Page 1

150

1920380

1615

A7 TIG Orbital System

EN

OPERATING MANUAL

Page 2

2

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

CONTENTS

1. Introduction ..........................................................................................4

1.1 General ......................................................................................................4

1.2 About the product ....................................................................................5

1.3 Weld head ..................................................................................................6

1.3.1 Tube diameters and weld head outline dimensions .......................................6

1.3.2 Collets ..................................................................................................7

1.3.3 Collet frame and collets ...........................................................................7

1.3.4 Flush collets ..........................................................................................8

1.3.5 Extended collets / combination .................................................................8

1.4 Controller unit ...........................................................................................9

1.4.1 Front panel ............................................................................................9

1.4.2 Gas ow................................................................................................9

1.4.3 Water cooler .........................................................................................9

1.5 Compatibility .............................................................................................9

2. Installation ...........................................................................................10

2.1 Controller unit connectors ......................................................................10

2.2 Connecting the weld head .....................................................................10

2.3 Suitable collets to the collet frame .........................................................11

2.4 Mounting the weld head ........................................................................11

3. Operation .............................................................................................12

3.1 Rotor gear ................................................................................................12

3.2 Tungsten electrode .................................................................................12

3.2.1 Diameter and length .............................................................................12

3.2.2 Holder ................................................................................................13

3.2.3 Geometry guidelines .............................................................................13

3.3 Electrode sharpeners ..............................................................................14

3.4 Filling water cooler with coolant ...........................................................14

3.5 Preparing for welding .............................................................................15

3.5.1 Preparing the workpiece ........................................................................15

3.5.2 Shielding and backing gas .....................................................................16

3.6 Instructions for welding .........................................................................16

3.7 Weld head control panel .........................................................................17

3.8 Controller unit control panel .................................................................17

3.8.1 Start-up ..............................................................................................18

3.8.2 Main screen/Menu ................................................................................18

3.8.3 Using Auto program..............................................................................20

3.8.4 Override Limit function .........................................................................21

3.8.5 Program information .............................................................................21

3.8.6 Alphanumeric labeling ..........................................................................23

3.8.7 Manual programming ...........................................................................23

3.8.8 Pulsing levels .......................................................................................24

3.8.9 RPM Step ............................................................................................24

3.8.10 Pre-purge – Upslope Screen ...................................................................25

3.8.11 Pass level screens .................................................................................25

3.8.12 Other screens ......................................................................................27

3.8.13 Override Limit function .........................................................................27

3.8.14 Maintenance Menu ...............................................................................28

3.8.15 Options Menu ......................................................................................28

3.8.16 Copying/transferring les to memory stick ................................................30

3.8.17 Deleting welds .....................................................................................30

3.8.18 Printing welds ......................................................................................31

3.8.19 Tungsten electrode length calculator .......................................................32

3.8.20 Advanced Help ....................................................................................32

3.8.21 Autotack .............................................................................................32

4. Additional details ..............................................................................33

4.1 Technical data ..........................................................................................33

5. Ordering information ......................................................................33

5.1.1 Collets ................................................................................................38

5.1.2 Tungsten electrode material ...................................................................41

Page 3

3

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

6. Troubleshooting ................................................................................42

6.1 Operation problems ................................................................................42

6.2 Tungsten electrode rotation not concentric to tube O.D. ......................42

7. Maintenance .......................................................................................44

7.1 Periodic maintenance .............................................................................44

7.1.1 Factory and eld calibration ...................................................................44

7.2 Weld head maintenance .........................................................................44

7.2.1 Calibrating the weld head ......................................................................44

7.2.2 Cleaning the weld head .........................................................................45

7.2.3 Internal arcing .....................................................................................45

7.3 Printer operation and maintenance .......................................................46

7.3.1 Installing paper in the printer..................................................................46

7.3.2 Cleaning the printer ..............................................................................46

7.4 Updating software ..................................................................................46

7.5 Service Workshop maintenance ............................................................46

8. Disposal ................................................................................................47

Page 4

4

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

1. INTRODUCTION

1.1 General

Congratulations on choosing A7 TIG Orbital System 150

welding equipment. Used correctly, Kemppi products can

signicantly increase the productivity of your welding and

provide years of economical service.

This operating manual contains important information on

the use, maintenance and safety of your Kemppi product.

The technical specications of the equipment can be

found at the end of the manual.

Please read the operating manual and the safety

instructions booklet carefully before using the equipment

for the rst time. For your own safety and that of your

working environment, pay particular attention to the

safety instructions in the manual.

For more information on Kemppi products, contact

Kemppi Oy, consult an authorized Kemppi dealer, or visit

the Kemppi website at www.kemppi.com.

The specications presented in this manual are subject to

change without prior notice.

Important notes

Items in the manual that require particular attention in

order to minimise damage and harm are indicated with

below symbols. Read these sections carefully and follow

their instructions.

Note: Gives the user a useful piece of information.

Caution: Describes a situation that may result in

damage to the equipment or system.

Warning: Describes a potentially dangerous situation.

If not avoided, it will result in personal damage or fatal

injury.

Disclaimer

While every eort has been made to ensure that the

information contained in this guide is accurate and

complete, no liability can be accepted for any errors

or omissions. Kemppi reserves the right to change the

specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit

the contents of this guide without prior permission from

Kemppi.

Page 5

5

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

1.2 About the product

A7 TIG Orbital System 150 is used for TIG orbital welding. It

is a semi-automatic welding method where the arc moves

automatically and without interruption 360° around tubes

or tting components.

The system consists of a weld head and a controller unit.

The controller unit includes an integrated TIG power

source and a cooling unit.

You can create and save up to 100 welding programs and

select the most suitable for each welding object by using

the unit’s graphic interface.

The system has been designed to weld tubes made of

various materials, including stainless steel, Duplex and

Titanium, up to wall thickness of 3 mm.

Weld heads of various (5) sizes enable welding pipes with

diameters from 3 to 150 mm.

The system oers a wide operating range and good

reach and is suitable for

• tube-to-tube

• tube-angle

• tube-to-tting welding.

Page 6

6

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

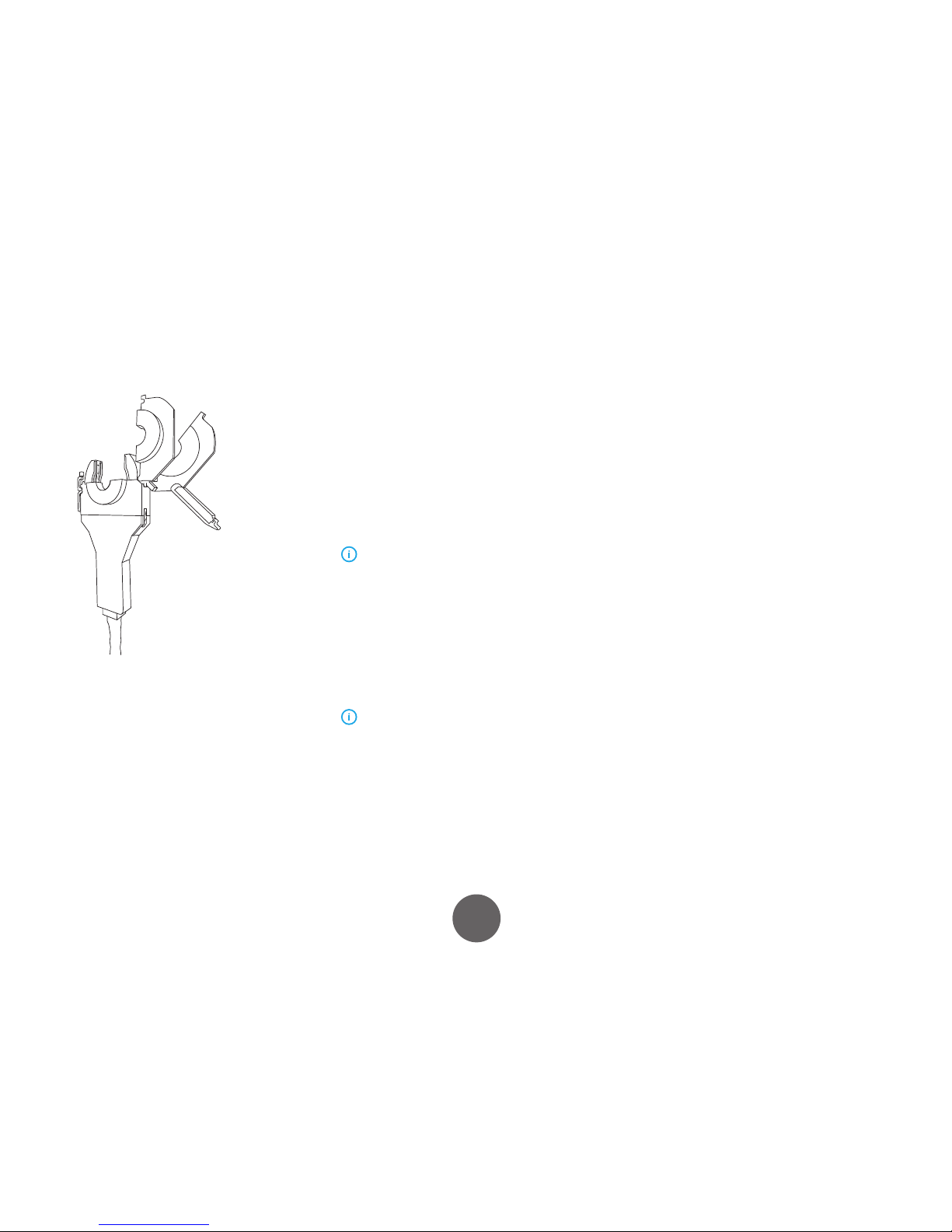

1.3 Weld head

W009315

The weld head contains a U-shaped rotor gear that moves

the tungsten electrode orbiting the non-moving tube. The

head totally encloses the weld joint and allows the interior

of the head to be ooded with shielding gas. The system

includes water cooling for heavy duty cycles.

