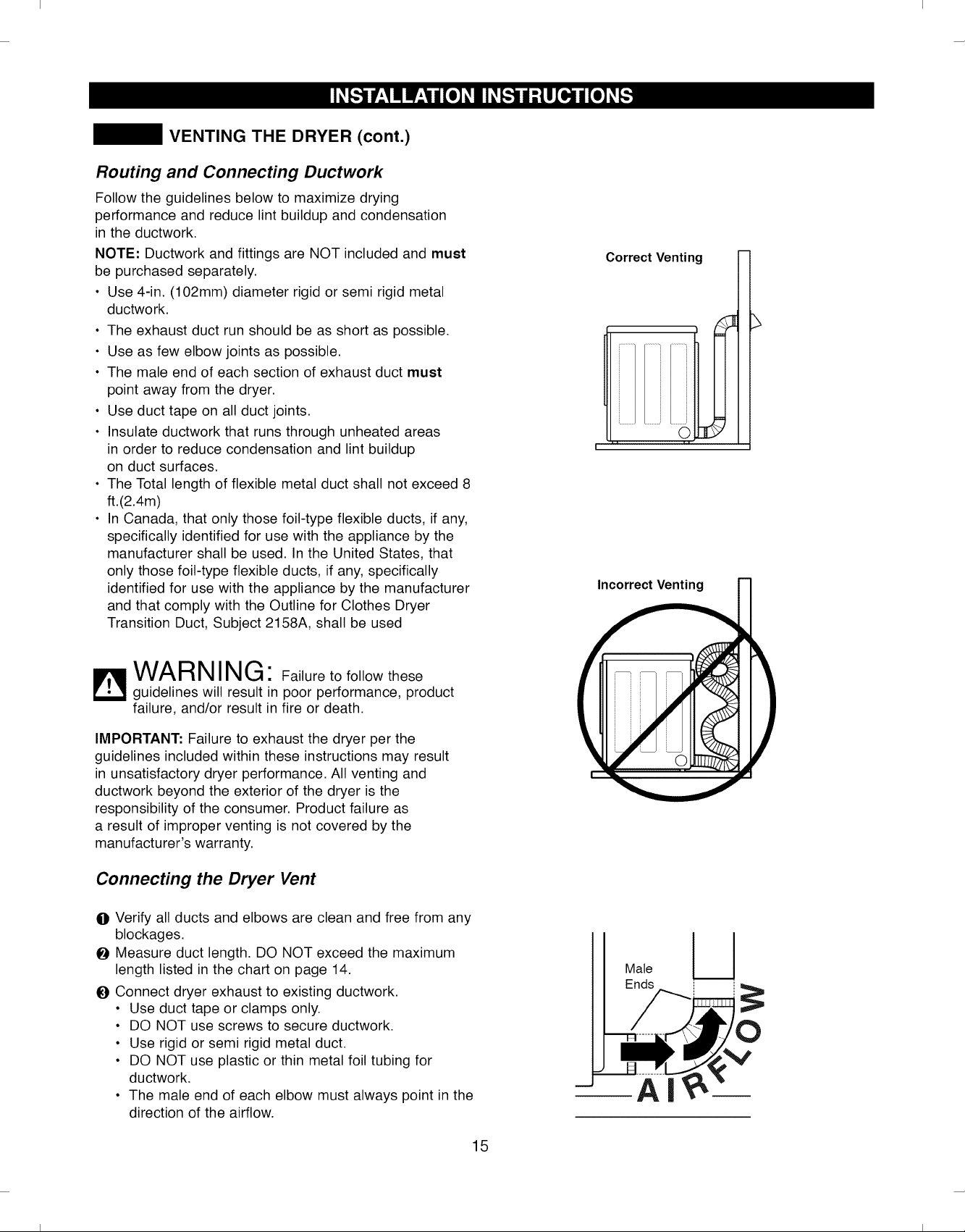

Routing and Connecting Ductwork

Follow the guidelines below to maximize drying

performance and reduce lint buildup and condensation

in the ductwork.

