Kenmore 11071062000, 11071082000 Owner’s Manual

Sensor Smart™ Gas Dryer

Use and Care Guide

Secadora de Gas Sensor Smart

Manual de Uso y Cuidado

™

3978713A

Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com

TABLE OF CONTENTS

W ARRANTY

WARRANTY......................................................................... 2

DRYER SAFETY.................................................................. 3

INSTALLATION INSTRUCTIONS....................................... 5

Tools and parts ............................................................................5

Location Requirements ...............................................................5

Electrical Requirements...............................................................6

Gas Supply Requirements...........................................................7

Venting Requirements..................................................................8

Determine Vent Length ................................................................8

Install Vent System.....................................................................10

Install Leveling Legs...................................................................10

Level Dryer .................................................................................10

Make Gas Connection ...............................................................10

Connect Vent..............................................................................11

Complete Installation .................................................................11

FEATURES AND BENEFITS............................................. 11

TOTAL CARE™ SYSTEM............................................................11

Auto Temp Control.....................................................................11

EVENHEAT

“SMART” Cool Down Period .....................................................11

Jeans Cycle................................................................................11

™

with Auto Temp Control Drying System...............11

DRYER USE....................................................................... 12

Loading.......................................................................................12

Drying and Cycle Tips................................................................12

Control Panel..............................................................................13

Starting Your Dryer.....................................................................13

Stopping Your Dryer ..................................................................13

Pausing or Restarting.................................................................14

Changing Cycles, Options and Modifiers..................................14

Cycles.........................................................................................14

Options.......................................................................................15

Modifiers.....................................................................................15

Dryer Status................................................................................16

TUMBLE FREE™ Heated Dryer Rack .......................................16

DRYER CARE.................................................................... 17

Cleaning the Lint Screen............................................................17

Cleaning the Dryer Interior.........................................................17

Vacation and Moving Care.........................................................17

Removing Accumulated Lint From

Inside The Dryer Cabinet ...........................................................17

Changing the Drum Light...........................................................18

TROUBLESHOOTING.......................................................18

WE SERVICE WHAT WE SELL ........................................ 19

Full One Year Warranty on Mechanical and Electrical Parts

For one year from the date of purchase, when this dryer is

installed and operated according to the instructions provided in

this Use and Care Guide, Sears will repair this dryer, free of

charge, if defective in materials or workmanship.

Exhausting this dryer with a plastic vent can void this

NOTE:

warranty. See "Install ation Instruct ion s" for the comp let e exhaus t

requir eme n ts fo r this dry e r.

Limited Two-Year W arranty on SENSOR SMART™

Electronic Control Board

For two years from the date of purchase, Sears will replace the

electronic control board if defective in material or workmanship.

You will be charged for labor after the first year.

Warranty Restriction

If the dryer is subject to other than private family use, the above

warranty coverage is effective for only 90 days.

Warranty Service

Warranty service is available by contacting the nearest Sears

Service Center. This warranty applies only while the product is in

use in the United States. This warranty gives you specific legal

rights and you may also have other rights which vary from state

to state.

For Sears Warranty information or to contact a Sears Service

Center, call 1-800-469-4663.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

In the space following, record your complete model number,

serial number, and purchase date. You can find this information

on the model and serial number label, located at the top inside

dryer door well.

Have this information available to help you quickly obtain

assistance or service when you contact Sears concerning your

appliance.

Model number 110. ___________________ __________________________

Serial number __________________________________________________

Purchase date __________________________________________________

Save these instructions and your sales receipt for future

reference.

2

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING.” These words mean:

You can be killed or seriously injured if you don't

immediately follow instructions.

You can be killed or seriously injured if you don't

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can

happen if the instructions are not followed.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

–

or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

–

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

Installation and service must be performed by a qualified installer, service agency, or

–

the gas supplier.

3

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic

WARNING:

precautions, including the following:

■ Read all instructions before using the dryer.

■ Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a load to catch fire.

■ Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable,

or explosive substances as they give off vapors

that could ignite or explode.

■ Do not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children.

■ Before the dryer is removed from service or dis-

carded, remove the door to the drying compartment.

■ Do not reach into the dryer if the drum is moving.

■ Do not install or store the dryer where it will be

■ Do not repair or replace any part of the dryer or

attempt any servicing unless specifically recommended in this Use and Care Guide or in published

user-repair instructions that you understand and have

the skills to carry out.

■ Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of

the fabric softener or product.

■ Do not use heat to dry articles containing foam rubber

or similarly textured rubber-like materials.

■ Clean lint screen before or after each load.

■ Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint,

dust, and dirt.

■ The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

■ See Installation Instructions for grounding require-

ments.

exposed to the weather.

■ Do not tamper with controls.

SAVE THESE INSTRUCTIONS

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

4

INSTALLATION

INSTRUCTIONS

T ools and parts

Check that you have everything necessary for correct installation.

Proper installation is your responsibility.

Location Requirements

■ 8” or 10” pipe wrench

■ 8” or 10” adjust able

wrench (for gas

connections)

■ flat-blade screwdriver

■ adjustable wrench that

opens to 1 in. or hexhead

socket wrench (for

adjusting dryer feet)

■ level

■

¹⁄₄

in. nut driver or socket

wrench

■ knife

■ safety glasses

■ duct tape

■ pipe-joint com p o un d

resistant to L.P. gas

■ caulking gu n and

compound (for installing

new exhaust vent)

■ gloves

■ pliers

Parts supplied

Remove parts package from dryer drum. Check that all parts

were included.

4 leveling legs

Parts needed:

Check local codes and with gas supplier, check existi ng gas

supply, electrical supply and venting, and read “Electrical

Requirements”, “Gas Supply Requirements” and “Venting

Requirements” before purchasing parts.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the

floor for a garage installation.

Failure to do so can result in death, explosion,

or fire.

You will need

■ A location that allows for proper exhaust installation. A gas

dryer must be exhausted to the outdoors. See “Venting

Requirements.”

■ A grounded electrical outlet located within 2 ft (61 cm) of

either side of the dryer. See “Electrical Requirements.”

■ A sturdy floor to support the dryer with a total weight (dryer

and load) of 175 lbs (79 kgs).

■ A level floor with a maximum slope of 1 in. (2.5 cm) under

entire dryer. (If slope is greater than 1 in. (2.5 cm), install

Extended Dryer Feet kit, Part No. 279810.) Clothes may not

tumble properly and automatic sensor cycles may not

operate correctly if dryer is not level.

Do not operate or store your dryer in a location wi th year-round

temperatures below 45ºF (7ºC). At lower temperatures, the dryer

might not shut off at the end of an automatic cycle. Drying times

can be extended.

Install the dryer where it is protected from water and/or weat her.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

No other fuel-burning appliance can be installed in the

NOTE:

same close t as a dryer.

WARNING:

BE EXHAUSTED OUTDOORS.

