Page 1

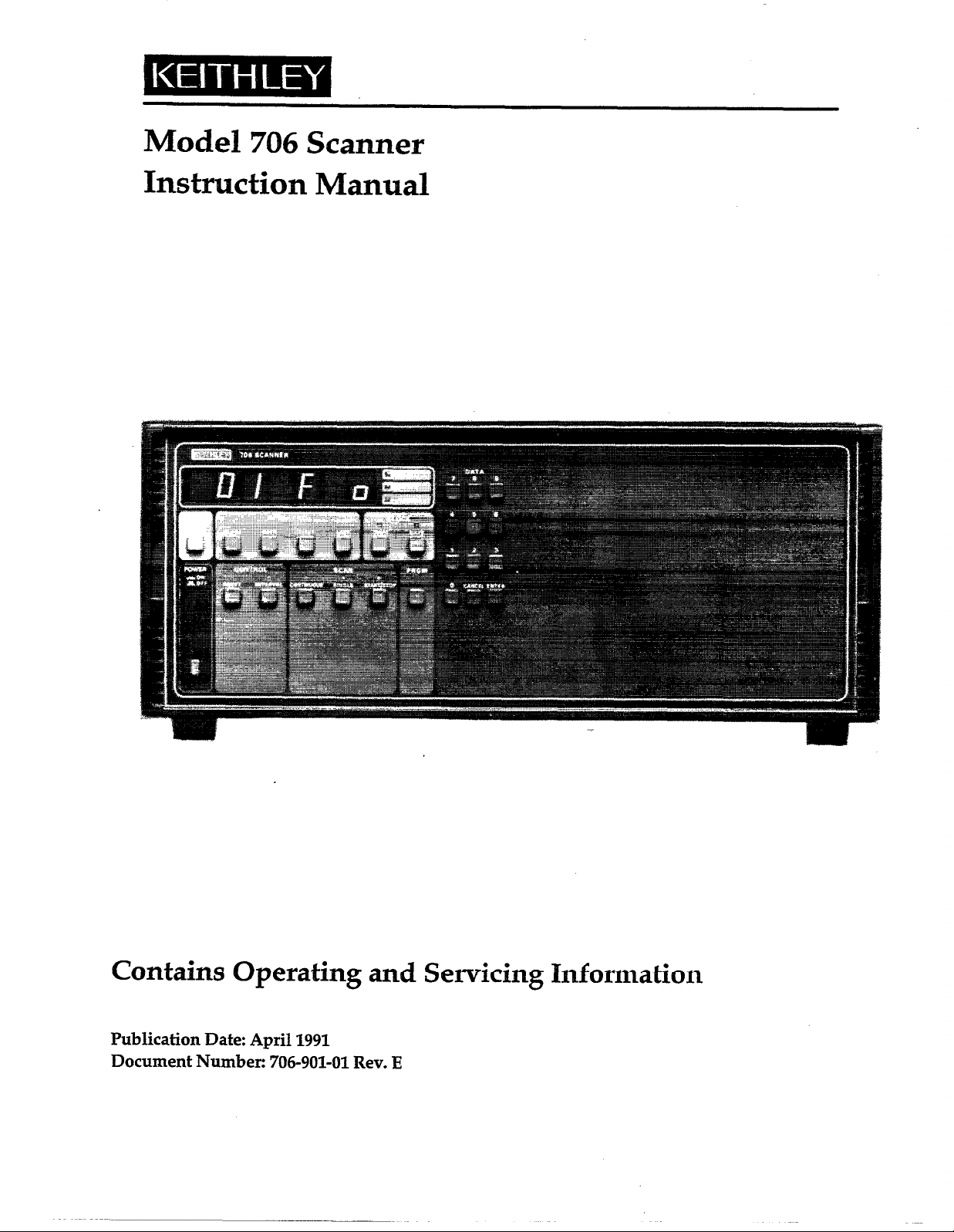

Model

706

Scanner

Instruction Manual

Contains Operating and Servicing Information

Publication Date: April 1991

Document Number: 706-901-01 Rev. E

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 (lays.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

‘ITHIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTlE S, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL QR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. l 28775 Aurora Road l Cleveland, OH 44139 l 216-248-0400 l Fax: 216-248-6168 l http://www.keithley.com

CHINA:

FRANCE

GERMANY:

GREAT BRITAIN:

ITALY: Keitbley Instruments SIk l Viale S. Gimigoano 38 l 20146 Milano l 39-2-48303008. Fax: 39-2-48302274

JAPAN:

NETHERLANDS:

SWITZERLAND:

TAIWAN

Keitbley Instruments Cl&m. Yuan Chen Xio Building, Room 705 l No. 12Yomin Road, Dewei, Madian. Beijing, China loo029 l 8610-2022886 l Fax: 8610-2022896

Keitbley Instruments SAkL l BP 60.3 al& des Garays -91122 Palaiseau C&&x l 31-6-0115155. Fax: 31-6-0117726

Keitbley Instruments GnibH l Laodsberger Stralk 65 l 82110 Germering l 49-89-849307-o l Fax: 49-89-84930759

Keitbley Instruments, Lt& l The Minster l 58 Portman Road l Reading, Berkshire RG30 IEA 9 44-01734-575666 *Fax: 44-01734-596469

Keitbley Instruments F& East KK l Aibido Bldg. * 7-20-2 Nishishinjuko . Shiojuku-ko, Tokyo 160 l 81-3-5389-1964 * Fax: 81-3-5389-2068

Keitbley Instruments Bv l Avelingen West 49 l 4202 MS Gorinchem l 31-(0)183-635333 l Fax: 31-(0)183-630821

Keithley Instruments Sk* Kriesbachstrasse 4 l 8600 Diibendorf* 41-1-8219444 l Fax: 41-l-8203081

Keitbley Instruments Taiwan l 1, Ming-Yu First SUeet * Hsinchu, Taiwan, R.0.C * 886-35-778462 l Fax: 886-35-778455

Page 3

Model 706 Scanner

Instruction Manual

01983, Keithley Instruments, inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

Fifth Printing, April 1991

Document Number: 706-901-01 Rev. E

Page 4

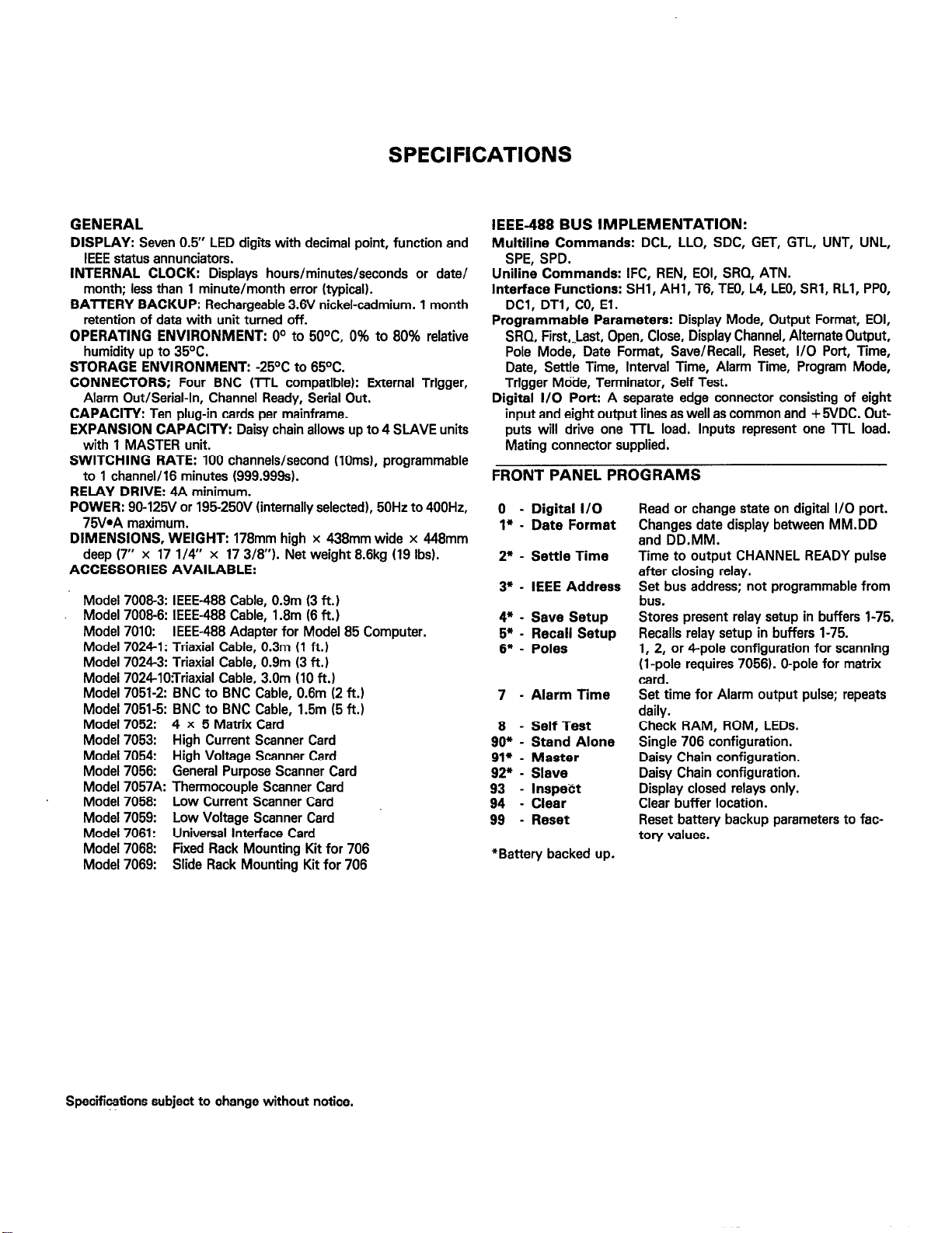

SPECIFICATIONS

GENERAL

DISPLAY: Seven 0.5” LED digits with decimal point, function and

IEEE status annunciators.

INTERNAL CLOCK: Displays hours/minutes/seconds or date/

month; less than 1 minute/month error (typical).

BATTERY BACKUP: Rechargeable 3.6V nickel-cadmium. I month

retention of data with unit turned off.

OPERATING ENVIRONMENT: O” to 50°C, 0% to 80% relative

humidity up to 35OC.

STORAGE ENVIRONMENT: -25OC to 65OC.

CONNECTORS; Four BNC (lTL compatible): External Trigger,

Alarm Out/Serial-In, Channel Ready, Serial Out.

CAPACITY: Ten plug-in cards per mainframe.

EXPANSION CAPACITY: Daisy chain allows up to 4 SLAVE units

with I MASTER unit.

SWITCHING RATE: 100 channels/second (IOmsl, programmable

to 1 channel/l6 minutes (999.999s).

RELAY DRIVE: 4A minimum.

POWER: 90-125V or 195250V (internally selected), 50Hz to 400H2,

75V.A maximum.

DIMENSIONS, WEIGHT: 178mm high x 438mm wide x 448mm

deep (7” x 17 l/4” x 17 3/8”). Net weight 8.6kg (19 Ibs).

ACCESSORIES AVAILABLE:

Model 7008-3: IEEE-488 Cable, 0.9m (3 ft.)

Model 70086: IEEE-488 Cable, 1.8m (6 ft.)

Model 7010: IEEE-488 Adapter for Model 85 Computer.

Model 7024-I: Triaxial Cable, 0.3m (I ft.)

Model 7024-3: Triaxial Cable, 0.9m (3 ft.)

Model 7024IO:Triaxial Cable, 3.0m (IO ft.1

Model 7051-2: BNC to BNC Cable, 0.6m (2 ft.)

Model 7051-5: BNC to BNC Cable, 1.5m (5 ft.)

Model 7052: 4 x 5 Matrix Card

Model 7053: High Current Scanner Card

Model 7054: High Voltage Scanner Card

Model 7056: General Purpose Scanner Card

Model 7057A: Thermocouple Scanner Card

Model 7058: Low Current Scanner Card

Model 7059: Low Voltage Scanner Card

Model 7061: Universal Interface Card

Model 7068: Fixed Rack Mounting Kit for 706

Model 7069: Slide Rack Mounting Kit for 706

IEEE-488 BUS IMPLEMENTATION:

Multiline Commands: DCL, LLO, SDC, GET, GTL, UNT, UNL,

SPE, SPD.

Uniline Commands: IFC, REN, EOI, SRQ, ATN.

Interface Functions: SHI, AHI, T6, TM, L4, LEO, SRI, RLI, PPO,

DCI, DTI, CO, El.

Programmable Parameters: Display Mode, Output Format, EOI,

SRQ, Fir&Last, Open, Close, Display Channel, Alternate Output,

Pole Mode, Date Format, Save/Recall, Reset, I/O Port, Time,

Date, Settle Time, Interval Time, Alarm Time, Program Mode,

Trigger Mode, Terminator, Self Test.

Digital I/O Port: A separate edge connector consisting of eight

input and eight output lines as well as common and + R/DC. Out-

puts will drive one lTL load. Inputs represent one lTL load.

Mating connector supplied.

FRONT PANEL PROGRAMS

0

- Digital I/O

I* - Date Format

2* - Settle Time

3* - IEEE Address

4* - Save Setup

5* - Recall Setup

6* - Poles

- Alarm Time

7

8 - Self Test

Stand Alone

go* 91, - Master

92* - Slave

93 - Inspect

- Clear

94

- Reset

99

*Battery backed up.

Read or change state on digital I/O port.

Changes date display between MM.DD

and DD.MM.

Time to output CHANNEL READY pulse

after closing relay.

Set bus address; not programmable from

bus.

Stores present relay setup in buffers l-75.

Recalls relay setup in buffers l-75.

1, 2, or Qpole configuration for scanning

(I-pole requires 7056). O-pole for matrix

card.

Set time for Alarm output pulse; repeats

daily.

Check RAM, ROM, LEDs.

Single 706 configuration.

Daisy Chain configuration.

Daisy Chain configuration.

Display closed relays only.

Clear buffer location.

Reset battery backup parameters to factory values.

Speclfi+lons subject to change without notice.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recog-

nize shock hazards and are familiar with the safety precautions re-

quired to avoid possible injury. Read the operating information

carefully before using the product.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present.

pect that hazardous voltage is present in any unknown circuit

before measuring.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jump-

ers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

A good safety practice is to ex-

Do not exceed the maximum signal levels of the instruments and

accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC main. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

Ifa @

#18 AWG or larger wire.

The

or more may be present on the terminals.

ual for detailed operating information.

Instrumentation and accessories should not be connected to hu-

mans.

Maintenance should be performed by qualified service personnel.

