Page 1

Model 7058 low Current Scanner

Plug-In Card

Instruction Manual

Contains Operating and Servicing Information

Page 2

Page 3

Model 7058 Low Current Scanner

Plug-In Card

Instruction Manual

0 1991, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

October 1991, Second Printing

Document Number: 7058-901-01 Rev. B

Page 4

Safety Precautions

The following safety precautioos should be obsewed before using this product and any asnociated instrumcntatioo. Although some inrtromeots and accessories woold nonnally bo used

with nowhazardous voltages, there arc situations wberc hazardous conditions may be present.

This product is intended for use by qualified personnel who rccogoiu: shock hazards and are

familiar with tbc safety pnxaotions rcqoircd to avoid possible injuly. Read lbe operating it]formation carefully before using the product.

‘The types of product users arc:

Kesponsiblc body is tbe iodividunl or group responsible for the USC sod owinleoaoce of

equipment, for ensuring tlnt the equipment ia operated within its spccilications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. Tbey most be trained in electrical safety

procedures and proper use of the iostrument. ‘lhey most be protected from electric shock and

~onmt with hazardous live circuits.

Maintenance personnel perform mutioe procedures oo the product to keep it operadog, for

example, setting the hoc voltage or replacing consumable materials. Maintenance proccdurcs

am dcacribed in the manual. The procedures explicitly state if the operator ~nay perform them.

Othcrwisc, they should be performed only by senice pcnonoel.

Service personnel are trained to work on live circuits, sod perfoonn safe installations sod repairs of products. Ooly properly trained setvice personocl may perform installation and scrvice procedures.

Exercise extreme caution whco a shock hazard is present. Lethal voltage may be present on

cable coonector jacks or test fixtures. 111~ American National Standards lostitute (ANSI)

stam that a shock hazard exists wheo voltage levels greater than 30V RMS, 42.4V peak, or

60VDC are present. A good safety practice is to expect that hazardous voltage is present

in any unknown circuit before measuring.

Users of this product must be protected fmm electric shock at all timer. The responsible body

must eosum thtat wets aw pwented a.cce~s aod/orinsulatcd from every connection point. lo some

cases, conoectiuns most be exposed to potential buman cootact. Product usa io these circuostances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or abovc 1wO volts, no conductive part of the circuit may be exposed.

AY described in the Ioteroational Electratechnical Commission (IEC) Standard IEC 664, digital multimcter measuring circuits (e.g., Keifhley Models 175A, 199, 2OOQ,2COl, 2002, and

2010) are Installation Category II. All other instruments signal tennioals are Installation Category I and must oat be conoected to mains.

Do not conoect switching cards directly to unlimited power circuits. They are inlendcd to bc

used with impedance limited sources. NEVER connect switching cards directly to AC mains.

Wheo conoccting sources to switching cards. iostall protective devices to limit fault current

sod voltage to tbc card.

Before operating ao instrument, make sure the line cord is connected to a properly grounded

power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear,

cracks, or breaks bcforc each oso.

For maximum safety, do not touch the product, test cables, or any other instrumcots while power is applied to the circuit under test. ALWAYS remove power from the entire test system sod

dischuge soy capxitors before: coooccting or disconnecting cables or jumpers, installing 01

Page 5

removing switching cards. or making iotemtil chaogcs, socb as installing or nzmoviog jumpers.

Vu not touch soy object that could provide a con-cot path to tbc common side of the circuit

under test or power line (eatth) ground. Always make measurements witb dry hands while

standing oo a dly, insulated surface capable of withstanding tbc voltage bciog measured.

The instrument and accessories most be used in accordance with its specifications and operatiog iostructioos or tbe safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories. as defined in

tbe speciticationr sod operatiog information, and es show on the instrument or test fixture

panels, or switcbiog cant.

When fores are used in a product, replace with same type sod rntiog forcootioued pmtectioo

against fire hazard.

Cbassir connections must only be used as shield coooectioos for me~suriog circoits, NOT as

safety eaflh ground connections.

If you are using II test fixture, keep the lid closed while power is applied to the device under

test. Safe operation requires tbe we of a lid interlock.

1ra@

screw is present, connect it to safety earth ground uaiog the wire recommended in

the user documentation.

