Kenmore 795.775736, 795.775796, 795.775726, 795.775696, 795.775636 User Manual

...

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

REFRIGERATOR

SERVICE MANUAL

R

Model #s:

795.77562600

795.77569600

795.77564600

795.77563600

795.77572600

795.77579600

795.77573600

P/No. 3828JL8091A (Last Revision: March. 28. 2008)

Safety Precautions

1. Specification.........................................................................................................................................................................

2. Parts Identification...............................................................................................................................................................

3. Operation ..............................................................................................................................................................................

3-1. Explanation of Each Function .........................................................................................................................................

3-2. Ice Maker Function..........................................................................................................................................................

4. Wiring Diagram.....................................................................................................................................................................

5. Adjustment............................................................................................................................................................................

5-1. Compressor.....................................................................................................................................................................

5-2. Positive Temperature Coefficient (PTC) – Starter...........................................................................................................

5-3. Over Load Protector (OLP).............................................................................................................................................

5-4. Remove the cover Positive Temperature Coefficient (PTC)

6. Troubleshooting...................................................................................................................................................................

6-1. Error Mode Summary......................................................................................................................................................

6-2. Troubleshooting With Error.............................................................................................................................................

6-3. Troubleshooting Else ......................................................................................................................................................

7. Component Testing Information.........................................................................................................................................

7-1. Defrost Controller Assembly ...........................................................................................................................................

7-2. Sheath Heater.................................................................................................................................................................

7-3. Door Heater Assembly....................................................................................................................................................

7-4. Switch (F, R)....................................................................................................................................................................

7-5. Solenoid..........................................................................................................................................................................

7-6. AC Motor Assembly ........................................................................................................................................................

7-7. Damper ...........................................................................................................................................................................

7-8. Lamp Socket...................................................................................................................................................................

8. Disassembly Instructions....................................................................................................................................................

9. PCB Assembly......................................................................................................................................................................

10. Exploded View....................................................................................................................................................................

CONTENTS

- 2 -

Please read the following instructions before servicing your

refrigerator.

1. Unplug the power before handling any elctrical

componets.

2. Check the rated current, voltage, and capacity.

3. Take caution not to get water near any electrical

components.

4. Use exact replacement parts.

5. Remove any objects from the top prior to tilting the

product.

SAFETY PRECAUTIONS

1. SPECIFICATIONS

- 3 -

1-1 DISCONNECT POWER CORD BEFORE

SERVICING

IMPORTANT – RECONNECT ALL

GROUNDING DEVICES

All parts of this appliance capable of conducting electrical

current are grounded. If grounding wires, screws, straps,

clips, nuts or washers used to complete a path to ground

are removed for service, they must be returned to their

original position and properly fastened.

1-2 IMPORTANT NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical, electronic

and mechanical experience. Any attempt to repair a major

appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible

for the interpretation of this information, nor can it assume

any liability in connection with its use.

1-3 ELECTRICAL SPECIFICATIONS

Temperature Control (F )...-6°F to +8°F

Defrost Control...................Total Comp Running Time 7 hrs

Defrost Thermostat.......................................................46°F

Electrical Rating : 115VAC, 60Hz.................................1-5 A

Maximum Current Leakage.......................................0.5 mA

Maximum Ground Path Resistance....................0.14 Ohms

Energy Consumption .....25 cu.ft. 579 kWh/yr (Energy Star)

1-4 NO LOAD PERFORMANCE

CONTROL POSITION: MID/MID

And Ambient of: ..................70°F..................................90°F

Fresh Food, °F....................33°F to 41°F.........33°F to 41°F

Frozen Food, °F..................-4°F to +4°F..........-4°F to +4°F

Percent Running Time........35%-45%.................50°F-70°F

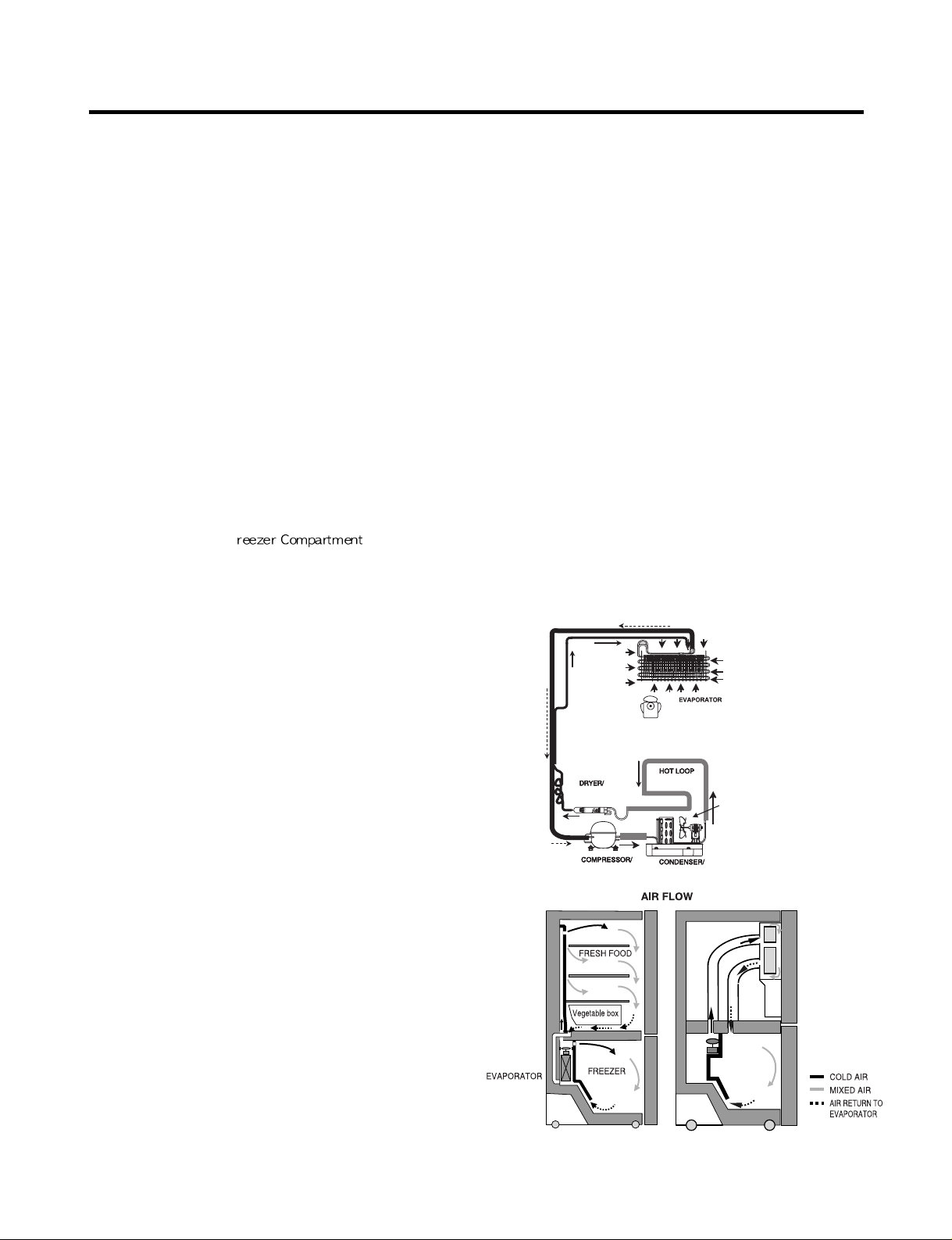

1-5 REFRIGERA TION SYSTEM

Minimum Compressor Capacity Vacuum ............... 21 MIN.

Minimum Equalized Pressure

@ 70°F ....................................................... 49 PSIG

@ 90°F ....................................................... 56 PSIG

Refrigerant R134a ................................................. 4.41 oz.

Compressor ..................................................... 956 BTU/hr

1-6 INSTALLATION

Clearance must be provided at top, sides and rear of the

refrigerator for air circulation.

AT TOP ......................................................................... 2 in

AT SIDES ...................................................................... 1 in

AT REAR ...................................................................... 1 in

1-7 REPLACEMENT PARTS

Relay..............................................................6748C-0004D

Overload........................................................6750C-0004R

Defrost Thermostat........................................6615JB2005H

Defrost Heater...............................................5300JK1005D

Evaporator Fan Motor....................................4681JK1004E

Capacitor (Running) .....................................0CZZJB2014B

*0CZZJB2012H

*0CZZJB2012K

Compressor (Hi-Side)...................................TCA31748001

Evaporator (Lo-Side)......................................5421JJ1007A

Condenser......................................................5403JJ1004B

Dryer..............................................................5851JA2002P

Condenser Fan Motor ...................................4681JB1029D

Temperature Control ..............................3551JA1132L(SW)

3551JA1132M(ST)

3551JA1132N(WB)

3551JA1132P(BI)