Control panel is in the handle, and assembly to the

controller is provided by a 7.5-metre hose (longer cables

are available).

The weld head is clamped on tubes by changeable collets.

It includes a chamber for shielding gas. Spesic collets are

recommended for each tube outer diameter (OD).

1.3.1 Tube diameters and weld head outline dimensions

A B

C D

15010 15020 15030 15040 15060

Weight (kg) 3.2 5.0 6.4 8.2 10.0

Tube Diameter (mm) 3–25 6–51 9–76 12–102 50–152.4

A (mm) 124 175 202 231 297

B (mm) 62 83 96 110 144

C (mm) 43 43 43 43 43

D (mm) 19 19 19 19 19

Page 7

7

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

1.3.2 Collets

Collets are used for clamping the weld head on the tube

or tting to be welded. Collets always come in pairs, and

they are mounted on the hinged collet frame with screws.

Collets are specied by:

• Weld head model

• Outer diameter (OD) of the tube or pipe.

Two types of collets are available: ush and extended.

1.3.3 Collet frame and collets

The collets mount in the weld head and are used to clamp

the head on to the tube or ttings to be welded.

• The collet frame swings open on a hinge and is

held closed using two latches on either side of

the head.

• Both sides of the collet frame open and close

independently.

• This allows one tube (or tting) to be clamped

in place and the second tube (or tting) to be

butted tightly to the rst clamped tube before it

is clamped.

Above function is solely to keep the head from moving

during welding, and it should not be used as a substitute for

external alignment xtures, clamps, or tack welding to hold

the workpieces aligned.

Each collet pair consists of two half-circle pieces that are

mounted on both sides of the hinged collet frame using

screws (see images below).

The collet frame and collets are connected to the work (+)

lead of the torch cable, and a separate return lead is not

needed.

Collet sets must be ordered separately. One weld head

requires two pairs of collets (1 set = two pairs).

Page 8

8

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

1.3.5 Extended collets / combination

Figure: A pair of extended collets

Extended collet is thicker than ush collet, and it extends

wider from the collet frame. Wider or thicker collets can be

used where the parts to be welded have enough straight

length to be clamped. The amount of extension is 18 mm

on each side of the weld head where extended collets are

used.

Advantages:

• More stable and more capability for holding both

welded pieces aligned with each other.

• Greater alignment capability due to longer

length.

Disadvantages:

• Takes more space, and may not allow welding in

tight places for example in certain tting-to-tube

welds, depending upon tting type.

• Requires a certain straight length of tube on

which to clamp.

1.3.4 Flush collets

Figure: A pair of ush collets

The outer surface of the collet pair is ush with the outer

face of the collet frame. Flush collets are used for joints

where there is very little straight length between the joint

and an obstruction.

Advantages:

• Enables welding in tight places where there is

not much room for clamping, for example when

welding ttings on a tube or pipe.

• Allows the minimum distance between the

tungsten electrode and an obstruction. For

example, if a tting must be welded there is

frequently only a minimal straight length on the

tting available for clamping.

Disadvantages:

• Less stable and less capability for holding both

welded pieces aligned with each other.

• The thicker or wider the collet, the greater

alignment capability it has to hold the tube

or tting so that both ends of the tubes to be

welded are squarely aligned. Therefore, ush

collets have minimal width alignment of tube

ends.

Figure: A combination of collets

Combination:

• Combination of extended and ush collet pair

can be used for tube-to-tting welding, for

example.

• If your application consists of tube-to-tting

welding but you need greater alignment

capability when mounting on the tube side, use

an extended collet pair on one side of the head

and a ush collet pair on the other

Page 9

9

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

1.4 Controller unit

A7 TIG Orbital System 150 power source and cooling unit

are integrated inside the controller unit. This unit also

involves a printer to print welding parameters on paper.

The parameters can be saved on a memory stick through

the USB port. Programs can be stored in internal memory

(100) and saved on a memory stick.

1.4.1 Front panel

A7 TIG Orbital System 150 features a clear color display, a

control knob, and press buttons. Its intuitive graphical user

interface oers easy-to-use menus and auto programming

for automatic calculation of welding parameters, including:

• Electrode length calculator

• Creation of custom programs

• Instructions and information for the operator.

The power source front panel provides the controls to

develop, save, and call up welding programs.

1.4.2 Gas flow

The power source is equipped with a gas ow sensor that

is factory preset. Shielding gas must be owing to the

weld head to initiate a welding arc.

• If gas ow is insucient, pressing the Start Weld

button will not initiate a welding arc.

• If the gas ow is interrupted during welding, the

sensor will immediately extinguish the arc. A

warning message is displayed.

1.4.3 Water cooler

The controller unit contains an integrated water cooler

that monitors water circulation, and any failure or block

causes an alarm.

The water ow function is factory calibrated. Interruption

or insucient water ow (less than 0.5 LPM) results in

termination of welding and a warning message on the

display.

Water ow

The water ow sensor has a factory preset trip point that

is not adjustable.

• If water ow is insucient to actuate the

sensor, a welding arc cannot be initiated.

• Pressing Start Weld causes pre‐purge. When the

arc should be initiated, the starting sequence is

interrupted and a warning is displayed.

1.5 Compatibility

A7 TIG Orbital System 150 controller is compatible with

the 150 series of weld heads.

Page 10

10

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

2. INSTALLATION

2.1 Controller unit connectors

A

E

B

F

C

G

D

All connections are located on the rear of the controller

unit:

A. Power ON/OFF

B. Resettable fuses

TRVL = Travel motor, (WIRE = Wire feed motor, not

available)

C. Weld head control cable

D. Gas Out (to weld head)

E. Gas In (from cylinder)

F. Welding power connector ( – )

G. Earth return connector ( + )

2.2 Connecting the weld head

A

B

C

D

All connections are located on the rear of the controller

unit. Do the following:

A. Connect the weld head’s control cable to the

connector marked with the weld head symbol.

B. Connect the weld head’s gas hose to the Gas Out

connector.

C. Connect the hose from gas cylinder to the Gas In

connector.

D. Connect the weld head’s power cable to the

negative terminal ( – ).

E

F

E. Connect the coolant hoses to two couplings. They

are dierent by their design to avoid incorrect

installation.

F. Connect the weld head’s power return cable to the

positive (+) terminal of the controller unit.

Page 11

11

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

2.3 Suitable collets to the collet frame

The collets are designed to clamp rmly on the outside

diameter (OD) of the tube or ttings to be welded. The

interior diameter (ID) of standard collets is oversize relative

to the tube to be welded by .075 mm to allow for standard

dimensional tolerances. The collet halves that make a pair

are identical. They are engraved to show the tube OD or

tube tting OD and type.

1. Install the two (2) pairs of appropriate collets on

either side of the weld head collet frame using

button head screws. The collet inserts are not

threaded to eliminate stripped threads in the collet

frame, which is more expensive to repair or replace.

2. Accomplish rm clamping by slight over-closure

of the collet frame. Compliance and preload are

provided by the collet frame adjustable latch

mechanism.

The latch lever provides very high clamping loads

with minimal eort. After adjusting the thumbscrew on

the latch mechanism, the toggle action of the lever should

require no more than light pressure of one nger to close.

Over-tightening can result in damage to the collet frame or

tubing.

2.4 Mounting the weld head

Do the following:

1. Install suitable collets on the weld head.

2. Install suitable electrode in the holder.

3. Mount the weld head on the tube and align the

tungsten electrode with the welding joint.

4. Close one side of the weld head and lock it

against the tube with the latch.

5. Place the other tube very tightly against the rst

tube already clamped.

6. Close the other side of the weld head and lock

with the latch.

