Page 1

MASTERTIG AC/DC

MASTERTIG AC/DC

9901

Operation instructions

MASTERTIG AC/DC 1600 1~ 230 V

MASTERTIG AC/DC 2500 3~ 230 V / 400 V / 460 V

MASTERTIG AC/DC 2500W 3~ 230 V / 400 V / 460 V

MASTERTIG AC/DC 3500W 1~ 400 V

1916110E

English

Read carefully these instructions before you use the welding machine !

Bitte, lesen Sie diese Gebrauchsanweisungen vor Gebrauch der Schweiß-

maschine !

Lees deze gebruiksaanwijzing aandachtig door voor u de lasmachine in

gebruik neemt !

Veuillez lire et appliquer ces instructions avant utilisation de la machine!

Page 2

English

OPERATION SAFETY............................................. 3

TERMS OF GUARANTEE....................................... 3

1. GENERAL .......................................................... 4

2. INSTALLATION OF THE MACHINE ...................5

2.1 Cabling the machine ....................................5

2.2 Siting the machine ....................................... 7

2.3 Start of installation ....................................... 7

2.4 Connecting the machine to the mains supply .. 7

2.5 Cable for MMA welding and return

current cable ................................................ 8

2.6 The welding torch ........................................ 8

2.7 Electrodes to be welded ..............................8

2.8 TIG DC welding ........................................ 8

2.9 TIG AC welding ............................................8

2.10 Shielding gas ............................................. 9

2.11 Gas flow regulator ...................................... 9

3. OPERATING PANELS ...................................... 10

3.1 Numerical displays and signal lights

English

of the panel ............................................... 12

3.2 Use of the remote control .......................... 12

3.3 MMA welding ............................................. 12

3.4 TIG welding ............................................... 12

3.5 Memory functions

(only with the pulse panel) ......................... 16

3.6 Code locking .............................................. 16

4. COOLING UNIT

(only Mastertig AC/DC 2500W, -3500W) .......... 18

5. INTERNAL PROTECTIONS OF THE MACHINE.. 18

5.1 Overheating protection .............................. 18

5.2 Over-voltage protection of the mains

supply voltage ............................................ 18

5.3 The wrong voltage selection ...................... 18

5.4 Protection of a water-cooled torch ............. 18

6. MAINTENANCE ............................................... 18

6.1 The welding torch ...................................... 18

6.2 Cables ....................................................... 19

6.3 The power source ...................................... 19

6.4 Regular maintenance ................................19

7. OPERATION DISTURBANCES ........................ 19

8. ACCESSORIES................................................ 19

8.1 Remote control units.................................. 19

8.2 Wheel barrows and transport chassises ....20

9. EXTRA FUNCTIONS ........................................ 20

10. TECHNICAL DATA .........................................21

2 / 1916110E / 9901

Page 3

OPERATION SAFETY

Never watch the arc without a face shield designed for arc welding!

The arc damages unprotected eyes!

The arc burns unprotected skin!

Be careful for reflecting radiation of arc!

Protect yourself and the surroundings against the arc and hot spray!

Dont use power source for melting of frozen pipes!

Remember general fire safety!

Pay attention to the fire safety regulations. Welding is always classified as a fire risk operation.

Welding where there is flammable or explosive material is strictly forbidden.

If it is essential to weld in such an area remove inflammable material from the immediate vicinity of the

welding site.

Fire extinguishers must always be on site where welding is taking place.

Note! Sparks may cause fire many hours after completion of welding.

Watch out for the mains voltage!

Take care of the cables - the connection cable must not be compressed, touch sharp edges or hot work pieces.

Faulty cables are always a fire risk and highly dangerous.

Do not locate the welding machine on wet surfaces.

Do not take the welding machine inside the work piece (i.E. In containers, cars etc.)

Ensure that neither you nor gas bottles or electrical equipment are in contact with live wires or connections!

Do not use faulty welding cables.

Isolate yourself by using dry and not worn out protective clothes.

Do not weld on wet ground.

Do not place the TIG torch or the welding cables on the power source or other electrical equipment.

Be careful of TIG ignition pulse voltage!

Dont press on torch switch, if the torch is not directed towards work piece.

Dont use wet TIG torch. Do not use damaged TIG torch.

Watch out for the welding fumes!

Ensure that there is sufficient ventilation.

Follow special safety precautions when you weld metals which contain lead, cadmium, zinc, mercury or

beryllium.

Note the danger caused by special welding jobs!

Watch out for the fire and explosion danger when welding container type work pieces.

English

TERMS OF GUARANTEE

KEMPPI OY provides a guarantee for products manufactured and sold by them if defects in manufacture and

materials occur. Guarantee repairs must be carried out only an Authorized KEMPPI Service Agent. Packing,

freight and insurance costs to be paid by third party. The guarantee is effected on the day of purchase. Verbal

promises which do not comply with the terms of guarantee are not binding on guarantor

Limitations on guarantee

The following conditions are not covered under terms of guarantee: defects due to fair wear and tear, noncompliance with operating and maintenance instructions, connection to incorrect or faulty supply voltage (including voltage surges outside equipment spec.), incorrect gas pressure, overloading, transport or storage damage, fire or damage due to natural causes i.e. ligthning or flooding.

This guarantee does not cover direct or indirect travelling costs, daily allowances or accomodation.

Note: Under the terms of the guarantee, Welding torches and their consumables, feed, drive rollers and feeder

guide tubes are not covered.

Direct or indirect damage due to a defective product is not covered under the guarantee.

The guarantee is void if changes are made to the product without approval of the manufacturer, or if repairs are

carried out using non-approved spare parts. The guarantee is also void if repairs are carried out by non-authorised agents.

Guarantee period

The guarantee is valid for one year from date of purchase, provided that the machine is used for single-shift

operation. The guarantee period for double and treble shift operation is six months and four months respectively.

Undertaking guarantee repairs

Guarantee defects must be informed to KEMPPI or authorised KEMPPI Service Agents within the guarantee

period. Before any guarantee work is undertaken, the customer must provide proof of purchase and serial

number of the equipment in order to validate the guarantee. The parts replaced under the terms of the guarantee

remain the property of KEMPPI. Following the guarantee repair, the guarantee of the machine or equipment,

repaired or replaced, will be continued to the end of the original guarantee period.

9901 / 1916110E / 3

Page 4

1. GENERAL

Mastertig AC/DC is a power source for TIG /MMA welding suitable for AC and DC welding and designed

for demanding professional use. The power source is an inverter, which is formed with IGB transistors.

The power source is available in three sizes, 160 A, 250 A and 350 A. The 250 A power source comes in

two separate versions for gas-cooled torches and for water-cooled torches. Three different exchangeable panel versions are available for the power source: a basic panel, a MINILOG panel and a pulse panel.

ACDC panel

TTM 25W

ACDC minilog ACDC pulse

TTM 15

English

C 100AC

Equipment

Mastertig AC/DC 1600 ............................... 6161600

Mastertig AC/DC 2500 ............................... 6162500

Mastertig AC/DC 2500W ........................... 6162505

Mastertig AC/DC 3500W ........................... 6163505

ACDC panel................................................. 6162801

ACDC minilog .............................................. 6162802

ACDC pulse ................................................. 6162803

Accessories

T 120 transport unit .................................... 6185252

T 22 transport unit ...................................... 6185256

GH 20 (gun holder) ...................................... 6256020

TTM 22

GH 20

C 100F

TIG torches, gas-cooled

TTM 13 .......... 4 m .................................... 6271421

TTM 13 .......... 8 m .................................... 6271422

TTM 15 .......... 4 m .................................... 6271424

TTM 15 .......... 8 m .................................... 6271425

TTM 15 .......... 16 m .................................... 6271428

TTM 15S ....... 4 m .................................... 6271434

TTM 15S ....... 8 m .................................... 6271435

TTM 22 .......... 4 m .................................... 6271426

TTM 22 .......... 8 m .................................... 6271427

TTM 22 .......... 16 m .................................... 6271429

TTM 22S ....... 4 m .................................... 6271436

TTM 22S ....... 8 m .................................... 6271437

Remote control units

C 100C ........................................................ 6185410

C 100D ........................................................ 6185413

C 100AC ...................................................... 6185417

C 100F......................................................... 6185405

Cables

Extension cable for remote control ... 10 m ..... 6185456

Start extension cable C 100F......... 10 m ..... 6185310

Welding cables

Cable for MMA welding .. 25 mm

......................................25 mm

Cable for MMA welding .. 50 mm

......................................50 mm

Return current cable ....... 25 mm

......................................25 mm

Return current cable ....... 50 mm

......................................50 mm

4 / 1916110E / 9901

2

.. 5 m ..... 6184201

2

.. 10 m..... 6184202

2

5 m..... 6184501

..

