Page 1

ArcFeed

200, 300, 300P, 300RC

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

操作手册 • 中文

ZH

Page 2

Page 3

OPERATING MANUAL

English

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

Page 4

CONTENTS

EN

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

1. PREFACE

1.1 General

1.2 About voltage-sensing technology

1.3 Introduction

........................................................................................................................................................ 3

................................................................................................................................................................. 3

................................................................................................ 3

..................................................................................................................................................... 4

2. BEFORE USE..............................................................................................................................................5

2.1 Connecting the cables ..............................................................................................................................5

2.2 Selecting the welding wire ...................................................................................................................5

2.3 Mounting the wire spool ........................................................................................................................ 5

2.4 Installing the MIG/MAG welding gun ............................................................................................6

3. MACHINE SETTINGS ......................................................................................................................6

3.1 Setting the maximum wire feed speed

3.2 Adjusting the pressure of the feed rolls .......................................................................................7

3.3 Adjusting the spool brake

3.4 Reversing polarity

........................................................................................................................................ 8

3.5 Changing the feed rolls

......................................................................................................................7

............................................................................................................................8

........................................................................................ 6

4. USING THE MACHINE ................................................................................................................ 10

4.1 Using the control panel functions ................................................................................................10

4.1.1 Switching the machine on and o .............................................................................................. 10

4.1.2 Selecting the CC or CV mode ........................................................................................................ 10

4.1.3 Selecting the welding gun operating mode ........................................................................... 11

4.1.4 Changing the wire feed speed adjustment scale ..................................................................12

4.1.5 Using the power source remote control (only 300 RC)........................................................ 12

4.2 Using the inside controls .....................................................................................................................13

4.2.1 Burn back time ................................................................................................................................... 13

4.2.2 Gas test ..................................................................................................................................................13

4.2.3 Wire inch ............................................................................................................................................... 13

4.2.4 Post gas time ....................................................................................................................................... 13

4.3 Hanging the device..................................................................................................................................13

5. MAINTENANCE .................................................................................................................................. 14

5.1 Daily maintenance

5.2 Regular maintenance ............................................................................................................................. 14

5.3 Disposal of the machine

..................................................................................................................................14

.......................................................................................................................14

6. ORDERING NUMBERS ...............................................................................................................15

7. TECHNICAL SPECIFICATIONS ........................................................................................ 16

2

Page 5

1. PREFACE

1.1 GENERAL

Congratulations on your choice of the Kemppi ArcFeed wire feeder. Used correctly, Kemppi

products can signicantly increase the productivity of your welding, and provide years of

economical service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the equipment can be found at the end

of the manual.

Please read the manual carefully before using the equipment for the rst time. For your

own safety and that of your working environment, pay particular attention to the safety

instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

EN

1.2 ABOUT VOLTAGESENSING TECHNOLOGY

The voltage-sensing wire feeder uses the welding voltage to generate the energy required for

controlling the wire feeder’s operations. Before starting to weld, you just select the desired

settings for the feeder and the power source according to the welding requirements, the base

and ller material, and the shielding gas to be used.

When you start welding in CC mode, the feeder controls the parameters so that the quality of

the welds always remains high.

In normal MIG/MAG welding, the parameters’ values are controlled by the power source via

the control cable, but voltage-sensing technology makes such a control cable between the

power source and the feeder unnecessary.

Constant Current (CC) power sources

The CC type of welding machine changes the wire feed speed according to the arc voltage.

The voltage will change with dierent arc lengths while only slightly varying the amperage.

Constant Voltage (CV) power sources

The CV type of welding machine maintains a relatively stable, consistent voltage regardless of

the amperage. It results in a relatively at volt-amp curve. The MIG/MAG welding machines are

typically CV type machines.

3

Page 6

1.3 INTRODUCTION

The Kemppi ArcFeed is a voltage sensing wire feeder for MIG/MAG welding. It can be

combined with a variety of power sources of various brands, also with the ones designed for

MMA welding. The recommended power sources to be used with Kemppi ArcFeed are Kemppi

Master 5001 and Kemppi Master MLS 3500.