7. Look through the hole on top of the weld head to

ensure that the alignment is right.

8. Close the hole cover.

Page 12

12

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3. OPERATION

3.1 Rotor gear

Weld head contains a rotor gear that drives the electrode

around the tube. Rotor gear is U-shaped to allow

easy placement of the weld head on and o the tube.

Electrode is fastened on the rotor gear with an easily

replaceable electrode holder. The holder prevents the

rotor gear from damage.

Electrodes and holders are available in the following

diameters:

• 1 mm (.040”)

• 1.6 mm (.062”)

• 2.4 mm (.094”)

3.2 Tungsten electrode

ø 1.0 /1.6 / 2.4 mm

20 – 30°

14 – 75 mm

0.25 – 1.0 mm

Electrode diameter, tip geometry, and arc gap are

important factors in repetitive precision welding. The

electrode must be exactly the correct length with a

maximum tolerance of 0.1 mm.

Inserted into the holder and carefully bottomed, the

electrode forms exactly the correct arc gap. Pre-grinded

and cut-to-length electrodes are available.

3.2.1 Diameter and length

You can use multiple tungsten electrode sizes in each

weld head by changing the tungsten electrode holder.

Order the tungsten electrodes or cut them to a precise

length by yourself. When the tungsten is inserted into

the holder and bottomed, it will create the desired tip-towork distance without the need for adjustment.

Weld head Rotor gear

radius

15010 28.7 mm

15020 42.0 mm

15030 54.6 mm

15040 66.8 mm

15060 100.6 mm

The electrode must be precisely the correct length with

a maximum tolerance of 0.1 mm. Its correct length

depends on the weld head size, electrode diameter and

tube diameter.

To determine correct electrode length, use the

150 series controller Tungsten Length Calculator. If the

controller is not available, calculate cut-length by using the

formula below or a calculator on the Kemppi website.

Length calculation formula:

Length = rotor gear radius – tube radius – arc gap

Page 13

13

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.2.2 Holder

To install the tungsten electrode and holder, do the

following:

1. Turn the controller power switch ON.

2. Using the +/- Rotation Jog on the weld head

handle, rotate the rotor until you can see the

electrode holder's postiion at the open throat

area of the weld head.

3. Using 3 mm x 6 mm cap screws, install the block

and tungsten electrode into desired position. The

tungsten electrode mount block is a split block.

a. Leave screws loose and push up against the

tungsten intu the holder.

b. Tighten screws, solid side rst, then split side.

The standard position of the tungsten electrode

as viewed from the side along the tube centerline is a 5°

down from 3 o’clock. This is to avoid breaking of tungsten

when installing the weld head on pre-tacked tube. You

can use alternative tapped holes in rotor (8 or 6 o’clock

position) e.g. in case of stripped threads in the rotor.

3.2.3 Geometry guidelines

Diameter

Use the smallest diameter tungsten electrode suitable

for the weld current range for positive arc ignition and

a stable arc. Thicker diameters handle high currents and

have a greater life at the expense of arc starting.

Electrode diameter Tube wall thickness

Up to 1.0 mm 1.0 mm

1.0–2.4 mm 1.6 mm (.062")

2.4–4.0 mm

2.4 mm (0.094”)

Arc gap

The tungsten electrode tip-to-work distance, the arc length

is kept to a minimum and produces a more stable arc and

deeper penetration. For general tube welding, the arc gap

should be adjusted between 0.75 mm (.03") and 1.8 mm

(.07").

Tube wall thickness Recommended arc length

0.5–1.0 mm 0.75 mm

1.0–2.0 mm 1.3 mm

2.0–4.0 mm

1.8 mm

Tip angle and at diameter

The tungsten electrode angles (included angle) between 15° to 30° enable the most automated welding.

Kemppi recommends 20° for autogenous welding in the general current range used with the 150 series

weld heads.

Tungsten electrode tip angle and at diameter

Electrode

Diameter mm

Flat diameter

mm

Included

Angle (deg)

Constant current

Range (amp)

Pulsed current

Range (amp)

1.0 mm 0.25 mm 20° 1

1.6 mm 0.5 mm 20° 8–50 8–100

1.6 mm 0.75 mm 20° 10–70 10–140

2.4 mm 0.75 mm 30° 12–90 12–180

2.4 mm 1.0 mm 30° 15–150 15–250

3.2 mm 1.0 mm 30° 20–200

20–300

Page 14

14

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.3 Electrode sharpeners

Ultima – TIG – cut NEUTRIX

Use sharpener to sharpen the electrodes, to cut them to

correct length, and to help gather and recycle welding

dust.

Desktop model (recommended) allows more precise

lengths. It recycles dust into liquid instead of air. You can

also use a hand-held model. Only sharpening is possible

with the hand-held model, not accurately cutting to

length.

You can obtain a faster and more uniform grinding result

compared to manual grinding with an optional auto-grind

device.

Tungsten is the most suitable material for welding

electrodes but it is hazardous as waste and when breathed.

3.4 Filling water cooler with coolant

You can ll the water tanks with normal tap water. However,

the degree of water purity as well as the temperature of

the environment determine if you need to apply additives

and/or otherwise take care of the water supply.

When employing TIG system at temperatures below

+8 °C, add an anti-freeze medium.

1. Fill the water tank with 3.5 liters of Kemppi torch

coolant uid or equivalent (Monopropylenglycol).

2. Use max. 40 % of coolant uid added to water. This

will provide freezing protection to ‐25 °C.

Do not use distilled or demineralized water. Zinc

deciency causes corrosion and a risk of leakage.

Even if the temperature stays above +8 °C, use a

small quantity (ca. 10 %) of anti-freeze additive. It prevents

adverse algal growth in warm water.

The amount of cooling uid required depends on the cable

length of the weld head. Normally, 3.5 litres is sucient.

Check the level of coolant after several minutes of rst

turning on power to top o the coolant level as required.

Page 15

15

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.5 Preparing for welding

1. Turn the power supply ON.

2. Clamp the weld head on the workpiece.

3. Purge the gas hose and chamber of the weld head

using the purge button on the power supply. Purge

the weld head and gas line for approximately ten

(10) minutes prior to the start of welding each shift.

4. Purge the tube ID in preparation for welding with

backing gas.

5. Load the appropriate weld program number as

described in the power supply manual. The red LED

on the handle next to the Home position ignites.

If this does not occur, press the Home button. The

rotor rotates until Start position is reached, and LED

ignites. Press the Start Weld button.

Do not start the head if it is out of its Home position

because it is then exposed to the walls of the chamber and

collets that are at work return potential. While welding, the

arc voltages are so low as to have no consequences, but

during the start sequence having the gear partially exposed

may cause misre. In rare cases this can create an arch- over,

allowing the follow on welding current to establish between

the rotating gear and the housing. This will only happen

if at the same time the tungsten-to-workpiece-to-collet

conductivity is poor due to oxidation or contaminated from

machining operations, primarily lubricants.

6. At the completion of the weld the auto rewind

function rotates the rotor into "open throat"

position to allow the weld head to be removed.

If you do not use this function, press the Home

button once again. The rotor rotates into correct

position to allow the weld head to be removed

from the workpiece.

7. Open both sides of the hinged collet frame and

remove the weld head from the workpiece.

3.5.1 Preparing the workpiece

For successful fusion welding, do the following:

1. Ensure that the tube ends (or ttings) are machined

square relative to their axis.

2. Place the two ends butt-tight together.

3. Leave no gap between the tube ends resulting

from lack of squareness or burrs left from the

machining process.

4. Once the tube end is faced o, check for burrs. Any

burrs must be carefully removed with a hand-held

deburring tool.

5. If the tube wall thickness variation exceeds 10%,

use chamfer cut of 5° on the inside of the tube

ends.

After the tube has been machined, it must be properly

cleaned using the following procedure:

1. Wipe the tube end with a lint-free towel dipped in a

solvent, such as acetone or denatured alcohol, and

immediately wipe with a second clean cloth before

the solvent dries. Use an abrasive cloth to remove

any surface oxides or contaminants. Clean the tube

end back to approximately 12 mm.

2. Repeat the cleaning operation. Ensure that tube’s

inner diameter is similarly cleaned.

Page 16

16

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.5.2 Shielding and backing gas

Select proper shield gas/gas mix for optimum results.

100% argon is normally used for TIG welding. In certain

cases, you can benet from using a mixed gas, such as 95%

argon, 5% hydrogen. This mixed gas gives better control of

the weld puddle and lower heat input. Adding hydrogen

or helium increases the arc voltage and creates a "stier",

more focused arc column.

Industrial grade inert gas is sucient for most stainless

steel welds. Use a higher purity grade for high quality

welds on easily oxidizable alloys.

The purpose of purging is to replace unwanted air and

other vapor contaminants from the root pass by a gas

that prevents oxidation during welding. Oxidation can

produce a variety of problems, such as root oxidation

(sugar), incomplete fusion, porosity and changes in weld

chemistry, which can aect weld mechanical and corrosion

resistance properties adversely.