The ! symbol on an iostroment indicates that the user should refer to the operating ill-

n

stmctions located io tbc manual.

The h

symbol on al iostmment shows that it CNI source or IIICRIIUII: loo0 volts or more, illeluding the combined etTect of normal ad common mode voltages. Use stiuldarrl safety precaulions to avoid pcrsooal cootect with these voltages.

TIE WARNING beading in A manual enplaios dangers that might result in personal injury or

death. Always read the associated information wy carefully hcfore ptxformiog the indicated

pC"CCdU~C.

The CAUTION beading in a manual explains hazards that could damage the instrument.

Such damage may invalidate the warrmty.

lostrumcntatioo and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain pmtcctioo from electric shock and ftre, replacement components in mains circoils, including the power transfouner, test leads, and ioput jacks, must he purchased from

Keithley Instruments. Standard fuses, with applicable national safety appmvals, may be used

if the ratiog sod type are the same. Other components that are not safety r&ted may hc por-

chased from other suppliers as long as they are equivalent to tbe original component. (Note

that selected parts should be purchased only through Keithley Iostmmcnts to maiotain accoracy sod fonctiooality of the product.) If you we unsure about the applicability of a replaccment component, call a Keithlcy Instruments office for information.

To clean an instrument. use a damp cloth or mild, water based cleaner. Clean the exterior

of the instrument only. Do not apply cleaner directly tb the instrument or allow liquids to

enter or spill on the instrument. Products that consist of a circuit hoard with no case or cbassis (e.g., data acquisition board for installation into a computer) should neverrequire cleaning if handled according to instructiuns. If the board becomes contaminated sod operation

is affected. the hoard should he returned to the factory for proper cleaninglserviciog.

