Page 1

INSTRUCTION MANUAL

MODEL 414A

PICOAMMETER

0

COPYRIGHT

PRINTED MAR.

1976,

1978,

KEITHLEY INSTRUMENTS, INC.

CLEVELAND, OHIO, U.S.A.

Page 2

CONTENTS

CONTENTS

MODEL

414A

1.

2.

3.

4.

5.

6.

7.

1

4

6

7

9

14

17

ii

0575

Page 3

MODEL 414A

Fig.

No.

I

LLU

ST

RAT

I0

N

S

Title Page

ILLUSTRATIONS

3

3

5

6

10

12

13

21

21

0974

iii

Page 4

S

PEC

IF

ICAT

ION

S

S

P

E C I

F

ICAT

MODEL

10

N

S

414A

RANGE:

ACCURACY:

ZERO DRIFT:

INPUT VOLTAGE DROP:

EFFECTIVE INPUT RESISTANCE:

RISE TIME, MAXIMUM:

MAXIMUM INPUT OVERLOAD:

CONNECTORS:

RECORDER OUTPUT:

POWER:

DIMENSIONS, WEIGHT:

ACCESSORIES SUPPLIED:

10-lo ampere full scale to

lx

and

3x

ranges, positive or negative currents.

&2%

*4%

of full scale on 3 x

0.05%

per "C on any range after a 10-minute warm-up and

with source voltages greater than

meter deflection on any range when properly zeroed.

ampere range, increasing to less than

ampere range.

Range,

ampere

Transient:

(or other

Continuous:

creasing to

Amphenol 8OPC2F.

Output:

deflection. Output polarity is opposite input polarity.

Noise:

414s:

414A: Less than

105-125 or 210-250 volts (switch selected),

5

watts.

net weight,

nectors.

of full scale on

Less than 0.5% of full scale per week plus

10.10

10.9

10.8

10-7

10

-6

10.5

and

1000

volts for

10

mA

600

12

volts on the ampere range.

Input: Teflon-insulated UHF type. Output:

il

volt or 1 milliampere for full-scale meter

Less than

8

pounds.

10-9

Less than 1 millivolt for full-scale

Seconds, from

above

limited) High Voltage Supply.

volts on 10-10 to

0.3%

1%

of full scale peak-to-peak.

5%w

lo2

ampere in seventeen

lo-*

to ampere ranges;

to 10-10 ampere ranges.

1

volt.

Less than

With

less

up

to 3 seconds using a Keithley

10-6

of full scale peak-to-peak.

high

x

Mating input and output con-

0.1

ohm on

lo7

ohms on

10%

to

90%.

up

to

500

0.75

0.15

0.13

0.09

0.05

wide

Input

0.001

pF

x

Across

than

ampere ranges, de-

8%"

50-60

10"

deep:

10-lo

Hz,

iv

0974

Page 5

MODEL

414A

GENERAL DESCRIPTION

SECTION

1-1.

GENERAL.

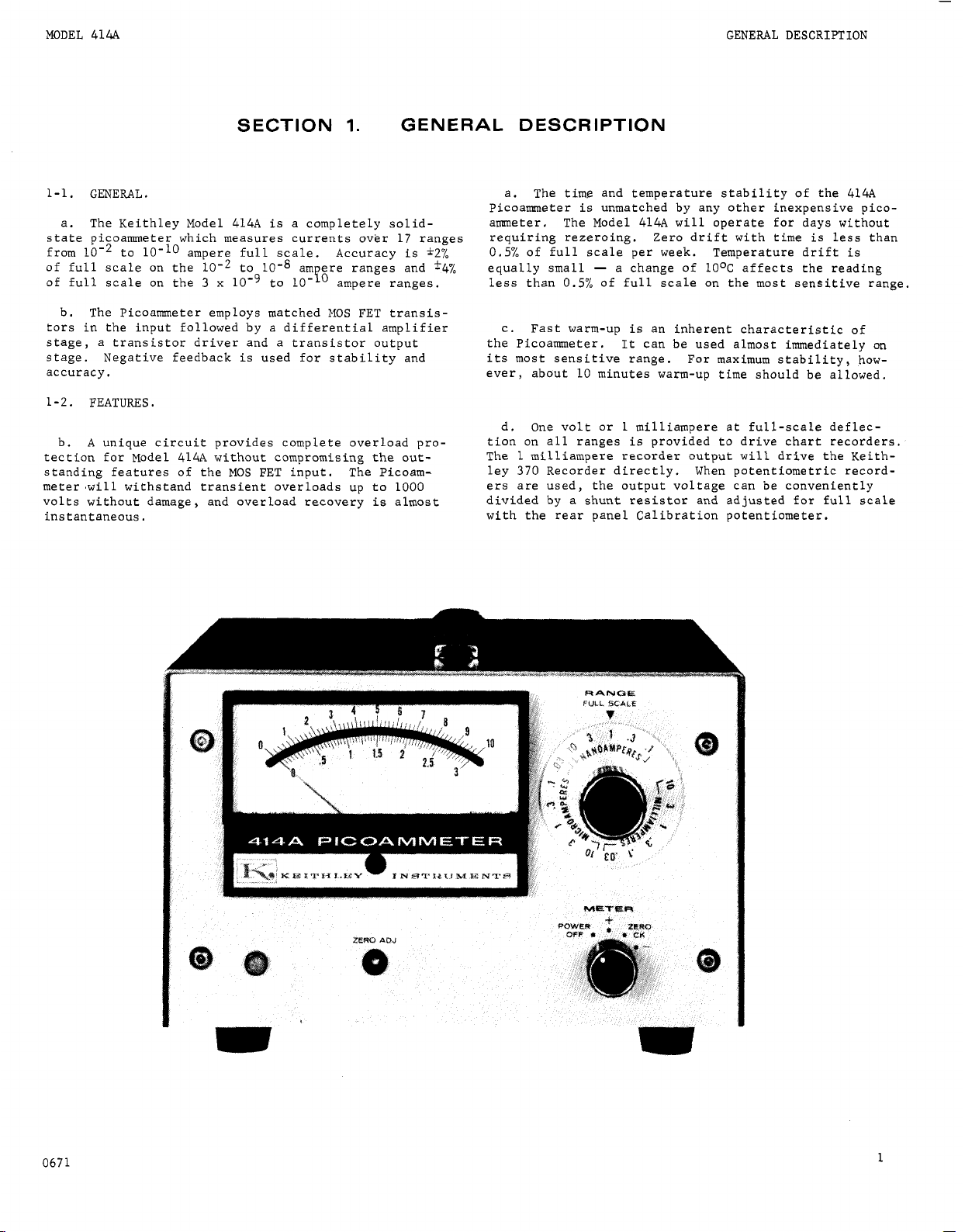

a. The Keithley Model 414A is a completely solid-

state picoammeter which measures currents over

LO-’

from

of full scale on the to

of full scale on the

b. The Picoammeter employs matched

tors in the input followed by a differential amplifier

stage, a transistor driver and a transistor output

stage. Negative feedback is used for stability and

accuracy.

1-2.

b. A unique circuit provides complete overload protection for Model 414A without compromising the outstanding features of the

meter .will withstand transient overloads up to

volts without damage, and overload recovery is almost

instantaneous.

to ampere full scale. Accuracy is

3

x

lo-’

FEATURES.

MOS

am ere ranges and

to

lo-‘’

FET input. The Picoam-

1.

ampere ranges.

MOS

GENERAL DESCRIPTION

17

ranges

*2%

FET transis-

1000

*4%

a. The time and temperature stability of the 414A

Picoammeter is unmatched by any other inexpensive picoammeter. The Model 414A will operate for days without

requiring rezeroing. Zero drift with time is less than

0.5%

of full scale per week. Temperature drift is

equally small

less than

c. Fast warm-up is an inherent characteristic of

the Picoammeter.

its most sensitive range. For maximum stability, however, about

d. One volt or

tion on all ranges is provided to drive chart recorders.

The

1

milliampere recorder output will drive the Keith-

370

ley

ers are used, the output voltage can be conveniently

divided by a shunt resistor and adjusted

with the rear panel Calibration potentiometer.

-

0.5%

Recorder directly. When potentiometric record-

a change

of full scale on the most sensitive range.

It can be used almost immediately on

10

minutes warm-up time should be allowed.