To reduce the risk of fire, this appliance MUST

5

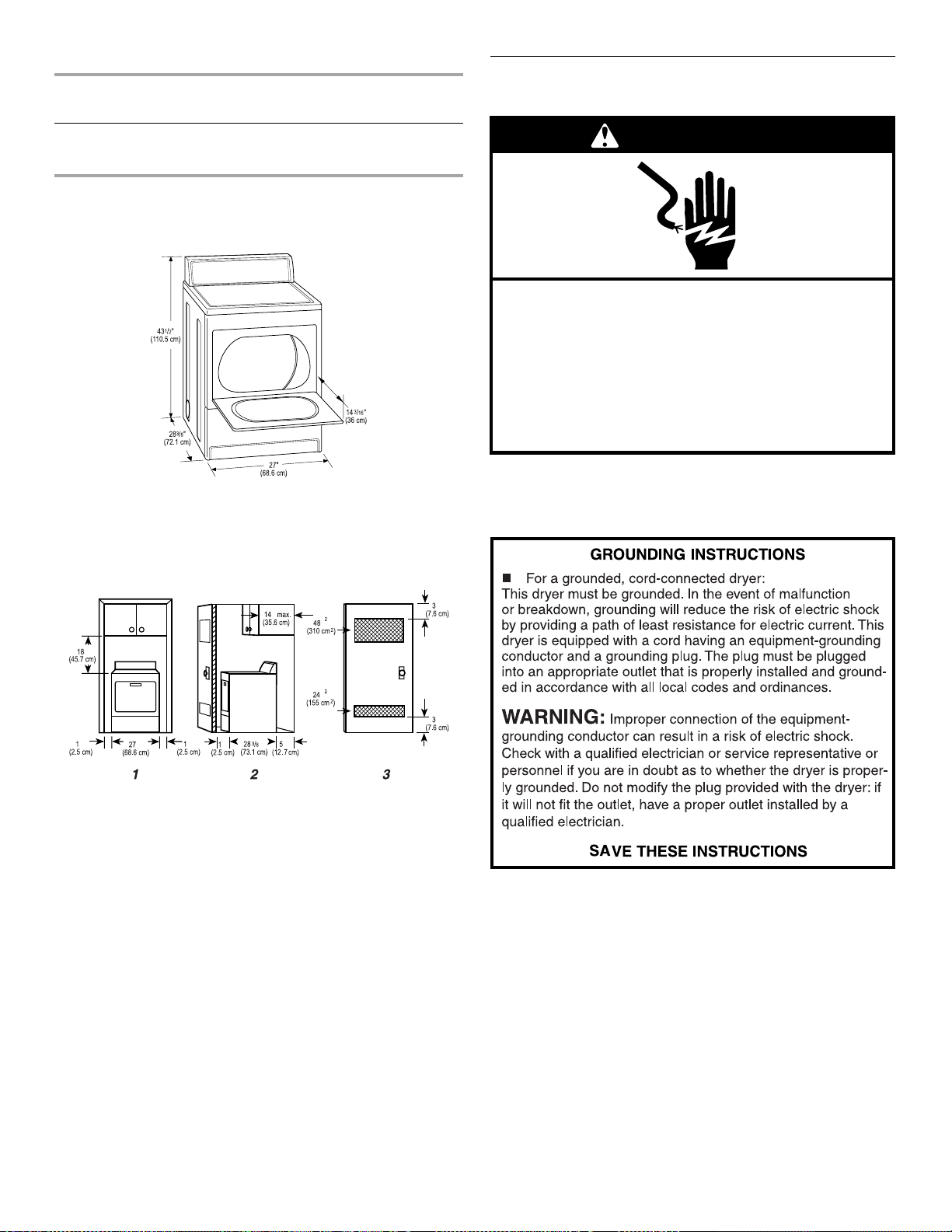

Recommended/Minimum Clearances

Back Sides Top Front

Electrical Requirements

(Closet only)

Recessed and

Closet

5”/0”

(12.7 cm)

1”/0”

(2.5 cm)

18”/18”

(45.7 cm)

1”/1”

(2.5 cm)

Most installations require a minimum 5 in. (12.7 cm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.” The location must be large enough to fully open

the dryer door.

Recommended installation spacing for recessed area or

closet installation

The dimension s shown following are for the recommended

spacing allowed, except the closet door ventilation openings.

The dimensions shown for the closet door ventilation openings

are the minimum spacings required.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

■ 120-Volt, 60-Hz., AC-only, 15- or 20-ampere fused electrical

supply is required. (Time-delay fuse or circuit breaker is

recommended.) It is recommended that a separate circuit

serving only this dryer be provided.

"

"

"

■ Additional spacing sh ould be considered for ease of

"

1. Recessed Area

2. Side view - closet or confined area

3. Closet door with vents

"

"

"

"

"

"

"

"

installation an d se rvi c ing .

■ Additional clearances might be required for wall, door and

floor moldings.

■ Additional spacing of 1 in. (2.5 cm) on all sides of the dryer is

recommended to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

Mobile home installations require:

■ Mobile home Installation Kit, Part Number 346764.

6

Gas Supply Requirements

Explosion Hazard

Use a new AGA or CSA approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make

sure gas pressure does not exceed 13" (33 cm)

water column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

There are many methods by which your gas dryer can be

connected to the gas supply. Listed here are some guidelines

for two different methods of connection.

Option 1 (Recommended Method): Rigid

¹⁄₂ in. IPS pipe used with a combination of pipe fittings.

■

■ Optional connection to dryer:

gas supply line:

If local codes permit, use flexible stainless steel tubing

(Design Certified by the American Gas Association or CSA

International) to connect your dryer to the rigid gas supply

line. Use an elbow and a ³⁄₈ in. flare x ³⁄₈ in. NPT adapter fitting

between the stainless steel tubing and the dryer gas pipe, as

needed to prevent kinking.

Option 2 (Alternate Method): Tubing

■ Lengths under 20 ft (6.1 m) can use ³⁄₈ in. approved tubing (if

gas supply line:

codes and gas supplier per mit).

■ If you are using natural gas, do not use copper tubing.

³⁄₈ in. flare x ³⁄₈ in. NPT adapter fitting between dryer pipe and

■

³⁄₈ in. approved tubing

■ Lengths over 20 ft (6.1 m) should use larger tubing and a

different size adapter fitting.

■ If your dryer has been converted to use L.P. gas,

³⁄₈

in. L.P.

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft (6.1 m), use larger pipe.

Pipe joint compounds that r esist the action of L.P. gas

NOTE:

must be used. Do not use TEFLON

®

tape.

Failure to do so can result in death, explosion,

or fire.

Gas Type

Natural Gas:

This dryer is equipped for use with NATURAL GAS. It is designcertified by CSA International for L.P. (propane or butane) gases

with appropriate conversion.

■ Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate

in the door well of your dryer. If this information does not

agree with the type of gas available, contact your local Sears

store or Sears Service Center.

L.P. gas conversion:

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

Conversion must be made by a qualified technician.

See gas valve burner base for gas conversion kit part number.

