Page 1

Master S

400, 500

Operating manual

Bruksanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Brugsanvisning

Instrukcja obsługi

Manual de utilização

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

Инструкции по эксплуатации

Bruksanvisning

操作手册

RU

SV

ZH

Page 2

Page 3

OPERATING MANUAL

English

Page 4

EN

CONTENTS

1. Introduction ......................................................................................................................... 3

1.1 General ....................................................................................................................................... 3

1.2 Product introduction ............................................................................................................ 3

1.3 Machine introduction ........................................................................................................... 4

2. Installation ............................................................................................................................. 5

2.1 Before use .................................................................................................................................. 5

2.2 Positioning of the machine ................................................................................................ 5

2.3 Distribution network ............................................................................................................. 5

2.4 Welding and earth return cable connections .............................................................. 6

2.4.1 Choosing welding polarity in MMA welding ................................................................. 6

2.4.2 Choosing welding polarity in TIG welding ..................................................................... 6

2.4.3 Earthing ............................................................................................................................ 6

3. Operation ............................................................................................................................... 6

3.1 Welding processes .................................................................................................................6

3.1.1 MMA welding ................................................................................................................... 6

3.1.2 TIG welding ...................................................................................................................... 6

3.2 Operation functions .............................................................................................................. 7

3.2.1 Power source .................................................................................................................... 7

3.2.2 Control panel and SETUP functions ............................................................................... 7

3.2.3 Activation and setup parameter adjustment ................................................................ 8

3.3 MMA welding ........................................................................................................................... 9

3.3.1 Filler materials and equipment ....................................................................................... 9

3.3.2 Earth return cable and clamp ......................................................................................... 9

3.3.3 Manual metal arc welding (MMA) .................................................................................. 9

3.3.4 Electrode welding parameter table ..............................................................................10

3.3.5 Arc force .........................................................................................................................10

3.3.6 Hot start ..........................................................................................................................10

3.4 TIG welding .............................................................................................................................11

3.5 Carbon arc gouging .............................................................................................................12

3.6 Wireless remote .....................................................................................................................12

2

4. Maintenance ......................................................................................................................13

4.1 Regular maintenance ..........................................................................................................13

4.1.1 Every six months ............................................................................................................13

4.2 Service contract ....................................................................................................................13

4.3 Storage .....................................................................................................................................13

4.4 Disposal of the machine ....................................................................................................13

5. Troubleshooting ..............................................................................................................14

5.1 Troubleshooting ...................................................................................................................14

5.2 Control panel error codes .................................................................................................15

6. Ordering codes.................................................................................................................16

7. Technical data ...................................................................................................................16

Master S 400, 500

Page 5

1. INTRODUCTION

1.1 General

Congratulations on choosing the Master S series power source. Used correctly, Kemppi

products can signicantly increase the productivity of your welding, and provide years of

economical service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the device can be found at the end of the

manual.

Please read the operating manual and the safety instructions booklet carefully before using

the equipment for the rst time. For your own safety and that of your working environment,

pay particular attention to the safety instructions.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

EN

1.2 Product introduction

Master S model welding machines are designed for industrial use and for welding all kinds of

covered electrodes. Master S is also suitable for carbon arc gouging.

In addition to the basic functions Master S 400 and 500 models include advanced functions

like HotStart, ArcForce, TIG mode and remote control, which are all set through the panel.

Both models come equipped with a voltage reduction device (VRD) that is designed to

maintain the open-circuit voltage (OCV) below 35 volts.

Master S 400 and 500 models can also operate in constant voltage (CV) mode as a parent

power supply for Kemppi voltage sensing wire feed systems and in-line TIG solutions – such as

ArcFeed and MasterTig LT 250.

Master S 400 Cel and 500 Cel models are available for cellulose welding.

