Page 1

Instruction Manual

Model 705 Scanner

Contains Operating and Servicing Information

705-001-01 Rev. F/ 4-00

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free frqm defects in material and workmanship for a period of I year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIE

S, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY LNSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC.. HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSO.N, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. l 28775 Aurora Road l Cleveland, OH 44139 l m-248-0400 l Fax: 440-248-6168 l http://www.keithley.com

BELGIUM:

CHINA

FRANCE:

GERMANY:

GREAT BRITAIN:

[NIXA:

ITALY:

NETHEHLANDS:

SWITZERLAND:

TAIWAN:

Keittdey lnshuments B.V.

Keitbley Instruments China Yuan Chen Xin Building. Room 705 * 12Yumin Road. Dew& Madian * Beijing loo029 * 8610-62022886 *Fax: 8610.62022892

Keithley Instruments Sari

Keithley Instruments GmbH

Keitbley Instruments Ltd

Keithley Instruments GmbH

Keitbley Instruments s.r.1.

Keithley Instruments B.V.

Keithley instruments SA

Keithley Instruments Taiwan

Bargensesteenweg 709 l B-1600 Sint-Pieters-Leeuw l OZ363 00 JO l Fax 02/363 00 64

B.P. 60 l 3. all&e des Ganys * 91122 Palaisuu CSdex l 01 64 53 20 20 * Fax: 01 60 1 I 77 26

Landsberg.% Stnsse 65. D-821 IO ‘&rowing l 089/g-193 07-40 * Fax: 089/8J 93 07-34

The Minster l 58 Portman Road * Reading. Berkshire RG30 I EA * 0118-9 57 56 66. Fax: 01 IS-9 59 6-l 69

Rat 2B. WILGCRISSA l 14, Rest House Crescent l Bangalore 560 001 l 91sSC-509-1320~21 l Fax: 91-80-509-1322

Viale S. Gimignano, 38 l 2OlJ6 Milano l CY2/48 30 30 08 . Fax: 02/48 30 22 74

Postbus 559 l 4200 AN Gorinchrm l 0183-635333 s Far;: 0183-630821

Kriesbachstrasse~. 8M)o Diibendorf. 01-821 94 J4 l Fax: 01-820 30 91

I Fl. 8.5 PO Ai Street * Hsinchu. Taiwan, R.O.C. * 886-3573-9077 * Fax 886-3572-903

10/99

Page 3

Model 705 Scanner

Instruction Manual

01982, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Sixth Printing, April 2000

Document Number: 705-901-01 Rev. F

Page 4

SPECIFICATIONS

CAPACITY: Two plug-in cards per mainframe.

EXPANSION CAPACITY: Daisy chain allows up to 4 SLAVE units with 1

MASTER unit.

SWITCHING RATE: 100 channels/second IlOms), programmable to 1

channel/l6 minutes 1999.999s).

RELAY DRIVE: 350mA minimum.

INTERNAL CLOCK: Displays hours/minutes/seconds or date/month; less

than 1 minute/month error (typical).

BATTERY BACKUP: Rechargeable 3.6V nickel-cadmium. 1 month reten-

tion of data (typical) with unit turned off.

IEEE-488 BUS IMPLEMENTATION

Multiline Commands: DCL, LLO, SDC, GET, GTL, UNT, UNL, SPE, SPD.

Uniline Commands: IFC, REN, EOI, SRQ, ATN.

Interface Functions: SHl, AHl, T6, TEO, L4, LEO, SRI, RLI, PPO, DCl,

DTI, CO, El.

Programmable Parameters: Display Mode, Output Format, EOI, SRQ,

First, Last, Open, Close, Display Channel, Alternate Output, Pole Mode,

Date Format, Save/Restore, Reset, l/O Port, Time, Date, Settling Time,

Interval Time, Alarm Time, Program Mode, Trigger Mode, Terminator, Self

Test.

Digital I/O Port: A separate I/O port consisting of eight input and eight out-

put lines as well as common (IEEE-488) and +SVDC. Outputs will drive

one TTL load. Inputs represent one TTL load. Mating connector supplied.

FRONT PANEL PROGRAMS

0 - Digital I/O

I* - Date Format

2’ -Settle Time

3” - IEEE Address

4* -Save Setup

5* - Restore Setup

6* - Poles

7 -Alarm Time

8 - Self Test

%I* - Stand Alone

91’ - Master

92’ - Slave

99 -Reset

*Battery backed up.

Read or change state on digital I/O port.

Changes date display between MM.DD and

DD.MM.

Time to output CHANNEL READY pulse after

closing relay.

Set bus address; cannot be programmed from bus.

Stores present relay setup in numbered (I - 5)

buffer.

Recalls relay setup in buffer 1 - 5.

1, 2 or 4-pole configuration for switching.

Set time for Alarm output pulse; repeats daily.

Check RAM, ROM, LEDs.

Single 705 configuration.

Daisy chain configuration.

Daisy chain configuration.

Reset battery backup parameters to factory values.

GENERAL

DISPLAY: Six 0.5” LED digits with decimal point, function and IEEE status

annunciators.

OPERATING ENVIRONMENT: O” to 50°C, 0% to 80% relative humidity

up to 35oc.

STORAGE ENVIRONMENT: -25O to 65°C.

CONNECTORS: Four BNC; External Trigger, Alarm Out/Serial-In, Channel

Ready, Serial Out (TTL compatible).

POWER: 105-125V or 210-250V (internal switch selected), 5OHz to4OOHz.25

V*A maximum. 90-IIOV and 180.220V version available.

DIMENSIONS, WEIGHT: 127mm high x 216mm wide x 359mm deep (5”

x 8%” x 14%“). Net weight 3kg (6% lbs.).

ACCESSORIES AVAILABLE:

Model 1019A: 5%” Universal Fixed Rack Mounting Kit

Model 1019s: 5%” Universal Slide Rack Mounting Kit

Model 4801:

Model 7008-3:

Model 7008-6: IEEE-488 Cable, 1.8m (6 ft.)

Model 7010:

Model 7024-3: Triaxial Cable, 0.9m (3 ft.)

Model 7024-10:Triaxial Cable, 3.0m (IO ft.)

Model 7055:

Model 7056:

Model 7057:

Model 7058:

Model 7059:

BNC-to-BNC Cable

IEEE-488 Cable, 0.9m I3 ft.)

IEEE-488 Adapter for Model 85 Computer

Quick Disconnect Card

General Purpose Scanner Card

Thermocouple Scanner Card

Low Current Scanner Card

Low Voltage Scanner Card

Specifications subject to change without notice.

SPECIFICATION ADDENDUM

1. Batten/ back-up time is for unit at 23OC. Operation or storage at higher

temperatures could reduce this time below 1 month. Even under extremes

a fully charged system should last a week.

2. Note that some plug-in card specifications may limit mainframe performance when installed (e.g. Humidity).

3. Relay drive capability at 400Hz is limited to 200mA typical and a maximum ambient temperature of 35OC.

Page 5

Table of Contents

1

2

General Information

Introduction.

Features

Warranty Information

Manual Addenda

Safety Symbols and Tenns..

Unpacking and Inspection

Specifications..

Accessories..

Repacking for Shipment

........................................................................................................................................................

................................................................................................................................................................

..........................................................................................................................................

.................................................................................................................................................

................................................................................................................................ l-1

...................................................................................................................................

....................................................................................................................................................

.................................................................................................................................................

.

.

.....

......................................................................................................................................

Operation

Introduction

Preparation for Use

Correct Line Voltage.

Plug-In Card (Scanner)

Power-up

Environmental Conditions

Operating Instructions

Front Panel Controls

Rear Panel Description

Basic Front Panel Operation

Front Panel

Program 0 Digital I/O

Program 1 Date Format

Program 2

Program 3 Primary Address..

Program 4

Program 5

Program 6 Pole Modes..

......................................................................................................................................................... 2-1

.............................................................................................................................................

..................................................................................................................................

Installation ............................................................................................................ 2- 1

...................................................................................................................................................... 2-l

.......

Programs..

Settle

Save

Recall

Program 7

Program 8 Self Test

Program 90 Stand Alone..

Program 9 1 Master.. ..................................................................................................................................

Program 92 Slave

Program 99 Reset..

Set

..................................................................................................................................

.........................................................................................................................................

...................................................................................................................................

................................................................................................................................

.......................................................................

................................................

..............

Time

Present

Stored

Alarm Time

......................................................................................................................................

........................................................................................................................ 2-13

....................................................................................................................

..........

,

.............................................................................................................................

..............................................................................................................................

....................................................................................................................

Relay

Set Up..

Relay

Set

............................................................................................................................

.......................................................................................................................

...................................................................................................................................

.........................................................................................................................

....................................................................................................................................

....................................................................................................

Up.. ................................................................................................... 2- 15

l-l

1-l

1-l

l-1

l-l

l-1

1-I

l-2

2-1

2-1

2-3

2-3

2-3

2-5

2-7

2-13

2-13

2- 1-l

2-14

2- 15

2-16

2-17

2-18

2-18

2- 18

2-19

2- 19

Page 6

3

IEEE Bus Operation

Introduction .........................................................................................................................................................

Soltwarc Considcrstions ..............................................................................................................................

HP-85 BASIC Statements

Interface Function Codes .............................................................................................................................

Model 705 Interface Commands..

IEEE-388 Bus Lines ............................................................................................................................................

Bus Management Lines.. .............................................................................................................................

Handshake

Data Lines.. ..................................................................................................................................................

System Set up Procedure.. ...................................................................................................................................

Bus Commands ....................................................................................................................................................

Uniline Commands.. ....................................................................................................................................

Universal Commands ..................................................................................................................................

Addressed Commands..

Device-Dependent Commands

Display Mode

Program (Scan) hlode.. ..............................................................................................................................

Prefix

EOI

Bus Response hlodc (SRQ I

Trigger Modes

Programmable Terminator I Y).

Inputs

Status Byte Format

Status Word (UO).

Front Panel Programs

Front Panel Error Messages

IDDC Error

No Remote Error..

Scanning Program

Lines

.........................................................................................................................................

..............................................................................................................................................

.........................................................................................................................................................

............................................................................................................................................................

..........................................................................................................................................

.........................................................................................................................................................

............................................................................................................................................ 3-23

.............................................................................................................................................

........................................................................................................................................

................

.............................................................................................................................................

........................................................................................................................... .3- I

...............................................................................................................

....................

................................... .........................................................................................

.......................................................................................................................

...............................................................................................................................

................................................................................................................................

.....................................................................................................................................

. . .........................................................................................................

.................................................................................................................

3-I

3- !

3-2

i-.3

.3-?

3-3

3-J

.3-J

3-4

j-5

.3-5

3-6

3-7

3-8

1-8

-

3- 12

3-12

.

3-12

.?- 13

3-35

.

3-15

i-15

-

3-23

.

3.24

_

3-24

.

1-25

.

3-25

.

3-25

-

5

Theory of Operation

Introduction

Power Supply..

