Page 1

OWNER’S

MANUAL

MODEL NO.

625.384500

Caution;

Read and Follow

All Safety Rules,

Installation and

Operating

Instructions

Before First Use

of This Product.

KGnmore

UNDERSINK

If you have questions

when installing and us

ing your water filter

housing call this toll

free number...

1 - 800 - 426 - 9345

SAVE THIS MANUAL

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

WATER FILTER

HOUSING

♦ Safety Guides

♦ Installation

♦ Operation

♦ Cartridge Replacement

♦ Repair Parts

System tested and certified by NSF International

to ANSI/NSF Standard 42 for the reduction of the

claims specified on the performance data sheet.

NSF

Page 2

SAFETY GUIDES / SPECIFICATIONS

Please read this entire manual before

installing and using your undersink water filter

housing. Be sure to follow all guides and rules

carefully. Failure to follow them could cause

personal injury or property damage.

^ Check with your local public works

department for plumbing codes. You must

follow their guides as you install the water

filter housing. In Massachusetts^ plumbing

codes of Massachusetts shall be adhered to.

Consult with your licensed plumber.

^ Use the filter on a potable, safe-to-drink,

home COLD water supply only. The filter

cartridge will not purify water, or make it safe

to drink. DO NOT use on HOT water (100°F,

Min. - Max. Supply Water Pressure

Min. - Max. Supply Water Temperature

Inlet - Outlet Thread Size

Rated Service Flow

max.). Do not use with water that is

microbiologically unsafe or of unknown

quality without adequate disinfection before

or after the system. This system is certified for

cyst reduction and may be used on disinfected

waters that may contain filterable cysts.

^ Protect the water filter housing and piping

fixim freezing. Water freezing in the housing

will break it.

^ Your undersink water filter housing works

on water pressures of 40 psi (minimum) to 100

psi (maximum). If your house pressure is over

the maximum, install a pressure reducing

valve in the water supply pipe to the water fil

ter.

40- 100 psi

40 - 100

3/8" NPT

0.6 gpm at 60 psi

WARRANTY

FULL ONE YEAR WARRANTY ON UNDERSINK WATER FILTER HOUSING

For one year from the date of purchase, Sears will replace this Undersink Water Filter Housing, {except filter

cartridge, which is purchased separately), free of charge, if defective in material or workmanship.

WARRANTY IS AVAILABLE BY SIMPLY RETURNING THE WATER FILTER HOUSING TO THE NEAREST

SEARS STORE THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

Sears, Roebuck and Co., DEPT. 817 WA, Hoffman Estates, IL 60179

Page 3

TABLE OF CONTENTS

Planning Installation / Typical Installation Drawings / Tools and

Materials Needed .................................................................................................................4-5

Water Filter Housing Installation...........................................................................................5-7

Using Compression Fittings........................................................................................5-6

Using Soldered Copper................................................................................................. 6

Using Threaded Fittings ............................................................................................... 7

Installing Filter Cartridge .............................................................................................. 7

Filter Cartridge Life / Replacement....................................................................................... 8-9

Repair Parts................................................................................................................................ 10

Locate the water filter housing on the cold water supply pipe, under the kitchen and / or bathroom sink, to filter

the cold drinking water. Refer to the following drawing.

FILTERtNG WATER TO ONE FAUCET

kitchen sink

n n n

a

HOT COLD

WATER

FILTER HOUSING

Page 4

PLANNING YOUR INSTALLATION

When planning your installation, use the drawings

below and on page 5 to guide you. There are many

variables to consider as you plan. Some of these are:

the water filter housing inlet and outlet internal

threads are 3/8" NPT.

existing plumbing type (copper, threaded, etc.)

and nominal size (1/4", 3/8" etc.)

y* tools you have, and your plumbing skills

y* cost of materials needed

y* space available for instaUing the filter housing

Sears has an optional kit available to make installing

the water filter housing easier (see below and page

5). These are:

A Installation Kit, Sears Item No. 42-38445 - In

cludes 3/8" fittings and tubing.

Make a simple sketch of your proposed installation,

and a list of plumbing materials you will need. Ob

tain every thing you need before starting the installa

tion. Be sure you have the tools required.