© Kemppi Oy / 1418

3

Page 6

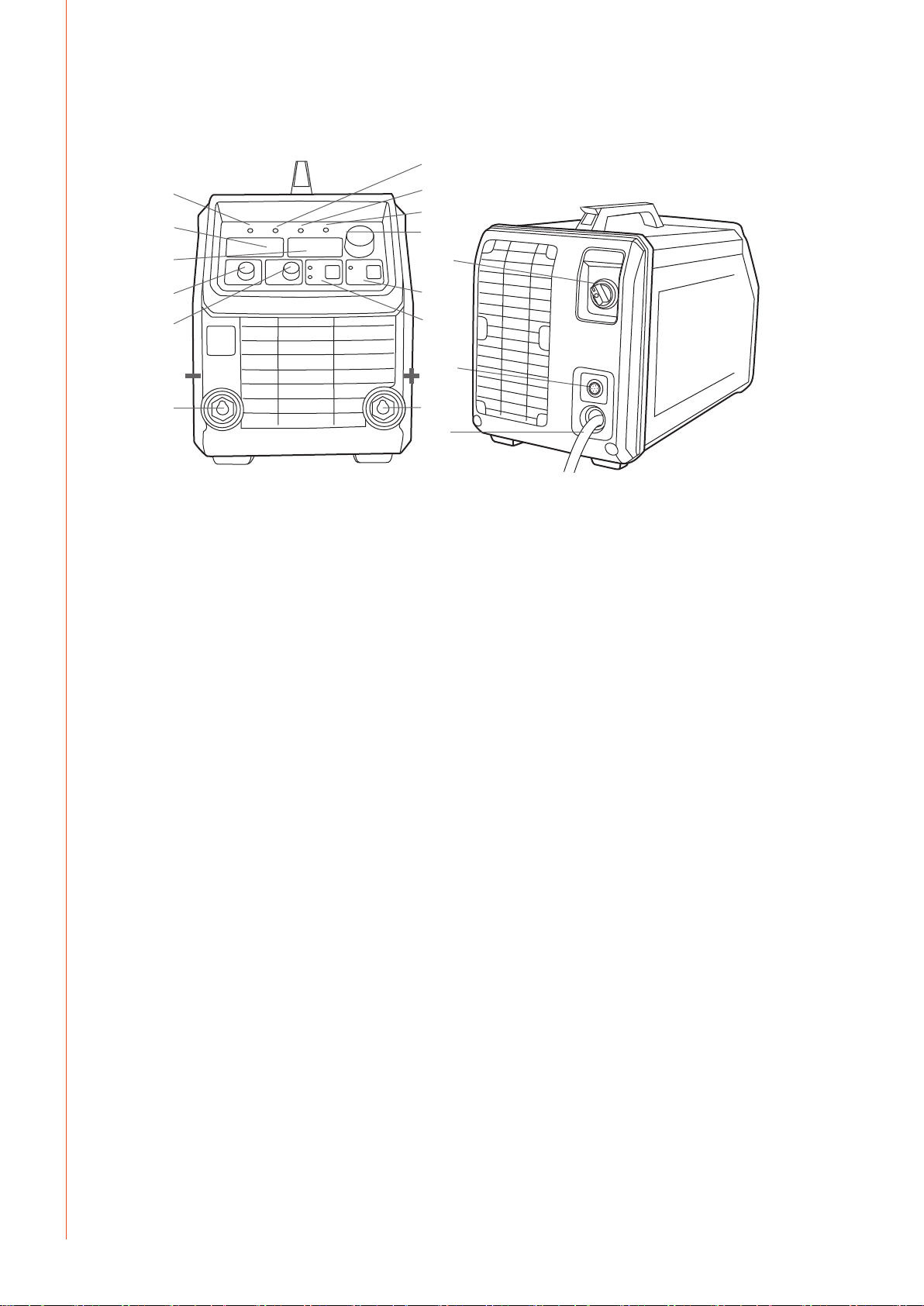

1.3 Machine introduction

Master S 400 and 500

1.

5.

6.

7. 9.

2.

3.

4.

11.

14.

EN

8.

12.

1. Power on pilot lamp

2. Overheating pilot lamp

3. CV mode pilot lamp

4. VRD ON pilot lamp

5. Amperage meter display

6. Voltage meter display

7. ArcForce

8. HotStart

9. Remote Control

10. Welding Mode

11. Welding current adjustment knob

12. Negative (-) pole connection socket

13. Positive (+) pole connection socket

14. Main switch (ON/OFF)

15. Mains power cable

16. Remote control connector

10.

16.

13.

15.

4

Display cover comes standard with Master S 400 and 500. It protects the panel form sparks,

dust and scratches.

Master S 400, 500

Page 7

2. INSTALLATION

2.1 Before use

The product is packed in cartons designed specically for them. However, always make sure

before use that the products have not been damaged during transportation.

Check also that you have received the components you ordered and the instruction manuals

needed. Product packaging material is recyclable.

