Page 1

Operation instructions • English

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

1910170E

0550

MinarcMig™ Adaptive 150

Page 2

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 1

EN

OPERATION INSTRUCTIONS

ENGLISH

Page 3

MinarcMig™ Adaptive 150

2 © Kemppi Oy 0550

EN

CONTENTS

1. INTRODUCTION ..................................................................3

1.1. PROPERTIES .............................................................................3

1.2. ABOUT WELDING ......................................................................3

2. SAFETY INSTRUCTIONS ...................................................4

2.1. USE OF PROTECTIVE ACCESSORIES .................................... 4

2.2. SAFE USE OF THE WELDING GUN .......................................... 4

2.3. FIRE SAFETY .............................................................................4

2.4. SUPPLY VOLTAGE ..................................................................... 5

2.5. WELDING CIRCUIT .................................................................... 5

2.6. WELDING FUMES ...................................................................... 5

3. MACHINE USE ....................................................................6

3.1. BEFORE IMPLEMENTATION .....................................................6

3.2. GENERAL VIEW OF THE MACHINE ......................................... 7

3.3. CABLE CONNECTIONS Connection to the mains ..................... 7

3.4. FILLER WIRE .............................................................................. 9

3.4.1. Changing the feed roll groove .................................................. 9

3.4.2. Threading the filler wire .......................................................... 10

3.4.3. Reversing polarity .................................................................. 11

3.5. CONTROLS AND INDICATOR LIGHTS ....................................12

3.5.1. Welding power adjustment ..................................................... 13

3.5.2. Arc length trimmer .................................................................. 13

3.6. THREADING THE SHOULDER STRAP .................................... 14

4. SERVICE ............................................................................14

4.1. DAILY MAINTENANCE ............................................................. 15

4.2. MAINTENANCE OF THE WIRE FEED MECHANISM .............. 15

4.3. MACHINE DISPOSAL ............................................................... 16

4.4. ORDERING NUMBERS ............................................................. 17

5. TROUBLESHOOTING ........................................................18

6. TECHNICAL DATA .............................................................19

7. TERMS OF GUARANTEE .................................................20

Page 4

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 3

EN

1. INTRODUCTION

MinarcMig™ Adaptive 150 is an easy-to-use MIG welding machine suitable for

both hobby and professional use. Before using or doing any maintenance work

on the machine, read the operating manual and keep it for further reference.

1.1. PROPERTIES

The welding machine is small, efficient and extremely light. It is easy to carry

with the help of a shoulder strap. The machine is suitable for a range of different

purposes and the possibility to use a long extention cord eases operation in

various sites. It is also suitable for generator use on construction sites.

Welding voltage and wire feed speed are adjusted with one control according to

the thickness of the welded sheet. Thus, selecting the right parameters is easy.

The length of the arc, or welding heat, is trimmed with another control, and

once the right value is found there usually is no need to change it even when

welding a thicker or thinner sheet.

The machine’s welding properties are optimum with a steel wire of

0.8 mm diameter. Also, 0.6 mm, 0.9 mm or 1.0 mm solid wire or cored wire

can be used as filler wire. Note, however, that the machine is designed for steel

wire welding only.

1.2. ABOUT WELDING

In addition to the welding machine, welding outcome is influenced by the piece

being welded and the welding environment. Therefore, recommendations in this

manual must be followed.

During welding electric current is led with the welding gun’s current nozzle to

the filler wire and via that to the welded piece. Earthing cable attached to the

workpiece guides the current back to the machine, forming the needed closed

circuit. Unrestricted current flow is possible when the earthing clamp is properly

attached to the workpiece and the fixing point of the clamp on the workpiece is

clean, paintless and rustfree.

Shielding gas must be used during welding in order to prevent air from mixing

with the weld pool. Carbon dioxide or a mixture of carbon dioxide and argon is

suitable for shielding gas. Some filler wires form a shielding gas from the wire’s

filling as it melts thus eliminating the need for a separate shielding gas.

Page 5

MinarcMig™ Adaptive 150

4 © Kemppi Oy 0550

EN

2. SAFETY INSTRUCTIONS

The machine is safe to use due to its plastic cover, which does not conduct

electricity. The welding gun has an overheating protector which prevents

operation when the machine is overheated. The machine is also protected from

too low or too high supply voltage.