tie”. 2rB

Page 6

SPECIFICATIONS

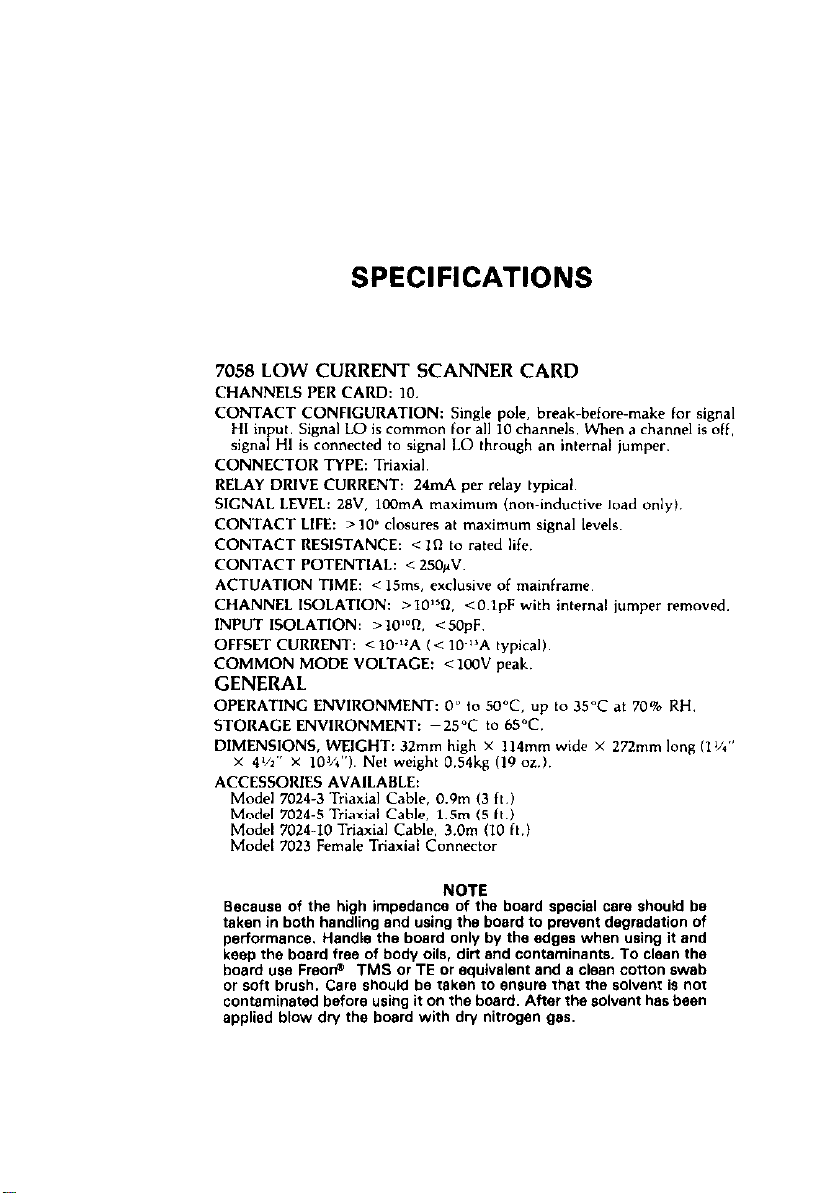

7058 LOW CURRENT SCANNER CARD

CHANNELS PER CARD: 10.

CONTACT CONFIGURATION: Single pole. break-before-make for signal

HI in ut. Signal LO is mmmon for all 10 channelr. When ., channel is off.

signa P HI IS connected to signal LO through an internal jumper.

CONNECTOR TT’E: Triaxial.

RELAY DRIVE CURRENT: 24mA per relay typical.

SIGNAL LEVEL: 28”. lOOmA maximum (non-inductive load only).

CONTACT LIFE: >I@ ~losum at maximum signal le~ek

CONTACT RESISTANCE: c ,R to rated life.

CONTACT POTENTIAL: < &QJ”.

ACTUATION TIME: < 15,~ exclwive of mainframe.

CHANNEL ISOLATION: >10”R. <O.lpF with internal jumper removed.

INPUT ISOLATION: >KPn. <SOpF.

OFFSET CURRENT: < ,@“A t < ,@“A typical).

COMMON MODE VOLTAGE: <X.3” peak.

GENERAL

OPERATING ENWRONMEM: 0” 10 50°C. up lo 35°C at 70% RH.

STORAGE ENVIRONMENT: -25°C lo 65°C.

DIMENSIONS, WEIGHT: 32mm high X 114mm wide

X 4%” X 10%“~. Net weight 0.54kS (19 oz.).

ACCESSORIES AVAILABLE:

Model 7024-3 Triaxial Cable, O.Pm (3 ft.)

Model 7024-S Triaxial Cable. 1.5m (5 ft.)

x

BBCBUSB of the high impedance of the board spatial care should be

taken in both handling and using the board to prevent degradation of

performance. Handle the board only by the edges when using it and

keep the bawd free of body oils. dirt and contaminants. To clean the

board use Freor6

or soft brush. Care should be taken to ensure that the solvent is not

contaminated before wing it on the board. After the solvent has been

applied blow dry the board with dry nitrogen gas.