NOTE! When moving the welding machine, always lift it from the handle, never pull it from the

welding or other cables.

Operating environment

This machine is suitable for both indoor and outdoor use. Always make sure that the air ow in

the machine is unrestricted. The recommended operating temperature range is –20…+50 °C.

Please read also the Safety Instructions concerning the operating environment.

2.2 Positioning of the machine

Place the machine on a sturdy, level surface that is dry and does not allow dust or other

impurities to enter the machines cooling air ow. Preferably site the machine to a suitable

carriage unit so it is above oor level.

Notes for positioning the machine

• The surface inclination may not exceed 15 degrees.

EN

< 15°

• Ensure the free circulation of the cooling air. There must be at least 20 cm of free space in

front of and behind the machine for cooling air circulation.

• Protect the machine against heavy rain and direct sunshine.

The machine is not allowed to be operated in the rain as the protection class of the machine,

IP23S, allows preserving and storing outside only.

NOTE! Never aim the spray of sparks from a grinding machine toward the equipment.

2.3 Distribution network

All regular electrical devices without special circuits generate harmonic currents into

distribution network. High rates of harmonic current may cause losses and disturbance to

some equipment.

This equipment complies with IEC 61000-3-12 provided that the short-circuit power Ssc is

greater than or equal to 4.0 MVA at the interface point between the user’s supply and the

public suply network. It is the responsibility of the installer or user of the equipment to ensure,

by consultation with the distribution network operator if necessary, that the equipment is

connected only to a supply with a short-circuit power Ssc greater than or equal to 4.0 MVA.

© Kemppi Oy / 1418

5

Page 8

2.4 Welding and earth return cable connections

2.4.1 Choosing welding polarity in MMA welding

You can change the welding polarity by choosing (+) or (–) cable connector. Typically, in MMA

welding, the welding cable is connected to the positive (+) pole connection socket and the

earth return cable to the negative (-) pole connection socket.

2.4.2 Choosing welding polarity in TIG welding

In TIG welding the welding cable must be connected to the negative (-) pole connection

socket and the earth return cable to the positive (+) pole connection socket.

2.4.3 Earthing

If possible, always fasten the clamp of the earth return cable directly onto work piece.

1. Clean contact surface of the clamp from paint and rust.

2. Fasten the clamp properly, so that contact surface is as large as possible.

3. Check that the clamp is fastened rmly.

EN

3. OPERATION

NOTE! Welding in places presenting an immediate re or explosion hazard is forbidden! Welding fumes

may cause injury, take care of sucient ventilation during welding!

3.1 Welding processes

3.1.1 MMA welding

MMA welding, as well as carbon arc gouging, is possible with Master S power sources.

Separate models including cellulose welding characteristic are also available. See 'Ordering

codes'.

3.1.2 TIG welding

For TIG welding a separate TIG-torch with gas valve is required. See 'Ordering codes'.

6

Master S 400, 500

Page 9

3.2 Operation functions

3.2.1 Power source

NOTE! Always switch the machine on and o from main switch. Do not use the mains plug for

switching!

NOTE! Never watch the arc without a proper face shield designed for arc welding! Protect yourself

and the surroundings against welding arc and hot spatters!

3.2.2 Control panel and SETUP functions

WeldData

After welding has nished, the display shows the measured average current of the last weld.

This weld data is only displayed if the welding cycle lasts for 5 seconds or more.

Advanced control panel

1.

7.

8.

1. The green ON light indicates that the power source is turned on.

2. Overheating indicator. Light indicates that the machine is overheated.

3. CV mode indicator. Light indicates that machine is in CV mode. Mode can be changed

from Setup.

4. VRD indicator. Light indicates that VRD is set on.

• Solid green light: VRD is used, OCV is under 35 V.

• Flashing red light: VRD is used, OCV is over 35 V.

5. Voltage meter display. Shows voltage.

6. Welding current adjustment knob. Turn the knob to set the welding current value.

7. Amperage meter display. Shows used current value during welding and the set current

value when not welding.

8. ArcForce. The smaller the value, the softer the arc. When using a bigger value, the harder

the arc gets. Adjustment range is -9...9. The value is shown on the right display when the

control knob is turned. Factory setting is 0 (control knob set pointing up).

9. HotStart. Adjust to value 0 = no HotStart, adjust to 10 = HotStartMax. The value is shown

on the right display when the control knob is turned. Factory setting is 5 (control knob

set pointing up).