However, there are some risk factors connected to welding. You should therefore

read and follow the following safety instructions carefully.

2.1. USE OF PROTECTIVE ACCESSORIES

The arc and its reflecting radiation damage unprotected eyes. Always protect

your eyes and face with an appropriate welding mask. The arc and welding

spatters burn unprotected skin. When welding, always use protective gloves

and clothing.

2.2. SAFE USE OF THE WELDING GUN

Parts of the machine, such as the end of the filler wire and welding gun, become

burning hot during use. The wire is also sharp and moves quickly, so be careful

when threading it to place.

Never carry the machine on your shoulder during welding, but place it on an

even surface. Also, do not store the machine by hanging it from the shoulder

strap. The shoulder strap is for carrying only.

Do not keep the machine near or on hot objects, as the plastic cover may

melt.

Do not move the shielding gas bottle when the control valve is in place. Fix the

gas bottle securely in an upright position to a separate wall rack or bottle cart.

Always close the gas bottle after use.

2.3. FIRE SAFETY

Welding is always classified as hot work, so pay attention to fire safety regulations.

Protect the environment from welding spatters. Remove inflammable material,

such as burning fluids, from the vicinity of the welding site and supply the site

with adequate fire-fighting equipment.

Take into account dangers caused by special workplaces, such as fire risk and

danger of explosion, when welding container-like pieces.

Page 6

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 5

EN

NOTE! Fire caused by sparks may brake out even after several hours!

CAUTION! Welding in inflammable and explosive sites is strictly

forbidden!

2.4. SUPPLY VOLTAGE

• Do not take the welding machine inside a workpiece, for example in to a

container or a car.

• Do not place the welding machine on a wet surface.

• Change faulty cables immediately for they are life-threatening and may

cause a fire.

• Ensure that cables are not squeezed or in contact with sharp edges or a hot

workpiece.

2.5. WELDING CIRCUIT

• Insulate yourself from the welding circuit by using dry and undamaged

protective clothing.

• Do not work on a wet surface.

• Do not use damaged welding cables.

• Do not place the welding gun or earthing clamp on the welding machine or

other electrical device.

2.6. WELDING FUMES

Make sure ventilation is sufficient. Take special precautions when welding

metals containing lead, cadmium, zinc, mercury or beryllium.

Supply of sufficient clean air can also be ensured with the use of a fresh air

mask.

Page 7

MinarcMig™ Adaptive 150

6 © Kemppi Oy 0550

EN

3. MACHINE USE

The machine is delivered ready for operation without adjustments with 0.8 mm

diameter filler wire.

If you use non-recommended filler wire, make sure that the feed roll groove,

welding gun contact tip and machine polarity are suited for the used wire size

and type.

3.1. BEFORE IMPLEMENTATION

The products are packed to durable packages especially designed for them.

However, always make sure before use that the products have not been damaged

during transportation. Check also, that you have received the products you

ordered and the instruction manuals needed. Product packing material is

recyclable.

Transportation

The machine should be transported in an upright position.

NOTE! Always move the welding machine by lifting it from the handle.

Never pull it from the welding gun or other cables.

Environment

The machine is suitable for both indoor and outdoor use, but it should be

protected from heavy rain and sunshine. Store the machine in a dry and clean

environment and protect it from sand and dust during use and storage. The

recommended operating temperature range is -20°C – +40°C.

Place the machine in such a way that it does not come in contact with hot

surfaces, sparks and spatters.

Make sure the air flow in the machine is unrestricted.

Page 8

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 7

EN

3.2. GENERAL VIEW OF THE MACHINE

Figure 3.1. General view

1. Welding gun

2. Earthing cable

3. Main switch

4. Supply voltage cable

5. Shielding gas hose connector

3.3. CABLE CONNECTIONS

Connection to the mains

The machine is equipped with a 3.3 m long supply voltage cable and plug.

Connect the supply voltage cable to the mains.

NOTE! The fuse size needed is 16 A delayed.

If you use an extension cord, its cross-sectional area should be at least as large

as the supply voltage cable’s (3 x 2.5 mm²). The maximum length for the

extension cord is 50 m.

The machine can also be used with a generator. The minimum power for the

generator is 3.5 kVA, and the recommended power 6.0 kVA in order for the

machine to be used at maximum capacity.

