Page 1

Model 7056

General Purpose Scanner Card

Instruction Manual

Contains Operating and Servicing Information

Document Number: 7056-901-01 Rev. D

Page 2

WARRANTY

Keithley Instruments, Inc. warranty this product to be free from defects in tnatcrial and

workmanship for a period of I year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of

shipment: probes, cables, rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product

that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact

Keithley headquarters in Cleveland, Ohio. You will be given prompt assistance and

return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired

or replaced products are warranted for the balance of the original warranty period, or at

least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without

Keitbley’s express written consent, or misuse of any product or part. This warranty also

does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES,

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES

SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KBITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES.

SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO:

COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE

RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Page 3

Model 7056

General Purpose Scanner Card

Instruction Manual

01992, Kcithlcy Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

January 1992, First Printing

Document Number: 7056-901-01 Ilcv. D

Page 4

Safety Precautions

The following safety precautioos should be obsewed before using this product and any asnociated instrumcntatioo. Although some inrtromeots and accessories woold nonnally bo used

with nowhazardous voltages, there arc situations wberc hazardous conditions may be present.

This product is intended for use by qualified personnel who rccogoiu: shock hazards and are

familiar with tbc safety pnxaotions rcqoircd to avoid possible injuly. Read lbe operating it]formation carefully before using the product.

‘The types of product users arc:

Kesponsiblc body is tbe iodividunl or group responsible for the USC sod owinleoaoce of

equipment, for ensuring tlnt the equipment ia operated within its spccilications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. Tbey most be trained in electrical safety

procedures and proper use of the iostrument. ‘lhey most be protected from electric shock and

~onmt with hazardous live circuits.

Maintenance personnel perform mutioe procedures oo the product to keep it operadog, for

example, setting the hoc voltage or replacing consumable materials. Maintenance proccdurcs

am dcacribed in the manual. The procedures explicitly state if the operator ~nay perform them.

Othcrwisc, they should be performed only by senice pcnonoel.

Service personnel are trained to work on live circuits, sod perfoonn safe installations sod repairs of products. Ooly properly trained setvice personocl may perform installation and scrvice procedures.

Exercise extreme caution whco a shock hazard is present. Lethal voltage may be present on

cable coonector jacks or test fixtures. 111~ American National Standards lostitute (ANSI)

stam that a shock hazard exists wheo voltage levels greater than 30V RMS, 42.4V peak, or

60VDC are present. A good safety practice is to expect that hazardous voltage is present

in any unknown circuit before measuring.

Users of this product must be protected fmm electric shock at all timer. The responsible body

must eosum thtat wets aw pwented a.cce~s aod/orinsulatcd from every connection point. lo some

cases, conoectiuns most be exposed to potential buman cootact. Product usa io these circuostances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or abovc 1wO volts, no conductive part of the circuit may be exposed.

AY described in the Ioteroational Electratechnical Commission (IEC) Standard IEC 664, digital multimcter measuring circuits (e.g., Keifhley Models 175A, 199, 2OOQ,2COl, 2002, and

2010) are Installation Category II. All other instruments signal tennioals are Installation Category I and must oat be conoected to mains.

Do not conoect switching cards directly to unlimited power circuits. They are inlendcd to bc

used with impedance limited sources. NEVER connect switching cards directly to AC mains.

Wheo conoccting sources to switching cards. iostall protective devices to limit fault current

sod voltage to tbc card.

Before operating ao instrument, make sure the line cord is connected to a properly grounded

power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear,

cracks, or breaks bcforc each oso.

For maximum safety, do not touch the product, test cables, or any other instrumcots while power is applied to the circuit under test. ALWAYS remove power from the entire test system sod

dischuge soy capxitors before: coooccting or disconnecting cables or jumpers, installing 01

Page 5

removing switching cards. or making iotemtil chaogcs, socb as installing or nzmoviog jumpers.

Vu not touch soy object that could provide a con-cot path to tbc common side of the circuit

under test or power line (eatth) ground. Always make measurements witb dry hands while

standing oo a dly, insulated surface capable of withstanding tbc voltage bciog measured.

