Kenmore 1250 User Manual

Kenmore

INSTRUCTIONS

MODEL 1230/1240/1250 • ZIG* ZAG SEWING MACHINE

#52917

il

ij

f'S

i

I

f

TABLE OF CONTENTS

Section I Knowing Your Sewing Machine

Section I

Page 1

Identifying Parts

Installing and Connecting Machine

Bobbin......................................................................5, 6, 7

Threading-Top Thread................................................... 8

Using the Controls

Top Tension Control

Bobbin Tension Adjusting......................................11

Checking Tensions

Stitch Length Control

Stitch Width Control

Reverse Stitch Control

Special Stitch Variegator........................................ 15

Special Stitch Dial...................................................16a, b

Pressure Regulator.................................................

Feed Dog Control.....................................................18

Sewing Light

Seam Guide...............................................................19

Accessories

Needles......................................................................20

Needle, Thread, Fabric Chart..................................21

Presser Feet..............................................................22

..........................................................

.............................

............................................

..................................................

..............................................

................................................

............................................

............................................................18

2, 3

9, 10

12

13

14

15

17

4

Section n Starting to Sew

Garment Construction Stitches

Straight Stitching

Zigzag Stitching......................................................... 4

Overcasting................................................................ 4

Stretch Stitching

Special Finishing Stitches

Blind Hemming ........................................................

Satjn Stitching........................................................... 7

Mending...................................................................... 7

Appliqueing.............................................................. 8

Buttonholing.........................................................9, 10

ButtonSewing, Bar Tacking....................................11

Maxi Stitch Stretch

Feather Stretch.........................................................12

Darning, Writing and Monogramming

Zipper Application....................................................14

Section HI Checking Performance Problems

Section W Caring For The Machine

Cleaning Feed Dogs and Shuttle ...........................

Oiling Under Arm Cover Plate

and in Face Cover Plate............................................ 2

Oiling Underside....................................................... 2

Parts List......................................................................3, 4

..........................................................

........................................................

.......................................................

..................................................

...................