Before performing any maintenance; disconnect the line cord and

all test cables.

screw is present, connect it to safety earth ground using

symbol on an instrument or accessory indicates that 1OOOV

t

Refer to the product man-

Page 6

TABLE OF CONTENTS

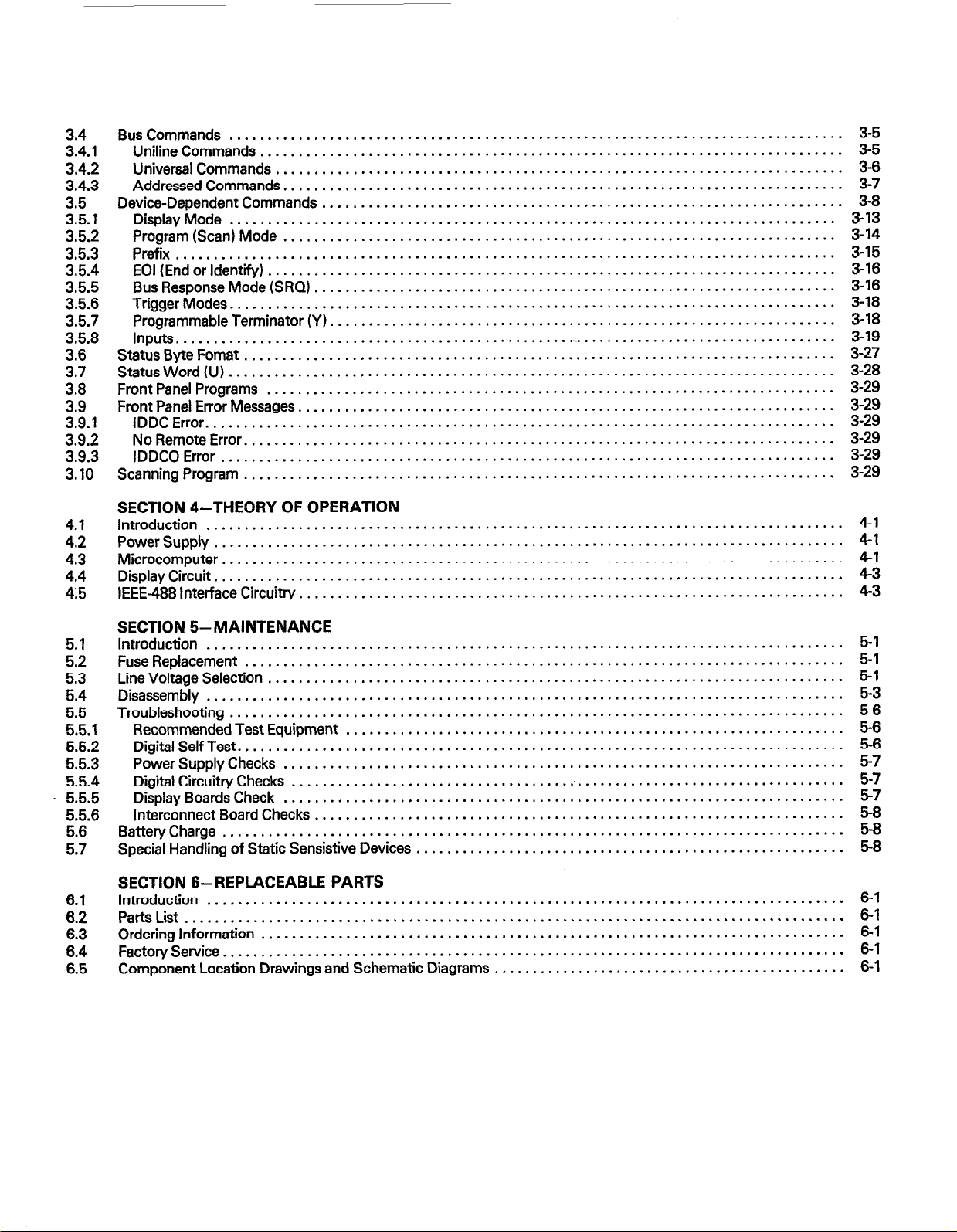

Paragraph

SECTION l-GENERAL INFORMATION

1.1

1.2

1.3

1.4

E

1:7

1.8

1.9

;-:

2:2.1

2.2.2

2.3

z.2

2:5.1

2.5.2

2.5.3

2.5.4

2.6

E

2:9

2.9.1

2.9.2

2.9.3

2.9.4

2.9.5

2.9.6

2.9.7

2.9.8

2.9.9

2.9.10

2.9.11

2.9.12

2.9.13

2.9.14

2.9.15

Introduction

Model 706 Features

Warranty information.

Manual Addenda

Safety Symbols and Terms

Unpacking and Inspection

Specifications.............................................;.-

Optional Accessories

Repackingforshipment

SECTION 2-OPERATION

Introduction

PreparationforUse

PowerUp .....................................................................................

Environmental Condition

Operatinglnstructions

Front Panel Clock Operation

Detailed Front Panel Controls Description

DetailedRearPanelDescription

Front Panel Programs.

...................................................................................

.............................................................................

...........................................................................

...............................................................................

.......................................................................

........................................................................

............................................................................

.........................................................................

...................................................................................

..............................................................................

CorrectLineVoltage

Plug-In Card (Scanner) Installation

FrontPanelControls

Rear Panel Description.

Basic Front Panel Operation

ScanningExamples

Program 0 Digital I/O

Program 1 Data Format

Program 2 Relay Settle Time

Program 3 Set IEEE Primary Address

Program 4 Save Relay Set Up

Program 5 Recall Relay Set Up

Program 6 Pole Configuration, Matrix Mode

Program 7 Set Alarm Time

Program 8 Diagnostic Self Test.

Program 90 Stand Alone

Program 91 Master.

Program92Slave

Program 93 Inspect

Program 94 Clear

Program 99 Reset

...........................................................................

............................................................... 2-l

.........................................................................

...........................................................................

...........................................................................

........................................................................

....................................................................

...........................................................................

..................................................................... 2-13

.......................................................... 2-14

..................................................................

..........................................................................

.........................................................................

.......................................................................

...................................................................

...........................................................

..................................................................

................................................................. 2-21

....................................................................

................................................................ 2-25

......................................................................

..........................................................................

............................................................................

.........................................................................

............................................................................

............................................................................

Title

...................................

....................................................... 2-22

Page

l-l

l-l

l-l

l-l

l-l

l-l

l-l

l-2

1-3

2-1

2-l

2-l

2-2

2-3

2-3

2-3

2-3

2-7

2-8

2-17

2-18

2-19

2-19

2-20

2-20

2-21

2-24

2-25

2-25

2-26

2-26

2-27

2-28

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.2

3.2.1

3.2.2

3.2.3

3.3

SECTION 3-IEEE BUS OPERATION

Introduction

Software Consideration

HP-85BASlCStatements

Interface Function Codes.

Mode 706 Interface Commands

IEEE488 Bus Lines

Bus Management Lines

Handshake Lines

Data Lines

System Set Up Procedure

...................................................................................

........................................................................ 3-l

......................................................................

......................................................................

.................................................................

..............................................................................

........................................................................

.............................................................................

................................................................................... 3-4

........................................................................

3-l

3-l

3-2

3-3

3-3

ifi

3-4

i

Page 7

;*i 1

31412

3.4.3

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.5.6

3.5.7

3.58

3.6

3.7

3.8

3.9

3.9.1

3.9.2

3.9.3

3.10

Bus Commands

Uniline Commands

Universal Commands

Addressed Commands

Device-Dependent Commands

DisplayMode

Program(Scan)Mode..

Prefix..

EOI(EndorIdentify)

BusResponseMode(SRQ)

TriggerModes

Programmable Terminator (Y)

Inputs....................................................-.

StatusByteFomat

Status Word (U)

Front Panel Programs

FrontPanelErrorMessages

IDDCError

No Remote Error.

IDDCOError

ScanningProgram

................................................................................

............................................................................

..........................................................................

.........................................................................

....................................................................

...............................................................................

......................................................................

....................................................................................

..........................................................................

.................................................................... 3-16

............................................................................... 318

..................................................................

.............................................................................

...............................................................................

..........................................................................

......................................................................

..................................................................................

............................................................................

................................................................................

.............................................................................

.................................

;1;

331:

3-14

3-15

3-16

3-18

3-19

3-27

3-28

3-29

3-29

3-29

3-29

3-29

3-29

4.1

4.2

4.3

f.2

5.1

5.2

5.3

5.4

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.6

5.6

5.7

6.1

6.2

6.3

6.4

6.5

SECTION 4-THEORY OF OPERATION

Introduction

PowerSupply

Microcomputer

DisplayCircuit

IEEE-488lnterfaceCircuitry

SECTION 5-MAINTENANCE

Introduction ...................................................................................

FuseReplacement

LineVoltageSelection

Disassembly ...................................................................................

Troubleshooting

RecommendedTestEquipment

DigitalSelfTest

PowerSupplyChecks

DigitalCircuitryChecks

Display Boards Check

InterconnectBoardChecks

BatteryCharge

Special Handling of Static Sensistive Devices

SECTION 6-REPLACEABLE PARTS

Introduction

Pa&List

Orderinglnformation..

Factory Service.

Component Location Drawings and Schematic Diagrams

...................................................................................

..................................................................................

.................................................................................

..................................................................................

.......................................................................

..............................................................................

...........................................................................

................................................................................

.................................................................

...............................................................................

.........................................................................

........................................................................

............. T

.....................................................................

.................................................................................

...................................................................................

......................................................................................

..........................................................................

................................................................................

...........................................................

........................................................

..............................................

4-1

4-l

4-l

4-3

4-3

5-l

5-l

5-1

5-3

5-6

5-6

5-6

5-7

5-7

5-7

z

5-8

6-l

6-l

6-l

6-l

6-1

Page 8

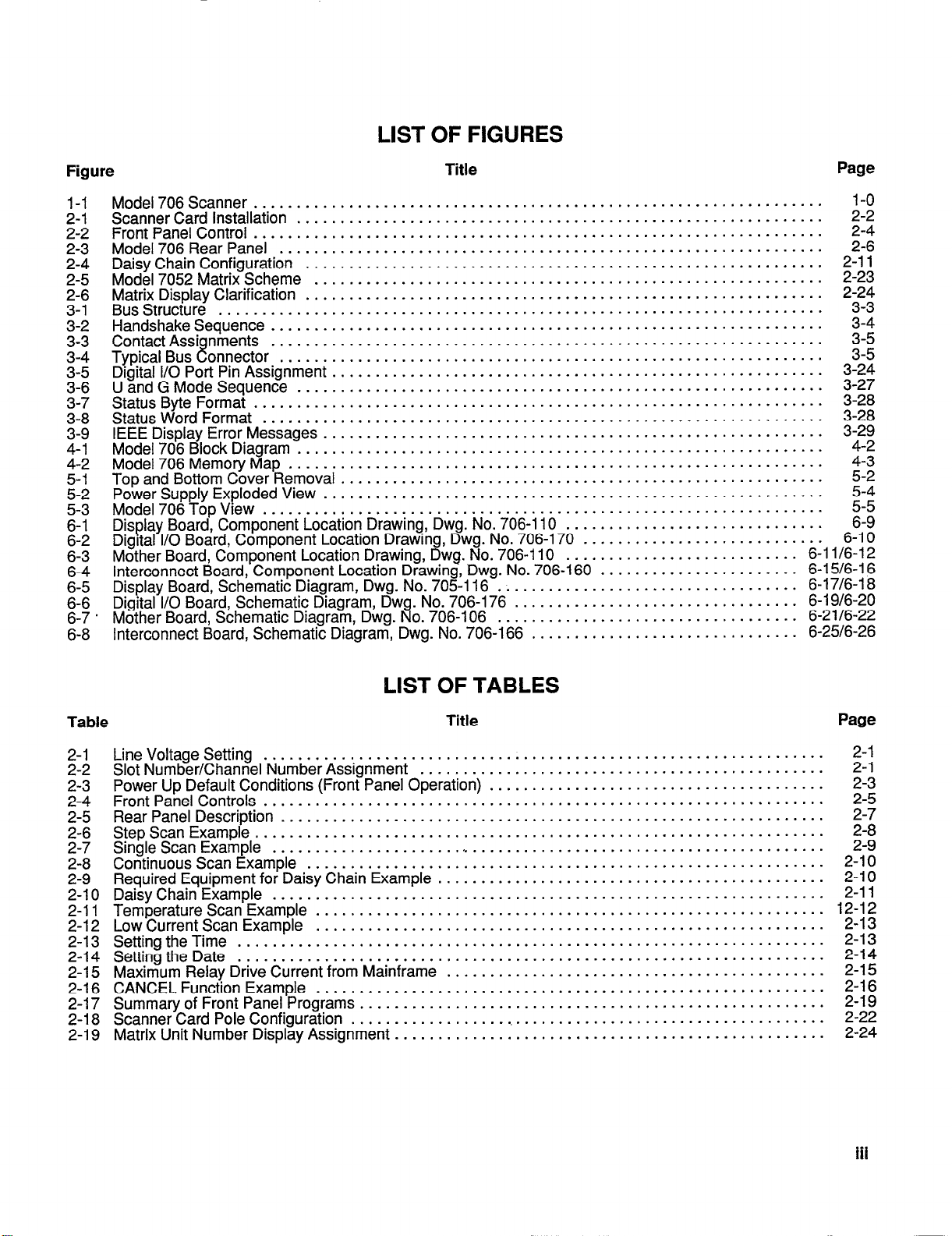

LIST OF FIGURES

.‘.

Title

..

lI. .~.._‘.... _.

................................... 6-17/6-18

................................... 6-21/6-22

Figure

1-I

Model706Scanner

Scanner Card Installation

;::

FrontPanelControl ..................................................................

Model706RearPanel

;:“4

Daisy Chain Configuration

Model7052MatrixScheme

2-5

Matrix Display Clarification

;:y

BusStructure

3-2

3-3

$2

HandshakeSequence ................................................................

ContactAssi

TypicalBus

Digital I/O Port Pin Assignment

UandGModeSequence

3-6

StatusByte Format

g;:

Status Word Format

IEEE Display Error Messages

3-9

Model706BlockDiagram

4-1

Model706MemoryMap

2::

Topand BottomCoverRemoval ........................................................

PowerSup IyExplodedView

2::

Model706

Display Board, Component Location Drawing, Dwg. No. 706-l 10

6-l

Digital I/O Board, Component Location Drawmg, Dwg. No. 706-170

6-2

Mother Board, Component Location Drawing, Dwg. No. 706-I 10

6-3

Interconnect Board, Component Location Drawing, Dwg. No. 706-I 60

6-4

Display Board, Schematic Diagram, Dwg. No. 705-l 16

6-5

Digital I/O Board, Schematic Diagram, Dwg. No. 706-176

6-6

Mother Board, Schematic Diagram, Dwg. No. 706-I 06

6-7

Interconnect Board, Schematic Diagram, Dwg. No. 706-l 66

6-8

8 onnector ...............................................................

L1-

opView

..................................................................

.............................................................

...............................................................

............................................................

...........................................................

............................................................

......................................................................

nments ................................................................

.........................................................

.............................................................

..................................................................

.................................................................

.........

..........................................................

.............................................................

..............................................................

..........................................................

.:. .:.

.. I ..

Page

1-o

;:$I

22;7

2-23

2-24

;:;

3-5

3-5

3-24

3-27

3-28

3-28

3-29

z

5-2

..............................

..............................

............................ 6-10

........................... 6-I 1/6-l 2

....................... 6-l 5/6-i 6

................................. 6-19/6-20

............................... 6-25/6-26

5-4

5-5

6-9

LIST OF TABLES

Table

LineVoltageSetting

2-1

2-2 Slot Number/Channel Number Assignment

2-3 Power Up Default Conditions (Front Panel Operation)

2-4 Front Panel Controls

2-5 Rear Panel Description

2-6 StepScanExample ..................................................................

2-7 SingleScanExample

2-8 ContinuousScanExample

2-9 Required Equipment for Daisy Chain Example

2-10 Daisy Chain Example

2-11 Temperature Scan Example

2-12 Low Current Scan Example

2-13 SettingtheTime

2-14 SettingtheDate

2-l 5 Maximum Relay Drive Current from Mainframe

2-l 6 CANCEL Function Example

2-17 Summary of Front Panel Programs

2-l 8 Scanner Card Pole Configuration

2-19 Matrix Unit Number Display Assignment

.................................................................

.................................................................

...............................................................

................................................................

............................................................

................................................................

...........................................................

...........................................................

....................................................................

....................................................................

...........................................................

......................................................

.................. .,

..................................................

Title

...............................................

.......................................

.............................................

............................................

....................................

Page

2-1

2-l

g:;

2-7

;:g

2-10

2-l 0

2-l 1

12-12

2-13

2-l 3

2-14

2-15

2-16

2-19

2-22

2-24

Iii

Page 9

LIST OF TABLES (CONT.)

2-20 Matrix Card Number Display Assignment

2-21 Program 99 Reset Condition

3-l HP-85 IEEE-488 BASIC Statements

3-2 Model 706 Interface Function Codes

3-3 IEEECommand Groups

34 IEEE Bus Connector Contact Designations

3-5 Power Up, DCL and SDC Default Conditions

3-6 Device-Dependent Commands Not Available to the Front Panel

3-7 Model 706 Device-Dependent Commands

3-8 Hierarchy of Command Execution

3-9 SRQ Commands and Conditions

3-10 Digital I/O Port Contact Pin Assignments

5-l Fuse Replacement 3AG Size.

5-2 Fuse Replacement 5mm Size

5-3 Line Voltage Selection.

54 RecommendedTestEquipment .....................................................................

5-5 PowerSupplyChecks

5-6 DigitalCircuitn/Checks ............................................................................

5-7 DisplayBoardChecks .............................................................................

5-8 InterconnectBoardChecks

5-9 Model 706 Static Sensitive Devices

6-l Model 706 Recommended Spare Parts List.

6-2 Index of Model 706 Schematics and Component Layouts.

6-3 Display Board Parts List

6-4 Mother Board Parts List

6-5 Digital I/O Board Parts List

6-6 Interconnect Board Parts List

6-7 Model 706 Mechanical Parts List

.......................................................................

............................................................................

...................................................................

.......................................................................

.......................................................................

............................................................................

.............................................................................

.........................................................................

........................................................................... 6-2

...........................................................................

.........................................................................

.......................................................................

....................................................................

............................................................

..................................................................

.................................................................

............................................................

..........................................................

..........................................

...........................................................

..................................................................

............................................................

..................................................................

...........................................................

...............................................

