Page 1

OWNER’S

MANUAL

MODEL NO.

UltraFilter 150

625.385700

UltraFilter 350

625.385720

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

If you have questions when

installing, operating or

maintaining your reverse

osmosis system, call this

toll-free number...

1-800-426-9345

(M - F, 7 am - 8 pm, CST)

For repair or replacement

parts, call this toll-free num

ber. ..

1-800-366-7278

See back cover for other

Sears service numbers.

WWW. Ken more Wate r.com

SAVE THIS MANUAL

Reverse Osmosis Drinking Water System

♦ Warranty

♦ Flow To Install

♦ How It Works

♦ Care Of

♦ Repair Parts

System tested and certified by NSF International

to NSF/ANSI Standard 58 for the reduction of the

claims specified on the performance data sheet.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U. S. A.

PRINTED IN U.S.A.

Part No. 7266568 (Rev. H 8/4/05)

Page 2

WARRANTY -

FULL WARRANTY ON REVERSE OSMOSIS DRINKING WATER SYSTEM

(except filter cartridges and R. O. membrane)

For one year from the date of purchase, when the Reverse Osmosis Drinking Water System is installed

and maintained in accordance with our instructions, Sears will repair, free of charge, defects in material

and workmanship, except filter cartridges and the R. O. membrane.

TO OBTAIN WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS SERVICE CENTER

THROUGHOUT THE UNITED STATES. This warranty applies only while this product is in use in the

United States.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

I__________________________________________________________ I

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be per

formed in a neat, workmanlike manner in accor

dance with generally accepted trade practices. Fur

ther, all installations shall comply with all local laws,

codes, regulations, and ordinances. Customer shall

also be protected during installation by insurance re

lating to Property Damage, Workman's Compensa

tion and Public Liability.

In addition to any warranty extended to you on the

Sears merchandise involved, which warranty be

comes effective the date the merchandise is installed,

should the workmanship of any Sears arranged

installation prove faulty within one year. Sears will,

upon notice from you, cause such faults to be cor

rected at no additional cost to you.

SEARS INSTALLATION WARRANTY

- SAFETY GUIDES -

Read all steps and guides carefully before instal

ling and using your reverse osmosis system. Follow

all steps exactly to correctly install. Reading this

manual will also help you to get all the benefits from

the reverse osmosis system.

^ Do not attempt to use this product to make safe

drinking water from non-po table water sources. Do

not use the system on microbiologically unsafe wa

ter, or water of unknown quality without adequate

disinfection before or after the system. This system

is certified for cyst reduction and may be used on

disinfected water that may contain filterable cysts.

^ Check with your local public works department

for plumbing and sanitation codes. You must fol

low their guides as you install the system. Follow

your local codes if they differ with guides in this

manual. Massachusetts plumbing code 248 CMR

shall be adhered to. Please consult your licensed

plumber.

This system shall only be used for arsenic reduc

tion on chlorinated water supplies containing de

tectable residual free chlorine at the system inlet.

Water systems using an inline chlorinator should

provide a one minute chlorine contact time before

the RO system.

Problems, Questions? Call 1

800-426-9345 Ken more Water Line

^ This system is acceptable for treatment of influ

ent concentrations of no more than 27 mg/L nitrate

and 3 mg/L nitrite in combination measured as N

and is certified for nitrate/nitrite reduction only for

water supplies with a pressure of 280 kPa (40 psig)

or greater. This system is supplied with a nitrate/nitrite test kit. Product water should be monitoredperiodically according to the instructions provided

with the test kit.

The reverse osmosis system works on water pres

sures of 40 psi (minimum) to 100 psi (maximum). If

your house water pressure is over the maximum,

install a pressure reducing valve in the water supply

pipe to the reverse osmosis system.

"Y Do not install the reverse osmosis system out

side, or in extreme hot or cold temperatures. Temper

ature of the water supply to the reverse osmosis sys

tem must be between 40 °F and 100°F. Do not install

on hot water.

Read the other limits (pH, hardness, etc.) in the

specifications and be sure your water supply con

forms. Also see "Water Supply" on page 4.

^ The reverse osmosis membrane contains a pre

servative for storage and shipment. Be sure to purge

as instructed on page 11 before using product water.

2

Page 3

- TABLE OF CONTENTS —

Where To install the RO System

Tools and Materials Needed

6 Steps to Install ..................................................... 4

Install Cold Water Supply Fitting

Install Drain Adapter

Install Faucet

Install RO Assembly

..........................................................

.............................................

.............................................

............................

..................................

.........................

4

4

5

6

6

9

WHAT YOUR REVERSE OSMOSIS SYSTEM WILL DO -

Your Reverse Osmosis (RO) Drinking Water System

is a water treatment unit. It uses household water

pressure to reverse a natural physical process called

osmosis. Water, under pressure, is forced through a

semi-permeable membrane where minerals and im

purities are filtered out. Clean drinking water goes to

the faucet or storage, while minerals and impurities

are sent to the drain with RO waste water. The miner

als and impurities are measured in water as total dis

solved solids (TDS).

The system includes replaceable pre and postfilter

sediment-carbon cartridges. The prefilter removes

sand, silt, dirt, rust particles, other sediments, and

chlorine from the water supply before it can enter the

Install Storage Tank, Make Tubing

Connections .......................................................... 10

Sanitizing, Pressure Test, Purging

Flow the RO System Works

Care of Your RO System

Dimensions, Specifications ..................................... 18

Remote Installation Locations

Repair Parts ............................................................. 20

RO membrane. The postfilter removes any tastes

and/or odors that may remain in the water, after

passing through the RO membrane, and just before

going to the RO faucet. To prevent water waste, an

automatic shutoff valve closes when the RO faucet is

closed and the storage tank is full.

Your reverse osmosis system gives you a continuous

supply of sparkling clear, delicious water for drink

ing, cooking and other uses. Foods will look and

taste better too. Fiaving high quality RO product wa

ter at your fingertips eliminates the need to buy

bottled water. The storage tank holds over 2 gallons

of RO product water for your needs.

...................................

........................................

.......................

................................

11

12

13

19

BEFORE YOU BEGIN TO INSTALL THE RO SYSTEM

FOR OPTIMUM PERFORMANCE YOUR KENMORE REVERSE OSMOSIS SYSTEM SHOULD BE

INSTALLED ON

CAUTION: A refrigerator icemaker may not operate

properly when connected to a reverse osmosis sys

tem that has been installed on a water system that op

erates outside of the specified pressures listed on

page 18.

Check Your Water Supply: The cold water supply to

the RO system must be within certain quality limits.

See the specification table on page 18. If supply water

is not within limits, the RO system can not make

product water as it should and reduced RO mem

brane life will result.

Trained sales people at Sears can perform a free water

analysis. This basic test can help determine if any

additional water treatment is required before the RO

system.

CAUTION: Chlorine in the water will destroy the

RO membrane. Most cities add chlorine to the water

supply to kill bacteria. The prefilter removes chlorine

up to the limits shown in the specifications before it

enters the RO membrane. It is important to replace

SOFTENED WATER.

the prefilter cartridge at least every 6 months. See

the RO care guide on page 15.