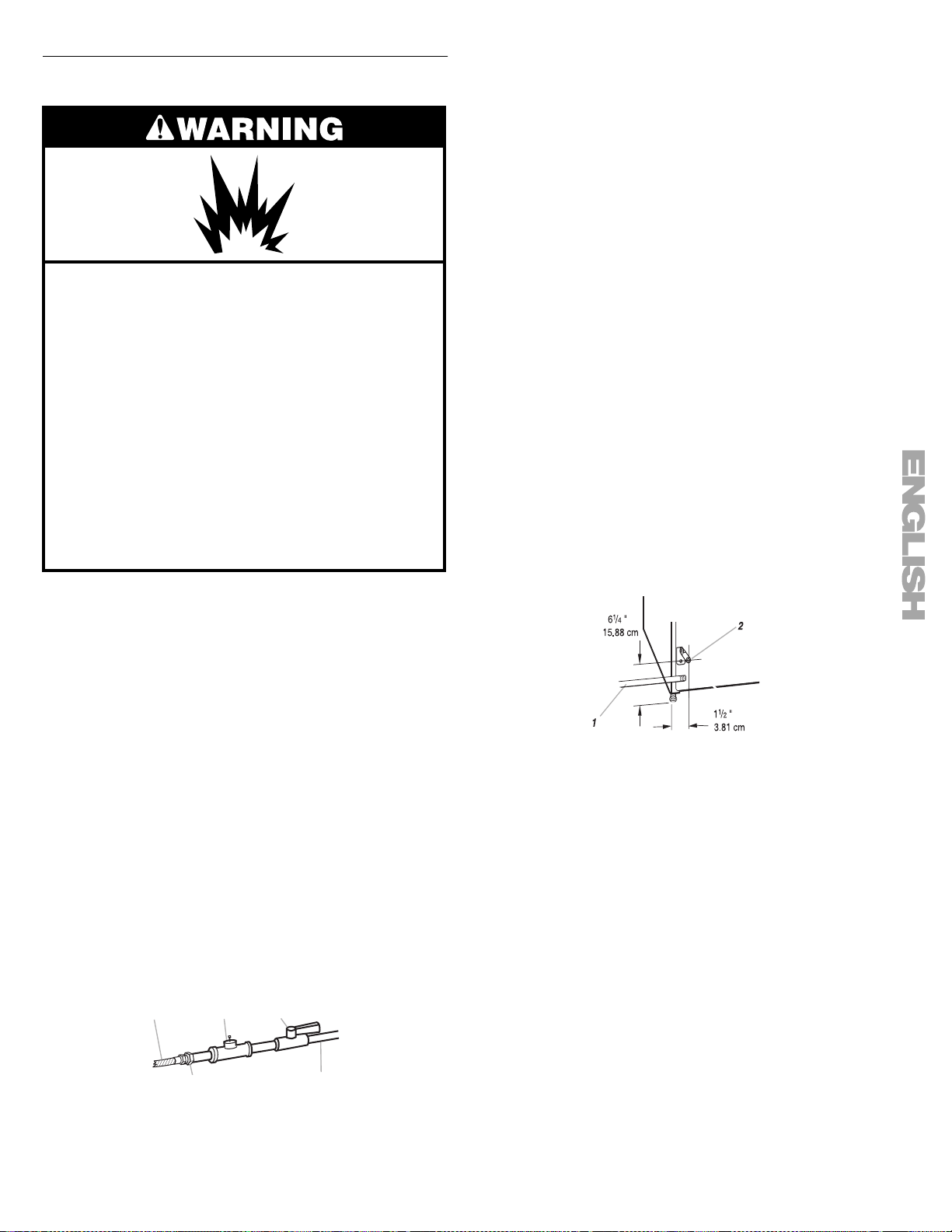

Gas Supply Line Must Have:

■

¹⁄₈

in. NPT plugged tapping, immediately upstream of the gas

connection (see illustration)

■ Shutoff valve:

Required

should be easy to reach for opening and clos ing.

to be within 6 ft (183 cm ) of appli ance. The loca tion

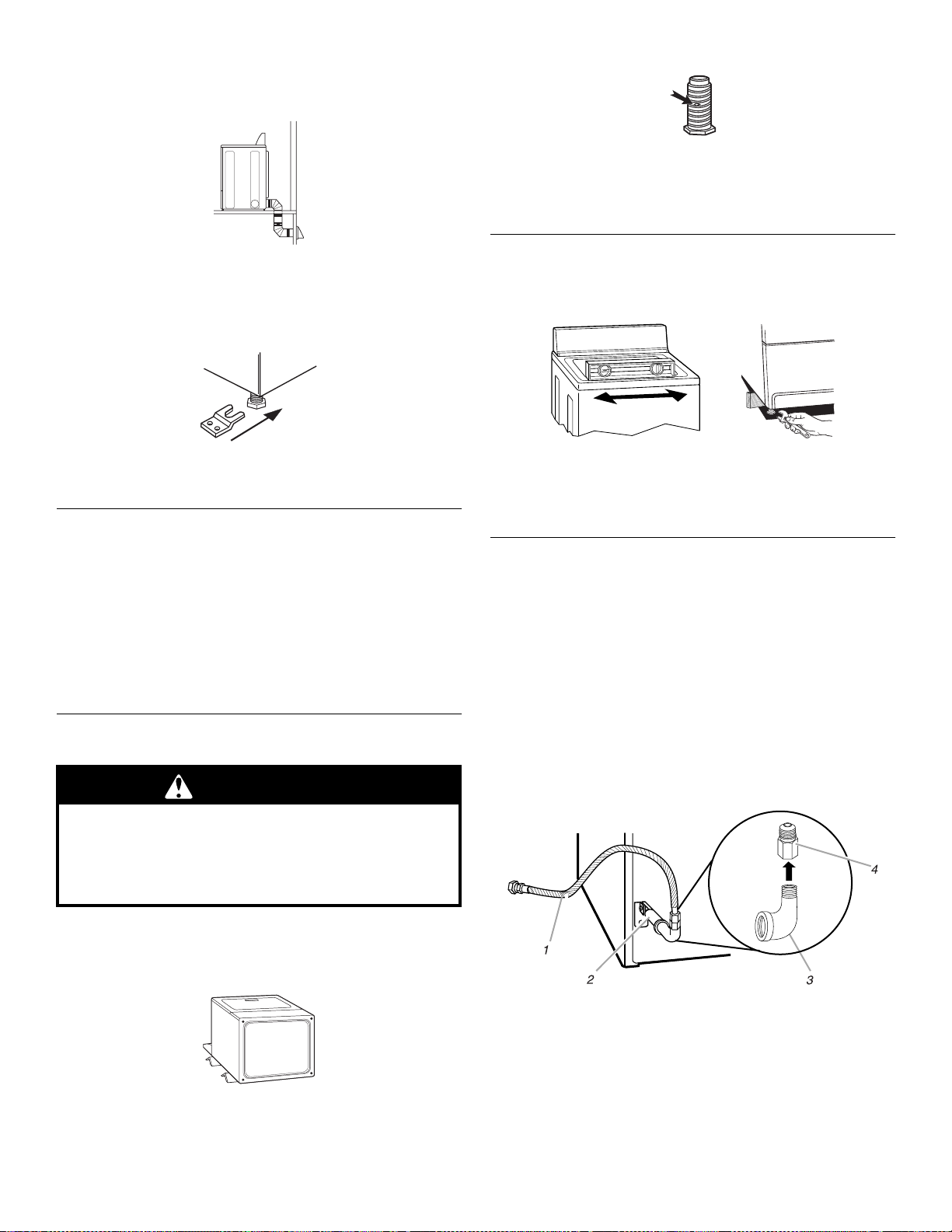

1

1.

³⁄₈

in. flexible gas connector

³⁄₈

in. pipe to flare adapter fitting

2.

¹⁄₈

in. NPT plugged tapping

3.

4. ½ in. NPT gas supply line

5. Gas shut-off valve

3

2

5

4

Dryer Gas Pipe

■ The gas pipe that comes out through the rear of your dryer

³⁄₈

has a

in. male pipe thread.

1. ½ in. NPT gas supply line

³⁄₈

in. NPT dryer pipe

2.

Burner Input Requirements:

Elevations up to 10,000 feet:

■ The design of this dryer is certified by CSA International for

use at altitudes up to 10,000 ft (3,000 m) above sea level at

the B.T.U. rating indicated on the model/serial number plate.

Burner input adjustments are not required when the dryer is

operated up to this elevation.

Elevations above 10,000 feet:

■ When installed above 10,000 ft (3,000 m) a 4% reduction of

the burner B.T.U. rating shown on the model/serial number

plate is required for each 1,000 ft (305 m) increase in

elevation.

Gas Supply Pressure Testing

■ The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system at test

pressures in excess of ¹⁄₂ psi.

■ The dryer mus t be isol ated fr om the ga s supply pi ping syst em

by closing the supply l ine shutoff valve during any pressure

testing of the gas supply piping system at test pressures

equal to or less than ¹⁄₂ psi.

7

V enting Requirements

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Lint should be removed again every 2 years, or more often,

depending on dryer usage. Replace any plastic or metal foil vent

with rigid metal or flexible metal vent.

Use duct tape to seal all joints.