TMS or TE or equivalent and a clean Norton swab

NOTE

Page 7

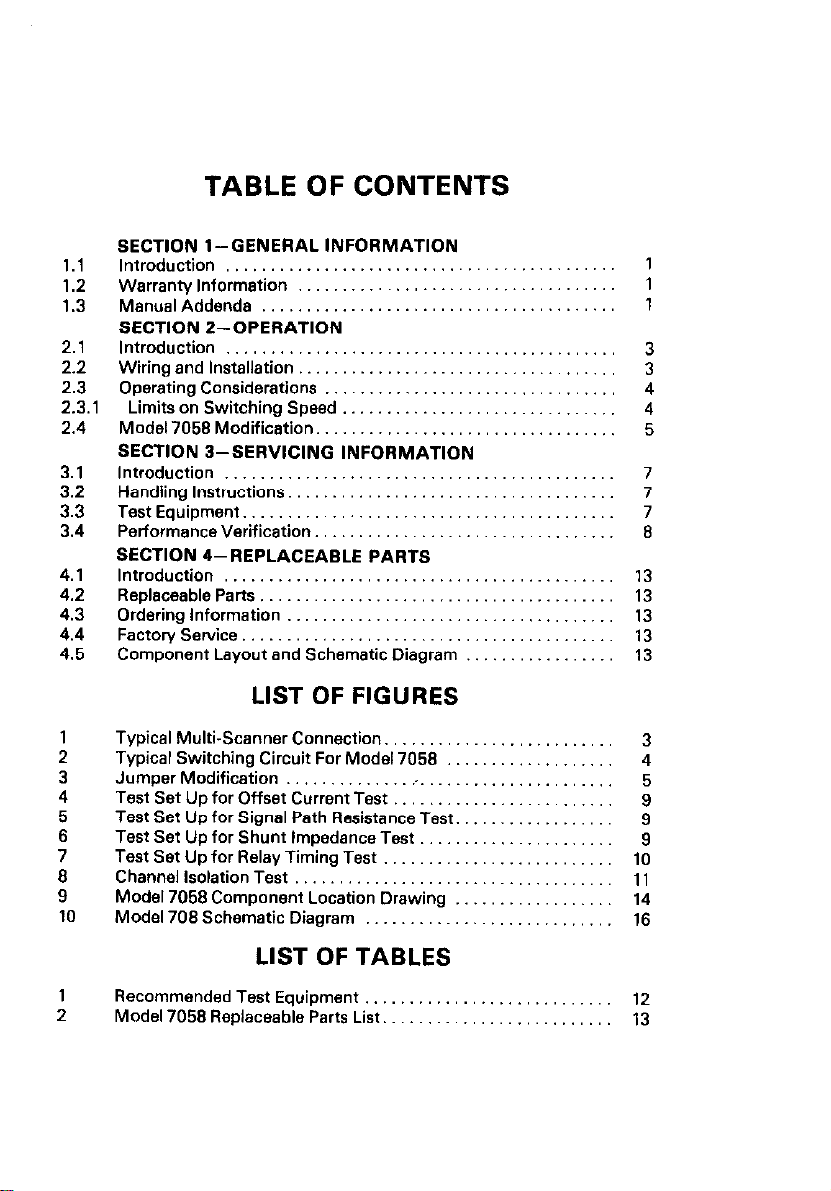

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

Introduction ............................................

1.1

Warranty Information

1.2

ManualAddenda

1.3

SECTION Z-OPERATION

2.1 Introduction ............................................

2.2 Wiring and Installation ....................................

Operating Considerations .................................

2.3

2.3.1

2.4

3.1

3.2

3.3

3.4

4.1

4.2

4.3

4.4

4.5

Limits on Switching SDeed ...............................

Model7058 Modification

SECTION 3-SERVICING INFORMATION

Introduction ............................................

Handling Instructions

TestEquipment

PerformanceVerification

SECTION I-REPLACEABLE PARTS

Introduction ............................................

ReplaceablePans ........................................

Ordering Information .....................................

FactoryService ..........................................

Component Layout and Schematic Diagram .................

....................................

........................................ 1

_

..................................

.....................................

.......................................... 7

..................................

LIST OF FIGURES

1

Typical Multi-Scanner Connection.

2

Typical Switching Circuit For Model 7058

3

Jumper Modlficatlon ......................................

4

Test Set Up for Offset Current Test

Test Set Up for Signal Path Resistance Test.

5

6

Test Set Up for Shunt Impedance Test

Test Set Up for Relay Timing Test

Channel Isolation Test

i

9

Model 7058 Component Location Drawing

10

Model 708 Schematic Diagram

....................................

.........................

...................

.........................

......................

..........................

..................

............................

.................

1

1

3

3

4

4

5

7

7

8

13

13

13

13

13

3

4

5

9

9

9

lo

I 1

14

16

1

Recommended Test Equipment,,

2

Model 7058 Replaceable Parts List

LIST OF TABLES

..........................

..........................

12

13

Page 8

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 7058 is a low-current scanner plug-in card which is field-installable in

the Model 705 scanner mainframe. The Model 7055 will switch up to 10 chan-

nels. For optimum low level current switching. the Model 7058 is designed to introduce a minimum of offset current error ( ( l.OpA), while guarding ensures

that high isolation (1Olsfll is maintained between input signals. The breakbefore-make. single-pole switching of the Model 705 scanner mainframe is

designed to maintain current paths for signals not connected to the output to

provide high input resistance for making voltage measurements. AC or DC

signals up to lOOmA or 28V may be switched. Triaxial input and output connections to the scanner plug-in card ere easily made through the rear panel of the

scanner mainframe using optional triaxial mating cables.

