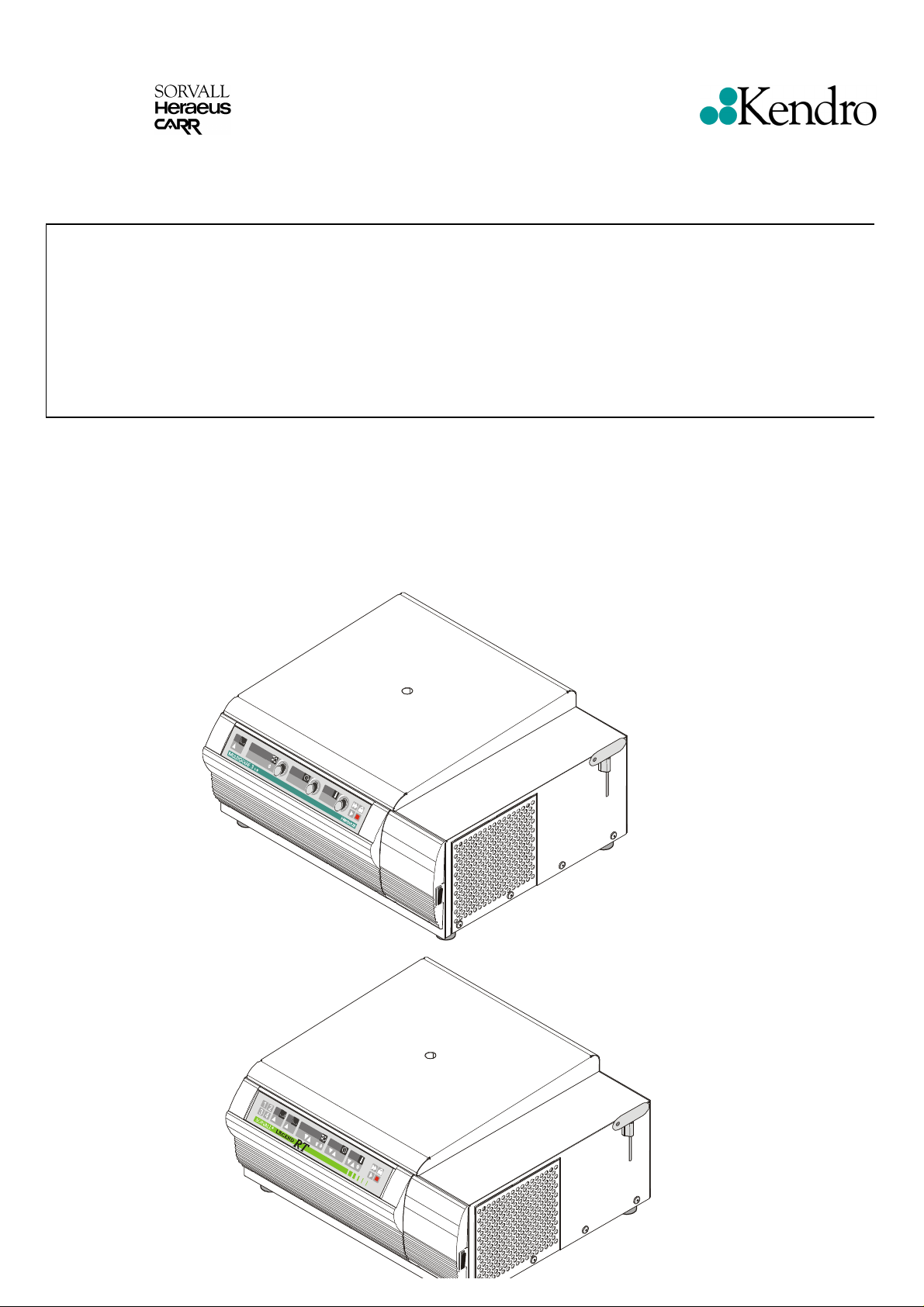

Kendro Multifuge 3 S-R, Multifuge 3 L-R, Legend RT User manual

®

Multifuge

3 S-R/3 L-R, Legend® RT

120V 50/60 Hz

SERVICE MANUAL P/N 12004376

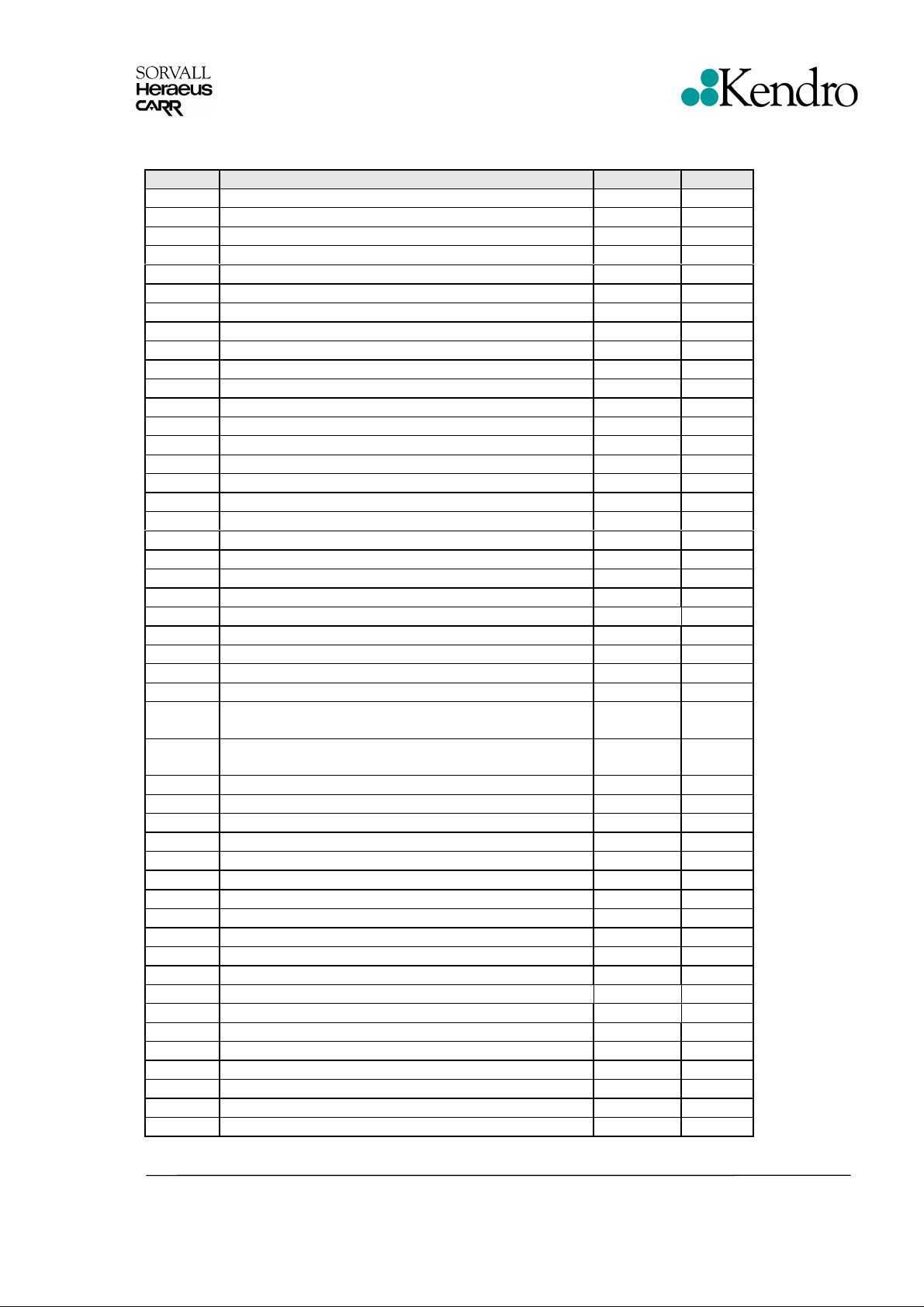

TABLE OF CONTENTS

Section Title Doc.- No. Page

1 OPERATING INSTRUCTIONS

2 SERVICE

2.1 Servicing Schedule 2-1/2

2.2 Trouble Shooting 2-3

2.3 Error Code 2-4/7

2.4 Test Points 2-8

2.5 Imbalance Behavior 2-9

2.6 Cleaning of Instrument Parts 2-9

2.7 Electrical Safety Check 2-10

3 FUNCTIONAL DESCRIPTION

3.1 Block Functions 3-1

3.2 Main Board Functions 3-1/2

3.3 Key and Indication Board - Easycontrol 3-3

Key and Indication Board - Quickcontrol 3-4

3.4 Speed Detection Board 3-5

3.5 Rotor Indication 3-5

3.6 Imbalance Detection 3-5

3.7 Lid Lock System 3-5

3.8 Cooling Plant 3-5

4 DIAGRAMS

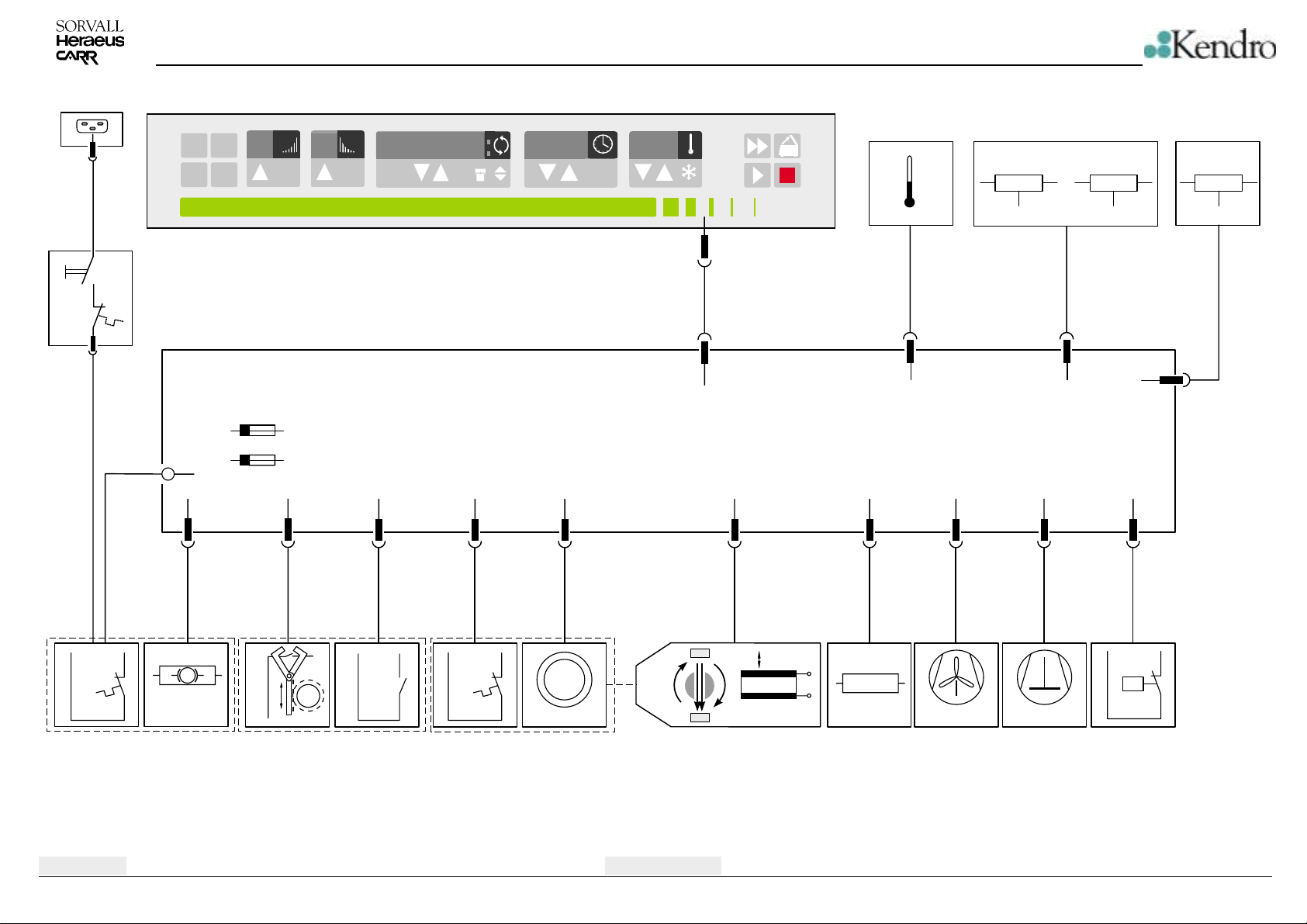

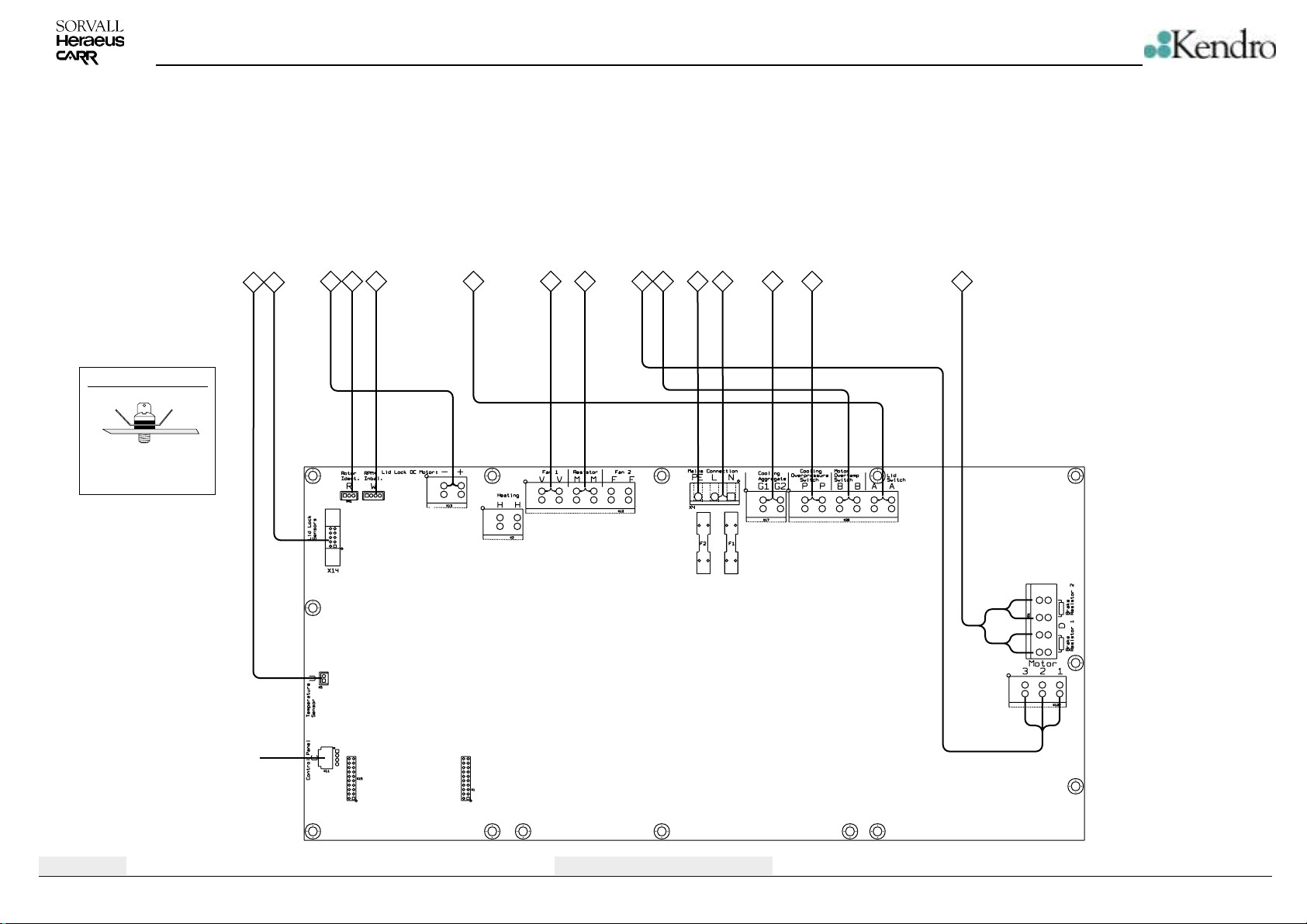

4.1 Block Diagram 4-1

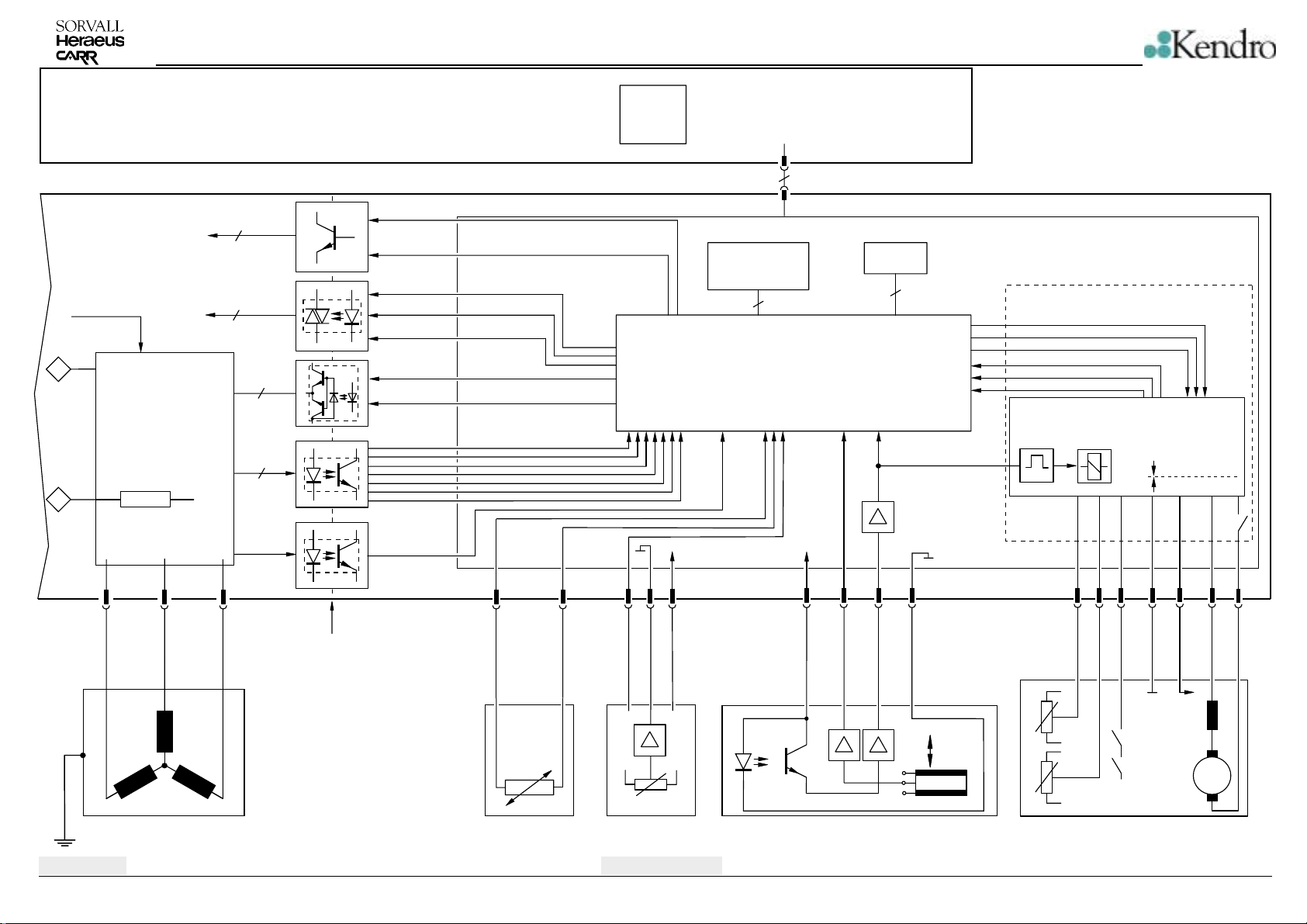

4.2 Wiring Diagrams 4-2/3

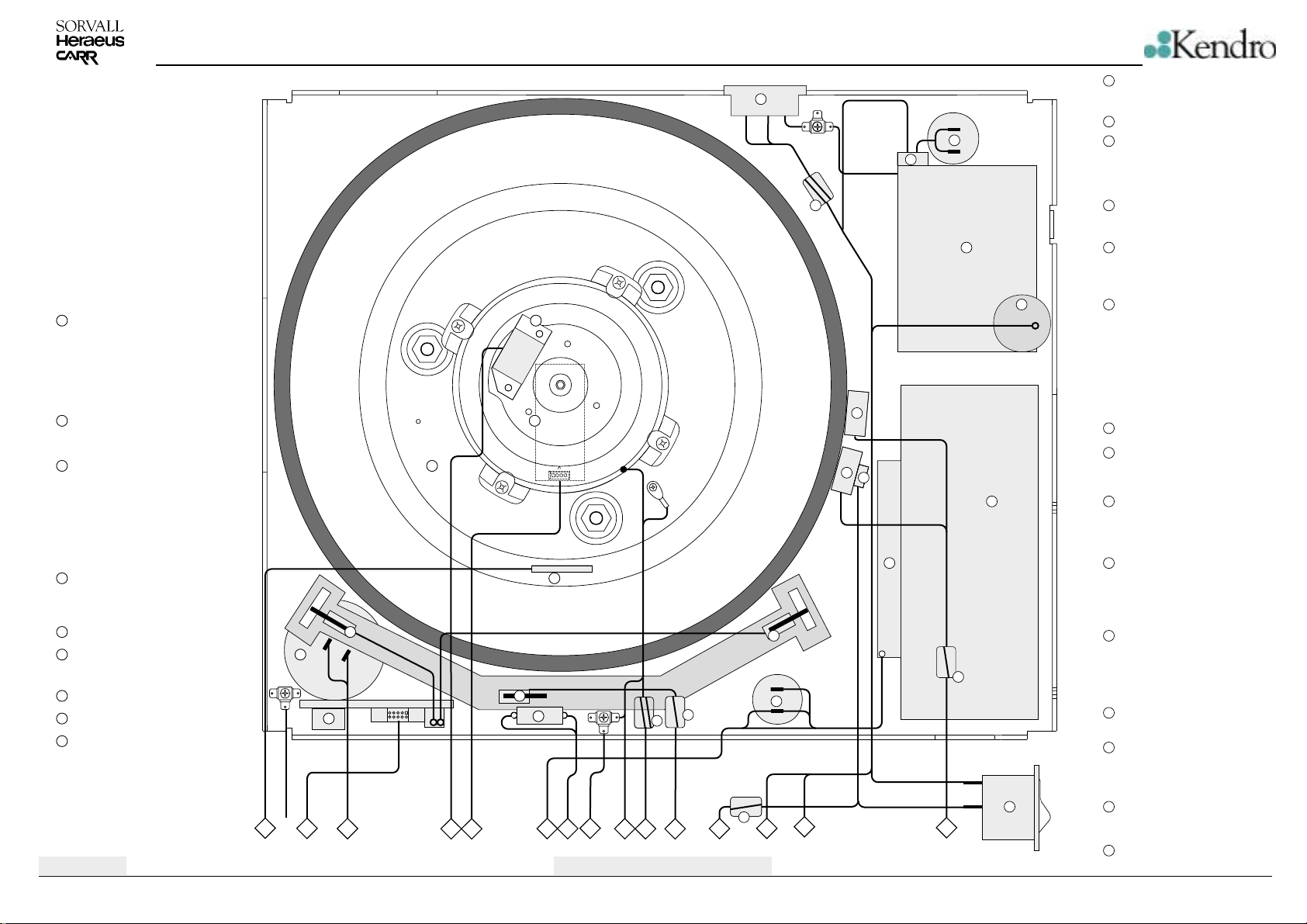

4.3 Wiring Connection Diagrams 4-4/6

