Kenmore 1206 User Manual

INSTRUCTIONS

MODEL 20/21/23/1206/1300

ZIG-ZAG SEWING MACHINE

Adjusting for Good Stitching ....

Bobbin:

Inserting & Threading

Picking up Bobbin Thread ......

Removing - -

Winding

Buttonholes.........................

Buttons

.........................................................

Cleaning *

........

...................*

....................

...............................................

...

..................

...................*........................

'•

.... • •

...

...

Connecting Machine..........

Corner, Turning

Darning .

.....

..................

...

Fastening a Seam

Feed Dog Control

Hems: Blind Stitched Hem . . • • * •

Identification, Head Parts

....................................

Installing Machine Head in Cabinet ■ ■

Inserting & Removing Material • . - . •

Needle:

Needle Size

Needle & Thread Chart.......

. ■ .26

. . . 8

. . TO

. . . 6

. . . 7

• . -17

■ ■ -21

.

- 22,23

... 4

- - -15

. . -20

- - -11

- . -15

- 18,19

. . 2,3

... 4

. . - 14

■ ■ 5

... 5

Placement

......

..................

...

Oiling Instructions

Overcasting

Parts List

Presser Foot, Changing .......

■ - • -15

Presser Foot Pressure, Adjusting • Sewing Light-

Stitch Length ..........

Stitch Width ...........

. . . Tl

... -16

Stitching:

Reverse ...................................

...

. . . - . - -11

Straight

Zigzag

Tension:

Upper Thread -

.........................

...

. . .

Lower Thread

Threading:

Bobbin Case

Upper Thread

Thread Chart

What To Do .............