1

of

10°C

affects the reading

milliampere at full-scale deflec-

for

full scale

0671

1

Page 6

GENERAL DESCRIPTION

TABLE

1-1

Front Panel Controls

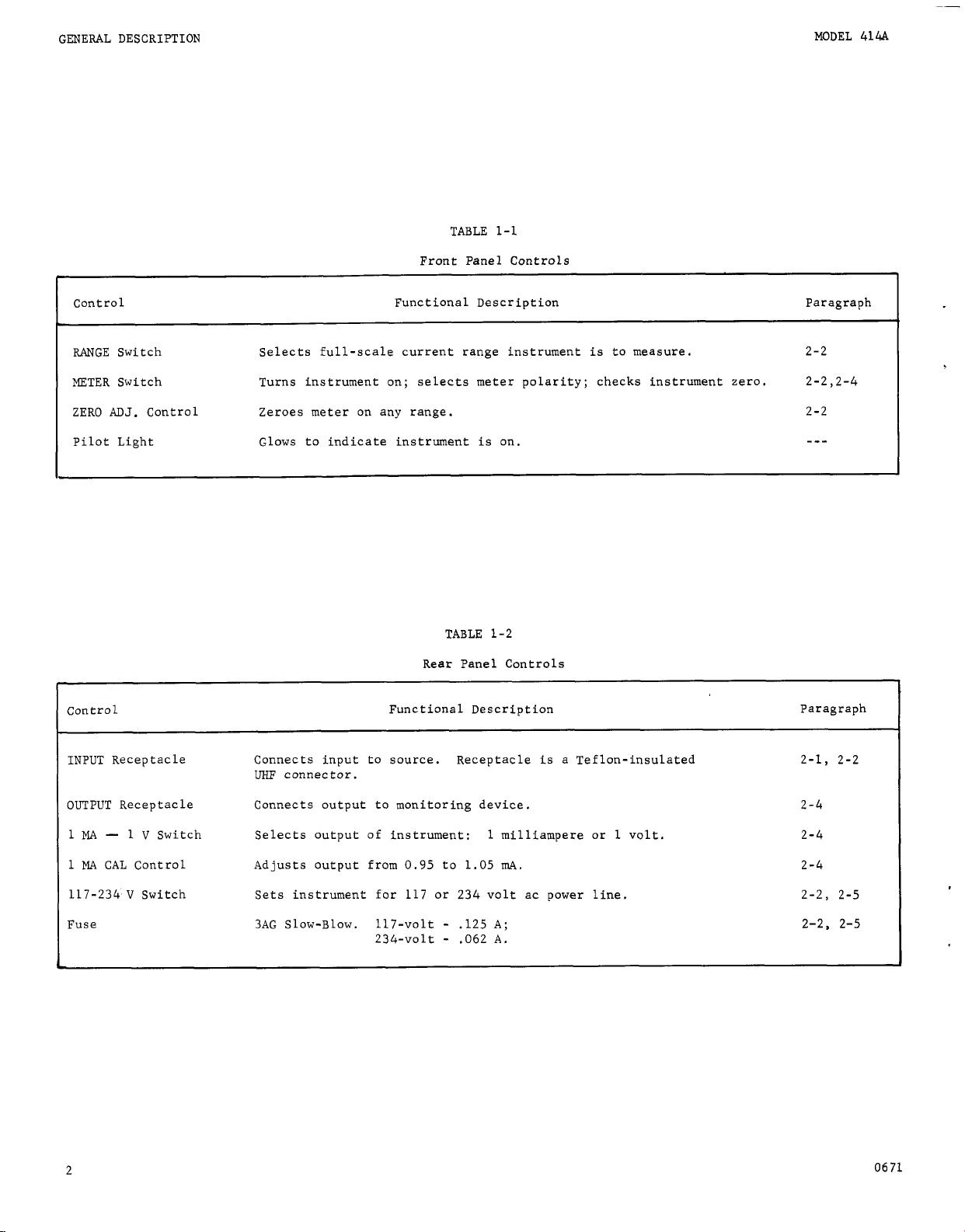

Control Functional Description Paragraph

MODEL

414.4

RANGE Switch Selects full-scale current range instrument is to measure.

METER Switch Turns instrument on; selects meter polarity; checks instrument zero.

ZERO

ADJ.

Control Zeroes meter on any range.

Pilot Light Glows to indicate instrument is on.

TABLE

1-2

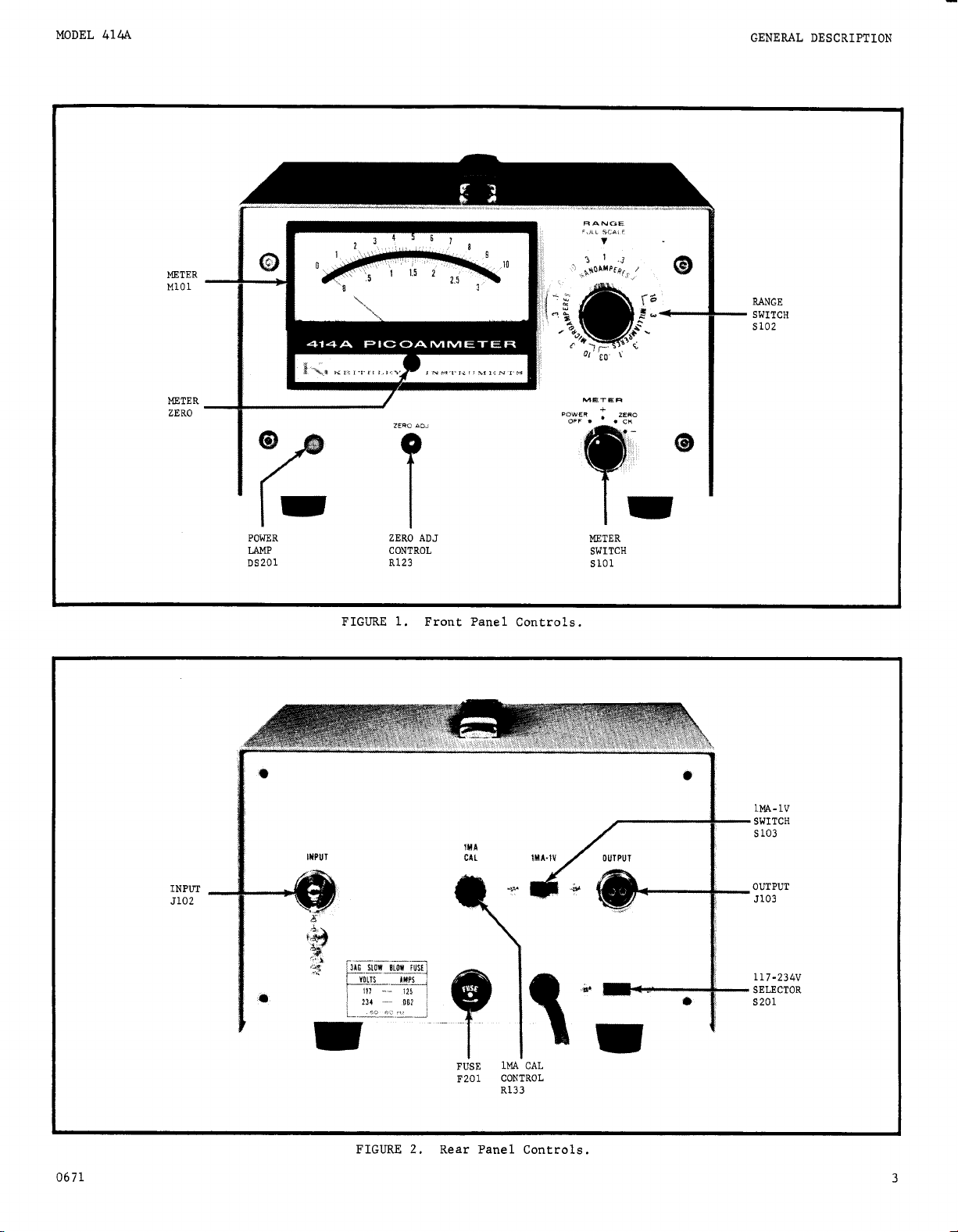

Rear Panel Controls

Control Functional Description Paragraph

INPUT Receptacle Connects input to source. Receptacle

UHF

connector.

is

a Teflon-insulated

2-2

2-2,2-4

2-2

---

2-1, 2-2

OUTPUT Receptacle Connects output to monitoring device.

1

MA

-

1

V

1

MA

CAL Control Adjusts output from

117-234

I

Fuse

2

V

Switch

Switch

Selects output

Sets instrument for

3AG Slow-Blow.

of

instrument: 1 milliampere or 1 volt.

117-volt

234-volt - .062

0.95

117

to

or

-

1.05

mA.

234

volt ac power line.

.125

A;

A.

2-4

2-4

2-4

2-2, 2-5

2-2.

2-5

0671

Page 7

MODEL

414A

METER

MlOl

-

GENERAL

RANGE

SWITCH

s102

DESCRIPTION

METER

ZERO

'I-

POWER

LAMP

DS201

FIGURE

t

I

ADJ

ZERO

CONTROL

R123

1.

Front Panel Controls.

METER

METER

SWITCH

SlOl

\

1

SWITCH

S

103

0671

INPUT

5102

FIGURE

F~SE

IMA'CAL

F201 CONTROL

R133

-

2.

Rear Panel Controls.

OUTPUT

5103

-

117-234V

SELECTOR

s201

3

U'

Page 8

MODEL

414A

0

PE

RAT

ION

PICOAMMETER

SECTION

2-1.

INPUT CONNECTIONS. Use the following precautions

when using the Picoammeter on the more sensitive ranges.

a. The INPUT Receptacle of the Model 414A

lon-insulated

the high impedance terminal, and the outer shield

case ground.

b. Carefully shield the input connection and the current source being measured, since power line frequencies

are well within the pass band of the Picoammeter on all

ranges. Unless shielding is thorough, pickup may cause

definite meter disturbances.

c. Use high resistance, low-loss materials

as polyethylene, polystyrene or Teflon

tion. The insulation resistance of test leads and fixtures should be several orders of magnitude higher than

the source resistance. Excessive leakage

accuracy. Any coaxial cable used should be a lownoise type which employs a graphite coating between the

dielectric and the surrounding shield braid.

d. Any change in the capacitance of the measuring

circuit to ground

ing, especially on the more sensitive ranges. Make the

measuring setup as rigid as possible, and tie

necting cables to prevent their movement. If a contin-

uous vibration

as a sinusoidal signal and other precautions may be

necessary to isolate the instrument and the connecting

cable from the vibration.

UHF

connector. The center terminal

will

cause disturbances in the read-

is

present,

it

may appear at the output

NOTE

is

-

for insula-

will

a Tef-

-

such

reduce

down

2.

is

is

con-

OPERATION

1.

