Kenmore 11070102311, 11070102312, 11072102310, 11072332510, 11072342510 Installation Guide

...

Dryer Installation instructions

Instrucciones de instalaci6n de la secadora

instructions d'lnstallation de la s_cheuse

English / Espa_ol / Fran_:ais

Table of Contents / [ndice / Table des Mafieres ......4

Ke

29" Wide Gas (U.S.A. and Canada) & Electric (Canada Only) Dryer

ModeJos de 29 °`a gas (EEoUUoy Canada) y EJ_ctrica (SoJo en Canada)

Mod@Jes de 29" de largeur @gas (EooUoet Canada) et EJectrique (Canada uniquement)

P/N W10562366A

Sears Brands Management Corporation

Hof_man Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Sears Canada inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

iNSTALLATiON NOTES

NOTAS SOBRE LA INSTALACION

NOTES CONCERNANT

L'INSTALLATION

Date of purchase:

Date of installation:

Installer:

Model number:

Serial number:

Fecha de compra:

Fecha de instalaci6n:

Instalador:

N6mero de modelo:

N6mero de serie:

Date d'achat :

Date d'installation :

Installateur :

Num6ro de module :

Num6ro de s6rie :

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - ...i.kof

- Clothes dryer installation must be performed by a qualified installer.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials or flexible metal

(foil type) duct. if flexible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

2

iMPORTANT."The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1iNFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSIiNFPA 70 or Canadian Electrical Code, CSA C22.1.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

• Do not try to light any appliance.

= Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

e Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

= if you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[] Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

[] Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

SAVE THESE INSTRUCTIONS

[] Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user=repair

instructions that you understand and have the skills to

carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] Clean lint screen before or after each load.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

[] See "Electrical Requirements" located in the installation

instructions for grounding instructions.

in the State of Massachusetts, the following installation instructions apply:

[] installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] if using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

IMPORTANT SAFETY INSTRUCTIONS

When discarding or storing your old clothes dryer, remove the door.

SAVE THESE INSTRUCTIONS

Table of Con_en_s

DRYER SAFETY ...................................................................................... 2

INSTALLATION REQUIREMENTS ........................................................... 5

Tools and Parts .............................................................................. 5

Location Requirements ................................................................... 6

ELECTRIC DRYER POWER HOOKUP-CANADA ONLY ........................... 7

Electrical Requirements ................................................................. 7

GAS DRYER POWER HOOKUP ............................................................. 7

Electrical Requirements ................................................................. 7

Gas Supply Requirements .............................................................. 8

VENTING .............................................................................................. 9

Venting Requirements ................................................................... 9

Plan Vent System ......................................................................... 10

Venting Kits.................................................................................. 11

Instcill Vent System ....................................................................... 12

INSTALL LEVELING LEGS..................................................................... 12

MAKE GAS CONNECTION .................................................................. 12

CONNECT VENT ................................................................................. 13

LEVEL DRYER ...................................................................................... 13

COMPLETE INSTALLATION CHECKLIST ............................................... 14

REVERSE DOOR SWING (OPTIONAL) ................................................. 14

TROUBLESHOOTING ........................................................................... 16

SEGURIDAD DE LA SECADORA .......................................................... 17

REQUISITOS DE INSTALAa6N .......................................................... 19

Herramlentas y plezas ................................................................ 19

Requlsltos de ub_caci6n ............................................................... 20

CONEXION DEL SUMINISTRO DE LA SECADORA

ELECTRICA=SOLO EN CANAD,_ ......................................................... 22

Requisffos el6ctricos .................................................................... 22

CONEXI6N DEL SUMINISTRO

DE LA SECADORA A GAS ................................................................. 22

Requisffos el_ctr_cos .................................................................... 22

Requisitos del suministro de gas .................................................. 23

Table des

SF:CURITF: DE LA SECHEUSE ............................................................... 34

EXIGENCES D'INSTALLATION ............................................................. 36

Outillage et pi@ces ....................................................................... 36

Exlgences d'emplacement ............................................................ 37

RACCORDEMENT )k L'ALIMENTATION ELECTRIQUE

DE LA Sf:CHEUSE ELECTRIQUE - CANADA SEULEMENT ...................... 39

Sp6ciflcations 61ectriques ............................................................. 39

RACCORDEMENT }k L'ALIMENTATION

D'UNE S_:CHEUSE ,_GAZ .................................................................... 39

Sp6ciflcations 61ectriques ............................................................. 39

Sp6citlcations de rcslimentation en gaz ....................................... 40

indite

VENTILACI6N .................................................................................... 25

Requisffos de ventilac_6n ............................................................. 25

Planiflcaci6n del sistema de ventilc=ci6n ...................................... 26

Juegos de ventilac_6n ................................................................. 27

Instalaci6n del slstema de ventilaci6n ......................................... 28

INSTALACI6N DE LAS PATAS NIVELADORAS .................................... 28

CONEXION DEL SUMINISTRO DE GAS .............................................. 29

CONEXION DEL DUCTO DE ESCAPE .................................................. 29

NIVELACION DE LA SECADORA ........................................................ 30

LISTA DE CONTROL DE LA INSTALACION TERMINADA .................... :30

CAMBIO DEL SENTIDO DE ABERTURA DE LA PUERTA ....................... 31

SOLUCI6N DE PROBLEMAS .............................................................. 33

ma_i_res

L'EVACUATION ................................................................................... 42

Exlgences ¢oncernant r_vacuatlon .............................................. 42

Planiflcafion du syst_me d'6vacuation ......................................... 43

Trousses d'6vacuation ................................................................. 44

Installation du ckcuit d'6vacuation ............................................... 45

INSTALLATION DES PIEDS DE NIVELLMENT ....................................... 45

RACCORDEMENT AU GAZ .................................................................. 46

RACCORDEMENT DU CONDUIT D'_:VACUATION ............................... 47

R_:GLAGE DE L'APLOMB DE LA SECHEUSE ......................................... 47

ACHEVER L'INSTALLATION = LISTE DE V_:RIFICATION ...................... 48

iNVERSiON DU SENS DE L'OUVERTURE DE LA PORTE (FACULITAF).. 48

DEPAN NAGE ....................................................................................... 31

4

iNSTALLATiON REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Tools needed for oil installations:

Flat-blade screwdriver

1/4" nut driver or socket

wrench (recommended)

Tape measure Vent clamps

#2 Phillips screwdriver

Tin snips (new vent

installations)

Tools needed for gas installations:

8" or 10" pipe wrench 8" or 10" adjustable wrench

(for gas connections)

Pipe-joint compound

resistant to LP gas

Ports supplied:

Level Pliers

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Utility knife

Caulking gun and compound (for

installing new exhaust vent)

Leveling legs (4)

Parts package is located in dryer drum. Check that all parts

are included.

Ports needed:

Check local codes. Check existing electrical supply and venting.

