REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

S/M No. RFP7102000

TYPE

STEP

UP

TYPE

OPP

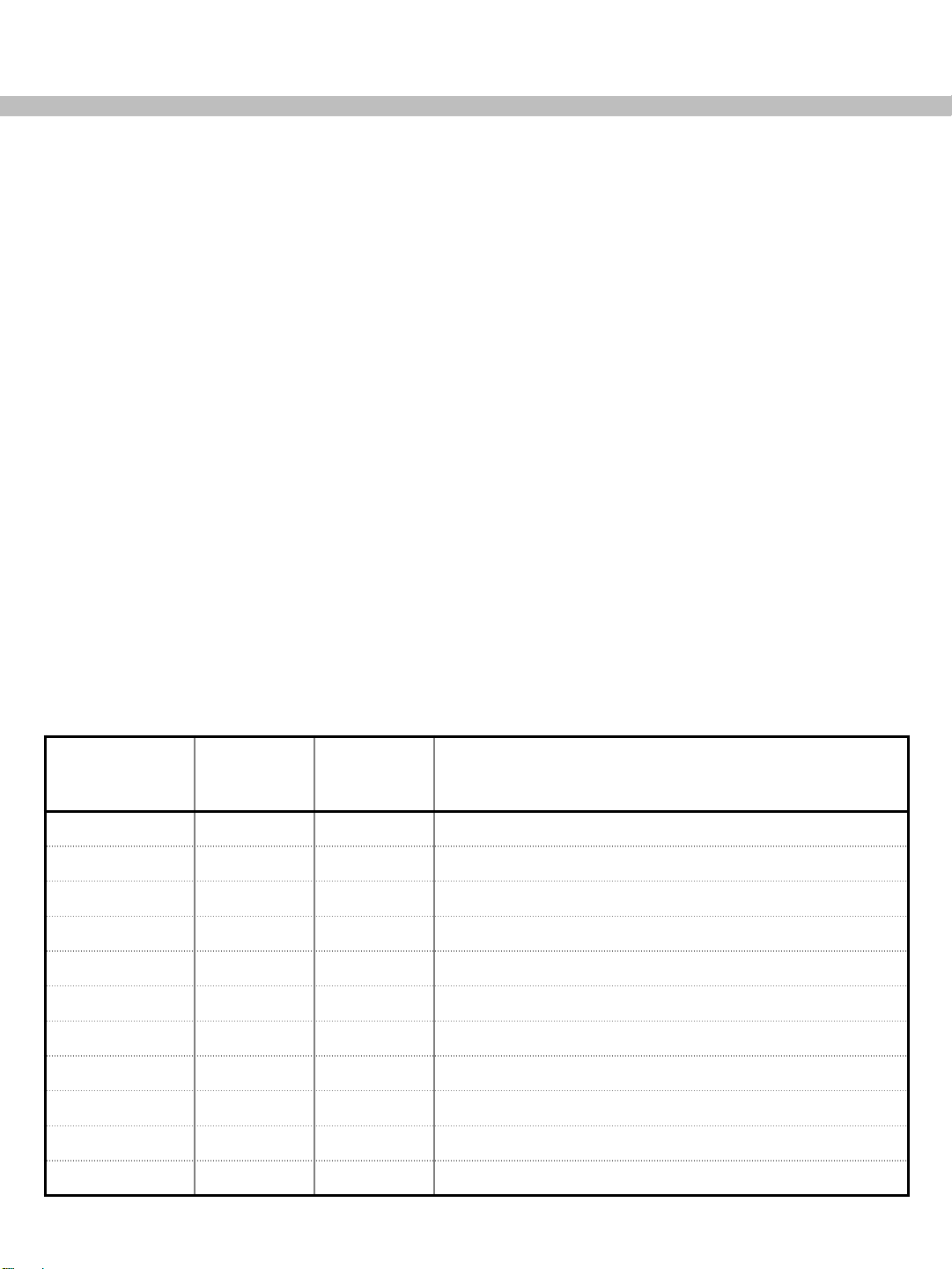

MODEL FACTORY MODEL Color

111.75505020

111.75507020

MODEL FACTORY MODEL Color

111.75035020

111.75032020

111.75039020

RFP71KETJ4E00-UEDB STAINLESS

RFP71KEBJ4E00-UEDB

RFP71KDTJ4E00-UECB STAINLESS

RFP71KDWC4E00-UECB

RFP71KDBC4E00-UECB BLACK

STAINLESS

BLACK

WHITE

√ Caution

In this manual, some parts can be changed for improving their performance without notice. So, If you need the latest parts

information, please visit and refer to PPL (Parts Price List) in Service Information Center.(http://webportal.winiadaewoo.com/sic)

Mar.2020

Content

1. Warnings and

Precautions for Safety

2. Specifications

3. Sensor / Voltage

4. External Dimensions

5. Features

6. Flow Diagram

6-1. Cold Air Flow

6-2. Water Flow

6-3. Refrigerant Flow

and Welding Point

7. Wiring Diagram

8. Operation and Function

8-1. How to Use Control Panel

8-2. Service Mode and Error Display

8-3. Compressor, Fan & Damper

……………………..…........... 5

……….…………………..…........... 10

…………………........ 4

………………...…..... 7

………………...…..... 9

……….……………........... 14

……….……………........... 15

……….…………........ 16

……….……………............ 17

……….….... 24

……... 26

……….... 28

9-5. Disconnection / Breaking

of Refrigerator Lights Ass’y

9-6. Refrigeration Failure

(Foods does not get cool or cold soon.)

9-7. Dews on Refrigerator Compartment

9-8. Comp. Operation Noise

9-9. Refrigerant Flow Sound

9-10. Fan Noise

9-11. Pipe Noise

9-12. Door opening alarm continues

though the door is closed.

10. Cooling Cycle Heavy Repair

10-1. Summary of Heavy Repair

10-2. Precautions During Heavy Repair

10-3. Practical Work for Heavy Repair

10-4. Standard Regulations

for Heavy Repair

………………….………... 45

………………….……... 46

……..…... 40

……………... 43

……………... 44

………….. 48

…………….... 52

.... 41

... 42

……. 47

.... 49

.... 50

8-4. Defrost Mode

8-5. Forced Defrost Mode

8-6. Icemaker in the Icemaker Room

8-7. Icemaker in the Freezer

8-8. Pantry Drawer

8-9. Dispenser Water/Ice Lever

8-10. Buzzer or Alarm

8-11. Compensation of Refrigerator

Sensor On/Off Temp …………….…. 35

9. How to Service

9-1. Faulty Start

(F/R lights Off, F-PCB Power Off)

9-2. Freezing Failure

(Foods are not frozen/cold.)

9-3. Ice Formation on F-Louver

9-4. Disconnection / Breaking

of Freezer Lights Ass’y

……………………….….. 28

………………….. 28

….. 29

………….... 32

………………………….. 34

……..… 34

………………….…. 34

…... 36

……..…... 37

……..…... 38

……..…... 39

11. Disassemble/Assemble Procedures

11-1. Holder Water Filter Ass’y

11-2. Water Tank and

Cover Vegetable Ass’y

11-3. Hose Ice Maker Tube Ass’y

11-4. Icemaker

11-8. Fixture Geared Motor

11-6. Pantry Drawer Cover

and Cover Multi-duct Ass’y

11-7. Refrigerator Sensor,

Pantry Drawer Sensor,

Dampers in Cover multi-Duct Ass’y

11-8. Control Panel PCB and Wires

in Pantry Drawer Cover Ass’y

11-9. Freezer Louver Ass’y

11-10. Freezer Sensor,

F Fan and Fan Motor

…………………………….. 57

…………... 53

………….….. 54

……….. 56

……………….. 58

…………...….. 59

…………...….. 60

…................. 62

…................. 63

…..... 61

Content

11-11. Refrigerator Fan

and Fan motor in Freezer

11-12. Freezer Defrost Sensor

and Heater in the Eva Ass’y

…………... 64

……..... 65

12. Service Part List

12-1. Cabinet

12-2. Machine Room

12-3. F-Room

……………………..…..….. 76

……………….………..….. 74

………………..….. 75

11-13. Sensor in Ice Maker Eva Ass’y

11-13. Heater in Ice Maker Eva Ass’y

11-14. Condenser Fan Motor

in Machine Room

11-15. Freezer and Refrigerator

Door Switch

11-16. Front Control Panel in Dispenser

11-17. Dispenser Lever Ass’y

11-18. Mullion Bar Ass’y

11-19. Interior F/R Lamp

※ Refer to user manual for installation

…………..... 68

………..... 69

…………..…. 71

………………..…. 72

………………..…. 73

Document History

Version

(S/M No.)

Date Author Description

..... 66

..... 67

…. 70

12-4. R-Room

12-5. F-Door & Handles

12-6. R-Door

……………………..…..….. 77

…………………………...….. 79

……………...….. 78

RFP7122000 2020.3/26 Lucas Register a document.

1. Warnings and Precautions for Safety

Please observe the following safety precautions in order to use safely and correctly the

refrigerator and to prevent accident and danger during repair.

1. Be care of an electric shock. Disconnect power cord from wall outlet and wait for more

than three minutes before replacing PCB parts.

Shut off the power whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than five minutes after power cord

was disconnected from the wall outlet.

3. Please check if the power plug is pressed down by the refrigerator against the wall.

If the power plug was damaged, it may cause fire or electric shock.

4. If the wall outlet is over loaded, it may cause fire.

Please use its own individual electrical outlet for the refrigerator.

5. Please make sure the outlet is properly earthed, particularly in wet or damp area.

6. Use standard electrical components when replacing them.

7. Make sure the hook is correctly engaged.

Remove dust and foreign materials from the housing and connecting parts.

8. Do not fray, damage, machine, heavily bend, pull out or twist the power cord.

9. Please check the evidence of moisture intrusion in the electrical components.

Replace the parts or mask it with insulation tapes if moisture intrusion was confirmed.

10. Do not touch the icemaker with hands or tools to confirm the operation of geared motor.

11. Do not let the customers repair, disassemble and reconstruct the refrigerator for

themselves.

It may cause accident, electric shock, or fire.

12. Do not store flammable materials such as ether, benzene, alcohol, chemicals, gas,

or medicine in the refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals, etc., or container with full of water

on the top of the refrigerator.

14. Do not put glass bottles with full of water into the freezer.

The contents shall freeze and break the glass bottles.

15. When you scrap the refrigerator, please disconnect the door gasket first and scrap it

where children are not accessible.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

4

/ 79

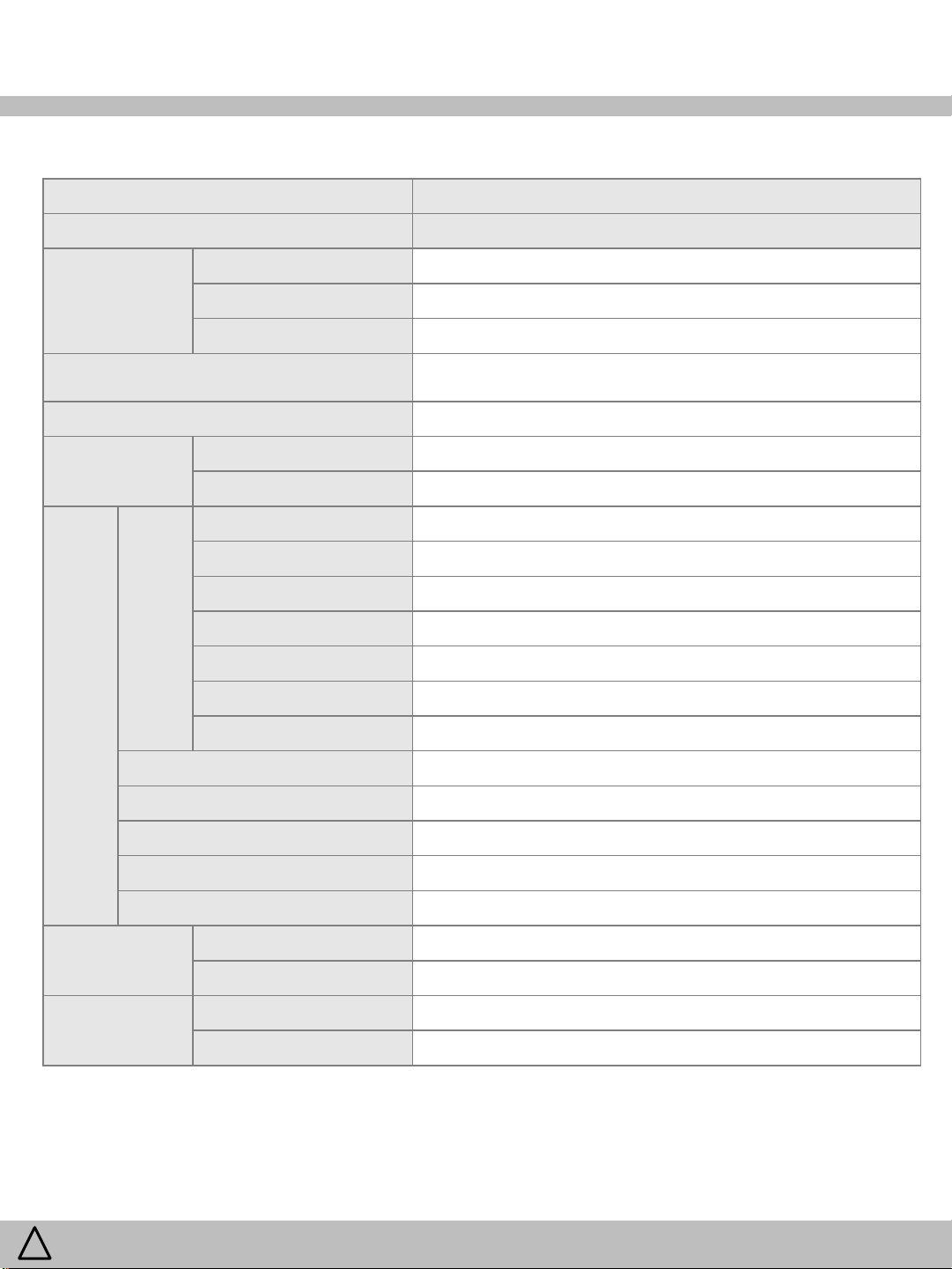

2. Specifications

Model Name 111.7550****, 111.7503****

Factory Model Name RFP71KE******-****, RFP71KD******-****

Volume

AHAM 2008

(Cu ft.)

(Width * Depth * Height)

Weight

(Kg)

Comp

C

O

O

L

I

N

G

Refrigerant R600a

Quantity 77g

Total 25.5

Freezer 7.8

Refrigerator 17.7

External Dimension

Rated Voltage 115~120V (60Hz)

Net 138

Gross (w/ Package) 151

Model NC4EVA5ALM (SAMSUNG)

Motor Type Inverter Driver

Motor Protection Running Capacitor Starting Device Type Inverter Driver

Starting Device Controller Unit (Inverter) ‘-

35.98 “ x 69.81” x 33.79” (w/o Handle)

WARNING

!