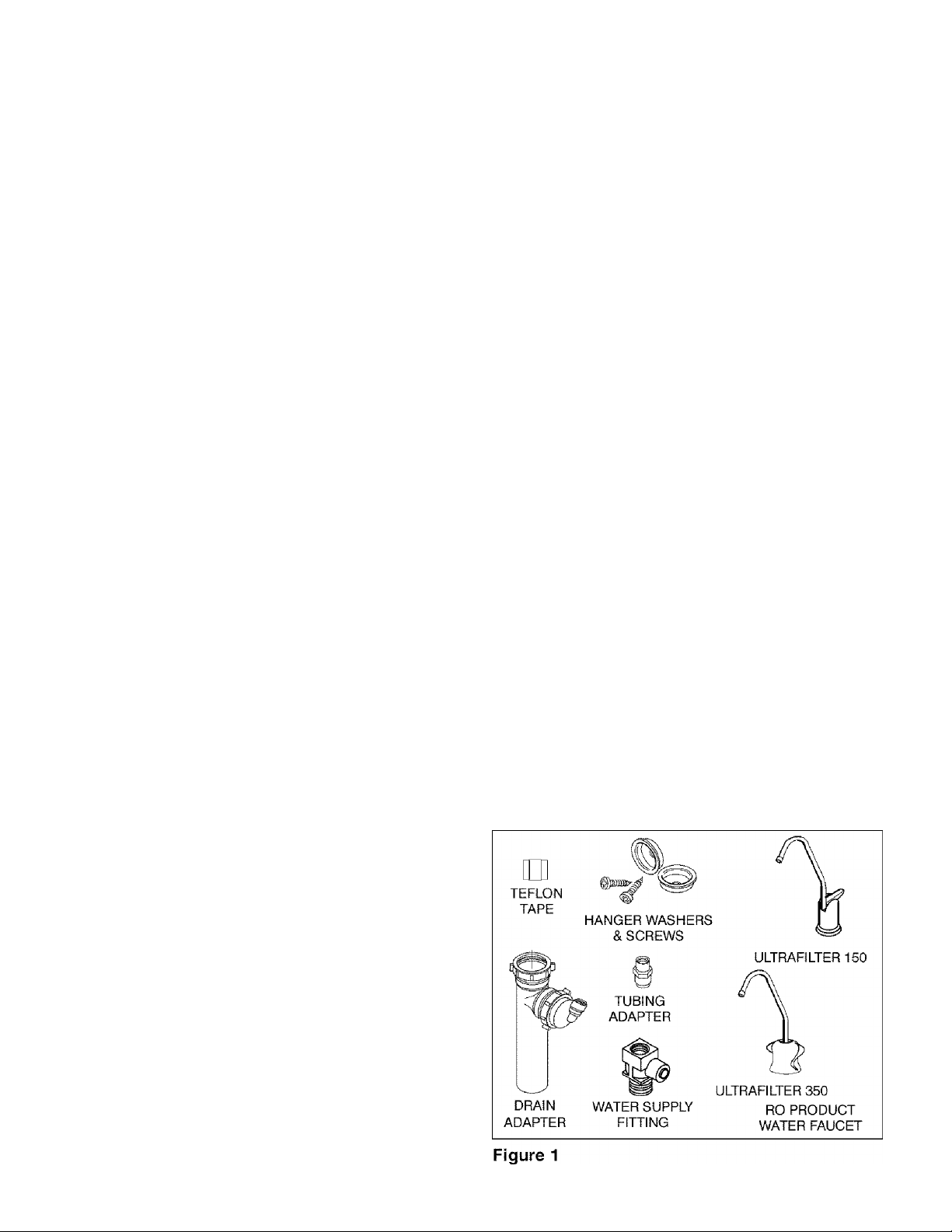

Check Parts Included: Unpack the carton and re

move the RO system. In addition to the assembled

RO and the storage tank, the system includes the

parts illustrated below, a separate length of tubing,

and this manual.

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 4

_ i"Q install the ro system “

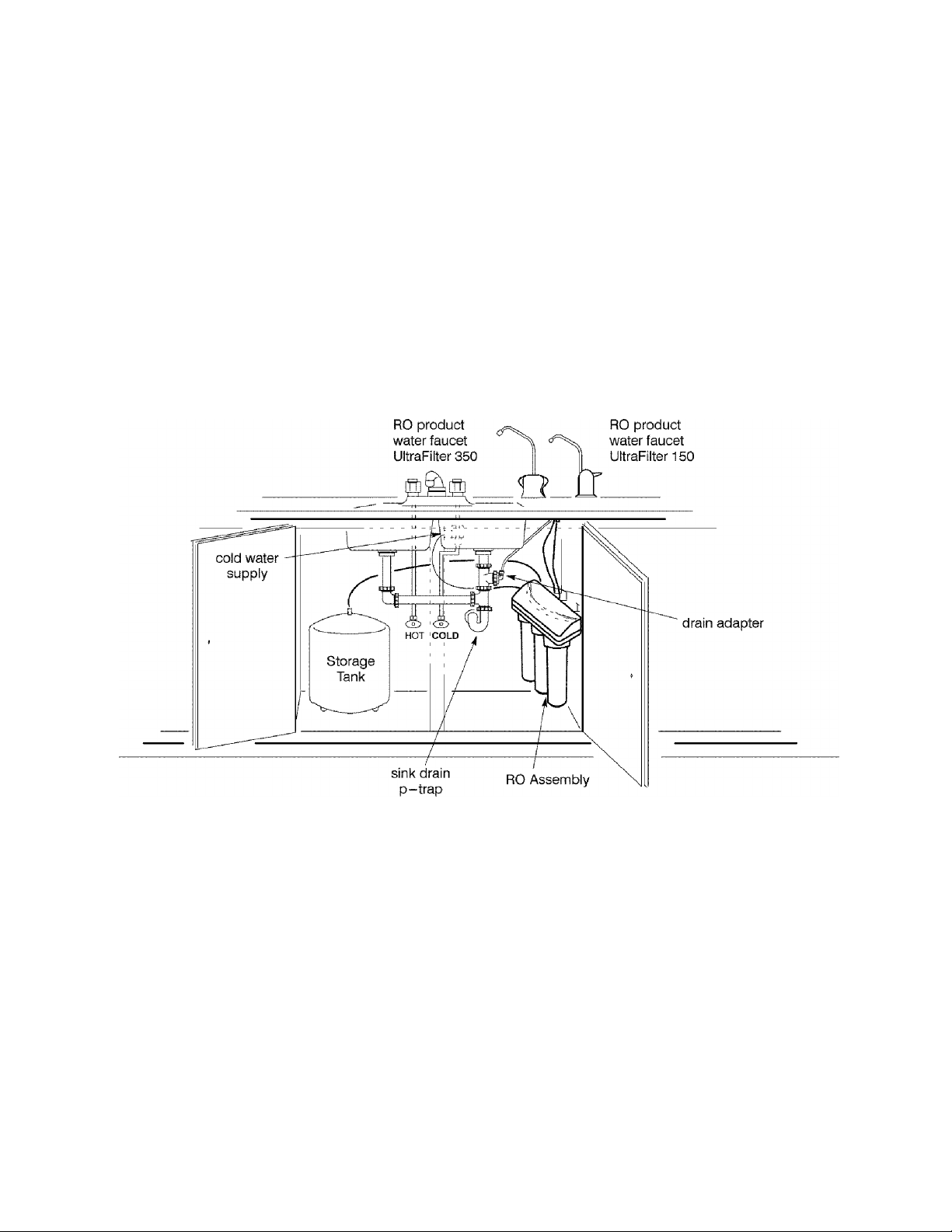

The RO assembly and storage tank is designed for

installation under the sink, usually in the kitchen or

bathroom. The RO assembly mounts on a wall sur

face, or can lay on the cabinet floor next to the storage

tank. Hanger washers and wood screws are included

for cabinet wall mounting. The RO product water

faucet installs on the sink, or on the countertop next

to the sink (page 6).

Note: Tubing lengths allow for the removal of the as

sembly from the hanger washers for servicing. If tub

ing lengths are shortened for neater appearance, it

may be necessary to keep the assembly on the hanger

washers for service.

You can also locate the RO assembly and storage tank

in any remote location from the faucet, observing

safety guides on page 2. You do need a nearby water

source and drain point (see page 19).

Water Supply: To provide supply water to the RO

system inlet use the included feed supply fitting or

install pipe fittings for tubing connection, as typical

ly shown on page 5.

Drain Point: A suitable drain point is needed for re

ject water from the RO membrane. A floor drain,

laundry tub, standpipe, sump, etc., is preferred, as

shown in the remote locations drawing, page 19. A

sink p-trap drain adaptor is included to install where

codes permit, as an optional drain point (page 6).

Figure 2

- TOOLS AND MATERIALS NEEDED

^ adjustable wrench, standard pliers, and larger ^ electric drill and bits, if hole is needed for the RO

adjustable jaw pliers or pipe wrench to fit sink drain faucet, page 6.