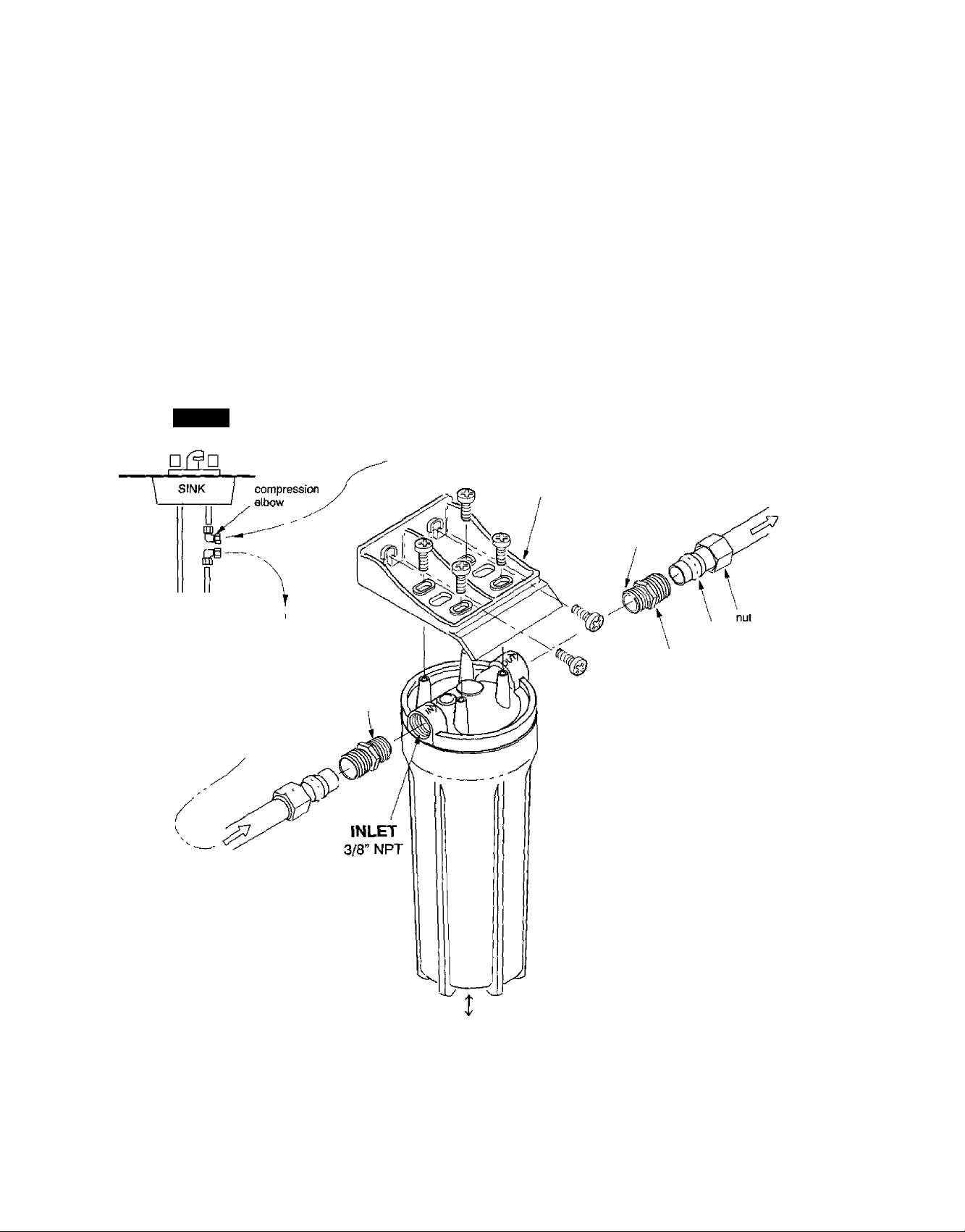

TYPICAL UNDERSINK INSTALLATIONS / TOOLS AND MATERIALS NEEDED

FIG. 1

INSTALLATION ON COPPER PLUMBING USING COMPRESSION FITTINGS

Mounting Bracket -

includes screws

apply several

wraps of

Teflon tape

FILTERED

WATER

HOT/^COLD

shutoff valve

Note: To change

the filter cartridge,

you must turn off

the water, A nearby

shutoff valve is con-

vienent. Most sinks

already have shut

off valves on the

supply pipes.