The instrument and accessories most be used in accordance with its specifications and operatiog iostructioos or tbe safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories. as defined in

tbe speciticationr sod operatiog information, and es show on the instrument or test fixture

panels, or switcbiog cant.

When fores are used in a product, replace with same type sod rntiog forcootioued pmtectioo

against fire hazard.

Cbassir connections must only be used as shield coooectioos for me~suriog circoits, NOT as

safety eaflh ground connections.

If you are using II test fixture, keep the lid closed while power is applied to the device under

test. Safe operation requires tbe we of a lid interlock.

1ra@

screw is present, connect it to safety earth ground uaiog the wire recommended in

the user documentation.

The ! symbol on an iostroment indicates that the user should refer to the operating ill-

n

stmctions located io tbc manual.

The h

symbol on al iostmment shows that it CNI source or IIICRIIUII: loo0 volts or more, illeluding the combined etTect of normal ad common mode voltages. Use stiuldarrl safety precaulions to avoid pcrsooal cootect with these voltages.

TIE WARNING beading in A manual enplaios dangers that might result in personal injury or

death. Always read the associated information wy carefully hcfore ptxformiog the indicated

pC"CCdU~C.

The CAUTION beading in a manual explains hazards that could damage the instrument.

Such damage may invalidate the warrmty.

lostrumcntatioo and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain pmtcctioo from electric shock and ftre, replacement components in mains circoils, including the power transfouner, test leads, and ioput jacks, must he purchased from

Keithley Instruments. Standard fuses, with applicable national safety appmvals, may be used

if the ratiog sod type are the same. Other components that are not safety r&ted may hc por-

chased from other suppliers as long as they are equivalent to tbe original component. (Note

that selected parts should be purchased only through Keithley Iostmmcnts to maiotain accoracy sod fonctiooality of the product.) If you we unsure about the applicability of a replaccment component, call a Keithlcy Instruments office for information.

To clean an instrument. use a damp cloth or mild, water based cleaner. Clean the exterior

of the instrument only. Do not apply cleaner directly tb the instrument or allow liquids to

enter or spill on the instrument. Products that consist of a circuit hoard with no case or cbassis (e.g., data acquisition board for installation into a computer) should neverrequire cleaning if handled according to instructiuns. If the board becomes contaminated sod operation

is affected. the hoard should he returned to the factory for proper cleaninglserviciog.