Evaporator Fin Type

Condenser Fan Cooling System

Dryer Molecular Sieve XH-9

Freezer On Right Front Side of Freezer Wall

Door Switch

Refrigerator In Top Cover Hinge

Freezer 5-LED

Lamp

Refrigerator 18-LED

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

5

/ 79

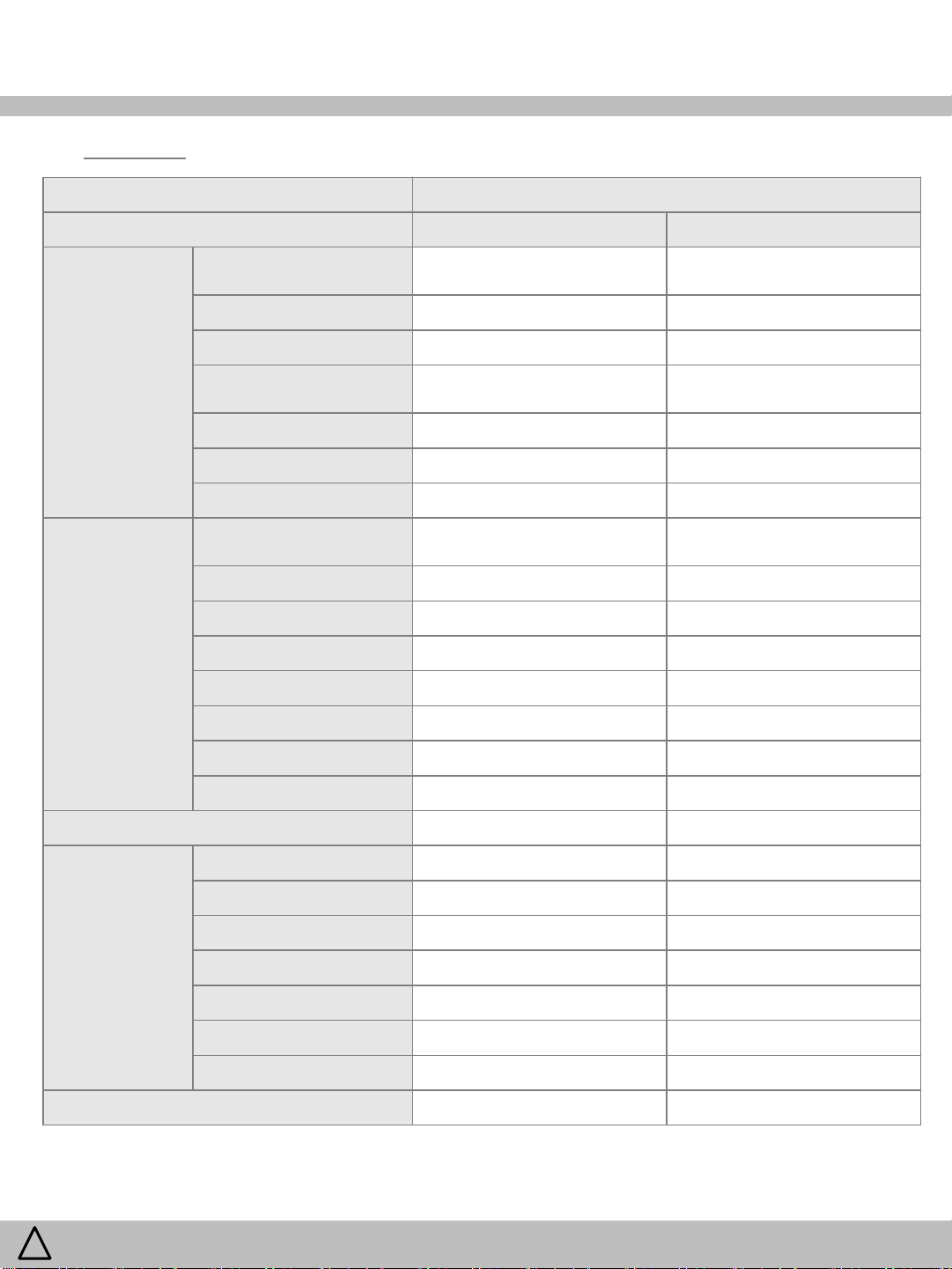

2. Specifications

(continued)

Model Name 111.7550****, 111.7503****

Factory Model Name RFP71KE******-**** RFP71KD******-****

Sensor

Heater

Defrost

Freezer In Louver Assembly

Refrigerator In Multi Flow Duct Assembly

RT

Icemaker Room Temp. In Fixture Geared Motor Assembly

Pantry Drawer Temp. In Multi Flow Duct Assembly

Water Flow In Valve Water Assembly

Freezer Eva.

Icemaker Eva. AC120V / 40W / 360Ω / Sheath

Division AC115V / 6W / 2028 ~ 2380Ω

Water Tank N/A

Dispenser Ice Flap N/A

R Motor behind Eva N/A

Icemaker Water Hose No Service Part

In Evaporator Assembly,

In Icemaker Evaporator Assembly

Between Top Cabinet and Top

Cover Hinge

AC120V / 380W / 35 ~ 41Ω /

Sheath

WARNING

!

Motor

Icemaker Room Heater N/A

Fuse Temp (Defrost)

Freezer Fan DC12V / DREP9020LJ

Refrigerator Fan DC12V / DREP9020LL

Condenser Fan DC13V / D4612AAA28

Dispenser Ice Shut DC 12V / STAB040D01

Ice Crusher 120V / 60Hz / ISG-3240DED

Ice Type Selector DC12V / STAB04D01

Ice Maker Fan DC12V / ODM-016F-57A

Damper DC12V / DU24-113 / 1pcs N/A

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

AC250V , 10A , 77℃

6

/ 79

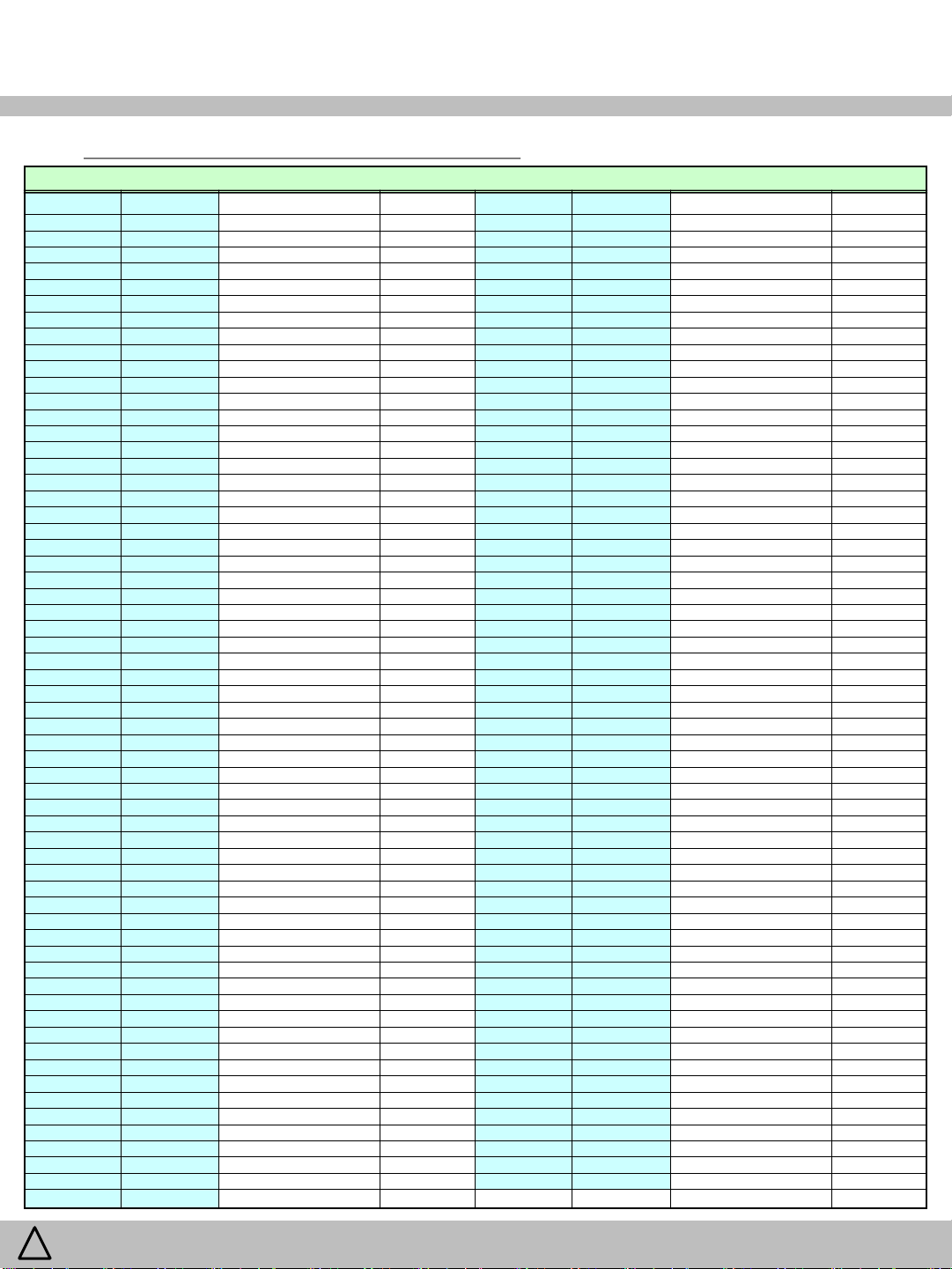

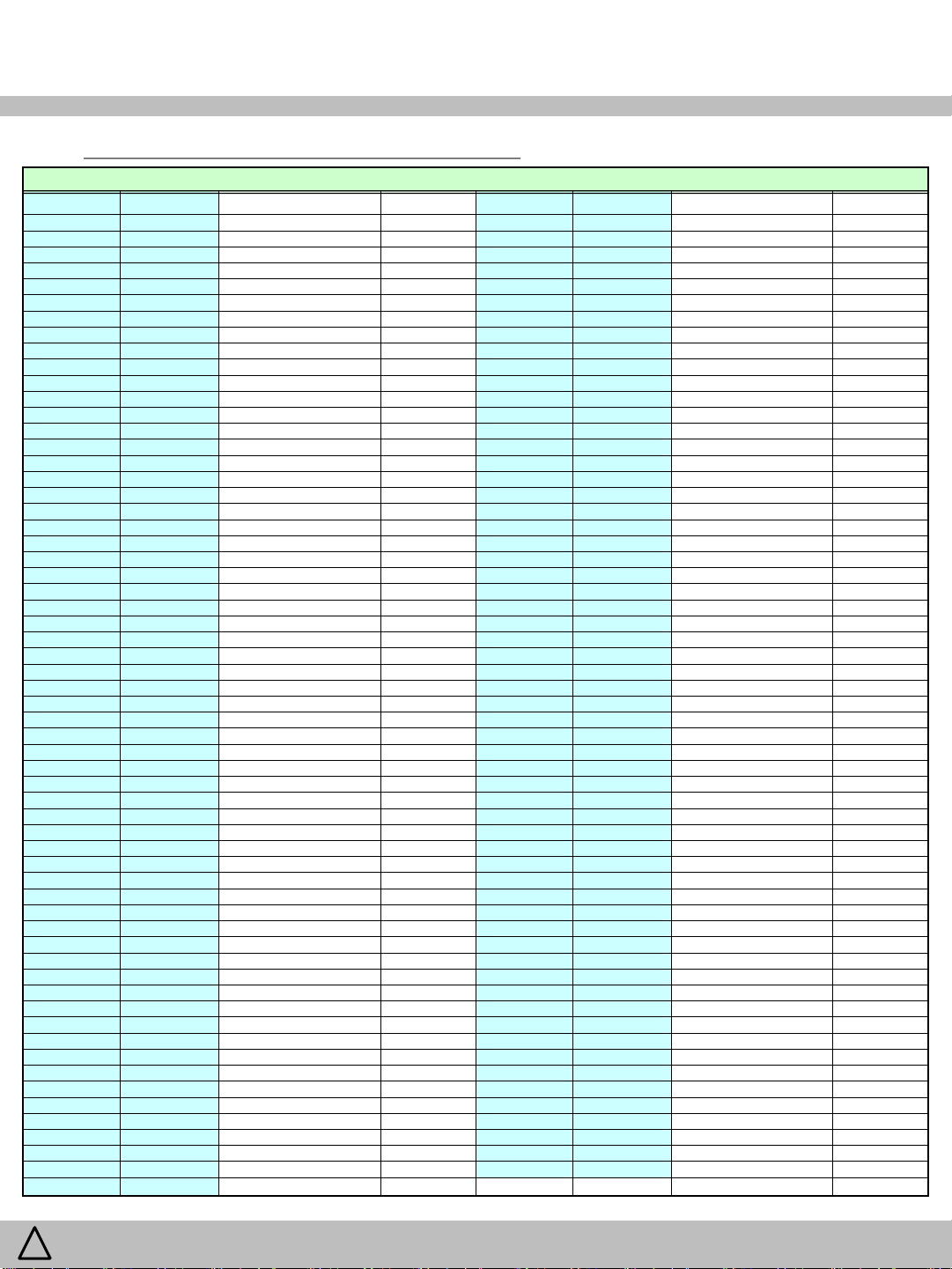

3. Sensor / Voltage

(Table of sensor resistance and measured voltage)

