Page 1

Instruction Manual

Model 415

Micro-Microammeter

Keithley Instruments, Inc.

Instrument Division

Cleveland, Ohio, U.S.A.

Page 2

WARRANTY

We warrant each of our products to be free

from defects in material and workmanship. Our

obligation under this warranty is to repair or

replace any instrument or part thereof (except

tubes and batteries) which, within a year after

shipment, proves defective upon examination.

To exercise this warranty, contact your Keithley

field engineering representative. You will be

given assistance and shipping instructions.

REPAIRS AND RECALIBRATION

Keithley Instruments and its internat.ional dis-

tributors maintain complete repair facilities.

To insure prompt repair or recalibration service,

please contact your Keithley field representative

before returning the instrument.

Estimates for repairs, normal recalibrations, and

calibrations traceable to the National Bureau of

Standards are available upon request.

Page 3

INSTRUCTION MANUAL

MODEL 415

MICRO-MICROAMMETER

Page 4

CONTENTS

SECTION

INTRODUCTION

SPWZIFICATIONS

REXlgeS

Accuracy

Zero Drift

Grid Current

output

Rise

Time

Current Suppress~ion

Zero Check

Tube Complement

Power

Accessories Supplied

Accessories Available

Dimensions

OPERATION

Operating Controls

Inout and Outpyt Connections

PrelimJ.nary Set Up

Makinp Measurements

Speed o.f Response

I

II

CIRCUIT DESCRIPTION

Circuit Block Diagram

Speed of Response

Detailed Circuj.t Description

MAINTENANCE AND CALIBRATION

General

Calibration

Trouble Shooting Procedure

Voltare Resistance Diagram

Circuit Schematic

Replaceable Parts List

415

ICE= mm, nio.

IV

v

cLEvEm, OHIO

Page 5

SkCTION I - INTRODUCTION

The Model h15 Micro-microammeter incorporates advanced

high-speed circuitry developed by Keithley Instruments for rocket

and satellite experimentation -- where measurements of LymanAlpha night slow, cosmic radiation, and upper air density require fast response,

The I~15 also provides zero suppression up to 100 full scales,

permitting full scale display of one per rant variatiors of a

signal, or suppression of a steady background signal.

Excelling other Keithley LOO Series Micro-microammeters in

speed of response, the Model hl5 is ideal for current measure-

ments in ion chambers, ionization pages, and photo-multipliers.

Other applications include uses with flame and Beta-ray

ionization detectors and in gas ChromatoKranhy, mass spectrometry.

Speed of respp? se of less than 600 milliseconds to 90% of

final value at lo-

capacity is less than 50 picofarads (uuf). Critical damping of

the circuit, with any input capacity, is maintained on all ranges

through one infrequent adjustment. There is no possibili.ty of

oscillation or poor transient response on any ranpe.

ampere is possible where external circui~t

-8

Accuracy is 22% of full scale o 10m3

ranses; -+3$ of full scale on 3 x 10

ranples.

Other features i

approximately 1 x 10

2% per day and a one volt output at one milliampere; a 1%

mirror scale pane:1 meter.

lude capability of detecting current of

-YE

ampere; zero stability of better than

-9

throuph 10

througQ210

ampere

ampere

415

-1

I

Page 6

SECTION II -

SPECIFICATIONS

RANGES: lo-=, 3 x 10-12, lo-, 3 x lo-=,

etc. to 10e3 ampere

full scale.

ACCURACY: Z 2% of full scale 10e3 ttiu lOWE ampere ranges;+ 3% of

full scale 3 x 10-9 thru lo-l2 ampere ranges.

Z!SO DRIFT: After 30-minute warmup, less than 2% of full scale per

2L hours on all ranges.

GRID CT:r'WNT: Less than 5 x 10-lL ampere.

~!ITPIIT:

One volt for ful! scalp

3~i.

up to 5 ma. Noise less than

20 m'llivolts.