See "Electrical Requirements" and "Venting Requirements" before

purchasing parts.

Mobile home installations require metal exhaust system hardware. For

more information_ see "Assistance or Service" section in your "Use and

Care Guide",

Optional Equipment: (Not supplied with dryer)

Refer to your "Use and Care Guide" for information about accessories

available for your dryer.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (460 ram) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need:

[] A location allowing for proper exhaust installation.

See "Venting Requirements."

[] A separate 30 amp circuit for electric dryers.

[] A separate 15 or 20 amp circuit for gas dryers.

[] if you are using power supply cord, a grounded electrical outlet

located within 2 ft. (610 ram) of either side of dryer.

See "Electrical Requirements."

[] A sturdy floor to support dryer and a total weight (dryer and toad) of

200 Ibs. (90.7 kg). The combined weight of a companion appliance

should also be considered.

[] Level floor with maximum slope of 1" (25 mm) under entire dryer. If

slope is greater than 1" (25 ram), install Extended Dryer Feet Kit, Part

Number 279810. If not level, clothes may not tumble properly and

automatic sensor cycles may not operate correctly.

Do not operate your dryer at temperatures below 45°F (7°C). At lower

temperatures, the dryer might not shut off: at the end of an automatic

cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will be

exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit, installation

of the dryer in garages, closets, mobile homes, or sleeping quarters.

Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the same

closet as a dryer.

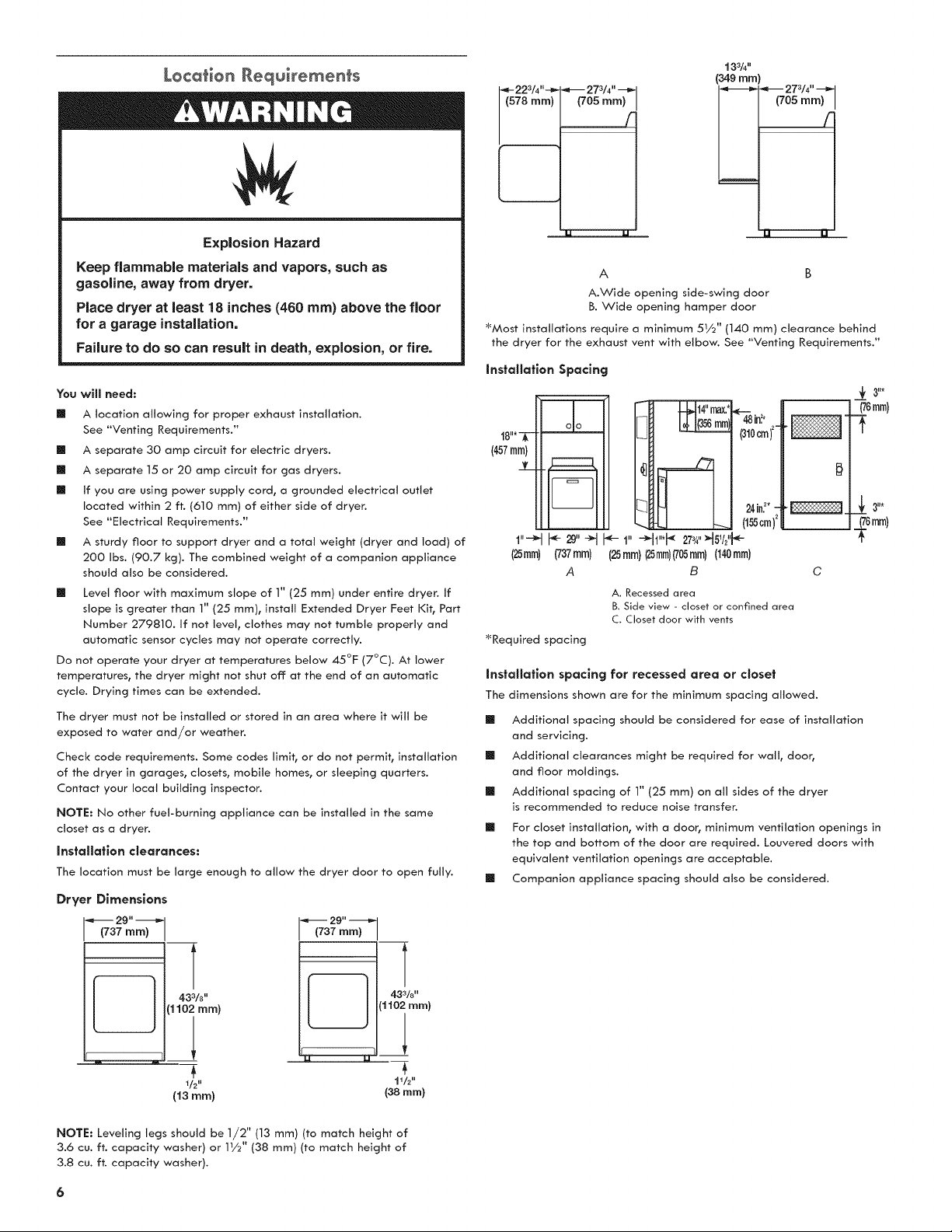

installation clearances:

The location must be large enough to allow the dryer door to open fully.

Dr_,er Dimensions

_,_ 2g" -_

(737 turn)

•_ 2g" _

(737 ram) I

133/4"

273/4. ___

(705 ram)

[

(34g ram)

(705 ram)

/-

_---- 27a/4,, _

A B

A.Wide opening side-swing door

B. Wide opening hamper door

_Most installations require a minimum 51/2 '' (140 ram) clearance behind

the dryer for the exhaust vent with elbow. See "Venting Requirements."

Installation Spacing

_f 3 I1_

_,m¢' max; _--_in._

I_ 14_ m (310cm)2=

[_ 24in._*-

._ (155cm)2

1"'-_ _- 2g"-_l _- 1" -_h"*_ 2734"H5V2"_e-

(25ram) (737mm) (25mm)(25mm)(705mm)(140ram)

A B

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

_Required spacing

installation spacing for recessed area or closet

The dimensions shown are for the minimum spacing allowed.

[] Additional spacing should be considered for ease of installation

and servicing.

[] Additional clearances might be required for wall, door,

and floor moldings.

[] Additional spacing of 1" (25 ram) on all sides of the dryer

is recommended to reduce noise transfer.

[] For closet installation, with a door, minimum ventilation openings in

the top and bottom of the door are required. Louvered doors with

equivalent ventilation openings are acceptable.

[] Companion appliance spacing should also be considered.

_76mm)

(76mm)

--T

43

110; ram)

t

I/2ml

(13 mm)

NOTE: Leveling legs should be 1/2" (13 mm) (to match height of

3.6 cu. ft. capacity washer) or 11/2'' (38 mm) (to match height of

3.8 cu. ft. capacity washer).