Main Control....................................................EBR3491102

Ice Fan Motor ................................................4681JB1029E

*OPTIONAL

1-8 AIR FLOW / CIRCULATION D’AIR

EVAPORTOR FAN MOTOR

CONDENSER FAN MOTOR

ICE

ROOM

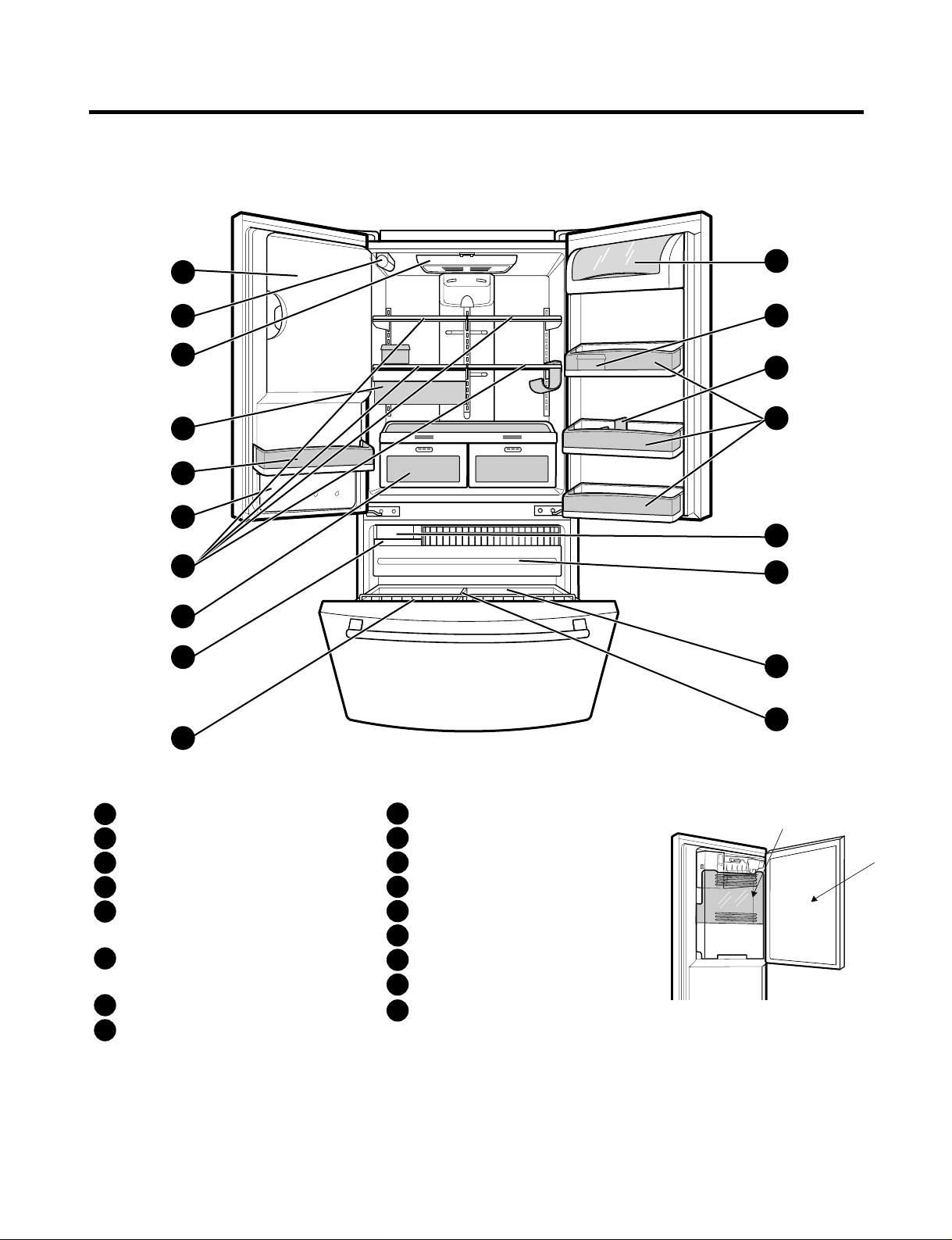

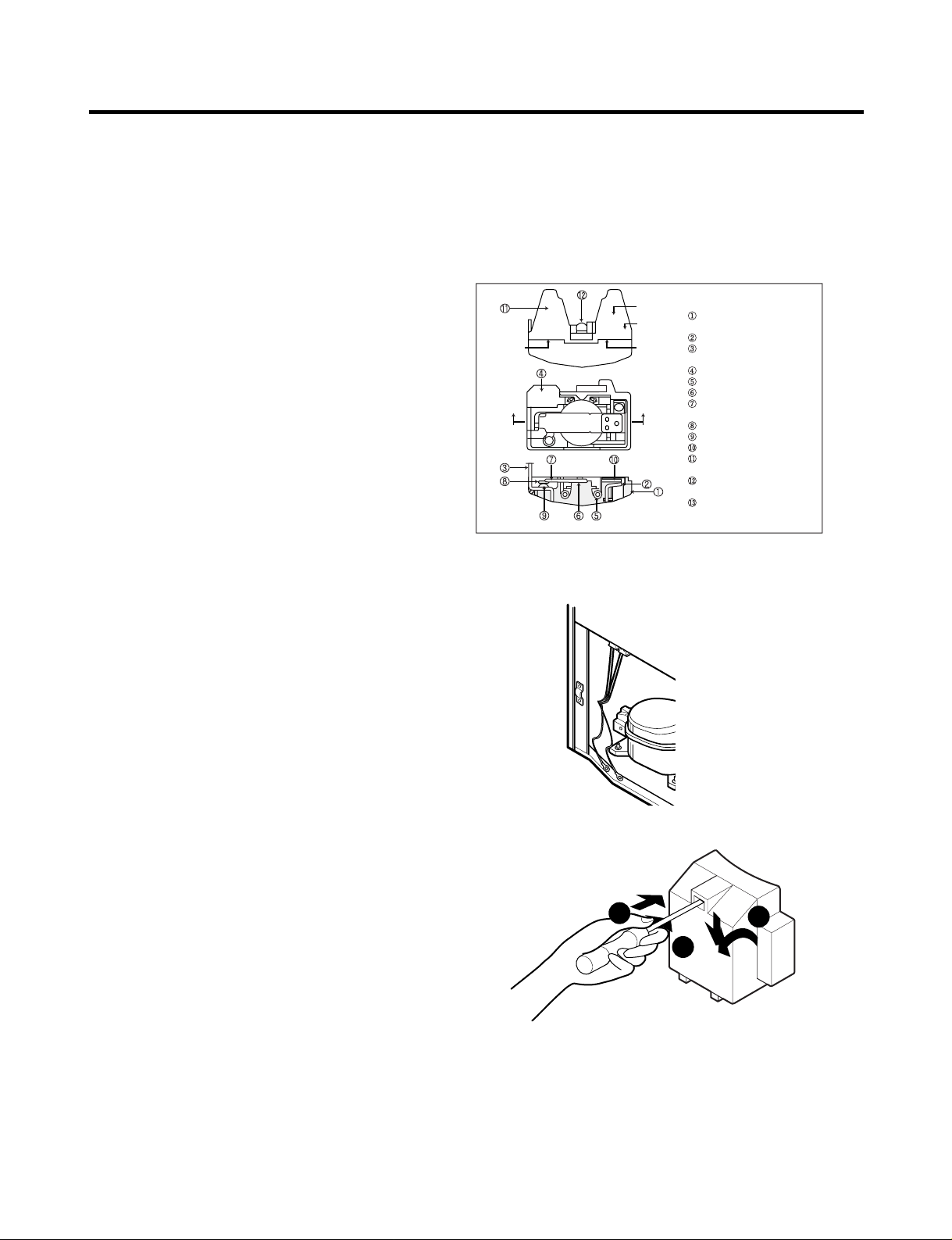

2. PARTS IDENTIFICATION

- 4 -

A

B

F

N

M

E

L

H

G

C

P

C

Q

O

D

I

K

J

Refrigerator Light

Filter (Inside)

Modular Door Bins

Refrigerator Shelves

Supra Fresh Crisper with

Tilt-Out Compartment

Ice Room

(ICEMAKER and ICE BIN)

Pull out Drawer

Turbo Motor

Tilt-Out Door Basket

Durabase

Divider

Ice Bin

Water Tank Cover

Snack Pan

Egg Box

Dairy Bin

Bottle Holder

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

Ice Bank

Ice Door

3. OPERATION

- 5 -

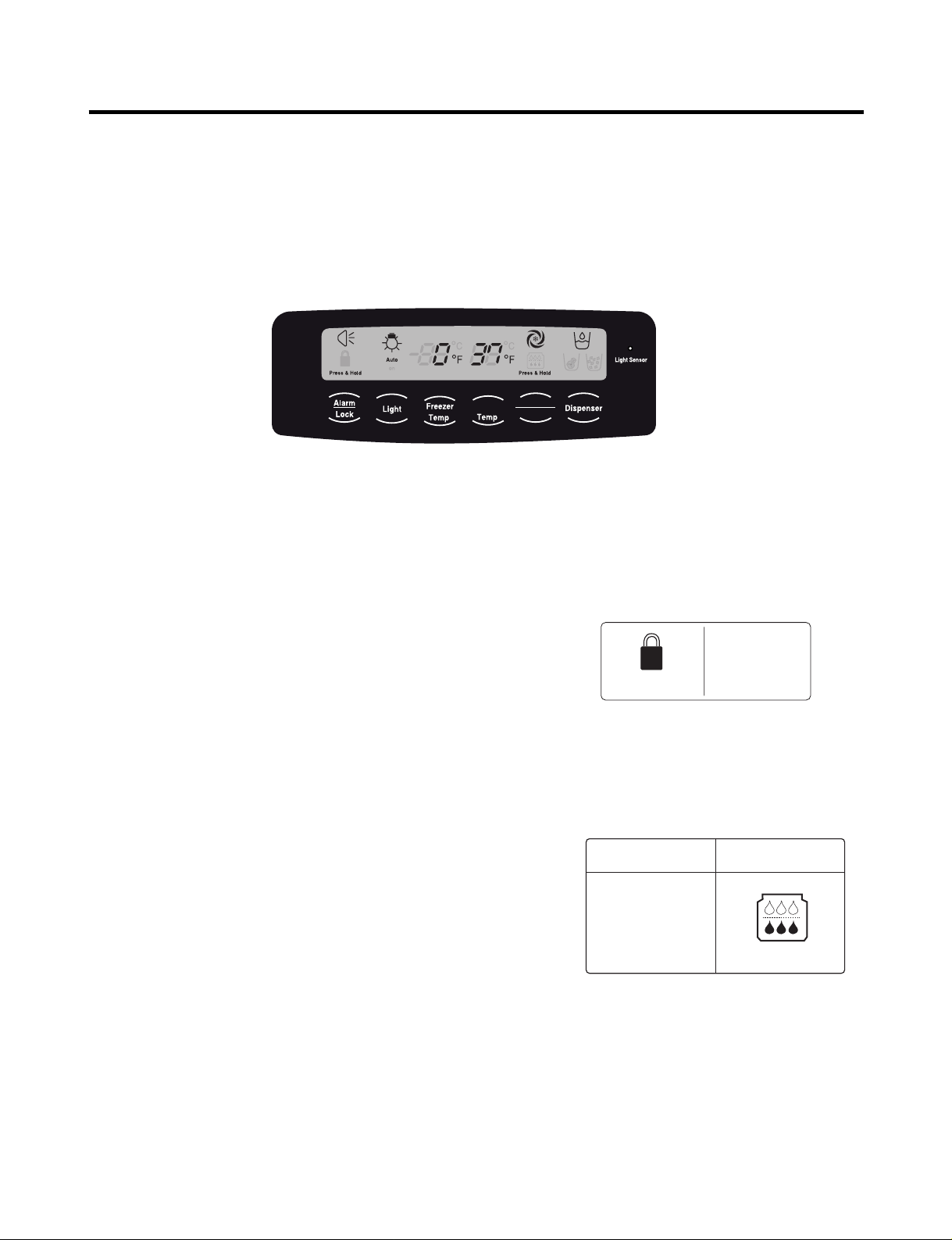

3-1. Explanation Of Each Function

1. Function

(1) When the appliance is plugged in, it is set to 37 °F for the refrigerator and 0 °F for the freezer.

You can adjust the refrigerator and the freezer control temperature by pressing the ADJUST button.

(2) When the power is initially applied or restored after a power failure, maintains its previously set temperature.

.

2 How to Toggle the Display between °F and °C

(1) The initial setting is °F and the display temperature mode can be changed from °F to °∆C or °∆C to °∆F by pressing and

holding the FRZ TEMP and the REF TEMP keys at the same time for over 5 seconds.

3. Lock function (dispenser and display button lock)

(1) When the refrigerator is first turned on, the buttons are not

locked. The display panel shows the padlock unlocked icon.

(2) To lock the display, the dispenser, and the control panel, press

and hold the LOCK button for 3 seconds. The locked pad lock

icon is displayed.

(3) The LOCK button is the only control feature that remains

active in the locked state. The buzzer sound, other control

buttons, and the dispenser are deactivated.

(4) To release from the locked state, press and hold the LOCK

button again for 3 seconds.

4. Filter condition display function

(1) There is a replacement indicator icon for the filter

cartridge on the dispenser.

(2)The water filter should be replaced approximately

every six months.

(3) The water filter icon will turn on every six months

to remind you to replace.

(4) After replacing the filter, press and hold the lock

button more than 3 seconds.

This will turn off the reminder icon and reset the timer.

Refrigerator

Ultra lce

Filter Reset

Ex) In selecting

"LOCK"

Ex) In selecting

"LOCK" again

Press & Hold Press & Hold

In initial Power On

/ Filter RESET

Replace indicator

light on

Classification

Filter Status

Display

Press & Hold Press & Hold

- 6 -

5. Ice Plus Selection

Please select this function for quick freezing.

(1) The ICE PLUS option starts counting its 24-hours period every time the

button is pressed.

(2) The ICE PLUS function automatically turns off after twenty-four hours pass.

6. Dispenser Use Selection

You can select water or ice.

∗ Select water, crushed ice, or ice cubes by cycling through the

selections when pressing the DISPENSER button,

∗ Hold your cup in the dispenser for a few seconds after dispensing

ice or water to allow the last pieces of ice or drops of water to fall

into the cup.

7. Dispenser Light

Whenever the light button is pressed, the display changes as shown below.

Normal status: When dispenser is operated, DISPENSER LIGHT is ON.

AUTO status: Detecting the lighting of room by LIGHT SENSOR, DISPENSER LIGHT is on and off automatically .

ON status: DISPENSER LIGHT is on continuously.

8. Control Of Freezer Fan Motor

(1) Freezer fan motor has high and standard speeds.

(2) High speed is used at power-up, for Ice Plus, and when refrigerator is overloaded.

Standard speeds is used for general purposes.