, c

- ' 22,23

, , . .21

. . . -27

- ■ ■ -10

.... 4

. . 11,16

... .16

- . - -12

■ . ■ -13

.... 8

... 9

... - 5

■ -24,25

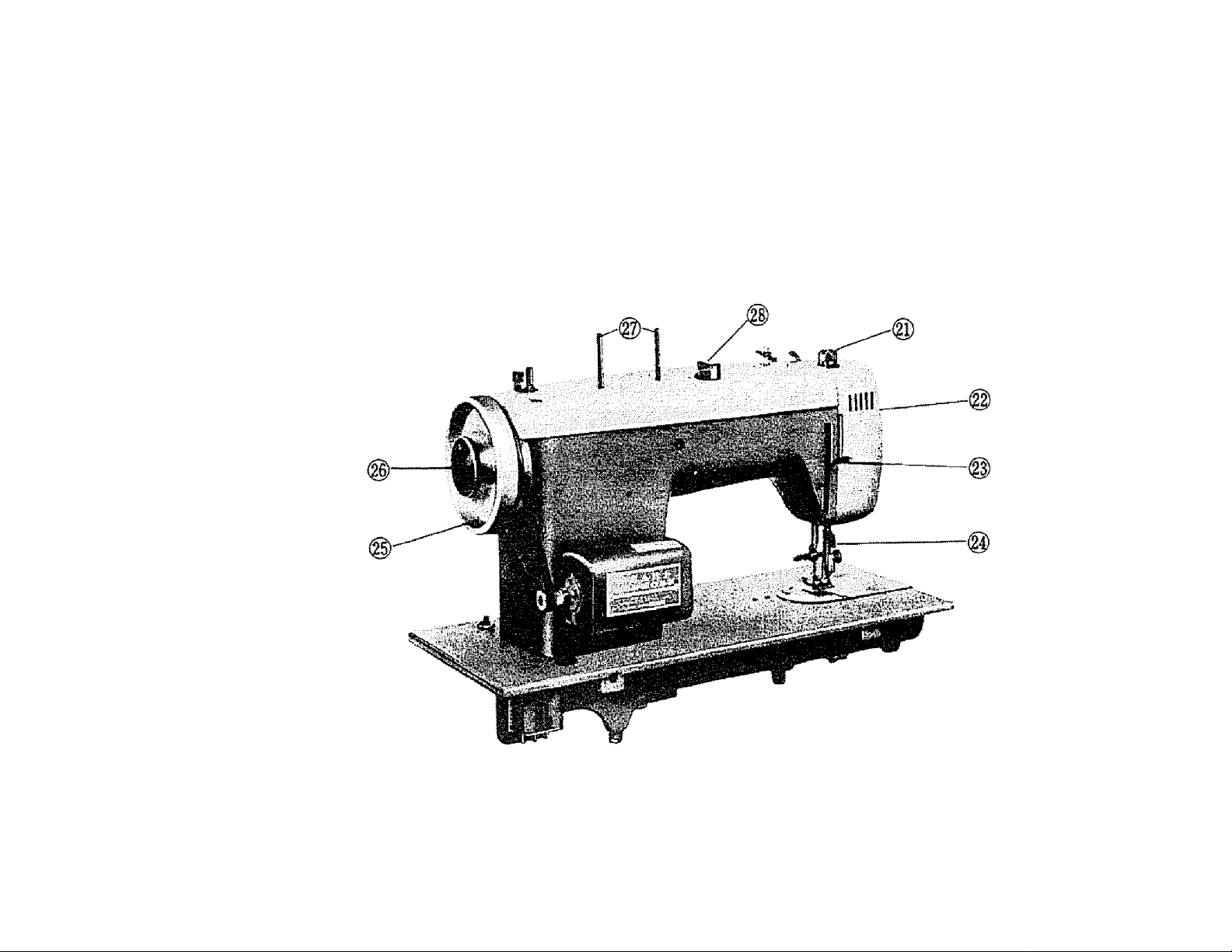

FRONT VIEW

(R)- -,

5'"^ ■ ■-

..

•>;v-

if

y

/

, .' /'1-4

y

■ a

"r

i.

Bobbin Winder Spindle

Bobbin Winder Latcb

Stitch Width Control

4.

Stitch Width Limner

•J! •

Stitch Length Control

6.

Reverse Stitch Push Button

7.

Light Switch

Feed Dog Control

9.

Nomenclature Plate

10.

Needle Plate

n.

Needle Clamp Screw

J2.

Feed Dog

¡3.

Hand Hole Cover Plate

14.

Pressor Foot

15.

Prosser Foot Screw

16.

Thread Guides

17.

Upper Thread Tension Control

IS.

Thread Take-up Lever

19.

Upper Thread Guide

20.