6

4,33/a''

(1102 ram)

(38 ram)

1lh"

Mobile home - Additional installation requirements

This dryer is suitable for mobile home installations. The installation must

conform to the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile Home

Construction

and Safety, Title 24, HUD Part 280) or the Canadian Manufactured Home

Standard CAN/CSA-Z240 MH.

[] Metal exhaust system hardware, available for purchase. For further

information, please reference the "Assistance or Service" section of

your "Use and Care Guide".

[] Special provisions must be made in mobile homes to introduce

outside air into the dryer. The opening (such as a nearby window)

should be at least twice as large as the dryer exhaust opening.

ELECTRIC DRYER POWER

HOOKUP - CANADA ONLY

E[e¢#ica[ Requirements

GROUNDING iNSTRUCTiONS

m For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

GAS DRYERPOWER

HOOKUP

Electrical Shock Hazard

Plug into a grounded 4 prong ou0et.

Failure to do so can result in death or electrical shock,

it is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with the Canadian Electrical Code, C22.1-1atest edition

and all local codes. A copy of the above codes standard may be

obtained from: Canadian Standards Association, 178 Rexdale Blvd.,

Toronto, ON M9W 1R3 CANADA.

[] To supply the required 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply on a separate 30-amp circuit,

fused on both sides of the line. A time-delay fuse or circuit breaker is

recommended. Connect to an individual branch circuit.

This dryer is equipped with a CSA International Certified Power Cord

intended to be plugged into a standard 14-30R wall receptacle. The

cord is 5 ft. (1.52 m) in length. Be sure wall receptacle is within reach

of dryer's final location.

E[ec[rica[ Requirements

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[]

120 Volt, 60 Hz., AC only, 15- or 20-amp fused electrical supply is

required. A time-delay fuse or circuit breaker is recommended. It is

also recommended that a separate circuit serving only this dryer be

provided.

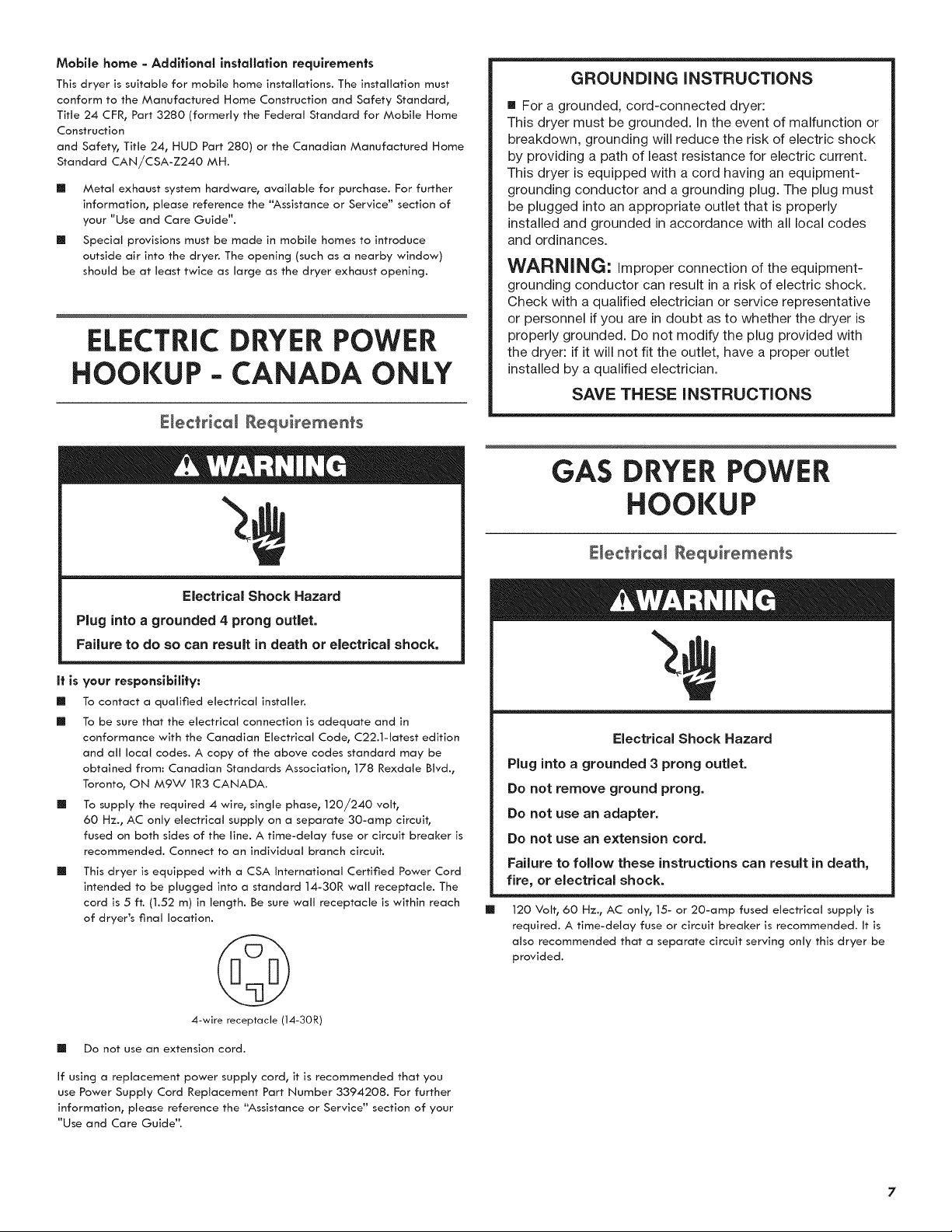

4-wire receptacle (14-30R)

[] Do not use an extension cord.

If using a replacement power supply cord, it is recommended that you

use Power Supply Cord Replacement Part Number 3394208. For further

information, please reference the "Assistance or Service" section of your

"Use and Care Guide".

GROUNDING iNSTRUCTiONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING-" Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Explosion Hazard

Use a new CSA International approved gas supply line.

instal[ a shut=off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the dryer from the gas specified

on the model/serial rating plate for use with a different gas without

consulting the serving gas supplier.

IMPORTANT: The gas installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code, ANSi Z223.1/

NFPA 54 or the Canadian Natural Gas and Propane Installation Code,

CSA B149.1.

Gas supply line

[]

1/2" NPT pipe is recommended.

[]

3/8" approved tubing is acceptable for lengths under 20 ft. (6.1 m) if

local codes and gas supplier permit.

[]

Must include 1/8" NPT minimum plugged tapping accessible for test

gauge connection, immediately upstream of the gas connection to

the dryer (see illustration).

[]

Must include a shutoff valve:

in the U.S.A.:

An individual manual shutoff valve must be installed within

six (6) feet (1.8 m) of the dryer in accordance with the National Fuel

Gas Code, ANSI Z223.1.

in Canada:

An individual manual shutoff valve must be installed in accordance

with the B149.1, Natural Gas and Propane Installation Code. It is

recommended that an individual manual shutoff valve be installed

within six (6) feet (1.8 m)

of the dryer.