(3) To improve cooling speed, the RPM of the freezer fan motor changes from normal speed to high.

(4) High speed (2700RPM) : Initial power on or load corresponding operation, Ice Plus

Normal speed (2400RPM) : General working conditions.

(5) Fan motor stops when a refrigerator or freezer door opens.

9. Cooling Fan Motor

(1) The cooling fan is switched ON and OFF in conjunction with the compressor.

(2) The cooling fan runs at a single speed.

(3) The Failure sensing method is the same as in the fan motor of the freezing fan motor(refer to failure diagnosis function

table for failure display).

10. Icing Fan

The Icing Fan is controlled by the the sensor on the top of the ice room.

The Failure sensing method is the same as in the fan motor of the freezer

(refer to failure diagnosis function table for failure display)

Pressing

Switch

Auto Auto

on

Light Sensor

- 7 -

11. Ice Plus

(1) The purpose of this function is to intensify the cooling speed of freezer and to increase the amount of ice.

(2) Whenever selection switch is pressed, selection/release, the LED will turn ON or OFF.

(3) If there is a power outage and the refrigerator is powered on again, Ice Plus will be canceled.

(4) To activate this function, press the Ice Plus key and the LED will turn ON. This function will remain activated for 24 hours.

The first three hours the compressor and Freezer Fan will be ON. The next 21 hours the freezer will be controlled at the

lowest temperature. After 24 hours or if the Ice Plus key is pressed again, the freezer will return to its previous

temperature.

(5) During the first 3 hours:

• Compressor and freezer fan (HIGH RPM) run continuously.

• If a defrost cycle begins during the first 90 minutes of Ice Plus, the Ice Plus cycle will complete its cycle after defrosting

has ended.

If the defrost cycle begins when Ice Plus has run for more than 90 minutes, Ice Plus will run for two hours after the

defrost is completed.

• If Ice Plus is pressed during defrost, Ice Plus LED is on but this function will start seven minutes after defrost is

completed and it shall operate for three hours.

• If Ice Plus is selected within seven minutes after compressor has stopped, the compressor (compressor delays seven

minutes) shall start after the balance of the delay time.

• The fan motor in the freezer compartment runs at high speed during Ice Plus.

(6) For the rest of the 21 hours, the freezer will be controlled at the lowest temperature.

12. Freezer and Refrigerator Lamp Auto Off

(1) To avoid heat damage caused by the lamp, it is turned off automatically when the refrigerator door is open for more than

7 minutes.

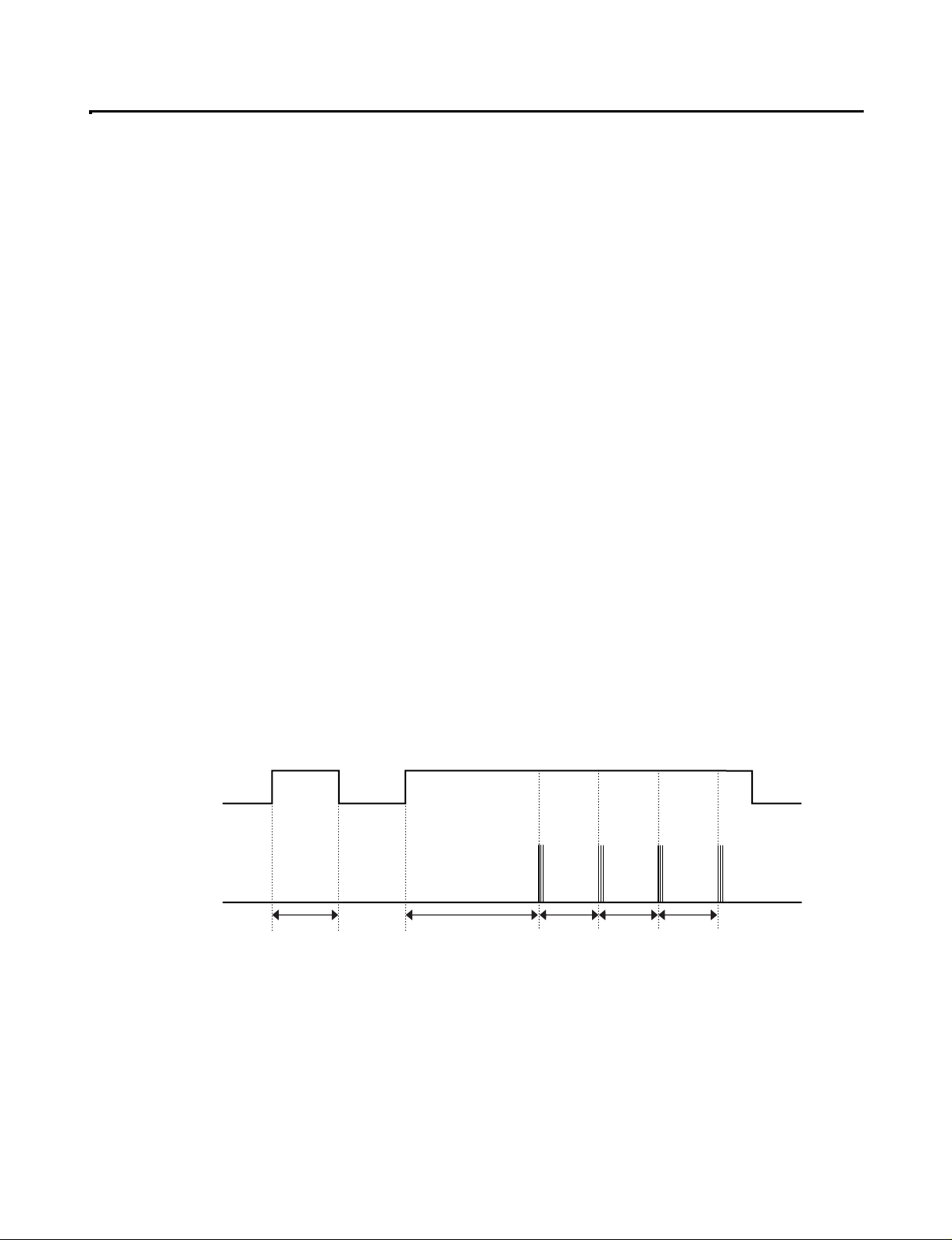

13. Alarm for Open Door

(1) This feature sounds a buzzer when the freezer or refrigerator door is not closed within 1 minute after it is opened.

(2 One minute after the door is opened, the buzzer sounds three times each for one half seconds. These tones repeat every

30 seconds.

(3) The alarm is cancelled when the freezer or the refrigerator is closed.

Closed Open Closed Open

3 Times 3 Times 3 Times 3 Times

Closed

Within 1 min. 1 min.

30 sec 30 sec 30 sec

Freezer Door

or Refrigerator

Door

Buzzer

- 8 -

14. Defrosting (removing frost)

(1) Defrosting starts each time the COMPRESSOR running time reaches 7 hours.

(2) For initial power on or for restoring power, defrosting starts when the compressor running time reaches 4 hours.

(3) Defrosting stops if the sensor temperature reaches 46.4°F (8°C) or more. If the sensor doesn’t reach 46.4°F (8°C) in

2 hours, the defrost mode is malfunctioning. (Refer to the defect diagnosis function, 15.)

(4) Defrosting won’t function if its sensor is defective (wires are cut or short circuited)

15. Defect Diagnosis Function

(1) Automatic diagnosis makes servicing the refrigerator easy.

(2) When a defect occurs, the buttons will not operate; but the tones will sound.

(3) When the defect CODE removes the sign, it returns to normal operation (RESET).

(4 The defect CODE shows on the Refrigerator and Freezer Display.

✽ LED check function: Press Ice Plus and Freezer buttons for a second, display LED graphics on.

If releasing the button, the LED graphic displays the previous status.

Press & Hold Press & Hold

Auto

on

- 9 -

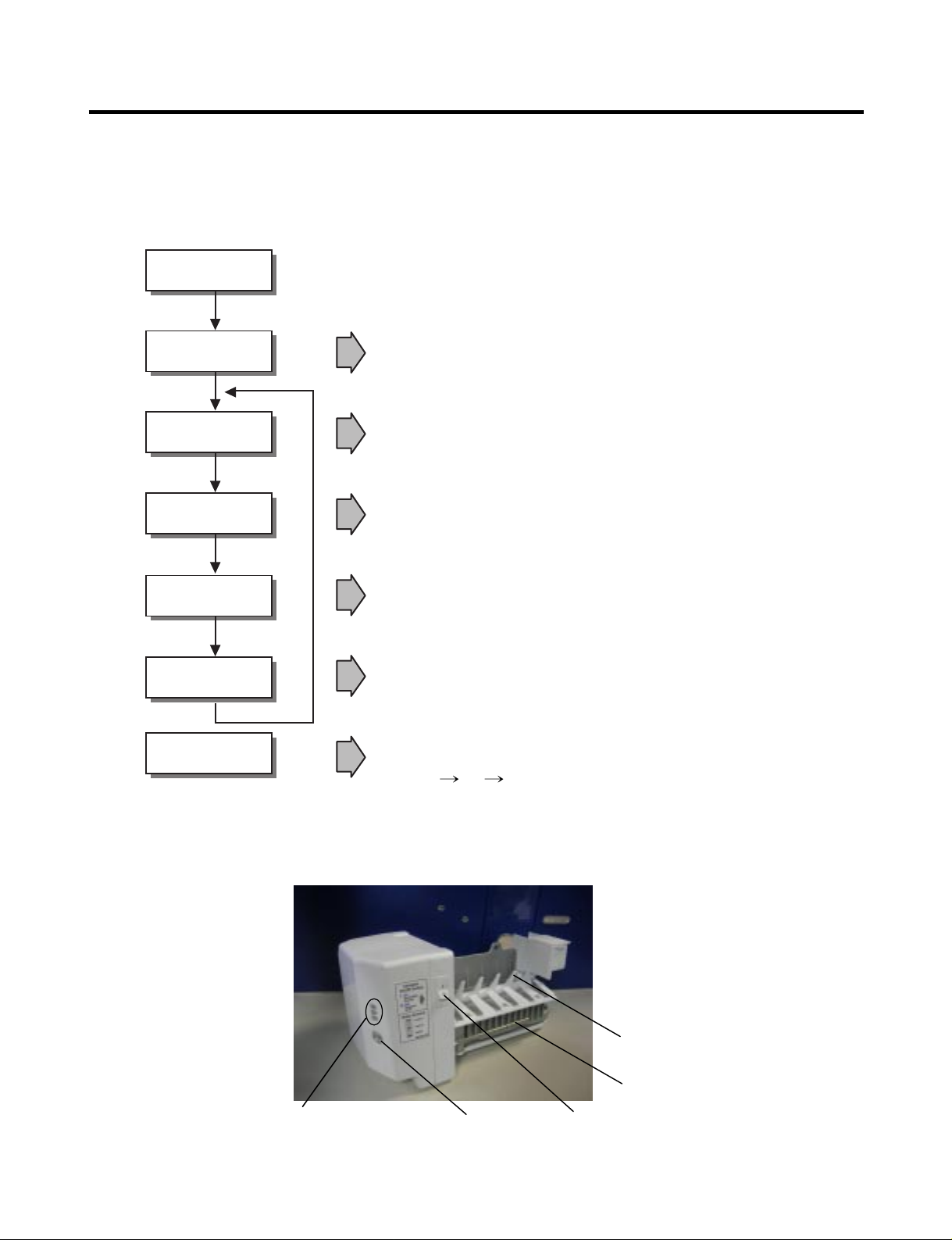

3-2. Ice Maker Function

1. Operation Principle of icemaker

(1) Turning the Icemaker stop switch off (O) stops the ice making function.

(2) Setting the Icemaker switch to OFF and then turning it back on will reset the icemaker control.

• Adjusts EJECTOR to Start Position with power on.