NOTE: Ductwork and fittings are NOT included and must

be purchased separately.

• Use 4-in. (102mm) diameter rigid or semi rigid metal

ductwork.

• The exhaust duct run should be as short as possible.

• Use as few elbow joints as possible.

• The male end of each section of exhaust duct must

point away from the dryer.

• Use duct tape on all duct joints.

• Insulate ductwork that runs through unheated areas

in order to reduce condensation and lint buildup

on duct surfaces.

• The Total length of flexible metal duct shall not exceed 8

ft.(2.4m)

• In Canada, that only those foil-type flexible ducts, if any,

specifically identified for use with the appliance by the

manufacturer shall be used. In the United States, that

only those foil-type flexible ducts, if any, specifically

identified for use with the appliance by the manufacturer

and that comply with the Outline for Clothes Dryer

Transition Duct, Subject 2158A, shall be used

Correct Venting

Incorrect Venting

guidelines will result in poor performance, product

failure, and/or result in fire or death.

WARNING" Failure to follow these (

IMPORTANT: Failure to exhaust the dryer per the

guidelines included within these instructions may result

in unsatisfactory dryer performance. All venting and

ductwork beyond the exterior of the dryer is the

responsibility of the consumer. Product failure as

a result of improper venting is not covered by the

manufacturer's warranty.

Connecting the Dryer Vent

O Verify all ducts and elbows are clean and free from any

O Measure duct length. DO NOT exceed the maximum

blockages. !

length listed in the chart on page 14. Male

O Connect dryer exhaust to existing ductwork, i

• Use duct tape or clamps only.

• DO NOT use screws to secure ductwork.

• Use rigid or semi rigid metal duct.

• DO NOT use plastic or thin metal foil tubing for

ductwork.

• The male end of each elbow must always point in the

direction of the airflow.

7'

1

O

15

I I

I I

LEVELING THE DRYER

WARNING

• Wear gloves during installation.

• Failure to follow these instructions can result

in injury.

To ensure that the dryer provides optimal drying

performance, it must be level. To minimize vibration,

noise, and unwanted movement, the floor must be

a level, solid surface.

NOTE: Adjust the leveling feet only as far as necessary

to level the dryer. Extending the leveling feet more than

necessary can cause the dryer to vibrate.

Level

REVERSING THE DOOR SWING

The swing of the dryer door can be reversed to fit your

installation location.

Door

Latch' _!_

Hinge

Screws

O Open the dryer door.

NOTE: Be sure to support the weight of the door before

removing the hinge screws.

O

Using a Phillips screwdriver, remove the 2 hinge

screws that secure the door hinge to the dryer door

opening.

Leveling Feet

O Position the dryer in the final location. Place a level

across the top of the dryer.

• All four leveling feet must rest solidly on the floor.

Gently push on the top corners of the dryer to make

sure that the dryer does not rock from corner to corner.

OUse a wrench to turn the leveling feet. Turning the foot

clockwise lowers the foot and raises the dryer; turning

the foot counterclockwise raises the foot and lowers the

dryer. Raise or lower the leveling feet until the dryer is

level from side-to-side and front-to-back. Make sure

that all 4 leveling feet are in firm contact with the floor.

NOTE: If you are installing the dryer on the optional

pedestal, the dryer leveling feet should be fully retracted.

Use the leveling feet on the pedestal to level the dryer.

O

Remove the 2 latch screws and the latch from the dryer

door opening.

O Remove the two screws above and below the latch.

" ._ Latch

. " -TScrews

O Carefully turn the door up-side-down so the hinge is

reversed. Reattach the door to the opposite side of the

door opening.

O Reinstall the door latch with the original latch screws.

O Replace the remaining screws in the open holes.

Q Test the door swing to make sure the door moves

freely and latches securely.