Use purging when welding stainless steel, nickel alloys,

and most nonferrous base metals. Argon is commonly

used.

The “chamber” created around the tube joint by the

installation of the weld head is ooded with inert gas

that both protects the weld puddle from oxidation and

the tungsten electrode. The gas hose material used

in the weld heads is specically designed to prevent

atmospheric moisture from contaminating the shielding

gas by permeation.

The gas regulator/ow meter should be set for 4

bar (60 PSI) and a suitable ow rate. Recommended gas

ow rate is 3 to 5 l/min for backing gas and 5-10 l/min

for shielding gas. Set pre-purge time so that backing gas

volume is about 10 times the volume to be put inside the

tube.

You can apply separate backing gas for root

protection. When using backing gas, also use dual owmeter regulator that allows having two independently

regulated (shielding and backing gas) circuits from one gas

bottle.

3.6 Instructions for welding

Use the following 5-step procedure to start welding:

1. Select and install suitable collets.

2. Mount weld head around the tube.

3. Pre-purge the tube ID with shielding gas.

4. Select the program you want to use.

5. Star t welding by pressing the Start button.

Page 17

17

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.7 Weld head control panel

W009315

A

B

C

D

A. Stop: immediately terminate the weld cycle and all

functions of the weld head.

B. Star t Weld: initiate the weld program. LED light

beside the button is lit during the weld cycle. This is

also a soft way to stop welding.

C. Home position: welding can be started only when

the rotor gear is in its home position. It also allows

easy installation and removal of the workpiece.

1. Press the Home button to move the rotor gear

to the home position.

2. A red LED ignites next to this button, when the

rotor gear reaches its home position.

D. Rotation forward or reverse: with these buttons you

can move the rotor gear to either direction when

welding arc is not on. This is useful when mounting

or replacing the electrode or checking its condition.

3.8 Controller unit control panel

D

E

B

C

AF

G

I

H

A. Color LCD display: shows the setup values,

parameters and the soft key functions.

B. Stop: terminates the weld cycle and all weld head

functions.

C. Start Weld/Start Downslope: starts welding or

initiates downslope if welding is in progress.

D. USB port: connect memory stick to back up

programs and copy them from one power source

to another, to download QC programs, and to save

welding parameters and print them on a PC.

E. Cursor up: highlight the item above on display.

F. Cursor down: highlight the item below on display.

G. Enter: activate the highlighted item.

H. Control knob: increase/decrease the value of the

selected item.

I. Soft keys (4): select menu items shown on the

display depending on the operation mode (Setup,

Programming, Operation etc.)

Page 18

18

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.1 Start-up

When the control is rst turned on the main display will

remain o except for backlighting. After approximately

12 seconds the model, S/N, software release date, and last

calibration date appear on the display.

3.8.2 Main screen/Menu

Four soft keys on the main screen allow access to:

1. Librar y of existing procedures

2. Help with detailed explanation of highlighted item

3. Menu that provides access to various functions and

system conguration

4. New to create a new weld program.

Library

Programs are listed. Use the up/down cursor to scroll

through programs. Select program with Select (soft key).

Library displays the following choices:

• Weld Number XX

• Run

• Review Parameters

• Review Notes

• Edit Weld

Scroll through the list to make your selection.

To run, review, and edit existing program in Library

Move cursor to desired program and press Select.

Only weld numbers 001 to 099 are in use to store

programs in internal memory. Weld number 100 and above

are used when exporting weld programs to another power

source.

To run a weld in Library

1. Move cursor to Run (highlighted in red). Press

Select.

Also use cursor and Select to Review Parameters, Review

Notes, and Edit Weld.

Page 19

19

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

2. Press Start Weld to initiate weld or press Purge to

pull in gas solenoid if you want to use a longer

purge time. (For example, to purge gas lines when

rst connecting the weld head to the power

source.)

Menu

Use the Up/Down cursor to select from software

accessories:

• Maintenance Menu

• Copy Welds

• Delete Welds

• Print Welds

• QC Set-up

• Options

New

Create procedures using either the Auto program or

standard manual entry.

Navigating

• Select and proceed through a task using four soft

keys (see Main screen/ Menu). The selected item

is highlighted in red. To select an item, use the

up/down keys to highlight the selection in red

(move the cursor).

• To change a numerical value, select Yes/No, or

select an item from a drop-down menu using the

control knob.

• To move to the next screen, press the Next soft

key.

• Certain items are selected using Enter: for

example, the digit to be changed (00.00) or the

text labeling subroutine.

Page 20

20

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.3 Using Auto program

You can automatically select certain default values by

using Autoprogram. For example, to always use four

levels. To change these default values, you must edit the

weld program after it has been generated.

1. Select Yes with the control knob. Press Next.

2. If Password Protection has been applied, you will

be asked for your password to continue.

3. Select Weld Number using the control knob.

4. Press Next when nished.

5. Use Back to move to previous screen.

1. Use the cursor to select each line (highlighted in

red).

2. Use the control knob to select Head Model and

Material.

3. Use Enter and the control knob to select and

change each digit of O.D. and Wall Thickness.

4. Press Next when nished.

Use cursor to select line and the control knob to modify

Next Weld to Run. You have two choices:

1. Repeat the weld program. At the completion of a

weld, the same program is automatically loaded so

that you don’t need to re-enter the weld number.

2. Run a dierent weld program to create work cycles.

Press Next when nished.

Page 21

21

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.4 Override Limit function

You may override any of the pre-programmed values,

but only within the limits dened during programming.

The percentage of override limits can be individually

programmed for each parameter between 0–100% of the

programmed value.

You can gain sucient override capacity to compensate

for tube t variations, for example, but avoid to modify

the original program outside of specied heat input

limitations. The override limits are saved with each weld,

which allows dierent override values based on which the

weld is run.

Use cursor to select line, the control knob to modify.

3.8.5 Program information

1. Use cursor to select item, the control knob to

modify.

Certain items have been previously selected and

cannot be changed (i.e. Weld No., Data, OD, etc.). The cursor

will bypass these items. To add description under Project

and Drawing, see Alphanumeric Labeling.

2. Recording notes

Use cursor to select line for additional notes. Save if all

program selections have been completed (or press Back

to make corrections).

Use cursor to select line, the control knob to modify.

3. Next Weld to Run

You have two choices:

a. Repeat the weld program. At the

completion of a weld, the same program

will automatically be loaded, eliminating

the need to enter the weld number again.

b. Run a dierent weld program. Press Next

when nished.

Completion of programming

Press Main to exit to Main Menu. Press Run to immediately

weld with the new program.

Page 22

22

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Editing a weld program

Move cursor to edit. Press Select (soft key).

Use cursor to select item. Modify with the control knob.

Certain items may not be modied. The cursor will

bypass these items.

Choose Next to move through levels and edit as you go.

The edited weld will overwrite the original program if the

same weld number is selected. To create a new program,

select an unused program number.

Page 23

23

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.6 Alphanumeric labeling

Using the oating keyboard

The keyboard is accessible when a highlighted line

requires keyboard input; such as in the Password Entry or

Program Notes screen or on any other text entry line.

Use the cursor to select the item to be labeled.

Entering text

1. Press Enter on a text entry line to display the

oating keyboard.

2. Use the control knob to select a character.

3. Press Enter to insert selected on the line.

Arrow keys move the highlighted character to the left or

right along the line. You can replace a typed character by

moving the highlighted cursor on it and using the control

knob.

Use Delete (Del) to erase a line. This function only deletes

the last character on the line.

To end text entry and move to the next line on the screen,

press Up or Down.

3.8.7 Manual programming

Use in the same way as Auto program but select each

parameter and technique that you want to use. If password

protection has been applied, you will need to submit

password to continue.

1. Select No with the control knob. Press Nex t.

2. Select Weld Number with control knob. Press Next.

Page 24

24

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

1. Input all information as in Autogen but select the

number of Passes and Levels.

2. Move the cursor to the desired line and use the

control knob or Enter and control knob for OD and

Wall Thickness.

3. You can turn on Auto tack program if necessary

using the control knob.

4. Press Next.

3.8.8 Pulsing levels

You can select pulsed or non-pulsed current. Move the

cursor and use the control knob to change selections.

Pulsing varies the current between high and low values.

3.8.9 RPM Step

RPM Step can be turned on/o. This function indexes

tungsten electrode rotation with pulsed current. Tungsten

electrode will rotate during low current pulse and stop on

high current pulse (or be set to run at a percentage of low

current speed). Press Next.

Page 25

25

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.10 Pre-purge – Upslope Screen

Move the cursor and enter values with the control knob.

Press Next when nished.

• Pre-purge: the time period when gas ows at

weld start before arc ignition (seconds).

