Kendro Heraeus CLINIFUGE User manual

Clinifuge

120V 60 Hz

SERVICE MANUAL

®

P/N 12003539

TABLE OF CONTENTS

Section |

Title |

Doc.- No. |

Page |

|

1 |

OPERATING INSTRUCTIONS |

|

|

|

|

(not part of this manual) |

|

|

|

1.1 |

Brochure |

Clinifuge_E |

|

|

|

|

|

|

|

2 |

SERVICE |

Clinifuge_2 |

|

|

2.1 |

Servicing Schedule |

" |

- " |

2-1/2 |

2.2 |

Trouble Shooting |

" |

- " |

2-3/4 |

2.3 |

Test Points |

" |

- " |

2-5 |

2.4 |

Cleaning of Instrument Parts |

" |

- " |

2-6 |

2.5 |

Electrical Safety Check |

" |

- " |

2-6 |

|

|

|

|

|

3 |

FUNCTIONAL DESCRIPTION |

Clinifuge_3 |

|

|

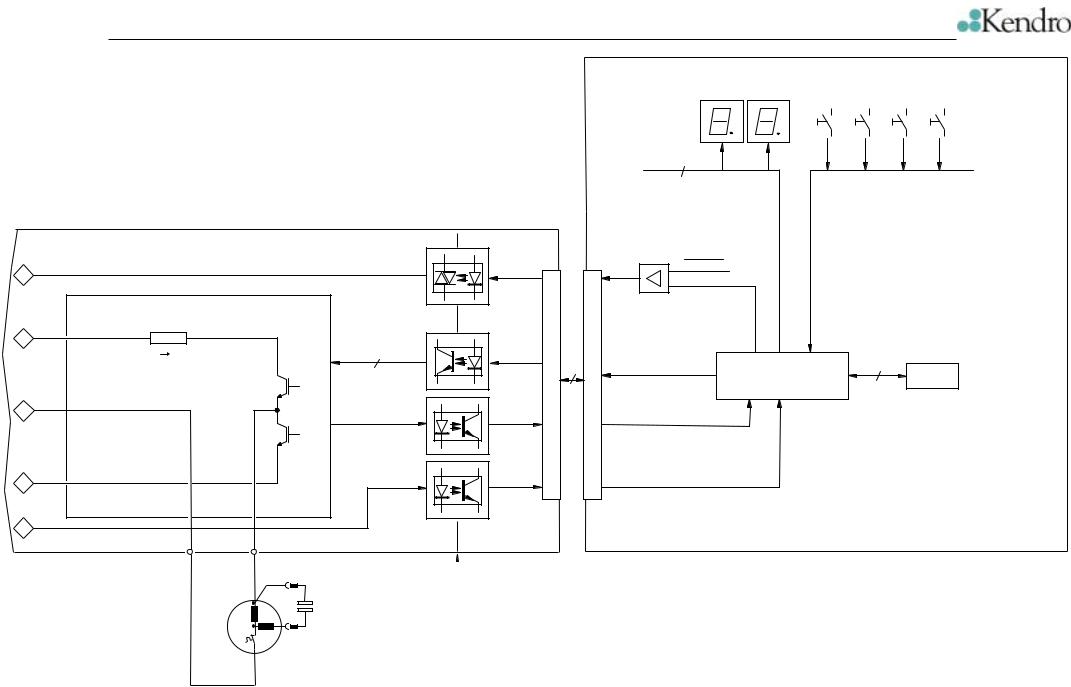

3.1 |

Block Functions |

" |

- " |

3-1 |

3.2 |

Functions of Main Board |

" |

- " |

3-1 |

|

|

|

|

|

4 |

DIAGRAMS |

Clinifuge_4 |

|

|

4.1 |

Block Diagram |

" |

- " |

4-1 |

4.2 |

Wiring Diagrams |

" |

- " |

4-2/3 |

4.3 |

Wiring Connection Diagrams |

" |

- " |

4-4 |

4.4 |

Main Board 14 - Component Plan |

" - " |

4-5 |

|

4.5 |

Main Board 14 - Wiring Diagram |

" |

- " |

4-6/8 |

4.6 |

Main Board 178 - Component Plan |

" - " |

4-9 |

|

4.7 |

Main Board 178 - Wiring Diagram |

" |

- " |

4-10/12 |

|

|

|

|

|

5 |

DISASSEMBLY OF INSTRUMENT PARTS |

Clinifuge_5 |

|

|

5.1 |

Housing / Casing Parts |

" |

- " |

5-1 |

5.2 |

Electrical Components |

" |

- " |

5-2 |

5.3 |

Drive Components |

" |

- " |

5-3 |

5.4 |

Mechanical Components |

" - " |

5-3 |

|

5.5 |

Service Kit |

" |

- " |

5-4 |

5.6 |

Dismantling and assembling the rotor |

" |

- " |

5-4 |

|

|

|

|

|

6 |

SPARE PART FIGURES AND LISTS |

Clinifuge_6 |

|

|

6.1 |

Spare Part Figures |

" |

- " |

6-1/2 |

6.2 |

Spare Part Lists |

" |

- " |

|

|

|

|

|

|

7 |

TECHNICAL BULLETINS |

Clinifuge_7 |

7-1/6 |

|

|

|

|

|

|

8 |

Preventive Maintenance Checklist |

|

|

|

Edition: 02 |

TABLE OF CONTENTS |

Clinifuge |

24.01.02 AH |

Page: 0 - 2 |

|

CLINIFUGE®

COMPACT CENTRIFUGE

Easy to Use

The Heraeus® Clinifuge is functional and sophisticated with an ergonomic design.

It is ideal for use in medical practices, clinical and small laboratories and as a stand-by unit in large laboratories.

▼

Benefits

■Easy to Use

■Able to run wide range of most popular medical tubes

■Maintenance free

■Safe

Clinifuge

Maintenance free

The Clinifuge is equipped with a brushless motor, so there is no need to replace carbon brushes. Beside saving time and money, this also ensures clean operating conditions.

Accessories

The Clinifuge comes complete with an adapter set and an autoclavable rotor. Made of impact resistant, fiber glass reinforced polyamide, this rotor offers high stability and outstanding run characteristics.

It is easily removed for cleaning in the laboratory washing machine. An extensive range of adapters permits centrifugation of all standard 5, 7, 10 and 15 ml tubes, including the popular “Monovette”, “Vacutainer” and “VenoJect” blood collection tubes.

Safety

Samples processed in today’s laboratories often harbor unknown risks. The Clinifuge complies with international safety standards and is equipped with a lid lock, lid interlock and steel armoured guard ring.

Functions

The microprocessor controlled Clinifuge is equipped with bright digital displays and touch-pad keys for quick and easy setting of speed and run-time. The values last used are stored. To repeat a run, simply press the start key.

It is also designed with a user friendly self diagnosis system which indicates faults directly on the display.