1.2 WARRANTY INFORMATION

Warranty information is stated on the inside front cover of the manual. If there is

a need for sawice. contact the Keithley representative or authorized repair facility

in your we’d. Check the back cover of this manual for addresses. The wvice

form supplied et the back of the manual should be used to provide the repair

facility with adequate information concerning any diiculty.

1.3 MANUAL ADDENDA

Any improvements or changes to this manual will be explained on en addendum

included with this manual.

1

Page 9

SECTION 2

OPERATION

2.1 INTRODUCTION This section provides information needed to use the Model 7058 with the Model

705 scanner mainframe.

2.2 WIRING AND INSTALLATION

1. Wiring Configuration-The Model 7058 incorporates e single pole. switching

configuration. The Model 7058 will switch any one of 10 signals to one output, or switch one signal to any one of 10 outputs.

A. All signal inputs and outputs are made by means of the triaxial connectors

on the card. The location for each channel input and the output is indicated on the shield covers.

8. The input connectors for channels 1 through 4 are located at the rear of

the card. The two OUTPUT connectors permit multiple Model 7058’s to

be connected together. For instance a 30 channel scanner system may be

connected es shown in Figure 1.

C. The signal HI path is switched end signal LO is common for all 10 chan-

nels. An additional relay serves to isolate all circuitry on the card from the

output connectors when no channel is selected.

D. The contact confiauration is desioned for aoolications where current

sources are to be sc&ned That is &ch source’is short-circuited when it is

not being selected This short &it is made through a removesblejumper

located on the underside of the board (see Figure 2). For applications

where such a shon circuit is not desired, es in high impedance voltage

measurements. the jumper may be removed completely or replaced with a

% watt composition resistor if desired

Caps are provided for all connectors. All unused input connector should

be capped to prevent the insulators from being contaminated Unused

output connectors should be capped unless the additional capacitive

coupling due to the cap between signal HI on the output connector and

the outside shell is undesireable. This consideration only becomes import

tent in the presence of very large or noisy common-mode voltages in the

system.

The outside shell of the triaxial connector is common for all channels in the

system and is not connected to the mainframe chassis ground. Care

should be taken that ground loops are not formed due to multiple ground

connections.

The outside shell connection for the card must be made at either

the sources or at the measuring instrument.

NOTE

Figure 1. Typical Multi-Scanner Connection

3

Page 10

2. Installation-Refer to the Model 705 Instruction Manual for scanner card installation instructions.

2.3 OPERATING CONSIDERATIONS

2.3.1 Limits on Switching Speed

1. Current Error in the Picoampere Region-Any time a channel is selected some

degree of charge transfer can be expected due to the mechanical release or

closure of the contacts This charge transfer causes a current pulse whenever

the channel is changed. The effect that this pulse will have on the signal will

depend on the magnitude of the SOU~CB to be measured. The amount of

charge which is transferred when a channel is changed is generally in the

picocoulomb range. When the scanner has been used to measure voltages.

that is, if a voltage has been applied between signal HI and LO, then caution

should be taken when measuring low currents in the scanner. In such a case

the offset currents caused by the di-electric absorption will decay after a

period of time. The rate of this decay is determined by ambient temperature

and the magnitude and duration of the applied voltage.

NOTE

In the case of high voltages at fairly low temperatures, time constants in excess of one hour may be observed for this effect.

Extreme environmental conditions can also cause the offset current to go

beyond 1pA. If the scanner has been exposed to very high humidity and/or

temperature ifor instance during shipping1 the board should be allowed to

stabilize at an environment within the specified limits for approximately 24

hours.

2. Signal LO Used as a Guard-All internal wiring of the scanner is designed in

such a way that the signal LO connection is used as a common guard which

surrounds all inputs That is, all wiring for the signal HI is done such that no

DC current paths exist between the signal HI terminals of any input channel

and any terminal other than signal LO. The additional switching at the output

of the card allows each card in a multiple scanner system to have an independent signal LO.

3. Noise Caused By Cable Flexing-Whenever low level signals (picoamps) are

being measured all signal cables should be kept as still as possible by fastening

them to a rigid surface. This will help to reduce noise caused by the flexing of

the cables. System response will be influenced by the amount of cable

capacitance in the system. This should be considered when the sources are

connected to the scanner. Using a feedback type ammeter lor en electrometer

in “FAST” mode) for currents below lo-SA is recommended to increase

measurement speed and decrease the effects of cable capacitance.