R, Pantry, Ice Maker, F Defrost, R Defrost, I/M Defrost, RT SENSOR

Temp(℉) Temp(℃) Resistance(kΩ) DC Volts Temp(℉) Temp(℃) Resistance(kΩ) DC Volts

-22.0 -30.0 129.30 4.02 32.9 0.5 29.34 2.42

-21.1 -29.5 125.90 4.00 33.8 1.0 28.71 2.39

-20.2 -29.0 122.50 3.98 34.7 1.5 28.08 2.36

-19.3 -28.5 119.30 3.96 35.6 2.0 27.47 2.33

-18.4 -28.0 116.20 3.94 36.5 2.5 26.88 2.31

-17.5 -27.5 113.20 3.91 37.4 3.0 26.30 2.28

-16.6 -27.0 110.20 3.89 38.3 3.5 25.74 2.25

-15.7 -26.5 107.40 3.87 39.2 4.0 25.19 2.23

-14.8 -26.0 101.60 3.82 40.1 4.5 24.65 2.20

-13.9 -25.5 101.90 3.82 41.0 5.0 24.13 2.17

-13.0 -25.0 99.30 3.80 41.9 5.5 23.62 2.15

-12.1 -24.5 96.70 3.77 42.8 6.0 23.12 2.12

-11.2 -24.0 94.30 3.75 43.7 6.5 22.63 2.09

-10.3 -23.5 91.90 3.73 44.6 7.0 22.15 2.07

-9.4 -23.0 89.60 3.70 45.5 7.5 21.69 2.04

-8.5 -22.5 87.30 3.68 46.4 8.0 21.24 2.02

-7.6 -22.0 85.10 3.65 47.3 8.5 20.80 1.99

-6.7 -21.5 83.00 3.63 48.2 9.0 20.36 1.97

-5.8 -21.0 80.90 3.60 49.1 9.5 19.94 1.94

-4.9 -20.5 78.90 3.58 50.0 10.0 19.53 1.92

-4.0 -20.0 76.90 3.55 50.9 10.5 19.13 1.89

-3.1 -19.5 75.00 3.52 51.8 11.0 18.74 1.87

-2.2 -19.0 78.20 3.57 52.7 11.5 18.35 1.84

-1.3 -18.5 71.40 3.47 53.6 12.0 17.98 1.82

-0.4 -18.0 69.60 3.45 54.5 12.5 17.61 1.80

0.5 -17.5 67.90 3.42 55.4 13.0 17.26 1.77

1.4 -17.0 66.30 3.39 56.3 13.5 16.91 1.75

2.3 -16.5 64.70 3.37 57.2 14.0 16.37 1.71

3.2 -16.0 63.10 3.34 58.1 14.5 16.26 1.71

4.1 -15.5 61.60 3.31 59.0 15.0 15.91 1.68

5.0 -15.0 60.10 3.28 59.9 15.5 15.59 1.66

5.9 -14.5 58.60 3.26 60.8 16.0 15.28 1.64

6.8 -14.0 57.20 3.23 61.7 16.5 14.98 1.61

7.7 -13.5 55.90 3.20 62.6 17.0 14.66 1.59

8.6 -13.0 54.60 3.17 63.5 17.5 14.39 1.57

9.5 -12.5 53.30 3.15 64.4 18.0 14.10 1.55

10.4 -12.0 52.00 3.12 65.3 18.5 13.83 1.53

11.3 -11.5 50.80 3.09 66.2 19.0 13.56 1.51

12.2 -11.0 49.60 3.06 67.1 19.5 13.29 1.49

13.1 -10.5 48.70 3.04 68.0 20.0 13.03 1.47

14.0 -10.0 47.30 3.01 68.9 20.5 12.78 1.45

14.9 -9.5 46.20 2.98 69.8 21.0 12.53 1.43

15.8 -9.0 45.10 2.95 70.7 21.5 12.29 1.41

16.7 -8.5 44.10 2.92 71.6 22.0 12.05 1.39

17.6 -8.0 43.10 2.89 72.5 22.5 11.82 1.37

18.5 -7.5 42.10 2.86 73.4 23.0 11.60 1.35

19.4 -7.0 41.10 2.83 74.3 23.5 11.37 1.33

20.3 -6.5 40.30 2.81 75.2 24.0 11.16 1.31

21.2 -6.0 39.30 2.78 76.1 24.5 10.95 1.29

22.1 -5.5 37.90 2.73 77.0 25.0 10.74 1.27

23.0 -5.0 37.50 2.72 77.9 25.5 10.54 1.26

23.9 -4.5 36.70 2.69 78.8 26.0 10.34 1.24

24.8 -4.0 35.80 2.66 79.7 26.5 10.14 1.22

25.7 -3.5 35.00 2.64 80.6 27.0 9.945 1.20

26.6 -3.0 34.30 2.61 81.5 27.5 9.768 1.19

27.5 -2.5 33.50 2.58 82.4 28.0 9.586 1.17

28.4 -2.0 32.70 2.55 83.3 28.5 9.408 1.15

29.3 -1.5 32.00 2.52 84.2 29.0 9.234 1.14

30.2 -1.0 31.30 2.50 85.1 29.5 9.063 1.12

31.1 -0.5 30.60 2.47 86.0 30.0 8.896 1.10

32.0 0.0 30.00 2.44

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

7

/ 79

3. Sensor / Voltage

(Table of sensor resistance and measured voltage)

F Sensor

Temp(℉) Temp(℃) Resistance(kΩ) DC Volts Temp(℉) Temp(℃) Resistance(kΩ) DC Volts

-22.0 -30.0 39.652 3.04 32.9 0.5 7.692 1.16

-21.1 -29.5 38.495 3.01 33.8 1.0 7.508 1.14

-20.2 -29.0 37.375 2.97 34.7 1.5 7.328 1.12

-19.3 -28.5 36.291 2.94 35.6 2.0 7.153 1.10

-18.4 -28.0 35.242 2.90 36.5 2.5 6.983 1.07

-17.5 -27.5 34.227 2.87 37.4 3.0 6.818 1.05

-16.6 -27.0 33.240 2.83 38.3 3.5 6.656 1.03

-15.7 -26.5 31.372 2.76 39.2 4.0 6.500 1.02

-14.8 -26.0 30.926 2.74 40.1 4.5 6.347 1.00

-13.9 -25.5 30.480 2.72 41.0 5.0 6.198 0.98

-13.0 -25.0 29.616 2.69 41.9 5.5 6.054 0.96

-12.1 -24.5 28.780 2.65 42.8 6.0 5.913 0.94

-11.2 -24.0 27.970 2.62 43.7 6.5 5.776 0.92

-10.3 -23.5 27.185 2.58 44.6 7.0 5.642 0.91

-9.4 -23.0 26.425 2.54 45.5 7.5 5.512 0.89

-8.5 -22.5 25.686 2.51 46.4 8.0 5.386 0.87

-7.6 -22.0 24.974 2.47 47.3 8.5 5.262 0.86

-6.7 -21.5 24.283 2.44 48.2 9.0 5.142 0.84

-5.8 -21.0 23.612 2.40 49.1 9.5 5.025 0.82

-4.9 -20.5 22.963 2.37 50.0 10.0 4.911 0.81

-4.0 -20.0 22.333 2.33 50.9 10.5 4.800 0.79

-3.1 -19.5 21.722 2.30 51.8 11.0 4.691 0.78

-2.2 -19.0 21.130 2.27 52.7 11.5 4.586 0.76

-1.3 -18.5 20.557 2.23 53.6 12.0 4.483 0.75

-0.4 -18.0 20.000 2.20 54.5 12.5 4.383 0.73

0.5 -17.5 19.460 2.16 55.4 13.0 4.285 0.72

1.4 -17.0 18.937 2.13 56.3 13.5 4.190 0.71

2.3 -16.5 18.429 2.10 57.2 14.0 4.097 0.69

3.2 -16.0 17.937 2.06 58.1 14.5 4.007 0.68

4.1 -15.5 17.459 2.03 59.0 15.0 3.918 0.67

5.0 -15.0 16.995 2.00 59.9 15.5 3.832 0.65

5.9 -14.5 16.545 1.97 60.8 16.0 3.749 0.64

6.8 -14.0 16.109 1.94 61.7 16.5 3.668 0.63

7.7 -13.5 15.635 1.90 62.6 17.0 3.587 0.62

8.6 -13.0 15.274 1.87 63.5 17.5 3.509 0.60

9.5 -12.5 14.875 1.84 64.4 18.0 3.433 0.59

10.4 -12.0 14.487 1.81 65.3 18.5 3.350 0.58

11.3 -11.5 14.111 1.78 66.2 19.0 3.287 0.57

12.2 -11.0 13.746 1.75 67.1 19.5 3.217 0.56

13.1 -10.5 13.391 1.72 68.0 20.0 3.148 0.55

14.0 -10.0 13.047 1.69 68.9 20.5 3.081 0.54

14.9 -9.5 14.712 1.83 69.8 21.0 3.015 0.53

15.8 -9.0 12.387 1.63 70.7 21.5 2.927 0.51

16.7 -8.5 12.072 1.61 71.6 22.0 2.839 0.50

17.6 -8.0 11.765 1.58 72.5 22.5 2.829 0.50

18.5 -7.5 11.467 1.55 73.4 23.0 2.769 0.49

19.4 -7.0 11.176 1.52 74.3 23.5 2.711 0.48

20.3 -6.5 10.897 1.50 75.2 24.0 2.655 0.47

21.2 -6.0 10.624 1.47 76.1 24.5 2.600 0.46

22.1 -5.5 10.358 1.44 77.0 25.0 2.546 0.45

23.0 -5.0 10.109 1.42 77.9 25.5 2.493 0.45

23.9 -4.5 9.849 1.39 78.8 26.0 2.442 0.44

24.8 -4.0 9.605 1.37 79.7 26.5 2.392 0.43

25.7 -3.5 9.368 1.34 80.6 27.0 2.343 0.42

26.6 -3.0 9.138 1.32 81.5 27.5 2.295 0.41

27.5 -2.5 8.913 1.30 82.4 28.0 2.246 0.40

28.4 -2.0 8.696 1.27 83.3 28.5 2.202 0.40

29.3 -1.5 8.484 1.25 84.2 29.0 2.158 0.39

30.2 -1.0 8.277 1.23 85.1 29.5 2.114 0.38

31.1 -0.5 8.077 1.20 86.0 30.0 2.072 0.38

32.0 0.0 7.882 1.18

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

8

/ 79

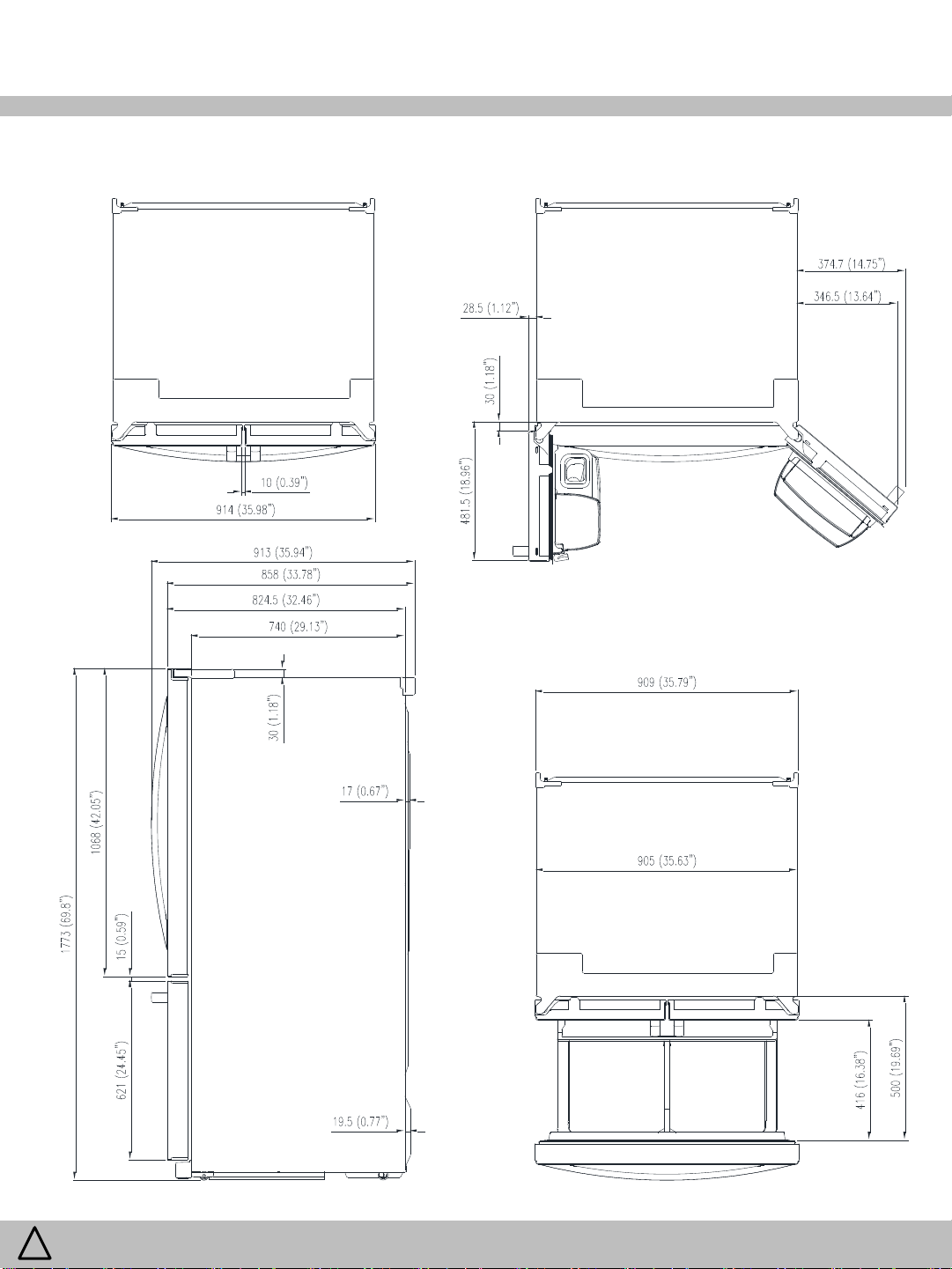

4. External Dimensions

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

9

/ 79

5. Features

5-1. Exterior

Front Control

Panel

LED, Touch

Water and Ice

Dispenser

1 Levers

Freezer Handle

Sticker written “F”

inside handle for

correct assembly

Refrigerator Handle

Sticker written “R”

inside handles for

correct assembly

WARNING

!

Included Parts

Hex Wrench(2.5mm) in User Manual Bag, Standoff

Screws on doors

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

10

/ 79

5. Features

5-2. Interior

Air Filter Cover

Icemaker Compartment

Icemaker and Ice Bin

Water Filter Filter Cover

Foldable Shelf

fixed by magnet

after folding

Slid Away Split

Shelf

Dispenser

Bin

Fixed

Shelves

Adjustable,

Spill proof

Small Bin

Fixed

Bottom Bin

Mullion Bar

- Temperature Controlled

Pantry Drawer(RFP71KE*)

3 Steps Select Produce / Deli / Meat

Dairy Bin

Utility Bin

Adjustable

Gallon Bin

Adjustable

Bottom Bin

Adjustable

Auto Pull Out Drawer

Humidity Controlled

Crisper

Vegetable & Fruit

- Wide Pantry

Drawer(RFP71KD*)

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Button Door Switch

Freezer Base Drawer

11

/ 79

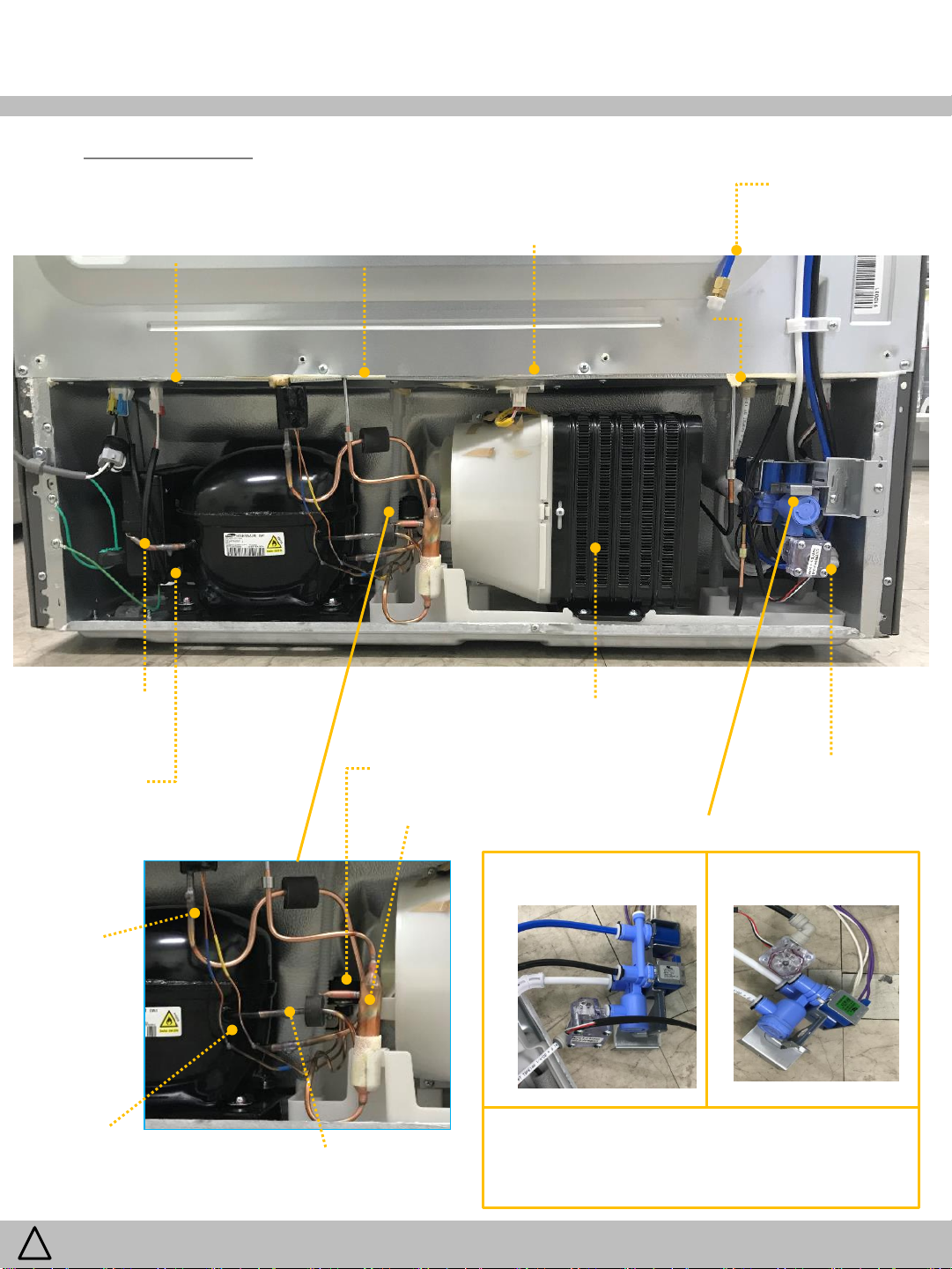

5. Features

5-3. Machine Room

Inverter Controller

Signal Connector

Hot Pipe

(Outlet)

Condenser Fan

Connector(front)

Step Valve

Connector(back)

Water Filter Inlet

1/4 “ Tube)

Hot Pipe

(Inlet)

Process Part

in Compressor

Inverter

Controller

Pipe Suction

Conn

Capillary Tube

- Blue : F Eva.