4.4 Main Board, Component Plan 4-7/14

4.5

4.6 Speed detection, Component Plan 4-17

4.7 Sensor Board, Component Plan 4-18

4.8 Rotor Detection Board, Component Plan 4-19/20

4.9 Cooling Plant 4-21

5 DISASSEMBLY OF INSTRUMENT PARTS

5.1 Housing / Casing Parts 5-1/2

5.2 Electrical Components 5-2/3

5.3 Drive Components 5-3/4

5.4 Cooling Plant 5-4

6 SPARE PART FIGURES AND LISTS

6.1 Spare Part Figures 6-1/9

6.2 Spare Part Lists

7 TECHNICAL BULLETINS

Display Board, “Easycontrol” Keypad version,

Component Plan

Display Board, “Quickcontrol” Rotary switch

version, Component Plan

4-15

4-16

8 Preventive maintenance checklist

Calibration Certificate

Edition: 03 TABLE OF CONTENTS

22.11.01 AH Page: 0 - 2

Legend RT

Multifuge 3S-R / 3L-R

Service

Service

2.1 Servicing Schedule (yearly procedure recommended)

2.1.1 Maintenance Routine without Dismantling the Centrifuge

2.1.1.1 Electrical Installation and Safety

• Switch OFF the centrifuge and disconnect the unit from power, check voltage supply and mains

fusing (16 Amps, slow blow characteristic)

