Page 1

Model 7074General Purpose Multiplexer Card

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cle veland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility . Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.keithley.com

BELGIUM: Keithley Instruments B.V.

CHINA: Keithley Instruments China Y uan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • F ax: 8610-62022892

FRANCE: Keithley Instruments Sarl 3, allée des Garays • 91127 Palaiseau Cedex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Keithley Instruments GmbH Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Keithley Instruments Ltd

INDIA: Keithley Instruments GmbH Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Keithley Instruments s.r.l. Viale S. Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

NETHERLANDS: Keithley Instruments B.V. Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWITZERLAND: Keithley Instruments SA Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: Keithley Instruments Taiwan 1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077 • Fax: 886-3572-903

Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 0118-9 57 56 66 • Fax: 0118-9 59 64 69

9/00

Page 3

Model 7074 General Purpose Multiplexer Card

Instruction Manual

©1989, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Document Number: 7074-901-01 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately into

the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Revision A (Document Number 7074-901-01)................................................................................... January 1989

Addendum A (Document Number 7074-901-02)............................................................................. February 1996

Revision B (Document Number 7074-901-01)..................................................................................... March 2001

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over -voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. The user should assume all measurement, control, and

data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

that hazardous voltage is present in any unknown circuit before

measuring.

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts,

exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry , insulated

surface capable of withstanding the voltage being measured.

A good safety practice is to expect

no conductive part of the circuit may be

Page 6

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The

WARNING heading in a manual explains dangers that might

result in personal injury or death. Alw ays read the associated infor mation very carefully before performing the indicated procedure.

The

CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

2/01

Page 7

7074-D General Purpose Eight 1 xl 2

Multiplexer Card (Dry Reed)

MULTIPLEX CONFIGURATION: Eight 1x12 banks. Adjacent banks can be connected together. Jun

can be removed to isolate any bank from the backplane.

CONTACT CONFIGURATION: 3 pole Form A (HI, LO, GUARD).

CONNECTOR TYPE: Four 75 pin connectors for bank connections, one 38 pin connector for row

connections.

MAXIMUM SIGNAL LEVEL: ZOOV, 1A tarry/0.5A switched, 1OVA peak (resistive load).

COMMON MODE VOLTAGE: ZOOV maximum behveen any 2 pins or chassis.

CONTACT LIFE:

Cold Switching: 108 closures.

At Maximum Signal Level: 105 closures.

CHANNEL RESISTANCE (per conductor): <0.6Q initial, <1.6R at end of contact life.

CONTACT POTENTIAL: <5pV per contact pair (HI to LO, <1 minute after actuation).

OFFSET CURRENT: <lOOpA.

ISOLATION:

Bank: >lOlOQ, <lOpF.

Channel: >lOIOQ <lOpF.

Differential: >109R, 55pF nominal.

Common Mode: >lOgn, 300pF nominal.

CROSSTALK:

Bank: <-55dB at IMHz, 5OQ load.

Channel: c-55dB at IMHz, 5OQ load.

INSERTION LOSS (lMHz, 5OS2 source, 5OQ load): O.ldB typical.

3dB BANDWIDTH (50R load): 1OMHz typical.

RELAY DRIVE CURRENT(per relay): 15mA.

RELAY SETTLING TIME: <3msec.

ENVIRONMENT:

Operating: 0” to 5O”C, up to 35°C @ 70% R.H.

Storage: -25” to 65°C.

ACCESSORIES SUPPLIED: Instruction manual, 8 spare backplane jumpers.

ACCESSORIES AVAILABLE:

Bank Connector Accessories:

Model 7074~CITz

Model 7074HCT:

Model 7074-m

Model 7074MTC.20:

Model 7074MTR:

Model 7074RTc:

Row Connector Accessories:

Model 7078-CIT:

Model 7078.HCT:

Model 7078-KIT:

Model 7078~MTC-5:

Model 7078MTC-20:

Model 7078MTR:

Specifications subject to change without notice.

All specifications applicable to eight 1x12 configuration only.

Contact Extraction Tool

Hand Crimping Tool

Mass Terminated Plug with Contacts

Mass Terminated Cable Assembly, 6m(20 ft.)

Mass Terminated Receptacle with Contacts

Relay Test Shorting Connector

Contact Insertion and Extraction Tools

Hand Crimping Tool

Mass Terminated Plug with Contacts

Mass Terminated Cable Assembly, 1.5m (5 ft.)

Mass Terminated Cable Assembly, 6x1(20 ft.)

Mass Terminated Receptacle with Contacts

Page 8

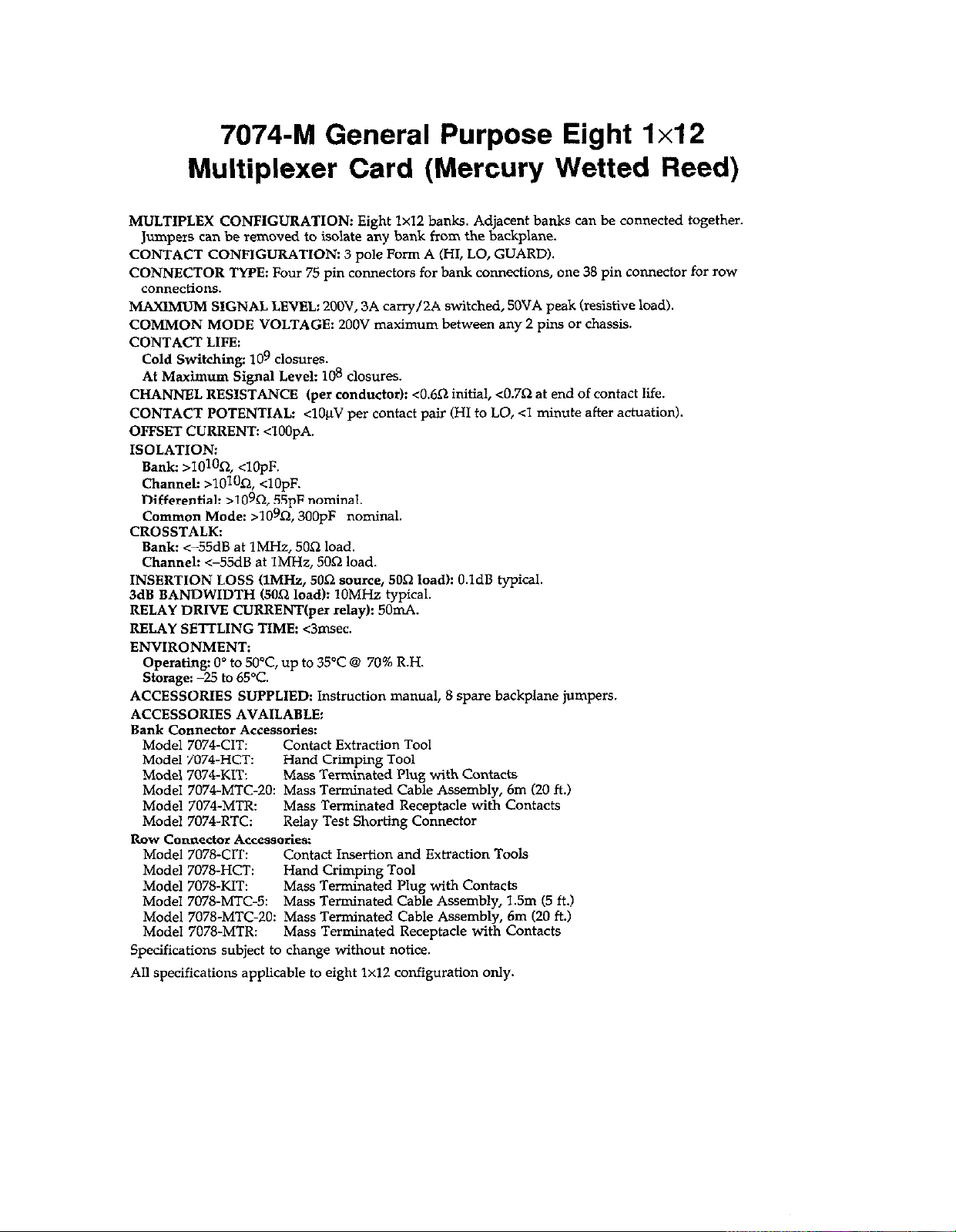

7074-M General Purpose Eight 1x12

Multiplexer Card (Mercury Wetted Reed)

MULTIPLEX CONFIGURATION: Eight 1x12 banks. Adjacent banks can be connected together.

Jumpers can be removed to isolate any bank from the backplane.

CONTACT CONFIGURATION: 3 pole Form A (HI, LO, GUARD).

CONNECTOR TYPE: Four 75 pin connectors for bank connections, one 38 pin connector for row

connections.

MAXIMUM SIGNAL LEVEL: 2OOV, 3A cany/2A switched, SOVA peak (resistive load).

COMMON MODE VOLTAGE: ZOOV maximum between any 2 pins or chassis.

CONTACT LIFE:

Cold Switching: 109 closures.

At Maximum Signal Level: 108 closures.

CHANNEL RESISTANCE (per conducted: co.60 initial, cO.7Q at end of contact life.

CONTACT POTENTIAL: <IO&V per contact pair (HI to LO, <I minute after actuation).

OFFSET CURRENT: <lOOpA.

ISOLATION:

Bank: >lOl&, <IOpF.

Channel: >lO%-L, <lOpF.

Differential: >I094 55pF nominal.

Common Mode: >lOgQ. 300nF nominal.

CROSSTALK:

Bank: <-55dB at IMHz, 5OQ load.

Channel: <-55dB at IMHz, 5On load.

INSERTION LOSS (lMHz, 5OQ source, 5OQ load): O.ldB typical.

3dB BANDWIDTH (5OQ load): 1OMHz typical.

RELAY DRIVE CURRENT(per relay): 5OmA.

RELAY SETTLING TIME: <3msec.

ENVIRONMENT:

Operating: 0” to 5O”C, up to 35°C @ 70% R.H.

Storage: -25 to 65°C.

ACCESSORIES SUPPLIED: Instruction manual, 8 spare backplane jumpers.

ACCESSORIES AVAILABLE:

Bank Connector Accessories:

Model 7074~CIT: Contact Extraction Tool

Model 7074-HCT: Hand Crimping Tool

Model 7074-KIT: Mass Terminated Plug with Contacts

Model 7074-MTC-20: Mass Terminated Cable Assembly, 6m (20 ft.)

Model 7074-MTR:

Model 7074-RTC: Relay Test Shorting Connector

Row Connector Accessories:

Model 7078~CIT:

Model 7078-HCT: Hand Crimping Tool

Model 7078-KIT:

Model 7078-MTC-5:

Model 7078-MTC-20: Mass Terminated Cable Assembly, 6m (20 ft.)

Model 7078-MTR: Mass Terminated Receptacle with Contacts

Specifications subject to change without notice.

All specifications applicable to eight 1x12 configuration only.

.

Mass Terminated Receptacle with Contacts

Contact Insertion and Extraction Tools

Mass Terminated Plug with Contacts

Mass Terminated Cable Assembly, 1.511-t (5 ft.)

Page 9

HOW TO USE THIS MANUAL

Contains information on Model 7074 features, specifications, and accessories.

Details installation of the Model 7074 General Purpose Multiplexer Card within the Model 707 Switching Matrix, ccw

ers card signal paths, and describes connections.

Gives typical applications for the Model 7074.

Contains performance verification procedures, troubleshooting information, and principles of operation for the multiplexer card.

SECTION 1

General Information

SECTION 2

Operation

SECTION 3

Applications

SECTION 4

Service Information

Lists replacement parts, and also includes component layout

and schematic drawings for the Model 7074.