2

.. 10 m..... 6184502

2

.. 5 m ..... 6184211

2

10 m..... 6184212

..

2

.. 5 m ..... 6184511

2

.. 10 m..... 6184512

TIG torches, water-cooled

TTM 20W ...... 4 m .................................... 6271511

TTM 20W ...... 8 m .................................... 6271512

TTM 25W ...... 4 m .................................... 6271521

TTM 25W ...... 8 m .................................... 6271522

TTM 25WS .... 4 m .................................... 6271531

TTM 25WS .... 8 m .................................... 6271532

TTM 35W ...... 4 m .................................... 6271541

TTM 35W ...... 8 m .................................... 6271542

= Warning

Page 5

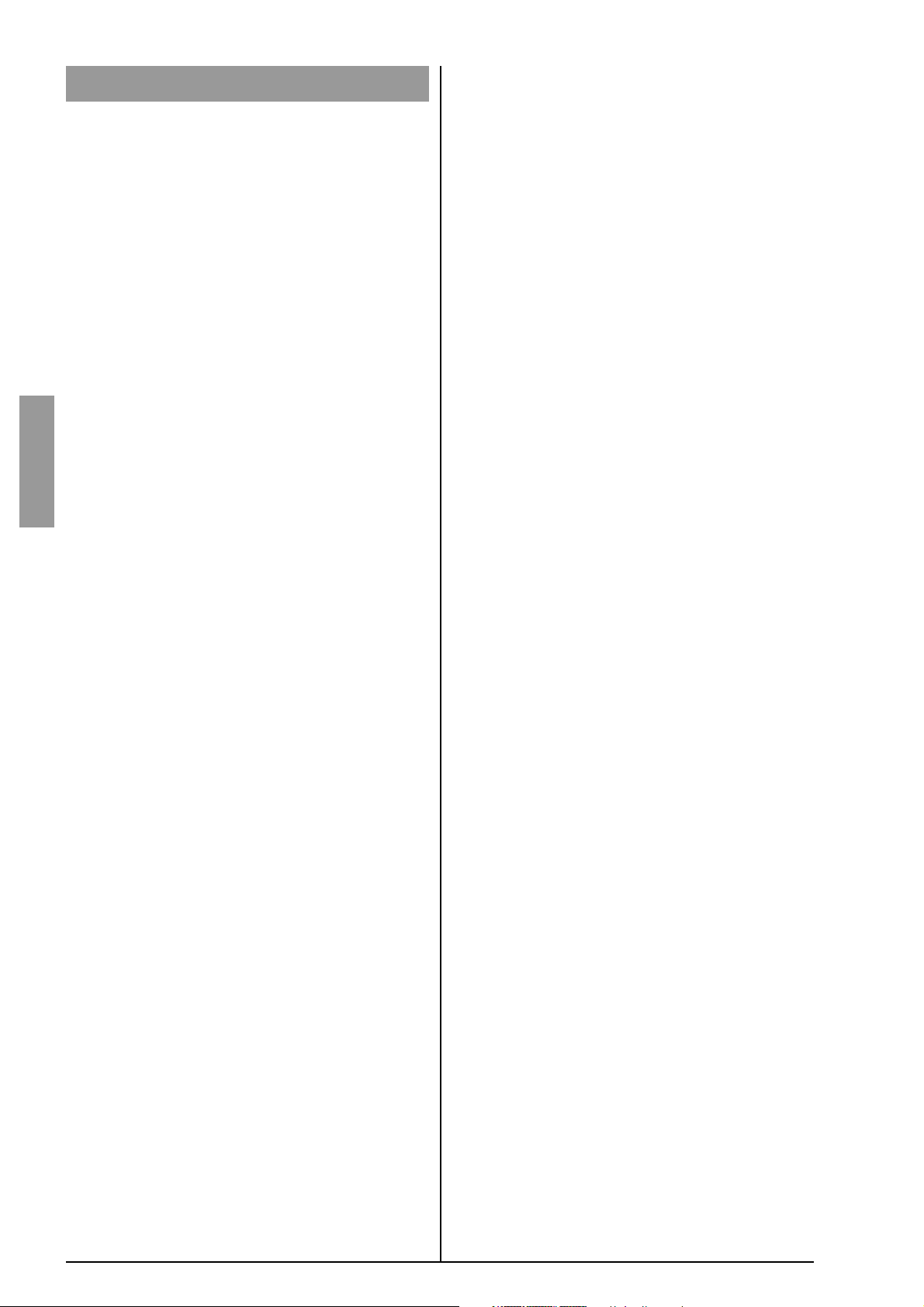

2. INSTALLATION OF THE MACHINE

2.1 Cabling the machine

Mastertig AC/DC 1600

Shielding gas hose

Gas-cooled TIG torch

Cable for MMA welding

Return current cable

Remote control unit

English

Mains cable

Mastertig AC/DC 2500

Shielding gas hose

Cable for MMA welding

Remote control unit

Gas-cooled TIG torch

Return current cable

Mains cable

9901 / 1916110E / 5

Page 6

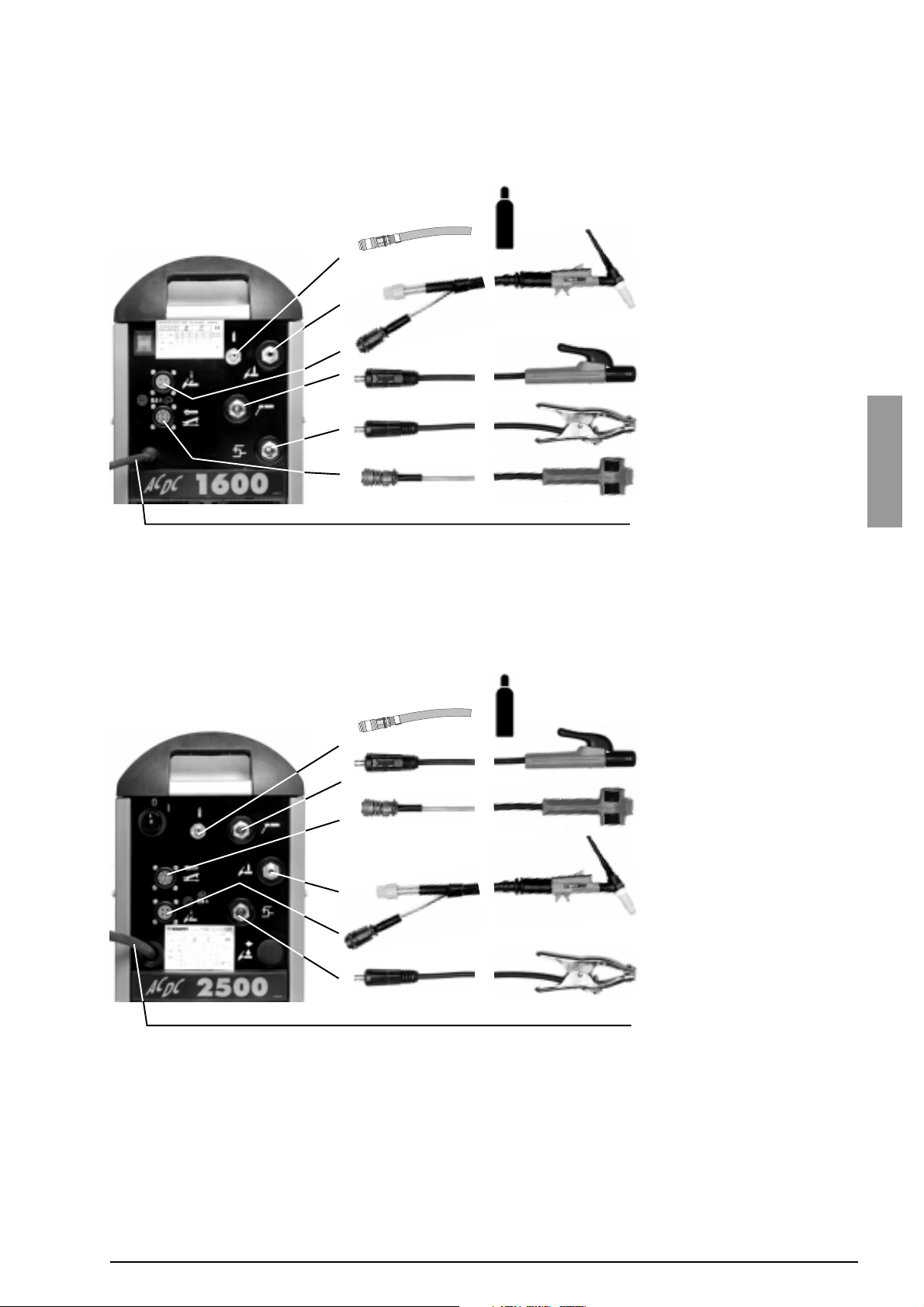

Mastertig AC/DC 2500W

English

Shielding gas hose

Cable for MMA welding

Remote control unit

Return current cable

Water-cooled TIG torch

Mastertig AC/DC 3500W

Cable for MMA welding

Remote control unit

Return current cable

Shielding gas hose

Water-cooled TIG torch

6 / 1916110E / 9901

Page 7

2.2 Siting the machine

When siting the machine, the following have to be

considered:

Site the machine on a fixed dry base, which does not

cause dust etc. into the suction air of cooling.

Make sure that the machine is placed away from

the line of particle spray from grinding tools.

Ensure the free circulation of the cooling air. Make

sure that there is at least a 20cm free distance

both in front of and at the rear of the machine for

the circulation of the cooling air.

Protect the machine against heavy rain and in hot

circumstances against direct sunshine.

