Kendro CRYOFUGE 6000i, CRYOFUGE 8500i Service manual

Service Manual

Cryofuge 6000iCryofuge

6000i

Cryofuge 8500iCryofuge

8500i

CRYOFUGE 6000i / 8500i

Cat.No.: 75007520 / 75007521 / 75007550 / 7500755175007526 /

PN 12007520

SERVICE

Table of Contents

Section Title Page

1 OPERATING INSTRUCTIONS Cryofuge 6000/8500i

2 SERVICE

2.1 SERVICING SCHEDULE 2-1+2

2.2 TROUBLE SHOOTING 2-3/7

2.3 TEST POINTS ON MAIN BOARD 2-8/10

2.4 ADJUSTMENT OF IMBALANCE SWITCH 2-11

2.5 CLEANING OF INSTRUMENT PARTS 2-12

2.6 ELECTRICAL SAFETY CHECK 2-12

3 FUNCTIONAL DESCRIPTION

3.1 BLOCK FUNCTIONS 3-1

3.2 CONTACTOR PLATE (MAINS INPUT) 3-2

3.3 MAIN BOARD FUNCTIONS 3-3+4

3.4 KEY AND INDICATION BOARD 3-5

3.5 SPEED DETECTION BOARD 3-5

3.6 IMBALANCE SWITCH 3-6

3.7 COOLING PLANT 3-6

COOLING PLANT – FLOW CHART 3-7

4DIAGRAMS

4.1 BLOCK DIAGRAM 4-1/4-3

4.2 WIRING DIAGRAMS 4-4/4-7

4.3 WIRING CONNECTION DIAGRAMS 4-8/4-13

4.4 MAIN BOARD - COMPONENT PLAN 4-14

4.5 MAIN BOARD - WIRING DIAGRAM 4-15/4-22

4.6 KEY AND DISPLAY BOARD - COMPONENT PLAN 4-23

4.7 KEY AND DISPLAY BOARD - WIRING DIAGRAM 4-24

4.8 NOISE FILTER BOARD - COMPONENT PLAN 4-25

4.9 NOISE FILTER BOARD – WIRING DIAGRAM 4-26

4.10 INTERFACE BOARD - COMPONENT PLAN AND WIRING DIAGRAM 4-27

4.11 SPEED DETECTION BOARD - COMPONENT PLAN AND WIRING DIAGRAM 4-28

4.12 FRONT KEYBOARD - COMPONENT PLAN AND WIRING DIAGRAM 4-29

5 REPLACEMENT OF COMPONENTS

5.1 DISMANTLING THE HOUSING 5-1

5.2 DISMANTLING OF SEALING ELEMENTS 5-2

5.3 REPLACEMENT OF MECHANICAL COMPONENTS 5-3+4

5.4 REPLACEMENT OF ELECTRICAL COMPONENTS 5-5+6

5.5 REPLACEMENT OF DRIVE ELEMENTS 5-7

5.6 REPLACEMENT OF CONDENSER FAN 5-8

5.7 REPLACEMENT OF PARTS OF COOLING PLANT - CHARGING INFORMATION 5-8+9

6 BREAK DOWN DRAWINGS AND LIST OF SPARE PARTS

6.1 BREAK DOWN DRAWINGS 6-1/14

6.2 SPARE PARTS LIST

7 CERTIFICATE

8 TECHNICAL BULLETINS

Edition: 01 Contents

26.12.01MH Page: 0-1

7-1/3

Cryofuge 6000i/8500i

SERVICE

Important Note

Technical Information for use of Cryofuges 6000i/8500i

__________________________________________________________________

Cat. No. 75007520 Cryofuge 6000i 3 x 400V 50/60Hz – 4,2kW

Cat. No. 75007521 Cryofuge 6000i 3 x 230V 50Hz – 4,4 kW

Cat. No. 75007526 Cryofuge 6000i Single Phase 230 V 50 Hz – 3,6 kW

Cat. No. 75007550 Cryofuge 8500i 3 x 400V 50/60Hz – 6 kW

Cat. No. 75007551 Cryofuge 8500i 3 x 230V 50Hz – 6 kW

Required door-width : 80 cm

Dimensions : 800 mm x 905 mm without wooden palette

Weight : Centrifuge 430 kg / Rotor 60 kg

Ground pressure : approx. 1450 N/m

Noise Level: CF 6000i - <64 dB(A); CF 8500i – <67 dB(A)

2

Voltage : 3 x 400V, 50/60 Hz, N capable handling

Required Fuses : 32 Amp slow blown

Connection 3 x 400V : Plug Cekon Type CEE 17, 32 A-6 H

3 L + N + PE or directly installed via master power switch

Voltage : 3 x 230V/ 50 Hz

Required Fuses : 32 Amp. slow blown

Connection 3 x 230V : Plug Cekon Type CEE 17, 32 A-9 H

3 L + PE or directly installed via master power switch

Voltage : Single Phase 230 V/50 Hz

Required Fuses: 32 Amp. slow blown

Connection 1 x 230V without plug

Heat rejection to environment : 15.120 kJ/h (14.330,993 BTU) CF 6000i

19.440 kJ/h (18.425,562 BTU) CF 8500i

12.960 kJ/h (12.283,708 BTU) Single Phase

Edition: 01 Contents

26.12.01MH Page: 0-2

Cryofuge 6000i/8500i

®

CRYOFUGES

LARGE VOLUME REFRIGERATED CENTRIFUGES

HS/Cf 1e

CRYOFUGES

LARGE VOLUME REFRIGERATED CENTRIFUGES

Precision for practical work: in blood banks and biotechnology.

Quality Products. Lifetime Care.

®

The Cryofuge 6000i is an attractively

designed, large volume floor standing

refrigerated centrifuge by Kendro

Laboratory Products offering

optimised technology for lowspeed

applications.

It is ideal for use in blood banks, biotechnology and the pharmaceutical industry,

where large volumes are centrifuged at

high speeds and constant temperatures.

It is also used for routine separation tasks

in laboratories and production facilities.

The use of sophisticated microelectronics

systems and high strength materials for

rotors and accessories guarantees outstanding reproducibility and highly

accurate centrifugation.

With a large 6 litre capacity and a top

speed of 4240 rpm (6010 x g), the

Cryofuge 6000i is designed for a wide

range of separation tasks. It can accommodate 1.5 ml tubes, 1 litre containers

and quad blood bags.

The Cryofuge 6000i is competitively

priced and comes with a wind-shielded

rotor and an extensive range of accessories. Back up from an international

support and service organisation ensures

maximum performance and reliability.

Typical applications

The Cryofuge is designed, in particular,

for the qualified production of human

blood components in blood banks. It is

also used for blood fractionation, serum

extraction, radio immuno assays (RIA),

cell preparation, fractionating protein and

enzyme precipitates, separating fine crystal

deposits – and in fact, in every situation

where high performance and capacity are

required.

Powerful technology

The Cryofuge is equipped with a powerful, maintenance free induction drive for

quiet and smooth operation. Its refrigeration system uses the environmentally

friendly CFC free refrigerant R 404a.

Acceleration and braking times have

been optimised for all application requirements. An automatic digital temperature

compensation system prevents samples

from freezing.

User friendly

A new automatic lid lock enables the

Cryofuge to be closed easily. The ergonomically designed keypad allows simple

entry and storage of operating parameters. Main control functions are

conveniently arranged for easy access,

while the

SEPACONTROL

®

control system

makes operation straightforward. The

"delay" function permits users to delay

system start-up.

Microprocessor control

The Cryofuge is equipped with 33 centrifugation programs for routine applications.

Nine acceleration and nine braking profiles

ensure reproducibility of all centrifugation

parameters. The Cryofuge is now also

equipped with a profile program for

defining up to 10 cut-off points with time,

speed, braking and acceleration curves.

Speed is controlled digitally with automatic RCF adjustment. Centrifuges can

also be connected to a computer for

data recording via a serial interface.

Safety

When designing the Cryofuge, all international safety standards were kept in

mind to guarantee the highest level of

safety. Diagnostic and fault messages are

clearly visible. Pre-selection of buckets

protects against overspeeding. The lid

lock system and steel armoured rotor

chamber further ensure safe operation.

A key operated switch safeguards

against unauthorised use.

Service friendly

The Cryofuge is equipped with a digital

self diagnosis system for monitoring

operability. If a fault is detected, a message is immediately displayed. Should

an error occur, however, our fast and

efficient international service team can be

relied upon.

The Cryofuge 6000i Refrigerated

Centrifuge is used for the qualified

production of human blood

components in blood banking.

CRYOFUGE 6000i REFRIGERATED CENTRIFUGE

CRYOFUGE 6000i REFRIGERATED CENTRIFUGE

02

Conveniently arranged function

keys and easy to read digital

display for simple operation and

quick access.

Ergonomically designed keypad

allows simple reproduction of

operating parameters.

Keys for controlling basic

functions are also located on

the front of the Cryofuge for

immediate access.

03

CRYOFUGE

6000i GMP

AND 8500i GMP

Wind-shielded rotor and lid, showing a selection of the extensive range of buckets and

adaptors.

CRYOFUGE

6000i GMP

AND 8500i GMP

Convenient operation

The SEPACONTROL operating panel is

systematically arranged, clearly displays

all functional areas and permits easy

access to operating parameters. The

user simply presses a few keys to select

the required centrifugation program and

start the Cryofuge. A design which

eliminates knobs and dials ensures high

reproducibility and easy cleaning of the

control panel.

SEPACONTROL provides users with

up-to-date information on the status of

the system. Visual diagnostic indicators

and acoustic signals supplement the

information supplied by the microcomputer. This makes it easy to use the

centrifuge right from the start.

Key operated switch

This switch protects programs against

unauthorised access. Depending on the

position of the switch, users are either

permitted to freely program the system,

call up one of the 33 programs in

memory or simply repeat the program

last used.

Panel

Five visual displays facilitate the identification of problems during centrifugation.

When the lid is opened (check lid), the

rotor is unevenly balanced (imbalance),

in the event of a system error (system

check), programming error (progr. error)

or if the temperature limit has been

exceeded (overtemp), an LED signals a

warning.

Memory control

33 memory locations are available to

save run parameters for future use. New

programs generated using the function

panel can be immediately added to the

library.

Status

The status field is systematically arranged

into the following areas: start-up and

braking curves, speed and rotor data,

time and temperature. LEDs prevent the

user from confusing the values on the

display.

Programming

The programming field permits easy

setting of the required parameters. Only

5 keys are required for completely programming all parameters! The keys are

used for changing the display setting,

values displayed and confirming input.

Simple, functional operation

The basic functions for opening the

centrifuge lid, starting and stopping the

system and quick-stop are located on

the front of the Cryofuge for immediate

access.

Rotor and accessories

An aerodynamic wind-shielded rotor and

6 different types of bucket ensure maximum performance and flexibility. The windshielded rotor is included in the basic

centrifuge package. The vast range of

accessories is listed in the tables overleaf.

Four buckets have been specially developed for centrifuging blood and producing thrombocyte concentrates. The

system can handle all standard blood

pack systems. Additional accessories

such as plastic inserts and balancing

accessories round off the package.

Two other buckets used in combination

with various adaptors permit all tubes

with nominal volumes between 1.5 ml

and 1000 ml to be centrifuged.

HERANET data documentation

The Heraeus HERANET data documentation system is available for data

documentation in accordance with GMP.

Please request our HERANET brochure

from your Kendro representative.

The Cryofuge 6000i GMP (Good Manufacturing Practice) offers the same performance and accessories as the Cryofuge

6000i. The Cryofuge 8500i GMP attains a

maximum centrifugal force of 8525 x g

and a maximum speed of 5050 rpm.

GMP Cryofuges are specially designed for

use in clean room applications.

Special features of the Cryofuge

6000i GMP and 8500i GMP

The special encapsulated casing is sealed

to prevent particles from escaping and

contaminating the clean room. The space

between the centrifuge and floor is equipped with a rubber gasket. Thanks to its

special smooth finish, the casing is very

easy to clean. The 6000i GMP and 8500i

GMP are equipped with connections for

an external cooling water system; the flow

rate of the cooling water is kept to a minimum. On request, the system can be

connected to an external cooling system.

The enclosed and sealed casing and

vibration insulation system ensure low

noise generation during operation. Heat

radiation is also minimised.

Before installing the Cryofuge GMP, please

be sure to contact the Kendro Service

Department.