SECTION 5

Replaceable Parts

Page 10

Table of Contents

SECTION 1 —

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 MANUAL ADDENDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.5 SAFETY SYMBOLS AND TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.6 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7 UNPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.1 Inspection for Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.2 Shipment Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.3 Instruction Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.8 REPACKING FOR SHIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.9 OPTIONAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.9.1 BANK Receptacle Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.9.2 ROW Receptacle Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SECTION 2 —

2.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 HANDLING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 ENVIRONMENTAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4 MULTIPLEXER CARD CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4.1 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4.2 1

2.4.3 Multiplexer Bank Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4.4 Backplane Connection Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.5 Switching ConÞgurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.5 CARD INSTALLATION AND REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.6 CONNECTION METHODS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.6.1 Connection Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.6.2 Connection Methods Using Mass Terminated Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.6.3 Connection Method Using Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6.4 Wiring Receptacles (Models 7074-MTR and 7078-MTR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7 TYPICAL CONNECTION SCHEMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.7.1 Single Mainframe, Single Multiplexer Card System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.7.2 Expanding the Multiplexer Using Multiple Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.7.3 Using the Multiplexer with Matrix Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.8 MULTIPLEXER PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.8.1 Banks and Rows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.8.2 Front Panel Multiplexer Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.8.3 IEEE-488 Bus Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

General Information

Operation

×

12 Multiplexer Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Page 11

2.9 MEASUREMENT CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.9.1 Path Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.9.2 Magnetic Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.9.3 Electromagnetic Interference (EMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.9.4 Ground Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.9.5 Keeping Connectors Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.9.6 Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.9.7 Guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.9.8 Multiple Card Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2.9.9 AC Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

SECTION 3 —

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 RESISTOR TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 2-Wire Resistance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.2 4-Wire Resistance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.3 Low-Level Resistance Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.4 Example Resistor Test Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 TRANSISTOR TESTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1 Current Gain Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.2 Common-Emitter Characteristics Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.3 Example Transistor Test Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4 TESTING WITH MATRIX CARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.1 Multiplexer and Matrix Card Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.2 Resistivity Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.3 Example Resistivity Test Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

SECTION 4 —

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 HANDLING AND CLEANING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 RELAY TEST PROGRAM SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3.1 Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.2 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.3 Running the Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 PERFORMANCE VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4.2 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4.3 Performance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.4 Initial Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.5 Path Resistance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4.6 Offset Current Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.4.7 Contact Potential Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.8 Path Isolation Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.4.9 Differential and Common Mode Isolation Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.5 SPECIAL HANDLING OF STATIC-SENSITIVE DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Applications

Service Information

Page 12

4.6 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.6.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.6.2 Rear Shield Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7.1 Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7.2 Using the Extender Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7.3 Input/Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.7.4 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.7.5 Relay Replacement Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.8 PRINCIPLES OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.8.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.8.2 ID Data Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.8.3 Relay Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.8.4 Power-on Safeguard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

SECTION 5 —

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 FACTORY SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.5 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Replaceable Parts

Page 13

SECTION 2 - Operation

List Of Illustrations

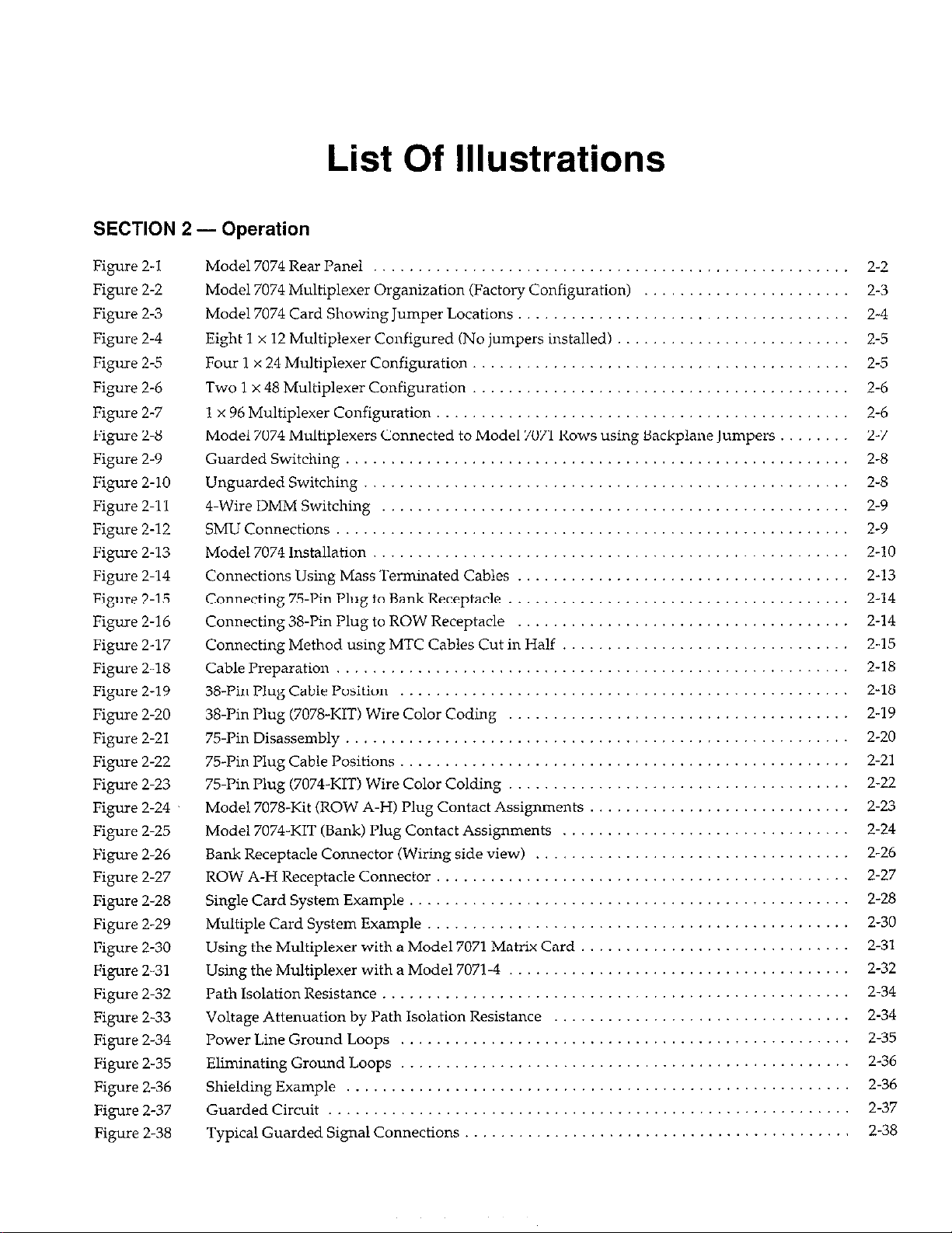

Figure 2-l

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-l 1

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure Z-16

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Figure 2-21

Figure 2-22

Figure 2-23

Figure 2-24

Figure 2-25

Figure 2-26

Figure 2-27

Figure 2-28

Figure 2-29

Figure 2-30

Figure 2-31

Figure 2-32

Figure 2-33

Figure 2-34

Figure 2-35

Figure 2-36

Figure 2-37

Figure 2-38

Model 7074 Rear Panel ..............................

Model 7074 Multiplexer Organization (Factory Configuration)

Model 7074 Card Showing Jumper Locations

Eight 1 x 12 Multiplexer Configured (No jumpers installed)

Four 1 x 24 Multiplexer Configuration

Two 1 x 48 Multiplexer Configuration

1 x 96 Multiplexer Configuration

Model 7074 Multiplexers Connected to Model 7071 Rows using Backplane Jumpers

Guarded Switching ................................................

Unguarded Switching .............................

4.Wire DMM Switching ...........................

SMU Connections .................................

Model 7074 Installation .............................

Connections Using Mass Terminated Cables

Connecting 75-I% Plug to Bank Receptacle

Connecting 38.Pin Plug to ROW Receptacle

Connecting Method using MTC Cables Cut in Half

Cable Preparation

38-I% Plug Cable Position

38-I% Plug (7078-KIT) Wire Color Coding

75-I+ Disassembly ...............................

75-l% Plug Cable Positions

75-I% Plug (7074-KIT) Wire Color Colding

Model 7078Xit (ROW A-H) Plug Contact Assignments

Model 7074~KIT (Bank) Plug Contact Assignments

Bank Receptacle Connector (Wiring side view)

ROW A-H Receptacle Connector

Single Card System Example

Multiple Card System Example

Using the Multiplexer with a Model 7071 Matrix Card

Using the Multiplexer with a Model 7071-4

Path Isolation Resistance ...........................

Voltage Attenuation by Path Isolation Resistance

Power Line Ground Loops

Eliminating Ground Loops

Shielding Example

Guarded Circuit

Typical Guarded Signal Connections

................................

......................................

.........................

.........................

........................

......................

.........................

.........................

...

............

.................

.................

.............

..............

.............

........

.............

.............

....

.......

.....

.............

........

2-2

2-3

2-4

2-5

2-5

2-6

2-6

2-7

2-8

2-8

2-9

2-9

Z-10

2-13

2-14

2-14

2-15

2-18

2-18

2-19

2-20

2-21

2-22

2-23

2-24

2-26

2-27

2-28

Z-30

2-31

2-32

2-34

2-34

2-35

2-36

2-36

2-37

2-38

Page 14

Figure 2-39

Figure Z-40 Model 7074 Frequency Response (RL = lMQ, 1 x 96 Configuration) 2-39

Figure 2-41

Figure 242 Model 7074 Frequency Response (Rr = 504 Eight 1 x 12 Configuration 2-41

Figure 243 Model 7074 Frequency Response (RL = 5OQ Eight 1 x 12 Configuration 242

AC Frequency Response Test Configuration

Model 7074 Frequency Response (RL = 50Q 1 x 96 Configuration 2-40

2-38

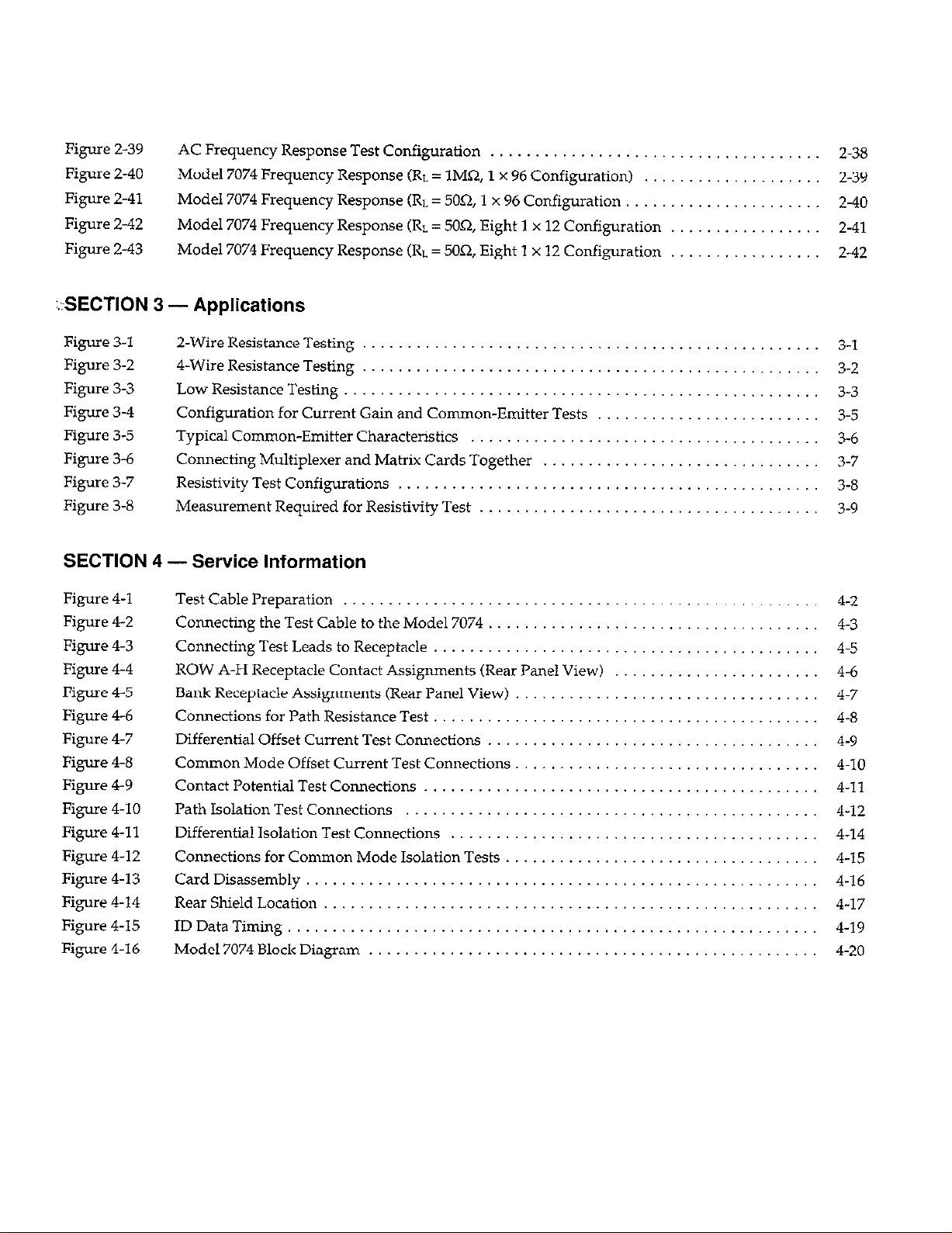

:SECTION 3 - Applications

Figure 3-l 2-Wire Resistance Testing

Figure 3-2 4-Wire Resistance Testing

Figure 3-3 Low Resistance Testing .................................... 3-3

Figure 3-4 Configuration for Current Gain and Common-Emitter Tests

Figure 3-5

Figure 3-6 Connecting Multiplexer and Matrix Cards Together

Figure 3-7 Resistivity Test Configurations ..............................

Figure 3-8 Measurement Required for Resistivity Test

Typical Common-Emitter Characteristics

..................................

..................................

........

...................... 3-6

..............

..................... 3-9

3-1

3-2

3-5

3-7

3-8

SECTION 4 - Service Information

Figure 4-l

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure 4-6

Figure 4-7

Figure 4-8

Figure 4-9

Figure 4-10

Figure 4-11

Figure 4-12

Figure 4-13

Figure 4-14

Figure 4-15

Figure 4-16

Test Cable Preparation .....................................................

Connecting the Test Cable to the Model 7074 .....................................

Connecting Test Leads to Receptacle ...........................................

ROW A-H Receptacle Contact Assignments (Rear Panel View)

Bank Receptacle Assignments (Rear Panel View)

Connections for Path Resistance Test ...........................................

Differential Offset Current Test Connections

Common Mode Offset Current Test Connections ..................................

Contact Potential Test Connections ............................................

Path Isolation Test Connections ..............................................

Differential Isolation Test Connections .........................................

Connections for Common Mode Isolation Tests ...................................

Card Disassembly

RearShieldLocation

IDDataTiming

Model7074BlockDiagram..

.........................................................

.......................................................

...........................................................

................................................

..................................

.....................................

.......................