Quality Products – Lifetime Care

Set the required speed…

…and set the required time

With the “start” button, repeat runs can easily be recalled

TECHNICAL DATA

Clinifuge |

120 V version |

Description |

Microprocessor controlled table top centrifuge |

Maximum speed (rpm) |

5000 |

Minimum speed (rpm) |

1600 |

Maximum RCF (x g) |

2600 |

Minimum RCF (x g) |

270 |

Maximum capacity (ml) |

12 x 15 (glass) |

Controller |

Microprocessor controller for time and speed |

Drive |

Brushless induction motor, microprocessor controlled |

Runtime |

1–99 min. and continuous operation (Hold) |

Program memory |

Stores values last entered, unlimited |

Safety |

Lid lock and lid interlock, steel armoured guard ring |

Design |

Fibre glass reinforced polyamide housing with high noise and |

|

vibration insulation properties |

Dimensions (H x W x D) (mm / inch) |

240 x 284 x 375 / 9.5 x 11.2 x 14.8 |

Weight (incl. rotor) (kg / Ibs) |

Approx. 10.7 / 23.5 |

Power consumption (W) |

65 |

ORDER NUMBERS

Model |

|

|

|

|

|

Order No. |

|

Clinifuge |

|

|

120 V; 60 Hz |

|

75003539 |

|

|

Accessories for Clinifuge |

|

|

|

|

|

|

|

Angle rotor1) |

|

|

75003760 |

|

|

|

|

Max. speed (rpm) |

|

5000 |

|

|

|

|

|

Max. RCF (x g) |

|

2600 |

|

|

|

|

|

Max. capacity (ml) |

|

12 x 15 |

|

|

|

|

|

Max. radius (cm) |

|

9.65 |

|

|

|

|

|

Acceleration time (sec) |

|

40 |

|

|

|

|

|

Braking time (sec) |

|

45 |

|

|

|

|

|

Accessories for angle rotor 75003760 |

|

|

|

|

|||

Tube volume |

Type of tube |

|

Dimension (mm) |

Tubes |

Type of |

Adapter |

|

(ml) |

|

|

Diam. x Length |

per rotor |

adapter |

Order No. |

|

7 |

Glass tubes (DIN) |

12 |

100 |

12 |

yellow |

750032271) |

|

15 |

Glass tubes (DIN) |

16 |

100 |

12 |

4) |

– |

|

|

|

|

|

|

|

|

|

3-5 |

VenoJect II (Terumo) |

13 |

75 |

12 |

cream + |

750032271) |

|

|

|

|

|

|

|

rubber pad |

|

7 |

VenoJect II (Terumo) |

13 |

100 |

12 |

yellow |

750032271) |

|

9-10 |

VenoJect II (Terumo) |

16 |

100 |

12 |

sleeves |

750037633) |

|

3-5 |

Vacutainer (BD)2) |

13 |

75 |

12 |

cream + |

750032271) |

|

|

|

|

|

|

|

rubber pad |

|

7 |

Vacutainer (BD)2) |

13 |

100 |

12 |

yellow |

750032271) |

|

7 |

Vacutainer (BD) |

16 |

75 |

12 |

sleeves + |

750037633) |

|

|

|

|

|

|

|

rubber pad |

75003266 |

10 |

Vacutainer (BD)2) |

16 |

100 |

12 |

4) |

– |

|

15 |

Vacutainer (BD) |

16 |

125 |

6 |

4) |

– |

|

|

|

|

|

|

|

|

|

4 |

Sarstedt Monovette |

11.5 |

83.5 |

12 |

cream |

750032271) |

|

5 |

Sarstedt Monovette |

13 |

90 |

12 |

cream |

750032271) |

|

7.5 |

Sarstedt Monovette |

15 |

92 |

12 |

4) |

– |

|

9 |

Sarstedt Monovette |

16.5 |

92 |

6 |

rubber pad |

75003762 |

|

12 (Urine) |

Sarstedt Monovette |

16.5 |

101.5 |

6 |

4) |

– |

|

|

|

|

|

|

|

|

|

Urine tubes |

BD, Terumo |

|

16 |

100 |

12 |

sleeves |

750037633) |

1) included with centrifuge |

2) tube incl. Hemoguard cap |

3) included with rotor |

4) not necessary |

||||

The adapter set 75003227 will contain the yellow and cream adapters and rubber pads.

For Ordering or Technical Information

Asia Pacific Kendro Laboratory Products (H.K.) Limited · Hong Kong · Tel. +852 2711-3910 · Fax +852 2711-3858 · info@kendro.com

Europe, Middle East, Africa

|

Kendro Laboratory Products International Sales · Hanau · Germany · Tel. +49 (6181) 35-300 · Fax +49 (6181) 35 59 44 · info@kendro.de |

Latin America |

Kendro Laboratory Products International Sales · Newtown · USA · Tel. 1 (203) 270-2080 · Fax. 1 (203) 270-2210 · info@kendro.com |

USA |

Kendro Laboratory Products · Newtown · Tel. 1 (800) 522-7746 · Fax. 1 (203) 270-2166 · info@kendro.com |

Internet |

http://www.kendro.com |

Quality Products – Lifetime Care

Registered to ISO 9001. Kendro Laboratory Products meet or exceed stringent quality and product safety standards: CE for the European Union, and UL, cUL or CSA standards for North America. ©2000 Kendro Laboratory Products. All Rights Reserved. S00254 Printed in Germany 5C 03/00 N 4t Künzel

Service

2.1 Servicing Schedule (yearly procedure recommended)

2.1.1 Maintenance Routine without Dismantling the Centrifuge

2.1.1.1 Electrical Installation and Safety

• Switch OFF the centrifuge and disconnect the unit from power, check voltage supply and mains fusing (16 Amps, slow blow characteristic)

• Check condition of plug and wall socket - (let) replace defective parts

• Check cord condition and fixing / connection - replace or refit it

2.1.1.2 Location and Mechanical Installation

• Check the base (ground, table, lorry with lockable wheels etc.) For resonance-free and stable conditions

• Check for a well ventilated place and sufficient distances to walls or adjacent equipment, without exposure to direct sunlight

• Check the leveling of instrument (use a spirit level)

2.1.1.3 Lid Locking Mechanism and Safety

•Connect the centrifuge to power and switch ON

•Check for easy lid closing and self-acting lid opening - if in disorder, readjust lid’s swivel hinge and/or lock assembly

•Check the central rubber gasket for lid sealing and replace it, if damaged

•For checking the safety: start the centrifuge, let it shortly run and stop it, the lid must not be unlocked by the microprocessor until the “end” message is shown on the display - if safety circuit is out of function, replace the main board

2.1.1.4 Cleanliness of Spin Chamber and Motor Casing

•Open the lid and remove the rotor (for loosening turn the central winged nut anti clockwise from the motor shaft)

•Clean the spin chamber with a dry and absorbent cloth (remove all dust and moisture - see also 2.5 Cleaning)

•Check the cleanliness of the motor casing and take care of the annular slot around the motor shaft: penetrating fluids can damage the upper motor baring, remove fluids with an injector and/or absorbent paper

2.1.1.5 Rotor and Accessories Condition and Sealing

• Check the condition of rotors and accessory parts (especially all supporting or stressed partitions): the rotor and/or accessory parts must not be used any longer, if there are visible traces of mechanical damage

2.1.1.6 Rotor Fixing and Motor Shaft

•Check the trouble-free condition of the locking nut and replace it in case of malfunction

•High performance rotors made of plastic have a limited service life. Due to safety reasons they have to be exchanged after 10,000 cycles or after being in use for five years. The expiry date can be seen on the date clock in the rotor lower shell. The two-digit number in the middle represents the year and the arrow points to the expiry month. The number of cycles may be checked at any time by closing the lid and keeping both “set” keys pressed. The accumulated rotor cycles will be displayed in the speed display.

