Kendro UPRIGHT CHEST FREEZER User manual

-40 C and –85 C

ULTRA LOW-TEMPERATURE

UPRIGHT & CHEST FREEZER

(1993 - PRESENT)

SERVICE MANUAL

November 2002

Kendro Laboratory Products

All rights reserved 301903H13

Copyright 2002

Kendro Laboratory Products All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of Kendro Laboratory Products Training Department.

TABLE OF CONTENTS

SECTION 100 -- GENERAL INFORMATION

MODEL

MODEL

NUMBER AND SERIAL NUMBER IDENTIFICATION ..............................................................................100.1

TYPES .............................................................................................................................................................100.2

REFRIGERATION SYSTEM ........................................................................................................................................100.5

SECTION 200 -- SAFETY

ELECTRICAL

SAFETY ................................................................................................................................................200.1

REFRIGERANT SAFETY ............................................................................................................................................. 200.2

SECTION 300 - TECHNICAL INFORMATION

FEATURES ....................................................................................................................................................................300.1

A

DDITIONAL ULTIMA II FEATURES. ................................................................................................................................. 300.2

RECOMMENDED

P

REVENTIVE MAINTENANCE............................................................................................................................................300.4

TOOL LIST..................................................................................................................................... 300.3

SECTION 400 - MAINTENANCE AND REPAIR PROCEDURES

C

ABINET

LEVELING

DEFROSTING

OF A CHEST OR UPRIGHT FREEZER....................................................................................................400.1

A CHEST OR UPRIGHT FREEZER ....................................................................................................400.2

DOOR ADJUSTMENT OF AN UPRIGHT FREEZER..................................................................................................400.3

LID ADJUSTMENT OF A CHEST FREEZER..............................................................................................................400.4

UPRIGHT

FREEZER GASKET REPLACEMENT .......................................................................................................400.5

CHEST FREEZER GASKET REPLACEMENT............................................................................................................400.6

HANDLE REPLACEMENT FOR CHEST FREEZER...................................................................................................400.8

UPRIGHT

FREEZER CAM LATCH DOOR LOCK REPLACEMENT........................................................................400.9

CHEST FREEZER LID LOCK REPLACEMENT .......................................................................................................400.11

UPRIGHT FREEZER EXTERIOR DOOR HINGE REPLACEMENT........................................................................400.12

CHEST

FREEZER HINGE REPLACEMENT.............................................................................................................400.13

UPRIGHT FREEZER INTERIOR DOOR REPLACEMENT......................................................................................400.14

DOOR ASSEMBLY REPLACEMENT AND SEAL CHECK ON UPRIGHT UNITS................................................400.15

LID

ASSEMBLY REPLACEMENT AND SEAL CHECK ON CHEST UNITS .........................................................400.16

BREAKER STRIP REPLACEMENT ON A CHEST OR UPRIGHT FREEZER.........................................................400.17

CHEST

LEVELING

AND UPRIGHT FREEZER FILTER REPLACEMENT.................................................................................400.18

LEG REPLACEMENT.............................................................................................................................400.19

CASTER REPLACEMENT .........................................................................................................................................400.20

E

LECTRICAL / ELECTRONIC

COMPRESSOR

CONTROL

CAPACITOR

RELAY EVALUATION AND REPLACEMENT ............................................................................400.21

RELAY EVALUATION AND REPLACEMENT.................................................................................... 400.23

EVALUATION AND REPLACEMENT ..............................................................................................400.25

VOLTAGE BOOST RELAY EVALUATION AND REPLACEMENT ......................................................................400.27

SURGE

SURGE

SUPPRESSER EVALUATION & REPLACEMENT (UPRIGHT FREEZER)..............................................400.29

SUPPRESSER EVALUATION & REPLACEMENT (CHEST FREEZER) .................................................. 400.31

“MICRO” CONTROL PRINTED CIRCUIT BOARD EVALUATION & REPLACEMENT .....................................400.33

“MICRO”

“MICRO”

POWER SUPPLY PCB EVALUATION AND REPLACEMENT..............................................................400.36

DISPLAY PCB ............................................................................................................................................400.38

CONTROL DISPLAY HARNESS REPLACEMENT (UPRIGHT AND CHEST) ...........................................................................400.41

HEAT

EXCHANGER SENSOR REPLACEMENT (UPRIGHTS) ..............................................................................400.44

HEAT

EXCHANGER SENSOR REPLACEMENT (CHESTS) ...................................................................................400.45

CABINET

AMBIENT/CONDENSER

AMBIENT/CONDENSER

CONTROL / DISPLAY SENSOR EVALUATION & REPLACEMENT.................................................. 400.46

SENSOR EVALUATION AND REPLACEMENT (UPRIGHT) .....................................400.48

SENSOR EVALUATION AND REPLACEMENT (CHESTS)........................................400.49

TEMPERATURE RECORDER REPLACEMENT......................................................................................................400.50

TEMPERATURE RECORDER SENSOR REPLACEMENT...................................................................................... 400.52

ALARM

BATTERY EVALUATION AND REPLACEMENT ...................................................................................400.54

VOLTAGE BOOST TRANSFORMER EVALUATION AND REPLACEMENT ...................................................... 400.56

EVALUATION AND REPLACEMENT OF FAN MOTOR AND BLADE ................................................................400.58

S

OLID STATE CONTROL BOARD REPLACEMENT FOR VALUE-FEATURED FREEZERS....................................................... 400.59

VOLTAGE BOOST CONTROL PCB ..........................................................................................................................400.60

INTERSTAGE

TEMPERATURE

INTERCONNECT (“D62”) PCB.........................................................................................................400.61

CALIBRATION PROCEDURE .....................................................................................................400.63

PRESSURE EQUALIZATION PORT HEATER REPLACEMENT PROCEDURE...................................................400.64

R

EFRIGERATION

FIRST

STAGE SYSTEM CLEAN-UP/FLUSHING .................................................................................................... 400.66

SECOND STAGE SYSTEM CLEAN-UP/FLUSHING ............................................................................................... 400.69

FIRST

STAGE PRESSURE SWITCH EVALUATION AND REPLACEMENT........................................................400.72

SECOND

STAGE PRESSURE SWITCH EVALUATION AND REPLACEMENT...................................................400.75

FIRST STAGE COMPRESSOR REPLACEMENT ...............................................................................................................400.78

SECOND

AIR

STAGE COMPRESSOR REPLACEMENT ................................................................................................400.81

COOLED CONDENSER REPLACEMENT (CHESTS).......................................................................................400.84

AIR COOLED CONDENSER REPLACEMENT (UPRIGHTS).....................................................................................400.85

FIRST

AND SECOND STAGE REFRIGERATION SYSTEM EVACUATION..........................................................400.86

FIRST STAGE REFRIGERATION SYSTEM CHARGING..............................................................................................400.87

SECOND STAGE REFRIGERATION SYSTEM CHARGING ..................................................................................400.88

A

CCESSORIES AND OPTIONAL EQUIPMENT

LCO2

DOOR SAFETY SWITCH EVALUATION AND REPLACEMENT...............................................................400.90

LCO2 LID SAFETY SWITCH EVALUATION AND REPLACEMENT....................................................................400.91

LCO2

PRESSURE SWITCH ASSEMBLY EVALUATION AND REPLACEMENT ................................................400.92

LCO2 RUPTURE DISC EVALUATION AND REPLACEMENT..............................................................................400.94

LCO2 DISTRIBUTION TUBE EVALUATION AND REPLACEMENT ...................................................................400.95

LCO2

BACKUP SYSTEM TEMPERATURE CALIBRATION, BUILT-IN...............................................................400.96

LCO2 BACKUP SYSTEM TEMPERATURE CALIBRATION, FREE-STANDING.................................................400.97

INSTALLATION

OF CHEST FREEZER INVENTORY CONTROL RACK SYSTEM.............................................400.98

COBEX TEMPERATURE RECORDER ................................................................................................................................400.98

SECTION 500 - APPENDIX

T

ABLE 1 FAHRENHEIT / CELSIUS CONVERSION CHART...............................................................................................500.1

TABLE 2 100 OHM PLATINUM RTD TEMPERATURE / RESISTANCE CHART .................................................................500.2

TABLE 3 MODEL NUMBER CROSS-REFERENCE........................................................................................................... 500.3

T

ABLE 4 REFRIGERANT CHARGE, CHEST .................................................................................................................... 500.9

ABLE 5 REFRIGERANT CHARGE, UPRIGHT ..............................................................................................................500.11

T

T

ABLE 6 HARRIS CLASSIC™ REFRIGERANT CHARGE ............................................................................................... 500.13

T

ABLE 7 OIL CHARGE, UPRIGHT............................................................................................................................... 500.14

ABLE 8 OIL CHARGE, CHEST .................................................................................................................................. 500.14

T

TABLE 9 TEMP / MV FOR COMPRESSOR, CONDENSER & AMBIENT SENSORS ............................................................ 500.15

T

ABLE 10 PARTS LIST.................................................................................................................................................500.16

EAT EXCHANGE JUMPER, UPRIGHT AND CHEST FULL-FEATURED FREEZERS ............................................................. 500.17

H

FIGURE 500-1 CASCADE REFRIGERATION ASSEMBLY, UPRIGHT FREEZER .............................................................500.18

F

IGURE 500-2 CASCADE REFRIGERATION ASSEMBLY, CHEST FREEZER.................................................................500.19

FIGURE 500-3 ELECTRICAL DECK, UPRIGHT FULL-FEATURED FREEZER ................................................................500.20

IGURE 500-4 ELECTRICAL DECK, CHEST FULL-FEATURED FREEZER.................................................................... 500.21

F

F

IGURE 500-5 ELECTRICAL DECK, UPRIGHT VALUE-FEATURED FREEZER .............................................................500.22

IGURE 500-6 ELECTRICAL DECK, CHEST VALUE-FEATURED FREEZER................................................................. 500.23

F

F

IGURE 500-7 ELECTRICAL DIAGRAM, UPRIGHT AND CHEST FULL-FEATURED FREEZERS .................................... 500.24

FIGURE 500-8 ELECTRICAL DIAGRAM, UPRIGHT AND CHEST VALUE-FEATURED FREEZERS..................................500.25

INTRODUCTION

Ultra Low Temperature -85C/-40C Upright and -85C/-40C Chest freezers are base units, manufactured wholly at the Kendro

Laboratory Products facility in Asheville, NC. Kendro Laboratory Products is a division of SPX Corporation

The Upright units come in 13, 17, 21, 25 and 32 cubic foot sizes. The Chest units come in 1, 3, 5, 7, 10, 14, 17, and 20 cubic

foot sizes.

The purpose of this manual is to provide procedures developed to assist the field refrigeration technician in troubleshooting

and repairing certain conditions.

Product Specifications Are Subject To Change Without Written Notice.