4-2

4-3

4-5

4-6

4-7

4-8

4-9

4-10

4-l 1

4-12

4-14

4-15

4-16

4-17

4-19

4-20

Page 15

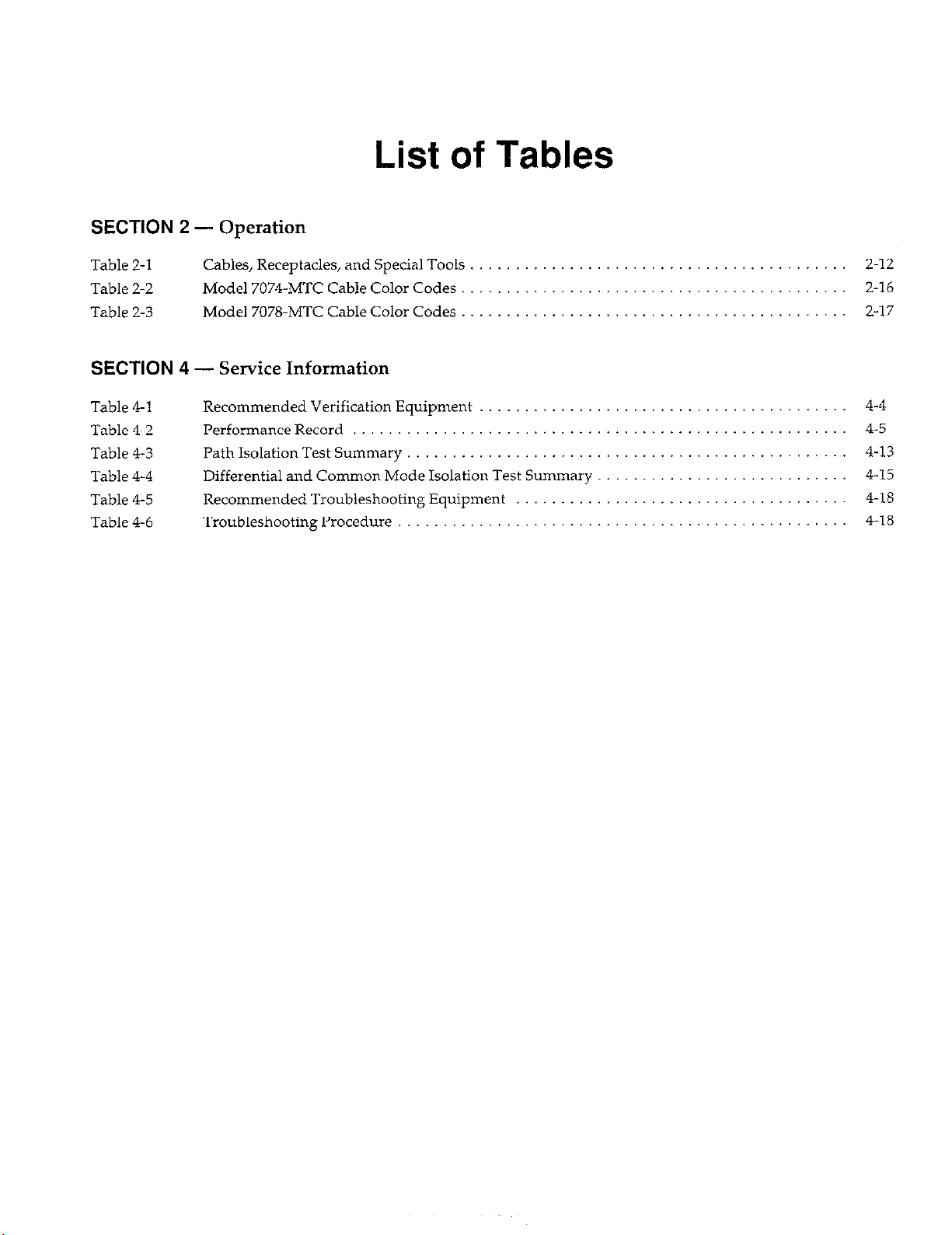

SECTION 2 - Operation

List of Tables

Table 2-l

Table 2-2

Table 2-3

Cables, Receptacles, and Special Tools

Model 7074-MTC Cable Color Codes

Model 7078.MTC Cable Color Codes

SECTION 4 - Service Information

Table 4-l

Table 4-2

Table 4-3

Table 4-4

Table 4-5

Table 4-6

Recommended Verification Equipment

Performance Record

Path Isolation Test Summary

Differential and Common Mode Isolation Test Summary

Recommended Troubleshooting Equipment

Troubleshooting Procedure

...........................

..............

...............

...............

.............

.....................

......................

.........

...........

...........

...........

...........

...........

...........

...........

2-12

2-16

2-17

4-4

4-5

4-13

4-15

4-1s

4-18

Page 16

SECTION 1

General Information

1 .l INTRODUCTION

This section contains general information about the

Model 7074.

Section 1 is arranged in the following manner:

1.2 Feafures

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safety Symbols and Terms

1.6 Specifications

1.7 Unpacking and Inspection

1.8 Repacking for Shipment

1.9 Optional Accessories

1.2 FEATURES

The Model 7074 General Purpose Multiplexer Card con-

sists of eight banks of 1 x 12 multiplexers that can be configured in various combinations. Three-pole switching

(HI, LO, guard) is provided for any of the 96 inputs.

Easy jumper configuration of single, dual, quad, or octal multiplexer banks.

Each of the eight multiplexer banks can be connected

to the 3-p& general-purpose backplane pathways

with user-installed jumpers, allowing simple internal

connections to the rows of those matrix cards.

Five mass-termination receptacles located on the rear

panel for quick-disconnect input and output connections.

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should your Model 7074 require warranty service, contact the Keithley representative or authorized repair facility in your area for further

information. When returning the card for repair, be sure

to fill out and include the service form at the back of this

manual in order to provide the repair facility with the

necessary information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the multi-

plexer card or manual will be explained in an addendum

included with the the unit. Be sure to note these changes

and incorporate them into the manual before using or

servicing the card.

1.5 SAFETY SYMBOLS AND TERMS

The following symbols and terms may be found on an instrument or used in this manual.

The Model 7074 is available with either dry or mercurywetted reed relays. The dry-reed version (Model 7074-D)

has lower thermal offset performance, while the mercury-wetted version (Model 7074-M) offers minimal contact bounce for and constant contact resistance overlife.

Throughout this manual, Model 7074 is used to refer to

both versions unless otherwise indicated.

Key features of the Model 7074 include:

The A

user should refer to the operating instructions located in

the instruction manual.

The symbol on an instrument shows that 1kV or

greater may be present on the terminal(s). Use standard

symbol on an instrument indicates that the

1-l

Page 17

SECTION I

General Information

safety precautions to avoid personal contact with these

voltages.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards which could damage the multiplexer card. Such

damage may invalidate the warranty.

1.6 SPECIFICATIONS

Model 7074-D and Model 7074-M specifications may be

found at the front of this manual. Note that some specifications, such as contact life, path resistance, and contact

potential, differ between the two versions of the card.

These specifications are exclusive of the matrix mainframe specifications, which are located in the Model 707

Instruction Manual.

removing the plastic wrapping, place the manual in the

binder after the mainframe instruction manual. Note that

a manual identification tab is included and should precede the multiplexer card instruction manual.

If an additional instruction manual is required, order the

manual package, Keithley part number 7074-901-00. The

manual package includes an instruction manual and any

pertinent addenda.

1.8 REPACKING FOR SHIPMENT

Should it become necessary to return the Model 7074 for

repair, carefully pack the unit in its original packing carton or the equivalent, and include the following~information:

Advise as to the warranty status of the multiplexer

card.

Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

Fill out and include the service form located a’t theback

of this manual.

1.7 UNPACKING AND INSPECTION

1.7.1 Inspection for Damage

Upon receiving the Model 7074, carefully unpack it from

its shipping carton and inspect the card for any obvious

signs of physical damage. Report any such damage to the

shipping agent immediately. Save the original packing

carton for possible future reshipment.

1.7.2 Shipment Contents

The following items are included with every Model 7074

order:

. Model 7074-D or 7074-M Multiplexer Card

l Model 7074 Instruction Manual

l Eight spare configuration jumpers

l Additional accessories as ordered

1.7.3 Instruction Manual

1.9 OPTIONAL ACCESSORIES

The following paragraphs discuss optional cables, connecting kits, and special tools that are available for use

with the Model 7074.

1.9.1 BANK Receptacle Accessories

The following accessories are designed for use with the

four BANK receptacles.

Model 7074-CIT Contact Extraction Tool -The Model

7074~CR includes a tool that is used to remove wire

crimp tail contacts from 75-pin “rack and panel” plugs

and receptacles.

Model 7074-HCT Hand Crimping Tool - The Model

7074-HCT is used to attach wire crimp tail contacts (for

75-pin connectors) to #l&3 to #26 AWG stranded wire.

However, provided contacts should only be used with

#20 to #24 AWG wire.

The Model 7074 Instruction Manual is three-hole drilled

so that it can be added to the three-ring binder of the

Model 707 Switching Matrix Instruction Manual. After

1-2

Model 7074-KIT Connector Kit-The Model 7074~KIT

contains the parts to assemble one 75pin “rack and

Page 18

General Information

SECTION1

panel” plug. This plug will mate to the BANK receptacle

on the rear panel of the card. Parts contained in the kit include the plug, 80 wire crimp tail contacts (for use with

#20 to #24 AWG wire), four corner pins, one tunable

male jackscrew, one tunable female jackscrew, and one

shield.

Model 7074-MTC-20 Mass Terminated Cable Assembly - The Model 7074~MTC-20 is a 20-foot (6-meters),

72-conductor cable terminated with a “rack and panel”

plug on both ends. This cable connects to the the BANK

receptacles on the rear panel of the card. This cable can be

cut in half to provide two separate cables, each of which

can be connected to one of the BANK receptacles. The unterminated ends of the cables are then connected to instrumentation and DUTs.

Model 7074-MTR Mass Terminated Receptacle with

Contacts-The Model 7074~MTR includes a 75-pin con-

nector, 80 crimp tail contacts, (for #20 to #24AWG wire),

one fixed female jackscrew, one fixed male jackscrew,

and four corner pins. The Model 7074-MTR mates with

the Model 7074MTC cables and the Model 7074-KIT

plug kit.

Model 707%CIT Contact Insertion and Extraction Tools

-The Model 7078~CIT includes an insertion tool that is

used to insert wire crimp tail contacts into 38-pin “rack

and panel” plugs and receptacles. Conversely, the extraction tool is required for the removal of the contacts.

Model 707%HCT Hand Crimping Tool - The Model

707%HCT is used to attach wire crimp tail contacts to #18

to #26 AWG stranded wire.

Model 7078-KIT Connector Kit-The Model 707%KIT

contains the parts to assemble one 38-pin “rack and

panel” plug. This plug will mate to the ROW A-H recep-

tacle on the rear panel of the card. Parts contained in the

kit include the plug, plug housing and 40 wire crimp tail

contacts.

Model 707%MTC-5 Mass Terminated Cable Assembly

-The Model 7078MTC is a 5-foot (1.5~meters), 36-conductor cable terminated with a “rack and panel” plug on

both ends. This cable connects to ROW A-H receptacle on

the rear panel of the card. This cable can be cut in half to

provide two separate cables when using two or more

Model 7074 cards. The unterminated ends of the cables

are then connected to instrumentation and DUTs.

Model 7074-RTC Relay Test Shorting Plug - The

Model 7074-RTC is intended for use with the relay test

software, as described in paragraph 4.2. The Model

7074-RTC consists of a 75-pin plug with pins and jumper

wires.

1.9.2 ROW Receptacle Accessories

The following accessories are intended for use with the

ROW A-H receptacle.

Model 707%MTC-20 Mass Terminated Cable Assembly - Thii cable is the same as the Model 707%MTC-5,

except that it is 20.feet (6-m&& in length.

Model 707%MTR Mass Terminated Receptacle with

Contacts-The Model 707%MTR includes a 3%pin connector and 40 crimp tail contacts. The Model 707%MTR

mates with the Model 7078-MTC cables and the Model

7078-KIT plug kit.

l-3

Page 19

SECTION 2

Operation

2.1 INTRODUCTION

This section contains information on multiplexer configuration, card connections, installation, and programming, and is arranged as follows:

2.2 Handling Precautions: Discusses precautions that

should be taken when handling the card to avoid contamination that could degrade performance.

2.3 Environmental Considerations: Outlines environmental aspects of using the Model 7074.

2.4 Multiplexer Card Configuration: Discusses the multiplexer rear panel as well as multiplexer configuration,

and expansion by jumpering two or more multiplexer

sections together.

2.5 Card Installation and Removal: Details installation

in and removal from the Model 707 Switching Matrix

mainframe.

2.6 Connection Methods: Discusses card connectors, cables, and ways to connect the card to other instruments

and test fixtures.

2.7 Typical Connection Schemes: Gives typical connections to other cards, mainframes, and test instrumentation.

safety precautions located at the front of this

manual before using the multiplexer card.

2.2 HANDLING PRECAUTIONS

To maintain high impedance isolation, care should be

taken when handling the multiplexer card to avoid contamination from such foreign materials as body oils. Such

contamination can substantially lower leakage resistances, degrading performance. To avoid any possible

contamination, always grasp the card by the handle or

the card edges. Do not touch board surfaces, components, or edge connectors.

Dirt build-up over a period of time is another possible

source of contamination. To avoid this problem, operate

the mainframe and matrix card only in a clean environment. If contamination is suspected, clean the card as discussed in Section 4. Also, the performance verification

procedures in Section 4 can be used to test the card for

low leakage resistances that could indicate contamination.