tie”. 2rB

Page 6

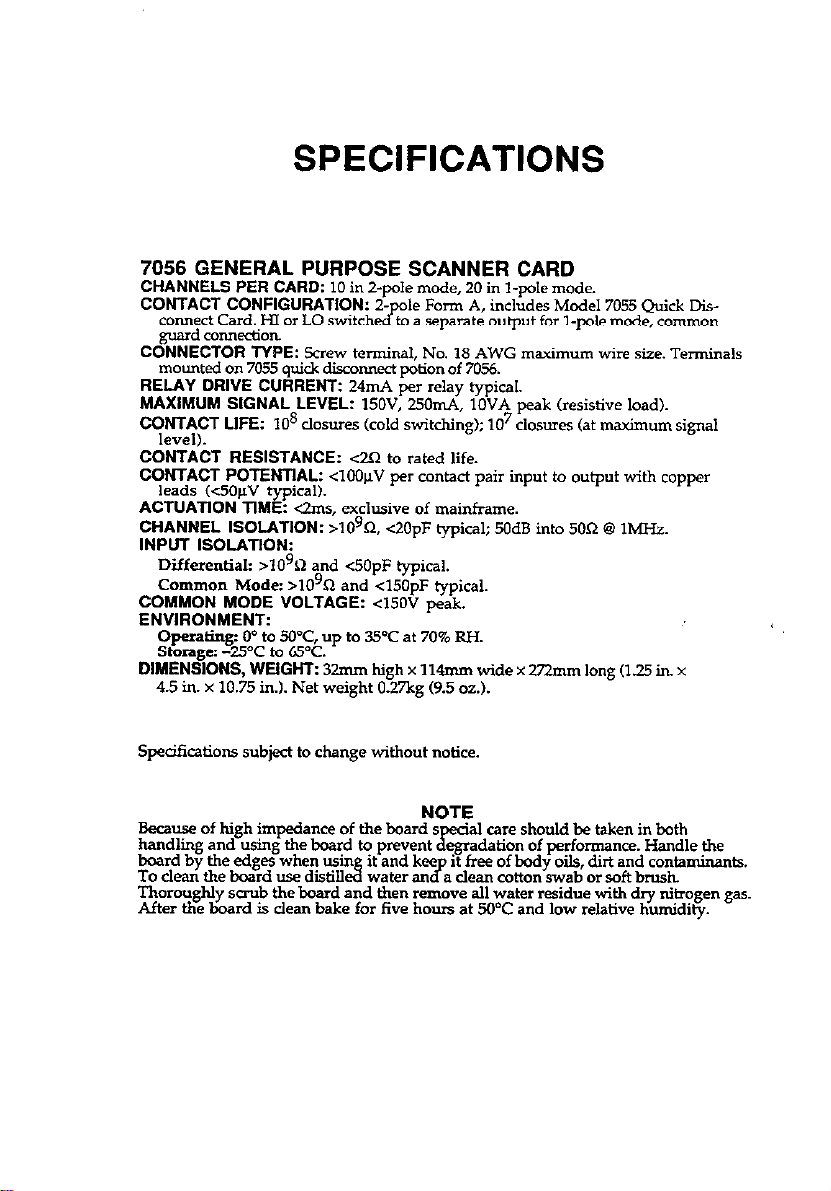

SPECIFICATIONS

7056 GENERAL PURPOSE SCANNER CARD

CHANNELS PER CARD: IO in 2-pole mode, 20 in I-pole mode.

CONTACT CONFIGURATION: 2- le Form A, includes Model 7055 Quick LXs-

~omeCt Card. HI or LO switch

guard connection

CONNECTOR TYFE: Screw temina,, No. 18 AWG ma.ximum wire size. Tem,i,,a,s

mounted on 7055 quick dtscok potion of 7056.

RELAY DRIVE CURRENT: 24mA per relay typical.

MAXIMUM SIGNALsLEVEL: 150”. 25hA, IOV.$ peak (resistive load).

CCl,“JT LIFE: 10 dosures (cold switching); 10 ciosores (at maximum signal

CONTACT RESISTANCE: cZI2 to rated life.

CONTACT POTENTIAL: <lC@V per contact pair input to output with copper

leads (c5OpV typical).

ACNATtON TIME: <2ms, exclusive of mainframe.

CHANNEL ISOLATION: >lOgQ, OOpF typical; MdB into 500 @ I-.

INPUT ISOLATION:

Differential: >lOgP and <50pF typical.

Common Mode: >lOgQ and 45OpF typical.

COMMON MODE VOLTAGE: <,50” peak.

ENVIRONMENT:

operating: 0’ to MT, up to 3sT at 70% RH.

storage -WC to WC.

DIMENSIONS, WEIGHT: 32mm high x 114mm wide x 272mm long K25 in. x

4.5 in. x 10.75 in.). Net weight 027kg (9.5 oz.).

to a eerlerete outout for l-m& mode, common

ecr

. . .

Spedfications subject to change without notice.

BecauseofhighimpedanceoftheboardsSedalcareshouldbetakeninboth

handling and using the board to prevent

board by the edges when win it and kee

To dean the board use distill

Thoroughly saub the beard and then remove all water residue with dry nitrogen gas.

After the board is dean bake for five hours at 54°C and low relative humidity.

e% %

NOTE

egradatmn of prfomence. Handle the

water an a dean cotton swab or soft brush

it free of body oils, dirt and contaminants.