2.3 Start of installation

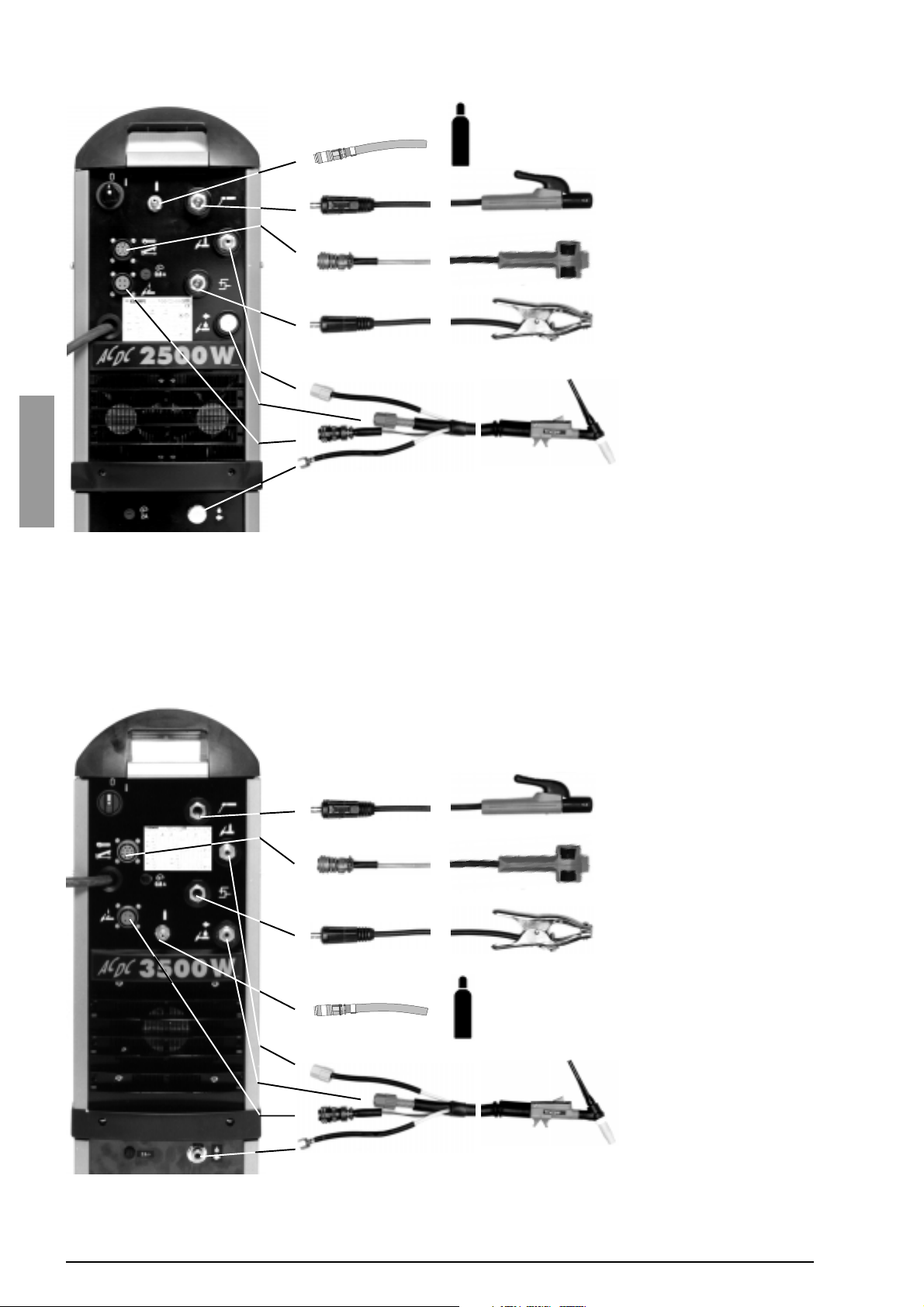

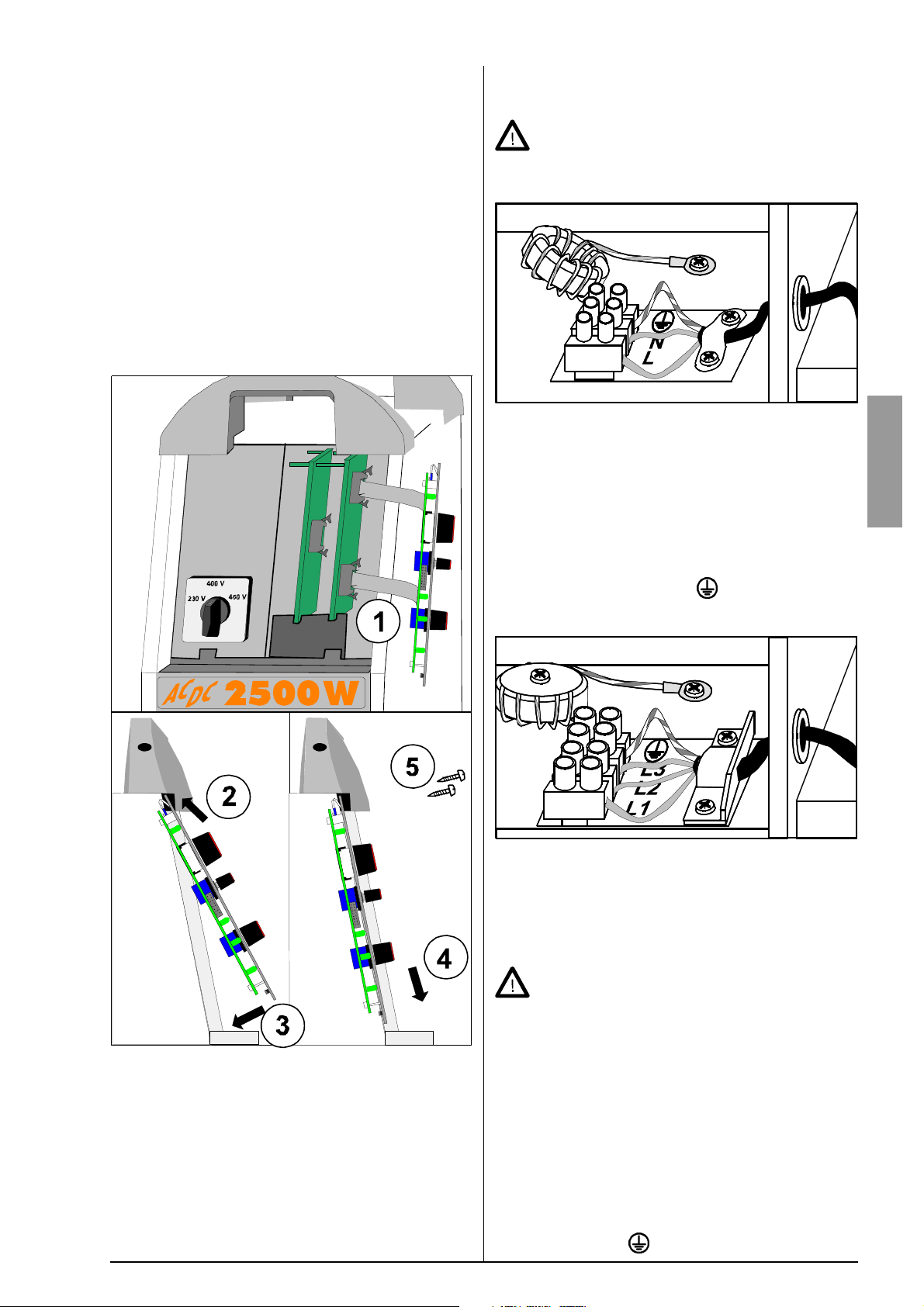

2.4 Connecting the machine to the mains

supply

The installation or replacement of the mains

cable and the plug may be carried out only by

an authorized electric shop or electrician.

Mastertig AC/DC 1600

1600

The Machine is delivered with a mains cable with a

schuko plug for connection to a mains supply of 230 V.

To be noted when replacing the mains cable:

The lifting handles, cover and the right-hand-side plate

have to be opened. The cable in brought to the machine

through the inlet ring on the rear panel and fastened

with a cable clamp. The phase lead of the cable are

coupled to connector L, the blue to the connector of

the N lead and the yellow-green to the connector of

the protective grounding lead .

English

Mastertig AC/DC 2500 and -2500W: Check first that the

mains voltage change-over switch is in right position.

If it is needed to change mains cable, do it before

mounting to the wheel barrow T120. Otherwise you

bossibly have to dismount the machine.

Before connecting the machine to the mains supply,

one of the three panels, the ACDC panel, the ACDC

minilog or the ACDC pulse panel, has to be installed.

Installation instructions 4283280 are in the package of

the panel.

Mastertig AC/DC 2500, -2500W and -3500W

2500, 2500W, 3500W

The machine is delivered with a 5m mains cable

(4×2.5mm2) without a plug. Mains cable is suitable

for all mains voltages with recommended fuse size

(please look at Technical data table). 4×6mm2 cable

can be assembled to the machine, if local regulations

are requiring it.

If you use greater fuse size than recommended

big short circuit current can cause extra damage in case of failure.

Mastertig AC/DC 2500, -2500W

Before connecting the machine to the mains supply,

make sure that the voltage change-over switch of the

machine is turned to the position corresponding to the

mains supply voltage (230 / 400 / 460V).

When replacing the mains cable, note the following:

The lifting handles, cover and right-hand-side plate of

the machine have to be opened. The cable is brought

to the machine through the inlet right on the rear panel

and fastened with a cable clight. The phase leads of

the cable are coupled to connectors L1, L2 and L3; the

yellow-green is coupled to the connector of the protective grounding lead .

9901 / 1916110E / 7

Page 8

2.5 Cable for MMA welding and return

current cable

The welding cables have to be at least 16 mm2 copper

cables for Mastertig AC/DC 1600 and 25 mm2 copper

cables for Mastertig AC/DC 2500, Mastertig AC/DC

2500W and 50 mm2 copper cables for Mastertig AC/

DC 3500W. Thinner cables will cause voltage losses

and heating.

Connect the grounding clight of the return cable carefully, preferably directly to the piece to be welded. Use

as short welding cables as possible. Unnecessarily long

cables will lower the maximum output voltage of the

machine. Coiling of the excess cable lowers the output voltage of the machine especially in AC welding

and decreases the ignition spark.

Clean the fastening surface of any paint and rust!

Choice of the electrode for DC welding. The table is

only given as a guide.

Welding

current

range

Electrode

Gas nozzle

Gas

flow

rate

DC– WC20 Argon

A ø mm number ø mm l / min

5...80 1,0 4/5 6,5/8,0 5...6

70...140 1,6 4/5/6 6,5/8,0/9,5 6...7

140...230 2,4 6/7 9,5/11,0 7...8

225...350 3,2 7/8 11,0/12,5 8...10

330...350 4,0 10 16 10...12

2.6 The welding torch