2.3 ENVIRONMENTAL CONSIDERATIONS

For rated performance, the card should be operated

within the temper&w and humidity limits given in the

specifications at the front of this manual.

2.8 Multiplexer Programming: Summarizes programming steps to control the multiplexer card from the

Model 707 Switching Matrix.

2.9 Measurement Considerations: Reviews a number of

considerations when making measurements using the

Model 7074.

WARNING

The information in this section is intended

for qualified personnel who have experience

with potentially hazardous voltages. Do not

attempt to perfolm these procedures unless

you are qualified to do so. Carefully read the

2.4 MULTIPLEXER CARD CONFIGURATION

The following paragraphs discuss the rear panel of the

card, the eight 1 x 12 multiplexers of the Model 7074, as

well as how to connect two or moremultiplexer banks together to make multiplexers as large as 1 x 96.

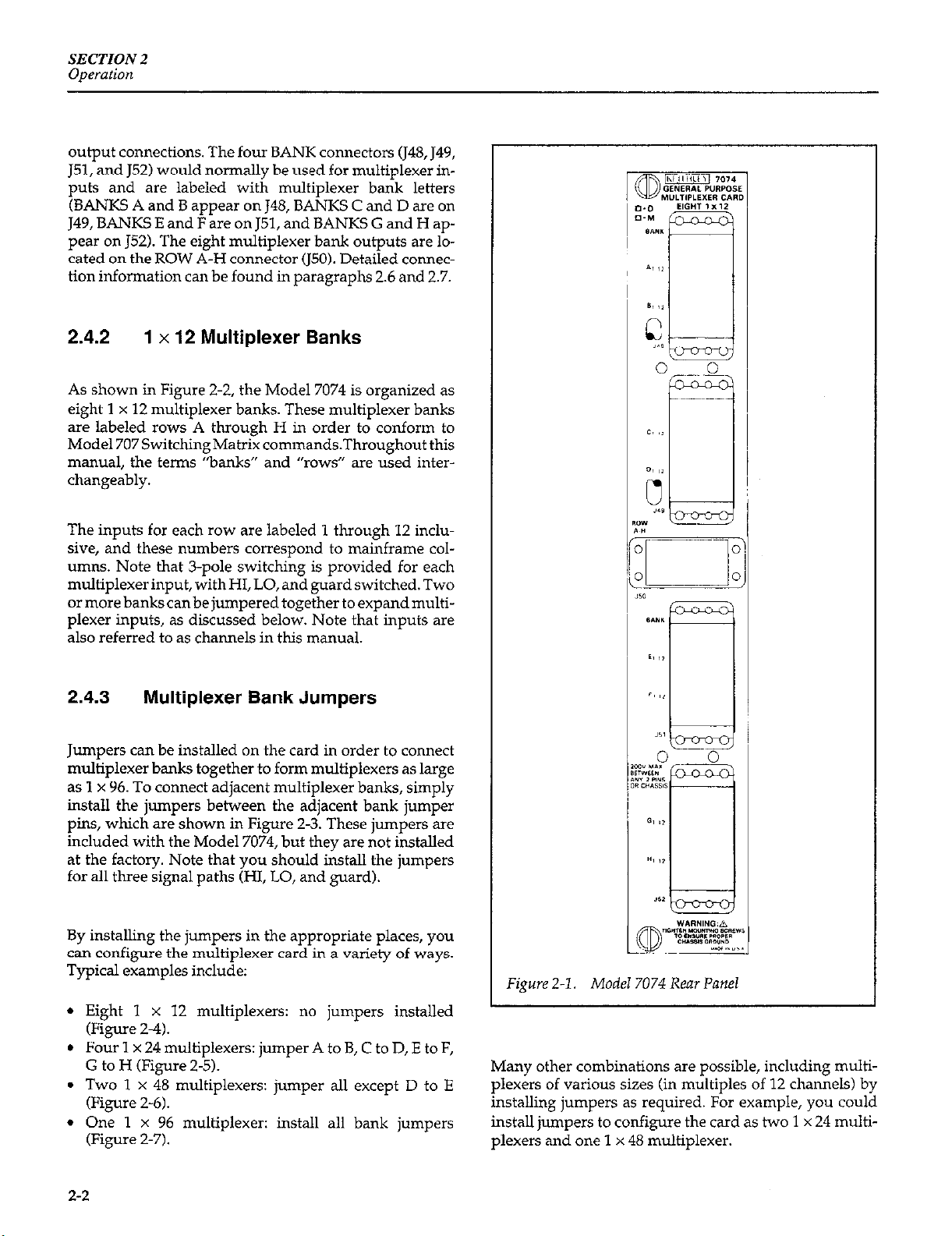

2.4.1 Rear Panel

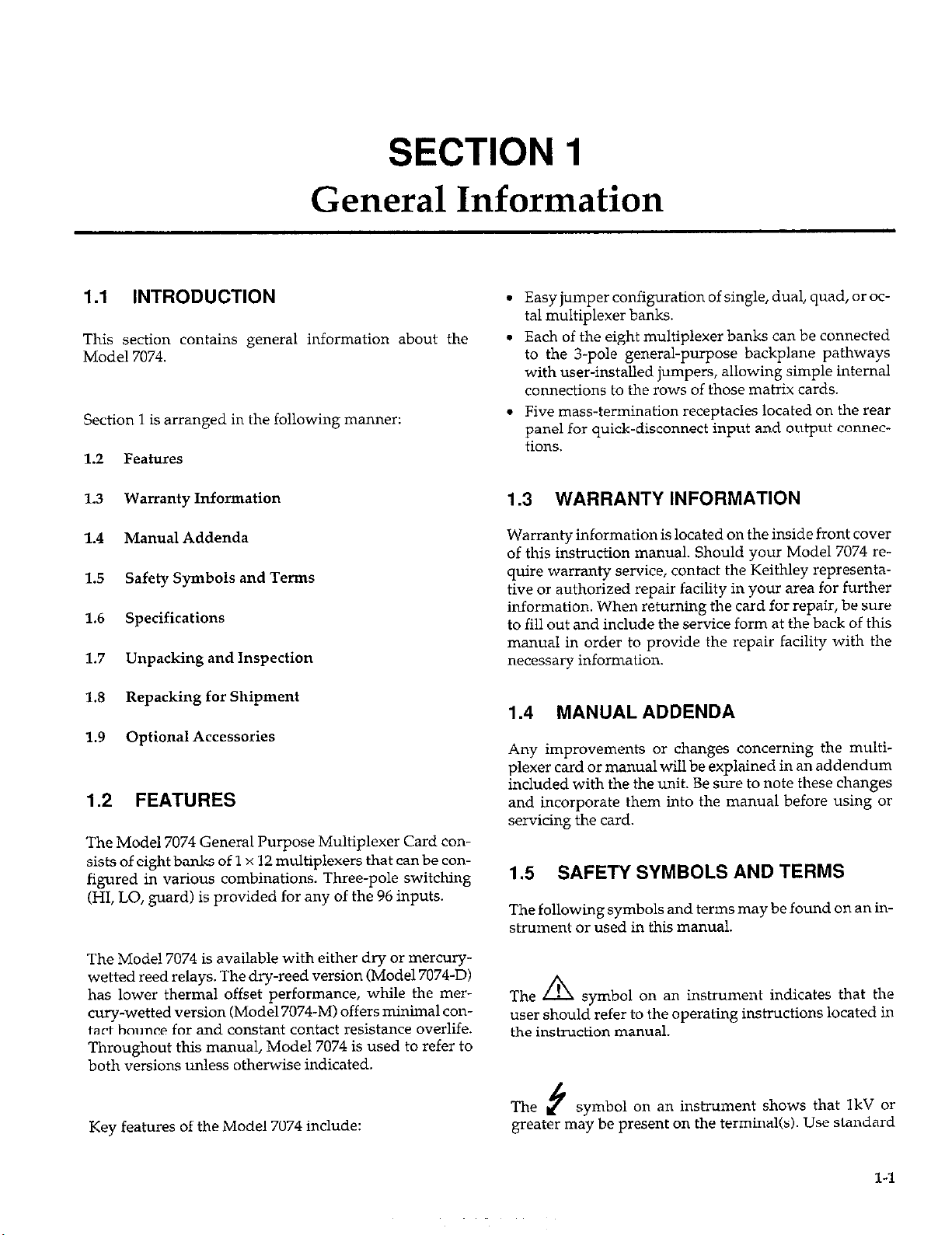

The rear panel of the Model 7074 is shown in Figure 2-1.

The rear panel has a total of five receptacles for input/

2-1

Page 20

SECTION2

Operation

output connections. The four BANK connectors (148, J49,

J51, and J52) would normally be used for multiplexer in-

puts and are labeled with multiplexer bank letters

(BANKS A and B appear on J48, BANKS C and D are on

J49, BANKS E and F are on J51, and BANKS G and H appear on J52). The eight multiplexer bank outputs are lo-

cated on the ROW A-H connector (JSO). Detailed connection information can be found in paragraphs 2.6 and 2.7.