Power On

Start Position

Icemaking

Mode

Harvest

Mode

Fill

Park Position

Test Mode

• Waits until water becomes ICE after starting the

icemaking operation.

• Runs MOTOR to drop ice from the tray into the ICE BIN.

(During harvest mode, check if the ice bin is full.)

• Performs Ice Making Mode after supplying water by operating

the SOLENOID in ICE VALVE.

• To operate LINE and SERVICE, press and hold the Cube Size button

for 3 seconds. The icemaker will run through 3 stages:

Harvest Fill Icemaking.

• Reaches Start Position

Cube Size

Indicator Light

Cube Size

Selection Button

Power

Switch

Automatic

Shut off Arm

EJECTOR

- 10 -

2. Icemaking Mode

(1) Icemaking refers to the freezing of supplied water in the ice tray. Complete freezing is assured by

measuring the temperature of the tray with Icemaking SENSOR.

(2) Icemaking starts after completion of the water fill operation.

(3) The icemaking function is completed when the sensor reaches 1 9 °∆F (-7 °∆C), 55 minutes after starting.

NOTE : After the icemaker power is ON, the icemaker heater will be on for test for 6 seconds.

3. Harvest Mode

(1) Harvest (Ice removing) refers to the operation of dropping cubes into the ice bin from the tray when

icemaking has completed.

(2) Harvest mode:

• The Heater is ON for 30 seconds, then the motor starts.

• The feeler arm senses the quantity of ice in the ice storage bin while rotating with the EJECTOR.

A. Ice storage bin is full : The EJECTOR stops (heater off).

B. Ice storage bin is not full : The EJECTOR rotates twice to open for ice.

* If the EJECTOR does not rotate once within 5 minutes in B mode, separate heater control mode starts operating to

prevent the EJECTOR from being constrained. (It is recommended that the user open for ice to return to normal mode.)

4. Fill/Park Position

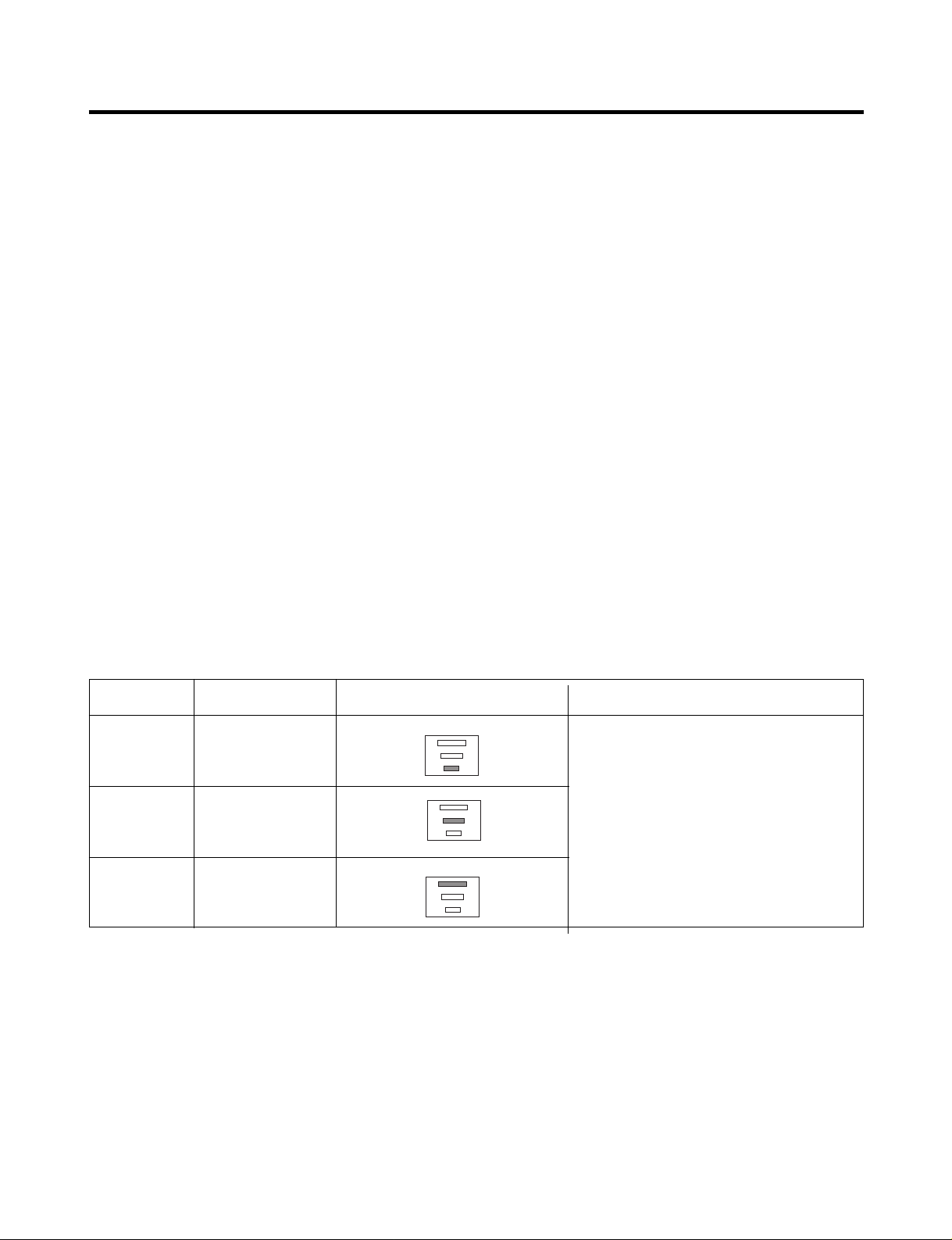

(1) Once a normal harvest mode has been completed, the water solenoid will be activated.

(2) The amount of water is adjusted by pressing the fill key repeatedly. This changes the time allowed for fill as illustrated in

the table below.

Water supply amount TABLE

ST AGE TIME TO SUPPL Y INDICA TIONS REMARKS

1

2

3

5 sec.

5.5 sec.

(FIRST STAGE)

6 sec.

The water amount will vary depending

on the water control switch setting as

well as the water pressure of the

connected water line.

- 11 -

5. Function TEST

(1) This is a forced operation for test, service, cleaning, etc. It is operated by pressing and holding the cube size button for 3

seconds.

(2) The test works only in the Icemaking Mode. It cannot be entered from the Harvest or Fill mode.

(3) Caution! Caution! Caution! Caution! If the test is performed before water in the icemaker is frozen, the ejector will pass

through the water. When the fill mode begins (Stage 4), unless the water supply has been shut off, added water will

overflow into the ice bin. If the control doesn ’ t

(4) After water is supplied, the normal CYCLE is followed: icemaking → Harvest → Park Position → Fill.

(5) Five seconds after Stage 5 is completed, the icemaker returns to MICOM control. The time needed to supply water

resets to the

Diagnosis TABLE

6. Error codes shown on the icemaker water supply control panel

STAGE ITEMS INDICATOR REMARKS

1

2

3

4

5

6

HEATER

MOTOR

HALL IC I

HALL IC II

VALVE

Reset

Five seconds after the heater starts, it

will go off if the temperature by

sensor is higher than 10°C

Five seconds after the heater starts, you

can confirm that the motor is moving.

Check whether ice bin is full. If the ice bin

if full, the motor and heater are off, but on

standby until the ice bin is empty.

You can confirm HALL IC detection of start

position.

Two seconds after the detection of start

position, you can confirm that the valve is on.

Five seconds after the fifth stage is

completed, the icemaker resets to initial

status.

Return to Status prior to

TEST MODE

NO DIVISION INDICATOR CONTENTS REMARKS

1

2

Normal

Icemaking

sensor

malfunction

Mark time to

supply

None

Open or short-circuited wire

Display switch

operates properly

Make sure that the wire

on each sensor is

connected.

- 12 -

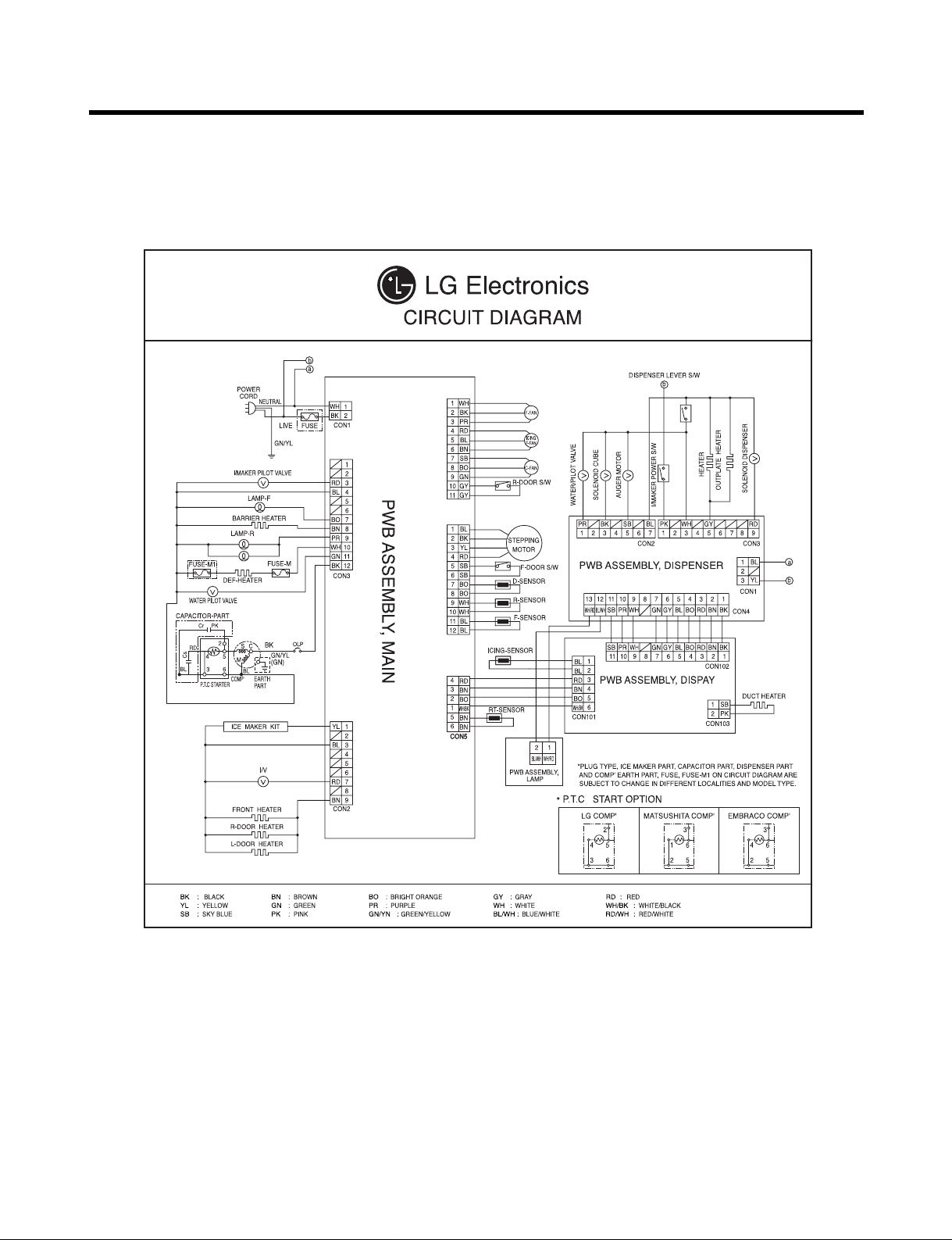

4. WIRING DIAGRAM

5-1. Compressor

1. Role

The compressor intakes low temperature and low pressure gas from the evaporator of the refrigerator and

compresses this gas to high-temperature and high-pressure gas. It then delivers the gas to the condenser.