^ slotted and Phillips head screwdrivers

► plumbers putty

- 6 STEPS TO INSTALL -

STEP 1: - Install Cold Water Supply fittings

STEP 2: - Install Drain Adapter

STEP 3: - Install Faucet

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

STEP 4: - Install RO Assembly

STEP 5: - Install Storage Tank, Make Remaining Tub

ing Connections

STEP 6: - Sanitizing, Pressure Testing, Purging

Page 5

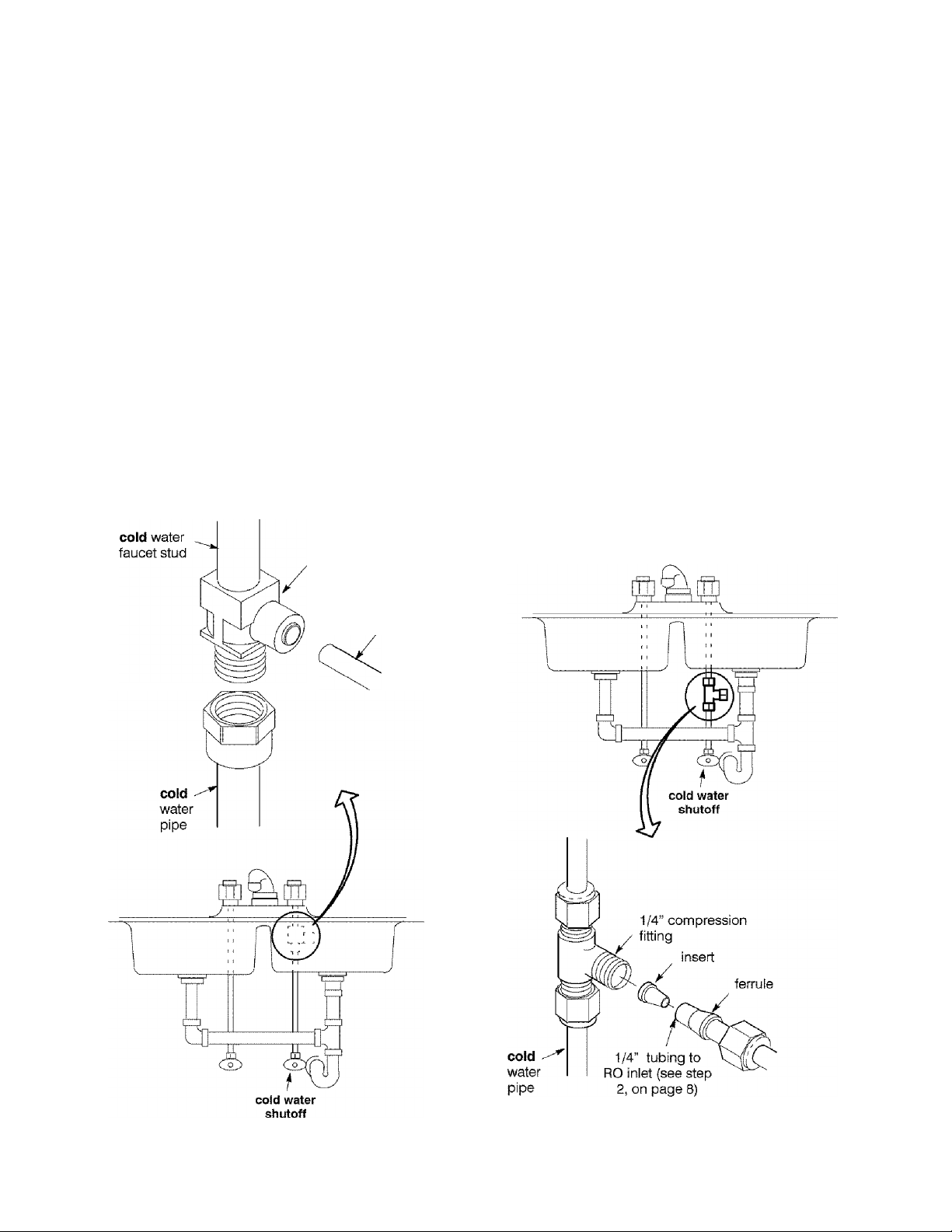

- STEP 1: INSTALL COLD WATER SUPPLY FITTING -

Check and comply with local plumbing codes as you plan, then install a cold feed (supply) water fitting. The

fitting must provide a leak-tight connection to the RO 1/4" tubing (see Figure 10, page 10). A typical connec

tion using the included water supply fitting is shown in Figure 3A below. An optional connection, using stan

dard plumbing fittings (not included), is shown in Figure 3B.

Note: Codes in the state of Massachusetts require installation by a licensed plumber, and do not permit the use of a saddle

valve. For installation, use plumbing code 248-CMR of the Commonwealth of Massachusetts.

A. WATER SUPPLY FITTING B. OPTIONAL PIPE FITTINGS (compression type

1. Close the house main water shutoff valve and open shown)

faucets to drain water from the sink cold water pipe. Note: Be sure to turn off the water supply and open

„ r> , ,1 , , ,1 u , r ,, a low faucet to drain the pipe.

2. Remove nut that connects the cold water faucet to ^ ^

cold water plumbing Complying with plumbing codes, install a fitting on

_ , „ , , the kitchen cold water pipe to adapt 1 /4" OD tubing.

3. Use pipe lomt compound or Teflon tape on cold water a . ■ i i ■ r- -»n Vr

. ^ , 1 ^ , r , A. typical connection is shown in Figure 3d. it

faucet stud threads and on the male threads of the water , i j j r-,, • j i , ■ ■ ■ ,

, , , , , - threaded fittings are used, be sure to use pipe loint

supply fittme that connect to the cold water pipe. i Id ^ - j ,i j

rf ^ f f compound or Teflon tape on outside threads.

4. Thread water supply fitting onto pipe and reconnect

nut to bottom of fitting.

A. WATER SUPPLY CONNECTION

(using Included water supply fitting)

water supply fitting

1/4” green tubing to

RO inlet (see step 2, on

page 8)

B. WATER SUPPLY TYPICAL CONNECTION

(using compression fitting)