- Yellow : Ice Maker Eva.

Step Valve

Dryer

Pipe Condenser Conn

(Discharge Part)

Condenser

Flow Sensor

in Valve Water

Valve Water

MODEL : RFP71KE** MODEL : RFP71KD**

①

④

①

③

②

① Black(1/4”) – Ice Maker Tube(R room)

② White(1/4”) – Water Filter Outlet

③ White(5/16”) – Water Tank Inlet

④ Blue(1/4”) - Ice Maker tube(F room)

③

②

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

12

/ 79

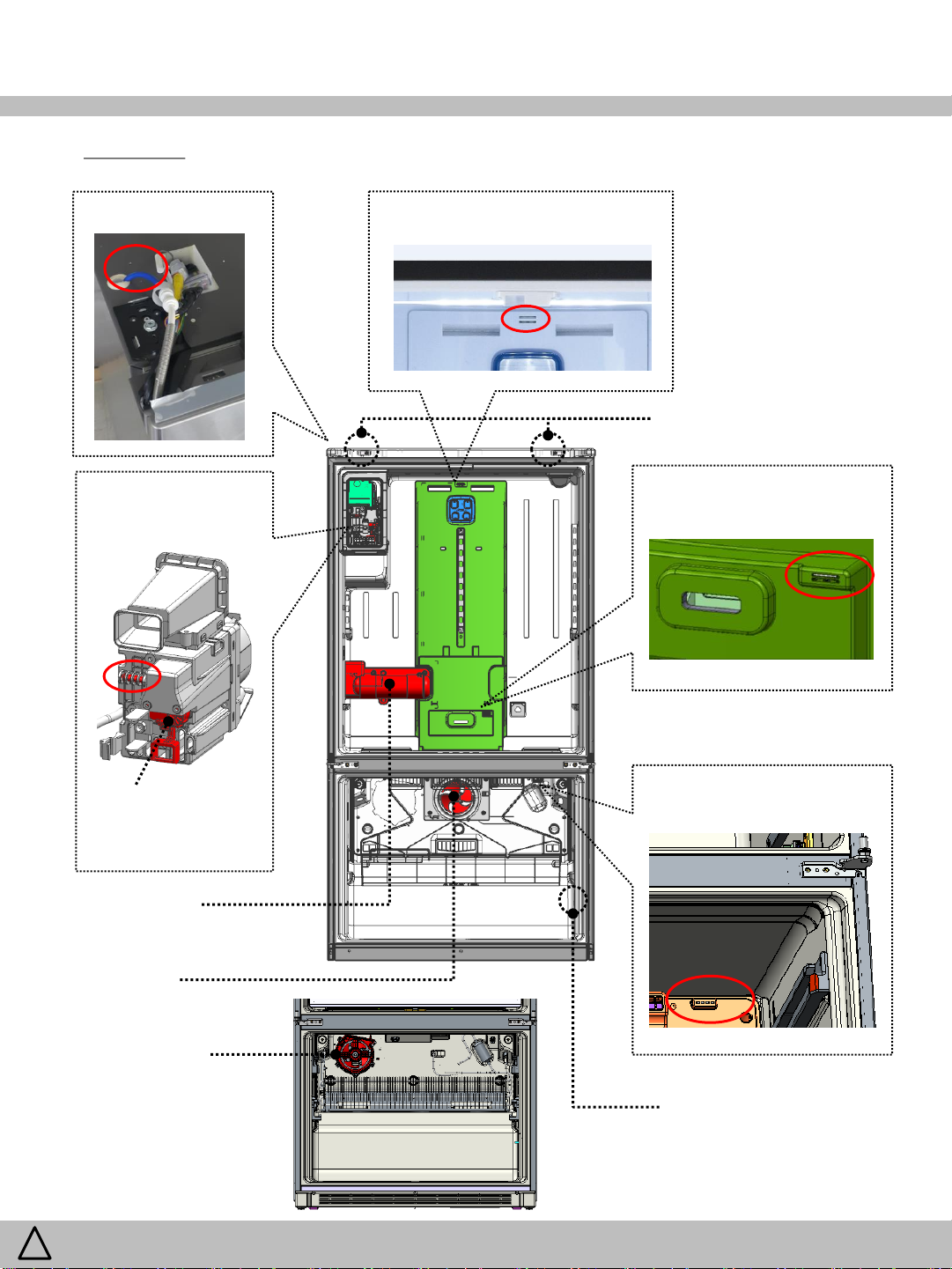

5. Features

5-4. Others

RT Sensor Refrigerator Sensor

Refrigerator Door Switches

Icemaker

Room Sensor

Ice Type

(Cubed/Crushed)

Selector

Water Tank

Assembly

Freezer

Fan Motor

Pantry

Drawer Sensor

Freezer Sensor

WARNING

!

Refrigerator

Fan Motor

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Freezer Door Switch

13

/ 79

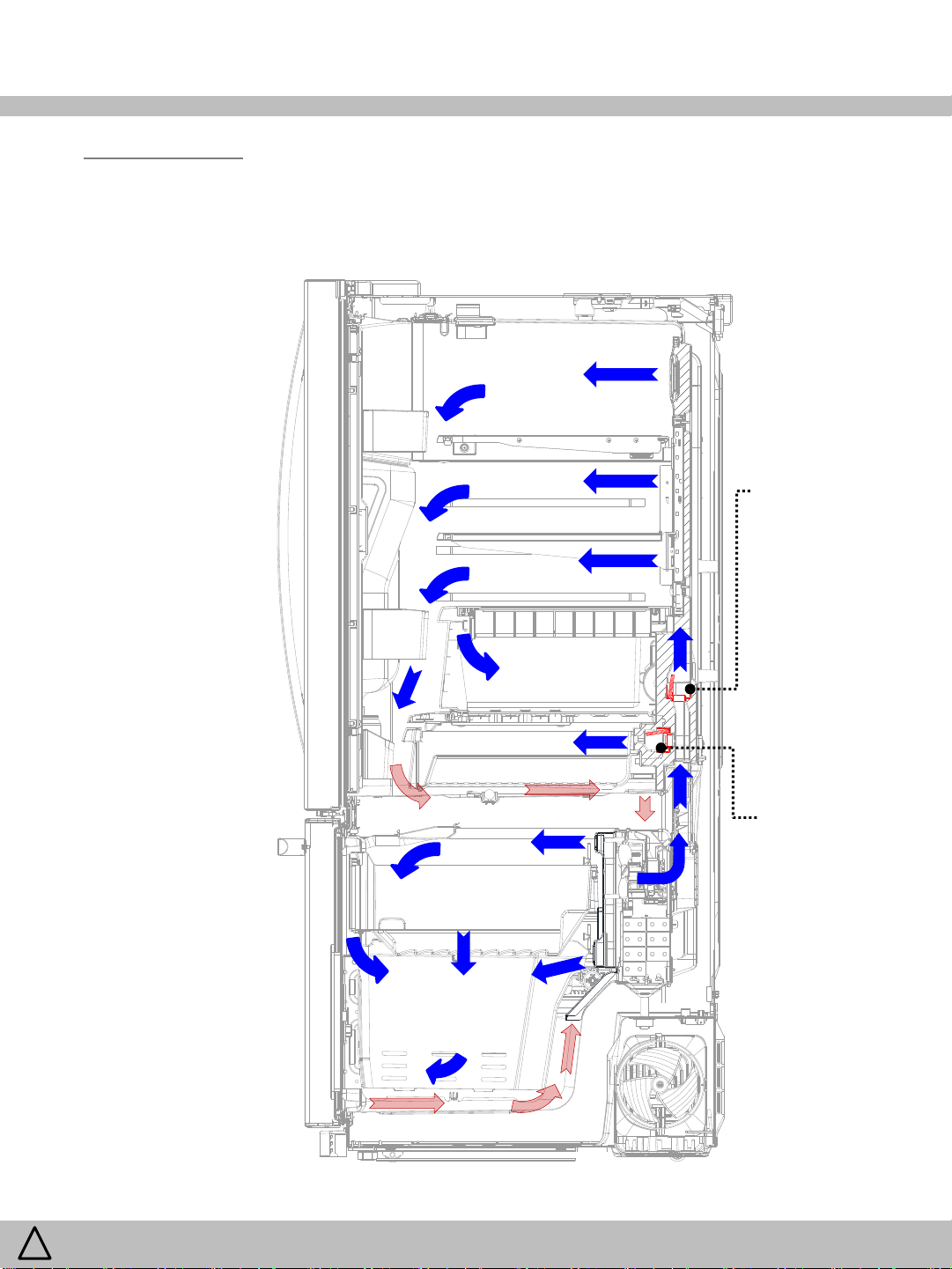

6. Flow Diagram

6-1. Cold Air Flow

Refrigerator

Compartment

Damper

Control Air of

Refrigerator

WARNING

!

Freezer

Compartment

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Damper

Control Air of Pantry

Drawer

(RFP71KE*)

14

/ 79

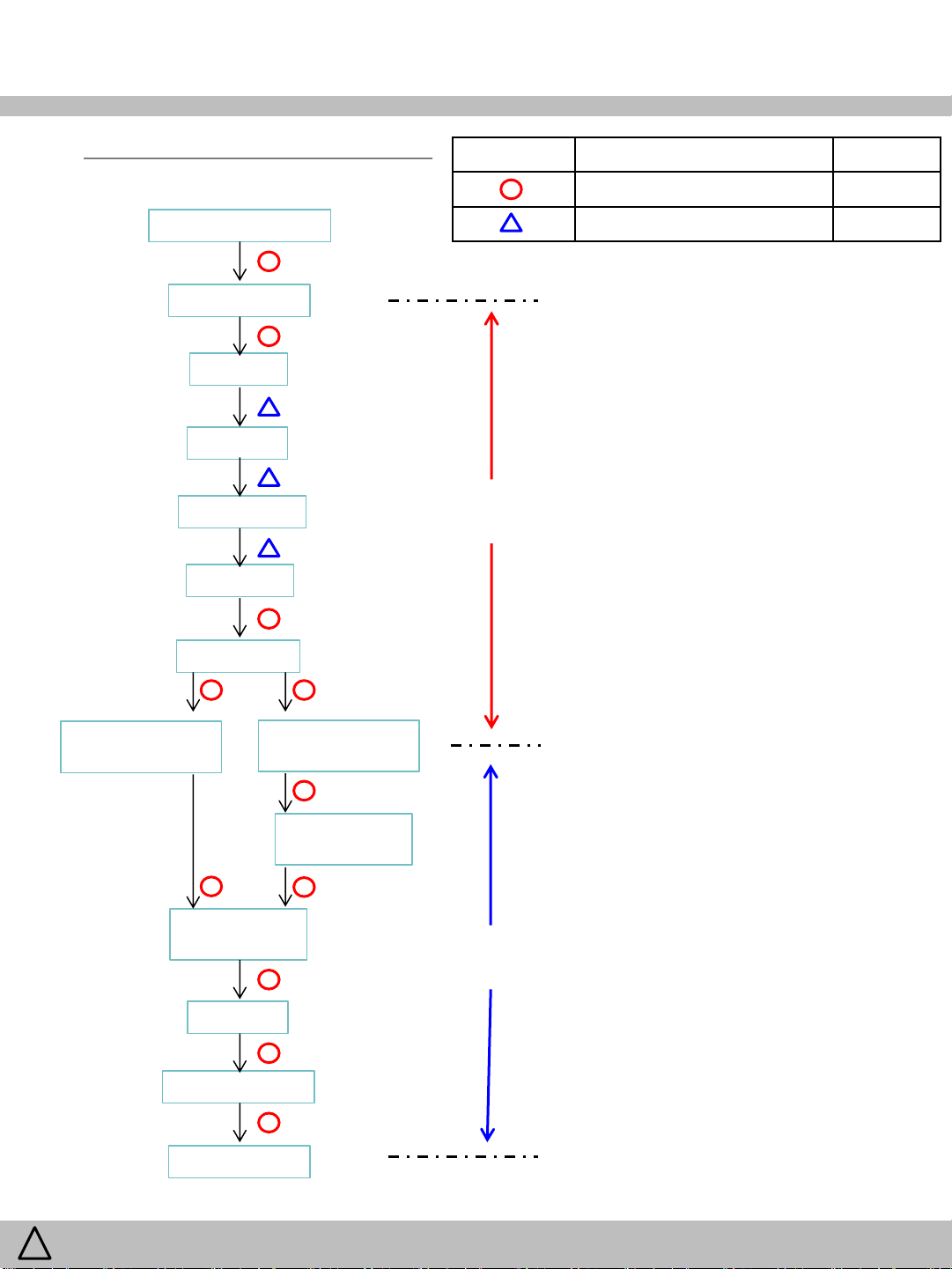

6. Flow Diagram

6-2. Water Flow

RFP71KE*

Main

Water

RFP71KD*

Main

Water

Water

Filter

Water

Filter

□ Water Supply Pressure must be :

Flow

Sensor

Water

Valve

Water

Valve

Water

Tank

Flow

Sensor

Water

Tank

Icemaker

(R Room)

Icemaker

(F Room)

Water

Dispenser

Icemaker

(R Room)

Water

Dispenser

Min 30psi (207kPa, 2.1kgf/㎠)

Max 125psi (862Kpa, 8.8kgf/㎠)

※ If the water pressure exceeds 125psi,

a pressure reducing valve must be installed.