Page 7

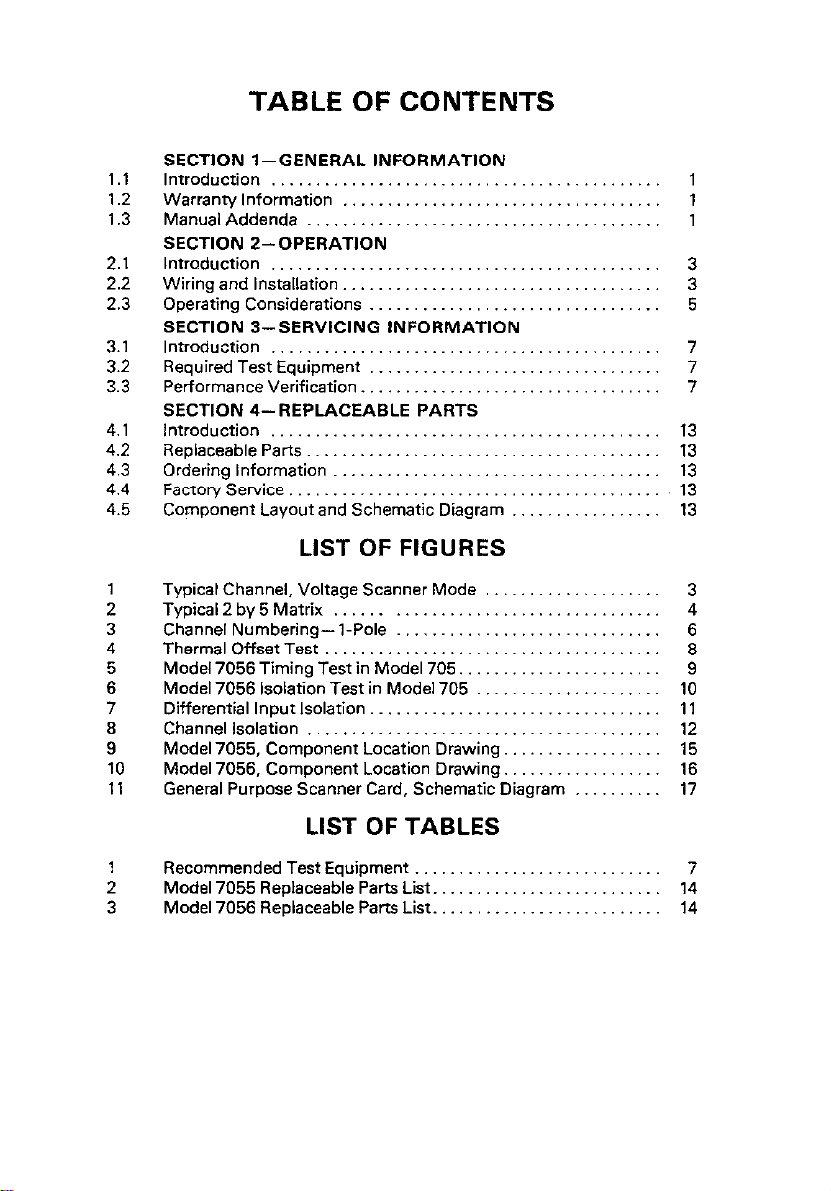

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

1.1

Introduction ............................................

1.2

Warrann/ Information ....................................

1.3

ManualAddenda ........................................

SECTION Z-OPERATION

lntraduction ............................................

2.1

2.2

Wiring and Installation. ...................................

2.3

Operating Considerations .................................

SECTION 3--SERVICING INFORMATION

Introduction ............................................

3.1

Required Test Equipment .................................

3.2

Performance Verification ..................................

3.3

SECTION 4-REPLACEABLE PARTS

4.1

Introduction ............................................

ReplaceablePans ........................................

4.2

Ordering Information .....................................

4.3

4.4

FactoryService ..........................................

Component Layout and Schematic Diagram

4.5

LIST OF FIGURES

.................

3

3

5

7

7

7

13

13

13

13

13

1

Typical Channel, Voltage Scanner Mode

Typical2by5Matrix ....................................

2

3

Channel Numbering-l-Pole ..............................

Thermal Offset Test ......................................

4

5

Model 7056 Timing Test in Model 705. ......................

Model7056 Isolation Test in Model 705

6

7

Differential Input Isolation .................................

Channel Isolation ........................................

a

Model7055, Component Location Drawing.

9

Model 7056, Component Location Drawing.