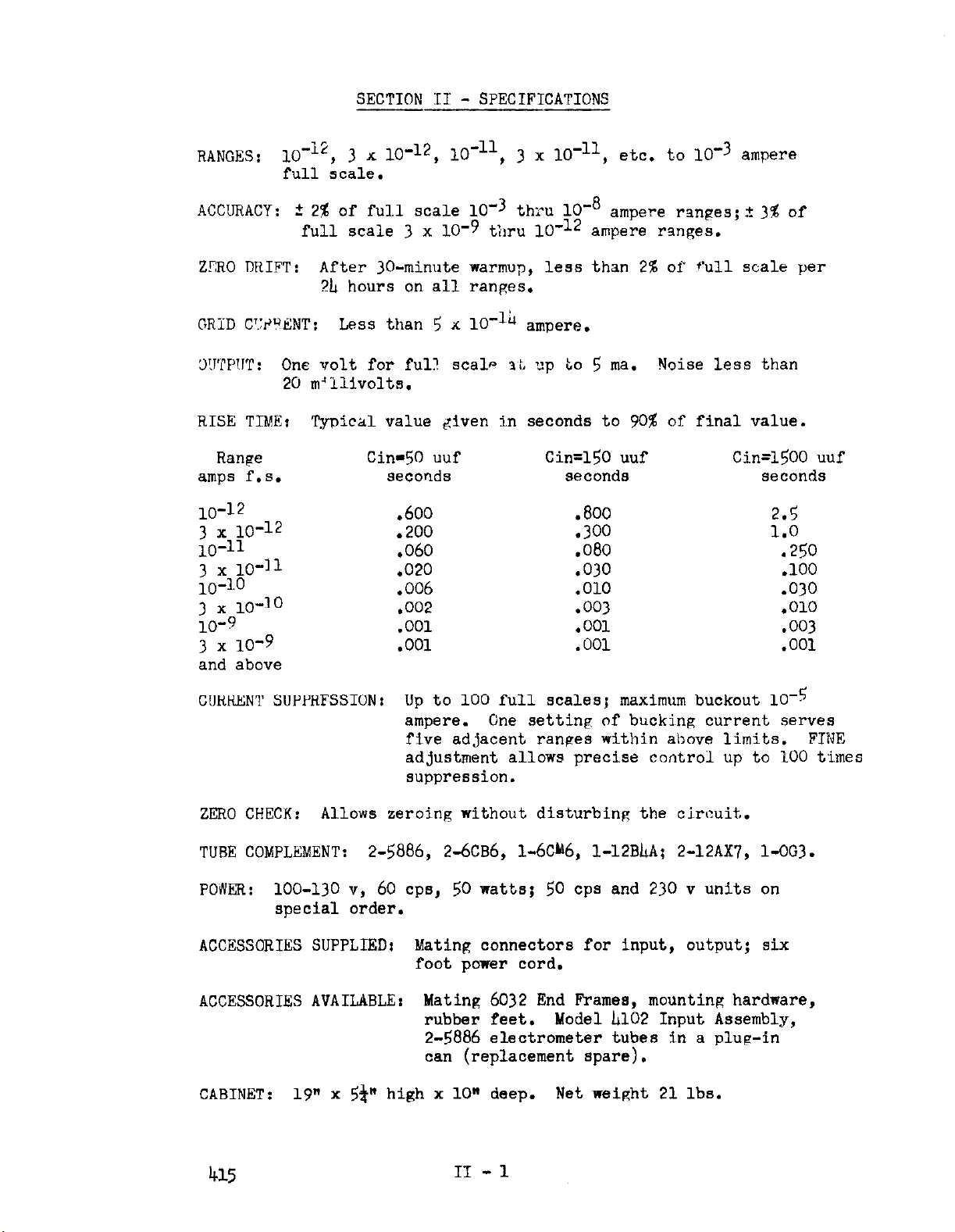

RISE TIME: Typical value &ven in seconds to 90% of final value.

Range Gin-50 uuf

amps f.s.

10-12

3 x 10-12

10-11

3&o-ll

seconds

.600

.200 .300 1.0

,060

.020

Cin=150 uuf

seconds

.800 2.5

.080 .250

,030 .lOO

Cin=1500 uuf

seconds

.006 ,010 .030

3 x 10-10

10-9

3 x 10'9

,002

.OOl

.OOl

.003 .OlO

.OOl .003

.OOl .OOl

and above

CURRENT SUPPRFSSION:

Up to 100 full scales; maximum buckout 10-5

ampere.

One setting of bucking current serves

five adjacent ranges within above limits. FINE

adjustment allows precise control up to 100 times

suppression.

ZERO CHECK:

TUBE COMPLEMENT:

POAER:

Allows zeroing without disturbing the circuit.

2-5886, 2-6CB6, l-6Ch6, l-12BLA; 2-12AX7, l-OG3.

loo-130 v, 60 cps, 50 watts; 50 cps and 230 v units on

special order.

ACCESSORIES SUPPLIED1 Mating connectors for input, output; six

foot power cord.

ACCESSORIES AVAILABLE:

Mating 6032 End Frames, mounting hardware,

rubber feet. Model L102 Input Assembly,

2-5886 electrometer tubes in a plug-in

can (replacement spare).

CABINET:

19" x 59 high x 10" deep. Net wei&ht 21 lbs.

415

II - 1

Page 7

SECTION III - OPERATION

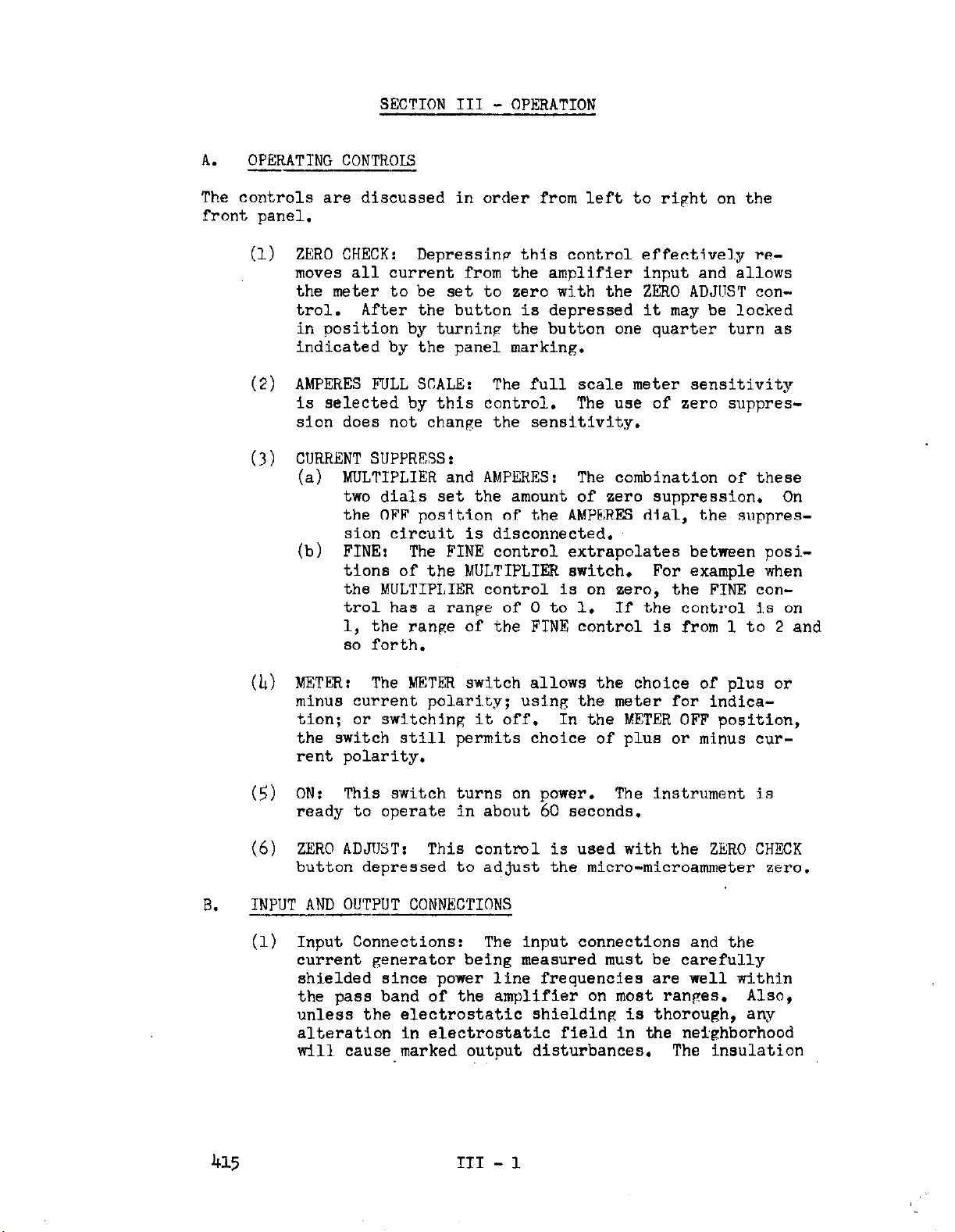

A. OPERATING CONTROLS

-

The controls are discussed in order from left to right on the

front panel.