16

I I

I I

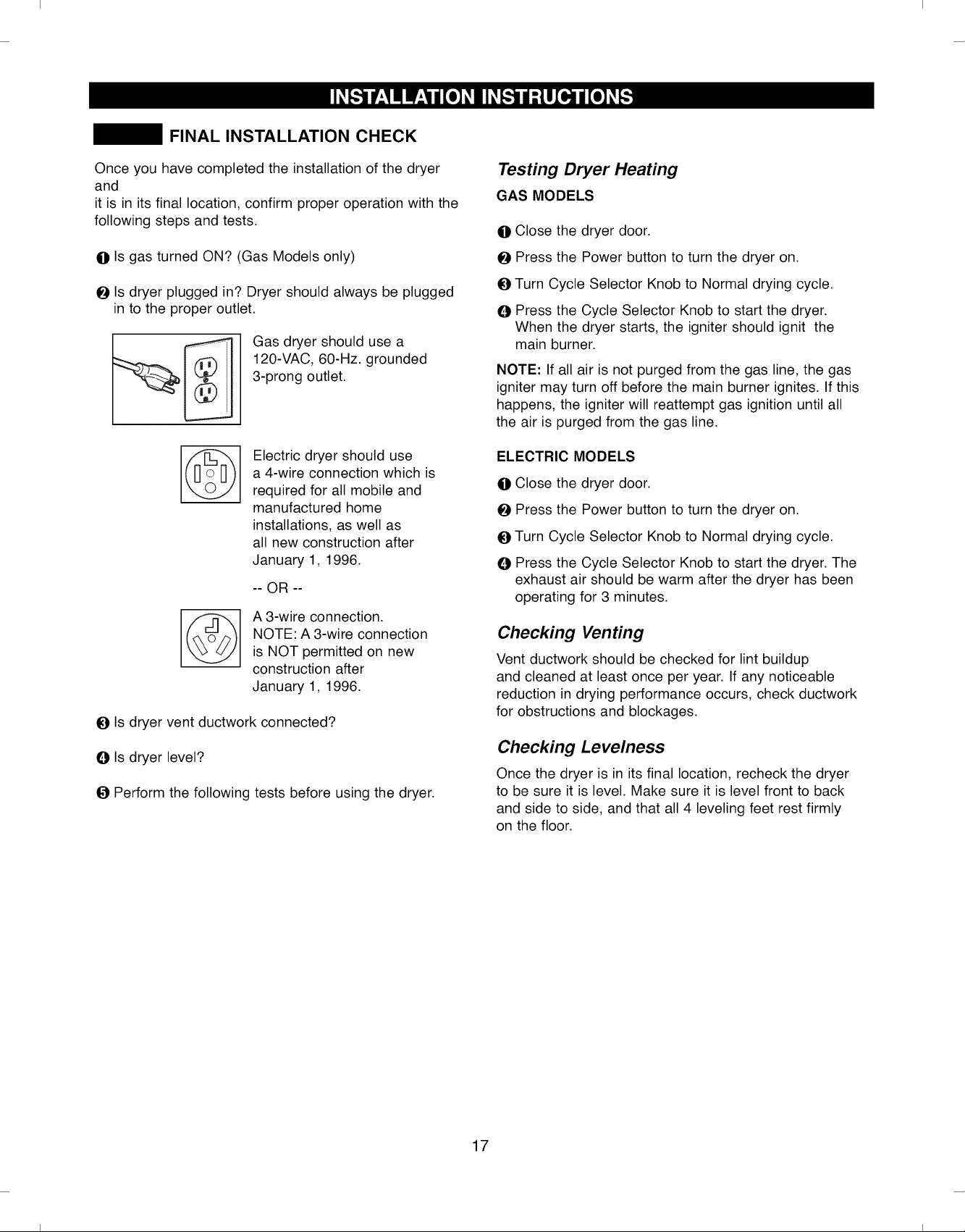

FINAL INSTALLATION CHECK

Once you have completed the installation of the dryer

and

it is in its final location, confirm proper operation with the

following steps and tests.

O Is gas turned ON? (Gas Models only)

O Is dryer plugged in? Dryer should always be plugged

in to the proper outlet.