•Check the condition of the drive motor shaft: the centrifuge must not be used any longer, if the drive shaft is damaged (bend, thread is worn out, horizontal grooves etc.)

2.1.1.7 Temperature Level

•Check the air inlet underneath the lid and under the bottom plate for free ventilation, insufficient air flow will lead to temperature rise of rotor, motor and electronic parts

Edition: 03 |

Servicing Schedule |

Clinifuge |

17.04.02 AH |

Page: 2-1 |

|

Service

2.1.2Maintenance Routine after Dismantling the Centrifuge Casing

2.1.2.1 |

Motor |

Supporting Elements |

• Check the |

supporting and damping elements of the drive motor and replace them in case of |

|

increased rubber abrasion or abundance of imbalance but at least every 3 years |

||

2.1.2.2 |

Braking Circuit |

|

•Check the function of the braking circuit (even brake effect)

2.1.2.3 Lead and Screwing Connection

• Check the terminal and plug connections of all leads and on all boards and electrical components, tighten all loosen screwing connections, refit or replace defective parts

• Check the screwing connections of all boards, mechanical and electrical components and retighten them if necessary (use screw locking lac for motor mounts and lid lock assembly)

2.1.2.4 Protection Earth Core and Grounding Connections

•Check the protection earth core for continuity and all grounding plug connectors

•Check isolation resistance and accessible current (see 2.5)