WATER

IN

apply several

wraps of

Teflon tape

Note: Be sure to allow a minimum space of 1 -112"

under the filter for removing the sump, to change

the cartridge.

brass

ferrule

compression

adaptor (use elbow or

straight tilting)

- MATERIALS AND TOOLS NEEDED -

► 2 compression adaptors (either straight fit

tings as shown, or elbows), 3/8” NPT x comp.

P- 2 compression elbows, 3/8” comp, x comp,

(compression end to fit existing pipe)

Note: Sears has an installation kit available

that fits 3/8” O.D. pipe size, Item No.

42-38445.

► Teflon tape

► tubing cutter

► sandpaper or emery-cloth

► 2 wrenches, either open end or adjustable

jaw, size to fit compression adaptors

Page 5

TYPICAL UNDERSINK INSTALLATIONS / TOOLS AND MATERIALS NEEDED

FIG. 2

FIG.3

TO SINK

FAUCET

HOT VCOLD,

shutoff valve

TO SINK

FAUCET

HOT

shutoff valve

SOLDERED COPPER INSTALLATION

{OBSERVE FIG. 1 NOTES)

J / pipe, as req'd

Q][

-------------------------

- MATERIALS AND TOOLS NEEDED -

(see page 6)

3/8” copper

adaptor,

3/6" NPT X sweat

(apply several wraps of

Teflon tape to threads)

THREADED INSTALLATION

(OBSERVE FIG, 1 NOTES)

union fitting

3/8” eltx)w (3)

3/8” street

apply several

wraps of Teflon

tape to all

threads

' MATERIALS AND TOOLS NEEDED ■

(see page 7)

90°ellJow (4)

elbow

INSTALLATION STEPS

A, USING COMPRESSION FITTINGS, FIG, 1

Note: If plumbing with flexible tubing, hang or sup

port the filter housing in some manner. Using the

mounting bracket (included) as shown in FIG. 1.

1. Apply several wraps of Teflon tape to the threads

of both compression adaptors.

2. CAREFULLY turn the compression adaptors into

the water filter head inlet and outlet and tighten. Do

not cross-thread and damage the threads. Do not

overtighten and crack the head.

3. CAUTION: Turn off the water supply to the sink

cold pipe. Open the sink cold faucet to relieve pres

sure in the pipe.

Note: If the sink faucet is a single lever mixing type

also close the shutoff valve on the hot water side.

4. Use a tubing cutter to remove a section of the cold

water pipe (catch trapped water with a rag or tow

el), Remove all burrs and rough edges with the sand

paper or emery-cloth.

5. Place a nut and brass ferrule (from compression el

bow fittings) onto both pipe ends. Connect elbows to

the sink cold water pipe as shown below.

FIG. 4

TO SINK

COLD FAUCET

Page 6

INSTALLATION STEPS

6. Using ferrules and compression nuts, cut and fas

ten a length of tubing (allow some slack) from the

cold water pipe, to the fitter head inlet compression

adaptor, FIG.4.

7. Cut tubing to the length needed to allow some

slack, fasten tubing to the filter outlet side compres

sion adaptor, returning to the sink cold water pipe,

as typically shown in FIG. 5.

8. Check to be sure all fittings are tightened.

9. Before turning on the water supply, remove the

sump from the filter head and install the filter car

tridge (see page 7).

B. SOLDERED COPPER FITTINGS, FIG. 2

MATERIALS AND TOOLS NEEDED: You wUI need

2 sweat adaptors, 3/8" NPT x sweat (sweat end to fit

your sink cold water pipe), 4 sweat 90“elbows,

copper pipe, lead-free solder and flux, soldering

torch. Teflon tape, sandpaper or emery-cloth, open

end (to fit sweat adaptor) or adjustable jaw wrench.