The shut off valve location should be easy to reach for opening and

closing.

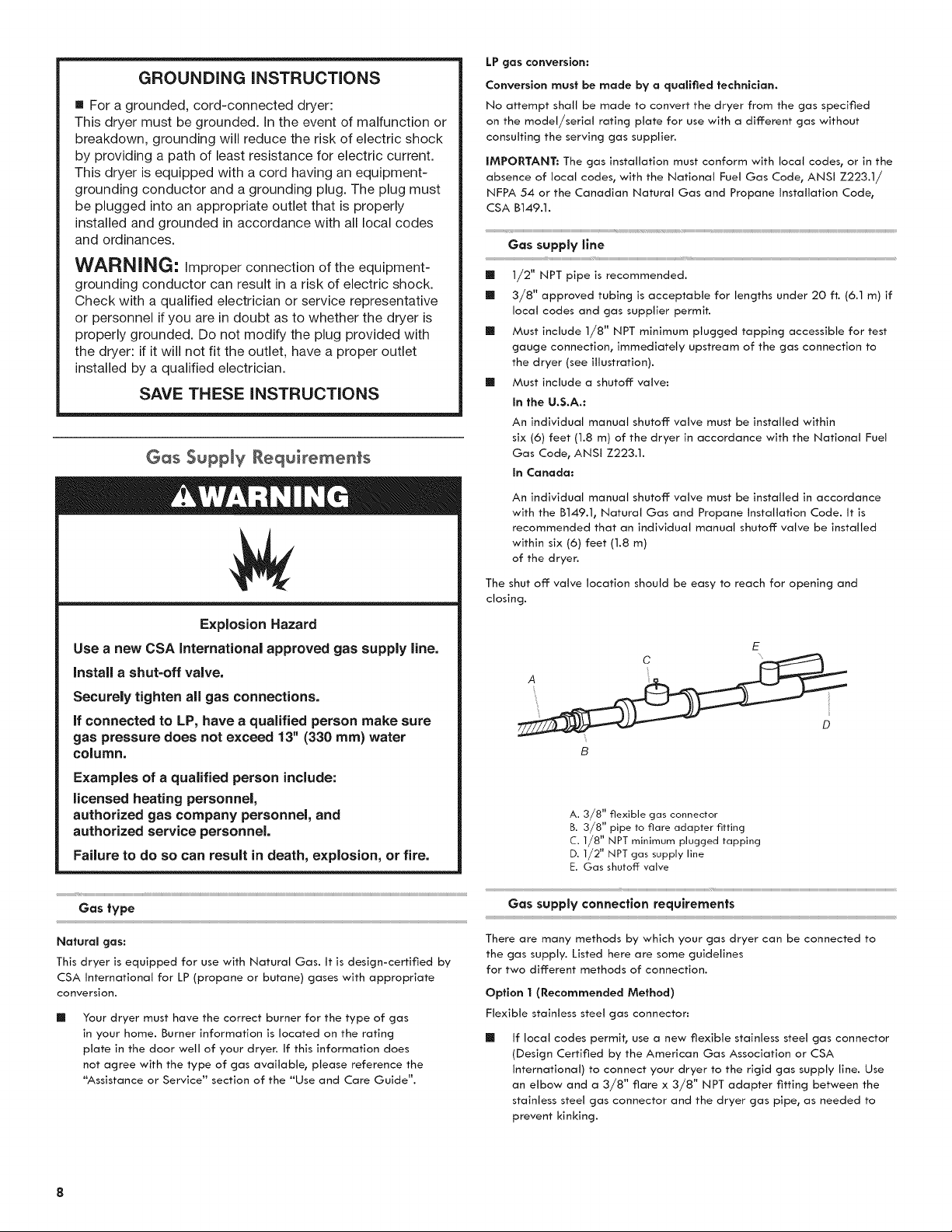

E

B

A. 3/8" flexible gas connector

B. 3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shutoff valve

Gas type

Natural gas:

This dryer is equipped for use with Natural Gas. It is design-certified by

CSA International for LP (propane or butane) gases with appropriate

conversion.

[]

Your dryer must have the correct burner for the type of gas

in your home. Burner information is located on the rating

plate in the door well of your dryer. If this information does

not agree with the type of gas available, please reference the

"Assistance or Service" section of the "Use and Care Guide".

Gas supply connection requirements

There are many methods by which your gas dryer can be connected to

the gas supply. Listed here are some guidelines

for two different methods of connection.

Option I (Recommended Method)

Flexible stainless steel gas connector:

[]

If local codes permit, use a new flexible stainless steel gas connector

(Design Certified by the American Gas Association or CSA

International) to connect your dryer to the rigid gas supply line. Use

an elbow and a 3/8" flare x 3/8" NPT adapter fitting between the

stainless steel gas connector and the dryer gas pipe, as needed to

prevent kinking.

Option2(AlternateMethod)

Approvedaluminumorcoppertubing:

[] Lengthsunder20ft.(6.1m)canuse3/8"approvedtubing

(ifcodesandgassupplierpermit).

[] ifyouareusingNaturalGas,donotusecoppertubing.

[] 3/8"flarex3/8"NPTadapterfittingbetweendryerpipeand3/8"

approvedtubing.

[] Lengthsover20ft.(6.1m)shoulduselargertubingandadifferent

sizeadapterfitting.

[] ifyourdryerhasbeenconvertedtouseLPgas,3/8"LPcompatible

coppertubingcanbeused.Ifthetotallengthofthesupplylineis

morethan20ft.(6.1m),uselargerpipe.

NOTE:PipejointcompoundsthatresisttheactionofLPgasmustbe

used.DonotuseTEFLON®ttape.

Dryer gas pipe

[] The gas pipe that comes out through the rear of your dryer has a

3/8" male pipe thread.

VENTING

Venting Requirements

Fire Hazard

Use a heavy rnetal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

1¼"

(32 ram)

//

A -=_-- 9¼"--_

A. 3/8" NPT dryer pipe

Burner input requirements

Elevations up to lO,O00 ft. (3,048 an):

[] The design of this dryer is certified by CSA international for use at

altitudes up to 10,000 ft. (3,048 m), above sea level at the B.T.U.

rating indicated on the model/serial number plate. Burner input

adjustments are not required when the dryer is operated up to this

elevation.

Elevations above 10,000 ft. (3,048 an):

[] When installed above 10,000 ft. (3,048 m) a 4% reduction of the

burner B.T.U. rating shown on the model/serial number plate is

required for each 1,000 ft. (305 m) increase in elevation.

Gas supply pressure testing

[] The dryer must be disconnected from the gas supply piping system

during pressure testing at pressures greater than

1/2 psi.