※ If the water pressure is under 30psi,

a booster pump must be installed.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

15

/ 79

6. Flow Diagram

6-3. Refrigerant Flow and Welding Point

PIPE SVC(Discharge)

COMPRESSOR

PIPE DEL

PIPE HOT

CONDENSER

DRYER AS

STEP VALVE

CAPILLARY TUBE

(BLUE)

EVAPORATOR

(F Room)

CAPILLARY TUBE

(YELLOW)

EVAPORATOR

(Ice maker)

SYMBOL METHOD POINTS

Copper Welding (Ag 3%) 11

Lokring 3

You can force open all the step valve for 2

evaporators by following the next steps:

1. Lock inner PCB

2. While pressing the “Refrigerator Temp”

and “Freezer Temp” buttons, then

press “Light” button 5 times

High Temperature

High Pressure

Refrigerant flow system :

When the refrigerator valve is open, the

refrigerant flows through the icemaker and

freezer compartment.

When the icemaker valve is open, the

refrigerant flows through the freezer and

icemaker compartment.

When the freezer valve is open, the

refrigerant flows through the freezer

compartment only.

There is no way to force open each

individual valve.

Low Temperature

Low Pressure

WARNING

!

PIPE SUC

PIPE SUC CONN

COMPRESSOR

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

16

/ 79

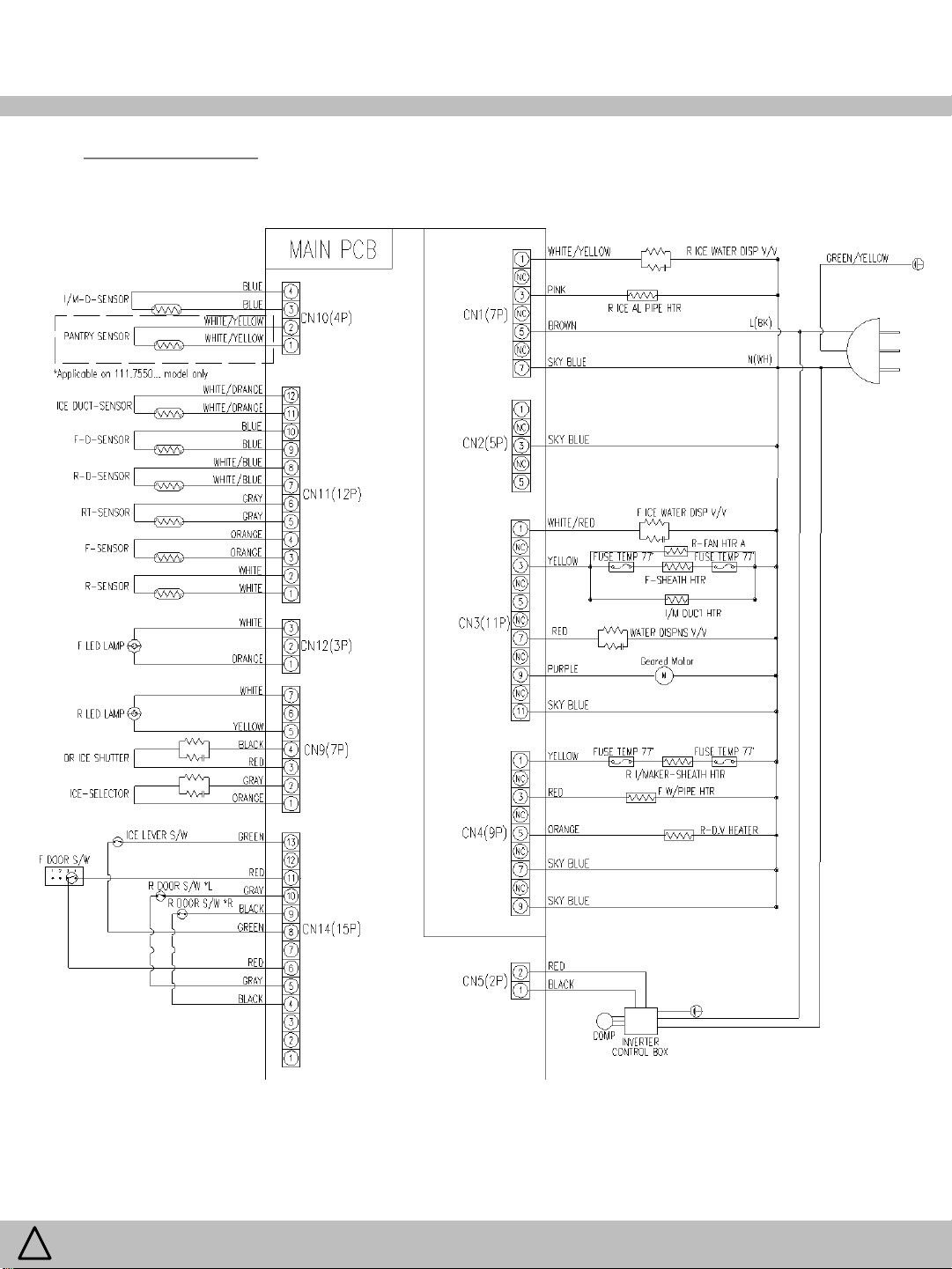

7. Wiring Diagram

7-1. Total View(1/2)

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

17

/ 79

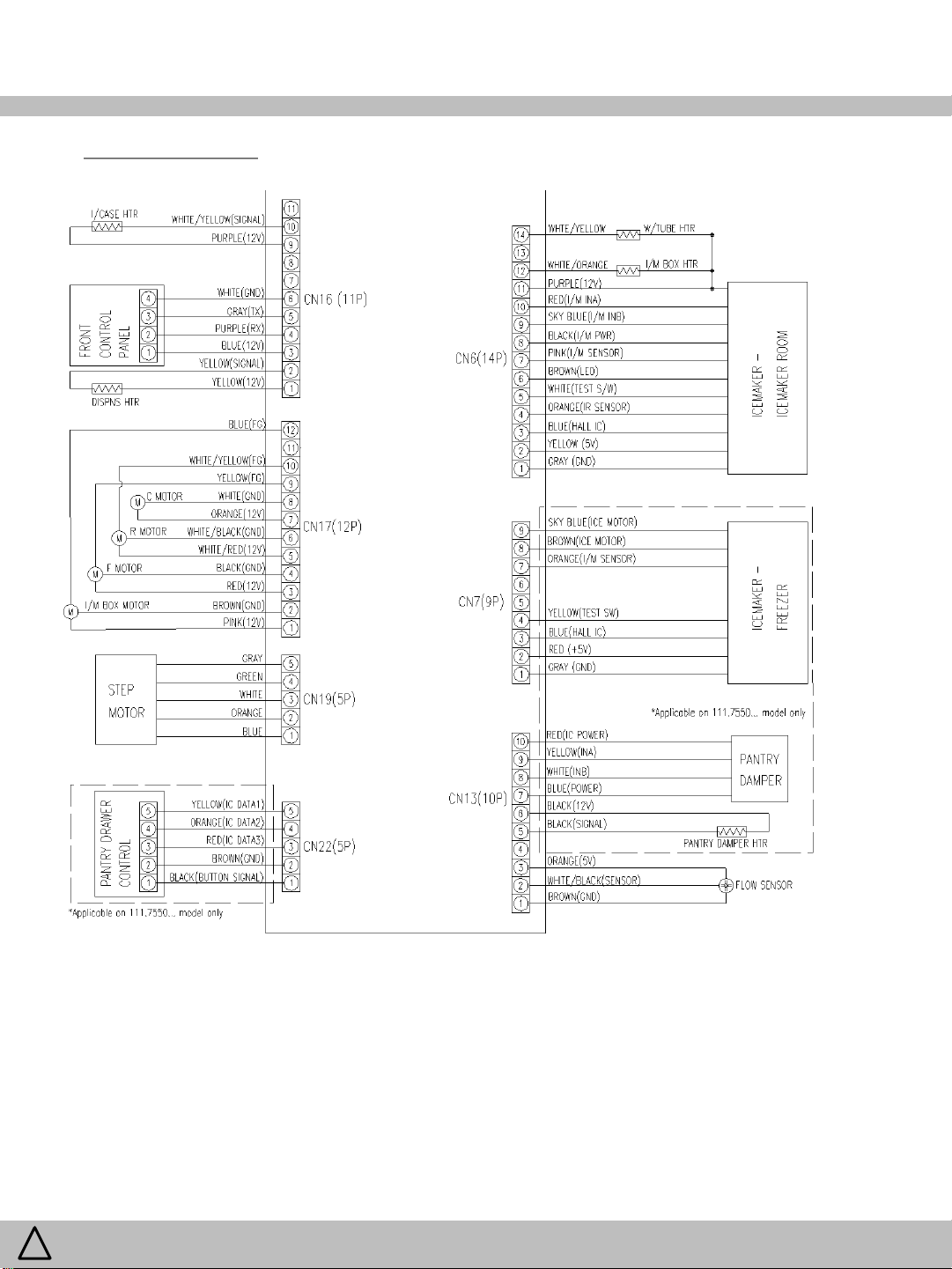

7. Wiring Diagram

7-1. Total View(2/2)

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

18

/ 79

7. Wiring Diagram

7-2. Part View – Sensors

CN11

CN10

7-3. Part View – Eva Heater (SHEATH HTR)

CN4

CN3

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

19

/ 79

7. Wiring Diagram

5 & 10

8 & 13

6 & 11

4 & 9

1 & 2

Frequency (Compressor Power

Consumption

the

7-4. Dispenser, DV(Mullion Bar), I/CASE Heater Operation

7-4-1. The dispenser heater is always on.

7-4-2. The DV heater is always on and located Between refrigerator doors.

7-4-3. The I/CASE heater cycles which is located inside the icemaker helps to remove residual

ice from the ice case.

The heater turns on when the temperature reaches 21.2°F(-6°C) on and turns off

when the temperature reaches 28.4°F(-2°C)

7-5. Other voltage

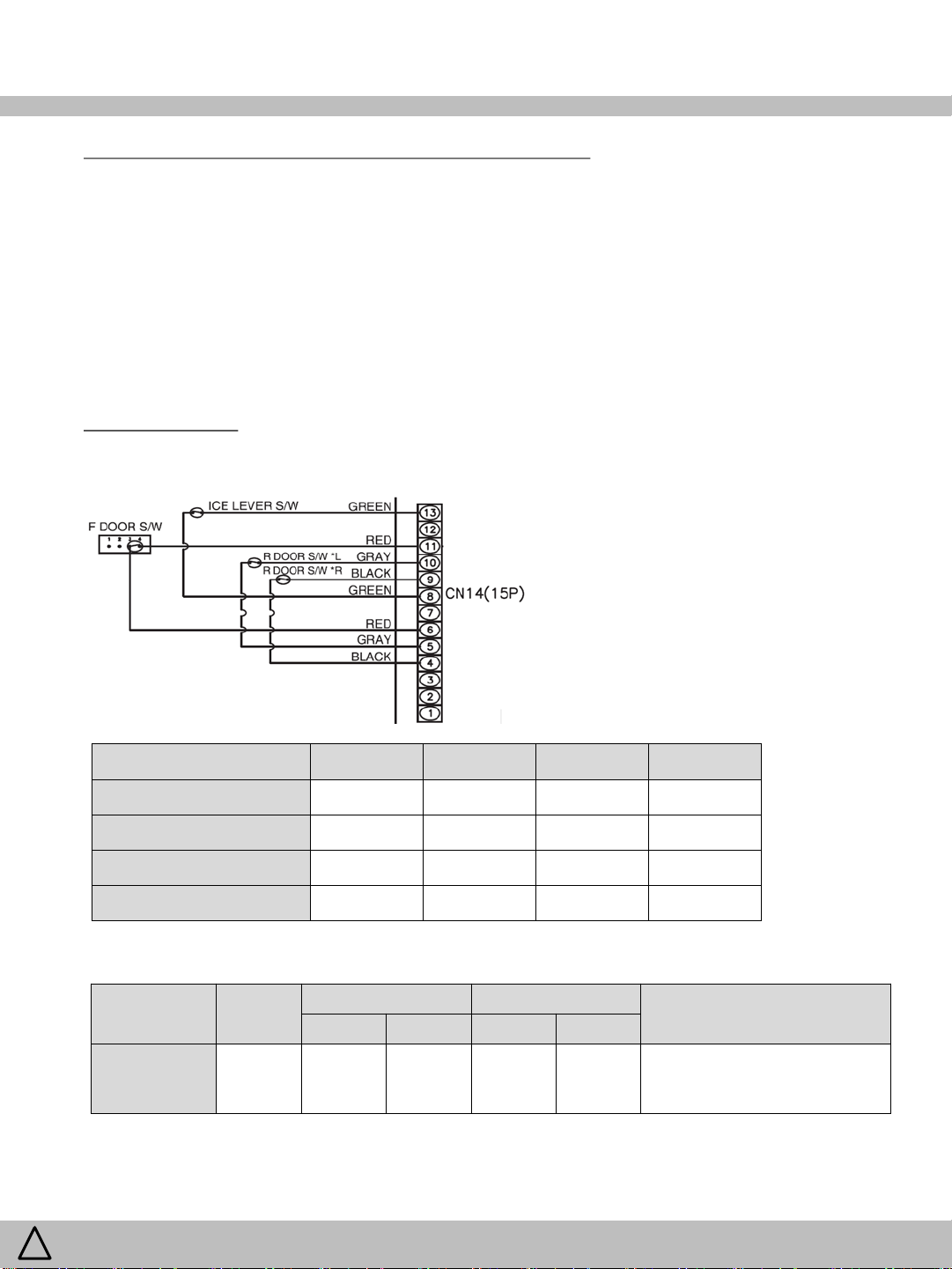

7-5-1. CN 14 (Switch)

Item Pin No. Open(On) Close(Off)

R DOOR S/W L

ICE LEVER S/W

F DOOR S/W

R DOOR S/W R

7-5-2. CN 5 (Compressor Inverter)

Item Pin No

!