Progressive product changes will be entered into the service manual as it is revised. The

manual is intended as an aid to persons qualified in the service of applicable equipment. It

is not intended to teach unqualified persons on applicable equipment all procedures necessary to make repairs.

SECTION 100 -- GENERAL INFORMATION

MODEL NUMBER AND SERIAL NUMBER IDENTIFICATION

Model numbers are important to know, since they

identify the unit as to what group it is in. This number does not identify a unit specifically; but rather,

indicates to what group this unit belongs.

The serial number is a unique number in that it identifies the unit as a specific unit. No other unit has that

same number.

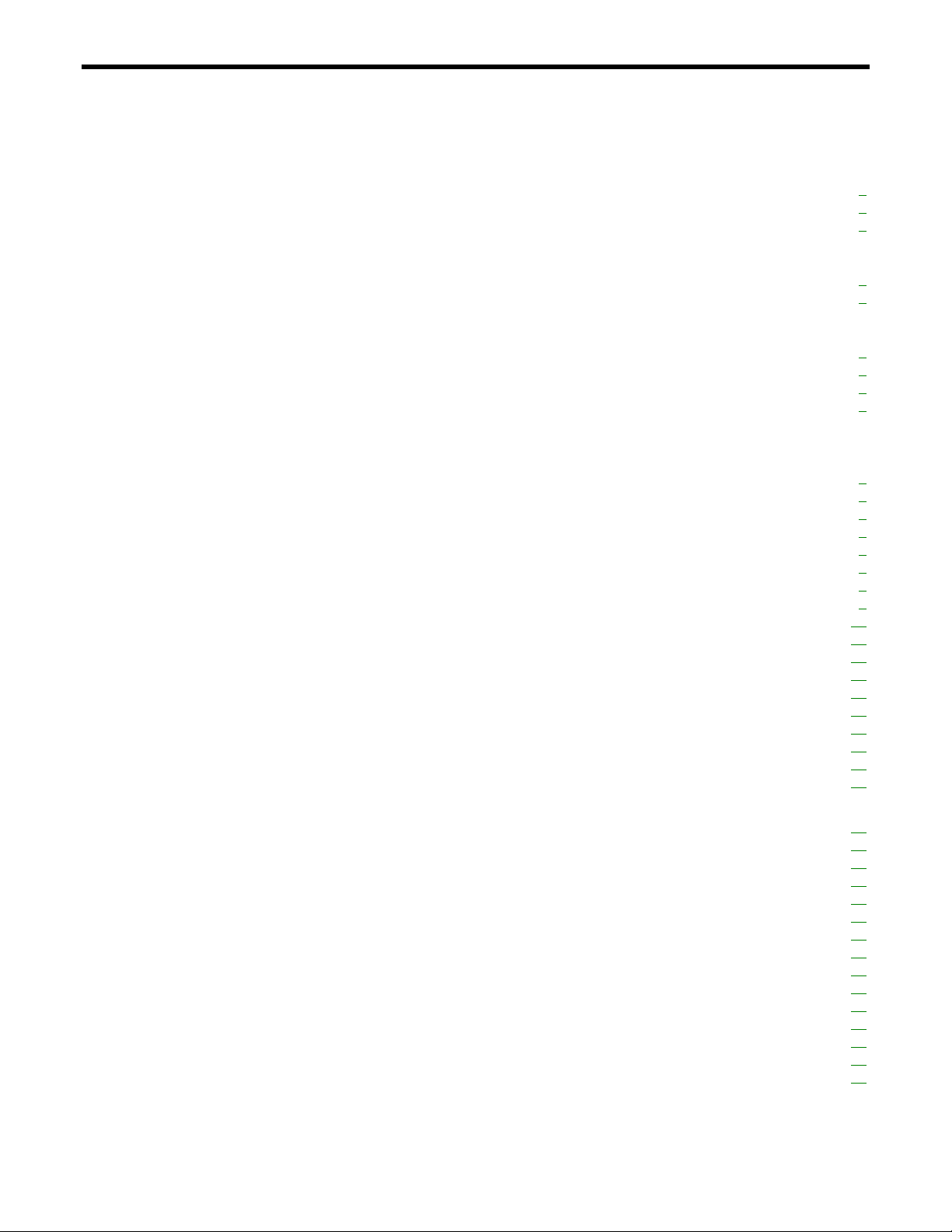

DATA LABEL LOCATION

The model and serial numbers of your refrigerator are

printed on a plastic identification label and mounted

on the unit. This label is commonly referred to as the

data label because the most important information

concerning your unit can be gathered from the model

number and the serial number identification.

The data label is mounted on the outside of the cabinet. It can be found by looking on the upper left-hand

side of the unit, near the front of the cabinet. Some

older models may have a metal plate located on the

outer, lower left hand side of the unit.

DATA LABEL INFORMATION

Much information can be gathered from a data label.

The model and serial numbers can be found there, as

well as information such as type of refrigerant, voltage rating, frequency rating, and current rating, are

also normally found on a data label.