10

11

General Purpose Scanner Card, Schematic Diagram

LIST OF TABLES

1

Recommended Test Equipment ............................

2

Model 7055 Replaceable Parts List ..........................

Model 7056 Replaceable Parts List ..........................

3

....................

.....................

.................

.................

..........

3

4

6

a

9

10

11

12

15

16

17

7

14

14

Page 8

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 7056 is e general purpose relay ecenner plug-in card which is field-

installable in en appropriate Kelthley ecenner mainframe (e.g. Model 706). The

Model 7056 w/II switch up to 10 channels. The card can be used 88 e voltage

ecenner. independent relay card or e matrix card. The Z-pole switching 18 eccompllshed in less than 2ms and the expected relay life is lo8 closure8 et the

maximum contact ratings. Barrier strips ere used to facilitate input end output

connections to the relay ecenner plug-in card. The plug-in card can easily be

removed through the rear panel of the ecenner mainframe. The Model 7066

provides the connection to the individual channels via the screw clamp type

terminal strips.

1.2 WARRANTY INFORMATION

Warranty information is staled on the inside front cover of the manual. If there is

e need for service, contact the Keithley representative or authorized repair facility

in your area. Check the back cover of this manual for addresses. The service

form supplied at the end of the manual should be used to provide the repair

facility with adequate informoiion concerning any difficulty.

1.3 MANUAL ADDENDUM

Improvements or changes to this manual will be explained on en addendum included with this manual.

1

Page 9

SECTION 2

OPERATION

2.1 lNTROOUCTlON

This section provides information needed to use the Model 7056 with an sppro.

priate scanner mainframe.

2.2 WIRING AND INSTALLATION

1. Wiring Configuration-Each channel on the Model 7066 card consists of 10-Z

Form A relays and 2-1 Form A relays for one pole mode. The card ten be

wired es e voltage scanner card, independent relay card, or e matrix card.

Channel 1, on the component designation. shows the terminal locations

which are similar to Channels 1 through 6. Channel 10 shows the terminal

locations typical for Channels 5 through 10.

A. Voltage Scanner Card-The Model 7056 can be used as a voltage scanner

card. Figure 1 shows e wpical channel in the voltage scenner mode. When

the Model 7056 card is used in e Model 705 scenner mainframe, one of 10

channels can be switched to the output et 8 time. When ecanning, the

relay contract8 of one channel will break before the relay confactS on e

second channel will make, ensuring isolation between channels.

B. Independent Relay Card-The Model 7066 plug-in card can be used es an

independent relay card. The relay switching 18 still controlled by the scanner mainframe. When using the circuit, do not exceed the maximum contact ratings.

C. Matrix Card-The Model 7066 ten be used 88 e 1 by 10 or a 2 by 6 matrix

card. The Model 7056 should be first set up 88 e voltage scanner card. To

use it es e 1 by 10 matrix card, the output HI or output LO can be used to

switch to any of the 10 input HIS or input LOS. For “88 88 e 2 by 6 matrix

card, refer to Figure 2. This allows the ueer to switch the output HI or output LO to sny of five inputs. Figure 2 shows the 2 by 5 matrix setup.

2. Installation-Refer to the Model 706 Instruction Msnual for installsdon instructions.

TO OTHER CHANNELS

Figure 1. Typical Chennel, Voltage Scanner Mode

3

Page 10

LO

OUTPUT

HI

CH.1

CHl LO

k-4

I \ F”1

-iy2 <

-Ii+, (

c

r---t

i-i-c”0 (

I \ F”C

“...”

CM5 LO

WI.7

CH7 LO

c

CM.2 HI

CM.4 LO

CH.0 HI

WI.6 HI

\ F”o.

rl

Figure 2. 2 by 6 Matrix

Page 11

2.3 OPERATING CONSIDERP,TIDNS

1. Signal Levels-The signal levels that the Model 7056 operates et are 1OV

115OV maximum~/lOmA 1250mA maximum). The load should only be

resistive, and 1OVA is the maximum switching level with a resistive load. The

contact life of the relays with normal signal levels is l~closures. At maximum

signal levels, the number of closures is degraded by a factor of 10.