Microcomputer

Display Circuit..

IEEE-488 Interface Circuitry

.........................................................................................................................................................

.....................................................................................................................................................

....................................................................................................................................................

...................................................................................................................................................

..............................................................................................................................

Maintenance

Introduction

Fuse Replacement

Lint Voltage Selection

Disassembly ............................................................................................................

Troubleshooting.. .................................................................................................................................................

Digital Self Test..

Battery Charge .....................................................................................................................................................

...................... ...................................................................................................................................

.................................................................................................................................................

........................................................................................................................................

:

............................................

.............................................................

....................................................................................

4- I

4 I

4- I

4-3

4-3

5-l

-

4-I

S-l

5-1

5-3

5-3

_

5-3

Page 7

Replaceable Parts

Introduction.. .......................................................................................................................................................

Parts List .............................................................................................................................................................

Ordering In~orniation .......................................................................................................................................... h- I

Factory Service.. .................................................................................................................................................. 6- I

Schematic Diagrams and Component Location Drawings ................................................................................. 6- I

h-l

6-I

III

Page 8

List of Illustrations

2

Figure 2- 1

Figure 2-2

Figure 2-3

3

Figure 3- 1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Operation

Scanner Card Installation

Model 705 Front and Rear

Daisy Chaining Three Model

............................................................................................................................

Panels.. .............................................................................................................

705’s.. ..........................................................................................................

IEEE Bus Operation

Bus Structure.... .

Handshake Sequence...

Contact Assignment .

Model 705 IEEE Bus

Digital I/O Port Pin Assignments..

LJ and G Modes Sequence . . . . . . . . .

Status B) te Format . . . . . . . . . . . . . . . . . . .

U4 Status Word (Reset conditions shown) . . .

IEEE Display Error Messages . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~..................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Theory of Operation

Figure 4-l

Figure 4-2

Model 705 Block Diagram

Memory Map

...............................................................................................................................................

..........................................................................................................................

. . . . . . . . 3-3

. . . ..I. 3-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7

i 2-6

2-9

3-5

_

3-5

1-19

3-23

7-23

1-24

3-25

4-2

4-l

5

Figure 5- 1

6

Figure 6- 1

Figure 6-2

Figure 6-3

Figure 6-4

Figure 6-5

Figure 6-6

Figure 6-7

Figure 6-8

Maintenance

Model 705 Exploded View

,,.................,.,......,............................................................................................

Replaceable Parts

Interconnect Board, Component Location Drawing, Dwg. No. 705- 160..

Display Board, Component Location Drawin,.

I/O Board, Component Location Drawing, Dwg. No. 705-173

Mother Board. Component Location Drawing, Dwg. No. 705-100

Mother Board,

Display Board, Schematic Diagram, Dwg. No. 705-I 16

I/O Board, Schematic Diagram, Dwg. No. 705-176

Interconnect Board, Schematic Diagram, Dwg. No. 705- 166

Schetnatic Diagram, Dwg.

u Dwg. No. 705-I 10

No, 7OS- 106..

.........................................................................

..........................................................................

.................................................................................

...........................................................

................................................................

.........................................................

..................................................................

.................................................

5-2

6-7

6-9

6-11

6-13

6- 17

6-23

6-25

6-27

Page 9

List of Tables

2

Table 2-l

Table 2-2

Table 2-3

Table 2-4

Table 2-S

3

Table I- 1

Table i-2

Table 3-3

Table i-4

Table 3-5

Table 3-6

Table 3-7

Table 3-8

Table 3-9

Table 3-10

5

Table 5-l

Table 5-2

Table 5-3

Operation

Line Voltage Setting

Power Up Default Conditions (Front

Summary of Front Panel Programs

Switchins Card Pole Modes

Program 99 Reset Conditions

...................................................................................................................................

Panel Operation). .............................................................................

...........................................................................................................

......................................................................................................................

...................................................................................................................

IEEE Bus Operation

HP-85 IEEE-488 BASIC Statements..

Model 705 Interface Function

IEEE Command Groups.. ............................................................................................................................

IEEE Bus Connector Contact

Power-Up Default Values

SDC Set Conditions

Device-Dependent Comtnands

Hierarchy of Command Execution

SRQ Commands and Conditions

Digital I/O Port Contact Pin Assignments.

.............

Codes.. ........................................................................................................

Designations.. ..............................................................................................

............................................................................................................................

.......................................................................................................................

........................................................................................................

...................................................................................................................

............................................................................................................

....................................................................................................

..........

...............................................................................................

Maintenance

Fuse Replacement. 3AG size..

Fuse Replacement. 5mm size..

Line Voltage Selection..

....................................................................................................................

....................................................................................................................

..............................................................................................................................

2- I

2-3

2- I.3

2- 16

2-20

3-2

3-3

3-3

3-5

1-6

1-7

-

3-9

_

Z-10

3-13

-

3-20

5- I

5-I

5-I

6

Table 6- 1

Table 6-2

Table 6-3

Table 6-4

Table 6-5

Replaceable Parts

Index of ~Modcl 705 Schematics and Component Layouts..

Display Board 705-I IO. Parts List..

Mother Board 705- 103. Parts

Digital I/O Board 705 173. Parts List..

k/lode1 705 Mechanical Parts List

............................................................................................................

List.. .............................................................................................................

.......................................................................................................

...............................................................................................................

.......................................................................

6- 1

6-2

6-3

6-5

6-6

vii

Page 10

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 705 is a low cost IEEE compatible scanner. The

basic mainframe can accomodate two plug-in scanner cards.

Each card can have different pole configurations. In the l-pole

configuration the card has 20 channels, The 4-pole configuration allows 10 channels with two cards (for four-wire ohms).

Using the “daisy chain” method the Model 705, along with

four additional Model 705’s, can provide up to 100 2-pole

channels. The time and the date are kept internally with a battery backed up clock allowing time dependent procedures to

be performed,

The controls on the front panel allow opening a selected channel, closing the channel, scanning between a selectable first

and last channel, selectable scan rate and mode. There are 13

internal programs that are accessible from the front panel. The

programs can select primary address, dwell time, store a relay

set up, recall the stored relay set up, control the digital l/O

port, switch from International to American date format, control interval stop/start and select I-, 2- or 4 pole measurement

modes.

The Model 705 Scanner adheres to standard IEEE-488 interface bus protocol. This enables the Model 705 to be incorporated into any measurement system that uses programmed

control through the IEEE-488 bus.

1.2 FEATURES

The Model 705 Scanner includes the following features:

*IEEE-488 bus operation.

*Selectable scan rate from IOms to 999.999sec.

*Selectable scan modes that allow the operator to scan the

first channel to the last channel once, continuously or

manually.

*Thirteen internal programs that are available through the front

panel.

*Model 705 mainframe can accomodate two scanner plug-in

cards.

aSeveral different scanner relay cards are available as options.

They include: a general purpose relay card; a thermocouple

relay card; a low voltage relay card; and a low current relay

card.

*Time and date are kept with a battery backed up clock.

*Digital I/O port with eight lines as inputs and eight lines as

outputs.

1.3 WARRANTY INFORMATION

Warranty information is provided on the inside front cover of

this manual. If there is a need to exercise the warranty, contact

the Keithley representative in your area to determine the proper

action to be taken. Keithley maintains complete repair and

calibration facilities in the United States, West Germany, Great

Britain, France, the Netherlands, Switzerland and Austria. Information concerning the application, operation or service of

your instrument may be directed to the applications engineer at

any of the above locations. Check the inside front cover of this

manual for addresses.

l’.4 MANUAL ADDENDA

Improvements or changes to this manual will be explained on

an addendum included with this manual,

1.5 SAFETY SYMBOLS AND TERMS

Safety symbols used in this manual are as follows:

A

The symbol

should refer to the operating instructions.

The symbol

more may be present on the terminal(s).

The WARNING used in this manual explains dangers that

could result in personal injury or death.

The CAUTION used in this manual explains hazards that

could damage the instrument.

1.6 UNPACKING AND INSPECTION

The Model 705 is inspected both mechanically and electrically

before shipment. Upon receiving the Model 705 unpack all

items from the shipping container and check for any obvious

damage that may have occurred during transit. Report any

damage to the shipping agent. Retain and use the original

packaging materials if reshipment is necessary. The following

items are shipped with all Model 705 orders:

*Model 705 Scanner

*Model 705 Instruction Manual

*Optional accessories per request.

1.7 SPECIFICATIONS

For Model 705 detailed specifications, refer to the specifications that precede this section.

1.8 ACCESSORIES

Model 1019A Rack Mounting Kit-The Model 1019A rack’

mounting kit can accomodate one or two Model 705’s. The’

dimensions are 133mm x 483mm (5% x 19in).

Model 1019s Slide Rack Mounting Kit-Enables one or

two half rack size instruments to be rack mounted with the

added feature of sliding the instrument(s) for easy access.

The dimensions are 133mm x 483mm (5% x Igin.).

on the instrument denotes that the user

on the instrument denotes that IOOOV or

/v

l-l

Page 11

Model 7055 Quick Disconnect Card-The Model 7055 is

an integral part of the Model 7056 General Purpose Scanner

Card. The Model 7055 is the section of the Model 7056 that

provides the input and output connections. Several Model

7055s can be prewired for particular applications, When that

particular application is required the present Model 7055 can

be replaced with another Model 7055.

Model 7056 General Purpose Scanner Plug-In Card-The

Model 7056 is field installable in the Model 705 Scanner mainframe. The general purpose card will switch up to 10 2-pole

channels. The card can be used as a voltage scanner, independent relay card or a matrix card. The 2-pole switching is accomplished in less than 10ms and the expected relay life is 106

closures at the maximum contact ratings. Barrier strips are

used to facilitate input and output connections to the relay

scanner plug-in card. The plug-in card can be easily removed

through the rear panel of the Model 705.

Model 7057 Thermocouple Scanner Plug-In Card-The

Model 7057 is a low voltage scanner card which is field installable in the Model 705 scanner mainframe. Since it combines

the functions of a thermocouple scanner and uniform temperature reference it is especially useful for scanning thermocouples. The input terminals are #I10 alloy-copper set in an

isothermal block to minimize temperature differences. A thermistor sensor within the isothermal block is used with a bridge

network on a Model 7057 to give an indication of the

temperature reference or cold junction. The temperature of the

heat sink is used to calculate the corrected thermocouple output. The output voltages of each thermocouple must be con-

verted to temperature (OC or OF) using appropriate thermo-

couple tables or polynomial equations. In addition any channel

may be used to monitor low level signals. The Model 7057

uses two form A contacts for scanning of signals up to 35V

peak or 100mA peak. Input and output connections are made

through the rear panel of the scanner mainframe using #4

screw terminals on the Model 7057.