2-24

2-29

3-2

3-3

3-3

3-5

3-6

3-9

3-10

3-12

3-16

3-24

5-l

5-l

5-l

5-6

5-6

5-7

5-7

5-8

5-8

6-l

6-l

6-3

6-5

6-6

6-7

Iv

Page 10

1-O

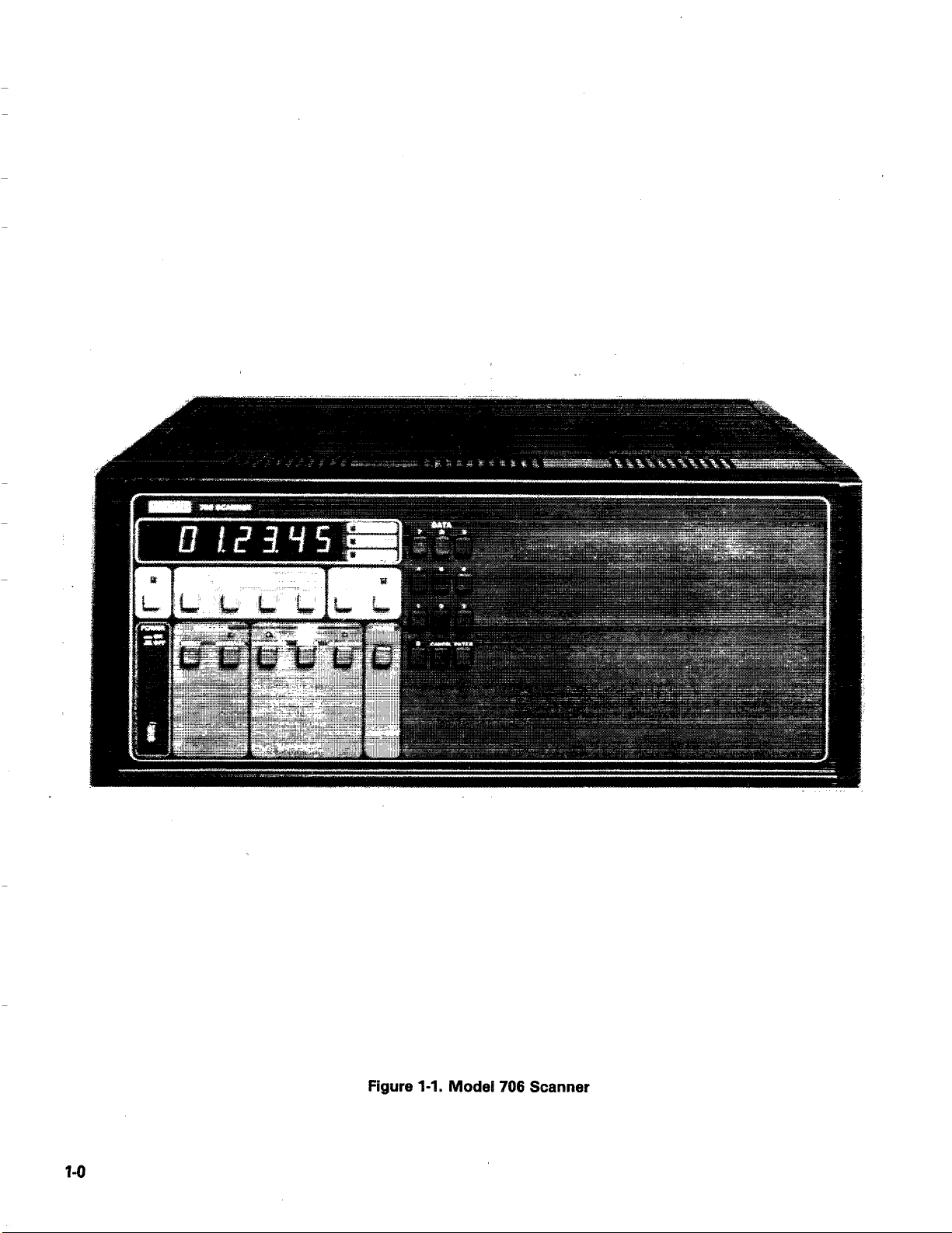

Figure l-l. Model 706 Scanner

Page 11

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 706 is an IEEE488 bus compatible scanner that

can accommodate ten plug-in scanner cards. With ten scanner cards installed up to 100 2-pole channels can be on the

same IEEE address. Using four additional Model 706s in a

daisy chain configuration up to 500 2-pole channels can be

on the same IEEE address. The Model 706 scanner adheres to

standard IEEE488 interface bus protocol. This enables the

Model 706 to be incorporated into any measurement that

uses programmed control through the IEEE-488 bus.

The front panel controls are clearly marked and easy to use.

These controls serve several functions such as opening a

selected channel, closing the channel, scanning between a

selectable first and last channel, selecting scan rate and

mode. There are 15 internal programs that are accessible

from the front panel. The programs can select primary address, settling time, store a relay set up, recall the stored relay

set up, control the digital I/O port, switch from International

to American date format, start or stop a scan sequence,

select 1, 2 or 4-pole measurement modes and program the

Model 706 as a master, slave or stand alone instrument in a

daisy chain configuration. The Model 706 may also be

operated in a matrix configuration.

The time and date are kept internally with a battery backed up

clock allowing time dependent procedures to be performed.

1.2 MODEL 706 FEATURES

The Model 766 scanner includes the following features:

.lJp to 100 2-pole channels.

aIEEE-488 bus operation.

*Selectable scan rate of IOmsec to 999.999sec.

aSelectable scan modes that enable the user to scan the first

channel to the last channel once, continuously or manually.

*Fifteen internal programs that are accessible from the front

panel.

aModel 706 mainframe can accomodate 10 scanner plug-in

cards.

*Several different plug-in scanner cards are available as op-

tions. They include: a general purpose relay card, a thermocouple card, low voltage card, low current card, high

current card, high voltage card, matrix card and universal interface card.

*Time and date are kept with a battery backed up clock.

*Digital I/O port with eight lines as inputs and eight lines as

outputs.

*External trigger input that accepts a greater than wet

negative going TTL compatible pulse for triggering the

Model 706 into a scan sequence.

@Channel ready output that outputs a greater than IOFec

negative going lTL compatible pulse upon the completion

of the programmed channel settling time.

*Alarm output that outputs a negative going lTL level

greater than 10,usec pulse when the programmed time is

reached.

1.3 WARRANTY INFORMATION

Warranty information is provided on the inside front cover of

this manual. If there is a need to exercise the warranty, contact your Keithley representative in your area to determine the

proper action to be taken. Keithley maintains complete repair

and calibration facilities in the United States, West Germany,

Great Britain, France, the Netherlands, Switzerland and

Austria. Information may be directed to the applications

engineer at any of the above locations. Check the inside front

cover of this manual for addresses.

1.4 MANUAL ADDENDA

Improvements or changes to this manual will be explained on

an addendum included with this manual.

1.5 SAFETY SYMBOLS AND TERMS

Safety symbols used in this manual are as follows:

The symbol ’

should refer to the operating instructions.

The symbol AM

voltage may be present on the terminals.

The, WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains hazards that

could damage the instrument.

1.6 UNPACKING AND INSPECTION

The Model 706 is inspected both electrically and mechanically

before shipment. Upon receiving the Model 706, unpack all

items from the shipping container and check for any obvious

damage that may have occurred during transit. Report any

damage to the shipping agent. Retain and use the original

packaging materials if reshipment is necessary. The following

items are shipped with all Model 706 orders:

*Model 706 Scanner

*Model 706 Instruction Manual

*Optional accessories per request. (Cards are shipped

separately. 1

1.7 SPECIFICATIONS

For Model 706 detailed specifications, refer to the specifica-

tions that precede this section.

on the instrument denotes that the user

Q

on the instrument denotes that high

1-l

Page 12

+

1.8 OPTIONAL ACCESSORIES

Switching Cards - Keithley offers over 20 different models of

switching cards. In addition to general purpose scanning and

matrix applications, cards are designed for special applications

with signal handling capabilities that include:

l

Low voltage switching to 20nV.

l

Low current switching to 1 OfA.

l

High frequency switching to 500MHz.

o Thermocouple switching with a precision temperature refer-

ence.

l

High voltage switching to 1 OOOV.

Further details on switching cards can be obtained by contact-

ing a Keithley representative or sales office.

Model 7008-3 IEEE-488 Cable-The Model 7008-3 is a 1 meter (3 feet) IEEE-488 cable. The cable has 24 stranded wire

conductors and is terminated on each end with IEEE-488 standard connectors.

Model 7008-6 IEEE-488 Cable-The Model 7008-6 is a 2 meter (6 feet) IEEE-488 cable. The cable has 24 stranded wire

conductors and is terminated on each end with IEEE-488 standard connectors.

Model 7010 Cable Adapter-The Model 7010 is an IEEE-488

cable adapter. The adapter extends the IEEE-488 connector by

one connector width.

Model 7051-2 1 The Model 7051-2 is a (2 feet) BNC to BNC

cable. It is especially useful for daisy chain operation.

Model 7051-5 - The Model 7051-5 is a (5 feet) BNC to BNC

cable. It is especially useful daisy chain configuration.

Model 7068 Fixed Rack Mount-The Model 7068 is a fixed or

stationary rack mounting kit that mounts the Model 706 in a

standard 19 inch rack. The dimensions are 13-3/4 inches deep

x 7 inches high (350mm x 178mm).

Model 7069 Slide Rack Mount with Handles - The Model

7069 is a sliding rack mount kit. It enables one Model 706 to be

rack mounted with the added feature of sliding the instrument

for easy access. The dimensions are 3-3/4 inches deep x 7

inches high (95mm x 178mm).

1.9 REPACKING FOR SHIPMENT

The Model 706 should be packed in its original carton. Before

packing, wrap the instrument in plastic. After it is placed in the

box, surround the instrument with Styrofoam packaging material. Remove all cards and ship separate.

If the Model 706 is to be returned to Keithley Instruments for

calibration or repair, include the following:

l

Write ATTENTION REPAIR DEPARTMENT on the address

label.

= Include the warranty status of the instrument.

l

Photocopy and complete the service form at the back of this

manual and return it with the instrument.

1-2

+

Page 13

SECTION 2

OPERATION

2.1 INTRODUCTION

Operation of the Model 706 is divided into two sections: front

panel operation and IEEE-488 bus operation. IEEE bus opera-

tion is located in Section 3. This section contains the follow-

ing information:

*Preparation for use

@Power Up

iEnvironmental Conditions

*Front and Rear Panels Description

@Examples of Scanning

aFront Panel Programs

2.2 PREPARATION FOR USE

2.2.1 Correct Line Voltage

Connect the Model 706 to the proper power receptacle (refer

to Table 2-l). For fuse replacement or line voltage setting

refer to Section 5 Maintenance.

WARNING

Ground the instrument through a properly

earth grounded receptacle before operation. Failure to ground the instrument can

result in severe injury or death in the event

of a short circuit or malfunction.

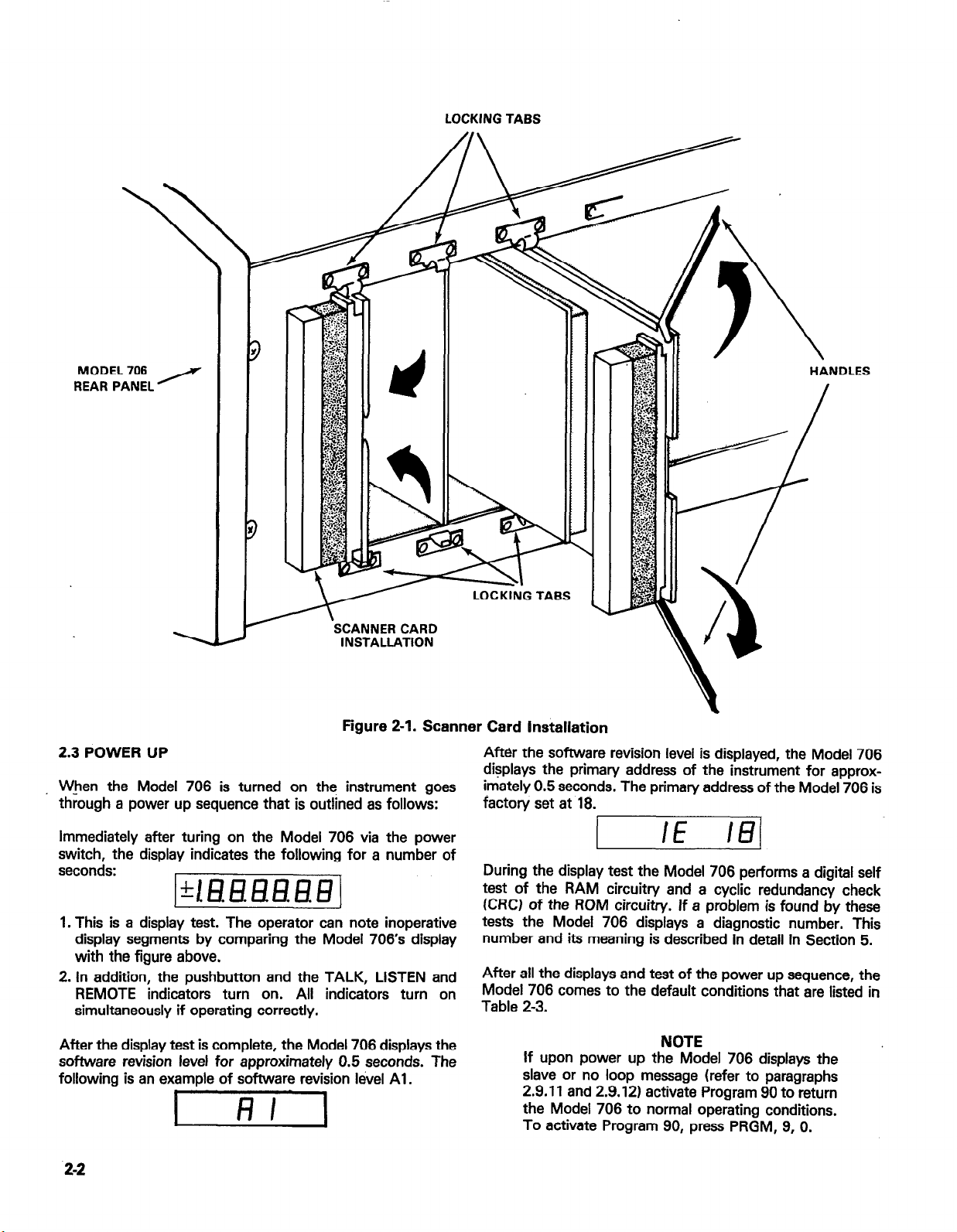

1. To install a scanner card, slide the card into the appropriate

vertical slot. The slots are numbered 1 through 10. Refer to

Table 2-2 for slot number/ channel numbers assignment.

Facing the rear panel of the Model 706, the scanner card

component side should face the left side of the slot. Make

certain the card edges are aligned with the top and bottom

grooves in the slot.

2. Once the card is aligned with the grooves, insert the card

to its full depth into the Model 706. Make certain the card

is properly seated into the connector on the interconnect

board. When the card is fully inserted, the locking tabs on

the card should be placed in the locked position as shown

in Figure 2-1.

3. To remove a scanner card, first turn the Model 706 off and

disconnect the line cord. Unfasten the locking tabs by pulling both tabs outward. Grasp the end of the card and pull it

out of the mainframe.

NOTE

Handle the scanner cards by the edges to avoid

contaminating them with dirt, body oil, etc.

WARNING

Do not insert scanner cards that have metal

clamps into the Model 706. Otherwise a

shock hazard will be present. Only use

scanner cards that have plastic clamps.

2.2.2 Plug-In Card (Scanner) Installation

Before operating the Model 706, the appropriate scanner

cards must be installed into the mainframe. Each scanner

card (up to 10 cards per the Model 706 mainframejis installed

in-the appropriate vertical slot in the rear panel of the Model

706. Refer to Figure 2-l for an overall picture of scanner card

installation.

WARNING

To prevent a possible shock hazard, turn

the instrument off and disconnect the line

cord before installing/removing any scanner card.