1

2, 3

5

6

11

13

1

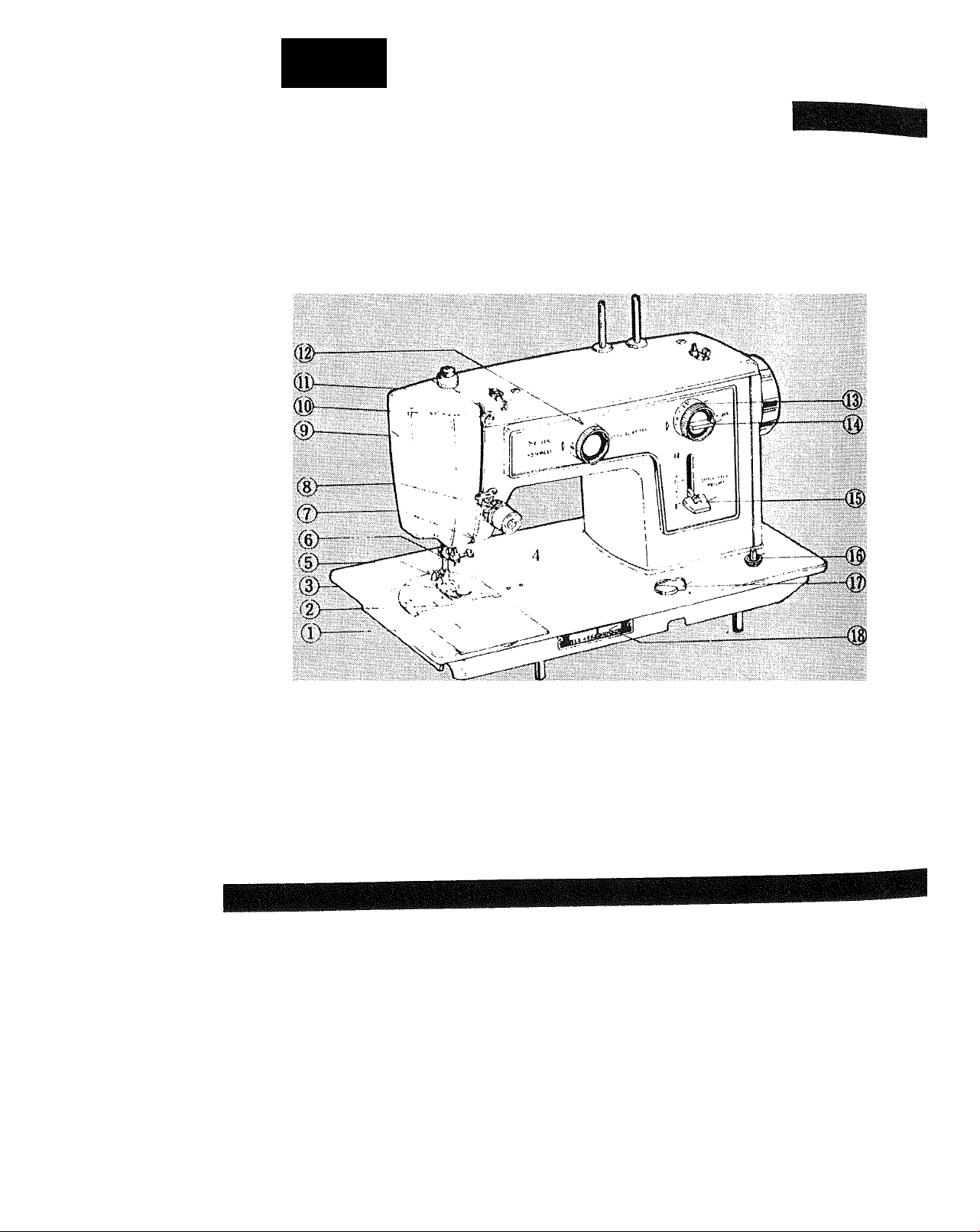

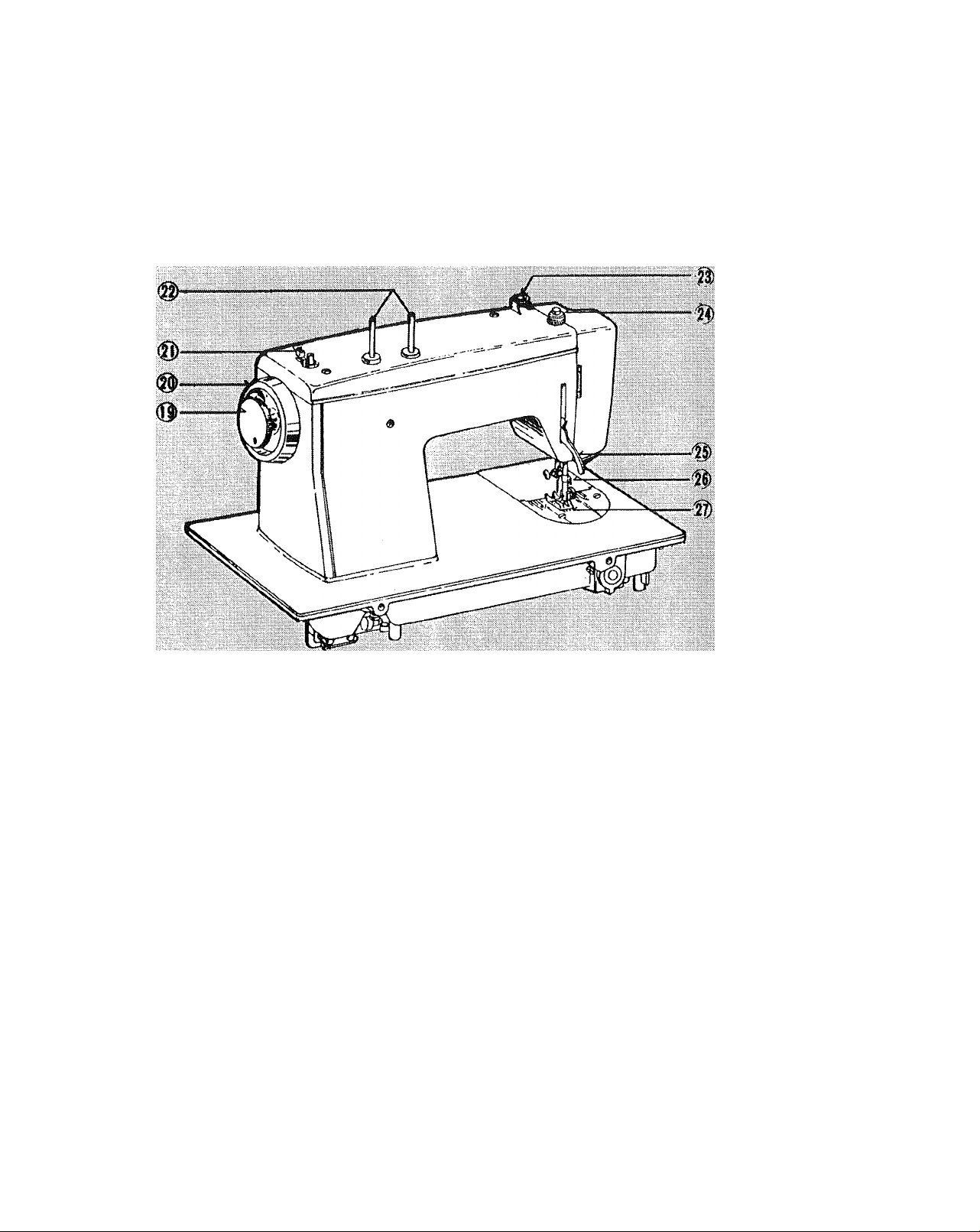

Section I

Page 2

Knowing Your Sewing Machine

1. Hand Hole Cover Plate

2. Seam Guide Lines

3. Presser Foot

4. Needle Clamp Screw

5. Presser Foot Screw

6. Thread Guide

7. Face Cover Thread Guide

8. Top Thread Tension Control

9. Face Cover Plate

10. Take-up Lever

11. Upper Thread Guide

12. Special Stitch Dial

(Model 1250 only)

13. Stitch Width Control

14. Special Stitch Variegator

(Models 1240,1250 only)

15. Stitch Length and

Reverse Stitch Control

16. Light and Power Switch

17. Feed Dog Control

18. Nomenclature Plate

19. Clutch Knob

20.

Hand Wheel

21.

Bobbin Winder

22.

Thread Spool Pins

23.

Bobbin Winder Tension Disc

24. Pressure Regulator

25. Presser Foot Lever

26.