Comp RPM

WARNING

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

0V 5V

0V 5V

5V 0V

0V 5V

On Off

V Hz V Hz

3.3 50~125

6.5 -

비고

main PCB

Remarks

) Feedback to

20

/ 79

7. Wiring Diagram

Water Tube

1 & 14

I/M

N/A

I/M Stepping

1 & 9,

Bi-Directional

Icemaker Power

1 & 8

Icemaker LED

1 &

Icemaker

1 & 7

Icemaker Test

1 & 5

Start Position Check Sensor

1 & 4

Ice Bucket Full

1 & 4

I/M Stepping

1 & 8, 9

Icemaker

1 & 7

Icemaker Test

1 & 4

Start Position Check Sensor

1 & 3

Ice Bucket Full

1 & 5

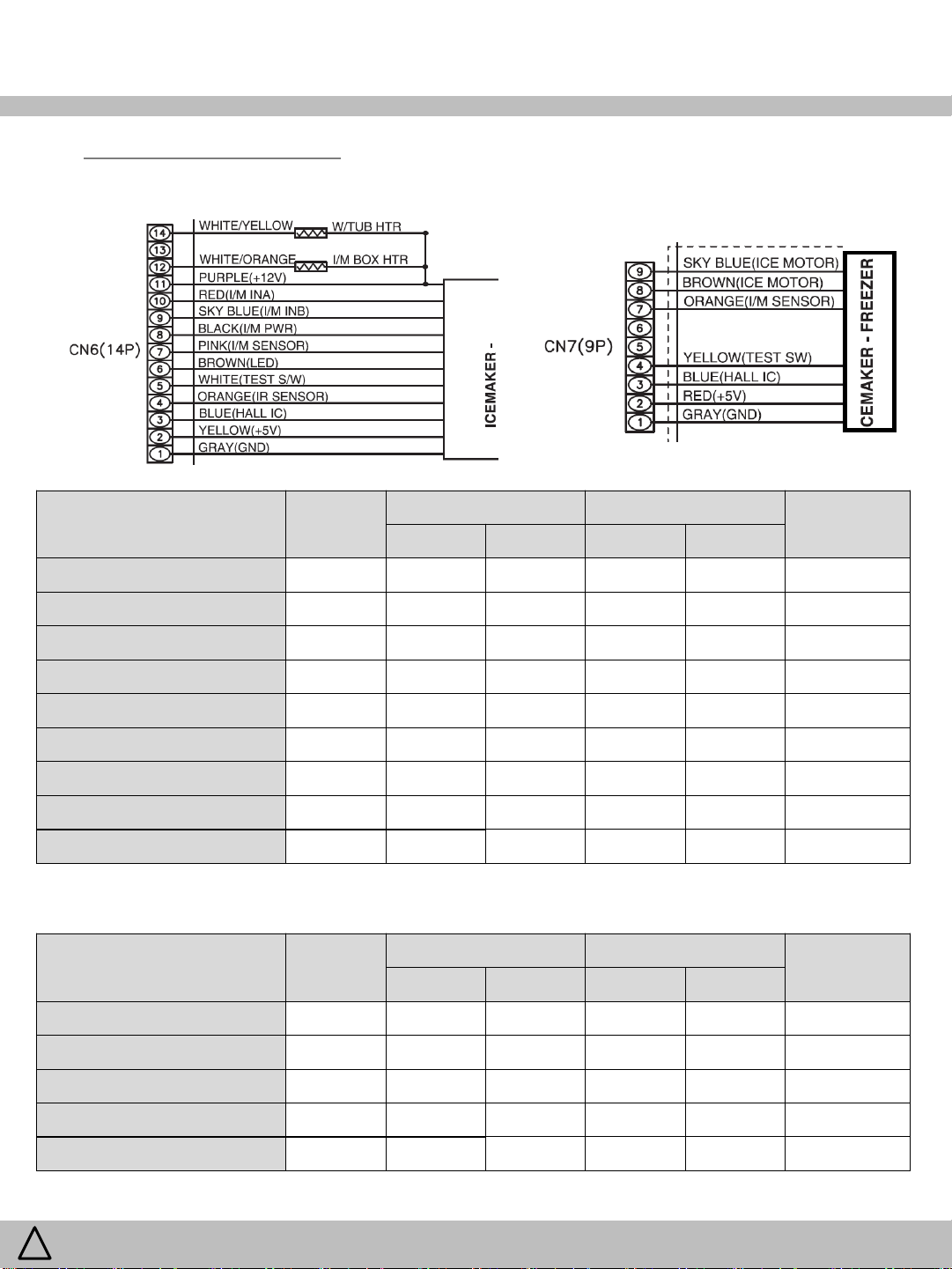

7-5. Other voltage (continued)

7-5-3. CN 6 (Icemaker in the ice room)

Item Pin No

Heater

Box Heater

Motor

Temp. Sensor

Switch

Check Sensor

0

N/A N/A N/A N/A

10 2.5

5

6 0

0

0

5

(Start)

On Off

V Hz V Hz

12

5

0

10

(Full)

5

5

0

7-5-4. CN 7 (Icemaker in the freezer compartment) ※ 111.7550… model only

Item Pin No

On Off

V Hz V Hz

Remarks

Sensor Table

Remarks

Motor

Temp. Sensor

Switch

Check Sensor

!

WARNING

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

2.5 5

0 5

0(Start)

5(Full)

5

0

Sensor Table

21

/ 79

7. Wiring Diagram

Damper

5 & 6

Damper Signal

1 & 7, 8, 9, 10

Step

5 & 1, 2, 3, 4

0~12

swing

1 & 2, 3, 4, 5

2 &, 3, 4, 5

3 & 4, 5

4 & 5

Pin

Color of lead wire

7-5. Other voltage (continued)

7-5-5. CN 13 (Damper)

Item Pin No

On Off

V Hz V Hz

Heater

0 - 12 -

6 - 0 -

7-5-6. CN 19 (Step Valve)

Item Pin No

Motor

※ Floating – pins 1, 2, 3, 4 are completed to circuit ground in sequence to operate the step valve

Step Motor

On Off

V Hz V Hz

- 12 -

Following is the correct pin for PCB and step motor pin:

PCB Pin 1 = Step Motor Pin 5

PCB Pin 2 = Step Motor Pin 4

PCB Pin 3 = Step Motor Pin 1

PCB Pin 4 = Step Motor Pin 2

PCB Pin 5 = Step Motor Pin 3

Remarks

Remarks

HOUSING "A"

No. 1 2 3 4 5

!

WARNING

Coil POINT [Ω]

Housing “A”

Pin No.

GRAY BLACK ORANGE BLUE YELLOW

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

40±4Ω

80±8Ω

80±8Ω

80±8Ω

22

/ 79

7. Wiring Diagram

1 & 2

2 & 12

7 & 8

3 & 4

4 & 9

5 & 6

6 & 10

7-5. Other voltage (continued)

7-5-7. CN 17 (Fan Motor)

Item Pin No

I/M BOX MOTOR

I/M BOX MOTOR

(Feedback signal)

C MOTOR

F MOTOR

F MOTOR

(Feedback signal)

R MOTOR

R MOTOR

(Feedback signal)

On Off

V Hz V Hz

12 ~ 14 - 0 -

12 ~ 14 - 0 -

12 ~ 14 - 0 -

12 ~ 14 - 0 -

5V Pulse,

Duty 50%

5V Pulse,

Duty 50%

5V Pulse,

Duty 50%

65~80 0 0

45~65 0 0

45~65 0 0

비고

Frequency

fluctuation

Frequency

fluctuation

Frequency

fluctuation

!

WARNING

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

23

/ 79

8. Operation and Functions

8-1. How to Use Control Panel

1 2

ⓕ

5

8

ⓐ

3 4

ⓑ

Button Item Display Description

ⓕ

Initial Temperature by power input

-

Freezer Temperature

Freezer Accela Chill Function

88 LED

88 LED

LED ①

Freezer : 0ºF / Refrigerator : 37ºF / Pantry room(optional) : “Produce”

ºF : 0 → -2 → -4 → -6 → -8(Coldest) → 6 → 4 → 2 → (repeat)

℃ : -18 → -19 → -20 → -21 → -22(Coldest) → -15 → -16 → -17 → (repeat)

□ How to Start : Press and hold this button for 3sec.

□ How to Proceed : the icon LED ON, Coldest Temp for 3000min

□ How to End : Time Limit or Any press for changing Temp or Power Rest

7

Button LED

ⓡ

ⓓ

6

ⓒ

ⓡ

ⓓ →

ⓕⓡ

ⓐ

ⓑ

ⓒ

ⓑⓒ

ⓓ

WARNING

!

Refrigerator Temperature

Refrigerator Accela Chill Function

Switch Temperature Unit ºF ↔ ℃

“Accela Ice” Function

Filter Reset

Select Cubed Ice

Select Crushed Ice

Icemaker off

Turn Dispenser Lamp On

Lock Control Function

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

88 LED

LED ②

ºF : 37 → 35 → 33(Coldest) → 45 → 43 → 41 → 39→ (repeat)

℃ : 3 → 2 → 1(Coldest) → 7 → 6 → 5 → 4→ (repeat)

□ How to Start : Press and hold this button 3sec.

□ How to Proceed : the icon LED ON, Coldest Temp for 360min

□ How to End : Time Limit or Any press for changing Temp or Power Rest

LED In lock mode, press and hold ⓕ and ⓡ buttons at the same time for 5sec

LED ③

LED ④

LED ⑦

LED ⑧

The icon LED On, Quick ice cube production mode for 24hr

If no water comes into the icemaker for 6hr, the operation is canceled.

Press and hold "Accela Ice” button for 3sec, “Replace Filter” icon LED OFF

※ After about 6 months from power on or Filter Reset, the icon LED ON.

The icon LED ON;

The cubed/crushed ice comes out by pressing the dispenser lever.

⑤ Press and hold ⓑ and ⓒ buttons for 3sec at the same time.

-

⑥

Press the “Light” button or push any dispenser lever.

Press and hold ⓓ button 3sec to stop operation of different buttons.

The ice or water dispenser does not work during lock mode.

24

/ 79

8. Operation and Functions

8-1. How to Use Control Panel (continued)

1 2

ⓕ

5

8

ⓐ

3 4

ⓑ

Button Item Display Description

ⓓ →

ⓐⓕⓡ

ⓓ →

ⓕⓡ

Service Mode

(Error Display)

Forced Defrosting

88 LED

-

□ How to Start : In lock mode, press ⓐ 5 times, while pushing ⓕ & ⓡ at once

□ How to Proceed : operating state values (ex : error codes) are displayed

※ Error display is skipped if no error.

□ How to End : Press “Light” button 1 time or No input for 4min.

□ How to Start : In lock mode, press ⓡ 5 times, while pushing ⓕ

□ How to Proceed : Heater is on regardless of F/R Defrost Sensor for first 30sec.

□ How to End : Same as normal defrosting or Power Rest

7

Button LED

ⓡ

ⓓ

6

ⓒ

ⓓ →

ⓐⓓ

ⓓ →

ⓐⓡⓓ

ⓓ →

ⓕⓡⓓ

Changing Sensor ON/OFF

Temp (for Service)

Showroom Mode

(Cooling Off)

(Demo Mode)

Forced Comp On Mode

(use this mode, when you

recharge refrigerant.)

88 LED

LED

□ How to Start : In lock mode, press ⓓ 5 times, while pushing ⓐ

□ How to Proceed :

Default Value Display F 88 LED “00” R 88 LED “00”

Value “01” = 0.13ºF (0.072℃) 0.18ºF (0.1℃)

Range of Value Change “00 ±30”

= Range of Temp Change 0±3.9ºF (0±2.16℃) 0±5.4ºF (0±3℃)

Control Button to be Warmer

Control Button to be Colder

□ How to End : No input for 10sec

□ If the refrigerator is disconnected from initial power on before 5 days

after setting change, the value is initialized.

□ How to Start : In lock mode, press ⓓ 5 times, while pushing ⓐ & ⓡ at once

□ How to Proceed : All electrical components are OFF

[except] Control Panel sequentially display; Dispenser LED ON;

All dampers open; Fans & interior lamps ON/OFF by door opening.

□ How to End : In lock mode, ⓓ 5 times + ⓐ & ⓡ at once or Power Rest

□ How to Start :In lock mode, press ⓓ 5 times, while pushing ⓕ & ⓡ at once

□ How to Proceed : Compressor operates continuously for 30 hours.

□ How to End : Power reset, or after 30 hours.

Freezer Refrigerator

ⓕ ⓡ

ⓐ ⓓ

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

25

/ 79

8. Operation and Functions

8-2. Service Mode and Error Display

□ How to Start :

Preparation Work INPUT

“Lock” Mode ON

Freezer

Temp

+

Refrigerator

Temp

+

□ How to Proceed :

ºF

• Unit

Press “Freezer Temp” button and the following value is displayed successively.

:

• Unit ℃ : Press “Accela Ice” button and the following value is displayed successively.

Example Display

STEP Content

etc. F 88 R 88 etc.

Operating Time 12 34 12hr 34min ※ reset every 24hr

1

Freezer Sensor Temp - F0 58 ºF -5.8ºF ※ Sensor Open / Short : R 88 = Hi / Lo

2

Refrigerator Sensor Temp r3 92 ºF 39.2ºF ※ Sensor Open / Short : R 88 = Hi / Lo

3

Freezer Defrost(FD) Sensor Temp - d1 39 ºF -13.9ºF ※ Sensor Open / Short : R 88 = Hi / Lo

4

Icemaker Room Defrost Sensor Temp - b0 58 ºF -5.8ºF ※ Sensor Open / Short : R 88 = Hi / Lo

5

Icemaker Sensor Temp

6

in the Icemaker Room

Icemaker Sensor Temp

7

in the Freezer (Dual Icemaker Model)

c0 95 ºF 9.5ºF ※ Sensor Open / Short : R 88 = Hi / Lo

n0 32 ºF 3.2ºF ※ Sensor Open / Short : R 88 = Hi / Lo

Accela

Ice

Description

Icemaker Room(IR) Sensor Temp i1 50 ºF 15ºF ※ Sensor Open / Short : R 88 = Hi / Lo

8

Pantry Drawer Sensor Temp u3 02 ºF 30.2ºF ※ Sensor Open / Short : R 88 = Hi / Lo

9

R Defrost(RD) Sensor Temp - E1 39 ºF -13.9ºF ※ Sensor Open / Short : R 88 = Hi / Lo

10

RT Sensor Temp t7 64 ºF Ambient Temperature : 76.4ºF

11

Filter remaining Life Time 43 17 4,317hr

12

Flow Sensor Pulse Value of the

13

icemaker in the freezer

Flow Sensor Pulse Value of the

14

icemaker in the icemaker Room

Error Code : F Sensor Er F1

15

Error Code : R Sensor Er r1

16

o1 00

P1 00

o100 / P100 (Default value) = 282 pulse

Do not change the default value.

!

(Icemaker is filled a certain amount of water

provided by flow sensor in water valve.)

※ if “Ice Select” button pushed :

ex) P100(default value)→P101→P102→…

→P150(max)→P50(min)→P51→…→P100→(repeat)

The sensor is read as open or shorted.

Check the wiring connections in each part and at Main

PCB.

※ The temperature by display in service mode is shown by sensor. The real temp of the cooling area could be different.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

26

/ 79

8. Operation and Functions

8-2. Service Mode and Error Display (continued)

STEP Content

Error Code : Icemaker Sensor in the

17

Icemaker Room

Error Code : Icemaker Room Sensor Er i3

18

Error Code : Icemaker Sensor in the freezer Er i2

19

Error Code : Pantry Drawer Sensor Er u1

20

Error Code : F Defrost Sensor Er Fd

21

Error Code : R Defrost Sensor Er rd

22

Error Code : Icemaker Room Defrost sensor Er id

23

Error Code : RT Sensor Er rt

24

Error Code : Cycle Er C1

25

Error Code : F Door Switch Er dF

26

Error Code : R Door Switch Er dr

27

Error Code : F Defrost Heater Er F3

28

Error Code : Icemaker Room Defrost Heater Er r3

29

Error Code : EEPROM Er EP EEPROM read / write error

30

Error Code : Dispenser Lever Time Er ES In case dispenser lever is pressed for over 1min

31

Example Display

etc. F 88 R 88 etc.

Er i1

Description

The sensor is read as open or shorted.

Or Icemaker Heating Error

The sensor is read as open or shorted.

Check the wiring connections in each part and at

Main PCB.

In case compressor works for over 3hr when FD

or RD sensor temp is over 23ºF(-5℃)

Check refrigerant leakage.

In case it senses that door is open for more than

1hr.