• Check condition of plug and wall socket - replace defective parts (customer’s responsibility)

• Check cord condition and fixing / connection - replace or refit it

• Check condition of instrument socket and replace it in case of bad contacts

2.1.1.2 Location and Mechanical Inst allati on

• Check the base (ground, table, lorry with lockable wheels etc.) for resonance-free and stable

conditions

• Check for a well ventilated place and sufficient distances to walls or adjacent equipment, without

exposition to direct sunlight

• Check the leveling of the centrifuge drive with use of a spirit level

2.1.1.3 Lid Tumbler Mechanism and Safety Device

• Connect the centrifuge to power and switch ON

• Check for correct automatic lid closing and self-acting lid opening - if in disorder, readjust lid,

swivel hinges, and/or locking devices

• Check the rubber gasket for lid’s and bolt’s sealing and replace, if damaged

• For checking the electronically safety circuit: start the centrifuge, let it shortly run and stop it, the

lid must not be unlocked by the microprocessor as long as the speed is more than 60 rpm - if

safety circuit is out of function, replace main board

2.1.1.4 Cleanliness of Spin Chamber and Motor Casing

• Open the lid and remove the rotor (for loosening turn the T-handle Allen key (5mm) in arrow

direction - see rim of rotor chamber)

• Clean the spin chamber with a dry and absorbent cloth (remove all dust and moisture - see also

section for Cleaning)

• Check the cleanliness of the motor flange and take care of the annular slot around the motor shaft:

penetrating fluids can damage the upper spindle bearing or electronics, remove fluids with an

injector and/or absorbent paper

2.1.1.5 Rotor and Accessories Condition and Sealing, bellows

• Check the condition of rotors and accessory parts (especially all supporting or stressed partitions):

the rotor and/or accessory parts must not be used any longer, if there are visible traces of

mechanical damage or rust

• Check the condition of rotor and/or accessory sealing and replace them in case of malfunction

• Bellows of gas lid stays have to be greased upside down with glycerin (part no. 70902649) once a

year.

2.1.1.6 Rotor Fixing and Drive Spindle

• Check the perfect condition of the collet chuck and replace it in case of malfunction (thread is worn

out, horizontal grooves etc. )

• Check the condition of the drive cone: the centrifuge must not be used any longer, if the drive

cone is damaged (e.g. bend or it’s bearings are worn out)

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 1

Legend RT

Multifuge 3S-R/3L-R

Service

2.1.1.7 Temperature Level (not at every unit)

• Check the wire gauze (behind the air inlet slots) left and right side for free ventilation, insufficient

air flow will lead to an inadmissible temperature rise of compressor, motor and electronic parts

2.1.1.8 Imbalance Behavior

• Install available and empty rotors and check the imbalance behaviour with rotor dependant cut off

and run through weights (see 2.5) and replace worn out motor rubber mounts, faulty main board or

sensor board

2.1.2 Maintenance Routine after Dismantling the Centrifuge Casing

2.1.2.1 Motor Supporting Elements

• Check the supporting and damping elements of the drive motor and replace them in case of

increased rubber abrasion or abundance of imbalance but at least every 3 years

2.1.2.2 Braking Circuit

• Check the function of the braking circuit (warming up of brake resistor, even and noiseless brake

effect) and replace defective parts in case of malfunction

2.1.2.3 Lead and Screwing Connections

• Check the terminal and plug connections of all leads and on all boards and electrical components,

tighten all loosen screwing connections, refit or replace defective parts

• Check the wedged connections of the board, mechanical and electrical components and re-tighten

them if necessary (use screw locking lacquer for motor mounts and lid lock assembly)

2.1.2.4 Protection Earth Core and Groundi ng Con necti ons

• Check the protection earth core for continuity and all grounding plug connectors (see also 2.7

Electrical Safety Check)

• Check isolation resistance and accessible current (see 2.7)

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 2

Legend RT

Multifuge 3S-R/3L-R

r

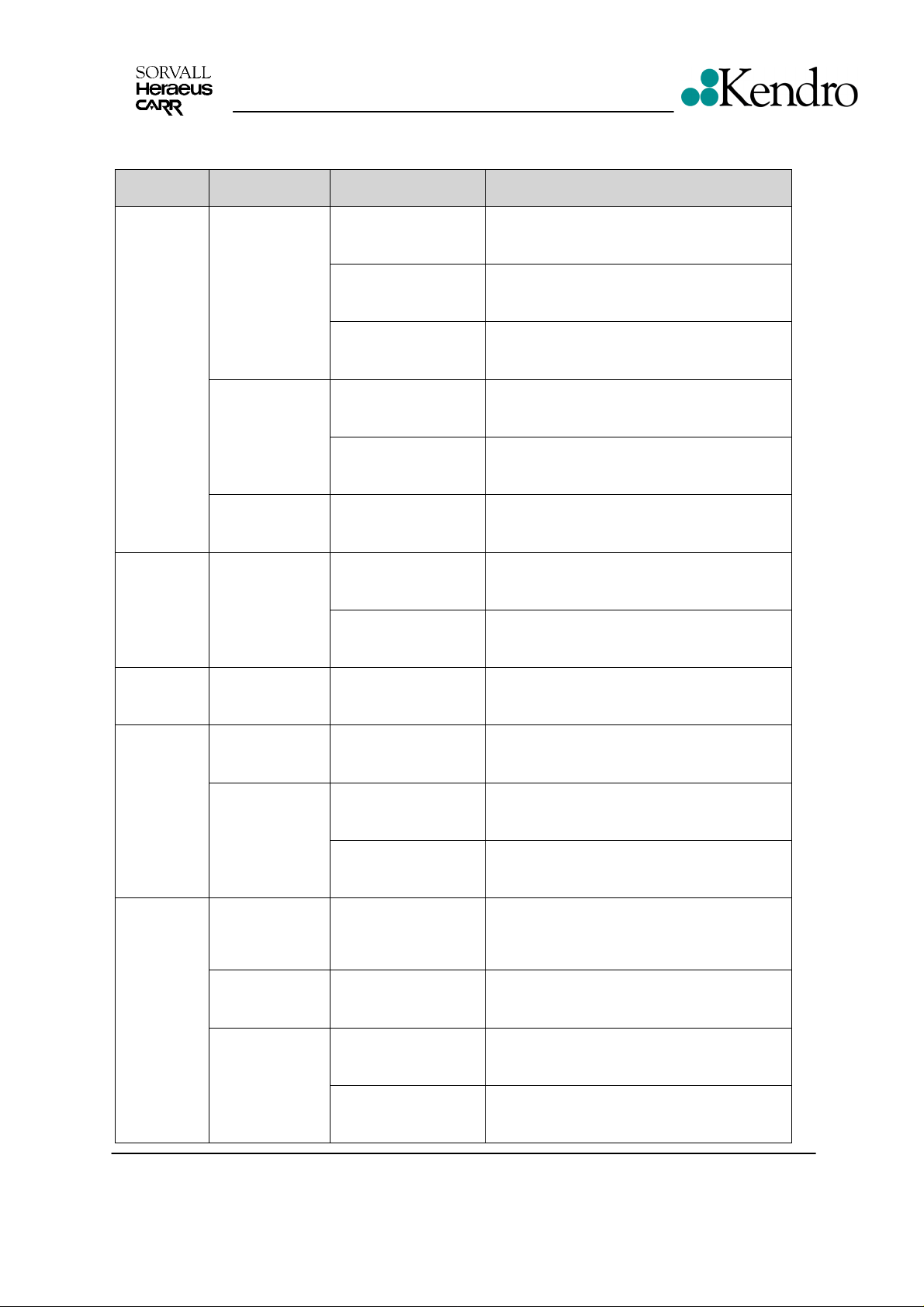

2.2 Trouble Shooting

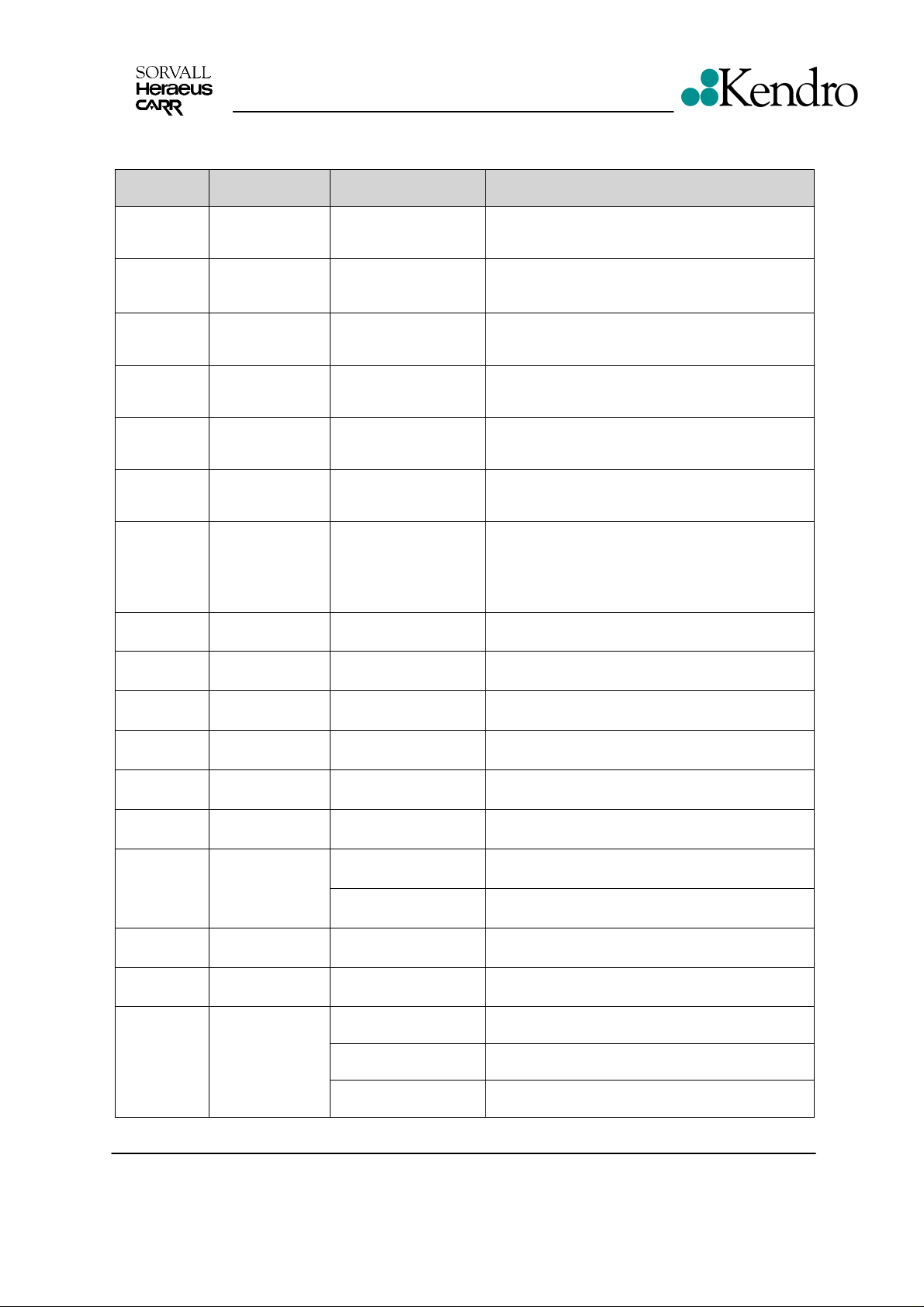

Error

Indication

Error Cause

Service

Possible Error

Source

Mains switch with

integrated fuse or

fuses on main board

Corrective Procedure

Switch on again, disconnect electric.

components success., search for other

faults

Displays

remain

dark

All display

Elements

are shortly

illuminated

Constant

No mains

voltage supply

No low voltage

supply for

indication board

Interrupted

program

CPU program

reset may be

caused by EMI

Interruption Parameter NV-RAM No or defective NV-RAM

Mains fuse or circuit

breaker failed

Faulty mains cord or

instrument socket

Faulty connection

from CPU to

indication board

Faulty indication or

CPU board

NV-RAM out of

socket or not

correctly placed

Reduced voltage

supply (<10%)