Thread Cutter

27. Feed Dogs

Section I

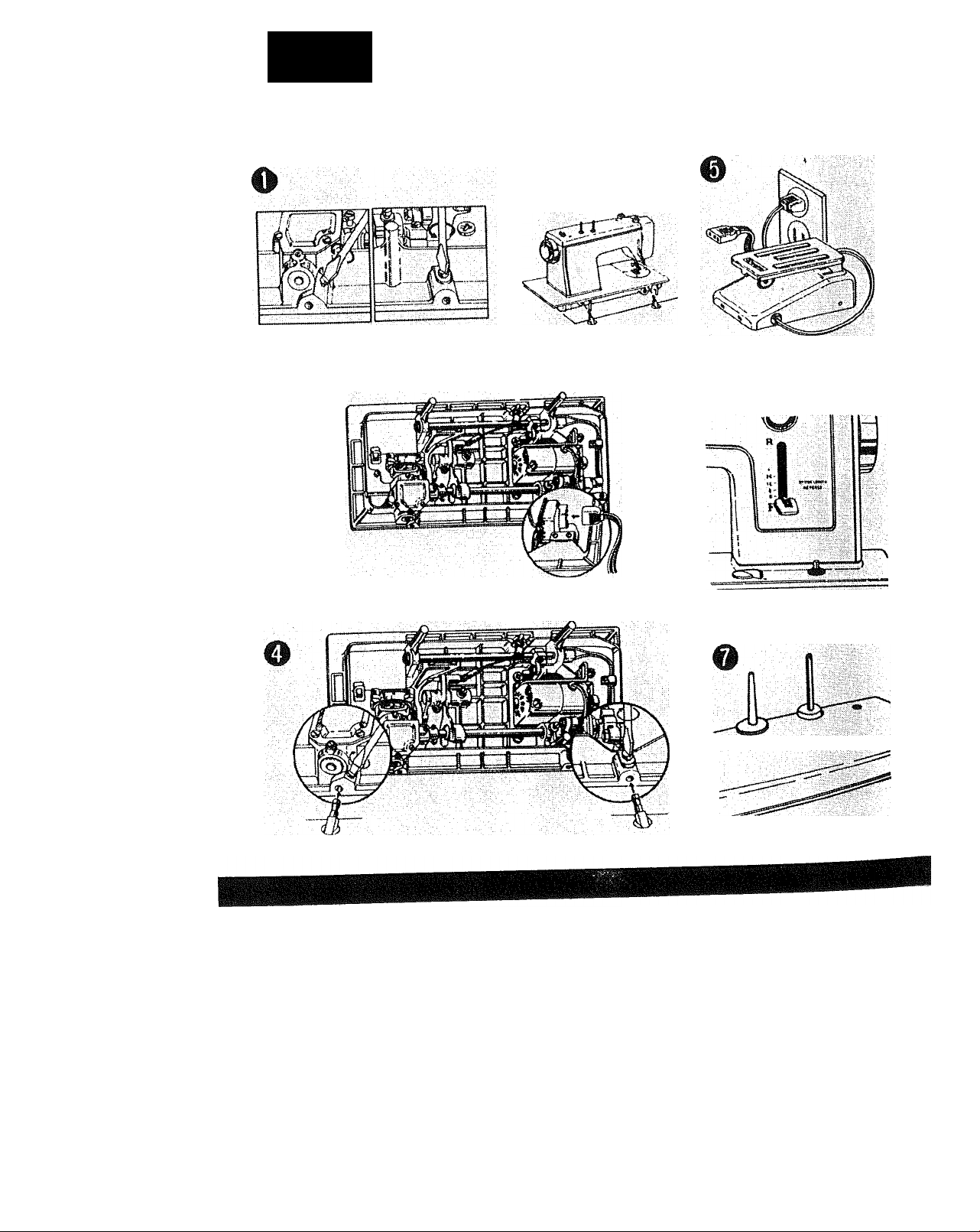

Page 4

INSTALLING MACHINE

0

0

1. Loosen the two hinge screws under

holes in the rear edge of the machine

bed.

2. Raise hinge pins in the cabinet cutout.

3. Slip machine head onto the pins and

tighten hinge screws securely.

4. Push the speed control plug onto

three-prong connector under the bed

plate. Lower machine head to front

cabinet flap.

Plug the speed control cord into any

110-120 volt wall outlet.

Turn on power by pushing light an

6.

power switch.

Screw spool pins firmly in place wUh

7.

