Page 1

MODEL 707

SWITCHING MATRIX

QUICK REFERENCE GUIDE

Page 2

Page 3

INTRODUCTION

This quick reference guide cOntai”S deScripfio”S Of Various

features and information concerning the operation of the

Model 707. Also included are programming examples using

“alio”S controllers.

01988, Keithley Instruments, 1°C.

Instruments Division

Document Number: 707-903-01 Rev. A

Cleveland. Ohio, U.S.A.

Page 4

Page 5

TABLE OF CONTENTS

SAFETYPRECAUTIONS ...................... 2

FRONT PANEL FAMlLlARlZATlON .............. 3

OlSPLAY MESSAGES,, ..................... 18

REAR PANEL FAM,L,ARlZATlON. .............. 20

,NSTALL,NG AND REMOVING CARDS .......... 25

MASTER,SLA”E SYSTEMS .................. 27

BASIC SWITCHING OPERATION. .............. 30

Selectins Make/Break and Break/Make Rows 31

Modifyilg a Relay Setup ............

storing Setup and Sending to Relays ...

IEEE-488 PROGRAMMING

Device-Dependent Commands ........

oata Formats .....................

Hit Key Commands ................

SRO Mask and Serial Poll Byte ........

staws Words. ....................

PROGRAMS ,.,..,......................

IBM PC/XT/AT with CEC PC < > 488

IBM PC,XT,AT with CEC PC< ,488 and ASYST

HP Mode, 9000 series 200,3OO.. 57

.............

Page 6

SAFETY PRECAUTIONS

2. Inspect the connecting cables and test leads for possi~

ble wear, cracks, or breaks before each use.

3. For maximum safety. do not touch the test cables or any

iktrumenfs while power is applied to the circuit under

test. Turn off the power and discharge any capacitors

before connecting or disconnecting cables from rhe

InmiX car*.

5. Da not exceed the maximum allowable input of the

matrix cards. as defined in the specifications and operas

tion sections of their manual.

2

Page 7

FRONT PANEL

FAMILIARIZATION

POWER

AC power switch turm the unit on or off,

3

Page 8

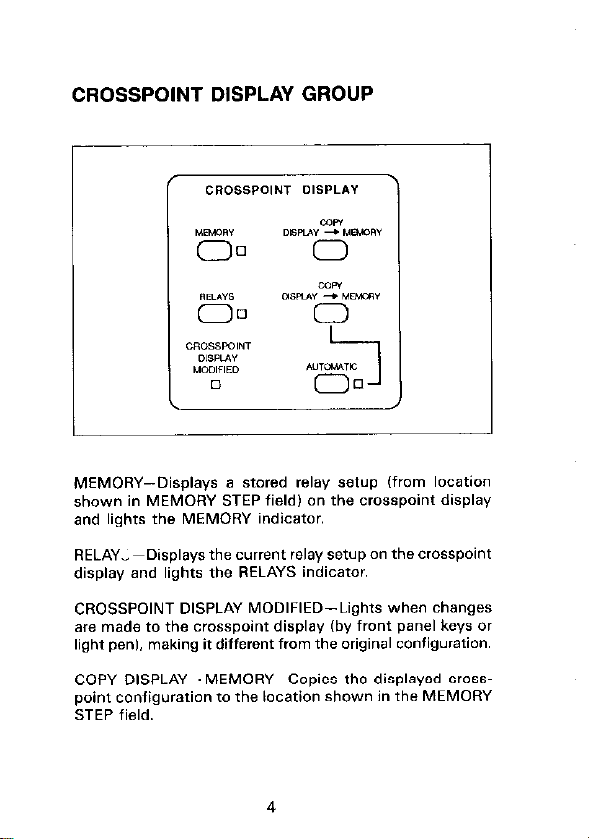

CROSSPOINT DISPLAY GROUP

MEMORY--Displays a stared relay setup (from location

shown in MEMORY STEP field) on the crosspoint display

and lights the MEMORY indicator.

RELAYl~Oisplays the current relay setup an the crosspoint

display and lights the RELAYS indicator.

CROSSPOINT DISPLAY MODIFIED-Lights when changes

are made to the crosspaint display (by front panel keys or

light pen), making if different from the original configuration.

COPY DISPLAY--MEMORY--Capies the displayed crosspoint configuration to the location shown in the MEMORY

STEP field.

4

Page 9

COPY DISPLAY-RELAYS-Copies the displayed crosspoint

configuration to the relays.

