Page 1

FastMig

MF 33

Operating manual

Bruksanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Brugsanvisning

Instrukcja obsługi

Manual de utilização

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

Инструкции по эксплуатации

Bruksanvisning

RU

SV

Page 2

Page 3

OPERATING MANUAL

English

EN

© Kemppi Oy / 1515

Page 4

EN

CONTENTS

1. Preface ...........................................................................................3

1.1 General ....................................................................................................................................... 3

2. Product introduction ..................................................................... 4

2.1 Operation control and connectors .................................................................................. 4

2.2 Connection of system ........................................................................................................... 5

2.3 4-roll wire feed mechanism ................................................................................................ 6

3. Installation ..................................................................................... 7

3.1 Assembly of MIG/MAG system .......................................................................................... 7

3.2 Mounting of MIG welding gun .......................................................................................... 8

3.3 Mounting and locking of wire spool ............................................................................... 8

3.4 Automatic wire feed to gun................................................................................................ 8

3.5 Adjustment of pressure ........................................................................................................ 8

3.6 Adjustment of tightness of spool brake ........................................................................ 9

3.7 Burn back time ........................................................................................................................ 9

3.8 Ground cable ............................................................................................................................ 9

3.9 Shield gas ................................................................................................................................10

3.9.1 Installing gas bottle .......................................................................................................10

3.10 Main switch I/O .....................................................................................................................11

3.11 Operation of cooling unit, FastCool 10 ........................................................................11

3.12 Hanging....................................................................................................................................11

4. Service, operation disturbances .................................................. 11

5. Disposal of the machine .............................................................. 11

6. Ordering numbers ....................................................................... 12

7. Technical data .............................................................................. 13

2

FastMig MF 33

Page 5

1. PREFACE

1.1 General

Congratulations on choosing the FastMig MF equipment. Used correctly, Kemppi products can

signicantly increase the productivity of your welding, and provide years of

economical service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the equipment can be found at the end

of the manual.

Please read the manual carefully before using the equipment for the rst time. For your

own safety and that of your working environment, pay particular attention to the safety

instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

EN

© Kemppi Oy / 1515

3

Page 6

EN

2. PRODUCT INTRODUCTION

FastMig MF is basic wire feeder designed for demanding enviroment. It can be used with

Kemppi's basic FastMig power sources KM 300, KM 400, and KM 500.

2.1 Operation control and connectors

1.

4.

5.

2.

6.

3.

1. Operation panel

2. Connection of welding gun EURO

3. Lead-in and clamping of cooling liquid

hoses

4T

2T

5

4

3

2

1

0

MIN

6

7

8

2

9

1

10

MAX MAXMIN

3

0

4. Shielding gas connection

5. Connection for control cable

6. Welding current cable connection

1.

5

4

6

7

8

2.

3.