Check F/R door or Door Switch.

In case defrosting return is done by time limit of

50 min

Check the Defrost HTR or Defrost sensor .

Error Code : Water Supply Error Er E9 Icemaker water supply error

32

Error Code : Icemaker Error Er EA Flat sensor error in the freezer icemaker

33

Error Code : Flow Sensor Error Er EF The sensor is read as open or shorted.

34

35

Error Code : F Fan Motor RPM Error

36

Error Code : R Fan Motor RPM Error

37

Error Code : I/Maker Fan Motor RPM Error

Mode Display : Forced Defrost Ξ Ξ D2 Forced Defrost

38

Mode Display : Forced Comp ON Ξ Ξ Co Forced Comp ON

39

Er FF Freezer fan motor RPM error

Er rF Refrigerator fan motor RPM error

Er iF Ice maker fan motor RPM error

□ How to End :

Preparation Work INPUT

“Lock” Mode ON

Light

※ Error code will be released automatically when the condition is normal.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

27

/ 79

8. Operation and Functions

Pantry Damper

Freezer

Refrigerator

Pantry Drawer

Ice

& Step Valve Location

F

R

Defrosting

Showroom Mode

(Demo Mode)

F

(Coldest Temp

for setting time)

(Coldest Temp

for setting time)

(Coldest Temp

for setting time)

R

(Coldest Temp

for setting time)

Accela

for setting time

(only ice making

for setting time

(only ice making

8-3. Compressor, Fan & Damper

On/Off On/Off On/Off - - -

Comp C FAN F FAN R FAN

Output

Icemaker

Room FAN

Temp

Sensor Target

Harvest Condition

Door Open - - - - - -

Door Open - - - - - -

INPUT

Accela Chill

- - - On/Off - -

- - - - Open/Close

Mode Off Off Off Off Off Close

- - - - On/Off -

Off Off

On/Off

On/Off

On only

F Door Open

On/Off

R Door Open

On only

- - -

On only

R Door Open

On/Off

Accela Chill - - -

On

Ice

condition)

■ Compressor will not restart within 6 min after the refrigerator is disconnected from power supply.

□ Fan voltage of control mode : Freezer 13V, Refrigerator 13V, Icemaker Room 13V, Condenser 13V

- - -

- Open/Close

On

condition)

Open

-

8-4. Defrost Mode

□ The defrost mode starts with compressor work time, defrost sensor temp, any error mode, etc.

□ The defrosting return is done by F or R Defrost sensor.

8-5. Forced Defrost Mode

□ How to Start :

Preparation Work INPUT

“Lock” Mode ON

□ How to Proceed and End: Same as normal defrost mode

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Freezer

Temp

+

Refrigerator

Temp

28

/ 79

8. Operation and Functions

8-6. Icemaker in the Icemaker Room

1) Icemaker Room Temperature Control : by IM Sensor On/Off

• Icemaker Room Temp is controlled by IM Sensor on/off setting value.

• In “Accela Ice” mode, the compress and icemaker room fan will turn on 24hr for Quick Icing.

In case of no icemaker water supply for 6hr, the “Accela Ice” function is canceled.

※

Icemaker

Optics

Sensors

Room Sensor

Icemaker

Room Fan

Ice Type

Selector

Ejector

2) Icemaker System :

start

Ice Making

Ice Harvest

Icemaker Water Supply

Return

Ice Tray

Heater

• Icemaker starts harvest process by sensing tray temp unless ice storage bin is full.

※ When the bin fills to the level of the optics sensors, the icemaker will stop making ice.

• Icemaker has a ejector and a heater for harvest.

• Ice cube surface is melted by the heater installed the ice tray and ice cubes are

swept for the ejector from the ice tray.

• Icemaker is filled a certain amount of water provided by flow sensor in water valve.

• If the water pressure is too low (under flow sensor pulse value 6), the icemaker

will not work.

• To operate the icemaker properly, water pressure of 20~125psi is required.

WARNING

!

※ Water Filter Operation Pressure : 30 ~125psi (207~862kPa, 2.1~8.8kgf/㎠)

※ If the water pressure exceeds 125psi, a pressure reducing valve must be installed.

※ If the water pressure is under 30psi, a booster pump must be installed.

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

29

/ 79

8. Operation and Functions

8-6. Icemaker in the Icemaker Room (continued)

3) Icemaker Power OFF :

□ How to Start :

Preparation Work INPUT

“Lock” Mode OFF

□ How to Proceed :

• Display : LED light of Icemaker will turn off. And “Ice off” icon of the control panel will light up.

• Icemaker stops making ice.

• Dispensing cubed / Crushed Ice doesn’t work, even if the dispenser lever is pressed.

□ How to End : same as input to start.

4) Icemaker Test Mode :

□ How to Start :

Preparation Work INPUT

-

□ How to Proceed :

• Display : Icemaker LED will flash red.

• Ice type(cubed/crushed) selector works 5 times

• Icemaker motor runs 1 cycle.

(Motor On → Heater On → Water Supply → Motor Off)

□ How to End : by finishing test

Water

+

Ice

Select

Press power button of the icemaker

6 times within 3sec.

Press and hold buttons

for 3sec at once.

Test Button,

Icemaker LED

flashing at test mode or

error condition

5) Icemaker Errors

□ Error Display :

• IM Sensor Error : Error code display and icemaker LED flashing

• IM Heater Error : icemaker LED flashing

□ How to Service :

1) Check the wiring connections in each part and at Main PCB.

2) If normal, change the icemaker to new one.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

30

/ 79

8. Operation and Functions

8-6. Icemaker in the Icemaker Room (continued)

6) Icemaker Conditions Display by control panel :

□ How to Start :

Preparation Work INPUT

1) Service Mode

2) Step : IM Sensor Temp

※ IM(Icemaker Room Sensor) Temp : “Accela Ice” or “ Freezer Temp” button 6 times in the service mode. (88 LED : Cx xx)

□ How to Display :

88 Display Icemaker Condition Display

F R Ice Bucket Full Check Ejector at Start Position

c 00 Not yet No

c 01 Not yet Yes

c 10 Full No

c 11 Full Yes

c 15 - Holding despite motor starting signal by PCB

Refrigerator

Temp

Press and hold the button for display

Remark

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

31

/ 79

8. Operation and Functions

8-7. Icemaker in the Freezer Compartment

1) Icemaker Room Temperature Control : by Freezer Temp Sensor On/Off

Icemaker

with 10 Cube Tray

Feeler Arm

Test Button

Icemaker Sensor,

Insulator and Cover

2) Icemaker System :

start

Ice Making

Ice Harvest

Icemaker Water Supply

Return

• Icemaker starts harvest process by sensing tray temp if the ice bin is not sensed as full.

• When the bin fills to the level of the feeler arm, the icemaker will stop producing ice.

• Icemaker is filled a certain amount of water provided by flow sensor in water valve.

• If the water pressure is too low (under flow sensor pulse value 6), the icemaker

will not work.

• To operate the icemaker properly, water pressure of 30~125psi is required.

※ If the water pressure exceeds 125psi, a pressure reducing valve must be installed.

※ If the water pressure is under 30psi, a booster pump must be installed.

Icemaker with 10 Cube Tray

Amount of Water Fill

Model

3.1~3.5oz (89~99g)

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

32

/ 79

8. Operation and Functions

8-7. Icemaker in the Freezer Compartment (continued)

3) Icemaker Power OFF :

□ How to Start :

Preparation Work INPUT

“Lock” Mode Off

□ How to Proceed :

• Display : “Ice off” icon of the control panel will light up.

• Icemaker stops making ice.

□ How to End : same as input to start.

4) Icemaker Test Mode :

□ How to Start :

Preparation Work INPUT

-

□ How to Proceed :

• Icemaker runs 1 cycle.

(Icemaker Motor On → the feeler arm down and up → twisting tray → Water Supply → Icemaker Motor Off)

※ After finishing the test, the ice bucket should be emptied

because the ice cubes in icemaker tray could be not fully frozen.

□ How to End : by finishing test

Water

+

Press test button of the icemaker for 5sec.

Ice

Select

Press and hold buttons

for 3sec at once.

WARNING

!

Test Button

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

33

/ 79

8. Operation and Functions

8-7. Icemaker in the Freezer Compartment (continued)

5) Icemaker control in case of errors

□ Error Type :

• IM Sensor Error : Error code display in service mode and icemaker will complete the harvest as time(4.8hr).

• Flow Sensor Error : The water valve is controlled by time.

• Water Supply Error : The ice maker operation stop.

After opening the freezer door, the Hose Icemaker Tube Heater will be on for 60min and then icemaker will try

to work again.

□ How to Service :

• Measure and record the freezer room temp and defrost sensor temp in service mode before opening freezer door.

• Check the error display in Service Mode before opening freezer door.

• Check the water pressure or shut-off valve of water main line.

• Check the wiring connections in each part and at Main PCB.

• Check the Hose Icemaker Tube is blocked with ice.

• Measure the resistance of Hose Icemaker Tube Heater.

8-8. Pantry Drawer

• The Temp is controlled by Pantry Drawer Sensor, RT Sensor and Pantry Drawer Damper.

• In case of Pantry Drawer Sensor error, the Pantry Drawer damper will repeat open and close every 5min.

8-9. Dispenser Water/Ice Lever

• The operating time using the water/ice dispenser will be max 1min at a time to protect electric parts.

To use ice/water dispenser for more than 1min, the dispenser lever should be pushed again every 1min.

8-10. Buzzer or Alarm

• Buzzer sounds if any button of Front Control Panel is pressed.

• Buzzer sounds after 3sec from initial power input.

• If door is left open for more than 1min, the alarm beeps 10 times every 1min until open total time 6min.

The beeping stops when door is close.

• Buzzer sounds 3 times when the “Forced Defrost“ mode starts.

• Buzzer sounds 3 times when the “Error Display“ mode starts.

• Buzzer sounds 3 times when the icemaker power ON/OFF.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

34

/ 79

8. Operation and Functions

8-11 Compensation of Refrigerator Sensor On/Off Temp

□ R42 : R-SENSOR standard resistance in normal mode (31.4㏀)

□ In case temperature of refrigerator compartment is week or insufficient, take the following action.

• Cut J2 to increase the standard resistance by 2㏀ ⇒ 1.5℃ down (2.7 ºF down)

• Cut J1 & J2 to increase the standard resistance by 4㏀ ⇒ 3℃ down (5.4ºF down)

R-SENSOR

R42

(31.4㏀)

R43

(2㏀)

R44

(2㏀)

J1

J2

J01

J2 - cut - cut

J1 - - cut cut

Temperature

compensation

Resistance

0℃ -1.5℃(-2.7 ºF) 0℃ -3℃(-5.4 ºF)

R42 R42+R43 R42 R42+R43+R44

31.4㏀ (31.4+2)㏀ 31.4㏀ (31.4+2+2)㏀

WARNING

!

J02

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

35

/ 79

9. How to Service

9-1. Faulty Start (F/R lights Off , F-PCB Power Off)

Start

Power input to

Main PCB is ok?

Y

Main PCB Fuse is

disconnected?

N

Voltage

DC5V on Main PCB is

OK?

Y

Wire connection

of Front PCB is OK?

N

Check power connection

from machine compartment

to CN1 of Main PCB.

Y

Change the fuse

(AC250V 4A)

on the Main PCB

N

Change Main PCB

Y

N

Checkup and connect

Front PCB wires.

■ How to check DC voltage on main PCB :

Never touch the bottom

face of PCB board directly

by hand to prevent electric

shock or injury.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Change Front PCB AS.

36

/ 79

9. How to Service

9-2. Freezing Failure . (Foods are not frozen/cold.)

Start

Any error code

on Front PCB?

N

Does Comp.

work?

Y

F-Fan & C-Fan

work ok?

Y

Temp-Fuse is ok?

(on the evaporator)

N

N

Y

N

Refer to error display

in operation and function

■ How to check the inverter controller :

1) Run “Accella Ice” function in condition of icemaker on.

The M-PCB will send the signal “comp on” to controller.

2) Disconnect the connector(2pin) of controller from cabinet.

3) Measure voltage of connector on cabinet.

∴ DC5.4~6.6V → Good

Inverter Controller

is OK?

Y

N

Change the

Change the Controller

Comp.

N

F-Fan & C-Fan

motor is ok?

Change the

defective motor

Y

Y

Wiring connection

is ok?

Change Main PCB

N

Check lead wire

WARNING

!

Y

N

Defrost heater

Is ok?

Y

Ice formation on Eva.

is ok?

■ How to check Defrost heater :

Measure resistance of the heater

∴ 35~42Ω → Good

N

Y

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Change Temp-Fuse

※ Left & Right side of evaporator

Change the

Defrost heater.

Check ice formation on Eva.

and if refrigerant leak

is found, repair it.

37

/ 79

9. How to Service

9-3. Ice Formation on F-Louver

Start

Dews are formed on the

gasket surface inside

F-compartment ?

N

Door is open and closed

too frequently ?

N

Heat appliances are too

close to the refrigerator ?

Y

Y

Y

Gasket has a gap

between cabinet ?

N

Door is hanged

down ?

N

Y

Remove the gap.

Y

Reassemble the door.

Explain not to open

doors too frequently.

WARNING

!

N

Watery or hot foods are

stored in refrigerator

compartment ?

Y

N

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Make enough distance

between heat appliances

and refrigerator.

Wipe out dews on the

louver surface and run

the refrigerator again.

38

/ 79

9. How to Service

Connected to F Switch

9-4. Disconnection / Breaking of Freezer Lights Ass’y

Start

Power of F Lamp

Is OK ? (DC12V)

Y

Change the Lamp Ass’y.

■ How to check power of F-Lamp :

Disassemble the F lamp window on the top wall in freezer.

∴ 10.8~ 13.2 V → GOOD

■ How to check connection of F Door switch :

1) Disassemble the F door switch on the right wall in freezer.

2) Connect the connector properly and check if lamp on.

3) Disconnect the connector and check the location of terminal pins.

4) Check the switch is open circuit without pushing button.

Or test the lamp with a new switch.

5) Check the pins of connector on M-PCB connected to the switch.

N

Connection of F door

switch is OK ?

Check the power connection?

(From Main PCB to F Lamp)

N

Y

Repair the F door switch.

Door Open(Lamp On) Door Close(Lamp Off)

F Switch Circuit Open Close

Terminal of F Switch Pin 1, 2

Connector on M-PCB

WARNING

!

Pin 11, 16 of CN14

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

F Switch

CN14

39

/ 79

9. How to Service

Connected to R Switch

9-5. Disconnection / Breaking of Refrigerator Lights Ass’y

Start

Power of R Lamp

Is OK ? (DC12V)

Y

Change the Lamp Ass’y.

■ How to check power of F-Lamp :

Disassemble the R lamp window on the top wall in refrigerator.

∴ 10.8~ 13.2 V → GOOD

■ How to check connection of F Door switch :

1) Disassemble the top hinge cover.

2) Connect the connectors properly and check if lamp on.

3) Check if the wires and connectors are no damage.

4) Check the each switch is close circuit without pushing button.

Or test the lamp with new switches.

5) Check the pins of connector on M-PCB connected to the switches.

N

Connection of R door

switch is OK ?

Check the power connection?

(From Main PCB to R Lamp)

N

Y

Repair the R door switch.