AUTOMATIC (COPY DISPLAY--RELAYS)-When this LED

is lit. any change to the crosspoint display is sent to the

relays at the same time. The pushbutton toggles the LED

on and off. ITo affect chanae in memarv, displav must be

copied to memory.~

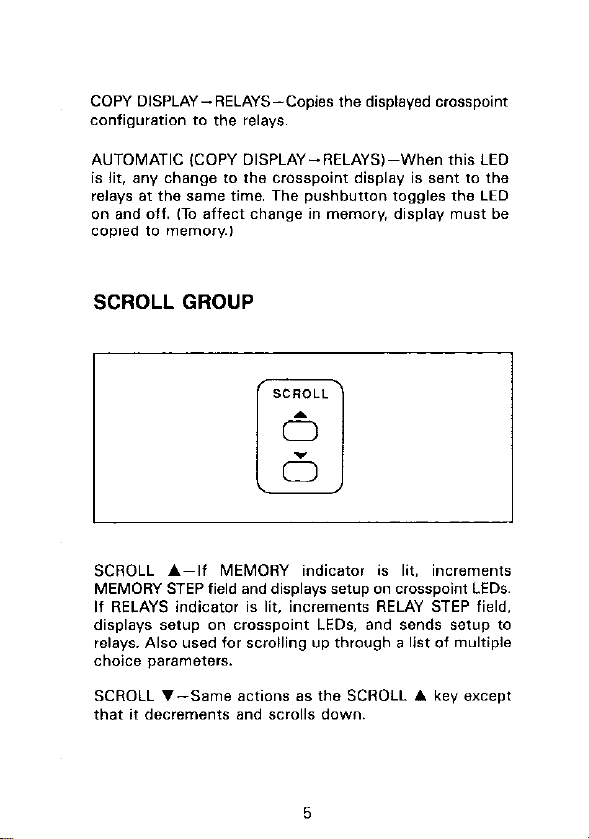

SCROLL GROUP

SCROLL A-If MEMORY indicator is lit, increments

MEMORY STEP field and displays setup on crosspoint LEDs.

If RELAYS indicator is lit. increments RELAY STEP field,

displays setup on crosspoint LEDs, and sends setup to

relays. Also used for scrolling up through a list of multiple

choice parameters.

SCROLL .-Same actions as the SCROLL A key except

that if decrements and SCrdS down.

Page 10

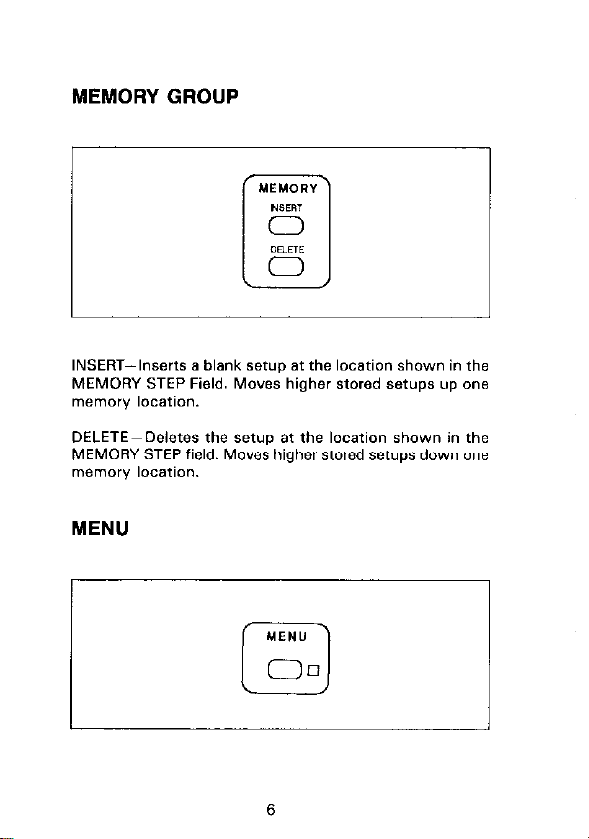

INSERT-Inserts a blank serup at the location shown in the

MEMORY STEP Field. Moves higher stored setups up one

memory location.

DELETE-Deletes the setup at the locafion shown in the

MEMORY STEP field. Moves higher stored setups down one

memory location.

MENU

r

MEN”

00

0

Page 11

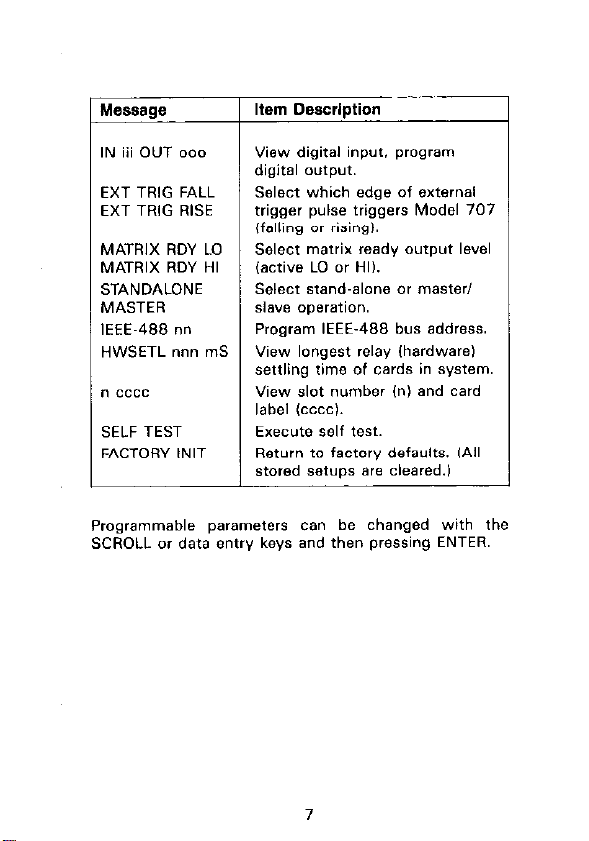

I

Message

I

Item Description

view digital input. program

digital output.