W001320

10

MF

MF

9

4

1. Selection of gun switch function

2. Adjustment of wire feed speed

3. Adjustment of welding voltage

FastMig MF 33

Page 7

2.2 Connection of system

EN

© Kemppi Oy / 1515

5

Page 8

EN

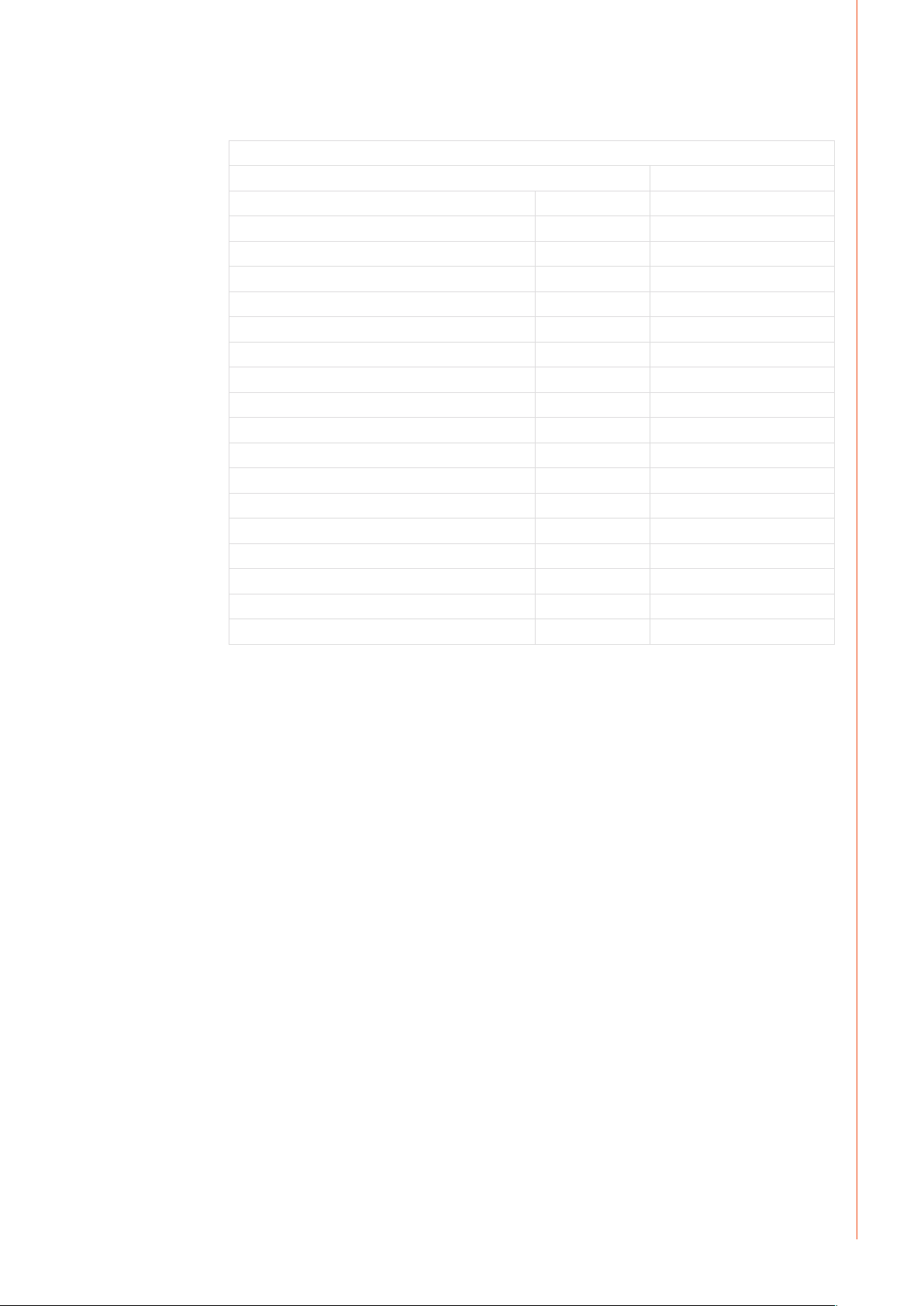

2.3 4-roll wire feed mechanism

Wire ø, mm Wire guide tube ø, mm

0,6...0,8 white

Fe,

Mc,

Fc

0,9...1,6 orange

1,6...2,4 blue

0,8...1,6 silver

Ss,

Al

1,6...2,4 yellow

1,0 mm

3134140

2,0 mm

3133700

4,0 mm

3134130

2,5 mm

3134290

3,0 mm

3134710

orange

2,0 mm

3134120

blue

4,0 mm

3134110

silver

2,5 mm

3134300

yellow

3,0 mm

3134720

plastic

2,0 mm

4267220

plastic

2,0 mm

4266970

plastic

4,0 mm

4270180

brass

4,0 mm

4267030

plastic

2,0 mm

4267220

plastic

4,0 mm

4270180

yellow

2,4 mm

4268210

for Promig 511

yellow

3,0 mm

4268560

Feed rolls, 4-rolls

Colour ø, mm

Fe, Ss, Al

Plain, V-groove

Fe, Fc, Mc

Knurled,

V-groove

Fe, Fc, Mc,

Ss, Al

Trapetsoid

groove

(L) = Fitted with ball bearings

white 0,6/0,8 3133810

white 0,8/0,8 (L) 3143180

red 1,0/1,2 3133210

red 1,0/1,0 (L) 3138650

orange 1,2/1,2(L) 3137390

yellow 1,4-1,6/2,0 3133820 Feed roll groove selection

yellow 1,6/1,6 (L) 3141120

black 2,4 3133880

blue 3,2 3133910

red 1,0/1,2 3133940

orange 1,2/1,2 (L) 3137380

yellow 1,4-1,6/2,0 3133990

yellow 1,6/1,6 (L) 3141130

black 2,4 3134030

blue 3,2 3134060 Transfer of gear wheel selector plate

orange 1,2/1,2 (L) 3142210

brown 1,4/1,4 (L) 3142220 ø 28 mm (0–18 m/min) 4265240 plastic

yellow 1,6/1,6 (L) 3142200 ø 28 mm (0–18 m/min) 4287860 steel

grey 2,0/2,0 (L) 3142230 ø 40 mm (0–25 m/min) 4265250 plastic

black 2,4 (L) 3142240 ø 40 mm (0–25 m/min) 4297270 steel

Gear wheel

6

FastMig MF 33

Page 9

NOTE! Mount the lower feed roll, ensuring that the pin on the shaft ts in the cut on the feed roll.

3. INSTALLATION

3.1 Assembly of MIG/MAG system

Assemble the units in order mentioned below and follow mounting and operation

instructions which are delivered in packages.

Installation of power source

Read paragraph: ”Installation” in operation instructions for FastMig power sources and carry

out the installation according to that.

Mounting of KM power sources to transport wagon

Read and follow the instructions given in the transport cart installation/assembly manual

EN

Mounting the FastMig MF on to the power source

Screw the fastening pivot on the power source. Lift the wire feeder on fastening pivot.

Connecting cables