Model 7058 Low Current Scanner Plug-In Card-The

Model 7058 is field installable in the Model 705 Scanner Main-

frame. The low current card will switch up to 10 l-pole chan-

nels. For optimum low level current switching, the Model 7058

is designed to minimize offset current error (less than I pAI,

while guarding ensures that high isolation is maintained between input signals. The break-before-make, single pole

switching of the Model 7058 is designed to maintain current

paths for signals not connected to the output, or when internal

jumpers are removed to provide high input resistance for mak-

ing voltage measurements. AC or DC signals up to 28V or

100mA may be scanned. Triaxial input and output connections

to the scanner plug-in card are easily made through the rear

panel of the Model 705 Scanner mainframe.

Model 7059 Low Voltage Plug-In Card-The Model 7059 is

a low voltage scanner plug-in card which is field installable in

the Model 705 Scanner mainframe. The Model 7059 will

switch up to 10 channels. For low level transducer and thermocouple output switching the Model 7059 is designed to

minimize thermal error voltage (less than 1p.V with respect to

copper) and ensure that high isolation (10X2) is maintained

between input signals. The break-before-make, 2-pole switch-

ing is accomplished in less than 5ms. Expected relay life (108

closures) is obtained when signals less than IOV or less than

10mA are scanned. However, peak signals up to 200V or

IOOmA may be scanned. Barrier strips are used to facilitate input and output connections to the scanner plug-in card. The

Model 7059 is easily removed through the rear panel of the

Model 705 Scanner mainframe.

Model 7008-3 IEEE-488 Cable-The Model 7008-3 is a three

foot (I meter) IEEE-488 cable. The cable has 24 stranded wire

conductors and is terminated with IEEE-488 standard connectors.

Model 7008-6 IEEE-488 Cable-The Model 7008-6 is a six

foot (2 meter) IEEE-488 cable. The cable has 24 stranded wire

conductors and is terminated with IEEE-488 standard connectors.

Model 4801 Low Noise BNC to BNC Cable-The Model

4801 is a low noise BNC-to-BNC cable which is especially

useful for “daisy chain” wiring configurations of multiple

Model 705’s.

Model 7010 Cable Adapter-The Model 7010 is an IEEE-488

cable adapter. The adapter extends the IEEE-488 connector by

one connecter width.

1.9 REPACKING FOR SHIPMENT

The Model 705 should be packed in its original carton. Before

packaging, wrap the instrument in plastic. After it is placed in

the box, surround the instrument with Styrofoam packaging

material.

If the Model 705 is to be returned to Keithley Instruments for

calibration or repair, include the following:

*ATTENTION REPAIR DEPARTMENT on the address label.

*Warranty status of the instrument.

*Completed service form.

1-2

Page 12

SECTION 2

OPERATION

2.1 INTRODUCTION

This section contains information necessary to operate the

Model 705 Scanner. Information is arranged as follows:

*Preparation For Use

*Power-Up

*Environmental Conditions

*Front and Rear Panels Description

*Front Panel Operation

*Front Panel Programs

2.2 PREPARATION FOR USE

2.2.1 Correct Line Voltage

Plug the Model 705 into the proper power receptacle, (See

Table 2-l 1. For fuse replacement or line voltage switch setting,

refer to the maintenance section.

WARNING

Ground the instrument through a properly

earth grounded receptacle before operation.

Failure to ground the instrument can result

in severe injury or death in the event of short

circuit or malfunction.

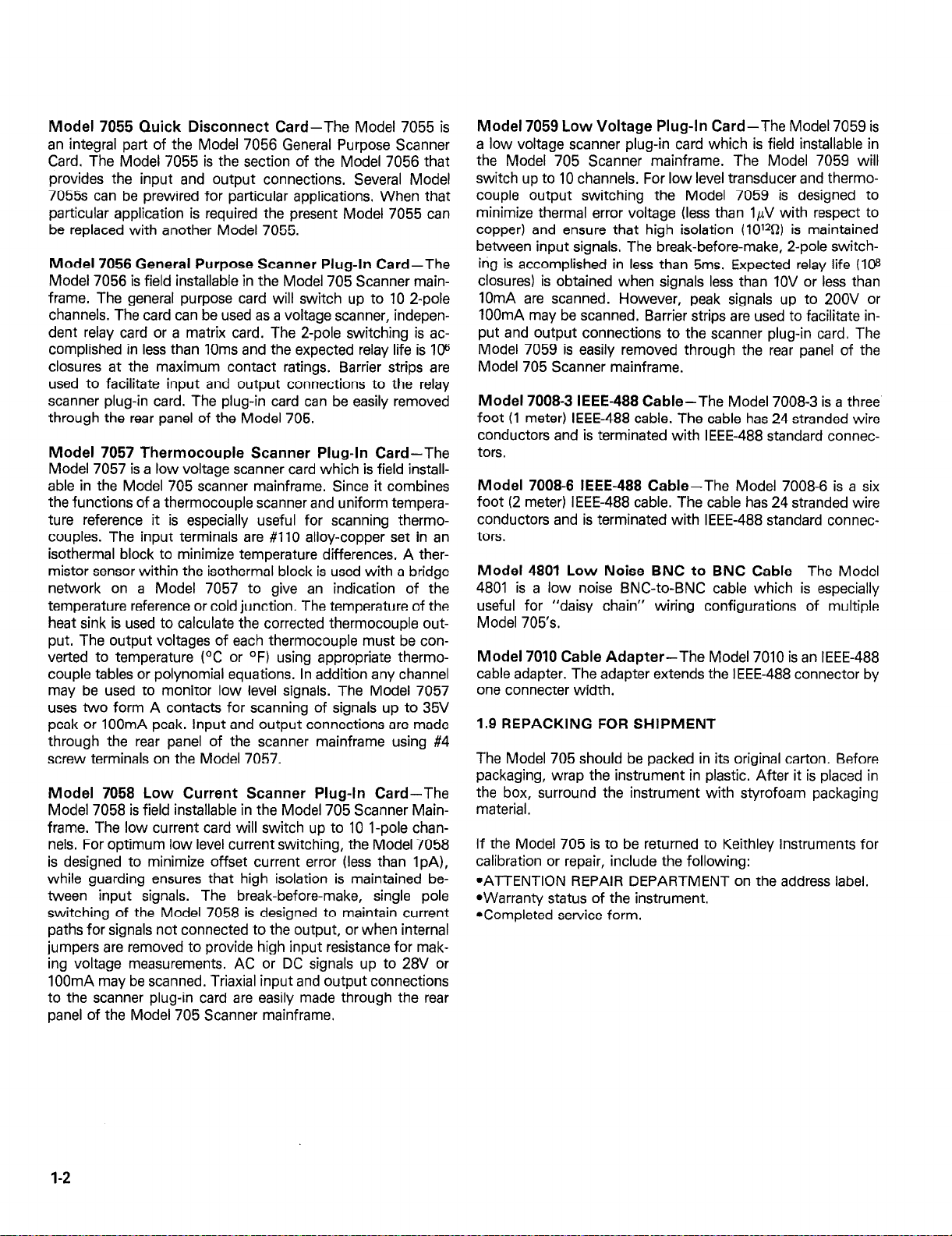

Table 2-1. Line Voltage Setting

on the

shown

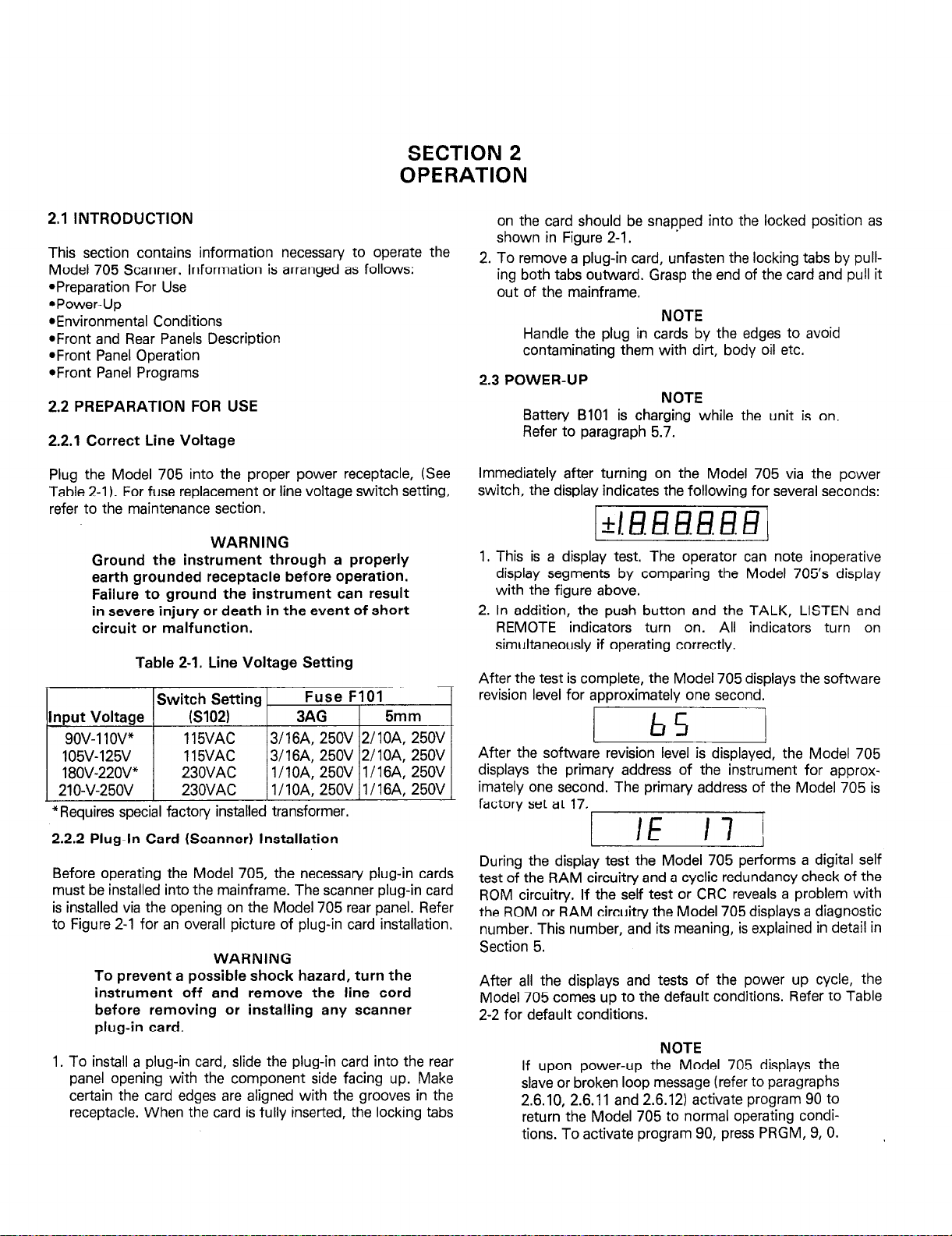

2. To remove a plug-in card, unfasten the locking tabs by pulling both tabs outward. Grasp the end of the card and pull it

out of the mainframe,

2.3 POWER-UP

Immediately after turning on the Model 705 via the power

switch, the display indicates the following for several seconds:

1. This is a display test. The operator can note inoperative

display segments by comparing the Model 705’s display

with the figure above.