EXT TRIG FALL

EXT TRIG RISE

Select which edge of external

trigger pulse triggers Model 707

(falling or rising).

MATRIX RDY LO

MATRIX RDY HI

STANDALONE

MASTER

IEEE-488 nn

HWSETL nnn mS

Select matrix ready output level

(active LO or HI).

Select stand-alone OI master,

~l.we operation.

Program IEEE-488 bus address.

View longest relay Ihardware)

settling time of cards in system.

n cccc

View slot number Ini and card

label tcccc,.

SELF TEST

FACTORY NIT

EYeCUte Self test.

Return to factory defaults. ,All

stored SetUpS a,0 cleared.,

Programmable parameters can be changed with the

SCROLL or data entry keys and then pressing ENTER.

I

7

Page 12

SETTLING TIME-Displays the current value of programmed

settling time. (This delay begins after the relay seftling time.1

To change the value. enter between 0.65000msec and press

ENTER.

MAKE/BREAK-Selects rows to operate as make/break

(make-before-break) for all setups. First enter row desigrw

fion IA-H), then press MAKE/BREAK fo roggle the state for

that row and immediately reprogram the Model 707 for the

new operation.

BREAK/MAKE-Same action 8s MAKE/BREAK except that

it selects break/make (break-before-make) rows. ISelecting

a row for break/make de-selects it for make/break and vice

versa.)

8

Page 13

LOCAL

When in remote WEMOTE on). return the Model 707 to local

made (REMOTE off). If restores operation of other front

panel ~onfrols unless LLO llocal Lockout) is in effect

TRIGGER GROUP

ENABLE-Toggles between triggers enabled and triggers

disabled. When triggers are enabled. the LED is lit.

Page 14

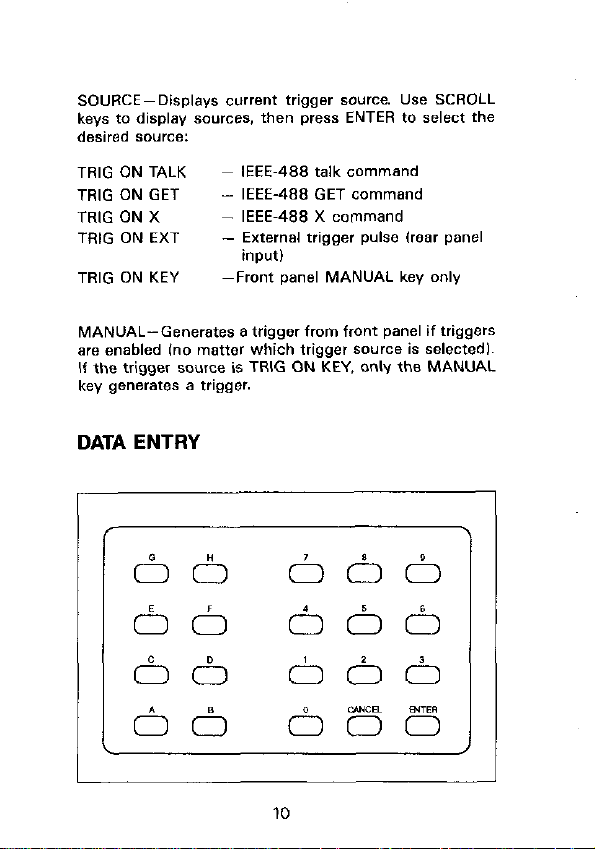

SOURCEPDisplays current trigger source. Use SCROLL

keys 20 display sources, then press ENTER to select the

desired source:

TRIG ON TALK

TRIG ON GET

TRIG ON X

TRlG ON EXT

TRIG ON KEY

MANUAL-Generates a trigger from front panel if triggers

are enabled (no matter which trigger source is selectedl.

If the trigger source is TRIG ON KEY. only the MANUAL

key generates a trigger

IEEE-488 talk command

- IEEE-488 GET command

- IEEE-488 X command

- External trigger pulse (rear panel

input)

-Front panel MANUAL key only

DATA ENTRY

Page 15

ASH, O-S-These keys are for entering row/column addresses

and setup locations, selecting make/break and break/make

rows, and entering various numeric values.

CANCEL-If the value in the alphanumeric display has been

modified, this key restores the currenf parameter value. If

the velue in the alphanumeric display has not been modified,

this key returns the Model 707 to the previous display.

CANCEL also exits from menu mode if no changes have

been made.