Connect the cables in accordance with the equipment notes provided.

The polarity of the welding wire (+ or -) can be changed by replacing the MF welding current

cable and return current cable with the FastMig power source welding cable connector.

Mounting of FastMig wire feed units to boom

NOTE! Wire feed unit must be mounted to boom in such a way that its chassis is galvanic separated

both from swing arm and boom.

Suspension angle of wire feed unit can be changed by moving xing point in handle.

© Kemppi Oy / 1515

7

Page 10

EN

3.2 Mounting of MIG welding gun

In order to ensure trouble-free welding check in operation instructions of gun used by you

that wire guide tube and contact tip of gun are according to manufacturer’s recommendation

suitable to be used for wire feed diameter and type in question. To tight a wire guide tube

might cause for wire feed unit a bigger stress than normally as well as disturbances in wire

feed.

Screw snap connector of gun tight that there won’t come any voltage losses on connecting

surface. A loose connection will heat gun and wire feed unit and feeder.

3.3 Mounting and locking of wire spool

LOCKED OPEN

• Release locking nails of wire spool hub by turning locking knob a quarter round.

• Mount the spool at its place. Note rotating direction of spool!

• Lock the spool with locking knob, locking nails of hub remain to outside position and

will lock the spool.

NOTE! Check that in ller wire spool there are no parts sticking out, which could e.g. chafe against

chassis or door of wire feed unit. Dragging parts might expose chassis of wire feed unit under

voltage.

3.4 Automatic wire feed to gun

Automatic wire feed makes change of wire spool more rapid. In spool change the pressure of

feed rolls need not to be released and ller wire goes automatically to correct wire line.

• Make sure that groove of feed roll matches the diameter of welding wire used.

• Release the wire end from spool and cut o the bent length. Be careful that the wire

does not spill from the spool to sides!

• Straighten about 20 cm of the wire and see that the end of it has no sharp edges (le

o if necessary). A sharp edge may damage the wire guide tube and contact tip of the

welding gun.

FastMig MF wire feed units:

• Draw a bit of loose wire from wire spool. Feed wire through back liner to feed rolls. Do

not release pressure of feed rolls!

• Press the gun switch and feed a bit wire until wire goes through feed rolls to gun. See

that wire is in grooves of both feed roll pairs!