04

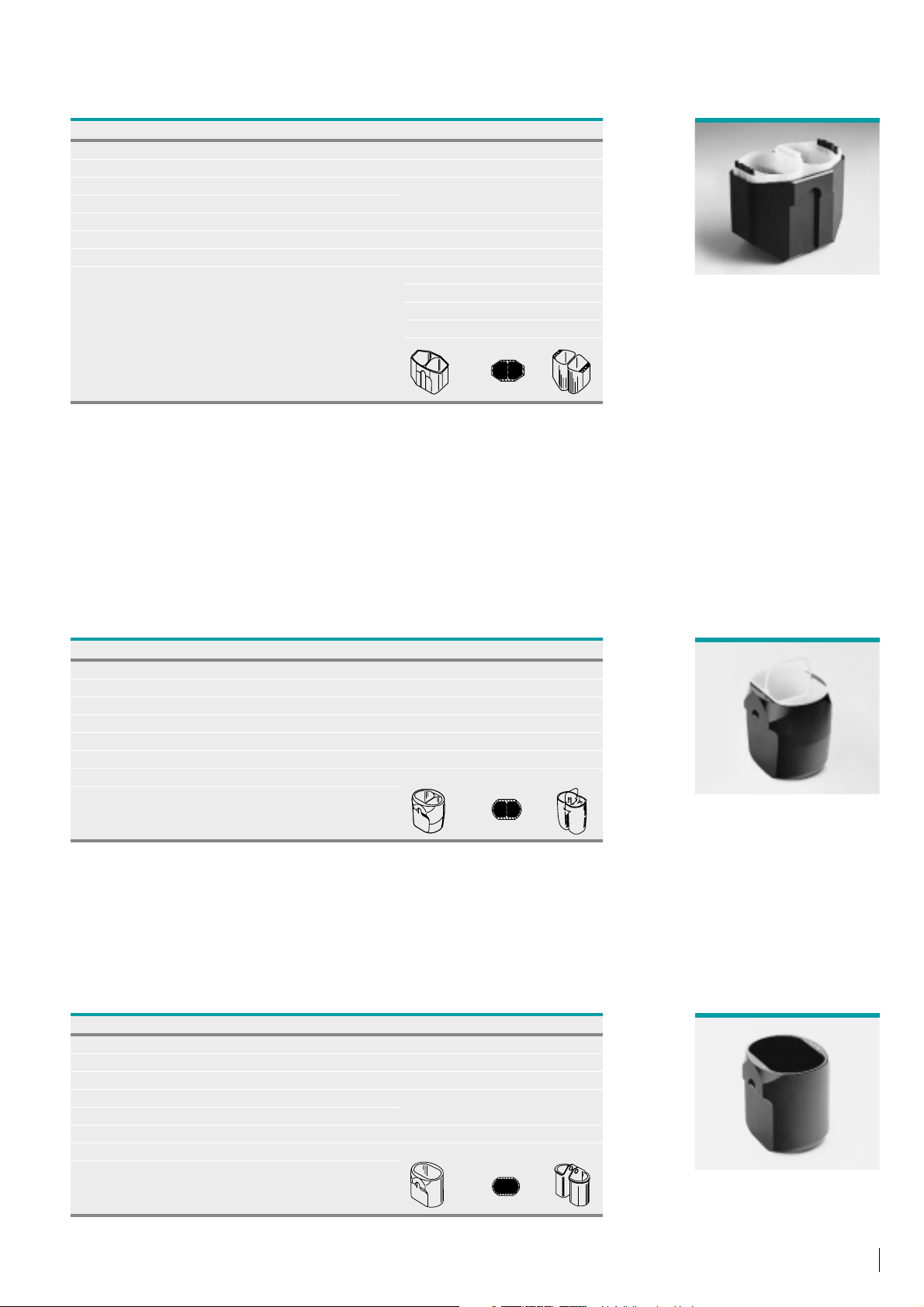

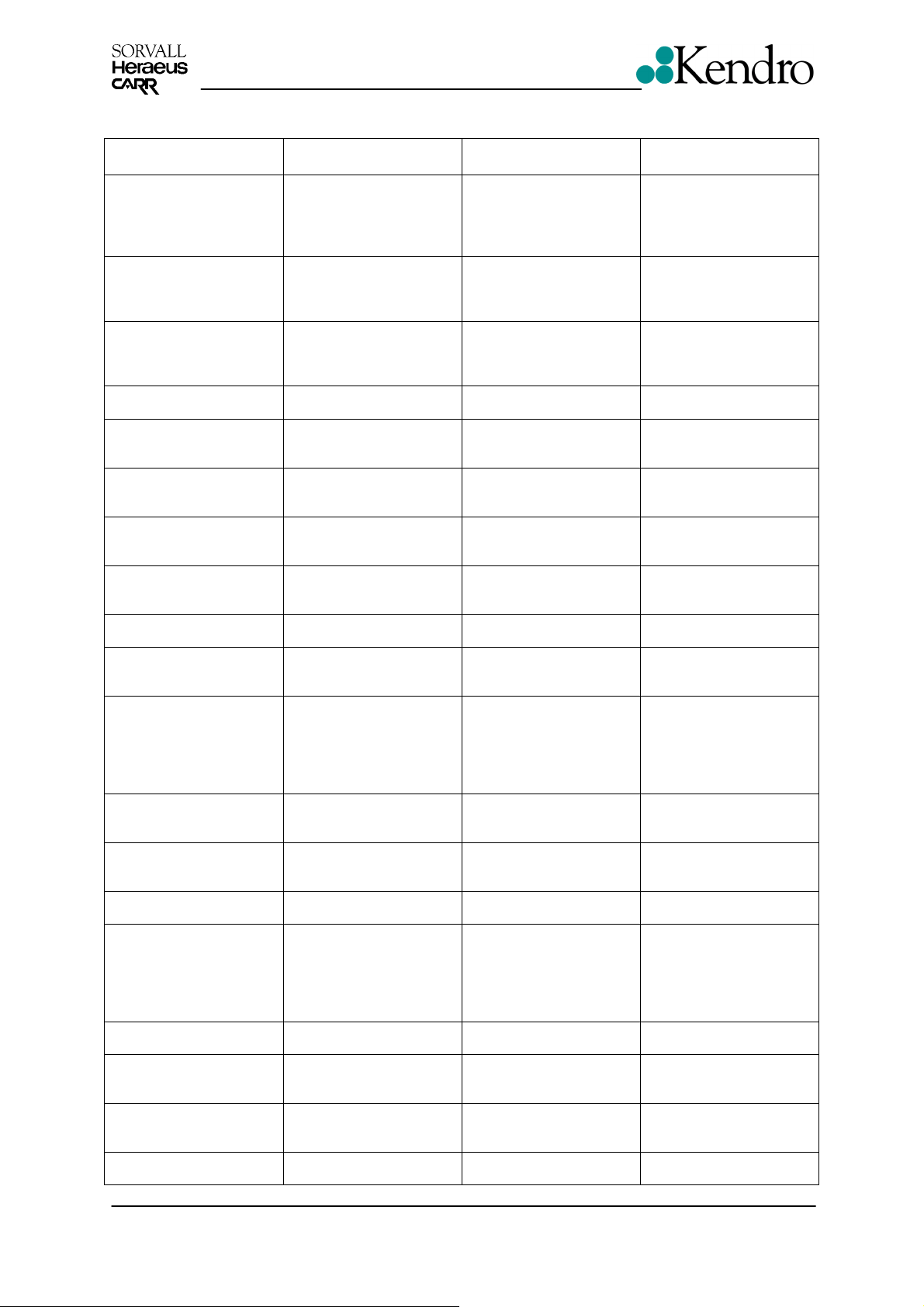

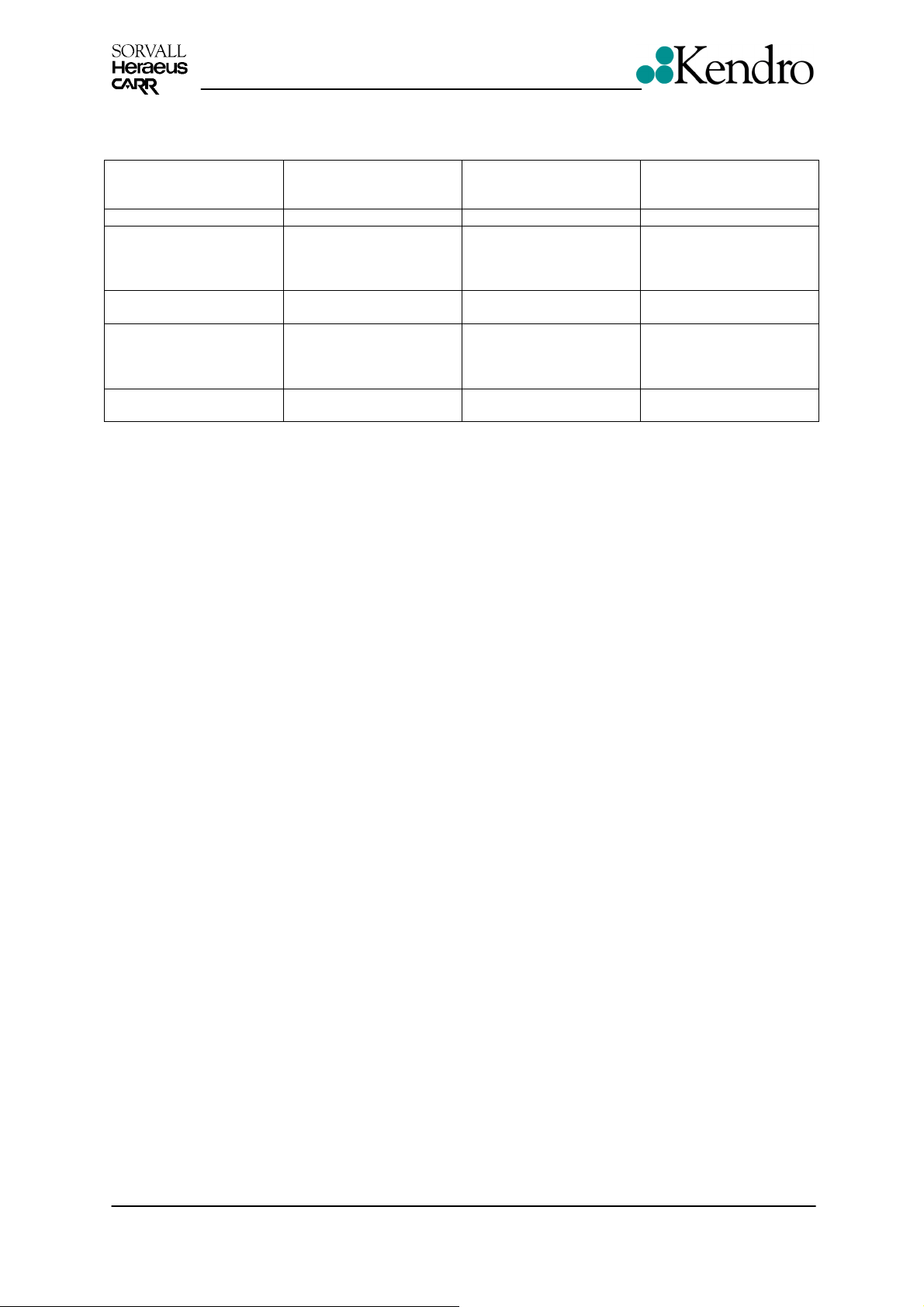

Model Cryofuge 6000i Cryofuge 8500i Technical data

Max speed (rpm) 4,000 4,000 Operation with blood packs double-quint

Max. RCF (x g) 5,312 5,312 No. of pack systems/bucket 2

Max. capacity 2 x 800 ml 2 x 800 ml Polyamide plastic inserts:

Max. perm. mass (g) 3,500 3,500 Order no. M

2)

76007667

Min. temp. at max. RCF* –5 °C –5 °C Opening M (mm) 110 x 57

Max. acceleration time (s) 140 140 Order no. L

1)

76007647

Min. braking time (s) 180 180 Opening L (mm) 110 x 70

Radius (cm) 29.9 29.9 Order no. XL

3)

76007657

Opening XL (mm) 110 x 76

Order no. XXL

4)

76007677

Opening XXL (mm) 110 x 88

* At ambient temp. of 25 °C

M, L and XL plastic inserts come complete with balancing weights 75007645. One set of balancing weights includes

4 weights of 6 and 15 g each. Balancing plates 75005759 can be used to compensate big weight differences. One set

includes 2 plates at 35 and 65 g each.

The balancing insert 75007668 consists of an XL plastic insert, 2 balancing weights and 30 balancing plates, enabling

compensation of up to a full bucket load.

1)

Suitable for triple and quad systems.

2)

Suitable for double systems.

3)

Suitable for quad systems, systems with soft filters.4)Suitable for quad and quintuple systems, systems with filters.

Double bucket for blood packs – Order no. 75007617

Model Cryofuge 6000i Cryofuge 8500i Technical data

Max speed (rpm) 4,240 5,050 Operation with blood packs double-trip.

Max. RCF (x g) 5,768 8,182 No. of pack systems/bucket 2

Max. capacity 2 x 750 ml 2 x 750 ml Opening measurements (mm) 99 x 70

Max. perm. mass (g) 3,700 3,700 Plastic insert order no. 75006695

Min. temp. at max. RCF* –4 °C +6 °C Plastic insert opening (mm) 95 x 60

Max. acceleration time (s) 150 190 Plastic insert material PE

Min. braking time (s) 190 220

Radius (cm) 28.7 28.7

* At ambient temp. of 25 °C

Bucket for blood packs 75006695 comes with plastic insert 75006694.

Double bucket for blood packs – Order no. 75006694

Model Cryofuge 6000i Cryofuge 8500i Technical data

Max. speed (rpm) 4,000 4,000 Operation with blood packs double-trip.