10. Welding Mode. Press to select TIG or MMA mode. Light indicates the selection.

11. Remote Control. Press to select remote or panel control. Light indicates remote control.

• Long press (> 3 s) activates setup function.

2. 3.

9.

10.

5.

4.

11.

6.

EN

© Kemppi Oy / 1418

7

Page 10

EN

3.2.3 Activation and setup parameter adjustment

1. Press remote selection button (11) for at least 3 seconds, until the text ”Set” appears on

the screen.

2. Choose the needed parameter with the welding current adjustment knob (6).

3. To select the required parameter, press the remote selection button (11). You can move

from adjustment mode to selection mode with a new press of the button (11).

4. Use the Welding current adjustment knob (6) to adjust the parameter value.

5. You can exit Setup mode with a long press of remote selection button (11). Setup

parameters are saved when you exit Setup.

Setup menu structure

Advanced control panel

Name Function Description Factory

Ant. Antifreeze If Antifreeze selection is On, the

machine cuts o the power and protects

the electrode if sticking occurs during

the welding

Cab. Long cables Long cable mode for welding circuits of

50 m and longer (max. 80 m)

Gen. Generator Generator mode for generator use and

uctuating mains networks

CU CV mode CV mode selection OFF On/OFF

rc Remote selection Remote operation mode. Selection

between analog and wireless remote

controllers (R10/R11T)

rcL Remote low current

limit

rcH Remote high current

limit

Urd VRD selection Reduces open circuit voltage below 35V OFF

Fac. Restore factory

settings

Limits the remote adjustment range.

Allows more exact remote adjustment.

Limits the remote adjustment range.

Allows more exact remote adjustment.

Restores setup and panel settings to

factory default

Adjustment range

default

On On/OFF

OFF On/OFF

OFF On/OFF

r10 r10/r11

30 30–MAX

MAX 30–MAX

On/OFF

(device specic)

OFF rES/OFF

8

Constant Voltage (CV)

In CV mode the welding machine maintains a relatively stable, consistent voltage regardless

of the amperage. This mode is recommended to be used with carbon arc gouging and in MIG/

MAG welding with Kemppi voltage sensing wire feed systems. CV mode is activated through

the setup menu.

Voltage Reduction Device (VRD)

Master S 400 and 500 contain a voltage reduction device (VRD), which reduces the opencircuit voltage below 35 V. This reduces the risk of electric shock in particularly dangerous

environments, such as closed or damp spaces. VRD is activated through the setup menu.

Master S 400, 500

Page 11

3.3 MMA welding

In manual metal arc welding (MMA), the ller material is melted from the electrode to the

weld pool. The rate of welding current is selected on the basis of the electrode size and

welding position. The arc forms between the electrode tip and work piece. The melting

electrode coating forms a gas and slag shield, which protects the molten metal in transfer

to the weld pool and during solidication. As the slag solidies over the hot weld metal, it

prevents weld metal from oxidation. This slag coating is removed after welding e.g. with a

chipping hammer. When removing the slag coating, ensure you protect your eyes and face

with suitable equipment.

For more info, visit www.kemppi.com > Welding ABC.

3.3.1 Filler materials and equipment

Master S series can be used with most of the common electrode types for DC welding. For

welding with cellulosic electrodes, the optional kit should be tted. Electrode sizes for the unit

are listed in Technical data section later in this manual. Follow the welding specications given

on the electrode package.

1. Check that the welding cable and earth return cable connections are hand tight.

If a cable connection is loose, it will result in a decrease of welding performance,

overheating of the connection, and it may aect your product warranty cover.

2. Select and mount the correct electrode type rmly in holder.

3.3.2 Earth return cable and clamp

If possible, always x the earth return cable and clamp directly to the welding work piece.

1. Clean the connection surface of the clamp from paint, dirt and rust.

2. Connect the clamp carefully so that contact surface is as large as possible.

3. Finally check that the clamp remains fastened.

EN

3.3.3 Manual metal arc welding (MMA)

Select your required welding parameters according to the manufacturer’s ller material

recommendations and the joint to be welded.

1. Select the required polarity (+ or –) of welding current cable (normally + ) and

earth return cable (normally –) according to the ller material manufacturers

recommendations.

2. Select MMA welding mode by pressing the process selection button on the control

panel.