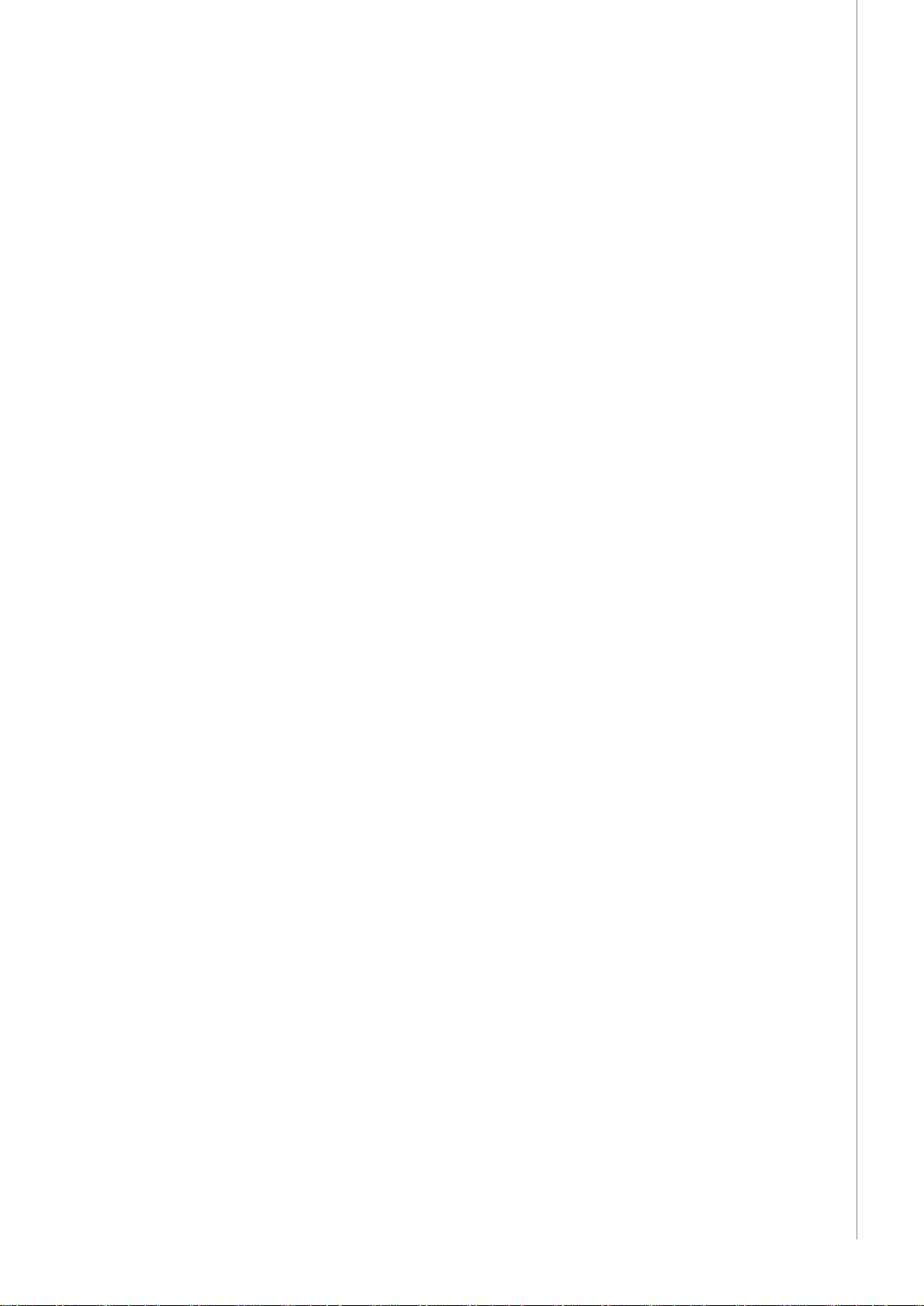

Front view

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

1.

2.

3.

4.