• Press still the gun switch until wire has come through contact tip.

Automatic feed may sometimes fail with thin wires (Fe, Fc, Ss: 0,6 – 0,8 mm, Al: 0,8 – 1,0 mm).

In that case you might have to open feed rolls and feed wire manually through feed rolls.

3.5 Adjustment of pressure

Adjust the pressure of feed rolls with the control screw so that the wire is fed into the wire

guide tube evenly and allows a little braking when coming out from the contact tip without

slipping at the feed rolls.

NOTE! Excessive pressure causes attening of the ller wire and damage to the coating. It also

causes undue wear of the feed rolls as well as friction.

8

FastMig MF 33

Page 11

3.6 Adjustment of tightness of spool brake

A

Brake force is adjusted through hole in locking device of spool hub by screwing the control

screw (A) with screwdriver.

Adjust brake force as so big that the wire is not allowed to become too loose on the spool so

that it would spill from the spool when the rotation of the spool stops. Need for brake force is

increased with increase of wire feed speed.

Since the brake loads for its part the motor, you shouldn’t keep it unnecessarily tight.

3.7 Burn back time

Electronics of feed unit controls stopping of welding automatically so that the wire end

doesn’t melt fastened to the contact tip or the work piece. Automatics work regardless of the

wire feed speed. Can be adjusted also from power source SETUP-menu ('PoC').

3.8 Ground cable

Connecting of earth cable should be preferably connected directly to the welding material.

Contact surface of press always should be as large as possible.

Clean the fastening surface from paint and rust!

Use in your MIG equipment at least 70 mm². Thinner cross-sectional areas might cause

overheating of connectors and insulations.

Make sure that the welding gun in your use is designed for max. welding current needed by

you!

NOTE! Never use a damaged welding gun!

EN

© Kemppi Oy / 1515

9

Page 12

3.9 Shield gas

NOTE! Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve is damaged!

For welding stainless steels, mixed gases are normally used. Check that the gas bottle valve

is suitable for the gas. The ow rate is set according to the welding power used in the job. A

suitable ow rate is normally 8 – 10 l/min. If the gas ow is not suitable, the welded joint will

be sporous. Contact your local Kemppi-dealer for choosing gas and equipment.

3.9.1 Installing gas bottle

NOTE! Always fasten gas bottle properly in vertical position in a special holder on the wall or on a

carriage. Remember to close gas bottle valve after having nished welding.

EN

A

Parts of gas ow regulator

A. Gas bottle valve

B. Press regulation screw

C. Connecting nut

D. Hose spindle

E. Jacket nut

F. Gas hose pressure meter

The following installing instructions are valid for most of the gas ow regulator types:

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities from

the bottle valve.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close needle valve, if there is one in the regulator.

4. Install the regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect the hose with the regulator and the other end with the wire feed unit. Tighten

the jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows the bottle pressure.

NOTE! Do not use the whole contents of the bottle. The bottle should be lled when the bottle

pressure is 2 bar.

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow (or

pressure). When regulating ow amount, the power source should be in switched on and

the gun switch pressed simultaneously.

NOTE! Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew the pressure regulation screw.

F

C

G

B

E

D

10

FastMig MF 33

Page 13

3.10 Main switch I/O

When you turn the main switch of the FastMig™ power source into I-position, the pilot lamp

closest to this switch will light up, indicating the power source is ready for welding.

NOTE! Always start and switch o the machine with the main switch, never use the mains plug as a

switch.

3.11 Operation of cooling unit, FastCool 10

Operation of cooling unit is controlled in such a way that pump is started when welding is

started. After welding stop pump is rotating for approx. 5 min cooling the gun and the cooling

liquid to ambient temperature.

Read in operation instructions for the FastCool 10 unit the trouble situations of the liquid

circulation system and protection against torch etc. damage.

3.12 Hanging

MF 33 can be hanged from the handle to the barrier.

4. SERVICE, OPERATION DISTURBANCES

The amount of use and the working environment should be taken into consideration when

planning the frequency of maintenance of MF. Careful use and preventive maintenance will

help to ensure trouble-free operation.