• Upslope: the time period in seconds that the weld

current ramps up from start amps value to level 1

value.

• Travel Delay: the period (seconds) beginning at

end of upslope before rotation begins. Used to

establish penetration.

• Start Amps: current level at which arc is initiated.

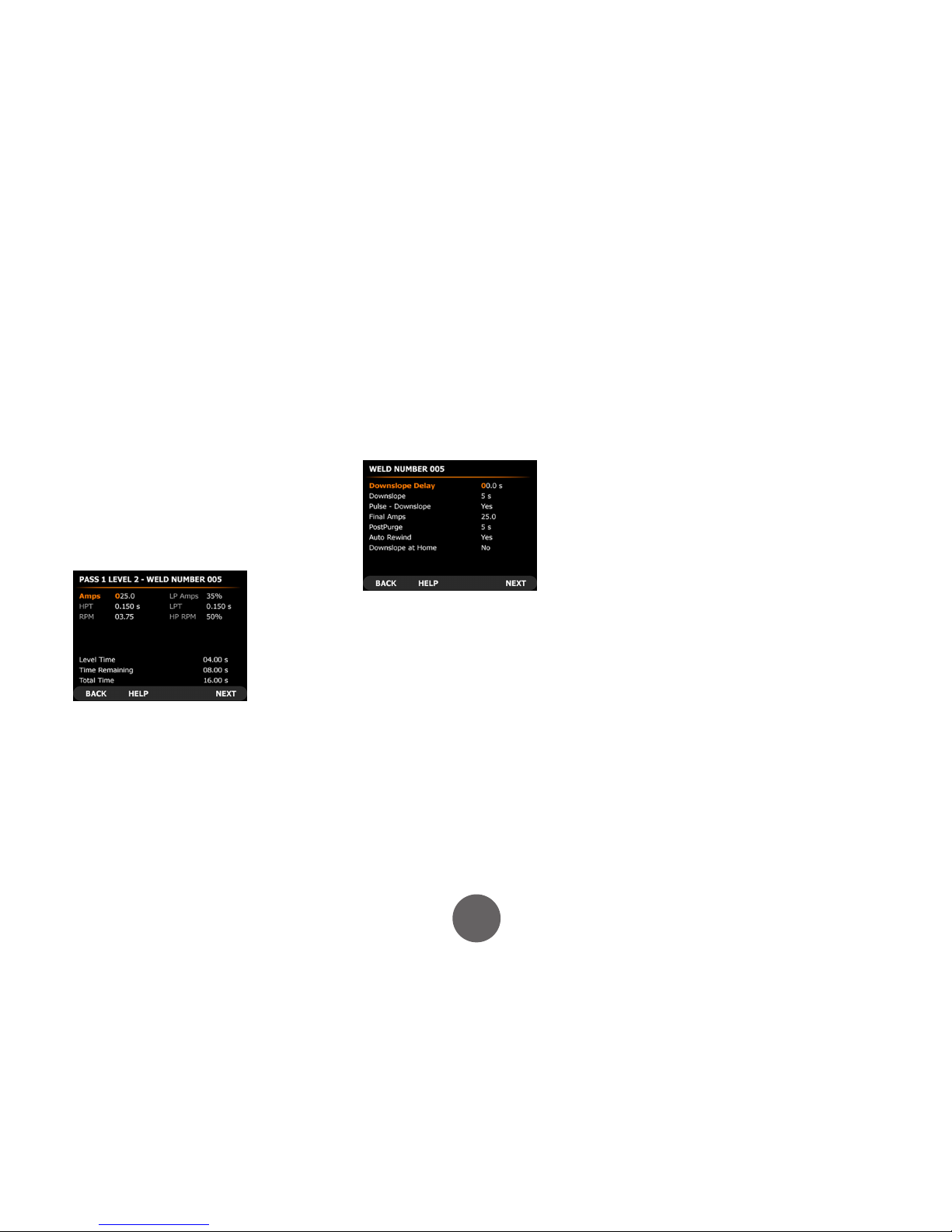

3.8.11 Pass level screens

Pass 1, Level 1

Move the cursor and enter values with the control knob.

• Amps: current at each level (using pulsed current,

this is high pulse current).

• RPM: Rotation Speed

• LP Amps: Low Pulse Amperage, shown as

percentage of high pulse current.

• HPT: High Pulse Time Period, in seconds.

• LPT: Low Pulse Time Period, in seconds.

• HP RPM: rotation speed on high current pulse

(shown only when RPM STEP is turned ON). Can

be set at any percentage from 0–99 of the low

pulse speed listed RPM.

• Level Time: the time during which these

parameters will be active in seconds.

• Time Remaining: as the tube size is input,

selection of RPM automatically calculates Total

(weld) Time.

• Time Remaining: automatically calculated once

Level Time is entered.

• Total Time: total time for weld in seconds. Enter

values and press Next soft key to go to Level 2.

Parameters are automatically carried down through

the levels.

The software of the 150 series controller makes it very easy

to copy parameters from one level to the next by merely

pressing Next.

Be careful when changing parameters at one specic

level to avoid unwanted changes.

Page 26

26

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Example

You wish to change the amperage originally programmed

in Level 4 of a one pass weld. However, other parameter

changes occur in a subsequent level, such as level 5 or 6.

If you make the change in amperage in Level 4 and press

Next, you will automatically copy all of the Program Level

4 values into Level 5. Therefore, note any other changes

that are occurring in subsequent levels within the pass

before modifying any parameter in that pass. This is only

true for Level parameters within any given pass. For a

multi‐pass weld, once you move to a subsequent pass,

the parameters will not be copied from the previous pass.

Pass 1, Level 2

Move the cursor and enter values with the control knob

and press Next, or if no change is necessary, just press

Next.

Pass 1, Level 3 to Final Level

Continue moving through the screens for each level and

change parameters as needed

Page 27

27

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.12 Other screens

Downslope Screen: move the cursor and enter values with

the control knob. Press Next when complete.

Downslope Delay: downslope of weld current will occur

immediately at the tie‐in of the start location. If you

want an overlap of the weld, set the desired seconds of

Downslope Delay.

Downslope: downslope or current taper time period in

seconds.

Pulsing Downslope: choice of pulse current or steady state

current during downslope period (Yes or No).

Final Amps: weld current level just prior to arc termination.

Post‐purge: time period gas ows after arc termination

(seconds).

Auto Rewind: if this feature is “switched on” (by selecting

Yes on the display), it will cause the weld head to

automatically rewind at completion of a weld and come

to a halt at the starting rotational position. Post‐purge will

also occur simultaneously with auto rewind.

Downslope At Home: if this function is left o, program

downslope will occur at the time out (completion) of the

nal level. If this function is turned ON with the control

knob, program downslope will begin exactly as Home

position is actuated. (If starting from Home position, this

will be one 360° revolution, then downslope will still occur

at 360° Home.

This may override level times. For example, if only

one level of 15 seconds is programmed, for a 1 RPM weld

(requiring 60 seconds), the weld will still be made with

downslope at Home, even though there was inadequate

time to complete the weld in the total level times. If the level

times are longer than 360°, then downslope will still occur at

360° Home.

Parameter Override: use cursor to select line, the control

knob to modify.

3.8.13 Override Limit function

You may override any of the pre-programmed values,

but only within the limits that may be dened during

programming. The percentage of override limits can be

individually programmed for each parameter between

0–100 % of the programmed value. You can have sucient

override capacity to compensate for tube t variations, for

example, but to avoid modifying the original program

outside of specied heat input limitations. The override

limits are saved with each weld so that they allow dierent

override values based on which the weld is being run.

Page 28

28

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.14 Maintenance Menu

In the Main Menu screen, press Menu. This will open the

Maintenance Menu screen. Most functions are passwordprotected if this option is selected.

Copy Welds (power source internal memory)

You may want copy an existing weld program as a starting

point for creating a new weld program for a dierent tube

size using the editing feature.

1. In the Maintenance Menu screen, select Copy

Welds and press Enter.

2. Enter the program numbers for source weld and

destination weld, then press Copy.

The Copy function allows you to copy a weld program

within the power source’s internal memory. (For example,

an existing weld number 2 could be copied to weld

number 10, assuming no program number 10 exists.)

The program will not be deleted from weld number 2;

two copies of the program now exist.

When per forming a Copy or Transfer to a destination

program of the same number, the new le does not write

over the existing le. You may delete the existing le or

select an unused destination program number.

Weld numbers 1–99 are les stored in the internal memory

of the power source.

3.8.15 Options Menu

Any changes made on this screen become active

immediately but are lost when the power is switched o. To

maintain changes, press Save after all changes are made on

the screen.

Setting the weld counter

At completion of each weld, the system stores the actual

parameters run and related weld ID number, operator

name, and time and date to print out if necessary. The

weld number sequentially increases by one digit per weld.