ZERO CHECK: Depressins this control effectively re-

(1)

moves all current from the amplifier input and allows

the meter to be set to zero with the ZERO ADJUST con-

trol. After the button is depressed it may be locked

in position by turning the button one quarter turn as

indicated by the panel marking.

AMPERES FULL SCALE:

(2)

The full scale meter sensitivity

is selected by this control. The use of zero suppression does not change the sensitivity.

CURRENT SUPPRESSI

(3)

(a) MULTIPLIER and AMPEHES: The combination of these

two dials set the amount of zero suppression. On

the OFF position of the AMPERES dial, the suppres-

sion circuit is disconnected.

(b) FINE8 The FINE control extrapolates between posi-

tions of the MULTIPLIER switch. For example when

the MULTIPLIER control is on aero, the FINE control has a ranpe of 0 to 1. If the control is on

1, the range of the FINE control is

from

so forth.

METER: The METER switch allows the choice of plus or

(Ii)

minus current polarity;

using the meter for indication; or switching it off. In the METER OFF position,

the switch still permits choice of plus or minus current polarity.

ON: This switch turns on power. The instrument is

(5)

ready to operate in about 60 seconds.

1 to 2 and

B.

415

ZERO ADJlJSTz This control is used with the ZERO CHECK

(6)

button depressed to adjust the micro-microammeter zero.

INPUT AND OUTPUT CONNECTIONS

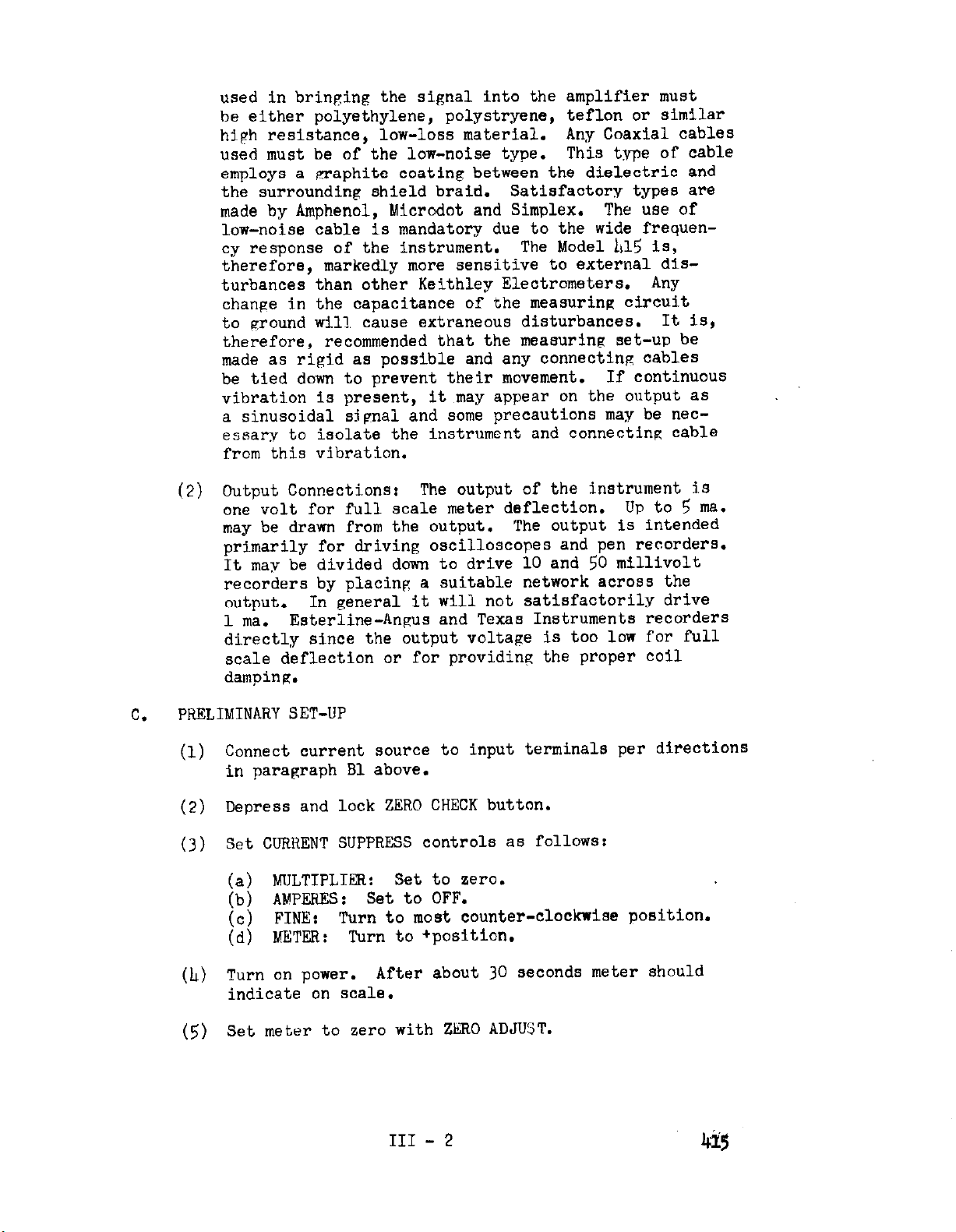

(1) Input Connections:

The input connections and the

current generator being measured must be carefully

shielded since power line frequencies are well within

the pass band of the amplifier on most ranges. Also,

unless the electrostatic shielding is thorough, any

alteration in electrostatic field in the neighborhood

will cause marked output disturbances. The insulation

III - 1

Page 8

used in brinping the signal into the amplifier must

be either polyethylene, polystryene, teflan or similar

hish resistance, low-loss material. Any Coaxial cables

used must be of the low-noise type.