In Mastertig AC/DC1600 and Masterig AC/DC2500,

only an gas-cooled torch can be used. In Mastertig AC/

DC 2500W and -3500W, you can use either an gascooled or a water-cooled torch. Make sure that the torch

English

you are using is designed for the maximum welding

current that you need.

Never use a damaged torch !

2.7 Electrodes to be welded

By the Mastertig AC/DC power sources you can use

all electrodes designed for DC or AC welding within

the current limits of the machine in question.

Mastertig AC/DC 2500, -2500W and -3500W power

sources is suitable for carbon arc gouging and cutting

according to its maximum power.

Reference max elecctrode diameters and yield

electrode type yield 1600

Fe-rutile 95 % ø 4 ø 5 ø 6

Fe-base 100 % ø 4 ø 5 ø 6

Fe-high-yield 180 %

Ss-rutile - - - ø 4 ø 6 ø 6

Ss-base - - - ø 4 ø 6 ø 6

Ss-high-yield 150 % ø 3,25 ø 5 ø 6

Hard facing by

welding

250-270 %

100 % ø 3,25 ø 5 ø 6

ø 2,5

- - -

2500,

2500W

ø 4

ø 4

2.8 TIG DC welding

DC current is used typically when welding different

kind of steel. We rekommend for DC welding a WC20

(grey) elctrode.

Sharpening of the electrode

The tip of the electrode is sharpened into a cone, so

that the arc becomes steady and the thermal energy is

concentrated on the spot being welded. The length of

the sharpening to the diameter of the electrode:

d

l

with small current sharp l = 3 x d

with large current blunt l = 1 x d

3500W

ø 5

ø 5

2.9 TIG AC welding

AC-current is typically used when welding aluminium.

We recommend for AC-welding a WC20 (grey) or a

clean wolfram electrode (green).

Balance

In AC-welding the ratio between the positive and negative half-cycle is called balance. With the balance you

can control heat between the electrode and work piece.

When balance is positive, it means that the positive

half-cycle is longer than the negative, more heat is

coming to the electrode than to the work piece. Correspondingly when balance is negative, negative halfcycles are longer, the work piece is hotter and the electrode is colder. Mastertig AC/DC-machines have buildin BALANCE-automatism, which chooses automatically

right balance value. User adjusts the BALANCE-knob

according to the electrode, and the machine takes care

of the balance control in different currents.

BALANCE automatics offers two benefits as compared to a constant balance:

In AC welding, you can use both a sharpened and

a rounded (cut) electrode. When welding starts,

the machine will round the cut tip so that its is suitable.

The current-range of the electrode is extended: the

current of the lower end is lowered and the current

of the maximum end is increased.

With BALANCE automatics, you can use the position

for a sharpened electrode with a

narrower arc to obtain a narrower

seam and to a deeper penetration

than with a rounded electrode. A narrow seam is useful especially in fillet

welding.

When using a rounded electrode, the arc is broad and

the cleaning area of the arc is also

wider, so it can be used for end-toend seams and outer corners.

8 / 1916110E / 9901

Page 9

The table is only given as a guide.

Welding current

range AC

min min max

A A A ø mm number ø mm l / min

15 25 90 1,6 4/5/6 6,5/8,0/9,5 6...7

20 30 150 2,4 6/7 9,5/11,0 7...8

30 45 200 3,2 7/8/10 11,0/12,5/16 8...10

40 60 350 4,0 10/11 16/17,5 10...12

Electrode

WC20 Argon

Gas nozzle

Gas

flow

rate

The table and the panel scale are based on the use of

WC20 (grey). When using pure wolfram electrode

(green) the tip rounds off slightly.