Bad or missing

ground connection

Check fuse or circuit breaker and replace o

switch on again

Check instrument cord and socket, replace

defective parts

heck connections on CPU, indication board

and connecting leads, replace defective

parts

Replace main board completely

Insert the valid NV-RAM and push it

correctly into socket

Remedy the failure if the voltage drops

often, use a voltage stabilizer

Check all ground connections and the

ground connection of all boards

Drive

makes

noises -no

good

separation

result

Lid cannot

be opened

by key at

standstill

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 3

Mechanics

Electrical

Locking drive is

not supplied

with voltage

Latch motor Faulty motor winding Replace complete motor

Lid is not

correctly locked

wear out of motor

rubber mount

Defective terminal

connection, faulty

lead or motor winding

Faulty power electr. Replace main board

24V supply

faulty relay K2

faulty driving circuit

Lid bolt is jamming

Lid is deformed Re-adjust the lid centrally

Replace motor rubber mounts (at least

winding resistances -see test points on

Push lid centrally into lock and press the

every three years)

Check voltage on motor terminal and

main board

Check voltage for drive motor

Check switch. after power ON

Replace the main board

No or defective NV-RAM

key again

Legend RT

Multifuge 3S-R/3L-R

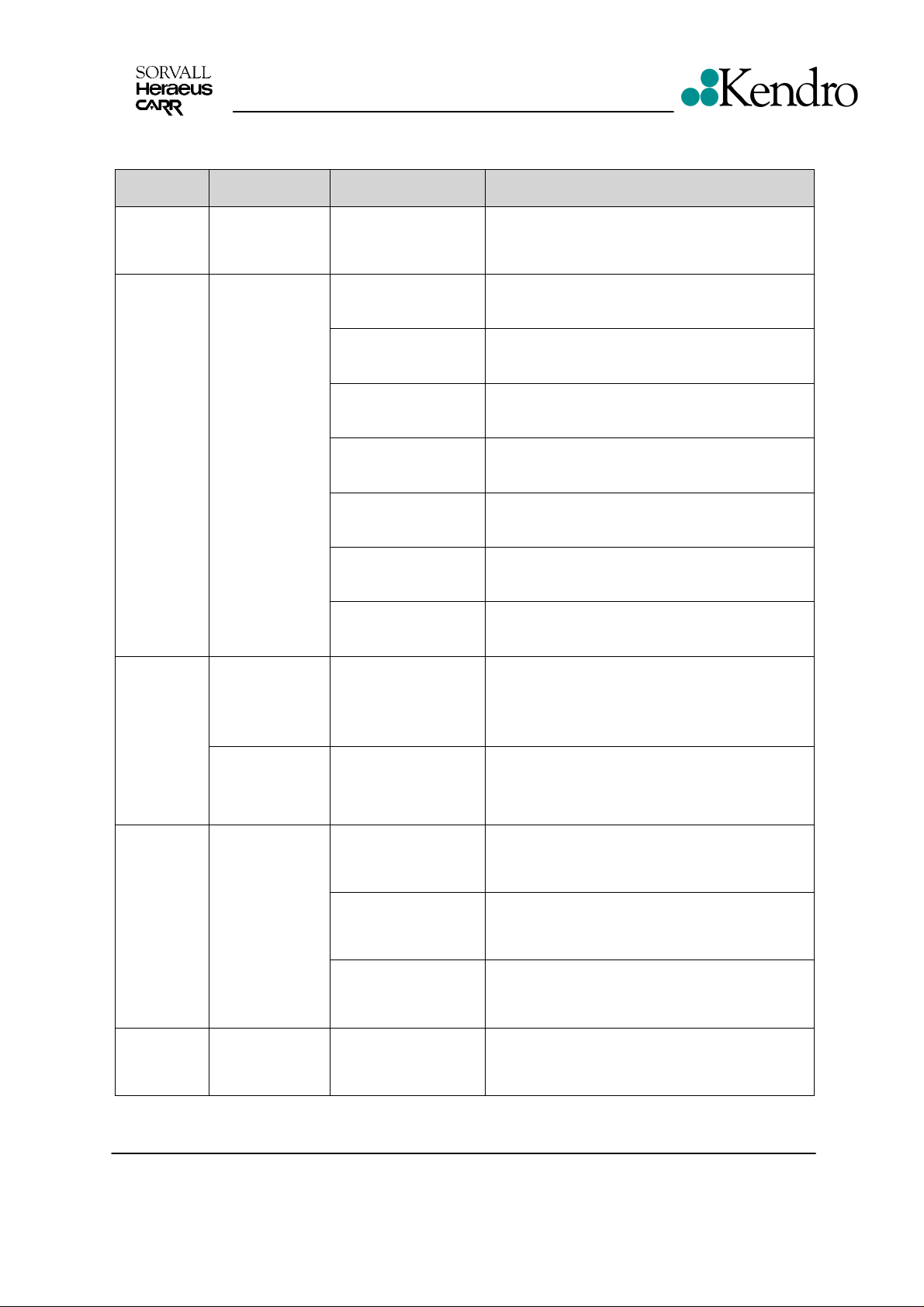

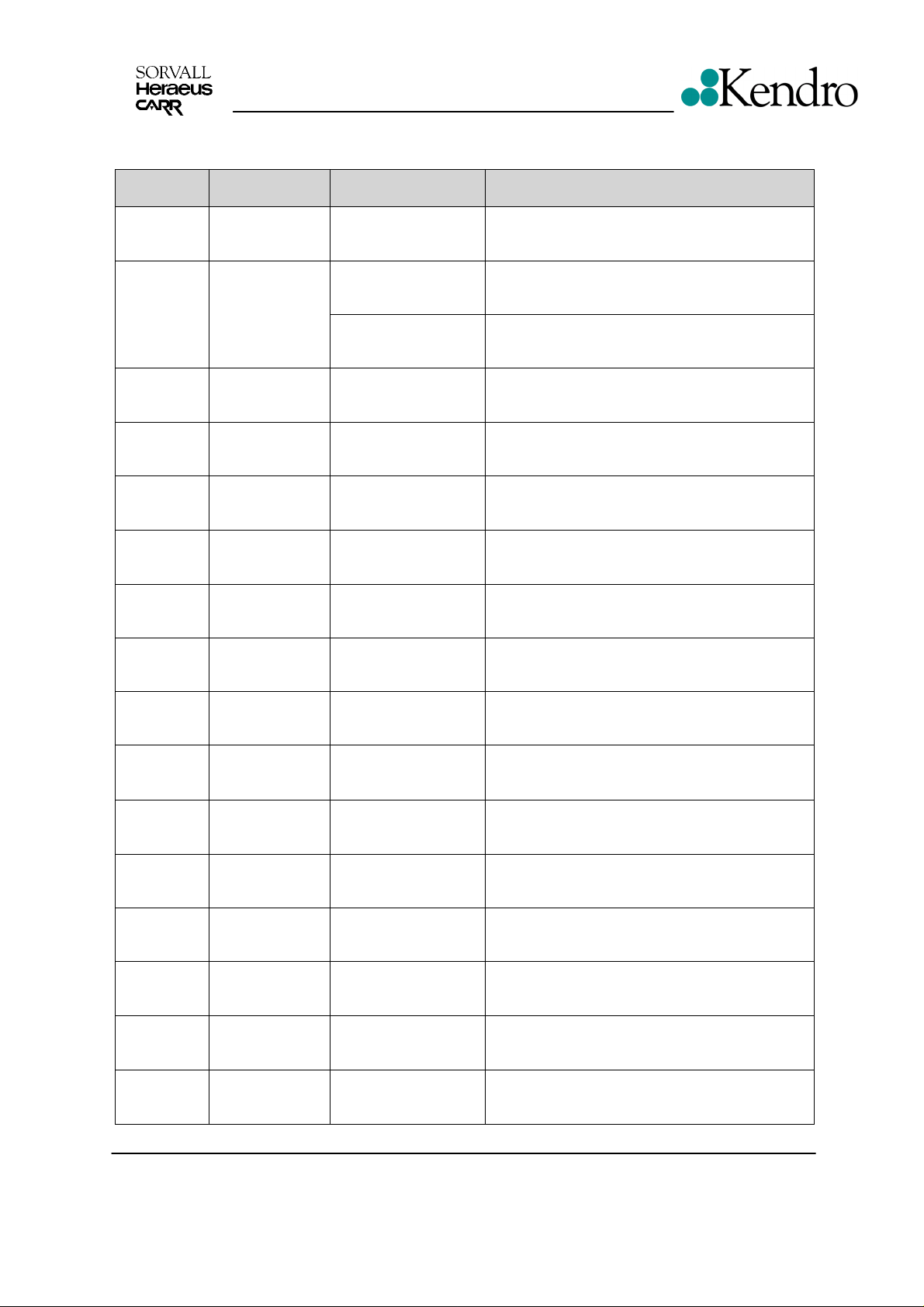

2.3 Error code

Error

Indication

„rotor“ in

speed

display

Error Cause

Wrong selection

of detected rotor

Service

Possible Error

Source

Inadmissible speed

or rcf value was pre-

selected

Corrective Procedure

Press start again (within 15s), else wait for

rotor standstill, lid OPEN/CLOSE, set value,

start

“bAL“

message

appears in

speed

display

“Lid“

appears in

speed

display

Imbalance run

Lid was opened

manually during

run

Protection circuit

(20V) interrupted

during run

Rotor not symmetri-

cally loaded

Base is not sturdy

enough and comes

into vibrations

Centrifuge drive is

not correctly leveled

Rotor itself has

imbalance

Drive shaft or rotor

fixing is damaged

Imbalance sensor Replace sensor board

Circuits of main

board

Forbidden

intervention

emergency opening

device must only be

used at standstill

Defective micro

switch or leads or

connectors to micro

switch are interrupted

Open lid, check rotor loading, close lid again

and restart

Change or reinforce the base (table, lorry with

lockable wheels, etc.)

Level the drive correctly by means of unit’s

feet

Rotor must no longer be used, send back to

Kendro

Replace collet chuck or motor

Replace the main board

Close lid immediately, turn power OFF/ON,

press lid down for locking, press start key,

press stop to finish run

Check leads and connectors to micro switch,

in case of a faulty micro switch, replace them

Loose plug

„OPEn“

appears in

speed

display by

supposedly

closed lid

“S-LID”