(235 ram)

WARNING; Toreducetheriskoffire,thisdryerMUSTBEEXHAUSTED

OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent, chimney, wall,

ceiling_ attic, crawlspace, or a concealed space of a building. Only rigid

or flexible metal vent shall be used for exhausting.

((),

(102mm)

t

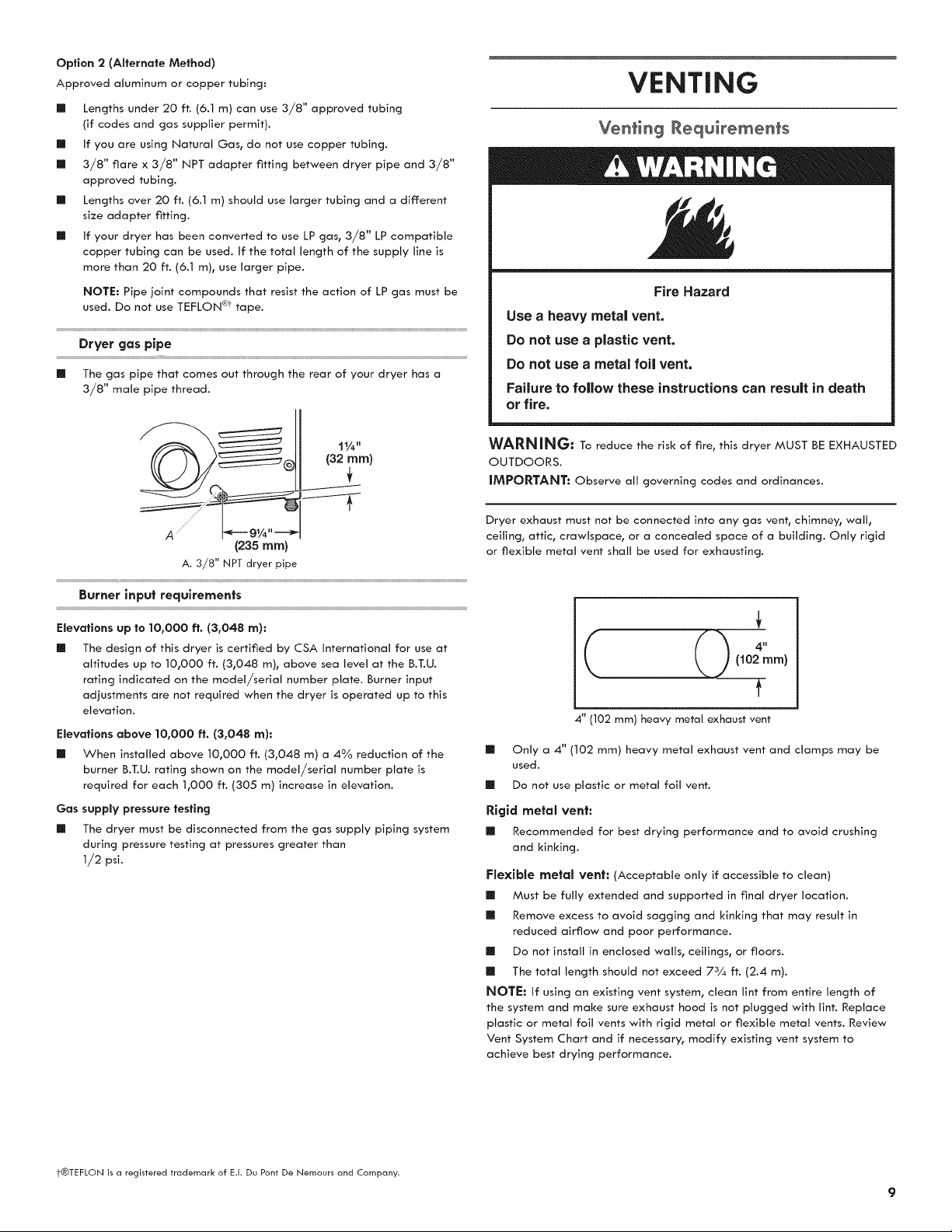

4" (102 ram) heavy metal exhaust vent

[] Only a 4" (102 mm) heavy metal exhaust vent and clamps may be

used.

[] Do not use plastic or metal foil vent.

Rig(c{ metal vent:

[] Recommended for best drying performance and to avoid crushing

and kinking.

F(ex(b(e mete( vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer location.

[] Remove excess to avoid sagging and kinking that may result in

reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 73¼ ft. (2.4 m).

NOTE: If using an existing vent system, clean tint from entire length of

the system and make sure exhaust hood is not plugged with lint. Replace

plastic or metal foil vents with rigid metal or flexible metal vents. Review

Vent System Chart and if necessary, modify existing vent system to

achieve best drying performance.

t®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Exhaust hoods:

[] Must be at least 12" (305 ram) from ground or any object that may

obstruct exhaust (such as flowers_ rocks_ bushes_ or snow).