You can set/reset the weld counter at any specic number

using the control knob.

Page 29

29

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Setting the password

Press Enter. Password screen appears. Press Enter. An

alphanumeric pop‐up eld appears. Enter a password up

to 10 characters using the technique described in section

Alphanumeric labeling. To conrm password, press Save.

Entering operator’s name

Enter operator’s name using the technique described in

section Alphanumeric labeling.

Setting date and time

Press Enter to select the Date/Time eld and set date and

time.

Setting the language

Use the control knob to scroll through the alternatives.

Setting the units of measure

The control knob lets you scroll between Standard and

Metric.

Using the test mode

If you need to use the test mode, use the control knob to

select Yes.

This mode allows simulation of an actual weld with

sequencing through the weld program and simultaneous

rotation of the weld head. By using this function You can

observe the rotation of the tungsten electrode while

changing the various levels of the program on the display.

It is a useful diagnostic tool if you suspect malfunction

during the weld mode. A service technician can operate

the system in a simulated weld mode without the need to

worry about the arc. In the test mode, the contactor signal

to the power supply is disabled, preventing initiation of

high frequency and a welding arc.

1. Exit the Options menu.

2. Select a program to run. TEST MODE appears on

the screen.

3. Press Start Weld.

Following the pre‐purge and current upslope time

interval, the rotation motor on the weld head becomes

operational. It will continue operation until current

downslope is over. If the Auto Rewind function has been

programmed to occur, it follows after the completion of

the simulated weld. The gas solenoid is pulled in during

pre‐purge, welding, and post‐purge.

Page 30

30

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.16 Copying/transferring files to memory stick

(*These are the actual weld programs, not print les. They

are special le types formatted for the welding control

system, not human-readable les.)

1. To transfer a weld program from internal memory

to a memory stick or vice versa, place the stick in

the USB port on the front of the power source.

The stick will require approximately 1 minute to

initialize, during which time the LCD on the side

of the key will slowly pulse. When it is ready, it will

blink rapidly 5 times.

2. In the Maintenance Menu, select Copy Welds and

press Enter. Enter the desired program numbers

for source weld and destination weld, then press

Copy. For weld programs 100 and above, indicate

a program to be stored (or presently stored) on the

stick.

When per forming a copy or transfer to a destination

program of the same number, the new le does not write

over the existing le. You can delete the existing le or select

an unused destination program number.

Until the stick has nished initializing, a message will

appear on the display “Data Key Not Ready”. If no stick is

installed, ERROR message will also display.

3.8.17 Deleting welds

The Delete function is used to remove unwanted programs

from memory.

1. In the Maintenance Menu, select Delete Welds and

press Enter.

2. Use the control knob to select a weld program.

3. Press Delete.

You can also use this feature to delete welds from a memory

stick if it has been installed and initialized. Program on the

stick is numbered 100 and higher.

Only existing weld programs are displayed in the

Delete screen.

Page 31

31

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

3.8.18 Printing welds

On the Print Weld Files screen you can print to the built‐in

paper tape printer and/or an internal memory location.

Printing to the printer provides an immediate hard copy

of the weld program. You can print weld programs to

memory one or more times over a period of time and then

download them to a memory stick for storage or transfer

them to other electronic media. The contents of memory

will be deleted.

1. On the Maintenance Menu, select Print Welds.

2. Select Weld To Print.

3. Using the control knob, enter the weld number to

print.

4. Select Print or Store File.

5. Use the control knob to select: Memory, Printer, or

Both.

6. Select Short Form (parameters only) or Long Form

(parameters, as well as all procedure information

and notes).

7. To save the settings that have been changed on the

Maintenance / Print Weld Files screen, press Save.

Memory Internal memory

Print Transfer les for printing to integrated printer

or transfer to memory stick for printing using

a PC.

Automatic

Printout

If set to Yes, the printout automatically occurs

following each weld.

3.8.20.1 Transferring print les to memory stick

You can use a memory stick to transfer or move les to

a standard PC equipped with a printer for later printout.

1. Select the weld number to transfer and use the

control knob to select Print to Memory, Print, or

Both.

2. Press Print. A screen will state that the weld has

been successfully saved to memory.

3. Save one or more welds to print later. (The memory

stick does not have to be installed at this time.)

To transfer a weld program from internal memory to a

memory stick:

1. Place the stick in the USB por t in the front panel.

2. The stick will require approximately 1 minute to

initialize, at which time the LCD on the side of the

key will slowly pulse.

3. When the stick is ready, the LCD blinks rapidly 5

times.

Page 32

32

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

4. If no stick is installed or it has not yet nished

initializing, an error message displays.

5. Press Dnload to download all stored print les to

the stick.

Dnload will delete these programs from memory.

You can open the print les saved on a memor y stick in any

text editor, such as Microsoft® Word, Microsoft® Notepad,

or Microsoft® Excel.

In case you see an error message, return to Main

Menu and re-enter the print screen. “Error” will change to

“Dnload”. If a memory stick is installed and initialized prior

to entering the print screen, this step is not required.

3.8.19 Tungsten electrode length calculator

To determine the optimum cut-length for the tungsten

electrode, refer to this screen. For 800 series weld heads,

tungsten electrode length is calculated based on tube OD.

3.8.20 Advanced Help

Advanced Help allows you to diagnose problems which

may result from an external situation (e.g. an empty

gas bottle) or an internal situation (e.g. the weld head

control cable is damaged or not connected). Advanced

Help provides assistance for the operator as well as for a

competent electric repair technician.

3.8.21 Autotack

Tack welding is useful when welding larger diameter tubes,

for which Autotack automatically generates a tack-welding

program. Select 4 or 8 equally spaced tacks. Tacking

parameters penetrate approximately 70% of the tube wall.

If the intention is to make the weld to immediately follow

tacking, set the welding program as the “Next Weld to Run”

and the program is loaded automatically.

Page 33

33

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

4. ADDITIONAL DETAILS

4.1 Technical data

Property Value

Mains connection voltage 230 VAC ± 10%

Fuse (delayed) 16 A

Maximum output current 220 A @ 40 %, 170 A @ 100 %

Weld heads 150 series

Pipe outer diameter (O.D.) 3.2−152.4 mm

Welding positions All

Auto-stop Yes

Type of ignition HF

Cooling (controller unit) Forced air

Cooling (weld head) Internal coolant circulator

Controller external dimensions (L x W x H) 501 x 273 x 670 mm

Weight 32 kg

Degree of protection IP 23

Operating temperature -20…+40 °C

5. ORDERING INFORMATION

The chart below shows the products and options required. A complete orbital welding

system requires an orbital controller, a weld head of suitable size, collets for the weld head

(extended or ush) and cut-to-length tungsten electrodes. There are several additional

pieces of equipment available as listed below to complete a productive orbital welding

environment.

Weld head

Gas purge kit

Oxygen content meter

Dual pressure regulator

Tungsten grinding &

cutting equipment

Electrodes 1.0, 1.6 and 2.4 mm

Extended cables

weld head model 15010

Collets

weld head model 15020

Flush

weld head model 15030

Extended

weld head model 15040

Electrode

weld head model 15060

A7 TIG Orbital Controller 150

Page 34

34

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Product ordering codes:

Product name Product code

A5 TIG Orbital Controller 150 6204150

15010 Orbital weld head 6206002

15020 Orbital weld head 6206003

15030 Orbital weld head 6206004

15040 Orbital weld head 6206005

15060 Orbital weld head 6206006

Tungsten electrode 1.0 mm, L = 175 mm, 10 pc 9873531

Tungsten electrode 1.6 mm, L = 175 mm, 10 pc 9873532

Tungsten electrode 2.4 mm, L = 175 mm, 10 pc 9873533

150 Series Orbital Tungsten Mount Kit 1.0 mm SP800681

150 Series Orbital Tungsten Mount Kit 1.6 mm SP800682

150 Series Orbital Tungsten Mount Kit 2.4 mm SP800683

Extension cable, 15 m A7 TIG Orbital Controller 150 SP800693

Dual ow meter regulator SP800680

Ultima TIG-cut, tungsten electrode cutting/sharpening machine 6270001

Neutrix, portable tungsten electrode sharpening machine 6270002

Auto grind, tungsten electrode automated grinder 6270003

Purge plug kit 10−100 mm 6206009

Oxygen content meter 10−1000 ppm 6206008

Printer paper roll 58 mm

SP800692

Electrode lengths for dierent tube OD, 15010 weld head

Electrode diameter

Tube OD Tube OD 1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

3.17 0.125 26.4 25.8 25.3

6 0.236 25.0 24.4 23.9

6.35 0.250 24.8 24.2 23.7

8 0.315 24.0 23.4 22.9

9.53 0.375 23.2 22.6 22.1

10 0.394 23.0 22.4 21.9

10.2 0.402 22.9 22.3 21.8

12 0.472 22.0 21.4 20.9

12.7 0.500 21.6 21.1 20.6

13 0.512 21.5 20.9 20.4

13.5 0.531 21.2 20.7 20.2

15.88 0.625 20.0 19.5 19.0

16 0.630 20.0 19.4 18.9

17.2 0.677 19.4 18.8 18.3

18 0.709 19.0 18.4 17.9

19 0.748 18.5 17.9 17.4

19.05 0.750 18.4 17.9 17.4

20 0.787 18.0 17.4 16.9

21.3 0.839 17.3 16.8 16.3

22 0.866 17.0 16.4 15.9

23 0.906 16.5 15.9 15.4

25.4 1.000 15.3 14.7

14.2

Page 35

35

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Electrode lengths for dierent tube OD, 15020 weld head