The following maintenance operations should be carried out at least every six months:

Check:

• The wear of the grooves of the feed rolls. Excessive wear of grooves causes problems in

wire feed.

• The wear of the wire guide tubes of wire feed. Badly worn feed rolls and wire guide tubes

should be discarded.

• The wire guide tube in the gun should be set as near the feed rolls as possible, but not

touching them and the wire must follow a straight line from the end of the tube to the

groove of the feed roll.

• Spool brake adjustment.

• Electric connections

– Oxidised couplings must be cleaned

– Loose couplings must be tightened

Clean dust and dirt from the equipment.

Lubricate the feed rolls twice a year.

NOTE! When using compressed air, always protect your eyes with proper eye protection.

In case of problems contact your KEMPPI dealer.

EN

5. DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

© Kemppi Oy / 1515

11

Page 14

EN

6. ORDERING NUMBERS

MF 33 6063300

KM 300 3-ph 400V 6033000

KM 400 3-ph 400V 6034000

KM 500 3-ph 400V 6035000

Cooling unit FastCool 10 6068100

Transport unit PM 500 6185291

Accessories

KWF 300 protection slides 6185287

MIG-guns

MMT 25 3 m 6252513MMT

MMT 25 4,5 m 6252514MMT

MMT 27 3 m 6252713MMT

MMT 27 4,5 m 6252714MMT

MMT 32 3 m 6253213MMT

MMT32 4,5 m 6253214MMT

MMT 35 3 m 6253513MMT

MMT 35 4,5 m 6253514MMT

MMT 42 3 m 6254213MMT

MMT 42 4,5 m 6254214MMT

MMT 30W 3 m 6253043MMT

MMT 30W 4,5 m 6253044MMT

MMT 42W 3 m 6254203MMT

MMT 42W 4,5 m 6254204MMT

MMT 52W 3 m 6255203MMT

MMT 52W 4,5 m 6255204MMT

Interconnecting cables

KM 70-1.8-WH 6260411

KM 70-15-WH 6260412

KM 70-1.8-GH 6260413

KM 70-15-GH 6260414

12

FastMig MF 33

Page 15

7. TECHNICAL DATA

MF 33

Operating voltage (safety voltage)

Connection capacity

Output 40 °C

Wire feed mechanism

Diameter of feed roll

Wire feed speed ¹)

Filler wires

Wire spool

Gun connection

Operation temperature range

Storage temperature range

EMC class

Degree of protection

External dimensions

Weight

24 V DC

100 W

60 % ED 520 A

100 % ED 440 A

4-roll feed

32 mm

0 – 25 m/min

ø Fe, Ss 0.6 – 1.6

ø Cored wire 0.8 – 2.0

ø Al 1.0 – 2.4

max. weight 20 kg

max. ø ø 300 mm

Euro

-20 ... +40 °C

-40 ... +60 °C

A

IP23S

LxWxH 590x240x445 mm

13.6 kg

EN

¹) Changes of speed are carried out by changing gear wheel (D 28/D 40).

© Kemppi Oy / 1515

13

Page 16

KEMPPI OY

Kempinkatu 1

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) LTD

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GMBH

Perchstetten 10

D-35428 LANGGÖNS

DEUTSCHLAND

Tel +49 6 403 7792 0

Telefax +49 6 403 779 79 74

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY LTD

Unit 105, 1/F, Building #1,

No. 26 Xihuan South Rd.,

Beijing Economic-Technological Development

Area (BDA),

100176 BEIJING

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区

西环南路26号

1号楼1层105室(100176)

电话:+86-10-6787 6064/1282

传真:+86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

Kazura Garden,

Neelankarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

KEMPPI WELDING SOLUTIONS SDN BHD

No 12A, Jalan TP5A,

Taman Perindustrian UEP,

47600 Subang Jaya,

SELANGOR, MALAYSIA

Tel +60 3 80207035

Telefax +60 3 80207835

sales.malaysia@kemppi.com

1906340

1515

www.kemppi.com

Loading...

Loading...