EN

1. Main switch

2. Control panel

3. Welding cable connection

4. Locking latch

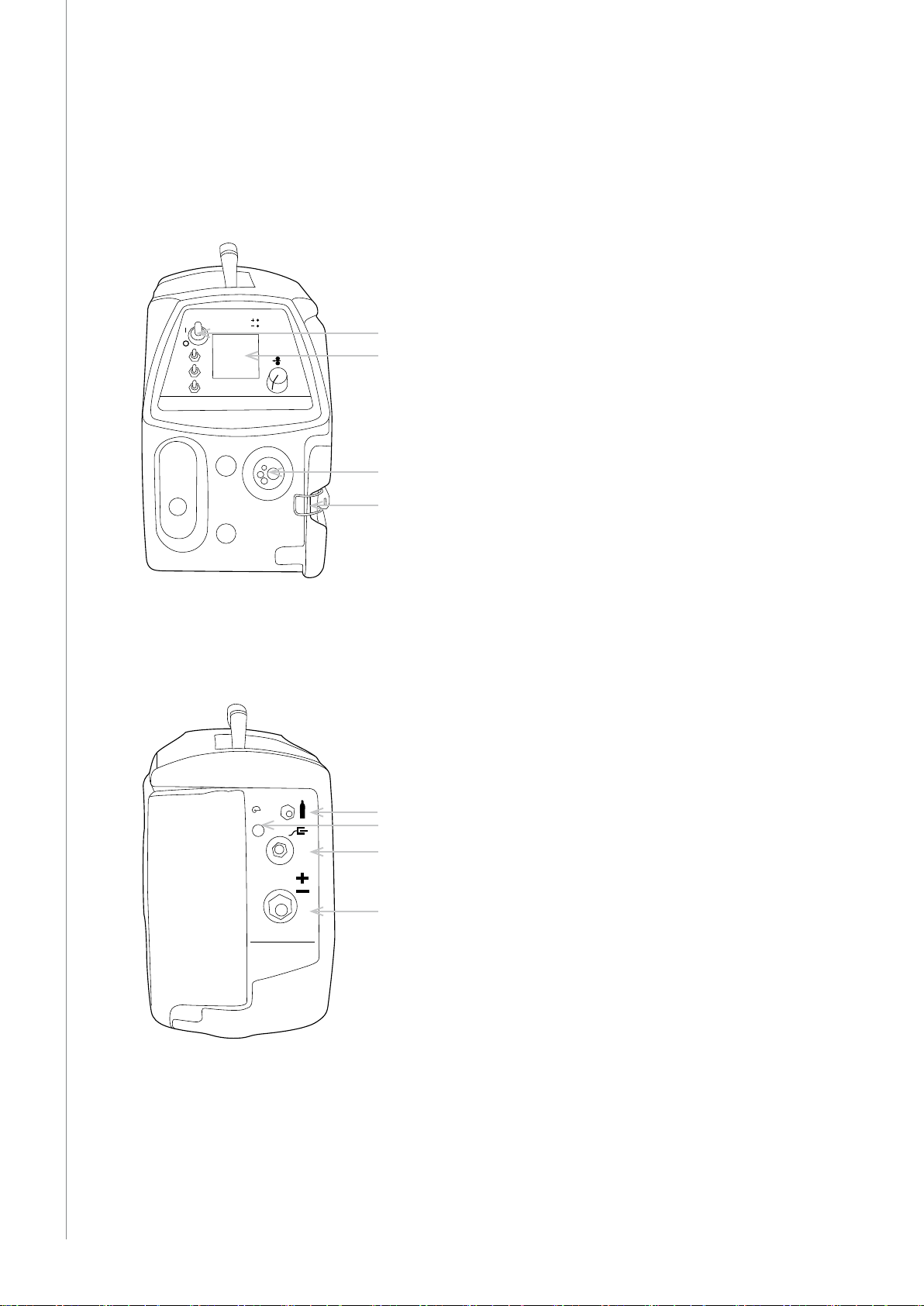

Back view

8 A

1.

2.

3.

4.

1. Shielding gas connection

2. Fuse

3. Earthing cable connection

4. Power source connection

4

Page 7

2. BEFORE USE

2.1 CONNECTING THE CABLES

Before starting to use the Kemppi ArcFeed, the necessary cable connections must be done in

the power source and the wire feeder.

To connect the cables, do the following:

1. Switch o the power source and connect its earthing clamp to the workpiece.

2. Switch o the Kemppi ArcFeed and connect the feeder earthing cable to the male DIX

connector (negative pole) in the back of the feeder. Then connect the feeder earthing

clamp to the workpiece.

3. Connect the welding cable from the power source to the female DIX connector (positive

pole) in the back of the feeder.