ENTER-If the value in the alphanumeric display has been

modified, pressing this key stores the parameter value. Also

invokes immediate action items from the menu and exits

menu mode (except when digital 110 is displaYedI

RESET

LI:

Performs the same functions as cycling power Call relays

are opened. triggers are disabled. RELAY STEP to 000,

MEMORY STEP fo 001, etc.). except powerup self-checking

and masterislave loop initieliration.

Page 16

CLEAR, OPEN, CLOSE

CLEAR--Turns Off a,, crosspoint display LEO% If the

AUTOMATIC ICOPY DISPLAY--RELAYS) indicator is lip. all

relays are opened immediately.

OPEN -Turns off ~rcmpoint LED of row,column shown on

alphanumeric display. If the AUTOMATIC (COPY DISPLAYRELAYSI indicator is lit. the corresponding relay opens

immediately

CLOSE~Same action as OPEN key except that it turns on

the crosspoint LED and relay.

Page 17

ALPHANUMERIC DISPLAY

pziizzs

A Wcharacter display that can show:

. Error messages.

l Menu item selections.

. Last setup sent from memory to the relays (RELAY STEP

field,.

Page 18

IEEE-488 STATUS INDICATORS

These three LED indicators apply to instrument operation

over the IEEE-488 bus. The TALK and LISTEN indicators

show when fhe unit has been addressed to talk or listen.

REMOTE turns on to show when the unit is in the IEEE-488

remote State.

Page 19

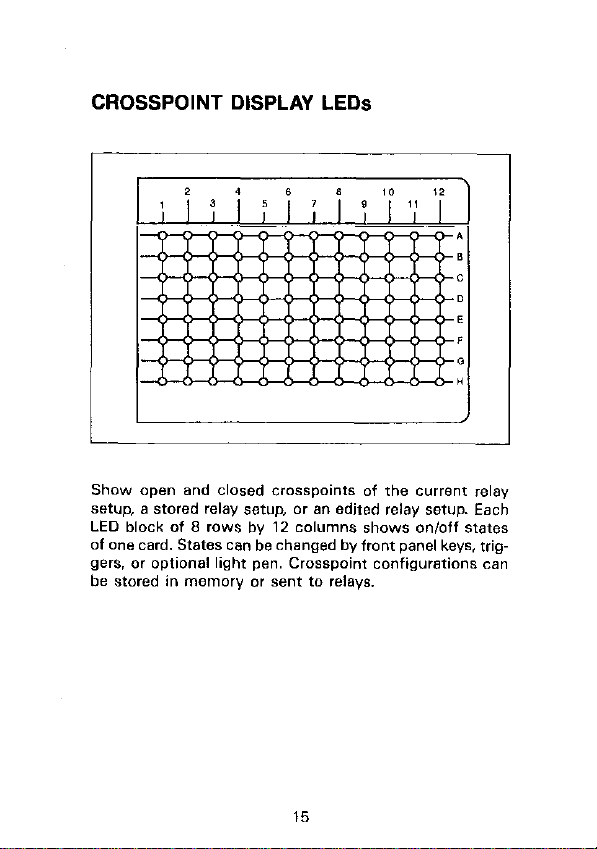

CROSSPOINT DISPLAY LEDs

Show open and closed crosspoinrs of the CUllem relay

setup, a stored relay setup, or an edited relay setup. Each

LED block of 8 rows by 12 columns shows on/off states

of one card. States can be changed by front panel keys. triggers. or optional light pen. Crosspoint configurations can

be stared in memory or sent to relays.

Page 20

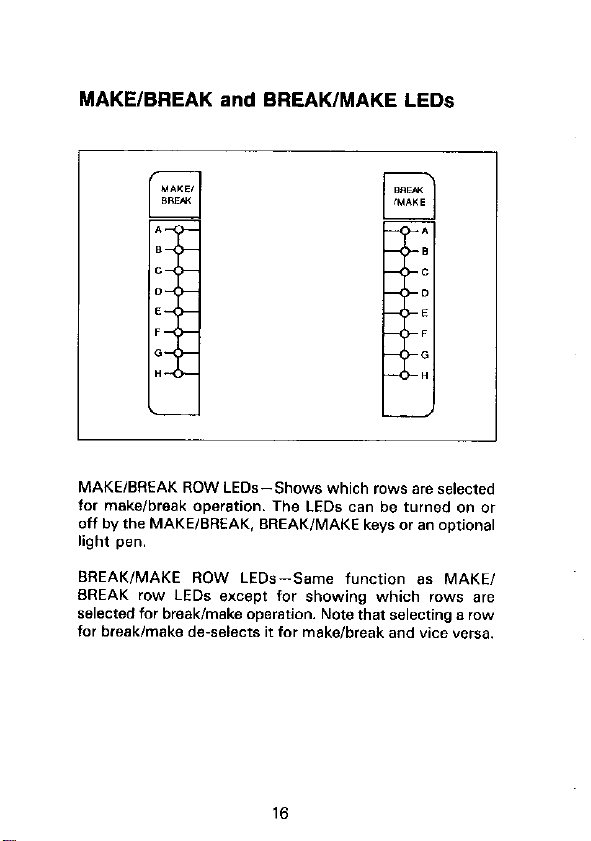

MAKE/BREAK and BREAK/MAKE LEDs

MAKE/BREAK ROW LEDs-Shows which rows are selected

for mskeelbreak operation. The LEDs can be turned on or

off by the MAKE/BREAK. BREAK/MAKE keys or an o,,tional

light pen.