PJan Ven_ System

Recommended exhaust JnstaJJatJons

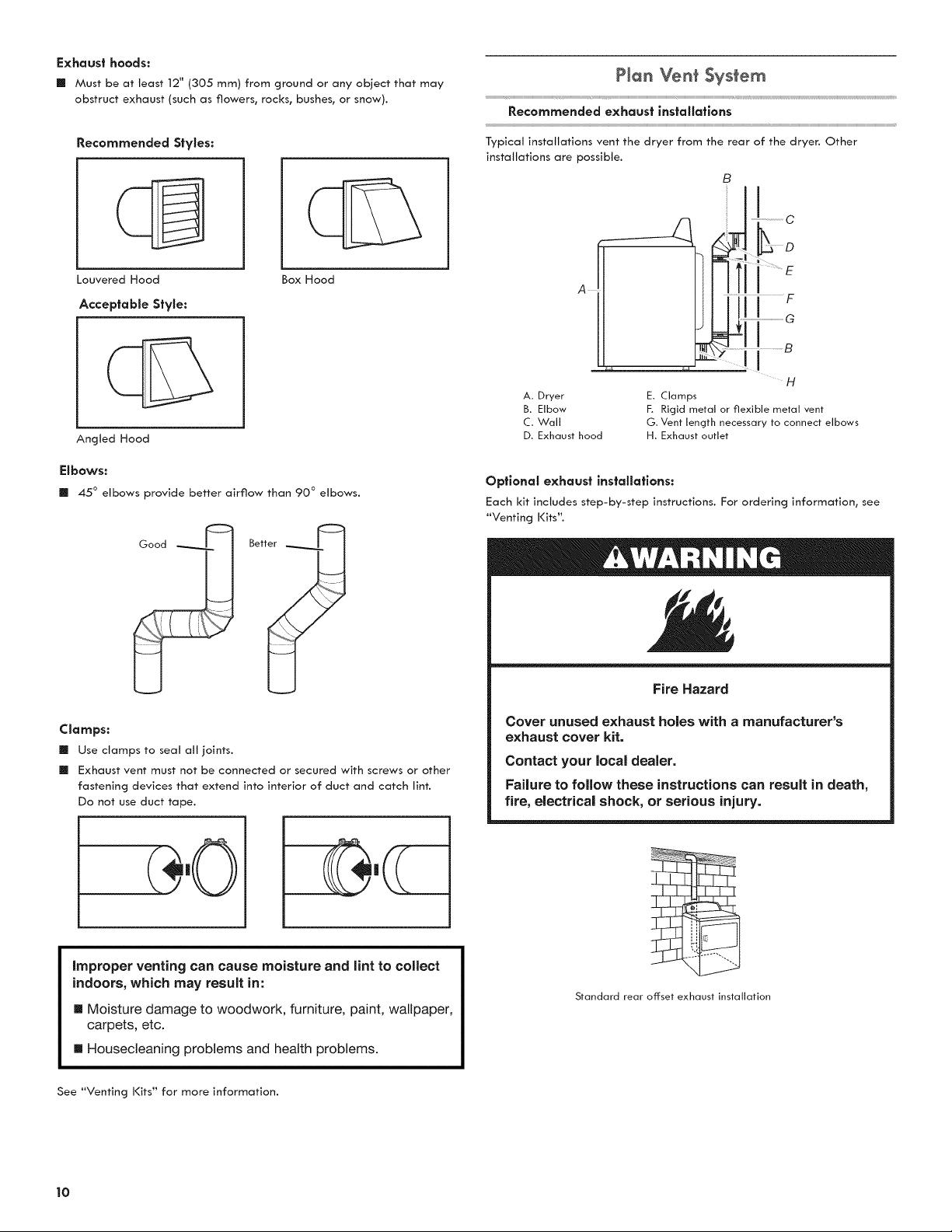

Recommended Styles:

Louvered Hood

Acceptable Style:

Angled Hood

Elbows:

[] 45 ° elbows provide better airflow than 90 ° elbows.

Box Hood

Typical installations vent the dryer from the rear of the dryer. Other

installations are possible.

B

H

A. Dryer E. Clamps

B. Elbow F. Rigid metal or flexible metal vent

C. Wall G, Vent length necessary to connect elbows

D. Exhaust hood H. Exhaust outlet

Optional exhaust installations:

Each kit includes step-by-step instructions. For ordering information_ see

"Venting Kits".

Clamps:

[]

Use clamps to seat all joints.

[]

Exhaust vent must not be connected or secured with screws or other

fastening devices that extend into interior of duct and catch lint.

Do not use duct tape.

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

See "Venting Kits" for more information.

Fire Hazard

Cover unused exhaust holes with a manufacturer's

exhaust cover kit.

Contact your local dealer.

Failure to follow these instructions can result in death,

fire, electrical shock, or serious injury.

Standard rear offset exhaust installation

10

Alternate installations for dose clearances

Venting systems come in many varieties. Select the type best for your

installation. Two close-clearance installations are shown. Refer to the

manufacturer's instructions.

Over-The-Top installation (also available with one offset elbow)

Periscope installation

NOTE: The following kits for close clearance alternate installations are

available for purchase.

Ven_ing Ki_s

For more information, call ]=800=469=4663, or visit us

at www.seors.com, in Canada, call

1-800-469-4663 or visit us at www.seors.co.

Port Number Descrlpffons

8171587RP 0-5" Metal vent periscope

4396037RP 0"-18" Metal vent periscope

4396011RP 18" - 29" Metal vent periscope

4396014 29" - 50" Metal vent periscope

4392892 In-Wall metal DuraVent TM Periscope

4396028 Sure Connect TM venting kit

(over-the-top installation)

4396009RP 5' Universal connect vent, flexible dryer venting

4396010RP 6' SecureConnect TM vent, flexible dryer venting

4396013RB Dryer vent installer's kit

4396033RP 5' flexible dryer venting with clamps

4396727RP 8' flexible dryer venting with clamps

4396004 Dryer offset elbow

4396005 Wall offset elbow

4396006RW DuraSafe TM close elbow

4396007RW Through-the-wall vent cap

4396008RP 4" steel dryer venting clamps - 2 pack

8212662 Flush mounting Iouvered vent hood 4"

Special provisions for mobffe home instaffations:

The exhaust vent must be securely fastened to a noncombustible portion

of the mobile home structure and must not terminate beneath the mobile

home. Terminate the exhaust vent outside.

Determine vent path:

[] Select route that will provide straightest and most direct

path outdoors.

[] Plan installation to use fewest number of elbows and turns.

[] When using elbows or making turns, allow as much room

as possible.

[] Bend vent gradually to avoid kinking.

[] Use as few 90 ° turns as possible.

Determine vent length and elbows needed for best drying

performance:

[] Use following Vent System Chart to determine type of vent material

and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified

in Vent System Chart. Exhaust systems longer than those specified

will:

[] Shorten life of dryer.

[] Reduce performance, resulting in longer drying times

and increased energy usage.

The Vent System Chart provides venting requirements that will help

achieve best drying performance.

(f Vent $, 'stem Chart

Number of

90 ° turns or

elbows

0

1

4

Type

of vent

Rigldmetol

Rigldmetol

Rigldmetol

Rigldmetol

Rigldmetol

Box/Iouvered Angled

hoods hoods

64 ft. (20 m) 58 ft. (17.7 m)

54 ft. (16.5 m) 48 ft. (14.6 m)

44 ft. (13.4 m) 38 ft. (11.6 m)

35 ft. (10.7 m) 29 ft. (8.8 m)

27 ft. (8.2 m) 21 ft. (6.4 m)

NOTE: Side and bottom exhaust installations have a 90 ° turn inside

the dryer. To determine maximum exhaust length, add one 90 ° turn

to the chart.