Earthing

The earthing cable is already connected to the machine. Clean the workpiece

surface and fix the earthing cable clamp to the piece in order to create a closed

and interference-free circuit needed for welding.

Page 9

MinarcMig™ Adaptive 150

8 © Kemppi Oy 0550

EN

Welding gun

The welding gun is already connected to the machine. The welding gun leads

the filler wire, shielding gas and electric current to the weld. When you press

the welding gun trigger, shielding gas flow and wire feed begin. The arc ignites,

when the filler wire touches the welded piece.

The gun neck can be rotated 360°. When turning the neck, always make sure

that the neck is twisted almost all the way to the bottom. This prevents damaging

and overheating the neck.

NOTE! If you use other than 0.8 mm diameter filler wire, change the

welding gun contact tip to match the wire thickness.

Shielding gas

The shielding gas used for steel wires is carbon dioxide or a mixture of argon

and carbon dioxide which replaces air in the arc’s area. Thickness of the welded

sheet and welding power define the flow rate of the shielding gas.

The machine is delivered with a 4.5 m long shielding gas hose. Connect the

bayonet socket of the shielding gas hose to the machine’s hose connector and

the hose connector end to the gas bottle’s control valve.

Figure 3.2. Connecting the gas hose to a typical control valve

1. Connect the hose to the gas

bottle’s control valve and

tighten the connector.

2. Adjust the flow rate with

the control valve screw. A

suitable shielding gas flow

rate is 8-15 l/min.

3. Close the bottle’s valve

after use.

NOTE! Use a shielding gas suitable for the material’s welding. Fix the gas

bottle securely in an upright position before installing the control valve.

Page 10

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 9

EN

3.4. FILLER WIRE

The machine is delivered with the welding gun connected to +pole making it

suitable for steel solid wire welding without adjustments.

3.4.1. Changing the feed roll groove

The feed roll groove is factory set for welding filler wires of 0.8-1.0 mm

diameter. The feed roll groove must be changed if you use 0.6 mm thick filler

wire.

Figure 3.3. Changing the feed roll groove

1. Open the feed roll from the pressure control lever.

2. Switch the machine on from the main switch.

3. Press the welding gun trigger and drive the feed roll in such a position that

its locking screw is up and can be opened.

4. Switch the power off from the main switch.

5. Open the feed roll locking screw with a 2.0 mm Allen wrench

approximately half a turn.

6. Pull the feed roll from its shaft.

7. Turn the feed roll and reinstall it to its shaft all the way to the bottom

making sure that the screw is on the shaft’s level.

8. Tighten the feed roll locking screw.

Page 11

MinarcMig™ Adaptive 150

10 © Kemppi Oy 0550

EN

3.4.2. Threading the filler wire

Figure 3.4. Threading the filler wire

1. Open the reel housing by pressing on the opening button and install the wire

reel in such a way that it rotates counter clockwise. You can use either a 5 kg

(diameter 200 mm) or 1 kg (100 mm) wire reel in the machine.

2. Attach the reel with a reel lock.

3. Unfasten the wire end from the reel, but hold on to it all the time.

4. Straighten the wire end for approximately 20 cm and cut the wire in the

straightened location.

5. Open the pressure control lever which then opens the feed gear.

6. Thread the wire through the wire’s rear guide to the gun’s wire guide.

7. Close the feed gear and fasten it with the pressure control lever. Make sure that

the wire runs in the feed roll groove.

8. Adjust the compression pressure with the pressure control lever no higher than

to the middle of the scale. If the pressure is too high, it removes metal fragments

from the wire surface and may damage the wire. On the other hand, if the

pressure is too low, the feed gear slips and the wire does not run smoothly.

Page 12

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 11

EN

9. Press the welding gun trigger and wait for the wire to come out.

10.Close the reel housing cover.

CAUTION! When driving the wire in to the gun, do not point the gun

at yourself or others or put, for example, your hand in front of the tip,

because the cut wire end is extremely sharp. Also, do not put your fingers

near the feed rolls, because they might get squeezed between the rolls.

3.4.3. Reversing polarity

Some filler wires are recommended to be welded with the gun in the –pole,

so the polarity should be reversed. Check the recommended polarity from the

filler wire package.