2. Composition

The compressor includes overload protection. The PTC starter and OLP (overload protector) are attached to

the outside of the compressor. Since the compressor is manufactured to tolerances of 1 micron and is

hermetically sealed in a dust and moisture-free environment, use extreme caution when performing repairs.

3. Note for usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor operation and noise may result.

(3) Use proper electric components appropriate to the particular compressor in your product.

(4) Keep the compressor dry. If the Compressor gets wet (in the rain or a damp environment) and rust forms

in the pin of the Hermetic Terminal, poor operation and contact may result.

(5) When replacing the compressor, be careful that dust, humidity, and soldering flux don’t contaminate the

inside of the compressor. Dust, humidity, and solder flux may contaminate the cylinder and may cause

noise, improper operation, or even lock up.

5. ADJUSTMENT

- 13 -

4. diagnosis

- 14 -

1

2

3

4

5

2

5

5

3

5

1

43

YES

NO

YES

The range of resistance is between 1~50Ω(ok)

Open or short

YES YES

NO

NO

Power Source.

No Voltage.

(Rated Voltage

±10%)?

Replace OLP.

Reconnect.

Reference 5-2

Reference 5-3

Did

compressor

start?

Compressor

is OK

Replace the

compressor

Check connection

condition.

OLP disconnected?

Advise customer that

power supply needs to be

checked by an electrician.

Replace

Compressor.

Supply

voltage rating

with ±10%.

Applied voltage isn't

in acceptable range.

(115V ±10%)

Remove PTC-Starter

from Compressor and

measure voltage

between Terminal C of

Compressor and

Terminal 5 or 6 of PTC.

Check resistance

between M-C, S-C and

M-S in Motor

Compressor.

Check resistance of

two terminals in

PTC-Starter.

Check resistance of two

terminals in OLP.

Check the power supply

under load.

(Compressor attempting

to re-start after being off

for 5 minutes).

Check

resistance of

Motor

Compressor.

Check

resistance of

PTC-Starter.

Check OLP.

Check

starting state.

- 15 -

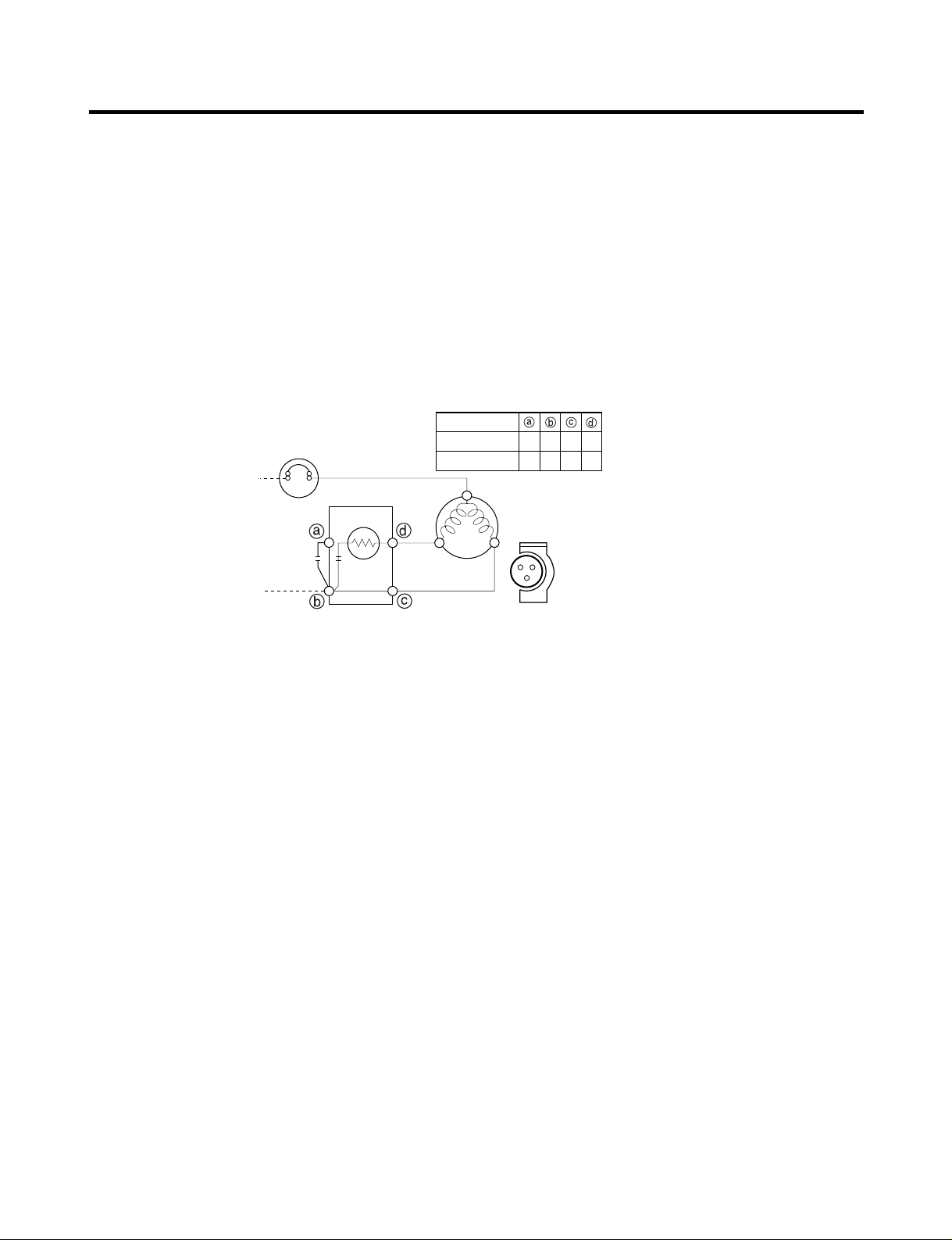

5-2. Positive Temperature Coefficient (PTC) – Starter

1. Composition

(1) PTC (Positive Temperature Coefficient) is a no-contact semiconductor starting device which uses ceramic

material consisting of BaTiO3.

(2) The higher the temperature is, the higher the resistance value. These features are used as a starting

device for the motor.

2. Role

(1) The PTC is attached to the sealed compressor and is used for starting the compressor motor.

(2) The compressor is a single-phase induction motor. For starting operation, the PTC allows current flow to

both the start winding and main winding.

3. PTC – Applied circuit diagram

● Starting Method for the Motor

4. Motor restarting and PTC cooling

(1) It requires approximately 5 minutes for the pressure to equalize before the compressor can restart.

(2) The PTC device generates heat during operation. Therefore, it must be allowed to cool before the

compressor can restart.

5. Relation of PTC – Starter and OLP

(1) If the compressor attempts to restart before the PTC device is cooled, the PTC device will allow current to

flow only to the main winding.

(2) The OLP will open because of the over current condition. This same process will continue (3 to 5 times)

when the compressor attempts to restart until the PTC device has cooled. The correct OLP must be

properly attached to prevent damage to the compressor. Parts may appear physically identical but could

have different electrical ratings. Replace parts by part number and model number. Use only approved

substitute parts.

6. Note for Using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid. If liquid such as oil or water enters the PTC, the materials may fail due to

breakdown of their insulating capabilities.

(4) If the exterior of the PTC is damaged, the resistance value may be altered. This can cause damage to the

compressor and result in a no-start or hard-to-start condition.

(5) Always use the PTC designed for the compressor and make sure it is properly attached to the compressor.

Parts may appear physically identical but could have different electrical ratings. Replace parts by part

number and model number. Use only approved substitute parts.

PTC STARTER

SEALED

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

S

N

L1

OVERLOAD PROTECTOR

Resistance Starter Capacitor Running

PTC

2

LFX21960**

LFX25960**

3 2 5 6

2 3 6 5

- 16 -

5-3. Over Load Protector (OLP)

1. Define

(1) The OLP (OVERLOAD PROTECTOR) is attached to the Compressor and protects the motor by opening the

circuit to the motor if the temperature rises and activating the bimetal spring in the OLP.

(2) When high current flows to the compressor motor, the Bimetal works by heating the heater inside the OLP,

and the OLP protects the Motor by cutting off the current flowing to the Compressor Motor.

2. Role

(1) The OLP is attached to the sealed compressor

used for the refrigerator. It prevents the motor

coil from being started in the compressor.

(2) For normal operation of the OLP, do not turn

the adjustment screw of the OLP in any way.

5-4. Remove the cover Positive Temperature Coefficient (PTC)

(1) Remove the cover of the mechanical area.

(2) Disconnect the two clamps holding

the compressor in place.

(3) Loosen two screws on compressor base.

(4) Use a screwdriver to pry off the cover.

(5) Assembly is the reverse order of disassembly.

Part

Customer part

number

Lot code/

date code

330 FBYY -S1 BOX98

12345678

Physical

termination

part number

Electrical

characteristics

part number

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V -0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

Quick-connect terminal, brass,

conforms to UL 310, MEMA

DC-2, DIN 46344

(OVERLOAD PROTECTOR cross section)

2

3

1

- 17 -

6-1. Error Code Summary

ww

WARNING : When you check the Resistance values, be sure to turn off the power.

And wait for the voltage-discharge sufficiently.

6. TROUBLESHOOTING

1

2

3

4

5

6

7

8

9

10

Normality

Freezer Sensor

Error

Refrigerator

Sensor Error

Defrosting

Sensor Error

Icing Sensor

Error

Poor Defrosting

Abnormality of

BLDC FAN Motor

for Ice Making

Abnormality of

BLDC FAN Motor

for Freezer

Abnormality of

BLDC FAN Motor

for Mechanic Room

Communication

Error

None

Short or Disconnection

of Freezer Sensor

Short or Disconnection

of Refrigerator Sensor

Short or Disconnection

of Defrosting Sensor

Short or Disconnection

of Icing Sensor

Even though it is passed

1 hour since then

Defrosting , if Defrosting

sensor is not over 8°C, it

is caused

It is caused when

feedback signal isn’ t

over 115

seconds during BLDC

FAN motor operating

It is caused when

feedback

signal isn ’ t over 115

seconds during BLDC

FAN motor operating

Communication Error

between Micom of Main

PCB and Display Micom

It is caused when

feedback

signal isn’ t over 115

seconds during BLDC

FAN motor operating

Normal operation of Display

Check each sensor and its

connector.

Temperature Fuse

Disconnection, Heater

disconnection, DRAIN Jam,

Poor Relay for Heater

Poor BLDC Motor

connection, DRIVE IC, and

TR Tx/Rx between icemaker

and main board.

Poor BLDC Motor

connection, DRIVE IC, and

TR Tx/Rx between icemaker

and main board.

Poor BLDC Motor

connection, DRIVE IC, and

TR Tx/Rx between icemaker

and main board.

Poor Communication

connection,Poor TR of

Transmitter and Receiver

Tx/Rx between icemaker

and main board.

Er

Er

Er

Er

Er

Er

Er

Er

Er

FS

rS

dS

IS

dH

IF

FF

CF

CO

NO

Error Detection

Category

Error Generation Factors Remark

Freezer

Temperature

Ref.