Gas dryer should use a

120-VAC, 60-Hz. grounded

3-prong outlet.

Electric dryer should use

a 4-wire connection which is

@

©

O Is dryer vent ductwork connected?

required for all mobile and

manufactured home

installations, as well as

all new construction after

January 1, 1996.

-- OR --

A 3-wire connection.

NOTE: A 3-wire connection

is NOT permitted on new

construction after

January 1, 1996.

Testing Dryer Heating

GAS MODELS

O Close the dryer door.

O Press the Power button to turn the dryer on.

O Turn Cycle Selector Knob to Normal drying cycle.

O Press the Cycle Selector Knob to start the dryer.

When the dryer starts, the igniter should ignit the

main burner.

NOTE: If all air is not purged from the gas line, the gas

igniter may turn off before the main burner ignites. If this

happens, the igniter will reattempt gas ignition until all

the air is purged from the gas line.

ELECTRIC MODELS

O Close the dryer door.

O Press the Power button to turn the dryer on.

O Turn Cycle Selector Knob to Normal drying cycle.

O Press the Cycle Selector Knob to start the dryer. The

exhaust air should be warm after the dryer has been

operating for 3 minutes.

Checking Venting

Vent ductwork should be checked for lint buildup

and cleaned at least once per year. If any noticeable

reduction in drying performance occurs, check ductwork

for obstructions and blockages.

O Is dryer level?

O Perform the following tests before using the dryer.

Checking Levelness

Once the dryer is in its final location, recheck the dryer

to be sure it is level. Make sure it is level front to back

and side to side, and that all 4 leveling feet rest firmly

on the floor.

17

I I

I I

If;qlWARNING" To reduce the risk of fire, electric shock, or injury to persons, read this entire

manual, including the Important Safety Instructions, before operating this dryer.