Page 11

2.4 MODEL 7058 MODIFICATION

On the Model 70% low current scanner card, Channel LO is connected to output HI. If isolation is required between Channel LO and Output HI, the Model

7058 can be modified to disconnect Channel LO from output HI when all the

relay8 are off (relay K311 not energized). Relay K311 is an isolation relay that

isolates all circuitry on the card from the output connectors when no channel is

selected. The modification involves removing a jumper wire that is shown in

Figure 3. After the jumper wire is removed. clean all the circuity involved with

Free@ TMS or TE or equivalent. Then blow dry the circuitw with dry nitrcgen

gas

Figure 3. Jumper Modification

5

Page 12

SECTION 3

SERVICING INFORMATION

3.1 INTRODUCTION This saction contains a performance verification procedure. Since there are no

calibration adjustments. no recalibration is necessary. Recommended maintenance would include inspection of the scanner plug-in board and card-adge

connector to ensure good electrical contact. In industrial environments annual

cleaning using FreorP TMS or TE and dry nitrogen gas. The verification procedure should be performed upon receiving the Model 7058 or at the time

maintenance is performed on the mainframe.

3.2 HANDLING INSTRUCTIONS Because of the high

special care should be taken in both handling and using the card to prevent

degradation of performance. Some precautions which should be followed are:

1. Avoid touching any exposed teflon insulators, the coaxial cable under the

card, or the inside of the cable connectors This will help prevent contamination of these surfacas.

2. Whenever the card is not being used in the mainframe it should be placsd on

a clean surface or preferably in a plastic bag.

3. If the factory installed jumpers are to be removed, they should be cut wt. not

unsoldered to prevent the possibility of flux vapor from contaminating the inSulators.

4. If it becomes necessary to solder the jumpers back an to the card, the solder-

ing should be done carefully and the board cleaned with Fre& TMS or TE

and blown dry with dry nitrogen gas.

5. If a large offset currant develops on the card from exposure to high humidity

this offset can be reduced by allowing the card to remain at an environment

of low humidity for about 24 hours. This will allow the condensed moisture to

evaporate.

6. Should it become necessary to clean the board due to contamination, the

following procadure should be followed:

A, The relay shield cwers should be removed to expose all internal wiring

before cleaning.

8. The racommended method of cleaning is spraying the board with a aolvent such as Fra& TMS or TE. Care should be taken to be sure that the

solvent is not contaminated before spraying it on the board. If necessary a

small bristle brush can be used to remove flux. grease. etc.

C. After cleaning, the board should be allowed to return to ambient

temperature and all traces of condensed moisture should be allowed to

evaporate before any low level measurements are made.

impedance

wiring techniques used on the Modal 7058.

3.3 TEST EQUIPMENT Recommended test equipment is given in Table 1. Test equipment other than

recommended may be substituted if specifications equal or exceed the stated

characteristics.

7

Page 13

3.4 PERFORMANCE VERIFICATION

1. The procedures necessary to verify that the Model 7059 is operating within its

specifications are given in this section. The tests should be carried Out in the

environment stated in the specifications.

2. General Considerations- Due to the low levels of the signals to be measured

in several of the tests the following considerations should be made:

A. Physical Layout-All triaxial test cables should be kept as still as possible

to help minimize noise. Use of Model 7024-3 triaxial cable is recommended, This is especially important on the offset current. and impedance tests.

In the shunt impedance and isolation tests it is necessary to make a power

supply and/or an electrometer input connection to a triaxial cable. This can

be accomplished by using a Kl Model 7023 connector and carefully soldering the leads on to it. To help eliminate noise in such a setup, the connector and exposed leads should be enclosed in a shield.

Et. Sequence of Measurements-The tests involving the application of high

voltages 10 the card should be done after the tesfs involving low &et

currents This will eliminate false offset readings due to dielectric absorption.

3. Offset Current Test ISee Figure 41.

A. Disconnect all leads from the input connectors on the Model 7058.

6. Connect the Model 7024-3 triaxial cable from one of the OUTPUT connectors on the Model 7059 to the input of the electrometer. Set the electrometer to the 10-“A range, and LB,O check,

C. Inself the Model 7058 into the Model 705 mainframe and select the chan-

nel which is to be tested.