Bobbin Winder Thread Guide

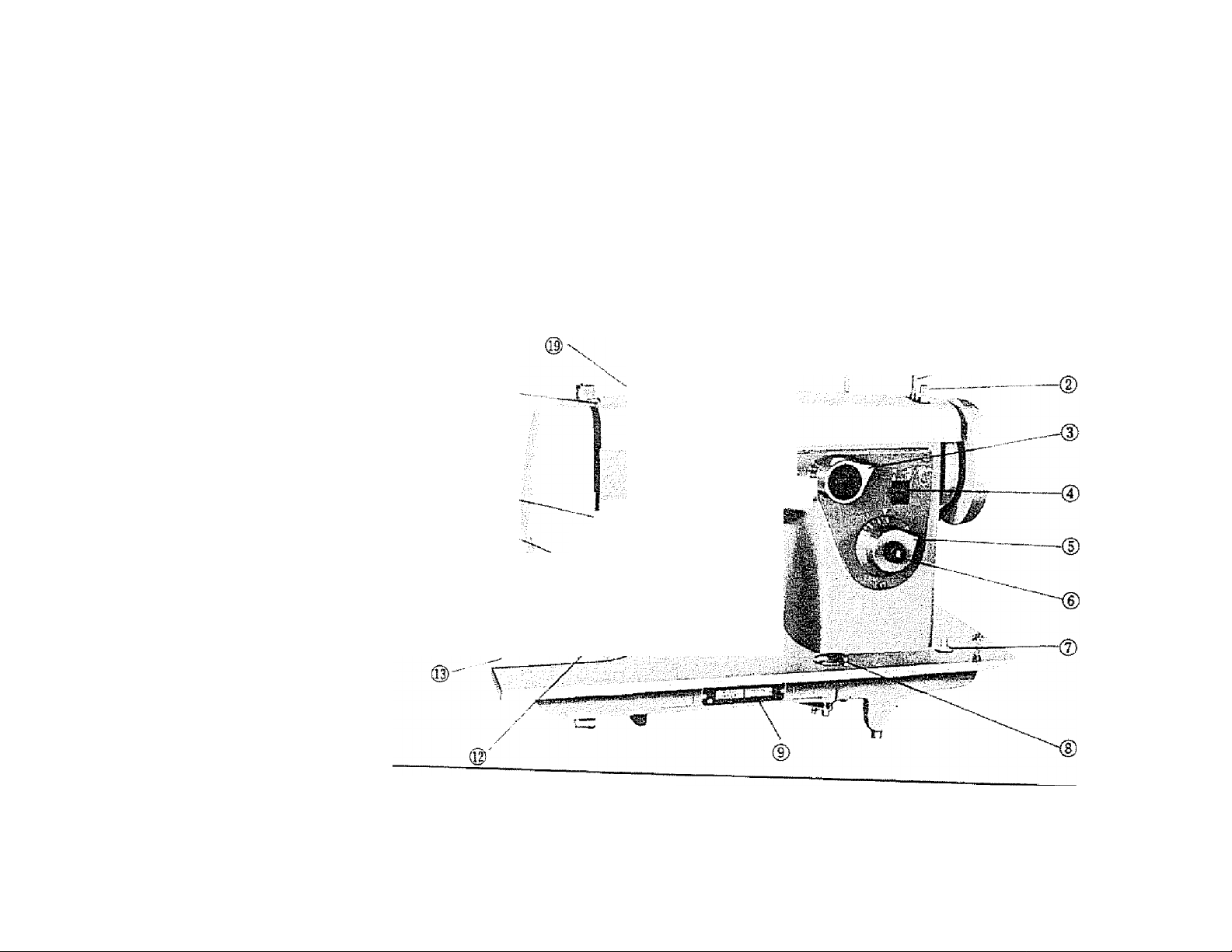

BACK VIEW

2L Presser Foot Pressure

Regulator

22. Face Plate

23. Presser Foot Lever

24. Thread Cutter

25. Hand Wheel

26. Clutch Release

2?. Thread Spool Pins

28. Blind Stitch Knob

(Modek21,1300 only)