2.4.2

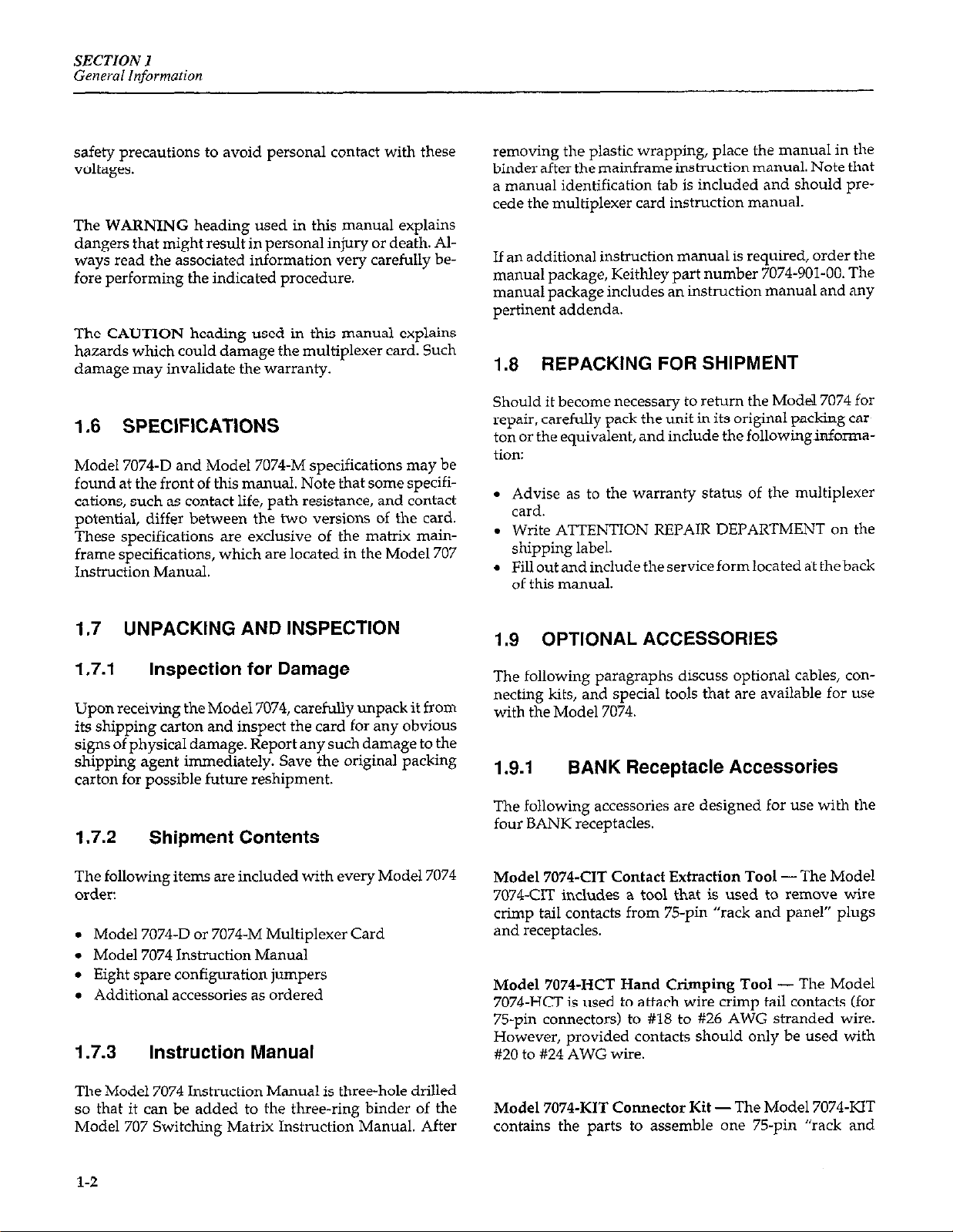

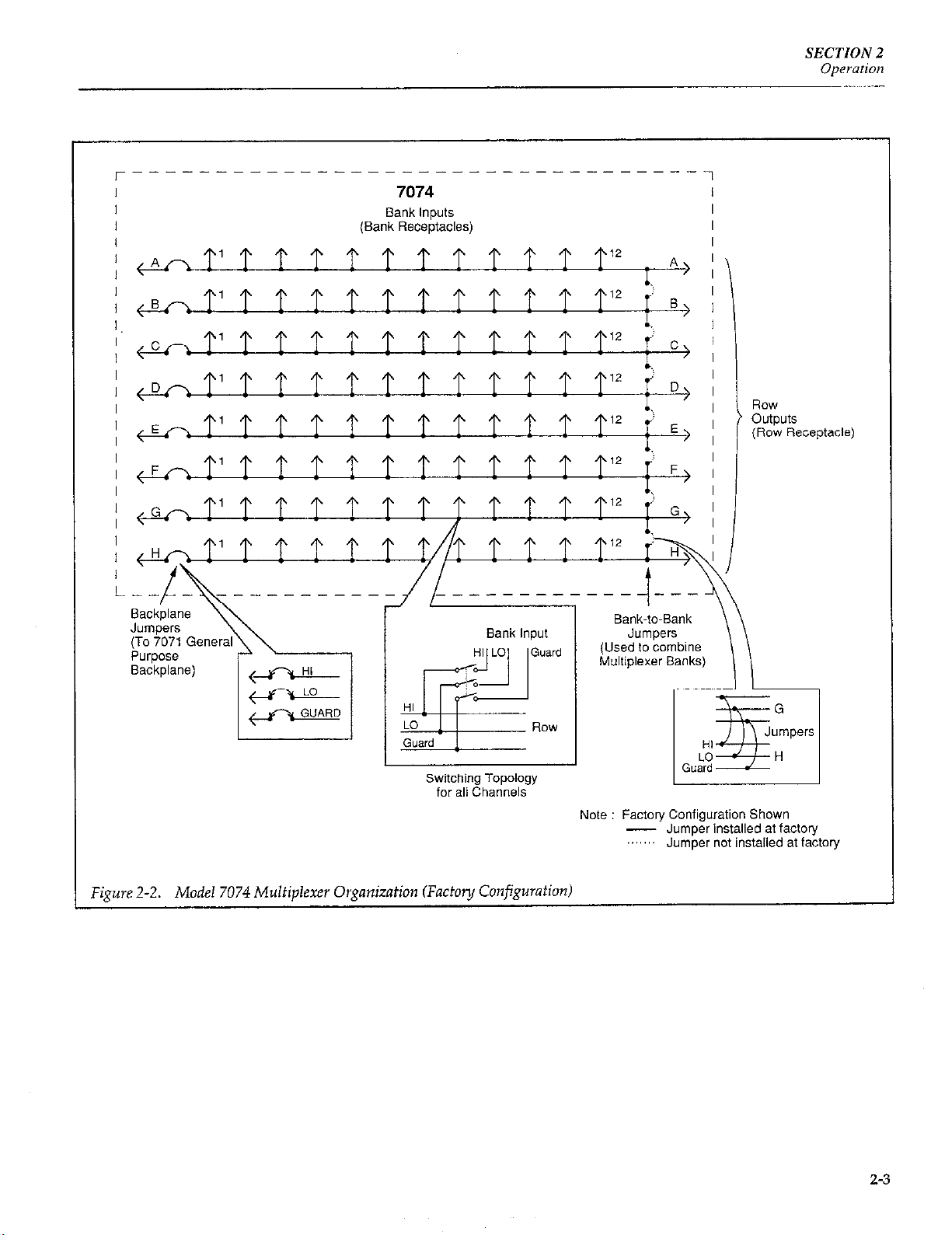

As shown in Figure 2-2, the Model 7074 is organized as

eight 1 x 12 multiplexer banks. These multiplexer banks

are labeled rows A through H in order to conform to

Model 707 Switching Matrix commands.Throughout this

manual, the terms “banks” and “rows” are used interchangeably.

The inputs for each row are labeled 1 through 12 inclusive, and these numbers correspond to mainframe columns. Note that 3-p& switching is provided for each

multiplexer input, with HI, LO, and guard switched. Two

or more banks canbe jumpered together to expand multiplexer inputs, as discussed below. Note that inputs are

also referred to as channels in this manual.

2.4.3

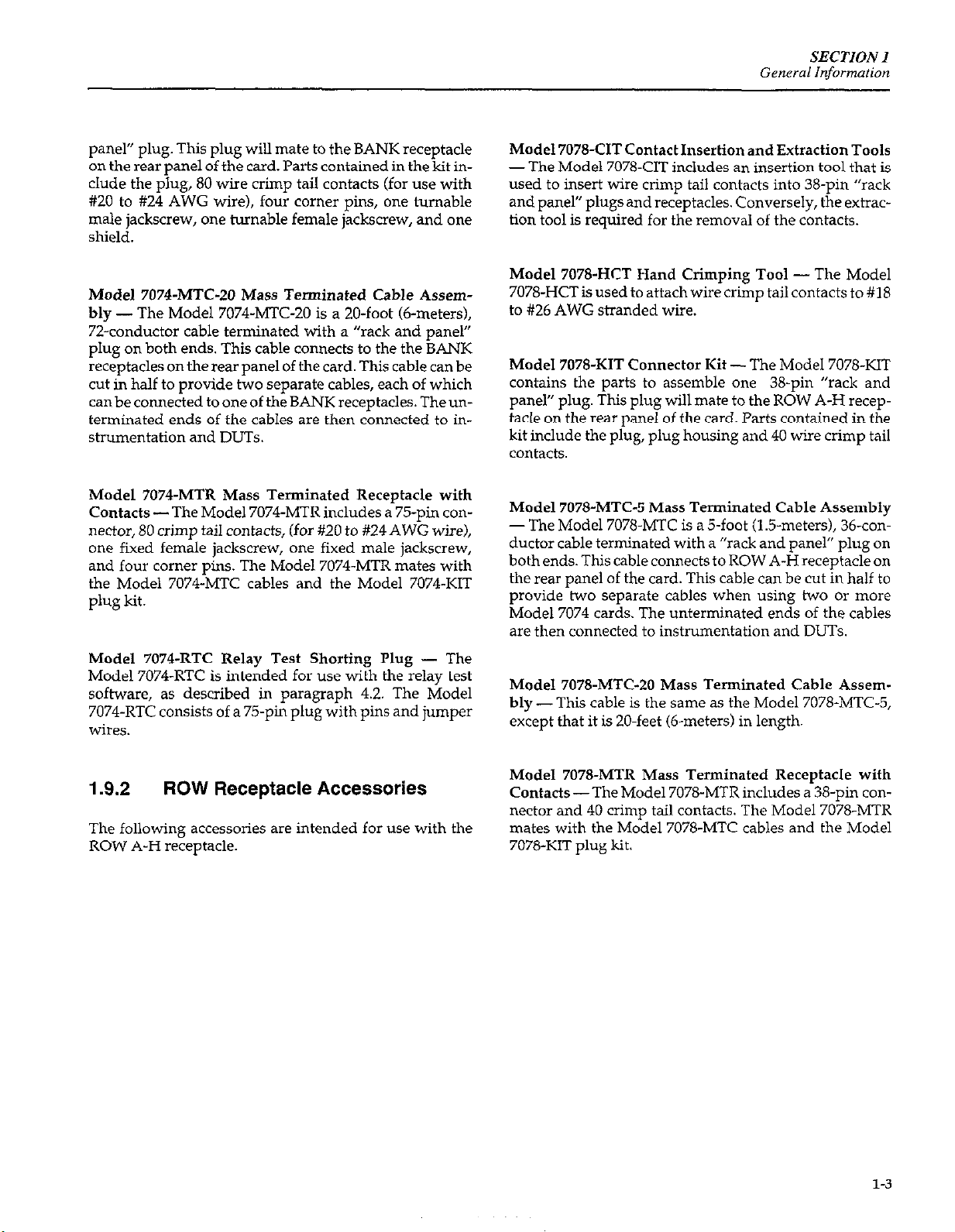

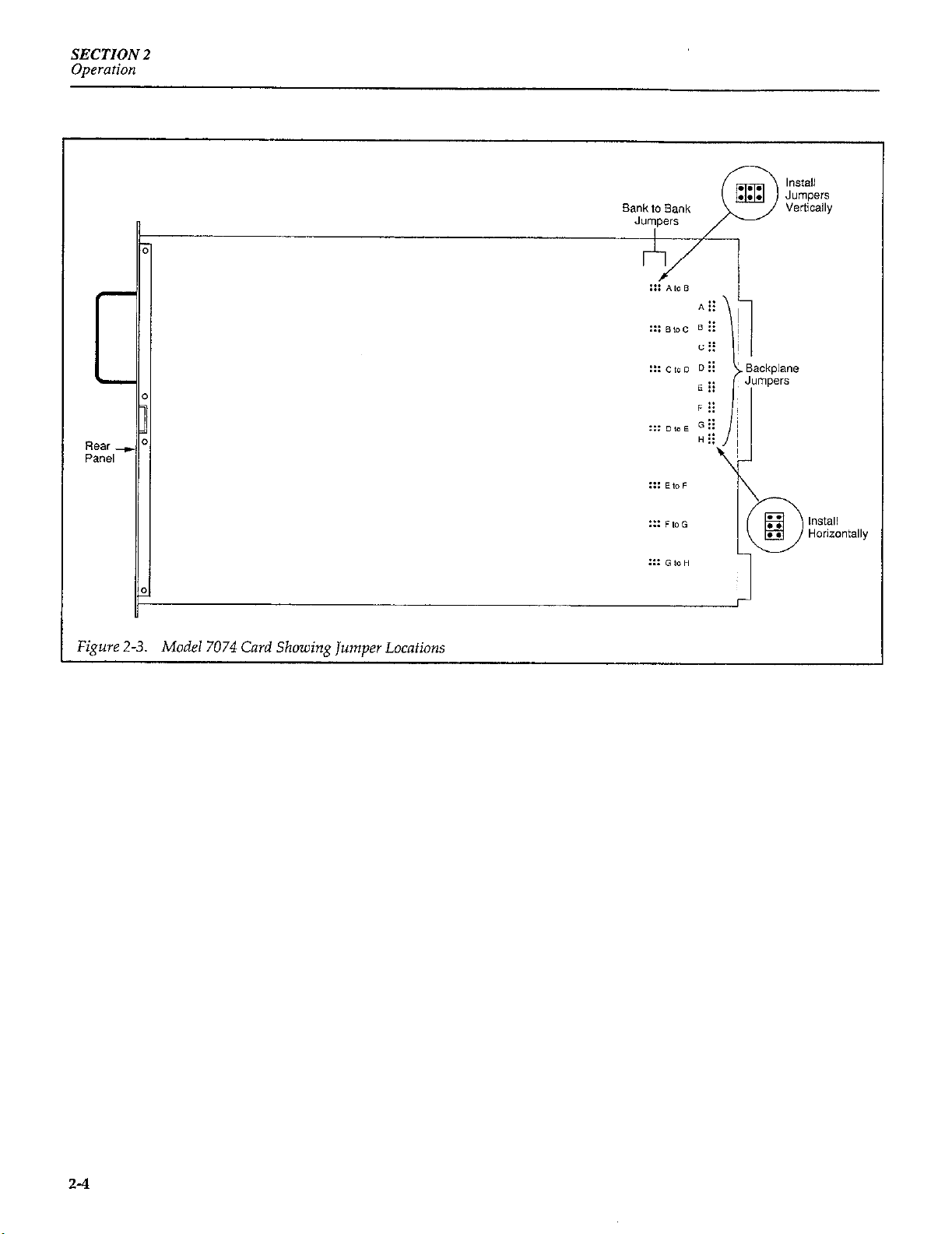

Jumpers can be installed on the card in order to connect

multiplexer banks together to form multiplexers as large

as 1 x 96. To connect adjacent multiplexer banks, simply

install the jumpers between the adjacent bank jumper

pins, which are shown in Figure 2-3. These jumpers are

included with the Model 7074, but they are not installed

at the factory. Note that you should install the jumpers

for all three signal paths (HI, LO, and guard).