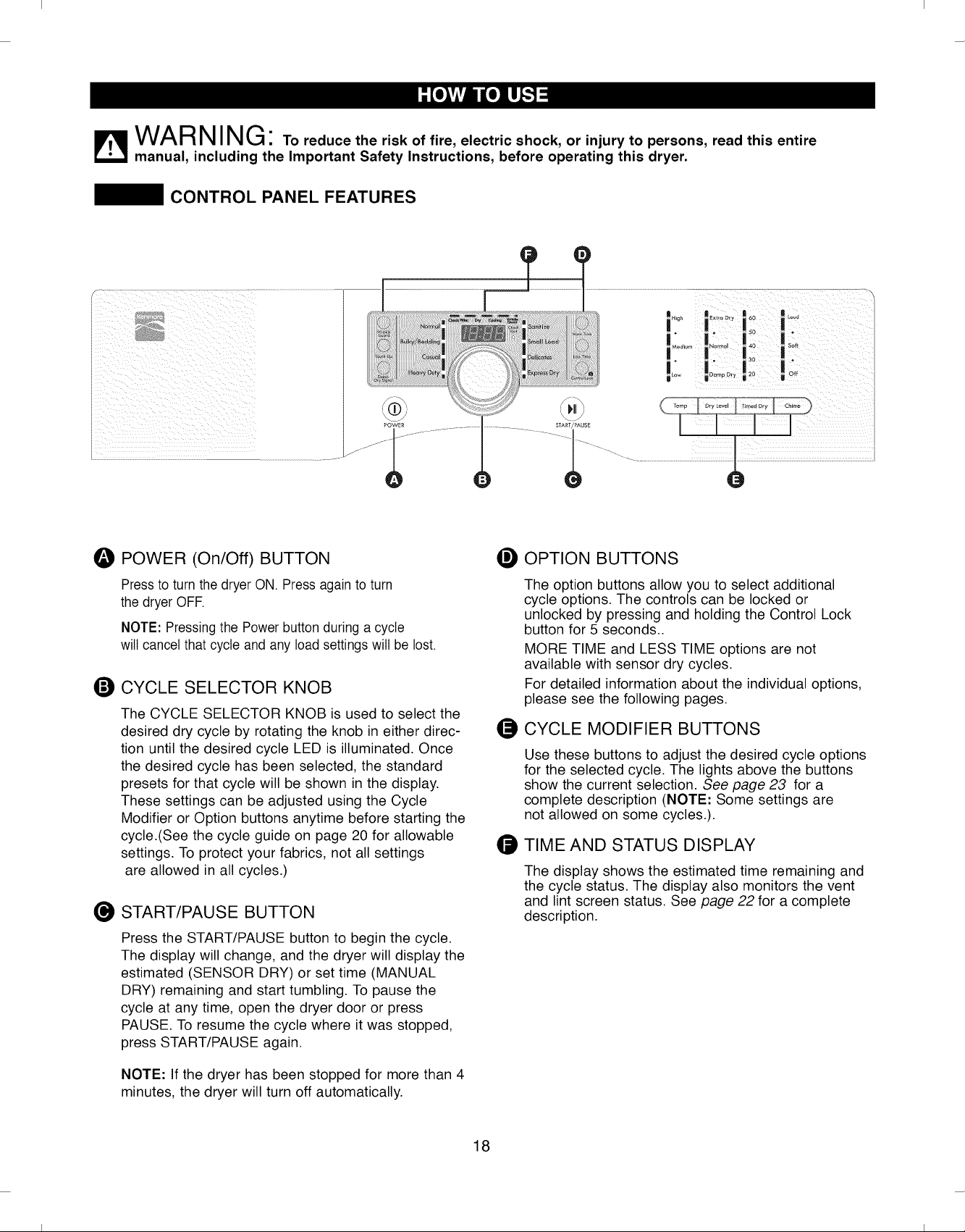

CONTROL PANEL FEATURES

0 POWER (On/Off) BUTTON

Pressto turn the dryer ON. Press again to turn

the dryer OFF.

NOTE: Pressingthe Power button during a cycle

wilt cancel that cycle and any loadsettings wilt be lost.

CYCLE SELECTOR KNOB

O

The CYCLE SELECTOR KNOB is used to select the

desired dry cycle by rotating the knob in either direc-

tion until the desired cycle LED is illuminated. Once

the desired cycle has been selected, the standard

presets for that cycle will be shown in the display.

These settings can be adjusted using the Cycle

Modifier or Option buttons anytime before starting the

cycle.(See the cycle guide on page 20 for allowable

settings. To protect your fabrics, not all settings

are allowed in all cycles.)

O START/PAUSE BUTTON

Press the START/PAUSE button to begin the cycle.

The display will change, and the dryer will display the

estimated (SENSOR DRY) or set time (MANUAL

DRY) remaining and start tumbling. To pause the

cycle at any time, open the dryer door or press

PAUSE. To resume the cycle where it was stopped,

press START/PAUSE again.

OPTION BUTTONS

The option buttons allow you to select additional

cycle options. The controls can be locked or

unlocked by pressing and holding the Control Lock

button for 5 seconds..

MORE TIME and LESS TIME options are not

available with sensor dry cycles.

For detailed information about the individual options,

please see the following pages.

O CYCLE MODIFIER BUTTONS

Use these buttons to adjust the desired cycle options

for the selected cycle. The lights above the buttons

show the current selection. See page 23 for a

complete description (NOTE: Some settings are

not allowed on some cycles.).

TIME AND STATUS DISPLAY

O

The display shows the estimated time remaining and

the cycle status. The display also monitors the vent

and lint screen status. See page 22 for a complete

description.

NOTE: If the dryer has been stopped for more than 4

minutes, the dryer will turn off automatically.

18

I I

I I

OPERATING THE DRYER

O LOAD THE DRYER

Load the dryer with the wet laundry from the washer. If

the load is extra large, you may need to divide it into

smaller loads for proper performance and fabric care.

O CLEAN THE LINT FILTER

If the lint filter has not already been cleaned, lift out the

filter and remove the lint from the last load. This will

help ensure the fastest and most efficient drying perfor-

mance.