2. In addition, the push button and the TALK, LISTEN and

REMOTE indicators turn on. All indicators turn on

simultaneously if operating correctly.

After the test is complete, the Model 705 displays the software

revision level for approximately one second.

card should be snapped into the locked position as

in Figure 2-1. .

NOTE

Handle the plug in cards by the edges to avoid

contaminating them with dirt, body oil etc.

NOTE

Batten/ BIOI is charging while the unit is on.

Refer to paragraph 5.7.

*Requires special factory installed transformer.

2.2.2 Plug-In Card (Scanner) Installation

Before operating the Model 705, the necessary plug-in cards

must be installed into the mainframe. The scanner plug-in card

is installed via the opening on the Model 705 rear panel. Refer

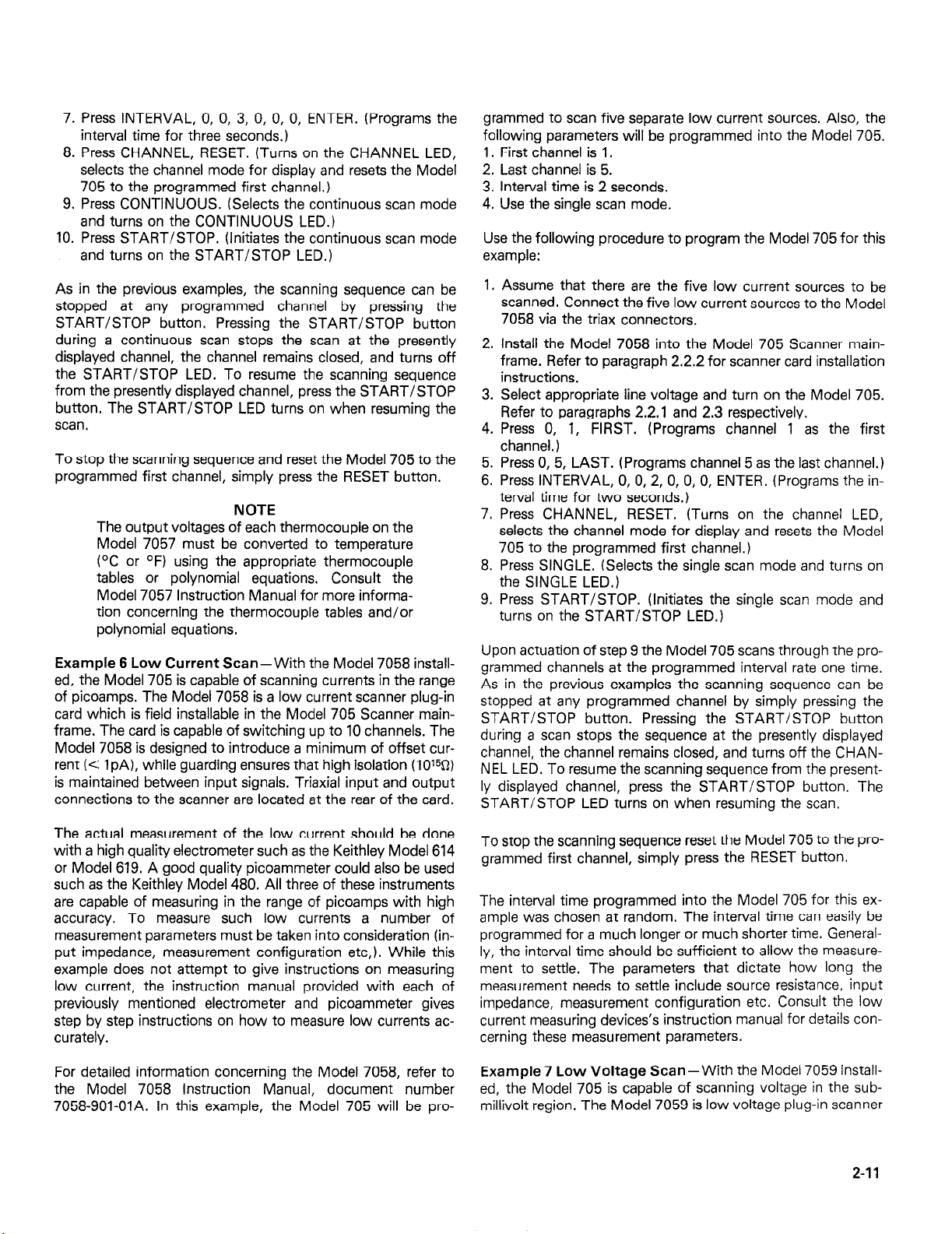

to Figure 2-l for an overall picture of plug-in card installation.

WARNING

To prevent a possible shock hazard, turn the

instrument off and remove the line cord

before removing or installing any scanner

plug-in card.

1. To install a plug-in card, slide the plug-in card into the rear

panel opening with the component side facing up. Make

certain the card edges are aligned with the grooves in the

receptacle. When the card is fully inserted, the locking tabs

After the software revision level is displayed, the Model 705

displays the primary address of the instrument for approximately one second. The primary address of the Model 705 is

factory set at 17.

During the display test the Model 705 performs a digital self

test of the RAM circuitry and a cyclic redundancy check of the

ROM circuitry. If the self test or CRC reveals a problem with

the ROM or RAM circuitry the Model 705 displays a diagnostic

number. This number, and its meaning, is explained in detail in

Section 5.

After all the displays and tests of the power up cycle, the

Model 705 comes up to the default conditions. Refer to Table

2-2 for default conditions.

NOTE

If upon power-up the Model 705 displays the

slave or broken loop message (refer to paragraphs

2.6.10, 2.6.11 and 2.6.12) activate program 90 to

return the Model 705 to normal operating condi-

tions. To activate program 90, press PRGM, 9, 0.

Page 13

-SCANNER CARD

INSTALLED

CARD-

SLOTS

r4x-SCANNER CARD

2-2

Figure 2-l. Scanner Card Installation

Page 14

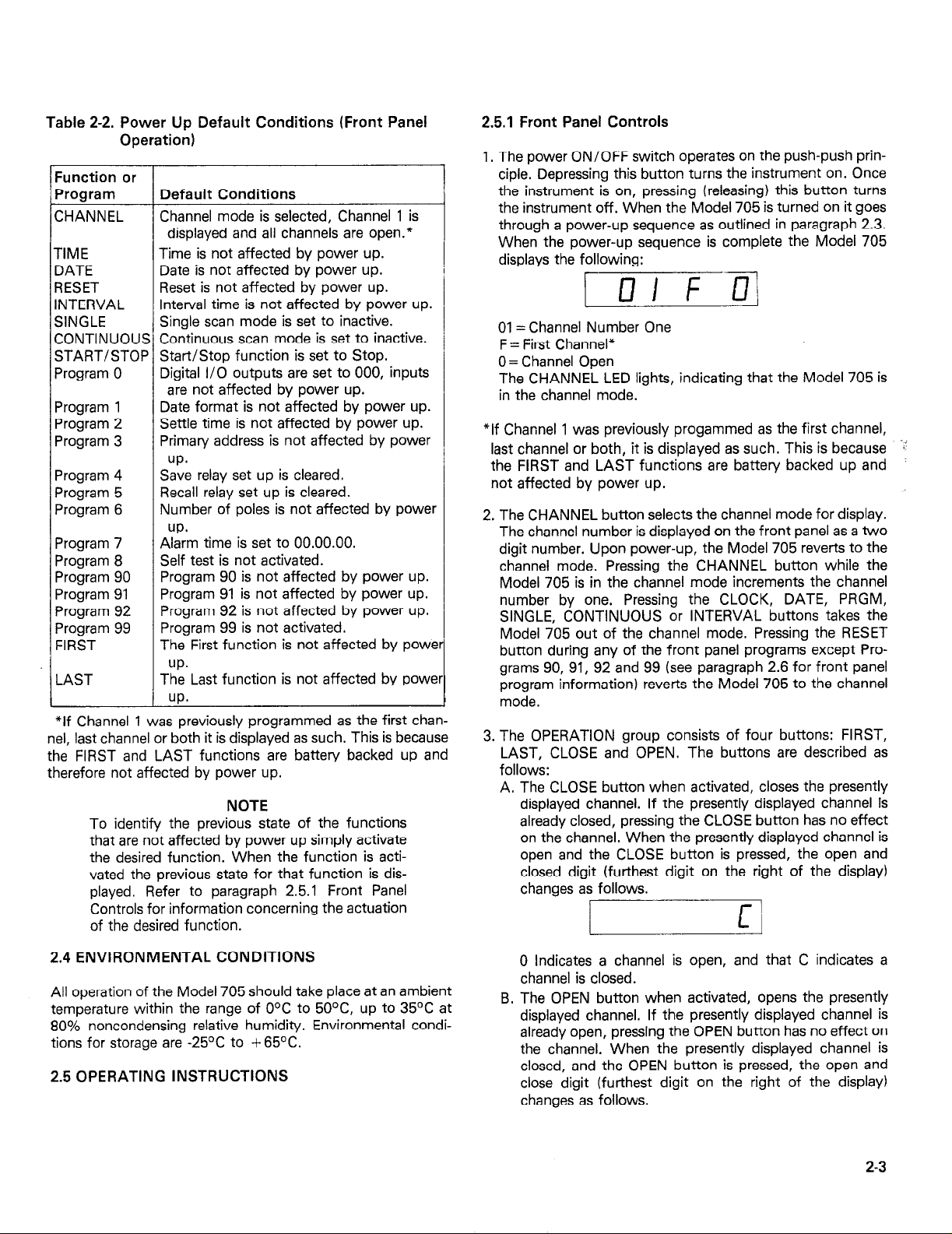

Table 2-2. Power Up Default Conditions (Front Panel

Operation)

Function or

Program Default Conditions

CHANNEL

TIME

DATE

RESET

INTERVAL

SINGLE

CONTINUOUS Continuous scan mode is set to inactive.

START/STOP Start/Stop function is set to Stop.

Program 0

Program 1

Program 2

Program 3

Program 4

Program 5

Program 6

Program 7

Program 8

Program 90

Program 91

Program 92

Program 99

FIRST

LAST

*If Channel 1 was previously programmed as the first channel, last channel or both it is displayed as such. This is because

the FIRST and LAST functions are battery backed up and

therefore not affected by power up.

To identify the previous state of the functions

that are not affected by power up simply activate

the desired function. When the function is activated the previous state for that function is dis-

played. Refer to paragraph 2.5.1 Front Panel

Controls for information concerning the actuation

of the desired function.

Channel mode is selected, Channel 1 is

displayed and all channels are open.*

Time is not affected by power up.

Date is not affected by power up.

Reset is not affected by power up.

Interval time is not affected by power up.

Single scan mode is set to inactive.

Digital I/O outputs are set to 000, inputs

are not affected by power up.

Date format is not affected by power up.