CAUTION: Heat created when soldering can dam

age the water filter housing. Be sure to use the fol

lowing procedures to protect the water filter.

FIG, 5

FIG. 6

TO SINK

FAUCET

HOT

shutoff valve

TO SINK

COLD FAUCET

U

B

apply several

wraps of Teflon

tape, or pipe

joint compound

to threads

1. CAUTION: Turn off the water supply to the sink

cold pipe. Open the sink cold faucet to relieve pres

sure in the pipe.

Note: If the sink faucet is a single lever, mixing type,

also close the shutoff valve on the hot water side.

2. Use a tubing cutter to remove a section of the sink

cold water pipe (catch trapped water with a rag or

towel). Use sandpaper or emery-cloth to thoroughly

clean and remove all burrs and rough edges from

both pipe ends.

Note: When soldering, use lead-free solder and flux

only. Be sure pipe and fittings are properly cleaned.

Observe caution note above.

3. Refer to FIG. 2, page 5, and to the following draw

ings. Make typical soldered assemblies A and B as

shown in FIG, 6. After they have cooled, apply Te

flon tape or pipe joint compound to the pipe threads.

Then turn them into the filter head and tighten.

4. Solder the filter housing, with assemblies A and B

installed, to the cold water shutoff valve C. Wrap a

n

TO SINK

COLD

FAUCET L

rtf

shutoff valve

D

■~1

----

hr6'

I

_____

!

wet rag around assembly A to reduce heat transfer

through the pipe and into the head,

5. Protect the filter housing from soldering heat, as

you did above, and complete the connections (D) to

the faucet cold water pipe.

6. Before turning on the water supply remove the

sump from the filter head and install the filter car

tridge (see page 7).

Page 7

INSTALLATION STEPS (cont.)

C. THREADED PIPE AND FITTINGS, FIG. 3

MATERIALS AND TOOLS NEEDED: For threaded

pipe installation you will need pipe wrenches, Teflon

tape or pipe joint compound, a union fitting and pipe

nipples. You may also need a pipe threading tool.

Connect the filter housing as typically shown in FIG.

3, page 5. Observe the following:

■ Use Teflon tape or pipe joint compound on all ex

ternal threads.

FILTER CARTRIDGE INSTALLATION

TURN TO PAGE 9 AND FOLLOW ALL STEPS UNDER "FILTER CARTRIDGE REPLACEMENT'

■ Do not turn pipe or fittings too tightly into the filter

head or you may break it.

■ It is important to have some movement in the sink

cold water pipe. This will allow you to tighten the

union fitting, without damaging the filter head, if

pipe lengths are not exact.

■ Before turning on the water supply remove the

sump from the filter head and install the filter car

tridge {see below).

Page 8

FILTER CARTRIDGE / USEFUL LIFE / REPLACEMENT

FILTER CARTRIDGE LIFE

Several variables determine how long a cartridge

will last. These include;

1, how much water you use.

2. how much sediment, taste and/or odor, or other

unwanted substance, is in the water.

Use the following information as a guide. However,

no matter which type of cartridge you are using, you

will know it is time to replace it when you first no

tice the return of the unwanted substance in your

water.

Kenmore Undersink Water Filter Housing model

625.384500 with replacement filter 42-34373 has

been tested and certified by NSF International for the

reduction of chlorine, taste and odors. The rated ca

pacity for this system is 4500 gallons.

Other filter cartridges are available from Sears to re

move sediments, tastes and odors. Following is a list

of filter cartridges available.

Taste and Odor Cartridges: Many bad tastes and/or

odors are removed from water by an activated car

bon cartridge. It is most often used to remove chlo

rine taste and smeU, usually to a single faucet such as

the kitchen cold.

Note: Small amounts of hydrogen sulfide (noticeable

as "rotten egg" odor) may be reduced by taste and

odor filters for a short time, quickly exhausting the

carbon media. Consult your Sears store for proper

continuous treatment.

Taste & Odor Filter Cartridge, Sears Item No.

42-34370: for 95% chlorine reduction.