When the

etc. positions, use the upper meter scale. Full

scale current range

ting.

2.

When the

etc. positions, use the lower meter scale.

scale current range is equal to the

setting

2-3, MEASUREMENT CONSIDERATIONS.

a. The Picoammeter employs the fast method

rent measurement

the amplifier input and output in the feedback loop.

This method largely neutralizes the effect of input

capacity and greatly increases the response speed.

Also, the input voltage drop

of one millivolt on any range.

b. Rise time varies with the current range and the

input capacity (see specifications, Table

time, though,

across the input; however,

Picoammeter nearer the current source than to the data

reading instrument, Transmitting the input signal

through long cables

of capacitance

noise.

c. The internal resistance

should not be less than the reciprocal of the current

range being used, otherwise the zero stability

affected. The instrument

ever, but the stability

amount given by equation

Stability = 0.5%/week x (R, + Rf)/Rs

.

RANGE

Switch is set to

is

equal to the

RANGE

Switch

-

the measuring resistor

is

not affected with up to 500 picofarads

-

-

with greater than

will

increase response time and meter

is

set to 3,

is

reduced to a maximum

it

is better to place the

of

the unknown source

will

will

still be operable, how-

be degraded by the

1.

10,

RANGE

RANGE

1).

500

Equation

1,

0.1,

Switch set-

0.3,

Full

Switch

of

is

between

The rise

picofarads

will

0.03,

cur-

be

1.

Keep the shield cap on the INPUT Receptacle

when the Picoarmneter

2-2.

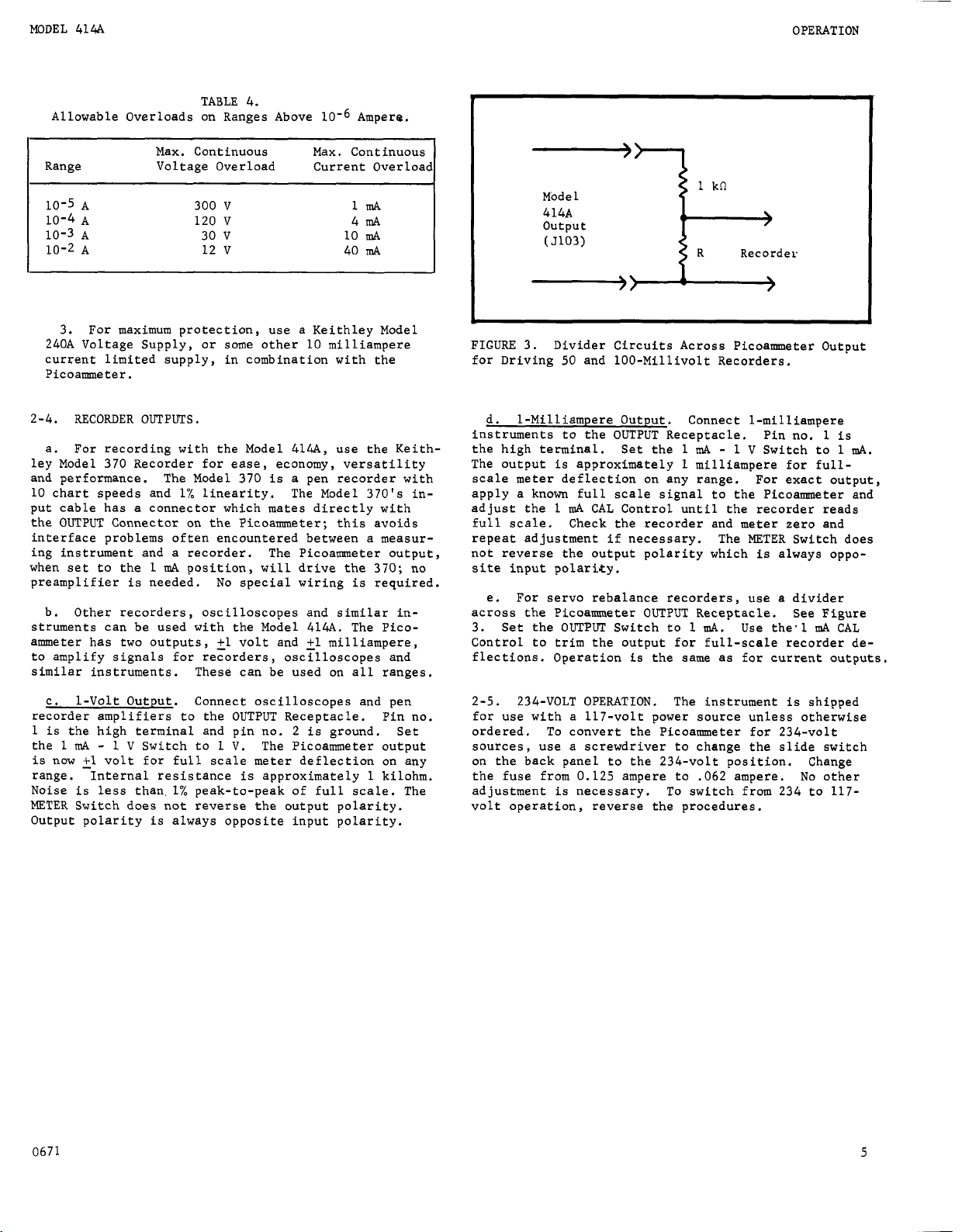

OPERATING PROCEDURES.

a. Check the fuse and the 117-2341 V Switch for the

proper line voltage.

b. Connect the power cord to the power source.

+

RANGE

(+).

Within seconds the meter needle should

RANGE

METER

or

Switch to the polarity of the input

-.

Increase sensitivity with the

c. Set the

S

itch to

read zero. Zero the meter with the

After a few moments increase the current sensitivity b

advancing the

ampere range. Continue zeroing with the

trol. The instrument

d. If long term measurements are to be made, allow

the instrument to warm up for at least

e. Attach the current source to the INPUT Receptacle

and turn the

signal,

Switch until the greatest

is

not in a circuit.

Switch to ampere, the

ZERO

Switch in decade steps to the

is

now ready to use.

10

on

scale deflection is achieved.

ADJ.

Control.

ZERO

ADJ

minutes.

METER

RANGE

10-

Con-

4

where

Rf

is the feedback resistance in ohms;

Rs

is

the source resistance in ohms.

For example, if the source to be measured has a resis-

tance of

back resistor

gain of the Picoammeter

stability of .5%/week

the offset due to temperature

.5%/OC. This is the reason that

have the source resistance at least equal to the feed-

back resistor.

18

d. Overload Protection.

complete overload protection for the Model 414A without compromising the features of the MOS

Recovery

meter can withstand overloads of up to

for

volts without damage.

is

105

ohms and the current is

will

be

106

ohms. This means that the

is

106/105

will

be

.5%

will

A

unique circuit provides

is

instantaneous for most overloads.

1.

At

the ampere range and below the Picoam-

3

seconds and continuous overloads of up to

2.

Above amperes, the max. continuous overload

a function of rated power dissapation in the resistor.

lom6

=

10.

X

10 = 5%/week, and

be .05%

it

is

advantageous to

FET

1000

then the feed-

Then the zero

X

lo.=

input.

volts

600

0671

Page 9

MODEL 414A OPERATION

TABLE

Allowable Overloads on Ranges Above 10-6 Ampere.

4.

Range Voltage Overload Current Overload

10-5

A

10-4 A

10-3

A

10-2 A

I

3. For maximum protection, use a Keithley Model

240A Voltage Supply, or some other

current limited supply, in combination with the

Picoammeter.