screwdriver. Place the plastic sp

holder onto the spool pin. Holder ana

pins are packed in the accessory o •

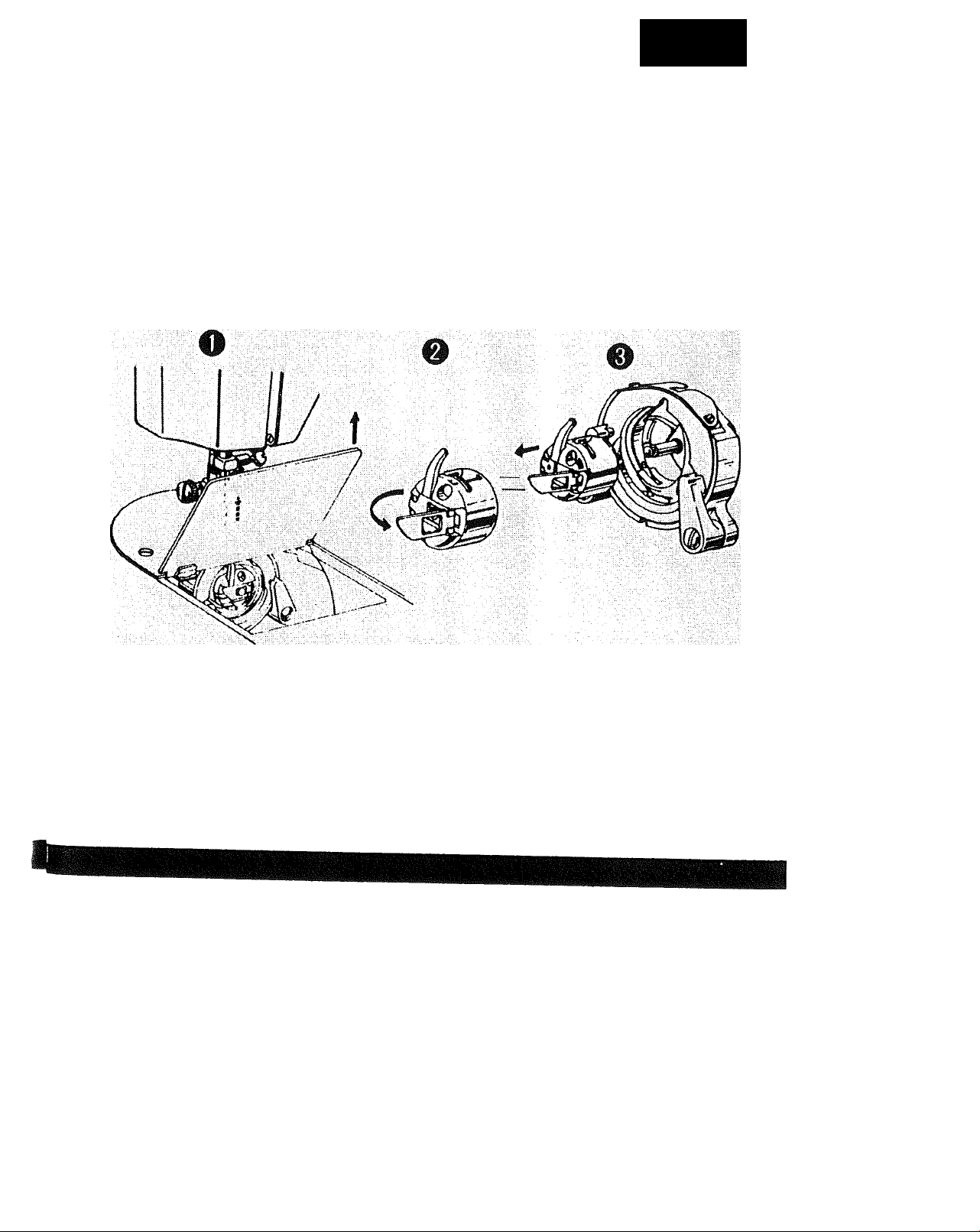

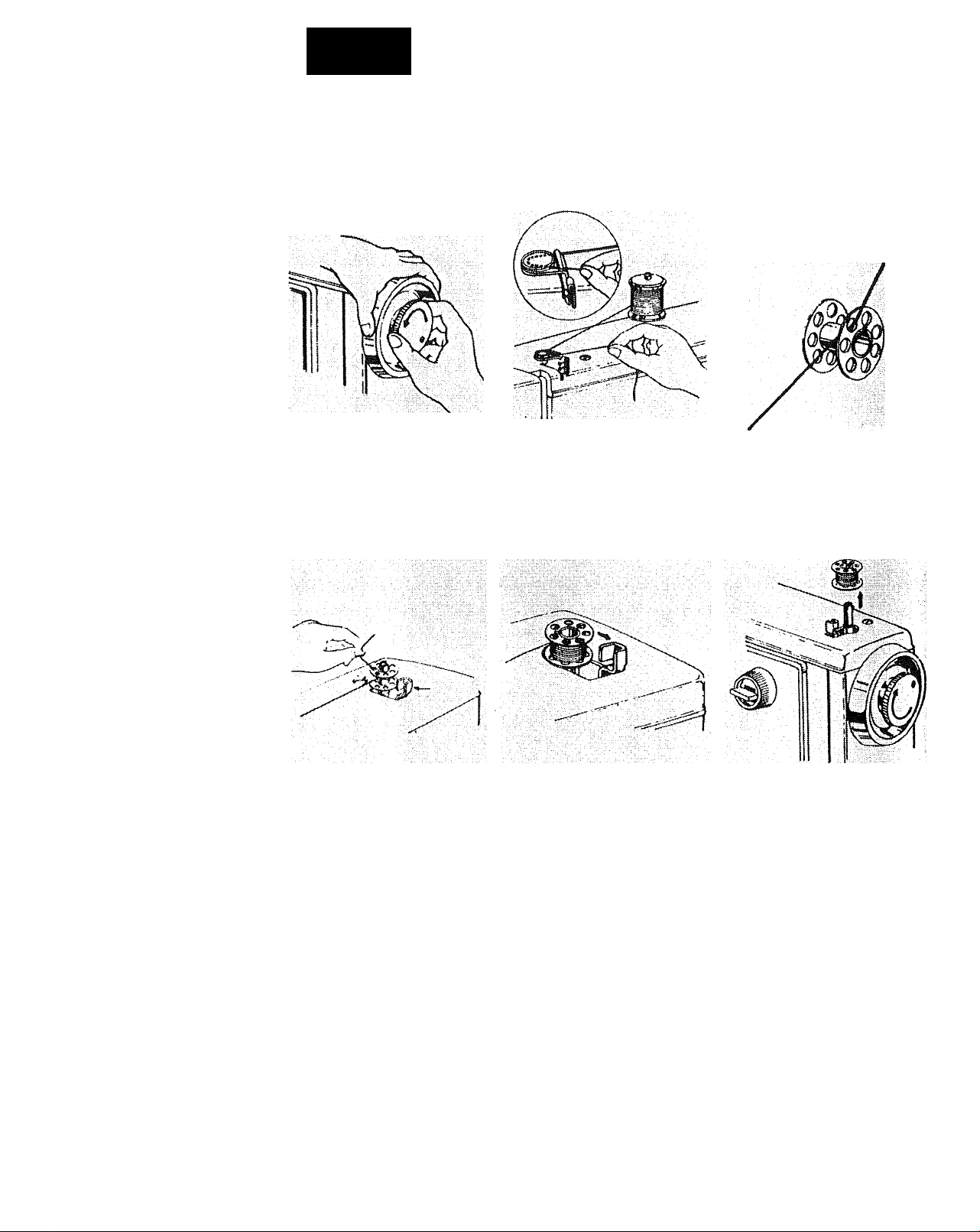

REMOVING BOBBIN CASE FROM SHUTTLE

Section I

Page 5

1. Turn hand wheel to raise needle to

its highest position. Lift hand hole

cover plate.

2. Pull open latch of bobbin case.

3. Pull bobbin case straight out of

shuttle.

To thread the bobbin case, see

page 7.

Section I

Page 6

WINDING THE BOBBIN

o

o

e

0

o

1. Release clutch by turning clutch knob

toward you.

2. Draw thread from spool through

bobbin winder tension discs as shown.

3. Pull end of thread through hole in

bobbin as shown.

4. Place bobbin onto bobbin winder shaft

with end of thread coming from the top

of the bobbin. Push bobbin winder

latch against bobbin until it clicks.

Holding onto end of thread, start

machine. When bobbin is slightly filled,

snip off end of thread.

5. Start machine. Wind thread until

bobbin winder latch releases.

6. Tighten clutch knob and remove

bobbin.

Two spool pins have been included with

this machine to aid in bobbin winding. By

placing a spool of thread on the second

spool pin, you may wind your bobbin

without unthreading the machine.