This type of cable

employs a graphite coating between the dielectric and

the surrounding shield braid. Satisfactory types are

made

by Amphenol, Microdot and Simplex. The use of

low-noise cable is mandatory due to the wide frequency response of the instrument.

The Model hl5 is,

therefore, markedly more sensitive to external disturbances than other Keithley Electrometers. Any

chance in the capacitance of the measuring circuit

to ground will, cause extraneous disturbances. It is,

therefore, recommended that the measuring set-up be

made as rigid as possible and any connecting cables

be tied down to prevent their movement. If continuous

vibration is present, itmay appear on the output as

a sinusoidal sJFna1 and some precautions may be nec-

essary to isolate the instrument and connectinS cable

from this vibration.

C.

(2) Output Connections:

The output of the instrument is

one volt for full scale meter deflection. up to 5 ma.

may be drawn from the output.

The output is intended

primarily for driving oscilloscopes and pen recorders.

It may be divided down to drive 10 and 50 millivolt

recorders by placing: a suitable network across the

output.

1 ma.

In general it will not satisfactorily drive

Ester-line-Angus and Texas Instruments recorders

directly since the output voltage is too low for full

scale deflection or for providing the proper coil

dampin!?.

PRELIMINARY SET-UP

(1) Connect current source to input terminals per directions

in paragraph Bl above.

(2) Depress and lock ZERO CHECK button.

(3) Set CURRENT SUPPRESS controls as follows:

(a) MULTIPLIER: Set to zero.

I”{ $W’BES: Set to OFF.

Turn to most counter-clockwise position.

(Z, METEA:

Turn to +position.

(b) Turn on power.

After about 30 seconds meter should

indicate on scale.

(5) Set meter to zero with ZERO ADJUST.

III - 2

Page 9

MAKING MEASUREMENTS

D.

Current Measurements 'Without Zero Suppression?

(1)

the current source attached and the AMPERES control

on OFF, turn the AMPERES FULL SCALr; switch to the

most insensitive range and open the ZERO CHECK switch.

Increase the instrument sensitivity until the largest

possible reading is obtained before full scale is ex-

ceeded, The reading is now %he actual current beinF

generated by the attached device,

Current Measurements With Zero Suppression: Proceed

(2)

as in paragraph (1) above. Then set the CURRENT SUPPRESS MULTIPLIER and AMPERES dials to correspond as

closely as their restilutlon permits to the current

reading obtained in para,sraph (1). This operation

should cause the meter needle to approach zero. Now

use the FINE control as necessary to set the meter exactly to zero.

Then

move

AMPERES FULL SCALE switch to

the next more sensitive range and ad,just the FINE con-

trol as necessary.

The input current is still the same.

Yowever , variations in current are beinp presented on

a scale three times as sensitive as before. Tf it is

desired to expand the scale further, the next more

sensitive range may be used. This nrocess

may

peated until one ner cent of the orifrinal scale is

presented as full scale. The sero suppression cir-

cuit is limited to this amount of suppression.

With

be re-

SPEED OF RESPONSE

E.

The specifications detail the possible speed of response with

various input capacities.

the less the input capacity,

It is evident from the data that

the better the speed of response.

Therefore, the Model hl5 should be located as closely as possible to the current source. The amount of capacity does not

affect the dampins.

Under all conditions, tho response will

be aprroximately critically damped.

III - 3

Page 10

SECTION IV

- CIRCIJIT DESCRIPTION

A.

CTRCIITT BLOCK DTACRAh~

I-

O

Eln A

+R- - +

FIG. 1

0

Eo

0 v

OUTPUT

X)BO

(1) The Electrometer:

lifier with electrometer

with a high degree of accuracy that current neither enters

or leaves its input terminals,

that

any positive voltaae appearing at the i~nout of A, ~1~11 cause

a nepatjve voltage applied through R and B. Tf, for the

moment, we omit the box labeled B from the discussion, the

voltage e,

the resistor. This is necessary since this feedback connec-

tion results in a circuit designed to keep the input drop to

a minimum, Therefore,

and a properly calibrated meter at the amplifier output will

read current directly.

(2) Current Suppression:

flowing, the output voltage is iR from (1). The output assumes

this voltage in order to

the input terminal remains at ground. Either the output must

supply this voltage, in which case the meter indicates a read-

ing; or a voltage may be inserted in series with the feedback

the output is the negative of the input.

sjnce a feedback connection exisj.ts between e, and the innut,

will increase until it equals iR, the drop across

i

In block A Figure 1 is a high rain amp-

tube

a8

= e,/R

In Figure 1, when an input current is

balance

input. It can be assumed

The amplifier is so arranged

Therefore,

a first approximation,

out the input current so that

(1)

415

IV - 1

Page 11

resistor opposite in polarity and equal to the dron across

the fppdback resistor, R.

buckout voltape.

vol:awe across R, the meter will return to zero, since no

vc!tape need be applied to keep the input at vound even

thouph a cur-ent !~s flowine.

the Vodel Lls for zero suppression.

from zero to 100 volts, up to 100 times zero sunnresslon

may be achieved if one full scale corresponds to a one

volt dron across the feedback resistor, R.

If B is now adinsted to precisely t'-ie

In Fipure 1, B represents this

This is the method used Sn

B.v havinp B variable

-I-

Cl-

"I -

SP":F:D OF RESPOMSE:

B.

I,

O!

Eov

I

5”

FIG. 2

In Fivure 2, the circuit of Fimre 1 is redrawn to show the capacities associated with the circuit.

3~s the capacltv across the feedback resistor, The buck-out supply,

has been omitted since it j~s bv-passed for ac. The response of this

circui~t to a current step is civen by

e”= 2,”

where the time constant T is

[‘- & (gk +c$] (21

Cl is the input capacity and C2

T .R+yk + c2)

IV - 2

,413 -’

Page 12

It can be seen that the input capacity, Cl, is decreased in

proportion to the loop Fain,

across the high megohm resistor represented by C:, is not

affected. In the Model 1115, the loop Pain of the amplifier

js approximatply 5000, so that the time constant of the

input capacitance is not too critical,

currents.

which is used on the most sensitive range, can amount to

10 seconds. Therefore,

if any sneed of resnonse is to be obtained.