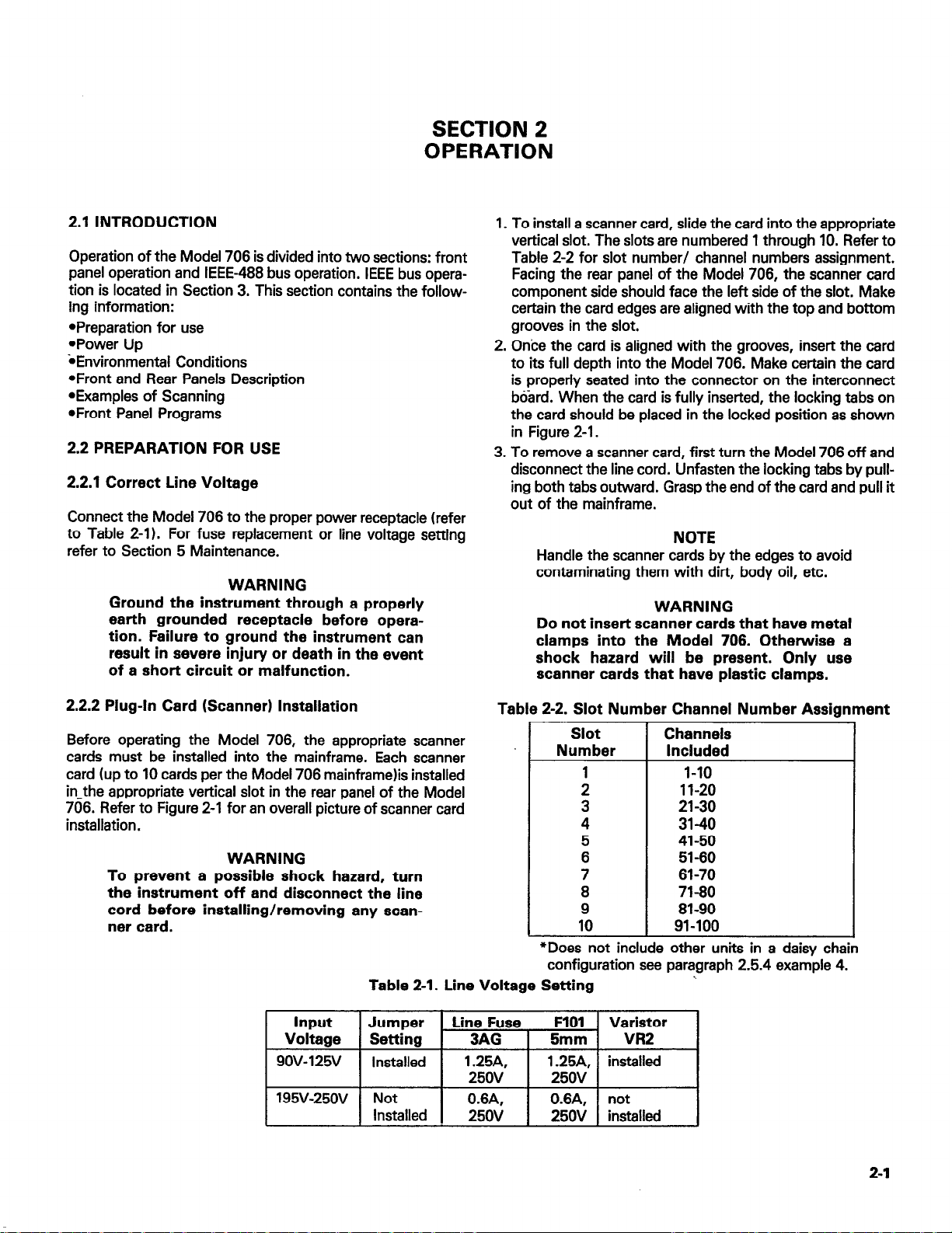

Table 2-l. Line Voltage Setting

Input Jumper I Line Fuse

Voltage

9OV-125v Installed

195v-250v

Setting 3AG

Not

Installed

Table 2-2. Slot Number Channel Number Assignment

Slot

Number

1

2

3

4

5

7”

ii

10

“Does not include other units in a daisy cha;

configuration see paragraph 2.5.4 example 4.

FlOl .

5mm

1.25A, 1.25A, installed

250V 250V

0.6A, 0.6A, not

250V 250V installed

Varistor

Channels

Included

l-10

11-20

2130

31-40

41-50

51-60

61-70

71-60

81-90

91-100

VR2

2-l

Page 14

LOCKING TABS

MODEL706 /

REAR PANEL

SCANNER CARD

INSTALLATION

Figure 2-l. Scanner Card Installation

2.3 POWER UP

When the Model 706 is turned on the instrument goes

through a power up sequence that is outlined as follows:

NDLES

After the software revision level is displayed, the Model 706

displays the primary address of the instrument for approximately 0.5 seconds. The primary address of the Model 706 is

factory set at 18.

Immediately after turing on the Model 706 via the power

switch, the display indicates the following for a number of

seconds:

1

1

1. This is a display test. The operator can note inoperative

display segments by comparing the Model 706’s display

with the figure above.

2. In addition, the pushbutton and the TALK, LISTEN and

REMOTE indicators turn on. All indicators turn on

simultaneously if operating correctly.

After the display test is complete, the Model 706 displays the

software revision level for approximately 0.5 seconds. The

following is an example of software revision level Al.

RI I

‘2-2

r---r-q

During the display test the Model 706 performs a digital self

test of the RAM circuitry and a cyclic redundancy check

(CRC) of the ROM circuitry. If a problem is found by these

tests the Model 706 displays a diagnostic number. This

number and its meaning is described in detail in Section 5.

After all the displays and test of the power up sequence, the

Model 706 comes to the default conditions that are listed in

Table 2-3.

NOTE

If upon power up the Model 706 displays the

slave or no loop message (refer to paragraphs

2.9.11 and 2.9.12) activate Program 90 to return

the Model 706 to normal operating conditions.

To activate Program 90, press PRGM, 9, 0.

Page 15

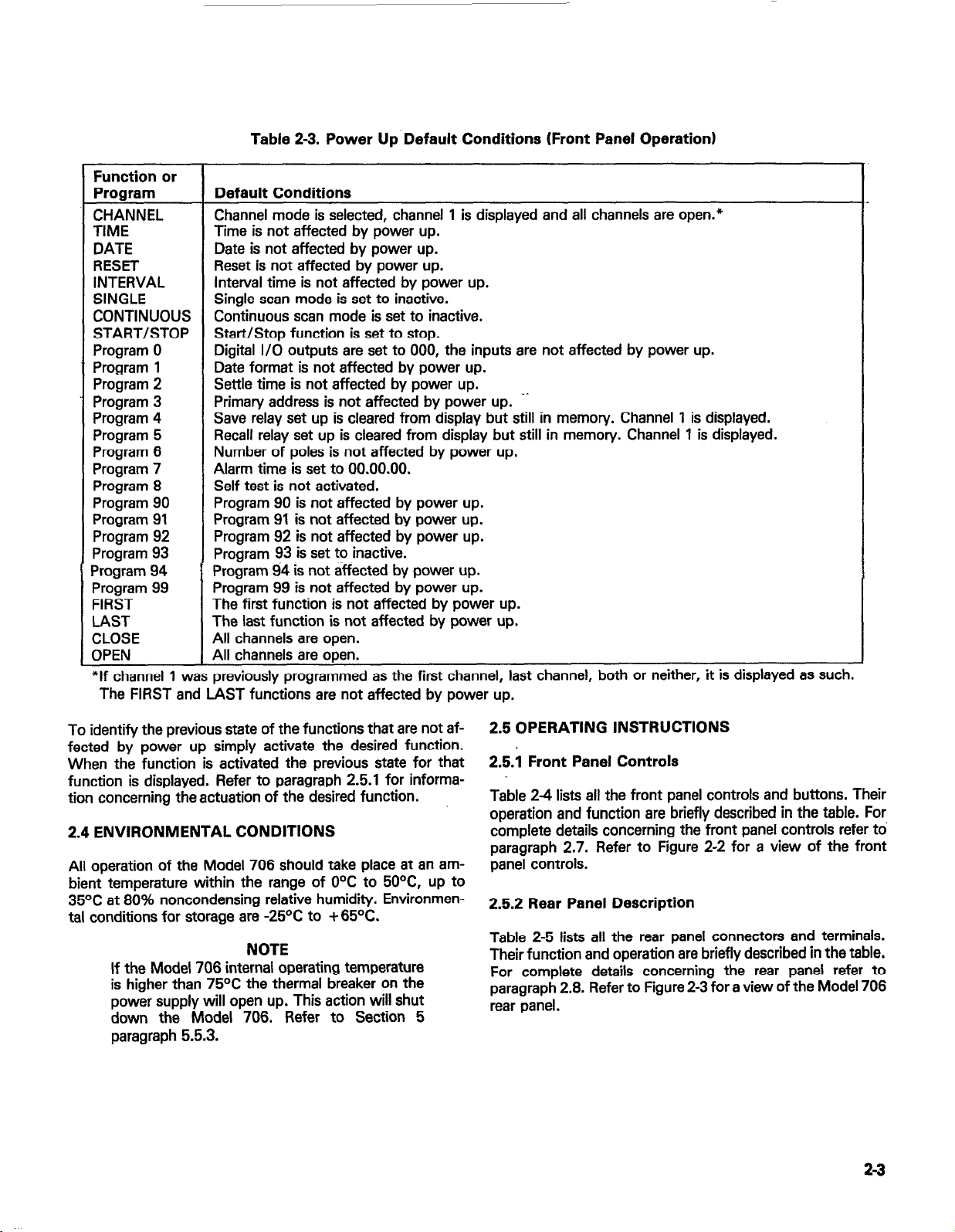

Table 2-3. Power Up Default Conditions (Front Panel Operation)

Function or

Program

CHANNEL

TIME Time is not affected by power up.

DATE

RESET

INTERVAL

SINGLE

CONTINUOUS Continuous scan mode is set to inactive.

START/STOP

Program 0

Program 1

Program 2 Settle time is not affected by power up.

Program 3

Program 4 Save relay set up is cleared from display but still in memory. Channel 1 is displayed.

Program 5

Program 6 Number of poles is not affected by power up.

Program 7 Alarm time is set to 00.00.00.

Program 8 Self test is not activated.

Program 90

Program 91

Program 92 Program 92 is not affected by power up.

Program 93

Program 94

Program 99

FIRST

LAST

CLOSE

OPEN

*If channel 1 was previously programmed as the first channel, last channel, both or neither, it is displayed as such.

The FIRST and LAST functions are not affected by power up.

Default Conditions

Channel mode is selected, channel 1 is displayed and all channels are open.*

Date is not affected by power up.

Reset is not affected by power up.

Interval time is not affected by power up.

Single scan mode is set to inactive.

Start/Stop function is set to stop.

Digital I/O outputs are set to 000, the inputs are not affected by power up.

Date format is not affected by power up.

Primary address is not affected by power up. ..

Recall relay set up is cleared from display but still in memory. Channel 1 is displayed.

Program 90 is not affected by power up.

Program 91 is not affected by power up.

Program

Program 94 is not affected by power up.

Program 99 is not affected by power up.

The first function is not affected by power up.

The last function is not affected by power up.

All channels are open.

All channels are open.

93 is set to inactive.

To identify the previous state of the functions that are not affected by power up simply activate the desired function.

When the function is activated the previous state for that

function is displayed. Refer to paragraph 2.5.1 for information concerning the actuation of the desired function.

2.4 ENVIRONMENTAL CONDITIONS

All operation of the Model 706 should take place at an am-

bient temperature within the range of O°C to 50°C, up to

35OC at 80% noncondensing relative humidity. Environmen-

tal conditions for storage are -25OC to +65OC.

NOTE

If the Model 706 internal operating temperature

is higher than 75OC the thermal breaker on the

power supply will open up. This action will shut

down the Model 706. Refer to Section 5

paragraph 5.5.3.

2.5 OPERATING INSTRUCTIONS

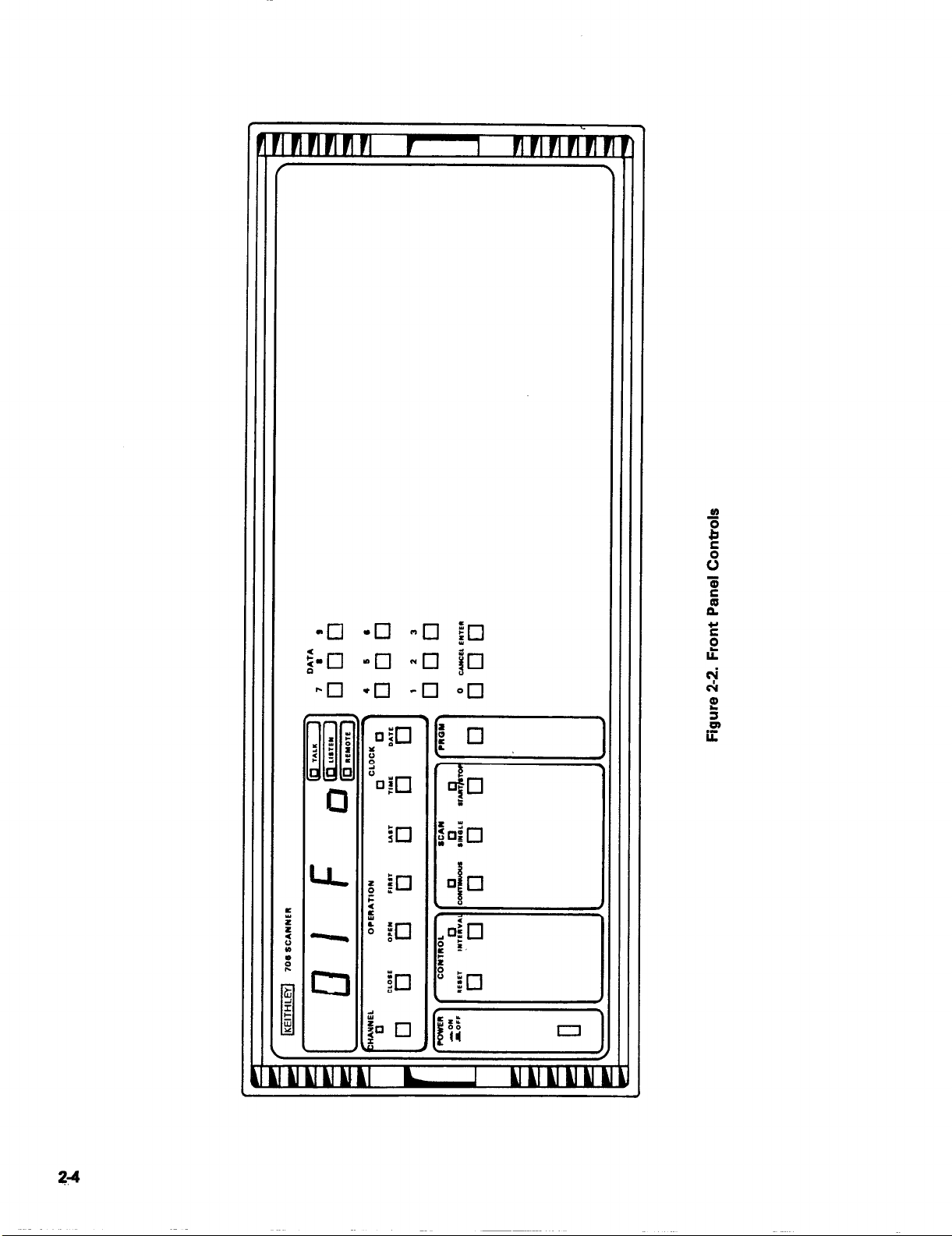

2.5.1 Front Panel Controls

Table 2-4 lists all the front panel controls and buttons. Their

operation and function are briefly described in the table. For

complete details concerning the front panel controls refer to

paragraph 2.7. Refer to Figure 2-2 for a view of the front

panel controls.