Edition: 03 |

Servicing Schedule |

Clinifuge |

17.04.02 AH |

Page: 2-2 |

|

Service

2.2Trouble Shooting

Error |

Error Cause |

Possible Error |

Corrective Procedure |

|

Indication |

Source |

|||

|

|

Mains fuse or circuit |

Check fuse or circuit breaker, replace or switch |

|

|

No mains |

breaker failed |

on again |

|

|

Defective mains cord |

Check instrument cord, replace defective parts |

||

|

voltage supply |

|||

Displays |

Defective unit fuse or |

Replace it, if fuse blows again, disconnect |

||

|

||||

|

fuses on main board |

electrical parts, otherwise replace main board |

||

remain |

|

Faulty connection |

Check connections on CPU, indicat. Board and |

|

dark |

|

from indication to |

||

No low voltage |

connecting leads, replace defective parts |

|||

|

power board |

|||

|

|

|||

|

supply |

Faulty indication or |

Replace main board |

|

|

|

|||

|

|

power board |

||

|

|

|

||

|

|

|

|

|

|

Motor over- |

Motor temperature is |

Let motor cool down, then check temperature |

|

|

temperature |

|||

|

switch has |

higher than 120°C |

switch and leads with Ohmmeter |

|

|

tripped |

|

|

|

Displays |

Rotor didn’t |

Rotor is jammed |

Check for easy rotor movement, remove any |

|

are |

||||

jamming objects |

||||

illuminated |

turn |

|

||

|

|

|||

, but drive |

|

|

|

|

|

Motor is jammed |

Replace motor |

||

doesn’t |

|

|

|

|

|

Connections inter |

Check terminal and lead connections, replace |

||

start |

Motor didn’t |

drive and main board |

faulty parts |

|

|

Defective drive |

Check resistance of motor windings, replace |

||

|

start |

faulty parts |

||

|

|

|||

|

|

Faulty condenser |

Replace condenser |

|

|

|

Faulty main board |

Remove main board completely and replace it |

|

Drive |

|

Wear out of motor |

Replace motor rubber mounts |

|

Mechanics |

rubber mount |

|||

makes |

|

|||

|

Motor bearing |

Change motor completely |

||

noises-no |

|

|||

|

Defective terminal |

|

||

good |

|

Check voltage on motor terminal and winding |

||

separation |

Electrical |

connection, faulty |

resistances -see test points on boards |

|

result |

|

lead or motor winding |

|

|

|

|

Defective driving |

Replace main board |

|

Drive |

No brake |

|

|

|

doesn’t |

Faulty main board |

Remove main board completely and replace it |

||

current |

||||

decelerate |

|

|

||

|

|

|

||

|

Lid coil is not |

Missing mains voltage |

Remedy see above, manual opening only at |

|

|

standstill |

|||

|

or not |

|

||

Lid cannot |

PTC resistor has |

After a waiting time of 1-2 minutes press key |

||

sufficiently |

||||

be opened |

released |

again |

||

supplied with |

||||

by key |

Faulty driving or triac |

|

||

voltage |

Replace the complete main board |

|||

pressure |

circuit |

|||

|

|

|||

at |

Faulty lid coil |

Faulty winding of coil |

Replace complete lid lock |

|

standstill |

Lid is not |

Lid bolt is jamming |

Push lid into lock and press the key again |

|

|

correctly |

Lid is deformed or |

Readjust the lid centrically |

|

|

locked |

disadjusted |

||

|

|

Edition: 03 |

Trouble Shooting |

Clinifuge |

17.04.02 AH |

Page: 2-3 |

|

Service

Trouble Shooting

Error |

Error Cause |

Possible Error |

Corrective Procedure |

|

Indication |

Source |

|||

|

Lid was |

Forbidden |

|

|

|

intervention |

Close lid immediately, turn power off/on, wait |

||

|

opened |

|||

|

Emergency opening |

for termination of br phase until end message |

||

“LId“ |