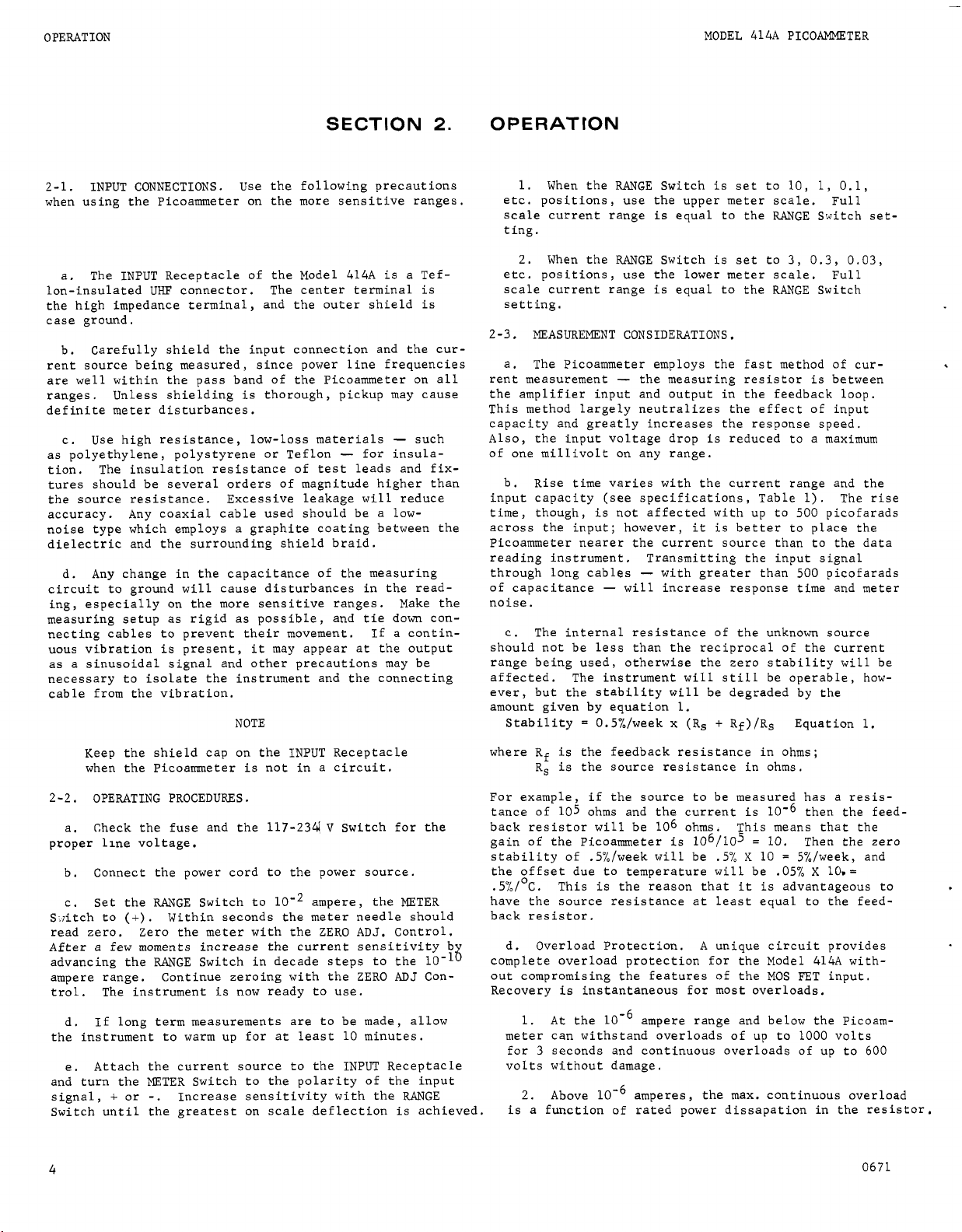

2-4. RECORDER OUTPUTS.

a. For recording with the Model 414A, use the Keithley Model 370 Recorder for ease, economy, versatility

and performance. The Model 370 is a pen recorder with

10

chart speeds and

put cable has a connector which mates directly with

the OUTPUT Connector

interface problems often encountered between a measuring instrument and a recorder. The Picoammeter output,

when set to the

preamplifier is needed.

b.

Other recorders, oscilloscopes and similar in-

struments can be used with the Model 414A. The Pico-

ammeter has two outputs,

to amplify signals for recorders, oscilloscopes and

similar instruments. These can be used on all ranges.

Max. Continuous Max. Continuous

300 V

120

v

30 V

v

12

1%

linearity. The Model 370's in-

on

the Picoammeter; this avoids

1

mA

position, will drive the 370; no

No

special wiring is required.

21

volt and

1mA

4mA

10

mA

40

mA

10

milliampere

21

milliampere,

I

J

$

1

1

Mode

414A

output

(5103)

FIGURE 3.

for Driving

d. 1-Milliampere Output. Connect 1-milliampere

instruments to the OUTPUT Receptacle. Pin no,

the high terminal. Set the

The output is approximately 1 milliampere for full-

scale meter deflection on any range.

apply a known full scale signal to the Picoammeter and

adjust the

full scale. Check the recorder and meter zero and

repeat adjustment if necessary. The METER Switch does

not reverse the output polarity which is always oppo-

site input polarity.

e. For servo rebalance recorders, use a divider

across the Picoammeter OUTPUT Receptacle. See Figure

3. Set the OUTPUT Switch to

Control to trim the output for full-scale recorder de-

flections. Operation is the same as for current outputs.

Divider Circuits Across Picoammeter Output

50

and 100-Millivolt Recorders.

1

mA

CAL Control until the recorder reads

kR

t

1

1

mA

mA.

Recorder

-

1

V Switch to

For exact output,

Use the.1

1

mA

is

1

mA.

CAL

c. 1-Volt Output. Connect oscilloscopes and pen

recorder amplifiers to the OUTPUT Receptacle. Pin

1

is the high terminal and pin no. 2 is ground. Set

1

mA

-

1

the

is now

range. Internal resistance is approximately

Noise is less than.l% peak-to-peak of full scale. The

METER Switch does not reverse the output polarity.

Output polarity is always opposite input polarity.

V Switch

21

volt for full scale meter deflection on any

to

1

V. The Picoarmeter output

1

kilohm.

no.

2-5. 234-VOLT OPERATION. The instrument is shipped

for use with a 117-volt power source unless otherwise

ordered. To convert the Picoammeter for 234-volt

sources, use a screwdriver to change the slide switch

on

the back panel to the 234-volt position. Change

the fuse from 0.125 ampere to .062 ampere.

adjustment is necessary. To switch from 234 to 117-

volt operation, reverse the procedures.

No

other

0671

5

Page 10

CIRCUIT

DESCRIPTION

MODEL

414A

SECTION

3-1. GENERAL. The Keithley Model 414A

amplifier with a full scale sensitivity of either

3 volts.

sistors are selected to make measurements over a total

17

of

22223D for circuit designations.)

3-2.

a. The amplifier has matched insulated-gate fieldeffect input transistors followed by a differential

transistor stage, a transistor amplifier and a transistor output stage. Figure

circuit for the Picoammeter.

By

using the front panel controls, shunt re-

current ranges. (Refer to schematic diagram

AMMETER

OPERATION.

4

shows the simplified

3.

is

a linear dc

CIRCUIT DESCRIPTION

1

or

3-3.

AMMETER

a. Two balanced insulated-gate field-effect tran-

sistors, ~101 and Q102, are used for the amplifier input. Resistors

21850B (see schematic) protect the gate of transistor

QlOl,

the active field-effect transistor, from overloads.

The gate of Q102

Turning the METER Switch to

b.

places a short from the input to the output and zeroes

the instrument.

c.

A

4104,

and

in

which

sistor

Control, R120, varies the source voltage of transistor

Q101

Control, R123, varies the drain voltage of transistor

QlOl

current through transistors

the source bias.

4106.

d. Two zero controls are used. The Coarse Zero

with respect to transistor Q102. The

with respect to transistor Q102.

e. The

CIRCUIT.

R117

and R118 and circuit designation

is

returned to amplifier ground,

ZERO

CK

position

differential amplifier stage, transistors Q103

drives an amplifier stage, transistor Ql05,

turn drives the output

DC

Bal Potentiometer,

emitter

Rl19,

QlOl

and

follower, tran-

ZERO

ADJ

sets the drain

Q102

by varying

FIGURE 4. Simplified Diagram for heter Circuit.

it

is

b. If

is

ein,

flows through the measuring resistor,

But the output voltage,

voltage times the amplifier gain.

Therefore, from equations

From whence,

where ein/iin

negligible, then all the input current,

eo

=

=

eo

A

ein

ein/iin

assumed that the input voltage drop,

R,,

-iin

R,.

eo,

is

also equal to the input

-A

ein. Equation 3.

2

and

=

iin

R,.

=

Rs/A.

is

the effective input resistance.

3

we

Equation

get

Equation 4.

Equation 5.

iin,

and

2.

f. The voltage drop across R115 plus R116, or R116

alone, determines the full scale sensitivity of the

amplifier

and 3 x

put causes a

R115 and R116. The meter

volt output. Resistors R130 and R131 set the meter

current.

g. The full scale current sensitivity is determined

by the range resistors

with resistors R115 and R116. The current measuring

resistor

figuration increases the response speed by minimizing

the effects of input capacity.

input voltage drop to less than

h. The

milliampere flowing through resistor R135. In the

milliampere output mode an external load

for R135. Potentiometer R133 varies the current to the

external load.

3-4.

negative supplies, which provide power to the ampli

fier and output,

a. +25 and

secondary of transformer T201 is rectified by diodes

D201 and D203 and filtered by capacitor C201 to provide

+25 volts for the output. Zener diode, D205, is used

to provide a regulated

-

either 3 volts from through 3 x

lom9

and

ranges. Applying a full scale signal to the in-

is

1

~xLO-~O

1

milliampere current to flow through

connected in the feedback loop. This con-

volt recorder output

or 1 volt on

is

connected across the 3-

RlOl

through R114 in combination

It

also reduces the

1

millivolt.

is

derived from

lom9

and

1

1

is

substituted

POWER

SUPPLIES, The Model 414A has positive and

+ll

volt supply. The power supplied from

+11

volts for the amplifier.

Thus, the input voltage drop

1/A,

tion,

put resistance

6

of the output voltage, and the effective in-

is

1/A

of the measuring resistor.

is

kept at a small frac-

b. -25 and

D202 and D204, capacitor C202 and zener D206 to perform the same functions as the positive supply.

-11

volt supply. This supply uses diodes

0671

Page 11

-

MODEL 414A

SECTION

4-1.

GENERAL.

troubleshooting procedures for the Model 414.4 Picoam-

meter. Follow these procedures

to maintain the performance of the instrument.

4-2.

SERVICING SCHEDULE. The value of the high-megohm

resistors,

ly every six months for specified accuracy, Except for

this the Model

beyond the normal care required of high-quality elec-

tronic equipment.

4-3.

PARTS REPLACEMENT.

a. The Replaceable Parts

the electrical components of the Picoammeter. Replace

components only as necessary. Use only reliable replacements which meet the specifications.

b. The MOS FET input transistors,

specially selected and matched; order only as a plug-

in unit, part number

Inc.

4-4. TROUBLESHOOTING.

a. The Procedures which follow give instructions for

repairing troubles which might occur in Model

Use the procedures outlined and use only specified

Section 4 contains the maintenance and

as

closely as possible

R113

and R114, should be checked approximate-

414A

requires no periodic maintenance

List

in Section 7.describes

Q101

and

23733

,

from Keithley Instruments,

Q102,

414.4.