Upright Freezers

Figure 100-1

Data Label

Chest Freezers

Figure 100-2

Dataplate Location

General Information 100.1

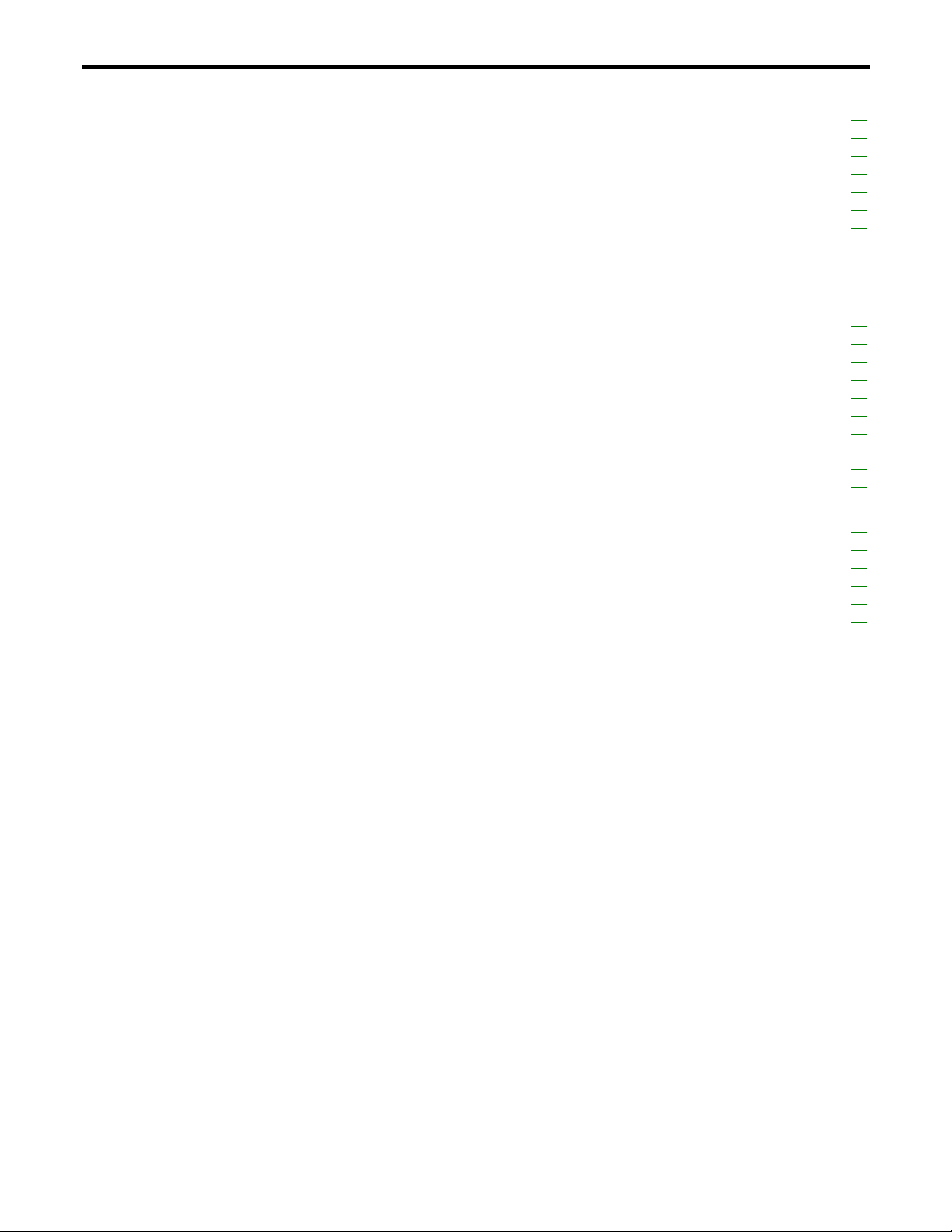

MODEL TYPES

New picture goes here

3

17 ft

, 21 ft3 25, & 32 ft3 Upright

Figure 100-3

Figure 100-4

3

1ft

Countertop

Figure 100-5

3

10 ft

Chest

General Information 100.2

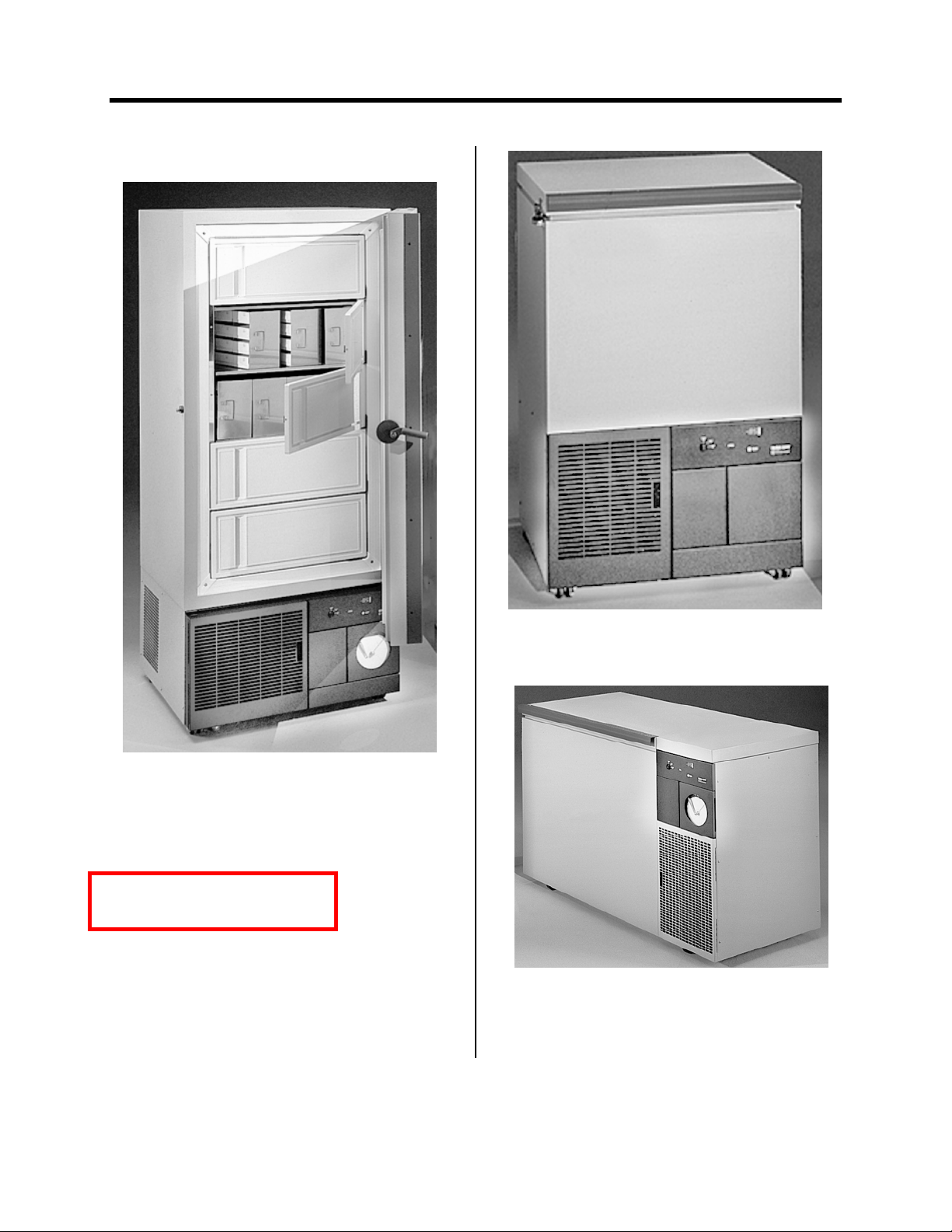

MODEL TYPES (CONT.)

Figure 100-6

3

14ft

Chest

Figure 100-7

3

5 ft

Chest

Figure 100-8

3

7ft

Chest

General Information 100.3

MODEL TYPES (CONT.)

(Optional Recorder shown)

New picture goes here

Figure 100-9

3

13 ft

Upright

Figure 100-10

5ft

3

Chest

Figure 100-11

3

7ft

Chest

(Optional Recorder shown)

General Information 100.4

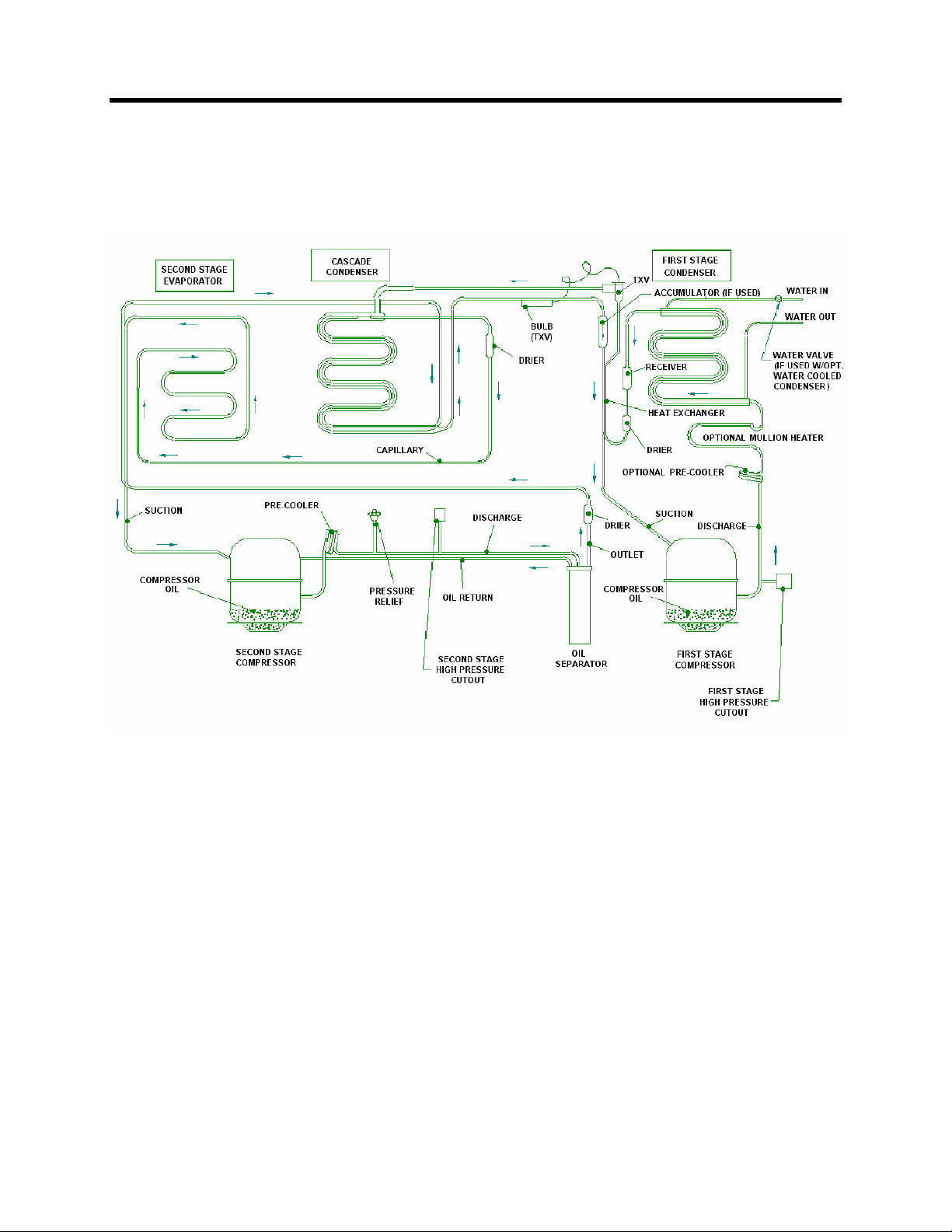

REFRIGERATION SYSTEM

Figure 100-12

Two Stage Cascade Refrigeration System

General Information 100.5

REFRIGERATION SYSTEM (CONT.)

All of the units covered by this service manual use a

one or two stage refrigeration system for cooling the

unit. The fundamental components of a refrigeration

system are the compressor, condenser, drier-strainer,

metering device (normally a capillary tube or txv),

and the evaporator. Every refrigeration system operates using some configuration of most, if not all of

these components.

The following is a description of the components of

the refrigeration cycle.

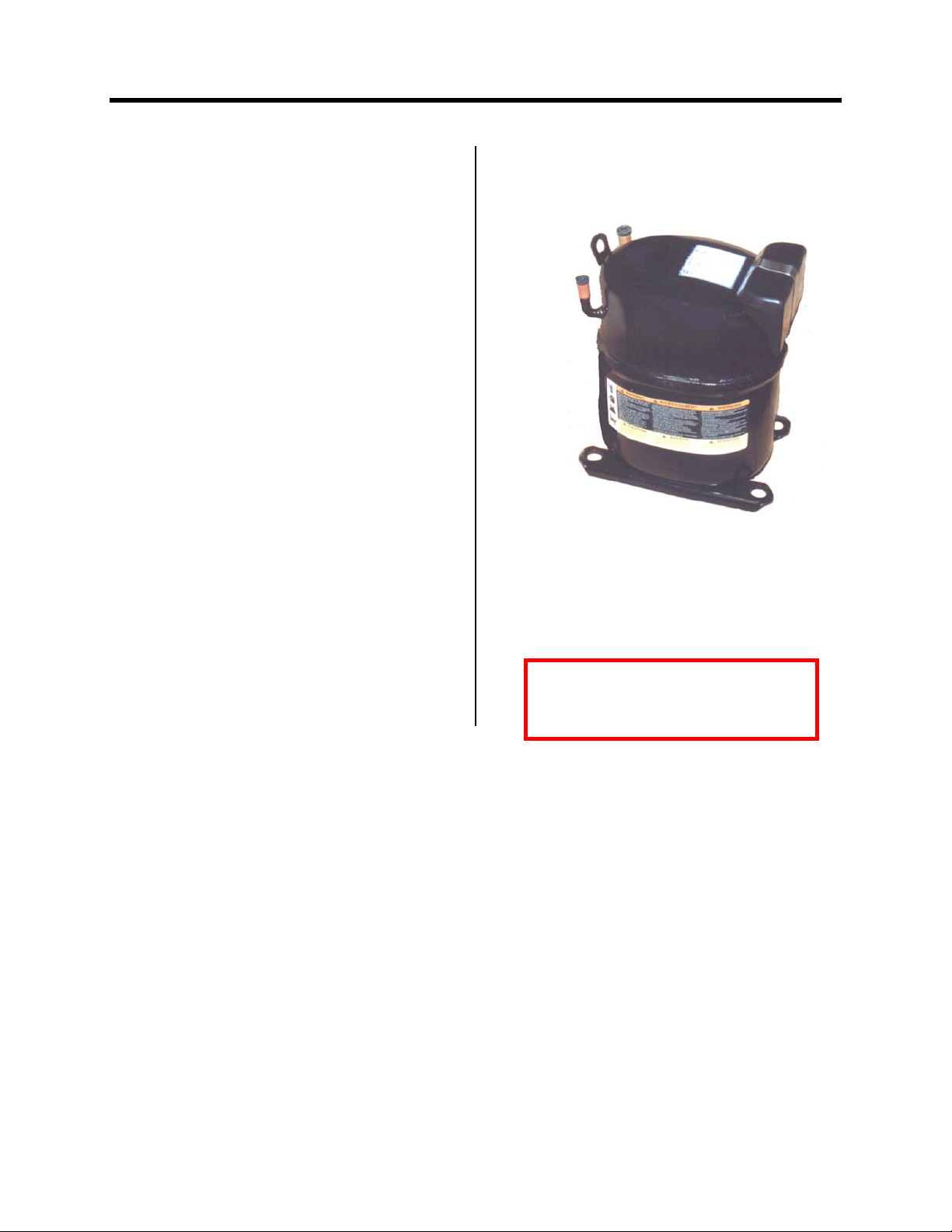

COMPRESSOR

The function of the compressor is to take the relatively cool gaseous refrigerant at its suction, and raise

the pressure and temperature of the refrigerant by

compressing it. Remember that any time a gas is

compressed, the temperature and the pressure are

increased. Since liquids such as water are incompressible, it very important that all of the refrigerant

be in a gaseous state before it reaches the compressor.

The function of the compressor is to add useful work

energy to the refrigerant. The size and ratings of the

compressors depends upon the application and size of

the system.

Add picture of Copeland Semi

Legaci

Figure 100-13

TM

Compressor

General Information 100.6

REFRIGERATION SYSTEM (CONT.)