The time constant RlC2 nj.th a 10

but that the effect of capacity

exce@

the effect of RlC2 must be eliminated

at very low

ohm resistor,

“I

-

Cl -

z

FIGa 3

0

I

A

0

0

,

0

0

To accomplish this, refer to Fiwre 3. Rl and C have

been added to the feedback loop. If RlC3 now eq als RC2,

we have a Vead” network cancelline a “lag” network and

effectively equation (3) becomes:

where both capacities are deRenerated.by loop sain. With

this arrangement the circuit is critically damped. The

addition of more capacity to the input will aIfect the

time constant as shown in (Ir). However, since basically

the circuit is a one lag or single time constant feedback

system, critical damping will not be affected by addit-ion

of capacity at the input.

415

Moreover, the adjustment is

IV - 3

a

Page 13

quite

stable and is made at the factory. Slight misadjustment

will not be serious and will not lead to oscillation.

C.

DETAIL,YD CIRCIJIT DESCRIPTION

Refer to DR 13102D at rear of manual.

Micro-microamneter: The micro-microammeter is contained

(1)

in the Model h102 input tube assembly, PC-lo, and the

associated windings of TRl.

tubes.

V2 is a dummy tube which serves to cancel out

changes in plate and filament voltages which otherwise

would appear in the output. These tubes operate effec-

tj,vely as a long-tail pair due to feedback from the common

cathode junction of V3 and V& to the commonly connected

screen electrodes of Vland V2. V3 and VL function as the

second amplifier stage and Vk is connected as a cathode

follower output stage. Feedback around the micro-microammeter is accomplished via the AMPERES FULL SC4LE switch,

SWl, selecting the various feedback resistors. One resistor is used per range and the feedback voltage is 1 volt on

all ranges.

(2) Micro-microammeter Power Supply:

instrument consists of a Sola reeulatine transformer and

simple condenser-rectifier systems for obtafning the voltapes for the various potentials used in the micro-microam-

meter.

V-l and V2 ara electrometer

The power supply for the

(3) Zero Suppression Circuit: Zero suppression is obtained bv

placing a dc voltage in series with the range resistor.

In this way, the dc supply "bucks out" the input current

flowinp in the range resistor as explained in detail in

paracraph A above.

The CURRENT SUPPRESS supply voltage is obtained from the

power

supply

contained within the dotted lines labeled

"PC 30" which corresponds to the printed circuit of the

same designation in the instrument. The power supply furnishes extremely stable voltages, employing a 2-stage dc

error-signal amplifier.

Also, its input voltage and the

filament voltages of the dc amplifier tubes are further

regulated bv the Sola regulating transformer.

A detailed

description of the oneration of the regulator is contained

in Daragraph h below.

If the suppression circuit is to be used on several ranges,

the suppression voltage must increase in the same ratio as

ranse resistor, so that the same bucking current will be

supplied.

The MULTIPLIER switch, SW-S, contains resistors Rhlg to

Rh27.

power supply.

selects the suppression voltage in ten volt

0 to 100 volts.

responds to a change of ten volts.

These resistors form a precision divider across the

The arrangement is such that this switch

steps

from

The full range of the FINE control cor-

The METEX switch, SW3,

changes polarity of the suppression voltage so that it is

IV - &

Page 14

always in opposition to the input current polarity

cated on the panel meter.

Resistors F&28 to R/432 divide the selected volt;#i,r~ lri the

ratio3 1, 3.3, 10, 33, and 100 for application I:$,) the range

resistors.

,Yne AMPERES switch, SW-~, applies the divided voltages in

sequence to five resistors at a time dependinfr on the sup-

pression range desire As an example, suppose it is de-

sired to supnress lo- 9 ampere.

The MULTIPLIE;R switch, SW-S,

would be szt at “9” and the FINE control set fully clockwise so thsT, 100 volts would be applied to F&28 to Rh72.

AMPEP.ES s~w;tch, SW-6, wruld be set On thB mbst clockwise

position (I;? the schematic).

Thus poi.nt K would be at

1% volt;, point L at 33.3 volts, M at 10 volts, N at 3.3

volts dnd 0 at 1 volt.

Now on the AMPERES FULL SCALE snitsh, SW-l, when the 10m5

ampere range is used, the range resistor Rll$lOOk is

returned to point 0, and point 0 is at. one volt plus with

respect to the T outp

supplies 1 volt = lo-

Thus The suppression circuit

t.

3

ampere, and the micro-microammeter

1OOk

reads zero. If the next range is selected, Rllh, a 333k

res stor is u ed and returned to point N. Similarly, the

h 9

lo- ,

ively increasing voltages, so that effectively low5

3 x lo- and 10-T ranges are supplied with progress-

ampere

is suppressed on each of these ranges. Therefore, any of

these ranges may be used with the same suppression settin&!.

With each change in suppression settine, the same sequence

i; set up for each current selected so that up to 100 times

buc’x-out is available for

an,y

sel.ected ranee. When usine

the zero sappprsssion system, ranges rn which the current

:!dicat:on wouid amount to leas than ol~le volt full sca!~e

are not connected into the suppression syslem, but the shunt

resistors are returned directly to the output cal:hode.

R.ance resistors on which more than 100 times full scale

buck-out would be necessary are operated at 100 volts.

This assures an off-scale reading, so that the user will

be aware when he is asking for more buck-out than is pos-

sible with the system.

415

Current Suppression Power-Supply: This power supply is a

doubly-regulated, isolated source of 200 volts dc. This

potential is divided down to provide buck-out as described

in paragraph 3 above.

V8 and V9.

The input to the regulator is supplied from

The regulator consists of V-6, V-7,

T2 and rectifier-filter combination RF105 and Cl106. T2

is supplied from a winding on Tl, a Sola regulating transformer.

This transformer also regulates the filaments of

~6, V7 and V8 providing further stability. V6 is the series

mss tube. Its output is compared against V9, the voltage

reference tube, by V8 the comparator tube.

The signal is

further amplified by V7 and applied to the grid of ~6 to

control the output.

This circuit supplies an exceedingly

stable and transient-free voltaRe for the zero suppression

circuit.

IV - 5

Page 15

SECTION V

- MAINTENANCE AND CALIBRATION

No periodic maintenance is necessary.

instructions are given below.

in regard to dc accuracy and transient response, requires special

equipment.

below.

ments unless it is in accord with the procedure as given below.