Temperature

Error Display

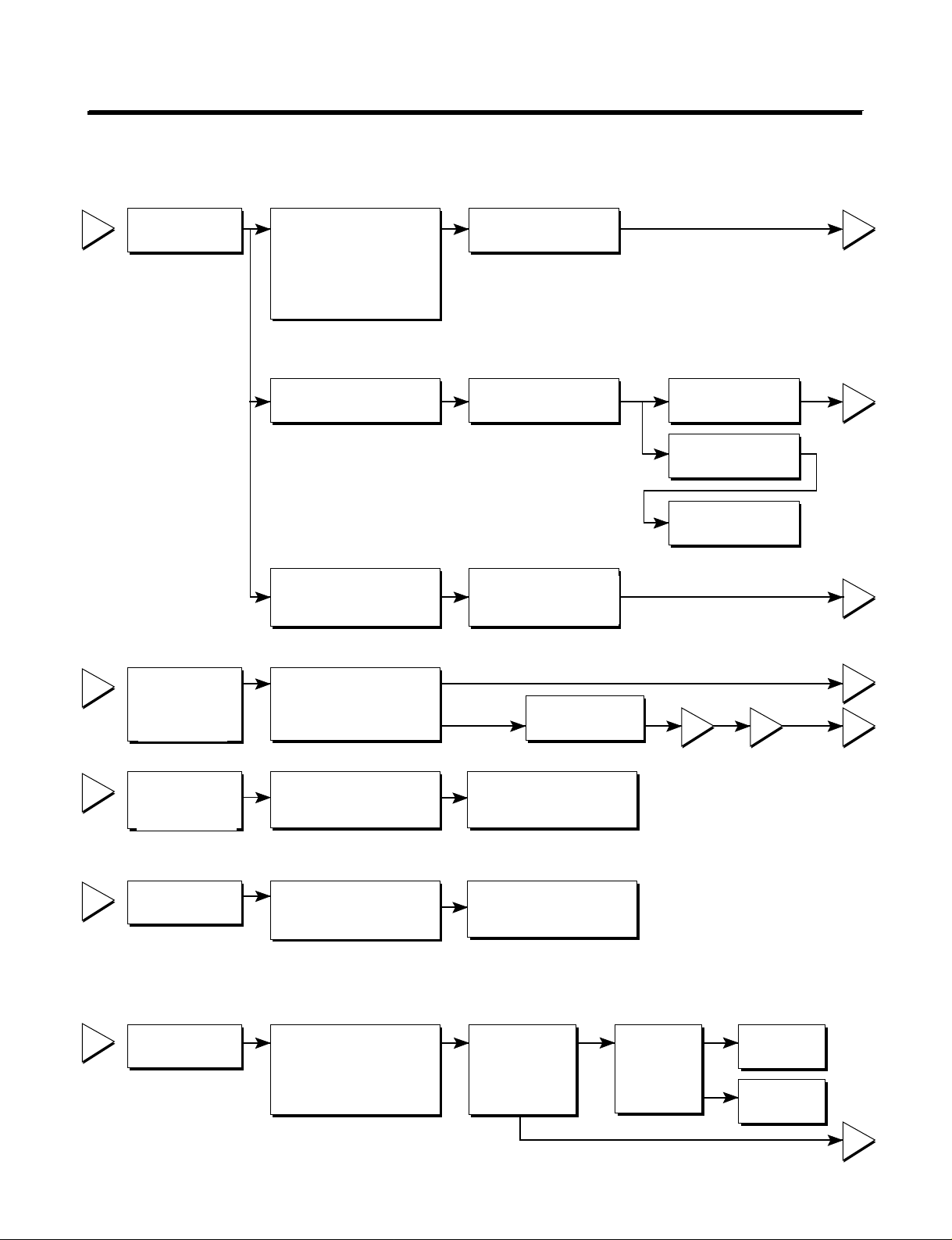

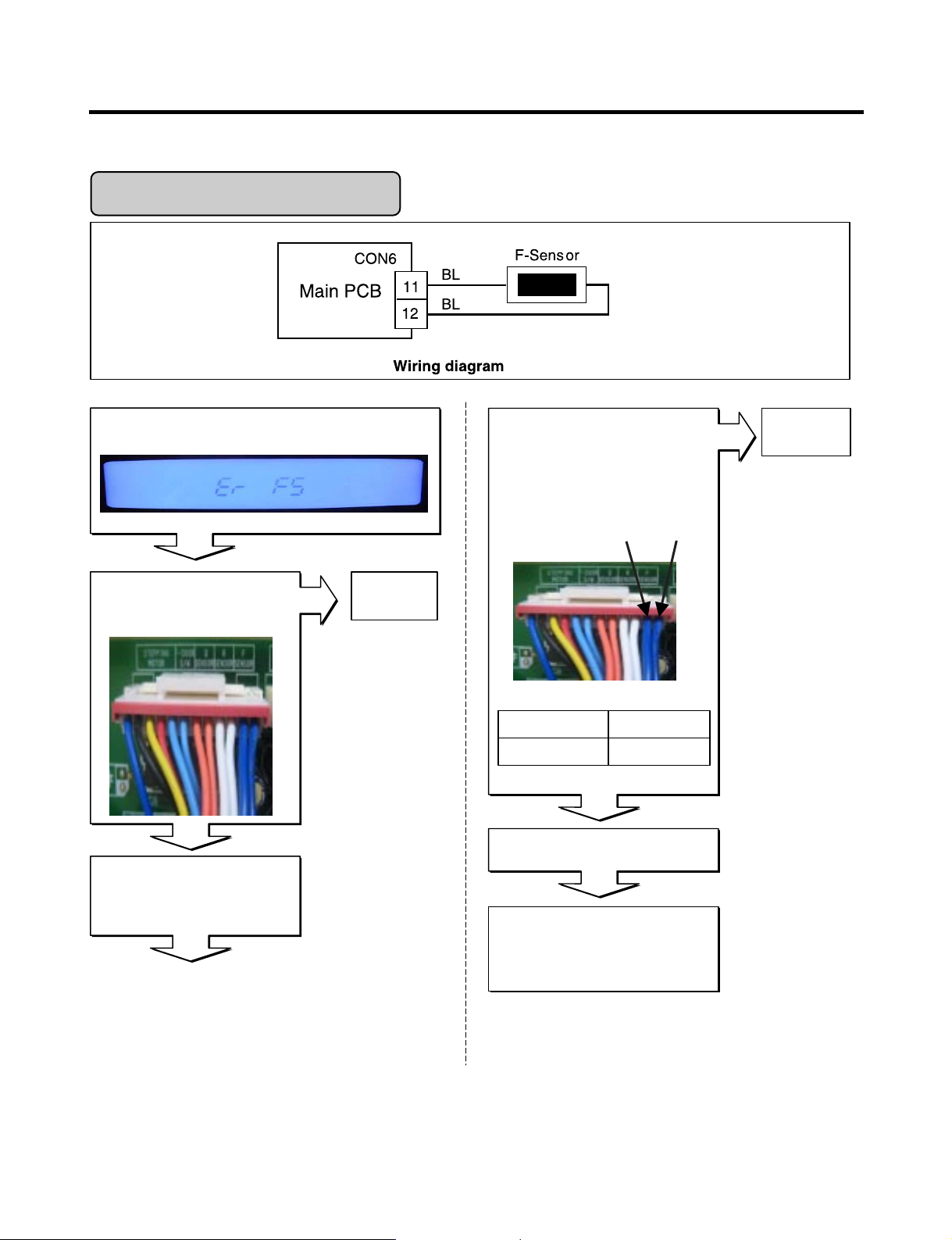

6-2. Troubleshooting With Error

- 18 -

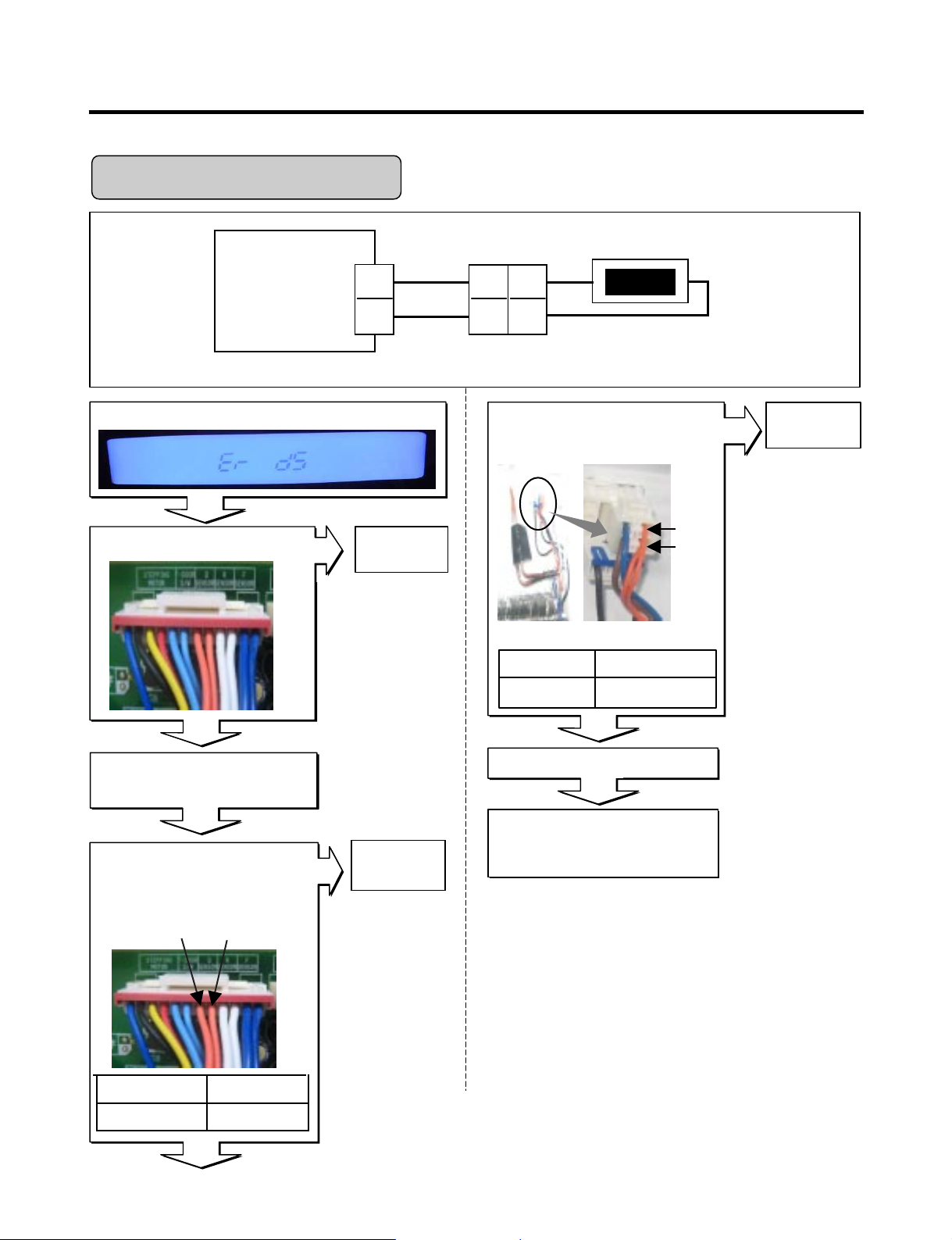

Is Er-FS dis played?

Disconnect CON6 and measure

the value. Is resistance value

between pins 11 & 12 of CON6

as below? (BL to BL)

Freezer Sensor Err or

Is the connection loose?

If the ER-FS appears, Replace

the main PCB. Otherwise,

explain to the customer!