CONDENSER

The purpose of the condenser is to take the hot gaseous refrigerant, remove latent heat of condensation,

and cause it to condense. This is needed in order to

extract energy from the refrigeration cycle. The reason the energy needs to be extracted is so that when

the refrigerant reaches the evaporator this energy can

be “put back in” which is where the cooling action

for the refrigerator and/or freezer takes place.

DRIER-STRAINER

As the condensed (liquid) refrigerant leaves the condenser, it passes through the drier-strainer, which

removes any moisture (except the liquid refrigerant)

or impurities before passing through the metering

device. It is important that a “molecular sieve dryer”

or other high quality dryer be used. This component

serves two purposes:

1. It prevents moisture, such as water, from staying

entrained in the refrigerant and possibly doing

damage to the compressor or other components in

the refrigeration cycle.

2. It prevents any foreign material from becoming

lodged in the metering device and decreasing the

efficiency of the cycle.

Figure 100-14

Forced Air Condenser

Figure 100-15

Typical Drier-Strainer

General Information 100.7

REFRIGERATION SYSTEM (CONT.)

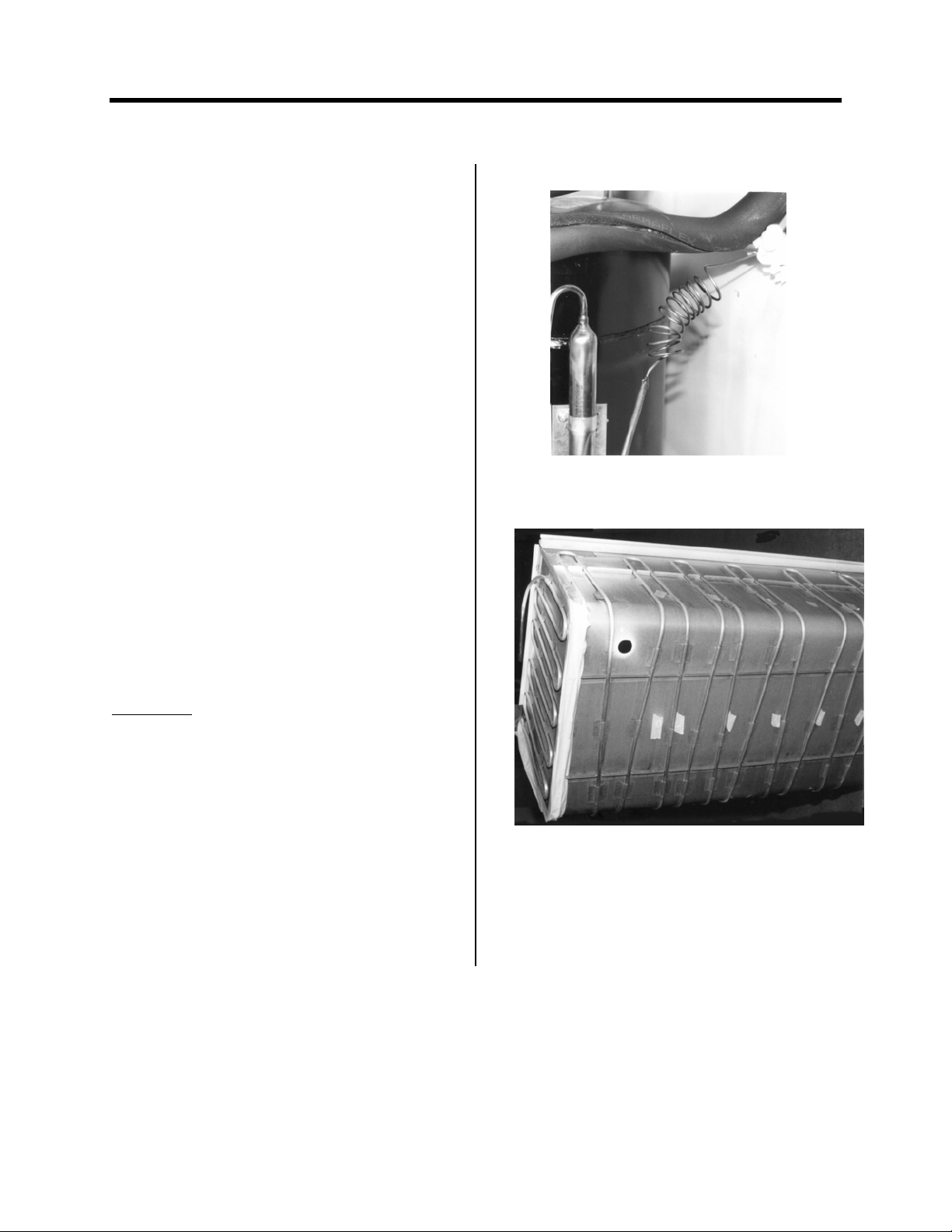

CAPILLARY TUBE

The capillary tube is simply a length of tubing attached to the outlet tubing somewhere downstream of

the drier-strainer and the inlet of the evaporator. The

diameter and length of the tube depends on the application of the system involved and the capacity of that

system, and are calibrated to meter the right amount

of refrigerant required for that particular model. A

predetermined length of the capillary tube is soldered

along the exterior of the suction line, forming a heat

exchanger which helps to cool the liquid refrigerant

in the capillary tube and heat the refrigerant in the

compressor suction line. The capillary tube then connects to the evaporator where the tubing expands

back to its original size.

EVAPORATOR

As the refrigerant passes through the evaporator, it is

changed from a liquid to a vapor. Since the pressure

of the refrigerant is at a slightly lower pressure and

with the addition of heat, from the internal compartment of the refrigerator, the liquids temperature is

raised above the boiling point for that refrigerant and

the change of phase from a liquid to vapor takes

place. All of the liquid should have been changed to a

vapor at the outlet of the evaporator, ensuring that

only gaseous refrigerant is sent to the compressor.

Suction Line

Immediately upon leaving the evaporator, the refrigerant must pass through the accumulator. This device

is another defense in preventing liquid refrigerant

from reaching the compressor. It simply accumulates

any liquid that may still be in the line after it has left

the evaporator. These devices are normally used on

units with capillary tube type metering devices, but

may also be used with systems that have the thermostatic expansion valves. Remember, also, that a

portion of the outlet line of the evaporator leading

back to the compressor suction is connected to the

capillary tube or thermostatic expansion valve inlet

line, which also adds additional heat to the refrigerant

prior to reaching the compressor.

Figure 100-16

Capillary Tube

Figure 100-17

Evaporator

General Information 100.8

SECTION 200 -- SAFETY

Freezers are complex machines. Any attempt to repair a freezer should be done with caution. There can never be too

much said or written concerning safety in any area of work, especially when dealing with electricity and refrigerants.

Safety should be every persons concern and is every person’s responsibility. Your personal safety begins with

knowledge of the equipment that you are working on. We are concerned with your safety; therefore, we have written

a few ideas and reminders of safety concerns while working on freezers.

ELECTRICAL SAFETY

1. Know the location of the freezer’s circuit breakers

or fuses. Ensure all breakers and/or fuses are

clearly marked for quick identification and reference.

2. Before servicing any freezer, unplug the power

cord. Do not perform any maintenance or remove

an access panel on an energized unit. None of the

repairs in this manual require the freezer to have

electrical power applied during maintenance.

3. Be careful when handling freezer access panels,

parts, or any components that may have sharp

edges that may cause damage to wiring and electrical connections, not to mention personal injury.

Always use the correct tool for a job and be sure

those tools are in good condition. Ensure that

tools to be used on electrical devices are well insulated, if applicable.

Never interfere with or bypass the operation of any

switch, component or feature of the unit. Interlocks, relays, and switches are designed with a

specific purpose and should, therefore, not be altered.

6. Use only approved replacement parts that are the

correct size, rating, and capacity as the original

part. If you have a question concerning replacement parts, call the Factory Technical Services

Department.

7. When replacing any component, be sure any green

ground wires are reconnected securely in their

original positions to avoid danger of shock or

short circuit.

8. Never interfere with or bypass the operation of

any switch, component or feature of the unit.

9. Before reconnecting the power supply, ensure

uninsulated wires or terminals are not touching

the cabinet

10. Never alter a power cord in order to make it fit

an electrical outlet.

11. Be sure and reference any applicable wiring diagram(s) when reconnecting and replacing

electrical components.

12. To avoid electrical shock, fire, and equipment

damage, ensure that any wires or terminals touching the cabinet are insulated before connecting the

power supply. Electrical wiring and all grounds

must be correctly reconnected and secured away

from sharp edges, components and moving parts.

All panels and covers should be reinstalled before

the freezer is plugged in.

13. Never alter a power cord in order to make it fit

an electrical outlet. The line cord must be plugged

into a grounded, three-prong receptacle. Never cut

or remove the third (ground) prong from the

power cord connector.

14. Never substitute ordinary wire for any internal

wiring of a freezer. The internal wiring of these

units carry a special rating due to the somewhat

high currents that they can be subjected to at

times. This heavy current load generates heat,

which can melt ordinary wire. It is vitally important that all connections are tight and secure.

15. Throughout this service manual, additional safety

precautions dealing with specific procedures may

be presented. This information should be carefully

read and observed.

Safety 200.1

REFRIGERANT SAFETY

1. The following is a list of the more common refrigerants that you will possibly be dealing with:

R290, R134a, R508b, and R404a.

CAUTION None of these refrigerants will

support life. All are classified as

asphyxiates.

2. The following are effects of over exposure:

light-headedness

giddiness

shortness of breath

unconsciousness

possibly death

Emergency and First Aid Procedures

Remove to fresh air

Call a physician

Do not give heart stimulating drugs such as epinephrine or similar drugs.

3. As all of the refrigerants listed have a vapor density of 3.00 or over 7.00, proper ventilation is

mandatory, especially in the low places where the

heavy vapor could collect.

4. Do not have open flames in this area. These refrigerants, when exposed to open flame, may

produce toxic compounds such as hydrogen chloride, hydrogen fluoride, and other acidic vapors

may be produced when these refrigerants are exposed to open flames.

5. Smoking should never take place around any of

the listed refrigerants. Deadly phosgene gas,

which can kill very quickly, is also one of the

compounds that these refrigerants can break down

into if they come in contact with a high enough

temperature flame.

6. Always use facial and eye protection, as well as

gloves when opening a system that has suffered a

“burn out”. The possibility of Hydrofluoric acid is

high.

7. Also use facial and eye protection and gloves

when handling liquid refrigerant.

8. The use of an air mask with an independent air

supply is recommended in areas of high concentrations and poor ventilation.

9. Avoid breathing all refrigerants if possible.

10. Treat all refrigerant cylinders with care. Store in

clean dry areas. Do not store at high temperatures.

11. The use of an air mask with an independent air

supply is recommended in areas of high concentrations and poor ventilation.