Mobile home installations require:

■

Mobile home Installation Kit, Part Number 346764*

■

Metal exhaust system hardware*

*Available for purchase from your local Sears store or Sears

Service dealer.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in

death or fire.

WARNING:

EXHAUSTED OUTDOORS.

4 in. (10.2 cm) heavy metal exhaust vent and clamps must be

used. DURASAFE™ venting products are recommended and are

available from your local Sears store or Sears Service dealer.

DURASAFE vent products ca n be purchased from your dealer or

by calling 1-800-366-PART (1-800-366-7278).

Visit our internet site at: www.sears.com

■

Do not exhaust the dryer into any gas vent, chimney, wall,

ceiling, or a concealed space of a building.

■

The diameter o f the h eav y m et a l exh au st vent mu st be 4 in.

(10.2 cm).

■

Do not use an exhaust hood with a magnetic latch.

■

Do not install flexible metal vent in enclosed walls, ceilings or

floors.

■

Do not use screws or other fastening devices that extend into

the interior of the vent to secur e ve nt.

IMPORTANT:

To reduce the risk of fire, this dryer MUST BE

Observe all governing codes and ordinances.

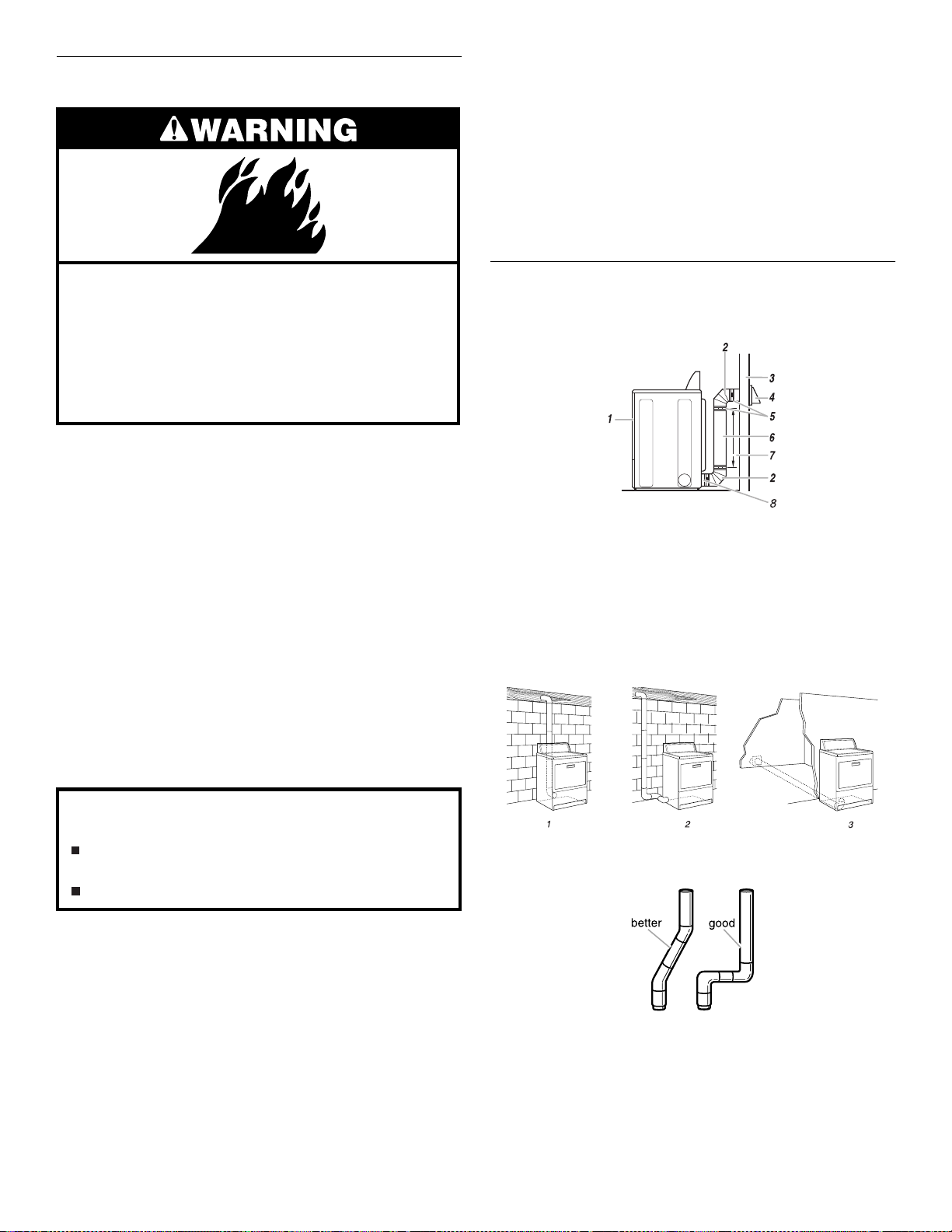

Determine V ent Length

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

1. Dryer

2. Elbow

3. Wall

4. Exhaust hood

5. Duct tape and clamps

6. Rigid metal or flexible metal vent

7. Vent length necessary to connect elbows

8. Exhaust outlet

Standard exhaust installations with rigid metal or flexible

metal vent

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wall-

paper, carpets, etc.

Housecleaning problems and health problems.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommende d to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its fina l position. Remove exce ss flexible met al vent

to avoid sagging and kinking that may result in reduced air flow.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home.

Exhaust hood must be at least 12 in. (30.5 cm) from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, etc.).

8

1. Standard rear offset exhaust installation

2. Left or right side exhaust installation

3. Bottom exhaust installation

1.

Select the route that will provide the straight est and most

direct path outdoors. Plan the installation to use the fewest

number of el bo ws and turns.

When using elbows or making turns, allow as much room as

possible. Bend vent gradually to avoid kinking. Avoid 90º turns.

Determine vent length

The maximum length of the exhaust system depends upon:

■ The type of vent (rigid metal or flexible metal).

■ The number of elbows used.

Recommended hood styles are shown here.

4"

(10.2 cm)

4"

(10.2 cm)

1. Box hood style

2. Louvered hood style

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

1

1. Over-The-Top installation (also available with one

offset elbow)

2. Periscope installation

2

The angled hood style (shown following) is acceptable.

4"

10.2 cm

2.5"

6.4 cm

See the exhaust vent length chart that matches your hood

2.

type for the maximum vent lengths you can use.

Do not use vent runs longer than specified in exhaust vent

length charts.

Exhaust systems longer than specified will:

■ Shorten the life of the dryer.

■ Reduce performance, resulting in longer drying times and

increased energy usage.

Determine the number of elbow s you will need.

3.

In the column li sting the t ype of metal ve nt you ar e using (rigid

metal or flexible metal); find the maximum length of metal

vent on the same line as the number of elbows.