NOTE

Reactances in the system will cause switching transient% during

switching. These transients should not exceed the ratings given.

If they do, the transients can degrade the relay contact life.

2. External Considerations-The Model 7056 specifications ere for a resistive

load; however, external circuit capacitances and inductances ten cow% excessive cur~%nt% and voltages across the relay contacts The currents and

voltages must be limited to within the contact ratings.

A. Capacitance-Charged capacitances in the circuit ten cease excessive

currents isurge current4 to flow through the relay contects, if the SOWC%

is shorted out or the output is switched to capacitive loads. This excessive

current can weld the relay contacts together. Therefore, use series

resistors where needed to limit the maximum current that can flow, to

within the contact ratings. For example. a DC power supply specification

mey indicate that the output current is limited to lOmA. However,

because of internal capacitors connected across the power supply output.

high surge currents can easily flow through the relay contacts. If they are

shorted or when switched to reactive loads lsuch as the input to %

voltmeterl. a surge may result. The surge current can be very high and

may only be a few microseconds in duration, but they can still weld the

relay contacts together. The currents must be limited to within the contact ratings of the relay. The limits are stated in paragraph 2.3.1.

6. Inductance-The inductance of cables can produce high voltage and arc-

ing across the relay contacts when switching. The peak transients must be

limited to within the contact ratings. The limit% 81% stated in paragraph

2.3.1.

C. Cables-Shielded cables should be used with the Model 7066 card when

switching above 5OV. The shield should be connected to the circuit LO or

Guard. This helps prevent excessive rod&ion from the cables from interfering with any equipment.

0. I-Pole Configuration-The Model 705 ten be used in the l-pole configura-

tion by utilizing front panel program number 6 on the Model 705 mainframe. Refer to the Model 705 instruction manuel for information concern-

ing the front panel programs. Generally, the l-pole configuration is used

for applications where a user can use % single common ground in the

meesurement. The channel numbering for the l-pole configuration ie

shown in Figure 3. The l-pole output is taken from the IP connector to

ground on the Model 7056.

Page 12

Flgure 3. I-Pole Mode Channel Numbering

6

Page 13

SECTION 3

SERVICING INFORMATION

3.1 lNTROOUCTlON

The following section contains 8 performance procedure. Since there are no

calibration adjustments, no recslibrotion is necessary. Recommended

maintenance would include inspection of the scanner plug-in board and card

edge connector to ensure good electrical contact.

3.2 REQUIRED TEST EQUIPMENT

Recommended test equipment is given in Table 1. Test equipment other than

recommended may be substituted if specifications equal or exceed the stated

characteristics.

Table 1. Recommended Test Equipment

Minimum Specifications

Zero drifi’less than .$N.

IV Full Scale Sensitivity

TTL compatible square

wave to 10Hz. and 1 pulse

Accessory Triax Cable

per 30 minutes.

Triggered Sweep

lOgA Sensitivitv

Triaxial with cl(p leads.

IOVDd, 1OOVDC ! “K; 1 %’

KI

TEK 7000 seril

KI 619or61

I I

705

3.3 PERFORMANCE VERIFICATION

This section gives the procedures needed to verify that the operation of the

Model 7056 is within spocificntions. For the following tests, the Model 7066

should be set up in the voltago scanning mode,

NOTE

The following test procedure is used for the Model 7066 card

when used in the Model 705 scanner mainframe.

1. Thermal Offset Test

A. Figure 4 shows the test setup for the ttwmal offset test. The Model 177

should be set to DCV and the 2OmV range. The Model 177 should be

allowed to stabilize for two hours. During this time the analog output

should be connected to the chart recordor and a recording made to

establish a baseline for the voltage measurements.

B The 10 input connections on the Model 7056 plug-in card should be

shorted together between HI and LO with a length of #14 to #22 AWG

solid copper wire, i.e.. 811 20 screws should be tied together. With a cable

attached to ths output, the plug-in card should then be inserted into the

7

Page 14

Model 705 mainframe and power applied to the Inainfram? Conn@ct the

cable from the Model 7056 outfxn to the input of the Model 177.