2.5.2 Rear Panel Description

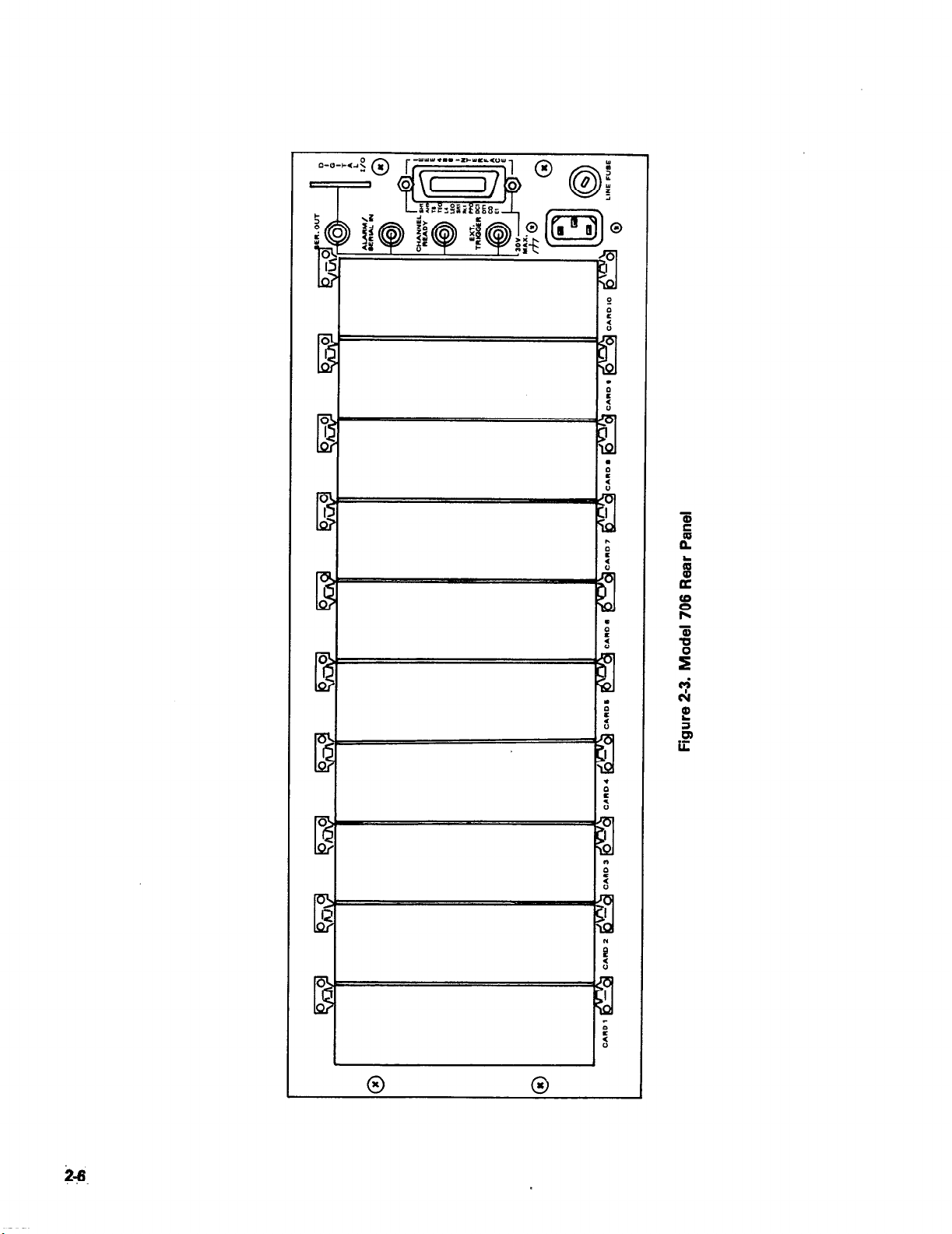

Table 2-5 lists all the rear panel connectors and terminals.

Their function and operation are briefly described in the table.

For complete details concerning the rear panel refer to

paragraph 2.8. Refer to Figure 2-3 for a view of the Model 706

rear panel.

2-3

Page 16

Page 17

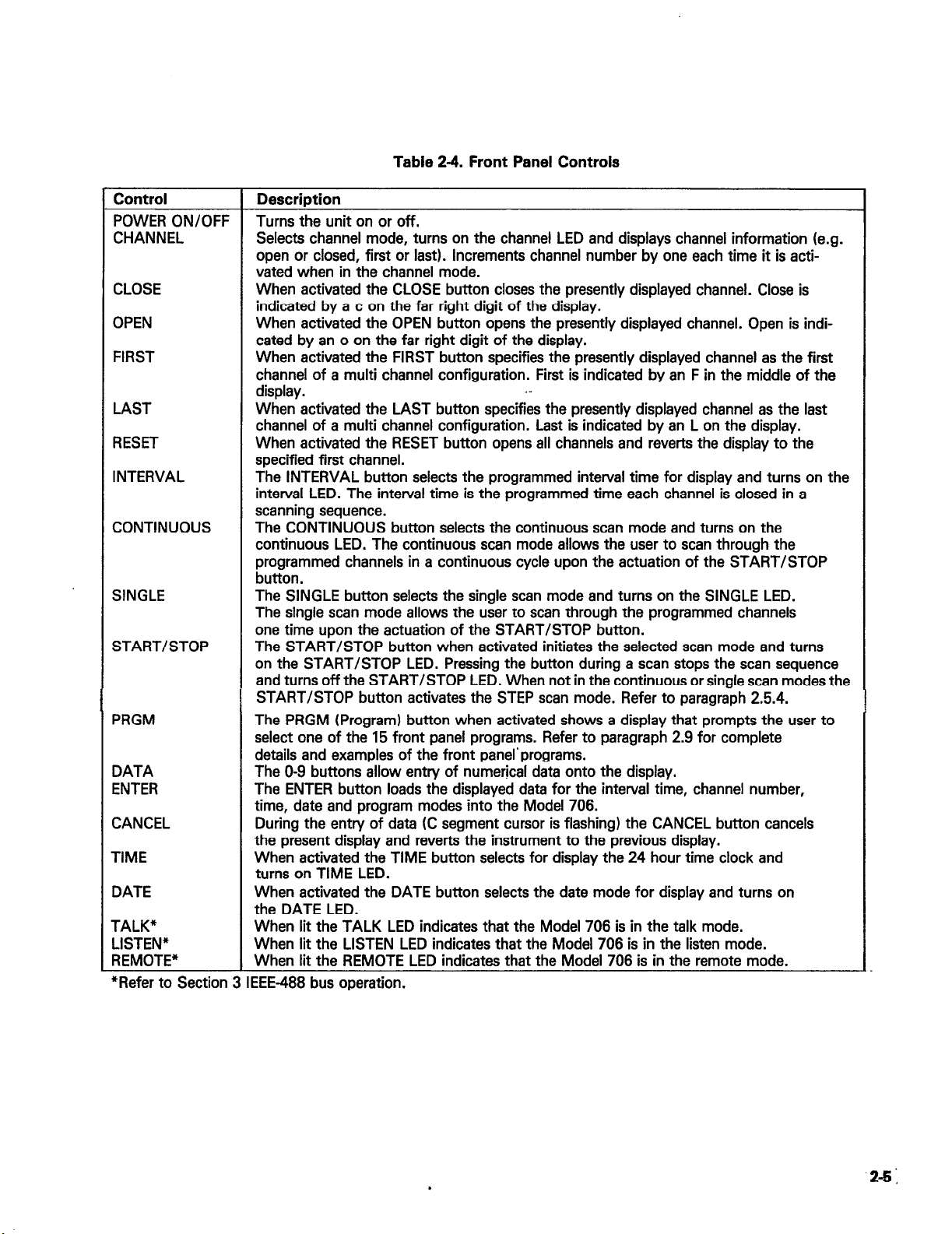

Table 2-4. Front Panel Controls

Control

POWER ON/OFF

CHANNEL

CLOSE

OPEN

FIRST

LAST

RESET

INTERVAL

CONTINUOUS

SINGLE

START/STOP

PRGM

DATA

ENTER

CANCEL

TIME

DATE

TALK”

LISTEN*

REMOTE*

*Refer to Section 3 IEEE-488 bus operation.

Description

Turns the unit on or off.

Selects channel mode, turns on the channel LED and displays channel information (e.g.

open or closed, first or last). Increments channel number by one each time it is activated when in the channel mode.

When activated the CLOSE button closes the presently displayed channel. Close is

indicated by a c on the far right digit of the display.

When activated the OPEN button opens the presently displayed channel. Open is indicated by an o on the far right digit of the display.

When activated the FIRST button specifies the presently displayed channel as the first

channel of a multi channel configuration. First is indicated by an F in the middle of the

display.

When activated the LAST button specifies the presently displayed channel as the last

channel of a multi channel configuration. Last is indicated by an L on the display.

When activated the RESET button opens all channels and reverts the display to the

specified first channel.

The INTERVAL button selects the programmed interval time for display and turns on the

interval LED. The interval time is the programmed time each channel is closed in a

scanning sequence.

The CONTINUOUS button selects the continuous scan mode and turns on the

continuous LED. The continuous scan mode allows the user to scan through the

programmed channels in a continuous cycle upon the actuation of the START/STOP

button.

The SINGLE button selects the single scan mode and turns on the SINGLE LED.

The single scan mode allows the user to scan through the programmed channels

one time upon the actuation of the START/STOP button.

The START/STOP button when activated initiates the selected scan mode and turns

on the START/STOP LED. Pressing the button during a scan stops the scan sequence

and turns off the START/STOP LED. When not in the continuous or single scan modes the

START/STOP button activates the STEP scan mode. Refer to paragraph 2.5.4.

The PRGM (Program) button when activated shows a display that prompts the user to

select one of the 15 front panel programs. Refer to paragraph 2.9 for complete

details and examples of the front panel’programs.

The O-9 buttons allow entry of numerical data onto the display.

The ENTER button loads the displayed data for the interval time, channel number,

time, date and program modes into the Model 706.

During the entry of data (C segment cursor is flashing) the CANCEL button cancels

the present display and reverts the instrument to the previous display.

When activated the TIME button selects for display the 24 hour time clock and

turns on TIME LED.

When activated the DATE button selects the date mode for display and turns on

the DATE LED.

When lit the TALK LED indicates that the Model 706 is in the talk mode.

When lit the LISTEN LED indicates that the Model 706 is in the listen mode.

When lit the REMOTE LED indicates that the Model 706 is in the remote mode.

I-

.2-G:

Page 18

I

I . I

Page 19

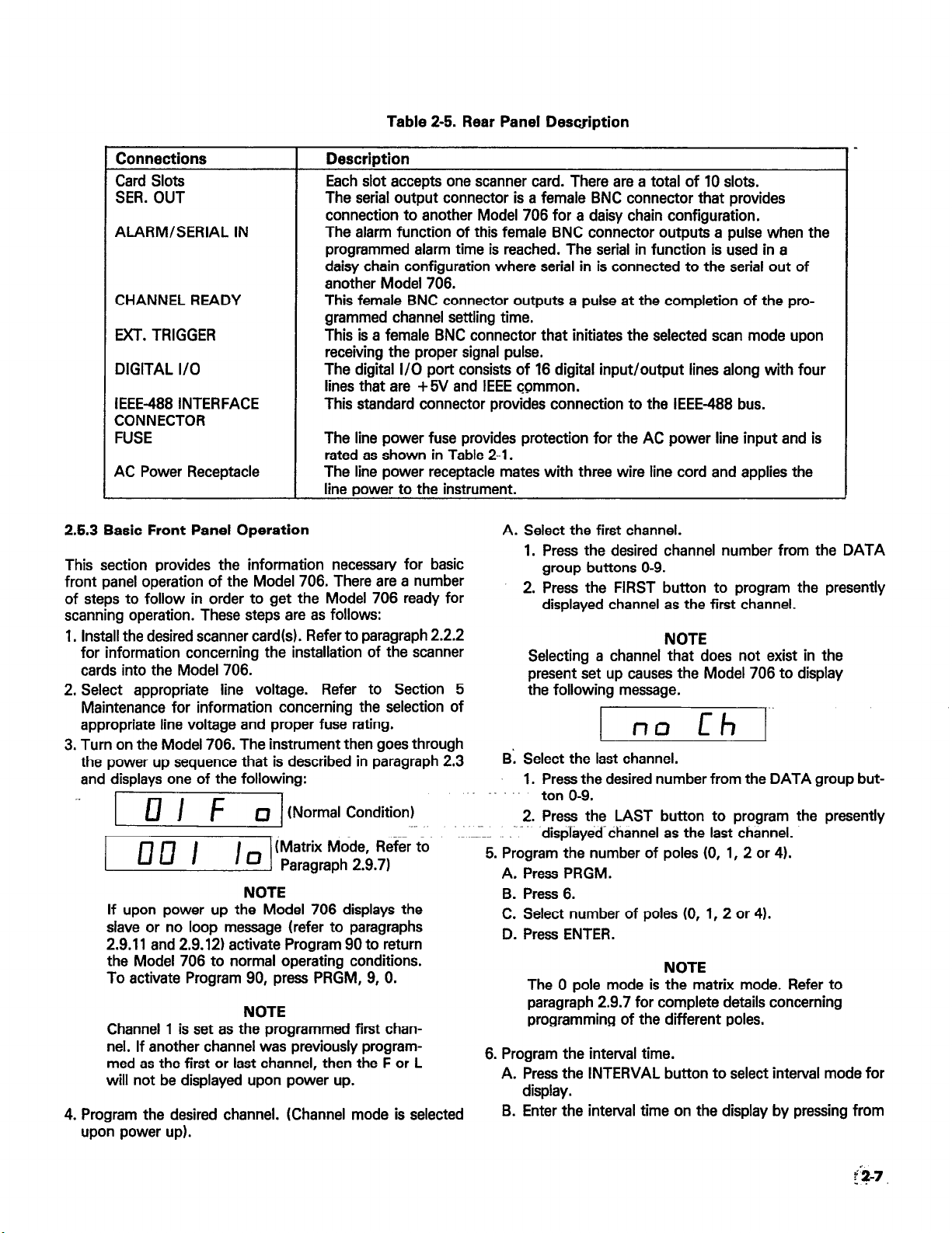

Table 2-5. Rear Panel Deswiption

Connections Description

Card Slots

SER. OUT

Each slot accepts one scanner card. There are a total of 10 slots.

The serial output connector is a female BNC connector that provides

connection to another Model 706 for a daisy chain configuration.

ALARM/SERIAL IN

The alarm function of this female BNC connector outputs a pulse when the

programmed alarm time is reached. The serial in function is used in a

daisy chain configuration where serial in is connected to the serial out of

another Model 706.

CHANNEL READY

This female BNC connector outputs a pulse at the completion of the programmed channel settling time.

EXT. TRIGGER

This is a female BNC connector that initiates the selected scan mode upon

receiving the proper signal pulse.

DIGITAL I/O

The digital I/O port consists of 16 digital input/output lines along with four

lines that are +5V and IEEE common.

IEEE-488 INTERFACE

This standard connector provides connection to the IEEE-488 bus.

CONNECTOR

FUSE

The line power fuse provides protection for the AC power line input and is

rated as shown in Table 2-l.

AC Power Receptacle

The line power receptacle mates with three wire line cord and applies the

line power to the instrument.

2.5.3 Basic Front Panel Operation

This section provides the information necessary for basic

front panel operation of the Model 706. There are a number

of steps to follow in order to get the Model 706 ready for

scanning operation. These steps are as follows:

1. Install the desired scanner card(s). Refer to paragraph 2.2.2

for information concerning the installation of the scanner

cards into the Model 706.

2. Select appropriate line voltage. Refer to Section 5

Maintenance for information concerning the selection of

appropriate line voltage and proper fuse rating.

3. Turn on the Model 706. The instrument then goes through

the power up sequence that is described in paragraph 2.3

and displays one of the following:

I[ (Normal Condition)

(Matrix Mode Refer to

I o 1 Paragraph 2 9 71

. .

NOTE

If upon power up the Model 706 displays the

slave or no loop message (refer to paragraphs

2.9.11 and 2.9.12) activate Program 90 to return

the Model 706 to normal operating conditions.

To activate Program 90, press PRGM, 9, 0.

NOTE

Channel 1 is set as the programmed first channel. If another channel was previously programmed as the first or last channel, then the F or L

will not be displayed upon power up.

4. Program the desired channel. (Channel mode is selected

upon power up).

A. Select the first channel.

1. Press the desired channel number from the DATA

group buttons O-9.

2. Press the FIRST button to program the presently

displayed channel as the first channel.

NOTE

Selecting a channel that does not exist in the

present set up causes the Model 706 to display

the following message.

no

Ch

B: Select the last channel.

1. Press the desired number from the DATA group button O-9.

2. Press the LAST button to program the presently

-

dispkyed channel as the last channel.

5. Program the number of poles (0, 1, 2 or 4).

A. Press PRGM.

B. Press 6.

C. Select number of poles (0, 1, 2 or 4).

D. Press ENTER.

NOTE

The 0 pole mode is the matrix mode. Refer to

paragraph 2.9.7 for complete details concerning

programming of the different poles.

6. Program the interval time.

A. Press the INTERVAL button to select interval mode for

display.

B. Enter the interval time on the display by pressing from

Page 20

the DATA group the desired time, within the limits of

000.010 to 999.999 seconds.

C. Press the ENTER button.

7. Program the desired scan mode. Press the SINGLE or

CONTINUOUS button to select one of these two scanning

modes. To select the step scan mode press the CHANNEL

button.

8. Press the START/STOP button to start the scanning se-

quence. For the step mode press the START/STOP button each time a single channel is to be scanned.

Upon the actuation of the START/STOP button in step 9,

channel 1 is closed and the START/STOP LED is turned on.

Channel 1 remains closed for two seconds (programmed interval rate) and then opens. The START/STOP LED turns off

and the Model 706 advances to the next channel.

To scan the remaining channels, press the START/STOP

button each time a channel is to be scanned. After the last

programmed channel is scanned the instrument reverts to the

first programmed channel and turns off the START/STOP

LED. At this point the step scan sequence may be activated

again by pressing the START/STOP button, if desired.

The previous steps 1 through 8, show a general procedure to

-get the Model 706 into a scanning sequence. Paragraph 2.5.4

shows how to use the different scan modes, how to

chain several Model 706s for an extended number of channels and how to scan using different scanner cards.