appears in

display

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 4

20V supply for

protection circuit

is interrupted at

standstill

Sensor signal not

clear

connectors

Interrupted leads to

micro switch

Defective micro

switch

Latch not in valid

position during power

on

Check plug X20

Check leads to micro switch for continuity

Replace micro switch

Switch unit “off” and “on” again

Legend RT

Multifuge 3S-R/3L-R

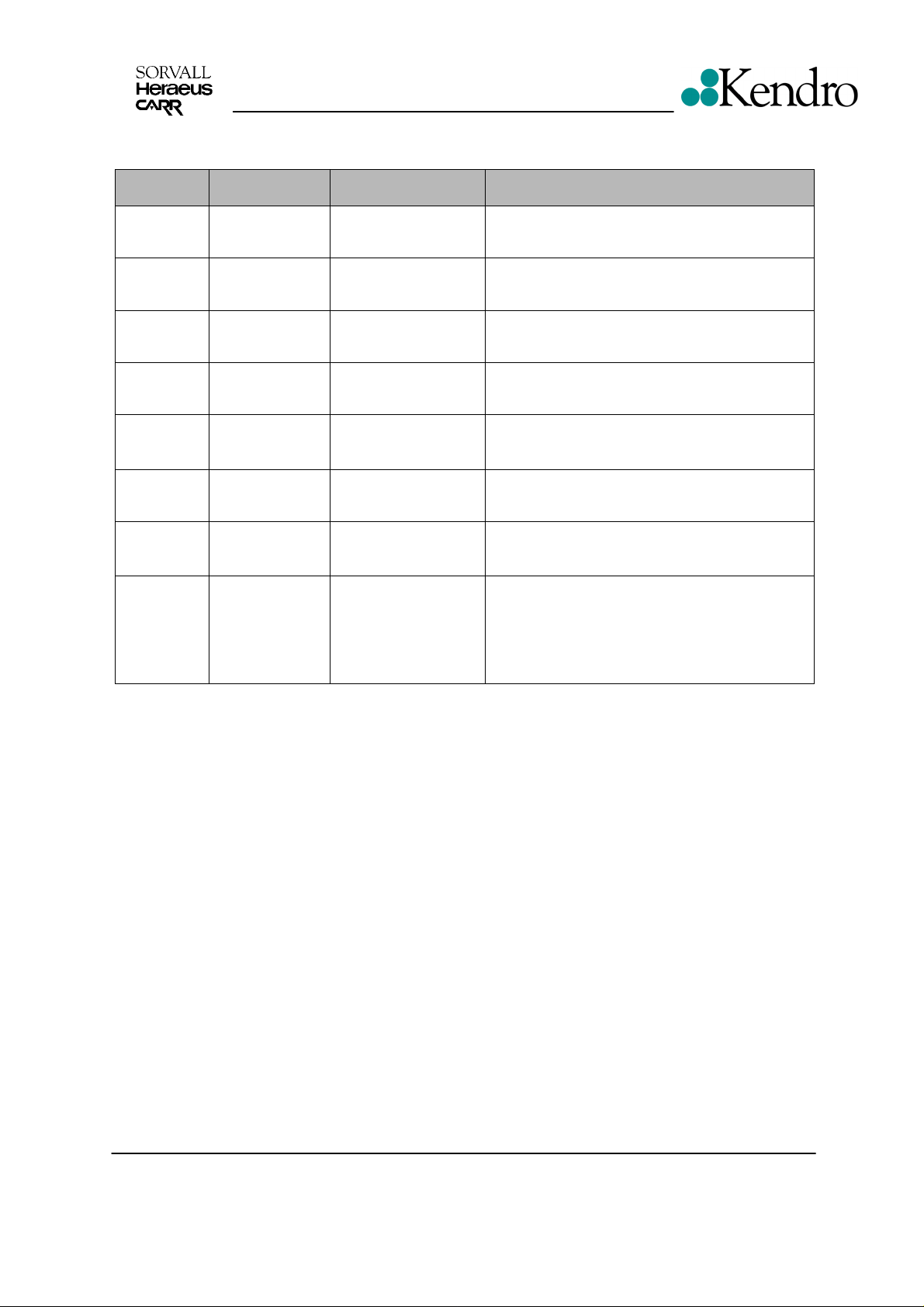

Error

Indication

Error Cause

Service

Error Code

Possible Error

Source

Corrective Procedure

„E-01“

message

„E-02“

message

„E-03“

message

„E-04“

message

“E-05”

message

“E-06”

message

“E-07”

message

“E-08”

message

“E-09”

message

“E-10”

message

“E-11”

message

“E-12”

message

“E-13”

message

„E-14“

message

System clock

pulse not stable

program

sequence was

disturbed

Stack overflow

Stack underflow

Reset by HW

watchdog timer

Data lines to key

board disturbed

Display board

doesn’t match to

main board

cooled/non-

cooled

Check sum error

E-PROM

Check sum error

NV RAM

NV RAM not

initialized

NV RAM doesn’t

match E-PROM

Check sum error

NV RAM

Check sum error

NV RAM

chamber over

temperature:

display >50°C

Hardware fault on

main board

Internal Software

problem

Internal Software

problem

Internal Software

problem

Software problem No action in the field possible

Wiring display board Check wiring and connectors

Check software Replace NV RAM and CPU

E-PROM failed Replace E-PROM

NV RAM failed Replace NV RAM

Initializing of NV-RAM

is not valid

Check versions of NV

RAM and E-PROM

NV RAM failed Replace NV RAM

NV RAM failed Replace NV RAM

Compressor didn’t

work

Faulty cooling cycle Exp. valve, refrigerant loss

Change CPU, replace main board

check NV-RAM and socket, insert the correct

Check leads, terminals, start relay, capacitor,

Change main board

No action in the field possible

No action in the field possible

NV-RAM

Replace NV RAM and E-PROM

compressor

„E-15“

message

„E-16“

message

„E-17“

message

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 5

Open temp.

sensor

Short cut temp.

sensor

wrong or faulty

rotor detection

Check sensor, control

circuits

Check sensor, control

circuits

a wrong rotor was

installed

Mains voltage failure press stop key, wait for standstill and restart

Faulty detection

circuit

wait for standstill, open the lid and install a

Replace sensor or main board

Replace sensor or main board

correct rotor

replace the main board

Legend RT

Multifuge 3S-R/3L-R

Error

Indication

„E-18“

message

„E-19“

message

Error Cause

Bucket code

not valid for this

rotor

Rotor code not

programmed

Service

Error Code

Possible Error

Source

Corrective Procedure

Not valid

Wrong rotor installed Check rotor

Interference during

recognition

Check rotor recognition board and wiring

„E-20“

message

„E-21“

message

„E-22“

message

„E-23“

message

„E-24“

message

„E-25“

message

„E-26“

message

„E-27“

message

„E-28“

message

rotor code not

valid

Recognition

disturbance

Speed signal

disturbance

Speed control

measuring

disturbance

Latch not in top

position

Time out latch

open

Time out latch

close

Signal given by

latch not valid

Wrong sense of

rotation

See E-19

wiring Check wiring

wiring Check wiring

nd

2

check was done

by rotor recognition

Check speed detection board

system

Micro switch failed,

Check micro switch adjustment, if necessary

de-adjusted, latch

Hall sensor signal not

applied

Hall sensor signal not

applied

Check latch motor and PCB

Check latch motor and PCB

Wrong identified

signal after power

“on”

After replacement of

the motor- wires

mixed

replace it

Check hall sensors

Check wiring at terminal

„E-29“

message

„E-30“

message

„E-31“

message

„E-32“

message

„E-33“

message

Motor doesn’t

turn

Control-voltage

interruption

over-

temperature

motor >150°C

Over-

temperature

Electronic

High-pressure

Cooling system

PCB faulty, see E-21,

E-22

PCB failed Replace PCB

Hot motor, no air

circulation

Faulty main board Replace main board

Faulty high pressure

switch, blocked

system

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 6

Change PCB, rotor recognition, speed

detection, fasten motor wiring at terminal

Check motor, check grill for dust

Inspect cooling system

Legend RT

Multifuge 3S-R/3L-R

Error

Indication

Error Cause

Service

Error Code

Possible Error

Source

Corrective Procedure

„E-34“

message

„E-35“

message

„E-36“

message

„E-37“

message

„E-38“

message

„E-39“

message

„E-40“

message

„E-41“

message

Over-voltage

Over-current Main board Replace main board

NMI

interruption

Over-current

continuously

Current

measurement

disturbed

Speed control

check >n max.

Acceleration of

the unit is too

slow

Offset voltage

from the

imbalance

sensor is in a

inadmissible

area

Brake resistor,

main board

Over voltage or over-

current

Main board Replace main board

Analog signal >

hardware over current

Speed > calculated

speed

Big imbalance

Motor or main board

faulty

Imbalance sensor

faulty

Wiring from the speed

detection board to the

main board is broken

Check brake resistors, replace main board

Replace main board

Replace main board

Check speed detection board, replace the

main board

Check rotor loading, motor and main board

Replace speed detection board

Check / replace the wiring

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 7

Legend RT

Multifuge 3S-R/3L-R

Service

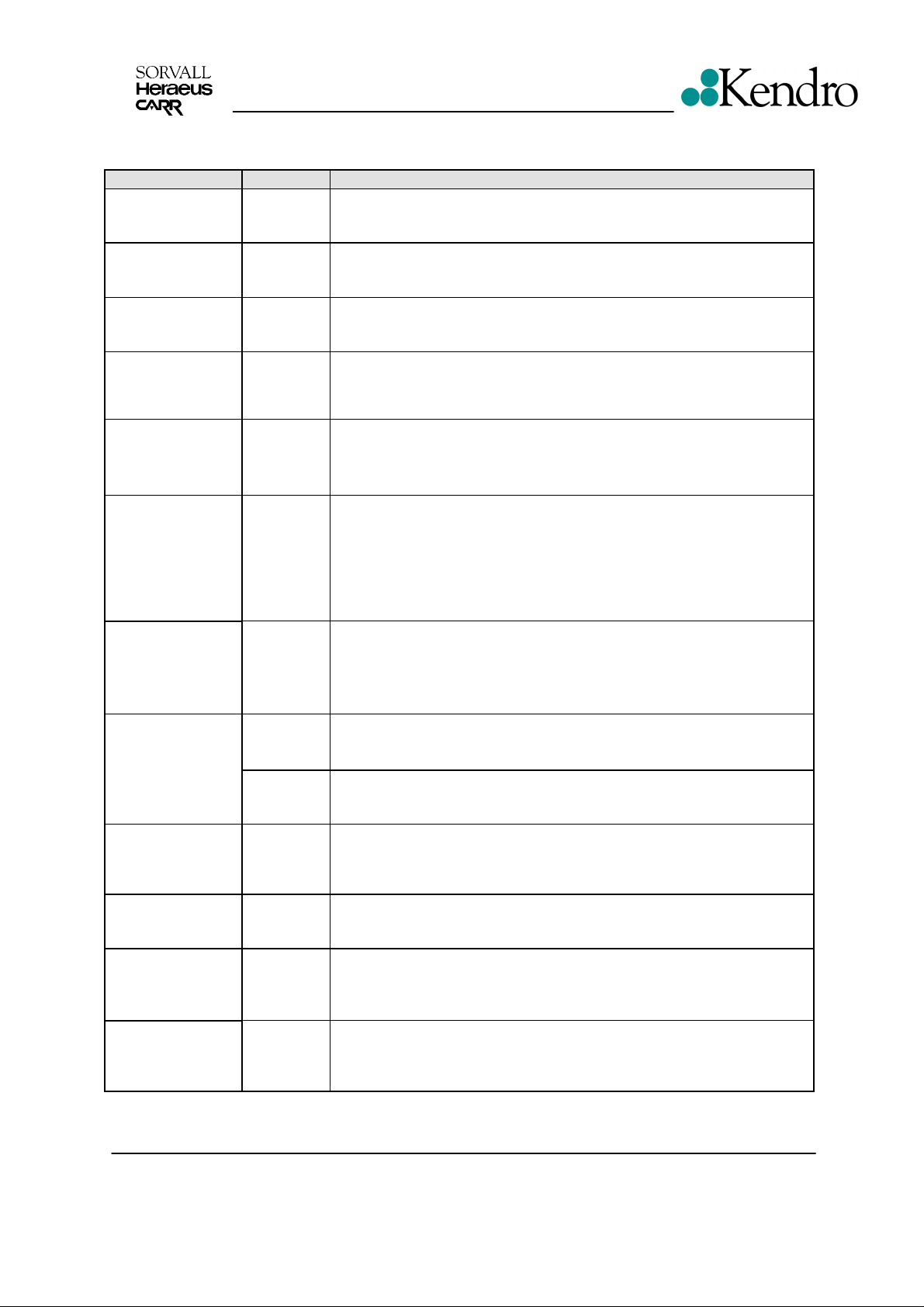

2.4 Test Points

Test Points Unit Value Conditions

Mains terminal

Board resistance

Motor over-temp.

terminal

X20/B3,B4*

Over-press switch

terminal X20/P

Fans cooling plant

terminal XK

Compressor

terminal XG

terminal box

–insulation value

Speed detection

plug XW

(1 to 4)

(3 to 4)

speed

Imbalance sensor

plug XW

(1→4)

(2→4)

120V

50Ω

20V DC

20V DC

100 Ω

82 Ω

6,5 A

1,6 Ω

4,8 Ω

> 10MΩ

5V DC

4,4V

0V

n=f*30

12V DC

a(t)

All given values are related on 120 V (+/- 10%) mains voltage for

board supply

Voltage drop by one disconnected lead (error case) and linked

terminal XR

Voltage drop by one disconnected lead (error case) and linked

terminal XO

Switch OFF unit, fan resistance temperature 20°C

wire black to blue

wire brown to blue

Switch OFF unit, compressor temp. 20°C

Resistance of main coil + (starting relay 0.1Ω)

Resistance of auxiliary coil (joints 13 -> 14)

Resistance inter phase and motor casing

Board with active filter circuit

Low voltage supply

Light barrier is passed through (slot position)

Light barrier is out (turn cone a little by hand)

When centrifuge is running

Low voltage supply of sensor board

Amplitude of lateral acceleration is rotor and speed dependent,

analyzed for n > 250 rpm

Motor current I

M

cable (U,V,W)

Motor winding

resistance 20°C –

insulation value

Brake resistor

terminal XD

Rotor detection

plug XR

Temp. measuring

plug XU

3 * 7A

3 * 5,2A

3 * 3,0A

3x2,5Ω

> 10MΩ

60Ω

5V DC

0V DC

Switch OFF unit, 2 resistors parallel connected, resistance at

pulse pause lengths, this pulse mode is generated by 4 alternately

Split core transformer with Flukemeter

maximum during acceleration

Rotor #6441, set speed = 3750min

Switch OFF unit, pull off motor plugs, measure inter

U -> V, V -> W, W -> U

Resistance inter each phase and motor casing

Per rotor revolution 2 different long

pulses are separated from 2 different

Chamber temperature 20°C (PT100:

Chamber temperature -10°C (PT100:

Chamber temperature 40°C (PT100:

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 8

20°C

polarized magnets

-1

, 560W

≈

108Ω)

96Ω)

≈

≈

116Ω)

Legend RT

Multifuge 3S-R/3L-R

Service

2.5 Imbalance Behaviour

• Install in table available rotor(s) in unloaded condition

Rotor/Bucket Run through

weight

75006445/75006441 20 grams 30 – 40 grams

• Insert rotor dependent cut-off weights and position them at angles of 90° to each other, the

centrifuge must stop 4 tim es indicating “bAL“ message - in case of false behaviour see trouble

shooting: no “bAL“ indicatio n.