4. Connect the shielding gas hose to the connector (1) in the back of the feeder.

The Kemppi ArcFeed is now connected to the power source.

2.2 SELECTING THE WELDING WIRE

Select the suitable welding wire according to the base material, ller material and shielding

gas. The Kemppi ArcFeed is optimized for use with 1.2mm rutile ux-cored or solid wire, but

the following wires can be used:

• Flux-cored wires 1.2–2.0 mm

or up to 2.4 mm with the 300P model

• Innershield wires 1.6–2.0 mm

or up to 2.4 mm with the 300P model

• Solid wires 1.0–1.6 mm

In Kemppi ArcFeed 200 you can use 200mm wire spools. In models 300, 300P and 300RC, you

can use 300 mm wire spools.

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

EN

2.3 MOUNTING THE WIRE SPOOL

Model 200:

A

1. Open the locking nut (A) of the spool holder.

2. Check the rotating direction of the wire spool and push the spool into its place so that it

rotates in the right direction.

3. Close the locking nut (A).

Models 300, 300P and 300RC:

1 2

1. Turn the locking knob (1) of the spool holder so that the locking clips are opened.

2. Check the rotating direction of the wire spool and push the spool into its place so that it

rotates in the right direction.

3. Turn the locking knob (2) of the spool holder to close the locking clips.

5

Page 8

2.4 INSTALLING THE MIG/MAG WELDING GUN

After mounting the wire spool, connect the welding gun cable to the connector (3) in the

front of the feeder.

Remember that you need to use suitable wire liner and feed rolls for the welding wire you are

using. Check also, that the correct groove is used in the feed rolls. If you need to change the

feed rolls or select dierent groove, look the instructions in chapter 3.5.

Before feeding the wire into the gun, release the wire from spool and cut o the bent length.

Be careful not to let the wire unwind from the spool. Check that the end of the wire has no

sharp edges, which may damage the wire guide tube and the contact tip of the welding gun.

NOTE! When feeding the welding wire into the gun, be sure that you are not pointing the gun at

anyone and that there isn’t anything in front of the gun. The cut wire can be very sharp.

To feed the wire from the spool to the welding gun, do the following:

1. Draw some loose wire from the wire spool and feed it through the back guide to the feed

rolls. Do not release pressure of feed rolls!

2. Locate the Wire inch button inside the feeder and push the button down to start the

wire inching. Let the wire go through the feed rolls and enter the wire liner.

3. Keep the wire inch button pressed, until the wire comes through the contact tip.

Check once again that the wire is still properly in the grooves of both feed roll pairs. Now the

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

Kemppi ArcFeed is ready to weld.

NOTE! When welding gun trigger is pressed, the welding current is connected to the wire. To avoid

accidents and electric shock, it is not recommended to use gun trigger for wire inching.

EN

3. MACHINE SETTINGS

3.1 SETTING THE MAXIMUM WIRE FEED SPEED

The maximum wire feed speed of Kemppi ArcFeed is by default 18 m/min. This is enough

for most welding work. However, if you need higher speed, you can raise it to 25 m/min by

replacing the gear wheel D28 with a larger one, model D40.

NOTE! After changing the gear wheel, you must also set the right jumper setting on the control card

of the feeder.

To change the gear wheel, do the following:

1

6

2 4 5 2 3 6 3

6

Page 9

1. Open the locking lever (1) and remove the lower feed rolls (2). Open the screw (4) and

remove its washer. Then remove the gear wheel (5) from motor shaft.

2. Loosen the screws (6) by one turn and replace the gear wheel with the larger one.

Tighten the screw (4).

3. Put the lower feed rolls (2) back to their place, but don't tighten the screws.

4. Lift the motor so that there is a clearance of about 0.2 mm between the gear wheel and

the lower feed rolls.

5. Tighten screws (6). Check the gear clearance and adjust the motor position if necessary.

Tighten the feed roll srews (3).

To set the jumper setting, do the following:

1. Turn the feeder o.

2. Remove the plastic cover of the feeder by unscrewing the xing bolts.

3. Locate the control card inside the feeder and change the position of the jumper X6 so

that it connects the two pins.