Max. RCF (x g) 5,170 5,170 No. of pack systems/bucket 2

Max. capacity 2 x 750 ml 2 x 750 ml Opening measurements (mm) 99 x 139

Max. perm. mass (g) 3,100 3,100 Plastic insert order no. 75006609

Min. temp. at max. RCF* –5 °C –5 °C Plastic insert opening (mm) 99 x 57

Max. acceleration time (s) 140 140 Plastic insert material PP

Min. braking time (s) 180 180

Radius (cm) 28.9 28.9

* At ambient temp. of 25 °C

Double bucket for blood packs – Order no. 75006801

Double bucket for blood packs

75007617

Double bucket for blood packs

75006801

Double bucket for blood packs

75006694

05

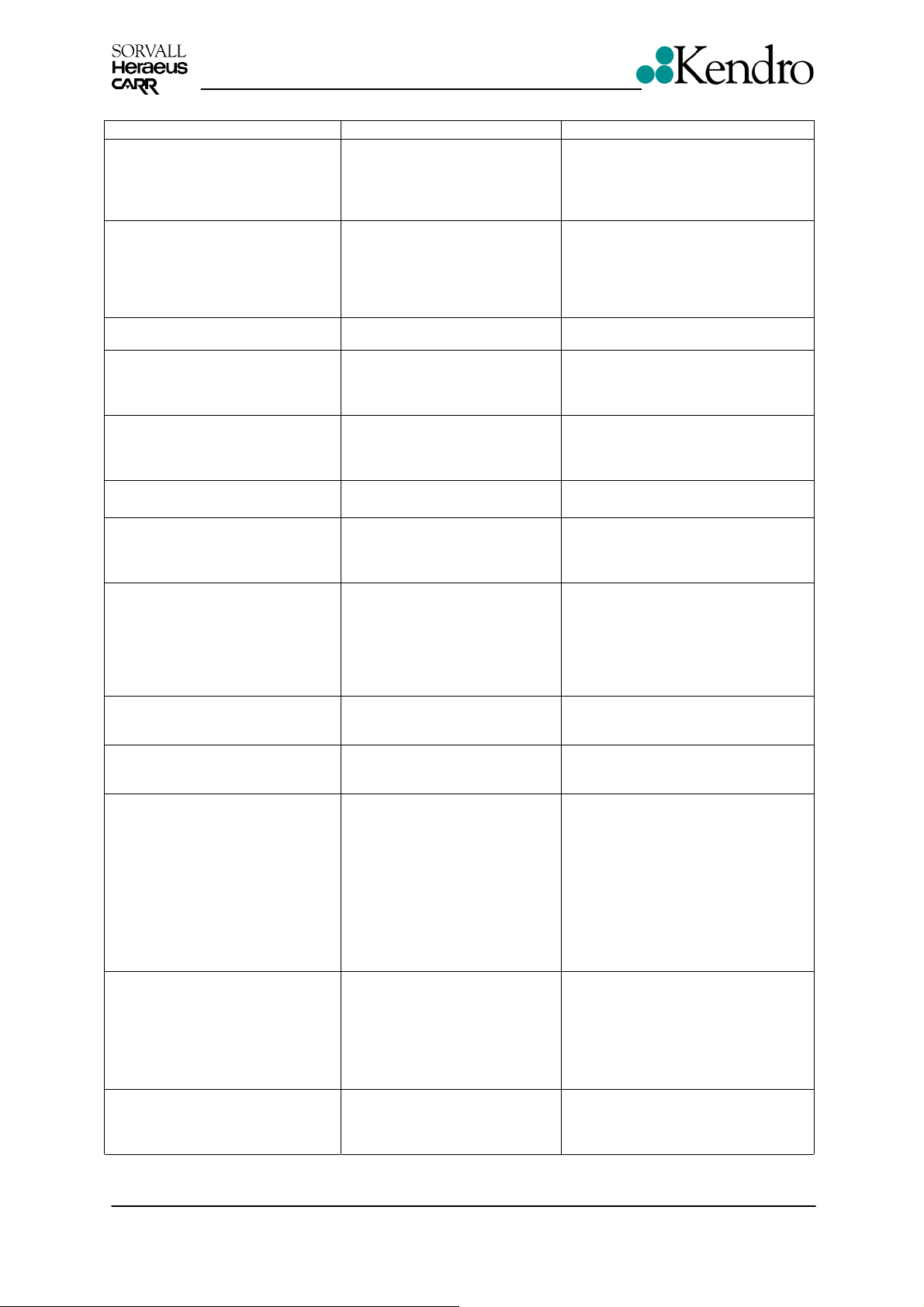

Nominal volume of tube (ml) 1.5 7 7 15 15 15 25 25 50 50 50 50 50 100 150

No. of tubes per adaptor 40 20 12 12 11 6

1)

542262111

No. of tubes per rotor 480 240 144 144 132 72 60 48 24 24 36 24 12 12 12

Type of tube ML DIN B. Coll. DIN B. Coll. Falc. DIN Univ. DIN Falc. Falc. Univ. Oil DIN DIN

Max. length of tube (mm) 45 110 110 111 109 121 100 120 130 120 117 120 S 120 120

Max. tube ø (mm) 11 13 14 17 17 17 25 25.5 35 29.5 29 29.5 S 45 55

Max. cap ø (mm) – 14 18 18 19.5 23 25.9 31 36 37.5 35 37.5 S 48 –

Colour of adaptor black yellow grey red white brown orange green green gr./yel. nat. gr./yel. nat. blue black

Adaptor order no. (7500xxxx) 5335 5321 5330 5322 5327 5387 5323 5391 5324 5386 2261 5389 5339 5325 5326

Stand. tube order no. (7500xxxx) 1163a)9001b)– 9003b)– 2845c)9006

b)

–

9005b)2844e)2844e)– 3113d)9007b)1132

b)

1)

Make sure that the bucket swings out correctly when all places are used.

Type of tube: ML = microlitre tube; B. Coll. = blood collection tube ("Vacutainer", "Monovette", etc.); Falc. = "Falcon

®

" (conical tube); Oil test = oil test tube, pear shaped;

Univ. = universal container (with vertical edge, Falcon type).

Standard tube:

a)

1.5 ml microlitre tubes, b)borosilicate glass, c)12 ml Nunc. screw cap tube, d)oil test tube, pear shaped, e)50 ml Falcon screw cap tube.

Adaptors can be used with tubes with the following shape bottom: F = flat, R = round, C = conical, S = special

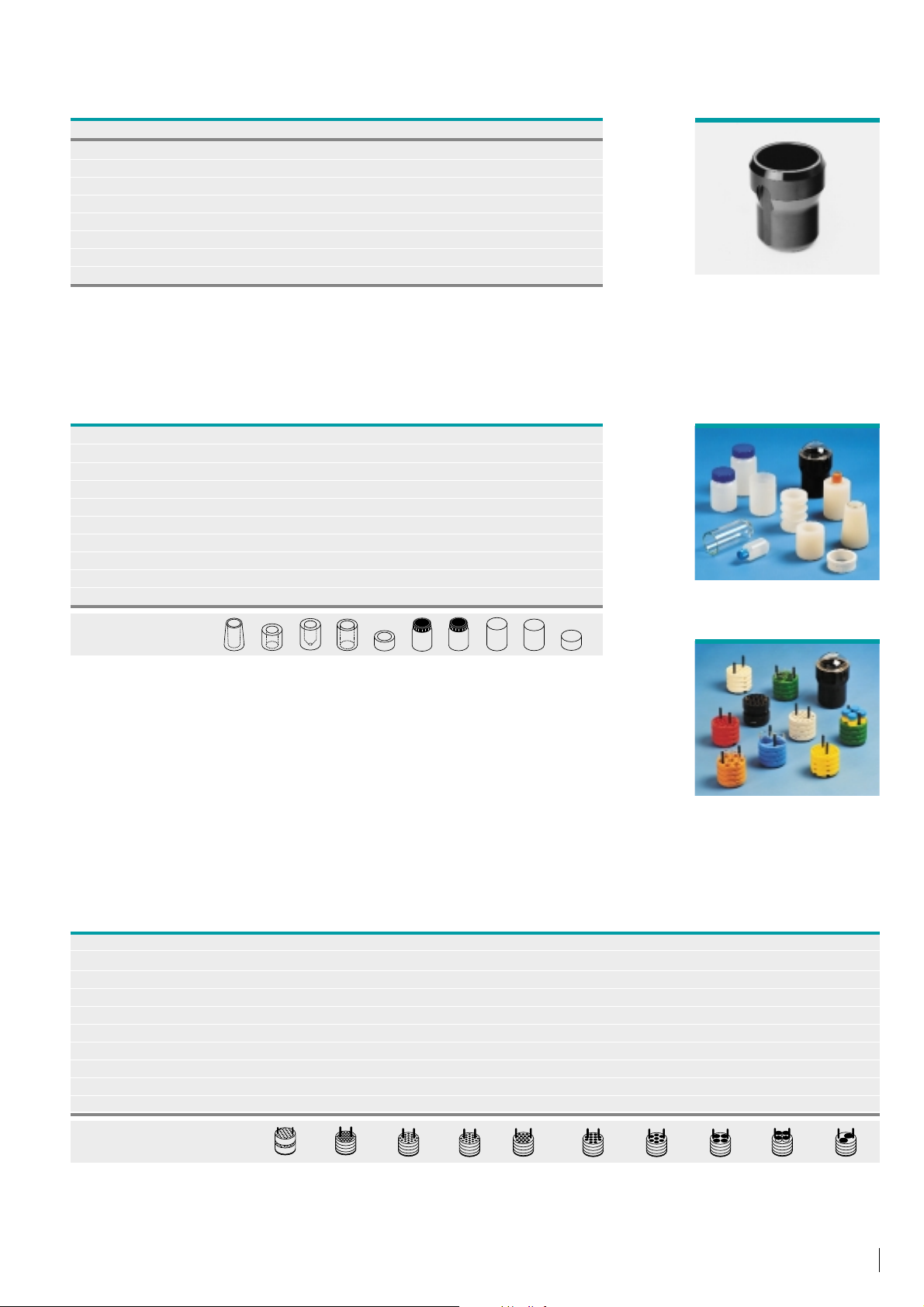

Model Cryofuge 6000i Cryofuge 8500i Technical data

Max. speed (rpm) 4,000 4,000 Operation with blood packs double-trip.

Max. RCF (x g) 5,310 5,310 No. of pack systems/bucket 2

Max. capacity 2 x 700 ml 2 x 700 ml Opening measurements (mm) 95 x 55

Max. perm. mass (g) 3,100 3,100 Accessories:

Min. temp. at max. RCF* –5 °C –5 °C Metal handles 75006728

Max. acceleration time (s) 140 140 Rubber spacer for shorter

Min. braking time (s) 180 180 packs fitted with

Radius (cm) 29.7 29.7 handle 75006728 76014725

* At ambient temp. of 25 °C

Double bucket for blood packs – Order no. 75006680

Additional accessories for blood pack operation

Order no. 75006683 Pack of "shoe horns" for inserting blood packs,

incl. 1 set of rubber rings

Order no. 75006684 Set of non stick plastic bags (150 each) for smooth insertion and removal of

blood packs

Order no. 75006681 12 rubber volume compensation plates

Order no. 75005759 4 rubber balancing plates

Model Cryofuge 6000i Cryofuge 8500i

Max. speed (rpm) 4240/3006 5050/3006

Max. RCF (x g) 4984/2506 7070/2506

Max. capacity 24 x 15 ml/3 racks

1)

24 x 15 ml/3 racks

1)

Max. perm. mass (g) 2500/1800 2500/1800

Min. temp. at max. RCF* –4 °C +6 °C

Max. acceleration time (s) 150 190

Min. braking time (s) 190 220

Radius (cm) 24.8 24.8

* At ambient temp. of 25 °C

1)

Boehringer Mannheim or Hitachi-5 sample racks

Double rectangular bucket – Order no. 76008078/75015501

Double bucket for blood packs

75006680

Double rectangular bucket

76008078 with adaptors for standard tubes

Double rectangular bucket

76008078

Accessories for standard tubes in double bucket 76008078

06

C F/R F/R F/R CF/R F/R F/R S R RF/CC F/R F

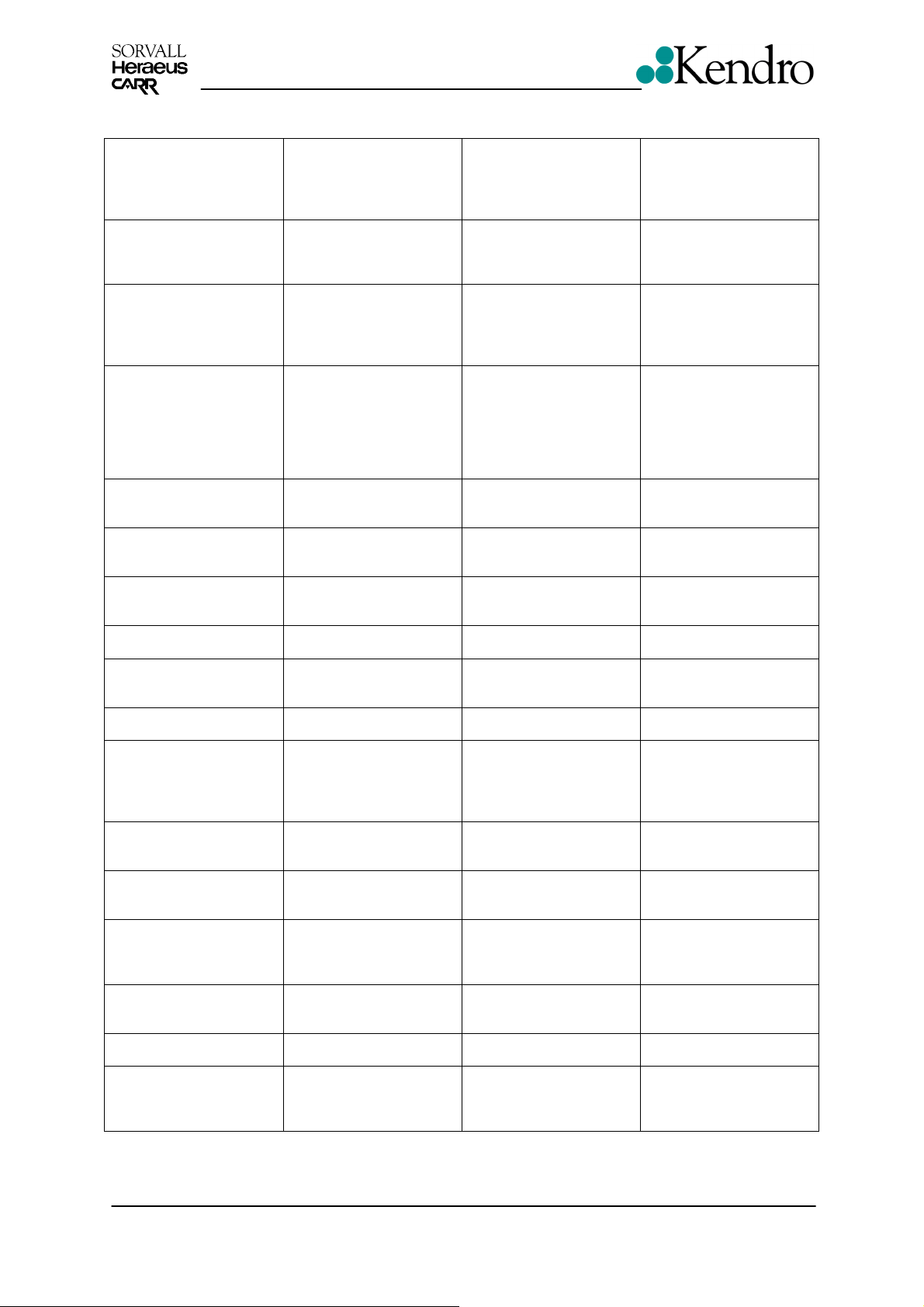

Round bucket 75008165 with

adaptors for standard tubes

Adaptor for large volume tubes

for round bucket 75008165

Model Cryofuge 6000i Cryofuge 8500i

Max. speed (rpm) 4,240 5,050

Max. RCF (x g) 6,010 8,525

Max. capacity 1 x 1000 ml 1 x 1000 ml

Max. perm. mass (g) 3,200 3,200

Min. temp. at max. RCF* –4 °C +8 °C

Max. acceleration time (s) 150 190

Min. braking time (s) 190 220

Radius (cm) 29.9 29.9

* At ambient temp. of 25 °C

Aerosol tight cap (order no. 75008081) available on request.