1 x 12 Multiplexer Banks

Multiplexer Bank Jumpers

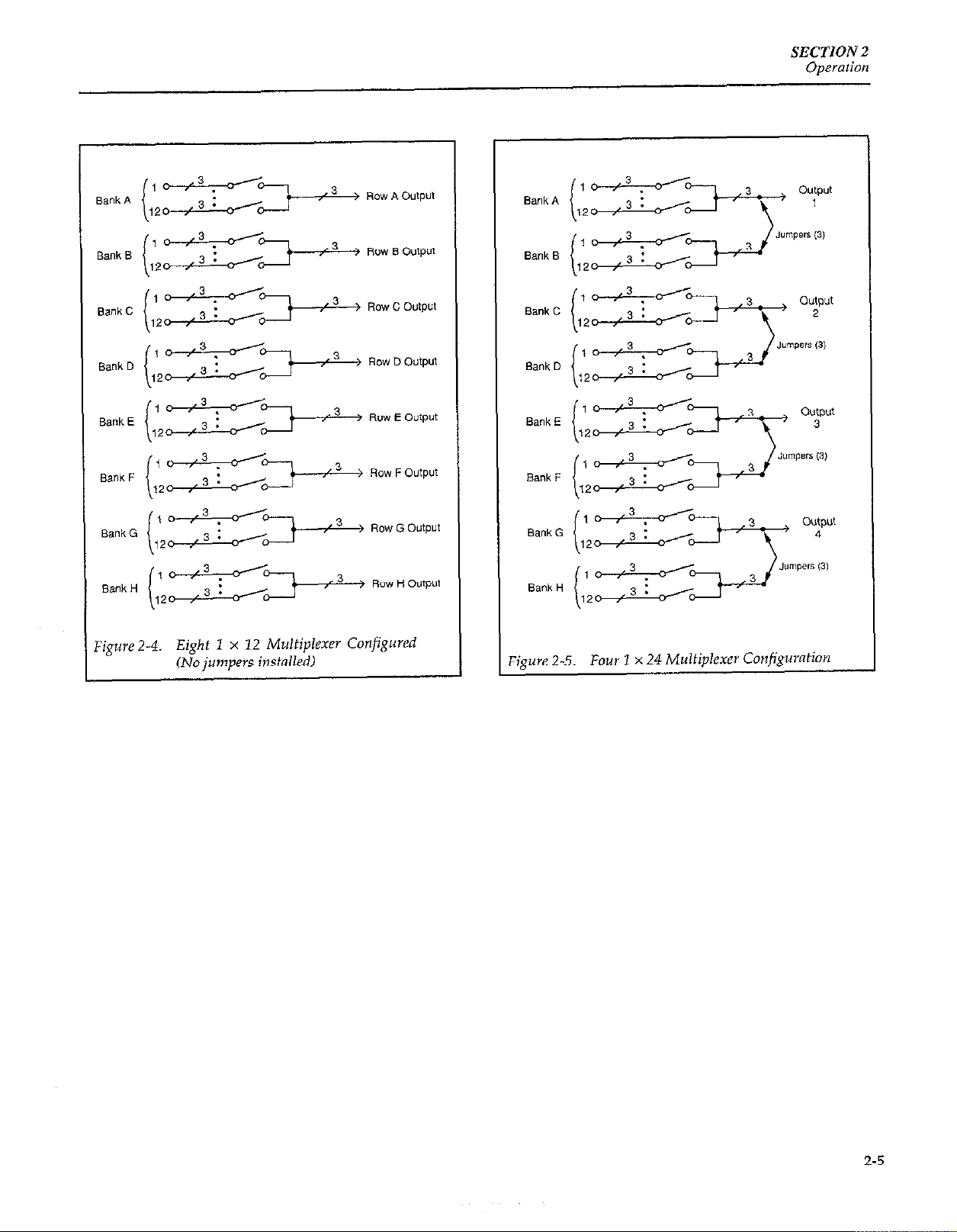

By installing the jumpers in the appropriate places, you

can configure the multiplexer card in a variety of ways.

Typical examples include:

l Eight 1 x 12 multiplexers: no jumpers installed

(Figure 2-4).

l Four 1 x 24 multiplexers: jumper A to B, C to D, E to F,

G to H (Figure 2-5).

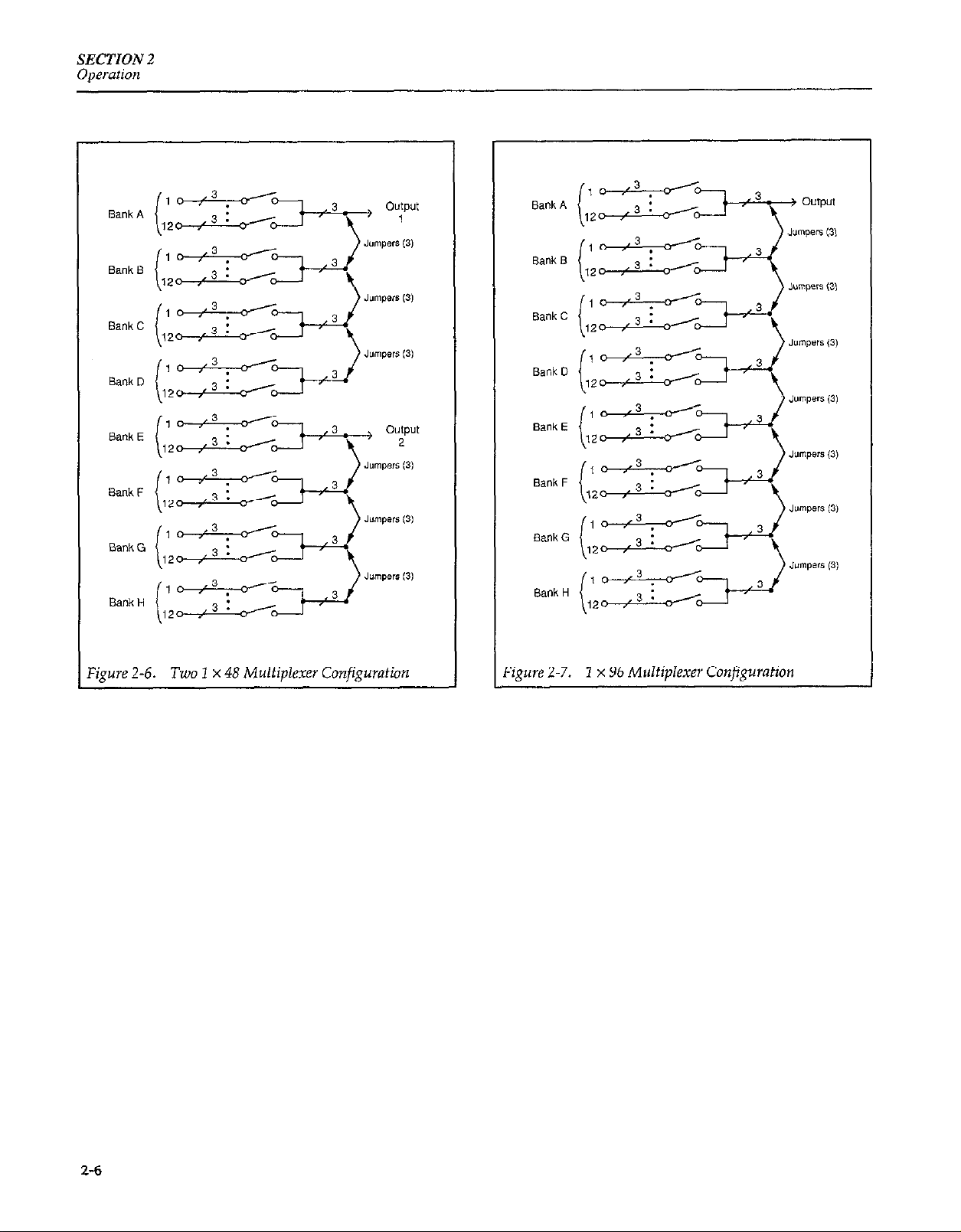

l Two 1 x 48 multiplexers: jumper all except D to E

(Figure 2-6).

l One 1 x 96 multiplexer: install all bank jumpers

(Figure 2-7).

2-2

Figure 2-l. Model 7074 Rear hnel

1

Many other combinations are possible, including multiplexers of various sizes (in multiples of 12 channels) by

installing jumpers as required. For example, you could

install jumpers to configure the card as two 1 x 24 multiplexers and one 1 x 48 multiplexer.

Page 21

SECTION 2

Opr&XI

for all Channels

Figure 2-2. Model 7074 Multiplexer Organization (Factmy Configuration)

Note : Factory Configuration Shown

- Jumper installed at factory

“““’ Jumper not installed at factory

2-3

Page 22

SECTION 2

Operation

0

Rear 0 -

Panel

::: - AlOB

::: EbaF

0

Figure 2-3. Model 7074 Card Showing Jumper Locations

::: F,OG

::: GbH

Z-4

Page 23

SECTION 2

Operation

-

Figure 2-4. Eight 1 x 12 Multiplexer Configured

(No jumpers installed)

Figure 2-5.

Four 2 x 24 Multiplexer Configuvntion

2-S

Page 24

SECTION 2

Operarion

?gure 2-6.

Two 1 x 48 Multiplexer Confi,quration

Tgure 2-7.

1 x 96 Multiplexer Configuration

2-6

Page 25

SECTION 2

Operarion

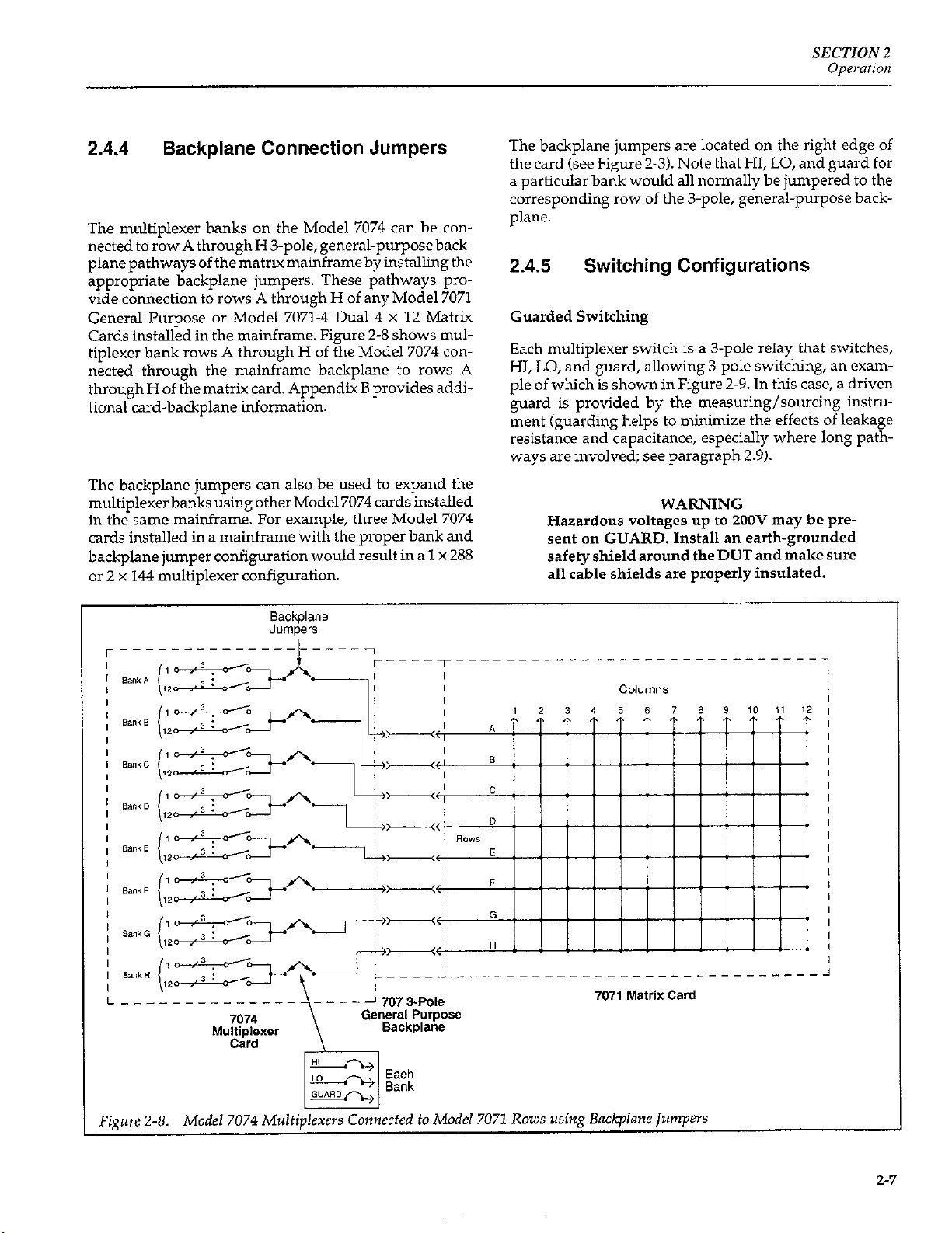

2.4.4 Backplane Connection Jumpers

The multiplexer banks on the Model 7074 can be connected to row A through H 3-p&, general-purpose backplane pathways of the matrix mainframeby installing the

appropriate backplane jumpers. These pathways provide connection to rows A through H of any Model 7071

General Purpose or Model 7071-4 Dual 4 x 12 Matrix

Cards installed in the mainframe. Figure 2-8 shows multiplexer bank rows A through H of the Model 7074 connected through the mainframe backplane to rows A

through H of the matrix card. Appendix B provides additional card-backplane information.

The backplane jumpers can also be used to expand the

multiplexerbanksusingotherModel7074cardsinstalled

in the same mainframe. For example, three Model 7074

cards installed in a mainframe with the proper bank and

backplane jumper configuration would result in a 1 x 288

or 2 x 144 multiplexer configuration.

The backplane jumpers are located on the right edge of

the card (see Figure 2-3). Note that HI, LO, and guard for

a particular bank would all normally be jumpered to the

corresponding row of the 3-pole, general-purpose backplane.