C. After the warm.up time has elapsed and a stable baseline is visible on the

chart recorder. set the Model 705 scanner mainframe’s interval time to 16

minutes. Also set the Model 705 to the Channel mode and the Step mode.

Scan each channel at the programmed interval rata (15 minutes). This is

accomplished by pressing the START/STOP button on the Model 705

nnce for each channel. Once the START/STOP button is activated for

one channel. the Model 705 closes that channel for the programmed interval rate 115 minutes1 then opens that channel and advances to the next

channel. To scan the next channel press the START/STOP button.

The thermal EMFs generated in each channel will be visible as a deflection

from the baseline on the recording. The maximum deflection should be no

more than f lOO,U from the baseline for any channel, exclusive of switching spikes. The ambient temperature should be kept at 23OC -t 3% for this

test.

MODEL 706/7066

I

COPPER WIRE

SHORTS ON

CHANNELS 1 TO 10

Figure 4. Model 7066 Thermal Offset Test In Model 706

2. Relay Contact Timing Test

A. The 10 input connections and the output should be shorted together be-

tween HI and LO with short pieces of wire, on the Model 7056 card. Do

not connect each channel together; just connect the individual HI and LO

of each channel.

B. Figure 5 shows the equipment setup for this test. Select Channel 1.

8

Page 15

C. The signal generator should be set 10 B 10Hz squorowave output. The

scanner should be selecting the desired channel when the signal

generator’s output is a 1 and all off when the generstor is 0.

0. The oscilloscope should be set to trigger on the signal generator’s output. The oscilloscope should be s@ as follows:

SWEEP: 0.5ms per division.

VERTICAL SENSITIVITY: 5V per division.

TRIGGER: External

E. With the oscilloscope on I + j trigger, the typical time to the first con-

tact la transition from 1OV to OVJ should be 0.3177~ or more. The contacts should settle in less than 2ms.

F. Turn the oscilloscope to (-1 trigger. The typical release time for a 0 to

1OV transition is less than 0.25ms.

G. Test all 10 channels as described in steps A through F.

NOTE

A series resistor lR$l must be used with the power supply output HI,

The resistor should be 1ktI or larger.

SIQNAL

QENERATOR

HI LO

I L

I-

HI LO

TRIQQER “I

INPUT

LO

OSCILLOSCOPE

Figure 5. Model 7066 Timing Test In Model 706

EXTERNAL

COM

TRIQQER

MODEL 706/7066 ; 2

INPUT OUTPUT - z

HI LO

HI I.0

1

CHANNEL

UNDER

TEST

&

Ra

- “’ VOLTAGE

MODEL 230

SUPPLY

Lo 1ov DC

g

Page 16

3. Isolation Tests

Input Isolation Common Mode

A. This test measures the common mode input isolation which is the leakage

resistance between the signal lines and power line ground. Figure 6 shows

the test setup for this test.

8. Short the output HI and LO connections together on the Model 7056 with

a short piece of wire.

C. Set up the test circuit shown in Figure 6.

0. Insert the Model 7056 into the mainframe and sit the Model 705 to STEP

(see Model 705 Instruction Manualland Channel 1.

E. Set the Model 230 for 1OOV DC and set the electrometer to lO7A range.

F. Program the Model 230 output to operate and take the electrometer out of

the ZERO CHECK position.

G. Take the reading and manually scan from Channel 1 through 10. The

readings for each channel should be less than 1 x lV7A. Using Ohms Law

calculate the input isolation. R = E/I = lOOV/lO-7A = llN1. Due to the

capacitance of the circuit, the offset current may be high until the

capacitance is charged up. Wait until the reading settles out.

MODEL 706,7058

OUTPUT HI LO

10

Figure 6. Model 7066 Isolation Test In Model 706

Page 17

Input 18oletion. Differential (Guarded)

A. This test meawre~ the differential input isolation which is the leakage

resistance between a guarded channel HI and LO. Set up the test circuit

shown in Figure 7.

l3. Set the Model 705 to Channel 1 end the Step mode. Program the Model

230 to output 1OOV. set the electrometer to Amps and take it out of zero

check.