4.

are

SERVICING

SERVICING

replacement

ded for troubleshooting. If the trouble cannot be

readily located or repaired, contact Keithley Instru-

ments, Inc., or

b. Table

might occur. If the repairs indicated in the table

do not clear up the trouble, find the difficulty

through a circuit-by-circuit check, such as given in

paragraph 4-5. Refer to circuit description in Sec-

3

tion

determine their function in the circuit. The complete

circuit schematic,

4-5.

a. If the instrument

power supplies. The typical voltage values, given

on the schematic, are referenced to chassis ground.

Zero the Model

a Model

b.

with the

this occurs, adjust the front panel

or, if necessary, the Coarse Zero Potentiometer,

located on the PC board. If this does not work, inspect all PC boards for a possible break in the

If these appear all right proceed with step c.

parts.

6

to find the more critical components and to

PROCEDURES TO

Table 5 lists

its

representative.

contains the more common troubles which

22223D,

GUIDE

414A

meter and make measurements with

is

TROUBLESHOOTING.

will

equipment recommen-

in Section

not operate, check the

7.

153.

At

times, the meter

METER

Switch in the

will

ZERO

not zero

CK

position, If

ZERO

on

any range

ADJ

Control

~20,

tapes.

Equipment Recommended for Mode1414A Troubleshooting and Calibration. Use these instruments or their equivalents.

Instruments Use

163

Keithley Model

reading,

Hewlett Packard

Keithley Instruments Model

10

racy, float

Keithley Instruments Model

10-14

Keithley Instruments Model

Keithley Instruments Model515AMegohm Bridge.

Keithley Instruments Model

Voltmeter;

Shielded resistors of different values, and shielded Rise time check.

50 pF and 500 pF polystyrene capacitors.

Tektronix Model

pV to

to

10

megohm input resistance.

1000

t500

10-4

100

Digital Voltmeter,

202A

Function Generator Rise

V,

200

MR

input resistance,

volts off ground.

ampere.

pV

to

500

V,

561A

Oscilloscope Noise and

153

Microvolt-Ammeter, General circuit checking.

261

Picoampere Source; Source to calibrate current.

370

Recorder Monitor drift.

662

Guarded Differential Calibrate meter zero.

*O.Ol%.

20.1%

*l'X

TABLE 5.

of General calibration.

time

check.

accu-

Verify high megohm resistors in Range Switch.

rise

time check.

0177

7

Page 12

SERVICING

MODEL 414A

TABLE

I

I

I

I

Difficulty

Excessive zero offset

Excessive offset current

Cannot zero on any range

Meter off scale on one of Faulty range resistor

range settings

One of ranges out of

soecif ication

c. Amplifier.

1.

To

back loop by removing Q106, D102, D105 and R129 from

the

Model WV98C, used as an ohmmeter, for shorts.

2.

and Q104. Adjust Coarse Zero Potentiometer, R120,

and front panel

be difficult to reach a steady null; however,

sufficient

smooth manner). If this

and Ql04 from the circuit and repeat the same process.

If null can now be reached, replace 4103 and Q104.

check the amplifier, disconnect the feed-

PC

board. Check diodes D102 and D105 with the

Connect a Model 153 between the bases of 4103

ZERO

to

be able to swing through zero in a

I

I

Input transistors m$y be defective

I

Power supply voltage low Check power supply

Excessive temperature fluctuations Check

or defective input transistors

Refer to paragraph 4-5. Refer to paragraph 4-5.

I

Defective range resistor Check resistor; replace if faulty.

ADJ

Control for a null (it may

is

not possible, remove Q103

6. Model 414A Troubleshooting,

Probable Cause

it

is

I

I

Check

QlOl

QlOl

Check resistor; replace if faulty

So

1

ut i on

and 4102; replace if faulty.

and QlO2; replace if faul

I

I

I

If

it

cannot be reached,

3. Check the next stage, 0105, by placing a Model

153 from the collector end of R128 to ground. Adjust the Model 414A Zero Controls for a null. If

this cannot be accomplished, check

ble open by shorting

can now be reached,

placed. If null cannot be reached, replace Ql05.

4. If null can now be attained at the collector

Ql05,

of

Q106 should be replaced. If this does not cure the

trouble, carefully check all the diodes associated

with the output stage

the trouble

QlOl

and Q102 are faulty.

DlOl

it

with a clip lead. If null

DlOl

is open and should be re-

is

in the output stage and

-

D102, D103, D104 and D105.

for a possi-

8

0671

Page 13

MODEL 414A

CALIBRATION

SECTION

5-1. GENERAL.

a. The following procedures are recommended for cali-

brating the Model 414A. Use the equipment recommended

in Table 5. If proper facilities are not available or

if difficulty is encountered, contact Keithley Instru-

ments, Inc., or its representatives to arrange for fac-

tory calibration.

b. If the Model 414A is not within specifications

after the calibration, follow the troubleshooting procedures or contact Keithley Instruments, Inc., or its

representatives.

5-2.

PRELIMINARY PROCEDURES.

a. Make sure the

on the rear panel are set to 1V and 117V respectively.

Set the Front Panel Controls as follows:

RANGE

Switch

METER Switch POWER OFF

ZERO ADJ. Control Mid-range.

b. Set the DC Bal Potentiometer, R119, Coarse Zero

Potentiometer, R120, and Meter Cal. Potentiometer,

R131, near mid-range.

c. Zero the meter with the Mechanical Zero Control.

d. Plug the Model 414A into a 117 volt source and

set the METER Switch to ZERO CK.

1.

If the Model 414A is operative, then the meter

should read

Adjust the Coarse Zero Potentiometer for a zero

dication on the meter.

2. If the Coarse Zero Potentiometer, R120, can

not zero the meter, check for a shorted heat sink

on the MOS

halves of the heat sink must

for the Coarse Zero potentiometer to function properly.

The Table lists all internal controls, the figure pic-

turing the location and the paragraph describing the

adjustment.

I

Control Desig. Ref. Paragraph

I

DC Bal. RL19 7 5-2,

Coarse Zero R120 7 5-2,

Meter Cal

FET

TABLE

~~

1

MA

-

1

V and 117-234 V Switches

10

MILLIAMPERES

on

scale for either polarity

transistors,

7.

Model 414A Internal Controls

Circuit Fig. Refer to

R131 7 5-2,

Q101

and Q102. The two

be

insulated

i

(+

in

5.

or

-7..

in-

order

5-4

5-4

5-6

CALIBRATION

I

5-3. POWER SUPPLY CHECK. (See Figure 7 for test

points for the Power Supplies.)

a. Check the positive and then the negative 25 volt

supply by connecting the Model

C201 and C202 respectively (Figure

should be plus and minus 25 volts

The ripple in each case should be less than 3 volts

peak-to-peak.

For all these power supply checks make sure

the Model

and the test points (Figure,7).

b. Check the positive and then the negative

supply by connecting the Model 7050 across Resistors

R202 and R205 respectively. The voltage for the plus

and minus

11

volts

case should be less than 30 mV peak-to-peak.

c. Monitor the plus and minus 11 volt supplies as

the line voltage is changed from 105 volts ac to 125

volts ac. The voltage change of the plus and minus

volt supplies should be less than k0.15 volt. Observe

the zener noise on the ripple. If the noise exceeds

5mV peak-to-peak, or if large random spikes are observed replace the zener

and D206 for the minus

d. Turn the Model 414A off and prepare the Picoam-

meter for 234 volt,

414A into a 220 volt ac, 50 cycle line and check the

positive and negative 25 volt supplies per paragraph

5-3a above. The same readings as in subparagraph a

above should be obtained except that an additional

volt tolerance should be allowed for each

ference between 234 volts ac and the actual line voltage

The remaining calibration procedures should

all be performed with the Model 414A operating from 117 volts ac,

5-4. MOS FET CURRENT ADJUST.

a. Set the Picoammeter RANGE Switch to

ERES and the METER Switch to ZERO CK.

b. Set the front panel ZERO ADJ. Control to approx-

imately mid-range and adjust the Coarse Zero Potenti-

ometer, R120, for a zero indication on the meter.

c. Connect the Model 7050

and adjust the DC BAL Potentiometer, R119, for an indication of -5.4 volts f0.2 volt.

7050

is connected between ground

11

volt supplies should be plus and minus

fl.10

volts respectively. The ripple in each

11

50

Hz

7050

across capacitors

7).

The voltage

*2

volts respectively.

NOTE

11

(D205

for the plus

volt supply).

operation. Plug the Model

NOTE

60

Hz.

DVM

across resistor R122

11

volt

10

volt dif-

10

MILLIAMP-

volt

11

1

0671

9

Page 14

-

CALIBRATION

5-5.

OFFSET

a. To check the offset:

1.

AMPERES and the

INPUT Receptacle and connect the Model 414A to the

Model

When checking the-offset noise, make sure

the Model 414A cover is on.

2.

for zero volts at the output.

3. Set the

sure that the output remains at zero volts, adjust-

ing the front panel

4.

remain within

b. To check the noise:

AND

NOISE CHECKS.

Set the Picoammeter

7050

If necessary, adjust the

METER

DVM.

RANGE

Set the METER Switch to

*10

millivolts.

RANGE

Switch to

NOTE

Switch to

ZERO

ADJ.

Switch to

ZERO

ZERO

.1

NANOAMPERES.

Control if necessary.

+.

The output should

CK.

ADJ.