Figure 3.5. Reversing polarity

1. Disconnect the machine from the mains.

2. Bend the rubber cover of the earthing cable’s pole in such way that the

cable can be disconnected.

3. Remove poles’ tightening nuts and washers. Note the correct order of the

washers!

4. Interchange the cables.

5. Install the washers in place and close the tightening nuts to spanner

tightness.

6. Put the rubber cover of the earthing cable’s pole firmly in place. The

rubber cover must always protect the earthing cable’s pole.

Page 13

MinarcMig™ Adaptive 150

12 © Kemppi Oy 0550

EN

3.5. CONTROLS AND INDICATOR LIGHTS

Figure 3.6. Machine's front panel

1. Welding power control

2. Arc length trimmer

3. Standby indicator light

4. Overheating indicator light

The welding power is adjusted according to the thickness of the welded sheet.

The machine also has a trimmer for arc length.

Indicator lights display the machine’s standby mode and inform of a possible

overheating.

When you switch the machine on, a green standby light switches on.

Simultaneously, the main switch indicator light switches on. If the machine

overheats or the supply voltage is too low or too high, the welding operation

automatically switches off and the yellow overheating indicator light switches

on. The light switches off when the machine is ready for operation again. Make

sure that there is enough space around the machine allowing air to freely flow

and cool the machine.

Page 14

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 13

EN

3.5.1. Welding power adjustment

Adjusting the welding power according to sheet thickness affects simultaneously

both wire feed speed and amount of current lead to the wire. This is a good

starting point for welding in different operating situations. However, connection

type and root opening may influence the amount of welding power needed.

Select the correct parameter with the welding power control according to the

welded fillet weld’s sheet thickness. If the fillet weld’s sheets are of different

thickness, use their average as a default parameter.

Sheet thickness scale has been given in millimetres and it is based on 0.8 mm

wire diameter. When using a 0.6 mm wire, set the welding power control slightly

higher than the used sheet thickness and correspondingly slightly lower with

0.9-1.0 mm wires.

NOTE! When welding for the first time, we recommend that you set the arc

length trimmer to the middle position.

3.5.2. Arc length trimmer

The arc length trimmer adjusts the length of the arc shorter or longer and affects

the welding temperature. A shorter arc is colder and a longer one hotter. The

arc length trimmer also affects the arc’s welding properties and spatters with

different combinations of filler wire diameters and shielding gases.

If the weld is too convex, the arc is too short or cold. Then adjust the arc longer

or hotter by turning the control clockwise.

If, on the other hand, you want to weld with a colder arc to prevent for example

the parent material from burning through, adjust the arc shorter by turning the

control counter clockwise. You can also adjust the welding power, if need be.

Once the arc has been trimmed, it usually does not need to be changed when

the welded sheet thickness changes.

Page 15

MinarcMig™ Adaptive 150

14 © Kemppi Oy 0550

EN

3.6. THREADING THE SHOULDER STRAP

Figure 3.7. Threading the shoulder strap in place

The machine is delivered with a shoulder strap which helps carrying the machine.

Thread the shoulder strap in place according to the picture.

NOTE! The machine should not be hung up from the shoulder strap.

4. SERVICE

When servicing the machine, its utilization degree and environmental

circumstances should be taken into account. If you use the machine

appropriately and service it regularly, you will spare yourself from unnecessary

malfunctions.

CAUTION! Disconnect the machine from the mains before handling the

electrical cables.

Page 16

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 15

EN

4.1. DAILY MAINTENANCE

• Remove welding spatters from the welding gun’s tip and check the

condition of the parts. Change damaged parts to new ones immediately.

Only use original Kemppi spare parts.

• Check that the insulating tips of the welding gun’s neck are undamaged

and in place. Change damaged insulation parts to new ones immediately.

• Check the tightness of the welding gun’s and earthing cable’s connections.

• Check the condition of the supply voltage and welding cable and replace

faulty cables.

4.2. MAINTENANCE OF THE WIRE FEED MECHANISM

Service the wire feed mechanism at least every time the reel is changed.

• Check the wear of the feed roll groove and change the feed roll when

necessary.

• Clean the welding gun wire guide with compressed air.