BREAK/MAKE ROW LED*-Same function as MAKE,

BREAK row LEDs except for showing which rows are

selected for break/make operstion. Note thaf selecting a ,a.,

for break/make de-selects it for make/break and vice versa.

16

Page 21

LIGHT PEN

r

An optional input device for toggling the on/off state of the

Crosspoint Display LED*. MAKE/BREAK row LEDs. and

BREAK/MAKE row LEDs. One light pen is used to control

the LEDs of up to five Model 707 mainframes.

Page 22

DISPLAY MESSAGES

Table 1. Additional Messages

Message

CARD ID ERROR’

IDDC

IDDCO

,N”ALlD lNPtJT

M/S ERROR’

M,S LOOP DOWN

NOT IN REMOTE

Description

Checksum test failed on one

or more matrix cards.

Invalid device-dependent

command.

Invalid device-dependent command option.

Light pen button pressed wher

pen was not painted at WOSS~

point LED or make/break or

breakimake LED.

Error in master/slave communication loop foverrun. parity,

framing. count imbalance, or

time-out).

One or more units connected

in masrer,sla”e loop are “Of

powered u,,.

“x” character received over

IEEE-488 bus b”t Model 707

is not in remote.

Page 23

Table 1. Additional Messages (Cont.)

Descrfptlon

Additional trigger received

before programmed settling

time expired (trigger is

wocessed).

Self-test detected error in

RAM.

Self-test detected checksum

error in ROM.

SETUP ERROR’

TRIG OVERRUN

“Message remains displayed until next operation.

Self-test detected checksum

error in stared setup.

An additional trigger was

received before the Model 707

asem the READY signal.

Page 24

REAR PANEL FAMILIARIZATION

CARD SLOTS

The Model 707 accepts up fo six plug-in matrix cards 18

rows by 12 colurnns~ per mainframe

MASTER/SLAVE

MASTER/SLAVE OUT-An S-pin DIN connector for connecting a cable to the next mainframe in a master/slave daisy

chain configuration.

MASTER/SLAVE IN-An S-pin DIN connector for connecting a cable from the previous mainframe in a master/slave

daisy chain configuration.

20

Page 25

BNC JACKS

EXTERNAL TRIGGER INPUT-A BNCjack for applying a trip

ger pulse to change to the next relay setup. if triggers are

enabled and TRIG ON EXT is selected as the source. Pulses

must be TTL-compatible. negative- or positive-going

lselected by a menu item). with a duration greater than

600nsec.

MATRIX READY OUTPUT-A BNC jack providing a TTL-

compatible, high- or low-true level (selected by a menu item).

If goes false when relays are switched and goes true after

the sum of the relay settling time and the programmed setfling time.

Page 26

RELAY TEST

A G-pin quick-disconnect terminal block with logic ground

and four logic inputs for testing crosspoint relay closures.

Wiring between this terminal block and rows A and B of

any card in the group of cards to be tested is necessary for

the test. Test connections are detailed in the card rn~~~als.

DIGITAL I/O

r

L

A DB-25 connector for the TTL-compatible digital I/O with

data lines for eight inputs and eight outputs. It also con-

22

Page 27

rains control lines ‘0, handsnaking r,nput Latch ana cl”T~

put Strobe). Input lines are viewed and output lines are pro-

grammed through a menu item

IEEE-488 INTERFACE

This connector interfaces the Model 707 to the IEEE-488

bus. IEEE-488 interface function codes are marked adjacent to the connector.

23

Page 28

AC POWER

LINE VOLTAGE SELECTED-The position of this switch

determines the operating voltage range of the instrument:

$0.1lOV. 105.125v, or 180.22ov. 210.25ov.

AC RECEPTACLE-Power is applied through the supplied

power cord to the S-terminal AC receptscle.

LINE FUSE-The line fuse provides protection for the AC

power line input. The fuse rating mu% match the line voltage

semng.

24

Page 29

INSTALLING AND REMOVING

CARDS

Figure 1. installing a Card

Turn 0” matnfmme power and dkonneet the

he cord before Installing or removing cards.

WARNING

Page 30

DO not touch the card surfaces, con”ecton, or DO not touch the card surfaces, con”ecton, or

CAUTION CAUTION

components to avold contamlnatlo” that could components to avold contamlnatlo” that could

degrade card pertormance. degrade card pertormance.

1. Ensure that the access door on top of the mainframe is

fully closed and lacked down. (The bottom side of the

access door has card guides.1

2. Remove the slot cover from the desired slot.

3. With one hand grasping the card’s handle, and the other

supporting its weight. line up the card with the card

guides in the slot. Ensure that the component side is facing the fan of the mainframe.