- parts not included -

Figure 3

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 6

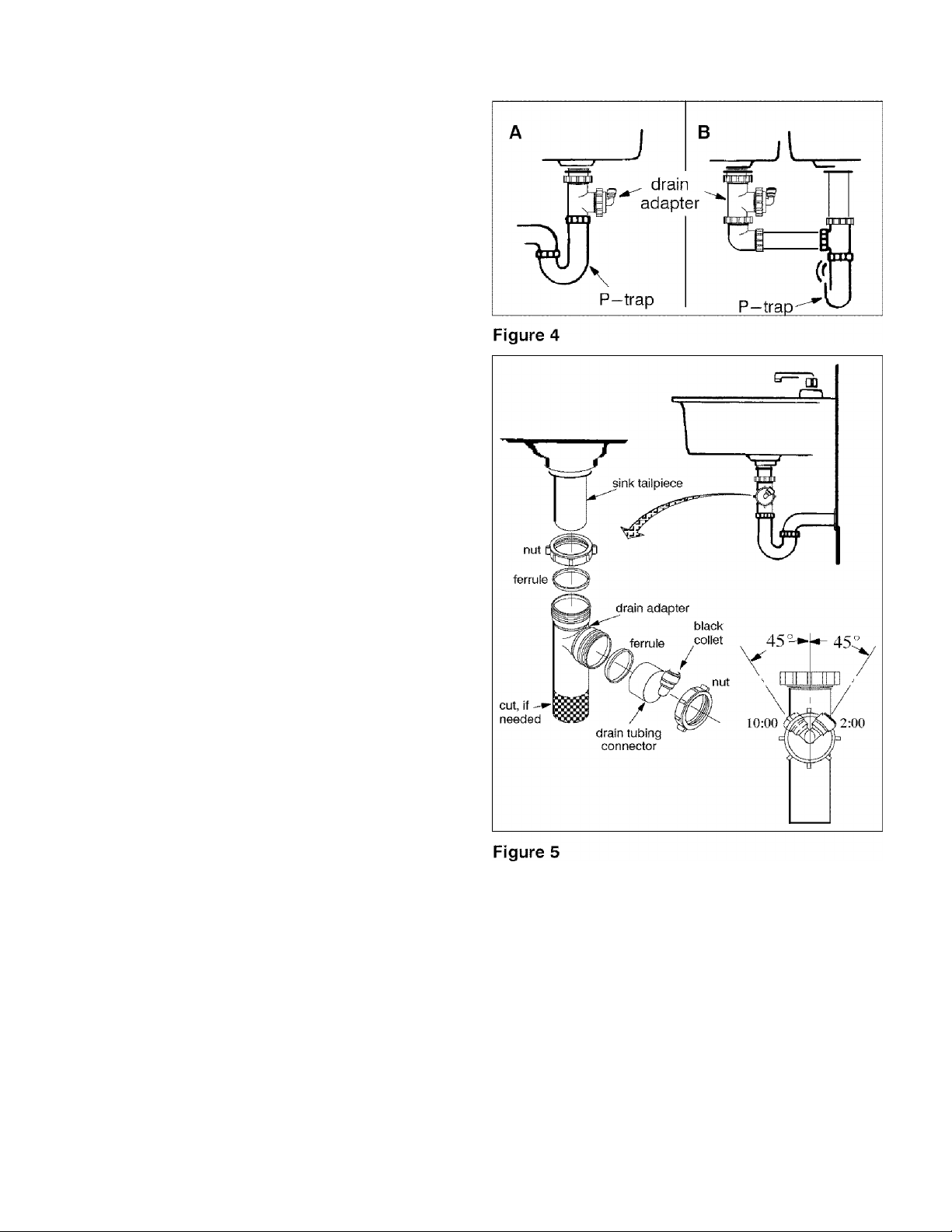

- STEP 2: INSTALL DRAIN ADAPTER -

■ Note: Running the drain tubing directly to a floor

drain, sump, standpipe, laundry tub, etc., as shown

on page 19, is preferred. However, if that is not pos

sible or practical, the included drain adapter installs

in the sink drain pipe, always above or ahead of the

p-trap, Figure 4. Be sure to comply with your local

plumbing codes. Other drain pipe fittings, in addi

tion to the adapter, may be needed.

■ The drain adapter fits 1-1/2" sink drain pipe.

■ The adapter installs directly onto the sink tailpiece

as typically shown in Figure 4 and Figure 5.

■ Locate so drain tubing from the faucet makes a

straight run to the adapter, without dips, loops, low

spots or kinks.

Note: Consult a plumber if you are not familiar with

plumbing procedures.

1. Use a ferrule and nut to assemble the drain tubing

connector to the drain adapter (Figure 5). Turn the

connector to about 45° from the 12:00 position, as

shown (to 10:00 or 2:00 position as needed). Tighten

the nut securely.

2. Carefully disassemble the sink drain pipe and

clean the tailpiece to assure a leak-tight fit.

3. Install the drain adapter onto the sink tailpiece,

using a ferrule and nut. Snug the nut, but do not

tighten.

Note: If needed, to make fit, you can cut to shorten the

unthreaded end of the adapter. Do not cut too short

so the adapter will make a leak-tight seal with the

connecting fitting.

4. Assemble the p-trap to the drain adapter, and oth

er drain pipe fittings as required (check codes) to

complete the drain run.

5. Tighten all connections, but do not overtighten and

break plastic fittings.

STEP 3: INSTALL FAUCET -

A. PREPARE MOUNTING HOLE

1. Select one of the following places for the faucet. Be

sure it will fit flat against the surface, and there is

space underneath for tubing (see Figure 10, page 10).

^ Use an existing sink top hole for a spray hose or

other faucet. A 1-1/4" diameter hole is needed.

^ Drill a new hole in the countertop next to the sink.

^ Drill a new hole in the sink top.

CAUTION: Drilling holes into countertops made of

stone or solid surface materials such as granite.

Problems, Questions? Call 1

800-426-9345 Ken more Water Line

marble, Corian™ or other plastic resin products

should only be performed by a fabricator installer

who is certified for fabricating such materials. Dril

ling of these type surfaces by any other means may

cause permanent, irreparable damage to the counter

top surface.

2. If drilling is needed, make the 1-1/4" diameter

hole.

3. Place plumbers putty around the drilled hole

(Figure 6 and Figure 7) to prevent water leakage

around the base of the faucet.

6

Page 7

- STEP 3: INSTALL FAUCET (cont.)-

B. ASSEMBLE FAUCET

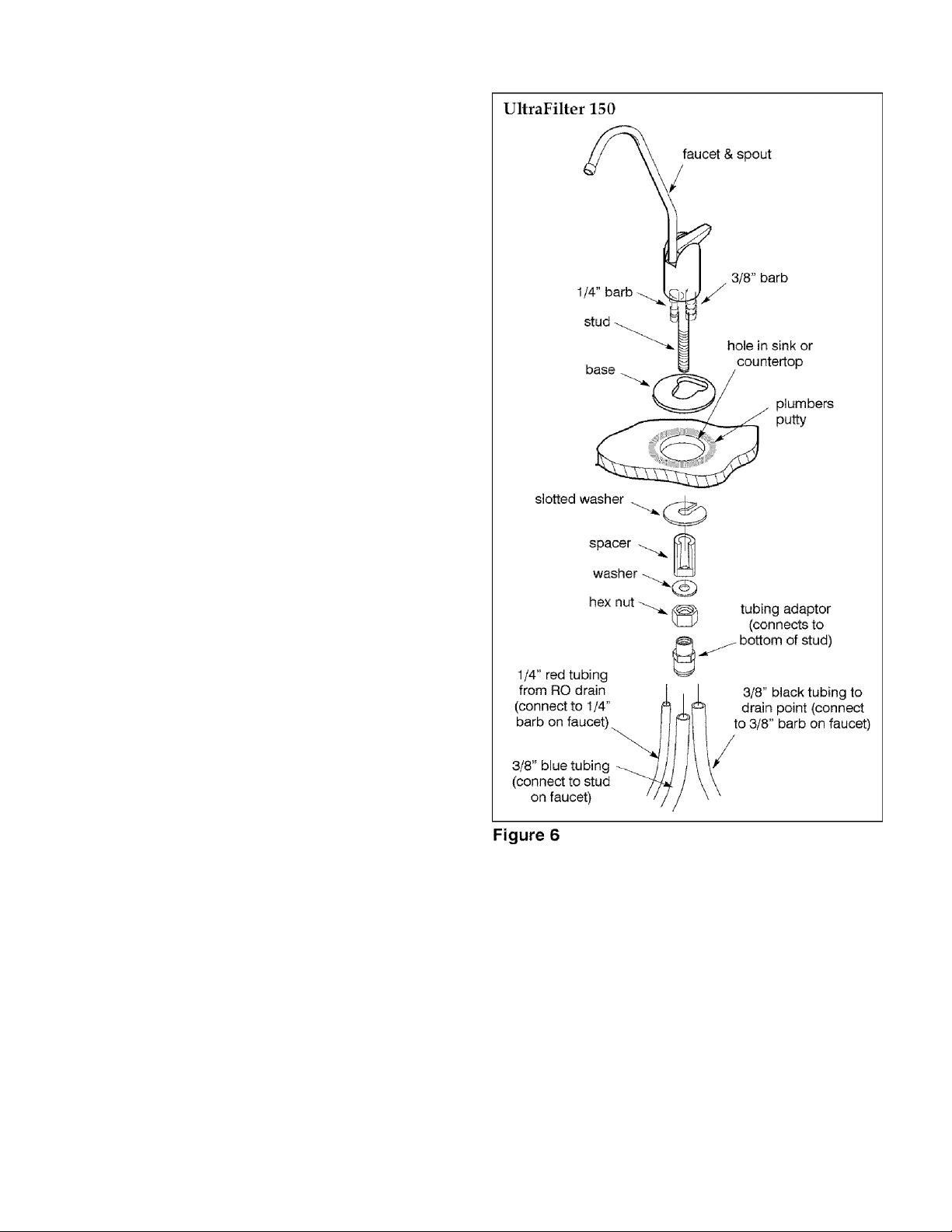

ULTRAFILTER 150

1. Loosely assemble the base, spacer, washer and

plastic nut onto the faucet stud.