Round bucket – Order no. 75008165

Nominal volume of tube (ml) 250 2502)250 500 650 750 1000 1000 Bp. DACS

No. of tubes per adaptor 11111–1–1 1

No. of tubes per rotor 666666666 6

Type of tube DIN Div./H. Corni. H DIN H H HST Sing.-trip. DACS

Max. length of tube (mm) 190 190 190 190 1953)148 190 175 – –

Max. tube ø (mm) 59 62.5 61.5 70 84 100 100 99.5 – –

Max. cap ø (mm) –––––8787–– –

Colour of adaptor nat. nat. nat. nat. nat. - - - nat. black

Adaptor order no. (7500xxxx) 66494)8144 8147 8145 66376)– – – 6639 5254

Stand. tube order no.(7500xxxx) 1135b)7894 – 7718 11587)8149 6613 6640 – –

Nominal volume of tube: Bp. = blood pack, DACS = Density Associated Cell Sorting (DACS™ 300, Fresenius)

Type of tube: Div. = diverse, Corni. = Corning bottle, H = Heraeus tube, HST = Heraeus stainless steel tube

Standard tube:

b)

borosilicate glass.

2)

Additional pad for conical tubes required from manufacturer, 3)Only use without cap 75008081,

4)

Pad 75001808 required, 6)Pad 75001913 required, 7)max. speed – 2,600 rpm

Adaptors can be used with tubes with the following shape bottom: F = flat, R = round, C = conical, S = special

Accessories for large volume tubes in

round bucket 75008165

Round bucket 75008165

Nominal volume of tube (ml) 1.5/2 7 7 15 15 15 25 50 50 100

No. of tubes per adaptor 48 35 19 19 17 12 7 4 4 2

No. of tubes per rotor 288 210 114 114 102 72 42 24 24 12

Type of tube ML DIN B. Coll. DIN B. Coll. Falc. DIN DIN Falc. DIN

Max. length of tube (mm) 42 177 177 177 177 177 177 177 177 177

Max. tube ø (mm) 11 13 14 17 17 17 25 35 29.5 45

Max. cap ø (mm) – 14 18.5 18.5 20 23.7 31 39 39 47.5

Colour of adaptor black yellow grey red white brown orange green gr./br. blue

Adaptor order no. (7500xxxx) 8132 8133 8134 8135 8136 8137 8138 8140 8141 8142

Stand. tube order no. (7500xxxx) 1163

a)

9001

b)

– 9003

b)

– 2845

c)

9006

b)

9005

b)

2844

e)

9007

b)

Type of tube: ML = microlitre tube; B. Coll. = blood collection tube ("Vacutainer", "Monovette", etc.); Falc. = "Falcon" (conical tube).

Standard tube:

a)

microlitre tubes, b)borosilicate glass, c)15 ml Falcon screw cap tube, e)50 ml Falcon screw cap tube.

Adaptors can be used with tubes with the following shape bottom: F = flat, R = round, C = conical.

Accessories for standard tubes in round bucket 75008165

07

F/C F/R F/R F/R F/C RF/R F/R F/R F/C

SFFF

C

FR

F

3)

R

S

S

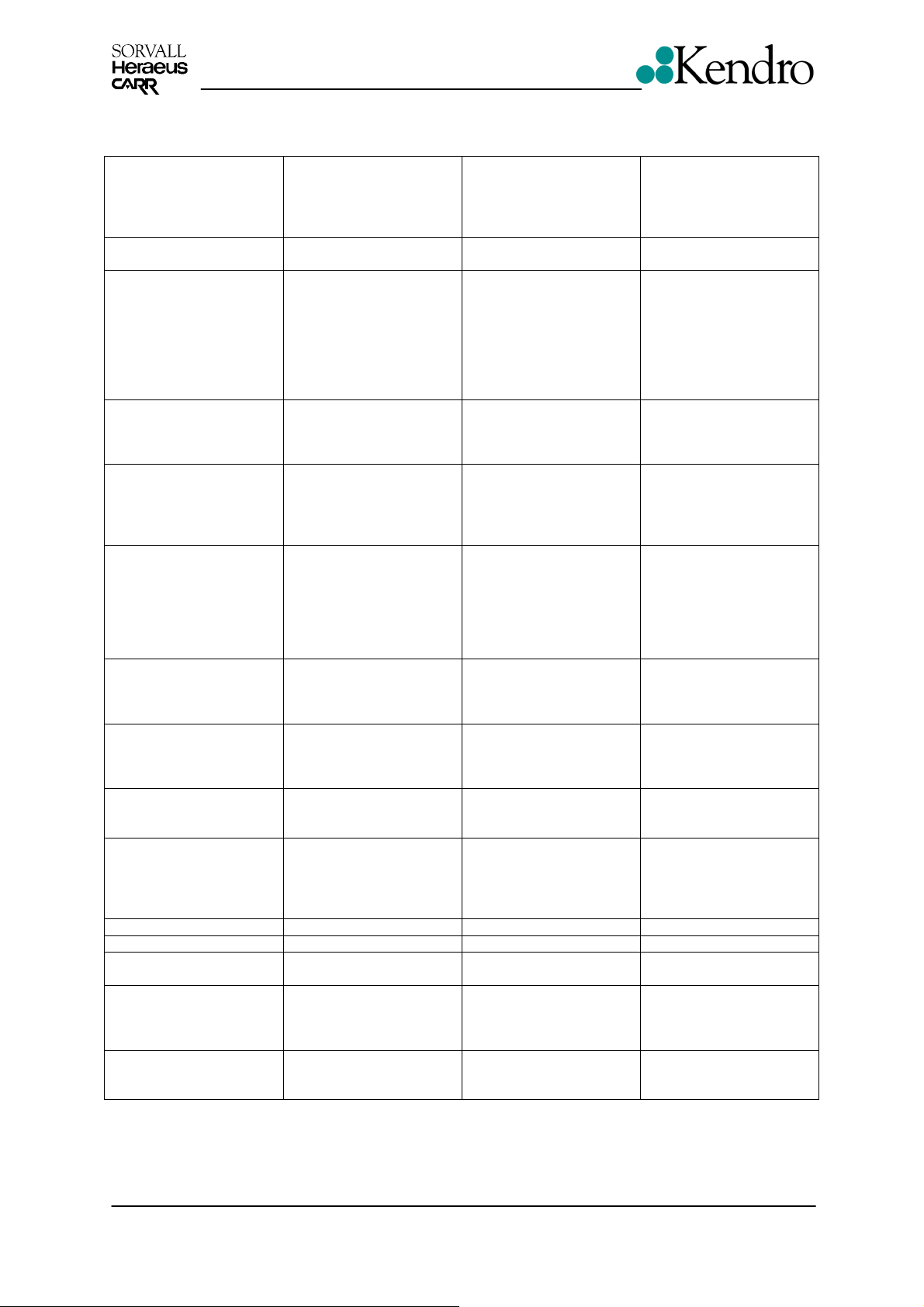

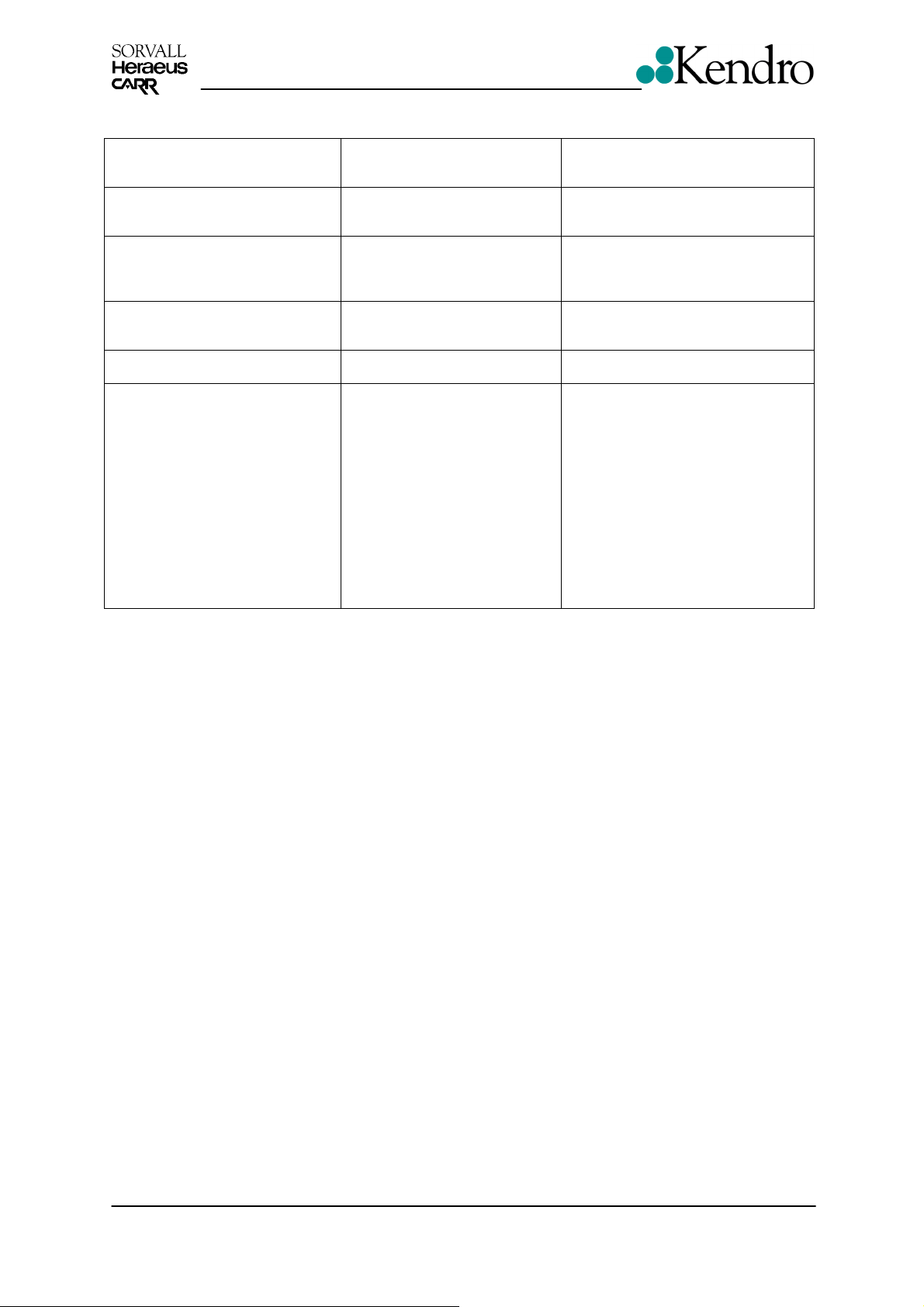

TECHNICAL DATA

Model Cryofuge 6000i Cryofuge 8500i

Description Large volume refrigerated Large volume refrigerated

floor standing centrifuge floor standing centrifuge

Max. speed 4240 rpm 5050 rpm

Max. RCF 6010 x g 8525 x g

Max. capacity 6 x 1000 ml bottles or 12 blood pack 6 x 1000 ml bottles or 12 blood

systems of 800 ml each pack systems of 800 ml each

Control and drive High performance induction drive, High performance induction drive,

SEPACONTROL with SEPACONTROL with

microprocessor microprocessor

Acceleration and

braking profiles 9/10 profiles 9/10 profiles

Runtime 1 min – 99 hrs, continuous operation 1 min – 99 hrs, continuous operation

Program memory 33 user centrifugation programs, one of which with freely combinable

braking and acceleration curves, key operated switch for protection

against unauthorised access, data last used saved, in the case of a

power interruption data saved for unlimited period of time.

Temperature control range –20 °C to +40 °C –20 °C to +40 °C

Safety features Lid lock and interlock, imbalance cut-out, steel armoured chamber

Design Sturdy, torsion resistant steel design with stainless steel rotor chamber

Dimensions (hxwxd) 1178 x 800 x 905 mm 1178 x 800 x 905 mm

Weight (excl. rotor) 445 kg 445 kg

Power consumption 4.2 kW 5.4 kW

Refrigeration unit 1.9 kW 1.9 kW

Recommended fuse 25A 25A

Designed and tested IEC 1010, UVV VBG 20, UVV VBG 7z, UVV VBG 4, DIN 58970 part 1,2,

in acc. with 4, radio interference suppression in compliance with VDE 0871 B

Rotor

Wind-shielded rotor 75006606 75006606

included in basic package included in basic package

Order number Cryofuge 6000i Cryofuge 8500i

220 V/3 Ph/50 Hz 75007521

230 V/1 Ph/50 Hz 75007526

400 V/3 Ph/50 Hz 75007520

GMP model

400 V/3 Ph/50 Hzwith built-in refrigeration unit 75007562 75007561

with external refrigeration unit 75007566

ORDER NUMBERS

The Cryofuges 6000i and 8500i

are now even more convenient

to operate with a load-relief lid

for easy opening and closing.