A.

CALIBRATION

(1)

The equipment will be described and the techniques given

It is not advisable to alter any of the calibration adjust-

D.C.: The initial calibration is performed on the 1 milliampere range with the CURRENT SUPPRESS off. R120, the

lk Calibrate Potentiometer, is set at precisely full scale

with a" accurate source of 1 milliampere. Now, if all the

other resistors on AMP&ES FULL SCALE switch SW-l are correct in value, the instrument will be within the rated

accuracy.

the high megohm resistors (109 ohms and above) for accuracy.

It is expected that the instrument will be within rated

accuracy for two to three years from the time it leaves the

factory.

some of the higher value high-megohm resistors will have

drifted out of tolerance and should be replaced.

In order to check these resistors, it is necessary to either

check the value of these resistors in a bridge capable of

better than 1% accuracy with resistances as high as 1012 ohms,

or to be able to generate currents of this accuracy. If it

is desired to generate currents of this accuracy, resistors

in series with a" accurate voltage source will have to have

better than 1% known accuracy.

bridge is necessary in either case. In check-out at the

factory, the resistors are bridged, and the completed instrument is further checked with an accurate current source. In

the field, unless a" accurate megohm bridge such as the

Keithley Model 515 Megohm Bridge is available, the instrument

should be returned to the factory for calibration; or the

high-megohm resistors may be replaced at periodic intervals

with a certified set from Keithley Instruments to assure

absolute calibration accuracy.

It is necessary, however, to occasionally check

At the end of this time it will be likely that

Calibration of the instrument, both

Detailed trouble shooting

Therefore, a" accurate megohm

415

Transient Response Measurement: The rise time of the

(2)

instrument is specified in response to a current step function.

tremely difficult to generate such a

ordinary methods in the region of 10

A voltage supply, a high megohm resistor, and a switch are

useless due to the inherent self-capacity of even the best

resistor.

of a vacuum photo-tube output or generation of a current

step by application of a ramp function to a capacitor.

It must be emphasized at the outset that it is ex-

-yyl];m"lp",m;;g*

More satisfactory methods are light modulation

V-l

Page 16

SCOPE

0

0

I

I

FIG 4

The second method is illustrated in Figure h. A triangular

wave generated bs a Hewlett-Packard Model 202A Function Generator is fed through an attenuator into a 5 mmf polystyrene

capacitor,

tude is equal to

where i is the current amplitude, a is the slope of one segment of the triangular wave in volts per second, and C in

farads is the capacitor Coupling the signal into the bl5.

Under these ciroumstandes, the current signal will be very

nearly a perfect current step and an oscilloscope at the

output will record the true transient response.

signal displays sag or over-shoot, it is adjusted by means

of Rh12 for the best square wave without overshoot.

The output is a current square wave whose ampli-

= aC

i

If the

(1)

B.

(3) Calibration of Buck-Out Supply:

to 9, AMPERE'S switch,

clockwise.

input terminal, set the instrument on the 10'

Then adjust. Rlllh so that the panel meter reads as close to

zero as possible.

out is not high, an approximate setting will suffice.

TROUBLE SHOOTING

(1) General Procedure:

CHECK suppressed, determine if the trouble is in the CURRENT

suppress supply or the micro-microammeter by turning the

AMPERES switch, SW6, to OFF.

depressing the ZERO CHECK button, and if the instrument

measures current on various ranpes correctly, the fault is

Now with 10'

SW

Since the absolute precision of the buck-

If instrument will not balance with ZERO

v-2

to 10'

!3

ampere exactly flow nF

F MULTIPLIER switch, SW5,

, and FINE control fully

into the

3

ampere range.

If the zero can now be set by

Page 17

Ian the buck-out supply. Otherwise it is in the micro-

mi~croammeter.

Next, check to be sure that the supply voltaRes as indicated

(2)

on the schematic are correct.

The plus and minus potentials used in the micro-microammeter are all approximately

130 volts. The ao ripple should be less than 1 volt

on all supplies, If a defect is noted here, it is caused

either bv a defective rectifier or capacitor, or possibly

by a defective ,resistor in the filter circuits. It is

possible, Ian some cases, that an excessive load is beinp

placed on the supply due to a micro-microammeter compon-

ent failure.

of the load.

Removal of the output tube will remove most

If the voltage then returns to normal, the

defect is probably in the micro-microammeter.

(3) Each section will now be considered separately.

Instrument will not balance with ZERO CHECK depressed:

(a)

In a dc amplifier, any defect occurrine between the

input and output terminals usually will lead to an

inability to balance the amplifier. In troubleshootins, the usual impulse is to replace tubes first

and ask ouestions later.

It is advisable in this case

to avoid this procedure unless it is shown that the

tubes are actually defective, since the stability of

the unit revolves mainly around the input tubes. If

these tubes are three years old, but functioninw pronerly, they most likely will be far superior in stabilitv

to any new tubes. Furthermore, electrometer tubes are

seldom the cause of the difficulty, Therefore, follow

the procedure outlined below.

RMS

Directly short the input terminal to ground. This removes the feedback.

When this is done the effective

forward loop gain rises and it becomes difficult to

hold some of the operating potentials of the later

stages at their proper value.

Thins, however, is a

normal effect and it is only necessary that it be

possible 'to swing the electrode potential through the

correct operating voltage by manipulatinp( the ZERO

control to show that the point in question is at

corrnct potential,

With the innut shorted measure the potential at pin 1

of V3 and turn the LYRO control through its range.

The potential should swi~ng through 10 volts near the

middle of the ZERO control ranwe. If it does not,

check pin 3 on the input tube assemb1.y connector.

The voltape should be about 3.@ volts. If it is

130 volts, V-l has an open filament and should be

replaced.

If the filament voltage is correct, check to see if

the screen voltage is correct. If it is not approximately

correct, the defect may be either in the following

stage, since the screens are connected to the

415

V-3

Page 18

cathodes of V3 and Vh, or it may be in Vl or V2.

screen voltape is markedly different from 8 volts, check

pin 7 of the input tube assembly connector.