V ent Length Chart

Number of 90º

turns or elbows

0

Rigid metal

Flexible metal

Box or

Louvered hoods

64 ft (20 m)

36 ft (11 m)

Angled hoods

58 ft (17.7 m)

28 ft (8.5 m)

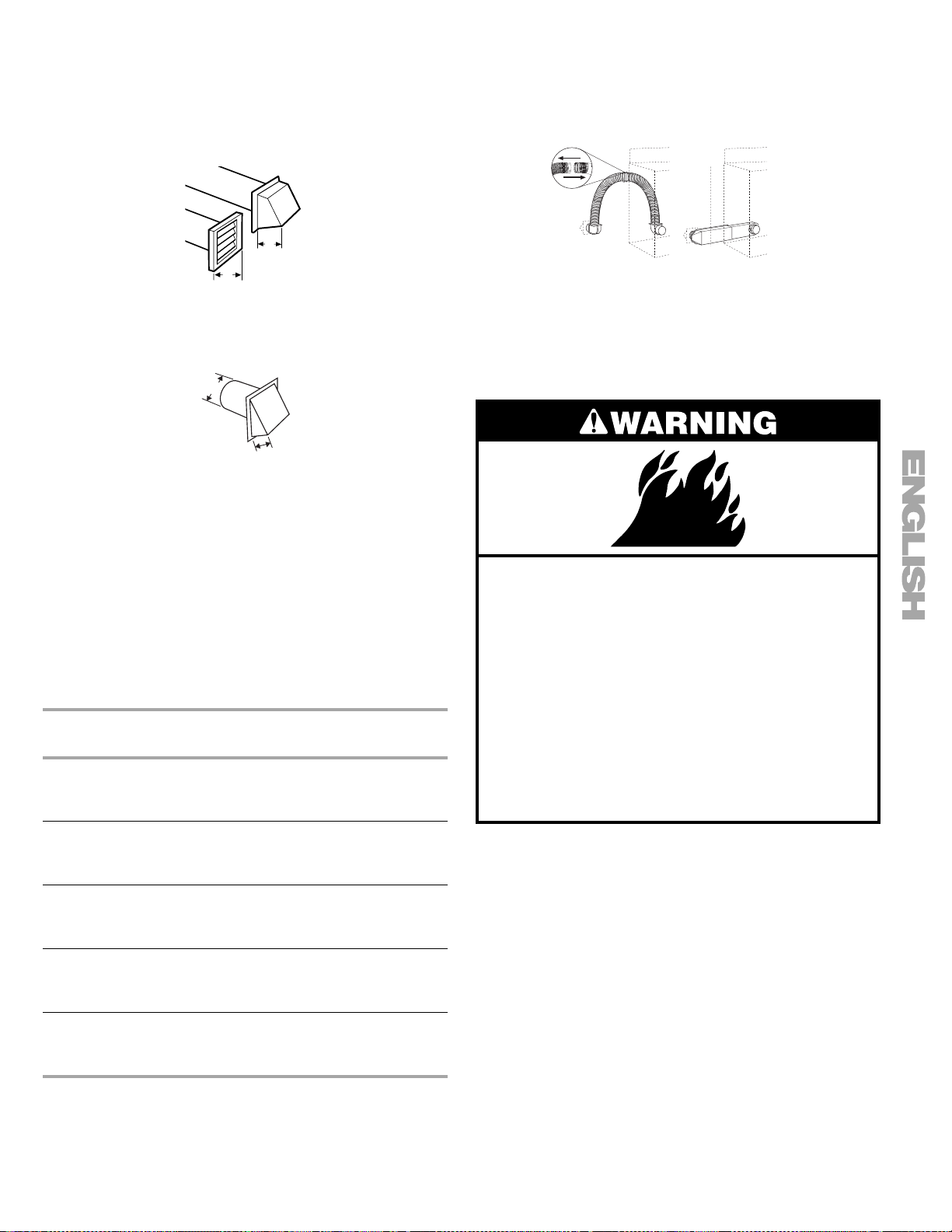

Side and bottom installations

This dryer can be converted to exhaust out the right side, left

side, or through the bottom.

Fire Hazard

Cover unused exhaust holes with one of the

following kits:

279818 (white)

279819 (almond)

279915 (graphite)

279925 (biscuit)

Contact your local dealer.

Failure to follow these instructions can result in

death, fire, electrical shock, or serious injury.

1

Rigid metal

Flexible metal

54 ft (16.5 m)

31 ft (9.4 m)

48 ft (14.6 m)

23 ft (7 m)

2

Rigid metal

Flexible metal

44 ft (13.4 m)

27 ft (8.2 m)

38 ft (11.6 m)

19 ft (5.8 m)

3

Rigid metal

Flexible metal

35 ft (10.7 m)

25 ft (7.6 m)

29 ft (8.8 m)

17 ft (5.2 m)

4

Rigid metal

Flexible metal

Side and bottom exhaust installations have a 90º turn

NOTE:

27 ft (8.2 m)

23 ft (7 m)

21 ft (6.4 m)

15 ft (4.6 m)

inside the dryer. To determine maximum exhaust length, add 1

90º turn to the chart.

Mobile Home-Additional Installation Requirements

This dryer is suitable for mobile home installations. Follow the

information in “Location Requirements.”

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

■ The dryer exhaust vent must not be connected or secured

with screws or other fastening devices which extend into the

interior of the vent.

9

■ The exhaust vent mu st be securely fastened to a

noncombustible p ortio n of the mo bile home st ructur e . Do not

use screws or other fastening devices that extend into the

interior of the vent to secure vent.

3. Examine the leveling legs. Find the diamond marking.

4. Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

5. Stand the dryer up. Move it close to its final location. Leave

enough room to connect the exhaust vent.

Terminate the exhaust vent outside. The exhaust vent must

not terminate beneath the mobile home and must not be

connected to any other duct, vent or chimney.

■ Securely fasten the dryer to the floor at the time of

installation.

To order a Mobile Home Installation Kit, call your local Sears

store or Sears Service Center. Call 1-800-366-PART

(1-800-366-7278). Ask for Part number 346764.

Install V ent System

1. (Optional) Put on safety gla ss e s an d gl o ves.

2. Install exhaust hood. Use caulkin g compou nd to s eal exte rior

wall opening around exhaust hood.

3. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4 in. (10.2 cm)

clamp.

4. Run vent to dryer location. Use the straightest path possible.

See “Determine Vent Length”. Avoid 90º turns. Use duct tape

to seal all joints.

Install Leveling Legs

WARNING

Level Dryer

Check the levelness of the dryer. Check levelness first

side-to-side, then front-to-back.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

NOTE: It might be necessary to level the dryer again after it is

moved into its final position.

Make Gas Connection

1. Remove the red cap from the gas pipe. Move the dryer to its

final position.

2. Using a wrench to tighten, connect the gas supply to the

dryer. Use pipe joint compound on all non-flared male

threads. If flexible metal tubing is used, be sure there are

no kinks.

NOTE: For L.P. gas connections, you must use pipe joint

compound resistant to the action of L.P. gas. Do not use

TEFLON

A combination of pipe fittings must be used to connect the

dryer to the existing gas line. Shown following is a

recommended connection. Y our connection may be different,

according to the supply line type, size, and location.

®

tape.

Excessive Weight Hazard

Use two or more people to move and install

dryer.

Failure to do so can result in back or other injury.

1. Place 2 of the carton corner posts on the floor behind the

back of the dryer. See illustration.

2. Firmly grasp the body of the dryer (not the to p or consol e

panel).

Gently lay the dryer on the cardboard corners.