4. Replace the cover of the feeder and tighten the xing screws.

3.2 ADJUSTING THE PRESSURE OF THE FEED ROLLS

1

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

The pressure adjustment knob is located at the end of the locking lever (1). With the

adjustment knob you can adjust the pressure of the feed rolls, so that the wire runs smoothly

into the wire liner and brakes a little when coming out of the contact tip.

Make sure that the pressure is hard enough to avoid wire from slipping in the feed rolls, but

not too hard, because then it might atten the welding wire or damage its coating. Too hard

pressure may also cause friction and excessive wearing of the feed rolls.

3.3 ADJUSTING THE SPOOL BRAKE

The Kemppi ArcFeed is equipped with a spool brake to prevent the wire from unwinding and

tangling when the spool stops rotating at the end of the weld. The need for spool brake force

is increased with the increase of the wire feed speed.

The spool brake causes extra load to the wire feed motor, so do not apply too high brake force.

To adjust the spool brake in model 200, do the following:

A

B

EN

Increase the spool brake force by turning the brake adjusting knob (B) clockwise. To decrease

the brake force, turn the knob anticlockwise.

7

Page 10

To adjust the spool brake in models 300, 300P and 300RC, do the following:

Adjust the spool brake force through the hole in the spool locking mechanism with a screw

driver. Increase by turning the screw clockwise and decrease by turning it anticlockwise.

3.4 REVERSING POLARITY

Polarity of the welding machine refers to the pole in which the welding cable is connected.

In MIG/MAG welding the gun is usually connected to the plus pole, i.e. you are using positive

polarity. However, some ller wires are recommended to be welded with the gun in negative

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

pole.

The Kemppi ArcFeed recognizes automatically the polarity you are using. This means that

it knows in which pole the welding cable is connected at the power source. The led on the

control panel indicates, whether you are using positive or negative polarity.

A

EN

To reverse the polarity, do the following:

Switch the welding cable and earthing cable from one pole to the other at the power source.

After that, the wire feeder recognizes the new polarity, and indicates it with the control panel

led.

3.5 CHANGING THE FEED ROLLS

There are dierent feed rolls for dierent welding wires. Also, each feed roll has two grooves

for dierent wire sizes.

The Kemppi ArcFeed is equipped with standard feed rolls, which are equipped with plain

grooves. These feed rolls can be used in welding with all kinds of wires. There are, however,

following feed roll groove shapes available for special purposes:

• Knurled groove is designed for cored wires and steel wires.

• U groove is designed for aluminium wires.

• Trapezoidal groove is designed for heavy welding applications.

The feed rolls and the wire liners have following colour codes in order to make identication

easier.

Feed rolls

colour of filler wire ø mm

white 0.6 and 0.8

red 0.9, 1.0, 1.2

yellow 1.4, 1.6, 2.0

black 2.4

Wire guide tubes

colour of filler wire ø mm

orange 0.6-1.6

blue over 1.6

8

Page 11

To change feed rolls, do the following:

1. Remove the feed rolls by unscrewing their xing screws.

2. Insert the new feed rolls into their place.

3. Select the right groove according to the wire you are using. See the instructions below.

4. Fasten the feed rolls with their xing screws and drive the wire into the welding gun as

instructed in chapter 2.4 'Installing the welding gun'.

To change the feed roll groove, do the following:

Each feed roll has two grooves for dierent ller wire diameters. When changing the feed rolls

select the groove according to the wire you are using.

1 1

Move the feed roll selector plates from one side to another.

Choose the correct groove by moving the groove selector plate (1) from one side to another in

feed roll as shown in the left-hand picture above.

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

Move also the gear wheel selector plate.

When changing the feed roll groove you must also set the gear wheel to new position. This is

done by changing the gear wheel selector plate to the other side of the wheel.

EN

9

Page 12

4. USING THE MACHINE

Before starting to use the Kemppi ArcFeed wire feeder, you must be aware of the power

source type you are using ( either CC, constant current, or CV, constant voltage). The suitable

welding wire for the welding application must also be loaded in the feeder. For more

information, see Chapter 3.

4.1 USING THE CONTROL PANEL FUNCTIONS

6

7

1

EN

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

4

1. ON/OFF switch

2. Gun operating mode selector (2T/4T)

3. CC/CV mode selector

4. Selector of the wire feed speed scale

5. Control knob.

6. Polarity indicator light

7. LCD display

4.1.1 Switching the machine on and o

To turn on the machine, set the main switch (1) to position ON. The LCD display of the control

panel lights up, and the machine is ready for use.