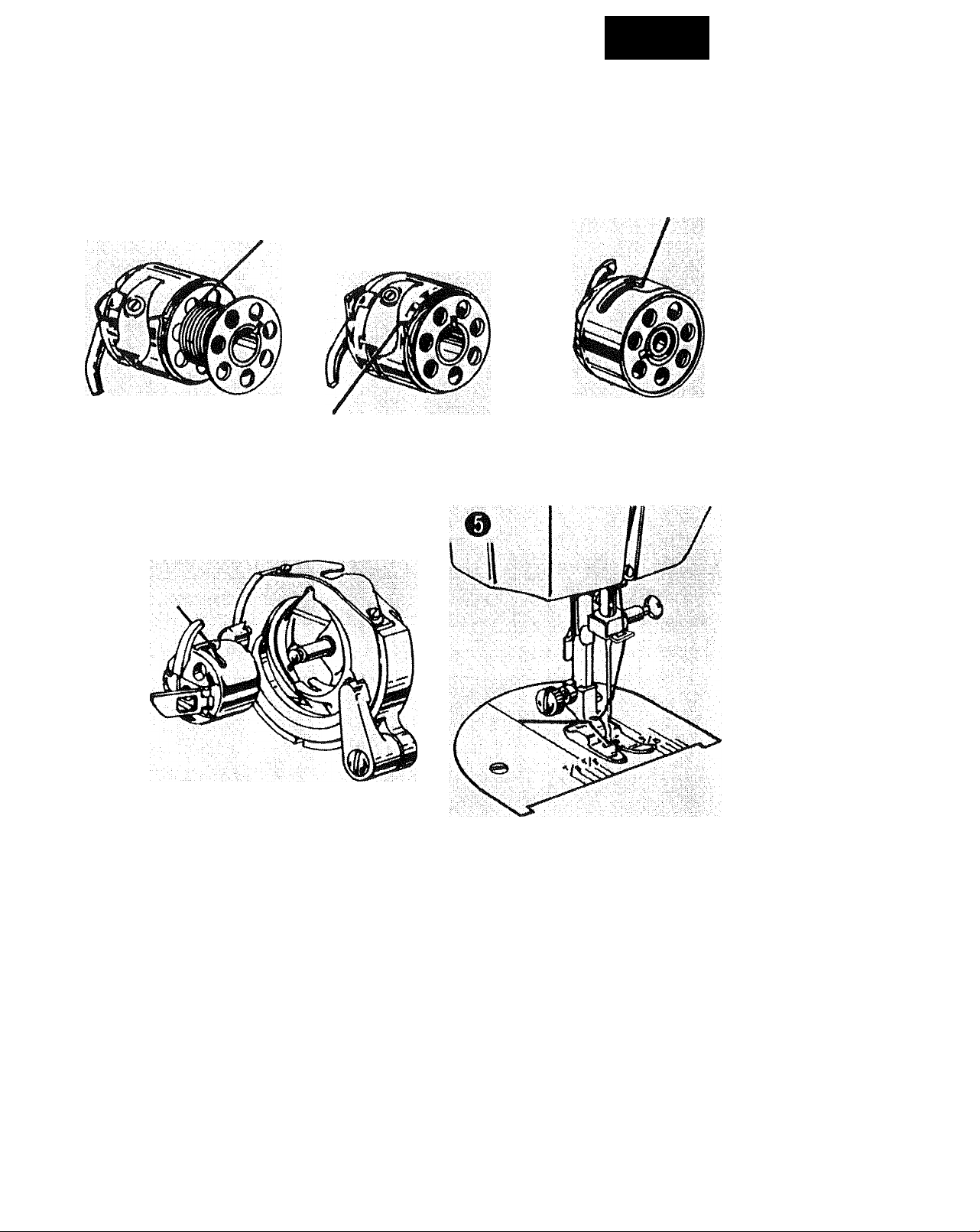

THREADING THE BOBBIN CASE

Section I

Page 7

o

e

0

1. Insert bobbin into bobbin case

making sure thread is coming from

bobbin as shown.

2. Pull thread through slot of case as

shown.

3. Pull thread under tension spring.

4. Turn hand wheel to raise needle to

its highest position. Holding latch

open, position case into shuttle, and

release latch. Case should lock into

place when latch is released.

Hold needle thread loosely in left

hand and rotate hand wheel toward

you one complete turn. Bring bobbin

thread up by pulling upper thread.