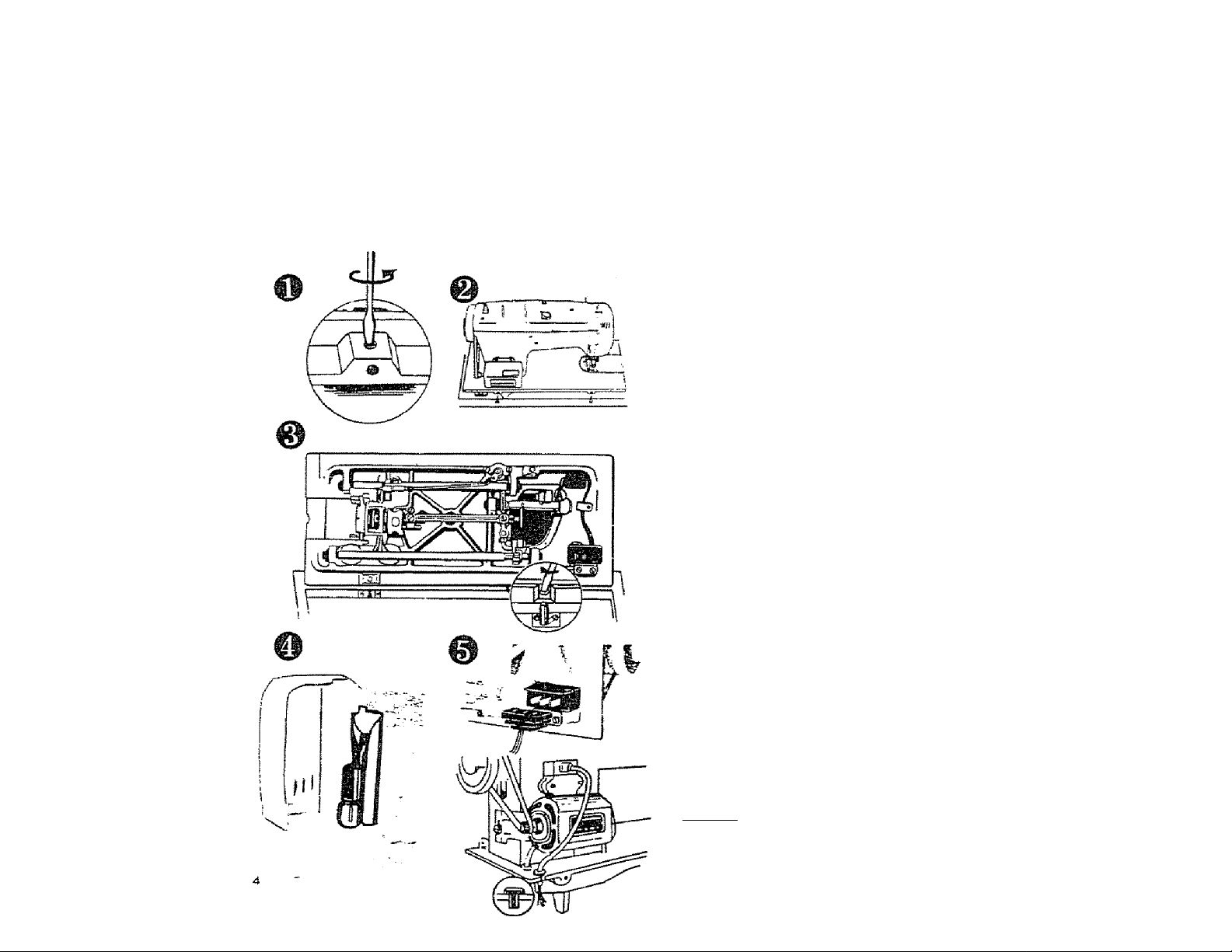

INSTALLING MACHINE HEAD IN PORTABLE

AND CABINET

Loosen the two hinge screws under holes in the rear edge of the

machine bed (1).

Raise hinge pins in the cabinet cutout (2),

Slip machine head onto the pins and tighten hinge screws securely

O).

Lower machine head to front flap.

Screw spool pins m place. Lay the plastic discs over the spool pins.

Discs and pins are packed m the accessory box.

SEWING LIGHT (Models 21, 1300 only)

The sewing light is located inside the face plate as shown.

It may be turned on or off by pushing the light switch.

To remove the buib, disconnect the sewing machine and swing open

the face plate. Push bulb in slightly, turn it counterclockwise and

remove. To replace, push new bulb in and turn clockwise. See

illustration 4.

CONNECTING MACHINE

Push foot or knee control connector onto connector under the

marbinfi bedplate, or over the motor. See illustratioii 5. Push the

two prong plug of the control into any 110*120 V. wall outlet. When

installing in cabinet. Insert grommet with cord in bedplate.

NEEDLE AND THREAD TABLE

THREAD SIZE

Cotton 60—100

Synthetic

Silk A

Cotton 60—80

Mercerized 50

Synthetic

Silk A

Cotton 40—60

Mercerized 50

Mercerized heavy duty

Cotton 30—50

Mercerized heavy duty

NEEDLE

SIZE

11

14

16

18

fabric

Sheer cottons, silks, and synthetics

Fine Laces

Medium weight cottons

Medium weight silks

Medium weight synthetics

Light weight woolens

Heavy weight cottons

Medium to heavy weight woolens

Heavy drapery fabrics

Heaviest cottons as for men's work clothes

Heaviest woolen coating

NEEDLE SIZE

Use KENMORE needles. The size of the needle should conform to the size

of the thread and both should be suitable to the material

The same size thread should be used in the bobbin as on the upper part of the

machine for ordinary sewing.

Never use a bent needle nor one with a blunt point.

This is the exact length of the needle to

be used in your machine. Comparison

with this illustration will determine

whether the needle you have is the cor

rect one for your machine.