11

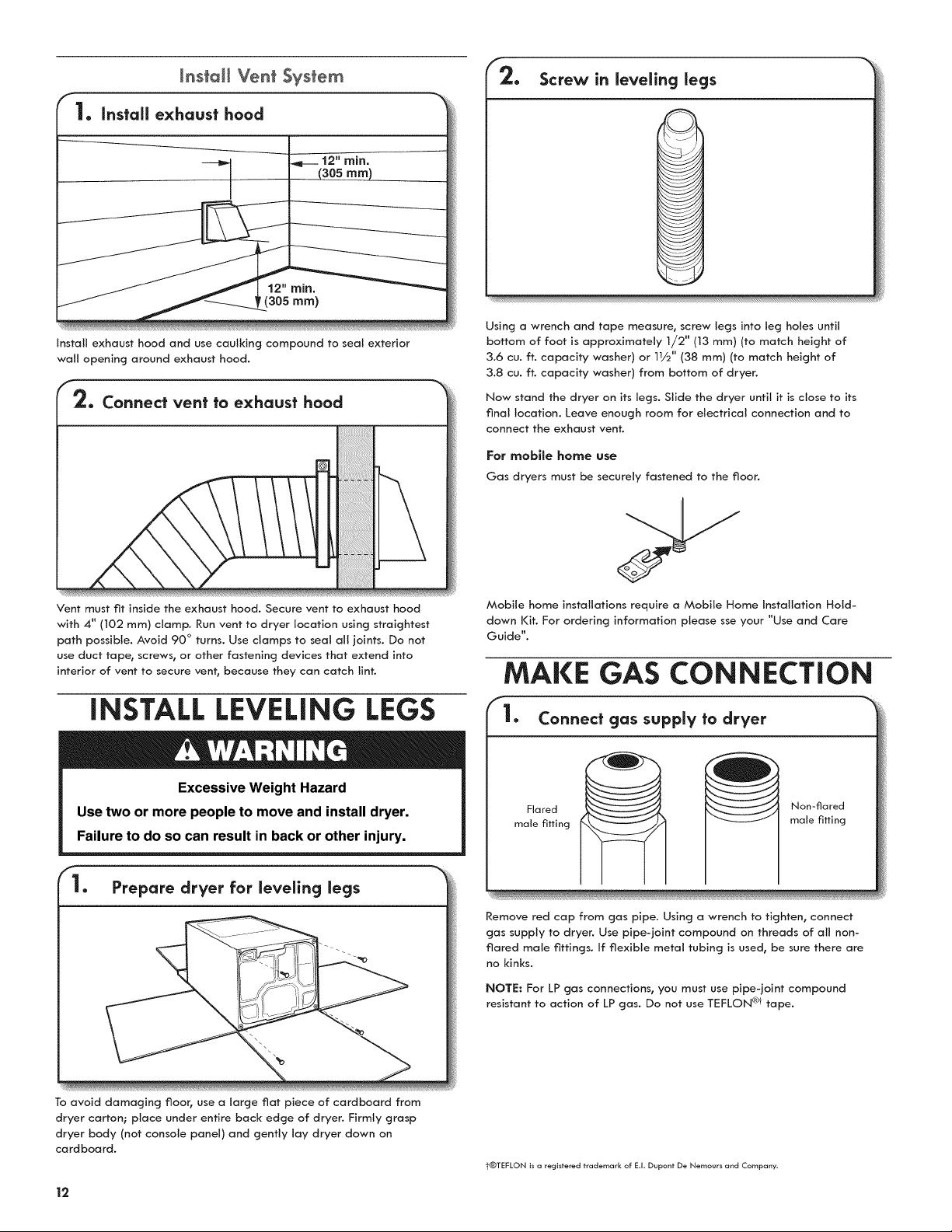

install exhaust hood and use caulking compound to seal exterior

wall opening around exhaust hood.

2. Connect vent to exhaust hood

Screw in leveling legs

Using a wrench and tape measure, screw legs into leg holes until

bottom of foot is approximately 1/2" (13 mm) (to match height of

3.6 cu. ft. capacity washer) or 11/2'' (38 mm) (to match height of

3.8 cu. ft. capacity washer) from bottom of dryer.

Now stand the dryer on its legs. Slide the dryer until it is close to its

final location. Leave enough room for electrical connection and to

connect the exhaust vent.

For mobffe home use

Gas dryers must be securely fastened to the floor.

Vent must fit inside the exhaust hood. Secure vent to exhaust hood

with 4" (102 ram) clamp. Run vent to dryer location using straightest

path possible. Avoid 90 ° turns. Use clamps to seal all joints. Do not

use duct tape, screws, or other fastening devices that extend into

interior of vent to secure vent, because they can catch lint.

INSTALL LEVELING LEGS

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

Prepare dryer for leveling legs

Mobile home installations require a Mobile Home installation Hold-

down Kit. For ordering information please sse your "Use and Care

Guide".

MAKE GAS CONNECTION

• Connect gas supply to dryer

Flared

male fitting

Remove red cap from gas pipe. Using a wrench to tighten, connect

gas supply to dryer. Use pipe-joint compound on threads of all non-

flared male fittings. If flexible metal tubing is used, be sure there are

no kinks.

NOTE: For LP gas connections, you must use pipe-joint compound

resistant to action of LP gas. Do not use TEFLON @ tape.

Non-flared

male fitting

To avoid damaging floor, use a large flat piece of cardboard from

dryer carton; place under entire back edge of dryer. Firmly grasp

dryer body (not console panel) and gently lay dryer down on

cardboard.

12

t®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

2. Plan pipe fitting connection

A. 3/8" flexible gas connector

g ¸

B. 3/8" dryer pipe

A combination of pipe fittings must be used to connect dryer

to existing gas line. A recommended connection is shown. Your

connection may be different, according to supply line type, size,

and location.

Co 3/8" to 3/8" pipe elbow

D. 3/8" pipe-to-flare adapter fitting

C

3. Open shut=off valve

Closed valve

Open valve

Open shut-off valve in supply line; valve is open when handle is

parallel to gas pipe. Then, test all connections by brushing on an

approved noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leaks found.

CONNECT VENT

Move dryer to final location. Avoid crushing or kinking vent. After

dryer is in place, remove cardboard from under the dryer.

LEVELDRYER

1. keveJ dryer

Place level here Place level here

Check levelness of dryer from side to side. Repeat from front to back.

NOTE: The dryer must be level for the moisture sensing system to

operate correctly.

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer, if connecting to existing vent, make sure vent is clean. Dryer

vent must fit over dryer exhaust outlet and exhaust hood. Check that

vent is secured to exhaust hood with a 4" (102 mm) clamp.

Not Level LEVEL Not Level

2. Adjust leveling legs

if dryer is not level or the same height as the washer, prop up using a

wood block. Use wrench to adjust legs up or down, and check again

for levelness. Once legs are level, make sure all four legs are snug

against the floor before tightening them.