10

Cap the

Control

MILLI-

Make

MODEL

b Set the Model 414A METER Switch to + and apply

lo-&

ampere with the Model

the

ZERO

ADJ.

output.

c. Adjust the Meter Cal Potentiometer, R131, for

full scale meter deflection.

d. Load the Model 414A output with a

sistor and set the

e. Adjust the rear panel

that the output voltage can be adjusted at least

volt either side of

f. Remove the

Switch to

g. Set the METER Switch to

output if necessary.

Control for exactly

1

1.5

1.5

1

V.

261.

If necessary, adjust

1.000

volt at the

1.5

V

-

1

MA

Switch to

1

MA

CAL

volts.

kilohm load and set the

ZERO

1

MA.

Control and note

CK

and re-zero the

kilohm re-

1V

414A

0.1

-

1MA

1.

Connect the Model 414A

561A

the Model

2.

Set the

voltage from

put noise should be less than

peak on all ranges. High noise is usually indica-

tive of faulty Zener Diodes

5-6.

METER

a. Set the

the Model

PUT

OUTPUT

261

Receptacle and connect the Model 7050

Receptacle.

Oscilloscope.

METER

105

AND

RANGE

Picoampere Source to the Model 414A

Switch to + and vary the line

volts ac to

1MA

OUTPUT CALIBRATION.

Switch to 1 MICROAMPERE, Connect

OUTPUT

125

D205

Receptacle to

volts ac. The out-

10

millivolts peak-to-

and

D206.

DVM

to the

IN-

5-7.

RANGE

ACCURACY

a. Connect the Model 414A INPUT Receptacle to the

261.

Model

DVM.

7050

b. Check the full-scale accuracy of all positions

the

RANGE

puts to ensure proper operation of both polarities at

various current input levels. Check the accuracy of

10

the

to

f2%

livolts). Check the accuracy of the 3

through the

at the output

Connect the OUTPUT Receptacle to the Model

Switch. Check both positive and regative

MILLIAMPERES

of full scale at the output

.1

(1.0

CHECK.

through the

NANOAMPERES ranges to

volt *40 millivolts).

10

NANOAMPERES ranges

(1.0

volt

NANOAMF’ERES

i.4

of full scale

*20

mil-

or

in-

5.

Test

FIGURE

tors or capacitor, UHF-Tee and the Shunt Capacitor.

10

Set-up for Model 414A Rise Time Check on all ranges. Be sure to properly shield the series resis-

0671

Page 15

MODEL

414A

5-8.

RISE

TIME

Model 414A requires two different test set-ups. The

first set-up

MILLIAMPERES through

set-up is for checking the rise times on the ranges

NANOAMPERES

a.

1

the test fixture as illustrated in Figure 5.

TABLE

ERES through

the Model 414A

Generator frequency settings, the series resistor used

for each

able rise time.

RANGE

1

.1

10

1

.1

10

MILLIAMPERE through

1.

Equipment used (Refer to Table 5): The Model

202A Function Generator, six shielded resistors ranging in value from 3 kilohms to

UHF

8), a

capacitor, the Model 414A and the Model 561A Oscilloscope. The oscilloscope used must be dc coupled.

8.

Model 414A Generator Maximum

Switch Series Frequency Rise Time

Setting Resistors

MILLIAMPERES

MILLIAMPERES

MICROAMPERES 300 kR

MICROAMPERES 3

MICROAMPERES

NANOAMPERES 300

2.

Procedures

CHECK. To check the rise time of the

is

for checking the rise tLmes on the

10

NANOAMPERES ranges. The second

and below.

10

NANOAMPERE ranges. Set

300

Tee connector, a 500 pF polystyrene shunt

Model 414A Rise Time Check for 1 MILLIAMP-

10

NANOAMPERES Ranges. The Table gives

RANGE

Switch settings, the Function

RANGE

Switch setting, and the maximum allow-

Function

(Hz)

250 less than

kR

3

30

MR

30

MR

:

250 less than

kR

250 less than

Ma

megohms (See Table

(milliseconds)

2.5

2.5 90

2.5

50

130

CALIBRATION

2.

Procedures:

1

1

I

t

1

1

1

ERE

Using the shunt increases the sensitivity

a) Apply a triangular wave from the Model'202A

across the capacitor, through the

Model 414A INPUT Receptacle. Monitor the Model

414A output with the Model 561A. Use the proper

Model 2.02A frequency setting as indicated in Table

b) Adjust the Model 202A amplitude control as

needed to obtain

414A output. Check the

figures shown in Table 9.

TABLE

9. Model 414A Rise Time Check for

and

.1

NANOAMPERES Ranges. The Table gives the Model

RANGE

414A

quency settings, and the maximum allowable rise time.

Model 414A Function Generator

RANGE

Setting

1

NANOAMPERES

.I

NANOAMPERES 0.25

5-9. DRIFT VERIFICATION.

a. Shunt the Input of the Model 414A with a 10-kil-

ohm resistor with the

and the

While doing the drift run make sure the

Model 414A cover is on.

Switch settings, the Function Generator fre-

Switch

METER

2

volts peak-to-peak at the Model

10 - 90% rise time to the

Frequency Rise Time

(Hz)

1.0

RANGE

Switch set to t or

Switch set to 1 MICROAMP-

NOTE

UHF

Tee to the

1

NANOAMPERES

Maximum

(milliseconds)

150

750

-,

as necessary.

100

times.

9.

I

a)

Apply

fixture

a square wave from the Model 202A

UHF

Tee to the Model 414A

2

volts peak-to-peak at the Model

10 - 90% rise time to the

.I

UP

NANOAMPERES ranges. Set

as illustrated in Figure 5, except

IN-

Function Generator across the selected series re-

sistor, through the

PUT

Receptacle. Observe the output of the Model

414A with the Model 5628

b) For each Model 414A range, use the Model 202A

frequency setting and the series resistor indi-

cated in Table 8.

c) Adjust the Model 202A amplitude control as

needed to obtain

414A output. Check the

figures shown in Table 8.

b.

1

this

that a shielded 50 pF polystyrene capacitor should be

substituted for the series resistors between the

Function Generator and the UHF Tee.

equipment of the previous set-up with the exception

of the 50 pF polystyrene capacitor. The capacitor in

this set-up serves a similar function as the series

resistors in the previous test set-up.

NANOAMPERE and

test

1.

Equipment Used: This test set-up uses the same

b. Connect the Model 370 Recorder to the Model 414A.

Set the Recorder attenuator to

drift full scale) or 0.3 volts

c. Set the METER Switch to

Control for near zero volts output. The

trol is very sensitive with the sensitivity increased

100

times. Set the METER Switch to - if the drift is

negative.

d. After a 10-minute warm-up, the Model 414A may

drift 700 microxolts per 24 hours plus or minus 500

microvolts per

e. In some cases, the 24-hour drift may appear marginal or

to a steep drift slope during the early part of the

drift. If this

the drift for an additional 24 hours and calculate a

weeks drift as follows:

times 6 and add the drift noted during the first 24-

hour period.

it

1.

Multiply the drift during second 24-hour period

2.

Total drift must add up to 5

C

change in temperature.

may be slightly out of specification due

is

so,

it

1

volt

(10

(3

mV

+

and adjust the

may be desired to continue

millivolts

full scale).

ZERO

ZERO

ADJ

mV

or less.

Con-

ADJ

0671

11

Page 16

CALI

BRATI

ON

MODEL 414A

12

FIGURE

6.

Chassis,

Top

View.

Page 17

bo

c

Page 18

ACCESSORIES

MODEL

414

SECTION

6-1.

GENERAL. The following Keithley accessories 6-2. OPERATING

can be used with the Model 414A to provide additional

convenience and versatility. operating information.

Model 6106 Electrometer Connection

Description

The Model 6106 contains a group

leads and adpaters for low current measurements.

components are housed in a rugged carrying case with Cable,

individual compartments. Cable, 24",

:

of

the most useful Description No. Part No.

6.

All

ACCESSORIES

INSTRUCTIONS.

is

Manual

Parts

Connector, UHF to

Adaptor, UHF

Adaptor, UHF

Adaptor Tee, UHF to UHF 6

Adaptor, Binding Post

The two cables (Items 1 and 2) are coaxial shie

leads useful for connections where low noise

tial. The 24" cable (Item

nect two instruments having

cable (Item

under test through the use of clip leads.

post adapter gives easy access to the electrometer

"high" terminal. Two

permit cables to be connected together.

connector simplifies galvanometric current measurements

when using a current source and electrometer or picoammeter. Adapters (Items 4 and

version from

supplied with each accessory giving complete

Kit

List:

30",

UHF to clips

UHF

to UHF

UHF

to

BNC

to

BNC

1)

can be used to connect to the circuit

UHF

to

A

separate Instruction

Item Keithley

2)

can be used to intercon-

UHF

receptacles.

UHF

female couplers (Item

5)

BNC

terminations.

1

2

3

4

5

7

are useful for con-

The

19072C

18265C

cs-5

cs

-

cs

-

cs-

190

is

The

A

binding

UHF

15

72

71

1B

ded

essen-

30"

3)

"tee"

Model 261 Picoampere Source

Description:

261

is

The Model

3

with

ampere to

eight decade ranges. Accuracy

-

+1.6% exclusive of input drop considerations.

A

The Model 261

brating picoammeters and electrometers.

used as an accurate current source for zero suppression

and for galvanometric measurements.