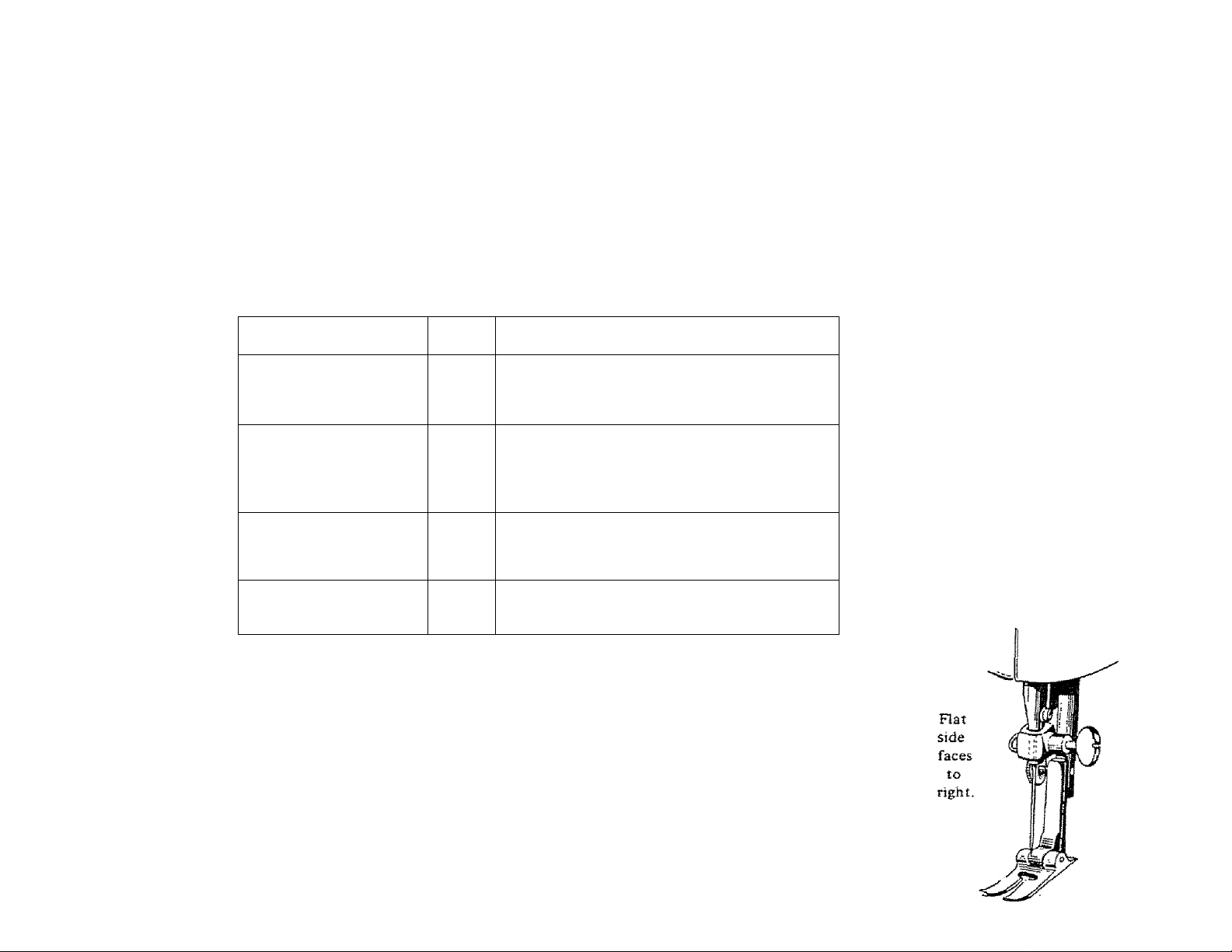

PLACEMENT OF NEEDLE

Raise take-up lever to its highest position

by turning hand wheel toward you.

Loosen needle clamp screw.

Hold needle so that the flat side is to your

right, slip blunt end of needle as far as n

will go into needle clamp.

Tighten needle into place with clamp

screw.