2. Route the 1 / 4" red tubing through the sink or

countertop hole and connect to 1/4" barb on faucet.

3. Route the 3/8" black tubing through sink or the

countertop hole and connect to 3/8" barb on faucet.

4. Attach the 3/8" blue tubing to the faucet stud us

ing the tubing adaptor.

5. Lower faucet into place on the countertop, on the

underside of the countertop or sink slide the slotted

washer into place and tighten plastic nut. Tighten

the nut so the faucet cannot move, but do not over

tighten.

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 8

- STEP 3: INSTALL FAUCET (cont.)-

B. ASSEMBLE FAUCET

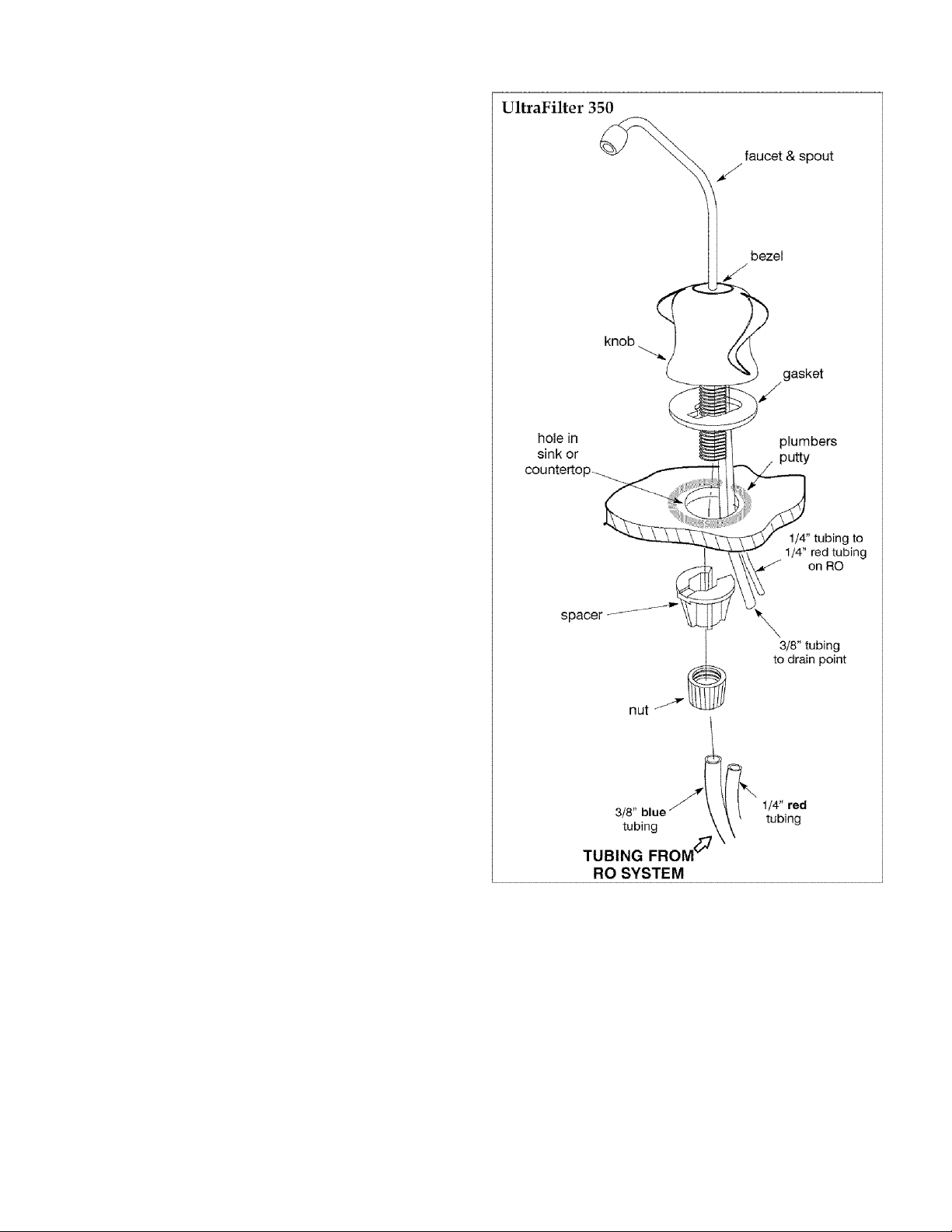

ULTRAFILTER 350

1. Remove the nut from the faucet threads.

2. Remove the spacer from the threads. To do this,

place a finger on either side of the threads and gently

press thumb against the bottom of the faucet threads

(where the quick connect is). The spacer should slide

past the stop.

3. Slide the two attached tubes through the sink or

countertop hole, aligning gasket under faucet base.

4. On the underside of the sink or countertop, slide

the spacer back onto the faucet threads. The spacer

should align with the tubing in the back. Tighten the

nut so the faucet cannot move, but do not overtigh

ten,

5. Connect tubing.

a. Connect the 3/8" blue tubing from the RO system

to the quick connect at the bottom of the faucet

threads.

Note: See page 16 for tubing connection instructions.

b. Connect the 3/8" tubing from the faucet to the

drain point (drain adaptor).

c. Connect the 1/4" red tubing (supplied with RO)

to the 1 / 4" tubing attached to the faucet using the

1 / 4" X 1 / 4" quick connector.

6. Remove the spout from the top of the faucet by

pulling it straight upward.

7. Remove the faucet knob by pinching the two lock

ing tabs inward and then pulling upward on the

knob while the tabs are pinched inward. See Figure 8.

8. Push the coin cell battery into the battery holder be

hind the circuit board. NOTE: the + side of the bat

tery goes against the gold metal bracket.

9. Replace the knob by centering it over the faucet

and aligning the channel on the inside of the knob

with the valve lever.

10. Lower the knob making sure the valve lever

slides into the channel, then make sure the top hole

in the knob is centered over the locking tabs.

11. Push the spout back into the top of the faucet so

that it is fully seated and push the bezel down until

fully seated. You may have to rotate the bezel until it

is in position to be fully seated.

Figure 7

8

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 9

- STEP 3: INSTALL FAUCET (cont.)-

FAUCET ELECTRONICS

The faucet will measure the length of time the filters

have been installed (6 months). The faucet has an in

dicator LED that flashes to inform you of the status

of the filter.

Green - Filter is good. Red - Filters need replacing.

In order to reset the monitor time feature, the battery

should be removed for a minimum of five seconds

and then reinserted.

The battery needs to be replaced when indicater

LEDs no longer light. Use only 3 volt sealed lithium

batteries. Improper placement of battery could dam

age electronics. Use care when inserting battery to

align it correctly.

To change the battery, pull the spout and bezel from

the faucet base. The bezel will stay on the spout.

Pinch the two tabs (under bezel on faucet) with one

hand and with the other, pull up on the knob.

Change battery. Assemble the the knob, and spout

and bezel back onto the faucet base.

STEP 4: INSTALL RO ASSEMBLY

Fiang the assembly on the included hanger washers,

or lay on the cabinet floor, as desired.

1. Refer to Figure 9 for wall mounting. ITold the as

sembly up to the wall surface and mark locations for

the hanger washers. Distance needed is 7.2"

(approx. 7-7/32") apart.

2. Install hanger washers at least 15-1/2" up from the

cabinet floor, allowing room to remove sumps from

filter heads. Wood screws are provided, or obtain

other fasteners as needed.

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 10

- STEP 5: INSTALL STORAGE TANK,

MAKE REMAINING TUBING CONNECTIONS

1. CONNECT DRAIN TUBING, FAUCET TO

DRAIN ADAPTER: Referring to Figure 10, run the

loose section of black 3/8" tubing from the faucet to

the drain adapter, with a black collet, installed on

page 6. Cut this tubing as needed to route in as

straight of a run as possible, without loops, dips,

low spots or kinks. Cut the end of the tubing square.