TECHNICAL DATA

ORDER NUMBERS

Australia Kendro Laboratory Products · Lane Cove DC · NSW 2066 · Tel. +61 (02) 9936 1540 · Fax. +61 (02) 9427 9765 · info@kendro.com.au

Austria Kendro Laboratory Products GmbH · Wien · Tel. +43 (1) 801 40-0 · Fax +43 (1) 801 40 40 · office@kendro.at

Canada Kendro Laboratory Products International Sales · Newtown · USA · Tel. +1 (203) 270-2080 · Fax. +1 (203) 270-2166 · info@kendro.com

Denmark Kendro Laboratory Products AB · Albertslund · Tel. +45-43 62 46 47 · Fax +45-43 62 46 41 · info@kendro.dk

France Kendro Laboratory Products · Courtaboeuf cedex · Tel. +33 (1) 69 18 77 77 · Fax +33 (1) 60 92 00 34 · info@kendro-lab.fr

Germany Kendro Laboratory Products GmbH · Hanau · Tel +49 (6181) 35-300 · Fax: +49 (6181)35-59 44 · info@kendro.de

India Kendro Laboratory Products (India) Pvt. Ltd. · New Delhi · Tel. +91 (11) 618 58 40 · Fax +91 (11) 618 53 97 · kendro.india@vsnl.com

Italy AHSI S.p.A. · Cavenago Brianza · Tel. +39 (02) 95 08 11 · Fax +39 (02) 95 08 12 77 · ahsidue@tin.it

Poland Kendro Spólka z.o.o.

· Warszawa · Tel. +48 (22) 663 43 23 · Fax +48 (22) 663 43 25 · kendro.warszawa@kendro.com.pl

Portugal Heraeus S.A. · Cacem · Tel. +351 (1) 912 08 65 · Fax +351 (1) 912 08 60 · heraeus@mail.telepac.pt

PR China Kendro Laboratory Products (H.K.) Ltd. · Hong Kong SAR · Tel. +852 2711-3910 · Fax +852 2711-3858 · 106122.205@compuserve.com

Spain Heraeus S.A. · Madrid · Tel. +34 (91) 358 19 96 · Fax +34 (91) 358 20 67 · heraeus@mx3.redestb.es

Sweden Kendro Laboratory Products AB · Upplands Väsby · Tel. +46 (8) 59 07 21 90 · Fax +46 (8) 59 03 16 00 · info@kendro.se

Switzerland Kendro Laboratory Products AG · Zürich · Tel. +41 (1) 454 12 12 · Fax +41 (1) 454 12 99 · kendro-ag@swissonline.ch

Kendro Laboratory Products SA · Carouge-Genève · Tel. +41 (22) 343 21 67 · Fax +41 (22) 342 38 31 · kendro-sa@swissonline.ch

U.K./Ireland Kendro Laboratory Products Limited · Bishop’s Stortford · Herts · Tel.+44 (1279) 827700 · Fax +44 (1279) 827750 · kendro@kendro.co.uk

USA Kendro Laboratory Products L.P. · Newtown · Tel. +1 (800) 522-7746 · Fax. +1 (203) 270-2166 · info@kendro.com

All other International Sales in Europe, Middle East, Africa

Kendro Laboratory Products International Sales · Hanau · Germany · Tel. +49 (6181) 35-300 · Fax +49 (6181) 35 59 44 · info@kendro.de

Asia Pacific Kendro Laboratory Products (H.K.) Ltd. · Hong Kong SAR · Tel. +852 2711-3910 · Fax +852 2711-3858 · 106122.205@compuserve.com

Latin America Kendro Laboratory Products International Sales · Newtown · USA · Tel. +1 (203) 270-2080 · Fax. +1 (203) 270-2210 · info@kendro.com

Internet http://www.kendro.com .http://www.heraeus-instruments.com

Kendro Laboratory Products – a worldwide company formed by the merger of Heraeus Instruments and Sorvall.

Should your country not be included in the address list, please contact Kendro Laboratory Products International Sales in Germany or USA.

Subject to change without notice. Printed in Germany 6C 07/99 VN 4t Frotscher

SERVICE

2. SERVICE

2.1 Servicing Schedule (Yearly Procedure)

2.1.1 Maintenance Routine without Dismantling the Centrifuge

1. Electrical Installation and Safety

Switch OFF the centrifuge and disconnect the unit from power.

Check voltage supply and mains fusing (3 x 32 Amps slow blow characteristic or other for

corresponding line voltages)

Check condition of plug and wall socket - replace defective parts.

Check main contactor for burnt out poles.

Check cord condition and fixing - replace or refit it.

2. Location and Mechanical Installation

Check the base for resonance-free and stable conditions.

Check for a well ventilated place and sufficient distances to walls or adjacent equipment (min.

30 cm), avoid direct sunlight.

Check the levelling of the centrifuge - use a spirit level.

3. Lid Locking Mechanism and Safety Device

Connect the centrifuge to power and switch ON

Check for easy lid closing and self-acting lid opening - if in disorder, re-adjust lid looped hooks

and/or hinges and/or move lid lock assembly aside and smear hooks slightly with grease.

Check the central rubber gasket for lid sealing and replace it, if damaged.

Open the lid and turn the rotor by hand, then close the lid and try to open it using the lid key: the

lid must not be opened as long as the speed values (> 10 rpm) are indicated - if safety circuit is

out of function, replace main board.

4. Cleanliness of Spin Chamber and Motor Cover

Open the lid and remove the rotor: for loosening turn rotor's collar nut with use of 19 mm fixed

spanner anti clock wise (in arrow direction - see rim of rotor bowl), thereby hold the rotor on it's

cross.

There is an additionally turn resistance after approx. one revolution which has to be overcome

with an further lever pressure of the fixed spanner. Then turn the drive shaft clockwise with the

10 mm socket wrench as long as the rotor can be lifted up. Two persons are necessary to seize

the rotor by it arms on opposite and to lift the rotor carefully out of the bowl.

Clean the wind-shield with a dry and absorbent cloth (remove all dust and moisture - see also

2.5 Cleaning)

Check the correct seat and condition of the motor cover.

Take care of the cleanliness of the annular slot around the motor shaft: there is shaft packing of

felt which has to be soaked with oil. - Penetrating fluids can damage the upper motor bearing.

5. Rotor and Bucket Condition and Sealing

Check the condition of rotor and buckets (especially all supporting or stressed partitions as jib

arms, rim of the bucket's bearing surface etc.): the rotor and/or buckets must not be used any

longer, if there are visible traces of mechanical damage or rust.

Check the condition of rotor and/or bucket sealing and replace them in case of malfunction

6. Rotor Fixing and Motor Shaft

Check the condition of the drive motor shaft: the centrifuge must not be used any longer, if the

drive shaft is damaged (bend, thread is worn out, horizontal grooves etc.)

7. Temperature Control Circuit

Clean the condenser (use a vacuum cleaner).

Check the thermal isolated fixing of the temperature sensor.

Re-install the rotor and run the centrifuge at 2000 rpm (1500 rpm with buckets #7719) and at

4°C

Check the temperature 30 minutes later: the displayed and measured value should be

approximately the same (tolerances +/-2K)

Edition: 02 Service

18.04.02 MH Page: 2-1

Cryofuge 6000i/8500i

SERVICE

2.3.2 Maintenance Routine after Dismantling the Centrifuge Casing (see Section 5)

1. Motor Supporting Elements

Check the supporting and damping motor elements (enlarged rubber abrasion, often imbalance

runs) and replace them by worse condition or at least every 3 years.

2. Imbalance Switch

Check the function of the imbalance switch and replace in case of malfunction.

3. Braking Circuit

Check the function of the braking circuit (warming up of brake resistor, even and noiseless

brake effect) and replace defective parts in case of malfunction.

4. Lead and Screwing Connections

Check the terminal and plug connections of leads on all boards and electrical components,

replace defective parts.

Check the screwing connections of boards, mechanical and electrical components and tighten

them if necessary.

5. Protection Earth Core and Grounding Connections

Check the protection earth core for continuity and all grounding plug connectors (see also 2.6

Electrical Safety Check).

Check insulation resistance and measure the substitutional leakage current (see 2.6)

Edition: 02 Service

18.04.02 MH Page: 2-2

Cryofuge 6000i/8500i

SERVICE

Trouble Shooting

Error Indication Error Cause Possible

Error Source

"check lid" LED on,

interval sound

circuit for lid switches

"check lid" LED on and

"OPEn"

"imbalance"

LED on, interval sound

2) base is not sturdy

3) centrifuge is not

4) disjusted or faulty

5) leads to imbalance

6) faulty component of

"overtemp"

LED on, interval sound

2) without programming

E-00 appears

system check

LED on and interval sound

2) motor is jammed 2) remove drive, replace

faulty speed signal

2) faulty processing

motor didn't start 1) connection: drive to

2) defective drive 2) check resistance of

3) faulty main board 3) replace main board

lid opened

mechanically

during run

FORBIDDEN!

interrupted

during run

15 V circuit for lid switches

is interrupted

at standstill

imbalance circuit has

released

just after starting: drive is

switched off

during longer operation:

rotor coasts to standstill

without braking

rotor didn't turn 1) rotor is jammed 1) check for easy

easy check:

turn rotor by hand and

close lid -

speed values must be

indicated

mechanical

emergency lid

opening must only be used

at standstill

lid switches or leads are

interrupted

1) leads to lid switches

interrupted or defective

lid switch

1) rotor not symmetrically

loaded

enough and comes into

vibrations

correctly levelled

imbalance switch

switch are interrupted

imbalance circuit

∆t alarm Rotor chamber must be

1) ∆t is programmed 1) check minimum

of ∆t

1) faulty plug or lead

connections or faulty

speed detection board

circuit on main board

main board

Corrective Procedure

close lid immediately,

turn power OFF/ON,

press start to continue run,

press stop to finish run

check leads to the lid

switches, if micro switch is

faulty, change lid lock

assembly

1) check leads to lid

switches, if micro switch

is faulty - replace lid lock

assembly

1) open lid, check load,

close lid again and start

2) change or reinforce the

base

3) level the centrifuge drive

correctly, use a spirit level

on top of installed rotor

4) readjust imbalance

switch or replace in

case of malfunction

5) check leads with

ohmmeter and replace if

faulty

6) replace main board

precooled before ∆t

activation

reachable temperatures

at maximum speed and

20°C, check cooling

plant in case of big

deviation

2) check compressor and

cooling plant (loss of

refrigerant)

movement, remove any

jamming objects

faulty parts

1) check plug contacts

and leads - measure

speed detection signal

on XW1, XW3 - replace

faulty parts

2) replace main board

1) check terminal and

lead connections,

replace faulty parts

motor windings, replace

faulty parts

Edition: 02 Service

18.04.02 MH Page: 2-3

Cryofuge 6000i/8500i

SERVICE

Trouble Shooting

E-02 flashes

system check

LED on and

interval sound

E-03 flashes

system check

LED on and interval sound

E-04 flashes

system check

LED on and interval

sound

2) defective amplifier or

E-06 flashes

system check

LED on and interval sound

2) faulty tracks or

E-08 flashes

System check

LED on and interval sound

2) faulty intermediate

2) faulty frequency

E-10 appears

system check

LED on and interval sound

E-12 flashes

system check

LED on and interval sound

E-15 appears

system check

LED on and interval

sound

E-17 appears

system check

LED on and interval sound

2) defective lid lock

E-22 appears

system check

LED on and interval sound

program sequence

disturbed

faulty speed signal

during run

faulty temperature

measuring

data lines to keyboard

disturbed during operation

over voltage in DC

intermediate circuit

over current in DC

intermediate circuit

over temperature of the

electronics

program sequence

disturbed

temperature signal

disturbed

program sequence

disturbed

micro switch didn't open

after pressing lid key

NV-RAM and micro

controller can not

cooperate

bad ground connection check all ground

connections,

tighten loose screws

see E-00

or e.g. missing rotor

1) faulty temperature

sensor (PT100) or leads

converter test:

substitute PT100 by

100Ω and 120Ω

1) faulty plug contact or

connecting leads

components

1) leads to brake resistor

interrupted or defective

resistor

circuit

1) defective motor 1) disconnect the motor,

converter

insufficient cooling of

power electronics

NV-RAM not initialised insert the correct NV-RAM

see E-04 see E-04

reading error of NV- RAM

(checksum)

1) faulty leads or micro

switch

micro controller or NVRAM are mixed up

wait until rotor has come to

standstill, then see E-00

1) check plug connection

and resistance of

PT 100, replace faulty

sensor

2) set the temperature to

20 °C and watch the

display: after power ON

100Ω ->(0±2)°C

120Ω ->(50±2)°C

replace defective main

board

1) replace plug contacts

or connecting leads

2) change key and

indication board or main

board

1) check leads and brake

resistor, replace defective

parts

2) replace main board

check motor windings,

replace defective motor

2) replace main board

check wall distance, air

ventilation and fan

function, change bad

conditions, replace

defective parts

if error indication occurs

repeatedly replace NVRAM

1) replace defective parts

2) replace lid lock

assembly

check the correct

identification

No's of micro controller

and NV-RAM

Edition: 02 Service

18.04.02 MH Page: 2-4

Cryofuge 6000i/8500i

SERVICE

Trouble Shooting

E-23 appears system

check

LED on and interval sound

2) defective driving of

2) F4: motor over

3) F5: over pressure

2) faulty driving of

displays remain dark no mains voltage supply

2) defective mains cord

2) faulty keyboard 2) replace keyboard

3) faulty main board 3) replace main board

interrupted program

all displays elements are

shortly illuminated

2) bad or missing

mains contactor didn't

pull up, hour counter

doesn't run

mains contactor has been

cut off, rotor coasts to

standstill without braking

mains contactor has

pulled, hour counter runs,

rotor doesn't start or

coasts to standstill without

braking

no low voltage supply for

key and display board

sequence

processor reset

caused by

electromagnetic

disturbance

1) interruption of the

mains security path

mains contactor

main security path is

interrupted by one of the

safety elements:

1) F3: compressor’s over

current protection

temperature switch

switch of cooling plant

1) missing mains phase

for supply of frequency

converter or defective 35

slow blown fuse

preloading for

intermediate circuit

1) Phase L2 or fuse F2

failed

or mains switch

1) faulty connection from

main board to key board

NV-RAM out of socket or

not correctly inserted

1) reduced voltage

supply (< 10%)

ground connection

1) check F3,F4,F5 and

closing contacts of K2

inclusive all connecting

lines and replace

defective parts

2) replace contactor or

main board

1) F3: check main

phases, measure the

compressor current and

compare with adjustion

of protection switch,

check compressor

windings, replace

defective compressor

2) F4: check air

ventilation and motor

windings, replace

defective parts

3) enlarge the lateral wall

distance, clean condenser, replace defective

fan or make clogged

injection valve free

1) check mains phase or

replace defective fuse, if

it blows again check for

other faults (drive

resistance's,

intermediate circuit),

replace defective parts

2) check the switching

action of relay K1 and

replace main board in

case of malfunction

1) check phase and fuse

or circuit breaker and if

faulty, replace or switch

on again

2) check leads and

switch, replace defective

parts

1) check plug

connections on main

and key board, check

connecting leads replace faulty parts

insert the right NV-RAM

correctly

1) if the voltage supply

drops often, use a

voltage stabiliser

2) check all ground

connections and

screwings of main board

Edition: 02 Service

18.04.02 MH Page: 2-5

Cryofuge 6000i/8500i

SERVICE

Trouble Shooting

drive makes noises -

no good centrifugation

results

2) motor bearing 2) replace motor

2) defective driving

drive accelerates but

doesn't brake normally -

(noisy braking)

2) defective brake control

mechanical

electrical

faulty brake circuit 1) defective lead or brake

1) wear out of motor

rubber mounts

1) defective terminal

connection or faulty lead

or mot. winding

circuit

resistor

circuit

1) replace motor rubber

mounts (damping

elements)

1) check voltage on

motor terminal (see test

points on main board),

replace defective parts

2) replace main board

1) check connection and

leads and brake resistor

25 Ω , replace faulty

parts

2) change main board

Edition: 02 Service

18.04.02 MH Page: 2-6

Cryofuge 6000i/8500i

SERVICE

2.3 Test Points on Main Board

Test Points Unit Value Condition

1) mains terminal XT

(L2 for low voltage supply)

2) mains terminal L1 to N (or 2

phase)(intermediate circuit)

terminal XM 1 to XM 3

motor voltage measured

inter 2 motor leads voltage values must be the same

between all 3 motor leads after the

selected speed is reached

motor current

cable 1

cable 2

cable 3

max. acceleration current

intermediate circuit voltage UD

bridge rectifier V49

current of intermediate circuit

through control resistor R29

measured as voltage drop:

U = I x R

motor winding resistance

inter 1 -> 2, 2 -> 3 and 1 -> 3

plug XD

resistance of brake resistor

plug XE

imbalance switch

voltage drop inter pin 1 and 4

plug XW

voltage drop

speed detection board

inter pin 1 and 3:

inter pin 1 and 2:

terminal XC

resistance of lid solenoid

terminal XC1/XC2

nd

230 V AC

230 V AC (-/+10%)

260 V AC

255 V AC

245 V AC

8.0 A

8.0 A

8.0 A

15 A rotor 75006606 with buckets 75008078

320 V DC

355 V DC

300 V DC

280 V DC

8.5 mV DC

31 mV DC

103 mV DC

250 mV DC

-12 mV DC

0.5 Ω

25 Ω

6.5 V DC

12 V DC

0 V DC

12.0 V DC

10.7 V DC

0.3 V DC

120 Ω

8 Ω

all given values refer to 230V

rotor 75006606 with buckets 75008078

1 000 rpm

2 500 rpm

4 240 rpm, acc. time: 95s, dec. time:

180s

soft iron or moving-iron or digital

effective current measuring instrument

rotor 75006606 with buckets 75008078

set speed = 4 240 rpm

(in the speed range of 2000 to 3000

rpm)

at standstill

during braking phase

rotor 75006606 with buckets 75008078

set speed = 4 240 rpm

shortly by max. acceleration

rotor 75006606 with buckets 75008078

set speed = 1 000 rpm

set speed = 2 500 rpm

set speed = 4 240 rpm

shortly by max. acceleration

shortly during braking phase

motor temperature: 20 °C

resistor temperature: 20 °C

installation:

mechanically closed,

electrically opened

plug inserted, open switch (no

imbalance)

plug removed, or leads interrupted

(imbalance message)

switch closed (plug re-inserted, active

imbalance signal)

active circuit

UB

transistor is cut in (slot position)

transistor is cut out

speed signal: two pulses per revolution

2 x 240Ω parallel – old version

latch motor pin 3 to 4

Edition: 02 Service

18.04.02 MH Page: 2-7

Cryofuge 6000i/8500i

Test Points on Main Board

plug XA

micro switches for lid locking

terminal XB

motor over temp. switch

terminal XN

compressor thermal over current

switch

terminal XO

pressostat

plug XU

voltage drop on PT100

compressor terminal box

1) voltage

2) current

3) resistance of compressor

winding

between C + R (C + P)

between C + S (C + A)

between R + S (A + P)

SERVICE

30 V DC

230 V AC

230 V AC

230 V AC

95 mV DC

3 x 400 V AC; 3 x 230 V AC;

single phase 230V

(depending on version)

3 x 3.8 A (400 V)

3 x 7,5 A (230 V)

7,5 A (single-phase)

3 x 400 V ; 3 x 230 V; 1 x 230V

6 Ω 1,8 Ω 1,9 Ω

6 Ω 1,8 Ω 6,4 Ω

6 Ω 1,8 Ω 7,9 Ω

by open lid

contact open

contact open

contact open

20 °C temperature indication

if contactor K3 has pulled

after 2 minutes run at room

temperature at 20 °C

compressor temperature 20 °C

Edition: 02 Service

18.04.02 MH Page: 2-8

Cryofuge 6000i/8500i

SERVICE

2.4 Adjustment of Imbalance Switch

2.4.1 Meaning of Imbalance Switch

The imbalance switch has the task to switch off the centrifuge by incorrect loading of the rotor before

reaching the normal speed.

NOTE!

1) Before starting with the re-adjustment procedure check the greasing of rotor trunnions and

cleanliness of bucket groves. Opposing buckets and racks must be identical and equal in

weight.

2) Check the motor's rubber mounts and the levelling of the drive with installed rotor (use a

spirit level).

2.4.2 Adjusting Procedure

Tools and accessories:

Rotor 75006606 with buckets 75008078

check weights: 40g + 80g

Procedure

Disconnect unit from power and open the front door.

Loosen both M6 screws on bottom of mounting angle of imbalance switch to keep it movable.

Pull imbalance assembly away from the drive.

Move the assembly very slowly in direction to the drive until a clicking noise is audible.

Refix both screws and start the test run.

2.4.3 Test Run Performance

Install the rotor 75006606 with all buckets 75008078.

Load one bucket with the check weight of 80g.

Close the lid, select acceleration curve 9 and then press the start key.

The imbalance message "bal" must appear when passing 1400 rpm.

If no imbalance signal occurs, correct the adjustment by pulling the assembly a little away from

the drive.

Exchange now the 40g weight and repeat the procedure.

The rotor must reach the max. programmed speed without imbalance signal

NOTE!

Both imbalance tests (with 40 and 80 grams) must be performed with in the buckets 1, 3 and 5 that

means 6 test runs are necessary.

Edition: 02 Service

18.04.02 MH Page: 2-9

Cryofuge 6000i/8500i

SERVICE

2.5 Cleaning of Instrument Parts

ATTENTION - WARNING!

Do not clean the electrical and electronic components with moist cleaners!

For Cleaning the housing or accessories see Operating Instructions section 1 §10.

1) Electronic components

Clean dusty components carefully with a dry and soft brush.

2) Fans

Scratch off carefully with a knife or similar tool the crusted dirt from the fan blades. Resulting

grooves or marks must be removed subsequently with a fine abrasive cloth. Loose dirt is to remove

with a vacuum cleaner.

3) Condenser of the cooling unit

The vents between the heat air deflectors have to be vacuum cleaned. By persistent dirt, the unit must

be carried to an appropriate place where the condenser can be cleaned from the inside to the outside

with compressed air.

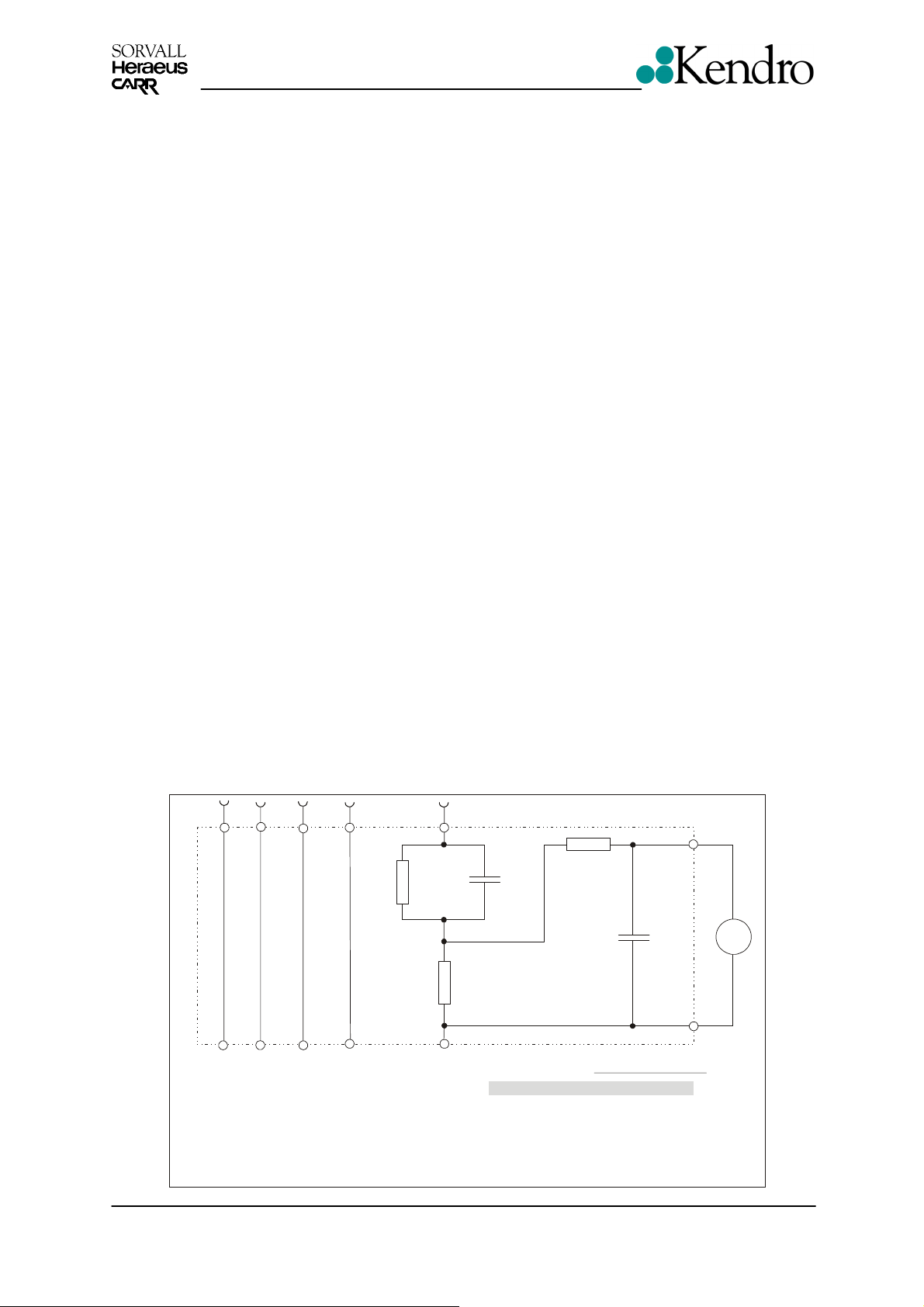

2.6 Electrical Safety Check

ATTENTION!

A final electrical safety check must be performed after each maintenance and/or repair.

Resistance check of protective conductor

The resistance between the mains plug's earthing pin and the earthing conductors of the

motor, electronic chassis and the casing must not exceed 200 mΩ.

Isolation resistance Check

Check also the isolation resistance between the poles of the mains plug and the earthing

conductor; the resistance value must be higher than 2 MΩ.

Accessible current measured to EN 61010

The accessible current must not exceed 3.5 mAmps in single fault condition (interrupted

protection earth wire)! In accordance with the EN61010, IEC1010 and UL3101 such a fault

condition can be reproduced by the following measuring circuit.

Steckergehäuse / plug-in casing

10k

Ω

5%

0,022µF

5%

1500

5%

0,22µF

Ω

5%

mV

AC

500

Ω

1%

L3 N

L2

L1

PE

Spezifaktionen für Meßgerät

- TRMS, DC - 5kHz oder mehr

- Eingangswi derstand > 1M

- Toleranz 5% oder besser

- Crest Faktor 5 oder besser

Edition: 02 Service

18.04.02 MH Page: 2-10

Körperstrom:

accessible current:

U = 1750mV I = 3,5mA

max

Ω

I [mA] = U [mV] / 500:

≡

max

Specifaction for the meter

- TRMS, DC - 5kHz or more

- Input resistance > 1M

- Tolerance 5% or better

- Crest Factor 5 or better

Ω

Cryofuge 6000i/8500i

Service

3. FUNCTIONAL DESCRIPTION

3.1 Block Functions

The Cryofuge 6000i/8500i is a microprocessor controlled and programmable floor standing

centrifuge with cooling plant and induction drive motor.