Door Open(Lamp On) Door Close(Lamp Off)

R Switch Circuit Close Open

Terminal of R Switch Pin 1, 2 (2pc.)

Connector on M-PCB

WARNING

!

Dispenser Door : Pin 5, 10 of CN14

Right Door : pin 4, 9 of CN14

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

CN14

40

/ 79

9. How to Service

9-6. Refrigeration Failure (Foods does not get cool or cold soon.)

Start

Any error mode

on Front PCB?

N

R-Fan

works ok ?

Y

R-Sensor is ok

(normal) ?

Y

Freezer compartment

Is ok ?

Y

Refrigerator gasket

have gap ?

N

Foods are placed just

close to R-Sensor ?

N

Y

N

Y

N

N

Y

R-Fan motor

is ok?

Y

Wiring connection

is ok ?

N

Gasket have

any gap ?

N

Door is hanged down

to make gap between

cabinet ?

Y

Solve error code

problem, if any.

N

the R-Fan motor.

Y

Change the Main PCB.

Check the wirings.

Change the R-Sensor

and check connector.

Refer to “Freezing

does not work.”

Repair to eliminate

the gap of gasket.

Y

Reassemble doors.

Change

WARNING

!

N

Refrigerator door

openings are too often ?

Y

N

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Explain not to place foods close to

R-sensor or cold air spout.

Explain not to open doors

unnecessarily or frequently.

Advise to use Fridge Dial

more colder setting

41

/ 79

9. How to Service

9-7. Dews on Refrigerator Compartment

Start

Dews are formed

on the gasket inside

R-compartment?

N

Door is open too long ?

N

Door is open and closed

too frequently ?

N

Heat appliances are

used near the refrigerator ?

N

Y

Y

Y

Y

Gasket has

Any gap ?

N

Door is

hanged down ?

Y

Repair to eliminate the gap.

Y

Reassemble the doors.

Explain not to open doors

too long.

Explain not to open

doors unnecessarily.

WARNING

!

N

Water or hot foods are

stored in the R-compartment?

Y

N

N

R-fan works OK ?

Y

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Make enough distance between

the appliances and refrigerator.

Advise to cool down foods, wrap

or cover foods with much water

before storing in the compartment.

Repair and change R-motor.

42

/ 79

9. How to Service

9-8. Comp. Operation Noise

Start

Refrigerator is leveled ?

Y

Front cover or door gasket

is assembled wrong ?

N

Absorber comp

is distorted or aged ?

N

Sound or Vibration from

Comp shell ?

N

Level the refrigerator by

adjusting wheels.

☞ Refer to User’s Guide

and SVC Manual.

Y

Set it right.

Y

Change the absorber comp.

Y

N

Change the compressor.

Remarks

• Compressor sound is somewhat normal because it works like a heart to circulate the refrigerant in the pipes

during the refrigerator operation.

• Rattling or metallic touch sound of motor, piston of comp. can be heard when it starts or stops.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Attach a restrainer on the comp

head to reduce vibration and

high frequency noise.

43

/ 79

9. How to Service

9-9. Refrigerant Flow Sound

Start

Water flowing or hiss sounds

from the refrigerator ?

N

Refrigerant sound of hiss or

sizzling sound when comp. starts ?

N

Refrigerant sound of hiss or

sizzling when comp. stops ?

N

Any shaking sound from

F-compartment

when comp. works ?

Y

Attach an absorber gum

on the capillary tube.

Y

Apply a gum on the

accumulator.

Y

Apply a gum on the

accumulator.

Y

N

Explain refrigerator work

mechanism and sound to the

users or customers.

Remarks

• Water flowing sound, hiss or sizzling sound can make while refrigerant in the pipes is changing from liquid to gas

state when comp. starts or stops. It is normal to the refrigerator.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Fasten the evaporator in F-

compartment tightly against

touching (liner) surfaces.

44

/ 79

9. How to Service

9-10. Fan Noise

Start

Fan is damaged

or transformed ?

N

Fan is touching

the surround ?

N

Fan-motor assembly

is moving or shaking ?

N

Motor has its own noise

or vibration when working ?

Y

Change the fan.

Y

Set it right not to touch.

Y

Set it right not to move.

Y

N

Explain to the customers

how fan is working to

circulate cold air in the

compartments.

Remarks

• The fan is sending out cold air to circulate it through the compartments. When the air is touching the surface of

louver or liner wall, such sound can make.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Change the motor

assembly.

45

/ 79

9. How to Service

9-11. Pipe Noise

Start

Pipes are touching

in the machine compartment ?

N

Tray drip makes

noise by Condenser shaking ?

N

Pipe itself is

shaking much ?

N

Compressor itself

is shaking much ?

Y

Separate the touching

pipes, if any.

Y

Apply cushion material between

Comp. base and Tray drip.

Y

Move or change the points of

vibration absorber rubbers on

the pipes to reduce the shaking.

Y

N

Explanation to the users.

Remarks

• Refrigerant is erupting rapidly from the compressor to circulate pipes, so pipe shaking noise can make to some degree.

• In case compressor vibration is sent to a pipe directly, apply vibration absorber rubbers to welding points of the pipe

and comp. or to a much bent point on the pipe.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Attach a restrainer on the comp head.

And adjust absorber comp by lifting

the comp

46

/ 79

9. How to Service

9-12. Door opening alarm continues though the door is closed.

Start

Door switch is pushed

well ?

Y

Door switch is soaked with

water or there is water in

the switch ?

N

PCB input is OK ?

N

Connector insertion to

Main PCB is OK ?

Y

N

Y

Check if F & R Lamp is ON.

Attach a thin pad on the

door liner or change the

door assembly.

Y

Change the door switch.

Repair any disconnection

of wires and defective

Door switch.

WARNING

!

N

Door switch itself is

OK ?

N

Check it up.

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Y

Repair the defective

connection.

Change the switch.

47

/ 79

10. Cooling Cycle Heavy Repair

Confirm N2 sealing and packing conditions before use.

10-1. Summary of Heavy Repair

Process Contents Tools

Remove refrigerant

residuals

Parts replacement

and welding

Vacuum Evacuate for more than forty minutes after connecting

Refrigerant charging

and charging inlet

welding

Cut charging pipe ends(compressor & dryer) and

discharge refrigerant from dryer and compressor.

Confirm refrigerant (R134a or R600a) and oil for

compressor and dryer.

Use good one for welding and assembly.

Weld under nitrogen gas atmosphere.

Repair in a clean and dry place.

manifold gauge hose and vacuum pump to high (dryer)

and low (compressor) pressure sides.

Weigh and control the bombe in a vacuum conditions

with electronic scales and charge through compressor

inlet (process tube).

Charge while refrigerator operates.

Weld carefully after inlet pinching.

Nipper, side cutters

Pipe, gas welder, N2 gas

Vacuum pump, manifold gauge

Bombe(mass cylinder),

refrigerant manifold gauge,

electronic scales, punching off

flier, gas welding machine

WARNING

!

Check

refrigerant leak

and cooling

capacity

Compressor

compartment and

tools arrangement

Transportation and

installation

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Check leak at weld joints.

※ Note :Do not use soapy water for check.

Check cooling capacity

→ Check condenser manually to see if warm.

→ Check hot pipe manually to see if warm.

→ Check frost formation on the whole surface of the

evaporator.

Remove flux from the silver weld joints with soft

brusher wet rag. (Flux may be the cause of corrosion

and leaks.(

Clean tools and store them in a clean tool box or in

their place.

Installation should be conducted in accordance with the

standard installation procedure. (Leave space of more

than 5 cm from the wall for compressor compartment

cooling fan mounted model.)

Electronic leak detector, driver.

Copper brush, rag, tool box

48

/ 79

10. Cooling Cycle Heavy Repair

10-2. Precautions During Heavy Repair

Items Precautions

Use of tools Use special parts and tools for R-134a or R-600a

Removal of retained

refrigerant.

Replacement of

dryer

1) Input ‘Forced Comp On Mode’ at Control Panel.

(

※ To force open the step valve for 2 evaporators in series:

Press/hold “Refrigerator Temp” and Freezer Temp” buttons,

then press “Light” button 5 times.)

Turn off a refrigerator after 10 Minutes to open STEP VALVE.

2) Remove retained refrigerant more than 5 minutes after turning off a refrigerator.

(If not, oil will leak inside.)

3) Remove retained refrigerant by cutting first high pressure side (dryer part) with a nipper

and then cut low pressure side. (If the order is not observed, oil leak will happen.)

Be sure to replace dryer when repairing pipes and injecting refrigerant.

WARNING

!

Nitrogen blowing

welding

Others

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

Weld under nitrogen atmosphere in order to prevent oxidation inside a pipe.

(Nitrogen pressure : 0.1~0.2 kg/cm2.)

1) Nitrogen only should be used when cleaning inside of cycle pipes inside and sealing.

2) Check leakage with an electronic leakage tester.

3) Be sure to use a pipe cutter when cutting pipes.

4) Be careful not the water let intrude into the inside of the cycle.

49

/ 79

10. Cooling Cycle Heavy Repair

10-3. Practical Work for Heavy Repair

Items Precautions

1. Removal of

residual refrigerant

2. Nitrogen

blowing

welding

1) Remove residual refrigerant more than 5 minutes later after turning off the refrigerator.

(If not, compressor oil may leak inside.)

2) Remove retained refrigerant slowly by cutting first high pressure side (dryer part) with a

nipper and then cut low pressure side.

When replacing a dryer :

Weld ①and② parts by blowing nitrogen (0.1~0.2kg/cm2) to high pressure side after

assembling a dryer.

When replacing a compressor :

Weld ③and④ parts by blowing nitrogen to the low pressure side.

※ Note) For other parts, nitrogen blowing is not necessary because it does not

produce oxidized scales inside pipe because of its short welding time.

■ KEYPOINTING ■

Welding without nitrogen blowing produces oxidized scales inside a pipe,

which affect on performance and reliability of a product.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

50

/ 79

10. Cooling Cycle Heavy Repair

10-3. Practical Work for Heavy Repair (continued)

Items Precautions

3.Vacuum

degassing

4.Refrigerant

charging

Pipe Connection :

Connect a “red” hose to the high pressure side and a “blue” hose to the low pressure side.

Vacuum Sequence :

Open ①,② valves and evacuate for 40 minutes. Close valve ①.

■ KEYPOINTING ■

1) If power is applied during

vacuum degassing, vacuum

degassing shall be more effective.

2) Operate compressor while

charging refrigerant.

(It is easier and more certain

to do like this.)

Charging sequence :

1) Check the amount of refrigerant supplied to each model after completing vacuum

degassing.

2) Evacuate bombe with a vacuum pump.

3) Measure the amount of refrigerant charged.

→ Measure the weight of an evacuated bombe with an electronic scale.

→ Charge refrigerant into a bombe and measure the weight.

→ Calculate the weight of refrigerant charged into the bombe by subtracting

the weight of an evacuated bombe.

■ KEYPOINTING ■

1) Be sure to charge the refrigerant at around 25°C.

2) Be sure to keep -5g in the winter and +5g in summer.

※ Calculation of amount of refrigerant charged (Wc)

Wc = Wa - Wb

Wa : weight after charging

Wb : weight before charging

( = weight of an evacuated cylinder)

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

51

/ 79

10. Cooling Cycle Heavy Repair

10-3. Practical Work for Heavy Repair (continued)

Items Precautions

4.Refrigerant

charging

(continued)

5. Gas-leakage test

6. Pipe arrangement

in each cycle

4) Refrigerant Charging

Charge refrigerant while operating a compressor as shown above.

5) Pinch a charging pipe with a pinch-off pliers after completion of charging.

6) Lockring the end of a pinched charging pipe with lockring and take a gas leakage test on

the welded parts.

Take a leakage test on the welded or suspicious area with an electronic leakage tester.

Check each pipe is placed in its original place before closing a cover back-M/C after

completion of work.

9-4. Standard Regulations for Heavy Repair

1) Observe the safety precautions for gas handling.

2) Use JIG (or wet towel) in order to prevent electric wires from burning during welding.

(In order to prevent insulation break and accident.)

3) The inner case shall be melted and insulation material (polyurethane) shall be burnt if not cared

during welding inner case parts.

4) The copper pipe shall be oxidized by overheating if not cared during welding.

5) Not allow the aluminum pipes to contact to copper pipes. (In order to prevent corrosion.)

6) Make sure that the inner diameter should not be distorted while cutting a capillary tube.

7) Be sure that a suction pipe and a filling tube should not be substituted each other during welding.

( High efficiency pump.)

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

52

/ 79

11. Disassemble/Assemble Procedures

11-1. Holder Water Filter Assembly

※ Follow the reverse order when assembling.

Step Description Step Description

Remove a screw

Turn off the main water supply to the appliance.

1 5

Separate the tube

fixture on the upper left

side cabinet back face.

2 6

Pull down the Holder Assembly and tubes gently

to remove.

Separate the tube

fixtures, if necessary.

3

Remove ¼” tube connected

to water filter outlet from the

water valve while pressing

4

□ Remark :

• Remove any residual matter inside the water supply line after installation.

1) Turn on the main water supply to the refrigerator .

2) Dispense water using dispenser for approx.10min to clean water and remove air from the lines.

3) And then check there are no water leaks or drips coming out from the water filter and dispenser.

4) If necessary, run water through the dispenser more.

the part (A). Remove the

locking clip before pushing

the part (A).

See the left figure.

MODEL : RFP71KE**

④

①

③

②

① Black(1/4”) – Ice Maker Tube(R room)

② White(1/4”) – Water Filter Outlet

③ White(5/16”) – Water Tank Inlet

④ Blue(1/4”) - Ice Maker tube(F room)

MODEL : RFP71KD**

①

③

②

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

53

/ 79

11. Disassemble/Assemble Procedures

11-2. Water Tank and Cover Vegetable Assembly

※ Follow the reverse order when assembling.

Step Description Step Description

Remove two vegetable cases.

1 5

2 6

Press two fixing hooks in top of the divider and

pull the divide out from the vegetable cover.

3 7

Push the underside of the divider back and lift it

up. And then remove it from the pantry cover.

Turn off the main water supply to the appliance.

Remove one screws

and pull the tank to

the front.

Take off the front cover from

the water tank assembly to

see the water storage

condition.

※ The water need to be

removed from the water line

of refrigerator to replace new

tank.

Unscrew the water valve

assembly in machine room.

And separate the 5/16”(the big

4 8

Remove the vegetable cover.

□ Remark :

• Remove any residual matter inside the water supply line after installation.

1) Turn on the main water supply to the refrigerator .

2) Dispense water using dispenser for approx.10min to clean water and remove air from the lines.

3) And then check there are no water leaks or drips coming out from the water tank and dispenser.

4) If necessary, run water through the dispenser more.

WARNING

!

To avoid risk of electrical shock that can cause death or severe personal injury,

disconnect unit from power before servicing unless tests require power.

one) tube from water valve.

Be careful not to be wet on

the floor. Remove the water

inside water tank and water line.

54

/ 79

11. Disassemble/Assemble Procedures

11-2. Water Tank and Cover Vegetable Assembly (continued)

Step Description

Separate the fixture to protect

5/16”(the big one) tube from

bending damage.

9

※ Follow the reverse order when assembling.

After removing the water

toward the machine room, put a

large cup on dispenser and

prepare to fill the remain water

10

11

Remove the top hinge cover and disconnect

water tube from the water tube fitting.

12

Remain