Then push all the way into the fitting. Pull on the tub

ing to be sure it's held firmly in the adapter fitting.

See page 16 for tubing connection instructions.

2. CONNECT TUBING TO WATER SUPPLY: Con

nect the feed (green) tube to the water supply fitting

installed on page 5. Connection to the fitting is as

described in Figure 14, page 16.

3. Move the storage tank into place next to the RO as

sembly. You can stand the tank upright, or lay it on

side. Apply no more than two wraps of Teflon tape

to the threads on the nipple at the top of the tank.

Eland tighten the other included tubing adapter fit

ting with the yellow collet onto the tank nipple, then

wrench 1/4 turn only. BE CAREFUE NOT TO

CROSS THREAD.

4. Run the 3 / 8" yellow tubing to the fitting installed

in step 3. Be sure the end of the tubing is cut square,

and insert all the way into the fitting. Again, pull on

the tubing to be sure it's held firmly in the fitting.

Figure 10

10

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 11

- STEP 6: SANITIZING, PRESSURE TESTING & PURGING

SANITIZING

Sanitizing is recommended upon installation of the

RO system, and after servicing inner parts. It is im

portant for the service person to have clean hands

while handling inner parts of the system.

CA UTION: Be sure to remove the RO membrane and

both filter cartridges as follows, before sanitizing.

Chlorine ivill destroy the RO membrane cartridge.

1. Be sure the water supply to the RO is turned off,

and the RO faucet is open to relieve pressure.

2. Referring to Figure 12, page 14, remove the RO

membrane sump by twisting 1/4 turn left (^J). Re

move the RO cartridge from sump. Place the car

tridge in a

3. Be sure the o-ring seal is on the sump. Replace the

RO sump by turning to the right (C,) to lock.

4. Remove the postfilter sump, turning to the left.

Take the cartridge from the sump and place in the

plastic bag. Replace the sump by turning to the right

(t^) to lock.

5. Remove the prefilter sump and cartridge. Also

place this cartridge in the clean bag.

clean plastic bag.

6. If needed to clean, flush the prefilter sump with

fresh water. Then fill with water to about 1" from the

top. Add 1.0 ounce of chlorine (ordinary 5.25%

household bleach...Hilex, Clorox, etc.) and mix in the

water. Do not add chlorine first. Concentrated it will

attack plastics.

7. Carefully replace the sump on the prefilter head

and turn to the right (C,) to lock.

8. Slowly open the water supply to the RO.

9. Open the RO faucet by turning knob to the left.

10. Allow water to circulate through the RO system

until you smell the bleach odor at the faucet. Then

close the faucet and allow the RO to stand idle for 20

minutes.

11. After the 20 minutes open the RO faucet and run

water until the bleach odor is gone.

12. Turn off the water supply to the RO.

13. Be sure your hands are clean. Then, repeat steps

1-5 and 7, only replace all cartridges.

Important: Refer to Figure 12, page 14, and to page 15

when replacing cartridges. The prefilter (left side)

cartridge and the postfilter (right side) have puple

end caps.

PRESSURE TESTING

1. Do the preceding sanitizing procedures before

pressure testing.

2. Open the water supply shutoff valve to the RO.

3. Open the main water supply valve and several

house faucets to purge air from the system. Close

faucets when water runs smooth.

PURGING RO MEMBRANE

Important purging instructions: The RO cartridge

contains a food grade preservative that should be rinsed

before using water from the system. The preserva

tive will give product water an unpleasant taste and

odor.

4. hi about 2 hours, pressure will start to build in the

RO system. Then, carefully check all fittings and con

nections for water leaks. Correct leaks if any are

found.

Note: When the system is first pressurized, water

may "spurt" from the faucet airgap hole until air is

expelled from the RO system.

1. Allow the storage tank to fill for about 4 hours.

Then open the RO faucet until the tank is empty and

flow stops. Close the RO faucet.

2. Repeat step 1 five more times (for a total of 6) to

purge the RO system. Then the RO system is ready

to make product water for use.

11

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 12

- HOW YOUR REVERSE OSMOSIS SYSTEM WORKS

PREFILTER

Water from the cold supply pipe enters the RO as

sembly prefilter first (Figure 10, page 10, and sche

matic, page 13).

The prefilter has a replaceable sediment cartridge

with activated carbon in its composition. The car

tridge (10 micron) removes sand, silt, dirt, other sedi

ments, and up to the ppm of chlorine shown in the

specifications from the feed water (page 18). Chlo

rine will destroy the RO membrane. Filtered, clean,

chlorine- free water flows from the prefilter, to the RO

membrane cartridge.

IMPORTANT: See prefilter maintenance, page 14.

REVERSE OSMOSIS (RO) CARTRIDGE

The RO cartridge is a tightly wound special mem

brane. The membrane removes the dissolved solids

and organic matter when water is forced through the

cartridge. Fligh quality product water (about one

ounce per minute) exits the RO cartridge and goes to

the storage tank, or to the postfilter and RO faucet.

Reject water, with the dissolved solids and organic

matter, is routed through the flow control and to the

drain.

STORAGE TANK

The storage tank holds up to 2.3 gallons of product

water. A diaphragm inside the tank keeps water

pressurized to about 30 psi, when the tank is full, to

provide fast flow to the RO faucet. The tank, when

empty, is pressurized to 5 - 7 psi.

POST FILTER

After leaving the storage tank, but before going to the

RO faucet, product water goes through the post filter.

The post filter is an activated carbon type filter. Any

remaining tastes and odors are removed from the

product water. Taste-free, odor-free, clean, high

quality drinking water is available for use.

FAUCET

The sink or countertop faucet has a hand operated

knob to access drinking water. An air-gap is built

into the faucet drain water connection to comply

with plumbing codes.

FAUCET ELECTRONICS (UltraFilter 350)

The RO system will monitor the length of time the fil

ters have been installed. The faucet has an indicator

light that flashes to inform you of the status of the fil

ters.

Green - Filters are good. Red - Filters need to be re

placed after 6 months of time has passed.

SHUTOFF ASSEMBLY

To conserve water, the drinking water system has an

automatic shutoff system. When the storage tank has

filled to capacity,

closed, pressure closes the shutoff to stop flow to

drain. Pressure in the storage tank is about half of the

water supply pressure. After drinking water is used,

and pressure in the system drops, the shutoff opens

to allow water flow again.

A check valve (Figure 16) is located in the RO man

ifold, above the center sump. The check valve pre

vents a backward flow of product water from the

storage tank. A backward flow could rupture the RO

membrane.

Water flow through the RO membrane is regulated

by the flow control. It maintains the desired flow rate

to obtain the highest quality drinking water. The

flow control is located in the end of the 1 / 4" red drain

tubing, at the RO manifold drain port.

and the drinking water faucet is

CHECK VALVE

FLOW CONTROL

12

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 13

- HOW YOUR REVERSE OSMOSIS SYSTEM WORKS

REVERSE OSMOSIS WATER FLOW SCHEMATIC

Figure 11

PRODUCT

WATER

^FAUCET

gravity

drain

PRODUCT WATER

BLACK

■CZH

AUTOMATIC

WATER GREEN

IN

---------------

SHUTOFF

^

____

red

drain flow

control

YELLOW

o-»>

PRODUCT

WATER

STORAGE

PREFILTER MEMBRANE POSTFILTER

RO

- CARE OF YOUR REVERSE OSMOSIS SYSTEM

To keep your reverse osmosis system operating and

producing high quality water, you must make sure

supply water is always within the limits shown in the

specifications. Good supply water (soft water is rec

ommended) helps to assure longer life from the RO

membrane cartridge, prefilter and postfilter car

tridges. However, each of these will wear out in time

and need replacement.

This reverse osmosis system contains a replace

able treatment component critical for effective

removal of total dissolved solids. The monitor

faucet feature provides continuous analysis of the

systems performance. For systems not equipped

with the monitor faucet function, it is highly

recommended that you have your water tested at

least every 6 months to verify your system is

performing properly. Test kits are available by

calling 1-800-826-8553 ext. 47, or check the water

testing section of your local phone directory.