Figure 4.1. Parts of the welding gun and wire guide

Cleaning the wire guide

Pressure of the feed rolls remove metal dust from the filler wire’s surface

which then finds its way to the wire guide. If the wire guide is not cleaned, it

gradually clogs up and causes wire feed malfunctions. Clean the wire guide in

the following manner:

1. Remove the welding gun’s gas nozzle, contact tip and contact tip’s adapter.

2. With a pneumatic pistol, blow compressed air through the wire guide.

3. Blow the wire feed mechanism and reel housing clean with compressed air.

4. Reattach the welding gun’s parts. Tighten the contact tip and contact tip’s

adapter to spanner tightness.

Page 17

MinarcMig™ Adaptive 150

16 © Kemppi Oy 0550

EN

Changing the wire guide

If the wire guide is too worn or totally clogged, change it to a new one according

to the following instructions:

1. Disconnect the welding gun from the machine.

a. Disconnect the cable clamp of the gun’s power cable by opening the

screws.

b. Disconnect the gun’s power cable from the machine’s pole.

c. Disconnect the connector of the trigger conductors from the machine.

d. Open the gun’s mounting nut.

e. Extract the gun gently from the machine whereupon all parts come

through the front part’s cable hole.

2. Open the mounting nut of the wire guide which exposes the end of the

wire guide.

3. Straighten the welding gun’s cable and withdraw the wire guide from the

gun.

4. Push a new wire guide in to the gun. Make sure that the wire guide enters

all the way into the contact tip’s adapter and that there is an o-ring at the

machine-end of the guide.

5. Tighten the wire guide in place with the mounting nut.

6. Cut the wire guide 2 mm from the mounting nut and file the sharp edges of

the cut round.

7. Reattach the gun in place and tighten the parts to spanner tightness.

4.3. MACHINE DISPOSAL

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment and its implementation in accordance with national

law, electrical equipment that has reached the end of its life must be collected

separately and returned to an environmentally compatible recycling facility. As

the owner of the equipment, you should get information on approved collection

systems from our local representative.

By applying this European Directive you will improve the environment and

human health.