Section I

Page 8

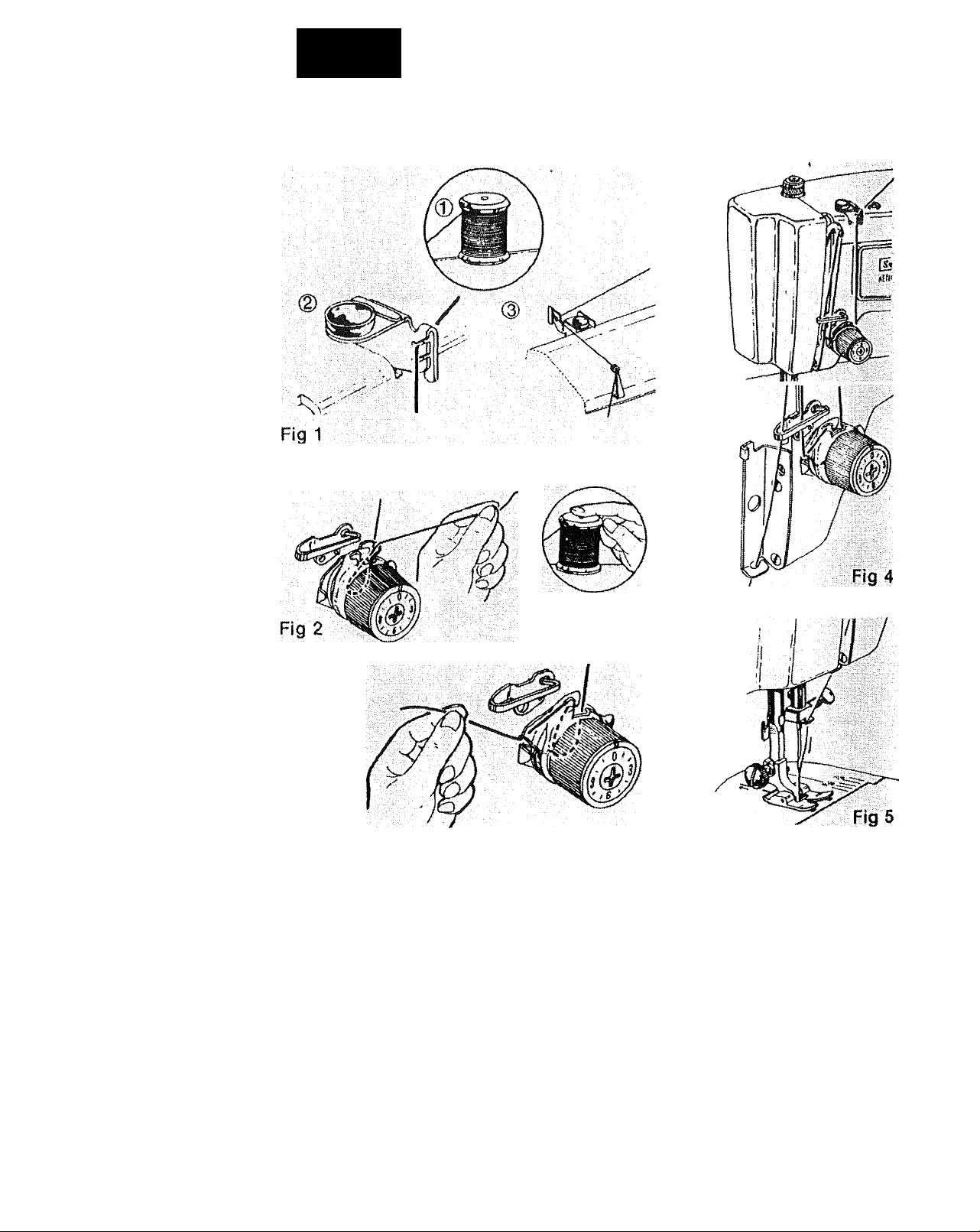

THREADING OF TOP THREAD

Fig3

Place thread on spool pin as shown,

with the thread coming from the back

of the spool (Fig. 1-©). Draw thread

through the top thread guide(s) (Fig.

1-@or ®).

Holding the spool with the right hand,

2.

pull the thread through the tension

discs. The spring wire loop should be

pulled up until the thread passes

beyond the beak of the hook. Fig. 2.

After the thread has slipped into the

hook, allow the spring wire to return to

position by releasing the thread spool.

Fig. 3.

Continue threading through the front

thread guide, hook thread into take up

lever and down through path shown in

Fig. 4 and 5.

Always thread needle in direction as

5.

shown in Fig, 5.

CONTROLS

TOP TENSION CONTROL

Section I

Page 9

Probably the most important control on your machine is this one that regulates your

top thread tension. It consists of discs between which the thread passes. The

pressure on these discs is regulated by turning the dial. The higher the number, the

tighter the tension.

There are many reasons for having to reset your tension. The best tension for one

fabric may not be correct for another. The required tension depends upon the

stiffness of the fabric, thickness of the fabric, numbers of layers of fabric being

sewn, as vyell as the type of stitch you are making.

It is best to test the stitching on a scrap of the fabric you are using before starting to

make a garment. To adjust for the correct stitch; see next page.

Section I

Page io

ADJUSTING TOP TENSIONS

^ Upper thread too tight

A perfect straight stitch will have

threads locked between the two

layers of fabric with no loops on

top or bottom.