14

digit resolution. The output ranges are

1.1

p

p

1

ica t ion

an accurate picoampere current source

x

10-4 ampere, positive or negative, in

:

is

a secondary standard for use in cali-

is

rated from 2.25% to

It

can also be

0671

Page 19

-

MODEL 414A

Model 4003A Rack Mounting Kit

Description: Parts List.:

The Model 4003A is a rack mounting kit with overall Item Qty. Per Keithley

dimensions, 5-1/4 inches high x 19 inches wide. Two

top covers are provided for use with either

13 inch deep instruments. 2 Panel Adapter Plate

Application

The Model 4003A converts the instrument from bench

mounting to rack mounting. It is suitable for mount-

ing one instrument in one-half of a standard 19-inch

rack.

:

10

inch or

No.

1

3

4

5 Connectinn Plate

6

7

8

Description Assembly

Top Cover,

Angle Support

Screw,#10 x 3/8"

Screw,

Angle

Top Cover, 13"

10"

+/16

x

1/21!

1

1 17452B

1

4

1 19126A

4

1 14624B

1

ACCESSORIES

No.

Part

18554B

174768

---

---

20015B

4004.4

Model

Description: Parts List:

The Model 4004A is a rack mounting kit with overall

dimensions, 5-1/4 inches high

top covers are provided for use with either

or

13

inch deep instruments.

Application

The Model 4004A converts the instrument from bench

mounting to rack mounting. It is suitable for mount-

ing two instruments in a standard 19-inch rack.

0671

:

x

19 inches wide.

10

Dual Rack Mounting Kit

Item

Two

inch

No.

1

4

5 Connecting Plate

6

7

8

9 Zee Bracket

10

Top Cover,

Screw,

Screw,

Angle 2

Top Cover, 13"

Plate (not shown)

Qty. Per Ke it hle y

Description Assembly Part

#lo

#lo

10"

x

x

1/2

1/2

2 18554B

8

1 19126A

4

2 20015B

1

1

---

---

14624B

19144A

17451rA

No.

15

Page 20

ACCESSORIES

MODEL 414

~

Models 240A,*244, 245, 246 Voltage Supplies

Description:

Keithley voltage supplies are highly-stable, low-noise

power supplies for voltages up to 23100 volts dc.

Application

:

Keithley voltage supplies are commonly used with pico-

of

ammeters in the measurement

resistance, light levels

(photomultipliers), and radiation intensity (ion chambers).

These high voltage supplies have been designed to

operate with the Keithley line of electrometers,

picoammeters and resistivity accessories.

application is shown using the Model 414s

A

typical

(6r 414A)

and the Model 240A in a photomultiplier experiment.

Output Ranges

:

Model

2 40A

244 -200 to

2 45

2

46

,,/,,,a

No.

..I.

1

-

Voltage

0

to i1200v

-2200v

0

to +2100v

0

~

I

I

to ~3100V

\\

Model 4104 Electronic Trip

The Model 4104 is an electronic trip installed in the

picoammeter to provide automatic current control.

Combinations of high, low,

2

polarity, and latching

is available.

16

Model 4109 Polarizing Supply

The Model 4109 provides

+300

volts at

1

KIA

for

applications requiring a stable voltage source. The Model

4109 can be ordered installed in the picoameter if

desired.

0671

Page 21

MODEL 414A

-

REPLACEABLE PARTS

SECTION

7-1.

REPLACEABLE PARTS LIST. The Replaceable Parts

List

describes the components of the Model 414A. The

List

gives the circuit designation, the part descrip-

a

tion,

number and the Keithley Part Number. The last column

indicates the figure picturing the part. The name and

address of the manufacturers listed in the "Mfg. Code''

column are in Table 14,

7-2.

suggested manufacturer, the manufacturer's part

HOW

TO ORDER PARTS, b. Order parts through your nearest Keithley rep-

a. For parts orders, include the instrument's model Instruments, Inc.

A

CbVar Carbon Variable

CerD Ceramic, disc

Comp

DCb Deposited Carbon

EA

1

F

Ampere

C

omp

o

s

it

ion

Electrolytic, Aluminum

Farad

7.

TABLE 12. Abbreviations and Symbols.

Fig. Figure

GCb Glass Enclosed carbon

k

ii:'

REPLACEABLE PARTS

and serial number, the Keithley Part Number, the circuit designation and a description of the part.

structural parts and those parts coded for Keithley

manufacture (80164) must be ordered through Keithley

Instruments, Inc., or

ing a part not listed in the Replaceable Parts List,

completely describe the part,

locat ion.

resentative or the Sales Service Department, Keithley

kilo (lo3)

micro (10-6)

Mega (lo6)

Manufacturer

Metal Film

Mylar

its

representatives. In order-

its

R

P

Pol'y Polystyrene

Ref. Reference

V

1

W

WWVa

ohm

pic0

Volt

Watt

r

Wirewound Variable

function and

-12

(10

)

All

its

MODEL

(Refer to Schematic Diagram 22223D for circuit designations.)

Circuit Mfg. Mfg.

Desig. Value Rating Type Code Part No.

ClOl

C103 .02 pF 600

C104 .02 pF 600

C105 .0047

C106 .0022

C107 680 pF 600

C108

c109 .0033

CllO

Clll

c112 220 pF

C113 47 pF

C114 22 pF

C115

C116

c201

c202

*Nominal value

.25

pF

.1

pF

UF

pF

.01

pF 600

p.F

.0022

WF

680 pF

.02

pF

.0068

pF* 600

100

pF

100

yF

400

400

600

600

600

600

600

500

500

500

600

400

400

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

414A REPLACEABLE PARTS LIST

CAPACITORS

MY

My 13050 SMlA

CerD 72982 ED-. 02

CerD

CerD

CerD

CerD 72982 ED-680 C22-680P 6

CerD 72982

CerD

CerD 72982

CerD

Poly

Poly

Poly

CerD

CerD

EA

1

EAl

13050 SMlA C73-.

72982 ED-.02

72982

72982

72982

72982 ED-680

71590

71590

71590 CPR-22J

72982

72982 851-Z5U0-682M C22-.0068M

73445

73445 C43 7AR/G100

ED-.

0047 C22-.0047M 6

ED-.

0022

ED-.

01

ED-

.0033 C22-.0033M 6

ED-.

0022 C22-.0022M 6

C

PR-220

C

PR- 47

J

ED-.

02

C

43

7AR/G

J

100

Ke

i

th ley Fig.

Part

No.

25M

1M

C73-.

C22-.

02M 6

C22-.

02M 6

C22-.0022M 6

C22-. 01M 6

C

2

2 - 680P 6

Cl38-22OP 6

C138-47P 6

Cl38-22P 6

C22-. 02M 6

C

150

-

lOOM

C

150

-LOOM

Ref.

6

6 c102

7

7

7

0575

17

Page 22

REPLACEABLE PARTS

DIODES

Circuit Mfg. Keithley Fig.

Desig. Type Number Code Part No. Ref.

MODEL

-

414A

DlOl

D102

D103 Rectifier,

D104 Rectifier,

D105 Rectifier,

D106

D107

D201

D202

D203

D204

D205

D206 Zener 1N715 12954

Circuit Mfg. Ke i th 1 ey Fig.

Desig. Description Code Part No. Ref.

21850B

DS 201

F201 (117

F201 (234

5101

PlOl

V)

V)

Silicon 1N645

Zener

lA,

800V

lA,

800V 1N4006

lA,

800V

Silicon

Silicon

Silicon

Silicon

Silicon

Silicon

Zener

MOS FET Input Plug-In Card

Pilot Light, Neon (Mfg. No. 2190)

Fuse, Slow blow, 1/8

Fuse, Slow blow, 1/16

Printed Circuit Contacts (Mfg. No. 02-005-113-6-200)

Printed Circuit Contacts, mate of

005-111-5-200)

vR47

1N4006 04713 RF-38

1N4006 04713

1N645

18645

1N645

1N645

1N645

1N645

1N715

MISCELLANEOUS

A

(Mfg. Type MDL)

A

(Mfg. Type MDL)

JlOl

01295 RF-14

84970 DZ-30

04713 RF-38

01295 RF-14

01295 RF-14

01295 RF-14

01295 RF-14

01295 RF-14

01295 RF -14

12954

PARTS

(Mfg. No. 02-

RF-38

DZ-22

80164

91802

71400

71400

91662

91662

DZ-22

7

23734A 6

PL-28

FU-20

FU-21

cs-199

cs-200

2

Receptacle,

(F) Plug, UHF, mate of 5102 (Mfg. No. 83-822)

Cap (Mfg. No. 7901)

Receptacle, Microphone,

(F) Plug, Microphone, mate

Meter

A.C.

Rotary Switch,

Knob Assembly, Meter Switch

Rotary Switch less components,

Rotary Switch with components, Range

Knob Assembly, Range Switch

Slide Switch,

Slide Switch,

---

T201

(F) Furnished Accessory

Knob Assembly, Calibration Control

Trans former

UHF,

INPUT (Mfg. No. 6804)

OUTPUT

Power Cable, 6 feet (Mfg. No. 4638-13)

METER

1

MA - 1

117

V

V

-

234

(Mfg. No. 80-PC2F)

of

5103 (Mfg. No. 80-MC2M)

RANGE

(Mfg. No. G326)

V

91737

02660

91737

02660

02660

80164

93656

80164

80164

80164

80164

80164

79727

80164

80164

80164

CS-64

cs-49

CAP-4

CS-32

cs-33

ME-79

CO-5

SW-244

21660A

SW-243

21848B

21649A

-

45

SW

SW-151

16373A

TR-112

2

6

2

2

7

18

0476

Page 23

MODEL 414A

RESISTORS

Circuit Mfg. Mfg. Keithley Fig.

Desig. Value Rating Type Code Part No. Part No. Ref.