O TURN ON THE DRYER

Press the POWER button to turn on the dryer. The

cycle LEDs will illuminate and a chime will sound, if

POWER

turned on. Refer to page 18.

_ Extra Dry _ 60

|_o

! _ormal 140

IO:m O y

, _ii_ii_ii_ijii!i!iii!_iii_iiii!i_i_ii!ii,il_iiiiiiiiiiiiii!!i!i

/iiiiiiiiiiiii_i_iii_ii_i!_J_!!_!ii!!i_i_:_i_i_i_i_i_i_i_i_i_i_/

_ jJ

ii_!iiiiiiiiiiiiiiiili

Louo

e

Soft

Off

START/PAUSE

O SELECT A CYCLE

Turn the Cycle Selector Knob either direction until the

LED for the desired cycle is on. The preset tempera-

ture, dryness level, and option settings for that cycle will

be shown. (TOUCH UP cycle is selected by pressing

the TOUCH UP button on the left.)

Refer to page 20.

_SELECT CYCLE MODIFIERS

Default settings for the selected cycle can now be

changed if desired. This can be done using the cycle

modifier buttons as shown on page 23 (temperature,

dryness level, and chime).

NOTE: Not all options or modifiers are available on all

cycles.

O SELECT CYCLE OPTIONS

Cycle options can be added using the options buttons

as shown on page 24 (wrinkle guard and control lock).

NOTE: Not all options or modifiers are available on all

cycles.

BEGIN CYCLE

Press the START/PAUSE button to begin the cycle.

The cycle can be paused at any time either by open-

ing the door or by pressing the START/PAUSE button.

If the cycle is not restarted within 4 minutes, the dryer

will shut off and the cycle settings will be lost.

O END OF CYCLE

When the cycle is finished, the chime will sound if it is

set. Remove your clothing from the dryer immediately

to reduce wrinkling. If Wrinkle Guard is selected, the

dryer will tumble briefly every few minutes to help pre-

vent wrinkles from setting in the clothes.