2.5.4 Scanning Examples

Example 1 Manual Scan (Step Scan&If it is desired to

scan through the programmed channels manually the Model

706 can be programmed for the step scan mode. In the step

scan mode the programmed channels can be scanned (closed

for the programmed interval rate and then opened) one chan-

nel at a time. Upon the actuation of the START/STOP button a single channel will be scanned. For this example we will

choose the following parameters.

1. First channel is 1.

2. Last channel is 10.

3. Interval time is 2 seconds.

4. Number of poles is 2.

5. Use the step scan mode.

Use the steps outlined in Table 2-6 to program the Model 706

for the preceding parameters. For the sake of simplicity we

will use the Model 7056 general purpose scanner card for this

example.

daisy

To stop the scanning sequence and reset the Model 706 to

the programmed first channel simply press the RESET button.

.-

Example 2 Single Scan-In the single scan mode all the

programmed channels are scanned sequentially one time

upon the actuation of the START/STOP button. The single

scan sequence operates as follows:

1. The START/STOP LED turns on.

2. The programmed first channel is closed for the pro-

grammed interval rate and then opened.

3. The Model 706 then advances to the next channel, closes

it for the programmed interval rate and then opens it.

4. This sequence is repeated up to and including the pro-

gammed last channel. At this point the Model 706 reverts

to the programmed first channel and turns off the

START/STOP LED.

5. The single scan sequence is now complete.

To help illustrate a single scan sequence we will choose the

following parameters. For the sake of simplicity we will use

the Model 7056 general purpose scanner card.

1. First channel is 5.

2. Last channel is 25.

3: Interval time is 0.5 seconds.

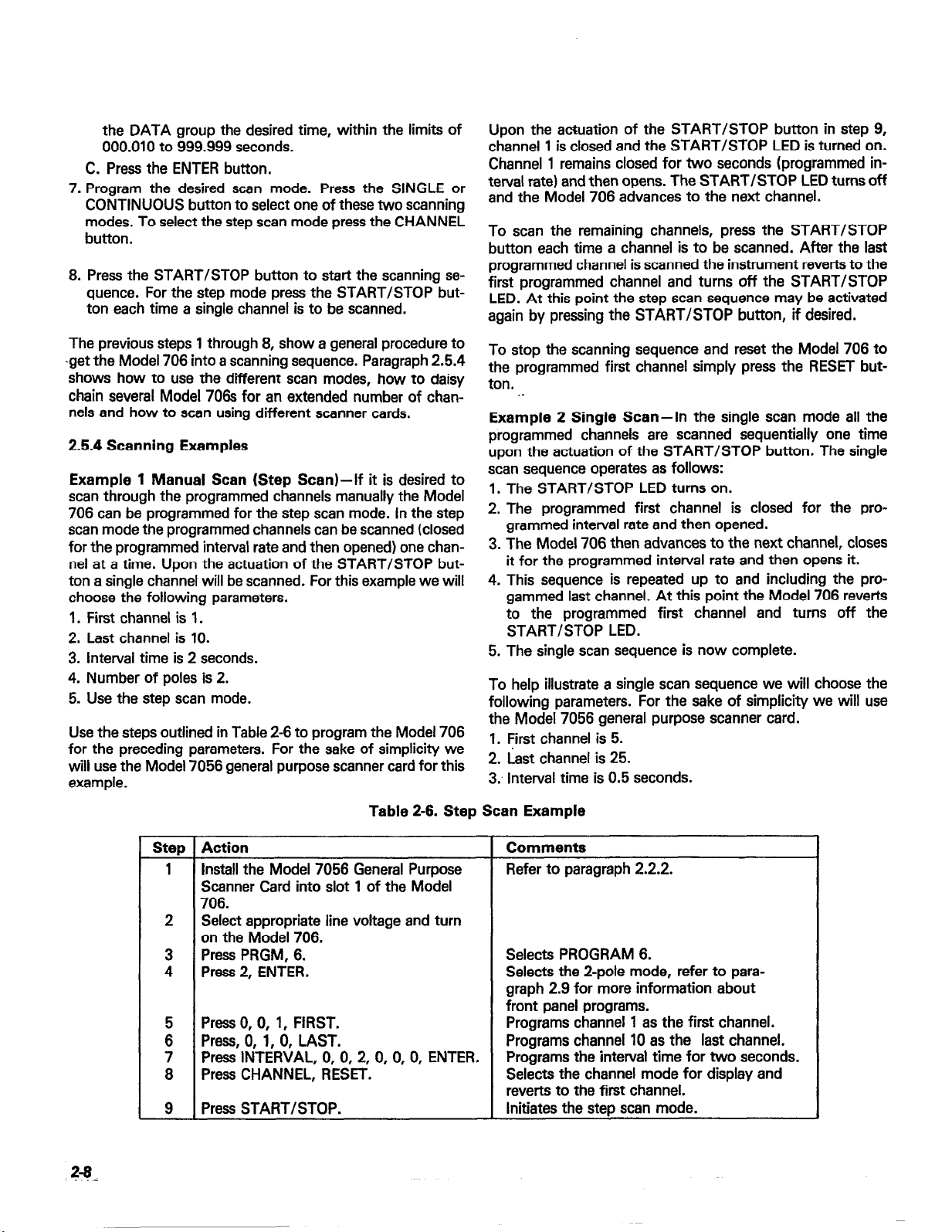

Table 2-6. Step Scan Example

Step Action Comments

1 Install the Model 7056 General Purpose

Scanner Card into slot 1 of the Model

706.

2 Select appropriate line voltage and turn

on the Model 706.

3 Press PRGM, 6.

4

Press 2, ENTER.

Press 0, 0, 1, FIRST.

i

Press, 0, 1, 0, LAST.

7

Press INTERVAL, 0, 0, 2,0,0,0, ENTER.

8 Press CHANNEL, RESET.

9 Press START/STOP.

Refer to paragraph 2.2.2.

Selects PROGRAM 6.

Selects the 2-pole mode, refer to paragraph 2.9 for more information about

front panel programs.

Programs channel 1 as the first channel.

Programs channel 10 as the last channel.

Programs the interval time for two seconds.

Selects the channel mode for display and

reverts to the first channel.

Initiates the step scan mode.

Page 21

.

4. Number of poles is 2.

5. Use single scan mode.

Use the steps outlined in Table 2-7 to program the Model 706

for the preceding parameters.

Upon the actuation of the START/STOP button in step 10,

channel 5 is closed for 0.5 seconds (programmed interval

rate) and then opens. The Model 706 advances to the next

channel and closes it for the programmed interval rate and

then opens it.

The sequence continues up to and including the last pro-

grammed channel. At this point the Model 706 reverts to the

programmed first channel and turns off the START/STOP

LED. The single scan sequence is now complete.

Pressing the START/STOP button during a single scan sequence stops the scan at the presently displayed channel.

The channel remains closed and turns off the START/STOP

LED. To continue the scanning sequence from the presently

displayed channel press the START/STOP button.

To stop the scanning sequence and reset the Model 706 to

the programmed first channel (which is 5 in this example)

simply press the RESET button.

Example 3 Continuous Scan-In the continuous scan

mode the scanning sequence described in example 2 repeats

continuously until at least one of the following conditions are

met:

1. Power is interrupted.

2. During the sequence, the START/STOP button is

pressed.

3. RESET button is pressed.

4. PRGM button is pressed.

5. DATE button is pressed.

6. TIME button is pressed.

7. CHANNEL button is pressed.

In the continuous scan mode all the programmed channels

are scanned sequentially and the scan sequence is repeated

continuously. The continuous scan is started by pressing the

START/STOP button and it operates as follows:

1. The START/STOP LED is turned on.

2. The programmed first channel is closed for the programm-

ed interval rate and then opened.

3. The Model 706 then advances to the next channel, closes

it for the programmed interval rate and then opens it.

4. This sequence is repeated up to and including the pro-

grammed last channel. At this point the Model 706 reverts

to the programmed first channel and repeats the sequence

continuously.

To help illustrate a continuous scan sequence we will choose

the following parameters. For the sake of simplicity we will

use the Model 7056 general purpose scanner card.

1. First channel is 1.

2. Last channel is 100.

3. Interval time is 0.3 seconds.

4. Number of poles is 2.

5. Use continuous scan mode.

Use the steps outlined in Table 2-8 to program the Model 706

for the preceding parameters.

-

Ster, 1 Action

Install the three Model 7056 scan- Refer to paragraph 2.2.2.

1.

ner cards into slots 1, 2

* and 3 of the Model 706.

Select appropriate line voltage

2

and turn on the Model 706.

Press PRGM, 6. Selects PROGRAM 6.

3

Press 2, ENTER. Selects the 2-pole mode. Refer to paragraph 2.9 for

4

Press 0, 0, 5, FIRST. Programs channel 5 as the first channel.

Press 0, 2, 5, LAST. Programs channel 25 as the last channel.

z

Press INTERVAL, 0, 0, 0, 5, Programs the interval time for 0.5 seconds.

7

0, 0, ENTER.

Press CHANNEL, RESET. Turns on the CHANNEL LED, selects the channel

8

Press SINGLE. Selects the single scan mode and turns on the

9

Press START/STOP.

10

Table 2-7. Single Scan Example

I Comments

more information concerning front panel programs.

mode for display and resets to the programmed first

channel.

SINGLE LED.

Initiates the single scan sequence.

2-9

Page 22

Table 2-9. Continuous Scan Example

Step

1

Action

Install 10 Model 7056s into slots

Comments

Refer to paragraph 2.2.2.

I-IO of the Model 706.

2

Select appropriate line voltage

and turn on the Model 706.

3

Press PRGM, 6.

4

Press 2, ENTER.

Selects PROGRAM 6.

Selects the 2-pole mode. Refer to paragraph 2.9 for more

information about front panel programs.

5

Press 0, 0, 1, FIRST.

6

Press 1, 0, 0, LAST.

7

Press INTERVAL, 0, 0, 0, 3,

Programs channel 1 as the first channel.

Programs channel 100 as the last channel.

Programs the interval time for 0.3 seconds.

0,0, ENTER.

8

Press CHANNEL, RESET.

Turns on the CHANNEL LED, selects the channel

mode for display and resets to the programmed first

channel.

9

Press CONTINUOUS.

Selects the continuous scan mode and turns on the

CONTINUOUS LED.

10

Press START/STOP.

Initiates the continuous scan sequence.

Upon the actuation of the START/STOP button in step 10,

channel 1 is closed and the START/STOP LED is turned on.

Channel 1 remains closed for 0.3 seconds (programmed inter-

val rate) and then opens. Model 706 advances to the next

channel and closes it for the programmed interval rate and

then opens it.

This sequence continues up to and including the last programmed channel. At this point the Model 706 reverts to the

programmed first channel and repeats this scan sequence

continuously.

Pressing the START/STOP button during a continuous scan

sequence stops the scan at the presently displayed channel.

The channel remains closed and the START/STOP LED

turns off. To continue the scanning sequence from the

presently displayed channel press the START/STOP button.

To stop the scanning sequence and reset the Model 706 to

the programmed first channel (which is 1 in this example)

simply press the RESET button.