Safety 200.2

SECTION 300 - TECHNICAL INFORMATION

The information provided in this section is intended to give you as much information about the unit you will be performing maintenance on as possible. All of the numbers given are general in nature and may possibly be different

for the model that you are working on. The reason for this may be the possibility that the particular unit that you

may be working with is a special order unit, and is unique for its specific application.

The following information contains specifications

that apply to the Value, Elite and the Ultima II ultralow temperature freezers.

FEATURES

ELECTRONIC CONTROL & ALARM SYSTEM

Tamper-resistant touchpoint setpoint selection with

adjustable operating temperature (Ultima II)

Key operated switch for main power and alarm system.

Large digital temperature display, with a resolution to

o

1

C.

Built-in safety alarm system with automatic continuous-charge battery back-up.

Low battery indicator (Not All Models)

Touchpad alarm test (Not All Models)

Power failure or temperature deviation outside alarm

set limits triggers audible and visual warning.

(Not all Models)

MICROPROCESSOR CONTROL

Tamper-resistant touchpoint data entry with adjustable operating temperature (Not all Models)

Key operated switch for main power and alarm system.

Extra large digital temperature display, with a resolution to 1

o

C.

On-board AC power monitoring with digital read-out

of actual line voltage. (Not All Models)

Clean filter indicator advises user to clean condenser

intake filter. (Not all Models)

ALARM/MONITORING SYSTEM

Built-in safety alarm system with automatic continuous-charge battery back-up.

A.I.M (Automatic Incident Monitor). (Not all Models) (see page 300.3 for details)

Low battery indicator (Not All Models)

Touchpad alarm power failure or temperature deviation outside alarm set limits triggers audible and

visual warning. (Selected Models)

Independent high and low alarm setpoints adjustable

o

in 1

C increments (Not all Models)

Low voltage indicator light (Selected Models)

Exterior alarm contacts for remote alarm

CABINET CONSTRUCTION

Recessed, heavy-duty casters

Noise abatement insulation package.

Minimum 5” foamed in placed urethane insulation,

CFC free.

Technical Information 300.1

All-steel cabinet with high-impact epoxy finish for

easy cleaning.

Built-in access port, 1” diameter

Four (4) stainless steel interior shelves, (3) adjustable.

Anti-roll brakes

Five inner doors with positive latches

ADDITIONAL ULTIMA II FEATURES.

EXTREME AMBIENT ALERT

This alarm monitors the ambient temperature in the

area of the freezer. If the temperature reaches 99f (+/3f), it could possibly effect the performance or reliability of your freezer, and the Extreme Ambient

Alert will activate. This alarm is also under the umbrella of AIM, so that you can be sure that safe

temperatures exist even when no one is present.

Comfortable ambient conditions lead to long life of

your freezer and safety of your samples.

LIFE GUARD

Life Guard actively monitors the condition of the

compressors in the freezer. If the compressors should

enter a harmful stress condition that could cause them

harm, the Life Guard automatically turns the unit off

and allows the compressors to cool down.

The compressors will be automatically started when

the conditions are improved. During a Life Guard

alert, the temperature inside your chamber may warm

Slightly

compared to having a compressor failure and a complete warm up of your samples. If Life Guard is ever

activated, please call a service provider immediately

to investigate. Factors that may cause Life Guard to

activate include extreme ambient conditions, extreme

. However, this is a far superior option when

voltage conditions, excessive loading with warm

product, extremely dirty condenser filters, doors left

open, and other unusual circumstances.

SET POINT SECURITY

Not available on all models

Set Point Security allows you to lock in the control

set point and alarm set points of your freezer to ensure that they may not be changed, accidentally or

intentionally. When the key is in the third key position (alarm on), Set Point Security deactivates the up

and down buttons on the control panel. This makes it

impossible for the control set point, warm alarm, and

cold alarm to be changed. Of course, pressing the

appropriate buttons can still see these temperatures.

AIM (AUTOMATIC INCIDENT MONITOR)

Not available on all models

Although you cannot see this feature, it is extremely

important for the ongoing safety of your stored samples. AIM monitors the temperature of the freezer

and compares it to the alarm limits you have set. If

the unit temperature ever exceeds an alarm limit, the

appropriate alarm will flash rapidly, about one flash

per second. If this condition ever occurs while you

are not present and then self-corrects, AIM is activated. AIM lets you know that a temperature

deviation occurred while you were gone but has selfcorrected. Instead of flashing rapidly, the alarm will

flash slowly, about one flash every 3 seconds. The

most extreme chamber temperature registered during

this deviation can be seen by simultaneously pressing

the appropriate alarm set point button and the cabinet

temperature button. This feature guarantees that you

always know the temperatures of your stored samples. The slow flash of the AIM alarm can be reset by

pressing the alarm reset button. The AIM monitor

works for warm alarm, cold alarm, Life Guard, power

failure, and extreme ambient alert.

Technical Information 300.2

RECOMMENDED TOOL LIST

One of the keys to doing a job correctly is using

proper tools. The following list is NOT all-inclusive

of the tools you might need to perform the procedures

listed in this manual. However, these tools will be

needed to perform many of the steps in these procedures.

* Vacuum Pump (Capability of 50 microns)

* Electronic Digital Thermometer (Reads below

200C) Compatable to Type “T”

* Compound Gauge Set (4 way) with Hoses

* AC Volt-Watt Meter

* Hermetic Unit Analyzer

* Manometer

* Tachometer

* Portable Oxy-Acetylene Torch Set

* Regulator and Lines for Nitrogen

* Flaring Set and Swaging Tool Set

* Standard Hand Tools (Screw Drivers, Wrenches,

Pliers, etc.)

* Refrigerants; R404, R134a, R508B, and R290

(Instrument Grade Propane)

* Grit Cloth for Cleaning Lines

* Cordless Driver-Drill (Reversible)

* Vacuum Gauge (Electronic) Televac

* Electronic Leak Detector (CFC and Non-CFC)

* Electronic Refrigerant Charging Scales

* Multimeter Volt-Ohm, Amp Meter (Analog and

Digital)

* On-Off Cycle Chart Recorder

* Sling Psychrometer

* Presto Light Torch

* Dry Nitrogen (Portable “R” Type Cylinder

* Set of Flare Hand Valves or Process Tube Adapters

* Tubing Cutter(s) Large and Small

* Pinch Off Tool

* Recovery System (with tanks)

* Good Set of Tubing Bender

* Tube Reamer

Technical Information 300.3

PREVENTIVE MAINTENANCE

Preventive maintenance is the best way to ensure that

the unit you own or service continues to operate at its

optimum level. The following instructions will help

you in your preventive maintenance program.

CONDENSER CLEANING

Clean the condenser at least semi-annually; or more

often if the equipment is located in a dust prone area.

CONDENSER FILTER CLEANING

Clean the condenser filter every two or three months.

Shake or vacuum the filter first, then rinse the filter in

clean water. Let the filter dry, then replace the filter

on the unit.

GASKET MAINTENANCE

Periodically check the gaskets around the door or lid

for punctures or tears. Gasket leaks are indicated by a

streak of frost build up in the interior of the cabinet.

Keep the lid and door gaskets clean and frost free by

wiping gently with a soft cloth or brush.

DEFROST PROCEDURE

Defrost the cabinet every six to twelve months, depending on the amount of ice or frost on the cabinet

interior. To reduce ice build up, daily brushing (with

a soft brush) of the cabinet interior keeps the normal

frost from turning into ice.

To defrost the cabinet, remove your product, turn the

unit off by the key switch, and unplug the power

cord. Let the cabinet warm to room ambient temperature, then wipe down the cabinet interior using dry

towels. Wash and rinse the interior of the cabinet

with a solution of baking soda and warm water. Turn

the unit on and allow it to pull down to set-point temperature, then reload your product back into the

freezer.

ALARM BATTERY MAINTENANCE

Check the condition of the alarm battery at least annually. Check the input charging voltage and the

battery output voltage. The charging voltage input is

14 to 35 VDC, depending upon the model. The battery voltage at full charge is 12 VDC.

FAN MOTORS

Most fan motors used today are a maintenance free

(sealed type) and do not require oil maintenance, but

some previous motors may come with an oil port.

Inspection of the motor will determine which type is

being used. If an oil port is present, then a couple of

drops of oil once annually is sufficient.

CABINET LEVELING

Check the cabinet to ensure that it is level. Check

from the front to the back and then side to side, check

the level on a (6) month schedule.

CABINET CLEARANCE

Ensure that the cabinet has proper clearance, a minimum of six inches of space from the sides, back and

top of the cabinet is required.

VOLTAGE REQUIREMENTS

Check the voltage requirements every three to six

months. Verify that the source voltage is within

+10% and –5% of the rated data plate voltage.

CENTER AIR TEMPERATURE VALIDATION

Check the center air temperature using a thermocouple located physically in the geometric center of the

cabinet versus the control panel electronic display.

The temperature should match the display within +/1C at the coldest setting for most models.

ELECTRICAL WIRES

Check the electrical control box for any burnt or discolored wires due to lose connections or low voltage

conditions.

a. Maintenance should only be performed by trained

personnel.

b. For additional information or assistance you may

contact TECHNICAL SERVICES at (800) 438 4851 or (828) 658 - 2818

Technical Information 300.4

SECTION 400 - MAINTENANCE AND REPAIR PROCEDURES

CABINET

LEVELING OF A CHEST OR UPRIGHT FREEZER

A unit that is not level will not operate properly. It

can cause imbalances in products and can cause problems in the refrigeration system. An unleveled unit

can also cause misalignments of other components

such as the door, lid, and/or the gasket.

The following steps will aid you in aligning a freezer

unit.

Step 1: Locate the freezer in a level area free from

vibration, with a minimum of six (6) inches

(15.24 cm) of space on the sides, rear, and

top. Also, allow enough clearance so that the

door or lid can swing open at least 90 degrees.

Step 2: Place a carpenters level along the rear edge

of the unit, and then along the right hand

edge of the unit, to determine the offset from

level.

Step 3: To level chest models, leave the casters in

place and shim the low wheel/caster until

the carpenter level indicates the unit is level

from front to back and from side to side. Use

strips of sheet metal at least 0.5 inches (1.25

cm) wider than the caster, placed underneath

the caster to level the unit.

Step 4: To level upright models, use a 3/4” (19mm)

open-end wrench to turn the leveling leg until the carpenter level indicates the unit is

level from front to back, and from side to

side.