4.1.2 Selecting the CC or CV mode

With the CC/CV switch you can choose between constant current (CC) and constant voltage

(CV) type of power source. Set this switch according to the power source you are using. See

the documentation of the power source to nd its type.

2

3

5

10

Page 13

Adjusting the welding values in CC mode:

In CC mode, the display shows the open-circuit voltage and a reference value for welding

current. The reference value is a pre-dened value that has been determined using 1.2 mm

ux-cored wire.

Before starting to weld, use the control knob (5) to set the welding current to match the

welding current of the power source.

NOTE! When welding in CC mode, the dynamics setting at the power source must be set to its

maximum value. For instructions on how to do it, see the documentation of the power source.

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

Adjusting the welding values in CV mode:

In CV mode the display shows the welding voltage and wire feed speed (WFS). The adjustment

range of the wire feed speed depends on the size of the wire drive roll. With the small drive roll

the WFS can be 0–18 m/min, and with the large drive roll it can be 0–25 m/min.

To adjust the welding values in CV mode, do the following:

1. Estimate the welding values to be used in the welding task.

2. At the power source, select the correct values for welding voltage and current, if

available.

3. Use the control knob of the Kemppi ArcFeed to enter the necessary WFS setting at the

feeder. The value is shown on the display.

EN

4.1.3 Selecting the welding gun operating mode

With the switch (2) you can set the MIG welding gun to either two-sequence (2T) or foursequence (4T) mode.

11

Page 14

EN

How to use the welding gun in 2T operating mode:

1. Press the gun trigger down to start welding.

2. Release the gun trigger to stop welding.

How to use the welding gun in 4T operating mode:

1. Press the gun trigger down to start the ow of the shielding gas.

2. Release the trigger to start welding.

3. Press the trigger down again to stop welding.

4. Release the switch again to stop the ow of the shielding gas.

4.1.4 Changing the wire feed speed adjustment scale

With the wire feed speed scale selector (4) you can aect the sensitivity of the control knob

when changing the wire feed speed.

• If you want to use exact wire feed speed adjustment, select the adjustment scale 0…9

(max 9 m/minute).

• If you want to use rough adjustment, select the adjustment scale 0…18

(max 18 m/minute).

4.1.5 Using the power source remote control (only 300 RC)

ArcFeed 300RC model is equipped with a power source remote control function. It allows

you to adjust the power source current level straight from the work site. Remote control can

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

be used in constant current (CC) mode only. For more information on CC mode, see 4.1.2

“Selecting the CC or CV mode”.

To use the remote control

1. Turn the selector switch (2) to up position (REMOTE) and keep it there.

2. Select the desired welding current with the adjustment knob (1). The scale is suggestive

for Master 5001 power source.

3. Release the selector switch.

ARCFEED

300RC

100

50

25

10

REMOTE

150

200

300

400

A

1 adjusting knob

selector switch

2

12

Page 15

4.2 USING THE INSIDE CONTROLS

WIRE INCH

GAS TEST

POST GAS

1 2 3 4

ArcFeed 200 ArcFeed 300, 300P and 300RC

4.2.1 Burn back time

Burn back time control knob (1) lets you adjust the length of the post-welding current. Using

Burn back feature makes it easy to stop welding without wire sticking or burning back to the

contact tip.

4.2.2 Gas test

Gas test button (2) lets you test the shielding gas and measure the gas ow.

4.2.3 Wire inch

Wire inch button (3) lets you drive the welding wire without turning on the welding current.

This feature can be used for example when feeding in the new wire.

BURNBACK

WIRE INCH

GAS TEST

POST GAS

BURN

1

BACK

POST

WIRE

GAS

GAS

INCH

TEST

2

3

4

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

EN

4.2.4 Post gas time

Post gas time (4) control knob lets you adjust the length of the post-welding gas ow. This

feature, combined with the burn back time, provides a smooth nish of the weld.

4.3 HANGING THE DEVICE

The Kemppi ArcFeed 200 wire feeder should never be hanged by its handle. Use a special

hanging frame for hanging it to a welding beam or other. See 'Accessories' in Chapter

'Ordering numbers' at the end of this manual.