10

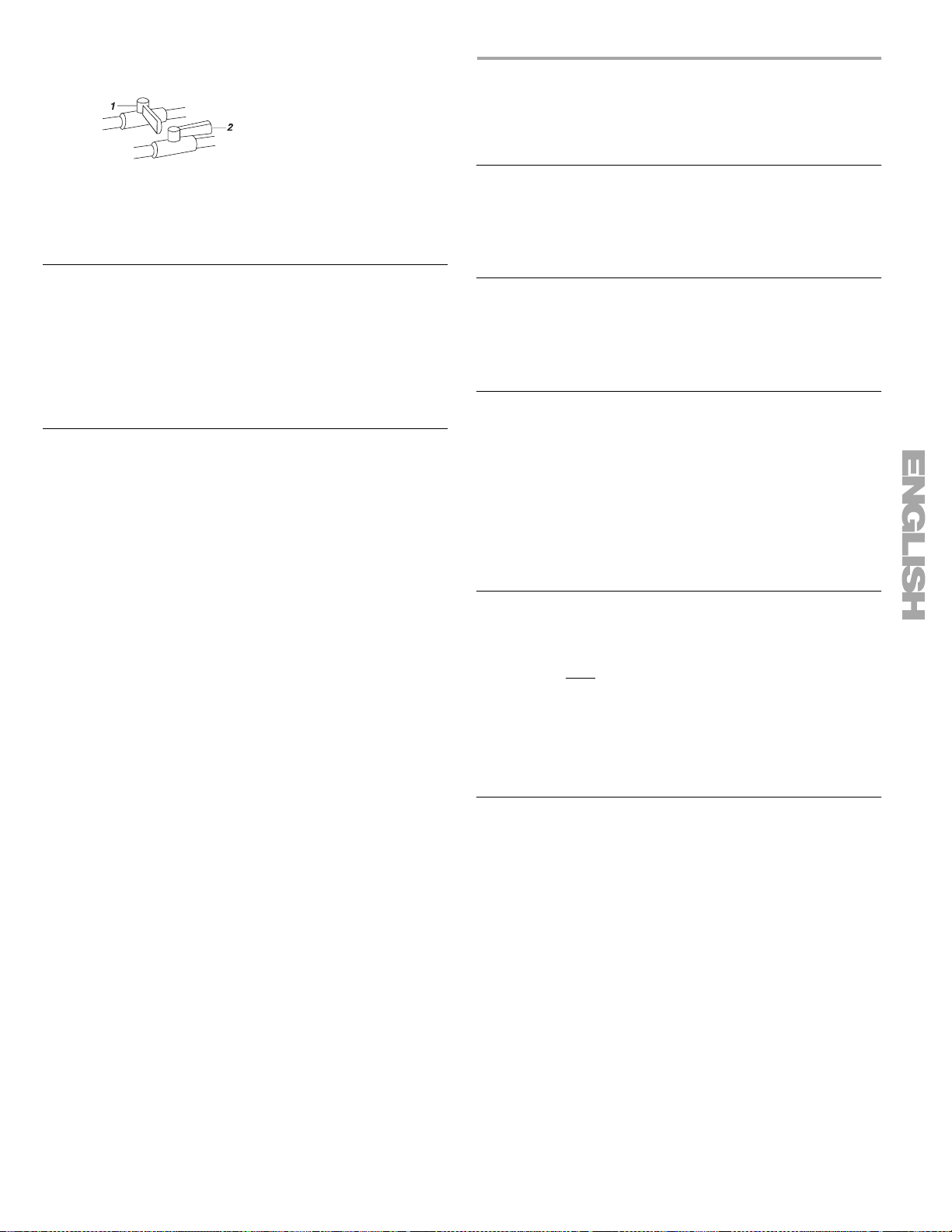

1.

³⁄₈

in. flexible gas connector

³⁄₈

in. dryer pipe

2.

³⁄₈

in. to

³⁄₈

3.

4.

³⁄₈

in. pipe elbow

in. pipe-to-flare adapter fitting

3. Open the shu toff valve in the supply. The valve is open when

the handle is parallel to the gas pipe.

1. Closed valve

2. Open valve

4. Test all connections by brushing on an approved

non-corrosive leak-detection soluti o n. Bubbles will show a

leak. Correct any leak found.

FEATURES AND

BENEFITS

TOT AL CARE™ SYSTEM

The exclusive TOTAL CARE SYSTEM combines the KING SIZE™

load capacity, EVENHEAT with Auto Temp Control, WRINKLE

GUARD™

ensure total drying care for any type of fabric and load size.

III, and the TUMBLE FREE™ heated dryer rack to

Connect V ent

1. Using a 4 in. (10.2 cm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exha ust hood. Make sure the vent is secured

to exhaust hood with a 4 in. (10.2 cm) clamp.

2. Move dr yer into final positio n. Do not crush or kink vent.

Make sure dryer is level.

Complete Installation

1. Check to be sure all parts are now installed. If there is an

extra part, go back through the steps to see which step was

skipped.

2. Check to be sure you have all of your tools.

3. Dispose of all packagi n g materials.

4. Check the dryer’s final location . Be sure the vent is not

crushed or kinked.

5. Check to be sure the dryer is level. (See “Level Dryer.”)

6. Plug into a grounded 3 prong outlet. Turn power on.

7. Remove the blue protective film on the console and any tape

remaining on the dryer.

8. Read “Dryer Use.”

9. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

10. Set the dryer on a full heat cycle (not the Air cycle) for 20

minutes to remove air fr om the gas line. Open the dryer door

after five minutes and feel for heat. If you do not feel heat,

turn the dryer off and wait five minutes.

Then check the following:

■ Controls are set in a running or “On” position.

■ Start button has been pushed firmly.

■ Gas supply line shutoff valve is open.

Repeat 5-minute test as outlined above. If dryer still does not

operate properly, check the following:

■ Dryer is plugged into a grounded 3 prong outlet.

■ Electrical supply is connected

■ House fuse is intact and tight; or circuit breaker has not

tripped.

■ Dryer door is closed.

■ If dryer makes an unusual noise, check that dryer is level.

Auto Temp Control

In automatic drying cycles, the temperature of the clothes is

reduced by automatically turning down the heat, as the clothes

become dry. This reduc es ov er dryi ng an d pro vides bett er car e o f

the fabrics in your clothes.

EVENHEA T™ with Auto T emp

Control

The EVENHEAT with Auto Temp Control system for drying uses

dual moisture sensing devices and SENSOR SMART™ controls.

EVENHEAT with Auto Temp Control shortens drying time and

dries the load at lower temperatures for optimal fabric care. The

EVENHEAT with Auto Temp Control system monitors the

temperature of the heated air to ensure that it is never too hot to

cause fabric damage. It also terminates the cycle when the

clothes are dry to reduce shrinkage.

Drying System

“SMART” Cool Down Period

When the selected leve l of dryness is reached, the dryer goes

into a cool dow n p erio d las ting 2-10 minutes. Un like o t he r d rye rs

that provide a fixed

"SMART" cool down is based on the cycle time and selected

dryness setting.

■ For small loads or loads that are dried at a lower temperature,

the cool down may be as low as 2 minutes.

■ For large loads or loads that are dried at a higher

temperature, the cool down will be closer to 10 minutes.

10 minute cool down, the length of the

Jeans Cycle

Auto T emperature Control monitors the temperature and moisture

of your clothes and turns down the temperature at the right time.

By sensing the temperature and moisture, jeans come out of the

dryer ready to wear. You can put them on without them being

damp or overdry.

11

CYCLE PRESET CYCLE SETTINGS

DRYER USE

Loading

Properly loading your dryer can lower your utility bill and prolong

the life of your garments .

Loading suggestions

■ Load the dryer by the amount of space items take up, not by

their weight.

■ Do not overload the dryer. This causes uneven drying and

wrinkling.

KING SIZE™ Capacity Dryers

Heavy Work Clothes

4 jeans

4 workpants

4 workshirts

Towels

10 bath towel s

10 hand towels

Mixed Load

3 sheets (1 king, 2 twin)

4 pillowcases

3 shirts

3 blouses

Drying and Cycle Tips

Select the correct cycle and temperature for your load.

The display shows the estimated cycle time when your dryer is

automatically sensing the dryness level of your load. If a cycle is

using Timed Dry, the display shows the exact number of minutes

remaining in the cycle.

Cool Down tumbles the load without heat during the last few

minutes of all cycles. Cool Dow n makes the loads easier to

handle. The length of the Cool Down depends on the load size

and dryness level.

Drying tips

■ Follow care label directions when they are available.

■ If you use fabric softener sheets, use only ones labeled as

dryer safe. Follow package instructions.

■ Remove the load from the dryer as soon as tumbling stops to

reduce wrinkling. This is especially important for permanent

press, knits, and synthetic fabrics.