Settle time is not affected by power up.

Primary address is not affected by power

up.

Save relay set up is cleared.

Recall relay set up is cleared.

Number of poles is not affected by power

Ayirrn time is set to 00.00.00.

Self test is not activated.

Program 90 is not affected by power up.

Program 91 is not affected by power up.

Program 92 is not affected by power up.

Program 99 is not activated.

The First function is not affected by powe

up.

The Last function is not affected by powe

up*

NOTE

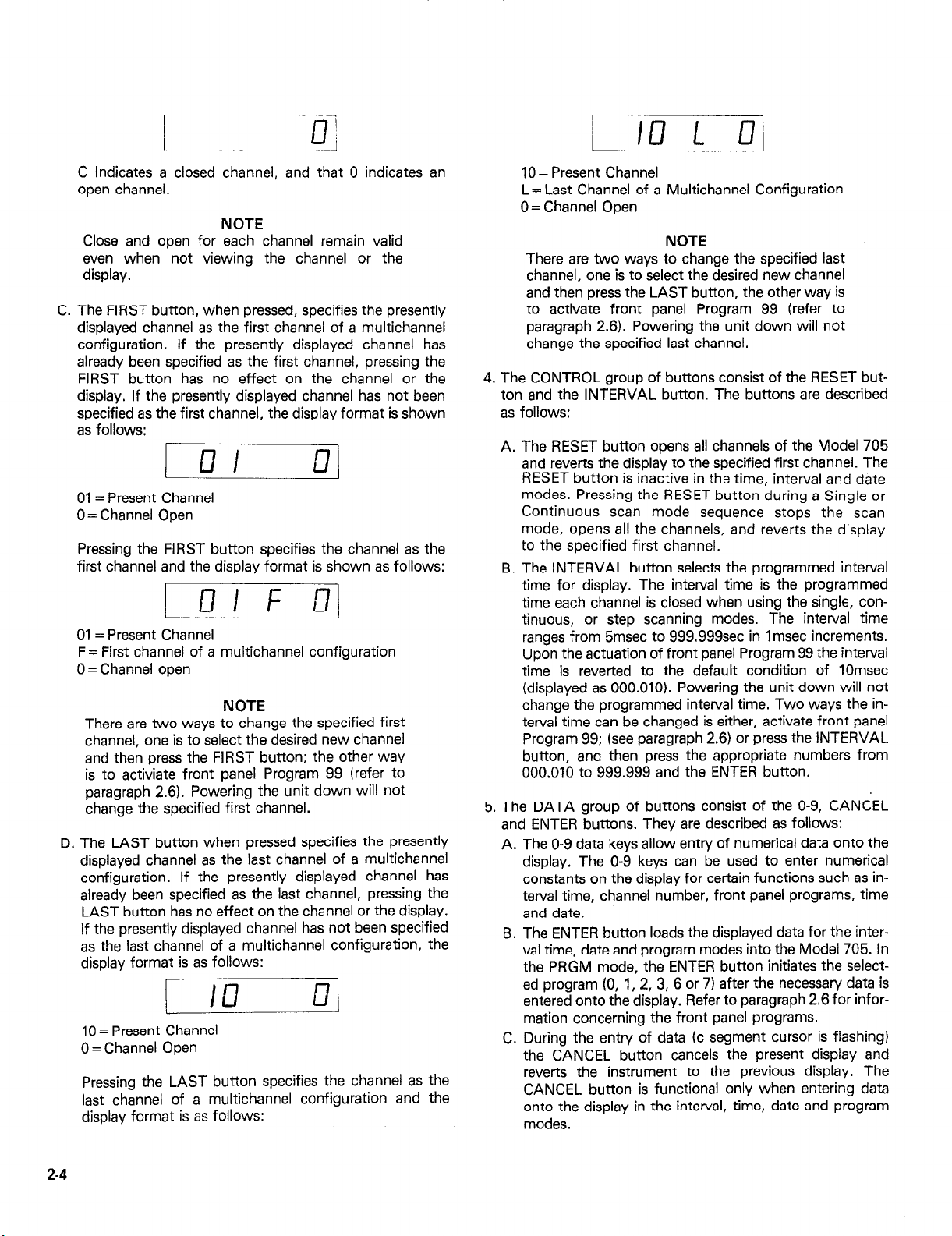

2.5.1 Front Panel Controls

1, The power ON/OFF switch operates on the push-push prin-

ciple. Depressing this button turns the instrument on. Once

the instrument is on, pressing (releasing) this button turns

the instrument off. When the Model 705 is turned on it goes

through a power-up sequence as outlined in paragraph 2.3.

When the power-up sequence is complete the Model 705

displays the following:

r D I F .a

I

01 = Channel Number One

F = First Channel*

0 = Channel Open

The CHANNEL LED lights, indicating that the Model 705 is

in the channel mode.

*If Channel 1 was previously progammed as the first channel,

last channel or both, it is displayed as such. This is because -li

the FIRST and LAST functions are battery backed up and

not affected by power up.

2. The CHANNEL button selects the channel mode for display.

The channel number is displayed on the front panel as a two

digit number. Upon power-up, the Model 705 reverts to the

channel mode. Pressing the CHANNEL button while the

Model 705 is in the channel mode increments the channel

number by one. Pressing the CLOCK, DATE, PRGM,

SINGLE, CONTINUOUS or INTERVAL buttons takes the

Model 705 out of the channel mode. Pressing the RESET

button during any of the front panel programs except Programs 90, 91, 92 and 99 (see paragraph 2.6 for front panel

program information) reverts the Model 705 to the channel

mode.

3. The OPERATION group consists of four buttons: FIRST,

LAST, CLOSE and OPEN. The buttons are described as

follows:

A. The CLOSE button when activated, closes the presently

displayed channel. If the presently displayed channel is

already closed, pressing the CLOSE button has no effect

on the channel. When the presently displayed channel is

open and the CLOSE button is pressed, the open and

closed digit (furthest digit on the right of the display)

changes as follows.

/

2.4 ENVIRONMENTAL CONDITIONS

All operation of the Model 705 should take place at an ambient

temperature within the range of O°C to 50°C, up to 35OC at

80% noncondensing relative humidity. Environmental conditions for storage are -25OC to + 65OC.

2.5 OPERATING INSTRUCTIONS

0 Indicates a channel is open, and that C indicates a

channel is closed.

B. The OPEN button when activated, opens the presently

displayed channel. If the presently displayed channel is

already open, pressing the OPEN button has no effect on

the channel. When the presently displayed channel is

closed, and the OPEN button is pressed, the open and

close digit (furthest digit on the right of the display)

changes as follows.

2-3

Page 15

L

I

C Indicates a closed channel, and that 0 indicates an

open channel.

NOTE

Close and open for each channel remain valid

even when not viewing the channel or the

display.

C. The FIRST button, when pressed, specifies the presently

displayed channel as the first channel of a multichannel

configuration. If the presently displayed channel has

already been specified as the first channel, pressing the

FIRST button has no effect on the channel or the

display. If the presently displayed channel has not been

specified as the first channel, the display format is shown

as follows:

11

01 = Present Channel

0 = Channel Open

Pressing the FIRST button specifies the channel as the

first channel and the display format is shown as follows:

1 UI f 3/

01 = Present Channel

F = First channel of a multichannel configuration

0 = Channel open

NOTE

There are two ways to change the specified first

channel, one is to select the desired new channel

and then press the FIRST button; the other way

is to activiate front panel Program 99 (refer to

paragraph 2.6). Powering the unit down will not

change the specified first channel.

The LAST button when pressed specifies the presently

D.

displayed channel as the last channel of a multichannel

configuration. If the presently displayed channel has

already been specified as the last channel, pressing the

LAST button has no effect on the channel or the display.

If the presently displayed channel has not been specified

as the last channel of a multichannel configuration, the

display format is as follows:

I 113 ul

t

10 = Present Channel

0 = Channel Open

Pressing the LAST button specifies the channel as the

last channel of a multichannel configuration and the

display format is as follows:

I

10 = Present Channel

L= Last Channel of a Multichannel Configuration

0 = Channel Open

NOTE

There are two ways to change the specified last

channel, one is to select the desired new channel

and then press the LAST button, the other way is

to activate front panel Program 99 (refer to

paragraph 2.6). Powering the unit down will not

change the specified last channel.

4. The CONTROL group of buttons consist of the RESET button and the INTERVAL button. The buttons are described

as follows:

The RESET button opens all channels of the Model 705

A.

and reverts the display to the specified first channel. The

RESET button is inactive in the time, interval and date

modes. Pressing the RESET button during a Single or

Continuous scan mode sequence stops the scan

mode, opens all the channels, and reverts the display

to the specified first channel.

The INTERVAL button selects the programmed interval

B

time for display. The inten/al time is the programmed

time each channel is closed when using the single, con-

tinuous, or step scanning modes. The interval time

ranges from 5msec to 999.999sec in 1 msec increments.

Upon the actuation of front panel Program 99 the interval

time is reverted to the default condition of 10msec

(displayed as 000.010). Powering the unit down will not

change the programmed interval time. Two ways the in-

terval time can be changed is either, activate front panel

Program 99; (see paragraph 2.6) or press the INTERVAL

button, and then press the appropriate numbers from

000.010 to 999.999 and the ENTER button.

5. The DATA group of buttons consist of the O-9, CANCEL

and ENTER buttons. They are described as follows:

The O-9 data keys allow entry of numerical data onto the

A.

display. The O-9 keys can be used to enter numerical

constants on the display for certain functions such as interval time, channel number, front panel programs, time

and date.

The ENTER button loads the displayed data for the inter-

B.

val time, date and program modes into the Model 705. In

the PRGM mode, the ENTER button initiates the selected program (0, 1,2, 3, 6 or 7) after the necessary data is

entered onto the display. Refer to paragraph 2.6 for information concerning the front panel programs.

During the entry of data (c segment cursor is flashing)

C.

the CANCEL button cancels the present display and

reverts the instrument to the previous display. The

CANCEL button is functional only when entering data

onto the display in the interval, time, date and program

modes.

2-4

Page 16

6.

The SCAN group of buttons consists of the SINGLE, CONTINUOUS and START/STOP buttons. These three buttons

select the different scan modes. The SCAN group of buttons are described as follows:

A. The CONTINUOUS button selects the continuous scan

mode. The continuous scan mode allows the user to

scan through the programmed channels at the program-

med interval rate continuously. The continuous scan

mode is initiated upon the actuation of the

START/STOP button or upon receiving the appropriate

external trigger pulse. Pressing the START/STOP but-

ton while the continuous scan mode is running stops the

scan at the presently displayed channel. Pressing the

START/STOP button again starts the continuous scan

at the channel in which it was stopped.

B.

The SINGLE button selects the single scan mode. The

single scan mode allows the user to scan through the

programmed channels at the programmed interval rate

one time. The single scan mode is initiated upon the actuation of the START/STOP button or upon receiving

the appropriate external trigger pulse. Pressing the

START/STOP button while the single scan mode is running stops the scan at the presently displayed channel.