19

I I

I I

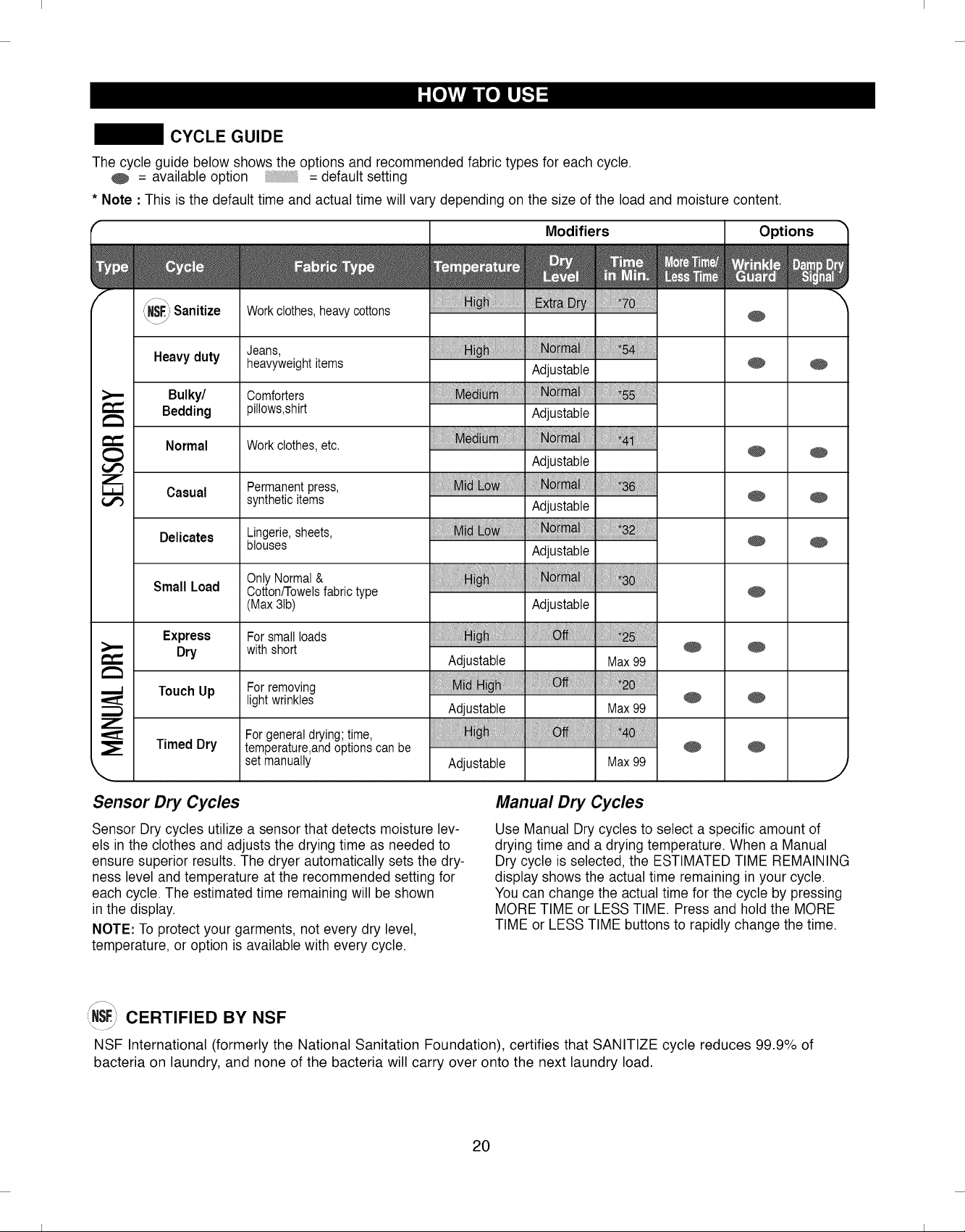

CYCLE GUIDE

The cycle guide belew shows the eptiens and recommended fabric types for each cycle.

= available eption = default setting

* Note : This isthe default timeand actual time willvary depending on the size of the lead and moisture content.

\NS_iSanitize

Heavyduty

Bulky/

Bedding

Normal

Casual Permanent press,

Delicates Lingerie, sheets,

Small Load Cotton/Towels fabric type

Express For small loads

Dry with short

Work clothes,heavy cottons

Jeans,

heavyweight items

Comforters

pillows,shirt

Work clothes, etc.

synthetic items

blouses

Only Normal &

(Max 31b)

Modifiers

Adjustable

Adjustable

Adjustable

Adjustable

Adjustable

Adjustable

Adjustable Max99

Options

Touch Up For removing

TimedDry

Sensor Dry Cycles

Sensor Dry cycles utilize a sensor that detects moisture lev-

els inthe clothes and adjusts the drying time as needed to

ensure superior results. The dryer automatically sets the dry-

ness level and temperature at the recommended setting for

each cycle. The estimated time remaining will be shown

in the display.

NOTE: To protect your garments, not every dry level,

light wrinkles

For general drying; time,

temperature,and options can be

set manually

Adjustable Max99

Adjustable Max99

Manual Dry Cycles

Use Manual Dry cycles to select a specific amount of

drying time and a drying temperature. When a Manual

Dry cycle is selected, the ESTIMATED TIME REMAINING

display shows the actual time remaining in your cycle.

You can change the actual time for the cycle by pressing

MORE TIME or LESS TIME. Press and hold the MORE

TIME or LESS TIME buttons to rapidly change the time.

temperature, or option is available with every cycle.

::NSF_:CERTIFIED BY NSF

NSF International (formerly the National Sanitation Foundation), certifies that SANITIZE cycle reduces 99.9% of

bacteria on laundry, and none of the bacteria will carry over onto the next laundry load.

20

I I

Loading...

Loading...