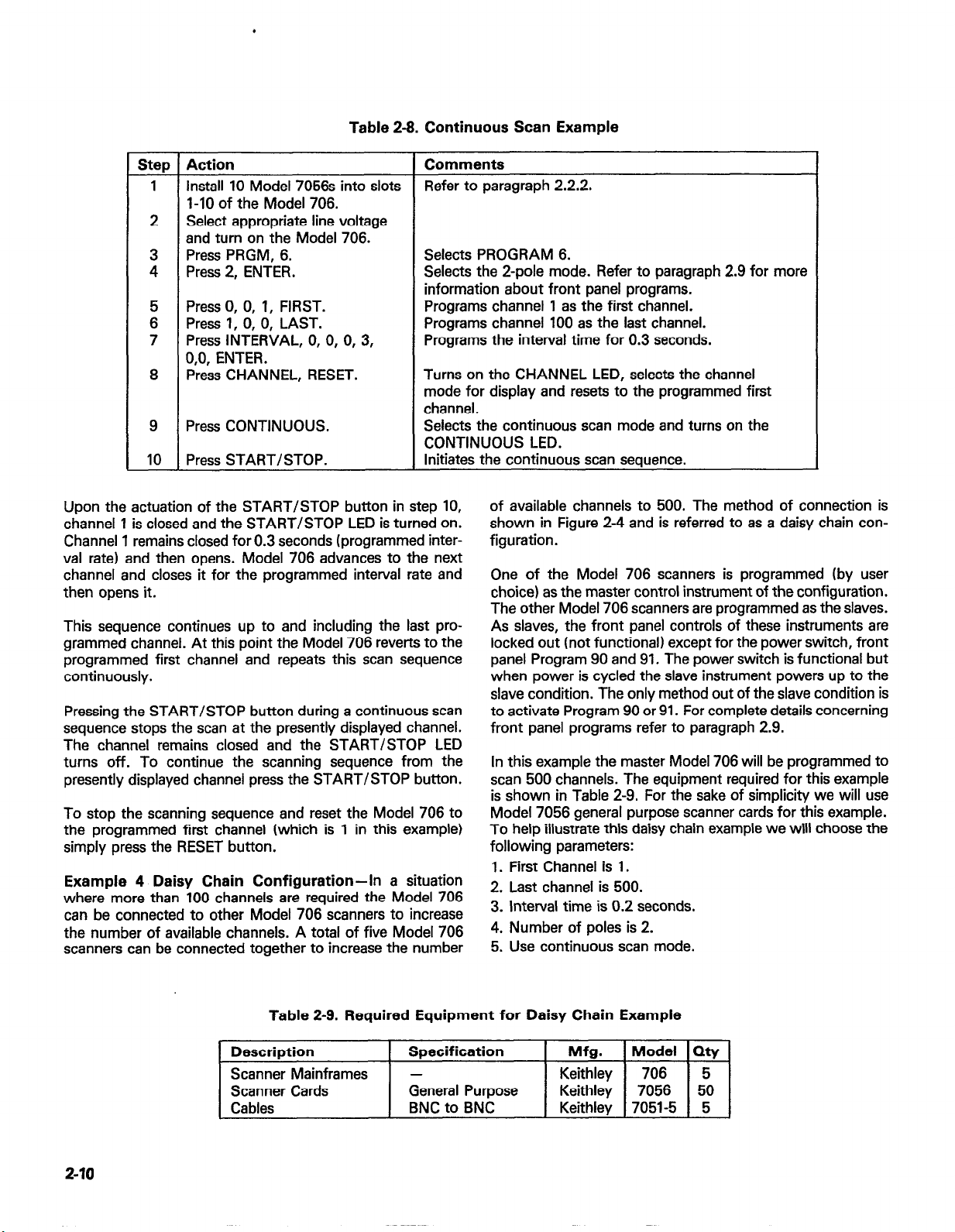

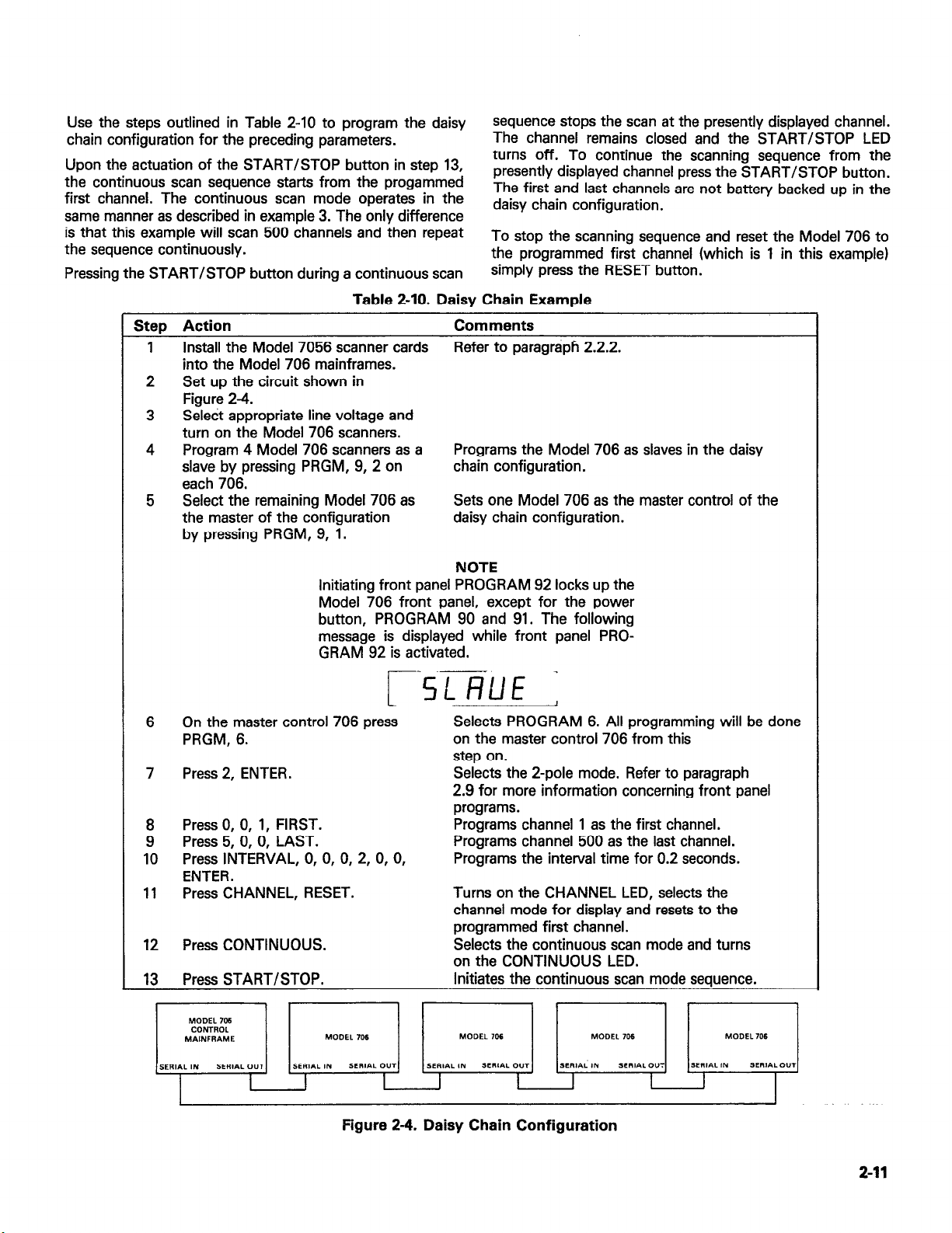

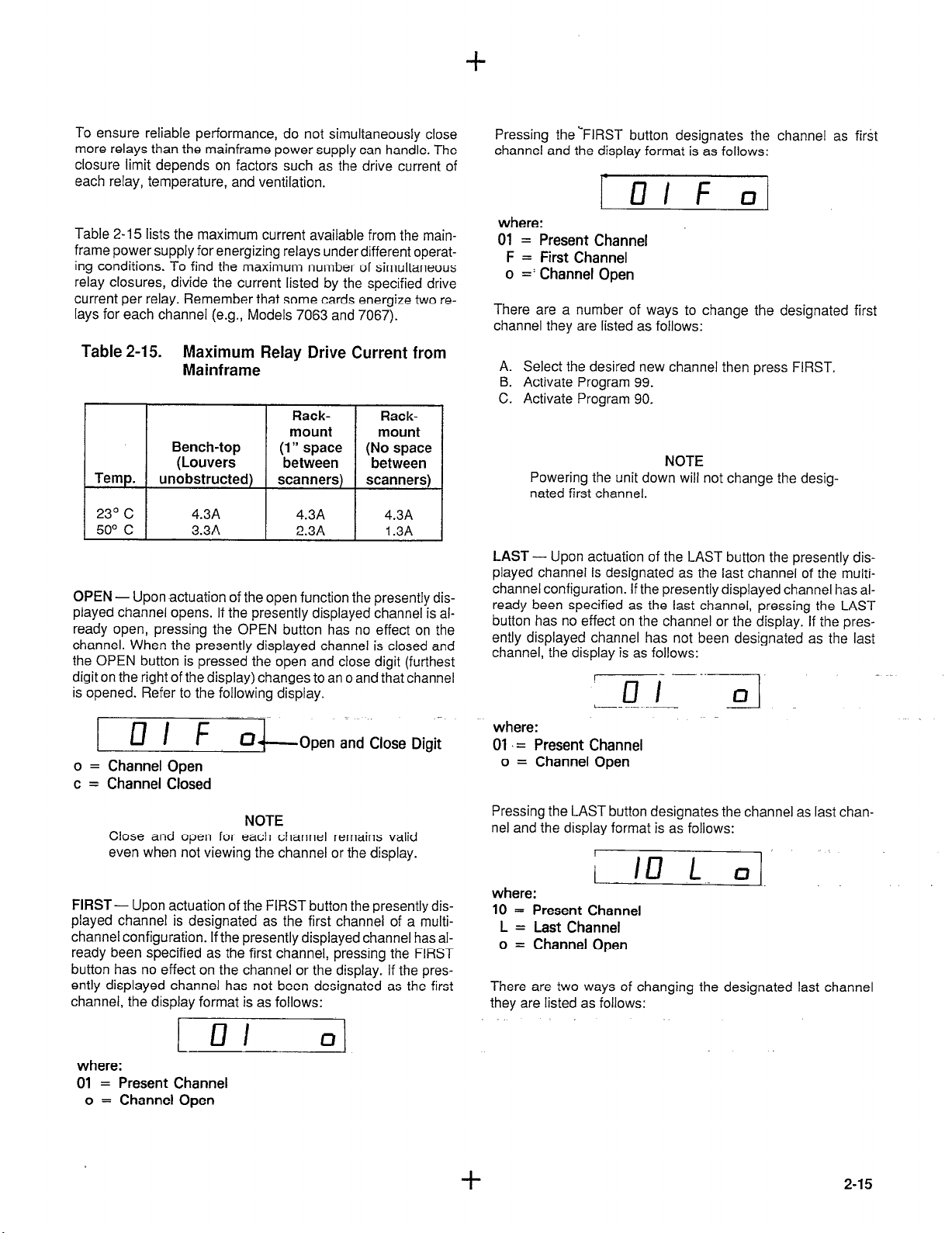

Example 4 Daisy Chain Configuration-In a situation

where more than 100 channels are required the Model 706

can be connected to other Model 706 scanners to increase

the number of available channels. A total of five Model 706

scanners can be connected together to increase the number

of available channels to 500. The method of connection is

shown in Figure 2-4 and is referred to as a daisy chain configuration.

One of the Model 706 scanners is programmed (by user

choice) as the master control instrument of the configuration.

The other Model 706 scanners are programmed as the slaves.

As slaves, the front panel controls of these instruments are

locked out (not functional) except for the power switch, front

panel Program 90 and 91, The power switch is functional but

when power is cycled the slave instrument powers up to the

slave condition. The only method out of the slave condition is

to activate Program 90 or 91. For complete details concerning

front panel programs refer to paragraph 2.9.

In this example the master Model 706 will be programmed to

scan 500 channels. The equipment required for this example

is shown in Table 2-9. For the sake of simplicity we will use

Model 7056 general purpose scanner cards for this example.

To help illustrate this daisy chain example we will choose the

following parameters:

1. First Channel is 1.

2. Last channel is 500.

3. Interval time is 0.2 seconds.

4. Number of poles is 2.

5. Use continuous scan mode.

2-10

Table 2-9. Required Equipment for Daisy Chain Example

Description

Scanner Mainframes -

Scanner Cards General Purpose

Cables

Specification Mfg. Model Qty

Keithley 706 5

Keithley 7056 50

BNC to BNC Keithley 7051-5 5

Page 23

Use the steps outlined in Table 2-10 to program the daisy

chain configuration for the preceding parameters.

Upon the actuation of the START/STOP button in step 13,

the continuous scan sequence starts from the progammed

first channel. The continuous scan mode operates in the

same manner as described in example 3. The only difference

is that this example will scan 500 channels and then repeat

the sequence continuously.

Pressing the START/STOP button during a continuous scan

Table 2-10. Daisy Chain Example

SteD Action

Install the Model 7056 scanner cards

into the Model 706 mainframes.

Set up the circuit shown in

Figure 2-4.

Select appropriate line voltage and

turn on the Model 706 scanners.

Program 4 Model 706 scanners as a

slave by pressing PRGM, 9, 2 on

each 706.

Select the remaining Model 706 as

5

the master of the configuration

by pressing PRGM, 9, 1.

Initiating front panel PROGRAM 92 locks up the

Model 706 front panel, except for the power

button, PROGRAM 90 and 91. The following

message is displayed while front panel PROGRAM 92 is activated.

Comments

Refer to paragraph 2.2.2.

Programs the Model 706 as slaves in the daisy

chain configuration.

Sets one Model 706 as the master control of the

daisy chain configuration.

NOTE

.-_

sequence stops the scan at the presently displayed channel.

The channel remains closed and the START/STOP LED

turns off. To continue the scanning sequence from the

presently displayed channel press the START/STOP button.

The first and last channels are not battery backed up in the

daisy chain configuration.

To stop the scanning sequence and reset the Model 706 to

the programmed first channel (which is 1 in this example)

simply press the RESET button.

On the master control 706 press

6

PRGM, 6.

7 Press 2, ENTER.

0, 0, 1, FIRST.

Press

8

9

10

11

5, 0, 0, LAST.

Press

INTERVAL, 0, 0,

Press

ENTER.

Press CHANNEL, RESET.

Press CONTINUOUS.

Press START/STOP.

-5LRl.E -

r

Selects PROGRAM 6. All programming will be done

on the master control 706 from this

step on.

Selects the 2-pole mode. Refer to paragraph

2.9 for more information concerning front panel

programs.

Programs channel 1 as the first channel.

Programs channel 500 as the last channel.

0, 2, 0,

Figure 2-4. Daisy Chain Configuration

0,

Programs the interval time for 0.2 seconds.

Turns on the CHANNEL LED, selects the

channel mode for display and resets to the

programmed first channel.

Selects the continuous scan mode and turns

on the CONTINUOUS LED.

Initiates the continuous scan mode sequence.

J

Page 24

The display in the daisy chain configuration includes an additional digit to accomodate up to 500 channels, 1000 channels

in l-pole mode. The display is shown as follows:

NOTE

Channels 1, 11 and 21 are the temperature

references for the cards.

I ml If 01

L I

NOTE

Scanning at a high rate of speed in the daisy

chain configuration may not show the scanned

channels on the mainframe’s display.

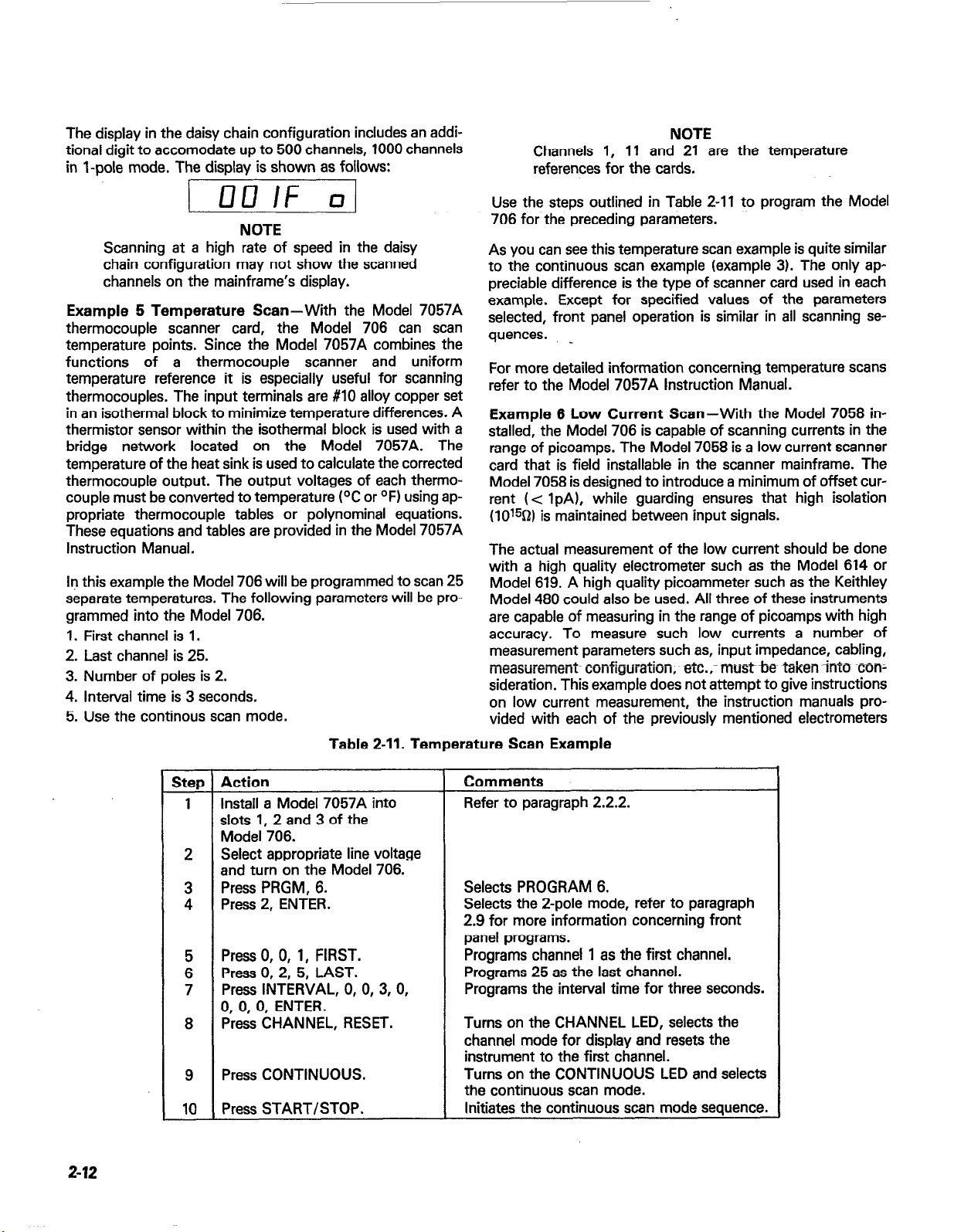

Example 5 Temperature Scan-With the Model 7057A

thermocouple scanner card, the Model 706 can scan

temperature points. Since the Model 7057A combines the

functions of a thermocouple scanner and uniform

temperature reference it is especially useful for scanning

thermocouples. The input terminals are #lO alloy copper set

in an isothermal block to minimize temperature differences. A

thermistor sensor within the isothermal block is used with a

bridge network located on the Model 7057A. The

temperature of the heat sink is used to calculate the corrected

thermocouple output. The output voltages of each thermocouple must be converted to temperature (OC or OFI using ap-

propriate thermocouple tables or polynominal equations.

These equations and tables are provided in the Model 7057A

Instruction Manual.

In this example the Model 706 will be programmed to scan 25

separate temperatures. The following parameters will be pro-

grammed into the Model 706.

1. First channel is 1.

2. Last channel is 25.

3. Number of poles is 2.

4. Interval time is 3 seconds.

5. Use the continous scan mode.

Table 2-11. Temperature Scan Example

Use the steps outlined in Table 2-11 to program the Model

706 for the preceding parameters.

As you can see this temperature scan example is quite similar

to the continuous scan example (example 3). The only appreciable difference is the type of scanner card used in each

example. Except for specified values of the parameters

selected, front panel operation is similar in all scanning sequences. _

For more detailed information concerning temperature scans

refer to the Model 7057A Instruction Manual.

Example 6 Low Current Scan-With the Model 7058 in-

stalled, the Model 706 is capable of scanning currents in the

range of picoamps. The Model 7058 is a low current scanner

card that is field installable in the scanner mainframe. The

Model 7058 is designed to introduce a minimum of offset cur-

rent (c IpA), while guarding ensures that high isolation

(10153) is maintained between input signals.

The actual measurement of the low current should be done

with a high quality electrometer such as the Model 614 or

Model 619. A high quality picoammeter such as the Keithley

Model 480 could also be used. All three of these instruments

are capable of measuring in the range of picoamps with high

accuracy. To measure such low currents a number of

measurement parameters such as, input impedance, cabling,

measuie~ment~ configuration, a&.,- must be taken into con;

sideration. This example does not attempt to give instructions

on low current measurement, the instruction manuals provided with each of the previously mentioned electrometers

2-12

Step

1

2

3

4

9

10

Action

Install a Model 7057A into

slots 1, 2 and 3 of the

Model 706.

Select appropriate line voltage

and turn on the Model 706.

Press PRGM, 6.

Press 2, ENTER.

Press 0, 0, 1, FIRST.

Press 0, 2, 5, LAST.

Press INTERVAL, 0, 0, 3, 0,

0, 0, 0, ENTER.

Press CHANNEL, RESET.

Press CONTINUOUS.

Press START/STOP.

Comments

Refer to paragraph 2.2.2.

Selects PROGRAM 6.

Selects the 2-pole mode, refer to paragraph

2.9 for more information concerning front

panel programs.

Programs channel 1 as the first channel.

Programs 25 as the last channel.

Programs the interval time for three seconds.

Turns on the CHANNEL LED, selects the

channel mode for display and resets the

instrument to the first channel.

Turns on the CONTINUOUS LED and selects

the continuous scan mode.

Initiates the continuous scan mode sequence.

Page 25

and picoammeter give step by step instructions on how to

measure low currents accurately.