4. Slide the card into the mainframe until it is fully seated

in the backplane connectors. Finger-tighten the springloaded mounting SCW.VS at the back of the card to lock

it in o,ace.

The mounting screws must be secured to ensuw

WARNING

a proper chassis gmund connection between the

card and the mainframe. Fallurn to property

secure this ground connectlo” may result in personal inJury or death due to electric shock.

5. To remove a matrix card. first turn off the mainframe and

disconnect the line cord. Ensure “a voltage is applied from

the u~er’~ circuit. Remove any infernal cabling between

cards through the unit’s accept door. Loose” the springloaded mounting screw and pull out the card by its

handle.

26

Page 31

MASTER/SLAVE SYSTEMS

A method of expanding a matrix with multiple mainframes

is tO connect up to five units in a masterlslsve configuration. This is done by connecting the rows of like cards in

separate units and by connecting the units in a closed loop

of OIN cables for communication and canfrof. A

masterislave system configuration appears as one unit with

expanded card capacity. That is. only the master unit is addressed by the IEEE-488 bus CO”~,O,,B, and controlled from

the front panel.

A mesterhlsve configuration extends matrix rows yielding

a long, narrow matrix. Figure 2 shows the connections between two units having Model 7071 cards. With five units.

the maximum matrix size is 8 rows by 360 columns. Table

2 shows the column assignments for the maXimm

configuration.

If the mainframes of a master/slave configuration contain

different card models, group like csrds 8s much as possi~

ble. This will reduce the need to extend the analog buses

with exfernsl cables.

27

Page 32

Flgure 2. Example of Master/Slave Interconnect Cables

28

D

Page 33

Table 2. Master/Slave Columns

unit

1

Master

2

Slave 1

3

save 2

4

Slave 3

5

Slave 4

Slot

1

2

3

4

5

6

1

2

3

4

5

6

1

z

4

5

6

1

:

4

:

1

2

3

4

5

6

Columns (l-12)

I-12

13.24

26-36

37-46

49-60

61~72

73-64

65-96

97-108

109-120

121-132

133-144

145-156

157-166

169-160

161-192

193-204

205-216

217-228

229-240

241-252

253-264

265-276

277-286

289-300

301-312

313~324

325-336

337-348

349-360

29

Page 34

BASIC SWITCHING OPERATION

The following paragraphs will take you through a simple,

general, step-by-step procedure to edit a matrix setup, store

it in memory. and send the setup to the relays. Althwgh

ihe steps are described with front panel operations. the procedure can be performed over the IEEE-488 bus.

Figure 3 shows the setup data paths for these steps.

Figure 3. Setup Data Transfers

30

Page 35

Selecting Make/Break and Break/Make ROWS

Select make-before-break, break-before-make. or don’t care

operation for the rows. The selections will be in effect for

alI relay switching. even if a stored setup is not used. IAs

a general rule, use makeibreak operation for current murces

and breakimake for voltage sources.,

“se the data entry keys to select a mw, then press

MAKE/BREAK or SREAK,MAKE fO toggle the state. lselec~

ting one state for a row de-selects it for th8 other.1 This

operation can also be performed with the light pen by using if to turn on/off the MAKWSREAK and SREAK,MAKt

LEDS.

Modifying a Relay Setup

Step 1: S&et a Stowd Setup

If you want to modify set”,, #I, just press the MEMORY

key. The MEMORY indicator light will light. To select another

setup fup fo location 1001. use the numeric data entry keys

(leading zeros are not necessaryl. then press the MEMORY

key.

Step 2: Modify the Displayed Setup

Use the data entry keys to select a crosspoint address IA1

fhrwgh H721. then press the OPEN or CLOSE key

Keystrokes will be shown an the alphanumeric display and

the CROSSPOINT DISPLAY MODIFIED indicator will light.

31

Page 36

If You have the optional light pen. toggle the state of a crosspoint LED by holding the light pen perpendicular to and

touching the front panel overlaY and pressing the light pen

button.

Continue editing with the front pane, key or light pen until

the ~ros~point display shows the desired configuration.

Storing Setup and Sending to Relays

Step 1: Storing Setup in Memory

To store the modified setup at the location shown in the

MEMORY STEP field, just press the COPY DISPLAYMEMORY KEY. This action wewrites the old setup data

at that location with the newly modified setup.

To select a different memory location, key in a valid local

tion number, then press the COPY DISPLAY-MEMORY key

The MEMORY STEP field is se, to the new location.

Step 2.4: Sending Setup to Relays

To make the newly modified setup the current relay setup,

just press the COPY DISPLAY-RELAYS key. The relay states

will be changed to reflect the modified setup data. If the

MEMORY LED is lit. the RELAY STEP field will be set equal

to the MEMORY STEP field. In effect. this copies a setup

from memory to the relays.