Cycle tips

■ Dry most loads using the preset cycle settings.

■ Use this chart as a guide to dry various loads. Dr yi ng

temperature and Auto Dry Level (Normal Dry) are pr eset when

you choose an Auto Dry cycle. You can select a different

dryness level, depending on your load. (See “Modifiers.”)

■ For a Timed cycle, drying temperature is preset. You cannot

choose an Auto Dry Level with a Timed Dry cycle.

2 sweatpants

2 sweatshirts

14 wash cloths

9 T-shi rts

9 shorts

10 handkerchiefs

Load Type

COTTON/

TOWELS

Heavyweight,

towels

JEANS

Denim pants,

jackets

NORMAL

Corduroys,

work clothes

BULKY

ITEMS

Bedspreads,

sleeping bags

DELICATE/

CASUAL

Sheets,

permanent

press, diapers

ULTRA

DELICATE

Exercise wear ,

sheer curtains,

lace

EXPRESS

DRY™

Small loads

AIR DRY

Rubber,

plastic,

special-care

TOUCH UP

Heavy Duty

Heavyweight,

sturdy fabrics

Delicate

Lightweight,

synthetics

* Estimated Time

** Actual Time

Drying Method

(Auto Dry Level)

Auto Dry

(Normal)

Auto Dry

(Normal)

Auto Dry

(Normal)

Auto Dry

(Normal)

Auto Dry

(Normal)

Auto Dry

(Normal)

Timed Dry High 23**

Timed Dry No heat 30**

Timed Dry

Temp. Time

High 54*

Medium

High

Medium 52*

Medium 60*

Low 36*

Ultra Low 22*

High

Low

(minutes)

64*

30**

20**

12

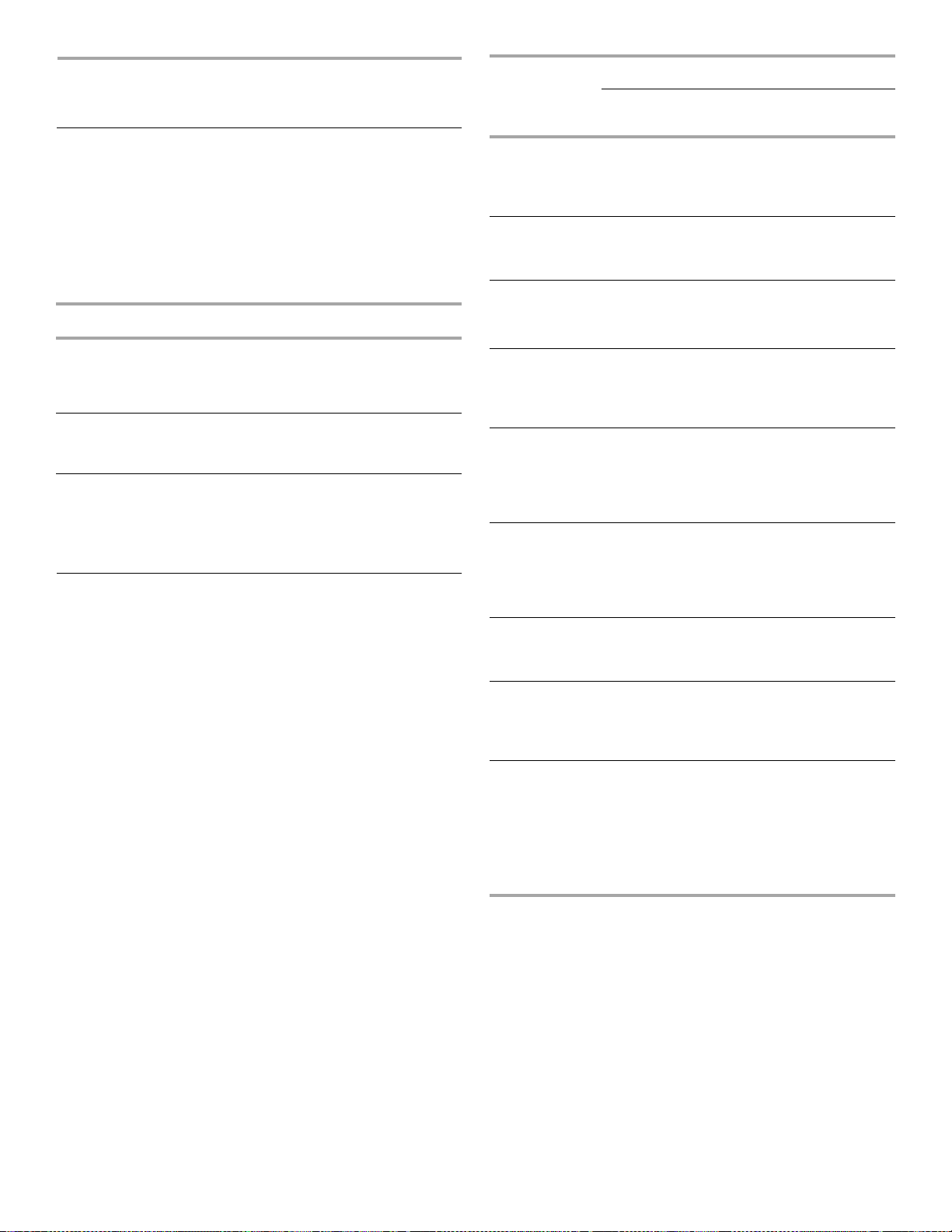

Control Panel

Starting Y our Dryer

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Failure to follow these instructions can result in

death, explosion, or fire.

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of

oil on it (including cooking oils).

Items containing foam, rubber, or plastic must be

dried on a clothesline or by using an Air Cycle.

Failure to follow these instructions can result in

death or fire.

The following is a guide to starting your dryer . Periodic r eferences

to other sections of this manual provide m ore detailed

information.

Check lint screen. Clean if needed.

1.

Put laundry into dryer and shut door. See “Loading.”

2.

Select the cycle you want by pressing one of the pads under

3.

SELECT CYCLE or by selecting TOUCH UP under OPTIONS.

See “Cycles” and “Options.” The pr eset settings for Auto Dry

or Timed Dry will glow. The estimated or actual cycle time (in

minutes) will show in the display.

■ The preset settings provide the recommended fabric care

for your selected cycle. For preset cycle settings, see

“Drying and Cycle Tips.”

■ If desired, you can change the Auto Dry (Estimated) time

by pressing AUTO DRY LEVEL until the desired level of

dryness and estimated dry time are displayed. Auto Dry

Level save y ou time by pr ov iding t he be st dryin g r esults in

the shortest ti me. Electronic sensors determine the

dryness level of your clothes. When your clothes are

almost dry, the drying time automatically changes from

estimated to the actual time remaining in your cycle. For

details, see “Modifiers.”

To change from an Auto Dry cycle to a Timed Dry

NOTE:

cycle, press MORE TIME or LESS TIME. The time

displayed will be the actual time.

■ If desired, you can change the Timed Dry (Actual) time by

pressing MORE TIME or LESS TI ME unti l the des ire d time

is displayed. See “Modifiers.”

■ For best fabric care, follow garment label instructions.

(OPTIONAL STEP) If desired, select OPTIONS. For more

4.

details, see”Options.”

(OPTIONAL STEP) If desired, set the END OF CYCLE S IGNA L.

5.

Press START. Be sure the door is closed.

6.

■ If you do not press START within 5 minutes of selecting

the cycle, the dryer will aut omatically shut off.

■ If you wish to end your drying cycle after pressing START,

press STOP/CANCEL twice.

Stopping Your Dryer

To stop your dryer at any time

Press STOP/CANCEL, or open the door.