REPLACEABLE PARTS

RlOl

R102

R103

R104

R105

R106

R107

R108

R109

RllO

Rlll

R112

R113

R114

R115

R116

R117

R118A*

R119

R120

R121

R122

R123

R124

R125

R126

R127

R128

R129

R130

R

300

1

kR

3

kR

10

kR

30

kR

100

kR

300

kR

1

MR

3 M1

10

Mil

30 MR

100

Mil

R

109

loLo

2

kR

1

kR

1 Mil

100

kR

5

kR

1

kR

11.8

18

kR

2

kR

18

kR

15

kR

680

R

2.2

k9

4.7

kR

1.2

kR

2

kR

R

kR

1%,

1/2

112

1/2

1/2

1/2

1

w

1/2

1/2

1/2

1

w

2

w

1/2

114

w

5

w

112

112

112

1/2

112

112

112

2

1/2

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

1%,

1%)

1%,

1%)

1%,

1%,

1%,

1%)

1%, 112

1%,

1%,

3

%

3

Yo

1/2%, 1/2

112%, 112

1%,

lo%,

20%, 2

lo%,

1%,

1%,

20%, 0.2

1%,

lo%,

lo%,

lo%,

lo%,

lo%,

1%,

w

w

W

w

w

w

w

w

DCb

DCb

DCb

DCb

DCb

EPOXY

DCb

DCb

DCb

DCb

DCb

DCb

GCb

GCb

MtF

MtF

DCb

Comp

WWVar

WWVar

MtF

DCb

CompV

DCb

Comp

Comp

Comp

Comp

Comp

DCb

91637

91637

07716

07716

91637

91637

07716

91637

91637

07716

91637

91637

63060

63060

07716

07716

91637

01121

71450

71450

07716

07716

71450

07716

01121

01121

01121

01121

01121

07716

DCF 1/2

DCF 1/2

DCC

DCC

DCF 1/2

MMF-1

DCC

DCF 1/2

DCF 1/2

DCC

DC-1

DC-2

RX-1

RX-1

CEC

CEC

DCF 1/2

CB

-

115

1NS

AW

CEC

DCC

70

DCC

EB

EB

EB

EB

HB

DCC

R12-300

R12-1K

R12-3K

-

1

OK

R12

-

3 OK

R12

R 150

-

1

OOK

R12-300K

R12-1M

R12-3M

R12-10M

R13-30M

1

OOM

R14~20-109

R20

-

1

010

R61-2K

R61-1K

R12-1M

R76

-

1

OOK

RP50-5K

RP34-1K

R94-11.8K

R12-18K

RP31-2K

-

18K

R12

R1-15K

R1- 680

Rl-2.2K

Rl-4.7K

R3-1.2K

R12-2K

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

7

7

7

7

7

7

7

7

7

7

7

7

7

r

2

R131

R132

R133

R134

R135

R201

R202

R203

Circuit

Desig. Number Code Part No. Ref.

Q106 NPN, Case TO-66, 40312 02735 TG-54 7

**

Replace R118, QlOl or Q102 by ordering Plug-in Board 23733

0177

1

1

1

1

27

1

1

kR

kR

kR

kR

kR

kR

kR

kR

20%, 2

112%, 112

lo%,

112%, 112

1/2%, 112

lo%,

lo%,

lo%,

PNP, Case R-110 F-I S17638

PNP, Case R-110 F-I S17638

2N3904

w

5

w

112

1/2

1/2

w

w

w

w

w

w

WWVa

MtF

WWVar

MtF

MtF

Comp

Comp

Comp

TRANS1 STORS

Mfg.

80164

80164

04713

71450

07716

71450

07716

07716

01121

01121

01121

1NS

CEC

AW

CEC

CEC

EB

EB

EB

-

115

Keithley

TG- 3 3

TG-33

TG-47

RP50 -2K

R61-1K

RP34-1K

R61-1K

R61-1K

R1-27K

R1- 1K

R1- 1K

7

7

6

6

6

7

7

7

Fig.

19

Page 24

REPLACEABLE PARTS

Description

TABLE

13.

Mechanical Parts List

Quantity Keithley Fig.

Per Assembly Part

No.

-

MODEL 414A

Ref.

1)

Chassis

11)

Front Panel

Top Cover Assembly

12) Cover, Sheet Metal

13) Screws

Handle Assembly

14) Handle

Screws #6-32

15)

.

Bottom Cover Assembly

2) Cover

3) Fastener

Feet Assembly

4)

Feet

5) Ball

Screws 1/8-32 x 3/8” Phillips, Pan Head

6)

Tilt Bail Assembly

7)

Bail

8)

Right Assembly

9) Left Assembly

Screws #6-32

10)

x

3/8” R.H. Slotted

x

1/4”

Phillips, Pan Head

1

1

---

1

4

---

1

2

---

1

2 FA-54

---

b

4

4

---

1

1

1

2

24021B

21657C

18553B

17131D

---

---

HH-18

---

19298C

19340B

---

FE-5

FE-6

---

---

17147B

19206B

19205B

---

8

8

9

20

0671

Page 25

MODEL

414.A

REPLACEABLE PARTS

FIGURE

8.

Top

Cover Assembly.

0671

FIGURE

9.

Bottom Cover Assembly.

21

Page 26

CODE-TO-NAME

LIST

Code List of Suggested Manufacturers.

TABLE

MODEL

14.

414A

(Based on Federal Supply Code for Manufacturers, Cataloging Handbook H4-1).

01121

01295

02660

02735

04713

07716

12954

13050

63060

71279

Allen-Bradley Corp.

1201

South 2nd Street

Milwaukee, Wis.

53204

Texas Instruments, Inc.

Semiconductor-Components Division

13500

North Central Expressway

Dallas, Texas

75231

Amphenol Corp.

2801

South

25th

Broadview, Chicago, Illinois

Avenue

60153

Radio Corporation of America

Commercial Receiving Tube and

Semiconductor Division

Somerville, N.J.

Motorola, Inc.

semiconductor Products Division

5005

East McDowell Road

Phoenix, Arizona

85008

International Resistance Co.

2850

Mt. Pleasant

Burlington, Iowa

52601

Dickson Electronics Corp.

302

S.

Wells Fargo Avenue

Scottsdale, Ariz.

Potter Co.

51

Highway

Wesson, Miss.

N.

39191

Victoreen Instrument Co.

5806

Hough Avenue

Cleveland. Ohio

44103

Cambridge Thermionic Corp.

430

Concord Avenue

Cambridge, Mass.

71450

71590

72982

73445

79727

80164

849 70

91637

91662

91737

91802

CTS Corp.

1142

W. Beardsley Ave.

Elkhart, Ind.

Centralab Division

of

Globe-Union, Inc.

932

E. Keefe Ave.

Milwaukee, Wis.

53212

Erie Technological Products, Inc.

644

W.

12th Street

Erie, Pa.

Amperex Electronic Co. Division

16512

of

American Phillips Co., Inc.

Hicksville, N

Continental-Wirt Electron

.Y,

cs Corp.

Philadelphia, Pa.

Keithley Instruments, Inc

28775

Aurora Road

Cleveland, Ohio

44139

Sarkes Tarzian, Inc.

E. Hillside Drive

Bloomington, Ind.

Dale Electronics, Inc.

P.O. Box

Columbus, Nebr.

609

68601

Elco Corp.

Willow Grove, Pa.

Gremar Mfg. Co., Inc.

7

North Avenue

Wakef ield, Mass.

Industrial Devices, Inc.

982

River Road

Edgewater, N.J.

07020

North

22

71400

Bussmann Mfg. Div.

McGraw-Edison Co.

2538

W. University St.

St. Louis. Mo.

of

93656

Electric Cord. Co.

1275

Bloomfield Avenue

Caldwell, No

J.

0671

Page 27

I

OF-

.ooze

r--

I

R131

ZK

A

2

3

II

5

6

7

8

3

A

Rl32

12134

IK

DESIGNATED

OTHERWISE NOTED

0

0

@

M MEGOHM

K

pf

f

IN

OHMS

FRONT PANEL COHTROL

INTERNAL SCREWDRIVER ADJ

REAR PANEL CONTROL

1000

OHM

PICOFARAD

CLOCKWISE ROTATION

DENOTES

N0UiNt.L

FACTORY

I

MA

LAL

If

IV

.$

MICROFARADS UNLESS

VALUE

SELECTED

Page 28

KEITHLEY

CLEVELAND,

INSTRUMENTS,

28775

AURORA

OHIO

SERVICE

INC.

ROAD

44139

FORM

MODEL

NAME

COMPANY

ADDRESS

NO.

Describe problem

readings

Show a block diagram

(whether power is turned

SERIAL

,

chart recordings , etc.

NO.

and

symptoms using quantitative data whenever possible (enclose

of

your measurement system including all instruments connected

on

or

P.O.

)

not).

NO.

CITY

(Attach additional sheets as necessary),

Also describe signal source.

DATE

PHONE

STATE

R-

I

ZIP

List the positions

the instrument.

a

Describe input signal source levels, frequencies, etc.

List

and

describe all cables used in the experiment (length, shielding, etc.).

161

List

and

-

for each.

11_]

Environment:

a

Additional Information.

please describe below.)

describe all other equipment used in the experiment. Give control scttings

Where is the measurement being performed? (Factory, control led

out-of-doors , etc.

What power line voltage is

Ambient temperature?

Other

of

-

all controls

)

(If special modifications have been made by the user,

..

us

and

-.

;ed?

OF.

switches on

~

Ition?

Varia

Var

both

front and rear panels of

i

ati

on? Frequency?

OF.

Rel. Humidity?

laboratory,

REV

0774

Loading...

Loading...