manually |

|||

can only be used at |

appears |

|||

during run |

||||

message |

standstill |

|

||

|

|

|||

appears in |

Protection |

|

|

|

speed |

circuit (15V) |

Defective micro |

Check leads and connectors to micro switch, in |

|

display |

for lid control |

switch or leads or |

||

case of a faulty micro switch, replace lid lock |

||||

|

was |

connectors to micro |

||

|

device completely |

|||

|

interrupted |

switch are interrupted |

||

|

|

|||

|

during the run |

|

|

|

“OPEn“ |

15V supply |

Defective micro |

|

|

message |

circuit is |

switch or leads or |

Check leads and micro switch |

|

in speed |

interrupted at |

connectors to micro |

||

|

||||

display |

standstill |

switch are interrupted |

|

|

“br “ |

Rotor comes |

|

|

|

message |

Short interruption of |

Wait for rotor standstill (appr. 75 seconds) and |

||

to standstill |

||||

appears in |

||||

without braking |

mains supply |

re-start |

||

speed |

force |

|

|

|

display |

|

|

||

|

|

|

||

„E-“„ 2“ |

Maintenance |

Rotor has reached |

Replace rotor, NV-Ram and motor supports |

|

message |

||||

counter |

||||

appears in |

10000 cycles |

(Service Kit) |

||

expired |

||||

speed field |

|

|

||

|

|

|

||

„E-“„ 3“ |

No brake |

|

|

|

message |

Faulty main board |

Remove main board completely and replace it |

||

appears in |

current |

|||

|

|

|||

speed field |

|

|

|

|

„E-“„12“ |

Checksum |

NV-RAM is not |

Check NV-RAM and socket, insert the correct |

|

error of NV- |

||||

initialized or false |

NV-RAM |

|||

message |

RAM |

|||

|

|

|||

appears in |

Disturbed data |

|

|

|

speed field |

transfer from |

Faulty main board |

Remove main board completely and replace it |

|

|

NV-RAM |

|

|

|

All dots in |

Maintenance |

Rotor has reached |

Replace rotor, NV-Ram and motor supports |

|

the display |

||||

counter |

||||

are |

10000 cycles |

(Service Kit) |

||

expired |

||||

illuminated |

|

|

||

|

|

|

Edition: 03 |

Trouble Shooting |

Clinifuge |

17.04.02 AH |

Page: 2-4 |

|

Service

2.3 Test Points

Test Points |

Unit value |

Conditions |

|

Mains terminal XA |

120V AV |

All given voltage and current values refer either to 120V (±10%) |

|

|

|

|

|

Lid micro switch |

160V DC |

Voltage drop by open lid at 120V units |

|

Plug XB |

|||

|

|

||

|

|

Rotor #3760 not loaded, in each case measured after reaching the |

|

|

approx. |

selected speed |

|

Terminal XC |

58V AC |

1600rpm |

|

105V AC |

4000rpm |

||

Motor voltage |

|||

120V AC |

5300rpm |

||

|

|||

|

80V AC |

at the beginning of the braking phase |

|

|

75V AC |

at the end of the braking phase |

|

|

|

Rotor #3760 not loaded, in each case measured after reaching the |

|

|

|

selected speed with a soft iron or digital effective measuring |

|

|

Approx. |

instrument |

|

Motor current IM |

1,2A |

1600rpm |

|

1,2A |

4000rpm |

||

|

|||

|

0,8A |

5300rpm |

|

|

3,3A |

maximum during acceleration |

|

|

2,0A |

maximum during braking phase |

|

|

14,6Ω |

switch OFF unit, pull off motor plug |

|

Motor windings |

mains winding (black – green) |

||

resistance 20°C |

14,6Ω |

auxiliary winding (black – yellow) |

|

-insulation value |

> 10MΩ |

resistance inter each phase and motor casing |

|

Lid solenoid |

|

switch OFF unit, |

|

terminal XD |

29Ω |

resistance at 20°C (68°F) |

Edition: 03 |

Test Points |

Clinifuge |

17.04.02 AH |

Page: 2-5 |

|

Service

2.4Cleaning of Instrument Parts

ATTENTION - WARNING!