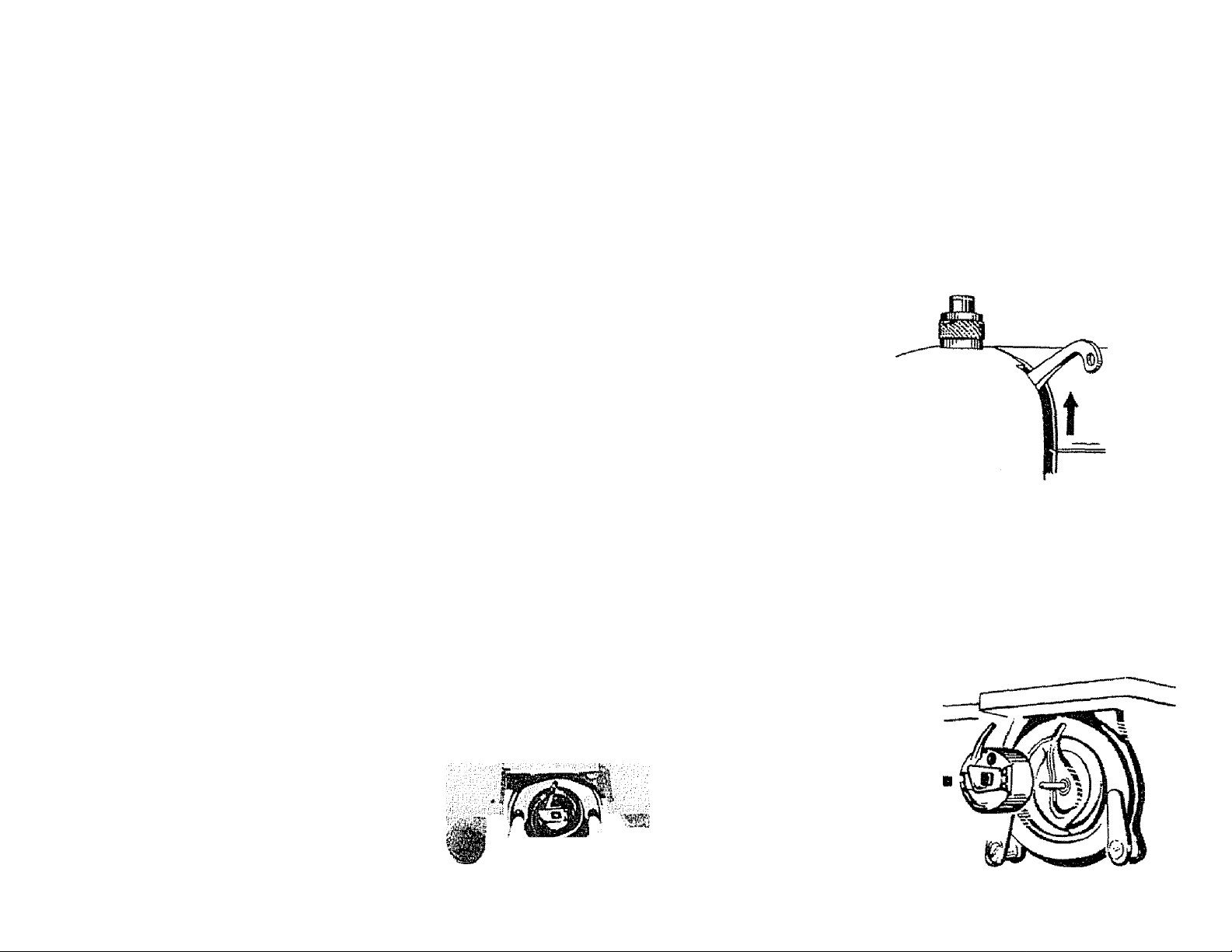

REMOVING BOBBIN CASE FROM SHUHLE

/

Puli

out

latch.

Take up

lever

at Its

highest

position.

C&¡

Pull bobbin /

case straight

out.