32

Page 37

Step 28: Triggering Setup to Relays

If you modified setup #I and restored it to memory at the

same location. a single trigger will copy the setup to the

relays. Do this by pressing the trigger SOURCE key. scrolls

ing to the “TRIG ON KEY” display and pressing ENTER.

Then press the trigger ENABLE key Pressing the trigger

MANUAL key will copy setup #I to the relays and set the

RELAY STEP field to 001.

33

Page 38

Page 39

IEEE-488 PROGRAMMING

DEVICE-DEPENDENT COMMANDS

Close crowpoint* of setup indicated by edit pointer frows A-H,

Dcccccccccccccc Display ASCII characters 114

35

Page 40

Edit Pointer

EO

E”

Enable/Disable Triggers

FO

FI

m

Point to CUrrent relay setup

Paint to stored relay setup 11-1001

Disable triggers

Enable triggers

1

Full output, all data

in one talk

1 G4

G5

G6

G7

._...

Condensed output, all data in one

talk

Condensed output. one mainframe per talk

Binary output, all data in one talk

Binary output, one mainframe per

talk

36

Page 41

Insert blank setup in memory

,l-1001

Self-test

JO Perform SewteSt

EOI and Hold-off

KO

Send EOI, hold-off on X until

Read”

K1

K2

K3

K4

No EOI. hald~off on X until Read”

Send EOI. do not hold-off on X

No EOI, do not hold-off on X

Send EOI. hold-off on X until

Matrix Ready

K6

No EOI, hold-off an X until Matrix

Read”

Download Setups

Lbbb...X Download setups from controller

to Model 707

SRQ

MO

MI

M2

M4

M6

Ml6

M32

Ml28

SRQ disabled

not used

Front pane, key press

Digital 110 interrupt

Matrix Ready

Ready for trigger

Error

not used

I

37

Page 42

/ Dfgftaf Output

0”“” Set states of digital output lines

1000-255~

Delete Setup

on

Delete setup from memory 11-100)

Restore Defaults

RO

Restore factor” defaults

Programmed Settling Time

S”

Program settling time in msec

10.65000,

38

Page 43

mgger

TO or T,

T2 or T3

T4 or T5

T6 0, T7

T6 o, Tg

Trigger on talk

Trigger on GET

Trigger on X

Trigger on External Trigger pulse

Trigger on front panel MANUAL

key only

status

“0

ut

“2.”

Send machine status word

Send error status word

Output setup “n” IO-1001 with

current G format

u3

u4

U5.U

Send RELAY STEP pointer

Send number of slaves

Send model number of each card

in unit “u” IO-41

U6

u7

Send relay settling time

Send digital input of unit

Send RELAY TEST input

Make/Break

“abcdefgh

Select rows for makeibreak opera-

tion (00000000 111111111

Break/Make

Wsbcdefgh Select rows for breaklmake opera-

tion ~00000000 11111111,

39

Page 44

Execute

x

EXeC”te commands

copy setup

ZO,”

Z”,O

Zm,n

copy current relay SefUp to

mamory location “n” (1.1001

copy SetUp frmn memOly location

“ll” w1001 to relays

Copy setup from location “m”

IO-1001 to location “n” 0100)

DATA FORMATS

When uploading setup data to the controller, the data will

be in one of the formats that follow. The example data

shown is for set”,, #3 of a stand-alone unit with crasspoints

Al. AZ, 919. 820. C27. C28. D37, D38, FL?,. and F62 being closed.

40

Page 45

GO and 01 Full Output

41

Page 46

62 and 03 inspect Output

64 and GS Condensed Output

42

Page 47

G6 and G7 Binary Output

43

Page 48

HIT KEY COMMANDS

Table 3 lists hit key commands sent over fhe IEEE~488 bus

to emulate front pane, key presses.

Table 3. Hit Keys

ammand Iby Command Key

44

Page 49

SRO MASK AND SERIAL POLL BYTE

Page 50

STATUS WORDS

UO Machine Status Word

Page 51

Ul Error Status Word

U3 Relay Step Pointer

47

Page 52

U4 Number of Slaves

/

48

Page 53

U5 Card Identifications

49

Page 54

U6 Relay Settling Time

U7 Digital Input

Page 55

U6 Relay Test Input

Page 56

PROGRAMS

IBM PC/XT/AT with Capital Equipment

Corporation PC< >466 Interface

(Kelthley PC-466~CEC)

The following program sends a command string from an

IBM PC/XT/AT computer to the Made, 707 and displays the

response an the CRT The computer must be equipped with

a CEC interface card and DOS 2.0 (or later revision)

opermng system.

DIRECTIONS

1. Using the front panel menu feature, set the primary

IEEE-488 address of the Model 707 to 18.

2. With the power off, connect the Model 707 to the

IEEE-488 interface card installed in the IBM computer.

3. Type in BASICA an the computer keyboard to get into

the IBM interpretive BASIC language.

4. Enter the lines below using the return key after each line.

5. Run the program and type in the desired command string

at the ENTER COMMAND STRING, ,,ram,,t. For example, $0 close crosspoint Al, type in CAIX and press the

return key. (The Model 707 software revision. e.g.