Replace

F-sensor

pin12

pin11

1.4 ~ 120k‰pin11 to pin12

ResultTest Point

Reconnect

Reconnect CON6 and Power ON

Power Off

Tip : To protection of MICOM

Yes

Yes

No

No

No

- 19 -

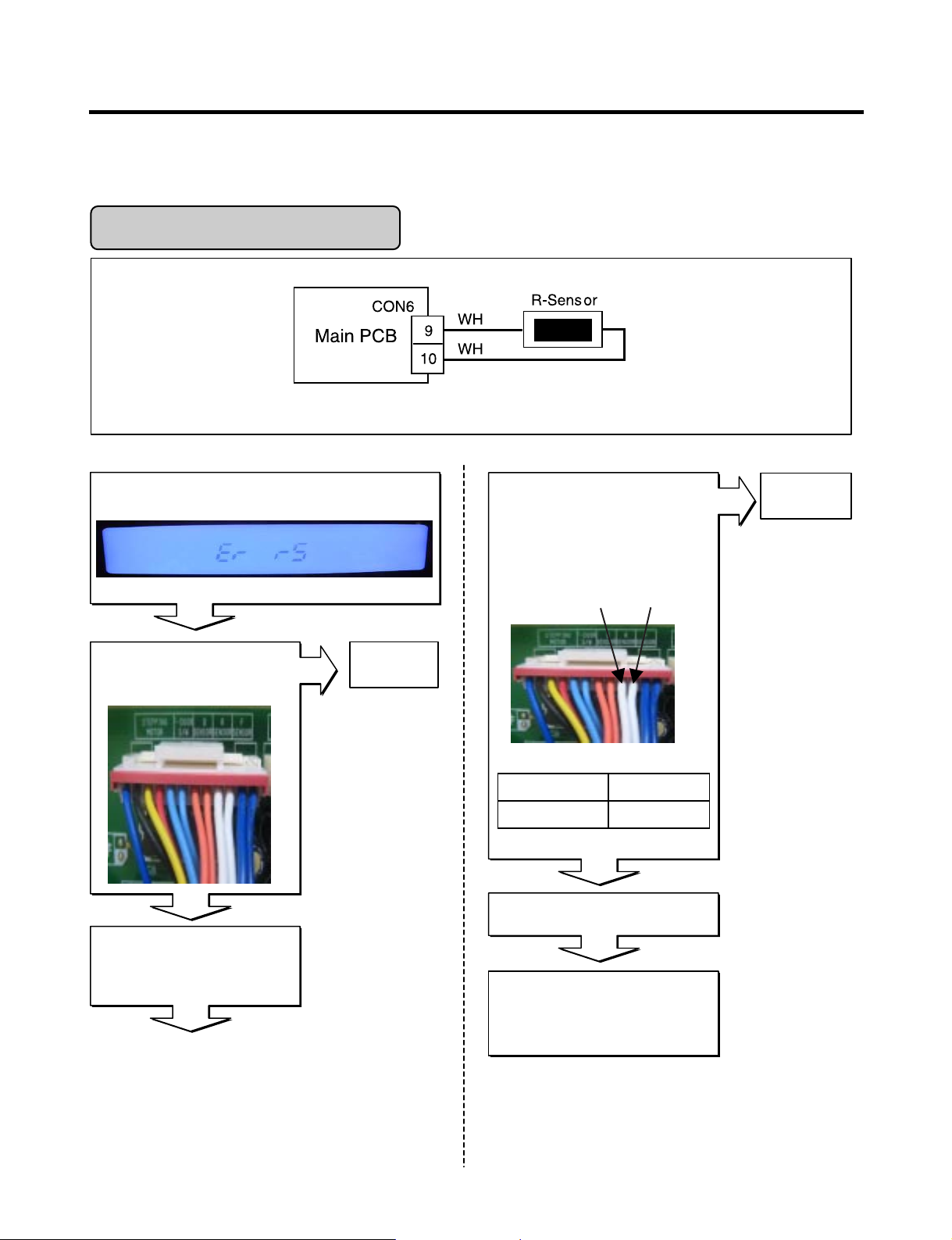

Refrigerator Sensor Error

Is Er-rS displayed?

Disconnect CON6 and measure

the value. Is resistance value

between pins 9 & 10 of CON6 as

below? (WH to WH)

Yes

Is the connection loose?

If the ER-rS appears, Replace

the main PCB. Otherwise,

explain to the customer!

Replace

R-sensor

No

pin10

pin9

Yes

6 ~ 300 k‰pin9 to pin10

ResultTpin10 pin9

Reconnect

Reconnect CON6 and Power ON

Power Off

Tip : To protection of MICOM

No

No

Wiring dia gram

- 20 -

Housing-A

Main PCB

BO

BO

BO

BO

D-Sensor

7

8

2

1

CON6

7

6

Defrost Sensor Error

Wiring dia gram

Is Er-dS displayed?

Disconnect CON6 and measure

the value. Is resistance value

between pins 7 & 8 of CON6 as

below? (BO to BO)

Yes

Is the connection loose?

If the ER-dS appears, Replace

the main PCB. Otherwise,

explain to the customer!

Replace

D-sensor

No

No

No

pin8

pin7

6 ~ 300k‰Pin7 to pin8

ResultTest Point

Reconnect

Reconnect and Power ON

Power Off

Tip : To protection of MICOM

Is resistance value between

pins 1 & 2 of Housing- A as

below? (BO to BO)

Replace a

D-Sensor

pin1

pin2

1.156 ~141.5k‰Pin1 To pin2

ResultTest Point

Checking Open or Short of wire

Yes

Yes

No

- 21 -

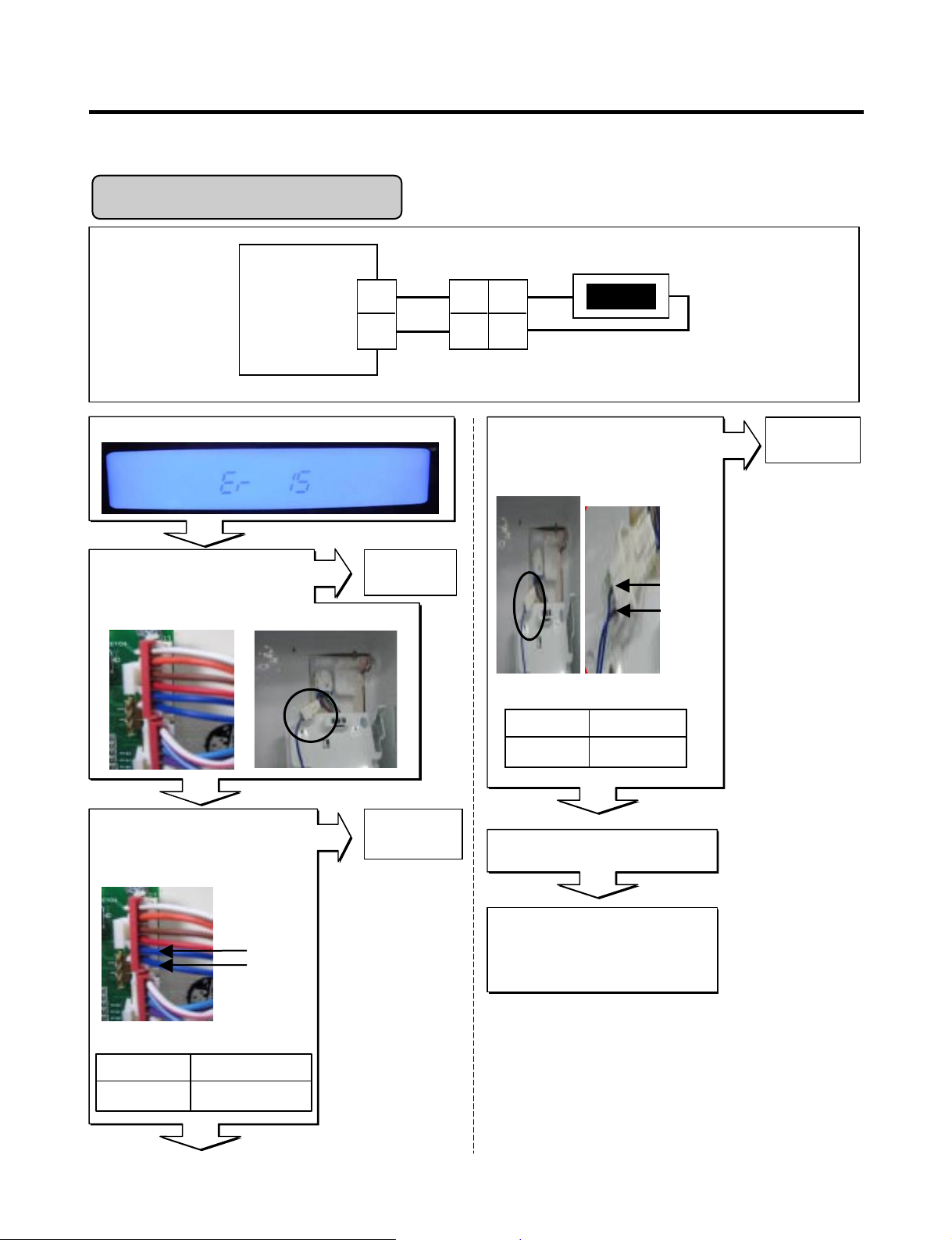

Is Er-IS displayed?

Yes

Yes

Yes

No

No

Yes

Housing-A

Display

PCB

BL

BL

BL

BL

Icing-Sensor

CON101

1

2

1

2

1

2

Is the connection loose?

Reconnect

pin1 BL

pin2 BL

Icing Room Sensor Error

1.156 ~141.5k‰pin1 to pin2

ResultTest Point

Icing room Sensor Resistance

Replace the

Icing-Sensor

(1) To (2)

Test Point Result

1.4 ~120k‰

Checking Open or Short of wire

pin2 BL

pin1 BL

Replace

Main PCB

If the ER-IS appears,

Replace Main PCB

Otherwise, explain

to the customer!

Reconnect and Power ON

Display PCB Inner of Icing door

Is resistance value between

pins 1 & 2 of Housing- A as

below? (BL to BL)

No

Disconnect CON101 and

measure the value. Is resistance

value between pins 1 & 2 of

CON101 as below? (BL to BL)

Wiring diagram

- 22 -

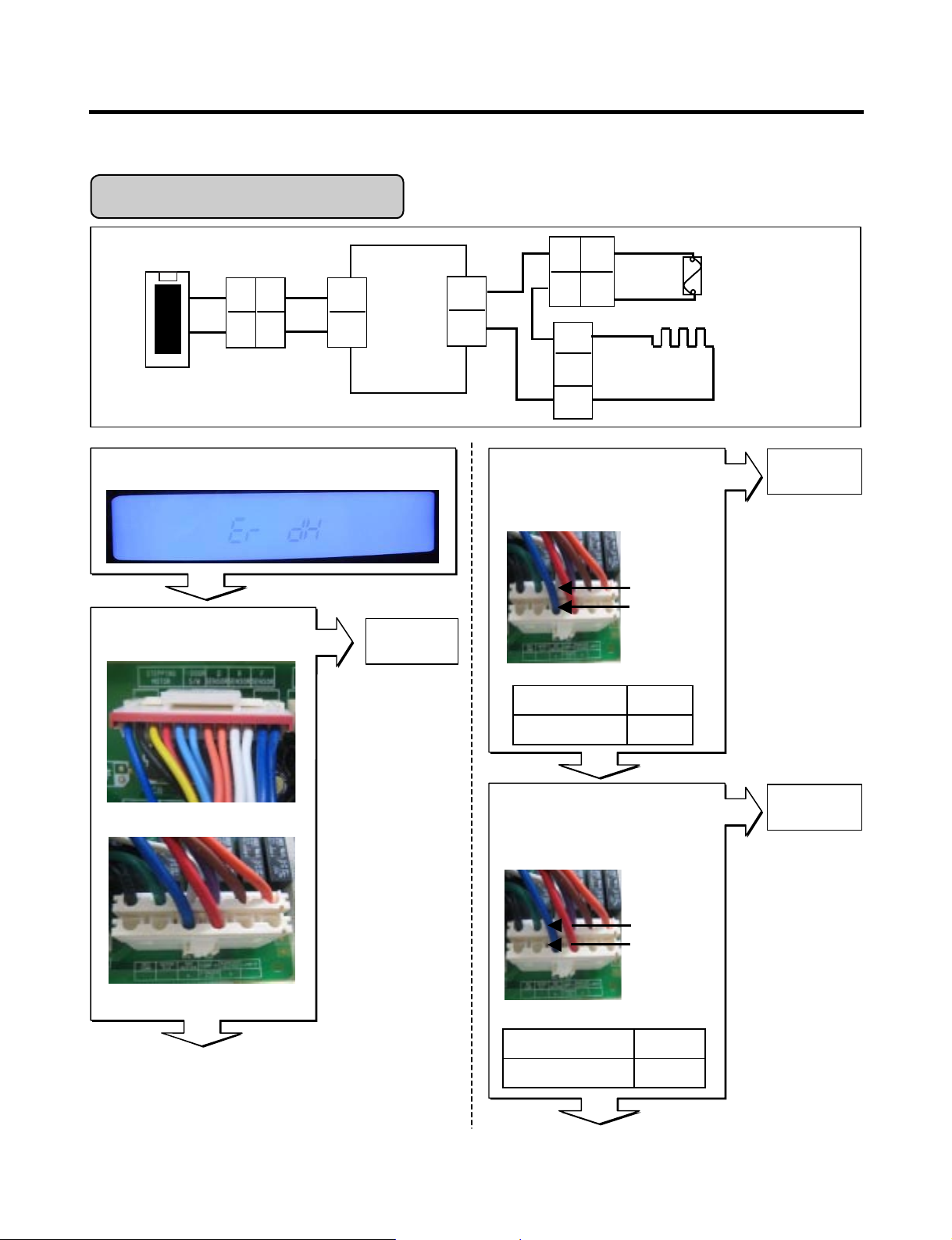

Enter the TEST 3 MODE

Is the voltage value

between pins 10 (WH) and

4 (BL) of CON3 115 V AC?