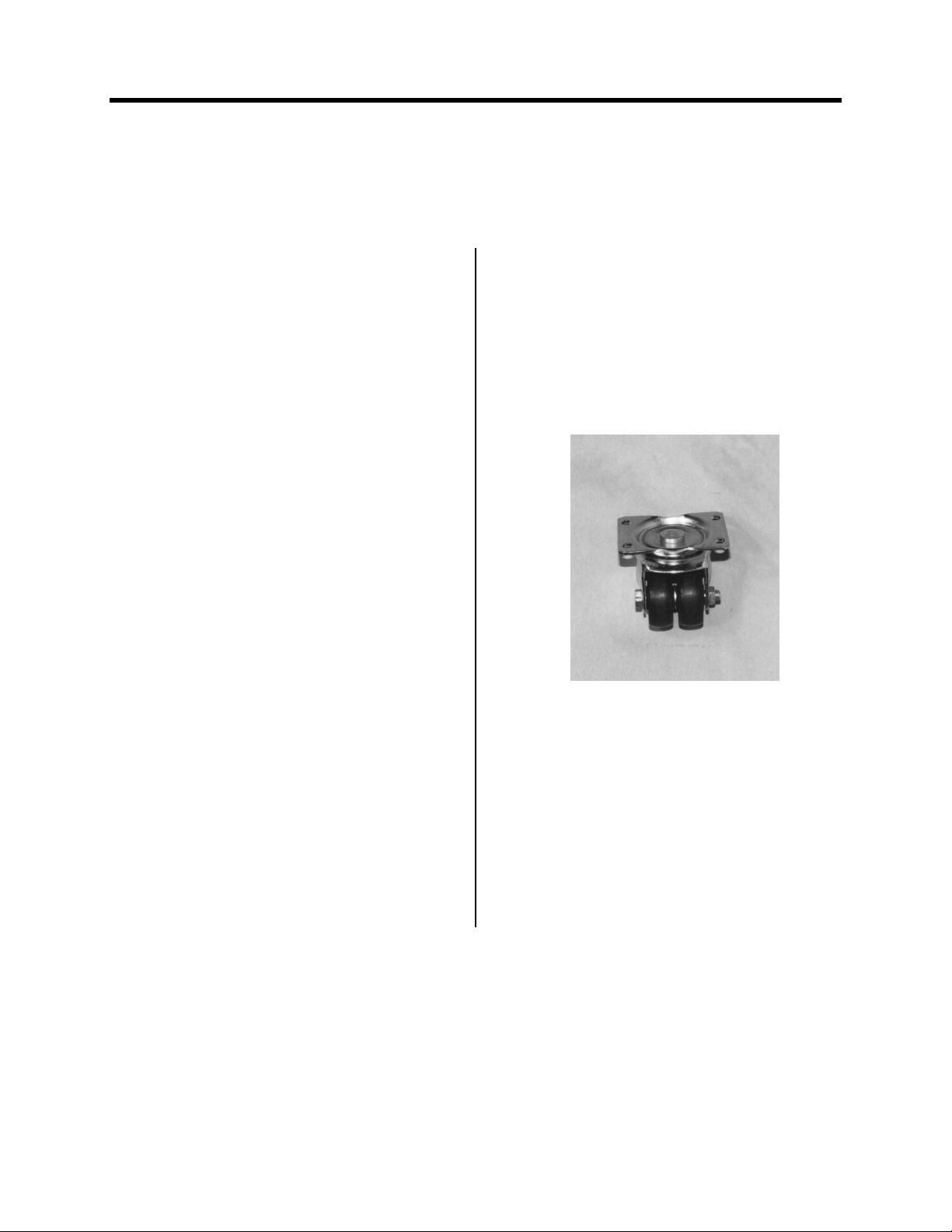

Figure 401-1

Typical Chest and Upright Caster

Maintenance and Repair Procedures 400.1

DEFROSTING A CHEST OR UPRIGHT FREEZER

Every time a freezer is opened, a certain amount of

water, depending on the relative humidity, enters the

freezer compartment. This water obviously turns to

frost, collecting on the sides and surfaces of the

freezer. This frost accumulation can lead to decreased

efficiency and temperature control.

It is recommended that the unit be defrosted when the

ice accumulation reaches a thickness of 0.25”

(6.4mm) or more.

Step 1: Transfer product to another freezer of equal

temperature.

Step 2: Leave the unit set for the desired operating

temperature, turn the power/key switch to

the Power Off position, and unplug the

unit’s power cord.

Step 3: Open the door or lid and leave the unit undis-

turbed for a minimum of twenty-four (24)

hours; failure to do so could cause oil logging problems when the unit is restarted,

thus preventing the unit from getting fully

cold.

Step 4: Use towels or a sponge and bucket to collect

the water on the cabinet floor and dry the

walls.

NOTE On upright models, towels should

Step 5: Start the unit by closing the door or lid, plug

Step 6: Leave the temperature control set for the

Step 7: If the unit has a selectable Alarm On posi-

Step 8: Monitor for proper operation.

be placed in the cabinet floor and

on the laboratory floor immediately

in front of the cabinet to prevent the

water from presenting a slip hazard.

the power cord into the wall receptacle, and

turn the power switch to the Power On position.

desired operating temperature and allow 1012 hours of operation in order for the unit to

return to operating temperature.

tion, select the Alarm On position after the

temperature display is colder than the Warm

Alarm setpoint.

Maintenance and Repair Procedures 400.2

DOOR ADJUSTMENT OF AN UPRIGHT FREEZER

The following steps will aid you in adjusting the

hinges of an upright Ultra Low Temperature freezer.

Step 1. Ensure the freezer cabinet is level from front

to back, and left to right.

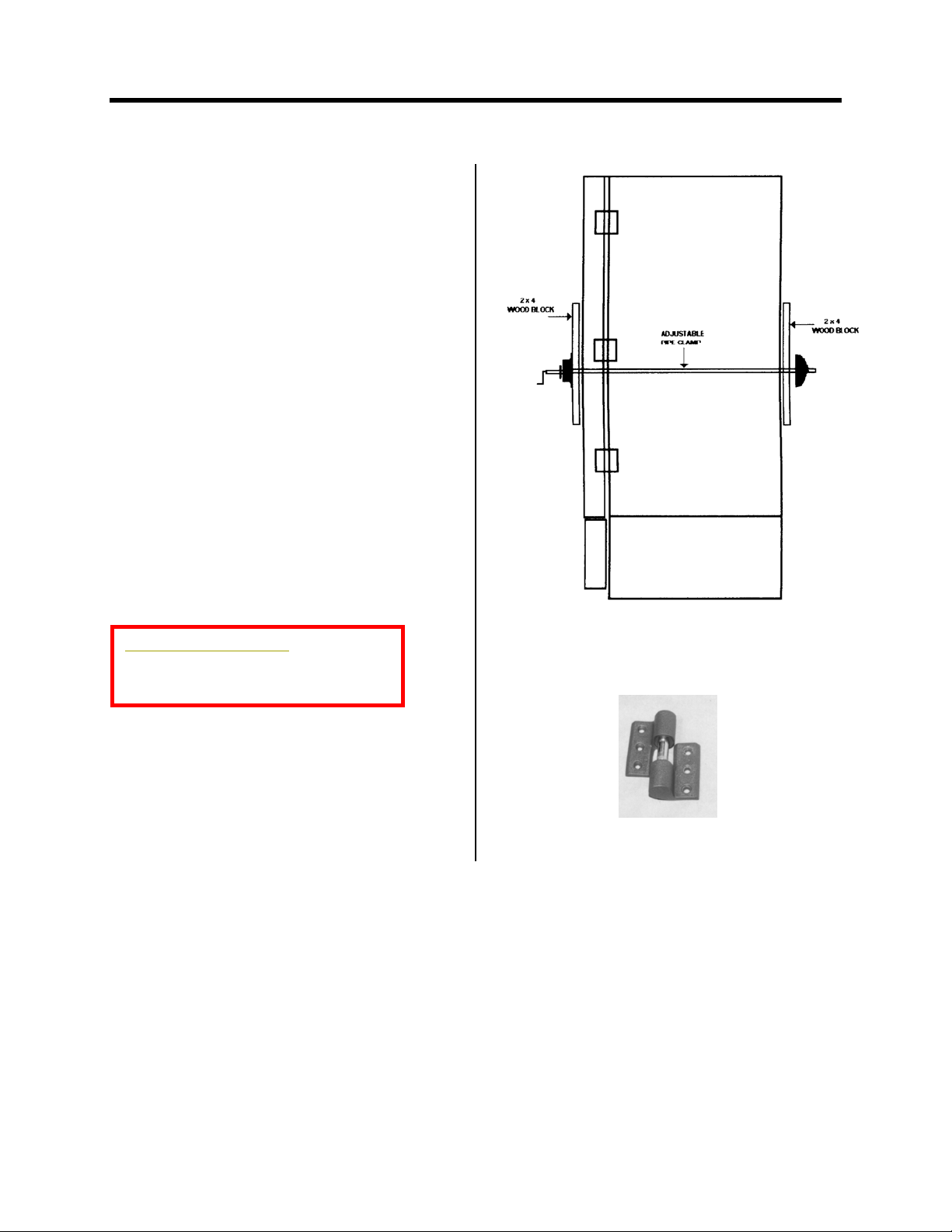

Step 2. Install a bar clamp with 2” x 4” wooden

blocks, as shown in Figure 403-1.

Step 3. Loosen the mounting screws that hold the

hinge to the door.

Step 4. Align the door so that the top and latch edges

are flush with the cabinet.

Step 5. Tighten the bar clamp to produce secure gas-

ket seal.

Step 6. Tighten all mounting screws.

Add picture for new hinge

Figure 403-1

Hinge Adjustment Configuration

Figure 403-2

Upright Freezer Hinge

Maintenance and Repair Procedures 400.3

LID ADJUSTMENT OF A CHEST FREEZER

The following steps will aid you in adjusting the lid

of a chest type Ultra Low Temperature freezer.

Step 1. Ensure the freezer cabinet is level from front

to back, and left to right.