130 volts is measured instead of 3.8 volts, the filament

of V2 is one*.

sure the voltare on pin 1 of VL while rotati.np the ZhRO

control. If this plate voltape is off and cannot be

broueht to 10 volts, as well as the plate of Vl, the

fault probably is in the second stage. Check at this

point , if changing V3 and Vh will bring the instrument

back into operation. With the input shorted to ground

and instrument operating, the output will be unstable

but should be able to swing rapidly throurth Zero.

If this does not solve the trouble, change the electometer tubes Vl and V2.

defect, check the values of the various circuit components associated with the two stages.

If on the other hand, the correct voltages are found

on pins 1 of V3 and Vb, check the voltafe on pin five

of Vl.

lation of the ZERO control. If it does not, V3 or Vk

is defective or a component associated with that stage

is defective. Finally, if the correct voltage is obtained on the plate of Vh, check to see that pin 3 of

V5 will swins through about minus &volts.

It should swing throuph plus 50 volts on manipu-

If the filament checks correctly, mea-

If this is not the cause of the

Again, if

If the

If it does not either R136, R137 or Cl22 is defective.

If it does have the correct value, V5 is defective or

Rl38 is defective.

Now, when the short at the input is removed the instrument should function properly.

Trouble Shooting the Power Supply:

b)

malfunction in the power supply is a tube failure, and

it is recommended that tube replacement be tried first.

If this doss not eliminate the trouble, check to see

that between R+ floating and pin 9 of v-6 there is approximately 300 volts. If not, remove V6 and check

the potential again. If it is now normal, the trouble

is on the cathode side of the tube. If the potential

is still low, check the output of the transformer, the

rectifiers RFlOh,to 106, CL06 and Rh06.

If it is determined that the trouble is on the cathode

side of ~6, check CL11 and ChO8. If these procedures

do not solve the difficulty it will be necessary to

check the resistors tifi to Rh27 for correct value and

to check the value of the other power supply components.

The most likely

v - I!

Ja

Page 19

REPLACEARLN PARTS LTST - MODEL

---~__-- ----.-.

Circuit

Designation

---

lrl5

._I--

-

Part No.

C-102

c-1.03

c-loll

c-105

C-106

c-107

C-108

c-109

c-l.10

c-111

c-117

c-113

C-114

Capacitor, 500 V. -+ 5% Tolerance

Capacitor, 500 V.i5% Tolerance 6.@ mmf.

Caycitnr, 200 V.+

Capaci~tcr, '200 V.?5% Tolerance 68. mmf.

Capacitor, 200 V.2 5% Tolerance

Canacjtor, 200 V.-t 5% Tolerance 6800. mmf.

Canacitor, Same as C-103

Canacitor, Same as C-102

Capacitor, Same as C-1Ol.~

Caoacitnr, Same as C-105

Capacitor, Same as c-105

Canacjtor, Same as C-106

Canacitor, Same as C-107

5%

Tolerance 22. mmf.

2.2 mmf.

270. mmf.

C56-2.2

~56-6.8

C55-22

G&68

w-220

CS5-680

C-115

C-116

c-117

c-11 8

c-119

c-120

c-121

c-122

c-123

c-12ll

c-l.25

Canncitor, 200 V. t5% Tolerance 2200. mmf.

Capacitor, 200 V.z

Capacitor, Same as C-116

Capacitor, Same as C-116

Capacitor, 200 V.

Capacitor, 600 V. 20% Tolerance .OOl mfd

Capacitor, 600 V. 20% Tolerance 150. mmf.

Capacitor, Same as C-121

Capacitor, 12 V. 1000. mfd.

Capacitor, Same as c-123

Capacitor, 600 V. 20% Tolerance 100 mmf

5%

Tolerance 6800. mmf.

.1 mfd.

C55-2200

CS5-6800

Clb.1

c22-.OOl

~22-150

Cll-1000

c22-100

Page 20

Circuit

Designation

REPLACEABLE PARTS LIST - MODEL bl5

Description

Part No.

c-Ilo1

C-LO2

c-1103

c-m

C-LO5

c-l106

C-k07

C-IL08

C-LO9

C-h10

C-L11

FIJ-1

Capacitor, Electrolytic LO x 250 V.

Capacitor, Electrolytic 150 x 150 V.

Capacitor, Same as C-LO1

Capaci~tor, Same as C-k02

Capacitor, Same as C-h01

Capaci~tor, Electrolytic IlO x h50 V.

Capacitor, Same as C-h02

Capacitor, Same as C-LO6

Supplied with T-l, 1.0 mfd.

Capacitor, Ceramic Disc. .02 x 600 V.

Capacjtor, Electrolytic

Fuse,

1.5 amp. SM-BIO

20 x &50 v.

I

C27-LO

cs-150

C33-bO/hO/20

ONE

CAN

c22-.02

C33-bO/hO/20

nJ-16

M-l

R-101

R-102

R-103

FL-1OL

R-105

R-106

R-107

R-108

R-109

R-110

R-111

Meter

Resistor, HiMeg Spiral 2%, 1012

Resistor, HiMeg Spiral 2%, 3.33 x lOI R20A-3.33~10~1

Resistor, HiMeg Spiral 2%, 1011

Resistor, HiMeg Sprial 2%, 3.33 x 1010

Resister, HiMeg Spiial 28, lOlo

Resistor, HiMeg Spiral 29, 3.33 x lo9

Resistor, HiMe@ Spiral 26, lo9

Resistor, HiMeg Spiral 2%, 3.33 x lO*

Resistor, Deposited Carbon 18, 2 watt, 100 M

Resistor, Deposited Carbon ,I%, 1 w&t, 33.3 M

Resistor, Deposited Carbon l%, 1 watt, 10 M

ME-23

R20A-1012

R20.4-lOI

R20"-3.33~101~

R20A-lOlo

R20A-3.33~10~

R20A-109

R20A-3.33~10'

RlL-100M

R13-33.3M

R13-1014

R-112

Resistor, Deposited Carbon I%, g watt, 3.33 M

R12-3.33M

Page 21

REPLACEABLE PARTS LIST - MODEL hl$

Ckcuit

Designation Description Part No.