13

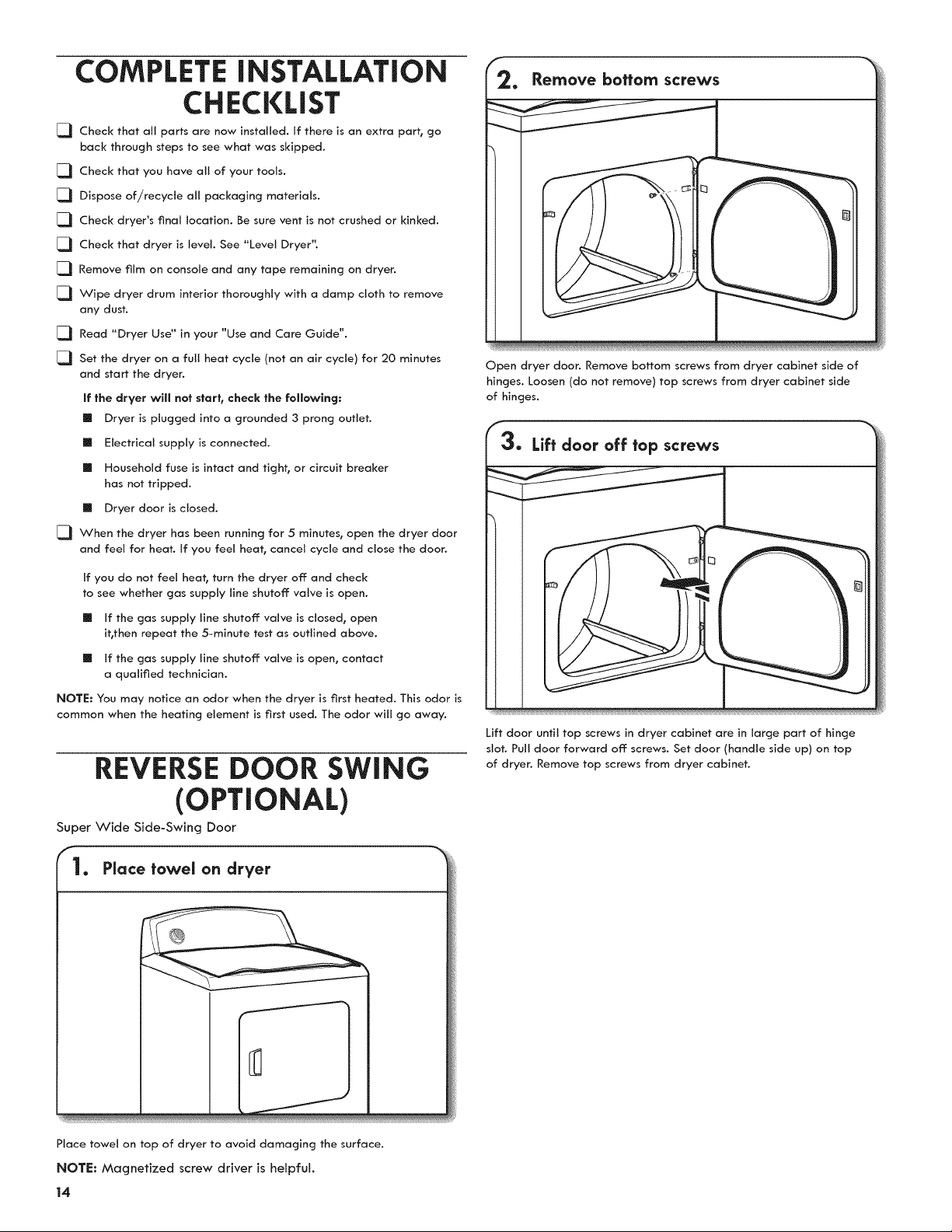

COMPLETE iNSTALLATiON

CHECKLIST

[_ Check that all parts are now installed. If there is an extra part, go

back through steps to see what was skipped.

[_ Check that you have all of your tools.

[_ Dispose of/recycle all packaging materials.

[_ Check dryer's final location. Be sure vent is not crushed or kinked.

[_ Check that dryer is level. See '"Level Dryer _".

[_ Remove film on console and any tape remaining on dryer.

[_ Wipe dryer drum interior thoroughly with a damp cloth to remove

any dust.

[_ Read "Dryer Use _ in your "Use and Care Guide".

[_ Set the dryer on a full heat cycle (not an air cycle) for 20 minutes

and start the dryer.

If the dryer wlll not start, check the following:

[] Dryer is plugged into a grounded 3 prong outlet.

[] Electrical supply is connected.

[] Household fuse is intact and tight, or circuit breaker

has not tripped.

[] Dryer door is closed.

[_ When the dryer has been running for 5 minutes, open the dryer door

and feel for heat. If you feel heat, cancel cycle and close the door.

Remove bottom screws

Open dryer door. Remove bottom screws from dryer cabinet side of

hinges. Loosen (do not remove) top screws from dryer cabinet side

of hinges.

If you do not feel heat, turn the dryer off: and check

to see whether gas supply line shutoff: valve is open.

[] If the gas supply line shutoff: valve is closed, open

it, then repeat the 5-minute test as outlined above.

[] If the gas supply line shutoff: valve is open, contact

a qualified technician.

NOTE: You may notice an odor when the dryer is first heated. This odor is

common when the heating element is first used. The odor will go away.

REVERSE DOOR SWING

(OPTIONAL)

Super Wide Side-Swing Door

1. Place towel on dryer

Lift door until top screws in dryer cabinet are in large part of hinge

slot. Pull door forward off: screws. Set door (handle side up) on top

of dryer. Remove top screws from dryer cabinet.

Place towel on top of dryer to avoid damaging the surface.

NOTE: Magnetized screw driver is heJpfuk

14

4. Remove screws from hinges

7. Rotate outer door

\

Remove screws attaching hinges to door.

5. Remove screws from door

Remove screws at top, bottom, and side of door (4 screws) that hold

the inner and outer door together. Holding door over towel on dryer,

grasp sides of outer door and lift to separate it from inner door. Set

outer door aside.

NOTE: Do not pry apart with putty knife or screwdriver. Do not pull

on door seal or plastic door catches.

F

6. Switch door catch, bezel, & plug

Rotate outer door 180 ° and set it back down on inner door. Reattach

outer door panel to inner door panel so handle is on the side where

hinges were just removed. Insert 4 door screws.

8. Rip door over

Flip door over so handle side is down.

f

9. Attach door hinges

f

Catch and bezel Plug

Remove the door catch, bezel, and plug from the inside of the inner

door by squeezing and pulling/pushing them. Place the door catch,

bezel, and plug on the sides opposite from where they were.

Reattach door hinges to dryer door so that the larger hole is at the

bottom of the hinge.

15

Remove door strike and door strike plug from dryer cabinet. Insert

the door strike into door strike plug hole and secure with screw. Insert

door strike plug into original door strike hole and secure with screw.

13. Check door strike alignment

Close door and check that door strike aligns with door catch. If it is

needed, slide door catch left or right within slot to adjust alignment.

Remove and transfer hinge hole plugs

Use a small, fiat-blade screwdriver to gently remove 4 hinge hole

plugs on left side of dryer cabinet. Transfer plugs into hinge holes on

opposite side of dryer cabinet.

Insert screws in hinge holes on dryer

cabinet

TROUBLESHOOTING

See the "Use and Care Guide" or visit our website and reference

Frequently Asked Questions to possibly avoid the cost of a service call.

NOTE: Two people may be needed to reinstall door.

Insert screws into the bottom holes on left side of dryer cabinet.

Tighten screws halfway. Position door so large end of door hinge slot

is over screws. Slide door up so screws are in bottom of slots. Tighten

screws. Insert and tighten top screws in hinges.

16

Loading...

Loading...