Unless interrupted, the single scan mode will scan

through the programmed channels at the programmed

interval rate and then stop at the programmed first channel.

C.

The START/STOP button is an alternate action control

that has three functions. The three functions are the

START function, the STOP function and the STEP scan

mode. They are described as follows:

a. The start function of the START/STOP button in-

itiates the selected scan mode. When all the parameters (interval, time, first and last channels, scan

mode, etc.) of a multichannel configuration have

been programmed and the user is ready to scan the

channels, press the START/STOP button to initiate

the scan. During the scan mode the START/STOP

LED is activated.

b. The stop function of the START/STOP button stops

the previously initiated scan mode. That is, pressing

the START/STOP button during a scan stops the

sequence at the presently displayed channel and turns

off the START/STOP LED. The stop function of the

START/STOP button is active only when a scanning

sequence is scanning.

c. The step scan mode allows the user to manually step

through the programmed channels. The step scan

mode is selected by pressing the channel button, programming the interval time and pressing the

START/STOP button. When the interval time has

been programmed and the user is ready to manually

scan the channels, press the START/STOP button to

scan (closed and open channel at the programmed interval time) one channel. Upon initiating the step scan

mode the START/STOP LED turns on, the presently

displayed channel is closed for the programmed interval rate, the channel is opened, the START/STOP

LED turns off and the Model 705 advances to the next

channel. To scan the next channel press the

START/STOP button and the Model 705 will go

through the same sequence.

7. The CLOCK group consists of two buttons that control the

display of the time function and the date function. The clock

continues to run after the instrument is powered down

because the clock’s power circuitn/ is backed up by battery

BTlOl. The two clock buttons are described as follows:

A. The TIME button selects for display the 24 hour time

clock. The format showing 2:45 p.m. is as follows:

I IYYS.UU /

i I

The time can be set by pressing the TIME button, entering the appropriate time onto the display and then pressing the ENTER button.

B. The DATE button selects the date mode for display. The

date display has two formats., The formats showing

Auaust 18th are as follows:

American date format

International date format

The formats are selected by front panel Program 1. Refer

to paragraph 2.5 6 for information concerning the front

panel programs. The date can be set by pressing the

DATE button, entering the appropriate date onto the

display and then pressing ENTER.

8. The PRGM button when pressed shows a display that prompts the user to select one of the 13 front panel programs.

Refer to paragraph 2.6 for complete details and examples of

the front panel programs.

9. The IEEE bus indicators (TALK, LISTEN and REMOTE)

identify the present status of the IEEE-488 bus. The in-

dicators are described as follows:

A. The TALK LED when lit indicates that the Model 705 is

in the talk mode. The Model 705 does not have to be in

the remote mode for it to be in the talk mode.

B. The LISTEN LED when lit indicates that the Model 705 is

in the listen mode. The Model 705 must also be in the

remote mode for it to be in the listen mode.

C. The REMOTE LED when lit indicates that the Model 705

is in the remote mode.

2.5.2 Rear Panel Description

1. The two plug-in slots in the Model 705 mainframe can accomodate two relay scanner cards. The Model 705 with two

relay scanner cards has up to 20 2-pole individual channels.

Refer to paragraph 2.2.2 for instructions on how to remove

or install the various plug-in cards.

cl0 I8

I I

Ifm3 I

2-5

Page 17

fi?ciEq

705 SCANNER

\ 4

OPERATION

DATA

7 8

9

q ncl

POWER

a ON

1 OFF

i

n

v

0

RESET

sl fl

L&l

INTERVAL CONTINUOUS

/\

SCAN

.

PRGM

4

q

IC

SERIAL

hxl

0 CANCEL ENTER

non

DIGITAL I/O

OUT SERIAL IN

ALARM /

I

@-/-@I

30V ‘MAX.

h

2-6

f~.:,~~;:G;O

m<~t~~cncoaouL

L

IEEE 488 INTERFACE

I

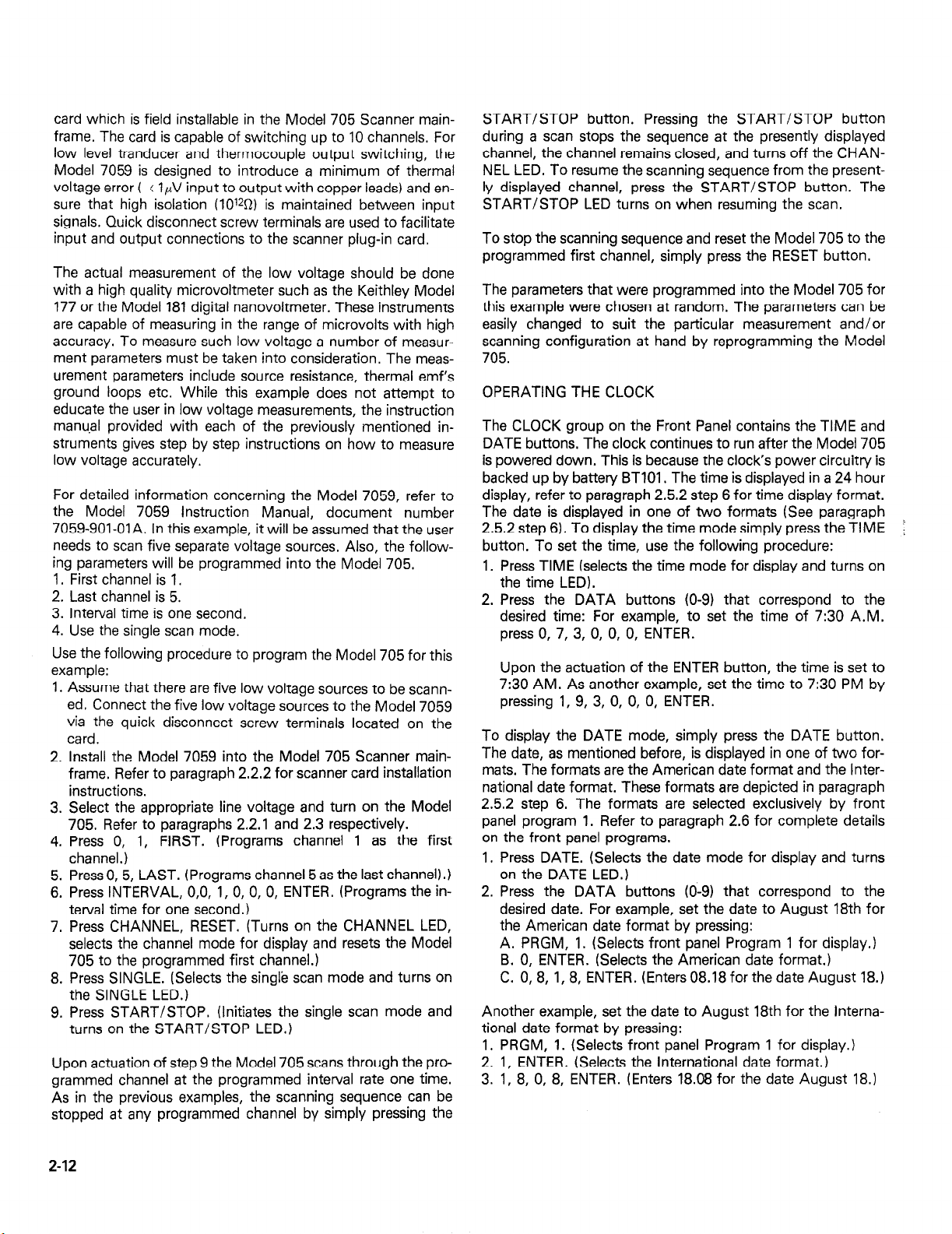

Figure 2-2. Model 705 Front and Rear Panels

LINE RATING

50-400 Hz AC ONLY

25 VA MAX

LINE

FUSE

SLOWSLOW

3ll6A 90- 125V

l/lOA 195-250V

LINE VOLTAGE

SELECTED (INTERNAL)

go-1lOV 0 195-235v a

105-125V 0 210-250V 0

Page 18

2. The EXTERNAL TRIGGER is a BNC connector that initiates

the selected scan mode (single, step or continuous) in the

same manner as the START/STOP button, The input trigger pulse must be a negative going pulse at a TTL level with

a minimum duration of 2+ec. The selected program mode

is initiated upon the negative transition of the pulse. This

feature can be used to trigger the Model 705 into the

selected scan mode using another instrument.

3. CHANNEL READY is a BNC output connector that provides

a negative going TTL level pulse of greater than lO@ec at

the completion of the programmed channel settling time.

This feature can be used to inform another instrument (e.g.

DMM, Source, etc,) that the present channel settling time is

completed.