13

Pausing or Restarting

To pause the dryer at any time

Open the door or press STOP/CANCEL once.

To restart the dryer

Close the door and pr ess START.

: Drying will continue fr om where the cycle was interrupted

NOTE

if you close the door and press START within 5 minutes. If the

cycle is interrupted for more than 5 minutes, the dryer will shut

off. You will need to select new cycle settings before restarting

the dryer.

Changing Cycles, Options

and Modifiers

You can change Cycles, Options and Modifiers any time before

START is pressed.

■ A short tone sounds when a change is selected.

■ Two short tones sound if an unavailable combination is

selected. The last selection will not be accepted.

Changing Cycles after pressing ST ART

Press STOP/CANCEL twice.

1.

Select the desired cycle.

2.

Press START. The dryer starts at the beginning of the new

3.

cycle.

If you do not press START within 5 minutes of selecting

NOTE:

the cycle, the dryer automatica lly shuts off.

Changing Options and Modifiers after pressing START

You can change an Option or Modifier anytime before the

selected Option or Modifier begins.

Press STOP/CANCEL.

1.

Select the new Option and/or Modifiers.

2.

Press START to continue the cycle.

3.

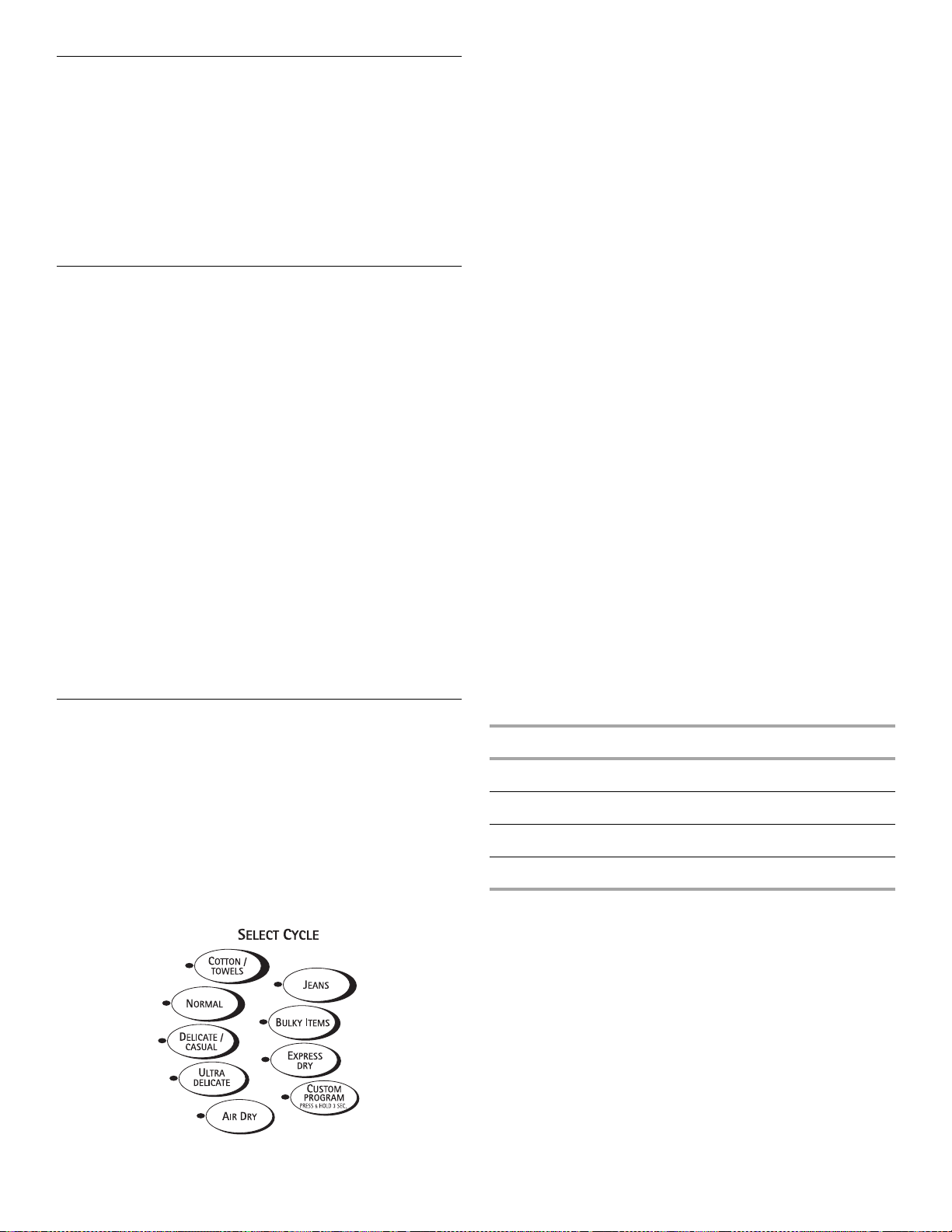

Cycles

Select the drying cycle that matches the type of load you are

drying. A preset range of heat is automatically set for the type of

fabric selected. (See “Drying and Cycle Tips” chart.)

When you select a cycle, your dryer selects a preset temperature,

AUTO DRY LEVEL (Normal) and either AUTO DRY (Estimated) or

Timed Dry (Actual) Time Remaining. The time displayed for the

AUTO DRY cycles are estimated times. Part way through the

cycle, the dryer turns the AUTO DRY (Estimated) Time Remaining

indicator light off and displays the actual time remaining on the

display. The TIMED DRY (Actual) indicator light will glow only if a

TIMED DRY cycle was selected. (See “Modifie rs.”)

Cotton/Towels

Use this cycle to get high heat for heavy fabrics. This Auto Dry

cycle is preset to an estimated 54 minutes.

Jeans

Use this cycle to get medium high heat for drying denims. This

Auto Dry cycle is preset to an estimated 64 minutes.

Normal

Use this cycle to get medium heat for drying sturdy fabrics. This

Auto Dry cycle is preset to an estimated 52 minutes.

Bulky Items

Use this cycl e f or dry ing la rge, bulky items that dry qu ickly on t he

outside, bu t st ay we t on th e in side . Th is cyc le uses m ediu m h eat.

This Auto Dry cycle is preset to an estimated 60 minutes.

Delicate/Casual

Use this cycle to get low heat for drying synthetic fabrics,

washable knit fa brics and no-iron finishes. This Auto Dry cycle is

preset to an estimated 36 minutes.

Express Dry

Use this 23 minute cycle for drying small loads or loads that need

a short drying time. This cycle uses 16 minutes of high heat

followed by 5 minutes of ultra low heat and 2 minutes of cool

down.

™

Ultra Delicate

Use this cycle to get ultra low heat to gently dry items such as

exercise wear or sheer curtains. This Auto Dry cycle is preset to

an estimated 22 minutes.

Air Dry

Air dry gives you all the benefits of hang drying with a shorter

drying time. Adjust the Air Dry cycle from 1 to 99 minutes at any

time during the cycle, or use the preset setting of 30 minutes.

Use the Air Dry cycle for items that require drying without heat

such as rubber, plastic and heat sensitive fabrics. This chart

shows examples of items that can be dried using the Air Dry

cycle.

Type of Load Minutes

Foam rubber - pillows, padded bras, stuffed toys 20 - 30

Plastic - Shower curtain s, tableclothes 20 - 30

Rubber-backed rugs 40 - 50

Olefin, polypropylene, sheer nylon 10 - 20

When using Air Dry

■ Check to see that coverings are sec urely stitched.

■ Shake and fluff pillows by hand periodically during the cycle.

■ Dry item completely. Foam rubber pillows are slow to dry.

An Auto Dry Level selection is not available when using

NOTE:

the Air Dry cycle.

14

Loading...

Loading...