If the RO assembly is wall mounted, you may be able

to replace parts with the assembly left on the wall. If

not, simply lift the RO assembly from the mounting

washers and lay on the cabinet floor when replacing

the prefilter and post filter cartridges and RO mem

brane.

Note: To prevent spillage, place a container under the

RO assembly, or put the RO assembly in a container

to catch the water.

CAUTION; Before disconnecting parts, be sure to

close the ivater supply valve to the RO.

Problems, Questions? Call 1

13

■800—426-

■9345 Ken more Water Line

Page 14

- CARE OF YOUR REVERSE OSMOSIS SYSTEM

PREFILTER AND POST FILTER CARTRIDGES

You must replace the prefilter cartridge often to pro

tect the RO membrane from being destroyed by chlorine,

and/or from plugging with sediments in your water

supply. If the water supply contains both chlorine

and sediments, replace the prefilter cartridge at least

every 6 months of product water use. Replace more

often than 6 months if it begins to plug with sedi

ments.

If the water has sediments only, with no chlorine, you

may notice a slower making of product water as the

prefilter collects the sediments. When this occurs, re

place the prefilter cartridge. Also replace the post filter

cartridge.

To replace the filter cartridges (see Figure 12):

1. Turn off the water supply and open the RO faucet

to relieve pressure.

2. Remove (turn to the left) both sumps from the filter

heads. Be careful.. .the sumps are full of water.

3. Remove and discard the inner cartridges in a prop

er manner. Flush the insides of the sumps with fresh

water.

Do not lose the large o-ring seals.

4. Insert new cartridges with o-ring*^ seals towards

the top, and with lubricated* o- rings in place, turn to

the right to reattach the sumps.

5. Remove and replace batteries to reset counter and

timer, (monitor models).

*Note: Use a lubricant approved for use on a potable

water supply.

14

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 15

- CARE OF YOUR REVERSE OSMOSIS SYSTEM

RO MEMBRANE CARTRIDGE

The life of the RO membrane cartridge depends

mostly on the pH of the supply water to the RO sys

tem (see specifications). Cartridge life is shorter with

higher pH. For example, if supply water pH is from 6.8

to 7.7, the cartridge may last for well over one year: Hoioever, cartridge life may be as short as 6 months if the pH

is as high as 8.5 to 10. Higher pH weakens the cartridge

membrane and causes pin-hole leaks.

It's time to replace the RO cartridge when the pro

duction rate and/or quality of product water drops.

Product water may begin to taste different or bad, in

dicating solids and organics are passing through the

RO membrane. To be sure it is the RO cartridge, re

place the prefilter and postfilter cartridges first.

To replace the RO cartridge (see Figure 12):

1. Turn off the water supply and open the RO faucet

to relieve pressure.

2. Remove (turn to the left) the sump from the filter

head. Be careful. . .the sump is full of water.

3. Remove and discard the RO cartridge in a proper

manner. Flush the insides of the sump with fresh wa

ter. Do not lose the large o-ring seals.

FLOW CONTROL

The flow control is vital for proper operation of the

RO membrane cartridge. The control keeps water

flow through the membrane at the needed rate to ob

tain the best quality product water.

Periodically check the flow control to be sure the

small hole through it is clean and unrestricted.

Note: Sanitizing is recommended after servicing in

ner parts of the system (see page 11).

4. Insert new RO cartridges with o-ring seals to

wards the top, and with lubricated o-ring in place,

turn to the right to reattach the sump.

5. Remove and replace batteries to reset counter and

timer, (monitor models).

6. Purge the RO membrane cartridge follaiuing instruc

tions on page 11.

15

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 16

- CARE OF YOUR REVERSE OSMOSIS SYSTEM

TUBING CONNECTION

(all push- in fitting locations)

This RO system includes push- in fittings for quick

tubing connection at most locations. If working with

the fittings, do the following.

Connection (Figure 14):

1. Use a sharp cutter or knife to cut the end of tubing

square.

2. Inspect the end (about 1") of the tubing to be sure

there are no nicks, scratches or other rough spots. If

needed, cut the tubing again.

3. Push tubing through the collet and all the way into

fitting. Full engagement is 11/16" for 1/4" tubing,

and 3 / 4" for 3 / 8" tubing.

If using tubing other than tubing supplied with the

system, be sure it is of high quality, exact size and

roundness with a smooth surface.

Tubing correctiy cut and connected

cut tubing square

collet.

CAUTION

DO NOT USE VINEGAR OR OTHER ACID BASED

CLEANERS ON THIS RO SYSTEM. THEY WILL

DEGRADE SOME RO SYSTEM PARTS. ALWAYS

USE SOAP AND WATER.

I-.

r'

This reverse osmosis system contains a replaceable

. J

■n

treatment component critical to the efficiency of the

system. Replacement of the reverse osmosis compo

nent should be with one of identical specifications,

as defined by the manufacturer; to assure the same

efficiency and contaminant reduction performance.

AUTOMATIC SHUTOFF SERVICE

If the shutoff assembly requires service, be sure to

reassemble parts exactly as shown in Figure 16.

end of tubing round and

smooth, with no cuts,

nicks or flat spots

11/16" (1/4" tubing)

engagement

3/4^' (3/8" tubing)

Figure 14

To Disconnect Tubing (Figure 15): Push the collet in

ward and hold with a finger while pulling the tubing

out.

Changing Collet and O-ring (Figure 15):

1. With a small screwdriver remove the collet and o

ring from the fitting. Be careful not to scratch the in

ternal walls of the collet port.

2. Be sure the port is clean, then lubricate and insert

the o-ring seal to the bottom of the port.

3. Push the collet inward until it locks in place.

Figure 16

16

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 17

- CARE OF YOUR REVERSE OSMOSIS SYSTEM

REVERSE OSMOSIS SYSTEM CARE GUIDE

MODEL NOs. 625.385700 & 625.385720

1. AT LEAST every 6 months, replace the prefilter and postfilter cartridges or when red LED flashes,

2. Replace the RO membrane cartridge when the percent rejection of total dissolved solids (TDS) is less than shown

in the specifications (see B, below).

3. Replace the battery once per year.

If any of the following occur before the 6 months, replace as directed.

A. Slow Making of Product Water: Replace the prefilter cartridge.

If the production rate does not improve, replace the post filter car

tridge and RO membrane cartridge.

B. High Total Dissolved Solids (TDS) in Product Water: You can

get a free TDS test through some Sears retail stores or service

departments. If the store or service department does not have a

TDS meter, you can send treated and untreated water samples to

a water analysis lab for testing. It Is important to test both the

treated and untreated water to determine system performance. If

the TDS is not within the system’s performance guidelines,

replace the prefilter, post filter and RO membrane cartridges.

OTHER TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Chlorine taste and/or

odor in the RO product

water

The ppm of chlorine In your water supply

exceeds maximum limits, and has de

stroyed the RO membrane.

C. Chlorine Taste and lor Odor: Replace the prefilter, post filter and

RO membrane cartridges.

If the water supply contains more than 2.0 ppm of chlorine, addi

tional filtering of the water supply to the RO is needed. Correct

this condition before doing maintenance on the RO system.

The prefilter is no longer removing chlo

rine from the water supply.

Other taste and/or odor Post filter expended. Replace the post filter cartridge. If taste and odor persists, re

RO membrane cartridge expended.

Replace the prefilter, post filter and RO membrane cartridges.

place the prefilter cartridge and RO membrane cartridge.

Contamination in product water storage. Use sanitizing procedures. Replace the post filter cartridge.

System makes product

water too slowly

System makes lower

amount of product water

than usual

High total dissolved sol

ids (TDS) in product wa

ter

Water supply to the RO system not within

specifications.

Prefilter or RO membrane cartridges

plugged with sediments.

Storage tank air-charge less than 5-7

psi.

Water supply to the RO system not within

specifications.

RO membrane cartridge expended. Replace the prefilter, postfilter and RO membrane cartridges,

Increase water pressure, precondition the water, etc., as needed

to conform before doing maintenance on the RO system.

Replace the prefilter cartridge. If rate does not increase, replace

the postfilter cartridge and RO membrane cartridge.