4. The ALARM/SERIAL IN connector has two functions. The

Alarm out function and the SERIAL IN function. As the

Alarm out function the Model 705 outputs a negative going

TTL level greater than 10pec pulse to the ALARM/SERIAL

IN connector. When the Alarm time is set to 00.00.00 the

pulse does not appear. The SERIAL IN function is used in a

daisy chain configuration where the SERIAL IN connector is

connected to the SERIAL OUT connector of another Model

705. Refer to paragraph 2.5.3 example 4 for more information.

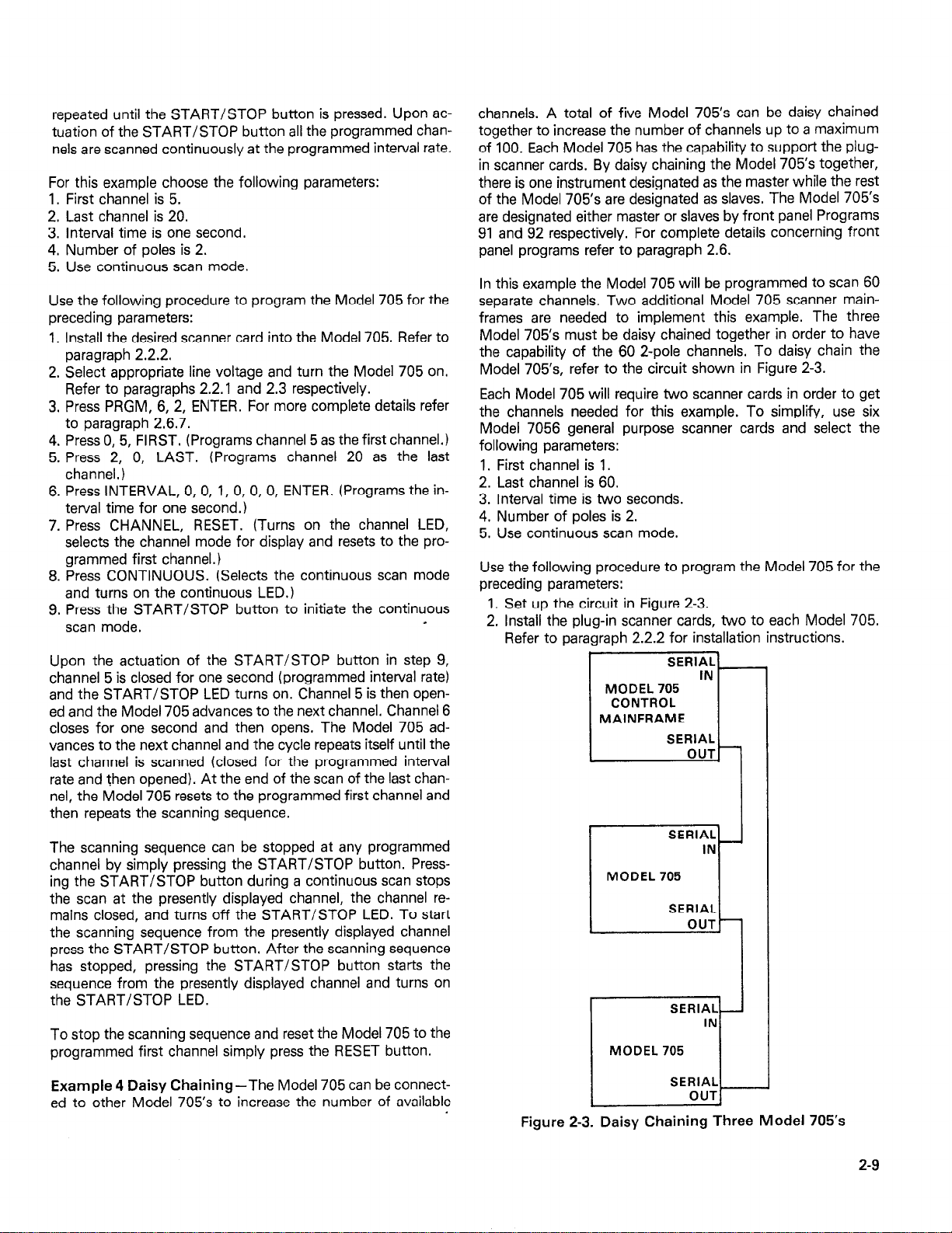

5. SERIAL OUT is a BNC output connector that provides connection to another Model 705 for a daisy chain configura-

tion. Refer to Figure 2-3 for a typical daisy chain configuration. The SERIAL OUT connector is applied to the

ALARM/SERIAL IN connector of another Model 705.

6. The Digital I/O port consists of 16 digital input/output lines

along with four lines that are + 5V and IEEE common. Eight

of the I/O lines can be used for inputs and eight can be used

for outputs. This allows the user a limited number of control

lines to the IEEE bus. The outputs will drive one TTL load

and the inputs are TTL compatible. For more information

concerning the digital I/O port refer to paragraph 3.5.8/16.

7. The IEEE bus connector provides bus connection to the

Model 705. The connector mates with the Keithley Model

7008-3 and Model 7008-6 cables. For more detailed infor-

mation concerning the IEEE connector refer to paragraph

3.3.

8. The line power fuse is rated as specified in Table 5-l.

9. The line power receptacle mates with three wire line cord

which provides connections to line voltage. For correct line

voltage selection refer to paragraph 5.3.

2.5.3 Basic Front Panel Operation

This section provides the information necessary for basic front

panel operation of the Model 705. There are a number of steps

to follow in order to get the Model 705 ready for scanning

operation. These steps are as follows:

1. Install the desired scanner card(s). Refer to paragraph 2.2.2

for information concerning the installation of the scanner

cards into the Model 705.

2. Select appropriate line voltage. Refer to paragraph 2.2.1 for

information concerning the selection of the appropriate line

voltage. Turn the Model 705 on. The instrument goes

through the power-up sequence described in paragraph 2.3

and displays the following:

I III f o!

NOTE

Channel 1 is set as the programmed first channel,

unless the unit was previously programmed for

another channel then that channel is displayed.

3. Program the desired channel.

A. Select the first channel.

a. Press the desired channel number from the DATA

group buttons O-9.

b. Press the FIRST button to program the present chan-

nel as the first channel.

NOTE

Selecting a channel that does not exist in the present set up causes the Model 705 to display the

following message.

/-Ia

9. Select the last channel:

a. Press the desired number from the DATA group but-

tons O-9.

b. Press the LAST button to program the present chan-

nel as the last channel.

4. Program the desired number of poles (I-, 2- or 4-pole).

A. Press PRGM.

9. Press 6 (refer to paragraph 2.6.7).

C. Select number of poles l-, 2- or 4-pole.

D. Press ENTER.

5. Program the interval time

A. Press the INTERVAL button to select the interval mode

for display.

9. Enter the interval time on the display by pressing from

the DATA group, desired time 000.010 to 999.999

seconds.

C. Press the ENTER button.

6. Program the desired scan mode. Press the SINGLE or CONTINUOUS button to select one of these two scanning

modes. To select the step scan mode press the channel but-

ton and the START/STOP button.

7. Press the START/STOP button to start the scanning

sequence. For the step scan mode press the START/STOP

button each time a single channel is to be scanned.

l-h

2-7

Page 19

Steps 1 through 7 show how to get the Model 705 into a

scanning sequence. The next examples show how to use

the different scan modes, how to daisy chain several Model

705’s for an extended number of channels, and scanning

using different scanner cards,

Example 1 Manual Scan-The Model 705 can be programmed for the step scan mode, if it is desired to scan through the

programmed channels manually. In the step scan mode the

programmed channels can be scanned (closed for the programmed interval rate and then opened) one channel at a time.

Upon the actuation of the START/STOP button a single channel will be scanned. For this example, choose the following

parameters:

1. First channel is 1.

2. Last channel is 10.

3. Interval time is two seconds.

4. Number of poles is two.

5. Use the step scan mode.

Use the following procedure to program the Model 705 for the

preceding parameters:

1. Install the desired scanner card into the Model 705. Refer to

paragraph 2.2.2.

2. Select the appropriate line voltage and turn the Model 705

on. Refer to paragraphs 2.2.1 and 2.3 respectively.

3. Press PRGM, 6, 2, ENTER. For more complete information

refer to paragraph 2.6.7.

4. Press 0, 1, FIRST. (Programs channel 1 as the first channel.)

5. Press 1, 0, LAST. (Programs channel 10 as the last

channel.)

6. Press INTERVAL, 0, 0, 2, 0, 0, 0, ENTER. (Programs the interval time for two seconds.)

7. Press CHANNEL, RESET. (Selects the channel mode for

display and resets to the first channel.)

8. Press the START/STOP button to initiate the step scan

mode.

Upon the actuation of the START/STOP button in step 8,

channel 1 is closed and the START/STOP LED is turned on.

Channel 1 remains closed for two seconds (programmed interval rate) and then opens, The START/STOP LED turns off

and the Model 705 advances to the next channel. To scan the

remaining channels press START/STOP button each time a

channel is to be scanned. When the last programmed channel

is scanned, in this example, it goes through the same procedure as previously stated. The difference is that after the

channel opens up and turns off the START/STOP LED, the

Model 705 resets to the first programmed channel.

grammed last channel, at this point the Model 705 reverts to

the programmed first channel and stops. Upon the actuation

of the START/STOP button all the programmed channels are

scanned at the programmed interval rate. For this example let

us choose the following parameters:

1. First channel is 3.

2. Last channel is 15.

3. Interval time is 0.5 seconds.

4. Number of poles is 2.

5. Use the single scan mode.

Use the following procedure to program the Model 705 for the

preceding parameters:

1. Install the desired scanner card into the Model 705. Refer to

paragraph 2.2.2

2. Select appropriate line voltage and turn the Model 705 on.

Refer to paragraphs 2.2.1 and 2.3 respectively.

3. Press PRGM, 6, 2, ENTER. For more complete details refer

to paragraph 2.6.7.

4. Press 0, 3, FIRST. (Programs channel 3 as the first channel.)

5. Press 1, 5, LAST. (Programs channel 15 as the last

channel.)

6. Press INTERVAL, 0, 0, 0, 5, 0, 0, ENTER (Programs the interval time for 0.5 seconds.)

7. Press CHANNEL, RESET. (Turns on the CHANNEL LED,

selects the channel mode for display and resets to the pro-

grammed first channel.)

8. Press SINGLE. (Selects the single scan mode and turns on

the SINGLE LED.)

9. Press the START/STOP button to inititate the single scan

mode.

Upon the actuation of the START/STOP button in step 9,

channel 3 is closed for 0.5 seconds (programmed interval rate

and the START/STOP LED turns on). Channel 3 is opened

and the Model 705 advances to the next channel. Channel 4 is

closed for 0.5 seconds and then opens. The Model 705 then

advances to channel 5 and the cycle repeats itself until the last

channel is scanned (closed for the programmed interval rate

and then opened). At the end of the scan of the last channel,

the Model 705 resets to the programmed first channel and

turns off the START/STOP LED. At this point the single mode

has been completed.

Pressing the START/STOP button during a single scan stops

the scan at the presently displayed channel. The channel remains closed and turns off the START/STOP LED. To start

the scanning sequence from the presently displayed channel

press the START/STOP button.

To stop the scanning sequence and reset the Model 705 to the

programmed first channel simply press the RESET button.

Example 2 Single Scan-In the Single Scan mode all the

channels are scanned one time. The Scan runs as follows: the

first channel is closed for the programmed interval rate and

then opened. The Model 705 advances to the next channel,

closes it for the programmed interval rate and then opens the

channel. The sequence is repeated up to and including the pro-

2-8

To stop the scanning sequence and reset the Model 705 to the

programmed first channel simply press the RESET button.

Example 3 Continuous Scan-In the Continuous scan mode

all the programmed channels are scanned continuously. The

scan runs as follows: the first channel is closed for the programmed interval rate and then opened. The Model 705 then

advances to the next channel, closes it for the programmed interval rate and then opens the channel. The sequence is

Page 20

repeated until the START/STOP button is pressed. Upon actuation of the START/STOP button all the programmed channels are scanned continuously at the programmed interval rate.

For this example choose the following parameters:

1. First channel is 5.

2. Last channel is 20.

3. Interval time is one second.

4. Number of poles is 2.

5. Use continuous scan mode.

Use the following procedure to program the Model 705 for the

preceding parameters:

I, Install the desired scanner card into the Model 705. Refer to

paragraph 2.2.2.

2. Select appropriate line voltage and turn the Model 705 on.

Refer to paragraphs 2.2.1 and 2.3 respectively.

3. Press PRGM, 6, 2, ENTER. For more complete details refer

to paragraph 2.6.7.

4. Press 0, 5, FIRST. (Programs channel 5 as the first channel.)

5. Press 2, 0, LAST. (Programs channel 20 as the last

channel.)

6. Press INTERVAL, 0, 0, 1, 0, 0, 0, ENTER. (Programs the in-

terval time for one second.)

7. Press CHANNEL, RESET. (Turns on the channel LED,

selects the channel mode for display and resets to the pro-

grammed first channel.)

8. Press CONTINUOUS. (Selects the continuous scan mode

and turns on the continuous LED.)