Following boards and components are located inside the unit (see also block diagram section 4

page 4-1):

Mains switch S1.

Mains input angle plate with fuses F1, F2, contactors K2, K3 and hour counter h.

Main board with central processor and ASIC80 component.

Indication board with key and display processor (SEPACONTROL programming) with key

switch for protection of all program parameters.

Serial interface board (RS 232) with plug connection for transferring the operational

parameters to a PC or Heranet system.

Driving stage for mains contactor K2

Main security path with protection for motor overtemperature F4, thermal compressor overload

F3 and overpressure of cooling plant F5.

Noise filter board.

Three phase induction drive motor with an integrated thermal overtemperature switch (cut-out

at 140°C).

Speed detection board is mounted underneath the drive motor.

Imbalance switch S6 mounted aside and in front of the drive motor (for adjustment see section

2 page 2-9).

Two lid lock assemblies each with motor locking system and integrated micro switches (S2, S3

and S4, S5).

Temperature sensor V1 (PT100).

Driving stage for compressor contactor K3 (cuts in compressor M2).

Heating element as brake resistor R1 with integrated fan M6 (mounted behind the casing's

back panel).

Three more Fans for cooling

a) of condenser, drive and compressor (M3)

b) of condenser also (M4, not used for models with water cooling)

c) of power electronics on main board (M5)

Edition: 01 Functional Description

26.12.01 MH Page: 3-1

Cryofuge 6000i/8500i

Service

3.2 Contactor Plate (Mains Input)

The following components are mounted on an angle plate, they are accessible after opening the

front door (see also wiring connection diagram in section 4 page 4-9 from right to left):

Terminal for protection earth (PE) connection of mains cable (yellow green).

Terminal for neutral line (N) of mains cable (blue, 400 V version only).

Screw fuse F2 (6 Amp slow blown) for protection of control circuit connected to mains phase

L2 (point 3 on mains contactor) via mains switch S1.

(Second 6 Amp fuse slow blown at 3 x 230 V units)

Screw fuse F1 (20 Amp slow blown) for protection of DC intermediate circuit for the drive's

power electronics connected to mains phase L1 via noise filter board.

(Second 20 Amp fuse slow blown at 3 x 230 V units)

Mains contactor K2 with 3 phased mains connection (points 1,3,5) to supply

1.) DC intermediate circuit for drive's power electronics on phase L1 (point 2)

2.) 3 pole compressor contactor K3 (terminal 2,4,6 and 1,3,5 supply via mains

contactor) to switch the compressor ON and OFF via the thermal over current fuse F3

(manual reset).

Thermal over current fuse F3 attached on compressor contactor's output to protect the

compressor indirectly for thermal overload (part of the mains security path, points 95,96).

Selected to running current of the compressor

Two double RC combinations are fixed with tape (bilateral adhesive) on both sides of the

compressor contactor to reduce the voltage spikes when switching the compressor ON and

OFF (bypassing K3 and F3 contacts).

Hour counter h is parallel connected to the main contactor's coil to determine the operational

time when the centrifuge is switch ON and the lid is closed. This is generally the possible

condition for the compressor's operation (standstill cooling).

Edition: 01 Functional Description

26.12.01 MH Page: 3-2

Cryofuge 6000i/8500i

Service

3.3 Main Board Functions

The main board is mounted beneath the operational panel behind the unit's back wall. The

components on main board are arranged in following groups (see wiring diagram).

Triac stage for coil of compressor contactor K3

Triac stage for fan M4 of cooling plant (condenser)

Triac stage for both parallel connected lid solenoids Y1 and Y2 (old mechanical latch)

Triac stage for three parallel connected fans (M3 for condenser and drive, M5 for electronics

on main board and M6 for brake resistor)

Triac stage for coil of main contactor K2 and hour counter h via main security path (F3, F4

motor overtemperature switch and F5 high pressure control switch)

Driver of new style motor latch system

Noise filter block (in interaction with the external noise filter board) for suppression of radio

interference, caused by the fast switching power electronics (<10 kHz), in accordance with the

German Regulation VDE 871, grade B

Bridge rectifier for DC intermediate circuit supplying brake control path and frequency

converter

Power pack for 3 different low voltage levels

Microcontroller (central processing unit) in interaction with ASIC80 functions for frequency

converter, speed and imbalance detection, temperature measuring and calibration

3.3.1 Power Pack

Transformer T1 with 2 different secondary coils, each connected to bridge rectifiers and voltage

regulators used for the following circuits:

1.) U1 = 5V: supplies central processor, key and indication board and temperature

measuring circuit

reference potential: connected to protective conductor (GND)

2.) U2 = 12V: supplies the circuits of speed measuring and imbalance detection

reference potential: GND2

Transformer T2 generates the low voltage supply for the power electronics:

3.) U3 = 15V: a) contacts of relay K1 (pre-loading of intermediate circuit)

- on troubles "Err. 23" will be displayed

b) and all lid switches (S2,S3,S4,S5)

- on troubles "OPEn" at standstill and "LId" during rotation will be displayed

reference potential: UD-

Edition: 01 Functional Description

26.12.01 MH Page: 3-3

Cryofuge 6000i/8500i

Service

3.3.2 Intermediate Circuit with Brake Path and Frequency Converter

The DC intermediate circuit serves as an energy store between the AC power input and the

transmitted motor performance.

The intermediate circuit consists of a bridge rectifier and 12 parallel connected reservoir capacitors

which are softly charged at the beginning over heavy-duty resistors (R61 and R100 parallel

connected). When the capacitor's loading has reached the defined value, the resistors are

bypassed by the relay K1 to supply frequency converter with maximum main power during

operation.

Brake Path

Electrical power is fed back into the intermediate circuit during motor deceleration (motor acts as

generator). This braking power is transformed into heat by brake resistor R1 (terminal XD) so that

the intermediate circuit voltage does not rise to an excessive level (see section 2 - test points on

main board).

The brake resistor R1 is switched into the intermediate circuit by a fast switching transistor. This

transistor is voltage dependent controlled by a self-acting stage (closed loop).

Frequency Converter

The motor is 3-phased provided with chopped direct voltage blocks. These blocks are variable in

frequency and pulse width modulation and are dephased to 120° between the motor windings.

Beginning with low frequency and small pulse width chopped blocks, both parameters will be

increased up to the operators set speed. By this variation the acceleration power of the drive motor

can be effected. For deceleration the frequency and pulse width parameters will be reduced. The

frequency converter is dynamically and absolutely protected against overcurrent and overvoltage

and also absolutely protected against excessive temperature.

When exceeding one of the absolute values (overcurrent, overvoltage or excessive temperature),

the message "Err.08" will be displayed.

3.3.3 Microcontroller (Central Processing Unit)

The controller block includes the central processor unit (CPU) P87C51FC and two of the data

storage (NV-RAMs) 93S66 with the software identification No's. for:

CPU: 0599 (second displayed No. in speed field)

1. NV-RAM: 7571 (third displayed No. in speed field) 7572 in CF 8500i only

2. NV-RAM: 7573 (fourth displayed No. in speed field)

The second parts of these No.'s (displayed in the time field) will be upgraded if necessary.

The ROM with control program is integrated in the CPU. The most important operating parameters

(e.g. the maximum data or the last operator settings) are stored in the non volatile (NV) -RAM.

The CPU co-operates with the ASIC 80 component via the 8 bit data bus and some control lines.

The ASIC 80 is a specially designed integrated circuit for the driving of Kendro centrifuges (with

induction motors), containing additional functions for speed and temperature measuring and

electronics protection.

Edition: 01 Functional Description

26.12.01 MH Page: 3-4

Cryofuge 6000i/8500i

Service

3.3.4 Latch Control-system

The mainboard allows a controlling of the new electrical latch system with current software (CPU

599) and controlling of the old mechanical latch with old software (CPU 498) as well.

Note! The new Software does not control the old latch system.

Electrical latch

Both latches are connected to the board via terminal XC1 and XC2.

Each latch will be driven forward and backward via a relay by a special driver IC which changes the

polarity of the voltage depending on status of the wanted operation - open or close the door.

The activating of the door latches is several times protected by addition status controls of the CPU.

The door can only be opened if the speed is “0” and the lid opening button was pushed.

Mechanical latch

These mechanical latches are connected at the terminal XC. They are controlled by a triac which is

fired via photodiac by CPU. Two tachogenator signal trigged flip-flops prevent an opening of the

door whilst rotor is spinning.

3.3.5 Temperature measurement

The temperature will be detected by a PT 100 temperature sensor.

Two reference resistors 100 ohm = 0°C and 120 ohm = 50°C will give the reference value. The

auto-calibration is done by the CPU which controls an analogue switch where the signals will be

transferred to a voltage/frequency converter. This select signals to the switch IC will come from the

ASIC TEMP_1 and TEMP_2.

3.4 Key and Indication Board

The SEPACONTROL key and indication board is mounted behind the operational panel.

A special microcontroller (P87C51FC) is located on this board controlling the 7 segment displays,

the control key LEDs and the operating keys

The communication with the central processor on the main board takes place via serial data lines in

both directions (plug XI).

The reading of the keys and the displaying of values takes place by multiplex operation. All

operational parameters and user programs are stored unlimited in 6 NV-RAMs (type 93C46).

The constant identification No. of the key board processor is 0497 (first displayed No. in speed

field). There is a second No. displayed in the time field at the same time. This version No. is subject

of the permanently technical outgrowth and will be counted up at any program changes on CPU or

parameter changes on NV-RAMs.

3.5 Speed Detection Board

The speed detection takes place opto-electronically through a slit in the motor shaft.

A light-emitting infrared diode and a photo-transistor are mounted on the speed detection board

and located on opposing sides of the motor shaft

So 2 trapezoidal pulses per motor revolution are generated and transformed into stable rectangle

pulses (Schmitt trigger circuit on board), by which the micro controller calculates the real rotor

speed or rcf value.

The speed detection board is connected to the main board via the 3-pin plug XW.

Edition: 01 Functional Description

26.12.01 MH Page: 3-5

Cryofuge 6000i/8500i

Service

3.6 Imbalance switch

If abnormal imbalance of the rotor occurs the imbalance switch will be triggered by the moving

motor. The switch closes and this signal will be given to the CPU which detects this as

“imbalance”

The connection to the switch is made of 4-pole wiring which allows a check of the cable for

defect. In this case the imbalance signal will also be displayed.

3.7 Cooling plant

The Cryofuge is equipped with a high-grade cooling plant, to meet it’s requirements of driving

power and compact design. The CFC free refrigerant R404A evaporates at low temperatures

(≤ -20°C) and absorbs through this the frictional heat from chamber produced by the spinning

rotor. Two fans serve for even air flow through condenser so that the refrigerant’s condensing

temperature is kept on a low level.

A condenser serves for essential under-cooling of the condensed refrigerant to ensure an

optimum evaporation and a perfect operation of the expansion valve. To maintain low

evaporation and resultant condensation temperatures on one hand and to support the starting

procedure of the compressor on other hand, a thermostatic expansion valve is used.

The minimum achievable sample temperatures are depending on speed, rotor type and a little

on ambient temperature. After a compensating time (at max speed – 3 hours) as optimal result,

the rotor has reached the selected set temperature within a tolerance of ± 2K.

Edition: 01 Functional Description

26.12.01 MH Page: 3-6

Cryofuge 6000i/8500i

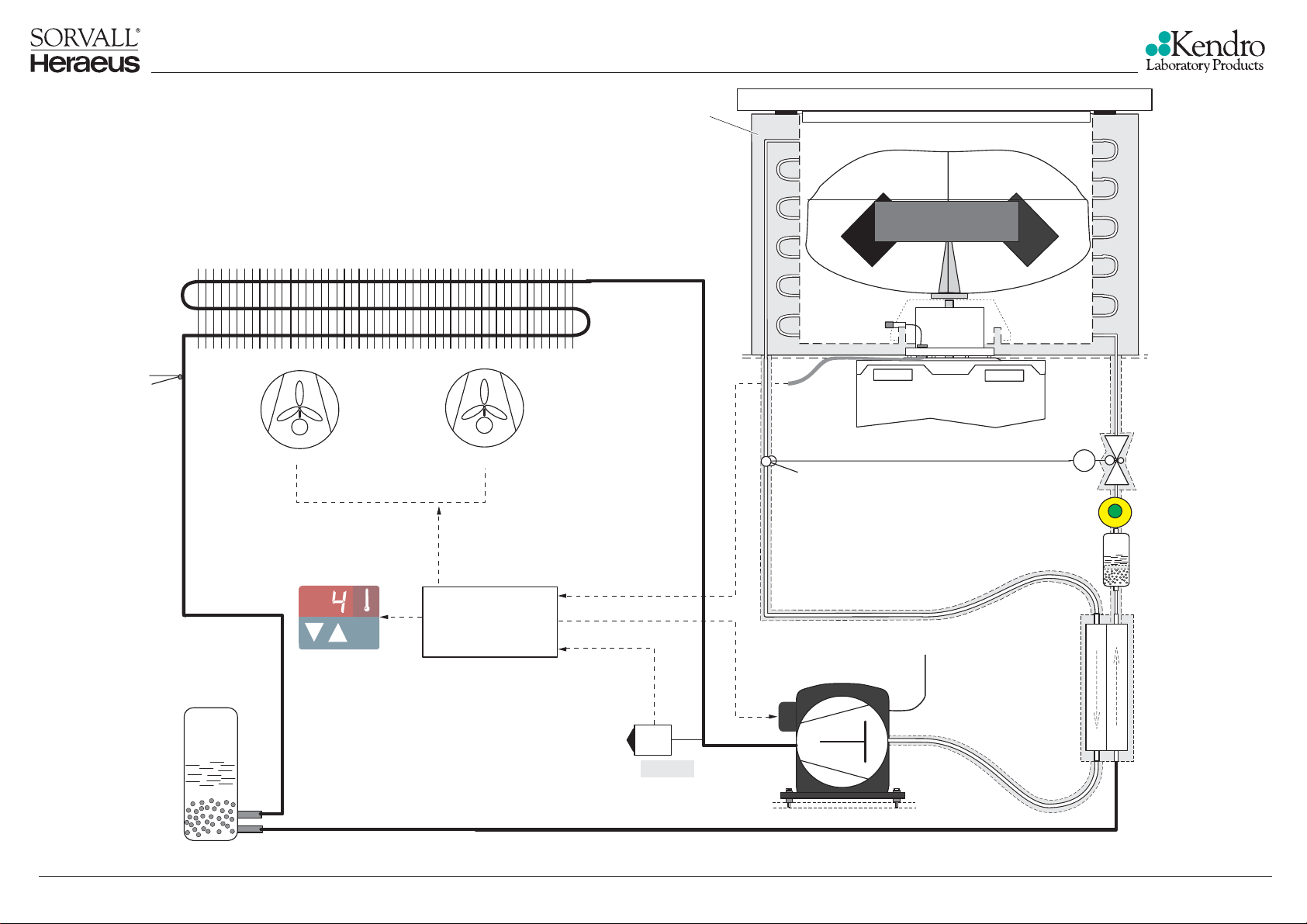

37 45°C

Verflüssiger

condenser

Kälteanlage

Cooling

Verdampferkessel

evaporator chamber

Lüfter Kühlmaschine

fans for cooling plant

2.2

J

07.05.01 MH

Sammler

accumulator

CPU

1

c.o.