The Kemppi ArcFeed 300, 300P and 300RC models can be hanged by their handle by using a

special hanging device, KFH 1000. See 'Accessories' in Chapter 'Ordering numbers' at the end

of this manual.

13

Page 16

5. MAINTENANCE

5.1 DAILY MAINTENANCE

Do the following always before starting to use the machine:

• Check the tightness of the earthing cable connections.

• Check the condition of mains and welding cables and replace damaged cables.

• Make sure that all extension cables used in the mains connection are in proper condition

and compliant with regulations.

NOTE! The mains cables may be repaired and installed only by electrical contractors and installers

authorised to perform such operations.

5.2 REGULAR MAINTENANCE

All electromechanical devices require routine service maintenance depending on usage. This

type of routine maintenance will prevent hazards and malfunctions.

We recommend that you schedule a service inspection of your welding machine every six

months. An authorised Kemppi service agent will inspect and clean your machine, ensuring

that all power connections are tight and secure. Power connections can become loose and

oxidised with frequent and high changes in temperature.

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

5.3 DISPOSAL OF THE MACHINE

NOTE! Disconnect the machine from the mains power supply before handling electric cables.

EN

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

14

Page 17

6. ORDERING NUMBERS

Wire feeders

Kemppi ArcFeed 200

Kemppi ArcFeed 300

Kemppi ArcFeed 300P

Kemppi ArcFeed 300RC

Accessories

Gas flow regulator

Hanging frame for ArcFeed 200

KFH 1000 hanger ArcFeed 300 and 300P

Protection slides for ArcFeed 200

Protection slides for ArcFeed 300 and 300P

Ordering number

6120200

6120300

6120310

6120301

W000364

6185285

6185100

6185286

6185287

Cables

Extension cable

Extension cable

Earthing cable

MIG guns

MMT 32

MMT 32

MMT 35

MMT 35

MMT 42

MMT 42

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

70 mm², 25 m 6183725

70 mm², 10 m 6183710

16 mm², 5m SKM25 6184015

EN

3 m 6253213MMT

4,5 m 6253214MMT

3 m 6253513MMT

4,5 m 6253514MMT

3 m 6254213MMT

4,5 m 6254214MMT

15

Page 18

EN

7. TECHNICAL SPECIFICATIONS

Kemppi ArcFeed 200 300/300RC 300P

Rated power (W)

Welding wire types

Flux-cored wires, ø (mm)

Innershield wires, ø (mm)

Solid wires, ø (mm)

Loadability (A)

Wire feed speed with small drive roll (m/min)

Wire feed speed with large drive roll (m/min)

Storage temperature range

Operating temperature range

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

Degree of protection

EMC class

Dimensions

Length (mm)

Height (mm)

Weight (kg)

Spool size (mm)

Gun connector type

60 % ED

80 % ED

100% ED

Width (mm)

150 150 150

1.2…2.0 1.2…2.0 1.2…2.4

1.6…2.0 1.6…2.0 1.6…2.4

1.0…1.6 1.0…1.6 1.0…1.6

300 300 300

0…18 0…18 0…9

0…25 0…25 0…12.5

-40 °C… +60 °C -40 °C… +60 °C -40 °C… +60 °C

-20 °C… +40 °C -20 °C… +40 °C -20 °C… +40 °C

IP23S IP23S IP23S

A A A

510 590 590

200 240 240

310 445 445

11 15 15

200 300 300

EURO EURO EURO

16

Page 19

ArcFeed 200, 300, 300P, 300RC / © Kemppi Oy / 1117

EN

17

Page 20

KEMPPI OY

Hennalankatu 39

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

ENGLAND

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GmbH

Otto-Hahn-Straße 14

D-35510 BUTZBACH

DEUTSCHLAND

Tel +49 6033 88 020

Telefax +49 6033 72 528

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD.

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY,

LIMITED

Room 420, 3 Zone, Building B,

No.12 Hongda North Street,

Beijing Economic Development Zone,

100176 Beijing

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区宏达北路12号

创新大厦B座三区420室 (100176)

电话: +86-10-6787 6064

+86-10-6787 1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

KAZURA Gardens,

Neelangarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

www.kemppi.com

1931570

1117

Loading...

Loading...