2.10 Shielding gas

Use as the shielding gas argon or other gas which is

suitable for TIG welding. The flow rate of the gas is

defined by the welding current and the size of the electrode. The table above shows the flow rate recommended.

Connect hose onto regulator and machine, tighten

jacket nuts.

Open valve of bottle slowly

Pressure meter (P1) shows pressure of bottle. Nev-

er use up all the gas in the bottle, send the bottle

for filling up when the bottle pressure still is 2 bar.

Open needle valve if there is one in regulator.

Screw regulation screw (2) inwards until hose pres-

sure meter (P2) shows flow (or pressure) required.

By regulation of flow amount the machine has to

be in operation and the gun switch should be

pressed on at the same time.

Close valve of bottle always after having stopped

welding

If the machine will be unused for a longer time, you

should also unscrew pressure regulation screw (2).

English

2.11 Gas flow regulator

Gas flow regulator should be suitable for shielding gas

used by you. The regulator being in your use might be

different from the one in picture, however, following general instructions are valid for all pressure regulators.

P1P2

51

53

55

54

56

57

Before mounting of flow regulator

Step aside, open cylinder valve (1) somewhat for a

moment, in this way you can blow out any dirt that

may be in the valve of bottle.

Screw the press regulation screw (2) of regulator

outwards so long that no spring pressure can be

felt (screw is turning freely).

Close needle valve (3) if there is one in regulator.

Connect regulator onto valve of bottle

Tighten connecting nut (4) preferably with a wrench.

Put hose spindle (5) of regulator with jacket nuts

(6) onto gas hose, connection should be ensured

with hose clamp (7).

52

56

9901 / 1916110E / 9

Page 10

3. OPERATING PANELS

BASIC

12

6

5

4

3

English

MINILOG

13

15

1

22

21

19

6

5

11

12

13

15

10 / 1916110E / 9901

4

3

2

1

22

21

21

19

Page 11

PULSE

10

79 8

ACDC

6

11

MINILOG

4

5

12

3

2

BALANCE

13

1

14

-9 ... 0 ... 9

15

3140530

3140050

16

1 Selection switches for TIG welding: TIG HF = spark TIG and TIG CONTACT = contact TIG

2 Frequency of AC welding,

3 Adjustment of post-gas time 0 ... 100 s

4 Adjustment potentiometer of the down-slope time of the welding current 0 ... 15 s

5 Current adjustment knob

6 Selection of local / remote control

CODE LOCK/ENTER

7 Adjustment of the pulse current of Pulse TIG PULSE 3 ... 160 A (250 A)

and the adjustment of the pulse ratio

8 Selection key of Pulse TIG

9 Adjustment of the background current of Pulse TIG

and adjustment of the frequency

10 Adjustment of the start current, starting with a current lower than the welding current

START, or with a current higher than the welding current HOT START -70 ... +50 %

11 Selection of Minilog operations and adjustment of the current level

12 Adjustment of the pre-gas time, and at the same time the key for code locking

13 Adjustment of the up-slope time of the welding current 0 ... 5 s

14 Selection of fusion spot welding and adjustment of time,

15 Selection of the operation mode of the torch switch

16 Calling the welding parameters from the memory or from the panel

17 Saving the welding values in the memory

18 Selection key of the memory channel

19 Selection key for broken-arc method

20 Adjustment of the dynamics (arc force) of MMA welding

21 Selection key of MMA welding

22 Adjustment potentiometer of the form of the AC TIG arc BALANCE -70 ... +70 %

17

FREQUENCY 50 ... 200 Hz

I

, used also to adjust the values of the parameters with keys.

2

REMOTE and at the same time the key for code locking

RATIO 10 ... 75 %

FREQUENCY 0.1 ... 300 Hz

SAVE.

CHANNEL 1 ... 9

BROKEN ARC.

MMA

2018 19

BACK 20 ... 40 %

MINILOG -80 ... +20 %

SPOT WELD 0 ... 10 s

2T / 4T.

MEM. / PANEL.

DYNAMICS -9 ... 9

22

21

SOFT

CODE LOCK.

English

9901 / 1916110E / 11

Page 12

kuvat 11 - 15

3.1 Numerical displays and signal lights

of the panel

Machine on

Display of welding

current or set value current

The signal light of thermal protection is on when the

machine has over-heated. Let the machine on so that

the fan will cool the machine. Wait until the light goes

off, and you can continue welding.

The light for the wrong voltage turns on if the mains

English

voltage is too high or too low. Check the voltage setting of the machine and/or the mains voltage. The wrong

voltage light will also turn on if there is a momentaneous over-voltage in the mains supply.

The current is displayed with a tolerance of 3 % ± 2 A;

the voltage with a tolerance of 3 % ± 0.2 V.

Heat protection

Display of

welding voltage

or parameters

Wrong mains

voltage, over or

under-voltage

Units of the

display

3.2 Use of the remote control

Broken arc method

Press the BROKEN ARC key and the signal light for

broken arc method turns on.

A broken arc method has to be used if the seam to be

welded cannot tolerate the heat of a continuous arc.

The heat of the welding is controlled by breaking the

arc. Usually the reason is thin material or various fittings. In the broken arc method position, the arc breaks

faster and the ignition pulse is smaller then in ordinary

MMA welding.

Control of MMA welding dynamics (only with

minilog and pulse panels)

-9 ... 0 ... 9

DYNAMICS

Press the DYNAMICS key and you will see the numerical value corresponding to the dynamics in the display. You can change the value by turning the current

knob. Numerical value zero is the normal setting for all

MMA electrodes. When the value is adjusted negative

(-1...9), the arc is softened. The amount of spatter

decreases when welding at the upper end of the recommended current range of the electrode. On the positive side (1...9) the arc is rough. It is suitable e.g. for

thin stainless steel rods when welding near the lower

end of the recommended current range.

3.4 TIG welding

The remote control is selected from the key REMOTE.

With the remote control you can adjust the welding

current of MMA and TIG welding. The values of the

parameters (up-slope and down-slope times, gas flow

times etc.) are adjusted from the current knob.

With remote control unit C100AC you can also change

the welding method (MMA / TIG). The machine selects

the polarity (type of current) in accordance with an advance selection on the panel.

3.3 MMA welding

Selection of type of current

Select MMA welding by pressing the selection key of

MMA welding. The signal light of the type of current

indicates the current type selected: AC, DC-, DC+.

Change the current type by pressing the MMA selection key again and the current type will change and the

signal light will show the current type selected.

12 / 1916110E / 9901

Selection of TIG welding and type of current

TIG

HF

TIG

AC

Press the selection key next to the selected TIG method, spark TIG (TIG HF) or contact TIG (TIG CONTACT),

and the signal light next to the key will show the method.

You can change the type of current by pressing the selection key again. (If you want to select DC+ as the current type for TIG, press both TIG keys at the same time.)

Spark ignition

Use contact ignition when you are welding in a

environment where are sensitive electronic

equipements. The ignition spark can cause interferences in equipements near the welding machine.

The arc is ignited with a high-frequency, high-voltage

spark without touching the work piece. If the arc is not

ignited in spite of the spark within one second, you will

have to try the ignition again by pressing the torch

switch. In some cases the spark ignition works better if

you touch the work piece with the gas nozzle lightly

before the ignition.

DC-

CONTACT

Page 13

kuvat 16 - 23

Contact ignition

2134

Press the electrode lightly against the work piece (1).

Press the switch and the shielding gas will start to flow

and a small current will pass through the electrode. Lift

the electrode away from the work piece by turning it so

that gas nozzle rests against the work piece (2 ja 3),

and the arc will ignite and the current will rise to the

welding level within the up-slope time (4).

Use and selection of operation of the torch

switch

4T

2T

4. Release the torch switch, and the welding current

will drop in accordance with the selected downslope time. After the arc is turned off, the shielding

gas will continue to flow for the post-gas time.

2

The down-slope time of the welding current can be interrupted by quickly pressing the torch switch.