• Insert the admissible imbalance weights in the same manner, the centrifuge must run through 4

times to maximum rotor speed.

2.6 Cleaning of Instrument Parts

ATTENTION - WARNING!

The electrical and electronic components must not be cleaned with moist detergents!

For Cleaning the centrifuge housing or its accessories see Operating Instructions section 1

(maintenance and care).

• Electronic components

Clean dusty components carefully with a dry and soft brush and remove loose dust with a

vacuum cleaner.

• Fans

Scratch off car efully with a knife or similar tool the cr usted dirt from the fans ’ blades. Resulting

grooves or marks must be removed subsequently with a fine abrasive cloth. Loose dirt is to

remove with an absorbent cloth or vacuum cleaner.

• Vent holes

Remove dirt from the vent grid behind the front panel by using a brush and vacuum cleaner.

• Condensers of cooling plant (if available)

The louvers between the c ondensers’ heat air deflect ors have to be vacuum c leaned. In case of

persistent dirt the unit must be carried to an appropriate place where the condensers can be

cleaned with compressed air from inside to outside. Bended heat air deflectors have to be

realigned correctly.

Cut off weight

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 9

Legend RT

Multifuge 3S-R/3L-R

Service

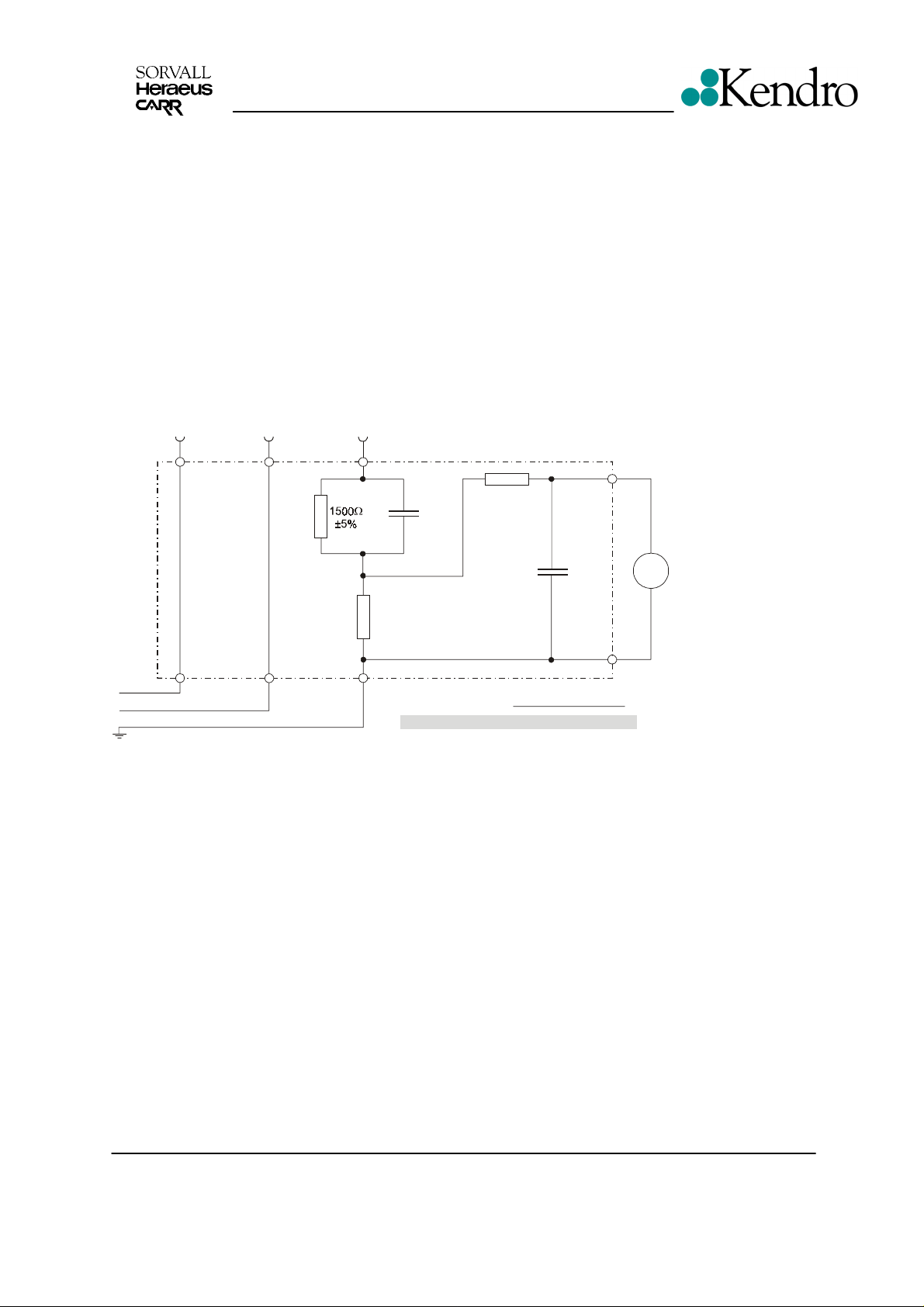

2.7 Electrical Safety Check

ATTENTION!

A final electrical safety check must be performed after each maintenance and/or repair!

• Resistance check of protective conductor

The measuring value of the resistance between the mains plug's grounding pin and the

grounding conductors of the motor, electronic chassis and the casing must not exceed 200 mΩ.

• Insulation resistance Check

Check also the insulation resistance between the poles of the mains plug and the grounding

conductor; the resistance value must be more than 2 MΩ.

• Accessible current measured to EN 61 010

The accessible current must not exceed 3.5 mAmps in single fault condition (interrupted

protection earth wire)! In accordance with the EN61010, IEC1010 and UL3101 such a fault

condition can be reproduced by the following measuring circuit.

Steckergehäus e / plug-in casing

L (N)

N (L)

PE

500

±1%

Ω

0,22µF

±5%

Ω

Körperstrom:

accessible current:

U = 1750mV I = 3,5mA

10k

±5%

0,022µF

±5%

I [mA] = U [mV] / 500 :

max max

≡

Spezifaktionen für Meßgerät

- TRMS, DC - 5kHz oder mehr

- Eingangswiderstan d > 1M

- Toleranz 5% oder besser

- Crest Faktor 5 oder besser

V

AC

Specifaction for the meter

- TRMS, DC - 5kHz or more

- Input resistance > 1M

- Tolerance 5% or better

- Crest Factor 5 or better

Ω

Ω

Edition: 04 Servicing Schedule

18.04.02/he/AH Page: 2 - 10

Legend RT

Multifuge 3S-R/3L-R

3 Functional Description

3.1 Block Functions

The Multifuge 3L-R/3S-R, Legend RT is a refrigerated microprocessor controlled laboratory

tabletop centrifuge with noise reduced induction drive motor incorporating automatic rotor and

imbalance detection and self-closing door locking systems.

The unit is equipped with following boards and components (block diagram 4-1):

• Instrument socket for mains cable at the back

• Two poles mains switch

• Main board with microprocessor part and power electronics

• Key and indication board (program: EASYCONTROL II with temp. Display or QUICK-CONTROL

with adjusting knob)

• Sensor board with rotor detection sensors

• 3 phase induction motor with integrated thermal over-temperature switch (C. O. 150°C)

• Speed detection and imbalance board with filter attached to the motor’s bottom by screws

• self-closing door locking system (mechanical bolt keeper, motor dis-locking)

• 2 parallel brake resistors mounted on safety chamber (one with overtemp.sensor)

• axial-flow fan for power electronics, motor and chamber

3.2 Main Board Functions

The Main board is mounted at the housing behind the front panel. The components on main

board are arranged in following function blocks (see wiring diagram page 4-2 and 4-3).

• Noise filter in accordance with EN 55011 for motor and triac circuits

• Power pack for low voltage supply of microprocessor part and power electronics

• Triac driving circuits for compressor cut-in relay, for 2 independent fan wiring terminals and for

connection of a heater (special use)

• DC intermediate circuit for supply of frequency converter equipped with automatic loading and

voltage (brake) controlling circuits

• Power part inclusive physically separated driving stages

• Microprocessor part with CPU, E-PROM and NV RAM

• Driving component for self-closing lid lock device

• Interface component for serial RS232 (option)

• Exchangeable NV-Ram and E-PROM containing specific data of the unit

3.2.1 Power Pack

The power pack consists of 2 transformers, 2 rectifiers (single diode) and 2 voltage regulators, which

generates the following low voltage levels:

• U1 = 5V: by switched-mode regulator LM2575T-5.0, VDD, VCC

supplies all processors and its electronic components on main and indication board

• U2 = 24V: unregulated

is used for the driving of lid lock motor and relays K2, K3;

the reference potential is GND, VSS

• U3 = 20V: by 2nd transformer, rectifier diodes and fix voltage regulator 7820

serves for supply of driving of the power electronics via the protection circuit by closed lid

switches

reference potential: 0V CAUTION - MAINS POTENTIAL!

Edition: 03 Servicing Schedule

13.03.01/he Page: 3 - 1

Legend RT

Multifuge 3S-R/3L-R

Main Board Functions

3.2.2 Intermediate Circuit

The DC intermediate circuit serves as an energy store between the AC power input and the

transmitted motor performance. The intermediate circuit consists of a heat-sink-cooled bridge

rectifier and several reservoir capacitors which are softly charged across a power resistor R76 when

ever the unit is switched on. After the loading time (CPU initialization time) the power resistor is

linked by the relay contacts of K3. When switching the unit off, the DC voltage of the intermediate

circuit is discharged across a path of resistor R1, R2.

3.2.3 Brake Path

Electrical power is fed back into the intermediate circuit during motor deceleration (motor acts as

generator). This braking power is transformed into heat by two parallel connected resistors so that

the intermediate circuit voltage does not rise to an excessive level. The brake resistors are switched

into the intermediate circuit by a fast switching transistor (pulse-width modulation, synchronized by

the double mains frequency). This transistor is voltage dependent controlled by a self-acting stage

(closed loop).

3.2.4 Frequency Converter

The motor is 3-phased, provided with chopped direct voltage blocks (chopped frequency approx.

5kHz, amplitude is height of DC intermediate voltage). These blocks are variable in frequency and

pulse-width modulation, 120° out of phase. These 3 phases are controlled during acceleration,

running at set speed and deceleration (e.g. for small speed: low frequency and small pulse-width

length will be affected). The FC is protected against over current, over temperature and over-voltage.

3.2.5 Microcontroller (Central Processing Unit) Part

The software identification No's of the CPU and data storage’s (NV-RAM) ST24C32 are sequentially

displayed in speed and time fields:

Press program place no 2 during switch on

• CPU Operating panel: 526 P05

• Firmware: 528 200

• NV-RAM: 4468 105

The actually indicated version No.'s are displayed in the time field and will be upgraded if program or

data changes are necessary.

The control program (ROM) is integrated in the controller component. The most important operating

parameters (e.g. the maximum data for all rotors, the last operator settings, the basic values for

speed and temperature controlling, data of acceleration and deceleration curves as well as 4 data

sets of program places are stored in the non volatile (NV)-RAM.

When calling this routine the actual value of all centrifugation cycles (“CYL“) is also shown in the

display (as fourth No.) before the check routine for all program places puts an end to the initialization

time (approx. 18s).

The CPU co-operates with the E-PROM component via the 16 bit data bus and some control lines.

The CPU is an integrated circuit, generating all required output signals, monitoring and analyzing all

input signals.