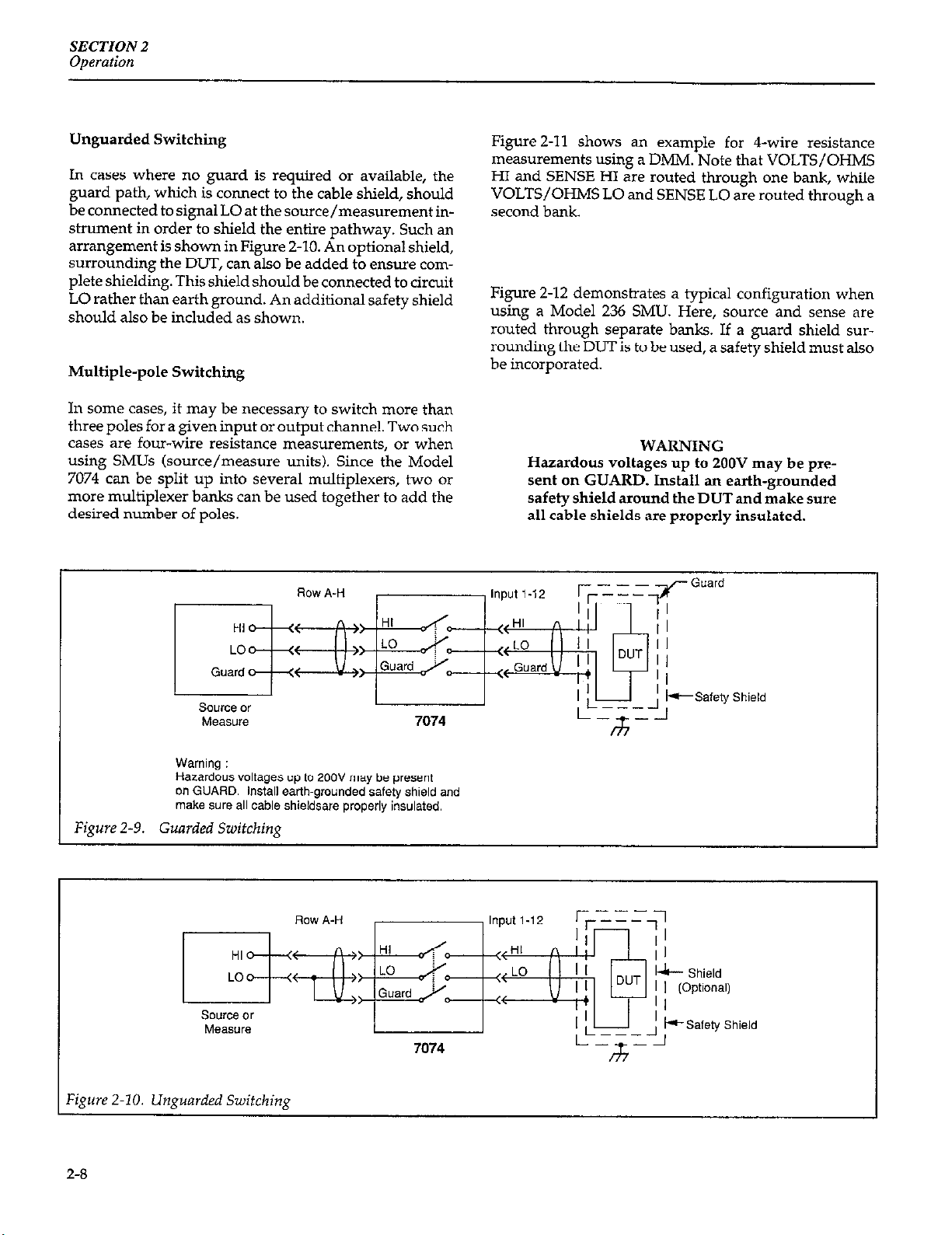

2.4.5 Switching Configurations

Guarded Switching

Each multiplexer switch is a 3-p& relay that switches,

HI, LO, and guard, allowing 3-p& switching, an exam-

ple of which is shown in Figure 2-9. In this case, a driven

guard is provided by the measuring/sourcing instmment (guarding helps to minimize the effects of leakage

resistance and capacitance, especially where long pathways are involved; see paragraph 2.9).

WARNING

Hazardous voltages up to 2OOV may be present on GUARD. Install an earth-grounded

safety shield around the DUT and make sure

all cable shields are properly insulated.

Backplane

Jumpers

---~q[----r ------------- ~~“m, -----------IZU

7071 Matrix Card

I

/

Figure 2-8. Model 7074 Multiplexers Connected to Model 7071 Rows using B&plane Jumpers

2-7

Page 26

SECTION 2

Operation

Unguarded Switching

In cases where no guard is required or available, the

guard path, which is connect to the cable shield, should

be connected to signal LO at the source/measurement instrument in order to shield the entire pathway. Such an

arrangement is shown in Figure Z-10. An optional shield,

surrounding the DUT, can also be added to ensure complete shielding. This shield should be connected to circuit

LO rather than earth ground. An additional safety shield

should also be included as shown.

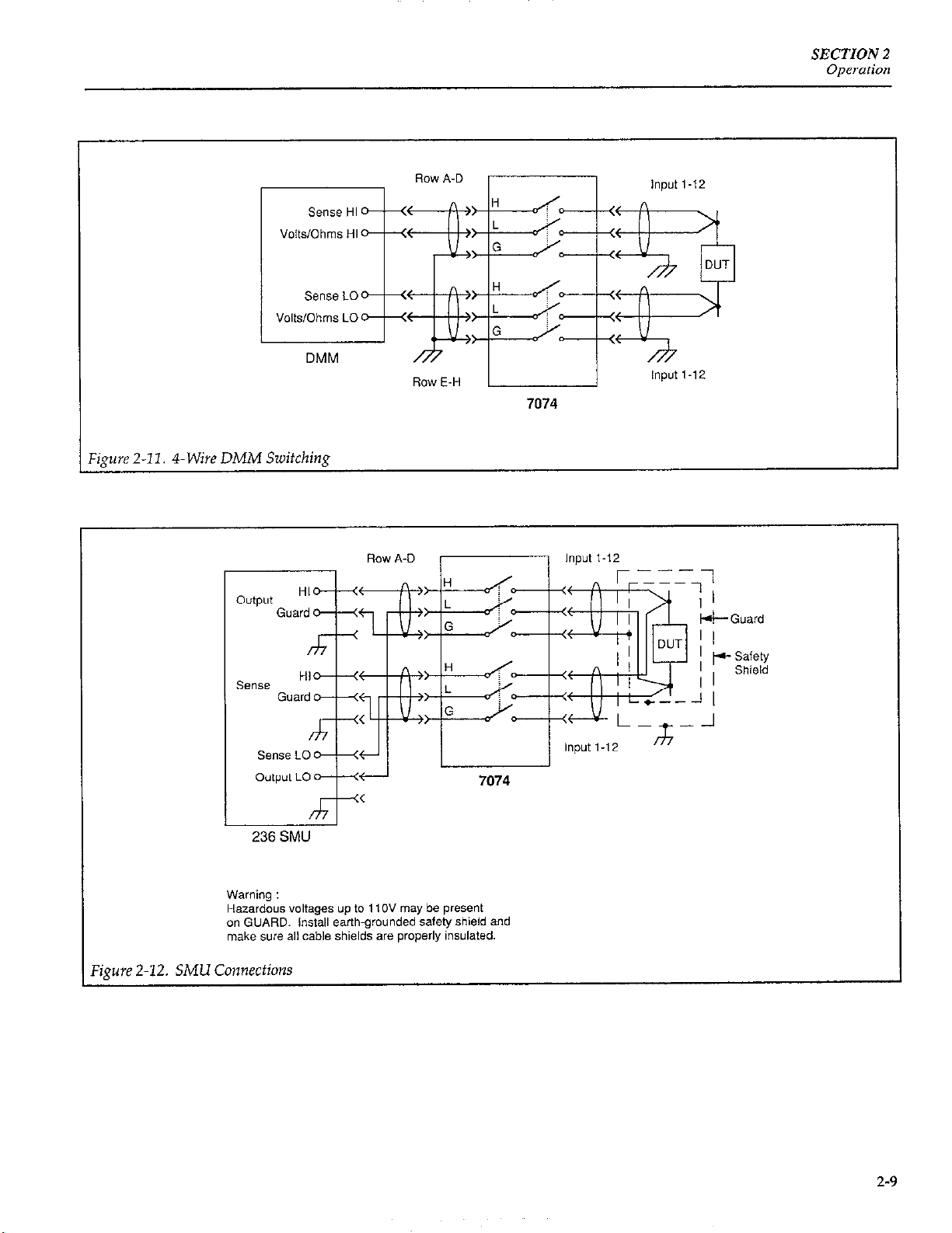

Multiple-pole Switching

In sc~me cases, it may be necessary to switch more than

three poles for a given input or output channel. Two such

cases are four-wire resistance measurements, or when

using SMUs

(source/measure

units). Since the Model

7074 can be split up into several multiplexers, two or

more multiplexer banks can be used together to add the

desired number of poles.

Figure 2-11 shows an example for 4-wire resistance

measurements using a DMM. Note that VOLTS/OHMS

HI and SENSE HI are routed through one bank, while

VOLTS/OHMS LO and SENSE LO are routed through a

second bank.

Figure 2-12 demonstrates a typical configuration when

using a Model 236 SMU. Here, source and sense are

routed through separate banks. If a guard shield SLITrounding the DUT is to be used, a safety shield must also

be incorporated.

WARNING

Hazardous voltages up to ZOOV may be present on GUARD. Install an earth-grounded

safety shield around the DUT and make sure

all cable shields are properly insulated.

-

Warning :

Hazardous voltages up to ZOOV may be present

on GUARD. install ear?h-grounded safety shield and

make sure all cable shieldsare properly insulated.

Figure 2-9. Guarded Switching

Figure 2-10. Unguarded Switching

-Safety Shield

2-8

Page 27

SECTION 2

Operarim

Figure Z-11. 4.Wire

DMM Switching

236

SMU

Warning :

Hazardous voltages up to 110” may be present

on GUARD. ,hs,a,l earth-grounded sa‘ety shield and

make sure al, cable shields are properly insulated.

=igure 2-12. SMU Connections

2-9

Page 28

SECTION 2

Operation

2.5

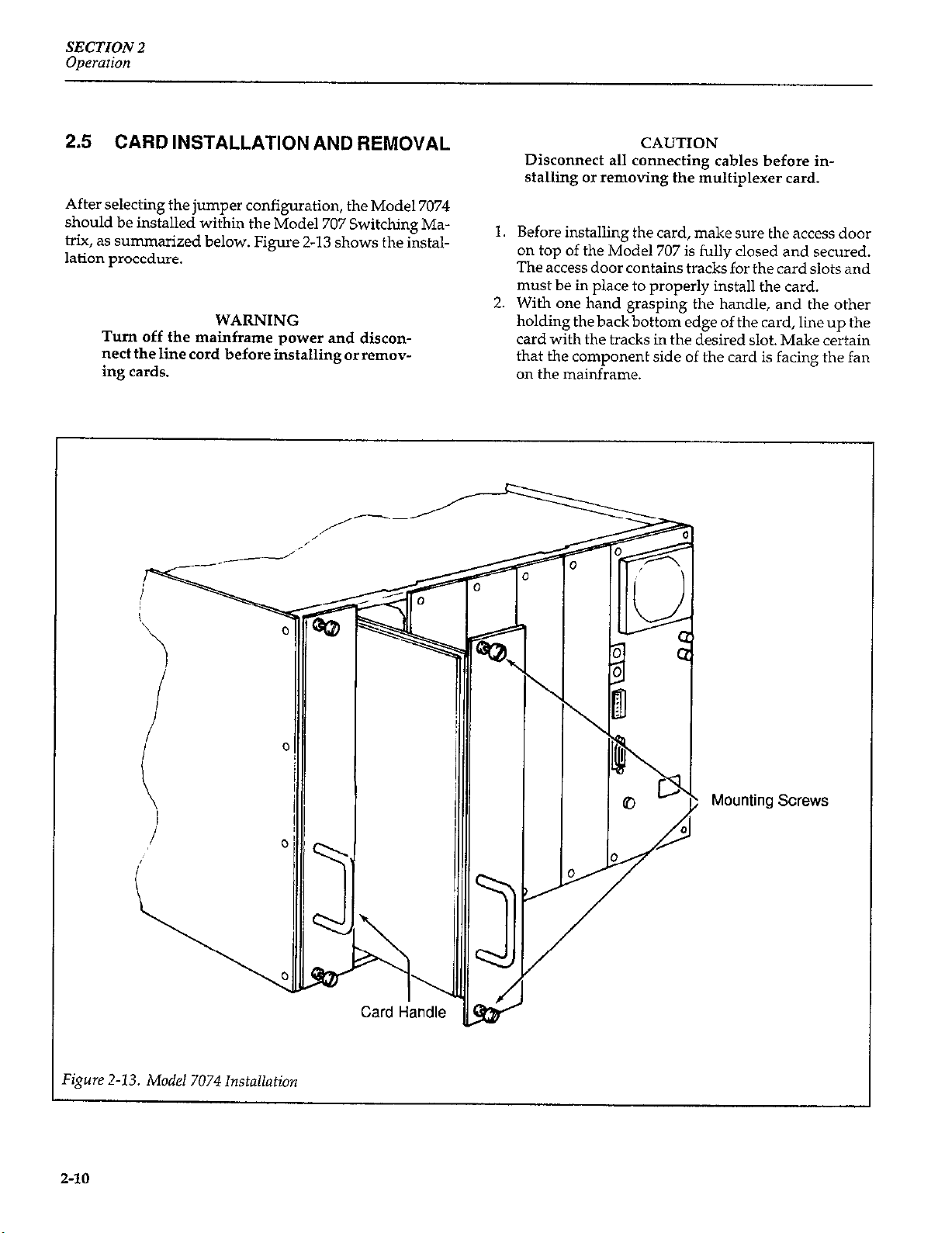

After selecting the jumper configuration, the Model 7074

should be installed within the Model 707 Switching Matrix, as summarized below. Figure 2-13 shows the install&ion procedure.

CARD INSTALLATION AND REMOVAL

WARNING

Turn off the mainframe power and disconnect the line cord before installing orremoving cards.

CAUTION

Disconnect all connecting cables before in-

stalling or removing the multiplexer card.

l. Before installing the card, make sure the access door

on top of the Model 707 is fully closed and secured.

The access door contains tracks for the card slots and

must be in place to properly install the card.