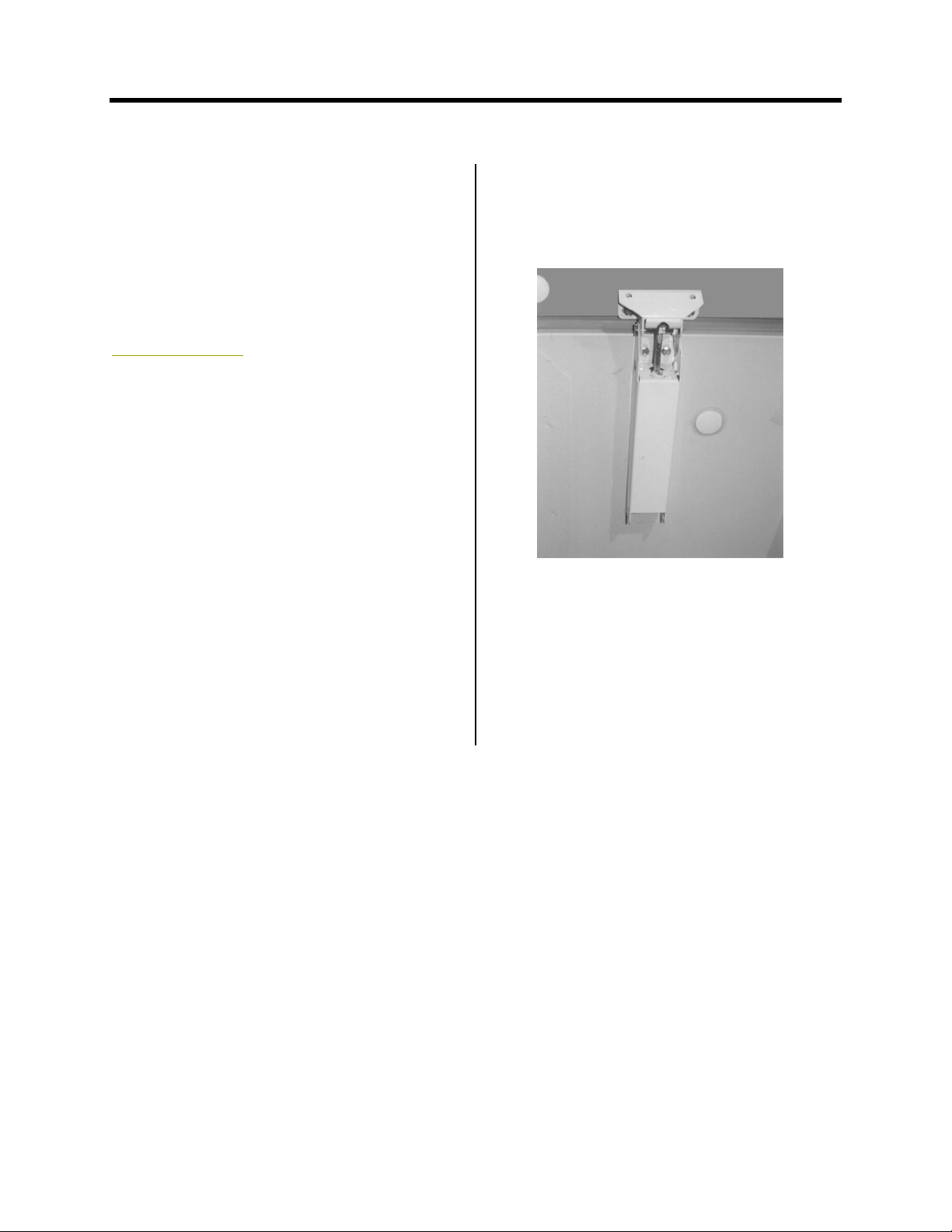

NOTE The hinge mounting screws are

elongated for up and down positioning to obtain proper gasket seal

on hinge side of lid.

Add warning symbol

CAUTION The hinge is under considerable

spring tension. Removal or excessive loosening of screws could

cause hinge to fly up and cause

injury.

Step 2. Loosen the hinge screws that attach the hinge

to the cabinet.

Step 3. Align the cabinet for proper gasket seal.

Step 4. Tighten the hinge mounting screws.

Step 3. Fully open the lid

Step 4. With a 3/4” wrench, turn the hinge tension

nut to compress the spring until the lid remains open.

Step 5. Close the lid and monitor unit for proper op-

eration

Figure 404-1

Chest Freezer Hinge

Maintenance and Repair Procedures 400.4

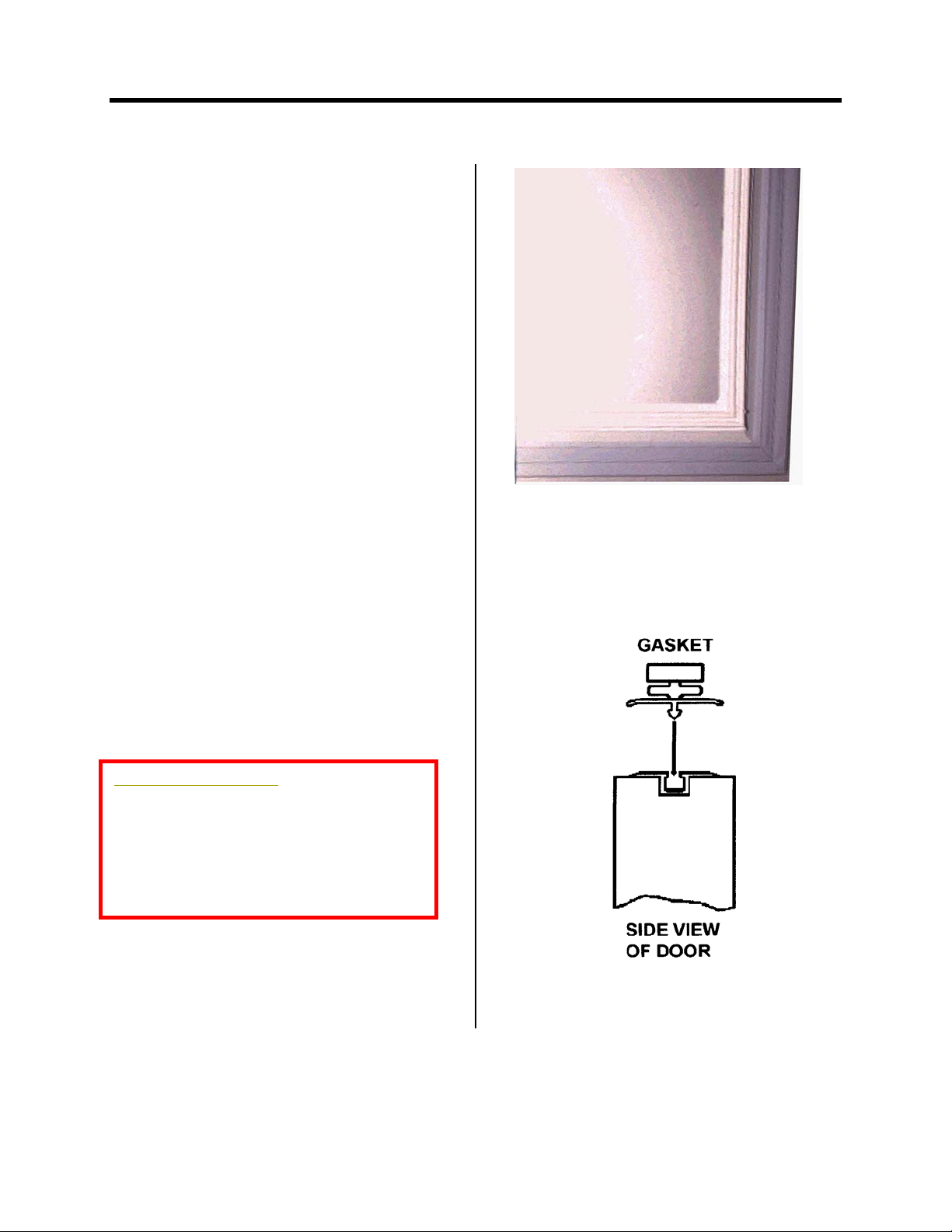

UPRIGHT FREEZER GASKET REPLACEMENT

The following steps will aid you in replacing the inner or outer gasket of an upright Ultra Low

Temperature freezer.

NOTE The new gasket will be wrinkled

and folded when it is unpacked.

Immerse the gasket in warm water

until it becomes pliable. Lay the

gasket flat and allow to dry. Care

should be taken not to stretch or

tear the gasket during handling.

Step 1. Transfer product to another freezer of equal

temperature.

Step 2. Leave the unit set for the desired operating

temperature, turn the power/key switch to

the Power Off position, and unplug the

unit’s power cord.

Step 3. Remove the desired (inner or outer) gasket

by pulling it straight away from the door.

Step 4. Align the corners

Step 5. Press the retaining rib (corners first) on the

new gasket into the groove in the door using

a rubber hammer if necessary.

NOTE You may find it easier to remove

the door and lay it on a flat surface

with the gasket side up.

Add picture of new gasket

Figure 405-1

Typical Gasket

(inner or outer)

Figure 405-2

Gasket Insertion

Maintenance and Repair Procedures 400.5

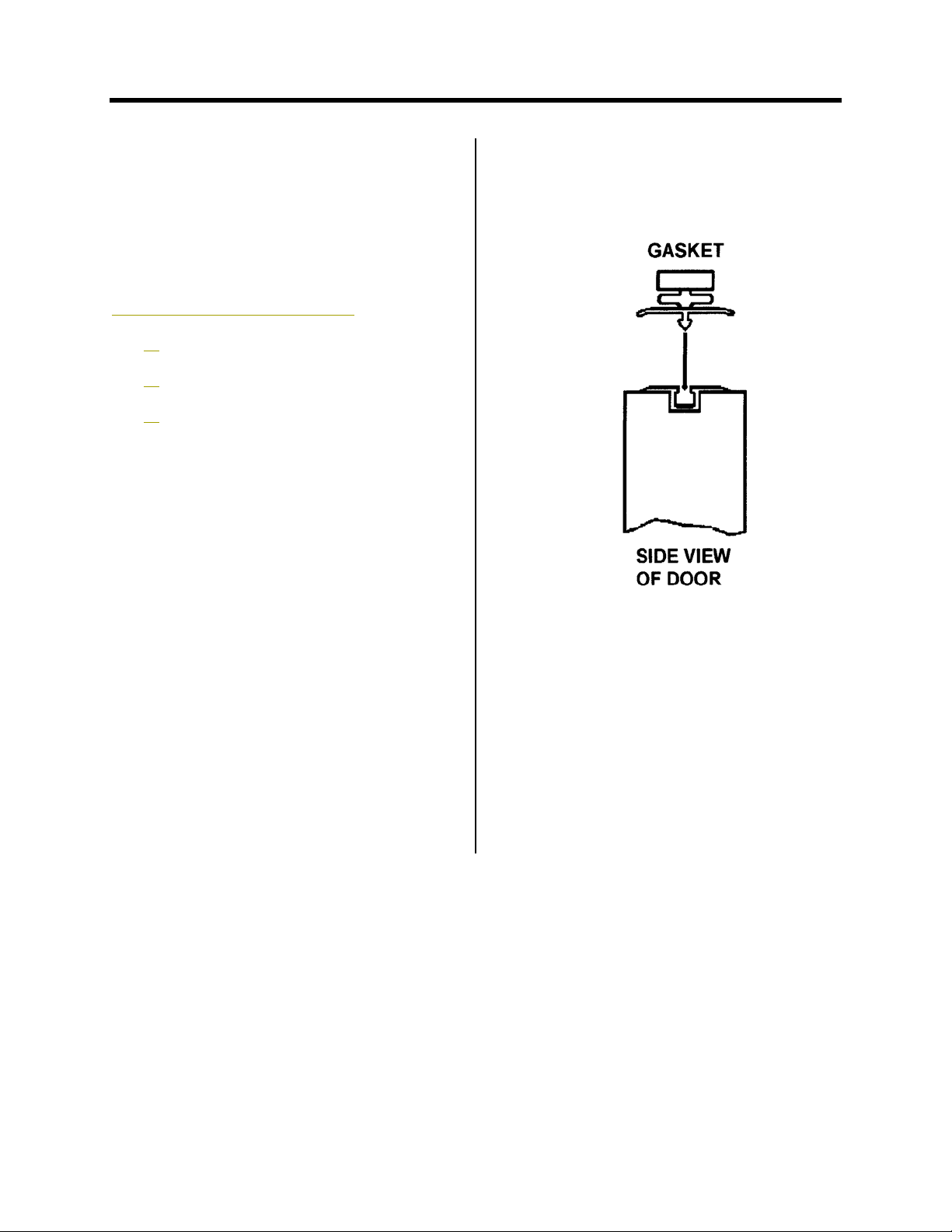

CHEST FREEZER GASKET REPLACEMENT

The following steps will aid you in replacing the gasket on a chest type Ultra Low Temperature freezer.