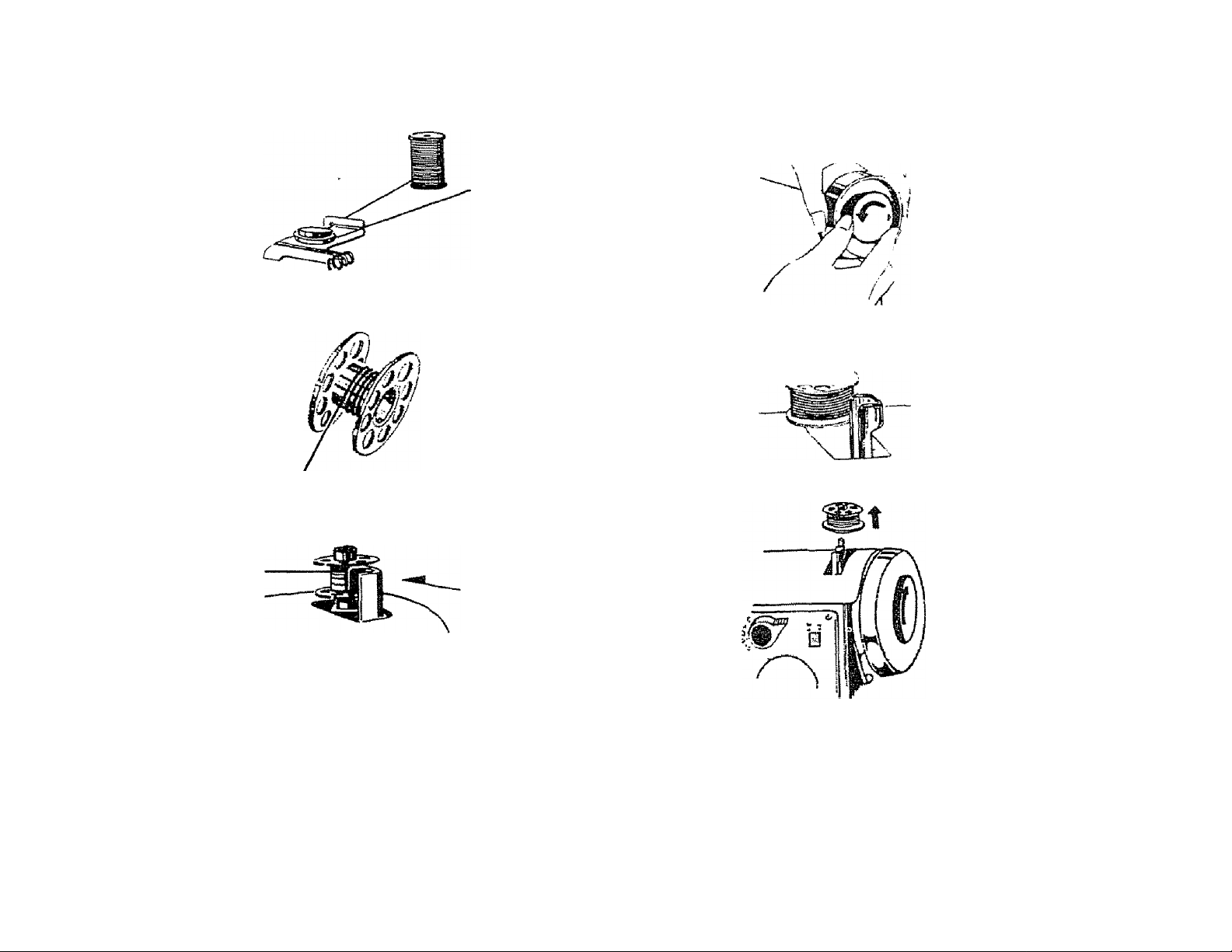

WINDING THE BOBBIN

o

Place thread on spool

post. Draw thread as

shown.

0

Wind thread around

bobbin a few times,

front to back.

m

Place bobbin onto bobbin

winder shaft.

Push bobbin winder latch

unti! it clicks.

Release clutch by turn

ing clutch knob toward

you. Start machine.

When bobbin is fuU, wind

ing mechanism stops.

Tighten clutch knob and

remove bobbin.