2. With one hand grasping the handle, and the other

holding the back bottom edge of the card, line up the

card with the tracks in the desired slot. Make certain

that the component side of the card is facing the fan

on the mainframe.

‘igure Z-13. Model 7074 Installation

Z-10

Mounting Screws

Page 29

SECTION 2

Operarion

CAUTION CAUTION

Do not touch the card surfaces oranycompo- Do not touch the card surfaces oranycomponents to avoid contamination

grade card performance.

Slide the card into the mainframe until it is properly

seated in the edge connectors at the back of the slot.

Once the card is properly seated, secure it to the

mainframe by finger tightening the spring-loaded

screws.

WARNING

The mounting screws must be secured to ensure a proper chassis ground connection between the card and the mainframe. Failure to

properly secure this ground connection may

result in personal injury or death due to electric shock.

To remove a card, first turn off the power and disconnect the line cord from the mainframe. Disconnect all cables from the multiplexer card. Loosen the

mounting screws, then pull the card out of the mainframeby the handle. When theback of the card clears

the mainframe, support it by grasping the bottom

edge near the rear of the card.

that

that

could de- nents to avoid contamination

could de-

2.6 CONNECTION METHODS

The Model 7074 has two types of “rack and panel” receptacles mounted on the rear panel. The four BANK (input)

receptacles are 75.pin receptacles that will mate with

either the optional mass terminated cables (Models

7074~MTC-5 or 7074~MTC-20) or the plug provided with

the optional connector kit (Model 7074~KIT). The ROW

A-H (output) receptacle is a 3%pin connector that will

mate with either the optional mass terminated cables

(Models 7078-MTC-5 or 7078-MTC-20) or the plug provided with the optional connector kit (Model 7078~KIT).

Model numbers for the two groups of cables, plugs, receptacles, and special tools are similar and are called out

together. Table 2-l summarizes the cables, receptacles,

and special tools that canbe obtained directly from Keithley Instruments. To avoid confusion, remember that all

7074 numbers pertain to the four BANK receptacles, and

all 7078 numbers are associated with the ROW A-H receptacle.

NOTE

The term receptacle refers to a connector

mounted on the rear panel of the multiplexer

card (and the connector supplied with the

Model 7074.MTR and 7078~MTR kits). The

term plug refers to a connector that attaches to

a cable such as the Model 7074.MTC and

7078-MTC cables, and the plugs supplied

with the Model 7074XIT and 7078-KIT kits.

2.6.1 Connection Methods

There are several ways to make connections to the Model

7074. These include:

Unmodified Mass Terminated Cable Method (Models

7074-MTC and 7078-MTC) - This method is probably

the most convenient method to make connections to the

multiplexer card. Using the whole cable (both plugs in-

tact) makes it most convenient to connect the multiplexer

card to a test fixture that uses the same “rack and panel”

receptacles as the multiplexer card. Additional receptacles that mate with these cables can be ordered from

Keithley Instruments; order Model 7074-MTR for the

BANK receptacles, or Model 707%MTR for the ROW

A-H receptacle. Detailed information on wiring these re-

ceptacles is located in paragraph 2.6.4.

Modified Mass Terminated Cable Method -By cutting

each MTC cable in half (or wherever appropriate), two

separate cables, unterminated at one end, will result.

These cables can then be hard-wired to DUTs or to your

test fixture. The plug on each Model 7074-MTC cable will

then connect to one of the BANK (input) receptacles, and

the plug on one end of a Model 7078-MTC cable will connect to the ROW A-H receptacle on the card.

The following paragraphs discuss how to make connections using the two connector types. Since the procedures

for the two connector types are virtually identical, only

one procedure for each type is given. Where applicable,

differences between the two connector types are called

out separately.

Connector Kit Method (Models 7074-KIT and

7078-KIT) - These kits contain plugs that mate to the

“rack and panel” receptacles, and they are designed for

custom-built mass terminated cables. An alternative to

building a complete cable from scratch is to cut the Model

2-11

Page 30

SECTION 2

Operadon

Table 2-1. Cables, Receptacles, and Special Tools

Model or Part

Model 7074~CIT: Extraction Tool

Model 7074-HCT: Hand Crimping Tool

Model 7074-m Connection Kit

Model 7074-MTC: Mass Terminated Cable

Model 7074~MTR: Mass Terminated Receptacle Contains one 75-pin “rack and panel” receptacle and contact sock-

Model 707%ClTz Insertion and Extraction Tools Used to install/remove wire crimp tails into/from 3%pin “rack

Model 707%HCT: Hand Crimping Tool

Model 7078-m Connection Kit

Model 707%MTC: Mass Terminated Cable

Description

Used to remove wire crimp tails in 75-pin “rack and panel” plugs

and receptacle

Used to connect wire crimp tails to #lt? to #26 gauge wire.

Contains one “rack and panel” plug, housing and 80 wire crimp

tail pins. Note: These pins are intended for use with #20 to #24

AWG wires.

6-meter (20 ft.) 72 conductor cable terminated with 75-pin “rack

and panel” plugs. Mates to “rack and panel” receptacles.

ets. Note: These sockets are intended for use with #20 to #24

AWG wire.

and panel” plugs and receptacles.

Used to connect wire crimp tails to #18 to #26 gauge wire.

Contains one 38-pin “rack and panel” plug, housing, and 40 wire

crimp tails.

6-meter (20 ft.), 36 conductor cable terminated with “rack and

panel” plugs. Mates to 3%pin “rack and panel” receptacles.

Model 707%MTR: Mass Terminated Receptacle

NOTE: All Model 7074 numbers pertain to BANK receptacles/plugs. All Model 7078 numbers pertain to ROW receptacle/plug

7074~MTC or 707%MTC cable at a length that is suitable

and then attach the plug to it.

WARNING

To avoid electrical shock, which could result

in injury or death, make sure all power is off

and stored energy in external circuitry is discharged before making any connections to

the multiplexer card. Do not exceed the voltage and current ratings for the card or connecting cables as stated in the specifications

and safety precautions at the front of this

manual. Do not connect this card to unlimited power circuits or directly to ac mains. Install appropriate protection devices to limit

fault currents from any supply connected to

this card.

3%pin “rack and panel” receptacle and contact pins.

CAUTION

Contamination will degrade the performance of the multiplexer card. To avoid contamination, always grasp the card by the

handle and side edges. Do not touch the edge

connectors of the card, and do not touch the

board surfaces or components. On “rack and

panel” receptacles and plugs, do not touch

areas adjacent to the electrical contacts.

2.6.2

Connection Methods Using Mass

Terminated Cables

The Model 7074~MTC-20 is a 6meter (20-foot), 75-conductor cable terminated with a 75.pin “rack and panel”

plug on each end. This cable is used to connect the BANK

(input) receptacles on the rear panel of the card to external equipment.

2-12

Page 31

SECTION 2

Operation

Similarly, the Model 7078.MTC-5 is a 1.5 meter &foot),

36-conductor cable terminated with a 3%pin “rack and

panel” plug on each end. The Model 7078-MTC-20 is the

same except that it is 6 meters (20 feet) in length. These cables are used to connect the ROW A-H receptacle on the

Direct Connections

Figure 2-14 shows how these cables can be used to con-

nect inputs and outputs of the multiplexer card to external “rack and panel” receptacles. The external recepta-

cles can then be hard wired to other connectors or wired

rear panel of the card to external instrumentation and test directly to instrumentation and DUTs. See paragraph

circuits.

2.6.4 for receptacle wiring information.

Figure 2-14. Connections Using Mass Terminated Cables

2-13

Page 32

SECTION 2

Operation

Connecting MTC Cables to the Multiplexer Card

Use the following procedure to connect the Model

7074~MTC and 7078-MTC cables to the multiplexer card:

1. Install the multiplexer card in the Model 707 mainframe as explained in paragraph 2.5.

WARNING

Turn off power to all instruments and discharge all capacitors before making ccmnections. Do not connect the Model 7074 to unlimited power circuits or directly to ac

mains. Install appropriate protection devices to limit fault currents from any Supply

connected to the multiplexer card.

CAUTION

Be careful not to bend the plug pins when

making connections.

2. Place the plug of the cable on the appropriate “rack

and panel” receptacle as shown in Figure 2-15

(BANK) or Figure Z-16 (ROW A-H). For the BANK

(input) receptacles, align the two locking screws of

theplugwiththescrewsinthereceptacle(maletofemale and female to male). For the ROW A-H receptacle, align the plug such that the large diameter keying pin of the plug fits into the large keyway of the

receptacle

ROW

RKX?piXle

(Top view)

Figure 2-16. Connecting38-Pin Plug to RO~WReceptacle

3. Using a screwdriver, turn the locking screw(s) clockwise until the plug is fully mated to the receptacle

(for the BANK plugs, both screws must be secured).

Disconnecting Cables

To

disconnect a cable from the multiplexer card, first

loosen the locking screw(s) completely using ,a scxmvdriver. Grasp the plug by its body, then wiggle it from

side to side or with a slight rotary motion while pulling

back on the plug.

CAUTION

Never pull on the cable itself. Always grasp

the body of the plug to remove cables.

-Panel

/

Bank

Receptacle

i

Figure 2-15. Connecting 754% Plug to Bank

Receptacle

2-14

Cutting MTC Cables

Another way to use the Model 7074-MTC or 707%MTC

cables is to remove one of the plugs. Cutting the Model

707%MTC-5 cable in half will provide two 2 l/2-foot cables. Cutting the Model 7074-MTC-20 or 7078-MTC-20

cable in half will provide two IO-foot cables. Each cable

can then be mated to a BANK (input) or ROW receptacle,

as shown in Figure Z-17.

The wire end of each cable can then be wired to another

connector or wired directly to instrumentation or DUTs.

Each cable contains bundles of wires each of which corresponds to a bank or channel. Each bundle contains three

wires; a bare wire (guard) and two insulated wires that

have a unique color combination for identification pur-

poses, with one wire HI, and the other wire LO. Table 2-2

provides the color combinations for each bundle of the

Page 33

SECTION 2

Operation

One half of Model

7074-MTC Cable

One half of Model 7078.MTC Cable

Model 7074~MTC (BANK) cables, and Table 2-3 summarizesthecolorcodingfortheModel707B-MTC(ROW) cables.

For example, with the cable connected to the ROW A-H

receptacle of the multiplexer card, Bank E can be identified by locating the bundle that has ablack insulated wire

(H) and a brown insulated wire CL). The bare wire in the

bundle is guard (G).

WARNING

The three wires in the brown and white bun-

dle should be collectively connected to common system ground of the test system to assure continued protection against a possible

shock hazard. These wires are connected to

Model 7074 chassis ground.

Insulating the Cable Wrappings

The outer wrapping of each bundle is insulated while the

inner wrapping is conductive (guard). When the cable is

cut, it is likely that the conductive side of the bundle

wrapping will become exposed. Thus, each bundle, as

well as each bare wire, should be insulated as outlined

below.

2-15

Page 34

SECTION 2

Operation

Table 2-2. Model 7074-MTC Cable Color Codes

Input #*

Al

A2

A3

A4

A5

A6

A7

A8

A9

A10

All

A12

Bl

82

83

EM

85

ii;

B8

B9

B10

Bll

812

‘Designation refers to row and input number. A also applies to rows C, E, and G. B also applies

to rows D, F, and H.

WARNING: Pins 40,41, and 42 and brawn/white cable bundle wires are earth ground and must be

connected to plug shell.

pin

-

31

12

28

8

32

13

29

i:

14

30

11

70

49

73

52 Yellow 46

71

50

74 Blue 80

53

72

51 White 45 Black 57 Clear

75

54

- -

High

GW3l 37

White 4 Blue

Brown 34

Yellow

Orange 38 Black 26 Clear

Blue 5

Red 35

Green 2

Green 39 White 27 Clear

Green

Red

Red

Yellow

Black

White 79 Orange 65 Clear

Yellow

Red

Green

Blue

Orange

Yellow 48

pin

1

7 Blue

36

3

76

43

77 Blue

44

47 Red 59 Clear

78 Red 64 Clear

82 Blue 67 Clear

LOW

Orange 25

Green 22

Green 15 Clear

Black 20

Black

Black

Brown

Orange

White 62

Brown 55

Black

White

Brown 66

Red

Pin#

-

18

23 Clear

16 Clear

21 Clear

24 Clear

17 Clear

58 Clear

63

56 Clt?X

60

Guard

Clear

Clear

Clear

Clear

Clear

Clear

Clear

Clear

Clear

2-16

Page 35

SECTION2

Operarion

TableZ-3. Model 707%MTC Cable Color

Codes

wire set

ROW A

rehd*

H

Insulation Color

Black

Blue

ROW B

ROW C

k

H

k

H

Bare Wiie

Red

BRW,Tl

Bare Wiie

Black

Red

ROW D

ROWE

ROW F

ROW G

ROW H

‘H = High

L=Law

k

H

L

G

H

L

G

H

L

G

H

L

G

H

L

G

Bare

Wire

Red

Y&WJ

Bare

Wire

Black

BIOWll

Bare Wiie

Red

Blue

Bare Wire

Black

OElIlge

Bare Wire

Red

GRY2n

Bare Wire

G =Guard

2.6.3

Connection Method Using Connector Kits

The Models 7074-KIT and 7078-KIT each contain the

parts of one “rack and panel” plug. The Model 7074~KIT

contalnsa75.pinplugandisintended tomatewithoneof

the BANK (input) receptacles, while the Model 7078~KIT