Sediment Filter Cartridge, Sears Item No. 42-38478

(25 micron): Sediment cartridges remove sand, silt,

clay, dirt, and other sediments from water. The 25

micron cartridge filters larger sediments from water,

and allows higher flows at less pressure drop.

Page 9

FILTER CARTRIDGE REPLACEMENT

CAUTION: Never remove the sump with water

pressure in the filter.

1. Close the nearest shutoff valve on the water sup

ply pipe to the filter. To relieve pressure in the filter,

open the sink cold water faucet.

2. Turn the sump off of the filter head, to the left or

clockwise. Be careful, the sump is full of water. Do

not lose the large o- ring seal.

Note; A special wrench is available from Sears for re

moving the sump. See the parts list on page 10,

3. Be sure the inside of the sump is clean. Cleaners are

available from Sears (see the parts list on page 10), or

use hot, soapy water.

4. Remove the wrapper from the new filter cartridge

and insert the filter cartridge in the sump. Some car

tridges fit either way, while others fit only one way.

Observe markings on the cartridge, or on the wrap

per.

5. Lightly lubricate the o-ring seal in the sump with

silicone grease or Vaseline. Be sure it is fully seated

in the groove.

6. Hold the sump up to the filter head aligning the

center hole in the cartridge with the protrusion on the

bottom of the head.

Note: If the sump will not tighten up to the head you

may have the cartridge in upside down. Take the car

tridge out and check for correct orientation,

7. Being careful not to cross- thread, turn (counter

clockwise) the sump onto the filter head and tighten

securely.

8. Open the sink cold faucet. Then slowly open the

water supply shutoff valve and allow the filter hous

ing to fiU,

9. Close the sink faucet. Then check for leaks between

the sump and the head.

Note: If leaking turn off the water supply and open

the sink cold faucet to depressurize the filter. Then

disassemble the filter and check the o-ring for cuts,

flat spots, etc., and sealing surfaces for foreign mate

rial. Clean the o-ring and lubricate "with silicone

grease or VaseUne. Carefully press into the groove in

the sump.

10. Taste and Odor Cartridges: A taste and odor car

tridge contains activated carbon, a black powder. Af

ter the new cartridge is installed open the filtered wa

ter faucet and allow fine, harmless carbon particles to

purge from the cartridge. Close the faucet when you

no longer see the "fines" in the filtered water, or

approximately 2-3 minutes.

Page 10

REPAIR PARTS

Kenmore Undersink Water Filter Housing, Model No. 625.384500

KEY

NO.

1 7231296

2 7156535 Head

3

4

♦ 7228073

•i.

PART

NUMBER

Mounting Bracket (includes screws)

42-34385

7156577

42-38478 Sediment Cartridge, 25 micron

0-ring, 3-3/8” I.D. x 3-5/8” O.D.

Sump

Owners Manual

DESCRIPTION

4- 42-38480 Sediment Cartridge, 5 micron

4. 42-34370 Taste & Odor Cartridge, 95% chlorine reduction

4*

•f* available options from Sears (at time of printing), not illustrated, and not included with

Water Filter Housing

♦ not illustrated

42-34373

Premium Taste & Odor Cartridge, 98% chlorine reduction

10

Page 11

и

Page 12

Kenmore

UNDERSINK

OWNERS

MANUAL

MODEL NO.

625.384500

The model number of

your water filter housing

is found on the rating de

cal, on the filter sump.

WATER FILTER

HOUSING

For the repair or replacement parts you need

Call 7 am - 7 pm, 7 days a week

1 - 800 - 366 - PART

(1 - 800 - 366 - 7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1 - 800 - 4 - REPAIR

(1 - 800 - 473 - 7247)

When requesting service

or ordering parts, always

provide the following in

formation:

♦ Product Type

♦ Model Number

♦ Part Number

♦ Part Description

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

^ ^ ~~ 7228073 (R. 01/05/01)

For the location of a

Sears Repair Service Center in your area

Call 24 hours a day, 7 days a week

1 - 800 - 488 - 1222

For information on purchasing a Sears

Maintenance Agreement, or to inquire

about an existing Agreement

Call 9 am - 5 pm, Monday - Saturday

1 - 800 - 827 - 6655

Loading...

Loading...