Tube OD Tube OD Electrode diameter

1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

6.0 0.236 38.3 37.7 37.2

6.4 0.250 38.1 37.6 37.1

8.0 0.315 37.3 36.7 36.2

9.5 0.375 36.5 36.0 35.5

10.0 0.394 36.3 35.7 35.2

10.2 0.402 36.2 35.6 35.1

12.0 0.472 35.3 34.7 34.2

12.7 0.500 34.9 34.4 33.9

13.0 0.512 34.8 34.2 33.7

13.5 0.531 34.5 34.0 33.5

15.9 0.625 33.3 32.8 32.3

16.0 0.630 33.3 32.7 32.2

17.2 0.677 32.7 32.1 31.6

18.0 0.709 32.3 31.7 31.2

19.0 0.748 31.8 31.2 30.7

19.1 0.750 31.8 31.2 30.7

20.0 0.787 31.3 30.7 30.2

21.3 0.839 30.6 30.1 29.6

22.0 0.866 30.3 29.7 29.2

23.0 0.906 29.8 29.2 28.7

25.4 1.000 28.6 28.0 27.5

26.9 1.059 27.8 27.3 26.8

28.0 1.102 27.3 26.7 26.2

29.0 1.142 26.8 26.2 25.7

30.0 1.181 26.3 25.7 25.2

33.7 1.327 24.4 23.9 23.4

35.0 1.378 23.8 23.2 22.7

38.1 1.500 22.2 21.7 21.2

40.0 1.575 21.3 20.7 20.2

41.0 1.614 20.8 20.2 19.7

42.4 1.669 20.1 19.5 19.0

44.5 1.752 19.0 18.5 18.0

48.3 1.902 17.1 16.6 16.1

50.8 2.000 15.9 15.3 14.8

Page 36

36

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Electrode lengths for dierent tube OD, 15030 weld head

Tube OD Tube OD Electrode diameter

1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

9.5 0.375 49.1 48.5 48.0

10.0 0.394 48.9 48.3 47.8

10.2 0.402 48.8 48.2 47.7

12.0 0.472 47.9 47.3 46.8

12.7 0.500 47.5 47.0 46.5

13.0 0.512 47.4 46.8 46.3

13.5 0.531 47.1 46.6 46.1

15.9 0.625 45.9 45.4 44.9

16.0 0.630 45.9 45.3 44.8

17.2 0.677 45.3 44.7 44.2

18.0 0.709 44.9 44.3 43.8

19.0 0.748 44.4 43.8 43.3

19.1 0.750 44.3 43.8 43.3

20.0 0.787 43.9 43.3 42.8

21.3 0.839 43.2 42.7 42.2

22.0 0.866 42.9 42.3 41.8

23.0 0.906 42.4 41.8 41.3

Tube OD Tube OD electrode diameter

1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

25.4 1.000 41.2 40.6 40.1

26.9 1.059 40.4 39.9 39.4

28.0 1.102 39.9 39.3 38.8

29.0 1.142 39.4 38.8 38.3

30.0 1.181 38.9 38.3 37.8

33.7 1.327 37.0 36.5 36.0

35.0 1.378 36.4 35.8 35.3

38.1 1.500 34.8 34.3 33.8

40.0 1.575 33.9 33.3 32.8

41.0 1.614 33.4 32.8 32.3

42.4 1.669 32.7 32.1 31.6

44.5 1.752 31.6 31.1 30.6

48.3 1.902 29.7 29.2 28.7

50.8 2.000 28.5 27.9 27.4

51.0 2.008 28.4 27.8 27.3

52.0 2.047 27.9 27.3 26.8

53.0 2.087 27.4 26.8 26.3

54.0 2.126 26.9 26.3 25.8

60.3 2.374 23.7 23.2 22.7

63.5 2.500 22.1 21.6 21.1

70.0 2.756 18.9 18.3 17.8

76.1 2.996 15.8 15.3 14.8

76.2 3.000 15.8 15.2 14.7

Page 37

37

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Electrode lengths for dierent tube OD, 15040 weld head

Tube OD Tube OD electrode diameter

1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

12.0 0.472 60.1 59.5 59.0

12.7 0.500 59.7 59.2 58.7

13.0 0.512 59.6 59.0 58.5

13.5 0.531 59.3 58.8 58.3

15.9 0.625 58.1 57.6 57.1

16.0 0.630 58.1 57.5 57.0

17.2 0.677 57.5 56.9 56.4

18.0 0.709 57.1 56.5 56.0

19.0 0.748 56.6 56.0 55.5

19.1 0.750 56.5 56.0 55.5

20.0 0.787 56.1 55.5 55.0

21.3 0.839 55.4 54.9 54.4

22.0 0.866 55.1 54.5 54.0

23.0 0.906 54.6 54.0 53.5

25.4 1.000 53.4 52.8 52.3

26.9 1.059 52.6 52.1 51.6

28.0 1.102 52.1 51.5 51.0

29.0 1.142 51.6 51.0 50.5

30.0 1.181 51.1 50.5 50.0

33.7 1.327 49.2 48.7 48.2

35.0 1.378 48.6 48.0 47.5

38.1 1.500 47.0 46.5 46.0

40.0 1.575 46.1 45.5 45.0

41.0 1.614 45.6 45.0 44.5

42.4 1.669 44.9 44.3 43.8

44.5 1.752 43.8 43.3 42.8

Tube OD Tube OD electrode diameter

1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

48.3 1.902 41.9 41.4 40.9

50.8 2.000 40.7 40.1 39.6

51.0 2.008 40.6 40.0 39.5

52.0 2.047 40.1 39.5 39.0

53.0 2.087 39.6 39.0 38.5

54.0 2.126 39.1 38.5 38.0

60.3 2.374 35.9 35.4 34.9

63.5 2.500 34.3 33.8 33.3

70.0 2.756 31.1 30.5 30.0

76.1 2.996 28.0 27.5 27.0

76.2 3.000 28.0 27.4 26.9

85.0 3.346 23.6 23.0 22.5

88.9 3.500 21.6 21.1 20.6

101.6 4.000 15.3 14.7

14.2

Page 38

38

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Electrode lengths for dierent tube OD, 15060 weld head

Tube OD Tube OD electrode diameter

1.0 mm 1.6 mm 2.4 mm

mm inch length [mm] length [mm] length [mm]

50.8 2.000 74.4 73.9 73.4

51.0 2.008 74.3 73.8 73.3

52.0 2.047 73.8 73.3 72.8

53.0 2.087 73.3 72.8 72.3

54.0 2.126 72.8 72.3 71.8

60.3 2.374 69.7 69.1 68.6

63.5 2.500 68.1 67.5 67.0

70.0 2.756 64.8 64.3 63.8

76.1 2.996 61.8 61.2 60.7

76.2 3.000 61.7 61.2 60.7

85.0 3.346 57.3 56.8 56.3

88.9 3.500 55.4 54.8 54.3

101.6 4.000 49.0 48.5 48.0

104.0 4.094 47.8 47.3 46.8

108.0 4.252 45.8 45.3 44.8

114.3 4.500 42.7 42.1 41.6

127.0 5.000 36.3 35.8 35.3

129.0 5.079 35.3 34.8 34.3

139.7 5.500 30.0 29.4 28.9

152.4 6.000 23.6 23.1 22.6

5.1.1 Collets

When ordering collets, it is important to specify the exact OD dimension of the tube or

tting. Because of the wide range of tting manufacturers, it is necessary to specify the

tting manufacturer and type. If possible, include data sheet or drawing dening the

specication for the tting in the order.

Each tting manufacturer has dierent tolerances on the dimensions of the ttings.

Several tting manufacturers have special product lines specically designed for orbital

welding.

Collets for each type of weld head are specied by:

• Weld head model

• Tube/pipe OD

• Flush or extended

The ordering codes in the above list are per pair of collets. One weld head requires two

pairs.