D. With the electrometer released from zero check. note the offset current

long enough to allow the switching transienta to decay and the current to

stabilize. The offset current as indicated by the electrometer reading

should be less than 1pA exclusive of noise.

E. The above procedure should be repeated for all 10 channels of the card

and also the all off mode.

4. Signal Path Resistance (See Figure 5).

A. Set the Model 195 to the 20R range. Zero the Model 195 with the leads

shorter.

9. Set up the circuit shown in Figure 5.

C. Install the Model 7059 into the mainframe and activate the channel to be

tested.

D. The resistance reading on the Model 195 will indicate the HI signal path

resistance.

E. Change the test leads to connect to the LO signal path.

F. Repeat the reading with the Model 195. This will indicate the LO signal

path resistance. The sum of the HI signal path and LO signal path

resistance should be less than 1R.

5. Shunt Impedance Test

A. Test Setup-Set up equipment as shown in Figure 6.

8. Turn the power supply on and select the channel to be tested.

C. Release the electrometer from the ZERO CHECK position. The current

reading should be (1 x 10 ~~8A. This corresponds to a shunt resistance of

1oov

1 x lOmBA

= 10%

Page 14

D. This process should be repeated for all 10 channels and also with all relays

off.

Figure 4. Test Set Up For Offset Current Test

Figure 5. Test Set Up For Signal Path Resistance Test

MODEL 7023 ..*

JIGITAL

LECTRO

-1

COAXIAL CABLE

DIELECTRIC

STRENtJTH

) 1oov

Figure 6. Test Set Up For Shunt Impedance Test

itl

Page 15

6. Relay Contact Timing Test

A. Set up the Model 7056 in the mainframe as shown in Figure 7. Select

channel 1.

6. Turn the generator on and the oscilloscope to IfI trigger. The

oscilloscope should be set as follows:

SWEEP: lmsldivision

VERTICAL SENSITIVITY: SV/division

C. Turn the power supply output on.

D. The time until the first 1OV to OV transition on the display should be less

than Gmsec.

E. The time for the contaciz to completely close should be less than Gmsec.

F. Set the oscilloscope to (-I trigger.

G. Verify that the time to the 0 to 1OV transition is less than lms.

H. Test all 10 channels as described in steps A through G.

GENERATOR

HI

LO

HI-2 =

TRIGGER

INPUT

OSCILLOSCOPE

Figure 7. Test Set Up For Relay Timing Test

10

EXTERNAL COM

TRIGGER

MODEL 705/7058

OUTPUT

T

I I

+

--a

%Z

wz-

[CHANNEL UNDER __ ;

TEST INPUT)

lkR.lO%

wv.,-- HI VOLTAGE

YlW

5

r

MODEL230

SUYPLI

Page 16

7. Channel Isolation

A. This test measures the leakage resistance between two channels on

the board. One channel is to be open and the other closed. Set up the

test circuit shown in Figure 8.

I3 Short the HI end LO connections of each channel on the Model 7058.

Do not connect the channels together. just short the HI and LO ter-

minals.

C. Set the Model 705 to the Channel mode, Channel 1 and the Step

mode. Set the electrometer to Amps and program the Model 230 to

OUtpUt 1oov.

D. Take the electrometer out of ZERO CHECK. Program the channel

under test es open and other channels as closed.

E. Take the reading on the electrometer. The reading should be less than

1 x lOt3A. Using Ohm’s Law calculate the channel isolation. For example: R=EII = lOOV/l x 10-t3A = 1 x 101%. Due to the

capacitance of the circuit, the offset current may be high until the

capacitance of the circuit is charged up. Wait until the readings settle

wt.

F. Manually scan through channels 1 through 10 repeating step D end E

for each channel.

MODEL 706/7069

CHANNEL

OUTPUT

HI

LO GUARD HI LO

UNDER

I_T_EsTI

MODEL HI

290

POWER

SUPPLY LO

ELECTRS HI

METER

(614

OR 619

SET TO

AMPS LD

Figure 9. Channel Isolation Test Set Up

L'

I

,

J

11

Page 17

Table 1. Recommended Test Equipment

tern Description

A Electrometer

B Chart Recorder

C Scanner Mainframe

D Accessmy Cable

E Ohmmeter-DMM

F

Accessoly Kelvin Leeds

G Accessory Connectors I:

H

Power Supply

I Oscilloscope

J Square Wave Generator

K Accessory Triaxial

Cables (21

L Tdaxial Connector

lFemalel

Specifications

Sensititin/ to

10. 12A

1v full range

Triaxial cable,

3 foot long

c 10 sensitivity

Triaxial connector

lO.CWDC, 1CWDC

DC Coupled Trigger

sweep

1OHr

Triaxial with clip

leads.