3. Select a suitable welding current by adjusting the current adjustment knob.

4. Make a small test weld to check the selections made.

© Kemppi Oy / 1418

9

Page 12

EN

Site your equipment in a suitable location, ensuring there is adequate cable length to

complete the weld pass. Before you start welding, ensure you are comfortably positioned in

front of the work piece, and that you are well balanced with your weight equally distributed.

Ensure that the power source current setting is correct for the electrode size selected. Draw

the welding face shield over your eyes. (Electronic welding face shields like Kemppi Beta

90X allow you to see the welding start point more accurately and better concentrate on the

welding process. This reduces the possibility of arc ash.)

NOTE! Ensure that others in the welding area are aware that you're going to weld.

To establish the arc, scratch the electrode on the surface of the work piece.

As the arc starts, move the welding electrode at a pulling angle. The boundary of the slag

formed is visible after the molten weld. It must be behind the molten weld. The distance of

the slag boundary from the molten weld can be adjusted with the welding current and the

angle of the electrode. Throughout the welding, concentrate on the length of the arc and

keep it as short as possible. The length of the arc increases easily as the electrode decreases in

length during the welding. End welding by moving the welding electrode slightly back to the

completed weld and then lifting the electrode straight away from the work piece.

Your completed weld bead should be straight and of even width and bead height, consistent

in its appearance. Travel too slowly during welding and the weld pool will get too big and may

burn through the weld piece, too fast and the resulting weld will be too small and may have

slag entrapments and/or poor strength. After welding, the solidied slag on the weld surface

should easily remove with a chipping hammer. Ensure you wear eye and face protection when

removing the slag from the weld surface.

3.3.4 Electrode welding parameter table

Electrode diameter (mm) Rutile E6013 (A) Basic E7018 (A)

1.6 30–60 30–55

2.0 50–70 50–80

2.5 60–100 80–110

3.25 80–150 90–140

4.0 100–200 125–210

5.0 150–290 200–260

6.0 200–385 220–340

7.0 280–410

3.3.5 Arc force

Adjusting arc force by turning the ArcForce knob will aect the roughness of the arc. Factory

setting for all electrode types is zero. If the value is set to -9...-1 the arc is softened and the

amount of spatter decreases when welding at the upper end of the recommended current

range of the electrode. If the value is set to 1...9 the arc gets rougher.

The value is shown on the right display during the adjustment.

3.3.6 Hot start

HotStart increases the current for the arc ignition momentarily. With very thin work pieces hot

start is generally not needed (depends on the electrode type).

The hot start value is selected between 0 and 10. Zero shuts HotStart o (no HotStart) and 10

sets it to HotStartMax. Factory setting is 5.

The value is shown on the right display during the adjustment.

10

Master S 400, 500

Page 13

3.4 TIG welding

NOTE! In TIG welding the welding cable must be connected to the negative (-) pole connection

socket and the earth return cable to the positive (+) pole connection socket.

Select your required welding parameters according to the manufacturer’s ller material

recommendations and the joint to be welded.

1. Select the required polarity of welding current cable (-) and earth return cable (+) for TIG

welding.

2. Select TIG welding mode by pressing the process selection button on the control panel.

3. Select a suitable welding current by adjusting the current adjustment knob.

4. Make a small test weld to check the selections made.

Shielding gas is used in DC TIG welding. Your dealer will give you advice on choosing gas and

equipment.

You can start welding after having made the necessary selections. Open the gas valve on the

TTM 15 V BC. When gas starts to ow, arc is lit by lightly scratching work piece with the tip of

the tungsten electrode, or with the touch and lift method (see 'Ignition by Lift TIG'). When arc

is lit, its length is regulated by holding the tip of the tungsten electrode at a suitable distance

from the work piece. Suitable arc length is usually about half the diameter of the electrode

core wire. Move the torch forwards from the starting point. If necessary, adjust current value.

The ller material, tungsten electrode and the welding current level are decided according to

the base material type and thickness, joint form and welding position.

Stop welding by lifting the torch o the welding piece and by closing the gas valve on the

torch.

NOTE! The torch voltage will remain on.

EN

NOTE! Always x the gas cylinder so that it stays steadily in upright position either in specially

made wall rack or cylinder trolley. Always close the cylinder valve after having nished welding.