Page 39

39

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Collet product codes for 15010 weld head

Tube OD

(inch)

Collet,

Extended

Collet, Flush Tube OD

(mm)

Collet,

Extended

Collet, Flush

0.125 1001227-0.125 1001232-0.125 6.0 1001234-6 1001236-6

0.250 1001227-0.25 1001232-0.25 8.0 1001234-8 1001236-8

0.375 1001227-0.375 1001232-0.375 10.0 1001234-10 1001236-10

0.402 1001227-0.402 1001232-0.402 12.0 1001234-12 1001236-12

0.500 1001227-0.500 1001232-0.500 13.0 1001234-13 1001236-13

0.625 1001227-0.625 1001232-0.625 13.5 1001234-13.5 1001236-13.5

0.677 1001227-0.667 1001232-0.667 16.0 1001234-16 1001236-16

0.750 1001227-0.750 1001232-0.750 18.0 1001234-18 1001236-18

0.839 1001227-0.839 1001232-0.839 19.0 1001234-19 1001236-19

1.000 1001227-1.00 1001232-1.00 20.0 1001234-20 1001236-20

22.0 1001234-22 1001236-22

23.0 1001234-23 1001236-23

Collet product codes for 15020 weld head

Tube OD

(inch)

Collet,

Extended

Collet, Flush Tube OD

(mm)

Collet,

Extended

Collet, Flush

0.250 1001238-0.250 1001240-0.250 6.0 1001242-6 1001244-6

0.375 1001238-0.375 1001240-0.375 8.0 1001242-8 1001244-8

0.402 1001238-0.402 1001240-0.402 10.0 1001242-10 1001244-10

0.500 1001238-0.500 1001240-0.500 12.0 1001242-12 1001244-12

0.625 1001238-0.625 1001240-0.625 13.0 1001242-13 1001244-13

0.677 1001238-0.677 1001240-0.677 13.5 1001242-13.5 1001244-13.5

0.750 1001238-0.750 1001240-0.750 16.0 1001242-16 1001244-16

0.839 1001238-0.839 1001240-0.839 18.0 1001242-18 1001244-18

1.000 1001238-1.00 1001240-1.00 19.0 1001242-19 1001244-19

1.327 1001238-1.327 1001240-1.327 20.0 1001242-20 1001244-20

1.500 1001238-1.50 1001240-1.50 22.0 1001242-22 1001244-22

1.669 1001238-1.669 1001240-1.669 23.0 1001242-23 1001244-23

1.902 1001238-1.902 1001240-1.902 26.9 1001242-26.9 1001244-26.9

2.000 1001238-2.00 1001240-2.00 28.0 1001242-28 1001244-28

29.0 1001242-29 1001244-29

30.0 1001242-30 1001244-30

35.0 1001242-35 1001244-35

40.0 1001242-40 1001244-40

41.0 1001242-41 1001244-41

44.5 1001242-44.5 1001244-44.5

Page 40

40

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Collet product codes for 15030 weld head

Tube OD

(inch)

Collet,

Extended

Collet, Flush Tube OD

(mm)

Collet,

Extended

Collet, Flush

0.375 1001246-0.375 1001248-0.375 10 1001250-10 1001252-10

0.402 1001246-0.402 1001248-0.402 12.0 1001250-12 1001252-12

0.500 1001246-0.500 1001248-0.500 13.0 1001250-13 1001252-13

0.625 1001246-0.625 1001248-0.625 13.5 1001250-13.5 1001252-13.5

0.677 1001246-0.677 1001248-0.677 16.0 1001250-16 1001252-16

0.750 1001246-0.750 1001248-0.750 18.0 1001250-18 1001252-18

0.839 1001246-0.839 1001248-0.839 19.0 1001250-19 1001252-19

1.000 1001246-1.327 1001248-1.327 20.0 1001250-20 1001252-20

1.327 1001246-1.327 1001248-1.327 22.0 1001250-22 1001252-22

1.500 1001246-1.500 1001248-1.500 23.0 1001250-23 1001252-23

1.669 1001246-1.669 1001248-1.669 26.9 1001250-26.9 1001252-26.9

1.902 1001246-1.902 1001248-1.902 28.0 1001250-28 1001252-28

2.000 1001246-2.00 1001248-2.00 29.0 1001250-29 1001252-29

2.500 1001246-2.500 1001248-2.500 30.0 1001250-30 1001252-30

3.000 1001246-3.00 1001248-3.00 35.0 1001250-35 1001252-35

40.0 1001250-40 1001252-40

41.0 1001250-41 1001252-41

44.5 1001250-44.5 1001252-44.5

51.0 1001250-51 1001252-51

52.0 1001250-52 1001252-52

53.0 1001250-53 1001252-53

54.0 1001250-54 1001252-54

60.3 1001250-60.3 1001252-60.3

70.0 1001250-70 1001252-70

76.1 1001250-76.1 1001252-76.1

Collet product codes for 15040 weld head

Tube OD

(inch)

Collet,

Extended

Collet, Flush Tube OD

(mm)

Collet,

Extended

Collet, Flush

0.500 1001254-0.500 1001256-0.500 12.0 1001258-12 1001260-12

0.625 1001254-0.625 1001256-0.625 13.0 1001258-13 1001260-13

0.677 1001254-0.677 1001256-0.677 13.5 1001258-13.5 1001260-13.5

0.750 1001254-0.750 1001256-0.750 16.0 1001258-16 1001260-16

0.839 1001254-0.839 1001256-0.839 18.0 1001258-18 1001260-18

1.000 1001254-1.00 1001256-1.00 19.0 1001258-19 1001260-19

1.327 1001254-1.327 1001256-1.327 20.0 1001258-20 1001260-20

1.500 1001254-1.500 1001256-1.500 22.0 1001258-22 1001260-22

1.669 1001254-1.669 1001256-1.669 23.0 1001258-23 1001260-23

1.902 1001254-1.902 1001256-1.902 26.9 1001258-26.9 1001260-26.9

2.000 1001254-2.000 1001256-2.000 28.0 1001258-28 1001260-28

2.500 1001254-2.500 1001256-2.500 29.0 1001258-29 1001260-29

3.000 1001254-3.000 1001256-3.000 30.0 1001258-30 1001260-30

3.500 1001254-3.500 1001256-3.500 35.0 1001258-35 1001260-35

4.000 1001254-4.000 1001256-4.000 40.0 1001258-40 1001260-40

41.0 1001258-41 1001260-41

44.5 1001258-44.5 1001260-44.5

51.0 1001258-51 1001260-51

52.0 1001258-52 1001260-52

53.0 1001258-53 1001260-53

54.0 1001258-54 1001260-54

60.3 1001258-60.3 1001260-60.3

70.0 1001258-70 1001260-70

76.1 1001258-76.1 1001260-76.1

85.0 1001258-85 1001260-85

Page 41

41

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

Collet product codes for 15060 weld head

Tube OD

(inch)

Collet,

Extended

Collet, Flush Tube OD

(mm)

Collet,

Extended

Collet, Flush

2.000 1001262-2.000 1001264-2.000 6.0 1001266-51 1001268-51

2.500 1001262-2.500 1001264-2.500 8.0 1001266-52 1001268-52

3.000 1001262-3.00 1001264-3.00 10 1001266-53 1001268-53

3.500 1001262-3.500 1001264-3.500 12.0 1001266-54 1001268-54

4.000 1001262-4.000 1001264-4.000 13.0 1001266-60.3 1001268-60.3

4.500 1001262-4.500 1001264-4.500 13.5 1001266-70 1001268-70

5.000 1001262-5.000 1001264-5.000 16.0 1001266-76.1 1001268-76.1

5.500 1001262-5.500 1001264-5.500 18.0 1001266-85 1001268-85

6.000 1001262-6.000 1001264-6.000 19.0 1001266-104 1001268-104

20.0 1001266-108 1001268-108

22.0 1001266-127 1001268-127

23.0 1001266-129 1001268-129

5.1.2 Tungsten electrode material

Kemppi uses ceriated tungsten to increase electrode life,

arc starting, and stability, and recommends this material

for orbital use.

2% ceriated = no radiation risk

These tungsten electrodes are commonly marked in grey

color.

Ordering codes for standard length (175 mm) tungsten

electrodes and sharpening / cutting machines:

9873531 10 pcs. 1.0 mm diameter, 175 mm long

9873532 10 pcs. 1.6 mm diameter, 175 mm long

9873533 10 pcs. 2.4 mm diameter, 175 mm long

6270001 Ultima – TIG – cut, tungsten electrode cutting/sharpening machine

6270002 Neutrix, portable, tungsten electrode sharpening machine

6270003 Auto Grind, Tungsten electrode automated grinder.

Page 42

42

A7 TIG Orbital System 150© Kemppi Oy 2016 1615

OPERATING MANUAL

6. TROUBLESHOOTING

6.1 Operation problems

Should you experience a malfunction from your machine, please consult the troubleshooting sections below rst, and complete some basic checks.

If the machine malfunction cannot be corrected with these measures, contact your

Kemppi maintenance service workshop.