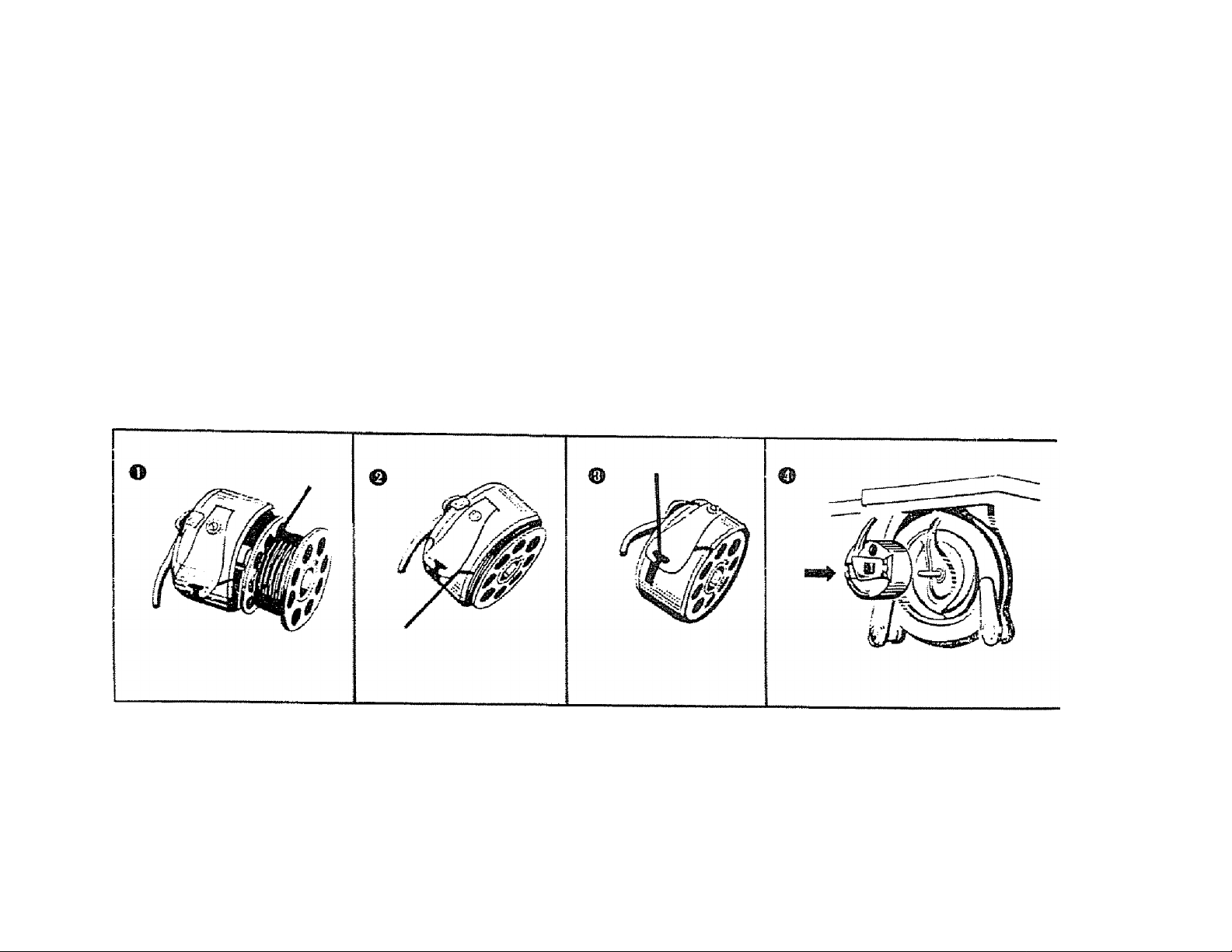

INSERTING BOBBIN INTO BOBBIN CASE...CASE INTO SHUTTLE

<1- Guide bobbin onto center pm of bobbin case.

Pull thread through slot.

Pull thread under tension spring.

O Holding latch, position case into shuttle, then release latch.

Loading...

Loading...