9. Press the START/STOP button to initiate the continuous

scan mode.

Upon the actuation of the START/STOP button in step 9,

channel 5 is closed for one second (programmed interval rate)

and the START/STOP LED turns on. Channel 5 is then opened and the Model 705 advances to the next channel. Channel 6

closes for one second and then opens. The Model 705 advances to the next channel and the cycle repeats itself until the

last channel is scanned (closed for the programmed interval

rate and then opened). At the end of the scan of the last chan-

nel, the Model 705 resets to the programmed first channel and

then repeats the scanning sequence.

The scanning sequence can be stopped at any programmed

channel by simply pressing the START/STOP button. Press-

ing the START/STOP button during a continuous scan stops

the scan at the presently displayed channel, the channel re-

mains closed, and turns off the START/STOP LED. To start

the scanning sequence from the presently displayed channel

press the START/STOP button, After the scanning sequence

has stopped, pressing the START/STOP button starts the

sequence from the presently displayed channel and turns on

the START/STOP LED.

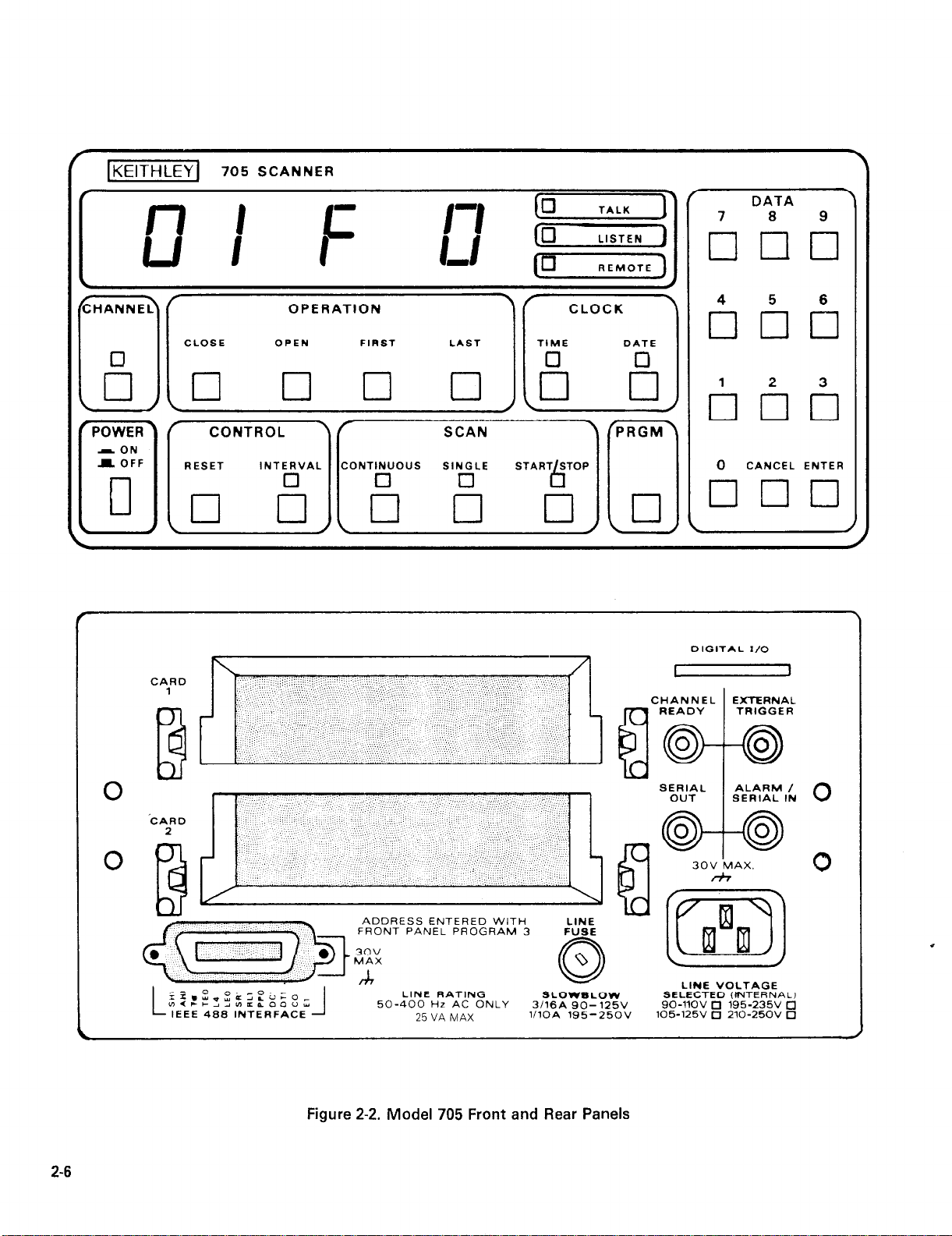

channels. A total of five Model 705’s can be daisy chained

together to increase the number of channels up to a maximum

of 100. Each Model 705 has the capability to support the plugin scanner cards. By daisy chaining the Model 705’s together,

there is one instrument designated as the master while the rest

of the Model 705’s are designated as slaves. The Model 705’s

are designated either master or slaves by front panel Programs

91 and 92 respectively. For complete details concerning front

panel programs refer to paragraph 2.6.

In this example the Model 705 will be programmed to scan 60

separate channels, Two additional Model 705 scanner mainframes are needed to implement this example. The three

Model 705’s must be daisy chained together in order to have

the capability of the 60 2-pole channels. To daisy chain the

Model 705’s, refer to the circuit shown in Figure 2-3.

Each Model 705 will require two scanner cards in order to get

the channels needed for this example. To simplify, use six

Model 7056 general purpose scanner cards and select the

following parameters:

1. First channel is 1.

2. Last channel is 60.

3. Interval time is two seconds.

4. Number of poles is 2.

5. Use continuous scan mode.

Use the following procedure to program the Model 705 for the

preceding parameters:

1. Set up the circuit in Figure 2-3.

2. Install the plug-in scanner cards, two to each Model 705.

Refer to paragraph 2.2.2 for installation instructions.

MODEL 705

CONTROL

MAINFRAME

SERIAL

IN

MODEL 705

r-r

To stop the scanning sequence and reset the Model 705 to the

programmed first channel simply press the RESET button.

Example 4 Daisy Chaining-The Model 705 can be connect-

ed to other Model 705’s to increase the number of available

Figure 2-3. Daisy Chaining Three Model 705’s

2-9

Page 21

3. Select appropriate line voltage and turn the Model 705’s

on. Refer to paragraphs 2.2.1 and 2.3 respectively.

4. Press PRGM, 6, 2, ENTER. For complete details refer to

paragraph 2.6.7.

5. Program one Model 705 as the master by initiating front

panel Program 91. For complete details concerning the

front panel programs refer to paragraph 2.6.

6. Program remaining Model 705’s as slaves by initiating front

panel Program, 92 for each of the remaining Model 705’s.

To do this press PRGM button and then press 9, 2.

All remaining Model 705’s will have to be programmed in

the same way. For complete details concerning the front

panel programs refer to paragraph 2.6.

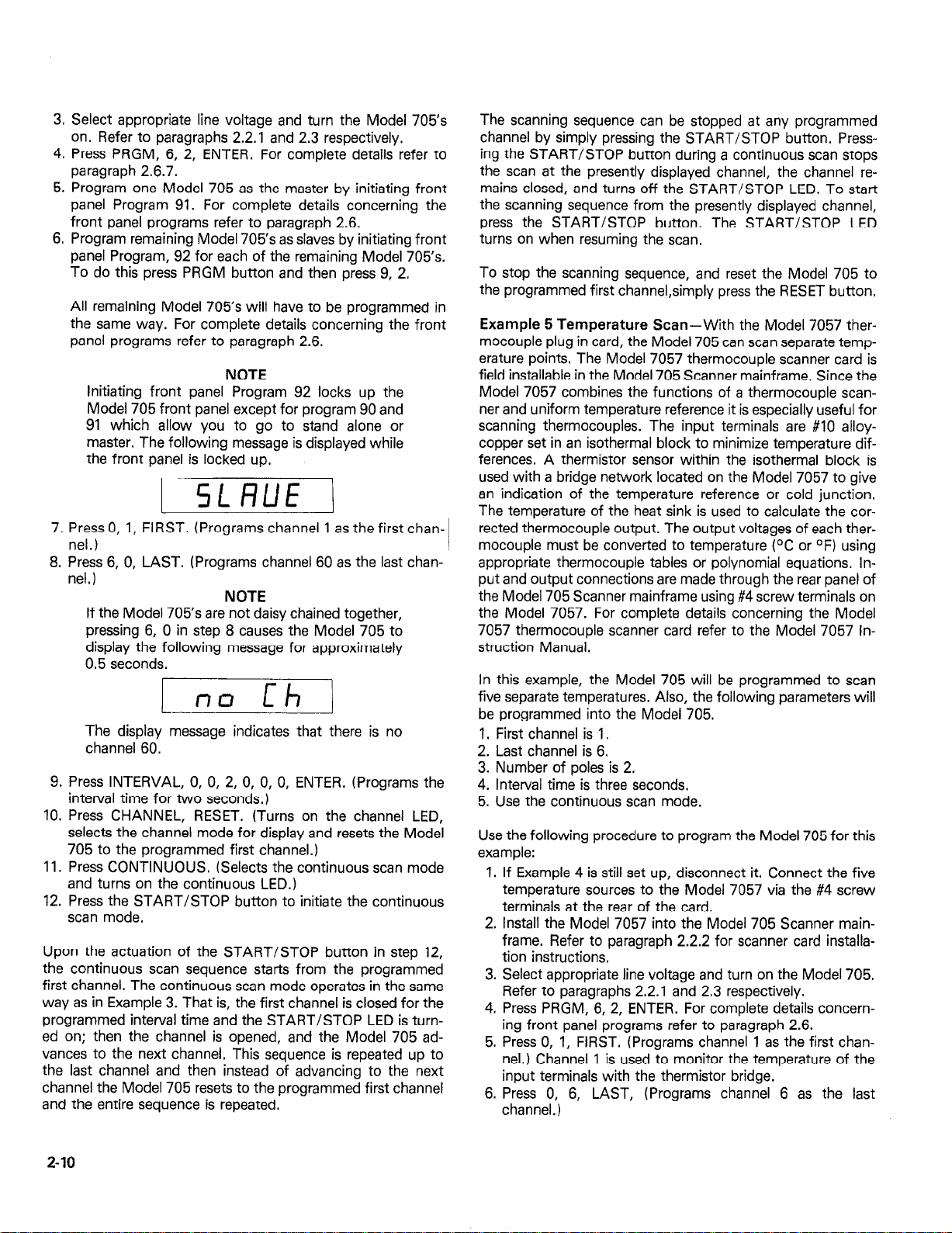

NOTE

Initiating front panel Program 92 locks up the

Model 705 front panel except for program 90 and

91 which allow you to go to stand alone or