Edition: 03 Servicing Schedule

13.03.01/he Page: 3 - 2

Legend RT

Multifuge 3S-R/3L-R

3.3 Key and Indication Board - Easycontrol

The key and indication board is mounted behind the operating panel. The connection to the main

board is done by a 4 pole cable by which the serial data transfer as well as the low voltage supply of

5V is verified. The 7-segment displays, the control LED’s and the operating keys are managed by an

own controller unit (first identification No. 591) in multiplex processing.

For the programming serves EASYCONTROL II (see Operating Instructions).

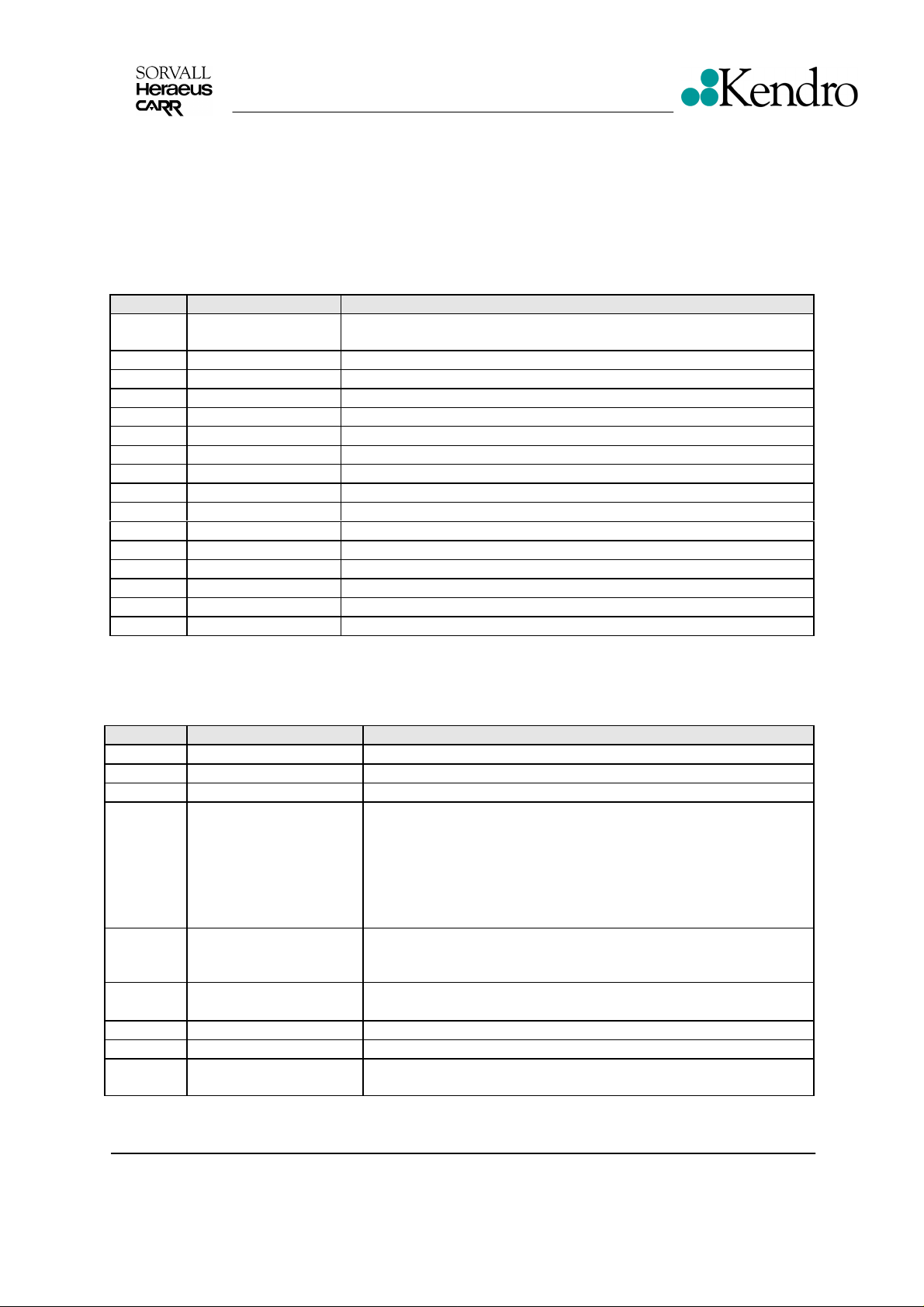

Functions of keys elements (Easycontrol)

Keys Designation Function(s)

S1 – S4

S5 Arrow up Acceleration profile 1 to 9

S6 Arrow down Deceleration profile 1 to 9

S7 Speed arrow down Decrement the value of the set speed

S8 Speed arrow up Increment the value of the set speed

S9 Bucket Setting of the rotor / bucket number

S10 At the same time Switching between rpm and rcf display

S11 Time arrow down Decrement the value of the set time

S12 Time arrow down Increment the value of the set time

S13 Temp. Arrow down Decrement the value of the set temperature

S14 Temp. Arrow up Increment the value of the set temperature

S15 Frost Pre cooling

S16 Double arrow Quick run – hold button pushed

S17 Lid symbol Open the lid

S18 Arrow right Normal start of the centrifugation

S19 Red square

Program

place 1 to 4

Store or recall programs

Manual stop of a run

Functions of Indicating Elements (Easycontrol)

Indicat. Designation Function(s)

H1 Buzzer Audio signal

H2 Accel. curve digit Display defined acceleration curves 1 to 9

H3 Decel. curve digit Display defined deceleration curves 1 to 9

Speed in rpm (rounded to full 10 rpms)

Rotor not yet detected (xxx „.“)

H4-H7,

H12

H13-H15 Time range

H16,H17 Temperature range

H18 Allocation LED For speed indication

H22 Allocation LED For rcf indication

H19,20,

24,25

Speed range

Rotation Rotor spinning

rcf-value (xg) or not yet possible to calculate „-----“

Identifications no.’s of controller and NV-RAMs,

Lid open condition („OPEn")

Centrifuge run is terminated („End")

Error messages („Lid“, „E-xx“, „bAL“, „rotor“)

Centrifugal time in h.min (count down process)

Count up process (hld) in h.min (count up process)

Actual version number („xx“)

Sample temperature in °C± 2K when pre-cooling or

pre-heating process is terminated

Edition: 03 Servicing Schedule

13.03.01/he Page: 3 - 3

Legend RT

Multifuge 3S-R/3L-R

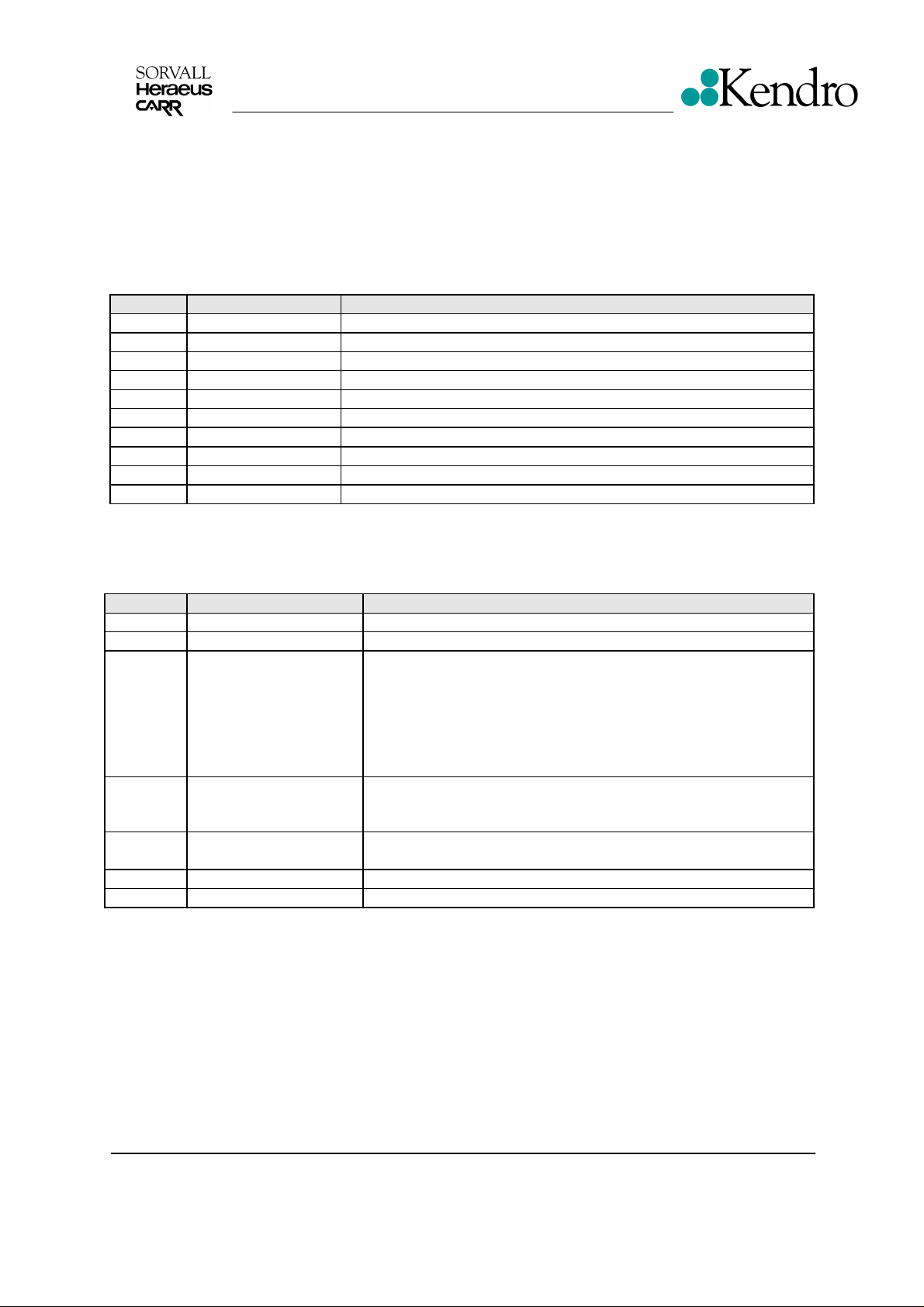

Key and Indication Board - Quickcontrol

The key and indication board is mounted behind the operating panel. The connection to the main

board is done by a 4 pole cable by which the serial data transfer as well as the low voltage supply of

5V is verified. The 7-segment displays, the control LED’s and the operating keys are managed by an

own controller unit (first identification No. 591) in multiplex processing.

For the programming serves Knob control system Quickcontrol (see Operating Instructions)

Functions of keys elements (Quickcontrol)

Keys Designation Function(s)

S1 Adjusting knob Set point temperature

S2 Adjusting knob Set point time

S3 Adjusting knob Set point speed

S6 Arrow up Deceleration profile 1 to 3

S9 Bucket Setting of the rotor / bucket number

S10 At the same time Switching between rpm and rcf display

S16 Double arrow Quick run – hold button pushed

S17 Lid symbol Open the lid

S18 Arrow right Normal start of the centrifugation

S19 Red square

Functions of Indicating Elements (Quickcontrol)

Manual stop of a run

Indicat. Designation Function(s)

H1 Buzzer Audio signal

H3 Decel. curve digit Display defined deceleration curves 1 to 3

Speed in rpm (rounded to full 10 rpms)

Rotor not yet detected (xxx „.“)

H4-H7,

H12

H13-H15 Time range

H16,H17 Temperature range

H18 Allocation LED For speed indication

H22 Allocation LED For rcf indication

Speed range

rcf-value (xg) or not yet possible to calculate „-----“

Identifications no.’s of controller and NV-RAMs,

Lid open condition („OPEn")

Centrifuge run is terminated („End")

Error messages („Lid“, „E-xx“, „bAL“, „rotor“)

Centrifugal time in h.min (count down process)

Count up process (hld) in h.min (count up process)

Actual version number („xx“)

Sample temperature in °C± 2K when pre-cooling or

pre-heating process is terminated

Edition: 03 Servicing Schedule

13.03.01/he Page: 3 - 4

Legend RT

Multifuge 3S-R/3L-R

3.4 Speed Detection Board

On a small board, which is attached underneath the motor, the circuits for speed detection and signal

shaping are arranged. The motor speed is optically detected by an infra-red light barrier. The motor

axle has a hole at the same level as the light barrier. This effects that the light beam will be

interrupted twice during one motor revolution. A following pulse shaping stage on board forms

square-topped pulses which are led via XW1 to the main board. The speed pulses are counted by

the CPU to display the exact motor speed.

3.5 Rotor Indication

In the rotor’s bottom 4 magnets are forced, being alternately arranged in polarity and positioned to

each other to different distances on a constant circular ring (segment steps of 20°).