NOTE The new gasket will be wrinkled

and folded when it is unpacked.

Immerse the gasket in warm water

until it becomes pliable. Lay the

gasket flat and allow to dry. Care

should be taken not to stretch or

tear the gasket during handling.

Add warning symbol

CAUTION The hinges on a chest freezer are

under tension when the lid is

closed. Care should be taken to

avoid injury.

Step 1. Transfer product to another freezer of equal

temperature.

Step 2. Leave the unit set for the desired operating

temperature, turn the power/key switch to

the Power Off position, and unplug the

unit’s power cord.

Step 3. Remove the 5/16” screws that attach the lid

hinges to the cabinet

Step 4. Remove the lid from the cabinet.

Step 5. Lay the lid, gasket side up, on a flat surface

and remove the desired (inner or outer) gasket by pulling it straight away from the lid.

Figure 406-1

Chest Freezer Hinge

Figure 406-2

Chest Gasket

Maintenance and Repair Procedures 400.6

Step 6. Lay the new gasket in place and align the

corners.

Step 7. Press the retaining rib (corners first) on the

new gasket into the groove in the lid using a

rubber hammer if necessary.

Step 8. Install the lid

Step9. Adj. Per Adjustment Procedure

Step 10

. Reattach power supply.

Step 11

: Turn power key on.

Step 12

: Check unit for proper operation.

Figure 406-3

Gasket Insertion

Maintenance and Repair Procedures 400.7

HANDLE REPLACEMENT FOR CHEST FREEZER

The most used manual component of a chest freezer

is the lid handle. The following steps are provided to

give instructions on how to replace the handle of a

-85C freezer.

Step 1: Locate and remove the screws securing the

handle. Be sure to retain the screws and any

washers used.

Step 2: Remove the handle from the lid.

Step 3: Set the new handle in its proper place and

secure it to the lid using the screws and

washers used in Step 1.

Figure 407-1

Lid Handle

Maintenance and Repair Procedures 400.8

UPRIGHT FREEZER CAM LATCH DOOR LOCK REPLACEMENT

The following steps are provided to give instructions

on how to replace the latch of an upright freezer.

Before repairing, identify any circumstances contributing to latch problem such as shipping damage,

excessive ice build-up, maneuvering overload, improper alignment of the latch of lid/door hinges,

cabinet breaker geometry, or other. Review with

owner and factory service department at 800-438-

4851.

REMOVE UNWANTED LATCH.

Step 1 If necessary, secure door temporarily with

strapping tape.

Step 2. Remove rear strike cover and rear strike.

Step 3. Remove front cover by removing fasteners

then sliding vertically upward. Note con-

cealed fasteners behind door handle.

Step 4. Remove latch assembly. Note, access holes

allow removal of latch mounting fasteners

without disassembly

Step 5. Inspect door and cabinet for damage. Pay

careful attention to mounting points.

Step 6. Repair threads as necessary with ¼-20 tap or

drill 25/64 (PN 38126H03) then replace with

nutsert (PN305465H01).

NSTALL NEW LATCH

Step 1. Inspect new latch for workmanship flaws

and/or handling damage. Mechanism should

have a tight feel, lock should engage

smoothly and fully.

Step 2. Attach new strike to cabinet with (4) ¼-20

fasteners and hardened washers. Align hori-

zontally flush with cabinet edge or with a

slight overhang. Torque 60 in-lb. (6.75 N-

m).

NOTE

Inability to achieve torque

may indicate damaged

threads

Strike (2b) and Latch (2c) Cover

Strike and Latch Mounting Screws

Figure 408-1

Mounting Screws

Figure 408-2

and / or Access Holes

Maintenance and Repair Procedures 400.9

Step 3. Attach latch assembly to door with (4) ¼-20

fasteners and hardened washers. Align verti-

cally so top surface is flush with rear strike.

Torque 60 in-lb. (6.75 N-m).

NOTE Disassembling latch is not required

nor recommended.

Step 4. Put a small amount of white lithium grease

at strike point.

CAUTION Excessive door compression may

damage latch and/or cabinet

.

Step 5. Adjust rear strike horizontally to achieve

exterior gasket compression thickness of ap-

proximately 11/16 inch (18mm).

Step 6. Fine tune gasket compression with miro-

adjustment screw located in catch. Install

front and rear covers. Top surfaces should

align.

CAUTION Only the micro-adjustment screw’s

chamfered portion should extend

beyond the catch surface to prevent snagging on the strike during

close. If necessary, loosen and

reposition strike rearward to assure

smooth operation.

Step 7. Verify operation. Neither latch nor cabinet

panels should deflect noticeably during op-

eration. No interference should exist

between latch components and freezer. Fas-

teners remain secure. Padlock and built in

lock engage smoothly.

NOTE 2 –4 drops ICI46H POE lubricant

may be squirted into main or interlink bearings to eliminate squeaks.

Maintenance and Repair Procedures 400.10

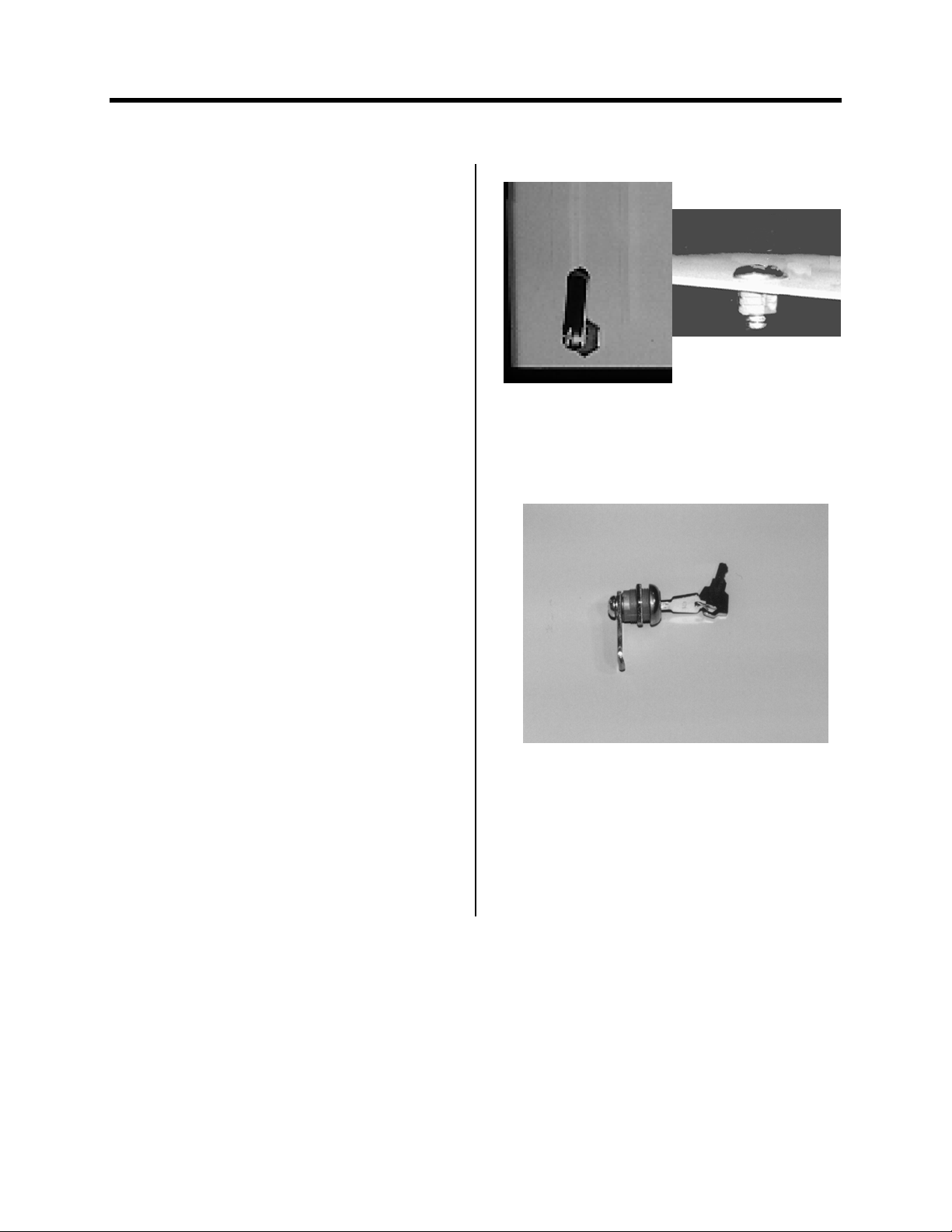

CHEST FREEZER LID LOCK REPLACEMENT

The following steps will aid you in replacing the lock

on the lid of a chest type Ultra Low Temperature

freezer.

CAUTION Disconnect all power to unit.

Step 1. Remove the screws at the rear of the control

housing cover.

Step 2. Slide the cover towards the rear of the unit

approximately two inches.

Step 3. Turn the control housing cover over. Remove

the screw securing the pivoting tab to the

locking mechanism.

Step 4. Remove the pivoting tab.

Step 5. Remove the nut securing the locking mecha-

nism to the cover.

Step 6. Remove the locking mechanism from the

cover.

Step 7. On the new locking mechanism, remove the

screw securing the pivoting tab to the lock-

ing mechanism.

Step 8. Install the locking mechanism into the cover.

Step 9. Install the pivoting tab.

Step 10: Verify the direction of rotation of the lock-

ing mechanism when the key is turned is

correct.

Step 11: Install the screw to secure the pivoting tab.

Step 12: Install the cover. A rubber hammer may be

needed to install the control housing cover.

Step 13: Install the screws at the rear of the control

housing cover.

Figure 409-1

Chest Freezer Lid Lock

(installed on the unit)

Figure 409-2

Chest Freezer Lid Lock Component Parts

Maintenance and Repair Procedures 400.11

Loading...

Loading...