Is Er-dH displayed?

Yes

Yes

Yes

No

Yes

Yes

No

CON6

CON3

Replace

MAIN PCB

Replace

MAIN PWB

Main

PCB

WH

BL

FUSE-M

CON3

10

4

DEF-Heater

Housing-A

BO

D-Sensor

7

8

BO

2

CON6

BO

BO

7

6

BL

BN

BK

2

1

7

6

1

3

1

2

BK

Is the connec tion loose?

pin4 BL

pin10 WH

pin4 BL

pin10 WH

115Vpin4 To pin 10

ResultTest Point

Reset TEST3 MODE(Normal)

Is the voltage value between

pins 10 (WH) and 4 (BL) of

CON3 for 0 V AC?

0 ~ 2 V

Reset/Norm op

ResultTest Point

Defrost Heater Error

Wiring dia gram

Relay Open

Reconnect

Relay operation

- 23 -

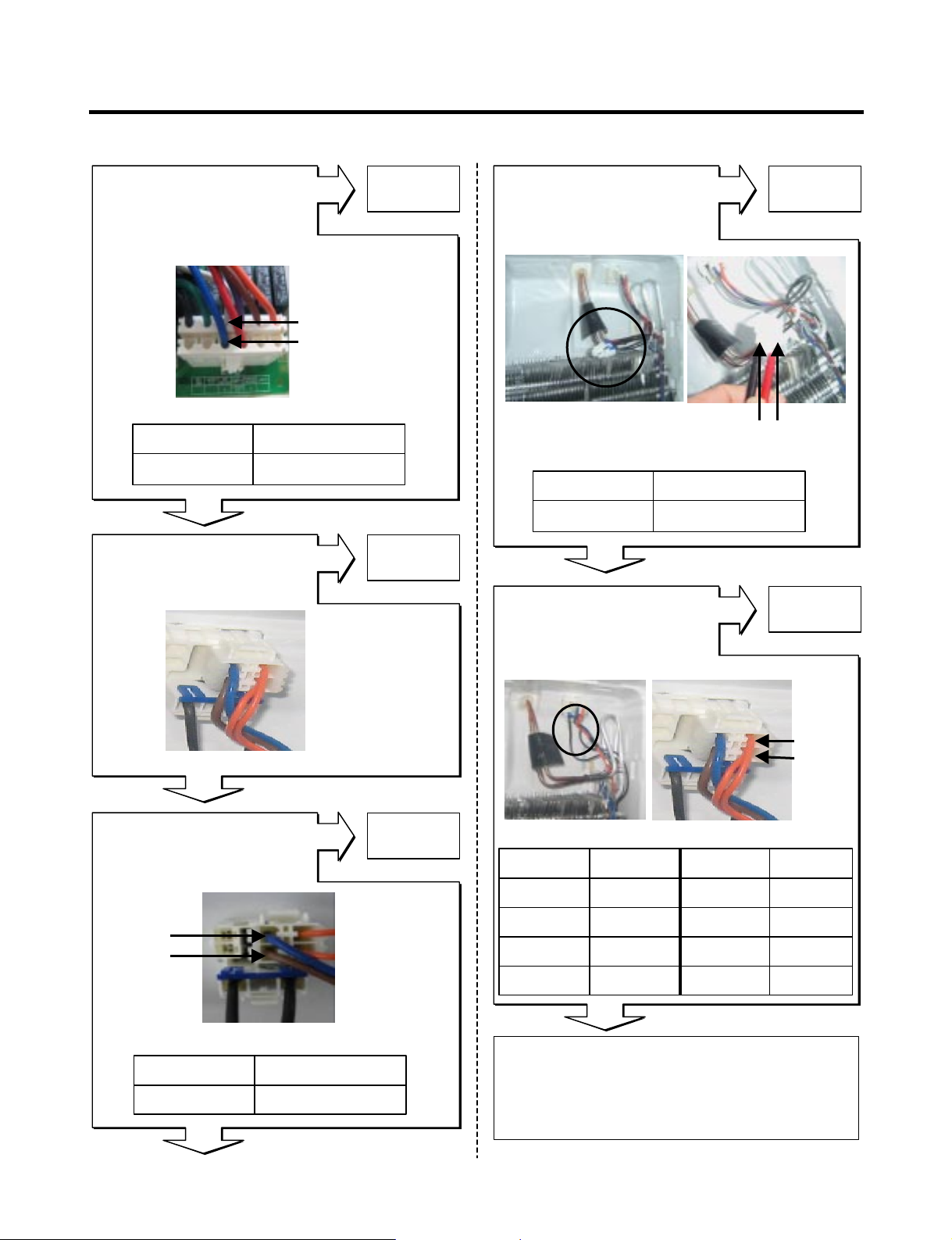

Explain to the customer! :

It can be occurred, when the gasket is not

stuck to product or when you put the high

temperature loads (hot foods) a lot

in the product.

Normal

Is the resistance value

between pins 10(WH)

And 4(BL) of CON3

like as below?

Replace

DEF-sensor

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Is the resistance value of

heater like as below?

(2)

(1)

Replace

Heater

Test Point Result Test Point Result

-30°C 129.3 kΩ 10°C 19.53 kΩ

-20°C 76.96 kΩ 20°C 13.03 kΩ

-10°C 47.34 kΩ 30°C 8.896 kΩ

0°C 30 kΩ 40°C 6.201 kΩ

(2) BO

(1) BO

Heater Resistance

Defrost Sensor Resistance

Is the resistance

value of DEF-sensor like

as below? It depends on

the temperature.

Replace

Fuse-M

Is the resistance value

of Fuse –M like

as below?

(2) BN

(1) BL

Open or Short of Fuse-M

pin4 BL

pin10 WH

34 ~ 42 Ω (1) To (2)

RessultTest Point

34 ~ 42 Ω (1) To (2)

RessultTest Point

0 Ω (1) To (2)

RessultTest Point

Resistance

Is the connection loose?

Reconnect

- 24 -

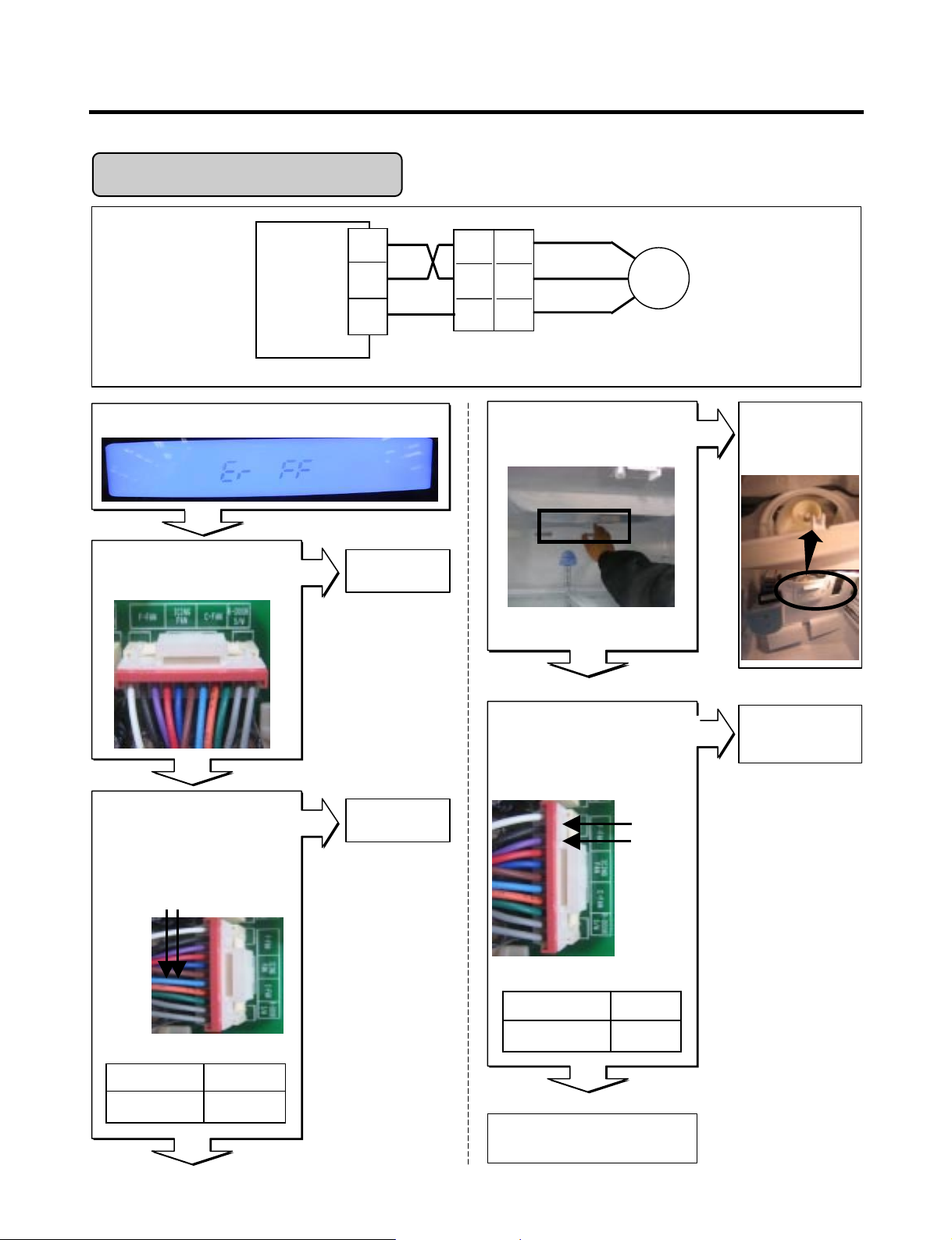

Is Er-FF displayed?

Yes

Yes

Yes

Yes

Yes

Is the connection loose?

Reconnect

Housing

Main

PCB

WH

CON4

1

2

3

1

2

3

BK

PR

F-FAN

1

2

3

BK

RD

PR

Check fan motor

(Connector,

Frozen,Locked)

Is the feedback voltage

between pin2 and pin3 of

CON4 like as below?

(from motor to main board)

No

No

No

No

Wiring diagram

Feedback Voltages

Replace

Main PCB

Replace

Main PCB

Pin1 WH

Pin2 BK

Pin3 PR

Pin2 BK

Freezer Fan Voltages

Reset and

Enter the TEST 1 MODE

Is the output voltage between

pin1 and pin2 of

CON4 like as below?

Does the cold-air come out

of the top of the main duct?

Explain to the customer!

Freezer Fan Error

12 ~ 16 V

pin1 to pin2

RessultTest Point

RessultTest Point

1 ~ 4 Vpin2 to pin3

Loading...

Loading...