Ignition by Lift TIG

You can ignite TIG arc with the Lift TIG method. Gently touch the work piece with the

electrode and quickly lift the electrode from the work piece to a suitable welding distance to

ignite the arc. If electrode contact with the work piece exceeds 1 second, the power source

ignition will automatically shut o preventing damage to the electrode.

To stop welding, quickly pull the electrode away from the work piece.

< 1.0 s

Order information for the additional equipment (TIG torch) required for TIG welding can be

found in 'Ordering codes' section later in this manual.

© Kemppi Oy / 1418

11

Page 14

EN

3.5 Carbon arc gouging

Constant voltage (CV) mode is recommended to be used with carbon arc gouging. In CV

mode the voltage is adjusted. Gouging is also possible in MMA mode. Refer to the table below

for voltage and amperage settings.

Electrode Voltage (V) / CV Mode Amperage (A) / MMA mode

6.35 mm (1/4”) 36–45 V 170–330 A

8 mm (5/16”) 39–45 V 230–450 A

9.5 mm (3/8”) 43–45 V 300–500 A

3.6 Wireless remote

In addition to the analog remote control unit, Master S also supports wireless remote. Wireless

remote is activated by selecting remote operation mode with the 'Remote' button in the panel

and then choosing 'r11' (wireless remote control R11T) through the panel's setup function.

VRD mode must be switched o. Wireless remote doesn't function when VRD is on.

Using wireless remote:

1. Set the desired welding current with the adjustment knob in the remote.

2. Touch the work piece with the remote tip and at the same time touch the remote's

contact surface with the electrode.

12

Master S 400, 500

Page 15

4. MAINTENANCE

NOTE! Watch out for mains voltage when handling electric cables!

Degree and circumstances of machine utilisation should be taken into consideration when

planning product maintenance. Careful use and preventive maintenance helps to avoid

unnecessary production disturbances and breaks. Check the condition of the welding and

connection cables daily. Do not use damaged cables.

4.1 Regular maintenance

4.1.1 Every six months

NOTE! Disconnect the plug of the machine from the mains socket and wait for about 2 minutes

before removing the casing plate.

The following maintenance operations should be carried out at least every six months:

• Electric connections of the machine – clean any oxidised parts and tighten any loose

ones.

NOTE! You must know the correct tension torques before you start repairing the connections.

• Clean the inner parts of the machine from dust and dirt e.g. with a soft brush and a

vacuum cleaner. Do not use compressed air because there is the danger that the dirt

is packed even more tightly in the gaps of the cooling proles. Do not use a pressure

washer.

NOTE! Only an authorised electrician may repair the machine.

EN

NOTE! The machine and control panel are at mains current potential. DO NOT remove either the

cover or control panel unless authorised to do so. Only authorised and trained personnel can carry

out maintenance and repair processes.

4.2 Service contract

Kemppi service workshops make special service contracts with customers about regular

maintenance. All parts are cleaned, checked and if necessary, repaired. Also the operation of

welding machine is tested.

4.3 Storage

The machine must be stored in a clean and dry room. Protect the machine from rain and direct

sunshine in places where temperature exceeds +25 °C.

4.4 Disposal of the machine

Do not dispose of electrical equipment with normal waste!

Electrical equipment that has reached the end of its life must be collected separately and

taken to an appropriate environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, as per the instructions of local authorities or a Kemppi representative. By

applying this you will improve the environment and human health.

© Kemppi Oy / 1418

13

Page 16

EN

5. TROUBLESHOOTING

The control panel will display any errors of the system. Error code numbers are shown in the

display and can be compared to the table below.

5.1 Troubleshooting

Power On light is not illuminated.

There is no electrical power to the machine.

• Check the mains electrical supply is connected.

• Check the mains fuses, replace blown fuses.

• Check the mains cable and plug, replace defect parts.

The machine is not welding properly. Welding creates spatter. The weld joint is porous or

power supply is insucient.

• Check the welding parameter settings and adjust if needed. See welding parameter

table on page 10.

• Check that the earth return clamp is properly fastened and that earth return cable has no

defects. If necessary change the clamp location and replace defective parts.

• Check the welding cable and connector. Tighten the connection(s) and replace defective

parts.

Power source overheating pilot lamp is illuminated.

Power source has exceeded the designed working temperature. Fans are running and the

machine is in a cooling down cycle. The machine will reset automatically.

• Check that there is enough free space around the machine for cooling air circulation.

• In some cases when error occurs, the machine turns o. Then user must turn the main

switch o and on again.