707A01. will then appear on the computer display for

device-dependent commands which have no response.)

If the command “G2U2,OX” is typed in at the prompt.

the response will be a display of the closed crosspoints

of the current relay setup.

52

Page 57

PROORAM

COMMENTS

Prompf for string

53

Page 58

IBM PC/XT/AT with Capital Equipment

Corporation PC < > 406 Interface and

ASYST Software

The ASYST program listed here sends a command string

from an IBM PC,XT,AT compufer to the Model 707 and

displays the response on the CRT. The computer must be

equipped with a CEC interface card and DOS 2.0 (or later

revisionI operating system.

The optional GPWEEE-488 software module for the ASYST

package is required. Hardware requirements for ASYST include: 640K RAM. math coprocessor. parallel port. and hard

drive IrecommendedL

DIRECTIONS

1. Using the front panel menu key, set the primary

IEEE-488 address of the Model 707 fo 18.

2. With the power off. connecf the Model 707 to the

IEEE-488 interface card installed in the IBM computer.

3. Boot ASYST software from DOS. You will get an OK

prompt.

4. Use the <F2> key to enter the Main Configuration

Menu. In addition to the usual configuration rep

quirements of ASYST, the GPl8 must be configured.

From the Overlay Configuration Menu. select overlays

GPIB Master snd TYpe 1 NEC GPl8 Driver.

From the GPIB Configuration Menu. select a bus

number. board type INational GPIB-PC1 or GPIB-PC21.

memory address f2881. primary address 101, and interrum line.

Page 59

5. Save your changes end return to the OK prompt.

8. Use the command line editor (EDIT 707.DMOI to enter

the following program. Save the program and exit the

editor.

7. When prompted. load the program with the L key, or

type LOAD 707.DMO from the OK prompf.

8. When the program loads properly, type MAIN from the

OK prompt to start execution.

8. Type in the desired command string at the “Enter corn-

mand string:” prompt. For example, to close crosspoinr

Al. type in CAlX snd press the refum key. (The Mode,

707 software revision. e.g. 707AOl. will then appear

an the computer dis.play for device-dependent commands which have no response.1

If the command “G2U2,OX” is typed in at the prompt,

the response will be a display of the closed crosspoints

of the current relay setup.

10. Type <Control-Break> to exit the program loop of

707.DMO and return to the OK prompt. The programdefined words can be removed from the ASYST dictionary by typing FORGET 707.

PROGRAM

BWINIT

SEND.INTERFACE.CLEAR

REMOTE.ENABLE.ON

SYNCHRONO”S.GP,B

?GPIE.DEVICES

18 GPIBDEVICE 707

COMMENTS

\ Initialize bus

\ Take control of bus

\ Allow remote operation

\ Mske sure ASYST is in

sync. mode

\ List controller

parameters

\ Set 707 address and

name

Page 60

EOI.ON

EOS.ON

\ Enable end or identify

\ Enable end of string

10 EOS.CHARACTER

1000 TIMEOUT

,GPIB.DE”ICE

100 STRING COMMAND

100 STRING RESPONSE

: GET.INP”T

CR .” Enter command

*tring: ”

“INPUT COMMAND “:=

: MAIN

BEGIN

ME

GET.INPUT

707

COMMAND GPIB.WRlTE

RESPONSE GPIB.READ

CR RESPONSE “TYPE

AGAIN

\ Use LF terminator

\ Set timeout of kc

\ List 707 parameters

, Allacate 100 bytes for

“SW Input

\ Allocate 100 bytes for

707 reSpO”*e

\ Get DOCs

\ Definition for main

program

\ start loop

\ Make controller current

device

\ Get DOCs from user

\ Make 707 current

device

\ Send DDCs to 707

\ Get response

\ Display response

\ Return for more

CO”TlW”dS

Page 61

Hewlett-Packard Model 9000 Series ZOO/300

The following progrsm sends a command string to the

Model 707 from B Hewlett-Packard Model 9000 Series

200/300 computer and displays the response on the com-

puter CRT. The computer must be equipped with HP BASIC

4.0.

DIRECTIONS

1. Using the front panel menu feature. set the primary

IEEE-498 address of the Model 707 to 18.

2. With the power off. connect the Model 707 to the

IEEE~4BB interface card installed in the HP computer.

3. Enter the lines in the program below, using the

ENTER/RETURN key after each line.

4. Press the RUN key and type in the desired command

string at the COMMAND STRING prompt. For example.

to close crosspoint Al, type in CAlX and press the

ENTER/RETURN key. (The Model 707 ~offware revision.

e.g. 707A01, will then appear an the computer display

for device-dependent commands which have no

response.,

If the command “GZU2,OX” is Typed in at the prompt.

the response will be 8 display of the closed crosspoints

of the current relay setup.

Page 62

Page 63

Page 64

-

Tat Instrumentation Group

28775 Aurora bad / Clewland, Ohio 44139

-

Loading...

Loading...