Page 18

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 17

EN

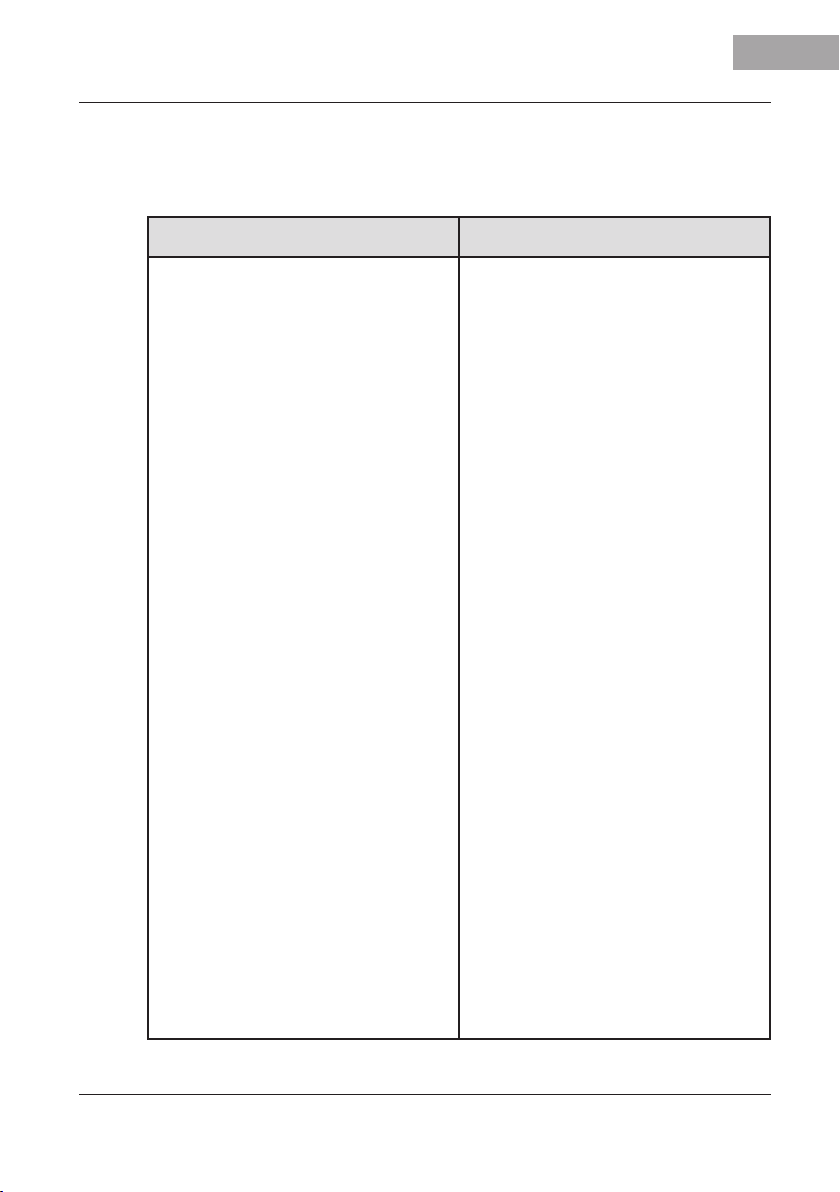

4.4. ORDERING NUMBERS

PRODUCT ORDERING NUMBER

MinarcMig™ Adaptive 150

(includung gun, cables, gas hose and

shoulder strap)

6108150

Welding gun MMG18 (3 m) 6250180

Earthing cable and clamp (3 m) 6184003

Shielding gas hose (4,5 m) W001077

Shoulder strap 9592162

Consumables for wire feed mechanism

Feed roll 0,6-1,0 mm W000749

Feed roll 0,8-1,0 mm, knurled W001692

Pressure roll 9510112

Wire rear guide W000651

Parts for wire reel hub

Reel flange W000728

Spring W000980

Wire reel lock W000727

Consumables for MMG18 gun

Gas nozzle 9580101

Gas nozzle insulating bush 9591010

Contact tip M6 ø 0,6 mm 9876634

Contact tip M6 ø 0,8 mm 9876635

Contact tip M6 ø 0,9 mm 9876633

Contact tip M6 ø 1,0 mm 9876636

Contact tip adapter 9580173

Neck insulating ring 9591079

Wire guide 0,6-1,0 mm 4307650

Page 19

MinarcMig™ Adaptive 150

18 © Kemppi Oy 0550

EN

PROBLEM CAUSE

The wire does not move

or wire feed entangles

Feed rolls, wire conduit or contact tips are

defective

• Check that feed rolls are not too tight or too

loose

• Check that the feed roll groove is not too

worn

• Check that the wire conduit is not blocked

• Check that there are no spatters on the

conduit tip and that the hole is not cramped

or worn loose

Main switch indicator

light does not switch on

The machine has no supply voltage

• Check supply voltage fuses

• Check supply voltage cable and plug

Machine welds badly Welding outcome is influenced by several

factors

• Tarkista, että langansyöttö on tasaista

• Check the trimming settings of welding

power control and arc length

• Check that the earthing clamp is fixed

properly, fixing point is clean, and both

cable and its connections are undamaged

• Check the flow of shielding gas from the tip

of the welding gun

• Supply voltage is uneven, too low or too

high

Over-heating indicator

light switches on

The machine has over-heated

• Check that cooling air can flow without

obstructions

• Machine’s volume-capacity ratio has been

exceeded; wait for the indicator light to

switch off

• The supply voltage is too low or too high

5. TROUBLESHOOTING

If the machine’s malfunction can not be corrected with these measures, contact

the KEMPPI maintenance service.

Page 20

MinarcMig™ Adaptive 150

© Kemppi Oy 0550 19

EN

6. TECHNICAL DATA

The machine complies with the CE mark standards.

MINARCMIG™ ADAPTIVE 150

Connection voltage 1 ~ 230 V ±15%, 50/60 Hz

Connection power:

• 35% ED 6,9 kVA 150 A

• 60% ED 5,3 kVA 120A

• 100% ED 4,2 kVA 100A

Connection cable/fuse 2,5 mm² S–3,3 m / 16 A delayed

Load capacity:

• 35% ED 150 A / 21,5 V

• 60% ED 120 A / 20,0 V

• 100% ED 100 A / 19,0 V

Adjustment range 20-150 A / 13,5-22 V

Wire feed adjustment range 1-11 m/min

Open-circuit voltage 22-31 V

Power ratio 0,58 (150A / 21,5V)

Operating efficiency 0,80 (150A / 21,5V)

Filler wires:

• Fe solid wire ø 0,6...1,0 mm

• Fe cored wire ø 0,8...1,0 mm

Shielding gases CO², Ar+CO² -mixed gases

Maximum size of the wire reel ø 200 mm

Temperature class H (180°C) / F (155°C)

Dimensions L 400 x W 180 x H 340 mm

Weight

(incl. gun and cables 3,0 kg)

9,4 kg

Operating temperature range -20°C...+40°C

Storage temperature range -40°C...+60°C

Protection class IP23C

Page 21

MinarcMig™ Adaptive 150

20 © Kemppi Oy 0550

EN

7. TERMS OF GUARANTEE

Kemppi Oy provides a guarantee for products manufactured and sold by them

if defects in manufacture and materials occur. Guarantee repairs must be carried

out only by an Authorised Kemppi Service Agent. Packing, freight and insurance

costs to be paid by orderer.

The guarantee is effected on the date of purchase. Verbal promises which do not

comply with the terms of guarantee are not binding on guarantor.

Limitations on guarantee

The following conditions are not covered under the terms of guarantee: defects

due to natural wear and tear, non-compliance with operating and maintenance

instructions, connection to incorrect or faulty supply voltage (including voltage

surges outside equipment spec.), incorrect gas pressure, overloading, transport

or storage damage, fire or damage due to natural causes i.e. lightning or flooding.

This guarantee does not cover direct or indirect travelling costs, daily allowances

or accommodation.

Under the terms of guarantee, welding torches and their consumables, feeder

drive rolls and feeder guide tubes are not covered.

Direct or indirect damage due to a defective product is not covered under the

guarantee.

The guarantee is void if changes are made to the product without approval of the

manufacturer, or if repairs are carried out using non-approved spare parts.

The guarantee is also void if repairs are carried out by non-authorised agents.

Undertaking guarantee repairs

Guarantee defects must be informed to Kemppi or authorised Kemppi Service

Agents within the guarantee period.

Before any guarantee work is undertaken, the customer must provide proof of

guarantee or proof of purchase , and serial number of the equipment in order to

validate the guarantee. The parts replaced under the terns of guarantee remain

the property of Kemppi.

Following the guarantee repair, the guarantee of the machine or equipment,

repaired or replaced, will be continued to the end of the original guarantee

period.

Page 22

KEMPPI OY

PL 13

FIN – 15801 LAHTI

FINLAND

Tel (03) 0899 11

Telefax (03) 899 428

www.kemppi.com

KEMPPIKONEET OY

PL 13

FIN – 15801 LAHTI

FINLAND

Tel (03) 899 11

Telefax (03) 7348 398

e-mail: myynti.fi@kemppi.com

KEMPPI SVERIGE AB

Box 717

S – 194 27 UPPLANDS VÄSBY

SVERIGE

Tel (08) 59 078 300

Telefax (08) 59 082 394

e-mail: sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N – 3103 TØNSBERG

NORGE

Tel 33 34 60 00

Telefax 33 34 60 10

e-mail: sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK – 2740 SKOVLUNDE

DANMARK

Tel 44 941 677

Telefax 44 941 536

e-mail: sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL – 4801 EA BREDA

NEDERLAND

Tel (076) 5717 750

Telefax (076) 5716 345

e-mail: sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK443WH

ENGLAND

Tel 0845 6444201

Fax 0845 6444202

e-mail: sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel (01) 30 90 04 40

Telefax (01) 30 90 04 45

e-mail: sales.fr@kemppi.com

KEMPPI GmbH

Otto-Hahn-Straße 14

D – 35510 BUTZBACH

DEUTSCHLAND

Tel (06033) 88 020

Telefax (06033) 72 528

e-mail: sales.de@kemppi.com

KEMPPI SP. z o.o.

UI. Piłsudskiego 2

05-091 ZĄBKI

Poland

Tel +48 22 781 6162

Telefax +48 22 781 6505

e-mail: info.pl@kemppi.com

KEMPPI WELDING

MACHINES AUSTRALIA PTY LTD

P.O. Box 404 (2/58 Lancaster Street)

Ingleburn NSW 2565, Australia

Tel +61-2-9605 9500

Telefax +61-2-9605 5999 e-mail:

e-mail: info.au@kemppi.com

www.kemppi.com

Loading...

Loading...