A Hall sensor is exactly fixed below to the sensor board. The magnets are switching a flip-flop stage

by which different pulse lengths and pulse intermissions are generated during one rotor rotation. By

this signal the CPU is able to detect up to 65 different rotors and the correct direction of rotation, too.

3.6 Imbalance Detection

On the speed detection board a piezoelectric acceleration detector is additional fixed. Dependent of

the rotor imbalance this sensor generates an analogous voltage signal which is led via a following

band-pass filter to plug connection XW1/2 to main board, where it is analysed by CPU. When the

CPU) has identified the installed rotor type, the speed dependent imbalance limitation curve from EPROM The analogue imbalance signal is filtered, converted into digital form and continuously

comperated with this specific limitation curve. If the actual imbalance signal will rise at any speed

beyond the limit, the error signal for imbalance load “bAL“ will be displayed and the unit slows down.

3.7 Lid lock system

The latch is directly controlled by CPU via a PWM motor driver. If all necessary signals are existing

which allow an opening the motor is fired with a pulsed voltage of 24 VDC. For additional safety the

relay K2 will be activated if the speed is below 120 rpm controlled by triggered mono-flops.

3.8 Cooling plant

The Multifuge 3SR/LR, Legend RT is equipped with a high-grade cooling plant, to meet it’s

requirements of driving power and compact design. The CFC free refrigerant R404A evaporates at

low temperatures (≤ -20°C) and absorbers through this the frictional heat from chamber produced by

the fast spinning rotor. 5 fans serve for even air flow through condenser so that the refrigerant’s

condensing temperature is kept on a low level (lateral front fans are only switched on, if n > 0 rpm).

A specially designed coaxial heat exchanger serves for essential undercooling of the condensed

refrigerant to ensure an optimum evaporation and a perfect operation of the expansion valve. To

maintain low evaporation and resultant condensation temperatures on one hand and to support the

starting procedure of the compressor on other hand, a thermostatic expansion valve with 3.0bara

MOP is used.

The minimum achievable sample temperatures are depending on speed, rotor type and a little on

ambient temperature. After a compensating time, given by the pre-cooling or pre-heating program as

optimal result, the rotor has reached the selected set temperature within a tolerance of ± 2K.

To reduce the power consumption of the unit the compressor will not be activated during

accelerating of the motor. When reaching the selected speed the compressor will be activated if a

low temperature had been selected.

Edition: 03 Servicing Schedule

13.03.01/he Page: 3 - 5

Legend RT

Multifuge 3S-R/3L-R

Unit's Plug

SCHEMATIC DIAGRAMS

132

0 0

4

SORVALL

S0

Mains Switch with Over-current Release

16A

X4

P/L/PE

XD1

D

®

F1

F2

LEGEND

X13

+/-

rpm

x g

xg

RT

KEY AND INDICATION BOARD

MAIN BOARD

X20

A

X20

B

X122

1/2/3

X11

C

XI

XW1

W

Temp. Sensor

PT

V1

100

X5

U

X12

M

Sensors for Lid Lock

X12

V

X17

G

X14

C

Rotor Detection

XXX

XR1

R

X20

P

Overtemp.

Edition: 04

04.07.02 AH

F3F4 F5

M4

R2 R3

R1

S1

Lid Lock SwitchBrake ResistorBrake Resistor

Overtemp. SwitchLid Lock

Motor

3~

M1

Motor

Speed Detection

2 Pulses/revolution

Imbalance Sensor

a(t)

Block Diagram

4-1

Resistor for

Speed Limit

Compressor

Fan

M3

Fan for

Compressor

p>

M2

Compressor

Pressure Switch

Multifuge 3S-R / 3L-R / Legend RT

16A

S0

Mains

NPE

120V

SCHEMATIC DIAGRAMS

L

4R7 11W

DC Intermediate Circuit

noise filter

+24V

K3

DC Charging Circuit

BYPASS

Autom. Brake Control

X4/L

+24V

F1

+5V

(VCC)

(VDD)

X4/N

F2

+24V

LM2575T-5.0

GND

VSS

+325V

1

0V

2

MAIN BOARD

X4/PE

K1

Chassis

Edition: 04

04.07.02 AH

Ground Motor

COOLING

GND

X17/G

2

1

M2

10

Î

11

13

14

Compressor

with Starting Relay

X12/M

4

C

S

240µF

Speed Reduction

R3

FAN2

FAN1

X12/V

3

2

4,0µF

1

C

L

XA2

S1

M3

Fan for CondenserResistor for

Lid Lock Switch

7820

0V

X20/B

4

3

F3

Motor

Overtemp.

X20/P

2

1

21bar

p>

F5

Overpressure

Switch

+20V

OVERPRESSURE

XD1/R

13

24

R1

F4

2 x 120W

R2

Brake Resistors with

Overtemperature Protector

Wiring Diagram

4-2

Multifuge 3S-R / 3L-R / Legend RT

SCHEMATIC DIAGRAMS

KEY AND INDICATION BOARD

MAIN BOARD

20V

+325V

1

Frequency Converter

0V

2

Current Control Restistor

X122/

1

20V

2

2

3

0V*

3

µC87C54

EASYCONTROL II

0526Vxx

5V

GND

XI

4

XI

COOLING (M2)

K3 (BYPASS)

0528Vxx

Fan1 (M3)

Fan2 ()

Heating ()

3

7

6 IGBT’s

RESET

LID_CLOSED

OVERVOLTAGE

OVERCURRENT

MOTOR_OVERTEMP.

ELECTRONIC_OVERTEMP.

OVER_PRESSURE

POWER_FAIL

36

CPU

NV-RAMEPROM

4467Vxx

4

µP - Part

LID_LOCK_BRAKE

LID_LOCK_ENABLE

LID_LOCK_DIRECTION

LID_NEARLY_CLOSED

LID_LOCK_CLOSED

LID_LOCK_OPEN

K2

24V

1s

5V

GND

24V

Lid Lock Driving

in:

+

out:

-

+

K2

i

dyn

X5/U1

X5/U2

XR/ 1 2 3

+5V +5V

GND

GND

1

XW/ X14/ 3 5 7

2

234

1

X13/

-

+

Edition: 04

04.07.02 AH

M1

Motor

3 x 2,5

Physical Separation

W

V1

PT100

J

Temperature Sensor

X

Hall Effective Sensor

Wiring Diagram

4-3

n=0:

n>0:

Speed Detection Board

a(t)

+5V

GND

X

X

M4

Lid Locking Device with

Switches and Sensors

Multifuge 3S-R / 3L-R / Legend RT

SCHEMATIC DIAGRAMS

Mains Input

10

10

Start Capacitor

12

12

13

13

Relay for Compressor

PCB Rotor Detection (fill up)

1

PCB Speed and Imbalance Detection

2

( under the motor)

Motor

3

Pt100 Temperature Sensor

4

Switch at the left Lid Lock

5

Motor for Lid Lock

6

Switch Lid Lock

7

PCB Sensors for Lid Lock

8

Resistor for Fan

9

Edition: 04

04.07.02 AH

14

15

16

1

2

3

5

-

6

+

8

1

2

3

5

4

XW1

4

21

7

9

11

7

8

10

25

23

9

12

6

22

25

13

14

17

17

18

19

20

25

Line

Out

24

15

Toroidal Core with

14

2 electrical windings

Compressor

15

Over Pressure Switch

16

17

Brake Resistor

18

Temperature Fuse

Condenser

19

Fan for Condenser

20

Switch at the right lid lock

21

Capacitor for Fan

22

Toroidal Core with

23

2 electrical windings

24

Mains Switch

Toroidal Core with

25

1 electrical winding

Wiring Connections Diagram

4-4

Multifuge 3S-R / 3L-R / Legend RT

Temperature Sensor

PCB sensors for Lid Lock

Motor for Lid Lock

PCB Rotor Detection

PCB Speed and Imbalance Detection

Switch Lid Lock

SCHEMATIC DIAGRAMS

Fan for Condenser

Resistor for Fan

Motor

Over Temperature Switch Motor

PE - Terminal

Mains Input

Compressor

Over Pressure Switch

Brake Resistors

Mounting of Unit Ground

1x PE terminal 3 pole

1x screw M4x10mm

2x fan washer 4,3mm

12

34 5 6 7 8 910 1112 13 14 15

XW1

MAIN BOARD

Edition: 04

04.07.02 AH

Key- and Indication Board

Wiring Connections Diagram

4-5

Multifuge 3S-R / 3L-R / Legend RT

SCHEMATIC DIAGRAMS

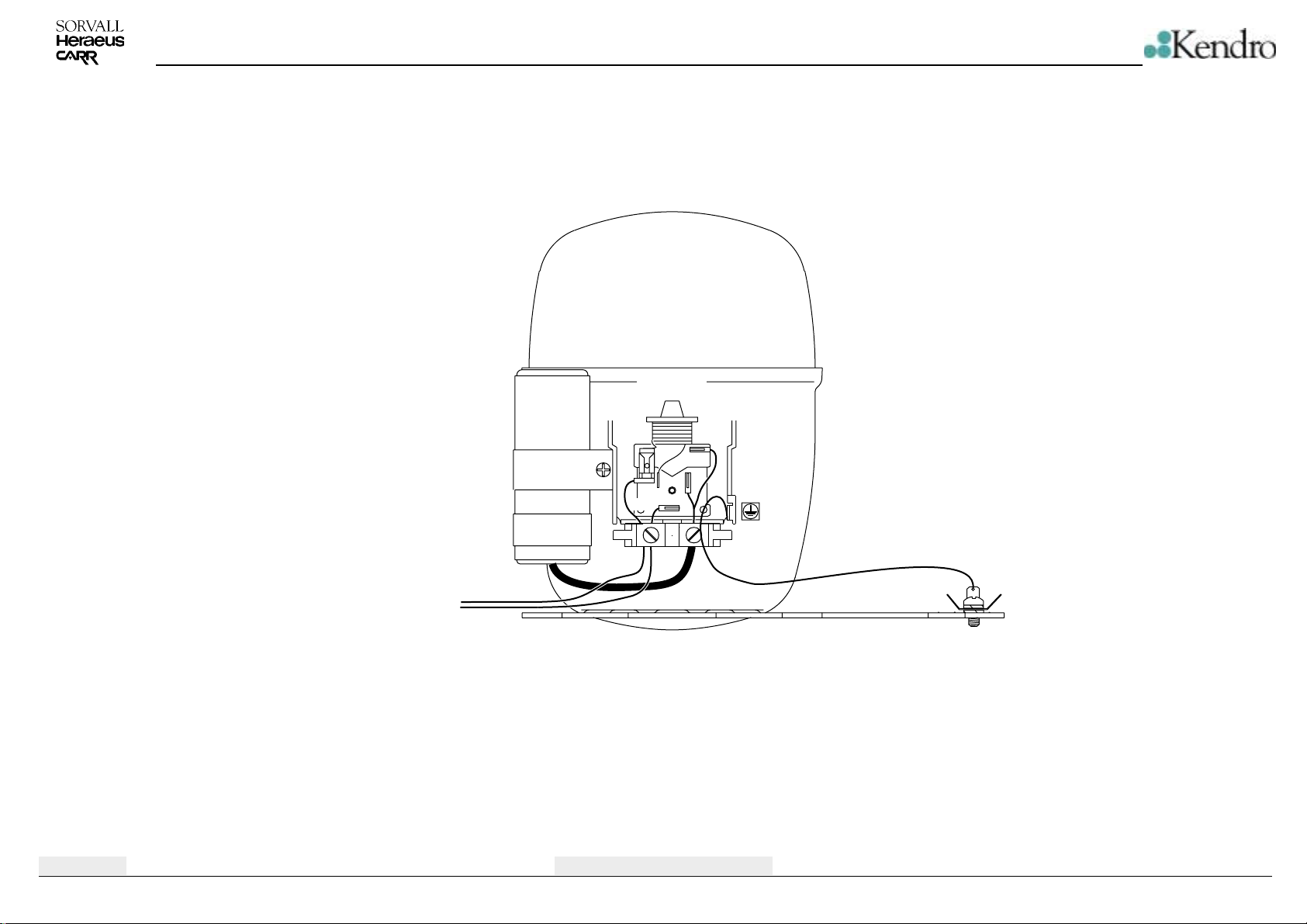

Connection Diagram Compressor

Compressor

Main Board G2, black

Main Board G1, white

Starting

Capacitor

Starting Relay

10

BLK

12

WHT

11

13

14

grn yel

Edition: 04

04.07.02 AH

Wiring Connections Diagram

4-6

Multifuge 3S-R / 3L-R / Legend RT

Loading...

Loading...