>P

"E-23"

18bar

c.i.

Druck-

28bar

wächter

pressure

switch

Fließbild / Flowchart

3-7

114 - 118°C

p = 13,8 bar

-26 -

-16°C

thermostatisches Expansionsventil

R404A

Verdichter

compressor

thermostatic expansion valve

Trockner+Schauglas

Dryer+Inspectionglas

p = 1,7 bar

0

Wärmetauscher

heat exchanger

7 - 8°C

TC

-45 +30°C

CRYOFUGE 6000i/8500i

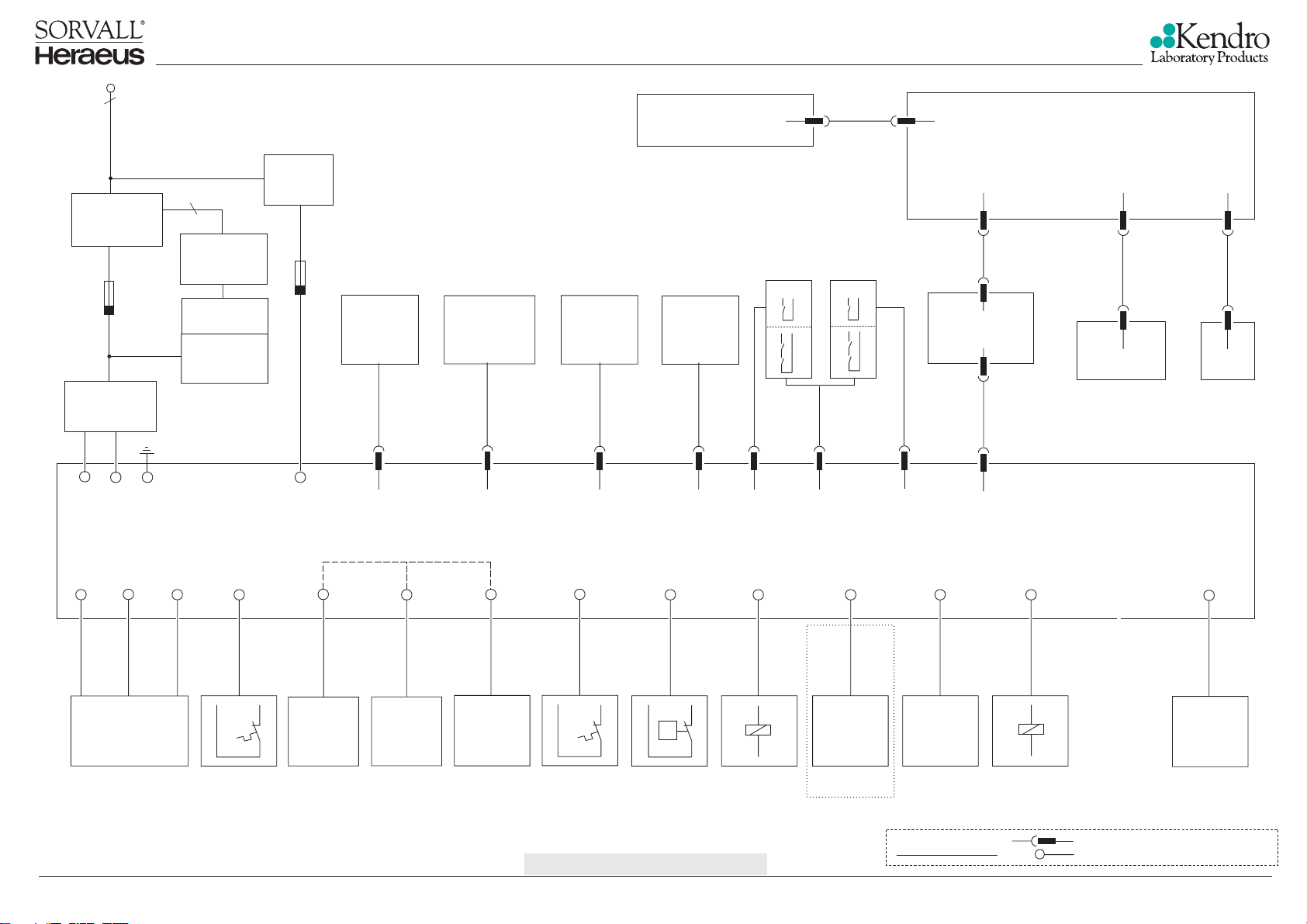

2.3

Netz

mains

noise filter board

3

Hauptschütz

main contactor

K2

F1

Funkentstör-

platte

3

KM-Schütz

compressor

contactor

Kühlmaschine

compressor

Kurbelwannen-

heizung

crankcase

filament

K3

Netzschalter

mains switch

M2

S1

F2

Unwucht-

schalter

imbalance

switch

S6

2 Impulse pro Motorumdrehung

2pulses per motor revolution

Drehzahler-

fassungsplatte

speed detection

board

SCHALTPLÄNE

SCHEMATIC DIAGRAMS

Schlüsselschalter

key switch

nicht belegt

not used

Temperatur-

sensor

temperature

sensor

V1

XJ XJ

Deckelschloss

Latch

Right

S2

S3

S4

Left

Motor M8Motor M7

S5

S6

S7

Tasten-und Anzeigenplatte

key and indication board

X2

RS-232

Schnittstelle

interface

X1

XI

operating panel

XZ

XZ

Bedienplatte

XY

XY

Option

NPE

L

XM1 XM2 XM3

Motor

23.04.01 MH

M1

XB

F4

Motorübertemperatur

motor over

temperature

XT

XH

Motor/KM

Lüfter

motor/compr.

fan

M3

XE XW XL XU XA

XC 1

Hauptplatte

main board

F3

TsÜ (KM)

thermal

fuse

XN

F5

P

Pressostat

overpressure

switch

4-1

XO XP

Deckelspulen

lid solenoids

K2

Ansteuerung

Hauptschütz

mains contactor

coil

XF

FET-Lüfer

fan for

electronics

M5

XS

Lüfter Brems-

widerstand

fan of braking

resistor

M6

Blockschaltbild / Block Diagram

Y1,Y2

Old/alte

XC

fan for cooling

(entfällt bei Wasser-

*

kühlung

not used with water

cooling

Legende / legend

XC 2

KM-Lüfter

plant

M4

XK

XI

XG

K3

Ansteuerung

Kühlmaschine

compressor

coil

3x400V+N+PE

XD

Bremswider-

stand

brake resistor

R1

Steckverbindung / plug connection

Schraubverbindung / screwing connection

CRYOFUGE 6000i/8500i

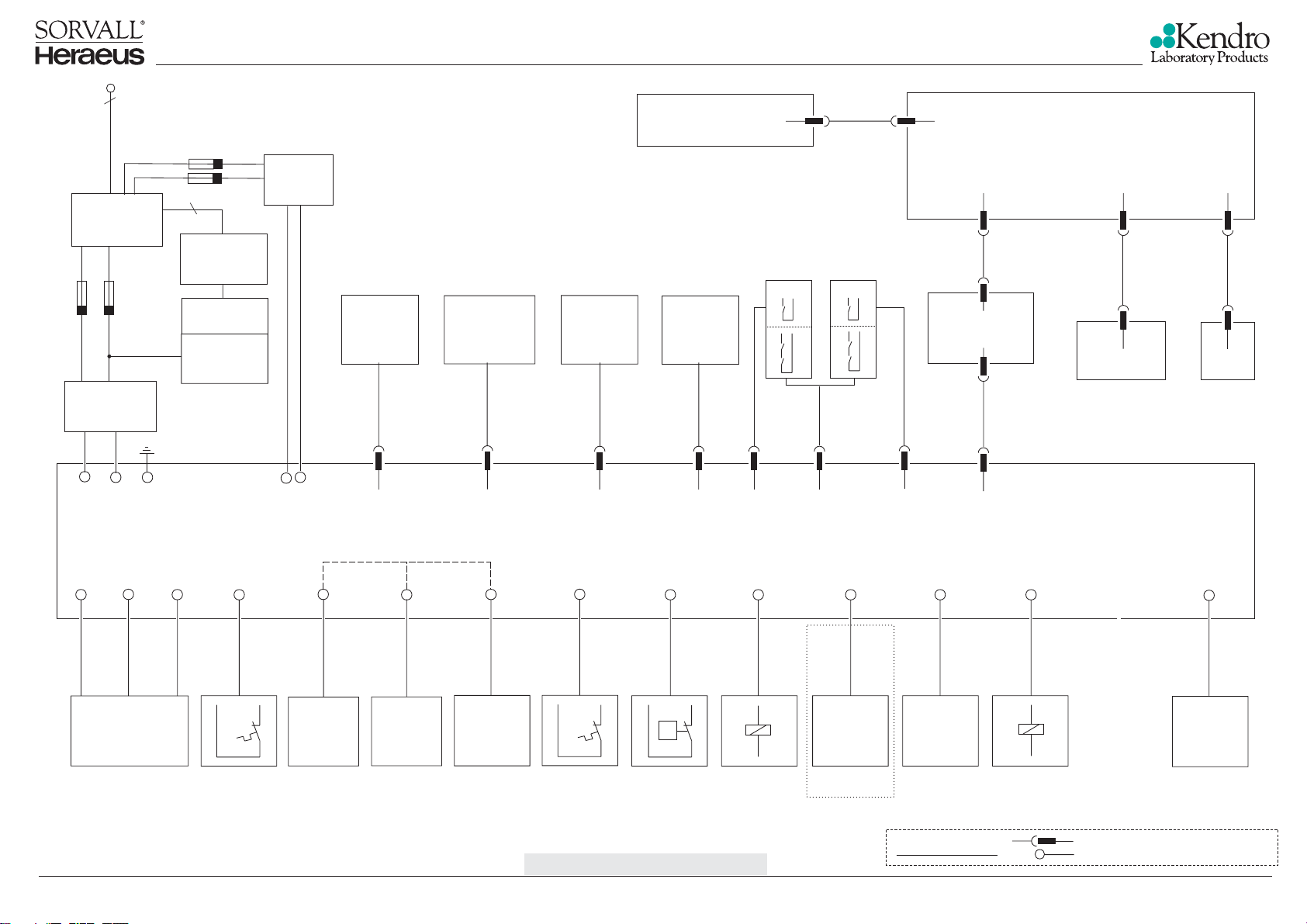

Netz

mains

F1

noise filter board

3

Hauptschütz

main contactor

K2

F2

Funkentstör-

platte

F3

F4

3

KM-Schütz

compressor

contactor

Kühlmaschine

compressor

Kurbelwannen-

heizung

crankcase

filament

K3

Netzschalter

mains switch

M2

S1

Unwucht-

schalter

imbalance

switch

S6

2 Impulse pro Motorumdrehung

2pulses per motor revolution

Drehzahler-

fassungsplatte

speed detection

board

SCHALTPLÄNE

SCHEMATIC DIAGRAMS

Schlüsselschalter

key switch

nicht belegt

not used

Temperatur-

sensor

temperature

sensor

V1

XJ XJ

Deckelschloss

Latch

Right

S2

S3

S4

Left

Motor M8Motor M7

S5

S6

S7

Tasten-und Anzeigenplatte

key and indication board

X2

RS-232

Schnittstelle

interface

X1

XI

operating panel

XZ

XZ

Bedienplatte

XY

XY

Option

NPE

L

XM1 XM2 XM3

Motor

23.04.01 MH

M1

XB

F4

Motorübertemperatur

motor over

temperature

XT

XH

Motor/KM

Lüfter

motor/compr.

fan

M3

XE XW XL XU XA

XC 1

Hauptplatte

main board

F3

TsÜ (KM)

thermal

fuse

XN

F5

P

Pressostat

overpressure

switch

4-2

XO XP

Deckelspulen

lid solenoids

K2

Ansteuerung

Hauptschütz

mains contactor

coil

XF

FET-Lüfer

fan for

electronics

M5

XS

Lüfter Brems-

widerstand

fan of braking

resistor

M6

Blockschaltbild / Block Diagram

Y1,Y2

Old/alte

XC

fan for cooling

(entfällt bei Wasser-

*

kühlung

not used with water

cooling

Legende / legend

XC 2

XK

KM-Lüfter

plant

M4

3x230V+PE

XI

XG

K3

Ansteuerung

Kühlmaschine

compressor

coil

XD

Bremswider-

stand

brake resistor

R1

Steckverbindung / plug connection

Schraubverbindung / screwing connection

CRYOFUGE 6000i/8500i