Mfg

H-P 70358

Tek ‘600 series

H-P

KI

KI

KI

KI

KI

KI

KI

KI

KI

Model

514 or 619

705

7024-3

195

1641

1563

230

33108

6011

7023

12

Page 18

SECTION 4

REPLACEABLE PARTS

4.1 INTRODUCTION This section contains replacement parts information, a schematic diagram and

component layout far the Model 7056.

4.2 REPLACEABLE PARTS

Parts are listed alpha~numerically in order of their circuit designation. Table 2

contains parts list information for the Model 7056.

4.3 ORDERING INFORMATION To place an order. or to obtain information concerning replacement parts. con-

tact your Keithley representative or the factory. See the inside front cover for addresses. When wdering include the following information:

1. Instrument Model Number

2. Instrument Serial Number

3. Part Description

4. Circuit Description lif applicable)

5. Keithky Pan Number

4.4 FACTORY SERVICE If the instrument is to be returned to the factory for sewice, please complete the

?.ewice form which follows this section and return it with the instrument.

4.5 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM A component layout of the Model 7056 is contained in Figure 10, while Figure 11

contains a schematic diagram of the Model 7056.

Table 2. Model 7058 Replaceable Parts

-

Description

Capacitor. 1OpF. 25V. Aluminum Electrolytic

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Silicon Diode, lN914

Connector, Triax 16 required)

Relay

.-

KeithleT

Part No.

-c-314-10

RF-28

RF-28

RF-26

RF-28

RF-26

RF-28

RF-28

RF-28

RF-28

RF-28

RF.28

CS-181

RL-46

Page 19

Table 2. Model 7055 Replaceable Parts lCo”t.1

Circuit

Desig.

K102

K103

K104

K105

K106

K107

KlOB

K109

KllO

Klll

cl101

RlOl

R102

Description

Relay

R&V

RCtlaV

Relay

Relay

Relay

Relay

Relay

R&V

lW3V

Transistor, Silicon PNP. 2N4355

Resistor, lk, 5%. 114W. Composition

Resistor, lk. 5%. 114W. Composition

MECHANICAL PARTS

Bracket, Rear, Connector Mounting

Connector, Triax 16 required1

Shield

No. 4.40 x 3/16 Slot Fil Head Screw

(20 required)

l/4” Flat Brass Washer 12 required)

No. 4-40 x 114 Nylon Slot Roung Head Screw

(4 required)

Bracket, Front, Connector, Mounting

Connector, Triax 16 required)

Shield

No. 4.40 x 3116 Slot Fil Head Screw

120 requiredl

114” Flat Brass Washer 12 reauiredl

No. 4-40x l/4 Nylon Slot Round Head Screw

I4 required1

No. 4-40x3/16 Sems Slot Round Head Screw

16 required)

Staking, Front Relay Cover

A. Cover, Front Relay

B. lnsuiator

C. Standoff

Staking, Rear Panel Cover

A. Cover, Rear Panel

B. Insulator

C. Standoff

No. 6-32x 114 Phillips Pan Head Screw

(2 required)

Protective Cap (12 required)

Test Lead

(eithley

‘art No.

3L-48

3L-46

7 L-46

?L-49

?L-48

?L-48

qL-48

?L-46

7L-48

qL-46

TG-90

3.76.lk

3.76.lk

27079

,s-161

27076

27079

cs-161

27076

7056-301

7056.302

27072

27377

7056.304

7056.3OI

27074

ST-129

CAP-18

7024-3

14

Page 20

Figure 9. Model 7059 Component Location Drawing

15

Page 21

Page 22

Service Form

Page 23

Keithley Instruments, Inc.

Test Instrumentation Group

28775

Aurora Road

Cleveland, Ohio

Printed in the U.S.A.

44139

Loading...

Loading...