R-113

R-lll4

R-115

R-116

R-117

R-118

R-119

R-120

R-121

R-122

R-123

R-12L

R-125

Resistor, Deposited Carbon l%, 3 watt 1 M

Resistor, Deposited Carbon l%, .$ watt 333 K

Resistor, Deposited Carbon l%, 3 watt 100 K

Resistor, Deposited Carbon l%, 4 watt 33.3 K

Resistor, Deposited Carbon l%, a watt 10 K

Resistor, Deposited Carbon l%, 5 'watt 3.33 K

Resistor, Deposited Carbon I%, $ watt 1 K

Potentiometer, Carbon - Linear Taper 1 K

Resistor, Deposited Carbon l%, 3 watt 3.9

K

Resistor, Composition lo%, + watt 22 Y

Resistor, Deposited Carbon l%, 1 watt 10 M

Resistor, Deposited Carbon Same as R-123

Potentiometer, 200 ohm

R12-1M

R12-333K

R12-100K

R12-33.3K

R12-10K

Rl2-3.33K

R12-1K

RP3-1K

R12-3.9K

RI.-22X$

R13-10M

RP23-200

R-126

R-127

R-128

R-3,29

R-130

R-131

R-132

R-133

R-13b

R-135

R-136

R-137

R-138

Resi~stor, Wire Wound l%, 25 watt 250 ohm

Resistor, Wire Wound 18, 25 watt 150 ohm

Resistor,

Wire

Wound 3%, 7 watt 12.5

K

Resistor, Wire Wound Same as R-128

Resistor, Deposited Carbon Same as R-119

Resistor, Deposited Carbon l%, 3 watt 50 K

Resistor, Deposited Carbon l%, 3 watt h.7 K

Resistor, Deposited Carbon l%, + watt 22 K

Resistor, &posited Carbon l%, 3 watt 35 K

Resistor, Deposited Carbon l%, $ watt

56

K

Resistor, Deposited Carbon l%, 4 watt 5 M

Resistor, Deposited Carbon l%, 1 watt 8 M

Resistor, Wire Wound Same as R-128

RlR-h-250

R18-6-150

R7-12.'K

R12-SOK

R12-L.7K

Rl%-22X

R12-35K

R12-L;6K

R12-5M

R13-8M

Page 22

REPLACEABLE PARTS LIST - VODEL h15

Ci rcu i~t

Desienatjon Description

Part No.

R-1!01.

R-II03

R-1103

R-h&

R-1~105

U~dOh

R-LO7

R-LO8

R-Log

R-410

R-k11

R 4 17

R4113

Resistor, Comnosition a watt, 10% 100 ohm

Resistor, Composition *watt, 10% I~70

RI-l.00

R&L70

Resj.stor, Same as R-LO1

ResIstor, Same as R-h02

Resistor, Same as R-LO1

Resistor, Same as R-LO1

Resi.stor, Composition + watt, 10% 2.2 M

Resistor,

Composition 2 watt, 10% 27 K

Resistor, Deposited Carbon $ watt, 1% 2 M

Rl-2.2M

R3-27K

R12-2M

Resistor, Same as R-LO9

Pesjstor, Deposited Carbon 3 watt, 1% 1.5 M RllF!-1.5M

Reaistv,

Potentiometer, Carbon - Linear Taper 500 K

Composition & watt, 10% 216

Rl-2M

RP2-l-500K

R4hJl

R-111s

Q-Ill6

R-1117

R-L18

H-1119

K-ll20

R-1121

R-L22

R-L23

F47II

R-1125

R-1126

Potentiometer, Carbon - Linear Taper 500 K ohm RP7-3-SOOK

Resistor,

Cnmnnslt?on h wat.t, 10% 3.3 M

RI,-3.3M

Resistor, Same as R-1102

Resistor, Same as R-117

Resistor, Same as R-119

Resistor, Same as R-119

Resistor, Same as R-119

Resistor,

Same as

R-119

Resistor, Same as R-119

Resistor, Same as R-119

Resistor, Same as R-11~9

Resistor, Same as R-119

Resistor, Same

as

R-119

Page 23

circuit

Designation

FU%ZXFABLX PARTS LIST - MODEL

Description Part No.

415

R-427

R-428

R-429

R-430

R-431

R-432

R-434

R-435

RF-101

RF-M2

RF-103

w-104

Helipot, Type A 5% Tolerance, .5$ Linearity

Resistor, Deposited Carbon $ watt, 1%

Resistor, Deposited Carbon $ watt, 1% 23.3

Resistor, Deposited Carbon & watt, 1%

66.7 K

K

6.67

K

Resistor, Deposited Carbon =& watt, l$ 2.33 K

Resistor, Same as R-lip

Red&or, Composition $-watt, 10%

47ohm

Resistor, Sam? as R-117

Rectifier, Selenium, 65 ma/130 V

Rectifier, Some as RF-101

Rectifier, Same as RF-101

Rectifier, Same as RF-101

Rp4-l.K

Rx?-66.7K

~12-23.3

Rl2-6.&K

RL?-2.33K

Rl-47

RF-18

RF-105

~~-106

T-l

T-2

SR-7

SF&

SW-1

SW-2

SW-3

SW-4A

SW-4B

Rectifier, Same as RF-101

Rectifier, Same a6 RF-101

Transformer, Sola - 71354

Transformer, 'l?zrimary - l.l7 VAC!/60 cycle

Rectifier,

Selenium Diode

65

ma/240 V

Rectifeir, Same as SR-7

Range Switch

Zero Check

Meter

On

Switch

- Off

Combined DPLY!

Meter Shorting

TR-17

RF-21

SW-72

1414aN

SW-is

SW-14

Page 24

REPLACEABLE PARTS LIST - MODEL ids

Cf.rcuit

Designation

----.-.-...---.---- ----_ -___.l_ ._--. -_,--.----.__----.._-

Description Part No.

SW-5

SW-6

V-l

v-2

V-3

V-b

v-5

V-6 Tube, Vacuum 12BLA

v-7

V-8 Tube, Same as V-7

V-9

Buckout Multiplier Switch DR 13212-A

Input Shieldinp Switch

Tube, Vacuum

Tube, Vacuum 5886

Tube, Vacuum 6~~6

Tube, Same as V-3

Tube, Vacuum 6CM6

Tube, Vacuum 1'2 AX7

Tube, Gas 003 EV-OG 3

5886

SW-03

SW-74A

Ev

5886-0

Ev

5086-0

6

CB 6

6 CM 6

12 Bh A

12 AX 7

Page 25

Page 26

Loading...

Loading...