Open RO faucet and drain tank until flow slows to a drip. Keep

faucet open and check tank pressure. If low, pressurize to 6 psi.

Close faucet to refill the tank.

Increase water pressure, precondition the water, etc., as needed

to conform before doing maintenance on the RO system.

flow control, and screen.

Water leaking from fau

cet airgap hole

Drain side of faucet airgap (3/8” tubing)

plugged, restricted, or incorrectly con

Inspect and eliminate restriction or plug. Refer to installation

instructions for proper drain connection.

nected to drain point.

Continual water flow to

drain

Faucet LED indicator

light does not function af

ter battery change

Continual water flow to

drain and no product wa ter

Faucet LED indicator

light flashing red

Check valve or automatic shutoff assem

bly plugged, restricted or parts worn

Batteries dead. Replace with new batteries.

Batteries installed Incorrectly.

Missing flow restrictor in red drain tube or

its corresponding port.

Filters need replacing. Change filters.

Clean, repair or replace as needed.

Install batteries correctly.

Replace flow restrictor.

Note: Sanitizing is recommended after servicing inner parts of the system(see page 11).

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 18

- DIMENSIONS and SPECIFICATIONS -

15”

Supply water pressure limits

Supply water temperature limits............................................ 40 - 100 °F

Maximum total dissolved solids (TDS) ................................. 2000 ppm

Maximum water hardness @ 6.9 pH..................................... 10 gpg

Maximum iron, manganese, hydrogen sulfide

Chlorine in water supply (max. ppm)

Supply water pH limits (pH) .................................................. 4-10

Product (quality) water, 24 hours

Waste water per gallon of product water

Percent rejection of TDS, minimum (new membrane)

Storage tank capacity (max.)

Automatic shutoff control....................................................... yes

Efficiency (2) ......................................................................... 8%

Recovery cs).......................................................................... 16 %

STORAGE

TANK

9” dia.

.................................................

......................

...................................

CD

...................................... 14 gal.

CD

..........................

CD

90 - 95

...............................................

11”

40 -- 100 psi

0

2.0

5 gal.

2.3 gal.

13”

Metric

280 - 690 kPa

5 - 40°C

53 liters

18.9 liters

8.7 liters

This system conforms to NSF/ANSI 58 for the specific performance claims as verified and sub

stantiated by test data.

(D

Feed water supply at 50 psi, 77°^ and 750 TDS - Quality water production, amount of waste

water and percent rejection all vary with changes in pressure, temperature and total dissolved

solids.

(2) Efficiency rating means the percentage of the influent water to the system that is available to

the user as reverse osmosis treated water under operating conditions that approximate typical

daily usage.

(3) Recovery rating means the percentage of the influent water to the membrane portion of the

system that is available to the user as reverse osmosis treated water when the system is operated

without a storage tank or when the storage tank is bypassed.

18

Problems, Questions? Call 1

■800—426-

9345 Kenmore Water Line

Page 19

- REMOTE INSTALLATION LOCATIONS -

Possible remote locations for the RO nearby the

kitchen or bathroom sink include; (1) a basement area

underneath the sink, and (2) an adjacent room or

closet. Longer lengths of tubing (see parts list on

page 20) may be needed.

You can run the drain tubing directly to one of several

suitable open drain points, as shown below, bypas

sing the faucet airgap and p-trap drain. This type of

drain is the preferred over the p-trap drain adapter.

Check your local codes. Always be sure to provide an

air gap between the end of the hose and the drain

point.

19

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line

Page 20

- REPAIR PARTS -

Kenmore Reverse Osmosis Drinking Water System,

Page 21

- REPAIR PARTS -

Kenmore Reverse Osmosis Drinking Water System, Model Nos. 625.385700 & 625.385720

Key

No.

1 7221128 Sump {3 req.)

2 7223633 O-Ring, 2-1/4” X 2-1/2” (3 req.)

3

4

5 7234317

6 7229451 Screw {4 req.)

7 7229532 Automatic Shut-off Cover

8

9

■

10

11 42-38476 Filter, Carbon Block (2 pack)

12 7267962

13 7208544 Connector, 1/4” X 1/4”

14

15 7205326

16 7251034

17

Part

Number

9006062 Screw (2 req.)

9041700

7250876 Diaphragm Kit

7234325 Plunger & Spacer Ring Kit

7095030

7265766

7208560

7208489

Hanger Washer (2 req.)

Check Ball Assembly

Cone Screen

Flow (Control) Insert

RO Membrane Cartridge

Connector, 1/4” X 3/8”

Storage Tank

Connector, 1/4 NPT x 3/8 Tube

Drain Adaptor

Description of Part

Key

No.

18 7227310 Tee, Feed Adaptor

19 Faucet, Model 625.385700

20 7234333

21 7209566 Push-in Fitting Kit, 1/4”

22 7255101 Manifold, incl. key nos. 5 thru 9

■

■

■

■

■

■

■

■

■

Part

Number

7266584

7209574 Push-in Fitting Kit, 3/8” •>

7266568

Optional Accessories and Tubing

7161823

7161784

7157280 Tubing, 3/8” X 20’ - white [D-f

7161750 Tubing, 3/8” X 100’ - white Hj-f

7122798

42-34707 Suppl. Storage Tank, 3.2 gallon >

7123613

Faucet, Model 625.385720

Cover

Owner’s Manual

Faucet Battery, Model 625.385720

only, purchase locally, Duracell

DL2032 or Eveready ECR2032

Tubing, 1/4” X 20’ - white [D-f

Tubing, 1/4” X 100’ - white [T]>

Optional Drain Adaptor -f

Grease for 0-Rings >

Description of Part

ffl Tubing for remote installations (not included) see page 19, also direct replacement for colored lengths of tub

ing.

A0 See page 20 for use locations - Note: This o-ring and collet are for replacement in the manifold housing only.

They do not fit the other push-in fittings, key nos. 13, 14, 15, 17, 18 and 19.

> not included

■ not illustrated

Problems, Questions? Call 1

21

■800—426- 9345 Kenmore Water Line

Page 22

NOTES -

Problems, Questions? Call 1

22

■800—426- 9345 Kenmore Water Line

Page 23

NOTES -

Problems, Questions? Call 1

23

■800—426-

9345 Kenmore Water Line

Page 24

OWNER’S

MANUAL

MODEL NO.

UltraFilter 150

625.385700

UltraFilter 350

625.385720

The model number of

your reverse osmosis

system is found on the

rating decal. This decal is

on the back of the R. O.

sump.

When requesting service

or ordering parts, always

provide the following in

formation:

Reverse Osmosis Drinking Water System

Get it fixed, at your home or ours!

Yoyr Home

For repair-- in your hótiné-óf all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no niiatter who sold Itl

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional inslaliation of home appílánces

and items like garage door openers and water heaters

1 -SOO-4-MY-HÓIVtE ■ {1 ..,^00-469.4653)

Cáii snytime, day Of nighi (U.S A arid Canacia)

www.seafs.com. wwwv.sears.ca

Our Home

For .repair of carry-in items ike vacuums, lawn equipment,

and etectronics, catl or go on-line fo.r the location of your nearest

S'ears Parte & Repair Center,

t it :2.

Cali anytime, day or night. (U S.A, only)

www.8ears.com

To purchase a protection agreement {U.S.A.)

or maintenance agree.ment (Canada) on a pro.duct serviced by Sears:

1 -800-827-6655 -u u a . 1 -800-361 -6665 (Canada)

♦ Product Type

♦ Model Number

♦ Part Number

♦ Part Description

www.KenmoreWater.com

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Para pedir servido de reparación

9 dornicilio. y para ordenar pie'zas:

íD R&UKfered 1

fí^arí|.{ít! m (

1-8S8-SU-HOGAR '

(1-8B8-784-6427)

Mask Pi-SCfSTS., RíSSílJUC.f

ivvi-.'c.it i'to Sefdiaiod.i>Sé7í!S., F

íiuHñ: nmb&Gk atuí Do.

Au Canadá póur service en frángáii

1-800-LE-FOYER

(1-80P-533-69-37)

Loading...

Loading...