C. Take the reading on the electrometer and manually ?san from Channel 1

through 10. The reading for each channel should be less then 1 x 10-7A.

Using Ohms Law calculate the input isolation R=Ell=lOOV/10~A

= lL%fl. Due to the capacitance of the circuit, the offset current may be

high until the capacitance is charged up. Wait until the readings settle out.

Flgure 7. Differential Input Isolation IGuarded) Test Set Up

Channel Isolation

A. This test measures the channel isolation which is the isolation between

channels. Set up the circuit shown in Figure 8.

i3 Short the HI and LO connections of each channel on the Model 7066.

C. Set the Model 705 to Channel 1 end the Step mode. Program the Model

230 to output 1OOV. set the electrometer to Amps end take it out of Zero

Check. Program Channel 1 es open end the other channels es closed.

D. Tako the reading on the electrometer and manually scan from Channel 1

through 10. The reading for each set of channels should be less then

lo-‘A. Using Ohms Law calculate the channel isolation for each set of

channels. R = E/I = lOOV/lO--7A = l@a. Duo to the capacitance of the circuit the offset current may be high until the capacitance of the circuit is

chargod up. Wait until the readings settle out.

11

Page 18

MODEL

230

POWER

SUPPLY

MODEL 706/7066 MODEL 706/7066

CHANNEL CHANNEL

OUTPUT OUTPUT

UNDER UNDER

c%l c%l

HI HI LO GUARD HI LO LO GUARD HI LO

I I

12

Figure 8. Channel Isolation Test Set Up

Page 19

SECTION 4

REPLACEABLE PARTS

4.1 INTRODUCTION

This eectlon conteln~ replacement ports information, e schematic diagram and e

component layout for the Model 7056.

4.2 REPLACEABLE PARTS

Porte ore listed alpha-numerically in order of their circuit dealgnstlon. Table 3

contains ports list information for the Model 7056.

4.3 ORDERING INFORMATION

To place en order, or to obtain information concerning replacement perte, contact your Keithley representative or the factory. See the inside front cover for addresses. When ordering include the following information:

1, Instrument Model Number

2. Instrument Serial Number

3. Part Description

4. Circuit Description lif applicable~

5. Keithley Part Number

4.4 FACTORY SERVICE

If the instrument is to be returned to the factan/ for service, please complete the

service form which follows this section and return it with the instrument.

4.6 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM

Figure 9 contains e component layout for the Model 7065, and Figure 10 contains the component layout for the Model 7056. A schematic diagram of the

General Purpose Scanner Cord is contained in Figure 11.

13

Page 20

Table 2. Model 7055 Replaceable Paris

ClrCUit

b3ig.

Description

Handle

Rivet

iooi

J1002

HO03

Connector

Connector

Connector

Ji 004 Connector

J1005

PI006

Connector

Connector, Male (mates for CS-455)

#2-56 x 706 Phillips Pan Head Screw

#2-56 Hex Nuts

Clamp Assembly, Upper

a. Clamp, Upper

b. Strip, Rubber

Clamp Assembly, Lower

a. Clamp, Lower

b. Strip Rubber

#6-32 x 5/i 6 Phillips Pan Head Screw

#6-32x 1 Phillips Pan Head SCI’eW

Table 3. Model 7056 Replaceable Parts

Keithley

Part No.

FA-119

FA-121

cs-457-l

CS-457-2

cs-457-l

CS-457.2

CS-457-2

CS-456

7055-303-l

7055305

26621

7055-306

7055-307

26621

Circuit

Deslg. Description

Cl01

Capacitor, IOpF, 25V, Aluminum Electrolytic C-314-10

JlOO6 Connector, Female

#B-56 y 7/16 Phillips Pan Head Screw

#2-56 Hex Nuts

KlOl- Relay

K112

interconnect Board

14

Kelthley

Part No.

cs-455

RL-I 30

7055

Page 21

Figure 9. Model 7099 Component Localon Drawing

,9

Page 22

18

Figure 10. Model 7066 Component Location Drawing

Page 23

Page 24

Page 25

Loading...

Loading...