2

You can go back to the welding current from the downslope current by pressing the torch switch down. After

that, the current will rise at a rate corresponding to the

down-slope time.

4-function (4T) / spark ignition

English

4T

/

2T

The operation of the torch switch is selected by pressing the 2T/4T key.

2-function (2T) / spark ignition

2

1. Press the torch switch. The gas starts to flow and

after the pre-gas time selected, the arc is ignited

and the current rises to the welding level within the

selected up-slope time.

2. Release the torch switch, and the welding current

will drop in accordance with the selected downslope time. After the arc is turned off, the gas will

continue to flow for the post-gas time.

2-function (2T) / contact ignition

21

2

2413

1. Press the torch switch down. The shielding gas

starts to flow.

2. Release the torch switch. The ignition spark ignites

the arc and the current will rise to the welding level

within the up-slope time.

3. Press the torch switch down. The welding continues.

4. Release the torch switch, and the current starts to

drop and after the selected down-slope time the

arc is broken. After this, the shielding gas will flow

for the time selected.

4-function (4T) / contact ignition

3

241

2

1. Press the tip of the torch lightly against the work piece.

2. Press down the torch switch.

3. Lift the electrode slowly away from the work piece.

The arc will ignite and the welding current will rise

to the welding level within the selected up-slope

time.

2

13

2

1. Press the electrode lightly against the work piece.

2. Press the torch switch down for a moment.

3. Lift the electrode slowly away from the work piece.

The arc will ignite and the welding current will rise

to the welding level within the up-slope time.

4. Press the torch switch down. The welding continues.

5. Release the torch switch, and the welding current

will drop and stop after the selected down-slope

time. After the arc is turned off, the shielding gas

will continue to flow for the post-gas time.

4

5

9901 / 1916110E / 13

Page 14

kuvat 24 - 31

2

By pressing the torch switch during the down-slope time

of the current, the current will remain at that level as

long as the switch is pressed down. After the release

of the switch, the current will drop further.

Adjustment of the form of the arc, BALANCE

The BALANCE function will adjust the balance so that

it is suitable for the selected electrode and current. At

the same time, it adjusts the pre-heating of the tip of

the electrode at the start in accordance with the tip

form selected.

2.4

3.2

BALANCE

4.0

2

By pressing the switch down for a moment, you can

raise the welding current back to the welding level.

Adjustment of the down-slope time of the

welding current

English

15 s

The adjustment of the down-slope time is done from

the potentiometer. The time can be adjusted between

0-15 s. When you adjust the down-slope time, you

can see the time in seconds in the right-hand numerical display. After 5 seconds, the display will return to

the start status.

Adjustment of the up-slope time of the welding current

AC

1a. When welding with a sharpened electrode, turn the

control knob to the left edge of the range of the

electrode that you have selected. (Narrow arc, deep

penetration, range: small seams)

1b. When welding with a rounded electrode, turn the

control knob to the right edge of the range of the

electrode that you have selected.

2. If you want more heat to the electrode, turn the knob

to the right, or if you want less heat, turn it to the left.

Frequency adjustment of TIG AC welding (only

with minilog and pulse panel)

The frequency of AC welding can be adjusted by means

of the MINILOG and PULSE PANEL. Raising the frequency will make the arc slightly more stable and narrow, but it will increase the noise caused by arc.

FREQUENCY

50 - 200 Hz

AC

1. Press the FREQUENCY key in the AC square.

2. Adjust the frequency with the current knob. The

adjustment range of the frequency is 50...200Hz.

When leaving the factory, the frequency of the

machine is 60Hz.

CODE LOCK

1. Press the key next to the up-slope of the current

pattern. The right-hand numerical display will show

the up-slope time in seconds.

2. Select the desired value by turning the current knob

(0-5s). 5 seconds after the adjustment, the displays will return to show the set value of the current.

Adjustment of the pre-gas and post-gas times

1. Press the switch in the panel next to the gas bottle

of the current model of either the pre-gas or the

post-gas.

2. Turn the current knob until the value that you want

is shown in the right-hand display. (Pre-gas 0-5s,

post-gas 0-100s)

14 / 1916110E / 9901

Minilog operation (only with minilog and pulse

panel)

MINILOG

OFF

+20%

-80%

With the Minilog operation you can select two currency levels, the welding current and the base current,

and you can move from one to the other by quickly

pressing the torch. The Minilog operation can be used

only with a 4-function torch switch operation.

Page 15

kuvat 32 - 37

The selection and adjustment of the Minilog operation

is done by means of the potentiometer. When the potentiometer is in the OFF position, the operation is not in

use. The welding current is selected from the current

knob like usually. The Minilog knob is used to select a

basic current, the minimum of which is 80% below the

welding current and the maximum is 20% above the

current level. During the adjustment, you can see the

set value of current in amperes in the current display.

2

You can move from the welding current to the basic

current by quickly pressing the torch.

By quickly pressing it again, you move back to the

welding current. The signal lights on the panel show

you the current level you are on.

You can stop the welding by a longer pressing of the

torch switch (>0.7 s).

The Minilog operation can be used to adjust the heat,

if the work piece is overheated or if you need more

heat for a moment.

With the Minilog operation you can go to a lower current level for example when you change the position or

the grip of the filler material wire without having to stop

the welding to do that.

A lower current can also be used as the crater filling

current if you do not want to use the down-slope time

for that.

Pulse welding (only with the pulse panel)

PULSE

RATIO

BACK.

pulse current, but please note that this will change

the average current.

6. When you press the key PULSE RATIO again, you

can adjust the pulse ratio, rAt. The pulse ratio is shown

as a percentage of the total length of the cycle.

7. When you press either of the parameter keys a

third time, the adjustment goes back to the average current AvE.

Control of the start current (only with the pulse

panel)

OFF

SOFT

START

By means of the control potentiometer of the start current you can select either a soft, normal or hot start.

The start current is available only with a 4-function torch

switch operation.

By turning the potentiometer to OFF, you have a normal start (see the use of the torch switch / 4-function)

By turning the potentiometer to the left, you get a soft

start (SOFT START). When you raise the torch switch,

the current rises in accordance with the up-slope of

the start current to the start current, which is smaller

than the welding current.

From the start current, you can move to the welding current by pressing the torch switch for a short moment.

The start current is proportional to the welding current.

You can see the value of the start current in the numerical display during the control.

HOT

START

+50%

-70%

2

English

FREQUENCY

ON /

PULSE

1. Switch the pulse welding on by means of the pulsesection key ON/OFF.

2. Adjust the average current that you want from the

current adjustment knob. The current display will

show you the average current.

3. Press the key BACK. FREQUENCY once. The text

bAc of the right-hand display shows you that now

you can adjust the background current from the

current knob. The background current is proportional to the average current, but it is shown in the

current display in amperes.

4. Press the key BACK. FREQUENCY again. The text

FrE of the current display shows that now you can

adjust the pulse frequency. The pulse frequency is

shown in Hz.

5. Press the key PULSE RATIO once. You will see

the pulse current in the current display. The righthand display reads PUL. You can also adjust the

OFF

2

When you turn the potentiometer to the right, the start

current is higher than the welding current (HOT

START). Otherwise the start is made in the same way

as with a soft start.

Fusion spot welding (only with a pulse panel)

0 - 10 s

SPOT

WELD

Select fusion spot welding by pressing the special operation key SPOT WELD. To show that you have selected fusion spot welding, the signal light next to the

9901 / 1916110E / 15

Page 16

kuvat 38 - 48

key goes on. You can select the spot time that you

want with the current knob. The time selected is shown

in the numerical display during the adjustment. Five

seconds after the adjustment, the display returns to

the set value of the current and you can adjust the

welding current.

The time shown in the display means the time you have

the welding current. The down-slope and the up-slope

times are increasing the burning time of the arc.

3.5 Memory functions (only with the pulse

panel)

By means of the memory functions you can save 9

panel settings in the permanent memory. All adjusta-

English

ble or chooseen values are saved in the memory. When

the memory function is not in use, the numerical display of the memory section is black.

With the CHANNEL key you can select the channel to

be read and used for the saving of a setting.

The MEM / PANEL key is used to select whether to

use the values in the memory or values controlled from

the panel.