The electrical and electronic components must not be cleaned with moist detergents!

For Cleaning the centrifuge housing or its accessories see Operating Instructions section 1 (maintenance and care).

•Electronic components

Clean dusty components carefully with a dry and soft brush and remove loose dust with a vacuum cleaner

•Vent holes

Remove dirt from vent holes of front panel or bottom plate using a brush and vacuum cleaner

2.5Electrical Safety Check

ATTENTION!

A final electrical safety check must be performed after each maintenance and/or repair!

•Resistance check of protective conductor

The measuring value of the resistance between the mains plug's grounding pin and the grounding conductors of the motor, electronic chassis and the casing must not exceed 200 mΩ.

•Insulation resistance Check

Check also the insulation resistance between the poles of the mains plug and the grounding conductor; the resistance value must be more than 2 MΩ.

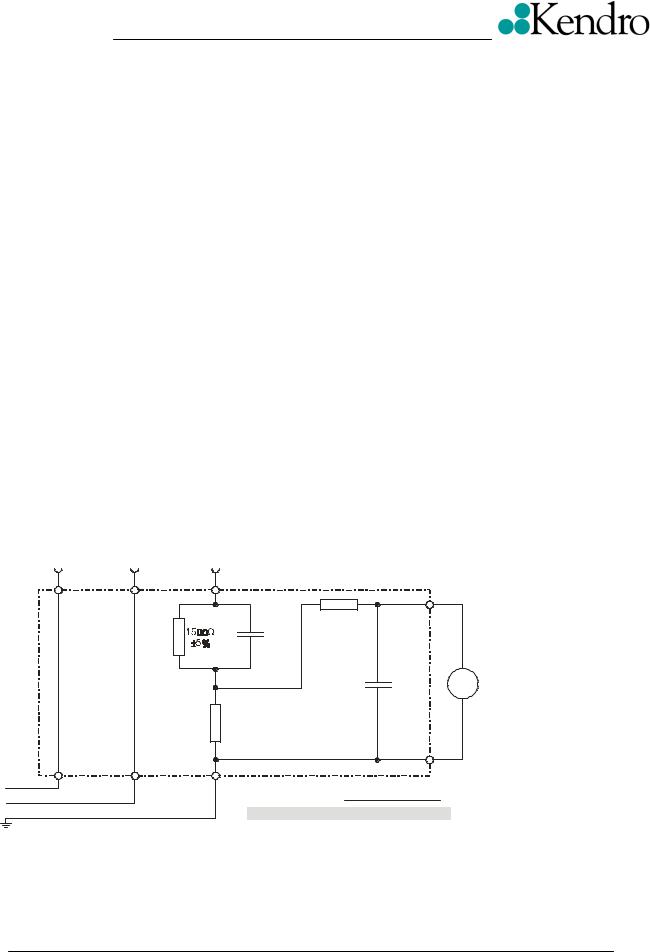

•Accessible current measured to EN 61 010

The accessible current must not exceed 3.5 mAmps in single fault condition (interrupted protection earth wire)! In accordance with the EN61010, IEC1010 and UL3101 such a fault condition can be reproduced by the following measuring circuit.

Steckergehäuse / plug-in casing

L (N) N (L) PE

10kΩ 0,22µF ±5%

±5%

0,022µF

±5%

500Ω ±1%

Körperstrom:

accessible current: I [mA] = U [mV] / 500: Umax = 1750mV ≡ Imax = 3,5mA

Spezifaktionen für Meßgerät

-TRMS, DC - 5kHz oder mehr

-Eingangswiderstand > 1MΩ

-Toleranz 5% oder besser

-Crest Faktor 5 oder besser

V

AC

Specifaction for the meter

-TRMS, DC - 5kHz or more

-Input resistance > 1MΩ

-Tolerance 5% or better

-Crest Factor 5 or better

Edition: 03 |

Cleaning, Electrical Safety Check |

Clinifuge |

17.04.02 AH |

Page: 2-6 |

|

FUNCTIONAL DESCRIPTION

3 Functional Description

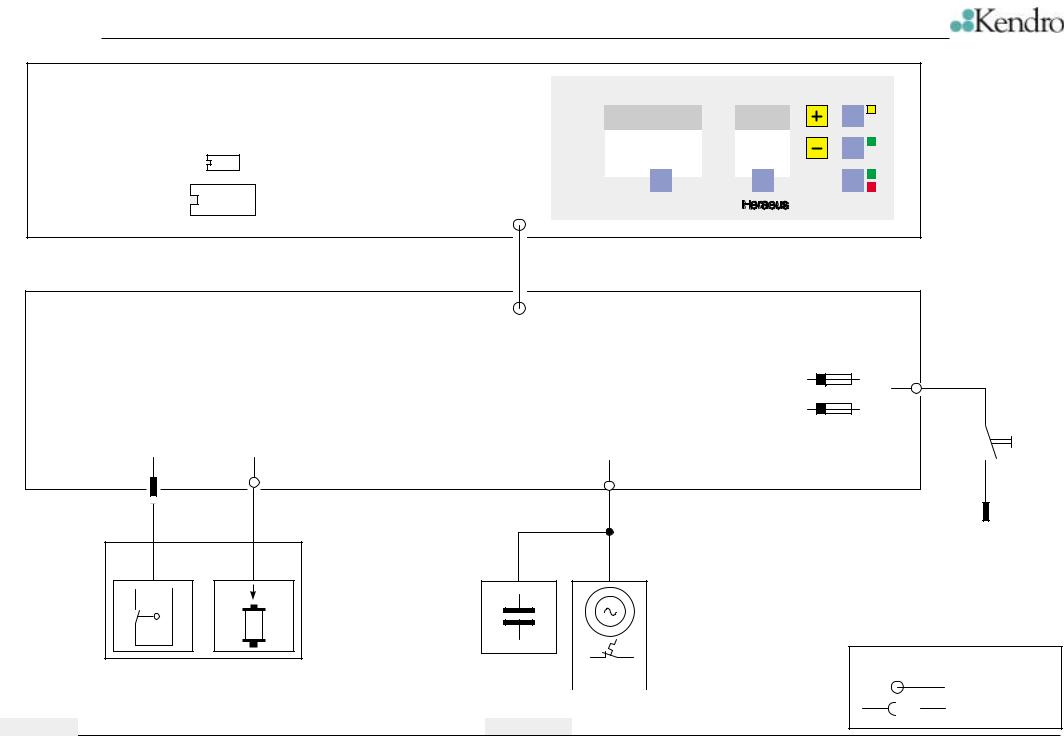

3.1Block Functions

The Clinifuge is a microprocessor controlled laboratory tabletop centrifuge with induction drive motor and integrated air cooling system.

The unit incorporates following boards and components (see block diagram 4-1):

Main board 14 or main board 178 with microprocessor part and power electronics

Key and indication board (programming: MEGACONTROL simple), part of the main board

1 phase induction motor with phase shift capacitor and integrated thermal over temperature switch (C. O. 125°C)

Double lid lock assembly with solenoid and integrated micro switch (mechanical bolt keeper, magnetically dislocking), attached in front on both sides of the vessel

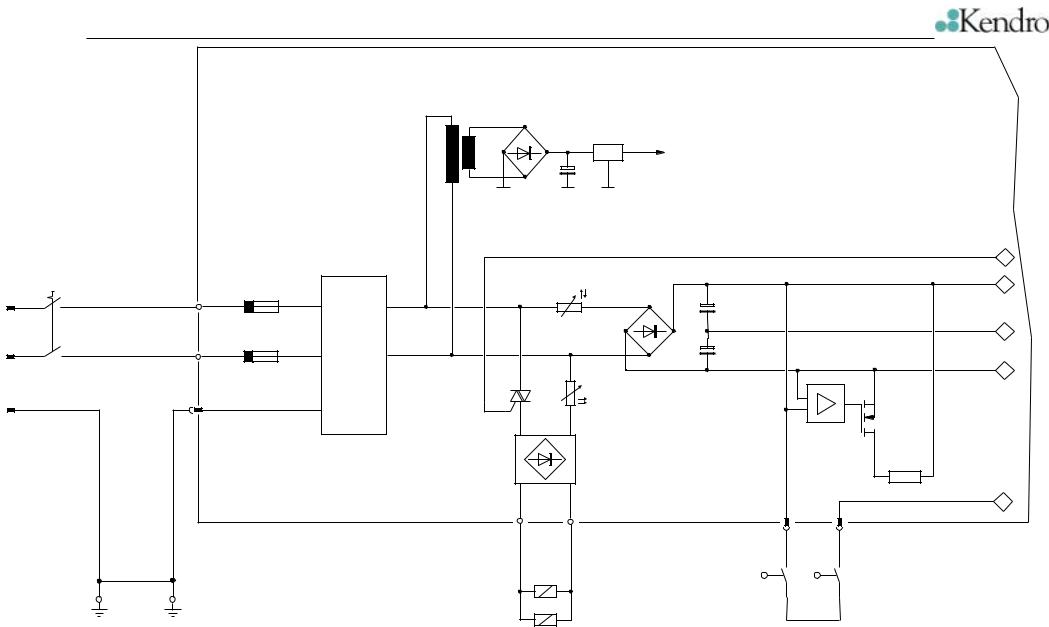

3.2Main Board Functions

The main board 14 / 178 is mounted completely behind the front panel. The components on main board are arranged in following groups (see wiring diagram page 4-2).