^ Upper thread too loose

Decrease Tension

Increase Tension

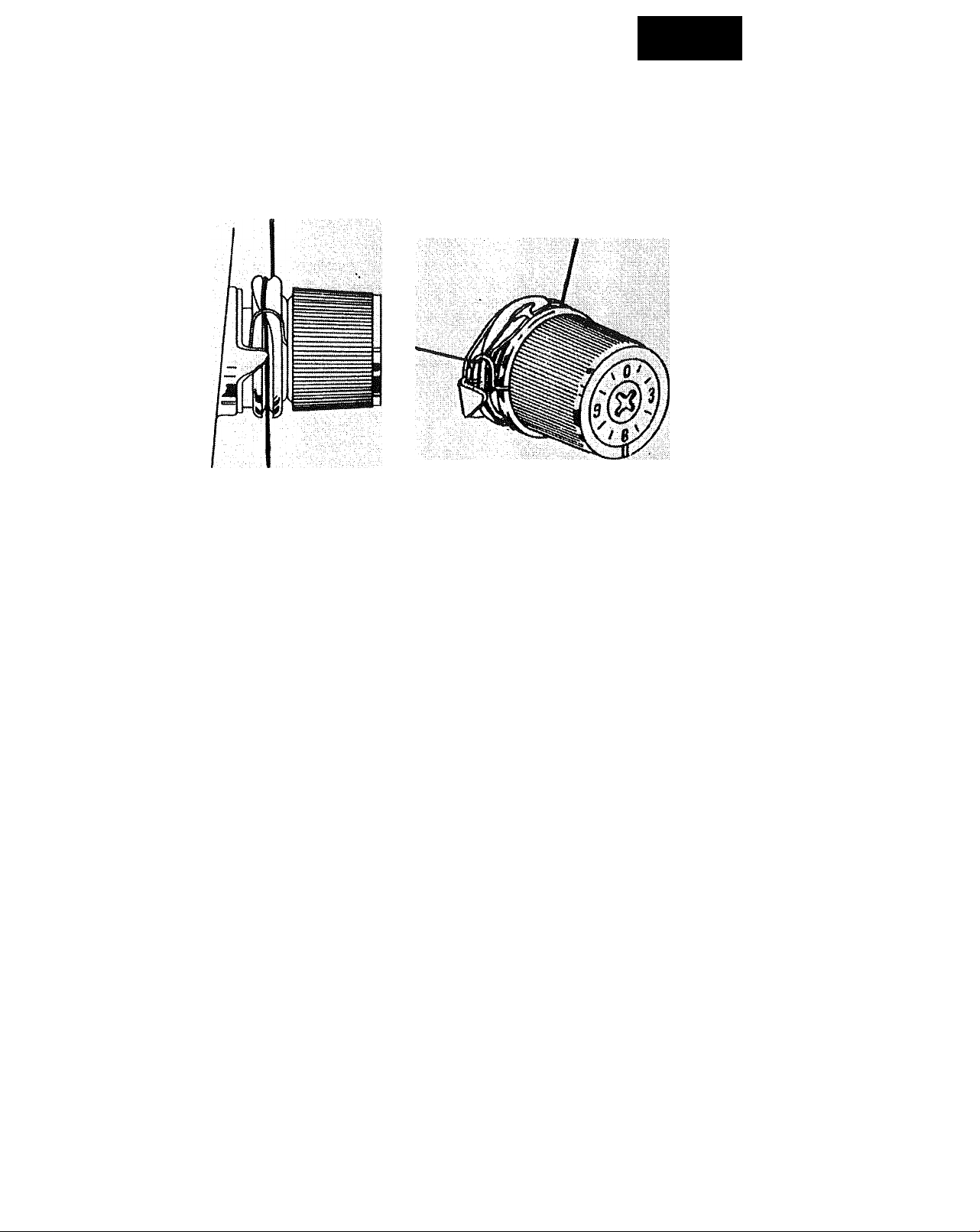

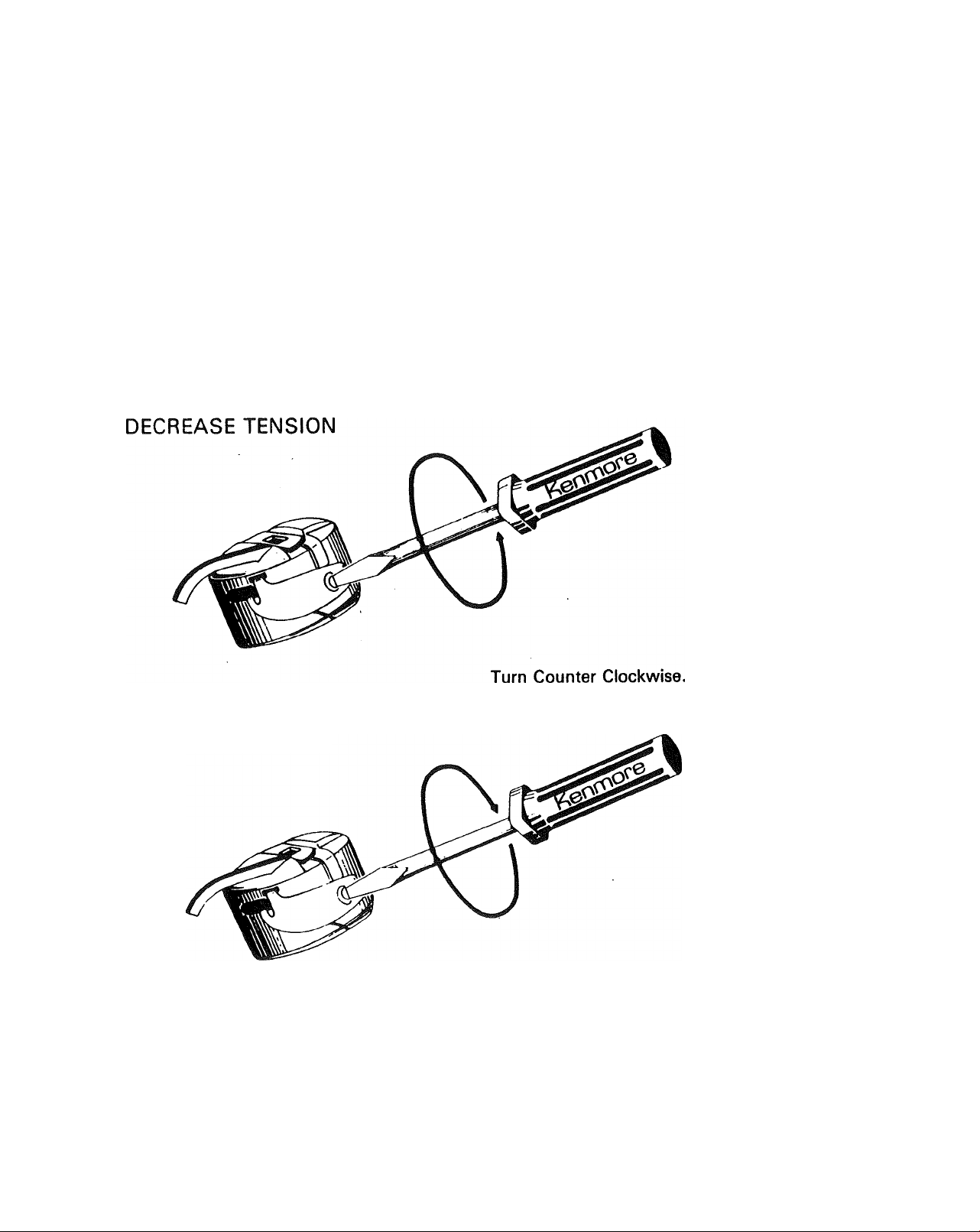

ADJUSTING BOBBIN TENSIONS

Bobbin tension requires adjusting less frequently than the upper thread tension.

If the stitch is satisfactory but the seanr) is puckered, it may be necessary to loosen

the tension on both the top and bottom threads. Be sure to balance them as

Indicated on page 10.

When adjusting the tension on the bobbin case, make slight adjustments with a

screwdriver. Correct tensions will produce the stitch shown on page 10.

INCREASE TENSION

Turn Clockwise.

Section I

Page 12

To check the thread tension balance, be sure to use mercerized thread of the same

size on the top and on the bobbin, and a sharp, correctly sized needle for the fabric

you are sewing. Begin with a full bobbin. Set the stitch length for about 12 stitches

per inch.