The function of the SAVE key is two-phased. When

you press it once, you select the values to be saved. In

this case the light SAVING is blinking to show that you

are performing a saving operation. When the light is

blinking, you can find the channel into which you want

to save the values. When you press the key again, the

information is saved in the memory.

Calling the values from the memory.

1. Press the CHANNEL key so many times that the

numerical channel display shows the number of

the channel that you want. At the same time, the

signal lights of the panel show you the selections

of the selected channel and the current display

shows you the set value of the current. You can

see the other values of the welding parameters by

pressing the parameter key or by turning the potentiometer. All the values are locked, which means

that you cannot change them while the MEM signal light is on.

Saving a welding situation (parameters) in the

memory.

You have good welding values, which you want to save

in the memory.

1. Press the SAVE key once and the SAVING light

starts to blink.

PANEL

SAVINGMEM.

2. Press the CHANNEL key so many times that the

number of the channel in which you want to save

the values is shown in the numerical display.

PANEL

SAVINGMEM.

3. Now press the SAVE key again and the values are

saved in the memory.

PANEL

SAVINGMEM.

Note! When you are saving (= the SAVING light is blinking) and you have rolled the number of the channel

that you want by using the CHANNEL key, you can see

the previous values of that channel by pressing the

MEM / PANEL key to bring the panel to the MEM status, so that you can check the present values of that

channel. In this case the values to be saved will not

change. After the check, press the MEM / PANEL key

again and you can again see the values to be saved

and you can save them by pressing SAVE.

3.6 Code locking

The welding machine has a theft protection. You can

install a three-digit machine-specific code into the machine, which the user must know in order to turn the

machine on. The code is saved in the panel. If you

change the panel the code is follows the panel.

When the machine leaves the factory, the code locking operation is not on.

Installing the code locking

1. Press the pre-gas key (CODE LOCK) and the key

of the remote control (REMOTE / CODE LOCK/

ENTER) at the same time.

PANEL

SAVINGMEM.

2. If you want to change the values found, press the

MEM / PANEL key and the PANEL signal light

comes on and you can change the values.

PANEL

SAVINGMEM.

16 / 1916110E / 9901

2. Select the first digit from the current adjustment

knob (e.g. 4).

3. Press the accept key (REMOTE / CODE LOCK/

ENTER).

Page 17

kuvat 49 - 52

4. Select the second digit from the knob (e.g. 3) and

again accept it by pressing the key (REMOTE /

CODE LOCK/ENTER).

5. Select the third digit in the same way (e.g.2).

Now the code locking is on with the number that

you have chosen (e.g. 432).

Turning the machine on when the code locking is on

When you turn on a machine in which the code locking

is on, you must always feed in the opening code that

you have installed in order to be able to use the machine.

3. Turn the machine off. The machine is now ready

for use.

Changing the code

1. Remove the code locking in accordance with the

above instruction.

2. Install the code locking again.

English

1. Feed in the first digit from the current adjustment

knob.

2. Accept the digit by pressing (REMOTE / CODE

LOCK/ENTER).

3. Feed in the second and third digits in the same

way.

The machine is ready for use.

If you enter wrong code, you can try again by

turning the machine off and on. If you can not

open the machine, you do not remember the right

code, contact an authorized service agent.

Removal of code locking

1. Press the key for pre-gas (CODE LOCK) and the

key for remote control (REMOTE / CODE LOCK/

ENTER) at the same time.

2. Feed in the digits of the code in the same way as

when opening the machine. The code locking will

be removed after you have fed in the last digit.

9901 / 1916110E / 17

Page 18

kuvat 53 - 54

4. COOLING UNIT

(only Mastertig AC/DC 2500W, -3500W)

P

e

English

no

pressure

overheated

liquid

diately turned off. If the over-voltages are short in duration, this may be seen as short breaks in the current.

The signal light of the panel showing an over / undervoltage comes on during a long period of over-voltage.

5.3 The wrong voltage selection

Mastertig ACDC 2500, Mastertig ACDC 2500W

If a multi-voltage machine is connected

to the wrong voltage, the machine will not

start and the signal light in the front panel comes on to indicate this. The machine

will not be damaged if it is connected to

the wrong voltage for a short time. Unplug the machine

from the mains supply and select the correct voltage

from the switch under the front panel.

5.4 Protection of a water-cooled torch

Mastertig ACDC 2500W and -3500W

If the switch of the cooling unit is in the position for an

gas-cooled torch and you start welding with a watercooled torch and a current is over 60 A, the welding is

broken.

gas- / water-cooled

torch GAS / WATER

Filling in the liquid and checking the liquid level is done

by pulling open the hatch in the lower part of the machine so that you can see the filling hole for the liquid.

The cooling units tank is filled with 2040% glycol/

water mixture according to antifreeze requirements.

Instead of glycol/water mixture you can also use another liquid according to your experience.

The circulation of the liquid is operation-controlled,

which means that the liquid is circulating only during

welding and for a while after the welding.

test run of the circulation

of the liquid TEST

5. INTERNAL PROTECTIONS OF

THE MACHINE

5.1 Overheating protection

The yellow signal light of the overheating

protection comes on and the machine

stops when the machine has overheated. The machine

may overheat if the machine is loaded for a long time

with a current higher than 100 % of the duty cycle or

when the circulation of the cooling air is prevented.

5.2 Over-voltage protection of the mains

supply voltage

If the over-voltages in the mains supply are

so high that they can endanger the ma-

chine, the supply of the machine is imme-

6. MAINTENANCE

The amount of use and an unusual working environment have a special effect on the need for maintenance.

Proper use and preventive maintenance will help to

ensure trouble-free operation of the machine without

unexpected interruptions.

6.1 The welding torch

Due to high temperatures and wear, the welding end

of the TIG torch requires maintenance most, but also

the condition of the other parts should be checked regularly.

The welding end

Check that...

all insulations of the welding end are undamaged

and in place.

the gas nozzle is undamaged and suitable for the

work.

the flow of the shielding gas is free and even.

the electrode is undamaged. Use an electrode size

and tip sharpening which are suitable for the weld-

ing job. Sharpen the electrode lengthwise.

the fastening parts of the electrode are undamaged

and that the electrode is tightly fastened in its place.

The torch cable

Check that...

the insulation of the handle and the torch cable is

undamaged.

the torch cable has not sharp bends.

Always replace any damaged parts immediately!

Follow the instructions of the torch manufacturer in all

maintenance and repair measures.

18 / 1916110E / 9901

Page 19

6.2 Cables

Check the condition of the welding and connection

cables daily. Do not use damaged cables!

Check also that the mains connection cables that you

use are in good condition and that they comply with all

the regulations!

Mains connection cables may be repaired and installed

only by an authorized electric shop or electrician.

6.3 The power source

NOTE! Disconnect the plug of the machine from the

mains socket and wait for ca. 2 minutes (capacitor

charge) before removing the casing plate.

Check at least very six months:

The electric connections of the machine clean any

oxidized parts and tighten any loose ones.

NOTE! You must know the correct tension torques

before you start to repair the connections.

Clean the inner parts of the machine from dust and

dirt e.g. with a soft brush and a vacuum-cleaner.

Do not use pressurized air, because there is the

danger that the dirt is packed even more tightly in

the gaps of the cooling profiles. Do not use a pres-

sure washing device.

Only an authorized electric shop or electrician may repair the machine.

C 100C

Control of MMA / TIG welding current, memory scale

1 - 10.

C 100D

Control and fine-tuning of MMA / TIG welding current,

memory scale 1 - 10.

C 100AC

Control of MMA / TIG welding current, memory scale

1 - 10 and MMA / TIG selection.

C 100F

Foot pedal control unit for TIG welding

start function

adjustment of the welding current with pedal move-

ments

limitation of the welding-current range with min and

max potentiometers

English

6.4 Regular maintenance

KEMPPI Service Repair Shops handle regular maintenance by agreement.

Regular maintenance includes e.g. the following:

Cleaning of the machine.

Checking and maintenance of the welding tools.

Checking the clamps, switches and potentiome-

ters.

Checking the electric connections.

Checking the mains cable and plug.

Replacement of any parts that are damaged or in

poor condition.