In this example, the Model 706 will be programmed to scan

37 low current sources. Also, the following parameters will be

programmed into the Model 706.

1. First channel is 1.

2. Last channel is 37.

3. Interval time is 2 seconds.

4. Number of poles is 2.

5. Use single scan mode.

Use the steps outlined in Table 2-12 to program the Model

706 for the preceding parameters.

As you can see this low current scan example is similar to the

other scanning examples. The only appreciable difference is

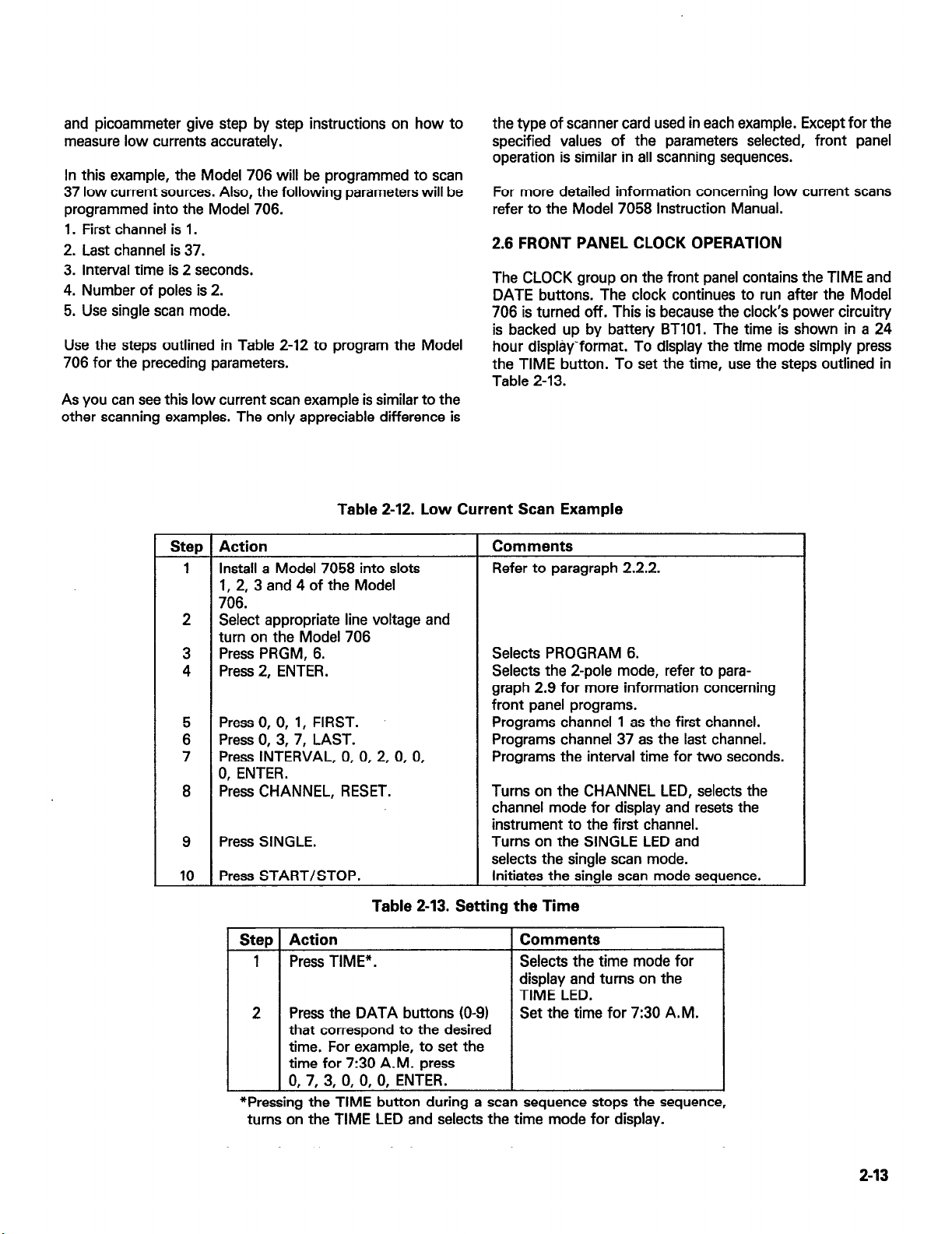

Table 2-12. Low Current Scan Example

the type of scanner card used in each example. Except for the

specified values of the parameters selected, front panel

operation is similar in all scanning sequences.

For more detailed information concerning low current scans

refer to the Model 7058 Instruction Manual.

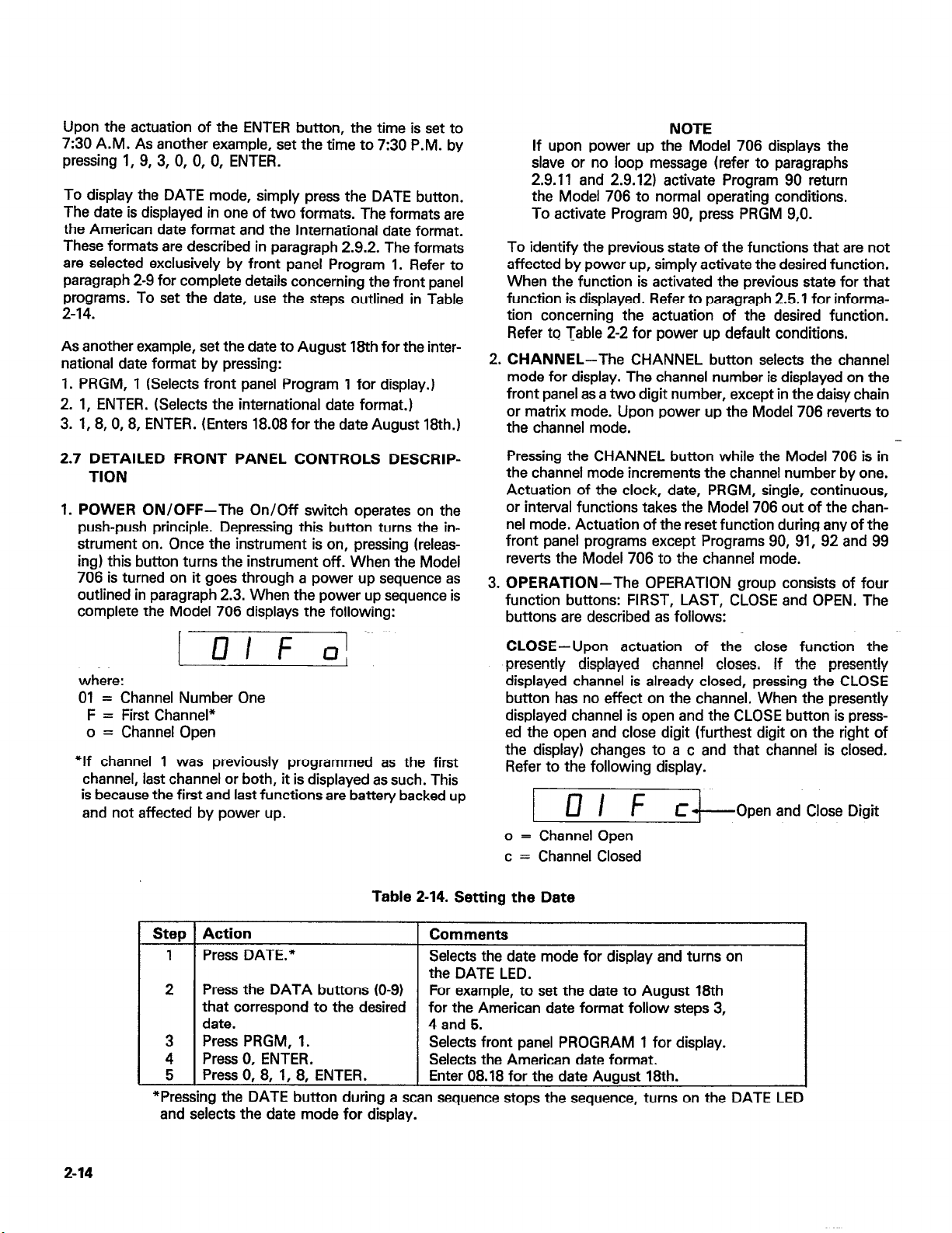

2.6 FRONT PANEL CLOCK OPERATION

The CLOCK group on the front panel contains the TIME and

DATE buttons. The clock continues to run after the Model

706 is turned off. This is because the clock’s power circuitry

is backed up by battery BTlOl. The time is shown in a 24

hour display-format. To display the time mode simply press

the TIME button. To set the time, use the steps outlined in

Table 2-13.

Step Action

Install a Model 7058 into slots

1

1, 2, 3 and 4 of the Model

706.

Select appropriate line voltage and

2

turn on the Model 706

Press PRGM, 6.

3

Press 2, ENTER.

4

Press 0, 0, 1, FIRST.

5

Press 0, 3, 7, LAST.

6

Press INTERVAL, 0, 0, 2, 0, 0,

7

0, ENTER.

Press CHANNEL, RESET.

8

Press SINGLE. Turns on the SINGLE LED and

9

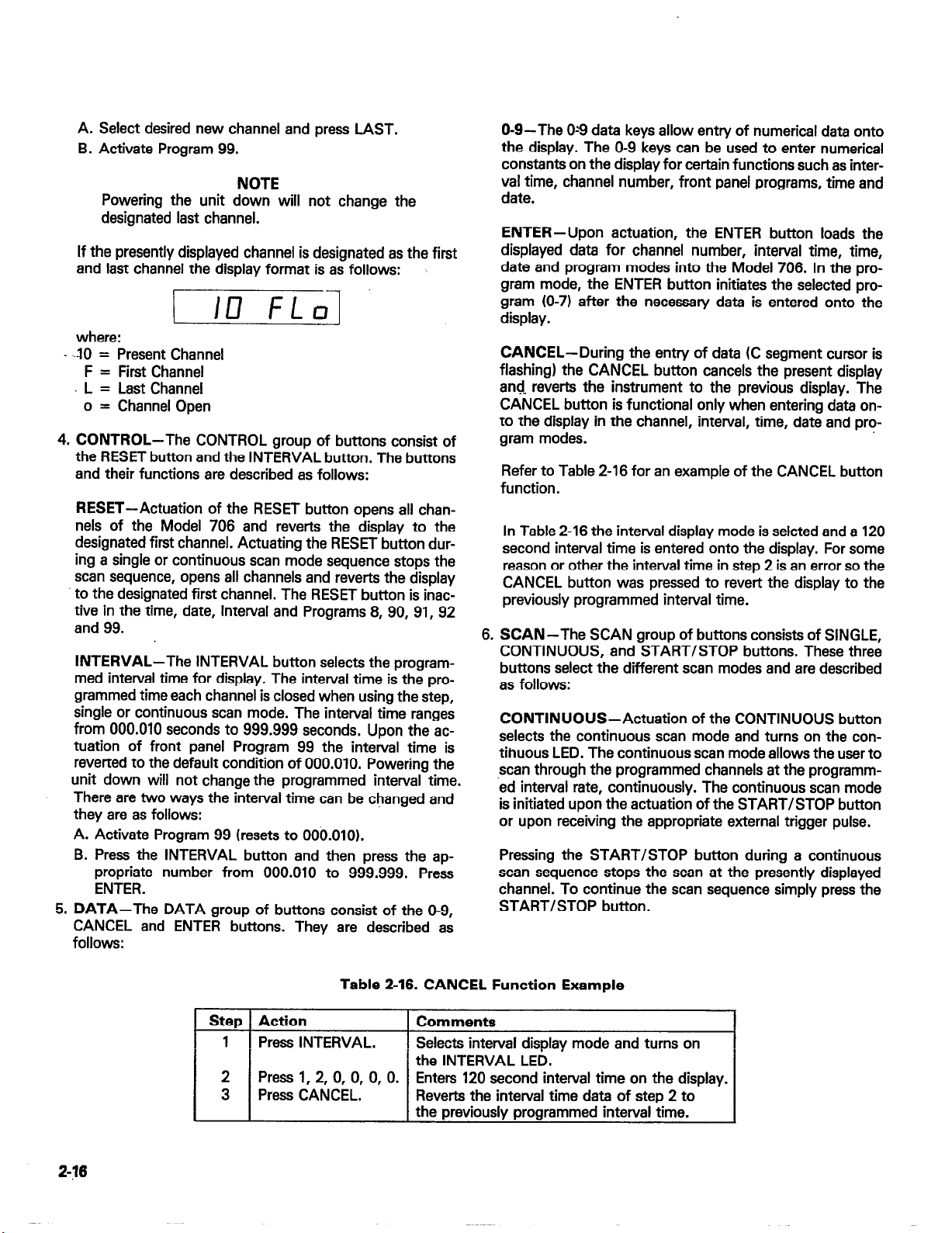

Press START/STOP. Initiates the single scan mode sequence.

10

SteD 1 Action I Comments

2

*Pressing the TIME button during a scan sequence stops the sequence,

turns on the TIME LED and selects the time mode for display.

Comments

Refer to paragraph 2.2.2.

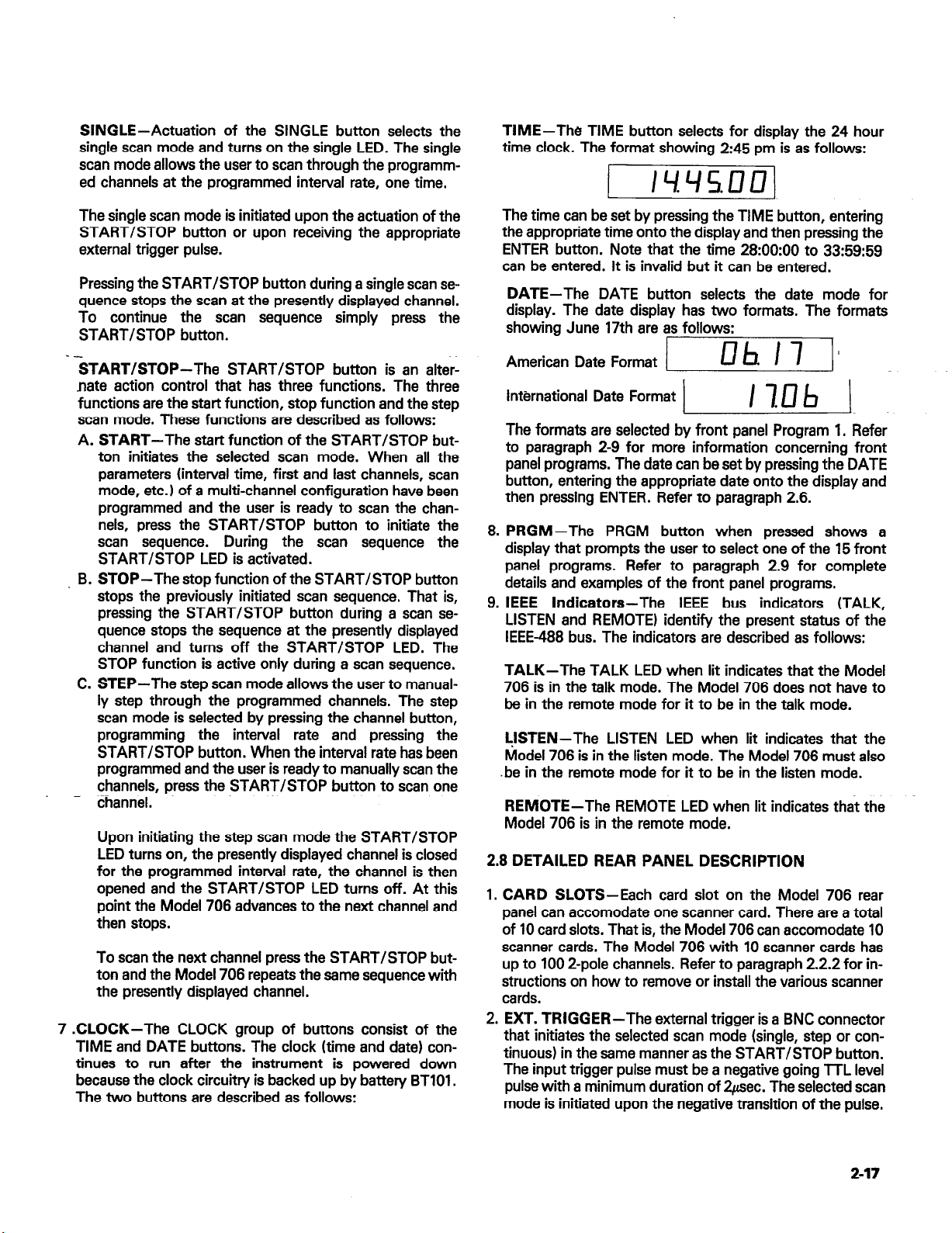

Selects PROGRAM 6.