Board fusing (2 x 6.25 Amps. slow blow feature)

Noise filter

Power pack for low voltage supply of microprocessor part and power electronics (potential separated by transformer)

Triac control circuit for lid solenoid ( DC supply via bridge rectifier)

Bridge rectifier for DC intermediate circuit supplying brake path and frequency converter

Microprocessor part with CPU

Exchangeable NV-RAM containing specific data of the unit

3.2.1Power Pack

The power pack (transformer, bridge rectifier and voltage regulator) generates:

U1 = 5V: supplies central processor, key and indication board reference potential: protective conductor (GND)

3.2.2Intermediate Circuit with Brake Path and Frequency Converter

The DC intermediate circuit serves as an energy store between the AC power input and the transmitted motor performance. The intermediate circuit consists of a bridge rectifier (4 diodes) and two serial connected reservoir capacitors. The intermediate circuit is over voltage protected.

Edition: 02 |

Block Functions, Main Board Functions |

Clinifuge |

17.01.02 AH |

Page: 3-1 |

|

Main Board (Controller, Key and Indication Part)

NV-RAM

µC

Main Board (Power Electronics)

XA |

XD |

S1 |

Y1 |

S2 |

Y2 |

Lid Switch |

Unlocking Solenoid |

Edition: 02

23.01.02 AH

DIAGRAMMS

|

|

lid |

|

|

quick |

speed |

time |

run |

|

||

set |

set |

start |

|

|

stop |

TM

Clinifuge

XF

XF

F1

XA

F2

S0

XC

XC

Mains

Mains Switch

C1

|

|

120°C |

|

|

|

Legend |

|

Phase shift |

|

|

|

|

|

||

|

|

|

|

|

|||

M1 |

|

|

|

|

|

||

capacitor |

|

|

|

|

solder connection |

||

|

Motor |

|

|

|

|||

|

|

|

|

|

plug connection |

||

Block Diagram |

|

|

|

|

|||

|

|

|

|

|

|

||

4 - 1 |

|

|

|

|

|

|

Clinifuge |

|

|

DIAGRAMMS |

|

|

|

|

|

|

Transformer, Rectifiers and Regulators |

|

|

||

|

Main Board |

|

|

|

|

|

|

|

|

|

7805 |

5V (VCC) |

|

|

|

|

|

A1=GND |

|

|

Mains Switch |

|

|

|

|

|

5 |

S0 |

F1 |

|

|

|

|

1 |

XL |

|

NTC |

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

|

|

|

2 |

XN |

F2 |

|

|

|

|

|

Filter |

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

PTC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC intermediate circuit |

|

XPE |

|

|

|

|

|

|

Mains |

F1, F2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

6,25 AT |

|

|

|

|

|

|

|

|

|

|

|

R4 |

|

|

|

|

|

|

4 |

|

|

XC/1 |

XC/2 |

|

XA/1 |

XA/2 |

|

|

|

Y1 |

|

S1 |

S2 |

|

|

|

|

|

|

|

|

|

|

Y2 |

|

|

|

PE |

PE |

|

|

|

Chassis |

Motor |

Lid solenoid |

Lid Switch |

Brake Resistor |

Edition: 02 |

|

|

Schematic Diagram |

|

23.01.02 AH |

4 - 2 |

Clinifuge |

||

DIAGRAMMS

H1 … H8 |

S1 … S7 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

A,B,C,D |

|

|

|

|

|

E,F,G,DP |

|

Main Board Part 2 |

|

|

|

|

|

Y1/Y2 |

|

XG |

XG |

RESET |

|

|

|

|

|

||

5 |

|

|

|

|

µP - Part |

|

|

|

|

|

|

Current Control Res. |

|

|

|

|

|

1 |

|

|

|

|

|

idyn |

10 |

HGTPs |

|

|

4 |

|

|

|

14 |

|

|

|

|

|

CPU |

NV-RAM |

|

|

|

|

|

||

2 |

|

idyn |

|

idyn |

|

|

|

|

|

||

3 |

|

“LId”... |

|

"LId" |

|

4 |

|

|

|

|

Key and indication part |

|

|

|

|

|

|

XC/1 |

XC/2 |

|

|

|

|

|

|

Physical Separation |

|

|

|

|

CL |

|

|

|

|

|

125°C |

|

|

|

|

|

CL = 12µF |

|

|

|

|

|

|

Motor and run capacitor |

|

||

|

|

|

|

||

Edition: 02 |

|

|

Schematic Diagram |

|

|

23.01.02 AH |

4 - 3 |

|

Clinifuge |

||

Loading...

Loading...