• Check that welding circuit is open.

14

Master S 400, 500

Page 17

5.2 Control panel error codes

Error 1 (E1)

Error 2 (E2)

Error 3 (E3)

Error 4 (E4)

Error 5 (E5)

Error 6 (E6)

Error 7 (E7)

Error 8 (E8)

Error 9 (E9)

Error 10 (E10)

Error 11 (E11)

Error 12 (E12)

Error 13 (E13)

Error 14 (E14)

Power source is not calibrated. Calibrate power source.

Undervoltage Check the mains network connection and fuses.

Overvoltage Check the mains network connection and fuses.

Overheating. Also the overheating pilot lamp

is on. Machine drops welding current for 30s. If

error conditions still apply:

Machine stops welding.

---

--NTC warning. (IGBT overheating). Machine

drops welding current.

NTC error. (IGBT overheating). If error

conditions (Err7) still apply:

Machine stops welding (model A)

Machine shuts down (model R).

Mains network phase alarm. Check the mains network connection and fuses. If

--VRD error.

Power source is locked. Too long short circuit.

Machine stops welding.

Wrong panel type. Check the panel.

Current feedback is missing. Contact Kemppi service representative.

Ensure free air ow. Let the machine cool down.

Ensure free air ow. Let the machine cool down. Check

the environment temperature.

Ensure free air ow. Let the machine cool down. Check

the environment temperature.

connected to generator check setup jumper Gen.

Avoid long short circuits (20s).

EN

© Kemppi Oy / 1418

15

Page 18

6. ORDERING CODES

EN

Master S 400

Master S 500

Master S 400 Cel

Master S 500 Cel

Welding cable

Earth return cable

Slide bars

Remote control R10

Wireless remote control R11T

TTM 15 V BC

7. TECHNICAL DATA

Master S 400 500

Connection voltage

Rated power at max. current

Fuse (delayed)

Output at 40 °C MMA

Output at 40 °C TIG

Max welding voltage

Stick electrodes

Welding current control

Power factor at 100 %

Efficiency at 100 %

Degree of protection

Operating temperature range

EMC class

Minimum short circuit power SSC of

supply network*

R

SCE

External dimensions

Weight

*) See paragraph 2.3.

6321400

6321500

including cellulose welding characteristic 632140001

including cellulose welding characteristic 632150001

50 mm², 5 m 6184501H

70 mm², 5 m 6184701H

50 mm², 5 m 6184511H

70 mm², 5 m 6184711H

SP007023

5 m 6185409

10 m 618540901

6185442

4 m 627143201

3~50/60 Hz 380 – 440 V (-10 %…+10 %) 380 – 440 V (-10 %…+10 %)

60 % ED 20kVA 26 kVA

25 A 35 A

60 % ED 400 A / 36 V 500 A / 40 V

100 % ED 310 A / 32.4 V 390 A / 35.6 V

60 % ED 400 A / 26 V 500 A / 30 V

100 % ED 310 A / 22.4 V 390 A / 25.6 V

400 A / 48 V 500 A / 46V

ø 1.6...6.0 mm ø 1.6…7.0 mm

stepless stepless

0.90 0.90

0.89 0.89

IP23S IP23S

-20…+50 °C -20…+50 °C

A A

4.0 MVA 4.0 MVA

214 235

L x W x H 570 x 270 x 370 mm 570 x 270 x 370 mm

20.5 kg 23.5 kg

16

Master S 400, 500

Page 19

Page 20

KEMPPI OY

Kempinkatu 1

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) LTD

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GMBH

Perchstetten 10

D-35428 LANGGÖNS

DEUTSCHLAND

Tel +49 6 403 7792 0

Telefax +49 6 403 779 79 74

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY LTD

Room 420, 3 Zone, Building B,

No.12 Hongda North Street,

Beijing Economic Development Zone,

100176 BEIJING

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区宏达北

路12号

创新大厦B座三区420室 (100176)

电话: +86-10-6787 6064

+86-10-6787 1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

Kazura Garden,

Neelankarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

KEMPPI WELDING SOLUTIONS SDN BHD

No 12A, Jalan TP5A,

Taman Perindustrian UEP,

47600 Subang Jaya,

SELANGOR, MALAYSIA

Tel +60 3 80207035

Telefax +60 3 80207835

sales.malaysia@kemppi.com

www.kemppi.com

1910110

1418

Loading...

Loading...