Maintenance testing. The operation and perform-

ance values of the machine are checked and,

where necessary, adjusted by means of test equip-

ment.

7. OPERATION DISTURBANCES

In the case of operation disturbances, contact an authorized KEMPPI Service Repair Shop.

Check the maintenance parts before sending the machine to the service shop.

Connecting the foot pedal unit:

The foot pedal unit has two connections, which are

connected to the remote control and start connections

in the rear of the power source. When using the foot

pedal unit, the maximum current output of the machine

is ca. 30 % below its maximum output unless the machine is calibrated for the foot pedal unit.

Calibration of the machine for the foot pedal unit:

1. Turn the machine off.

2. Press the REMOTE key and at the same time turn

the machine on; the display will show the text rEn 01.

3. Turn the current adjustment knob so that the display will show rEn02. (01=C 100C, 02=C 100F)

4. Press the REMOTE key so that the setting is saved

in the memory.

8. ACCESSORIES

8.1 Remote control units

C 100C C 100D

C 100AC

9901 / 1916110E / 19

Page 20

8.2 Wheel barrows and transport chassises

T 120 (transport unit)

Mastertig AC/DC 1600, 2500, 2500W, 3500W

lifting ear

Do not lift the

welding machine

and the transport

unit with a gas

bottle.

English

T 22 (transport unit)

Mastertig AC/DC 2500,

2500W, 3500W

post gas button. All jumper settings are then saved

in the memory.

Jumper functions are:

(Factory settings are underlined)

J01: [On] = slope of up slope is constant, up slope time

depends on set value of current.

Off = up slope time is independed of set value

of current.

J02: [On] = slope of down slope is constant, down

slope time depends on set value of current.

Off = down slope time is independed of set value of current.

J03: On = TIG antifreeze is on.

[Off] = TIG antifreeze is not in use.

J04: [On] = manual AC balance control.

Off = balance function in use.

J05: [On] = tag welding automatics on.

Off = tag welding automatics is not in use.

J06: [On] = down slope falls to minimum end level cur-

rent (3 A DC, 10 A AC)

Off = down slope falls down to end level which

is 20 % of the welding current

J07: [On] = open-circuit voltage is 39 V

Off = open-circuit voltage is 70 V

J08: [On] = when stopping welding with 4T function

the down slope starts by pressing torch connector. Slope continues as long as you press the connector. Current stays at end level in case you press

longer than down slope´s normal time (look J06).

Off = 4T function is as it has been described on

the operation instructions.

J09 ... J15 Not in use.

J16: Length of positive start cycle of AC-TIG 0.0...2.0,

factory setting is 1.

J17: Adjustment of MMA ignition pulse 0.0...2.0, fac-

tory setting is 1.

lifting ears

on the both sides (total 4 pcs)

9. EXTRA FUNCTIONS

There is extra functions and selections in the machine,

which are not seen in the panel. The welder needs these functions not in normal welding, but they may be a

solution in some special cases. These function are called jumper-functions, because they are behind jumper

numbers. Function can be On/Off -type or adjustable

parameter.

Jumper functions are used as follows:

1. Turn off the machine.

2. Press the post gas button and in the same time

turn the machine on. You can see text (SE.1 000)

on the panel.

3. Press once the pre gas button. Now text (J01 OFF)

or (J01 On) is on te panel.

4. Choose jumper number, which you want by pressing REMOTE button.

5. Change setting of the jumper with current knob I2.

6. When you have done all changes press once the

20 / 1916110E / 9901

Page 21

Technical data Mastertig AC/DC 1600

Mains voltage 1~ 50 / 60 Hz 230 V ± 10 %

Rated power TIG 25 % ED

TIG 100 % ED

MMA 15 % ED

MMA 100 % ED

Connection cable 3 x 1,5 mm2 S - 3 m

Fuse 16 A slow

Welding current range TIG DC

AC

MMA DC

AC

Maximum load **) TIG AC 50 % ED (T = 40 °C)

TIG AC 100 % ED (T = 40 °C)

MMA 15 % ED (T = 40 °C)

MMA 100 % ED (T = 40 °C)

TIG AC 60 % ED (T = 20 °C)

TIG AC 100 % ED (T = 20 °C)

MMA 15 % ED (T = 20 °C)

MMA 100 % ED (T = 20 °C)

Open circuit voltage (AC and DC) 70 V DC

Frequency of AC fixed / adjustable *) 60 Hz / 50 ... 200 Hz

Efficiency 75 % (160 A / 26 V)

Power factor 0,8 (160 A / 26 V)

Open circuit power 18 W

Storage temperature range -40 ... +60 °C

Operating temperature range -20 ... +40 °C

Temperature class / Degree of protection B (130 °C), H (180 °C) / IP 23C

External dimensions length, width, height 540 mm, 260 mm, 510 mm

Weight 28 kg

160 A / 4,7 kVA

90 A / 2,3 kVA

160 A / 6,8 kVA

90 A / 3,5 kVA

3 A / 10 V ... 160 A / 16,4 V

10 A / 10 V ... 160 A / 16,4 V

10 A / 20 V ... 160 A / 26,4 V

10 A / 20 V ... 160 A / 26,4 V

160 A / 16,4 V

120 A / 14,8 V

160 A / 26,4 V

90 A / 23,6 V

160 A / 16,4 V

135 A / 14,8 V

160 A / 26,4 V

100 A / 24 V

English

Technical data Mastertig AC/DC 2500 2500W 3500W

Mains voltage 3~ 50 / 60 Hz 230 V ± 10 %

Rated power (U1=400V) TIG 70 % ED

Connection cable 4 x 2,5 mm2 S - 5 m

Fuse 230 V

Welding current range

Maximum load (T=40 °C) TIG AC 60 % ED

Maximum load (T=20 °C)

Open circuit voltage (AC and DC) 70 V DC

Frequency of AC fixed / adjustable *) 60 Hz / 50 ... 200 Hz

Efficiency 80 % (250 A / 30 V) 80 % (350 A / 34 V)

Power factor 0,9 (250 A / 30 V) 0,9 (350 A / 34 V)

Open circuit power 18 W

Storage temperature range -40 ... +60 °C

Operating temperature range -20 ... +40 °C

Temperature class / Degree of protection B (130 °C), H (180 °C) / IP 23C

External dimensions

Weight 39 kg 65 kg 74 kg

Max liquid pressure of cooling unit – – – – 350 kPa 350 kPa

Rated power of cooling unit – – – – 1300 W 1300 W

TIG 100 % ED

MMA 40 % ED

MMA 60 % ED

MMA 100 % ED

400 V

460 V

TIG DC

AC

MMA 10 A / 20 V ... 250 A / 30 V 10 A / 20 V ... 350 A / 34 V

70 % ED

100 % ED

MMA DC 40 % ED

60 % ED

100 % ED

TIG AC 100 % ED 250 A / 20 V 310 A / 22,4 V

MMA DC 80 % ED

100 % ED

length

width

height

400 V ± 10 %

460 V ± 10 %

250 A / 7,5 kVA

200 A / 6,7 kVA

250 A / 10,3 kVA

– – – –

200 A / 7,9 kVA

20 A slow

16 A slow

16 A slow

3 A / 10 V ... 250 A / 20 V

10 A / 10 V ... 250 A / 20 V

– –

250 A / 20 V

220 A / 18,8 V

250 A / 30 V

– –

200 A / 28V

250 A / 30 V

240 A / 29,6 V

690 mm

260 mm

550 mm

690 mm

260 mm

830 mm

3 A / 10 V ... 350 A / 24 V

10 A / 10 V ... 350 A / 24 V

– – – –

400 V ± 10 %

– – – –

350 A / 11,7 kVA

320 A / 9,3 kVA

– – – –

350 A / 15,7 kVA

280 A / 11,2 kVA

– – – –

20 A slow

– – – –

350 A / 24 V

– –

280 A / 21,2 V

– –

350 A / 34 V

280 A / 31,2 V

350 A / 34 V

300 A / 32 V

690 mm

260 mm

870 mm

*) Adjustable with MINILOG- and PULSE panels.

**) Fuse can reduce maximum load.

The products meet conformity requirements for CE marking.

9901 / 1916110E / 21

Loading...

Loading...