Fold a 6" square of fabric in half diagonally, forming a triangle. Make a line of

stitching W' in from the fold.

a. If seam is puckered-both tensions are too tight.

b. If the bottom thread lays on the fabric-tighten upper thread tension, and

repeat test. See Fig. 3, Page 10.

c. If the top thread lays on the fabric-loosen upper thread tension, and repeat

test. See Fig. 2, Page 10.

Grasp the stitching and pull with a snap to make the threads break.

a. If both threads break-tensions are balanced.

b. If neither thread breaks-both tensions are too loose.

c. If upper thread breaks-loosen top tension,

d. If lower thread breaks-tighten top tension.

Both threads do not have to break at the same place, but they should break on the

same snap.

It is necessary to reduce the upper thread tension somewhat when zigzag stitching.

The wider the stitch, the less tension that is needed. This Is particularly important

when making designs. It is not desirable to have any of bottom thread visible on the

right side of the fabric when satin stitching.

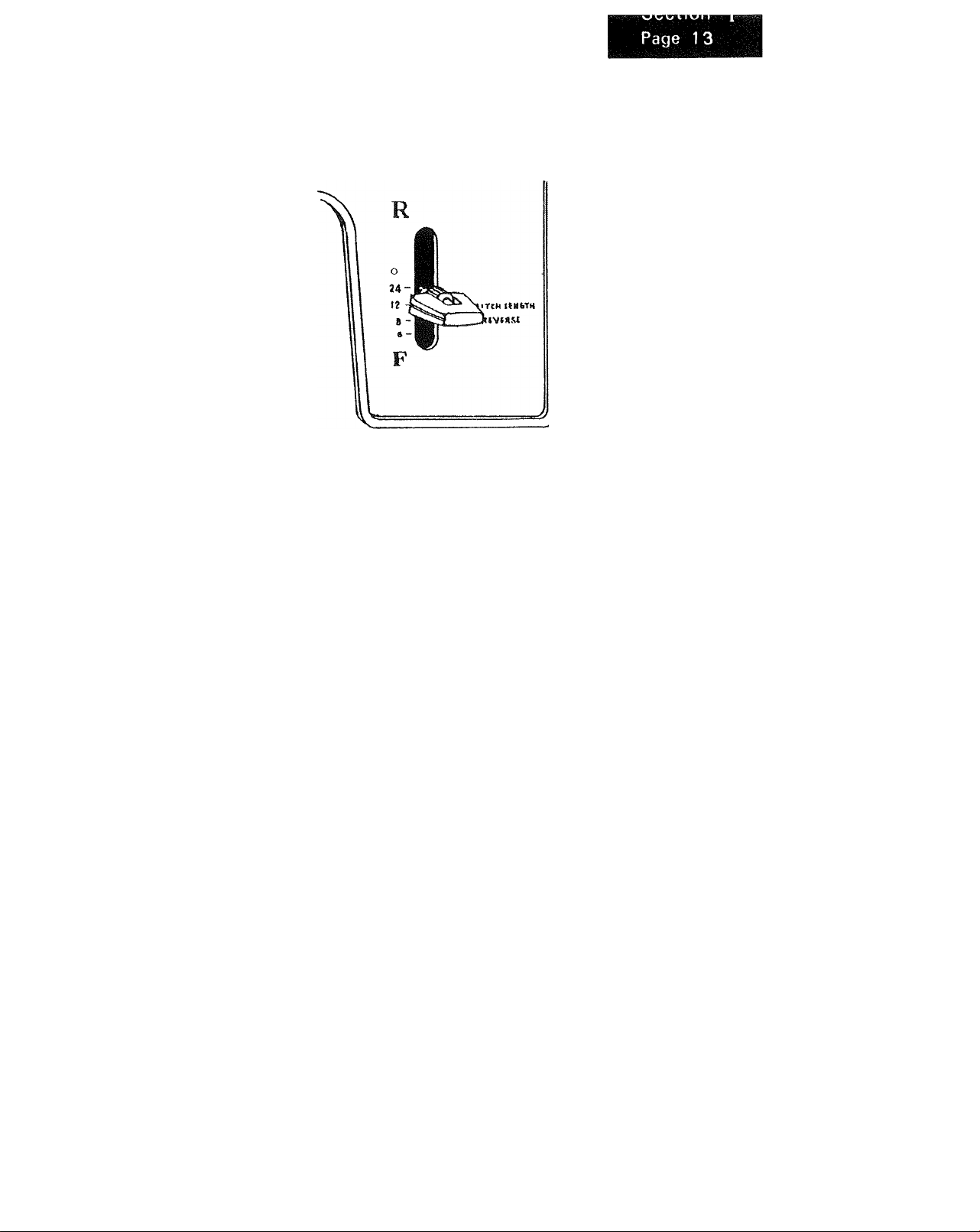

The stitch length control regulates the length of the stitch you select. THE

HIGHER THE NUMBER-THE SHORTER THE STITCH.

The stitch setting you use will be determined by the thickness of the fabric you

are sewing. A longer stitch setting should be used for thicker fabric or more

layers of fabric.

The middle range of the control is the 10-12 stitch per inch range which Is the

most commonly used.

The basting and stretch stitch are made by adjusting the lever to make the

longest possible stitch. When adjusting for shorter stitches, select the stitch

length and tighten the knob In the center of the lever handle to remain at the

same setting. The knob must be loosened to readjust the lever.

Section I

Page 14

The stitch width control regulates the width of the stitch you select. THE

HIGHER THE NUMBER, THE WIDER THE STITCH.

You may vary your zigzag stitch width by adjusting this control to the setting you

desire.

This control must be on the Red Dot in order to do straight stitching. Before

turning control, make sure needle is above fabric.

You will note a simulated buttonhole between the numbers 2 and 1 on the

control. This is the setting to be used when a buttonhole is sewn. The control

may have to be adjusted slightly in either direction depending on the weight of

the fabric being used.

Loading...

Loading...